Patents

Literature

470results about How to "Uniform heat transfer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

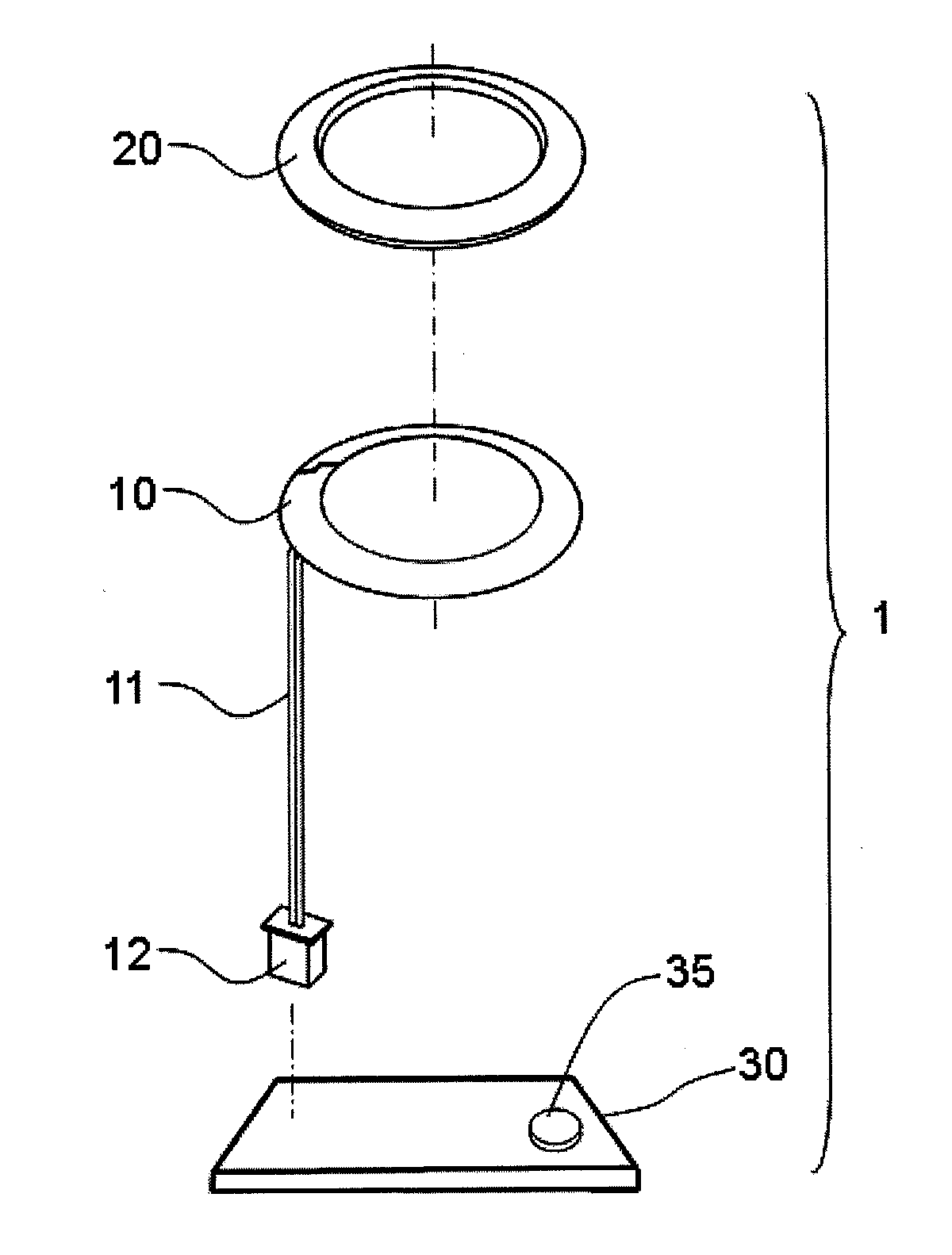

Wafer holder, heater unit used for wafer prober having the wafer holder, and wafer prober having the heater unit

InactiveUS20090050621A1Improve thermal uniformityAvoid measuringSemiconductor/solid-state device manufacturingHot plates heating arrangementsEngineeringSilicon

A wafer holder that prevents positional deviation of the wafer mounted on the wafer-mounting surface of a chuck top and enables better thermal uniformity of the wafer, as well as a heater unit including the wafer holder and a wafer prober mounting these are provided. The wafer holder has a chuck top mounting and fixing the wafer and a supporter supporting the chuck top, and the chuck top has water absorption of at least 0.01% and preferably at least 0.1%. Preferable material of the chuck top is a composite of metal and ceramics, and particularly, a composite of aluminum and silicon carbide, or a composite of silicon and silicon carbide.

Owner:SUMITOMO ELECTRIC IND LTD

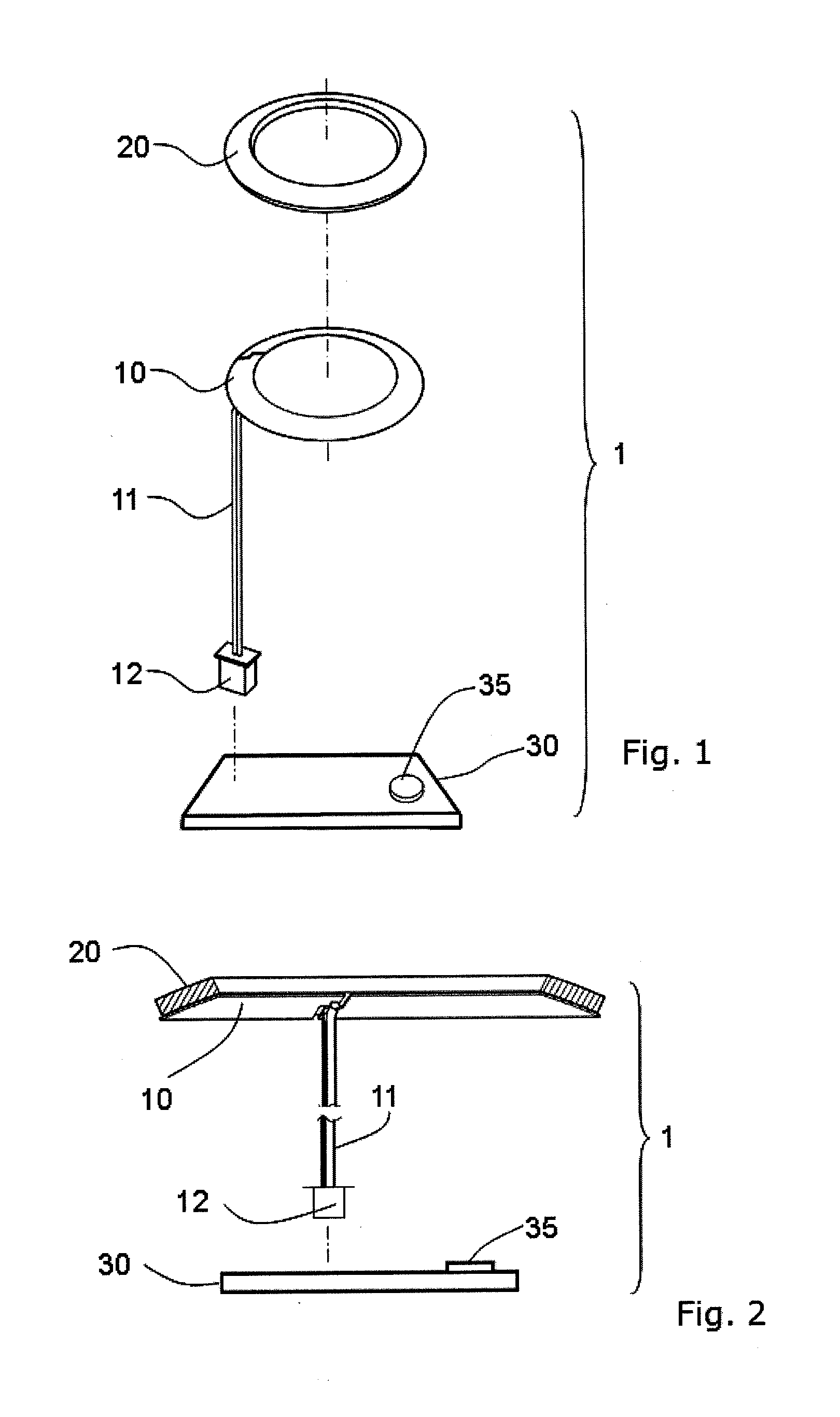

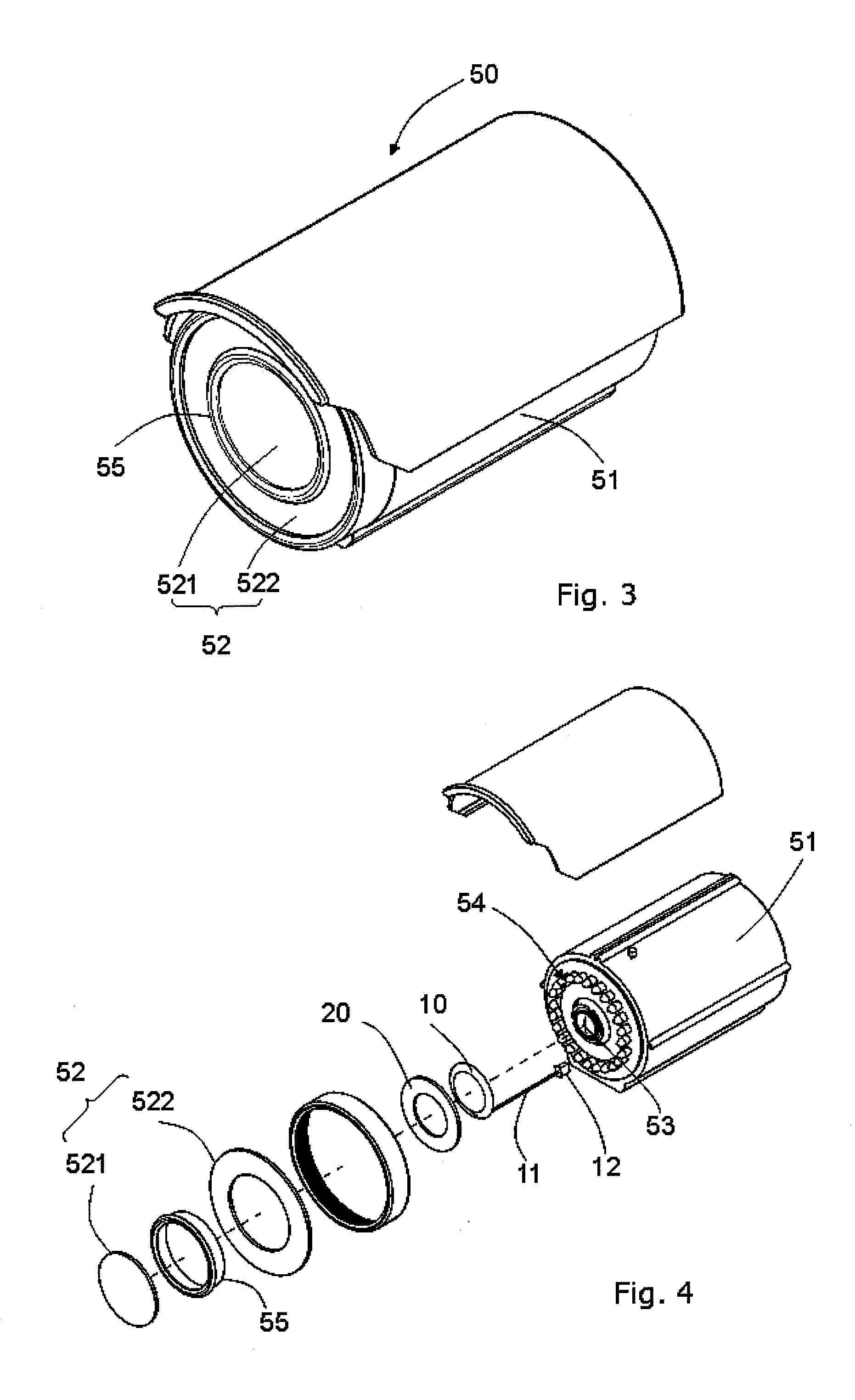

Defogging and defrosting device for protective lens of a camera

InactiveUS20120170119A1Avoid and eliminate humidificationEliminate lossCamera filtersMountingsEngineeringControl circuit

The present invention relates to a defogging and defrosting devices for the protective lens of camera, which includes a heater that is coupled to a control circuit panel, a thermal gasket that is in contact contacting with the heater, receives the heat from the heater and transmits the heat to the glass or mirror object which contacts with in order to avoid and prevent the loss of lucidity of the glass or mirror object due to humidity. The defogging and defrosting device is installed on the body of the camera instead of on the protective lens in order to avoid shading the camera view and to facilitate the removal of protective lens while adjusting the focus of the camera. It also facilitates the replacement of the protective lens of the camera.

Owner:TOPVIEW OPTRONICS CORP

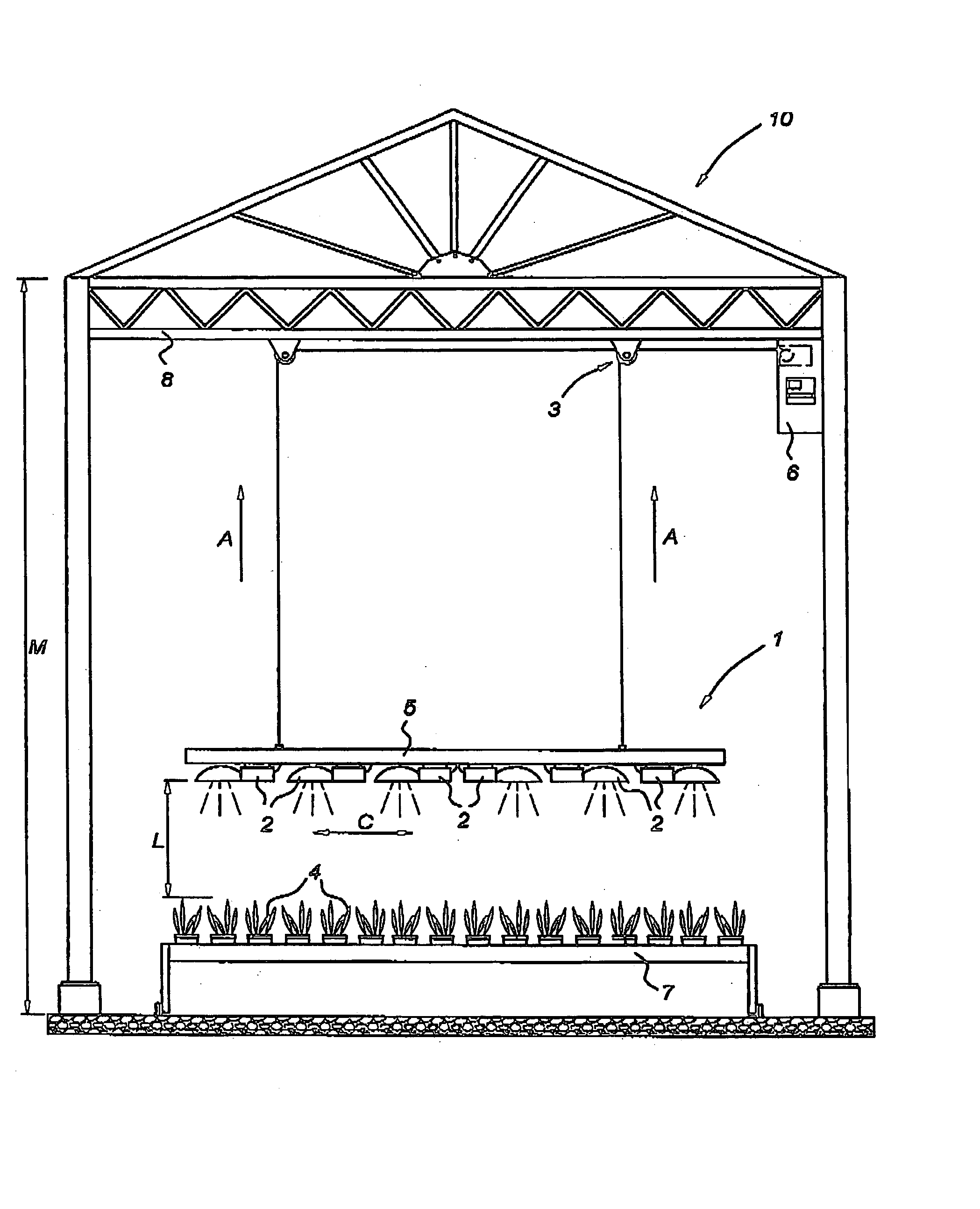

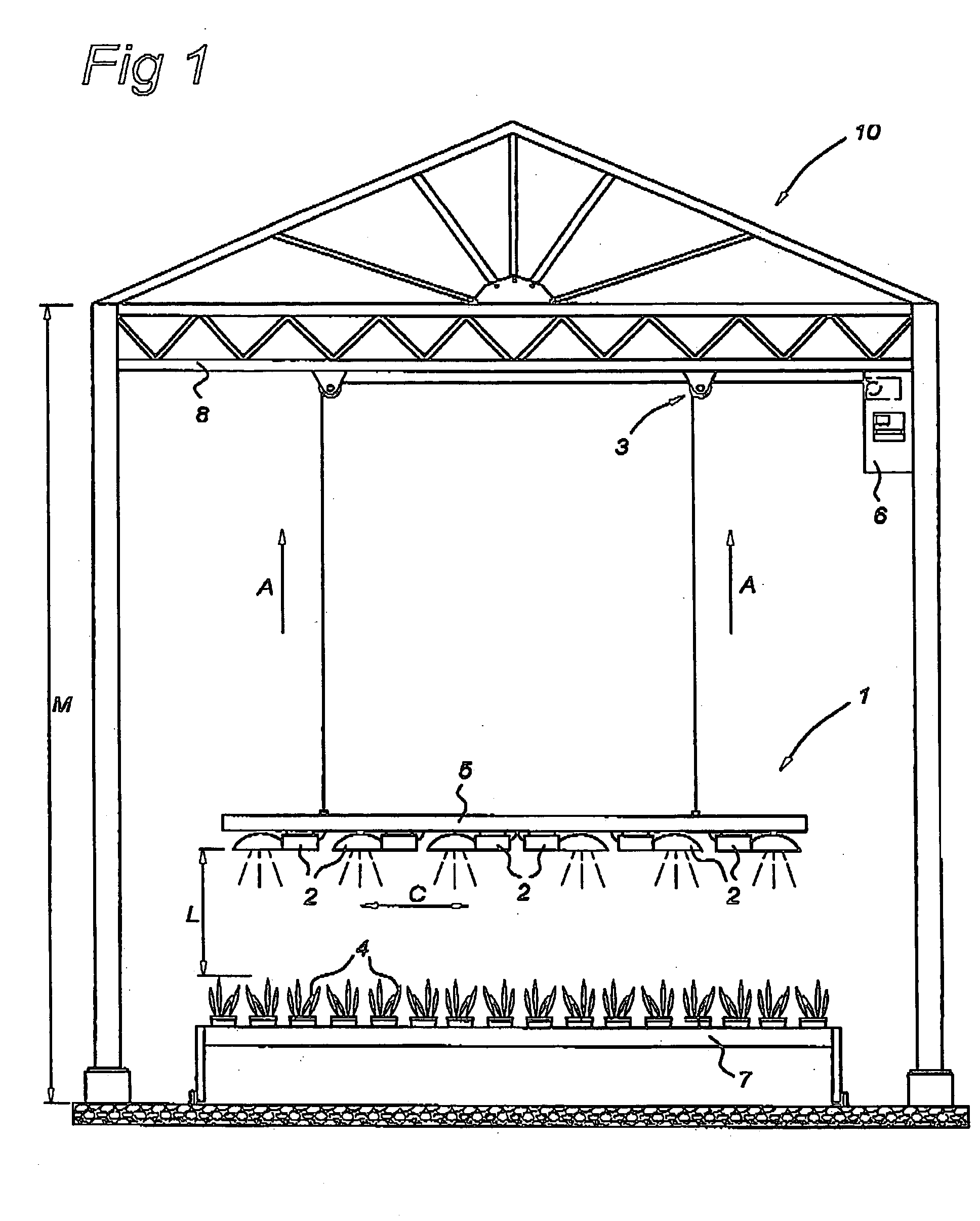

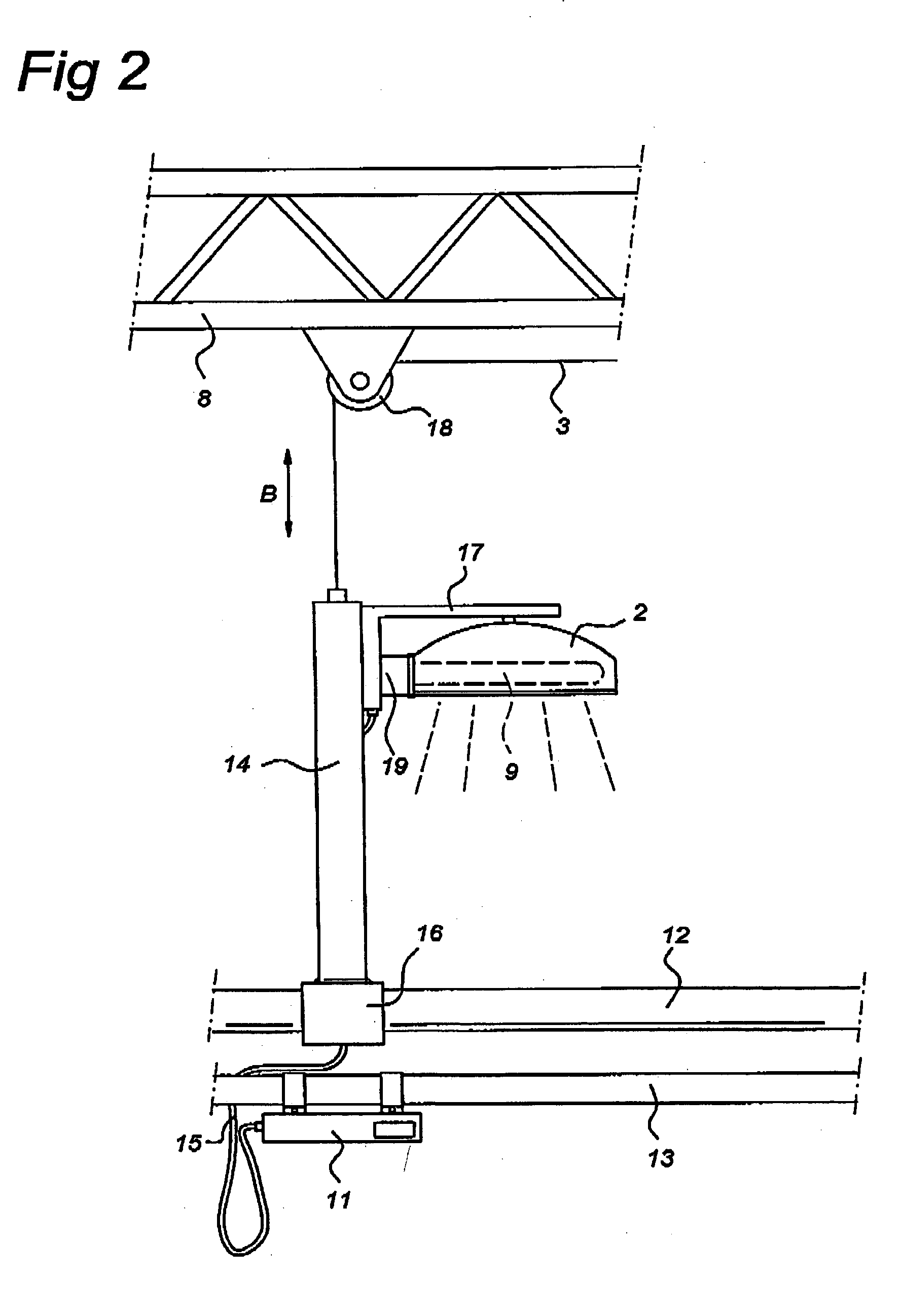

Method, greenhouse and an installation for illuminating plants

InactiveUS20060032115A1Uniform heat transferMore energyClimate change adaptationSaving energy measuresGear wheelGreenhouse

The present invention relates to a method for illuminating plants in a greenhouse, comprising the provision of a lamp above the plants, with adjustment of the distance between the lamp and the tip of the plants growing upwards to the height of the growing plants, this distance being kept between 80 cm and 240 cm. The present invention furthermore relates to a greenhouse, containing plants and an installation for illuminating plants, wherein the installation comprises a lamp, lifting gear for moving the lamp in the height direction relative to the plants and control means for measuring and / or setting the distance between the lamp and the tip of the plants growing upwards, and also relates to an installation for illuminating plants intended for use in such a greenhouse.

