Double-twisting and sanding integrated machine for chemical fiber filaments

An all-in-one, sanding technology, applied in textiles and papermaking, etc., can solve the problems of shortening the process, many processes, and long production time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

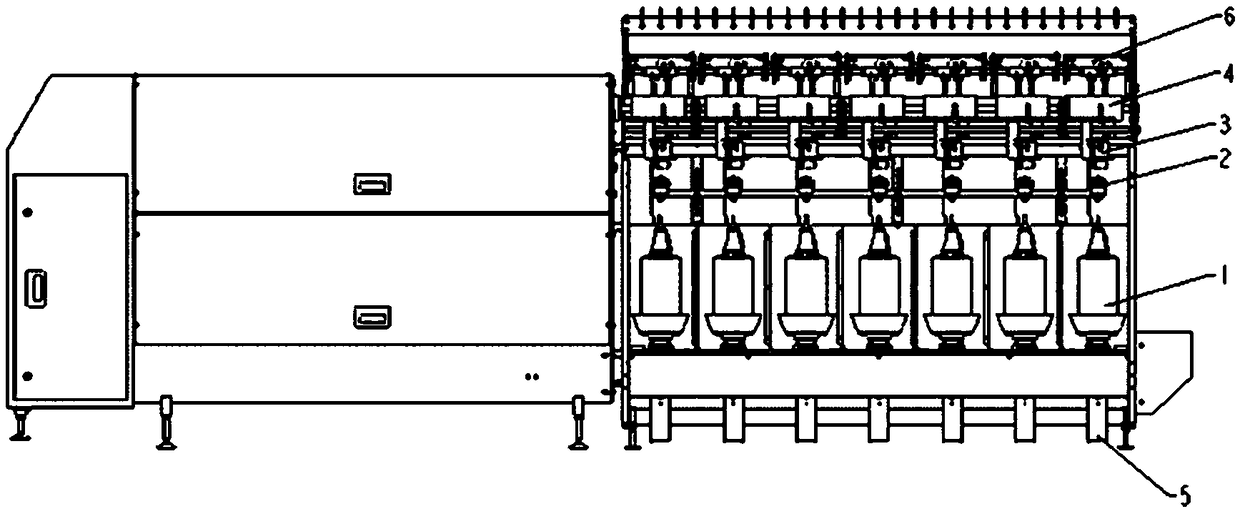

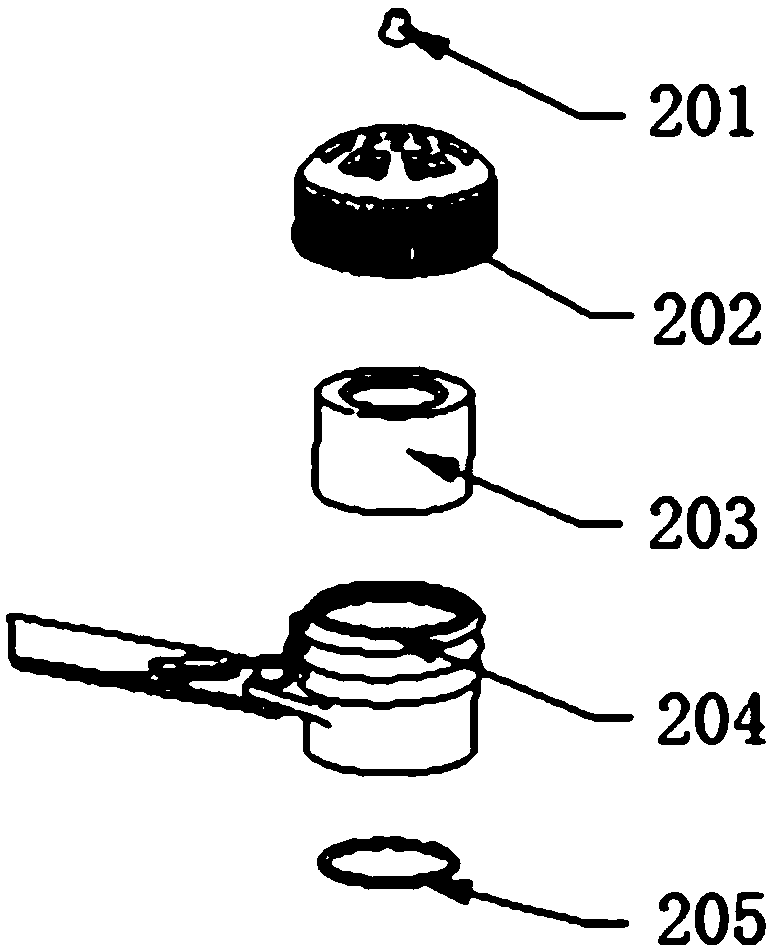

[0016] Such as Figure 1-2 , the present invention includes a two-for-one twisting spindle 1 and a sanding device 2, the two-for-one twisting spindle 1 and the sanding device 2 are installed on the fuselage, the top of the sanding device 2 is provided with a double-roller roller 3, and the double-roller roller 3 is movably connected On the fuselage, the top of the double-roller roller 3 is provided with a friction roller 4, and the friction roller 4 is installed on the fuselage. Seat 204 and balloon ring 205, yarn guide ceramic part 201 is installed on the top of sanding cover 202, and sanding cover 202 is set on the top of sanding seat 204, and the movement of sanding emery wheel 203 is connected in the inside of sanding seat 204, The balloon ring 205 is installed on the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com