Patents

Literature

68results about How to "Easy process adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

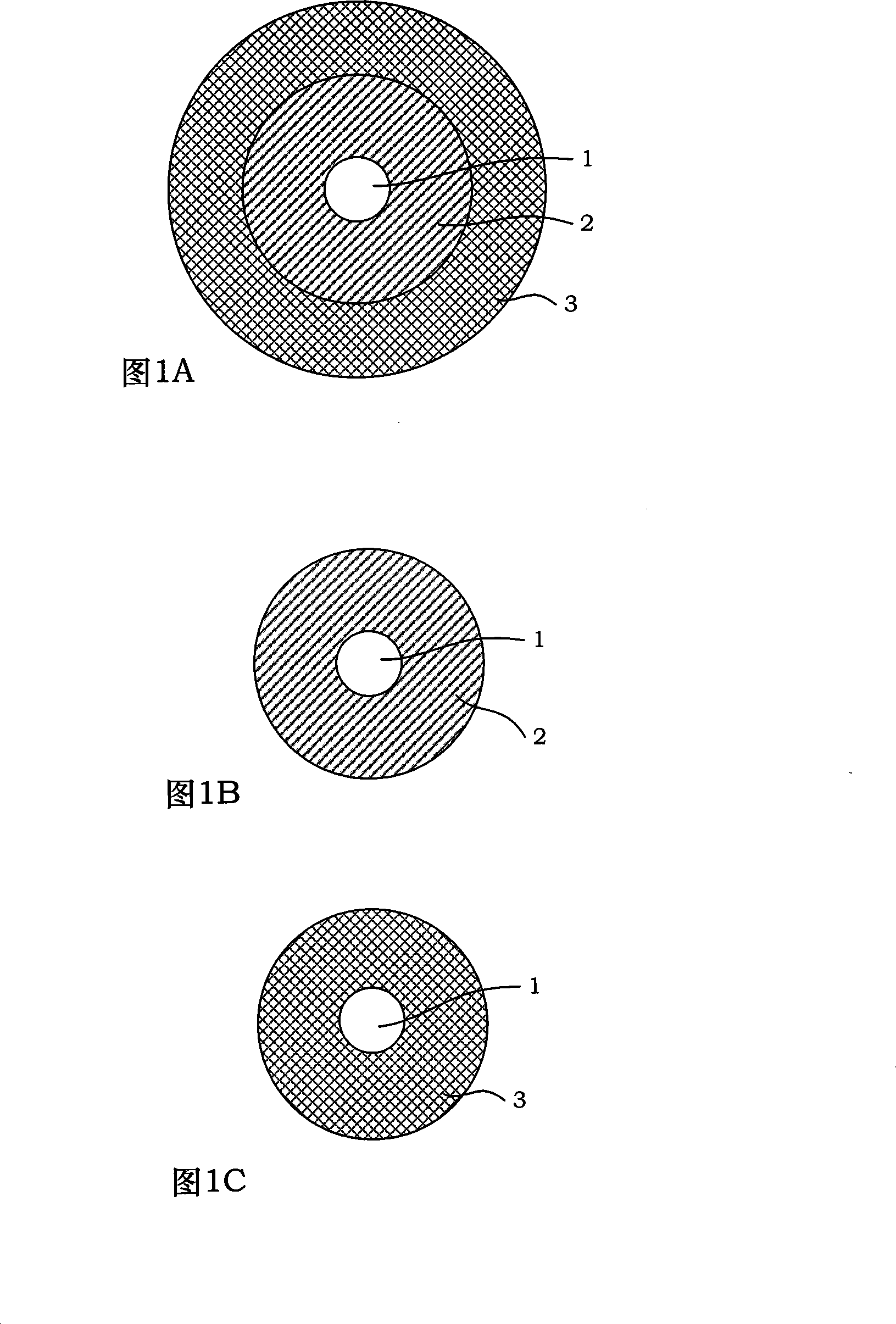

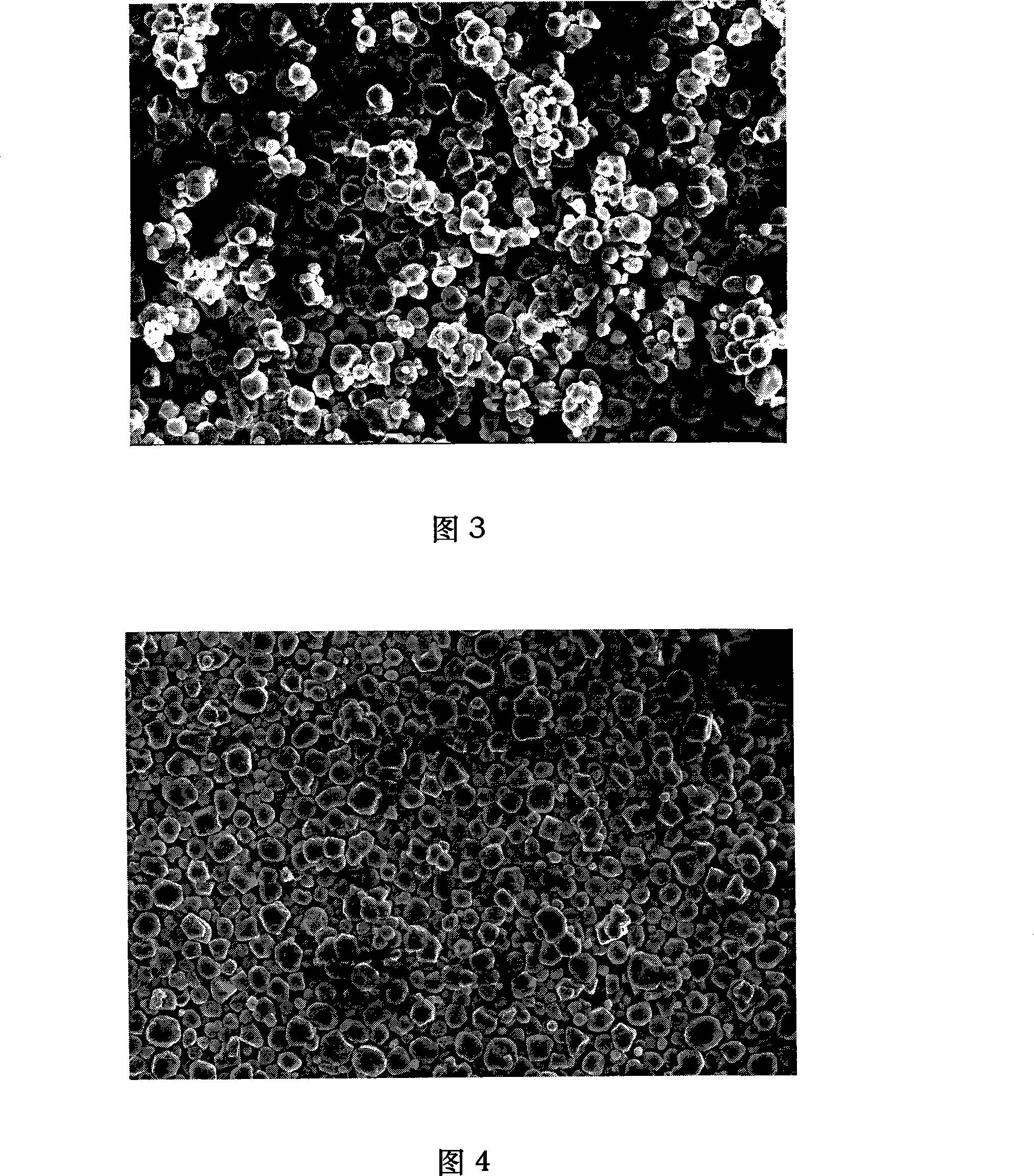

High-fluidity and strong-hydrophobicity starch and preparation method thereof

The invention discloses high flowing and strong hydrophobic starch and a preparation method thereof. The method comprises the following steps: the dry modification processing is performed to the starch by adopting the high-speed stirring equipment commonly used in the industry; a layer of hydrophobic film is wrapped on the surface of a starch granule, thereby obtaining the hydrophobic starch; simultaneously, a layer of flowing improver is wrapped on the surface of the hydrophobic starch granule, to ensure that the hydrophobic starch has good fluidity, thereby obtaining high flowing and strong hydrophobic starch granules. The technological process is simple, feasible, stable and reliable, the cost is low, the method has versatility, and the production can be operated under the prior production process and equipment condition, and the industrial large scale production can be realized. The modified starch prepared by adopting the method flows like water, floats on the water surface and cannot sink, has good fluidity as well as good hydrophobicity.

