High-speed glass fiber chopping machine

A glass fiber, high-speed technology, applied in the field of glass fiber shearing equipment, can solve the problems of low production efficiency, high labor intensity, and inability to guarantee the cutting length requirements, etc., and achieve the effect of fast switching and easy process adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

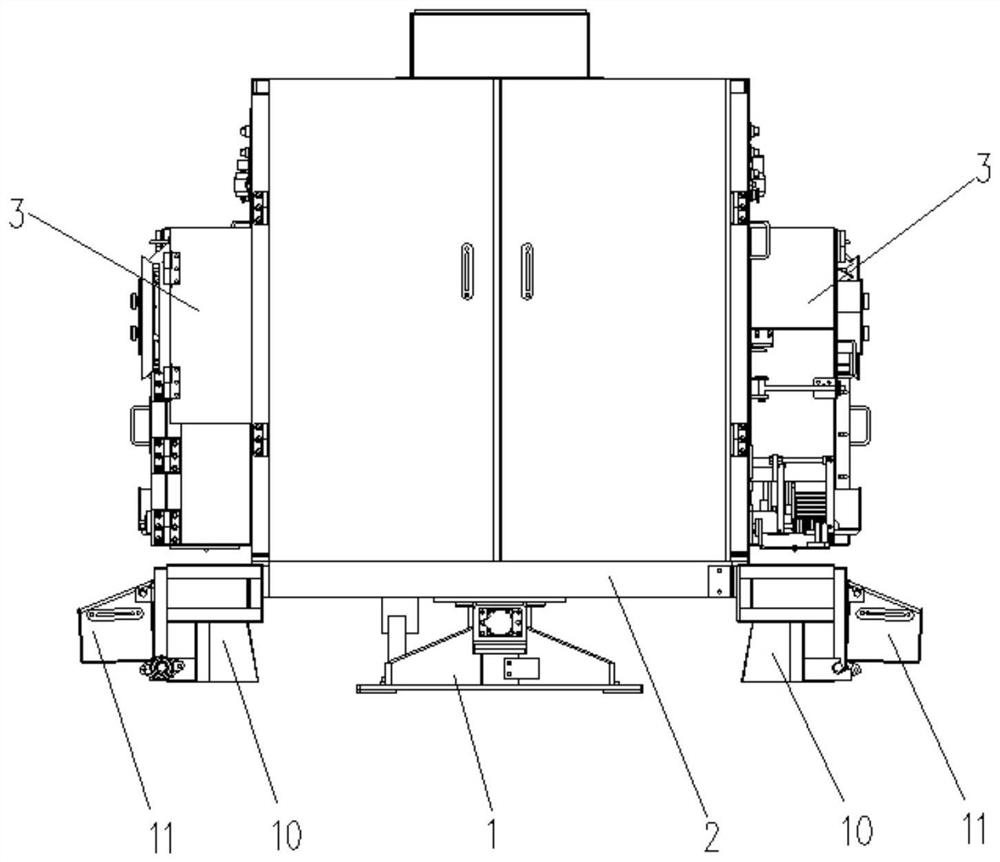

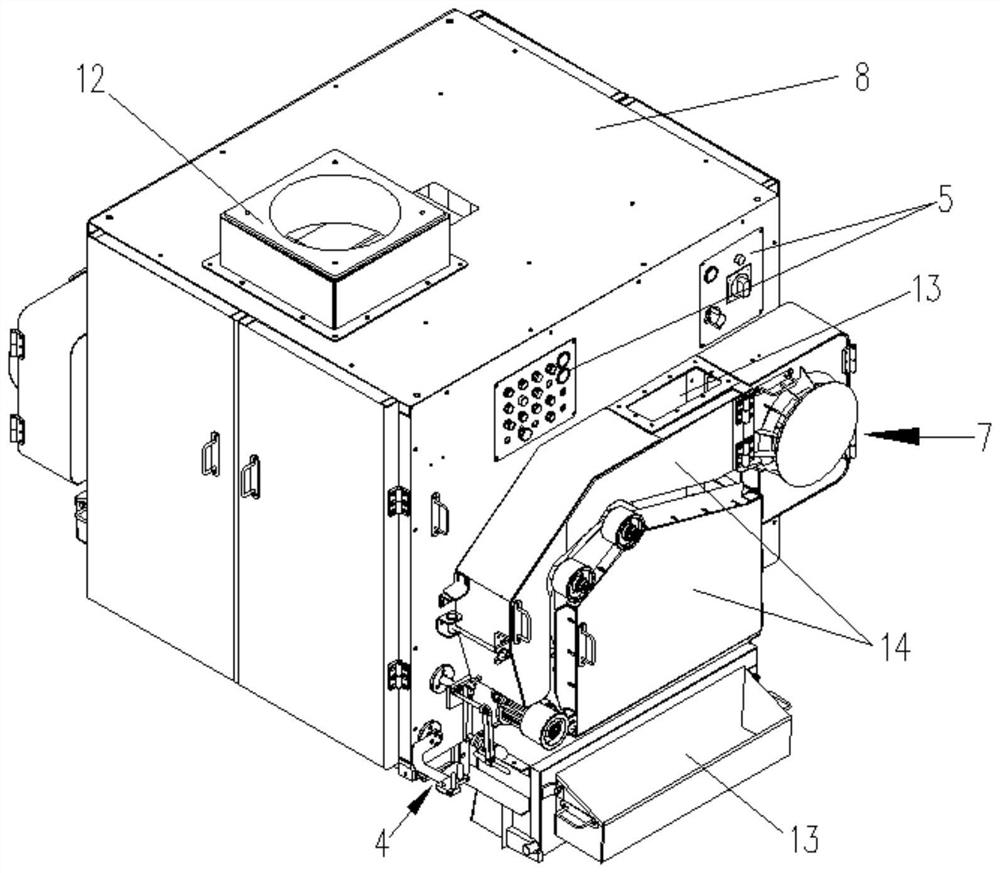

[0087] A specific embodiment of the present invention discloses a glass fiber high-speed chopping machine, such as Figure 1 to Figure 4 As shown, including installation platform, cutting device 3 and loading device 4;

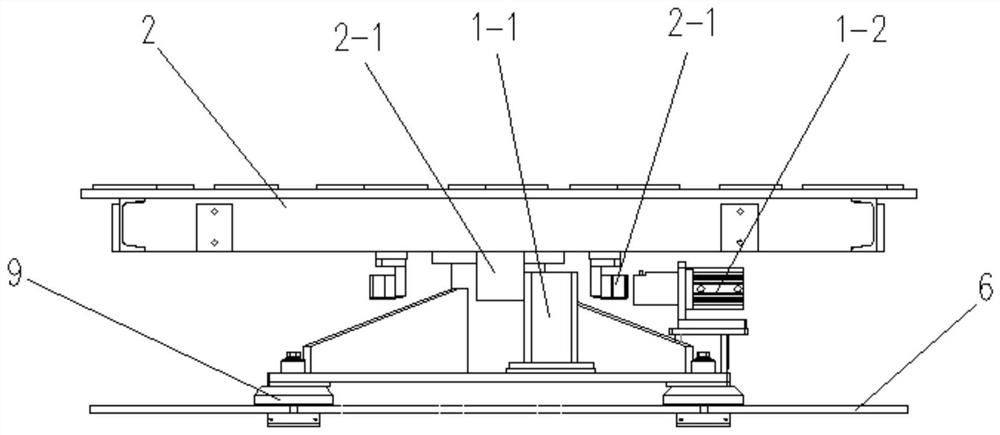

[0088] Wherein, the installation platform is used for installing the bearing cutting device 3 and the loading device 4, the installation platform includes a base plate, a main frame 3-1, the main frame 3-1 is vertically arranged on the base plate, and the base plate of the installation platform is located on the machine base 1 , base 1 is connected with installation base 6 .

[0089] The cutting device 3 is used to cut the glass fiber to a preset fiber length. The cutting device 3 includes a knife roller mechanism, a rubber roller mechanism and a grinding device 3-7. The knife roller mechanism, the rubber roller mechanism and the grinding device 3-7 are arranged on the main frame On 3-1, the working ends of the knife roller mechanism, the rubber roller mechan...

Embodiment 2

