High-fluidity and strong-hydrophobicity starch and preparation method thereof

A high-fluidity and hydrophobic technology, applied in coating and other directions, to achieve the effect of no three wastes, short production process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] Example 1: Preparation of High Fluidity and Strong Hydrophobic Corn Starch

[0090] Step 1: Make Dry Corn Starch

[0091] Dry corn starch with a particle size of 80-100 μm to obtain dry corn starch; the drying temperature is 120° C., and the drying time is 4 hours;

[0092] The second step: the modified starch

[0093] Place 1.5Kg of dried cornstarch in the high mixer, accounting for 2 / 3 of the volume of the high mixer cavity;

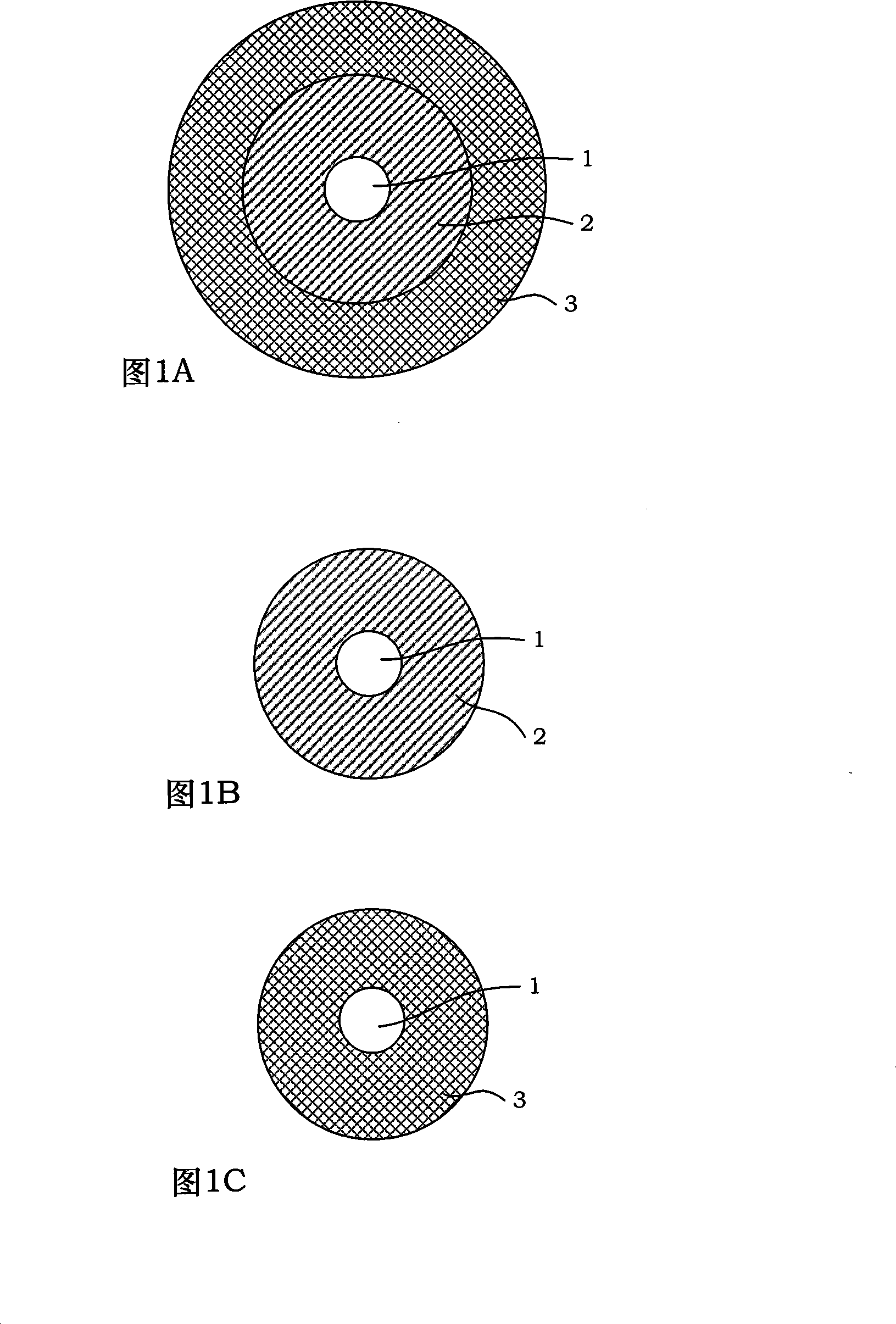

[0094] (A) 3.75 g of hydrophobic modifier was added under the condition of stirring speed of 1500 r / min, and the first coating layer 2 was prepared after the modification temperature was 120 ° C and the modification time was 30 min under continuous stirring;

[0095] The hydrophobic modifier is compounded with titanate coupling agent NDZ-105 and silane coupling agent A-151, titanate coupling agent NDZ-105: silane coupling agent A-151=2:1;

[0096] (B) After adding 1.5g of hydrophobic 16nm silicon dioxide R972 under the condition of stirring ...