Owner:BEIHANG UNIV

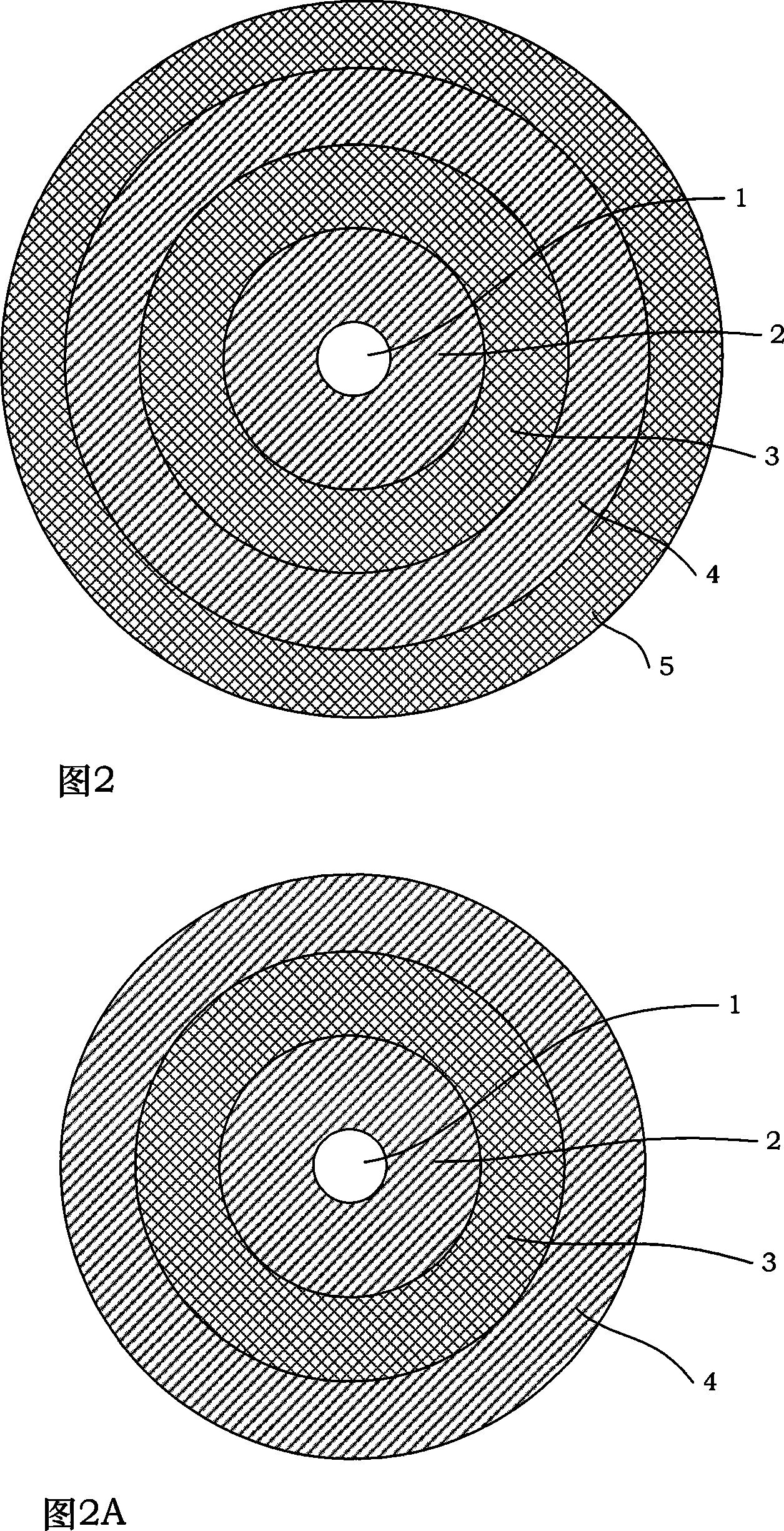

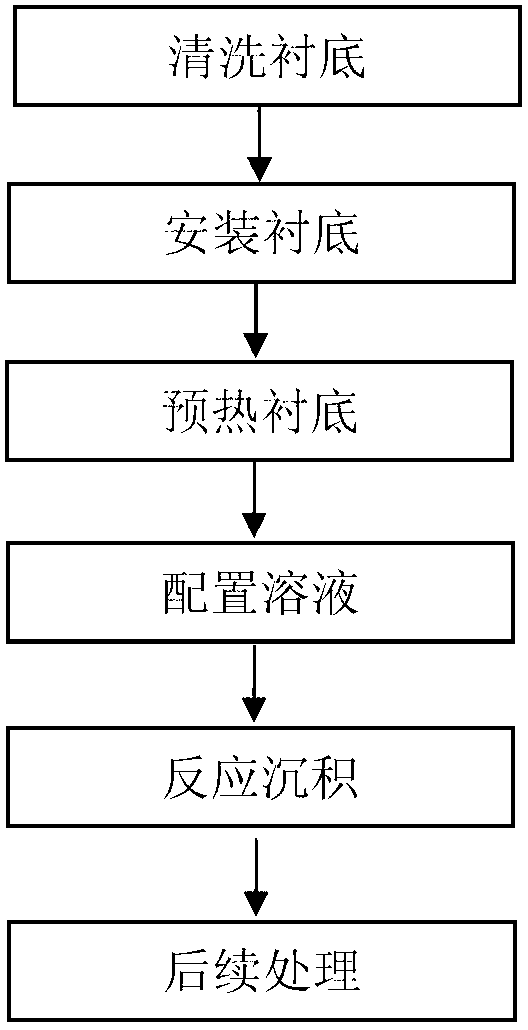

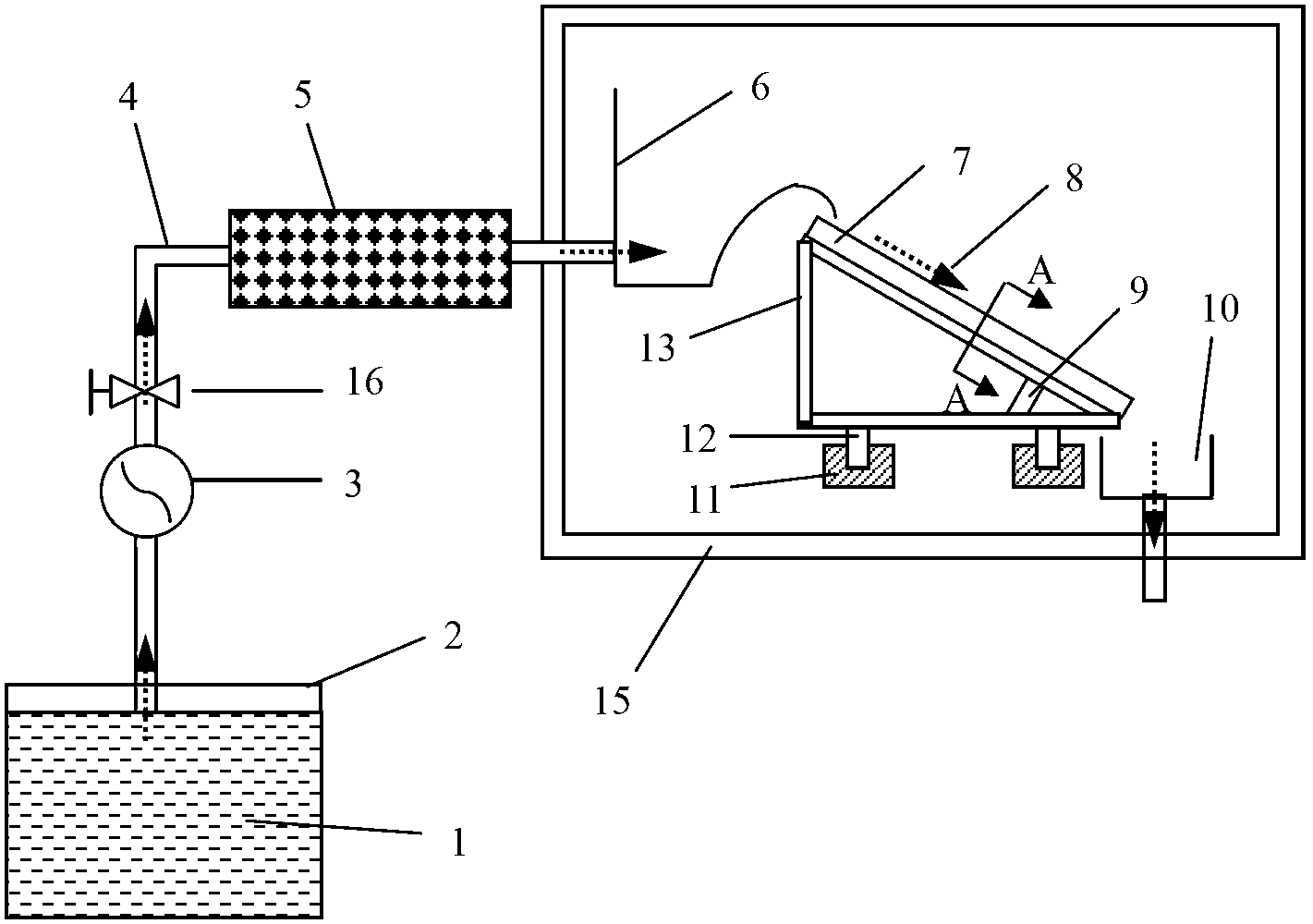

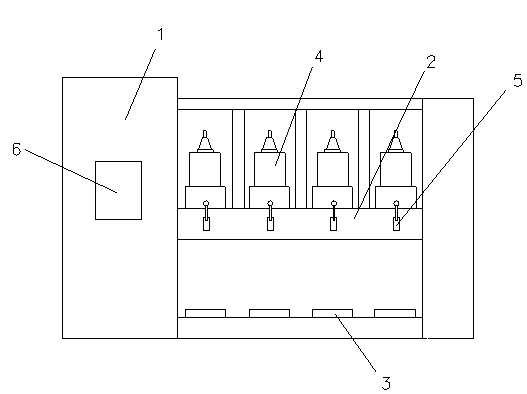

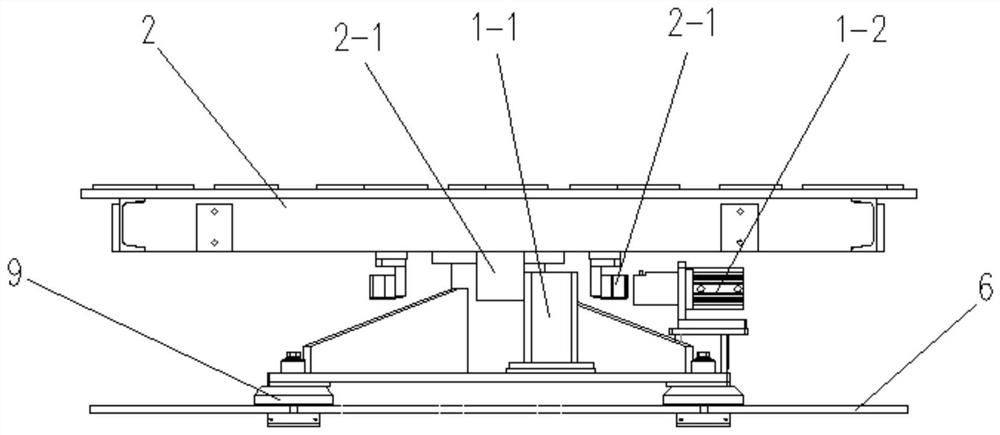

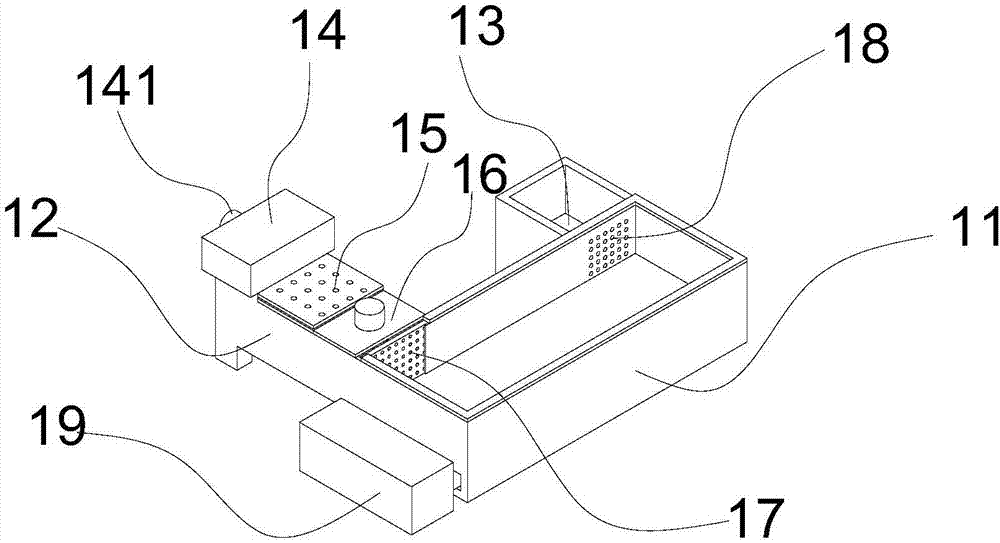

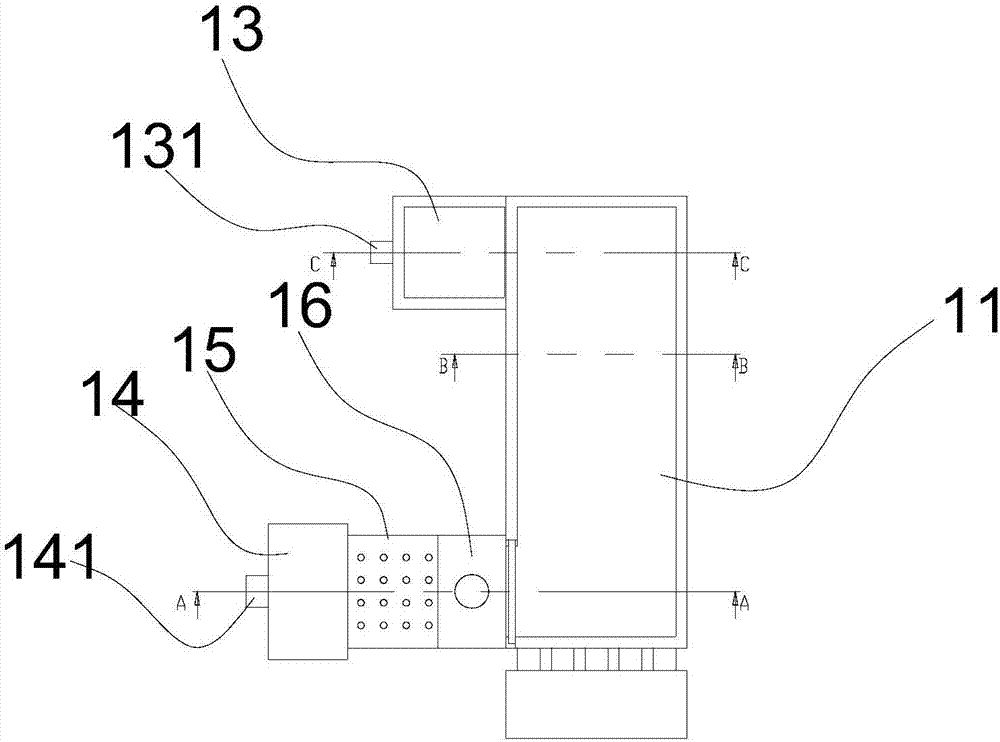

Chemical bath deposition method of cadmium sulfide film and device thereof

ActiveCN103320774AGuaranteed uniformityGuaranteed compactnessFinal product manufactureLiquid/solution decomposition chemical coatingWater bathsUltrasonic assisted

The invention discloses a chemical bath deposition method of a cadmium sulfide film and a device thereof. The method comprises the following steps: (1) cleaning a substrate and blow-drying; (2) installing the substrate; (3) preheating the substrate; (4) preparing a solution; (5) reacting and depositing; and (6) carrying out subsequent processing: washing the coated substrate by the use of deionized water and blow-drying or drying. The device comprises a reaction vessel and a thermotank. A diffuse spray groove, a substrate, a special fixture and a transmission unit are all placed inside the thermotank. A reaction solution flows through a heater and is then injected into the diffuse spray groove. The transmission unit is arranged at the bottom of the special fixture and the substrate. According to the invention, a thermostatic waterbath device, a stirring device and ultrasonic-assisted deposition are not adopted; the method provided by the invention is suitable for continuous production; production efficiency is raised; only one side of the substrate is coated, and aesthetic degree after the substrate is coated is improved; the deposited cadmium sulfide film is uniform and compact; film formation quality is high; and thin-film solar cell buffer layer requirements are met.

Owner:BEIJING SIFANG JIBAO AUTOMATION

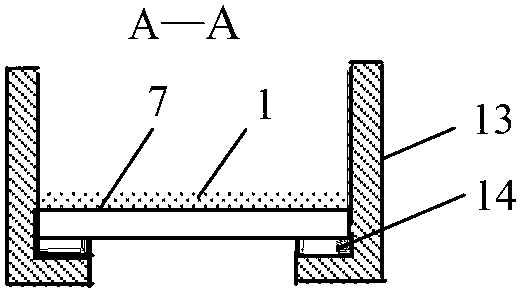

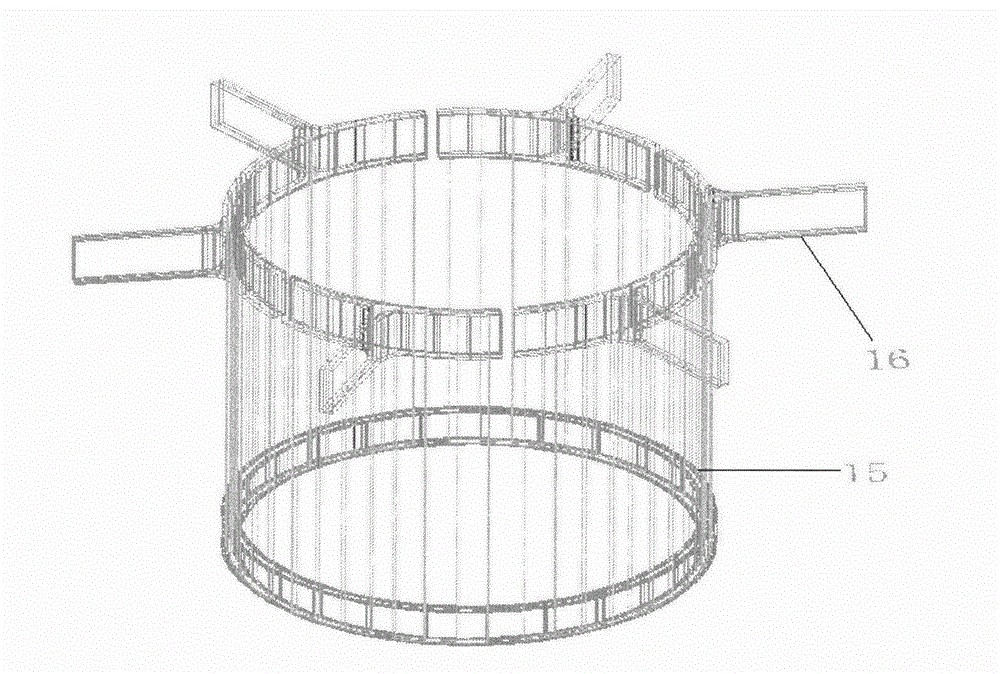

Novel heating system of sapphire crystal growing furnace

InactiveCN102978691AProcess flexible adjustmentImprove performancePolycrystalline material growthBy pulling from meltEngineeringProcessing cost

The invention discloses a novel heating system of a sapphire crystal growing furnace. The heating system comprises an upper heating body, a middle heating body and a bottom heating body. The heating system is flexible in regulation, stable in performance and low in processing cost, facilitates process regulation of a user, greatly reduces the forming time of the process technology, and also reduces the production cost.

