Chemical bath deposition method of cadmium sulfide film and device thereof

A technology of chemical water bath and cadmium sulfide, applied in the direction of liquid chemical plating, coating, electrical components, etc., can solve the problems of affecting appearance, high energy consumption, unsuitable for continuous production, etc., and achieve improved aesthetics, low energy consumption, The effect of ensuring uniformity and compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

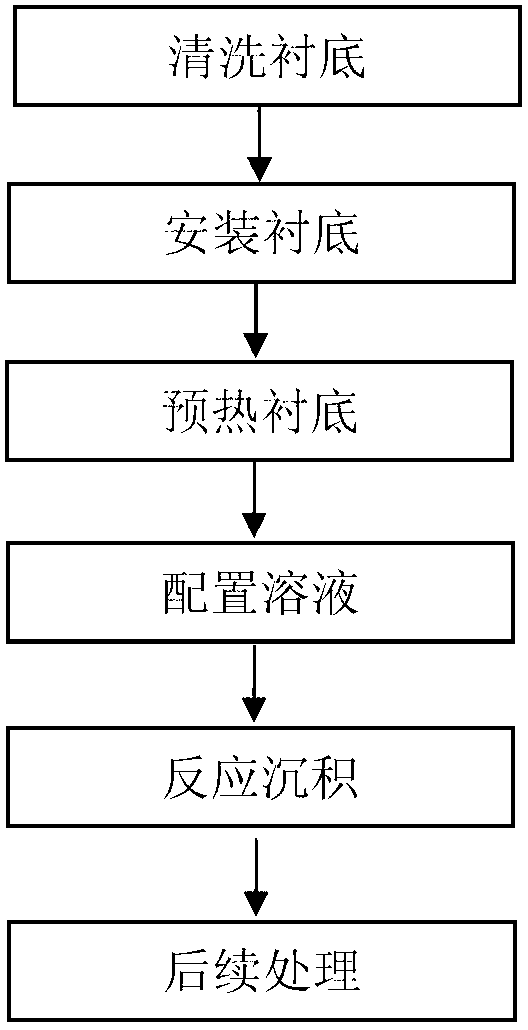

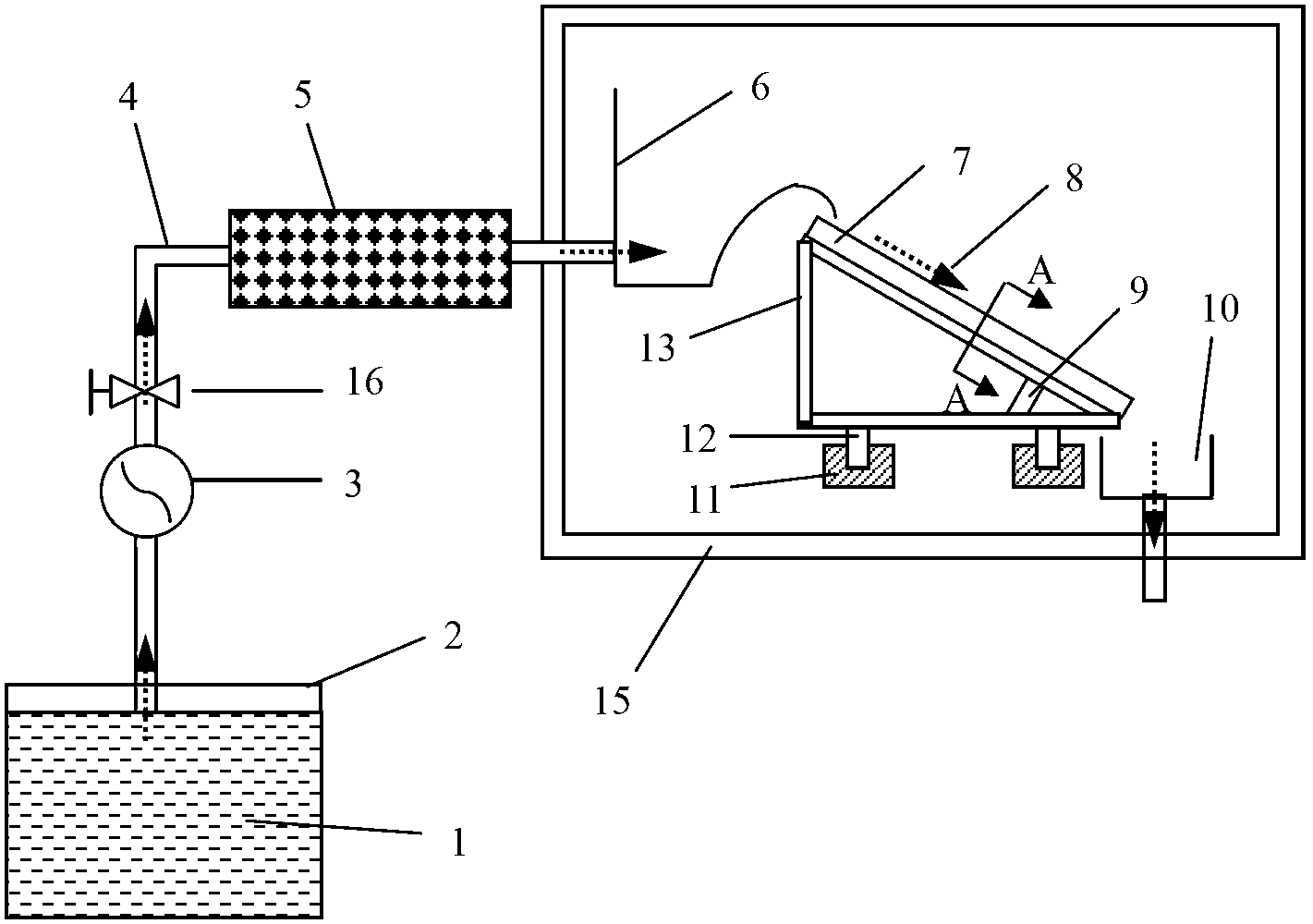

[0047] (1) Clean the substrate: clean the soda-lime glass substrate, and then dry it;

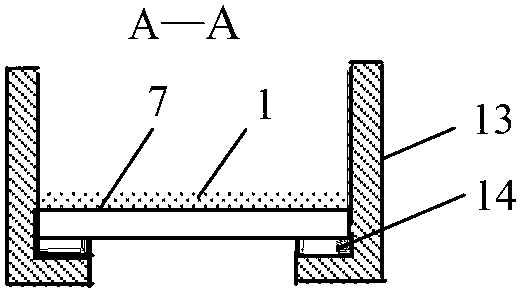

[0048] (2) Install the substrate: place the substrate on the fixture, and set the angle between the substrate and the horizontal plane at 15°;

[0049] (3) Preheat the substrate: heat the thermostat to preheat the substrate temperature to within 75°C±10°C;

[0050] (4) Preparation solution: Mix 2mM cadmium sulfate, 0.5mM ammonia water, 20mM ammonium chloride, 30mM thiourea and deionized water to make a reaction solution, and then mix it into the reaction container;

[0051] (5) Reactive deposition: pump out the reaction solution with a water pump, the reaction solution flows through the heater and is rapidly heated to a reaction temperature of 75°C at 20°C / s, and then flows through the drenching tank and continuously overflows; the reaction solution is deposited on the substrate Spread evenly and continue to flow, the total reaction time is 30min;

[0052] (6) Subsequent processing: After...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com