Embodiment 2

[0107] Example 2: High fluidity hydrophilic corn starch

[0108] Step 1: Make Dry Corn Starch

[0109] Dry corn starch with a particle size below 60 μm to obtain dry corn starch; the drying temperature is 80°C, and the drying time is 3.5 hours;

[0110] The second step: making a single-layer coated hydrophilic starch with high fluidity

[0111] Place 1.5Kg of dried cornstarch in the high mixer, accounting for 2 / 3 of the volume of the high mixer cavity;

[0112] Add 15g of hydrophilic 13nm alumina particles Al under the condition of stirring speed 2800r / min 2 o 3 C (degussa.), and at a modification temperature of 90°C, the second coating layer 3 was obtained after a modification time of 30 minutes under continuous stirring; that is, a single-layer coated hydrophilic starch with high fluidity (section structure as shown in Figure 1C).

[0113] The obtained cornstarch with high fluidity and hydrophilicity has an angle of repose of 26° and an activation index of 0%.

[011...

Embodiment 3

[0115] Example 3: Strong Hydrophobic Corn Starch

[0116] The first step: making dry starch

[0117] Dry corn starch with a particle size of 30-60 μm to obtain dry corn starch; the drying temperature is 100°C, and the drying time is 2.5 hours;

[0118] The second step: making modified starch

[0119] Place 1.5Kg of cornstarch dried in the first step in the high mixer, accounting for 2 / 3 of the volume of the high mixer cavity;

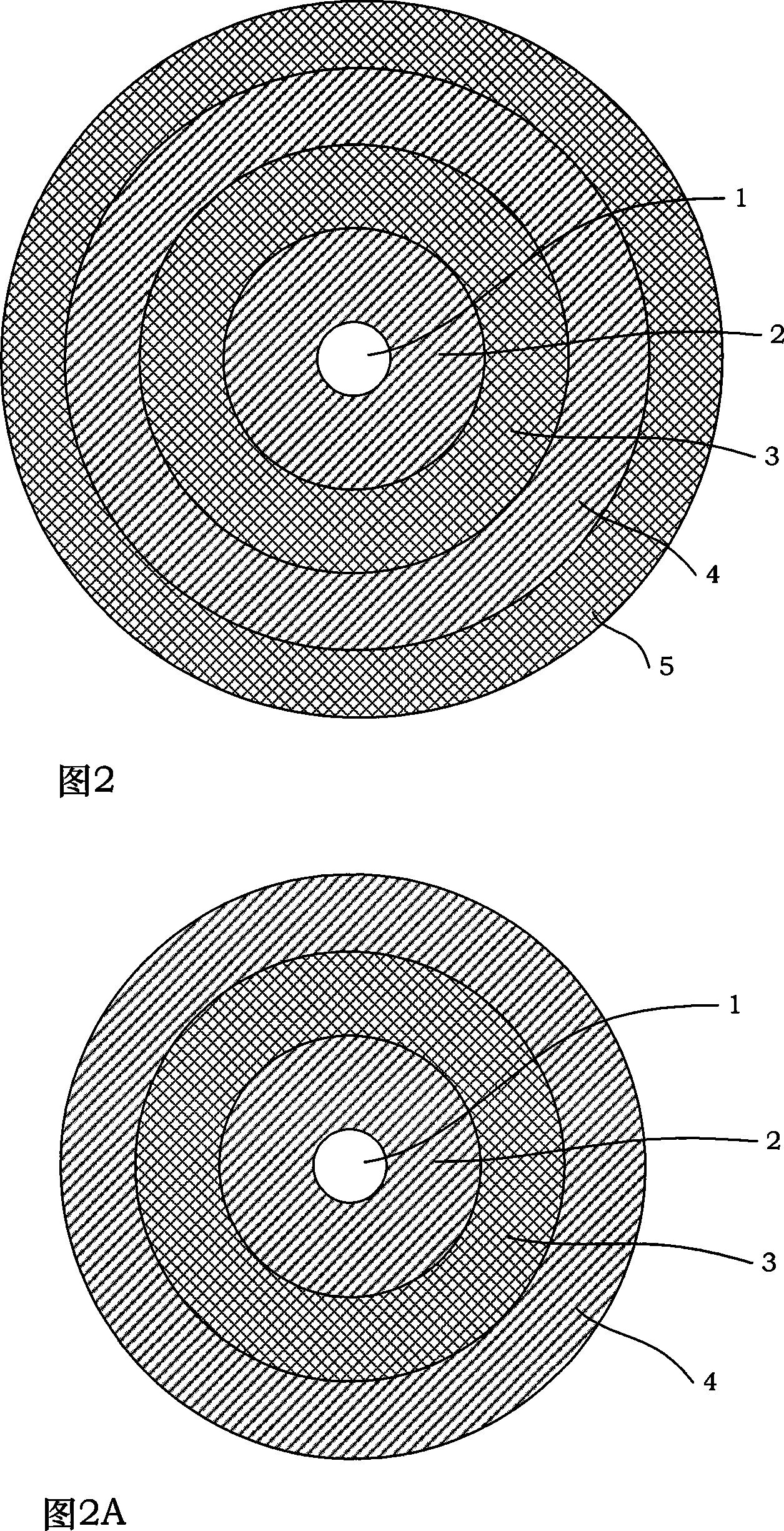

[0120] (A) Add 7.5g of aluminate coupling agent DL-2411-A at a stirring speed of 2000r / min, and make the first package after the modification temperature is 100°C and the modification time is 60 minutes under continuous stirring. cladding2;

[0121] (B) After adding 1.5 g of 10 μm silicon dioxide at a stirring speed of 2500 r / min, the second coating layer 3 was prepared after the modification temperature was 90° C. and the modification time was 15 minutes under continuous stirring;

[0122] (C) Add 7.5 g of aluminate coupling agent DL-2411-A at a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle of repose | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com