Owner:SUZHOU INDAL PARK JIESHITONG VACUUM TECH

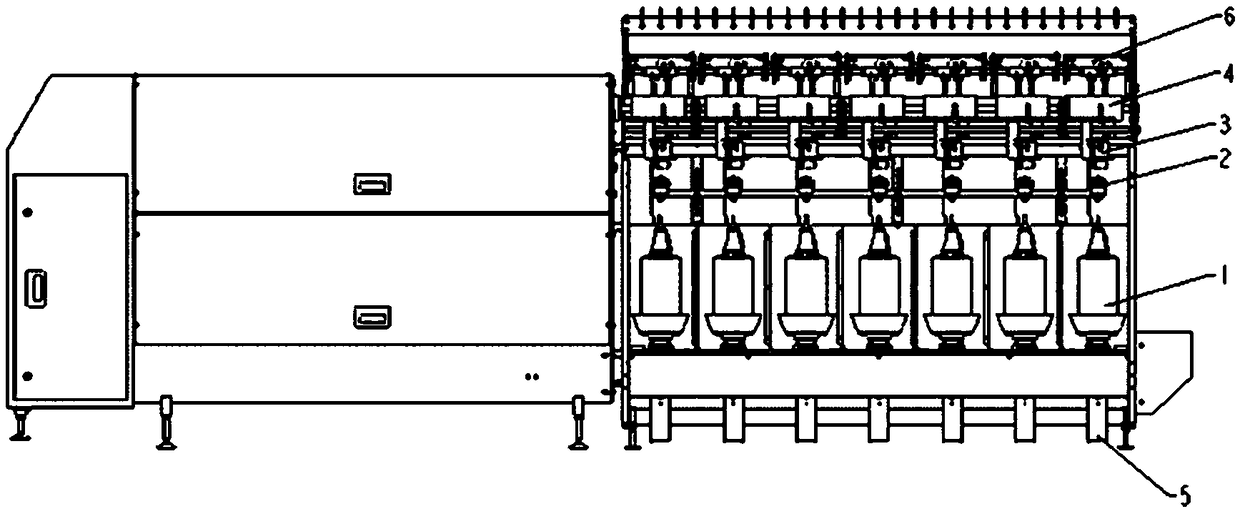

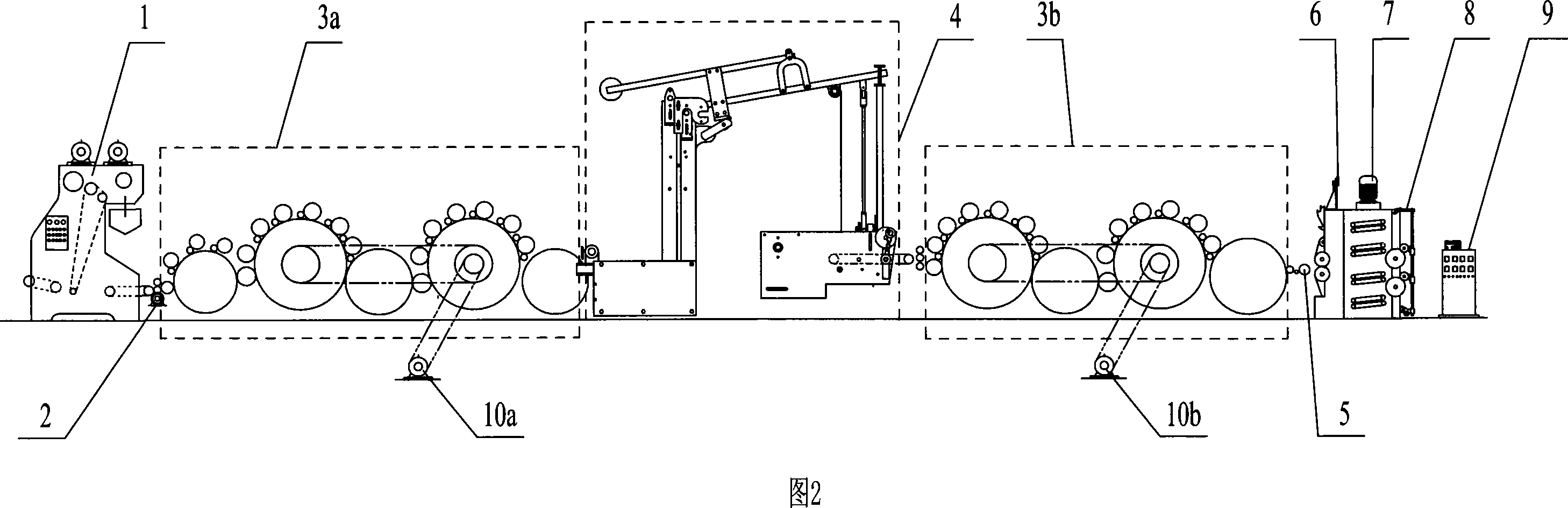

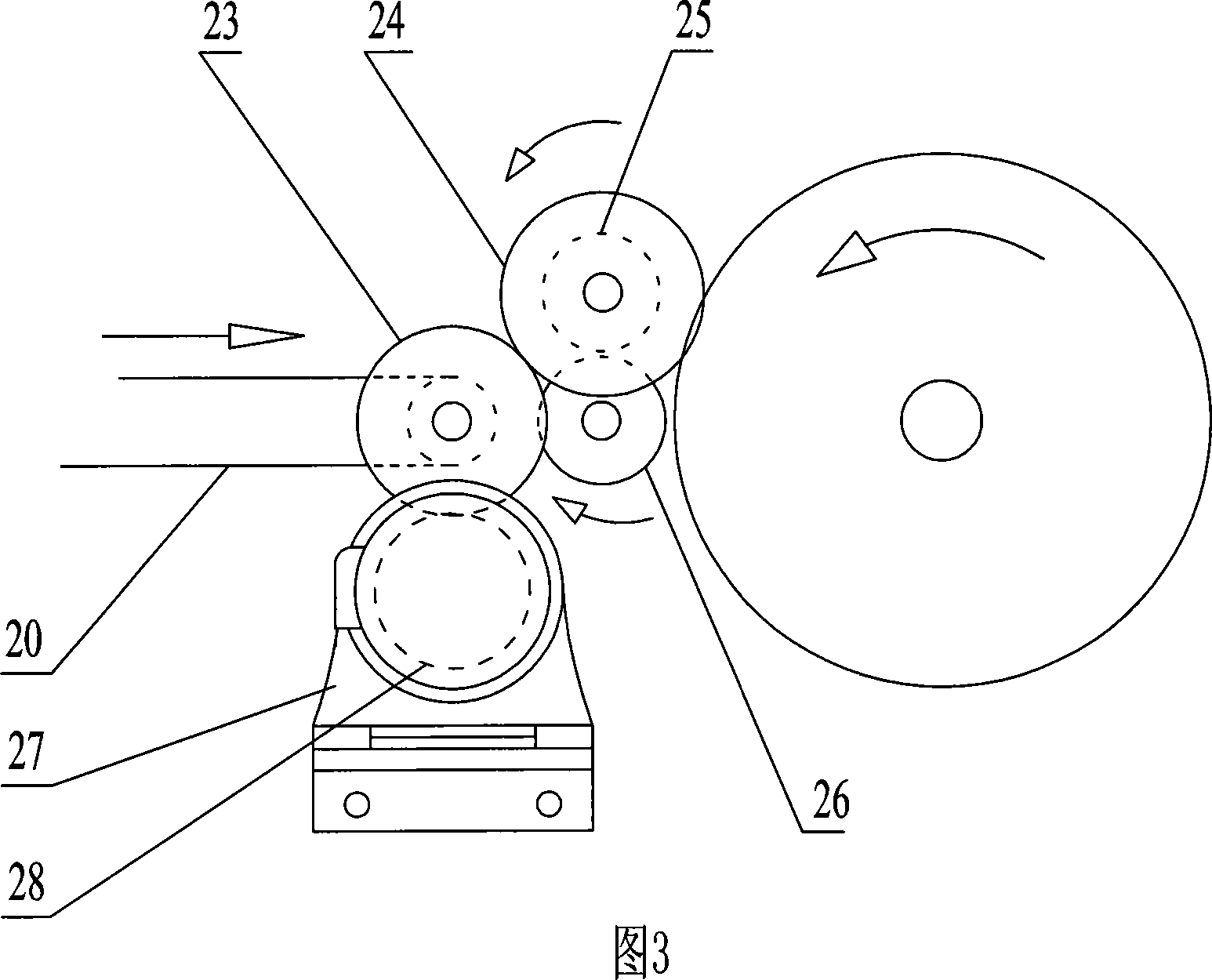

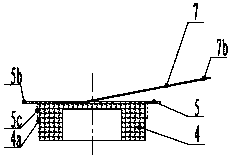

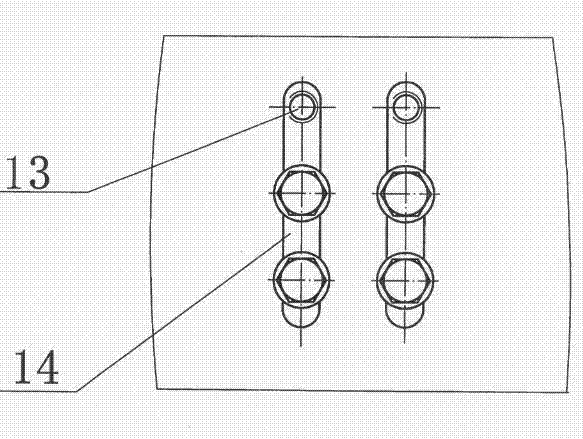

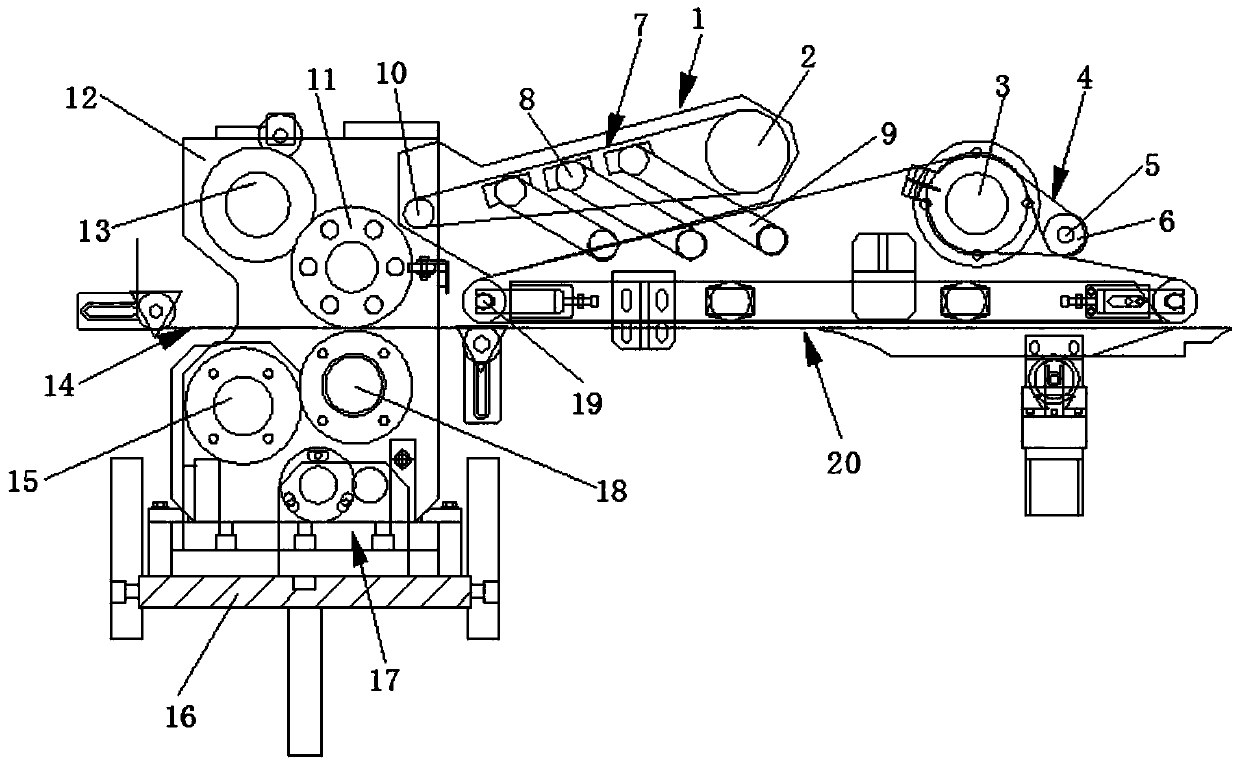

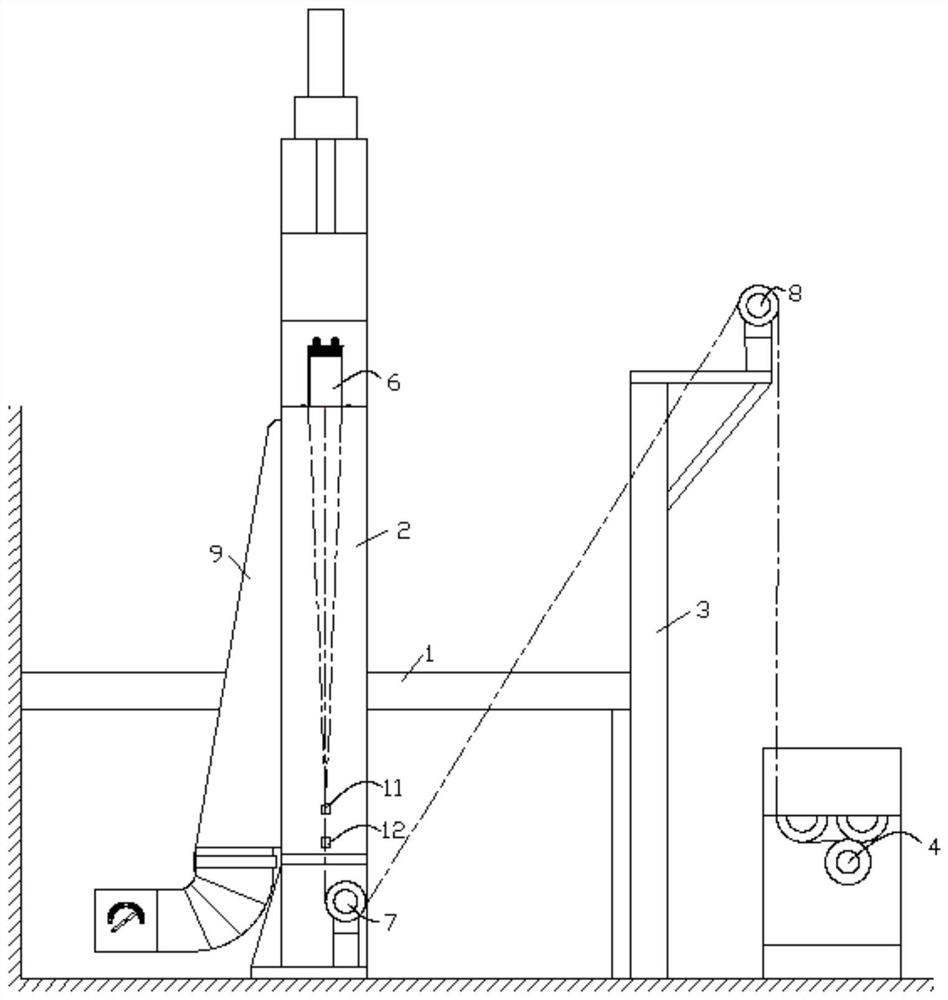

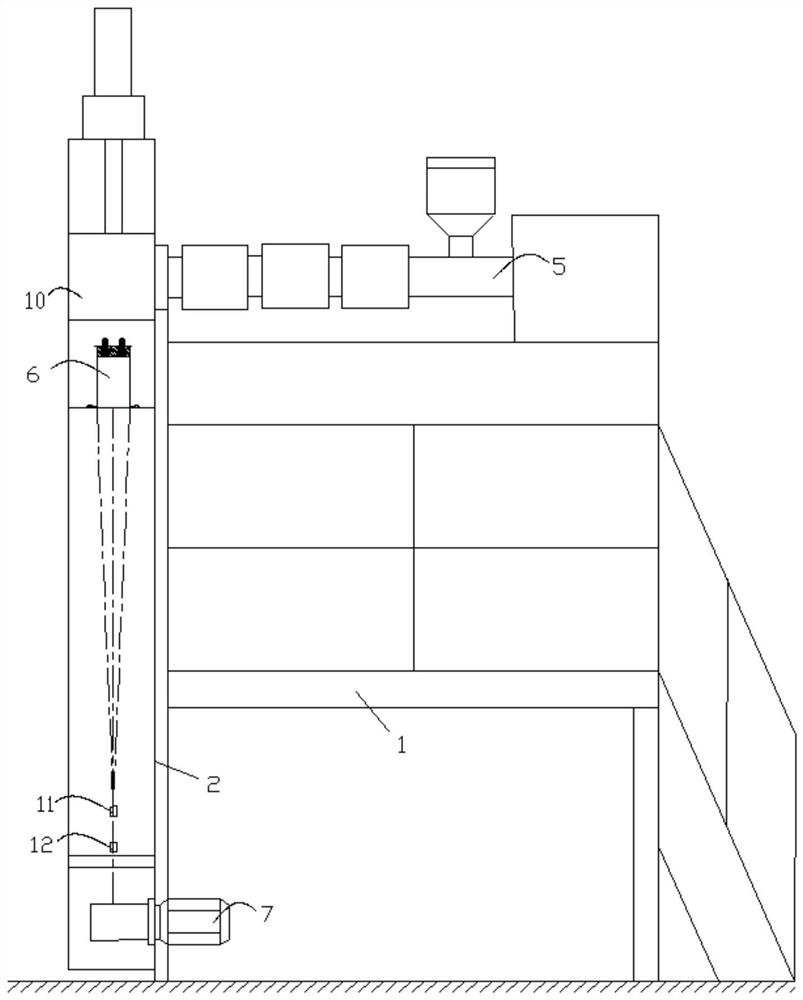

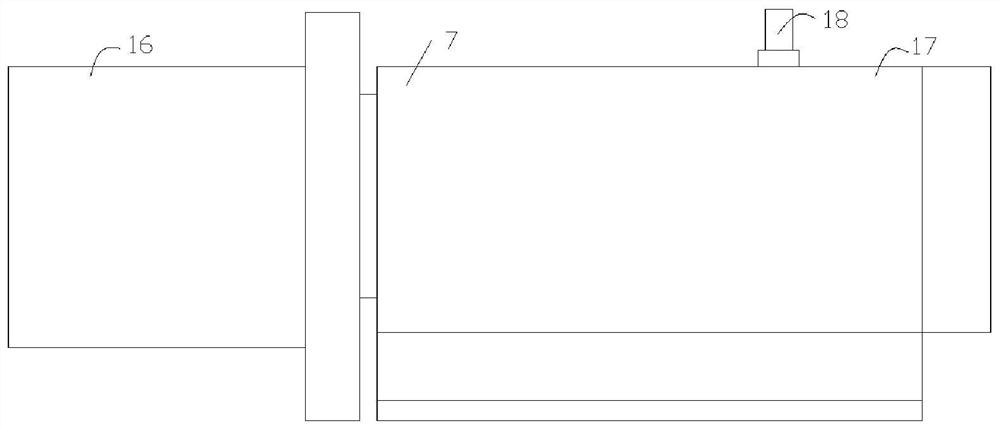

Double-twisting and sanding integrated machine for chemical fiber filaments

The invention discloses a double-twisting and sanding integrated machine for chemical fiber filaments. The double-twisting and sanding integrated machine comprises a double-twisting spindle and a sanding device, wherein the double-twisting spindle and the sanding device are mounted on a machine body; a double-roll roller is arranged at the top of the sanding device and is movably connected to themachine body, a friction roll is arranged at the top of the double-roll roller, and the friction roll is mounted on the machine body; and the sanding device comprises a yarn guiding porcelain component, a sanding cover, a sanding grinding wheel, a sanding seat and an air ring. By adjusting the height of the sanding device and the interval between the air ring in the sanding device and the yarn guiding porcelain component, ideal feathers can be obtained in a filament double-twisting link; and by controlling the sanding quantity, the outer surfaces of filaments are directly sanded when twisted chemical fiber filament products are twisted by virtue of double-twisting machine, and proper adjustment can be carried out according to the demands, so that the procedure is shortened, the cost is saved, and the problems that procedures of producing the filaments with the feathers from chemical fiber filaments are more, the production time is long, and the cost is high are solved.

Owner:ZHEJIANG RIFA TEXTILE MACHINERY TECH CO LTD

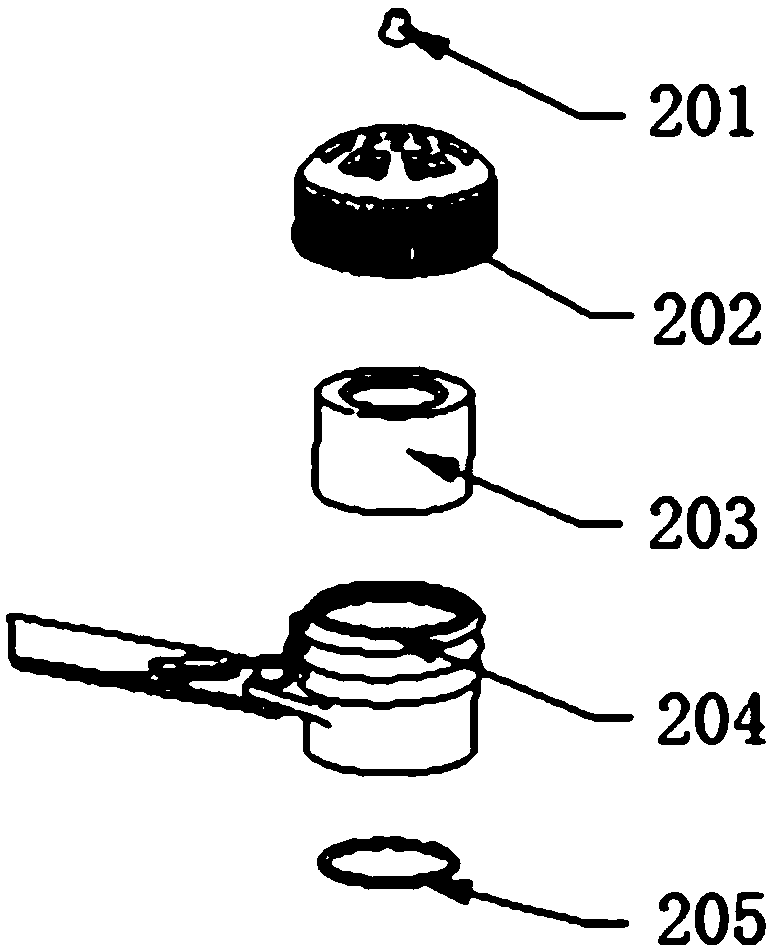

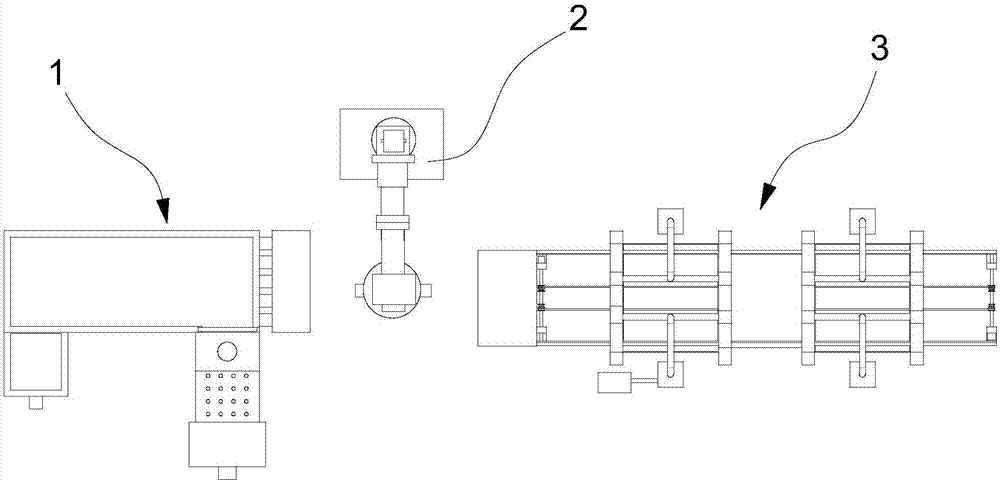

Comber

InactiveCN101086090AFeed hair evenlyEasy process adjustmentCarding machinesSynchronous motorCross over

The invention discloses a new carding machine which belongs to carding machine technology area. It includes electronic feeding bucket, metal anti-rolling device, three groups of carding device on rear vehicle, cross over device on middle vehicle, two groups of carding device on fore vehicle, wiping roller device, single leather lacing dividing device, frequency conversion motor washboard device and strip-length device which are controlled by program-controlled electronic cabin and installed consecutively, among them, three groups of carding device on rear vehicle and two groups of carding device on fore vehicle are transmitted by two frequency changing synchronous motors separately and synchronously. The invention has simple structure, smooth running, high manufacturing precision, high production efficiency and high product quality.