Owner:HORTILUX SCHREDER

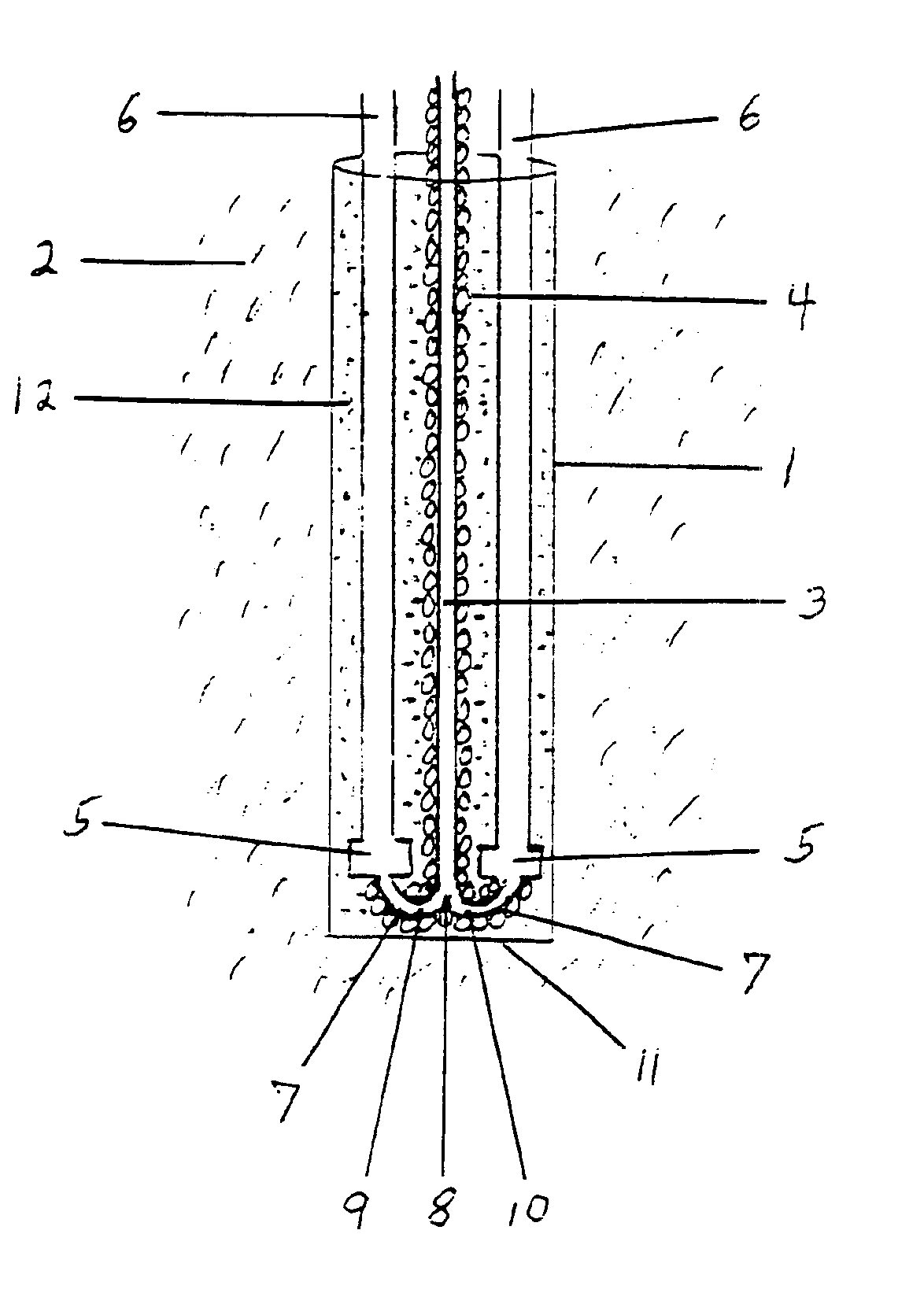

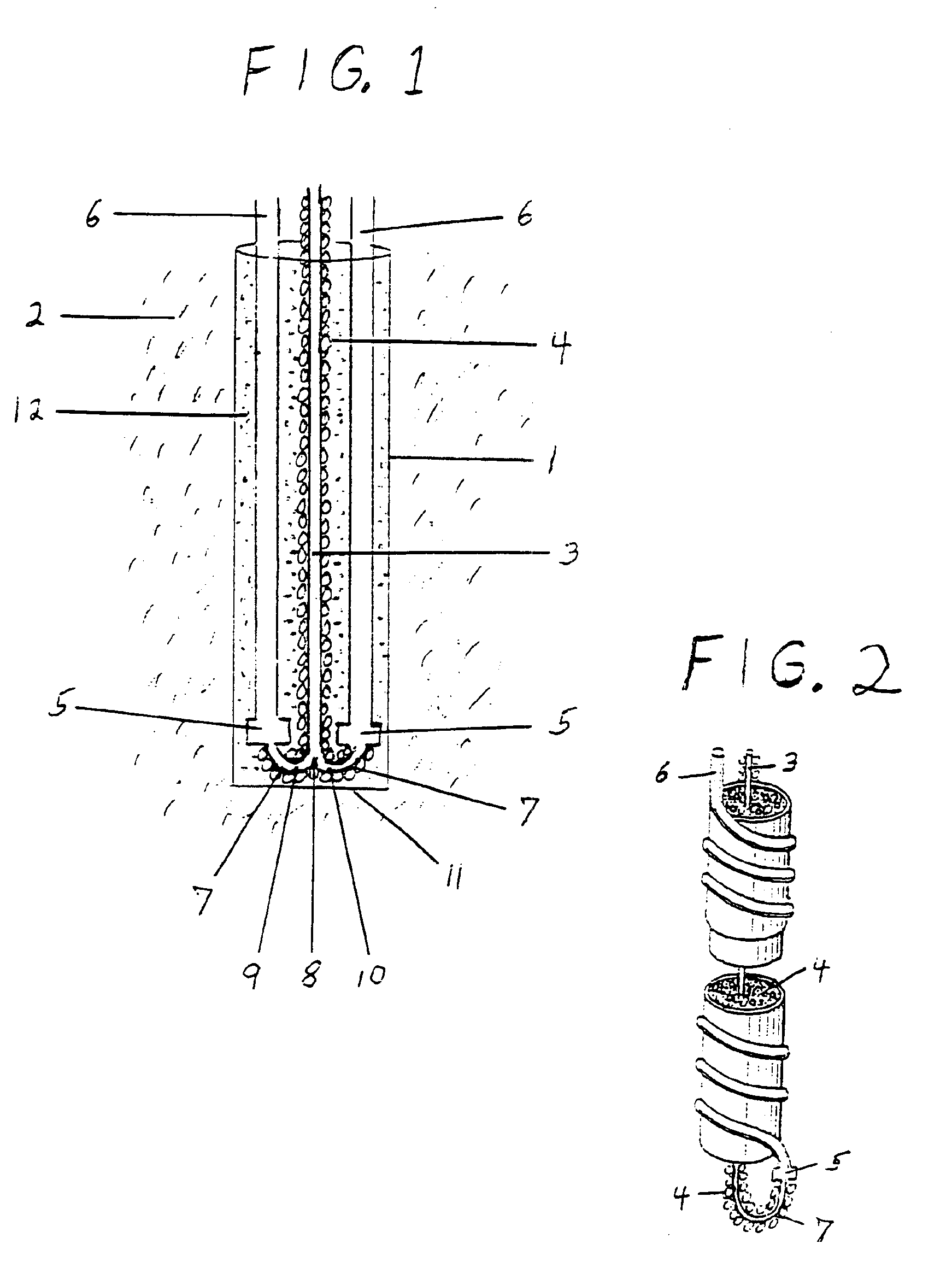

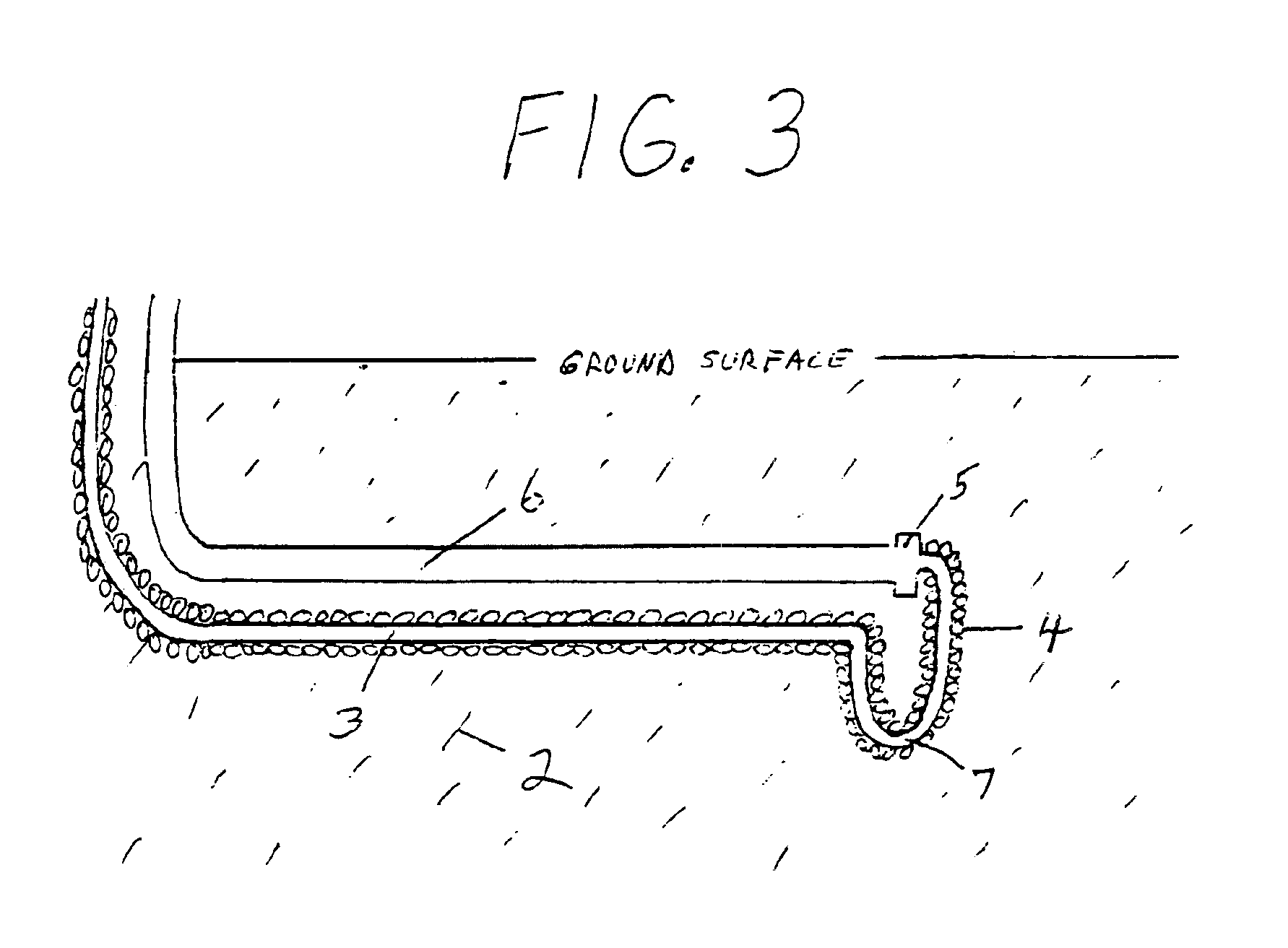

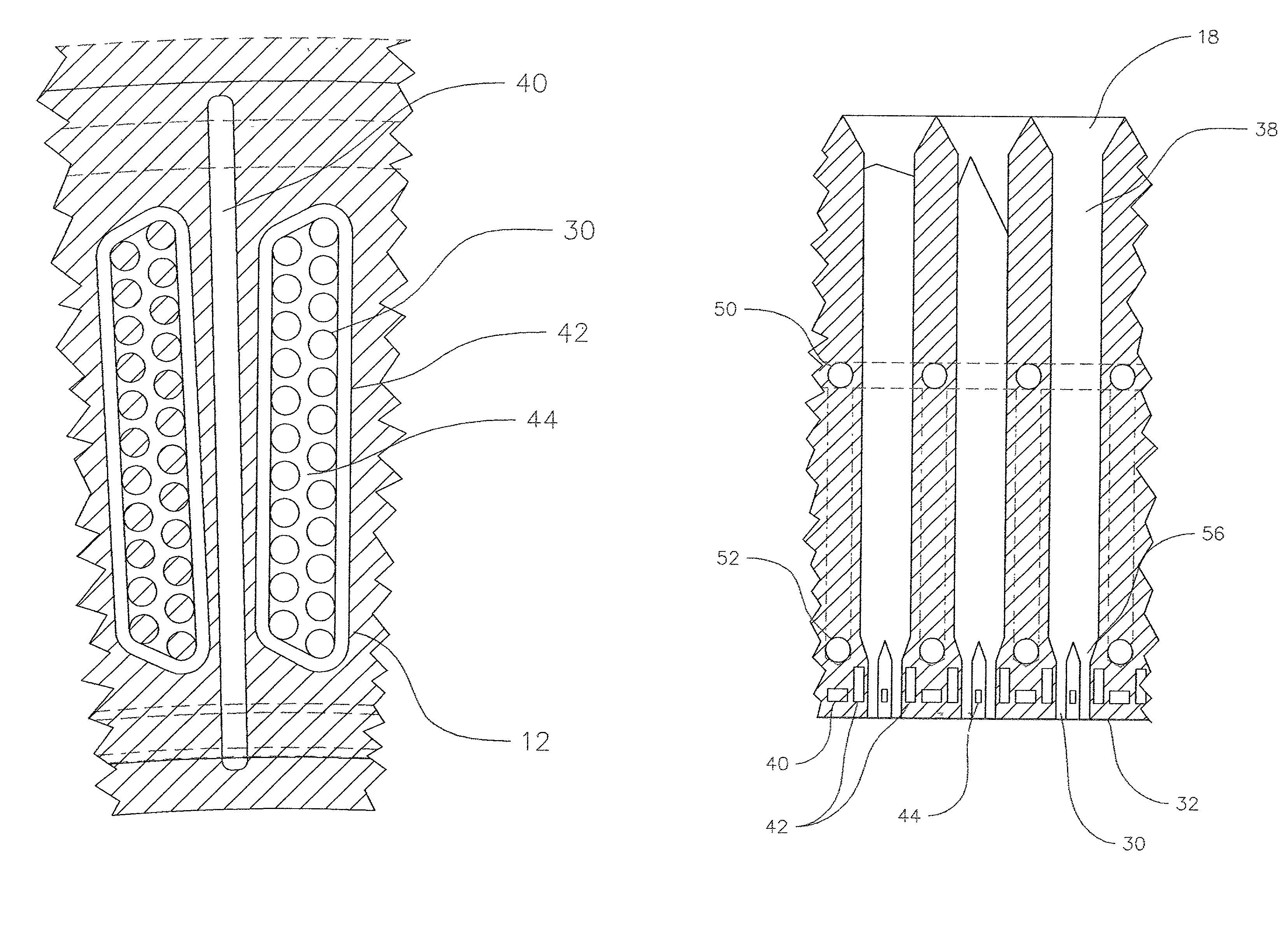

Insulated sub-surface liquid line direct expansion heat exchange unit with liquid trap

InactiveUS6932149B2Operation efficiency can be improvedReduce installation costsDomestic cooling apparatusOther heat production devicesLiquid lineFilling materials

A direct expansion geothermal heat exchange unit, which can be placed in sub-surface ground and / or water, consisting of at least one insulated refrigerant liquid / fluid line, with a liquid trap at the bottom of the liquid / fluid line, with at least one un-insulated refrigerant vapor / fluid line operatively connected to the insulated liquid / fluid line at a point above the liquid trap, where the un-insulated vapor / fluid line is in thermal contact with its adjacent sub-surface surrounding elements by means of a heat conductive fill material inserted as necessary to fill any void space, in any borehole or excavated area, between the vapor / fluid line and its respective adjacent sub-surface surroundings.

