Novel heating system of sapphire crystal growing furnace

A sapphire crystal and heating system technology is applied in the field of structural design of a sapphire crystal growth furnace, which can solve the problems of long crystal growth cycle and high cost, and achieve the effects of low processing cost, stable performance and reduced time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

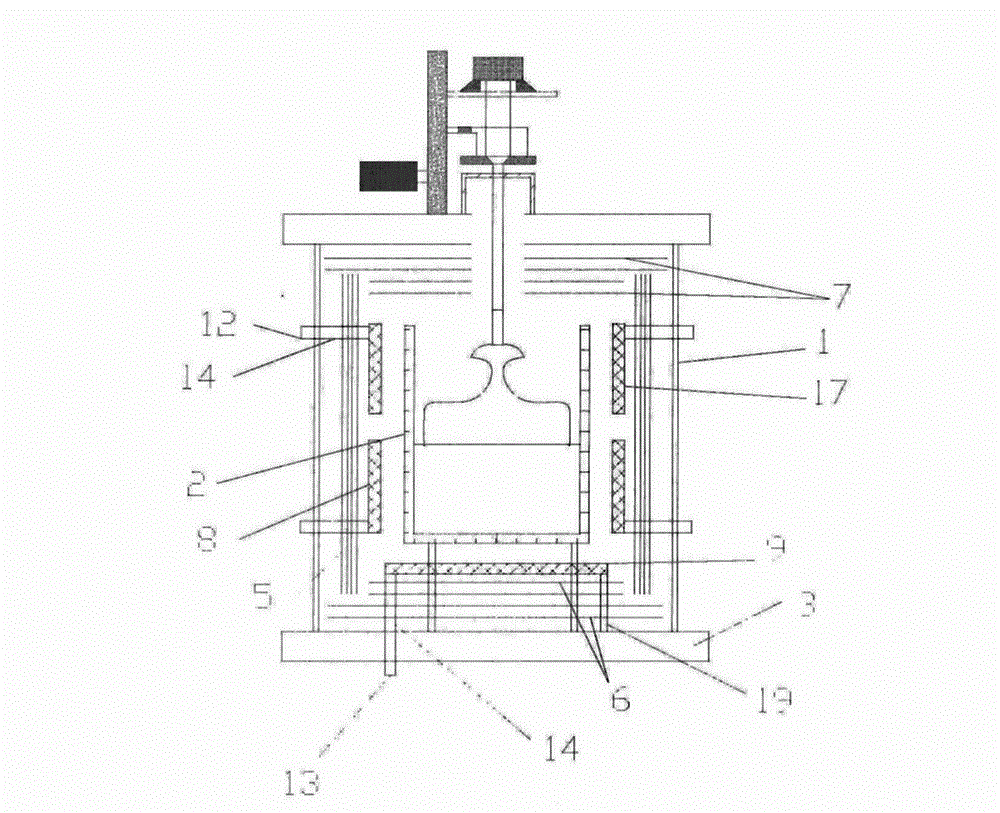

[0018] figure 1 As shown, the heating system of the sapphire crystal growth furnace includes an upper heating element 17, a middle heating element 8 and a bottom heating element 9. The three heating elements are fixed around the crucible 2, side heat shields 5, top heat shields 7 and bottom heat insulation Inside screen 6. In order to prevent temperature field changes caused by the aging of heat shields and other thermal field components and to facilitate customers' process experiments, the power of the three heating elements can be adjusted independently to form the temperature gradient required for crystal growth.