Owner:绍兴市偏门毛纺织有限公司

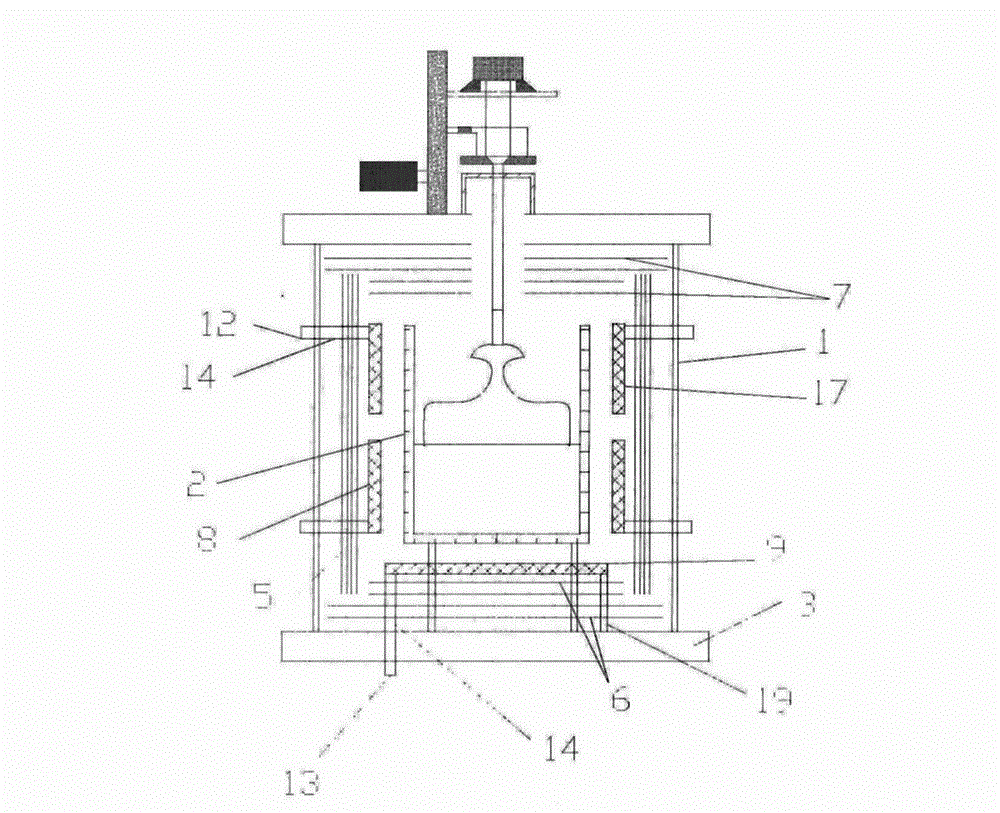

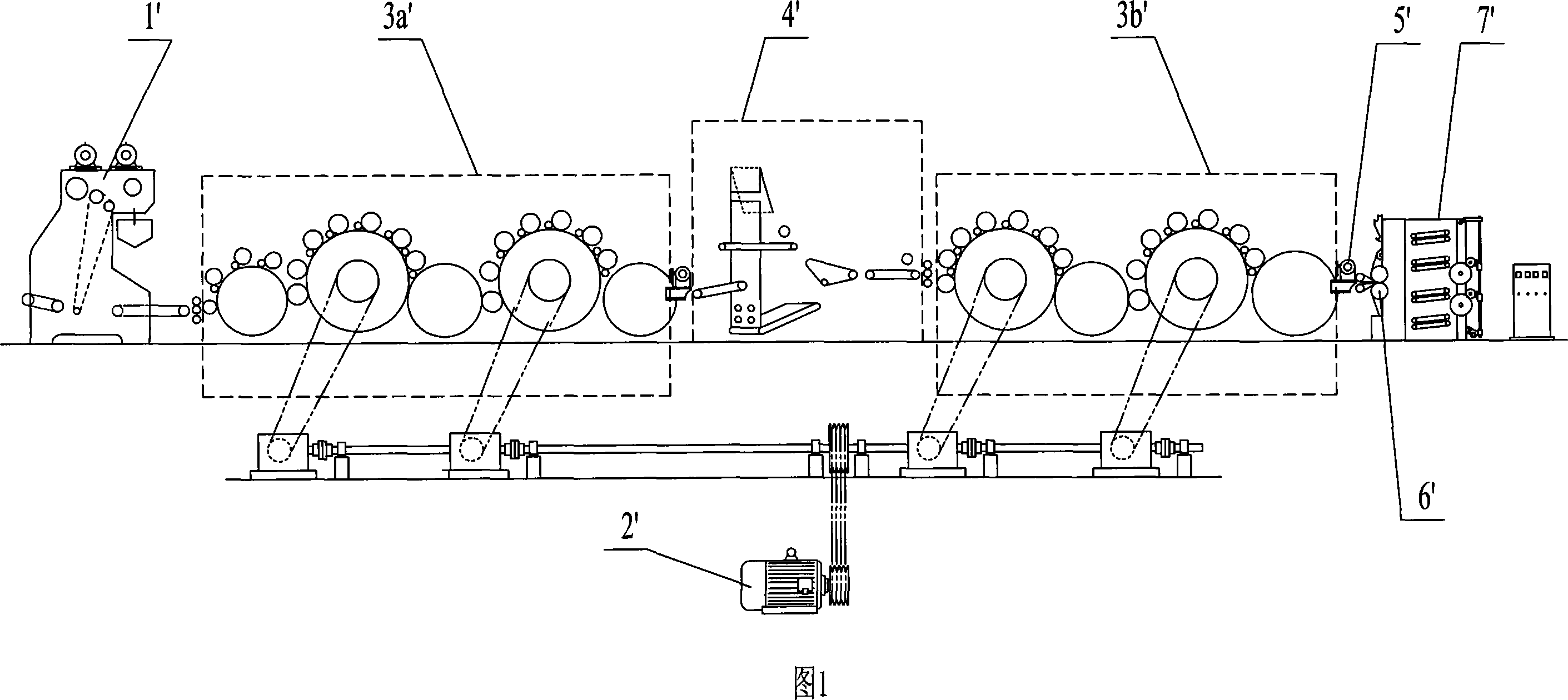

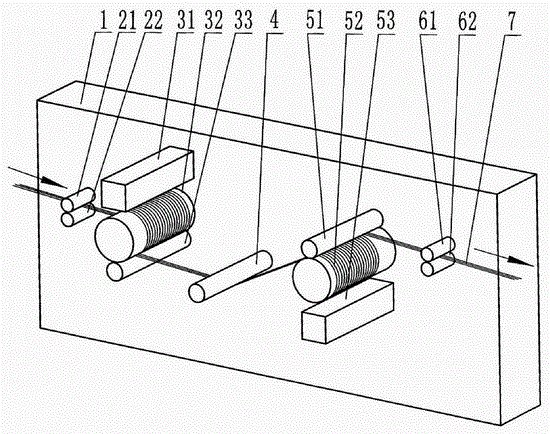

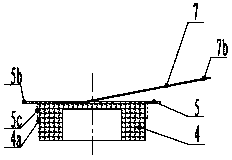

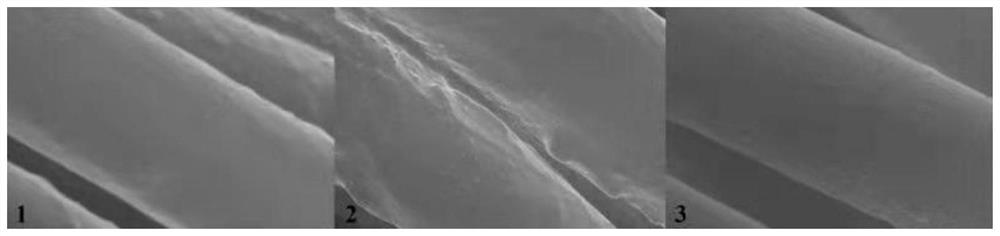

Polytetrafluoroethylene (PTFE) membrane crack short-fiber re-splitting method and device used for same

ActiveCN105624873AQuantity Percentage LowHigh fiber splitting rateTextiles and paperPorosityFiber bundle

The invention relates to a polytetrafluoroethylene (PTFE) membrane crack short-fiber re-splitting method and a device used for the same. The method comprises the steps of merging conventional PTFE membrane crack fiber bundles, then continuously feeding a drum-type spunlace unit only provided with a spunlace head for twice successively, and enabling the merged fiber bundles to be wound on a drum in a spiral form for 6-20 circles along a Z direction for running so as to enable the fiber bundles to be impacted by spunlace for 12-40 times along the positive surface direction and the negative surface direction for splitting to obtain the PTFE membrane crack fiber bundles which are high in fine fiber number percentage and low in fiber branching rate. By adopting a flexible splitting technology, the prepared fiber bundles are not easily broken by tearing, and re-splitting can be continuously carried out at high speed. The improved drum-type spunlace splitting device has the characteristics of being compact in structure, simple in operation and convenient in process adjustment. The fiber bundles prepared by the method are evenly carded into a web after being cut off, thus being widely used for preparing high-temperature-resistant filter material with small porosity and high efficiency of dust removal.

Owner:灵氟隆新材料科技江苏有限公司 +1

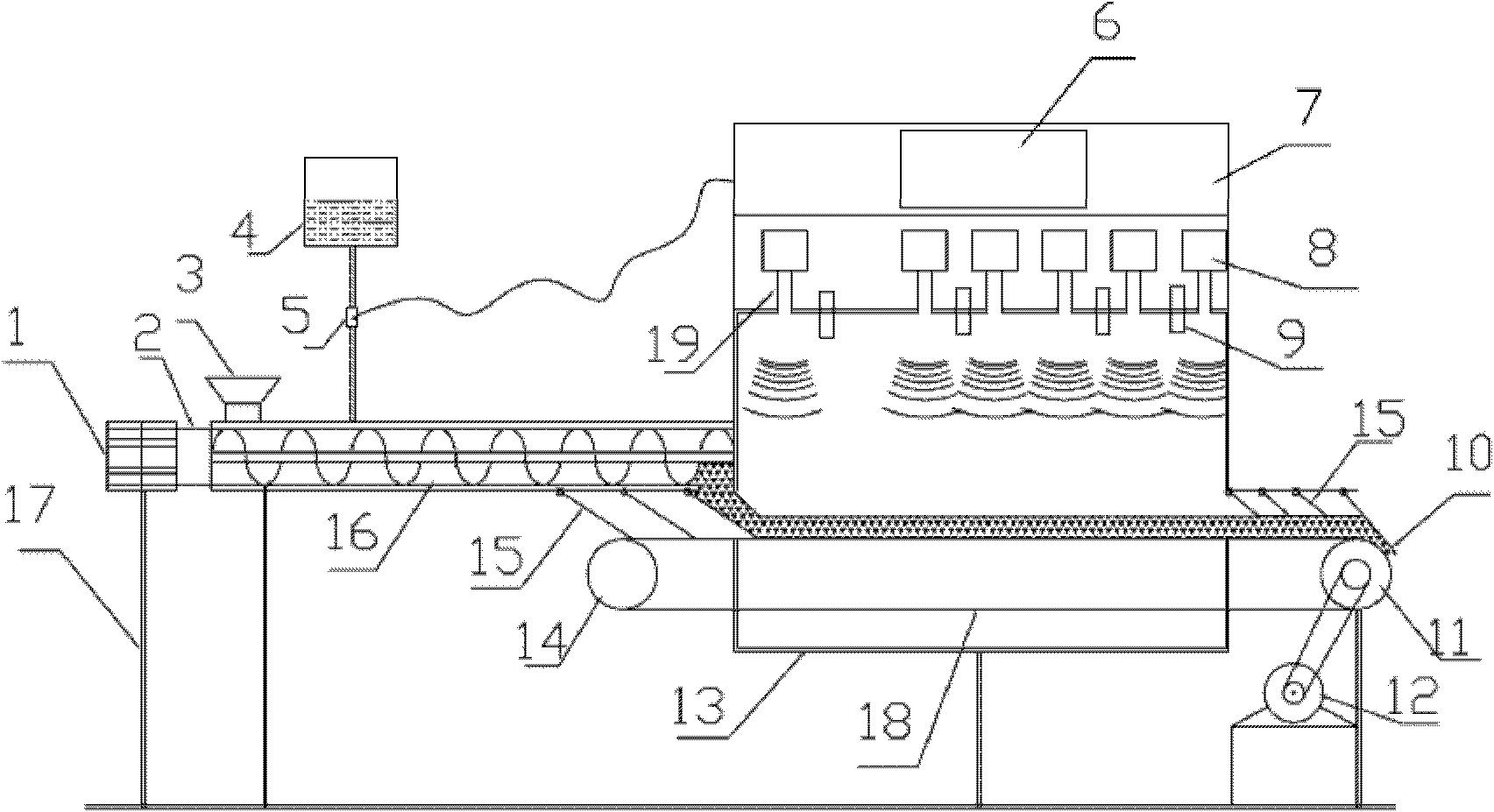

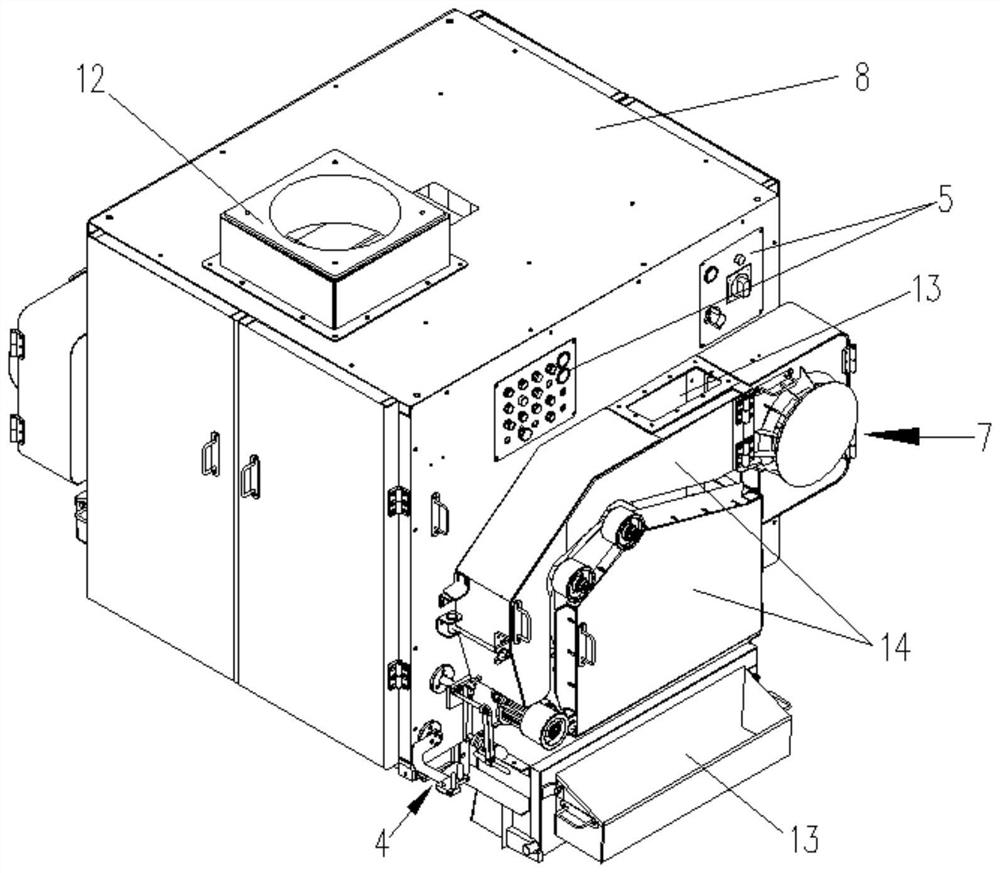

Module coupling biomass microwave dry or semidry pretreatment reactor

InactiveCN102321520ASimple structureTightly boundBioreactor/fermenter combinationsBiological substance pretreatmentsMicrowaveCoupling

The invention discloses a module coupling biomass microwave dry or semidry pretreatment reactor, which structurally comprises a material continuous input system, a material humidity regulating system, a microwave treatment system and a material output system after pretreatment. In the invention, a material is continuously conveyed through a spiral material stirrer and is continuously regulated ina required humidity range through the material humidity regulating system; moisture is uniformly distributed; and the material after humidity control is subjected to wall breaking treatment through early preheating and back-end high-power microwave in the microwave treatment system and is exported through the material output system, so that continuous pretreatment of biomass is realized. The system is of module coupling; and a plurality of systems can be connected in parallel for use to increase treatment speed and treatment capacity and can also be connected in series for use to meet the special pretreatment requirement of some biomasses. Through the reactor, continuous pretreatment of the biomass under normal pressure is realized; the equipment investment is low; the energy consumption is low; the speed is high; and the pretreatment cost is greatly reduced.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