Owner:EARTH TO AIR SYST

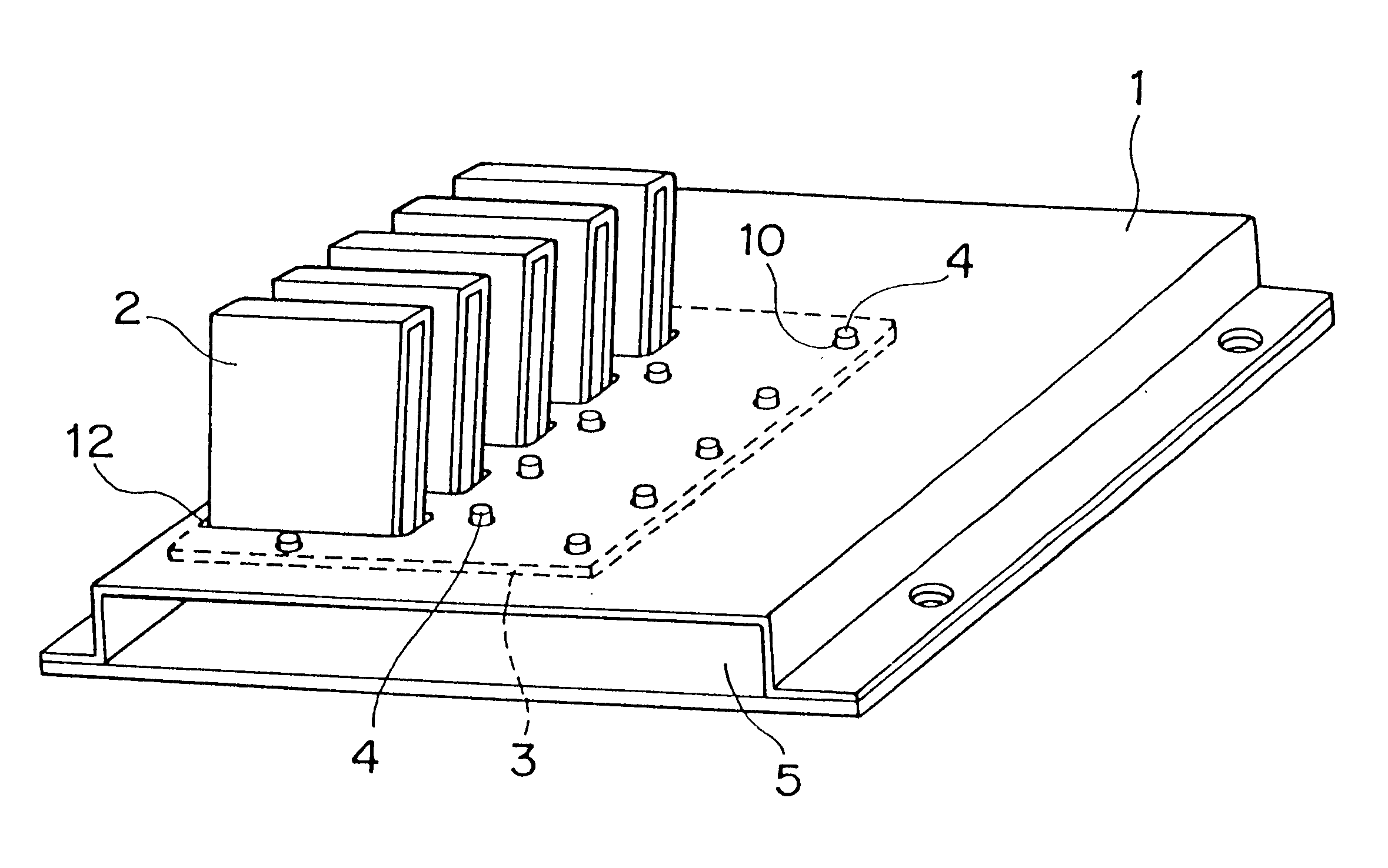

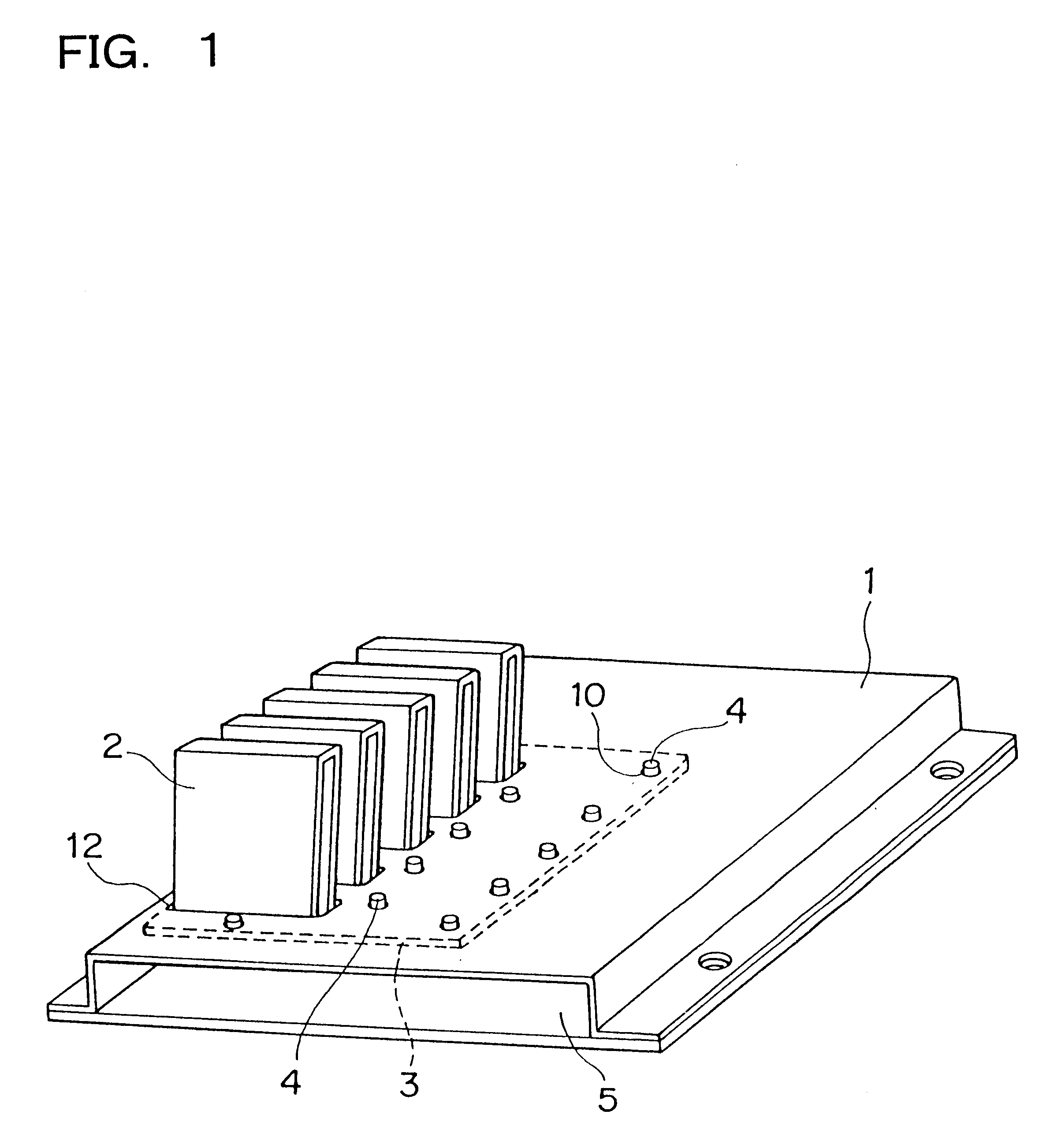

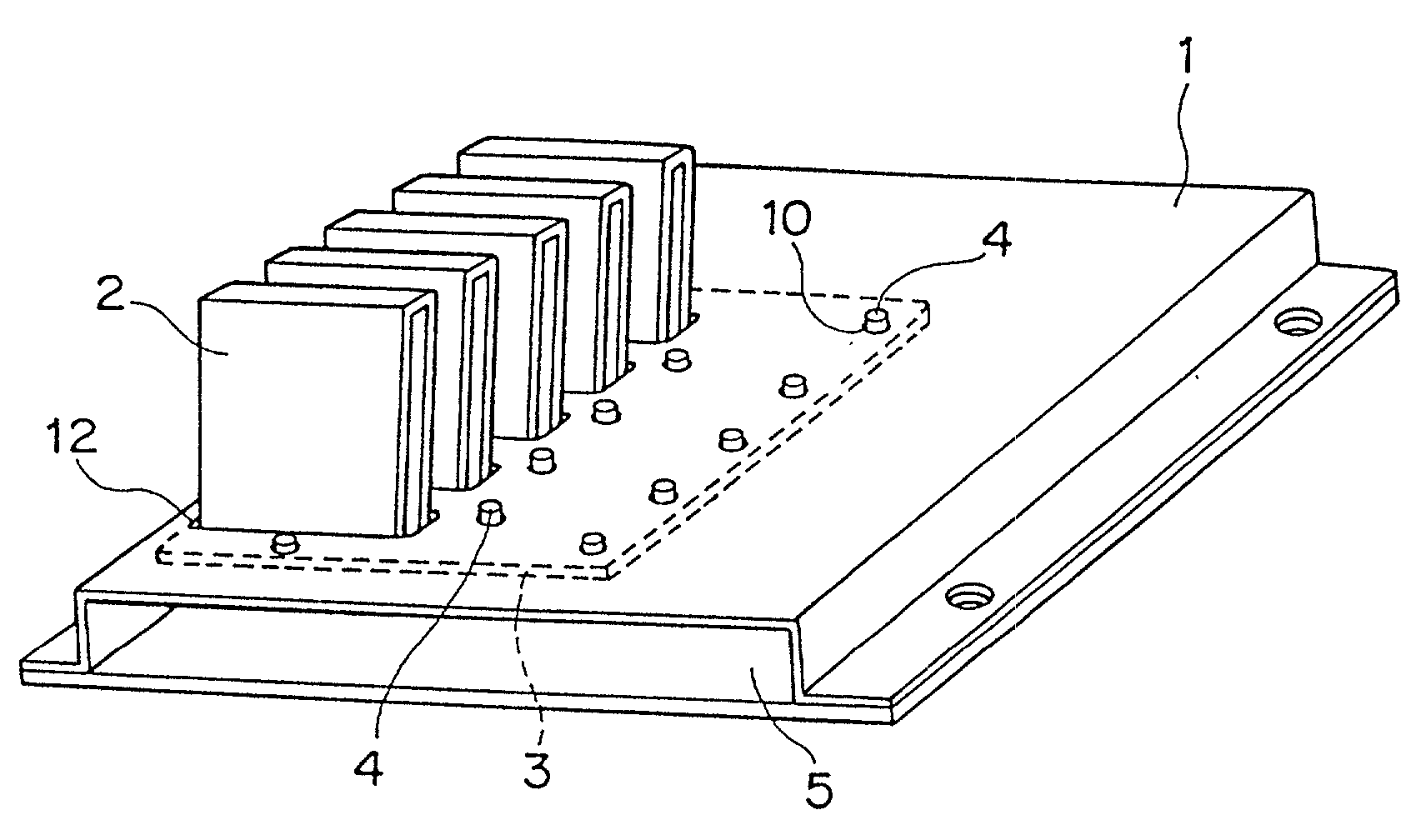

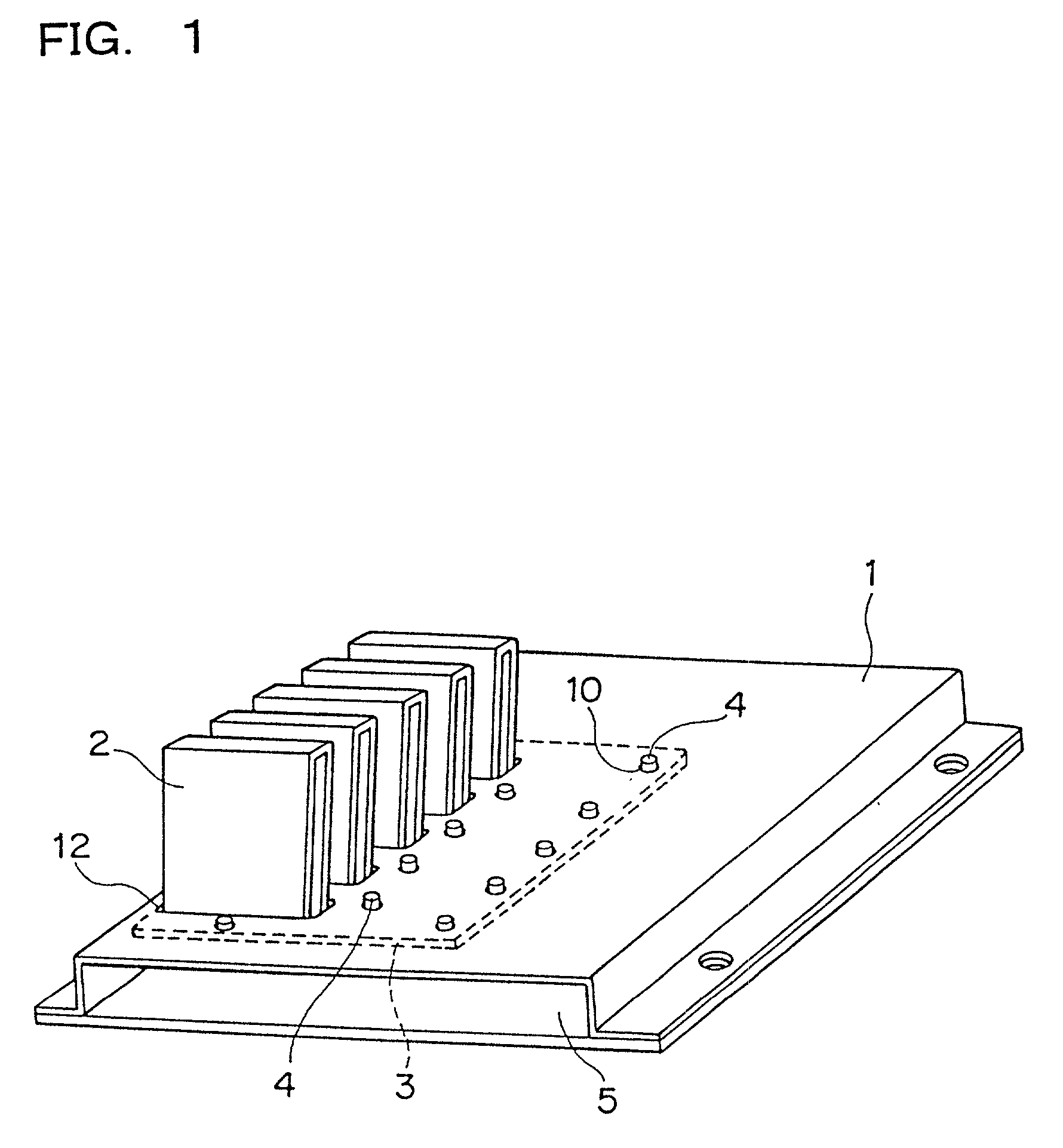

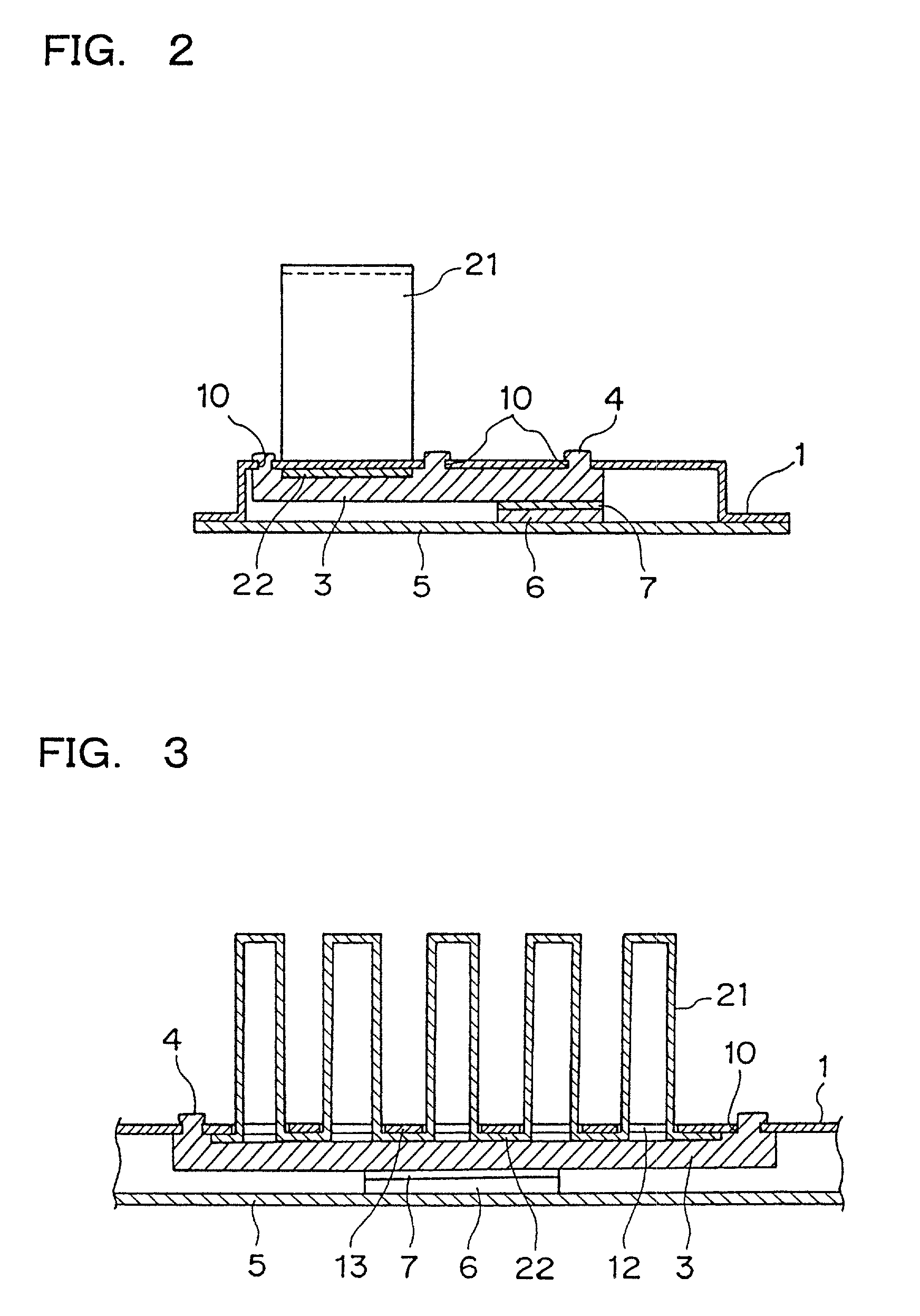

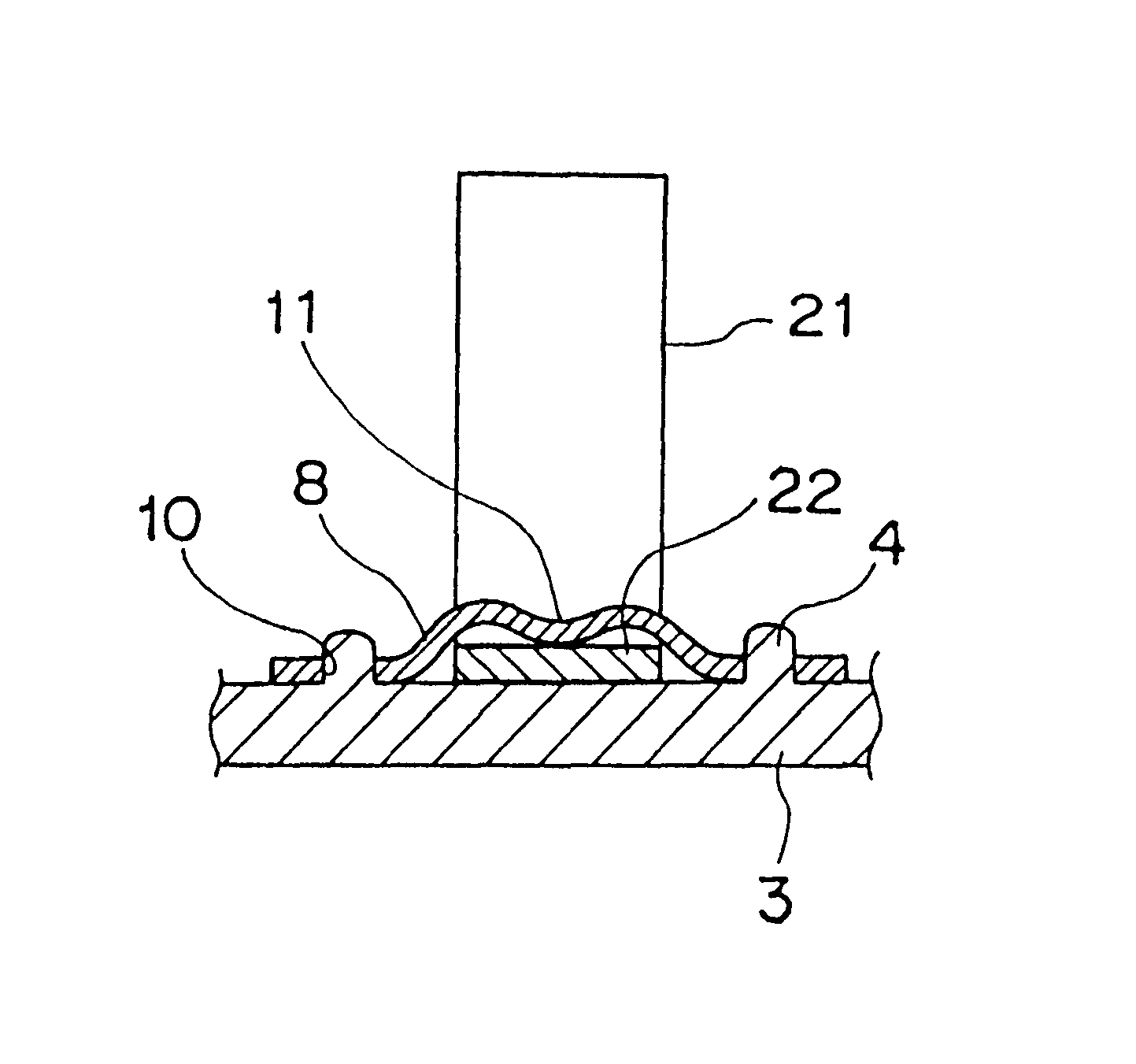

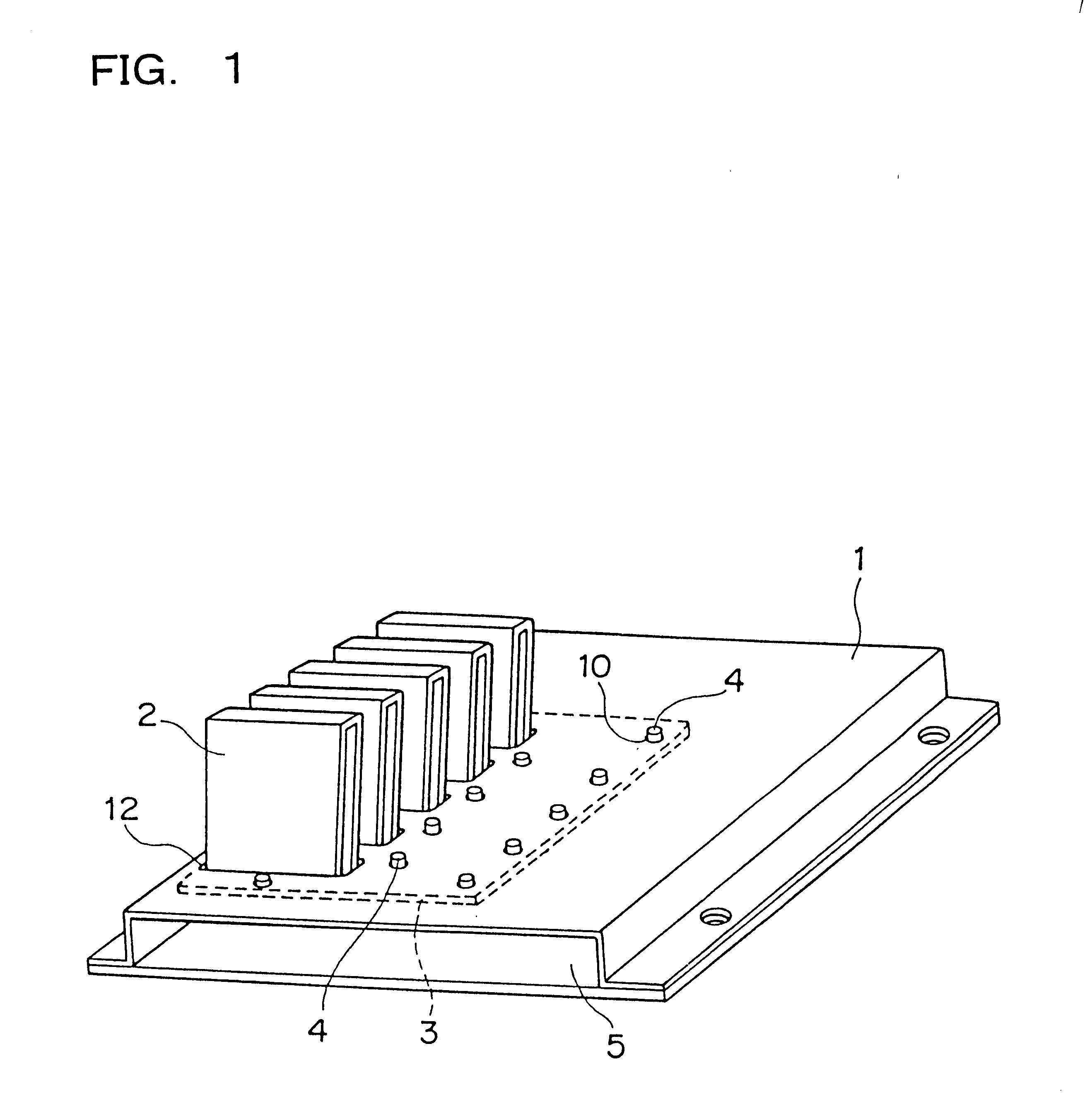

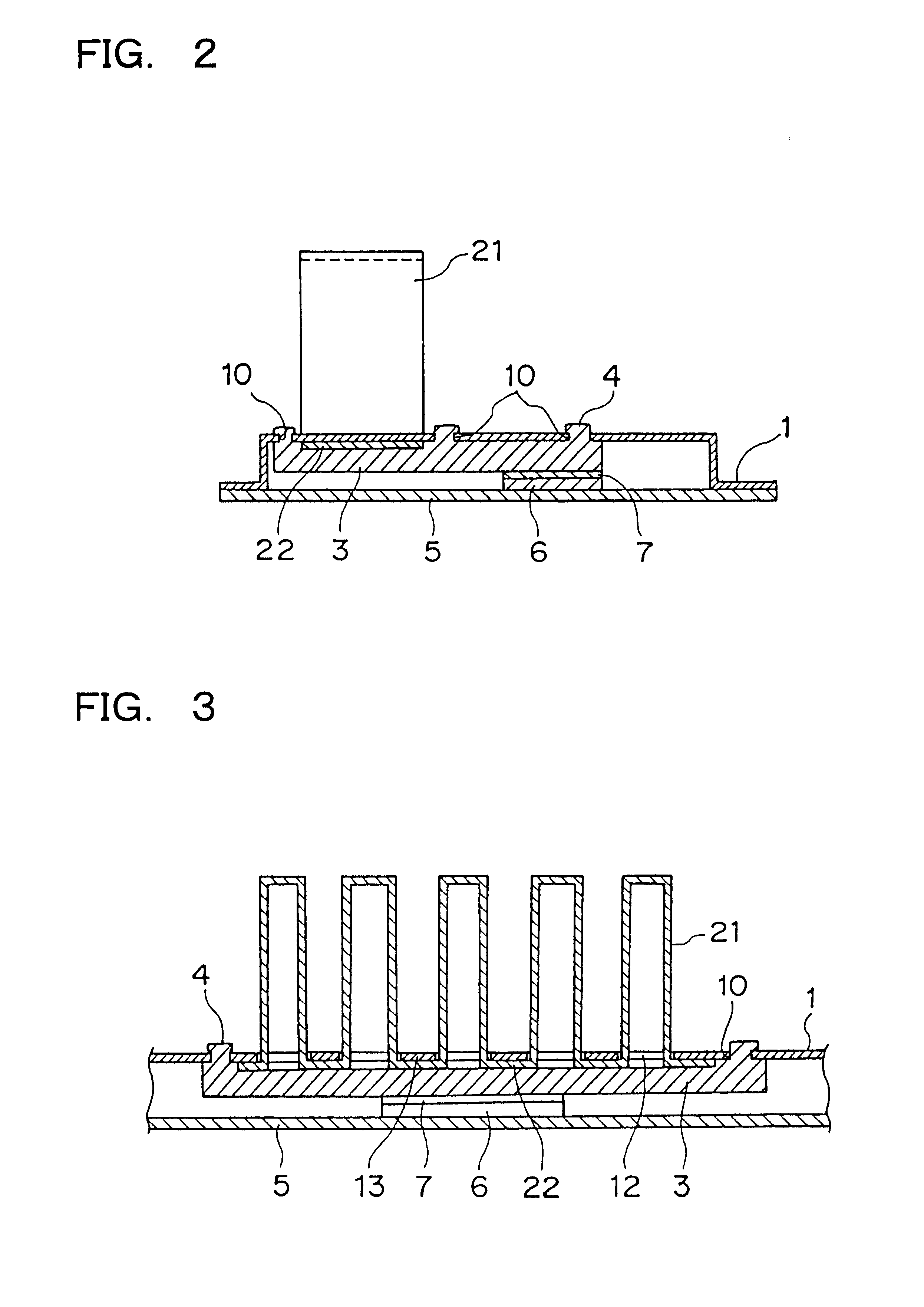

Heat sink including a heat dissipating fin and method for fixing the heat dissipating fin

InactiveUS6357514B1Reduce processing costsHigh strengthSemiconductor/solid-state device detailsSolid-state devicesEngineeringBiomedical engineering

A heat sink including a heat dissipating fin comprises (1) a heat dissipating fin having a plurality of mountain-shaped portions and base portions supporting the mountain-shaped portions, (2) a base member having a plurality of slits into which the mountain-shaped portions of the heat dissipating fin are to be inserted and a plurality of holes for fixing the heat dissipating fin, and (3) a fitting member, provided with a plurality of projecting portions corresponding to the plurality of holes of the base member, for fixing the heat dissipating fin between the base member and the fitting member itself.

Owner:FURUKAWA ELECTRIC CO LTD +1

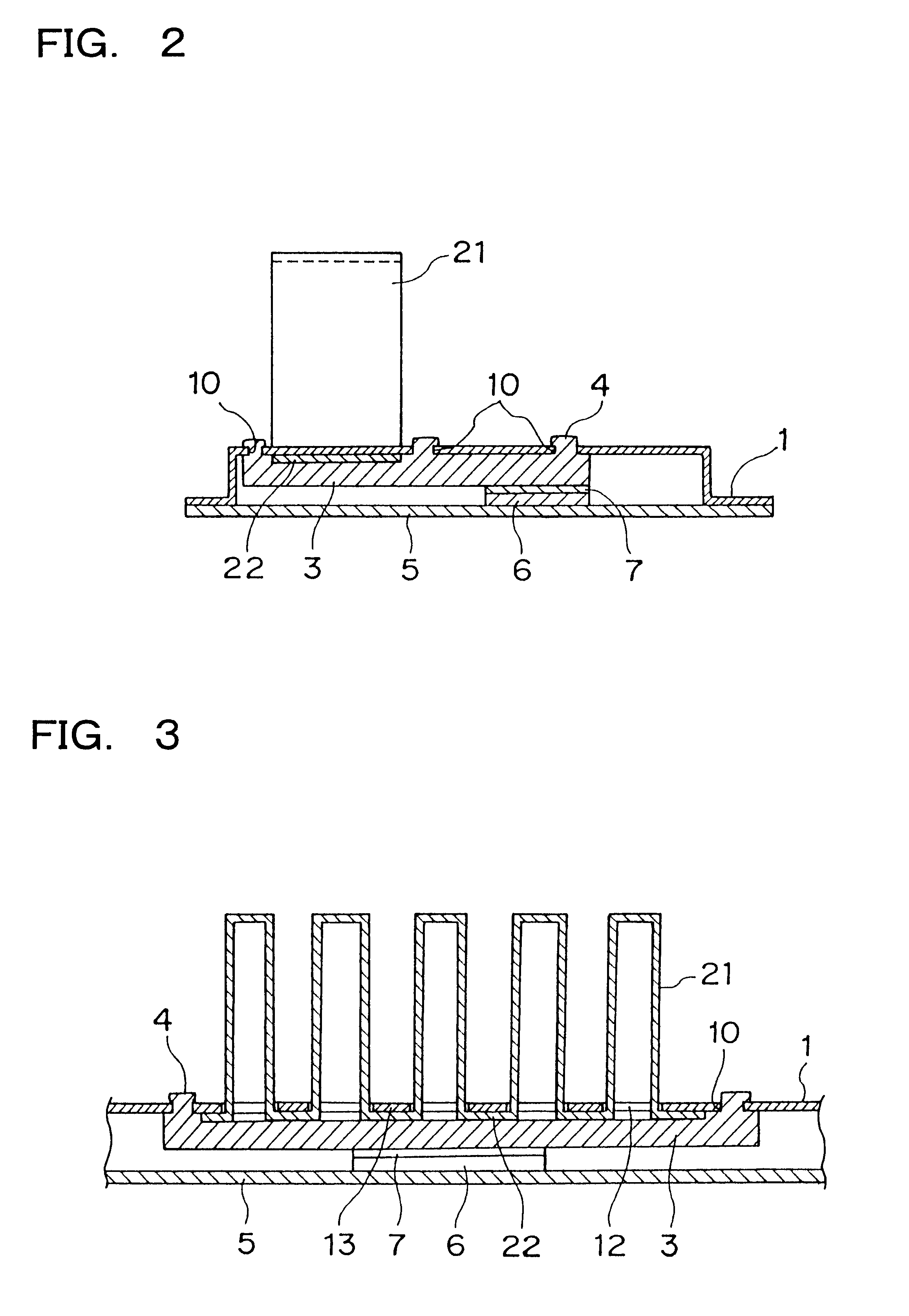

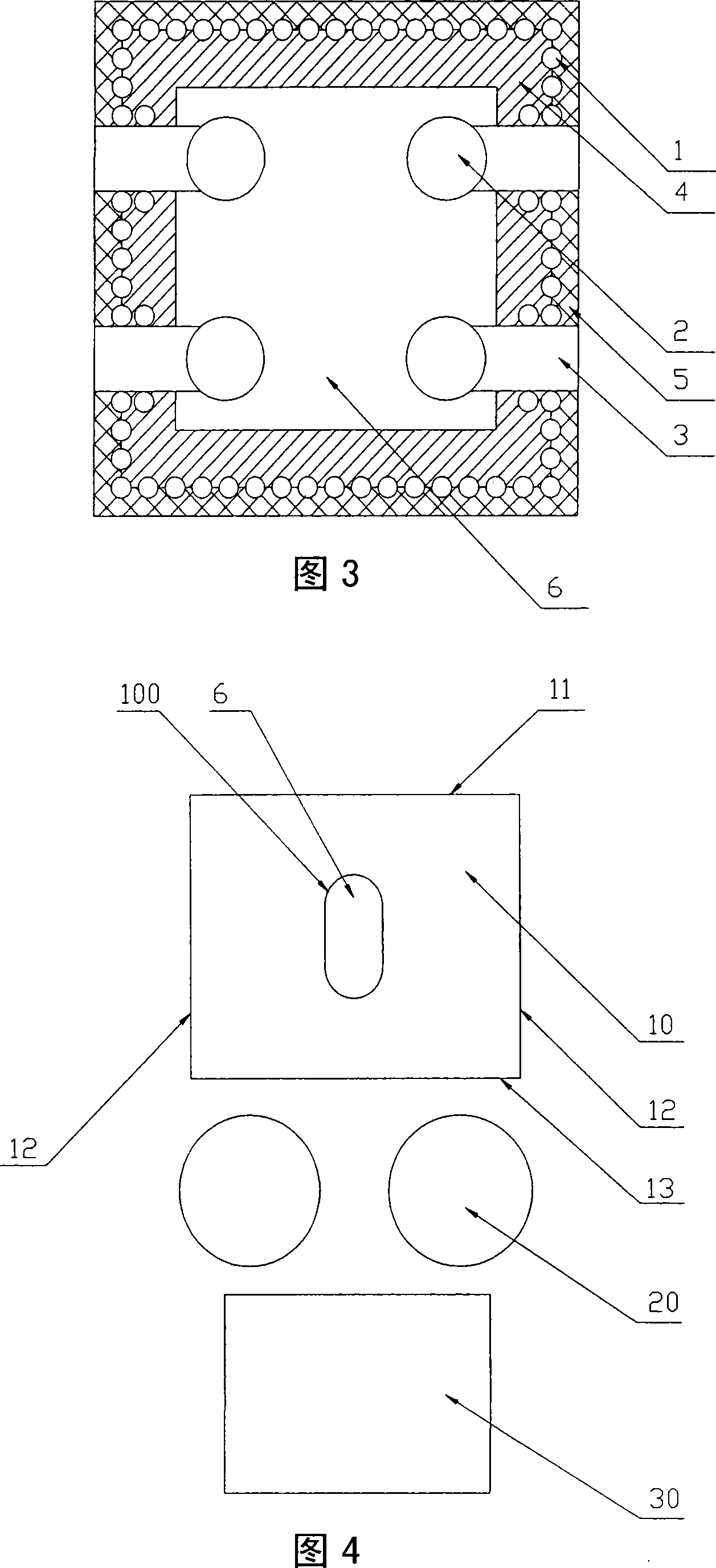

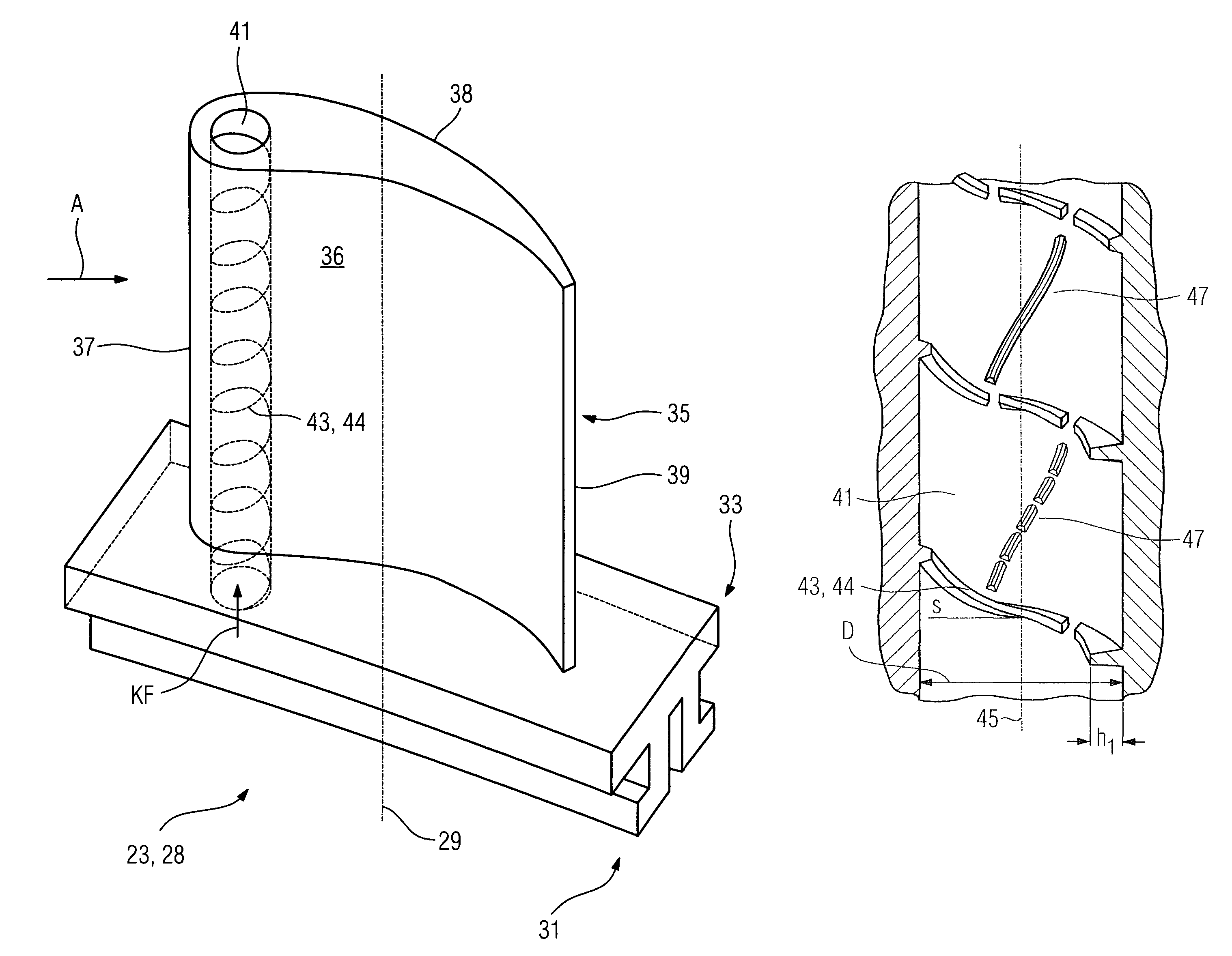

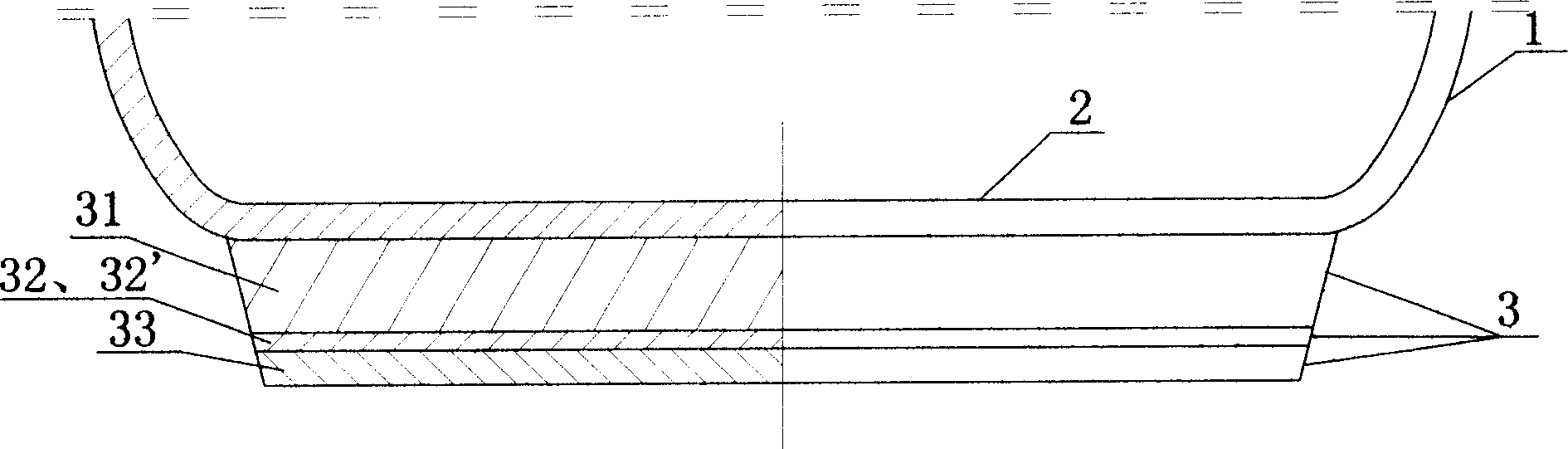

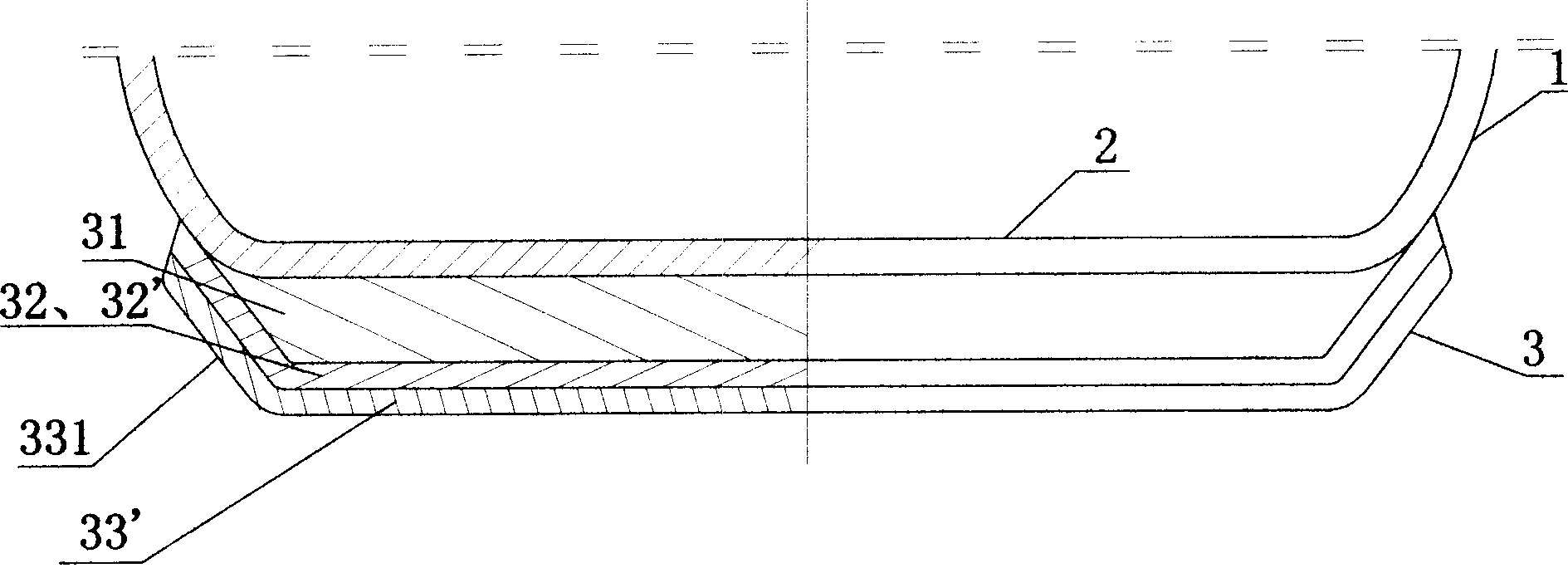

Boiler furnace of circulating fluidized bed with water-cooled column

ActiveCN101196297AEvenly heatedIncreased hydrodynamic safetyFluidized bed combustionApparatus for fluidised bed combustionBoiler furnaceCirculating fluidized bed boiler

The invention relates to a circulating fluid bed boiler furnace with water-cooled posts, which is characterized in that: the water-cooled posts arranged in the boiler furnace are able to provide enough heating area; meanwhile, enough space is left between posts for mixing materials at lower section of the boiler furnace, so as to ensure the concentration, temperature and the evenness of heat transfer; the heating status of the heat face of the water-cooled posts and the wall around the boiler furnace are similar, which is particularly beneficial for enhancing the hydrodynamic force safety of supercritical circulating fluidized bed boiler furnace. The water-cooled posts are able to be internally provided with dusts being able to through with secondary winds at the central area of the boiler furnace. The invention arranges the vertical water-cooled posts encircled by film walls between boiler furnace grid plate and a ceiling and working substance are provided from up to down in the film wall pipe; the external side of the water-cooled post faces to the burning space of the boiler furnace.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Method for preparing low temperature solid oxide fuel cell supported by porous metal

InactiveCN1960047AAffect performanceAffect lifeSolid electrolyte fuel cellsElectrochemical responseAir atmosphere

Method for preparing the disclosed fuel cell includes steps: (1) using porous stainless steel as supportor; depositing porous anodal thin film, compact solid electrolyte film, and reaction barrier layer in sequence on the supportor to be as half cell; carrying out sintering under reducing atmosphere or inert atmosphere; (2) cooling after sintering, depositing active layer of cathode and contact layer of cathode on solid electrolyte film right along; carrying out sintering under air atmosphere so as to obtain cell; (3) dipping reforming catalyst for supportor of porous stainless steel so as to obtain fuel cell. Through the supportor, various fuel gases reformed to anodic gas rich in hydrogen enters into anode to carry out electrochemical reaction.

