Color matching device for polyamide 6 color masterbatch

A color masterbatch and polyamide technology, which is applied in the direction of adding pigments to single-component polyamide artificial filaments and spinning solutions, filament/thread forming, etc., which can solve the problems of high power consumption, waste of materials, and restrictions on coloring colors Diversification and other issues, to achieve the effect of equipment volume reduction, high efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

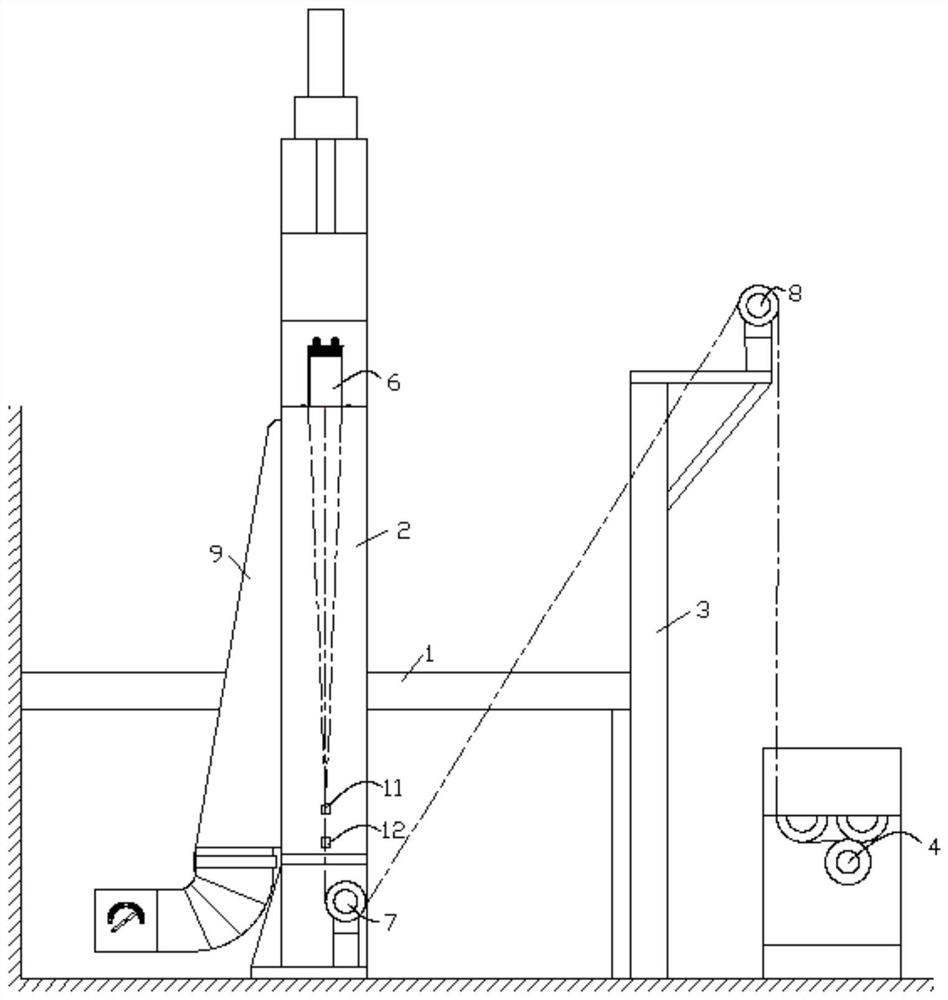

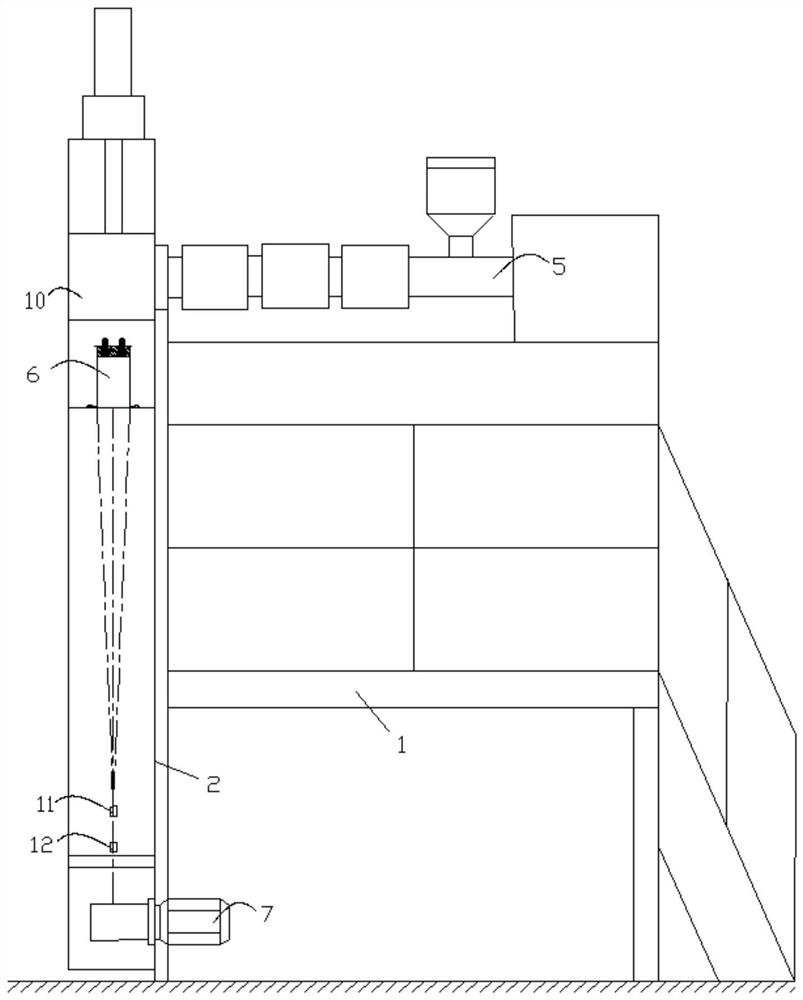

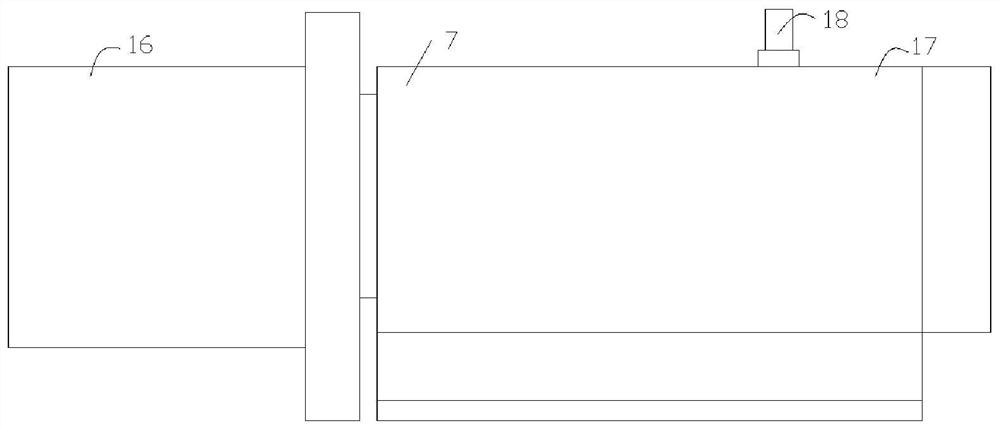

[0024] Such as figure 1 and 2 As shown, the present invention provides a kind of color matching device of polyamide 6 color masterbatch, comprises high-speed winder 4, and it comprises first frame 2, second frame 3 and side blowing device 9, described second Frames 3 are respectively located between the first frame 2 and the high-speed winding machine 4, and the first frame 3 is provided with a screw extruder 5, a component spinneret 6 and a lower godet sequentially from top to bottom 7. The upper end of the second frame 3 is provided with an upper godet 8, and the spinning jetted from the component spinneret 6 passes through the lower godet 7 and the upper godet 8 in turn at a high speed. On the machine 4, the side blowing device 9 is arranged on one side of the first frame 2, and the air outlet of the side blowing device 9 is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com