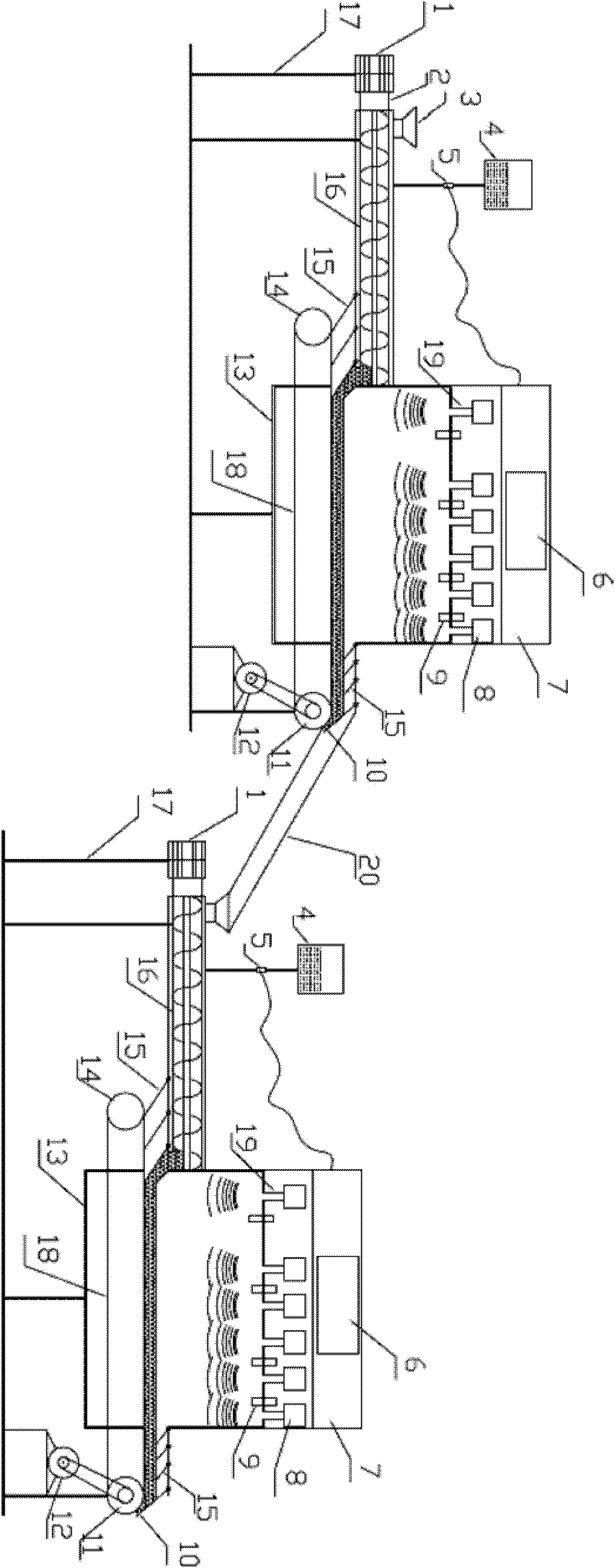

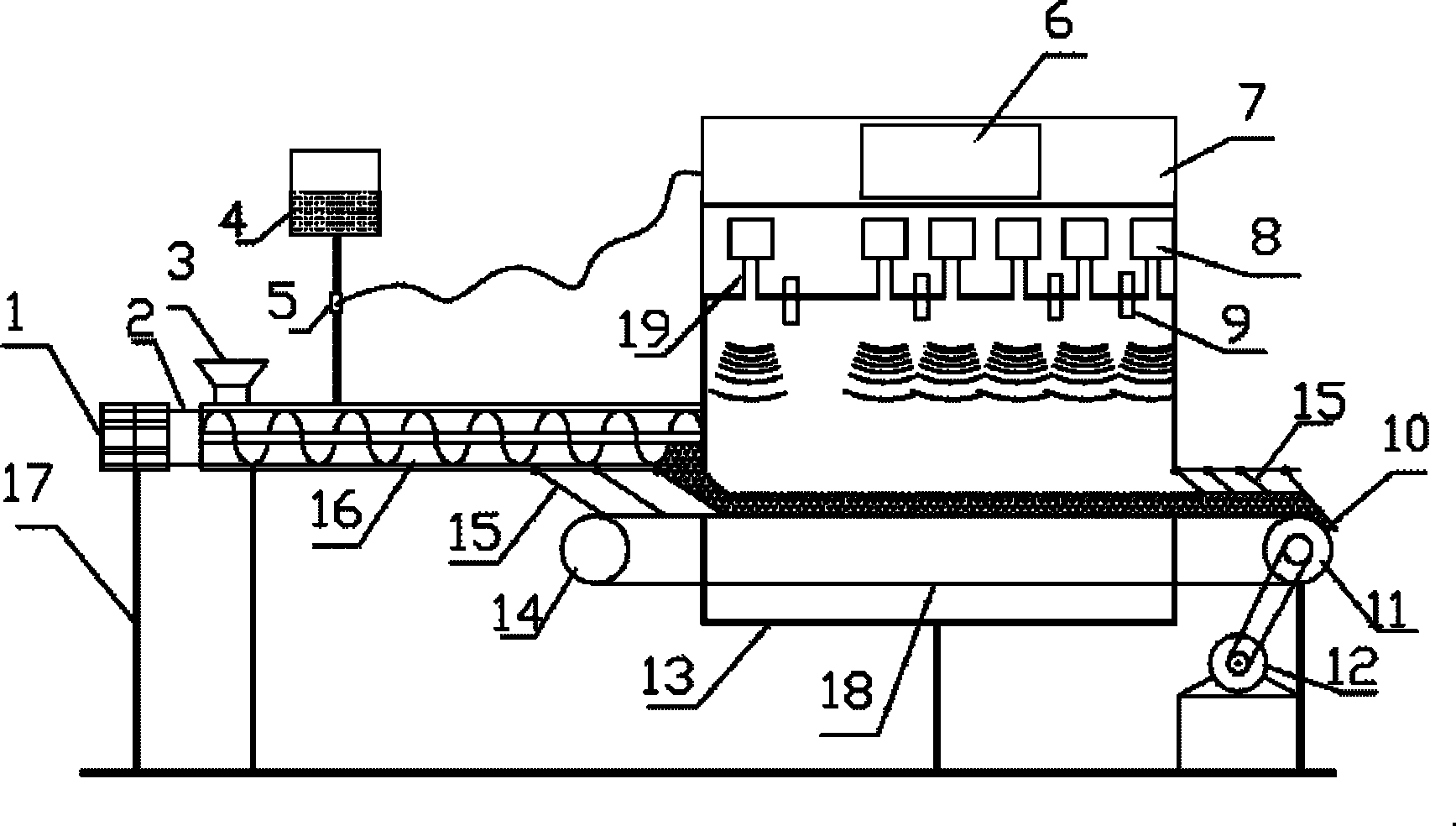

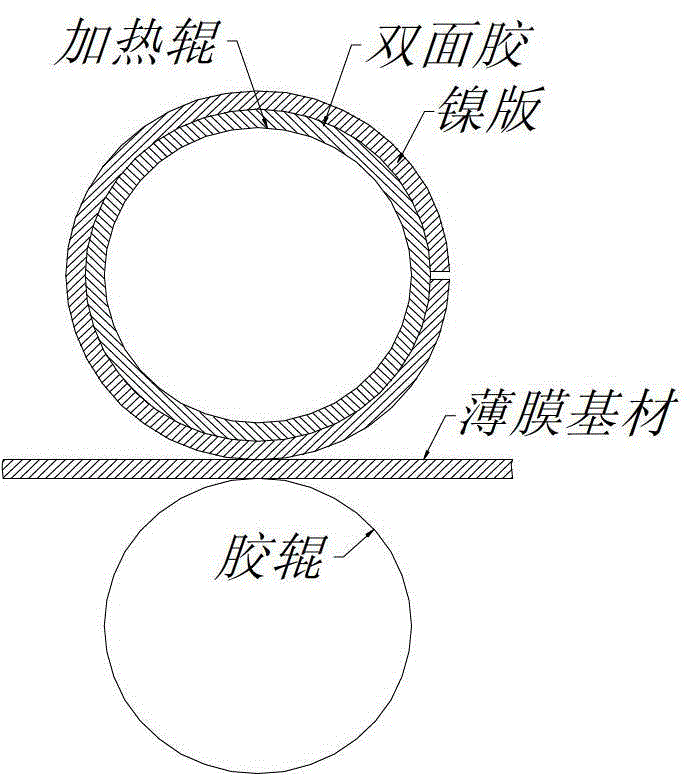

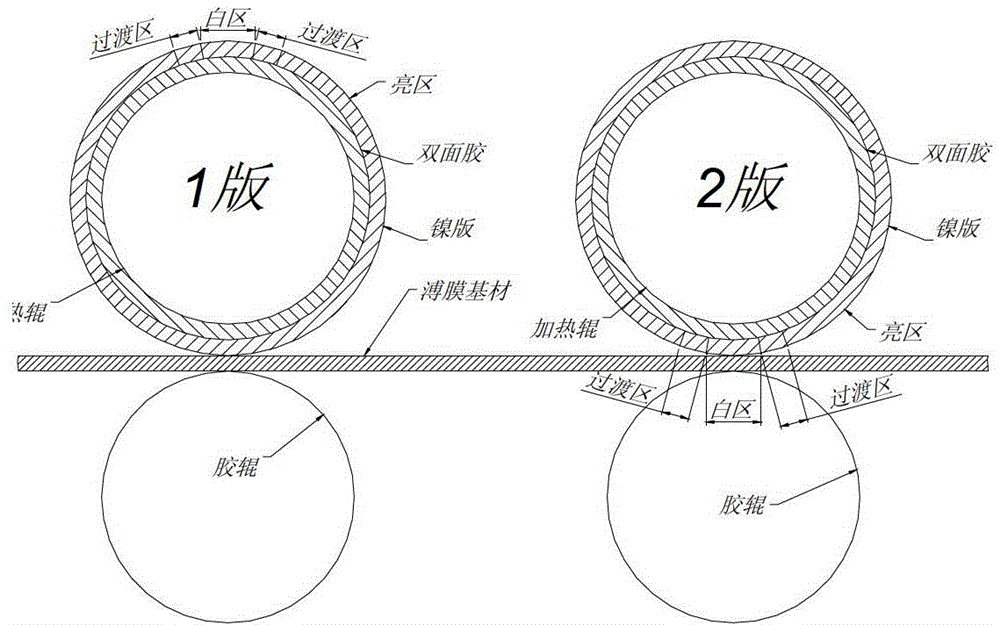

Single mold pressing continuous printing process and device

InactiveCN102909946ARealize single-shot continuous printingFlexible adjustment of production volumeRotary pressesOther printing apparatusPolyethylene terephthalatePolyethylene terephthalate glycol

The invention provides a single mold pressing continuous printing process and a device. The process comprises the following steps of: sleeving a seamless flexible annular metal soft belt outside more than two plate inner rollers; tightly opening the seamless flexible annular metal soft belt by the plate inner rollers; stamping patterns of the seamless flexible annular metal soft belt outside the plate inner rollers through opposite pressing of the plate inner rollers and an opposite pressing roller; and heating and cooling the patterns to ensure that the patters are developed to a film base material, wherein polyethylene terephthalate (PET), polyvinyl chloride (PVC), biaxially-oriented polypropylene (BOPP) and the like are generally used as the base material, and a layer of developing coating material is coated on the surface of the base material. Through the process and the device, seamless printing can be realized in a true sense, the production output is doubled and redoubled, and the process steps and the structure of the device are simple, so that the process and the device are suitable for industrial production.

Owner:上海联净电子科技有限公司

High-penetrating agent and preparation method thereof

ActiveCN103257021AReduce tensionEasy to detectDetection of fluid at leakage pointOrganic solventWork in process

The invention discloses a high-penetrating agent and a preparation method of the high-penetrating agent. The high-penetrating agent comprises, by weight, 0.05%-1.0% of surfactant, 2%-8% of organic solvent, 0.05%-1.0% of pigment, and the balance water. The surfactant is anionic surfactant or nonionic surfactant. The invention further provides the preparation method of the high-penetrating agent. Experiments show that the high-penetrating agent is good in detection effect of tightness of pull ring cutting mark and welding of a plastic infusion container, and capable of shortening the detection time. Particularly, the welding tightness of semi-finished products can be directly detected, the detection period can be controlled to be within two hours. The above advantages bring great convenience to adjustment of equipment and the technology on production site, reduce detection cost, and greatly reduce potential quality hazard caused by detection errors of the products.

Owner:SHIJIAZHUANG NO 4 PHARMA +1

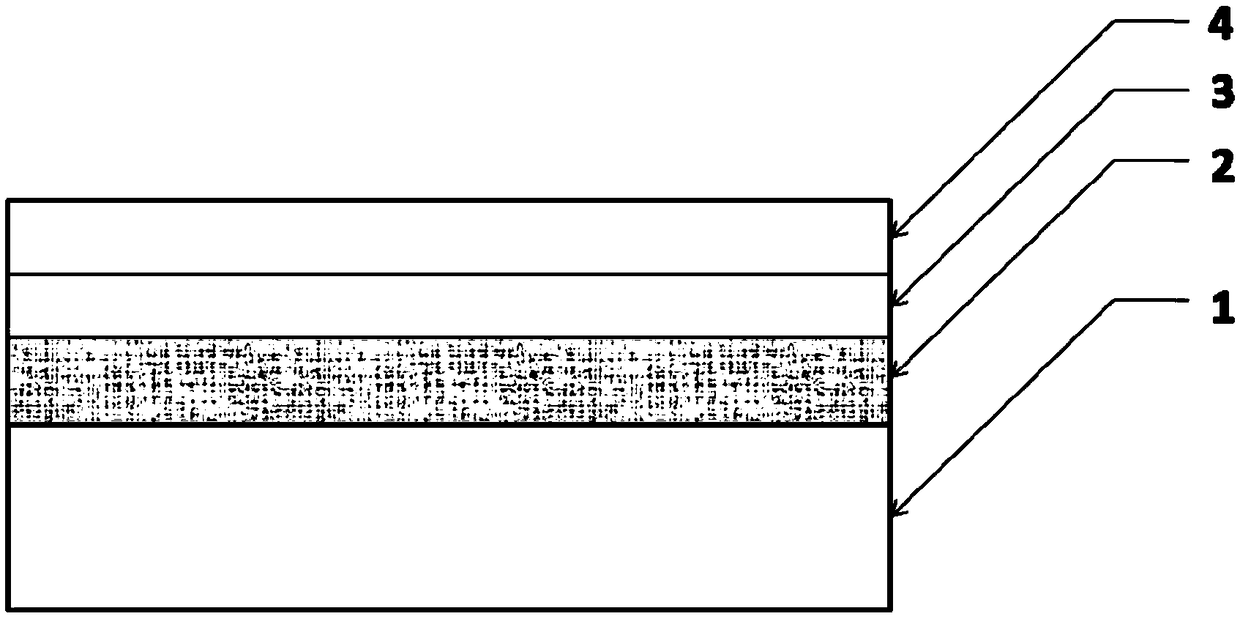

Composite transparent conductive film and preparation method thereof

ActiveCN108998772AHigh precisionMeet different levels of antistatic requirementsLiquid surface applicatorsVacuum evaporation coatingElectricityConductive polymer

The invention discloses a preparation method of a composite transparent conductive film and application thereof in antistatic electricity. The composite transparent conductive film comprises a transition layer, a conductive layer and a protective layer, wherein the transition layer is formed on a glass or plastic surface substrate and is a polyurethane acrylate or polysiloxane coating; the conductive layer is one of an ITO film, an AZO film, an IZO film, a TiO2 film, a GAO film and a ZAO film, and is deposited on the transition layer; the protective layer is deposited on the conductive layer,and is one of silicon oxide, titanium nitride and silicon nitride. According to the invention, a problem that electrostatic charges are accumulated on a surface of a transparent piece is solved whilesalt spray and moist heat resistances and other environmental properties of the conductive layer are improved by controlling the thickness and density of the protective layer.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

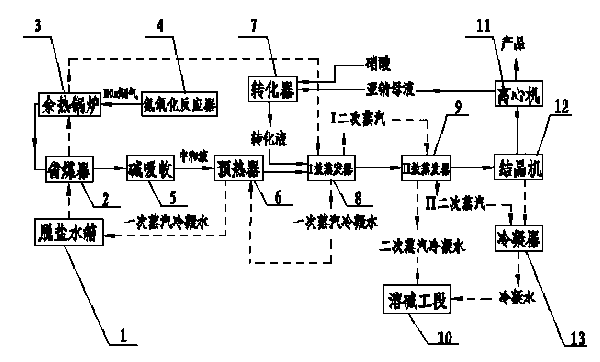

Steam self-supply system for producing sodium nitrate/sodium nitrite

ActiveCN103848443AConducive to emission reductionReduce the temperatureEnergy inputAlkali metal nitrate preparationEngineeringSodium nitrite

The invention discloses a steam self-supply system for producing sodium nitrate / sodium nitrite, which is suitable for preparing sodium nitrate / sodium nitrite. A desalination water tank is connected with a waste heat boiler through a coal economizer, and the waste heat boiler is connected with an ammoxidation reactor; the coal economizer is communicated with a crystallizer through an alkaline absorber, a preheater, an I-effect evaporator and an II-effect evaporator; the preheater is connected with the desalination water tank; a converter is respectively connected with the I-effect evaporator and a centrifugal machine; the II-effect evaporator is respectively connected with an alkaline dissolving workshop section and the crystallizer; the alkaline dissolving workshop section is connected with the centrifugal machine through a condenser and the crystallizer. The steam self-supply system is remarkable in energy saving benefit, convenient for process regulation and pollutant discharge reduction, high in degree of automation, remarkable in steam saving effect and high in recycling ratio.

Owner:襄阳泽东化工集团股份有限公司

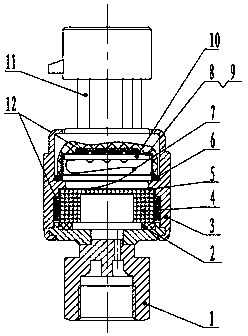

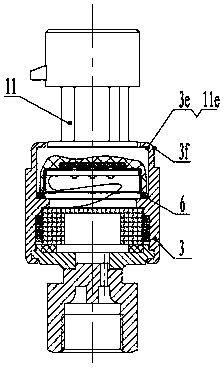

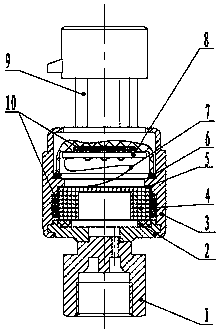

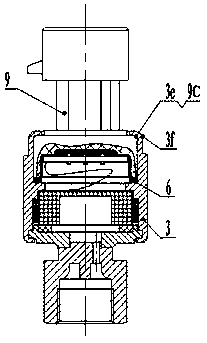

Pressure transmitter

ActiveCN103411726APrevent crushingImprove stabilityFluid pressure measurementElectrical resistance and conductanceEngineering

The invention discloses a pressure transmitter. A contactor component of a packaging structure of the pressure transmitter is connected with a boiler or a pressure container or a pressure pipeline to provide a pressure source for a sensitive element. According to the pressure transmitter, an inner metal shielding case structure is adopted to shield a circuit board, EMC performance is increased, and insulation resistance and electric strength of products are greatly improved; meanwhile, a split type riveting connection structure is adopted to package the contactor component and an outer shell, the outer shell and an electric plug-in are connected through a riveting connection mode, and a corresponding seal ring, the sensitive element and the circuit board are installed in a shell body. According to the pressure transmitter, due to the fact that the simple package structure is adopted, the structure is simple, processing adjustment is convenient to achieve, and manufacturing cost is reduced.

Owner:SHANGHAI JUNLE REFRIGERATION CONTROL

Improved pressure transmitter

ActiveCN103411722APrevent crushingImprove stabilityFluid pressure measurement by electric/magnetic elementsTransmitterPressure vessel

The invention discloses an improved pressure transmitter. A connector component of a packaging structure of the improved pressure transmitter is connected with a boiler or a pressure container or a pressure pipeline to provide a pressure source for a sensitive element. The improved pressure transmitter is connected with an outer shell through a circuit board, carries out shielding on the circuit board, and improves the EMC performance. Meanwhile, the connector component and the outer shell are packaged through a split-body riveting connecting structure, the outer shell and an electrical insertion part are connected in a riveting mode, and a corresponding seal ring, the corresponding sensitive element and the corresponding circuit board are installed in the shell body. Due to the fact the simple packaging structure is adopted, the improved pressure transmitter is simple in structure, facilitates technology adjustment, and reduces manufacturing cost.

Owner:SHANGHAI JUNLE REFRIGERATION CONTROL

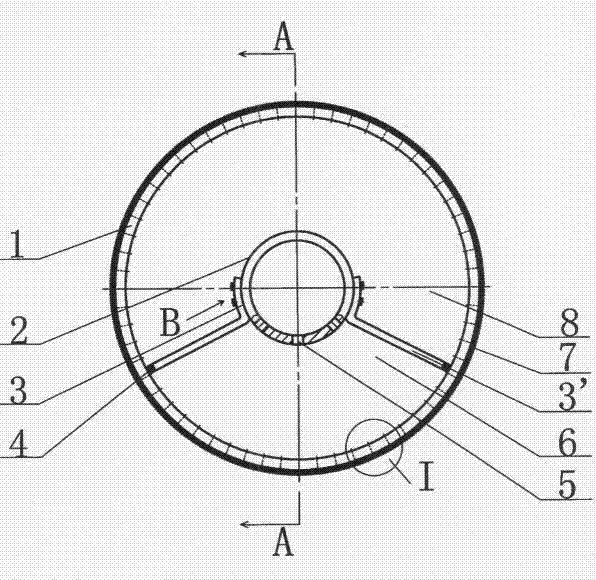

A suction type doffer device installed on a nonwoven carding machine

InactiveCN102260936AGood density uniformityThe total utilization rate of raw materials is highCarding machinesAirflowEngineering

The invention relates to a suction type doffer device arranged on a nonwoven carding machine. The device comprises a roller body, a core shaft, front and rear wind shields, left and right end covers, card clothing, a synchronous belt pulley and a synchronous belt. The traditional basic doffer structure is reserved in the device; an airflow passage communicated with a suction fan is formed for theroller body, the core shaft and the card clothing, and an inner suction system is formed, so that the device has adsorption effect on the fibers with low curling degree and low length to prevent the fibers from being dissociated and stripped in the high-speed production process; and an adjustable negative pressure suction area is formed by arranging the components such as the wind shields, a brush and the like to meet different installation position requirements of different fiber raw materials, a main cylinder and a condensation roller. The device has the advantages of compact structure, simplicity in operation, convenience for process adjustment, wide range of the processed fiber raw materials and high production speed; and compared with the traditional doffer device, the device has theadvantages that: the density uniformity of a fiber web surface carded and processed by the device is improved by 16 to 27 percent, and the total utilization rate of the raw materials is improved by 12 to 22 percent.

Owner:SHAOXING COUNTY ZHUANGJIE NONWOVEN MATERIAL +1

Green float glass and production method thereof

The invention relates to a green float glass and a production method thereof. The green float glass comprises 70.0 to 75.0% of SiO2, 0 to 3.0% of Al2O3, 8.0 to 11.0% of CaO, 2.0 to 4.8% of MgO, 13.0 to 16.0% of Na2O, 0.3 to 0.8% of K2O, 0.2 to 0.23% of SO3 and 0.570 to 0.630% of Fe2O3. The green float glass also contains FeO which accounts for 24 to 27% of the total mass of Fe2O3. Through introduction of the colorant Fe2O3 powder on the basis of a formula for common white float glass, no extra colorant is needed and special clarification equipment is not needed. The production method for the glass is simple, controllable and stable in process; process adjustment is convenient and easy; production cost is lower; and the prepared glass can be changed in color, transmittance and reflectivityso as to meet the requirements of market customers.

Owner:梁泽超

Large package two-for-one twisting device

InactiveCN103255510AEasy process adjustmentEasy to operateContinuous wound-up machinesYarnEngineering

The invention discloses a large package two-for-one twisting device which comprises a control box and a two-for-one twisting mechanism. The control box is arranged on one side of the two-for-one twisting mechanism. The two-for-one twisting mechanism comprises a rack. The lower end of the rack is provided with a yarn storage device, a plurality of spindles are fixed at the upper end of the rack, the spindles are connected with the yarn storage device through a yarn winding device, a plurality of hand brakes are arranged on the rack, and the hand brakes are connected with the spindles in a one-to-one corresponding mode. The large package two-for-one twisting device is simple in structure, convenient to operate, high in degree of intelligentization, safe and reliable, greatly improves yarn technology speed, enables the speed to be improved by 40%-60% compared with that of traditional yarn and improves yield by 40%-60%. Besides, the amount of yarn with enough strength can be improved by 100%.

Owner:范绍明

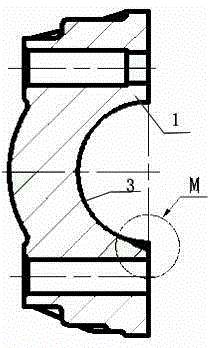

Novel engine main bearing cover tile locking trough testing fixture

InactiveCN105258604ARealize measurementResolve detectionMechanical diameter measurementsClassical mechanicsEngineering

The invention provides a novel engine main bearing cover tile locking trough testing fixture. The middle part of a testing platform is provided with a neutral gear opening. A mandrel is transversely arranged from one side of the testing platform. The mandrel penetrates through the testing platform and penetrates out of the other side of the testing platform. Furthermore the other side of the testing platform is provided with a gauge stand. A dial gauge is arranged on the gauge stand, wherein the measuring head of the dial gauge corresponds with the top end of the mandrel. The upper part of the testing platform is provided with a clamping device. The pressing head of the clamping device corresponds with the portion above the neutral gear opening. The testing platform is provided with floating positioning pins at two sides of the neutral gear opening. The floating positioning pins correspond with pinholes at two sides of the main bearing cover. The mandrel is also provided with a mandrel cover at the position of the neutral gear opening. The mandrel sleeve is provided with a first clamping board and a second clamping board with different diameters, wherein the diameters respectively correspond with an upper limit dimension and a lower limit dimension of the tile locking trough. The novel engine main bearing cover tile locking trough testing fixture has an advantage of convenient use. The novel engine main bearing cover tile locking trough testing fixture has functions of testing the position dimension and the shape dimension of the tile locking trough, visually feeding a processing condition back through numbers of the dial gauge, and facilitating process adjustment.