Owner:SHANGHAI JIAO TONG UNIV

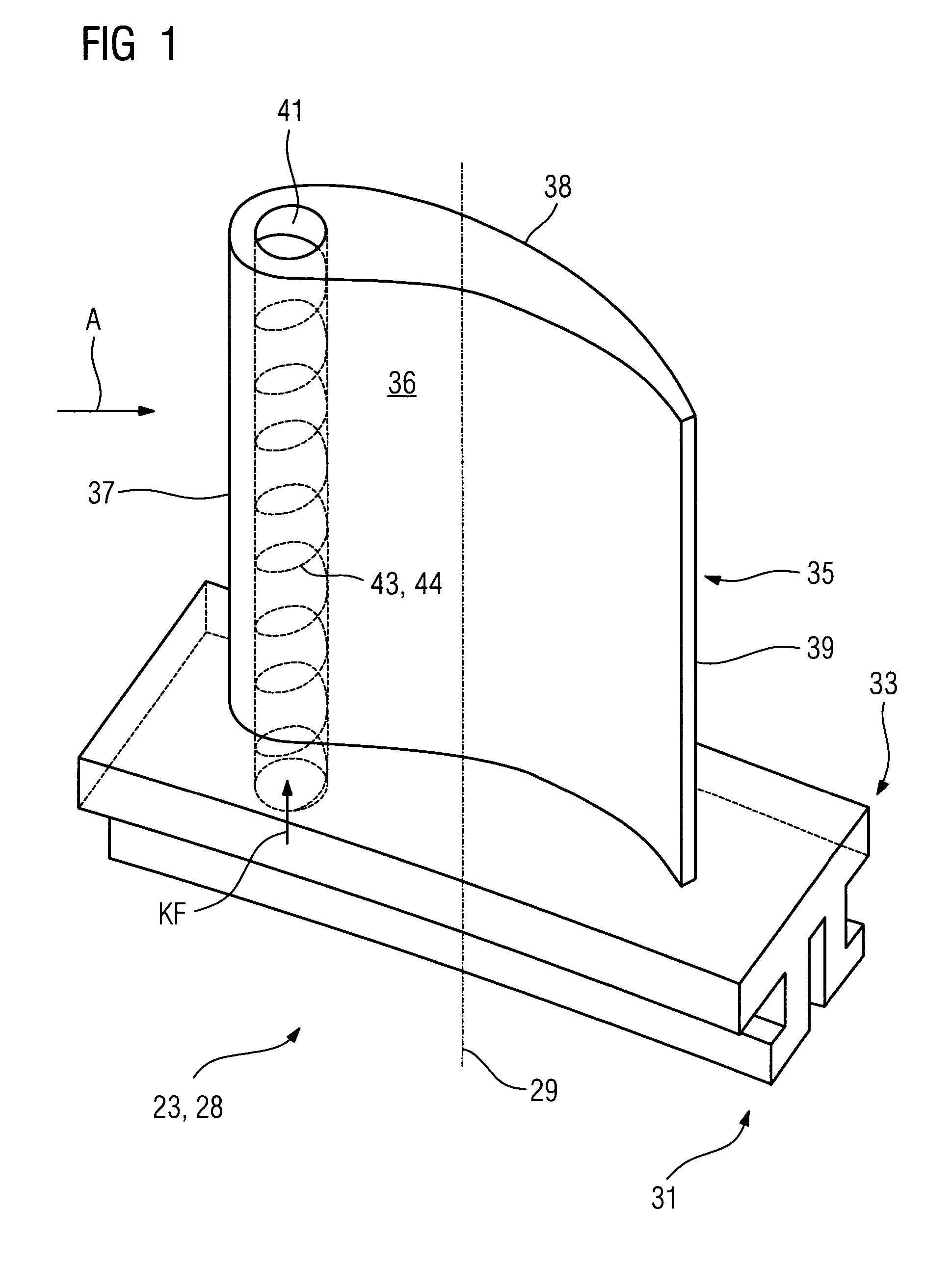

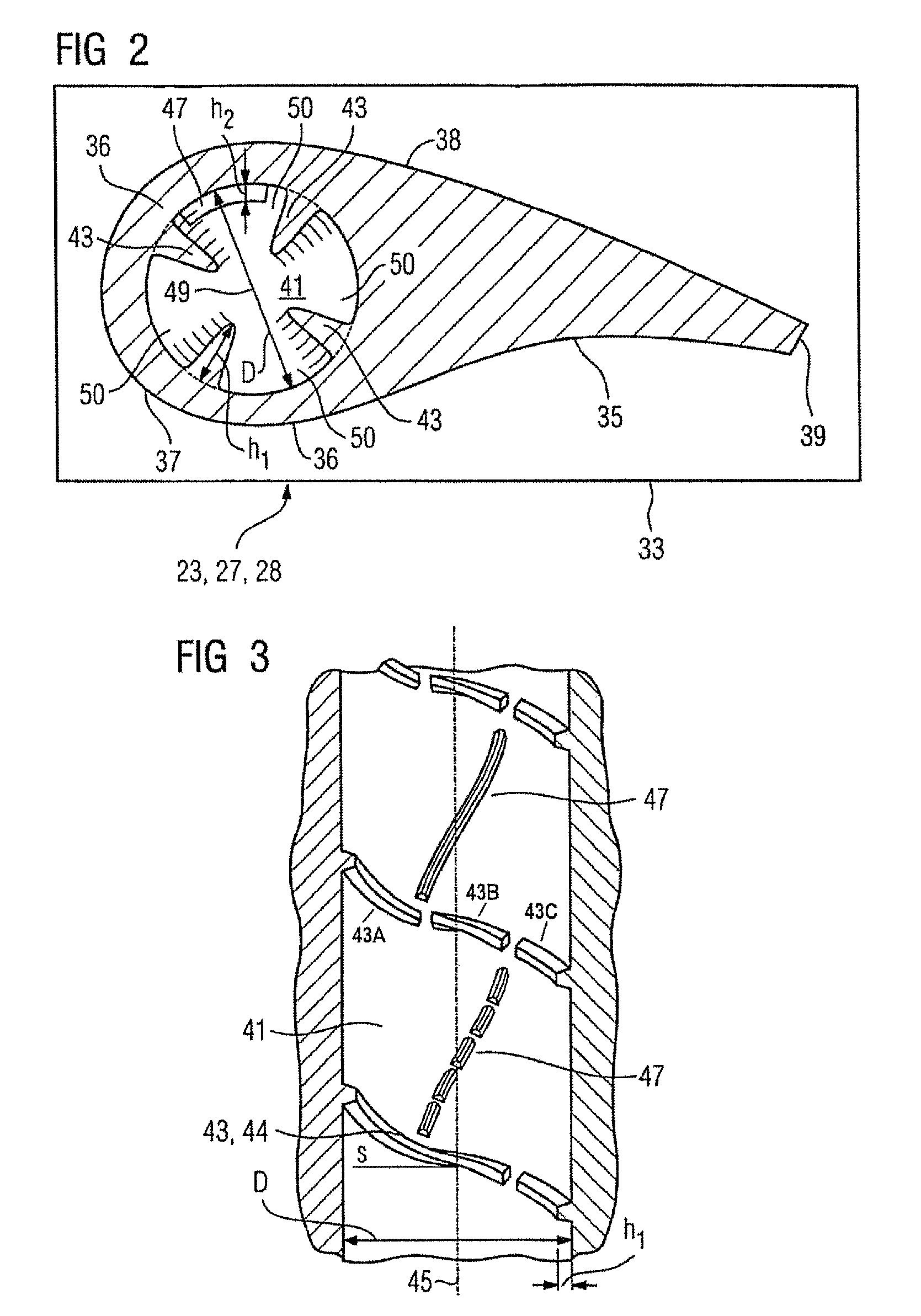

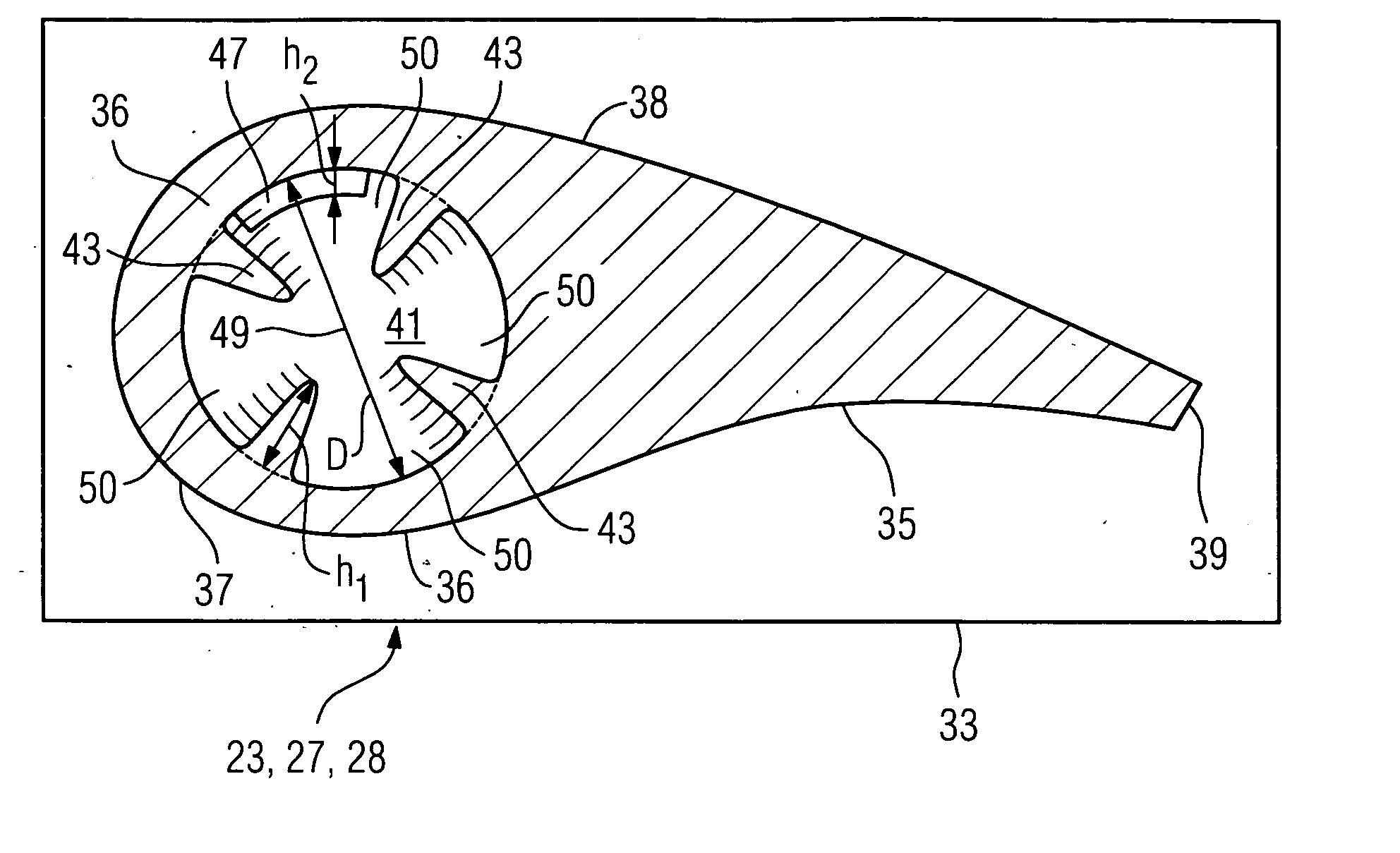

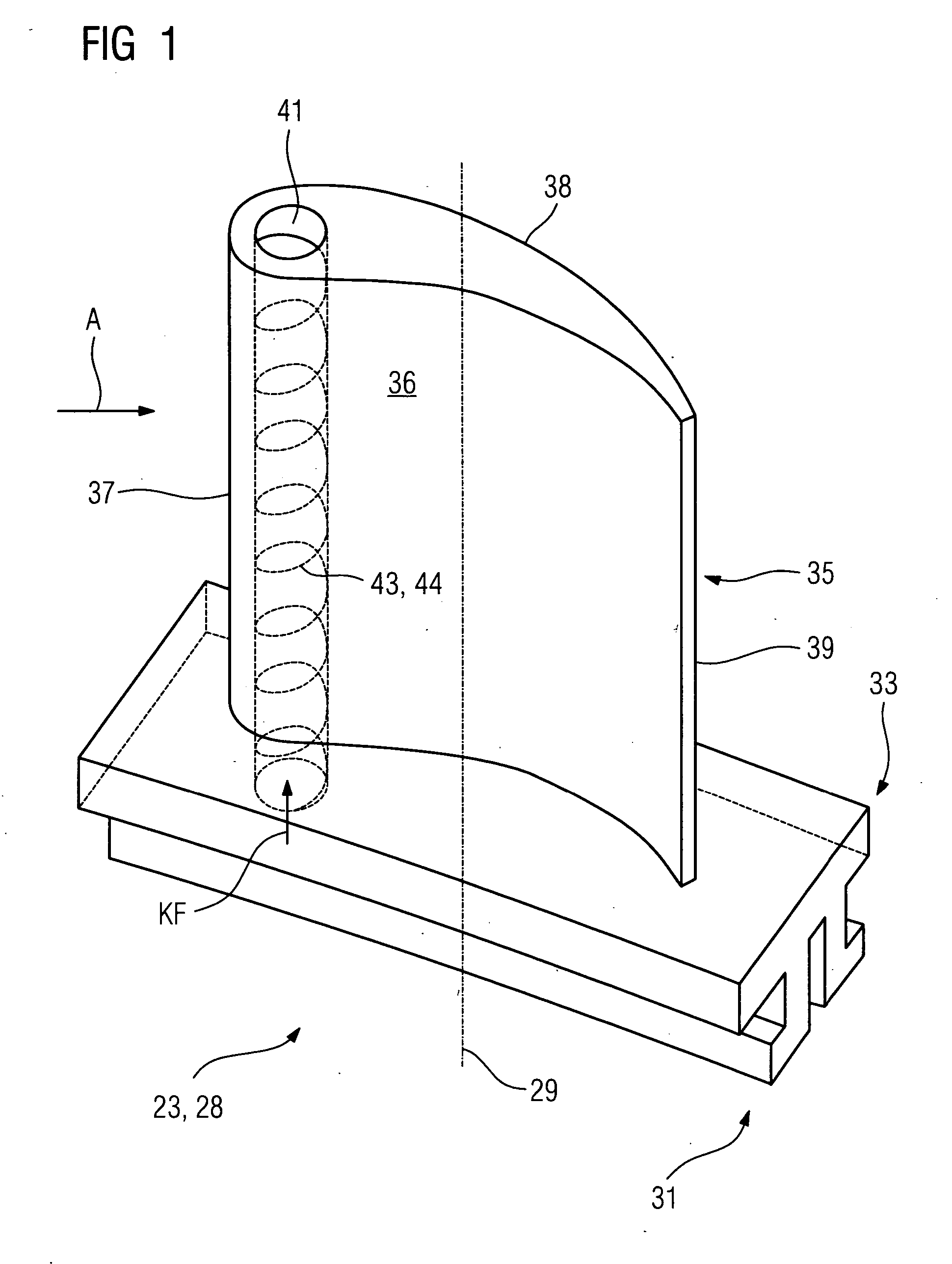

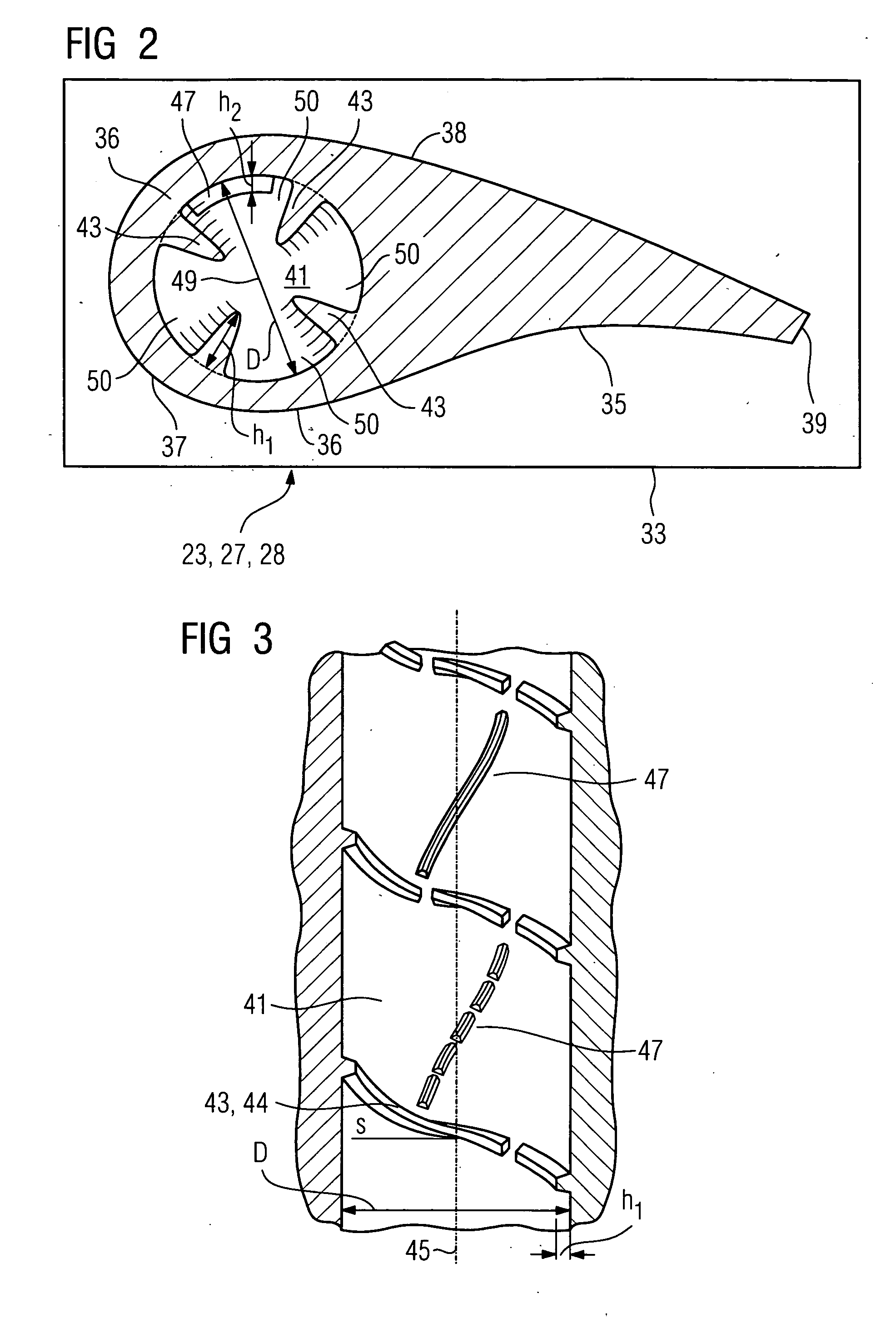

Cooled component of a fluid-flow machine, method of casting a cooled component, and a gas turbine

InactiveUS7824156B2Reduce heat loadUniform heat transferPropellersEngine manufactureTurbine bladeEngineering

A cooled component of a fluid-flow machine, through which a hot working medium flows, in particular a turbine blade of a gas turbine, in whose outer wall, to which the working medium can be applied, a cooling passage is provided, through which a cooling fluid can flow along its longitudinal axis.

Owner:SIEMENS AG

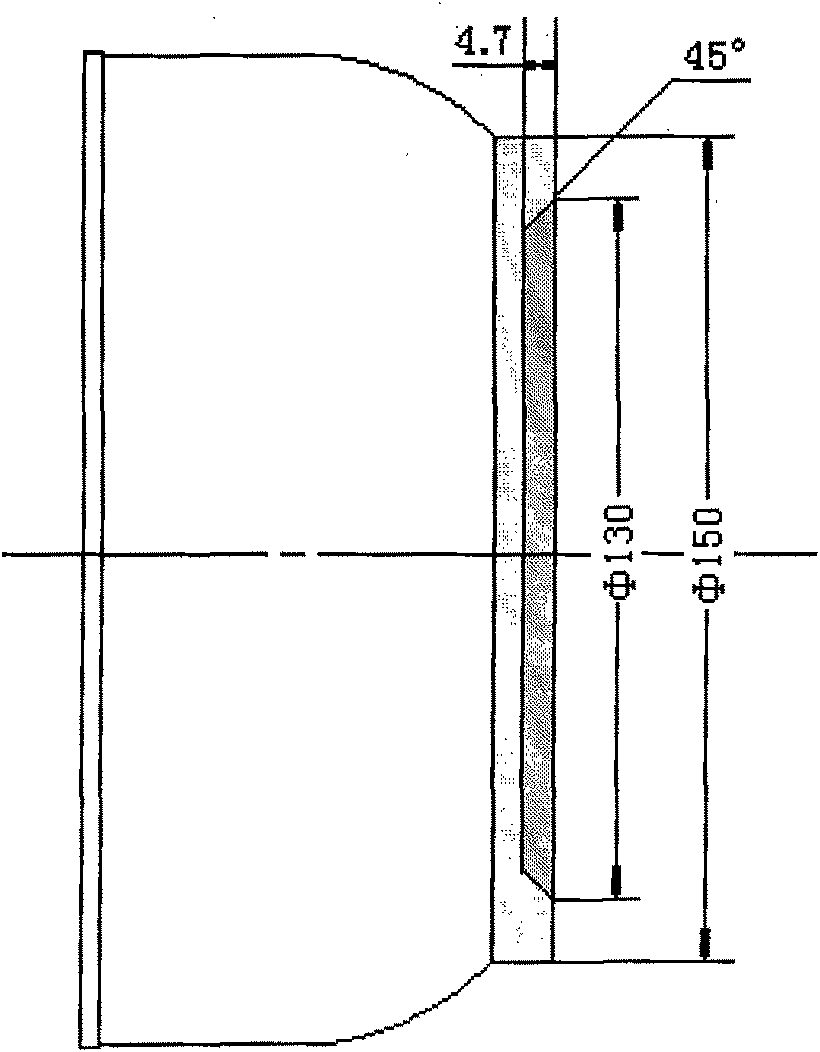

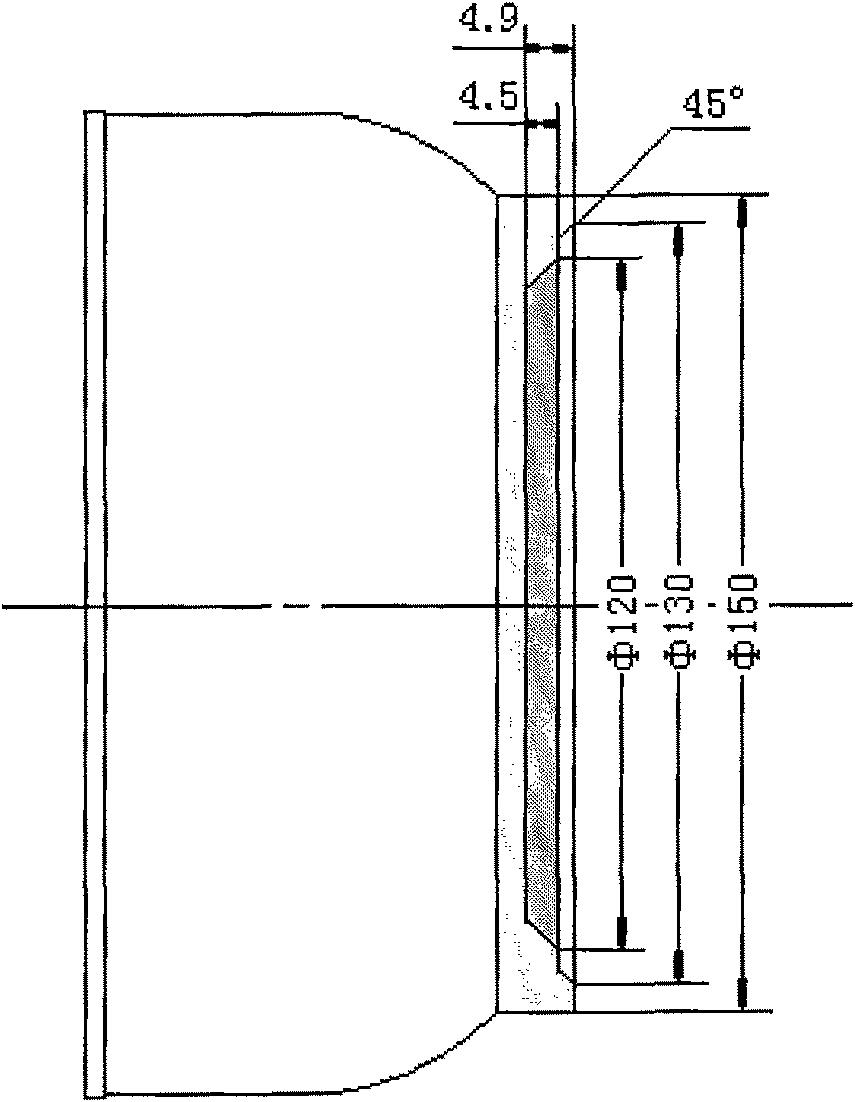

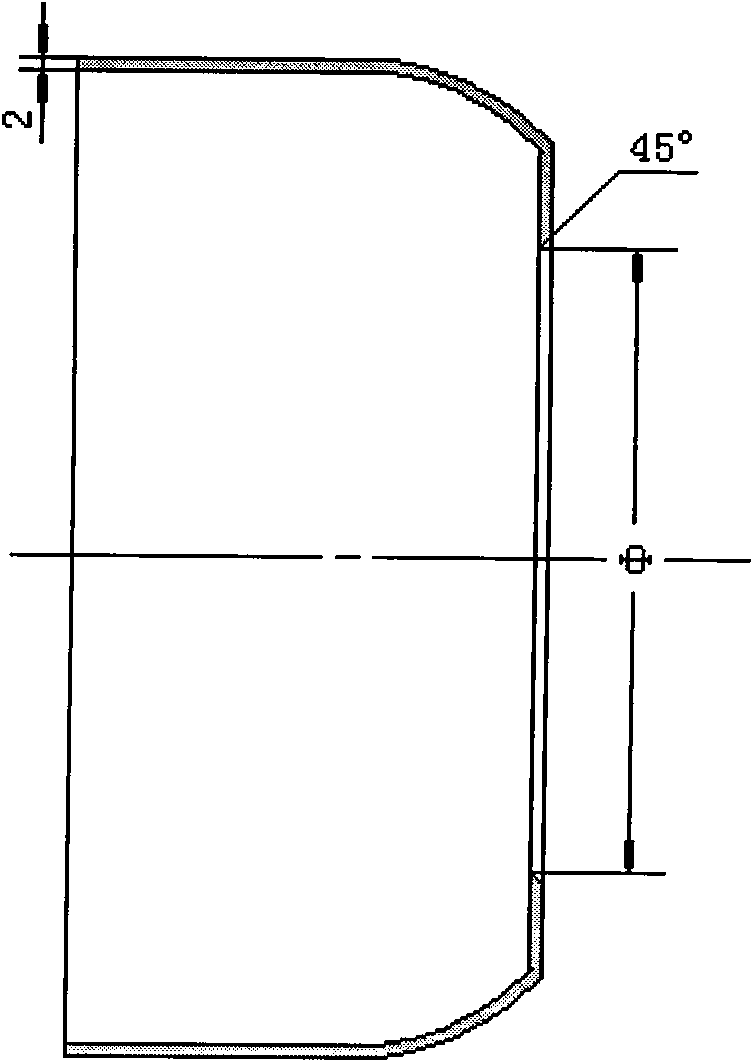

Method for thermal spraying of composite bottom layer of aluminum pan of electromagnetic oven

InactiveCN101880850AWide range of choicesImprove product qualityCooking-vessel materialsDomestic stoves or rangesThermal sprayingThermal printing

The invention discloses a method for thermal spraying of a composite bottom layer of an aluminum pan of an electromagnetic oven, which is used in the manufacturing industry of food cookers and is as shown by a drawing appended to the abstract. A magnetic composite layer with a certain thickness is formed by using an automatic spraying method, designing the joint of a coating and the pan bottom into a concave mosaic structure and spraying a magnetic material (pure iron, iron alloy or 430 stainless steel) to the bottom of the aluminum pan so as to meet the operating requirements of the electromagnetic oven. According to the requirements of a product, one or more material (copper, stainless steel, aluminum, nickel, chromium or ceramic) coatings with different thicknesses or functions can be sprayed to realize aesthetic property, practicability and functionality of the electromagnetic oven pan to ensure that the pans for the electromagnetic oven become various middle-grade and high-grade series products.

