Crystallizer covering slag for continuously casting high-manganese high-aluminum steel and preparation method of crystallizer covering slag

A mold flux and high-aluminum steel technology, applied in the field of metallurgy, can solve the problems of reducing the surface tension of the flux, deteriorating the performance of the flux, and increasing the probability of slag entrainment, so as to ensure the network formation ability, avoid uneven cooling, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

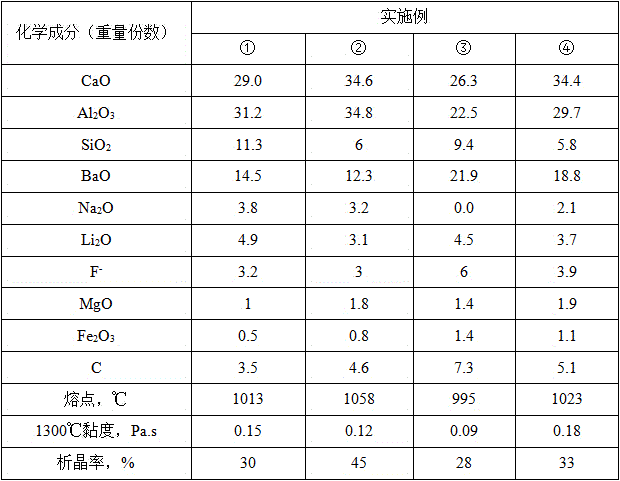

Examples

preparation example Construction

[0042] The preparation method of above-mentioned mold powder comprises the following steps:

[0043] 1) Using wollastonite, limestone, quartz sand, fluorite, bauxite, barium carbonate, magnesia, soda, lithium carbonate and carbonaceous materials as raw materials, calculate the Describe the amount of each raw material, and weigh each raw material according to the calculated amount;

[0044] 2) Mix the wollastonite, limestone, quartz sand, fluorite, lithium carbonate, soda, bauxite, barium carbonate and magnesia weighed in step 1), and keep warm at 1350~1450°C for 30~40 minutes to make each The raw material is melted evenly, and then it is cooled naturally after being taken out of the furnace to obtain a premelt;

[0045] 3) Crushing the premelted material obtained in step 2) so that the particle size of the crushed premelted material is ≤200 mesh, adding the carbonaceous material weighed in step 2), and mixing evenly to obtain a dry material;

[0046] 4) Put water, cellulose ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com