Owner:东实汽车动力零部件(湖北)有限公司

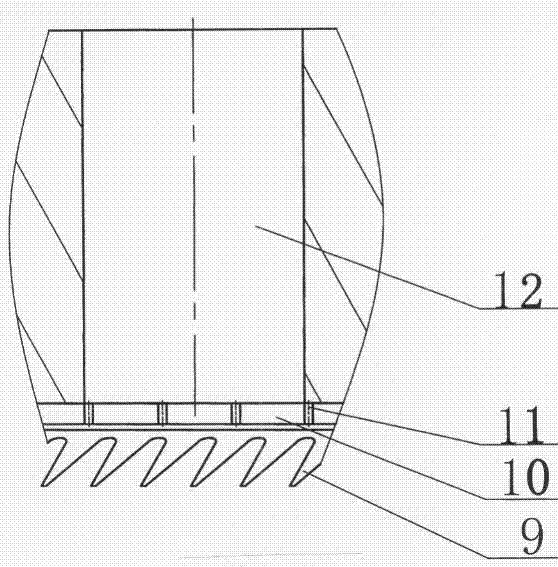

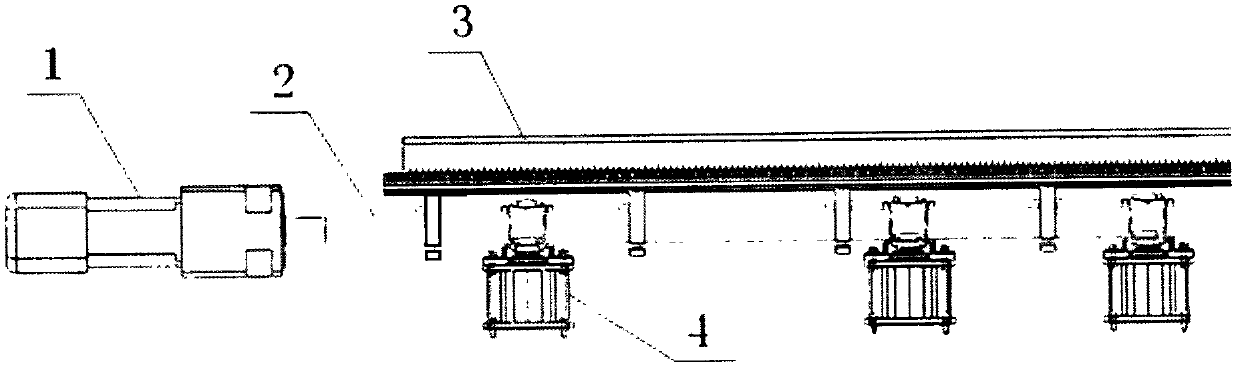

High-speed glass fiber chopping machine

ActiveCN112047621AQuick switchEasy process adjustmentGlass making apparatusGlass productionGlass fiberYarn

The invention discloses a high-speed glass fiber chopping machine, belongs to the technical field of glass fiber shearing equipment, and solves the problems of incapability of meeting the requirementon cutting length, high labor intensity and low production efficiency due to adoption of a radial cutter head pressing wheel internally-tangent cutting technology in an existing cutting machine. The high-speed glass fiber chopping machine comprises a cutting device and a loading device, the loading device is used for pulling the fiber yarn to be cut to the meshing area of the cutting device; the cutting device cuts off the glass fibers to the preset fiber length in a radial cutter head pressing wheel external cutting mode. The chopping machine innovatively provides a radial cutter head pressing wheel externally-tangent type cutting-off technology, glass fibers with various diameter specifications can be drawn and chopped, the labor intensity is reduced, and the production efficiency is improved.

Owner:泰安景行新材料有限公司

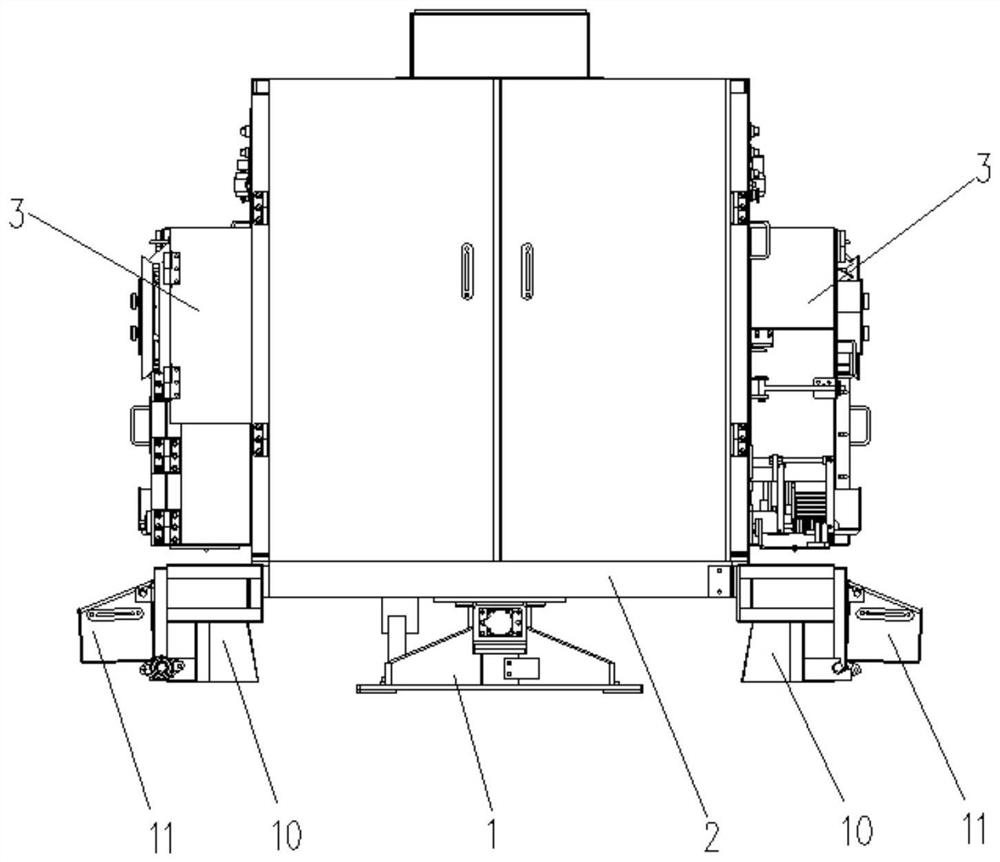

Silicon wafer cleaning and texturing device

ActiveCN107968062AHigh temperature control accuracyChemical reaction stabilityPolycrystalline material growthAfter-treatment detailsTemperature controlChemical reaction

The invention discloses a silicon wafer cleaning and texturing device, which can be convenient for texturing temperature control and ensure that a silicon wafer is always in a wet state when the silicon wafer undergoes the silicon wafer cleaning and texturing processes. The silicon wafer cleaning and texturing device comprises a silicon wafer texturing trough, a silicon wafer transfer device and asilicon wafer cleaning device, wherein the silicon wafer transfer device is arranged between the silicon wafer texturing trough and the silicon wafer cleaning device. By adopting the silicon wafer cleaning and texturing device, the texturing temperature control precision is high, the chemical reaction in the entire process tank is stable and controllable, effective control of the reaction speed and volatilization amount of a solution can be realized, and the adjustment of the process is facilitated; and the silicon wafer is sprayed during the transfer process so as to ensure that the siliconwafer always maintains a wet state during operation, thereby effectively avoiding the occurrence of ''edge scratched wafer'', and improving product quality.

Owner:LESHAN TOPRAYCELL

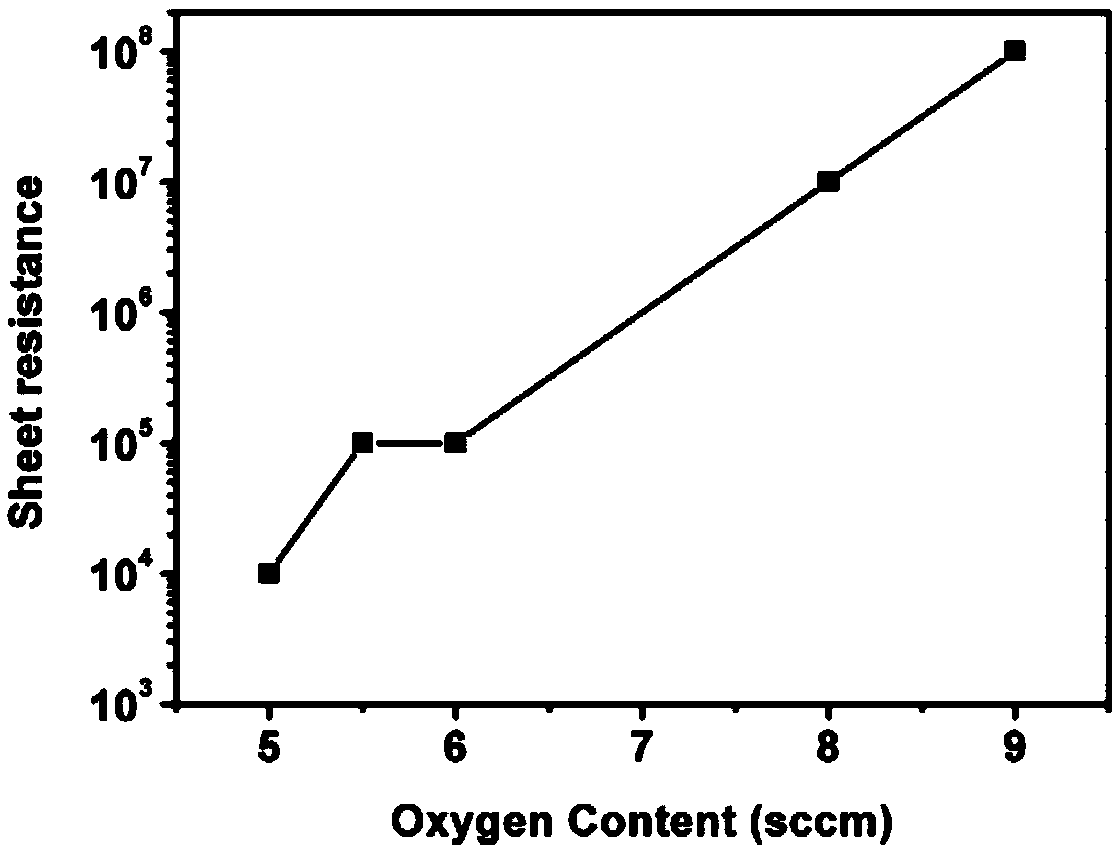

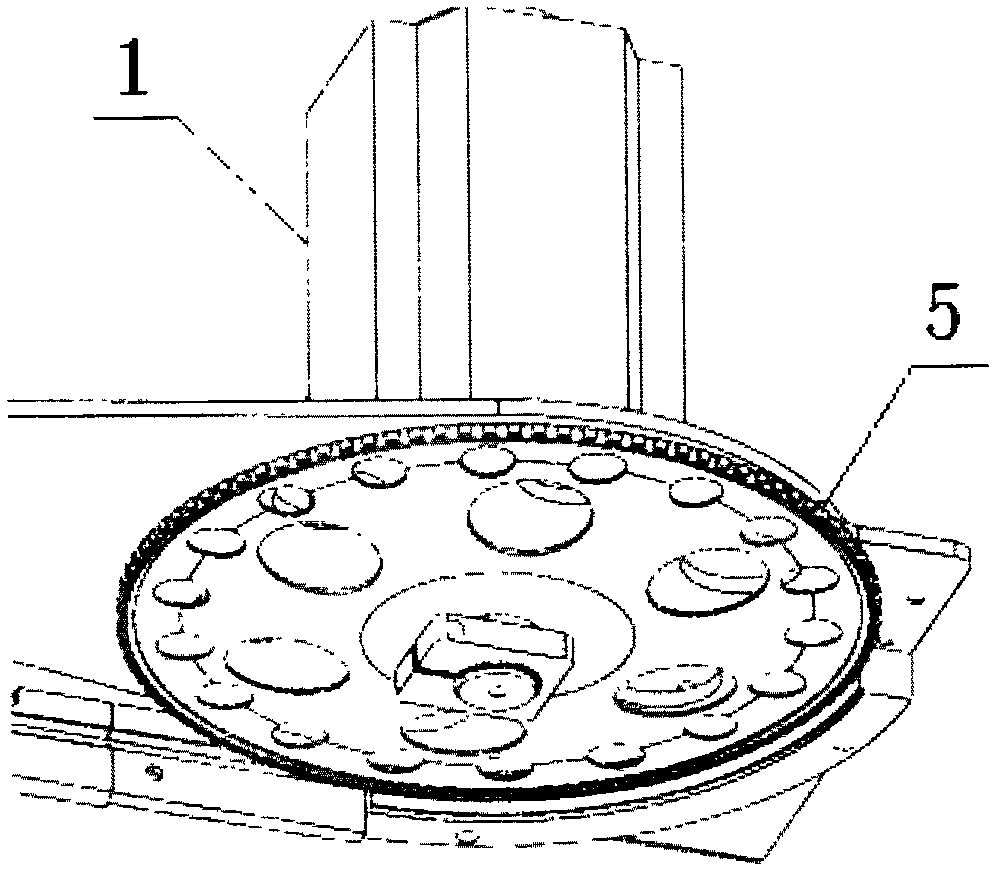

A kind of electrode material processing method for liquid flow battery

ActiveCN103825033BEasy process adjustmentSurface Treatment Effect ControlCell electrodesElectric dischargePlasma technology

The invention discloses an electrode material treating method for an electrochemical flow cell. In the method, low temperature and normal pressure plasma technology is adopted for conducting surface treatment on electrode materials, gas flow is adopted to adjust the intensity of the plasma, and the surface treatment effect is adjusted through adjusting the relative motion speeds and the distance between the electrode materials and the nozzle of a low temperature plasma electric discharging device. The method provided by the invention has the benefits that etching in electrode materials treatment is conducted under room temperature, and damage on the electrode materials caused by high temperature is avoided; the surface treatment effect can be effectively controlled solely by adjusting the distance between the gas flow and the nozzle through the adoption of the plasma technology; continuous treatment on materials is realized without arranging a vacuum environment or an airtight cavity; no inorganic or organic solvent is required during a treating process, and as only electric energy and oxygen are consumed, the method is low in energy consumption, safe and environmental-friendly; the material surface is treated uniformly, the treatment time is short, the electrode material treating method is extremely easy to be used for mass production, and is simple in technology and low in cost.

Owner:DALIAN RONGKE POWER

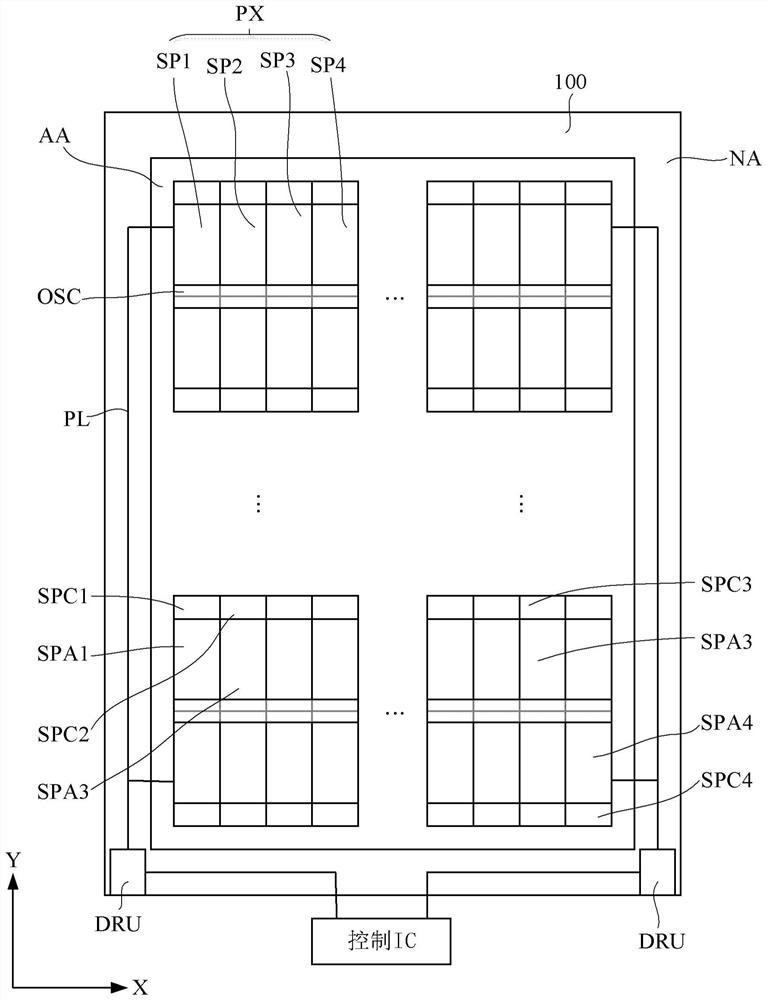

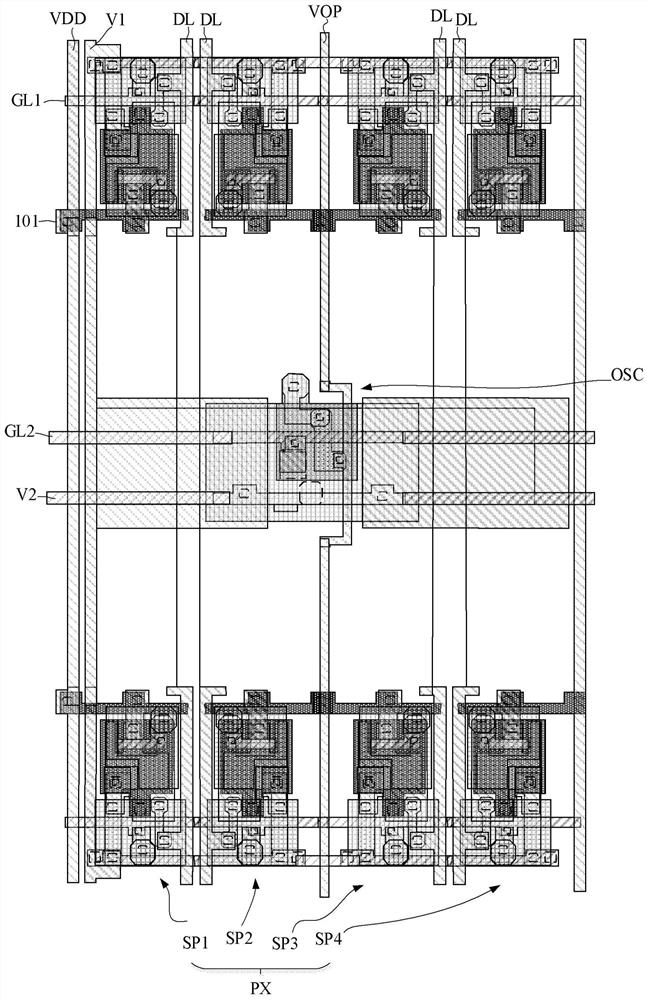

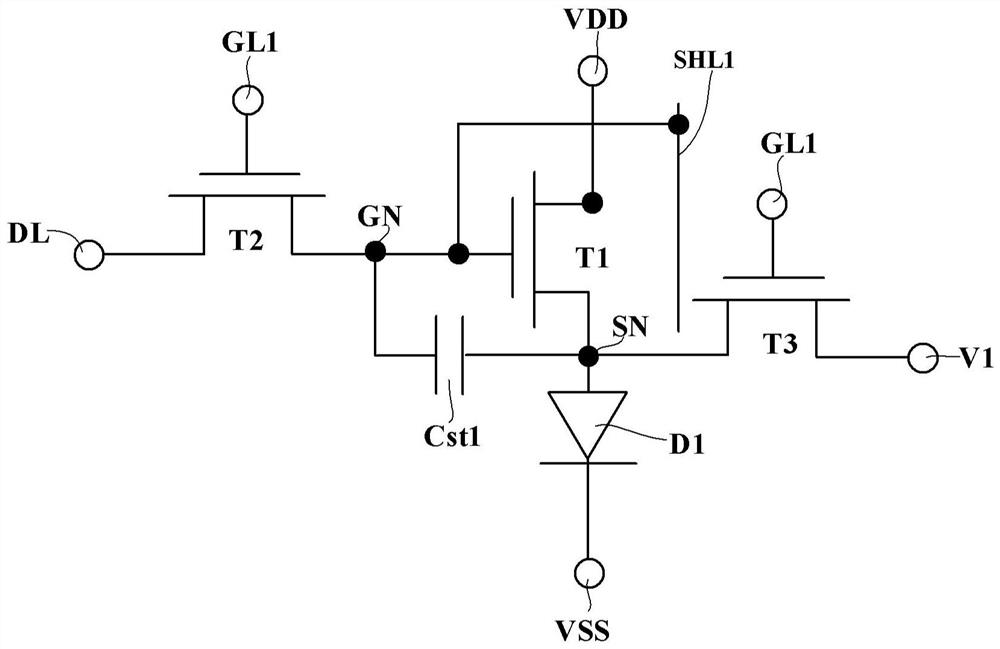

Display substrate and display device

PendingCN114256296AImprove output characteristicsEasy process adjustmentStatic indicating devicesSolid-state devicesDisplay deviceHemt circuits

The invention provides a display substrate and a display device. The display substrate comprises a substrate; the pixel units are arranged on the substrate, each pixel unit comprises a plurality of sub-pixels, and each sub-pixel comprises a light-emitting element and a pixel driving circuit used for driving the light-emitting element; the photosensitive circuit is arranged on the substrate; and the first conductive film layer is arranged on the substrate. The pixel driving circuit comprises a driving transistor, a grid electrode of the driving transistor is located on the side, away from the driving active layer, of the driving active layer, and the orthographic projection of the grid electrode of the driving transistor on the substrate and the orthographic projection of the driving active layer on the substrate are at least partially overlapped. The first conductive film layer at least comprises a first shading part, the first shading part is located between the substrate and the driving active layer, and the orthographic projection of the first shading part on the substrate and the orthographic projection of the driving active layer on the substrate are at least partially overlapped. The first light shielding portion is electrically connected to a gate of the driving transistor.