Owner:慈溪光华金属复合材料有限公司

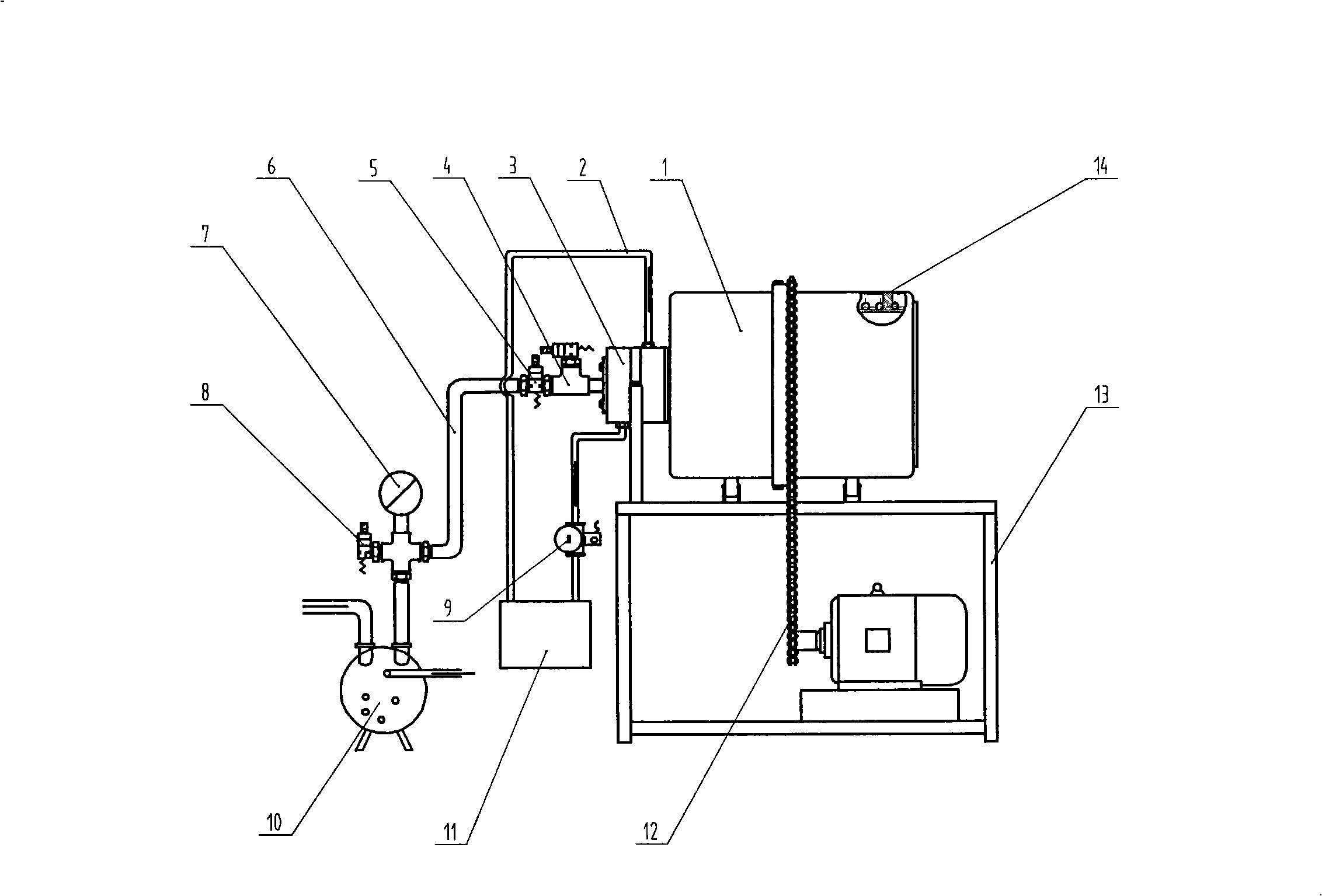

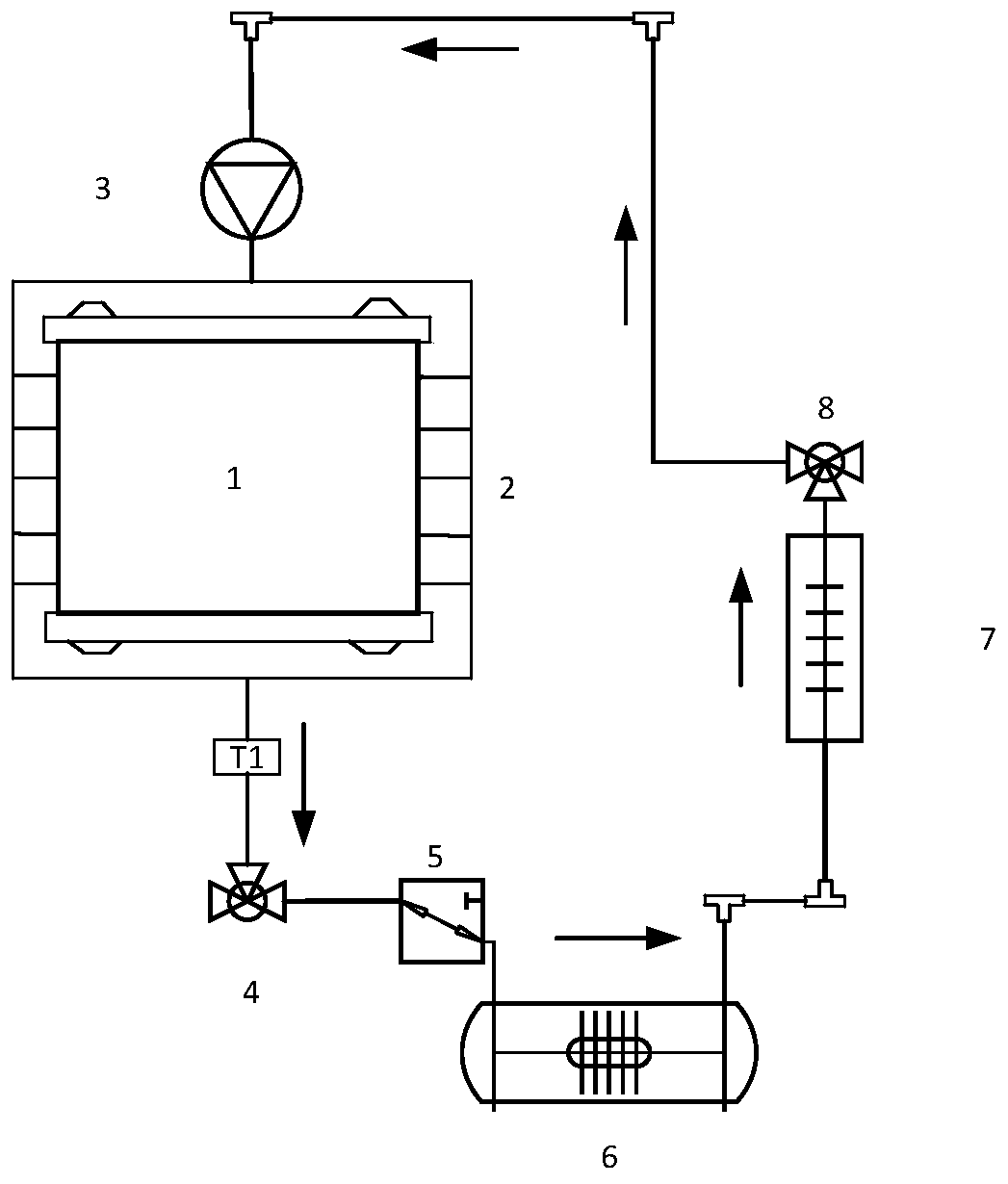

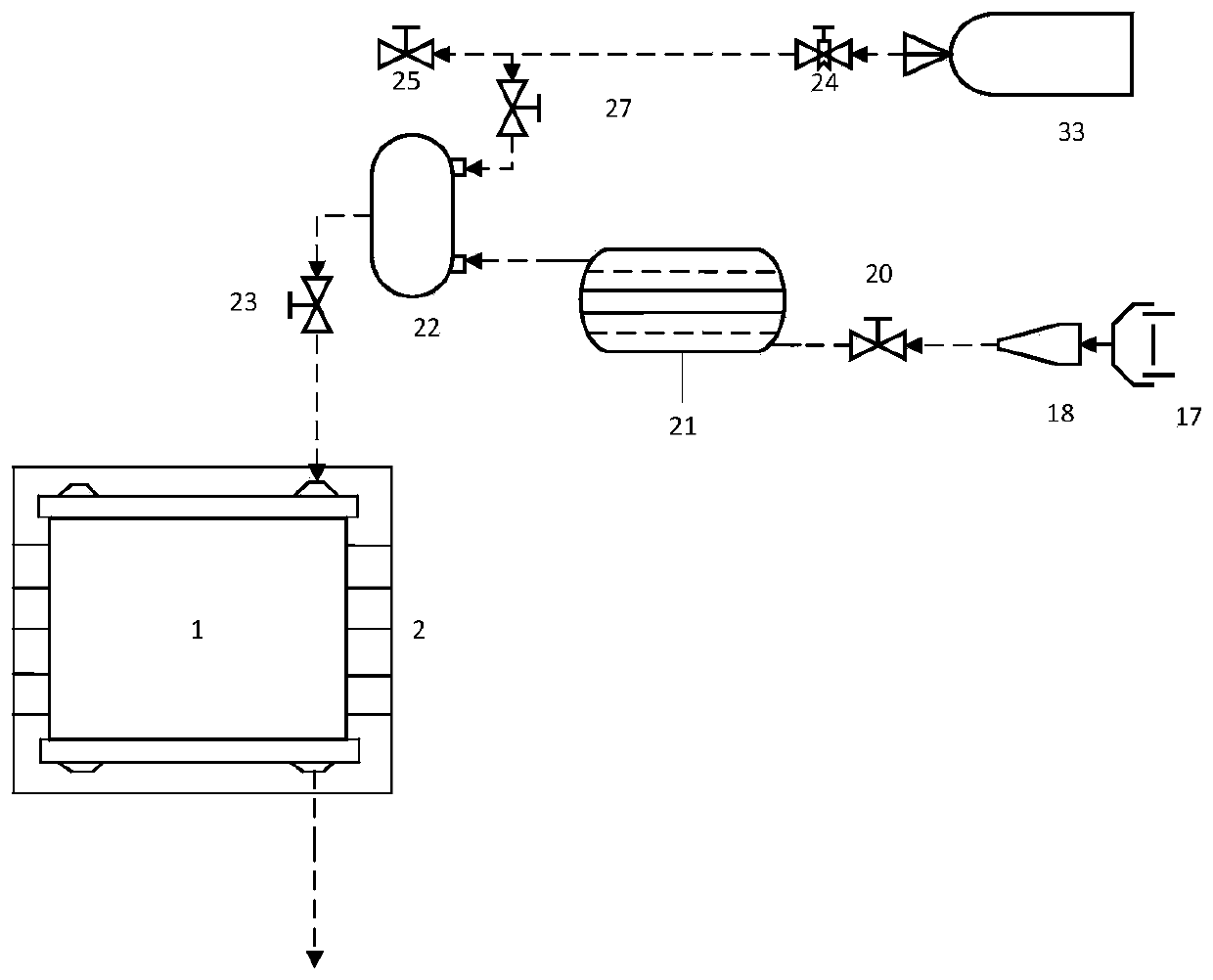

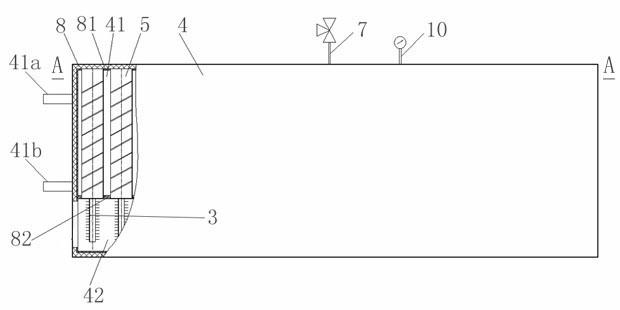

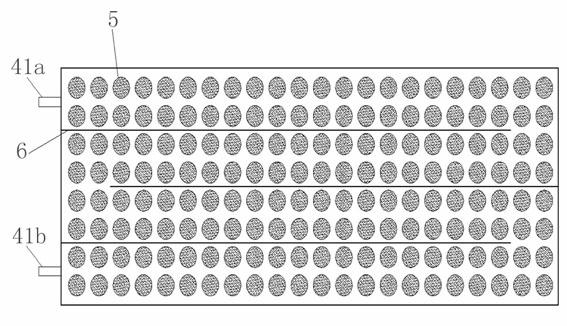

Drum-type vacuum pulsing temperature-variable drying method and apparatus

InactiveCN101261073AKeep drySolve delivery difficultiesDrying using combination processesDrying solid materials with heatControl systemChemical products

The invention discloses a drum-type vacuum pulsing transformation temperature drying method and a device, comprising a sealed circular roller, a heating circulating system, a pulsing vacuum system connected with the roller and a control system, wherein, the vacuum degree of the pulsing vacuum system connected with the roller varies with the material arranging from 0.097 MPa to 0 MPa, the heating temperature of the heating circulating system varies with the state of the material. The device has good heat transmitting performance, preserves the nutrient content and the active material of the material as well as the color and luster of the material well, greatly raises the drying speed, shortens the drying time, reduces the drying energy consumption and lowers the drying cost. The drum-type vacuum pulsing transformation temperature drying method and the device are suitable for drying the foods, the biological products, the drugs and the chemical products with good fluidness, particularly for drying the products thermally sensitive; especially, the effect for drying the foods and the biotechnology products with high added value is better.

Owner:CHINA AGRI UNIV

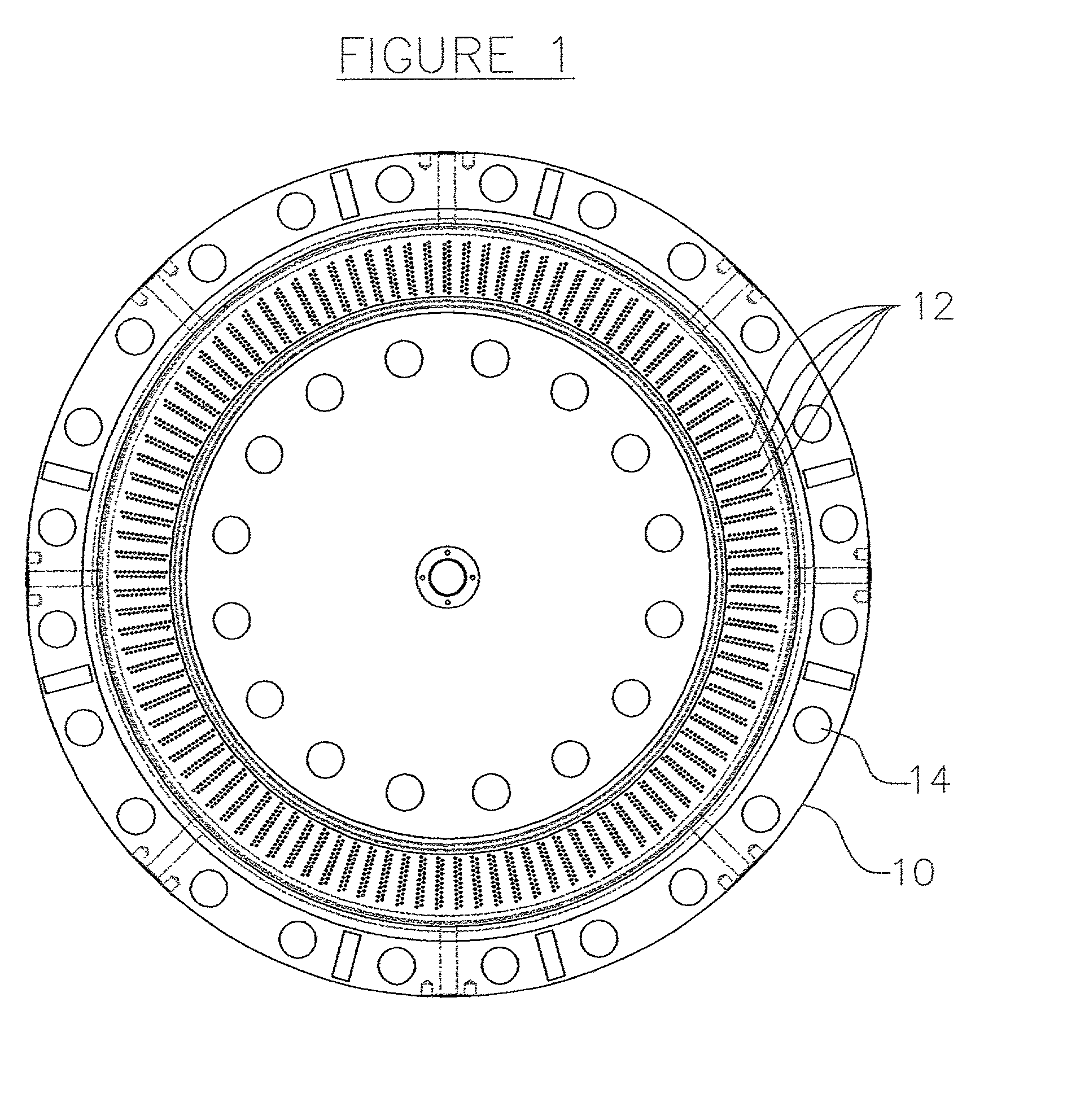

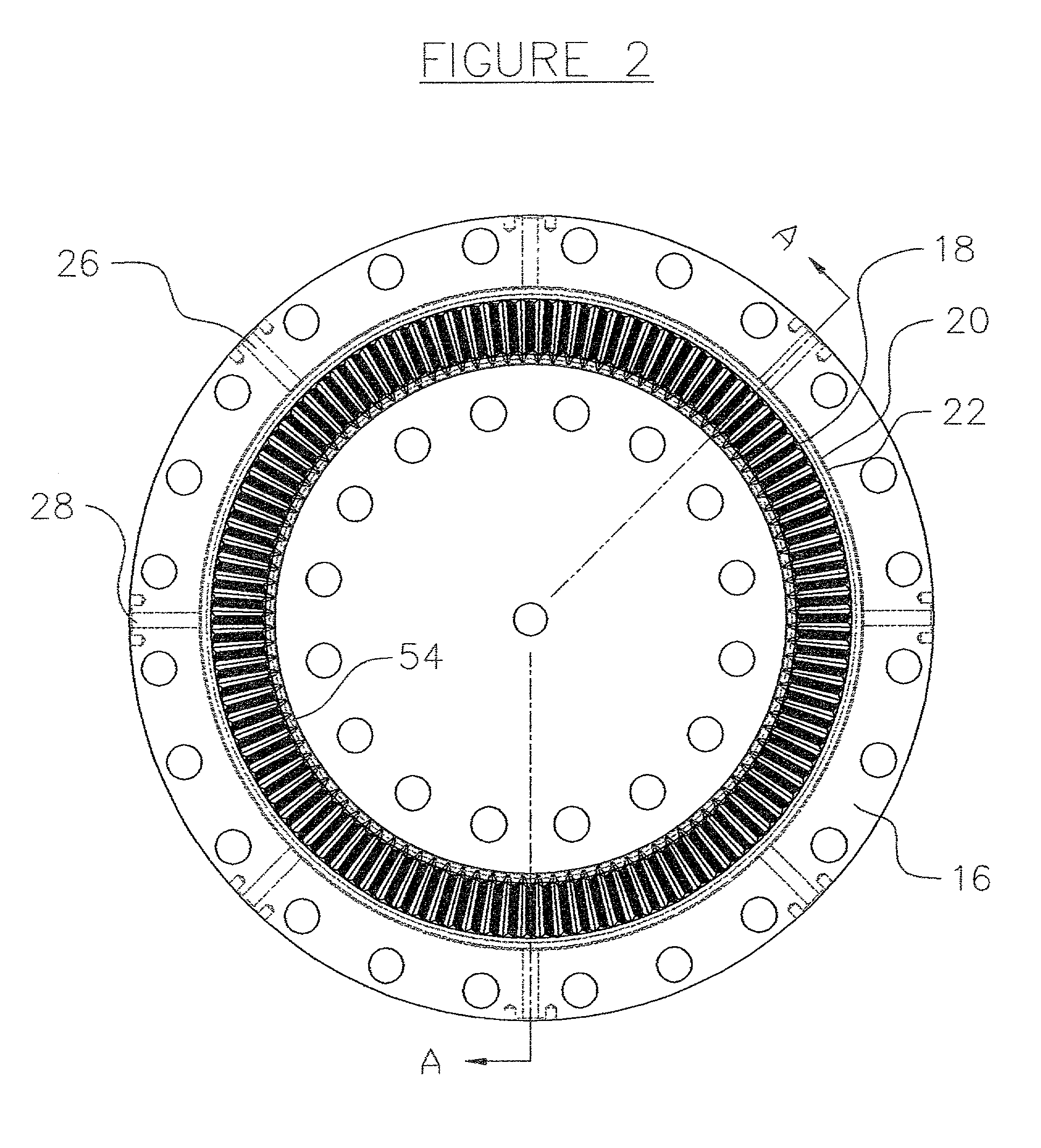

Pelletizing die with even heat distribution and with polymer channel to orifice transition zone, process for orifice thermal stabilization and process for forming a pelletizing die with brazing and thin hard face layer

InactiveUS6976834B2Improve pellet qualityImprove throughputMouldsConfectioneryEngineeringCooling fluid

A pelletizing die includes a pelletizing die member with a die exit side exposed to cooling fluid and a die entry side for receiving polymer fed thereto. The die member has a plurality of polymer channels and a plurality of extrusion orifices connected to a respective one of the channels to form a extrusion orifice section. A heating medium system has additional heating medium conduits between channels and a supply and intermediate header for heating the channels (radially from each side) and providing once in and once out heating medium flow. The die member may be formed by high temperature brazing of components using coordinated solder (Ni based or gold-nickel) and component heat treatment temperature. A thin hard face coating may be provided on raised extrusion orifice ring faces around each extrusion orifice section.

Owner:BORSIG AG

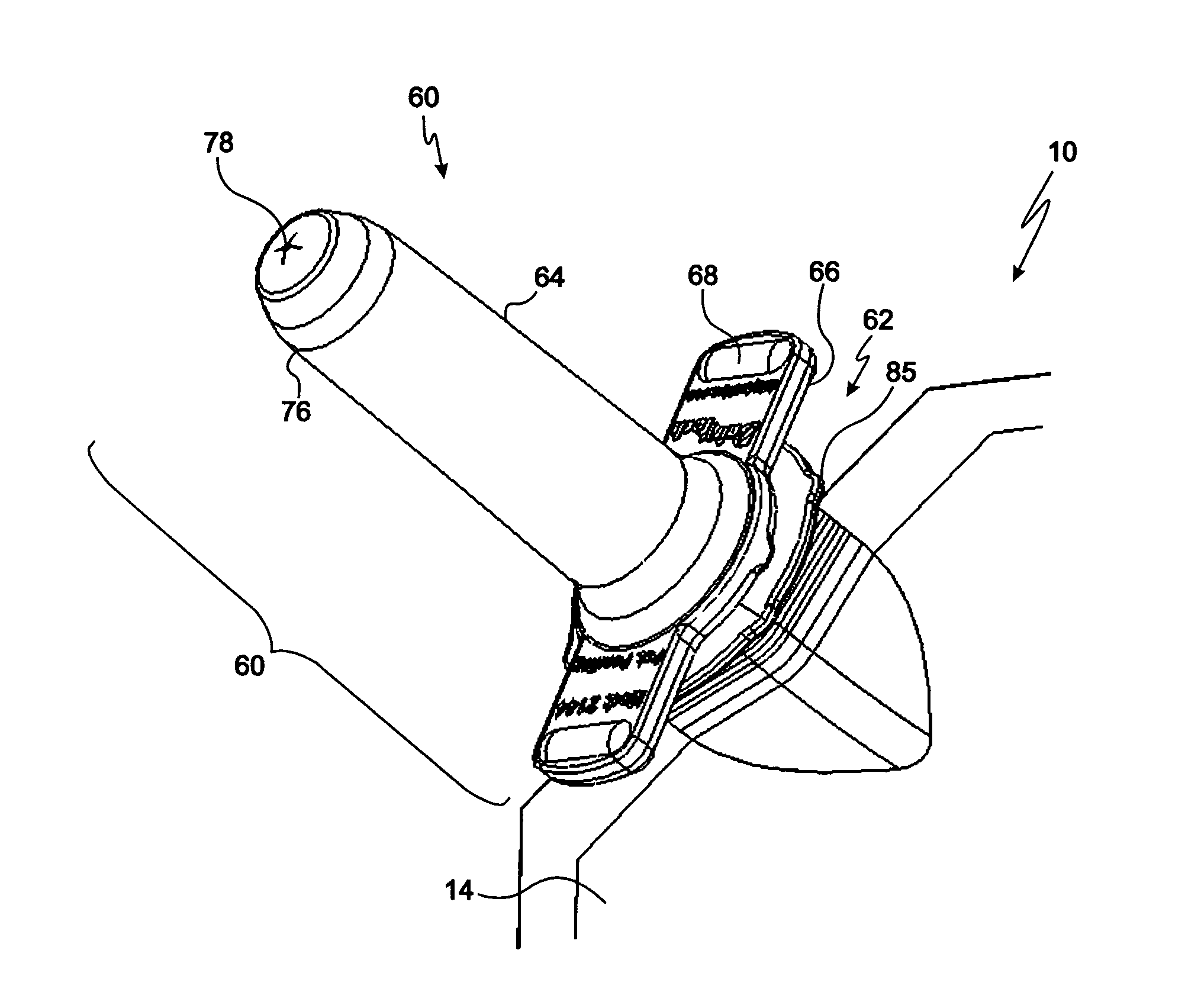

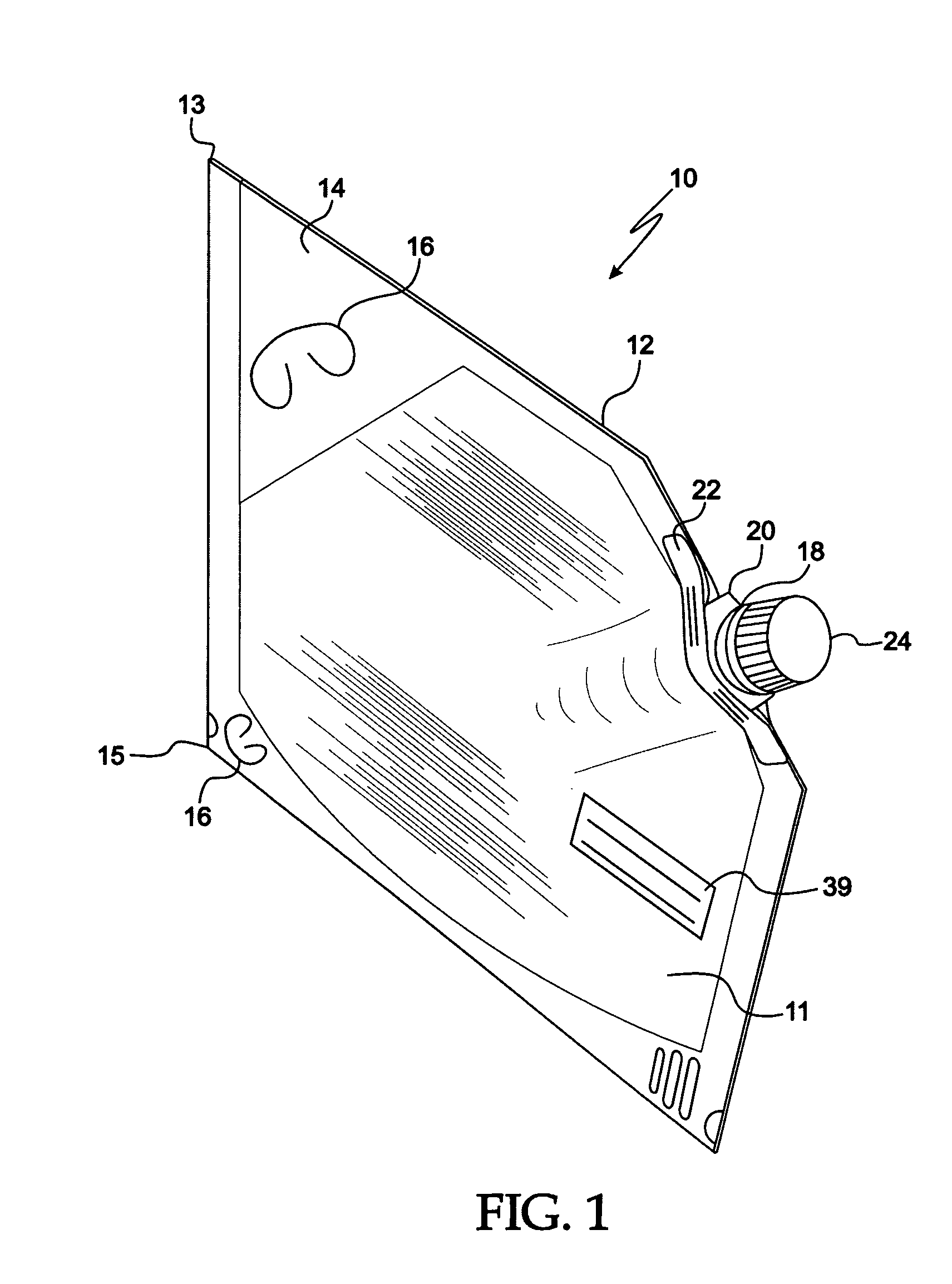

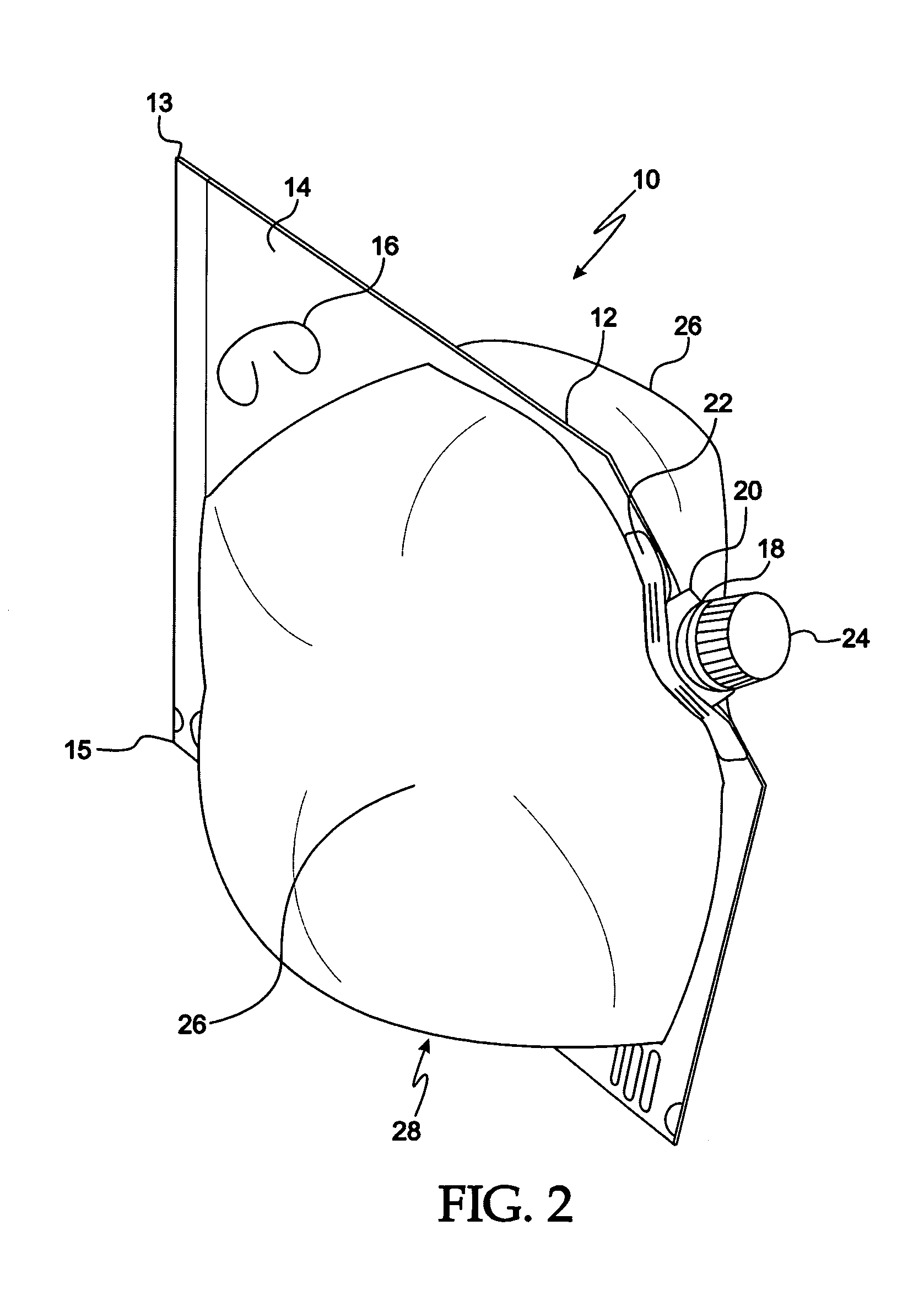

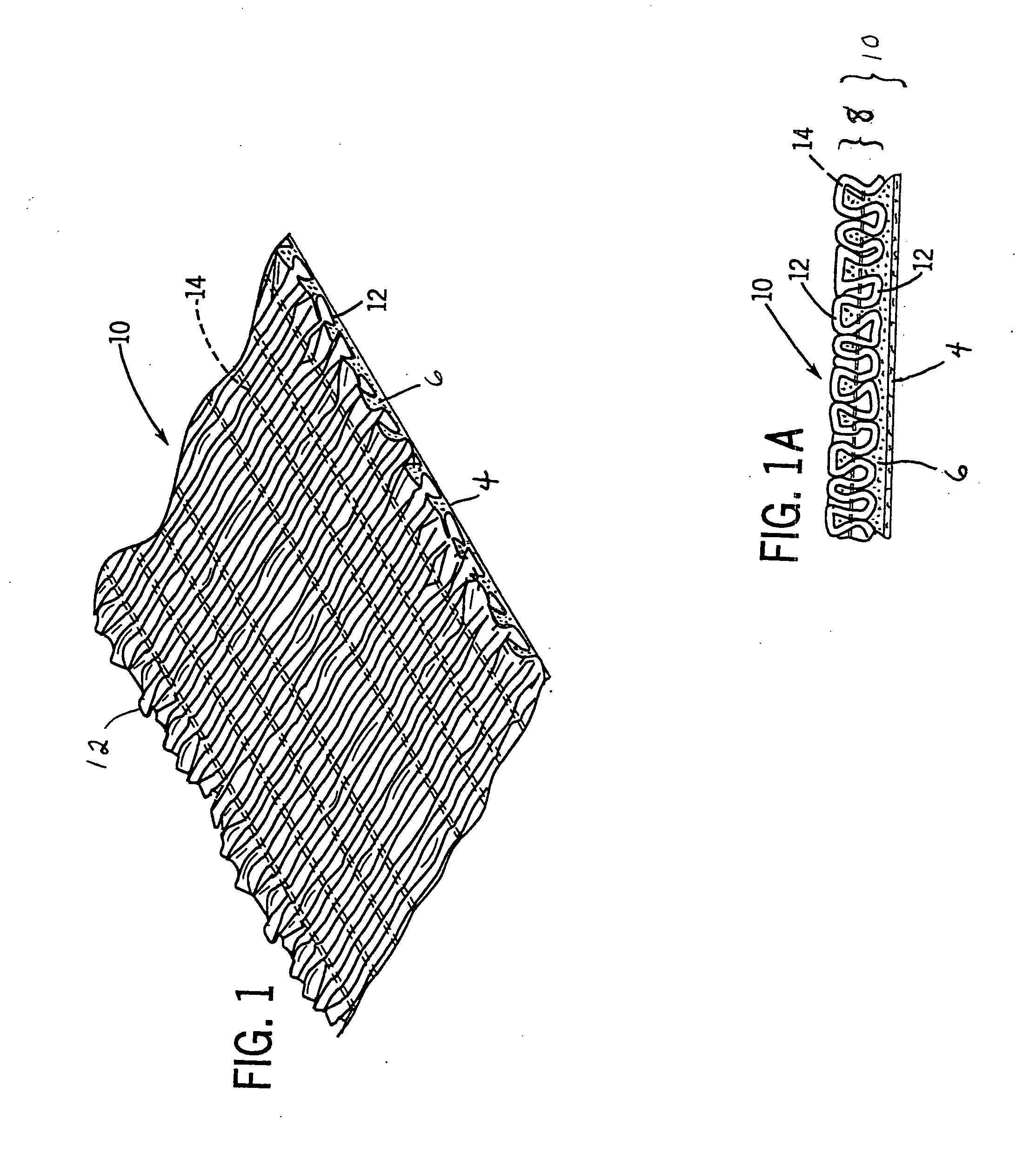

Flexible heat treatment and storage bag

ActiveUS8336495B1Easily agitatedConveniently tippedMilk preservationAnimal feeding devicesEngineeringMilk products

Flexible, collapsible, liquid-tight containers are described. The containers are formed of heat-conductive sheet material and having a pouring or dispensing spout with closure for same. The sheet material is preferably a laminate having at least three layers, including a central, heat-conductive layer, an outer layer of a polymer resistant to physical damage and an inner layer of a thermoplastic polymer which can be fused to another inner layer to seal the edges of the bag. Dispensing fixtures such as a nipple assembly and an esophageal feeder are described, and can be used in feeding calves and other young animals. Processes of heat treating liquids in the containers, including the pasteurizing of dairy products, are described.