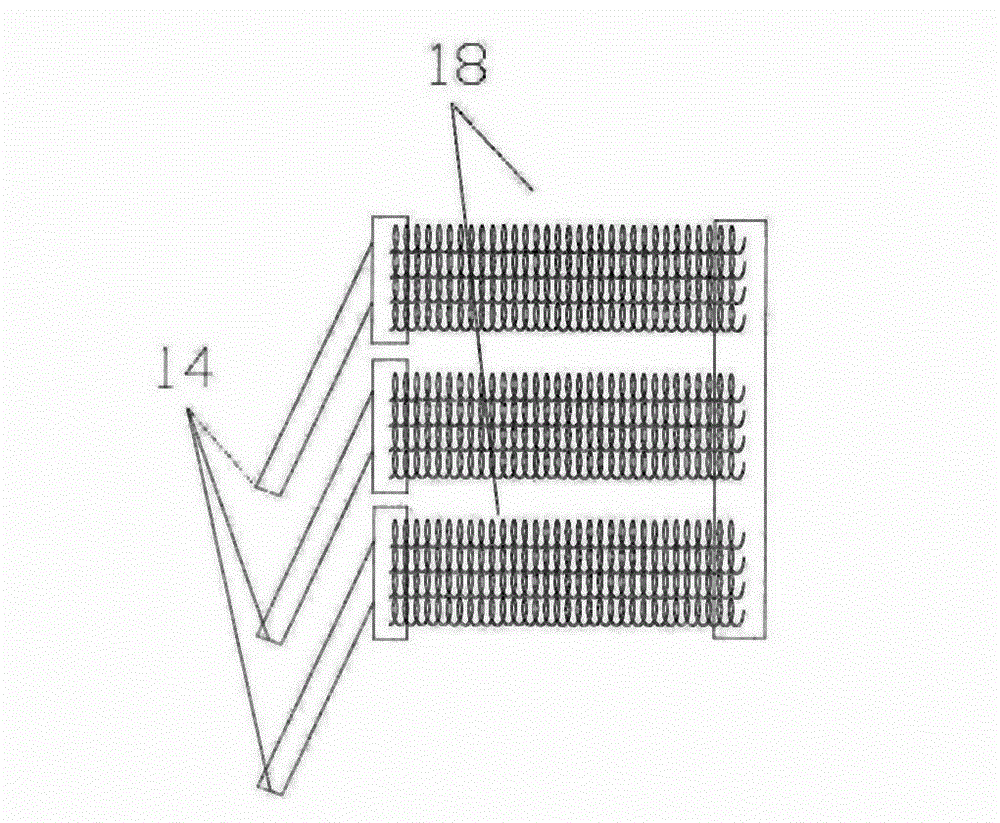

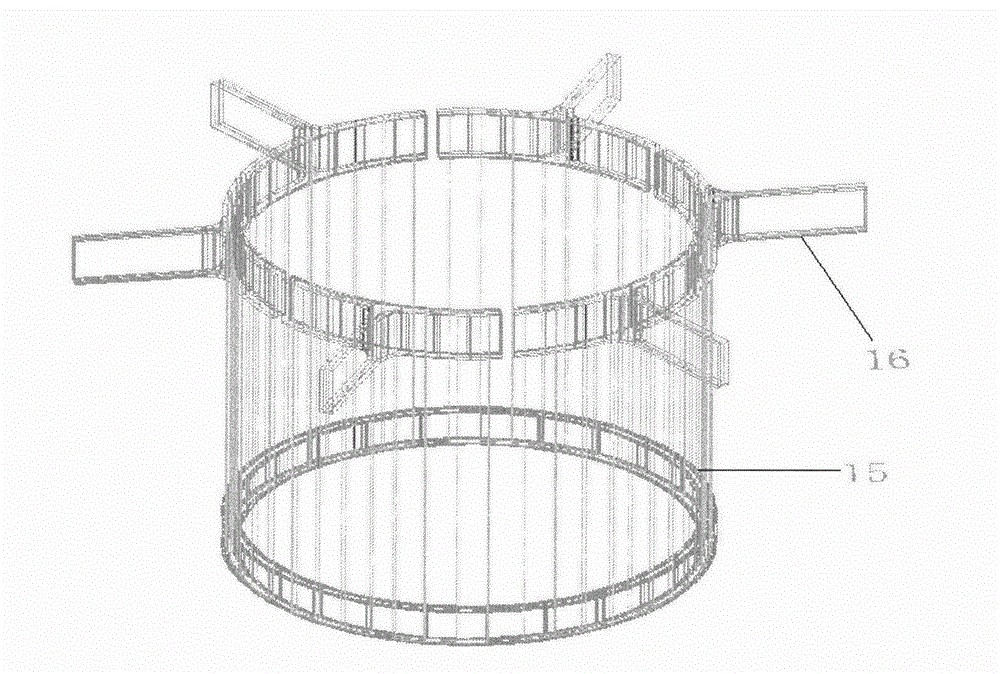

[0019] figure 2 , image 3 and Figure 4 As shown, the upper heating element is suspended on the electrode pile 12 on the furnace shell 1 through 6 electrode claws 16, and the middle heating element is the same as the upper heating element, and is supported on the electrode pile 12 on the furnace shell 1 through 6 electrode claws 16. . The bottom heating el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com