Owner:BOE TECH GRP CO LTD

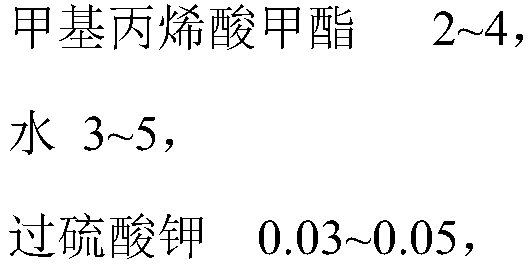

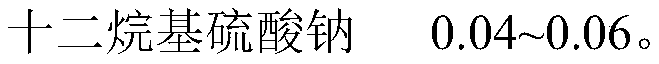

Water-based acrylic fluorescent coating and preparation method thereof

ActiveCN110655841ADoes not affect luminosityChange film formationAntifouling/underwater paintsLuminescent paintsEmulsionNano sio2

The invention provides a water-based acrylic fluorescent coating and a preparation method thereof. The preparation method comprises the following steps: preparing silicon dioxide coated modified fluorescent powder; adding the obtained silicon dioxide coated modified fluorescent powder into a water-based solvent and stirring to obtain modified fluorescent powder suspension; adding the modified fluorescent powder suspension into an emulsion containing an acrylate monomer, adding an initiator, carrying out a reaction, and adjusting the pH value to 6.5-7.5 to obtain a stable nano SiO2 / acrylate composite emulsion, wherein the component of the emulsion B comprises methyl methacrylate, and the component of the emulsion C comprises n-butyl acrylate; and uniformly mixing the obtained nano SiO2 / acrylate composite emulsion with a curing agent and an auxiliary agent to obtain the water-based acrylic fluorescent coating. The silicon dioxide is adopted to coat and modify fluorescent powder, the modified fluorescent powder is used as a core, and the acrylate copolymer is used as a shell, so that the luminescence property of the fluorescent powder is enhanced, and the stability of the emulsion isimproved.

Owner:广西经正科技开发有限责任公司

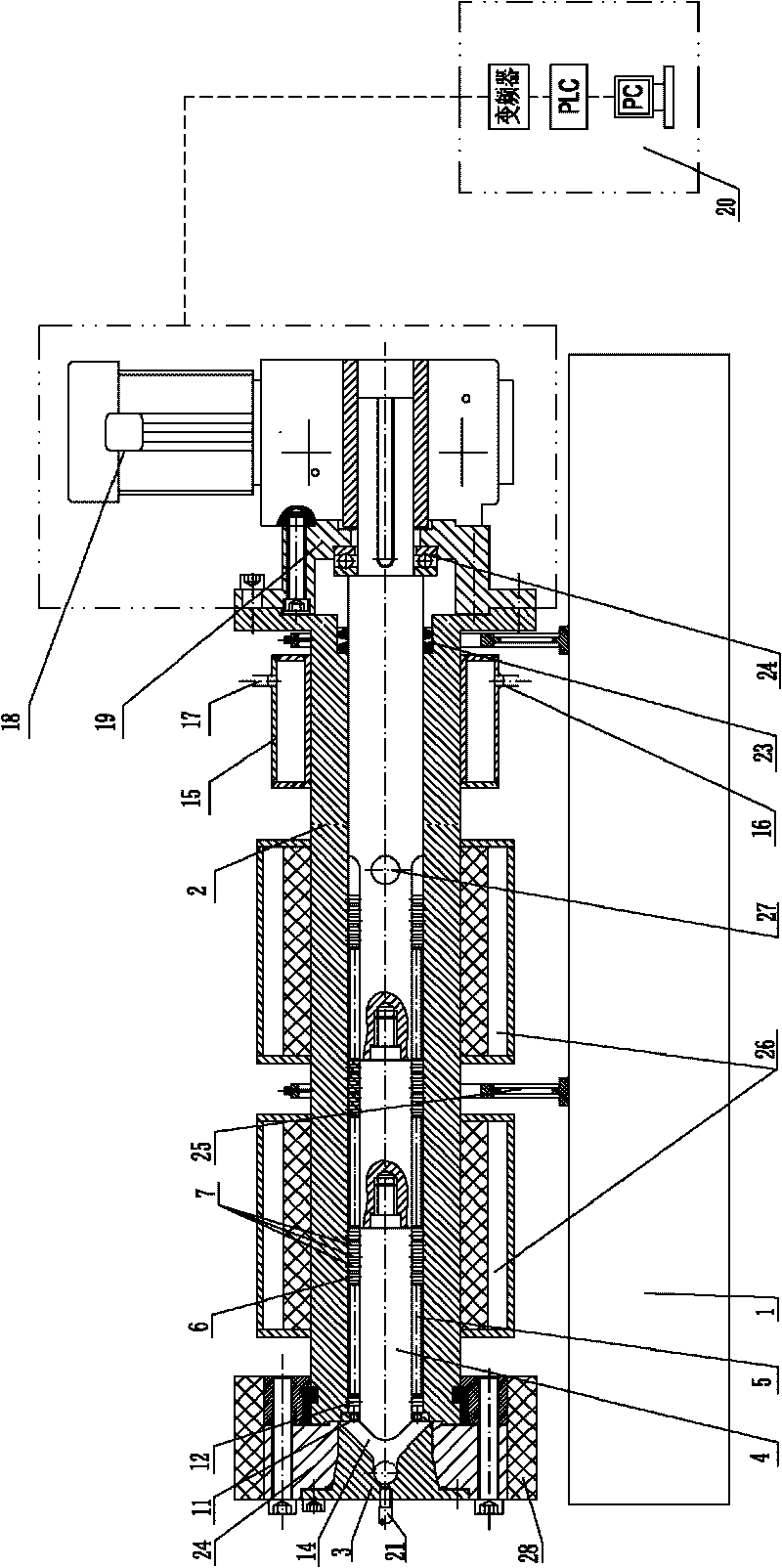

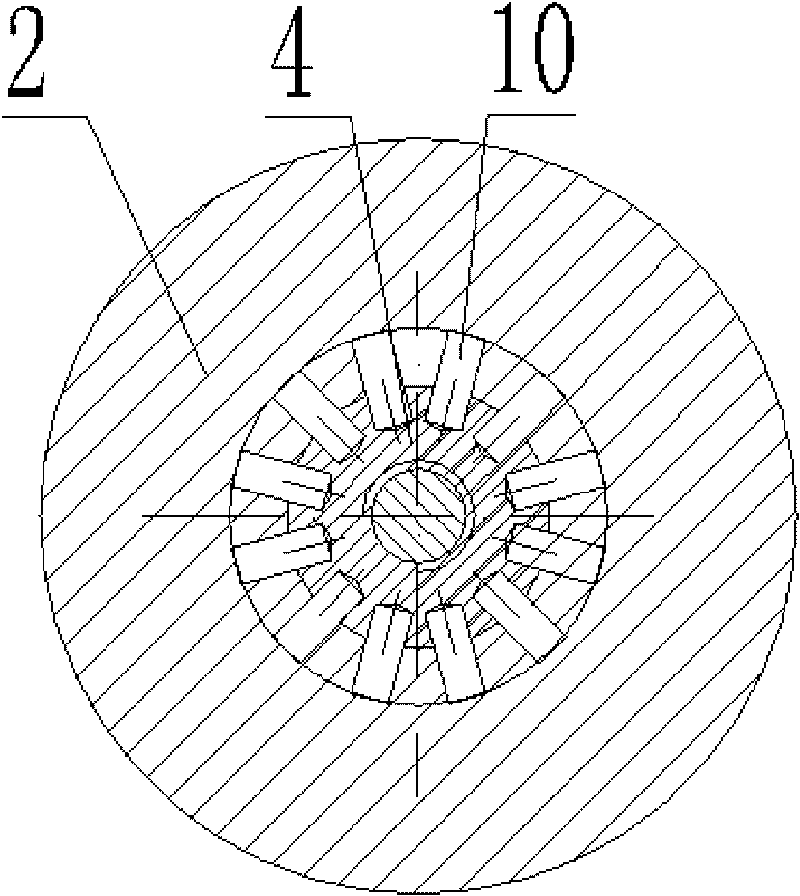

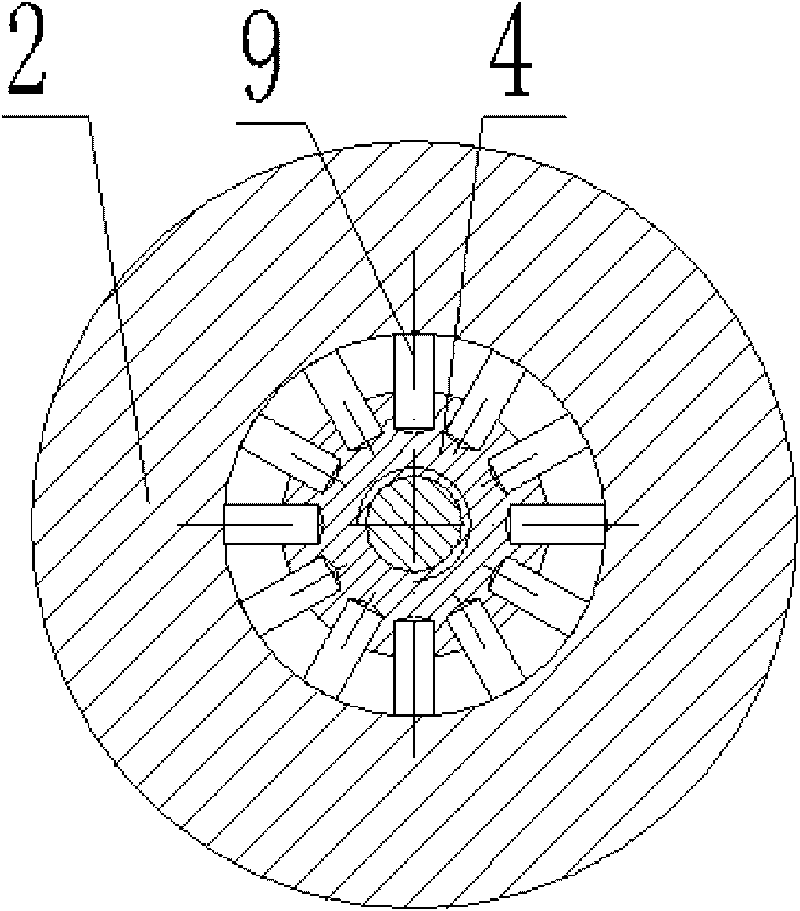

Combined efficient low-temperature trickle dynamic mixing device and special method thereof

The invention relates to a production method of a synthetic fibre, in particular to a combined efficient low-temperature trickle dynamic mixing device and a special method thereof, which mainly solve the technical problems that the prior art cannot apply on-line addition on a direct spinning production line and that a fusion method has high cost, high energy consumption and the like. The combined efficient low-temperature trickle dynamic mixing device comprises a framework, wherein the framework is provided with a sleeve component which is provided with a feeding component and a discharge outlet; the inside of the sleeve component is provided with an efficient mixing shaft component; the shaft body of the efficient mixing shaft component is provided with a blending mechanism; and the blending mechanism consists of a trickle mixing unit, a cutting unit and a low-temperature homogenizing unit which are arranged in order. The special method comprises the following steps: inletting a blended melt into an arc-shaped ring groove through the feeding component; introducing the blended melt into a pre-cutting unit to be cut after being trickled by a pre-trickling unit; introducing the blended melt into the blending mechanism to blend uniformly; and discharging a mixture from the discharging outlet.

Owner:ZHEJIANG HUAXIN ADVANCED MATERIALS

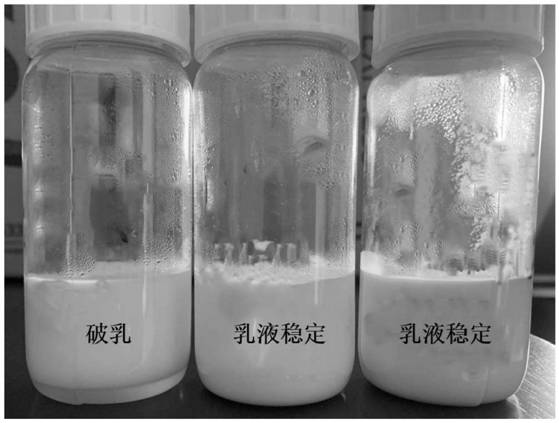

Soft nanoparticle-stabilized silicone oil emulsion and preparation method thereof

The invention belongs to the technical field of textile assistants, and particularly relates to a silicone oil emulsion with stable soft nanoparticles. The product comprises the following components in parts by mass: 20-30 parts of amino silicon oil, 2-8 parts of an emulsifier, 3-32 parts of a soft nanoparticle emulsion, 0.8-1.5 parts of a pH regulator and 50-60 parts of deionized water. The invention further provides a specific preparation method. The problems that a traditional silicone oil emulsion is poor in stability and the textile finishing effect is poor are solved, the emulsion stability is excellent, the adhesiveness on fibers is good, the air permeability and softness of textiles can be effectively improved, and therefore the practicability and comfort of the textiles are improved; meanwhile, the product has the characteristics of low cost and simple process.

Owner:ZHEJIANG SCI TECH UNIV SHAOXING KEQIAO RES INST CO LTD +1

Velcro slitting device for pull-up diaper production

PendingCN109534077AEasy to processReduce labor intensityAbsorbent padsArticle deliveryDrive wheelTransmission belt

The invention discloses a velcro slitting device for pull-up diaper production. The velcro slitting device comprises a fixing seat, a bottom plate, a short cutting conveying mechanism, a material adsorption disc, a transmission gear, a composite material feeding mechanism, a splitting mechanism and a folding mechanism; the short cutting conveying mechanism comprises a first driven gear, a first driven shaft, a transmission belt, a driving shaft, a driving wheel and a short cutting conveying belt; one end of the driving shaft is fixedly connected with the output end of a first driving motor, and the driving wheel is fixedly installed on the circumferential shaft body of the driving shaft; the first driven wheel and a transmission wheel are fixedly installed on the circumferential shaft bodyof the first driven shaft; the driving wheel is connected with the transmission wheel through the transmission belt; and a second driven wheel is fixedly installed on the circumferential shaft body of a second driven shaft. The velcro slitting device for pull-up diaper production has the advantages of being easy and convenient to debug, short in consumed time and the like and can be widely applied and popularized.