Owner:DAIRY TECH LLC

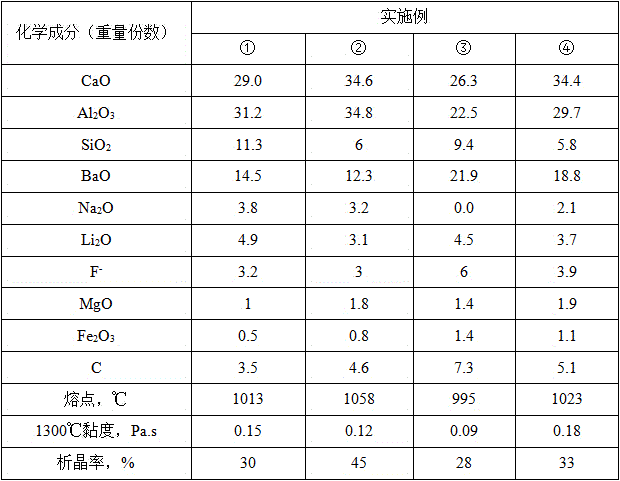

Continuous casting crystallizer casting powder for large circular blank abrasion resisting high manganese steel

The invention discloses continuous casting crystallizer casting powder for large circular blank abrasion resisting high manganese steel. According to the continuous casting crystallizer casting powder for the large circular blank abrasion resisting high manganese steel, cracks are reduced by adopting low carbon amount and high viscosity, reducing thermal stress inside blank shells and increasing powder consumption amount. The alkalinity of the casting powder is 0.8-1.1, the cracks caused by uneven heat transmission are avoided; through the adoption of 8-12% of Na2O, 6-8% of F- and 3-4.5% of Li2O, weak coldness and even heat transmission of the upper portion in a crystallizer are achieved, inclusion absorbing effects are improved, and the cracks are reduced; through the adoption of 2-8% of MnO, lattice vibration and conduction heat transmission are weakened, and the crystallization properties of the casting powder and the casting blank quality are improved. Raw materials of the continuous casting crystallizer casting powder for the large circular blank abrasion resisting high manganese steel are easy to obtain, and production cost is low. Through field testing, the casting power is good in spreadability and good in air permeability and can be smelted stably and be free of caking, the consumption amount of the casting powder is around 0.3-0.42kg per ton of steel, the consumption cost is relatively low, and the qualified rate of the first grate casting blanks is improved significantly.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

Heat sink including a heat dissipating fin and method for fixing the heat dissipating fin

InactiveUS20020084060A1Reduce processing costsHigh strengthSemiconductor/solid-state device detailsSolid-state devicesBiomedical engineeringHeat spreader

A heat sink including a heat dissipating fin comprises (1) a heat dissipating fin having a plurality of mountain-shaped portions and base portions supporting the mountain-shaped portions, (2) a base member having a plurality of slits into which the mountain-shaped portions of the heat dissipating fin are to be inserted and a plurality of holes for fixing the heat dissipating fin, and (3) a fitting member, provided with a plurality of projecting portions corresponding to the plurality of holes of the base member, for fixing the heat dissipating fin between the base member and the fitting member itself.

Owner:FURUKAWA ELECTRIC CO LTD +1

Heat sink including a heat dissipating fin and method for fixing the heat dissipating fin

InactiveUS6742573B2Reduce processing costsHigh strengthSemiconductor/solid-state device detailsSolid-state devicesBiomedical engineeringHeat spreader

A heat sink including a heat dissipating fin comprises (1) a heat dissipating fin having a plurality of mountain-shaped portions and base portions supporting the mountain-shaped portions, (2) a base member having a plurality of slits into which the mountain-shaped portions of the heat dissipating fin are to be inserted and a plurality of holes for fixing the heat dissipating fin, and (3) a fitting member, provided with a plurality of projecting portions corresponding to the plurality of holes of the base member, for fixing the heat dissipating fin between the base member and the fitting member itself.

Owner:FURUKAWA ELECTRIC CO LTD +1

Laminated mould of multi-layer circuit board

InactiveCN1780535AEliminate defects prone to micro-dislocationsPrecise positioningPrinted circuit assemblingMultilayer circuit manufactureDigital controlMaterials science

The invention is made by means of following steps: takes high grade mirror surface stainless steel as material of lower mold plate and upper mold plate; the counter bore perpendicular to axial line of location hole is located at the bottom surface of location hole in the lower mold plate; the step locating pin is composed of the locating column and the foundation; the locating column is perpendicular to the foundation, and the upper mold plate and the lower mold plate are jointed through the step locating pin. Because the location holes in the lower mold plate and the up mold plate coincides with designing basis for each layer of circuit in multi layer circuit board, and is processed by using digital control equipment, the laminating mold has not only precise location, but also low weight, and can process 8 piece multi layer circuit board at on time by hot-pressed.

Owner:李小元

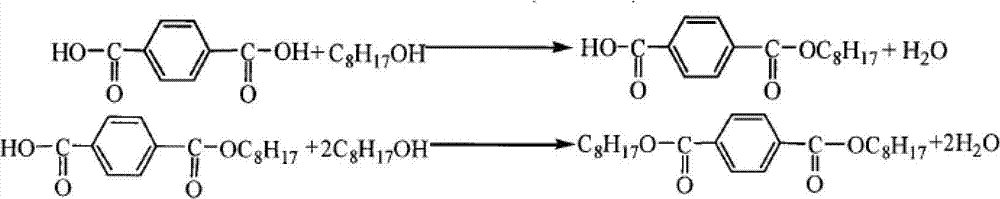

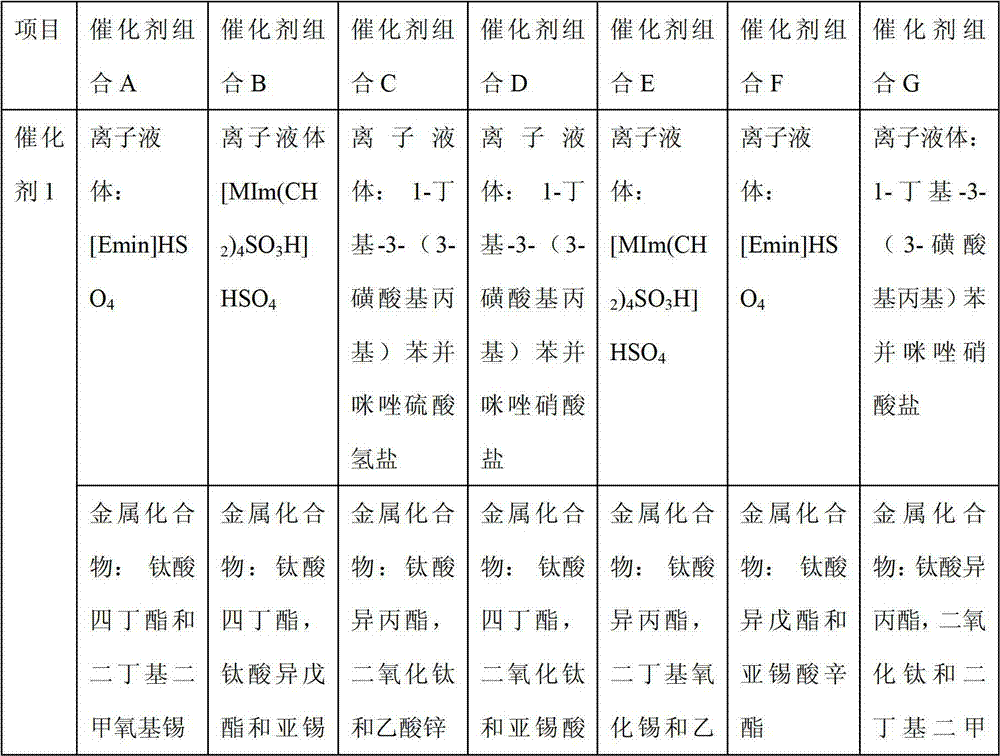

Preparation method of dioctyl terephthalate and used catalyst

InactiveCN102824929AIncrease contact areaShrink wellOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsDibutyltin oxideTitanium metal

The invention provides a catalyst for use in synthesis of dioctyl terephthalate and a method for preparing dioctyl terephthalate by applying the catalyst. The catalyst consists of a catalyst 1 and a catalyst 2, wherein the catalyst 1 consists of an ionic liquid and a metal compound; the catalyst 2 consists of a titanium metal compound and other metal compound; the positive ion of the ionic liquid are an imidazole ion or a benzimidazole ion; the negative ion of the ionic liquid is a bisulfate ion; or the positive ion of the ionic liquid is a benzimidazole ion or an imidazole ion with one or two sulfonic acid radicals; the titanium metal compound is selected from at least one compound of tetrabutyl titanate, isopentyl ester titanate, isopropyl titanate or titanium dioxide; and the other compound is selected from at least one compound of dibutyldimethoxytin, dibutyltin oxide, monooctyl ester stannite, zinc acetate and cobalt acetate. Due to the adoption of the technical scheme provided by the invention, the cost can be reduced, the reaction speed is increased, energy consumption is lowered, and the quality of an obtained product is high.

Owner:FOSHAN GAOMING XIONGYE CHEM

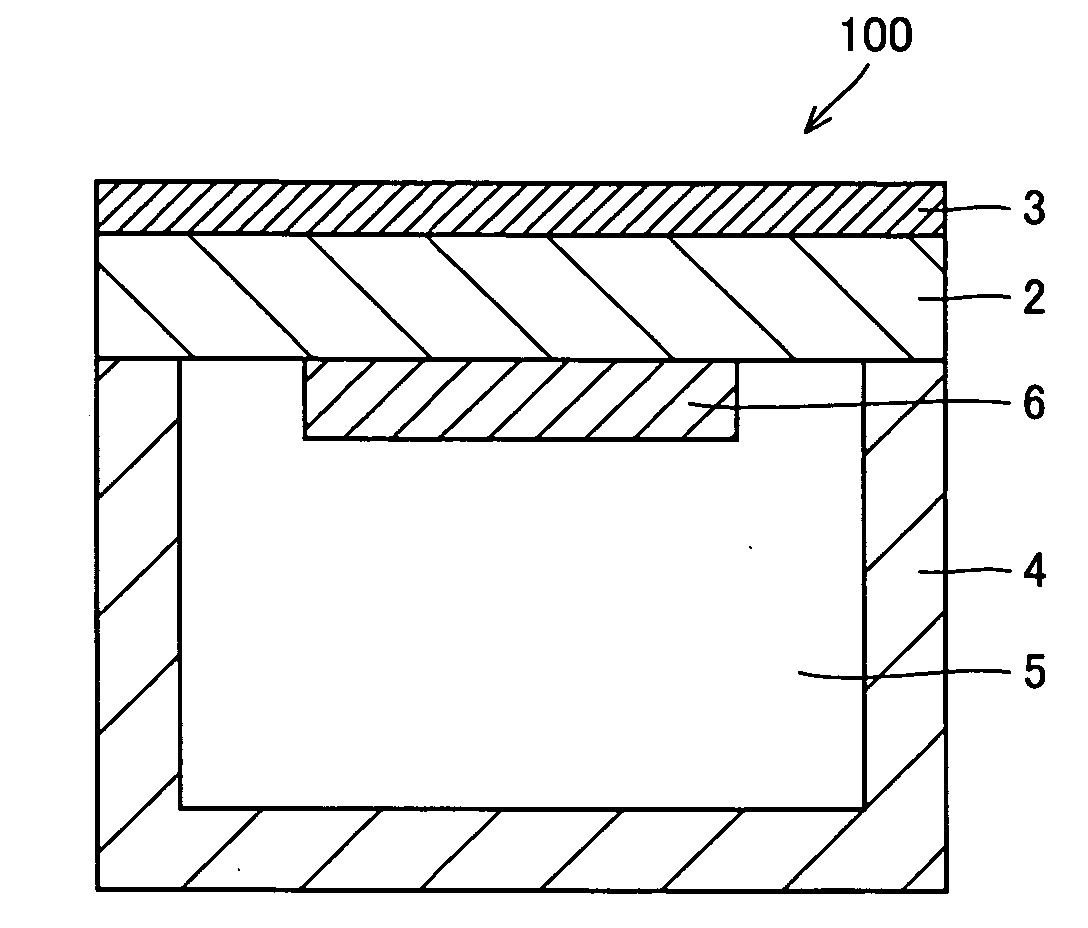

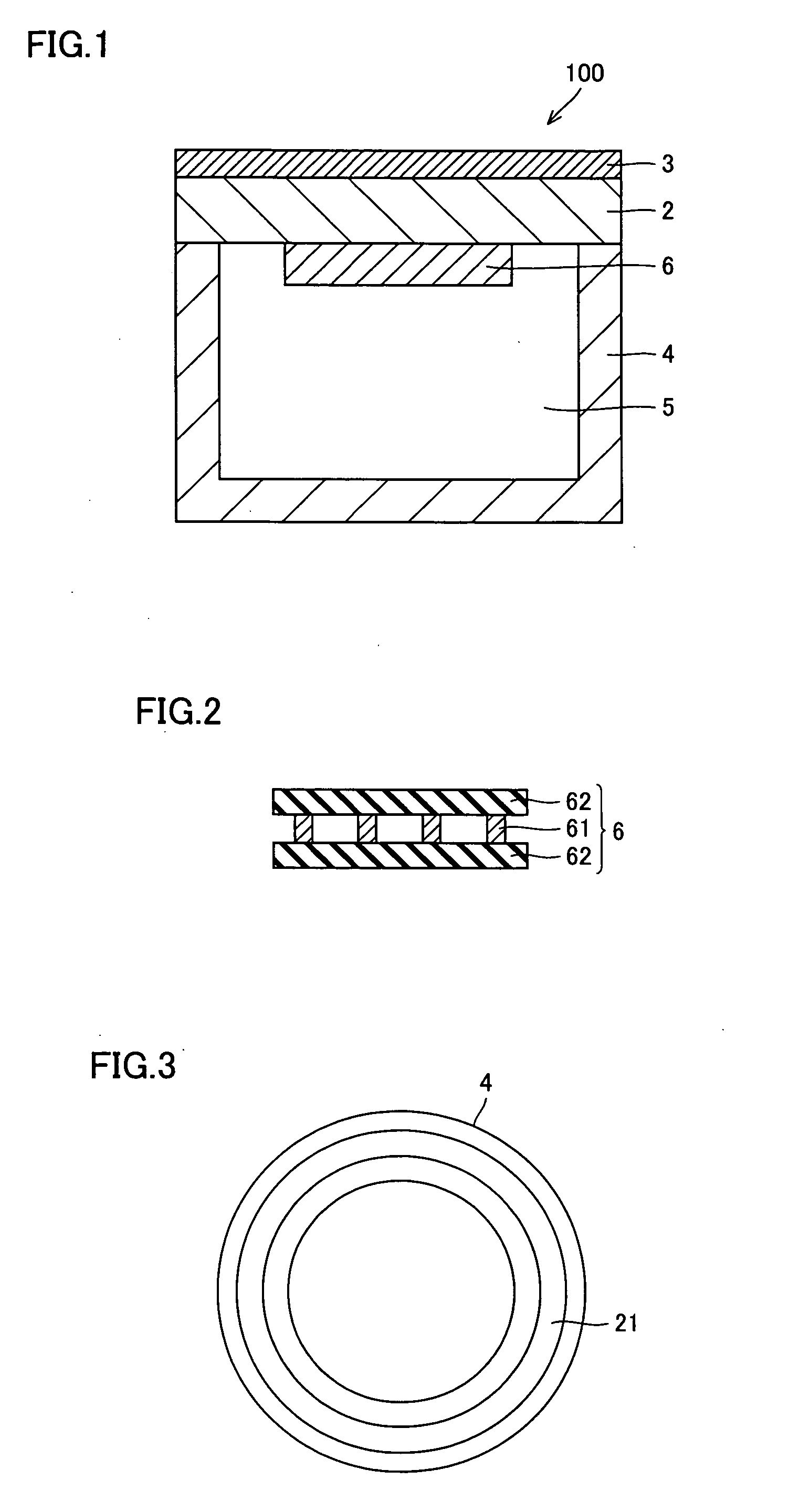

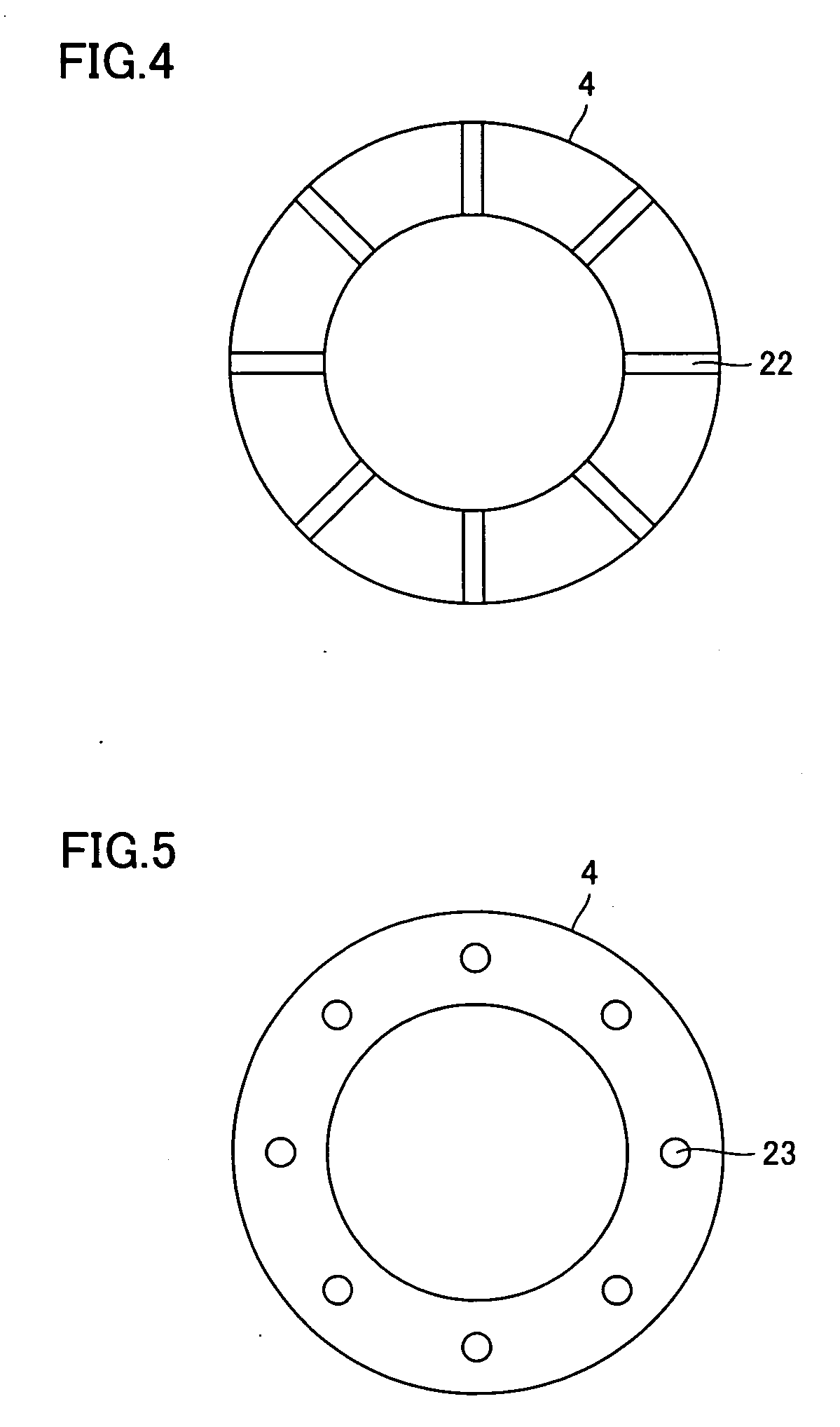

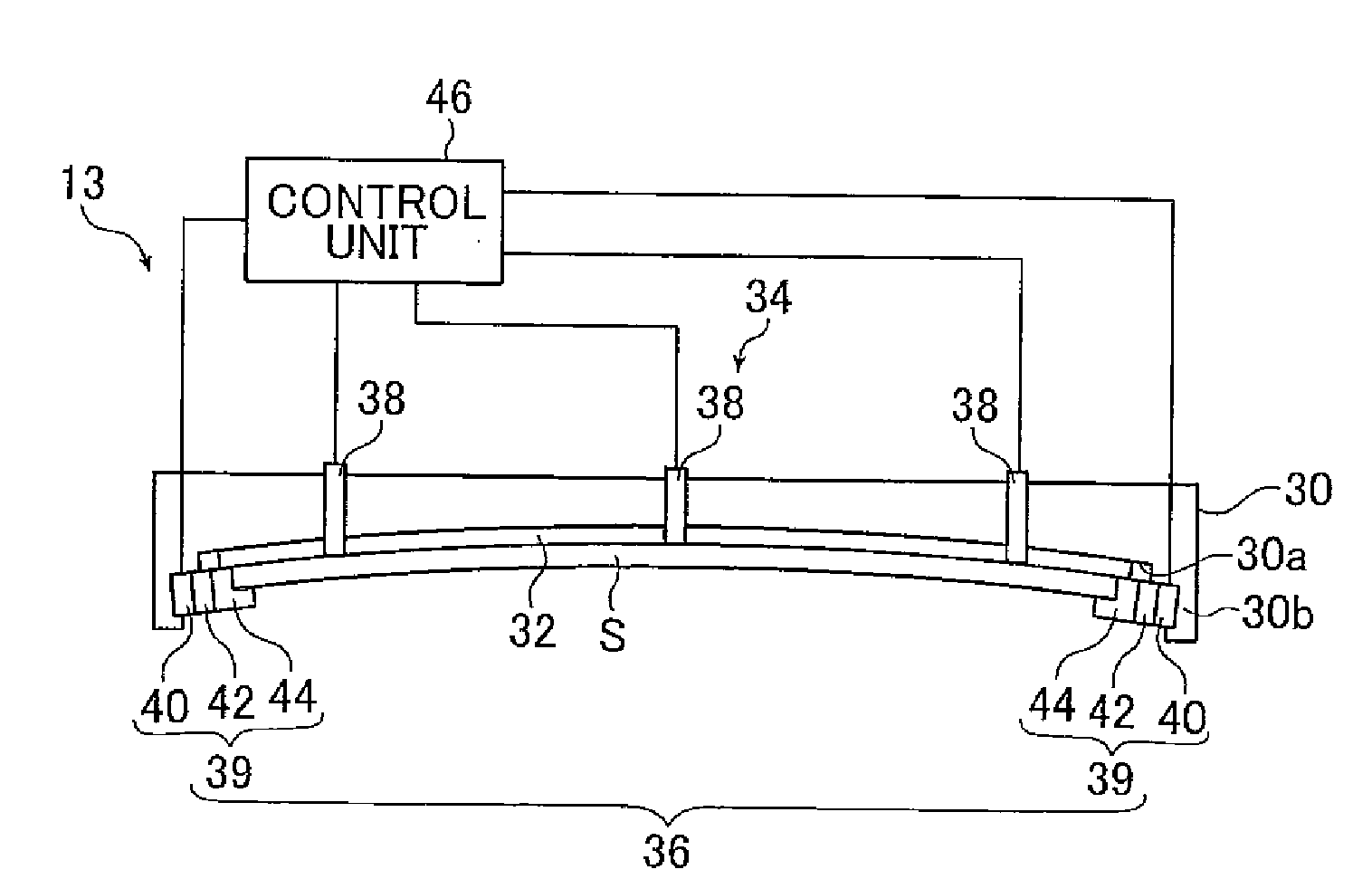

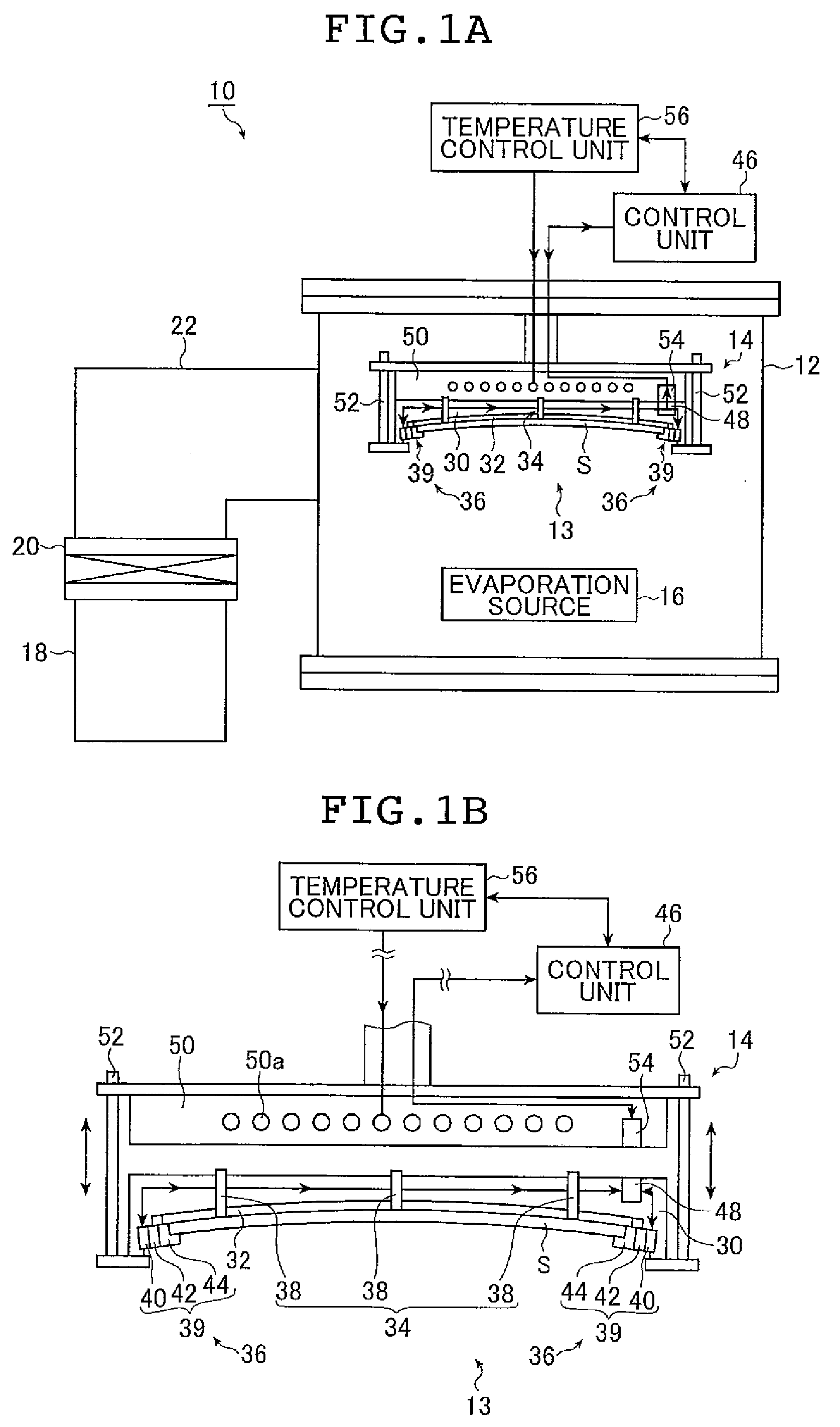

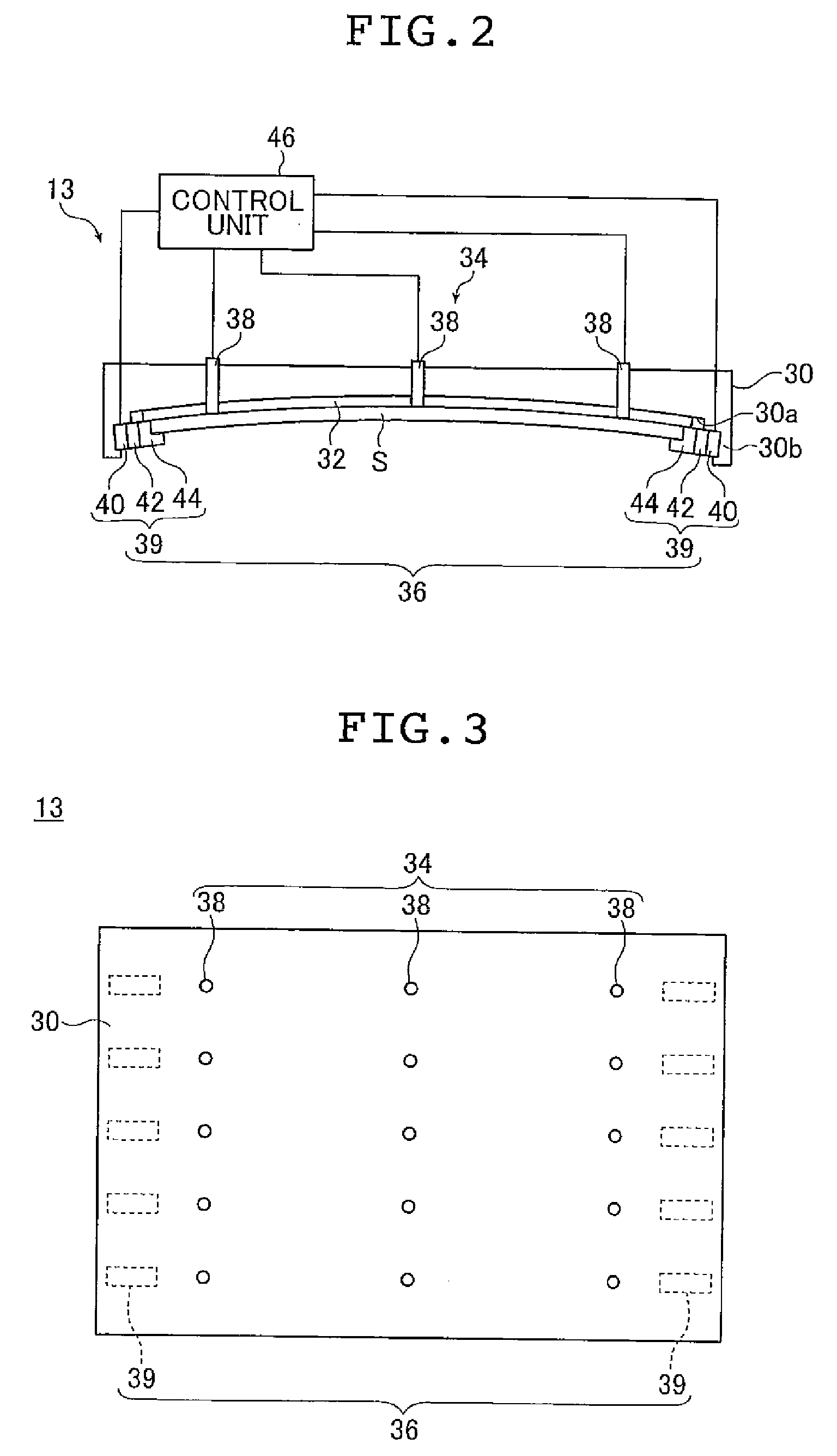

Substrate holder and vacuum film deposition apparatus

InactiveUS20090000552A1Uniform heat transferAvoid excessive loadsVacuum evaporation coatingSputtering coatingDeposition processSupport surface

A vacuum film deposition apparatus in which a film is formed on a substrate by a vacuum film deposition process includes a holder which has a substrate supporting surface which is in a curved shape and is brought into contact with the substrate. A substrate holder for holding the substrate includes a base having the substrate supporting surface. The apparatus and the substrate holder further include a contact detection mechanism which detects a state of contact between the substrate and the substrate supporting surface, a load applying mechanism which is provided outside the substrate supporting surface and supports the substrate by applying a load to end faces of the substrate and a control unit which controls the load the load applying mechanism applies to the substrate based on output from the contact detection mechanism.