[0103] A specific embodiment of the present invention discloses the cutting device 3 in Embodiment 1, and specifically discloses a glass fiber swinging roller traction type high-speed cutting device, such as Figure 5 to Figure 6 Shown, comprise cutter roller mechanism, rubber roller mechanism and grinding device 3-7, cutter roller mechanism, rubber roller mechanism and grinding device 3-7 are all arranged on the main body frame 3-1, cutter roller mechanism includes cutter roller motor 3- 2 and the cutter head 3-3, the cutter roller motor 3-2 is used to drive the cutter head 3-3 to rotate; the rubber roller mechanism includes a rubber roller 3-4 and a rubber roller cylinder 3-5, and the rubber roller cylinder 3-5 is used to drive Rubber roller 3-4 is close to or away from rubber roller 3-4; Grinding device 3-7 comprises grinding motor 3-7-1, grinding cylinder 3-7-2, transmission case 3-7-5 and grinding wheel 3-7- 6. The grinding motor 3-7-1 drives the grinding wheel 3-7-6 to r...

Embodiment 3

[0111] A specific embodiment of the present invention discloses the cutterhead 3-3 in Embodiment 2, specifically discloses a glass fiber radial self-cleaning cutting cutterhead, such as Figure 8 to Figure 10 As shown, the glass fiber radial self-cleaning cutting cutter head includes a connecting body 3-3-1, a tooth seat 3-3-2, a first gland 3-3-3, a pressure ring 3-3-4, and a blade 3- 3-5, elastic body 3-3-6, positioning pin 3-3-7, fastening nut 3-3-8, fastening screw 3-3-9, end cover 3-3-10, long bolt 3 -3-11 and the transition sleeve 3-3-12, the connecting body 3-3-1 is connected with the output shaft of the cutter roller motor 3-2; the outer circumference of the cutter head 3-3 is radially evenly distributed with several blades 3-3- 5. The number of blades 3-3-5 can be increased or decreased according to the requirement of fiber cutting length.

[0112] The connecting body 3-3-1 is a hollow structure with a connecting hole, the connecting hole is a tapered hole, the trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com