Owner:福建溢泰科技有限公司

Fully-independent servo drive rapier loom

Owner:JIANGSU S&S INTELLIGENT SCI & TECH CO LTD

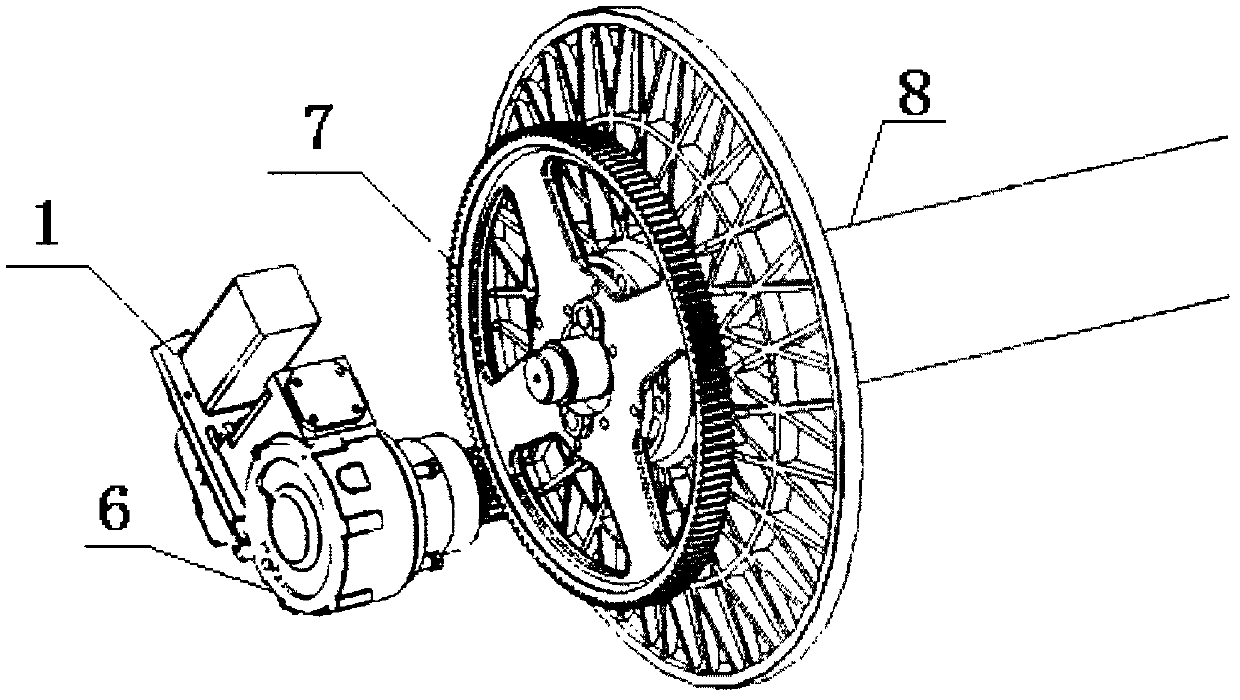

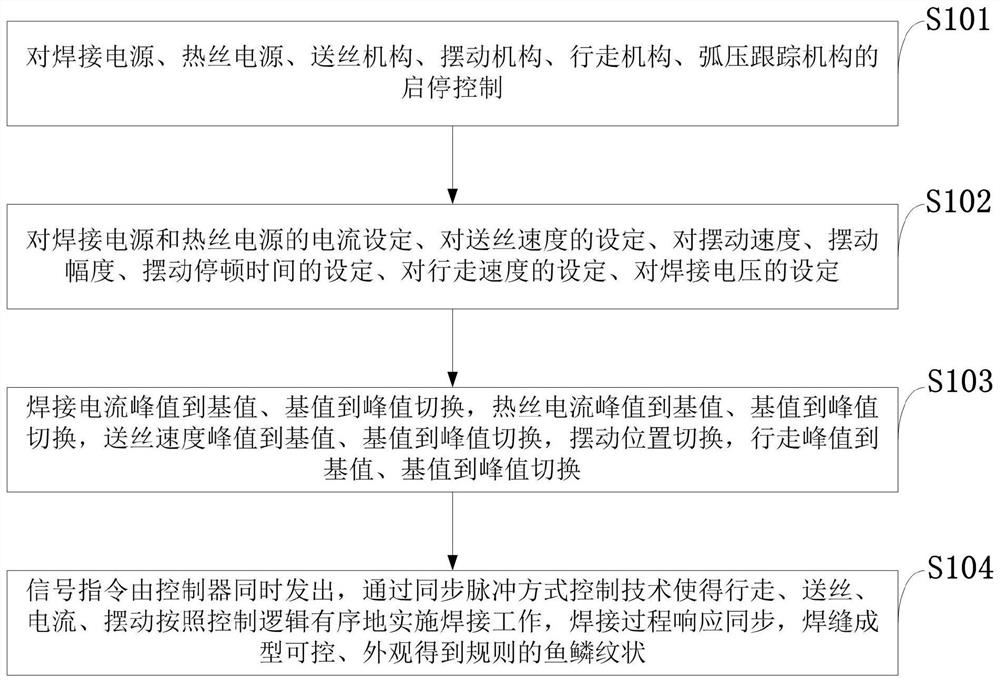

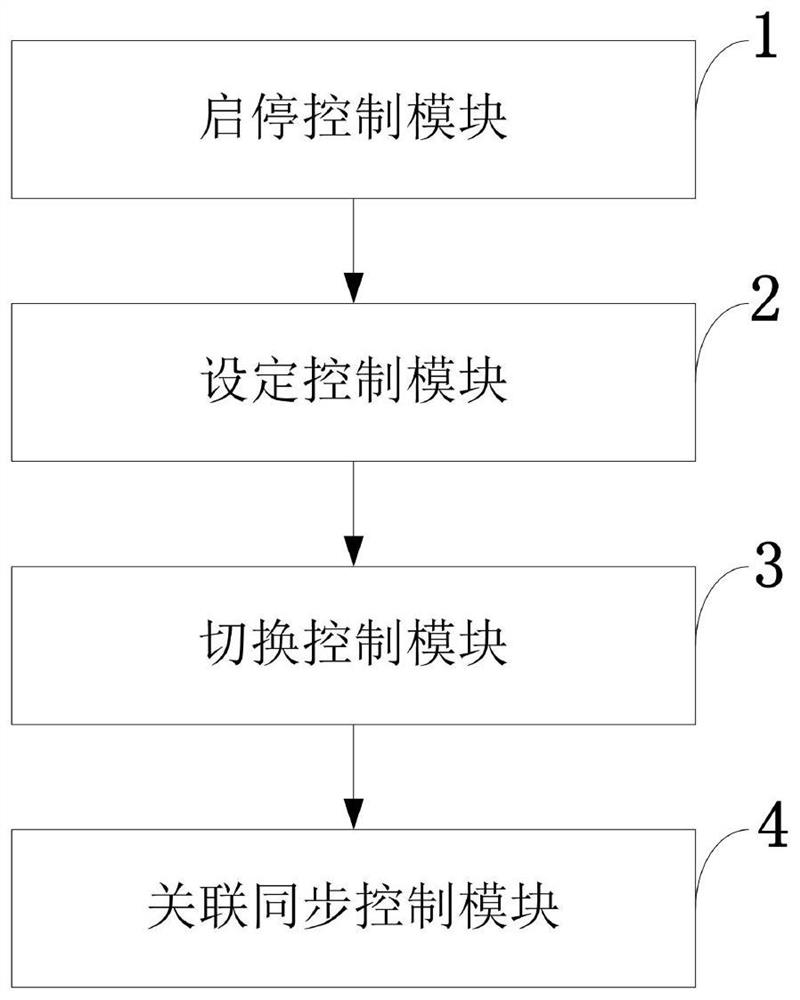

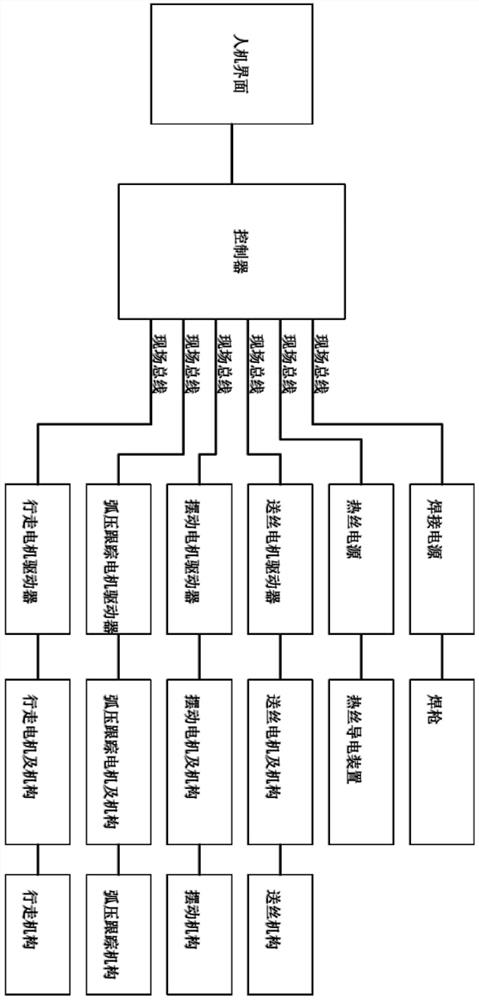

Tungsten electrode argon arc welding process control method and system, computer equipment and application

PendingCN113319401AEasy process adjustmentEasy to adjustArc welding apparatusHuman–machine interfaceWelding power supply

The invention belongs to the technical field of tungsten electrode argon arc welding processes, and discloses a tungsten electrode argon arc welding process control method and system, computer equipment and application. A controller manages a welding power source, a wire heating power source, a wire feeding motor driver, a swing motor driver, a walking motor driver and an arc voltage tracking motor driver module in a unified mode, and signal and data interaction between the controller and a subordinate controlled object is realized through a field bus. A new technical scheme is provided for welding modes, the welding modes comprise a direct-current welding mode, a low-speed pulse mode, a high-speed pulse mode, a synchronous pulse mode and a double-pulse mode, and the innovation of the welding modes is embodied in control logic and process control. The process control logics are all generated by a controller, so that process adjustment is facilitated; welding parameters are all set on a human-computer interface, so that adjustment and management are facilitated; and welding control is an organic whole and is not scattered any more, welding seam forming is attractive, and the process quality is controlled.

Owner:XIHUA UNIV

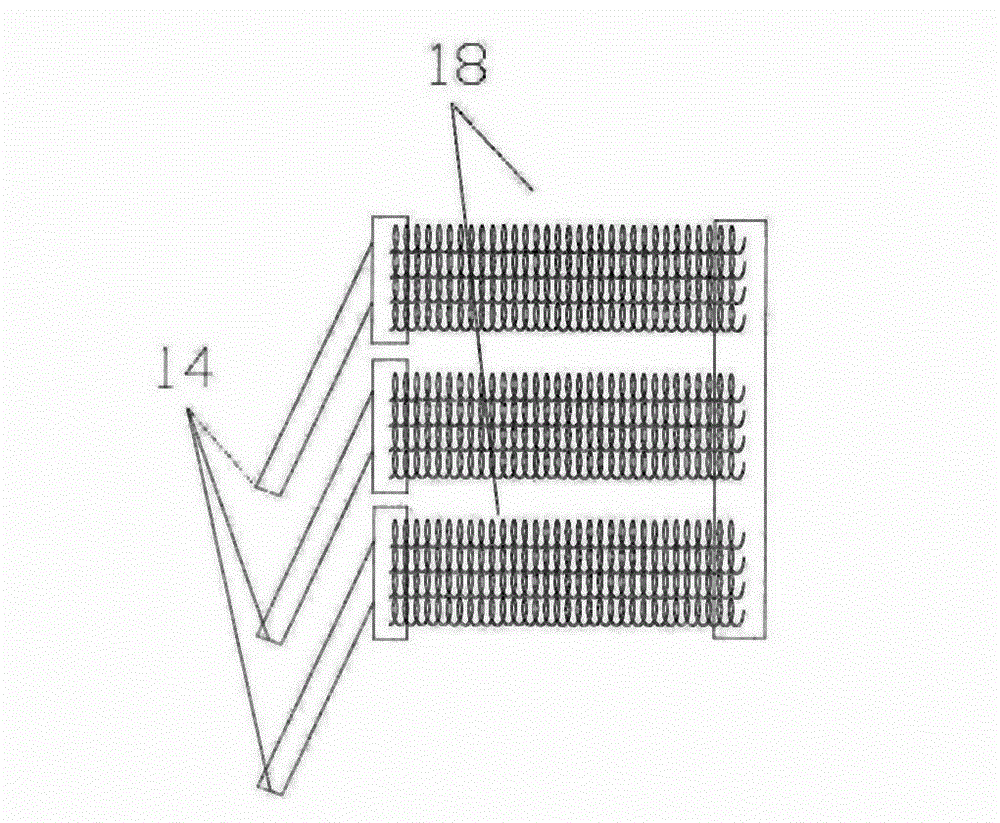

Color matching device for polyamide 6 color masterbatch

PendingCN112111798ALow costReduce volumeFilament/thread formingPigment addition to spinning solutionMasterbatchPolyamide

The invention discloses a color matching device for polyamide 6 color masterbatch. The color matching device comprises a frame, wherein a plurality of rectifiers are sequentially arranged in the framefrom top to bottom, are parallel to one another and are obliquely arranged, the heights of the front ends of the rectifiers are larger than those of the rear ends of the rectifiers. The invention provides the color matching device for polyamide 6 color masterbatch, and the color matching device has a good spinning cooling effect.

Owner:GUANGDONG XINHUI MEIDA NYLON

Method for preparing titanium alloy spherical powder through recycled titanium materials

PendingCN110560696AImprove mechanical propertiesImprove wear resistanceAdditive manufacturing apparatusTransportation and packagingHydrogenDehydrogenation

The invention provides a method for preparing titanium alloy spherical powder through recycled titanium materials. According to the method, the recycled titanium materials are subjected to oil removal, vacuum oxygen removal, four cycles, hydrogenation, dehydrogenation and screening, and then plasma balling is adopted for preparing the titanium alloy spherical powder. A hydrogen source can come from the hydrogenated titanium sponge titanium purification dehydrogenation step, the resource is saved, and finally the high-effect high-performance titanium alloy spherical powder for additional material manufacturing is prepared. By means of the method, a new raw material channel is provided for additional material manufacturing, waste resources are changed into wealth from waste, and economic benefits are increased.

Owner:江苏思睿迪快速制造科技有限公司

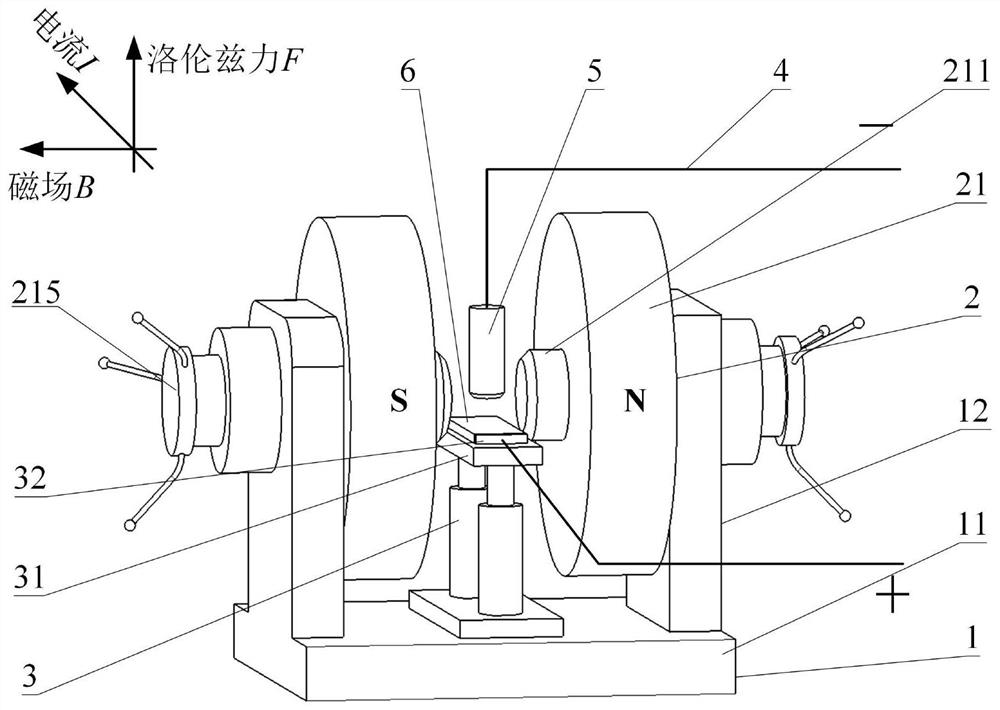

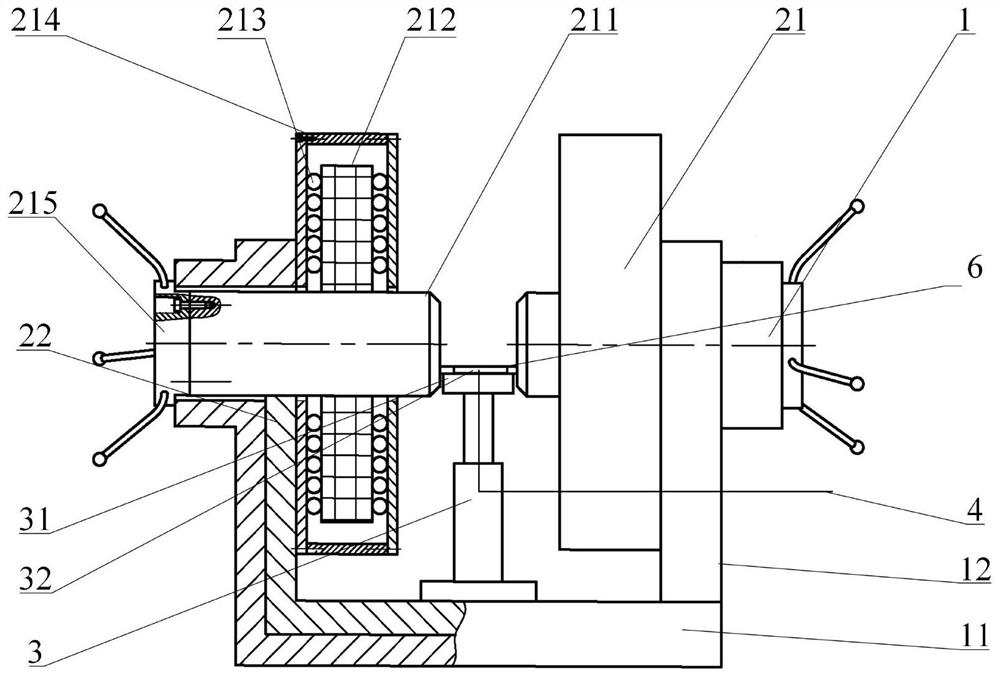

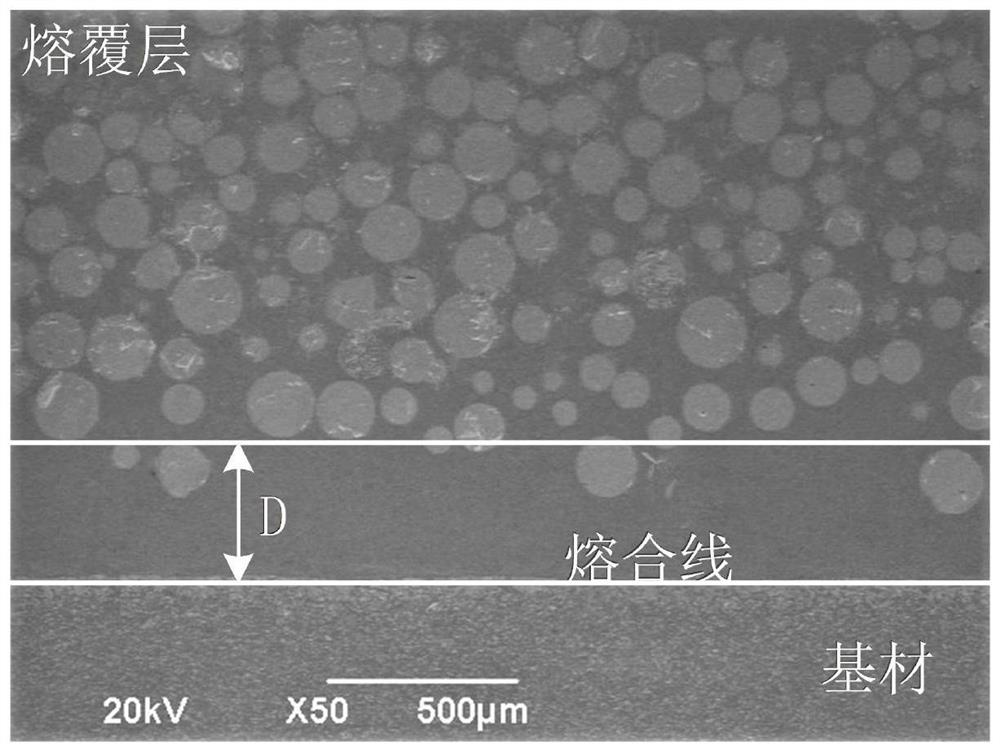

A method and device for preparing distribution-controllable wc-reinforced metal-based composite coatings assisted by an electromagnetic composite field

ActiveCN111607791BPrevent sinkingEvenly distributedElectromagnets without armaturesTransportation and packagingMetal matrix compositeLorentz force

The invention discloses a method and device for preparing a distribution-controllable WC reinforced metal-based composite coating assisted by an electromagnetic composite field. The metal-based self-fluxing alloy powder is used as the coating base material, and the WC particle powder is used as the coating reinforcement. Phase, through electromagnetic composite field assisted plasma cladding to form WC reinforced metal matrix composite coating on the surface of the workpiece to be treated. In the process of plasma cladding, the invention applies a magnetic field and an electric field to the workpiece at the same time, so that the charged particles and the charged fluid in the molten pool are subjected to an upward Lorentz force under the joint action of the magnetic field and the electric field, and the WC particles are prevented from sinking to the bottom , so that the WC particles are evenly distributed in the composite coating.

Owner:HEFEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com