Owner:FUJIFILM CORP

Cooled component of a fluid-flow machine, method of casting a cooled component, and a gas turbine

InactiveUS20070014664A1Reduce heat loadUniform heat transferContinuous combustion chamberEngine manufactureTurbine bladeEngineering

A cooled component of a fluid-flow machine, through which a hot working medium flows, in particular a turbine blade of a gas turbine, in whose outer wall, to which the working medium can be applied, a cooling passage is provided, through which a cooling fluid can flow along its longitudinal axis.

Owner:SIEMENS AG

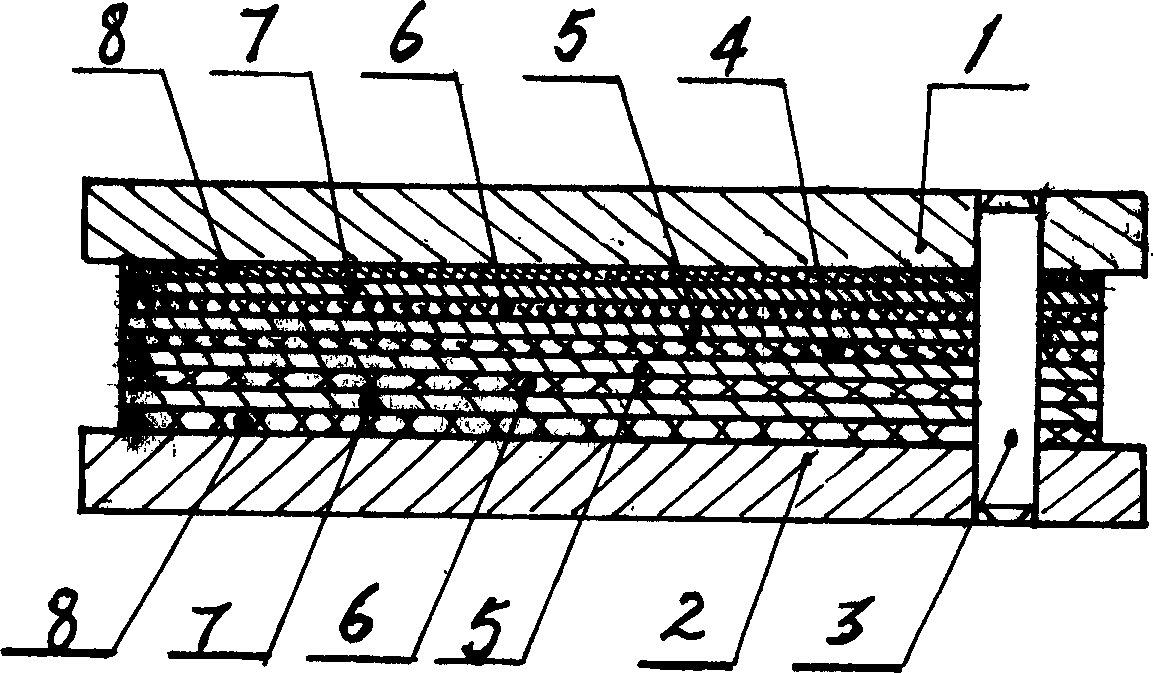

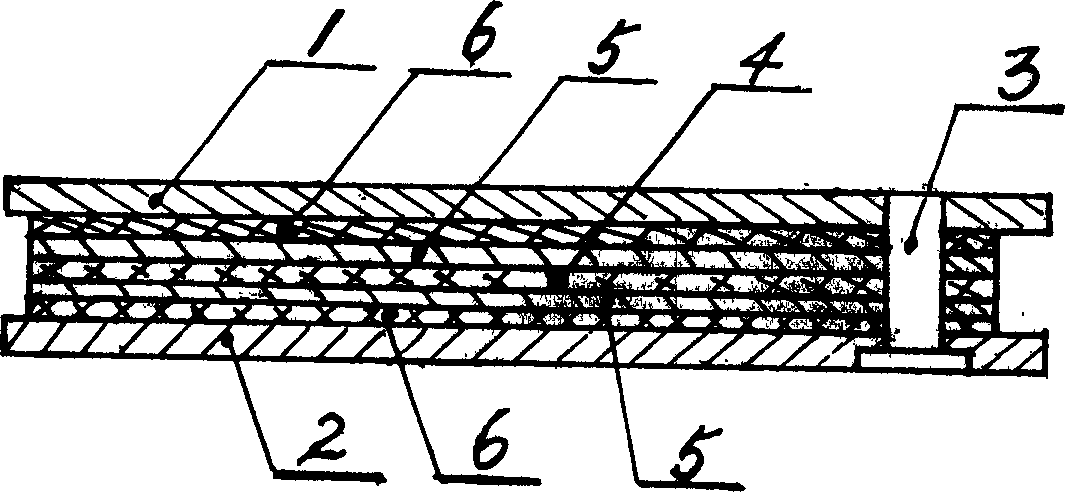

Stainless steel pot with welded bottom, and its making method

InactiveCN1692863AImprove bindingAvoid formingSoldering apparatusCooking vesselsHigh resistanceCopper

A stainless steel pot with complex bottom, which is a laminated one composed sequentially of original pot bottom, aluminium plate, stainless steel plate and copper plate, is disclosed. A technology for making its complex bottom includes such steps as braze welding of a copper plate onto a stainless steel plate, overlaying it with an aluminium plate and original pot bottom, and hot-pressure welding. Its advantages are high thermal conductivity and high resistance to high temp.

Owner:广东欧亚家居有限公司

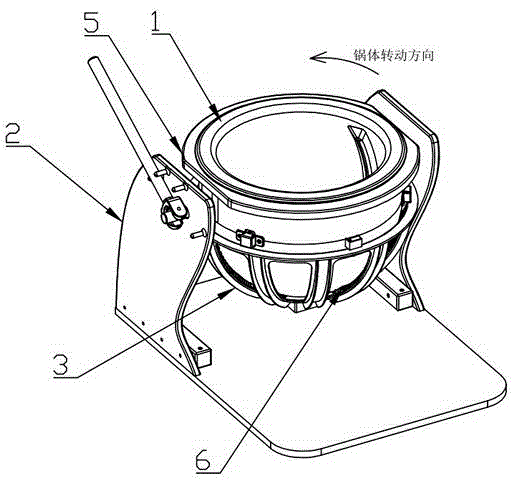

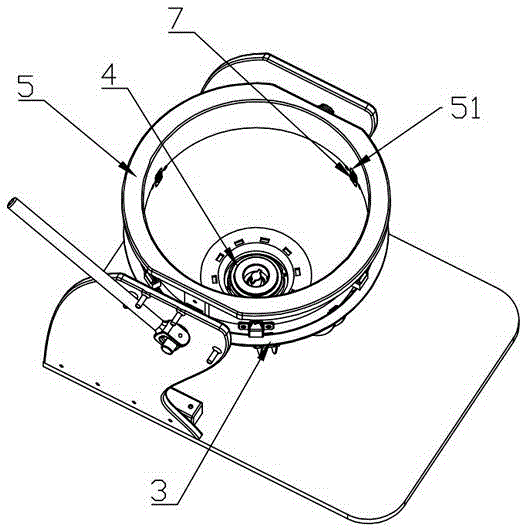

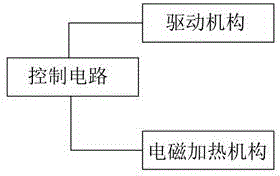

Multifunctional cooking machine

InactiveCN104013300AAchieve large capacityWith cookingCooking vesselsRoasters/grillsEngineeringFood material

The invention relates to a multifunctional cooking machine which comprises an inner pot and a host for driving and controlling the inner pot to work, wherein the inner pot is detachably shafted with the host; the host comprises a host frame, a positioning mechanism, a driving mechanism, a pot seat, an electromagnetic heating mechanism which can heat the inner pot by regions and is close to the arc-shaped surface of the inner pot, and a control circuit; the control circuit is connected with the driving mechanism and the electromagnetic heating mechanism respectively; the driving mechanism is fixedly connected with the positioning mechanism and the pot seat respectively; the electromagnetic heating device is fixed on the positioning mechanism and is positioned between the positioning mechanism and the pot seat. A large volume is realized as much as possible through the specific structure of the inner pot; food materials with different shapes and volumes can be stir-fried; the cooking machine is convenient to clean and use, long in service life, large in heating area, quick in heating and uniform in heat transfer.

Owner:GUANGDONG SHUNDE JIN YI CHU ELECTRICAL APPLIANCE +1

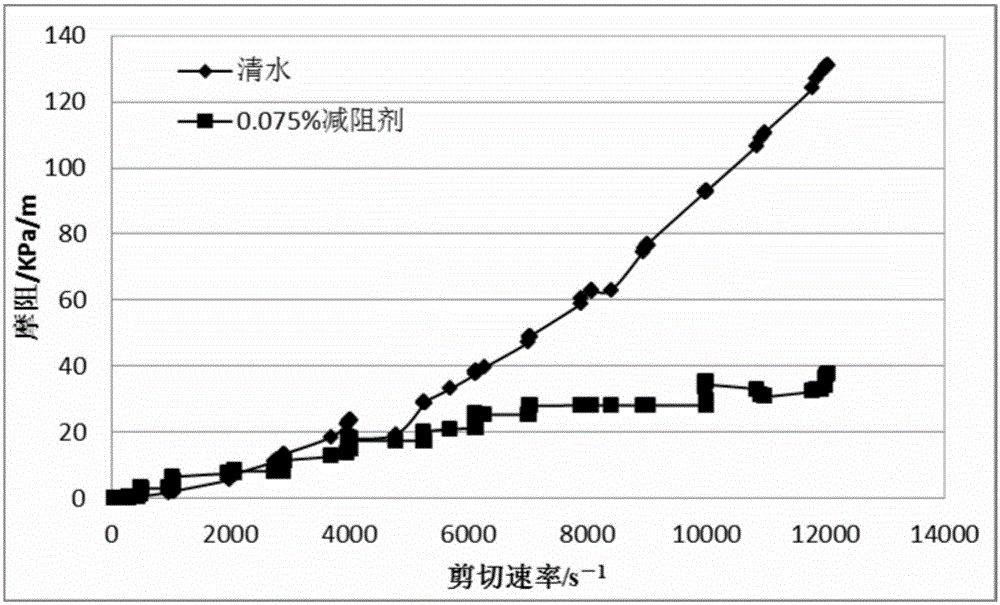

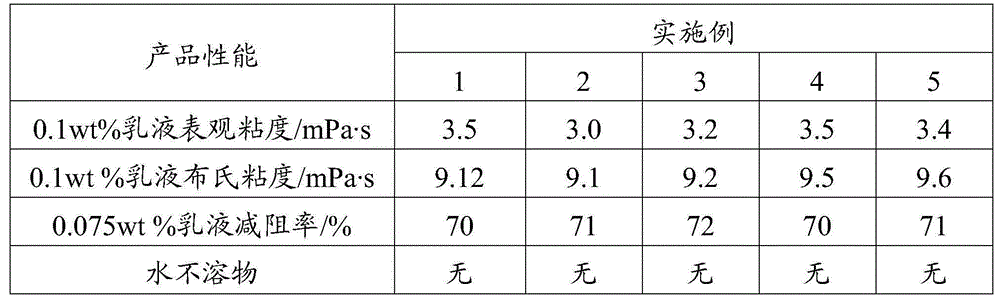

Inverse emulsion polymer drag reducer, and preparation method and application thereof

InactiveCN106565900AGood temperature and salt resistanceFast dispersionDrilling compositionPolymer scienceEmulsion polymerization

The invention provides an inverse emulsion polymer drag reducer, and a preparation method and an application thereof. The method comprises the following steps: adding an aqueous-phase material into an oil-phase material, and carrying out emulsifying so as to obtain a monomer emulsion, wherein the aqueous-phase material comprises 130 to 165 parts by mass of water, 6 to 36 parts by mass of acrylic acid, 24 to 77 parts by mass of 2-acrylamido-2-methyl propane sulfonic acid, 32 to 82 parts by mass of an organic amide monomer and 0.5 to 0.9 part by mass of a hydrophilic emulsifier, and the oil-phase material comprises 104 to 120 parts by mass of base oil with a specific viscosity and 4 to 8 parts by mass of a lipophilic emulsifier; and mixing the monomer emulsion with an initiator at 20 DEG C to 30 DEG C, then carrying out standing, and carrying out a polymerization reaction under the condition of 50 DEG C to 55 DEG C for 1 h to 2 h so as to obtain the inverse emulsion polymer drag reducer. The inverse emulsion polymer drag reducer prepared by using the method provided by the invention has high drag reducing rate and low cost under the condition of small addition amount.

Owner:中石化石油工程技术服务有限公司 +1

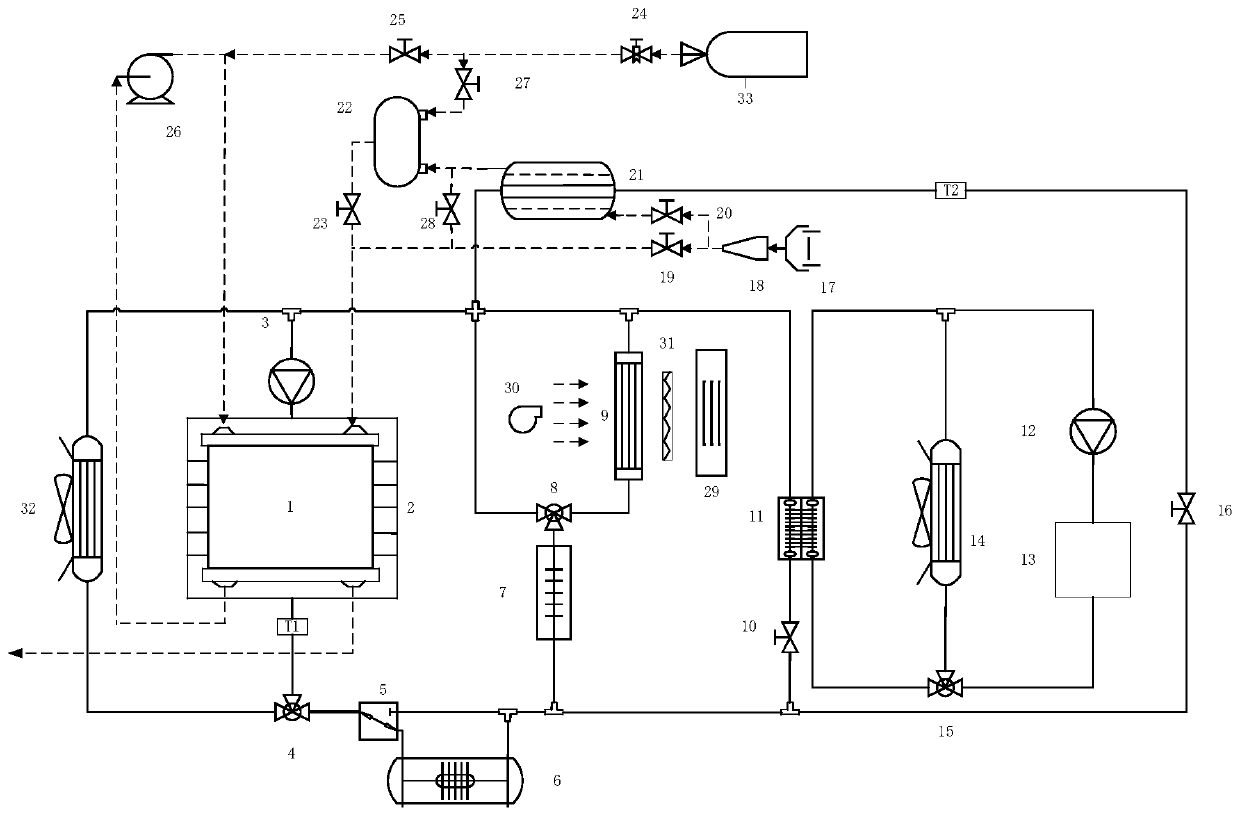

Fuel cell thermal management system with phase change heat storage and preheating functions

ActiveCN111463453AImprove cold start speedReduce consumptionFuel cell heat exchangeMotive system fuel cellsFuel cellsEngineering

The invention discloses a fuel cell thermal management system with phase change heat storage and preheating functions. The fuel cell thermal management system comprises a heat pipe heat exchange part,a liquid path preheating loop, a liquid path heating loop, a gas path preheating loop and a gas path heating loop, wherein the heat pipe heat exchange part is embedded into a heat pipe in a polar plate to exchange heat with an external liquid path, a first phase-change heat exchanger is connected with a liquid path, a second phase-change heat exchanger is simultaneously connected with a gas pathand the liquid path, the liquid path preheating loop heats the liquid path through the first phase change heat exchanger, the gas path preheating loop heats the gas path through the second phase change heat exchanger to jointly preheat a fuel cell, waste heat of a fuel cell in the liquid path heating loop accumulates heat for the phase change heat exchanger or heats a lithium battery and a passenger compartment, the gas path heating loop indirectly heats inlet gas through cooling liquid. The fuel cell thermal management system is advantaged in that the waste heat of the fuel cell can be storedin the phase change heat exchanger and used for preheating the fuel cell through a liquid path and a gas path or for heat preservation of the fuel cell, in addition, the waste heat of the fuel cell can heat intake air, a lithium battery or a passenger compartment, and the energy utilization rate is increased.

Owner:JILIN UNIV

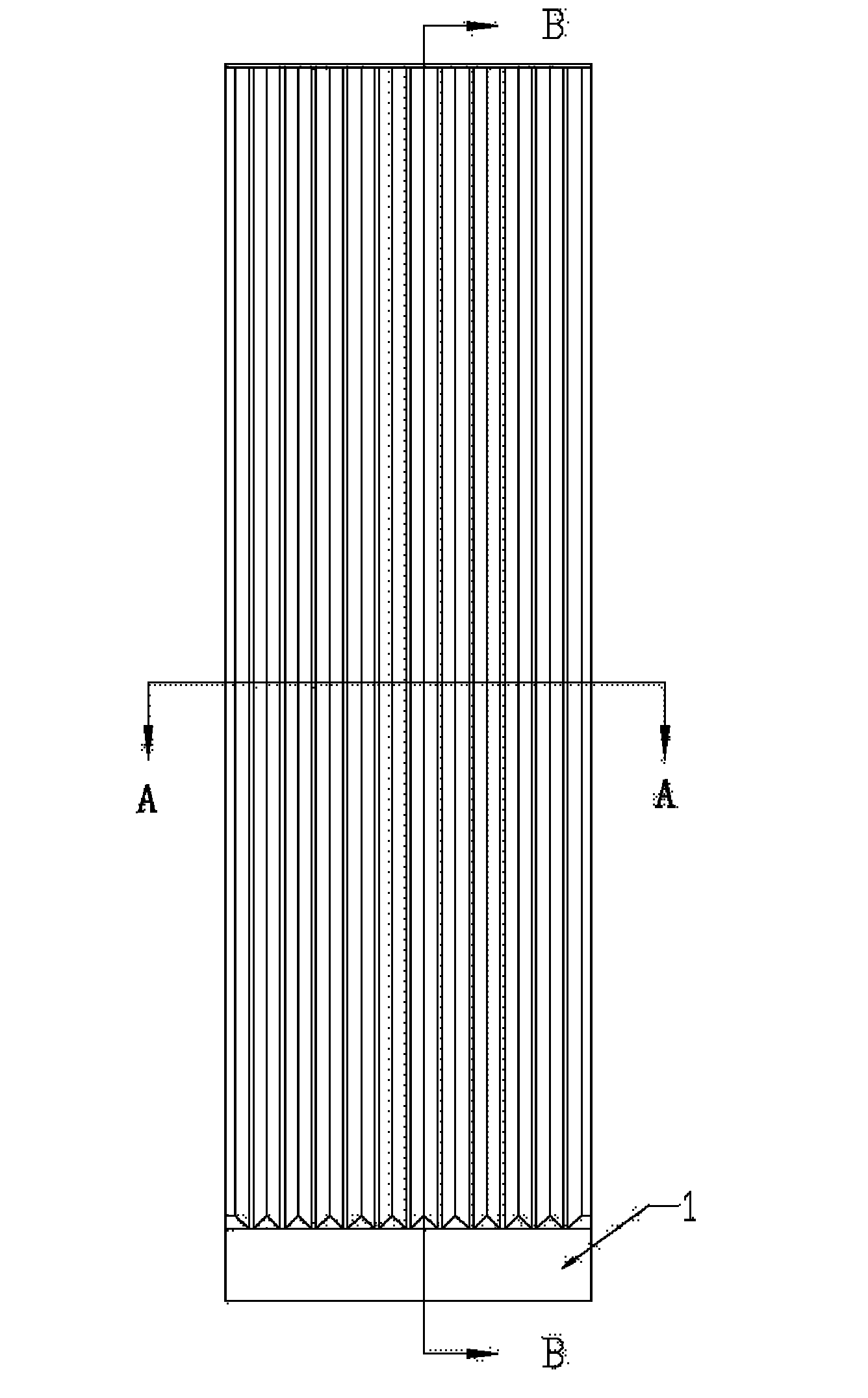

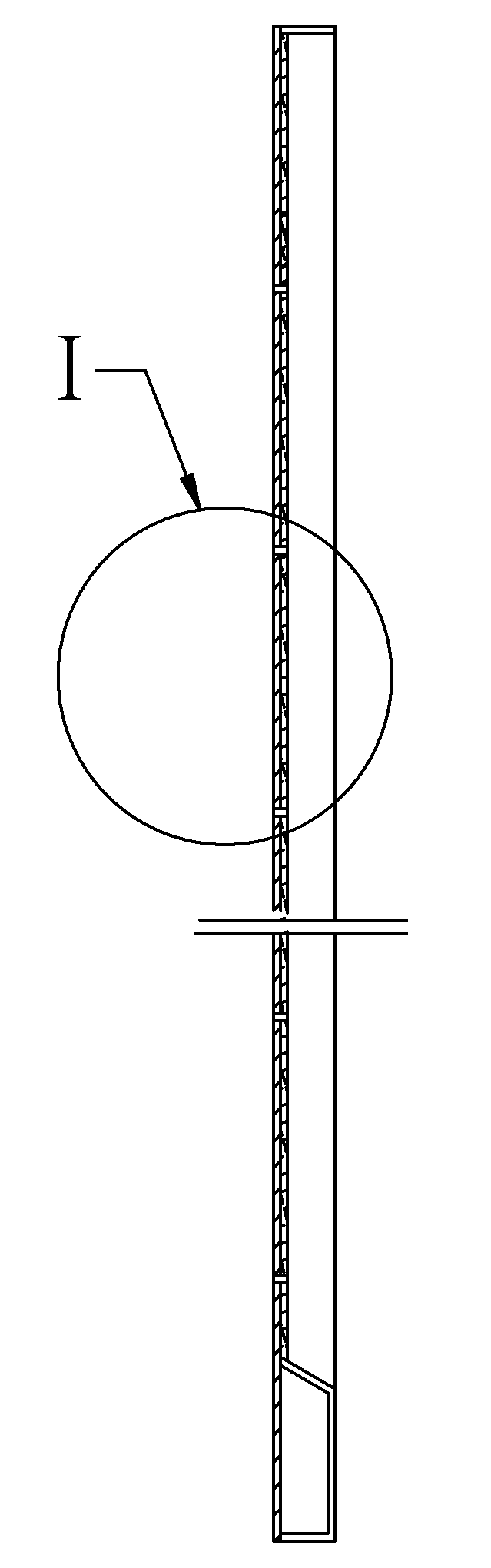

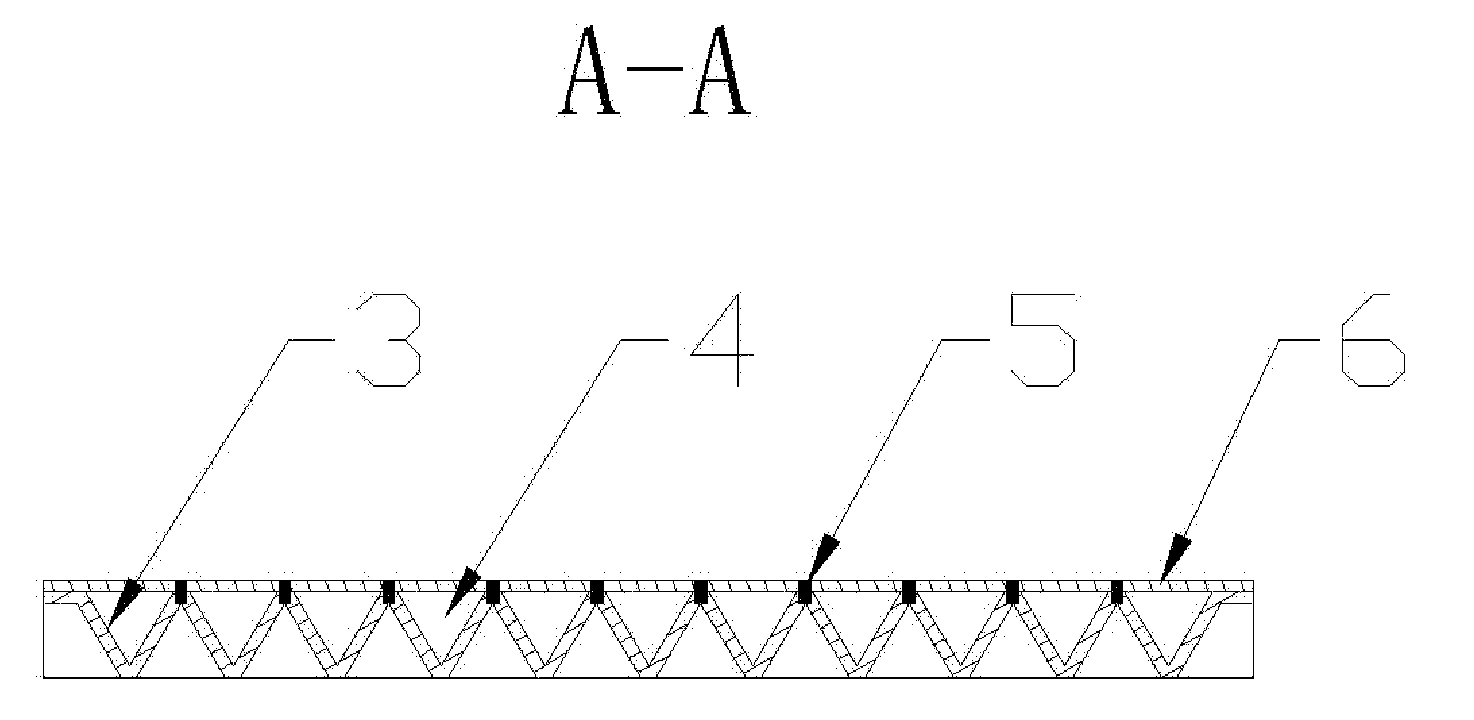

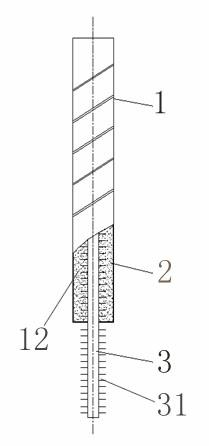

Single-sided corrugated plate type pulsating heat pipe

InactiveCN102128552AHigh heat transfer efficiencyExtensive sources of materialsSemiconductor/solid-state device detailsSolid-state devicesCurve shapeAluminium

The invention discloses a single-sided corrugated plate type pulsating heat pipe which comprises a bottom plate, a corrugated plate and a first communication cavity and is characterized in that: the bottom plate is a plane metal plate; one end of the bottom plate is provided with the first communication cavity in sealed connection with the bottom plate; the section of the corrugated plate is of a continuous triangular shape, sinusoidal shape or other periodical curve shape; the two ends along the extension direction of the wave of the corrugated plate are in sealed connection with the bottom plate; one end vertical to the extension direction of the wave of the corrugated plate is in sealed connection with the first communication cavity, and the other end is in sealed connection with the bottom plate; two adjacent troughs of the corrugated plate are welded on the bottom plate through spot welding to form multiple pulsating channels vertical to the extension direction of the wave of the corrugated plate; and adjacent channels are communicated through hair cracks. The equivalent coefficient of heat conductivity of the single-sided corrugated plate type pulsating heat pipe is two orders of magnitude higher than that of an aluminum extruded radiator and 2-3 times higher than that of the related flat heat pipe; and the single-sided corrugated plate type pulsating heat pipe can be horizontally mounted and is particularly suitable for recycling the ventilation energy of an air conditioner as well as radiating and cooling electronic devices.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

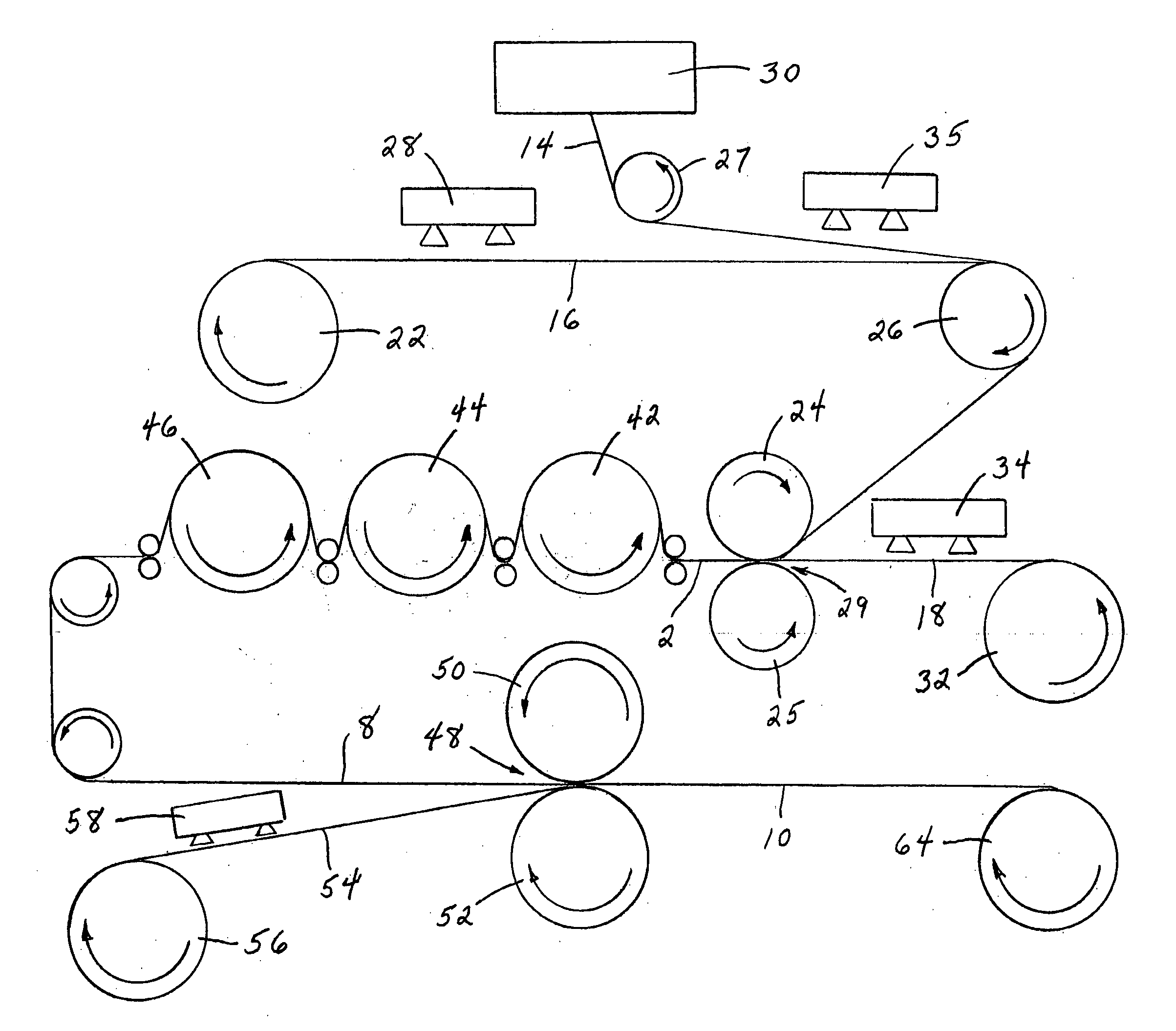

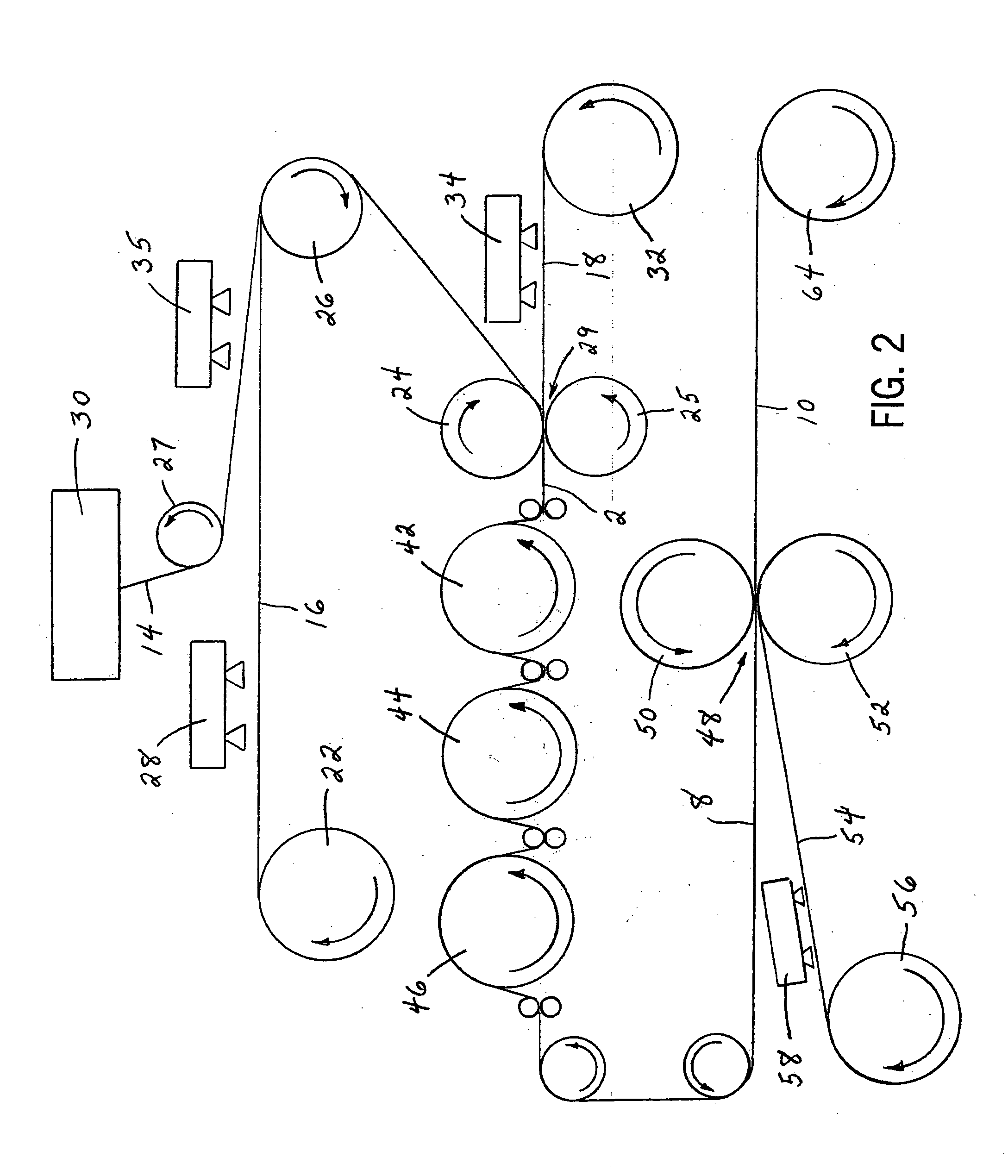

Method of making an elastic laminate using direct contact thermal rolls for controlling web contraction

InactiveUS20060137810A1Undesirable skewingUndesirable stove-pipingLamination ancillary operationsPersonal careElastomerWire rod

A method of making an elastic laminate includes the steps of feeding a first substrate in a machine direction, feeding a second substrate aligned with the first substrate in the machine direction, and feeding an array of elastomeric strand material stretched in the machine direction between the first and second substrates. A hot melt adhesive is applied onto the strand material, and a curable adhesive is applied to one or both of the substrates. The two substrates and the elastomeric strand material are then compressed to form an elastomeric preform web while maintaining the elastomeric strand material in its stretched state. The stretched elastomeric preform web is then heated in line by feeding it over heated rolls, and thereafter allowed to relax and contract in the machine direction as it cools and moves downstream from the heated rolls to form a gathered elastomeric laminate. A release liner is fed in the machine direction and aligned with the gathered elastomeric laminate, and a pressure sensitive adhesive is applied to the release liner. The gathered elastomeric laminate and release liner are then compressed to form the elastic laminate which is particularly useful as window flashing.

Owner:BOSTIK INC

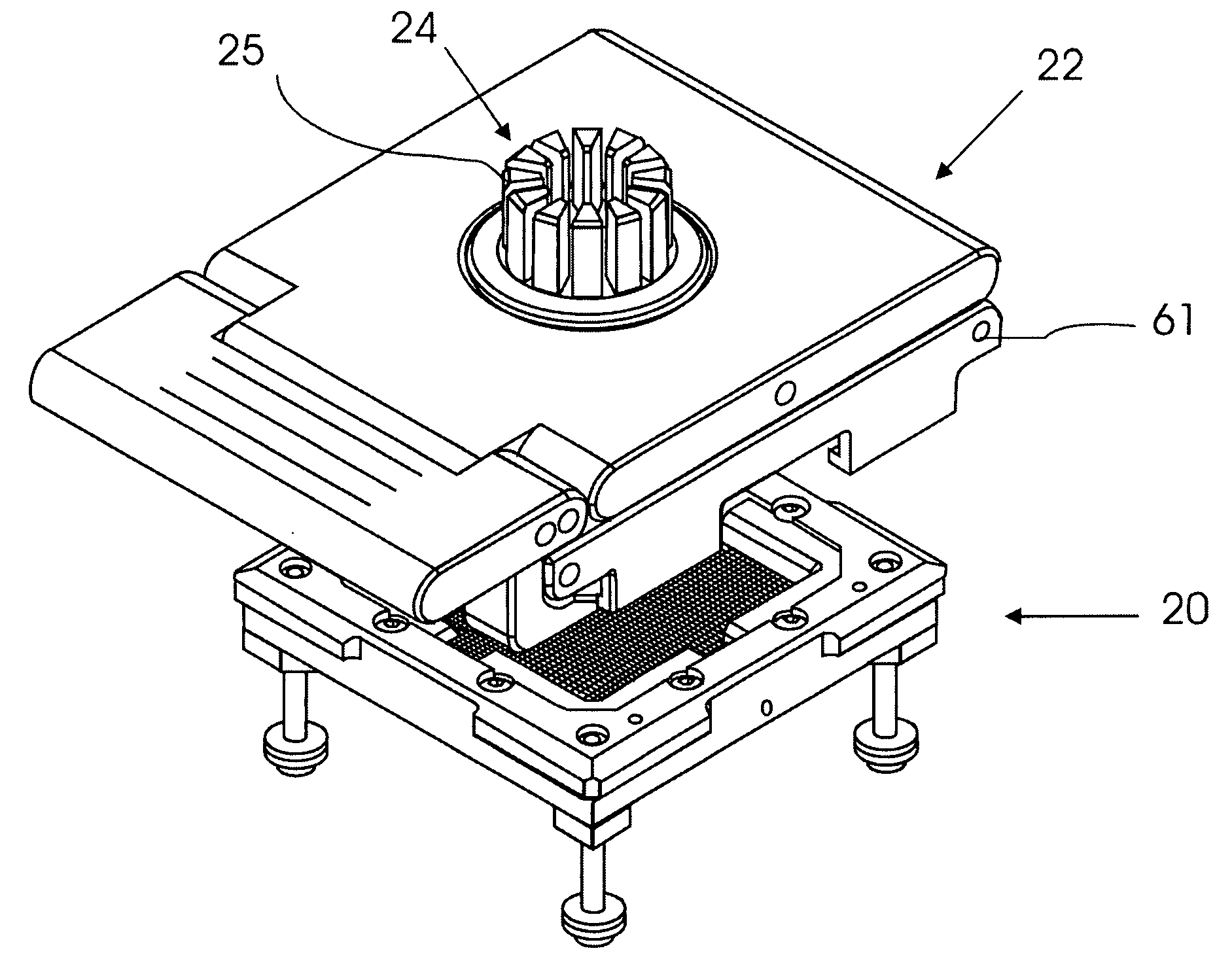

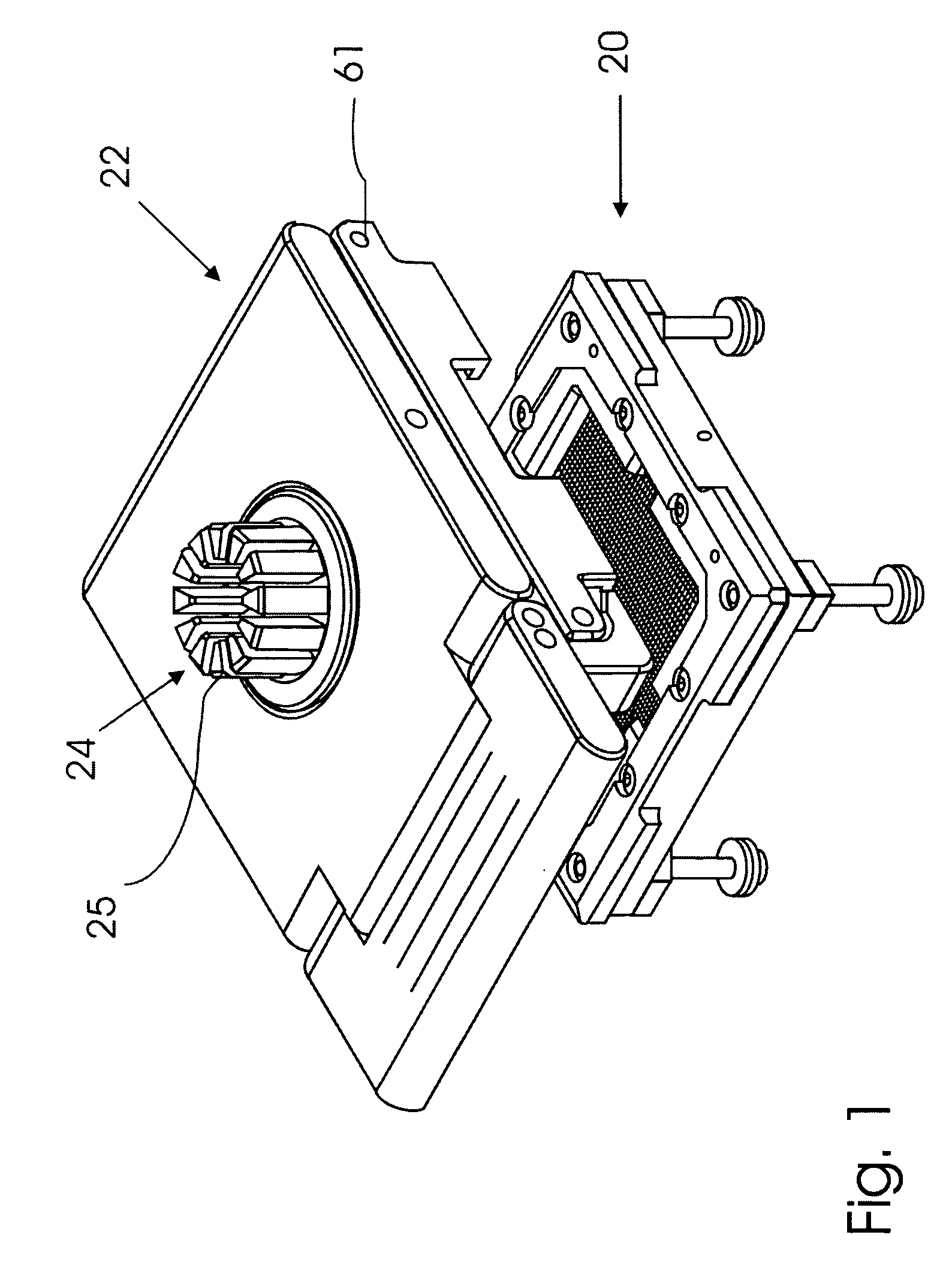

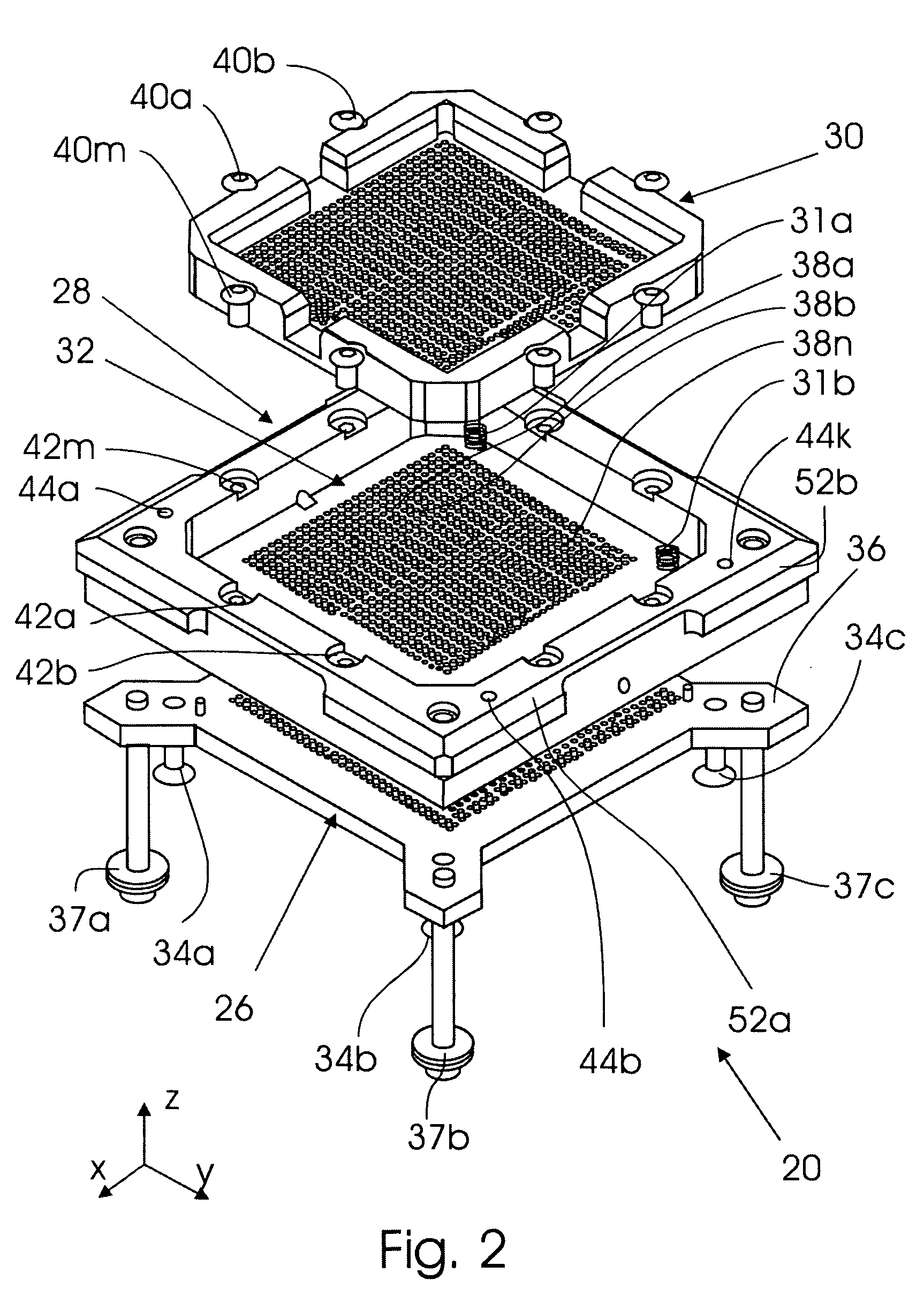

Test socket-lid assembly

InactiveUS20080020623A1Uniform clamping forceUniform heat transferEngagement/disengagement of coupling partsCoupling contact membersComposite structureBiomedical engineering

A test socket-lid assembly for testing electronic devices such as IC chips consists of a socket sub-assembly and a lid-sub-assembly, which is separated from the socket sub-assembly. In the lid sub-assembly, the lid is pivotally connected to the frame and supports a spring-loaded pusher that can slide in a vertical direction relative to the lid and can perform rocking movements relative to the lid. The assembly is distinguished from existing devices of this type in that the IC chip is supported and clamped in the lid sub-assembly and in that the entire lid sub-assembly together with the clamped and spring-loaded pusher is attached to the socket by guiding the lid sub-assembly in a transverse direction along the socket guide to the position wherein the spring plungers are locked into their respective openings on the surface of the socket. In one embodiment the pusher is a single part that has three degrees of freedom relative to the IC chip; in another embodiment, the pusher is of a composite structure and has five degrees of freedom.

Owner:PROTOS ELECTRONICS

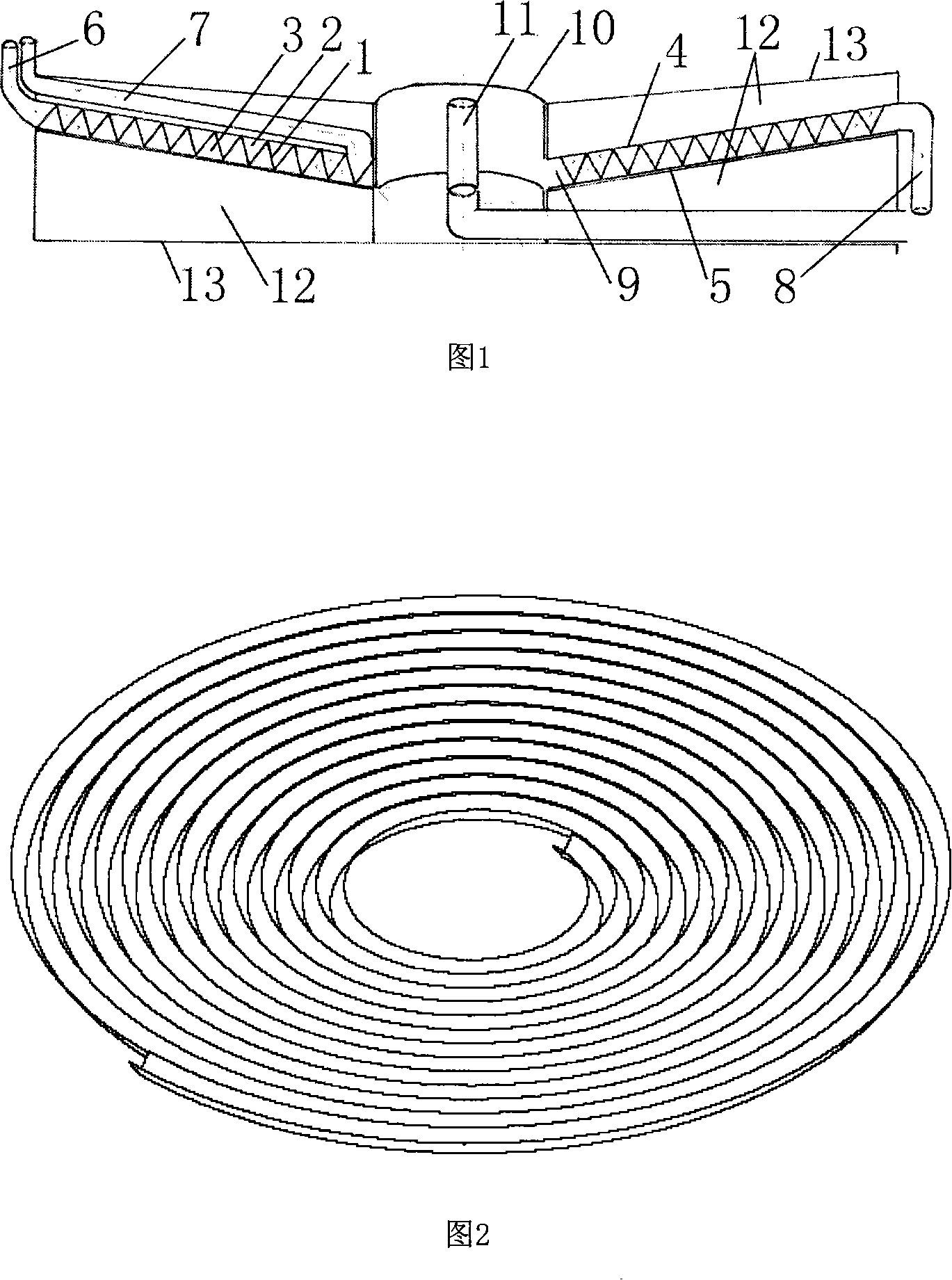

Novel slab type spiral heat exchanger

InactiveCN101118133AEnhanced convectionIncreased turbulenceStationary plate conduit assembliesWastewaterProcess engineering

The present invention relates to a novel plate type spiral heat exchanger, which has the characteristics of a plate heat exchanger, a spiral plate heat exchanger, and a spiral shell tube heat exchanger, and is characterized in that the size is small, the heat exchanging efficiency is high, the countercurrent heat exchange can be operated, the requirement of heat exchange in low temperature difference is met, a modular structure filter is provided, and a novel heat exchanger is easy to disassemble and clean, the present invention is easy for modularization process and assembly production, and the production cost is low. The present invention is particularly suitable for recycling of the after heat of bathing waste water and pre heating clean tap water in the process of household bathing, and more than 60 percent of waste heat can be effectively recycled, and the water heater power can be doubled in the condition of using lower cost and no energy consumption is added.

Owner:杨杰

Ultra-supercritical strengthening fluid heat-transferring method and heat-transferring medium

InactiveCN101284984AImprove heat transfer performanceAchieve heat transferHeat-exchange elementsBulk chemical productionEnhanced heat transferWorking temperature

The invention discloses a supercritical multiphase enhanced heat transfer method and a heat transfer medium. The method is to add an auxiliary phase change heat transfer material to a basic heat transfer medium, so as to ensure that: when no phase change heat transfer is carried out in the working temperature range of the basic heat transfer medium, the auxiliary phase change heat transfer material carries out phase change heat transfer; when the basic heat transfer medium carries out phase change heat transfer, the auxiliary phase change heat transfer material carries out phase change heat transfer at the phase change temperature lower than a basic phase change heat transfer medium. The method and the medium can realize the integral thermal control and thermal management on heat transfer.

Owner:李建民

Crystallizer covering slag for continuously casting high-manganese high-aluminum steel and preparation method of crystallizer covering slag

The invention provides a crystallizer covering slag for continuously casting high-manganese high-aluminum steel and preparation method of the crystallizer covering slag. The covering slag is prepared from the following components in parts by weight: 20-38 parts of CaO, 20-35 parts of Al2O3, 5-18 parts of SiO2, 10-22 parts of BaO, 2-7 parts of Li2O, 5-12 parts of F<->, 1-4 parts of MgO, 2-8 parts of C and Fe2O3 which is less than or equal to 2 parts. According to the preparation method disclosed by the invention, wollastonite, limestone, quartz sand, fluorite, bauxite, barium carbonate, magnesia, soda, lithium carbonate and carbonaceous materials are used as raw materials, and the covering slag is prepared through the following steps of: calculating of consumption, melting, smashing, fine grinding, drying and granulation. The covering slag disclosed by the invention has the characteristics of being low in reactivity and good in property stability, the lubrication and the thermal transmission of casting blanks can be effectively coordinated and controlled, the smooth performing of the continuous casting process of the high-manganese high-aluminum steel can be guaranteed, high-manganese high-aluminum steel continuous casting blanks with excellent surface quality are cast, and multi-heat continuous casting can be realized.

Owner:CHONGQING UNIV

Phase change heat storage element and heat storage and supply device adopting same

InactiveCN102538533AUniform heat transferAdaptableCentral heating with accumulated heatHeat storage plantsThermodynamicsHeat storage material

The invention discloses a phase change heat storage element and a heat storage and supply device adopting the same. The phase change heat storage element comprises a shell, wherein a hollow cavity is formed in the shell; a phase change heat storage material is filled in the hollow cavity; a heat pipe is arranged in the hollow cavity; and part of the heat pipe is exposed out of the shell. The heat pipe is used for transmitting heat, so that the heat storage time of the phase change heat storage element disclosed by the invention is short. The heat storage and supply device comprises a box body, wherein a phase change heat storage chamber and a heat supply heating chamber are formed in the box body; a cold water inlet and a hot water outlet are formed in the phase changer heat storage chamber; a heat source inlet is formed in the heat supply heating chamber; at least one phase change heat storage element is arranged in the phase change heat storage chamber; and the part, exposed out of the shell, of the heat pipe arranged in the phase change heat storage element is arranged in the heat supply heating chamber. The phase change heat storage chamber and the heat supply heating chamber are separated from each other, so that the heat pipe can be heated by using industrial smoke or media, such as steam, hot water and the like; and therefore, the phase change heat storage element can well adapt to outside heat sources.

Owner:HUNAN HUITONG HEAT SOURCE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com