Patents

Literature

97results about How to "Smooth inflow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Specific crystallizer casting powder for sulphur free-cutting steel and production method thereof

The invention discloses a specific crystallizer casting powder for sulphur free-cutting steel and production method thereof, mass percents of chemical components thereof are as follows: 29-35% of CaO, 25-30% of Sio2, 2-5% of MgO, 3-5% of Al2O3, 2-6% of Fe2O3, 5-11% of NaO?, 0-2% of Li2O, 5-9% of CaF2?, 0-5% of MnO, 0.5-2.0% of Al grey, 0-2% of B2O3, 5-11% of solid carbon, and allowance is building material adhesive and water. The sulphur free-cutting steel has low high-temperature strength and high crack sensitivity, and the casting powder should have properly high basicity. Basicity of a slag is improved, so that diffusion velocity is accelerated, and absorption of impurities in molten steel is benefited. So, improvement of basicity is an effective means for improving absorption of the impurities and control of surface longitudinal crack.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

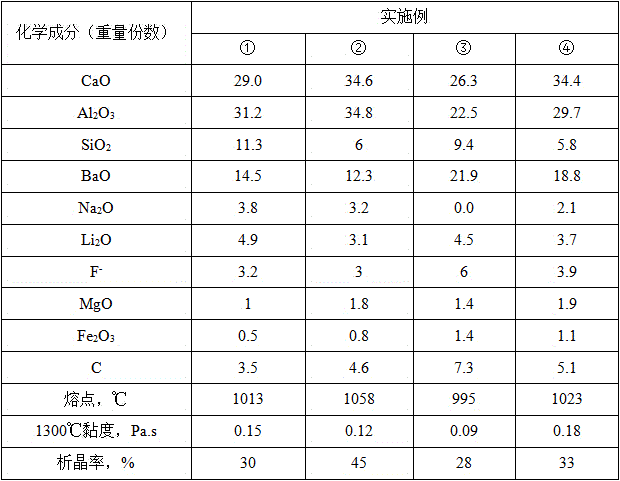

Crystallizer covering slag for continuously casting high-manganese high-aluminum steel and preparation method of crystallizer covering slag

The invention provides a crystallizer covering slag for continuously casting high-manganese high-aluminum steel and preparation method of the crystallizer covering slag. The covering slag is prepared from the following components in parts by weight: 20-38 parts of CaO, 20-35 parts of Al2O3, 5-18 parts of SiO2, 10-22 parts of BaO, 2-7 parts of Li2O, 5-12 parts of F<->, 1-4 parts of MgO, 2-8 parts of C and Fe2O3 which is less than or equal to 2 parts. According to the preparation method disclosed by the invention, wollastonite, limestone, quartz sand, fluorite, bauxite, barium carbonate, magnesia, soda, lithium carbonate and carbonaceous materials are used as raw materials, and the covering slag is prepared through the following steps of: calculating of consumption, melting, smashing, fine grinding, drying and granulation. The covering slag disclosed by the invention has the characteristics of being low in reactivity and good in property stability, the lubrication and the thermal transmission of casting blanks can be effectively coordinated and controlled, the smooth performing of the continuous casting process of the high-manganese high-aluminum steel can be guaranteed, high-manganese high-aluminum steel continuous casting blanks with excellent surface quality are cast, and multi-heat continuous casting can be realized.

Owner:CHONGQING UNIV

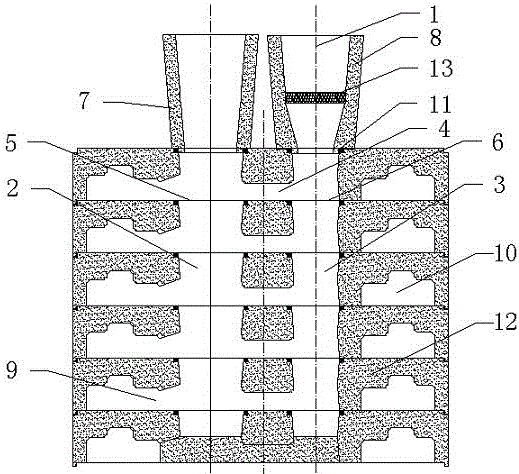

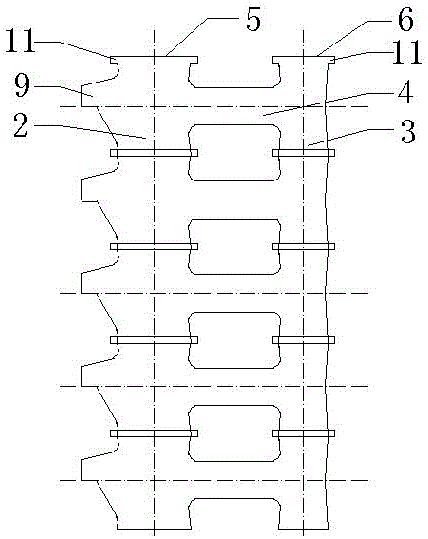

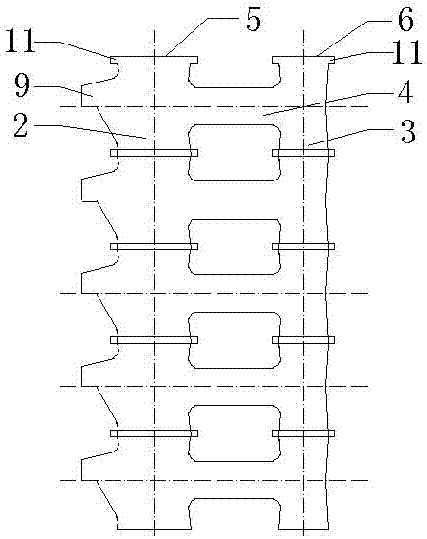

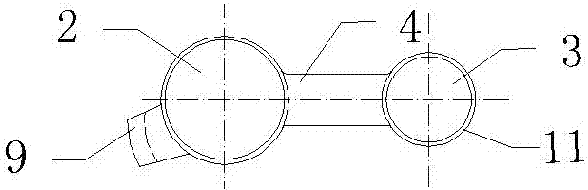

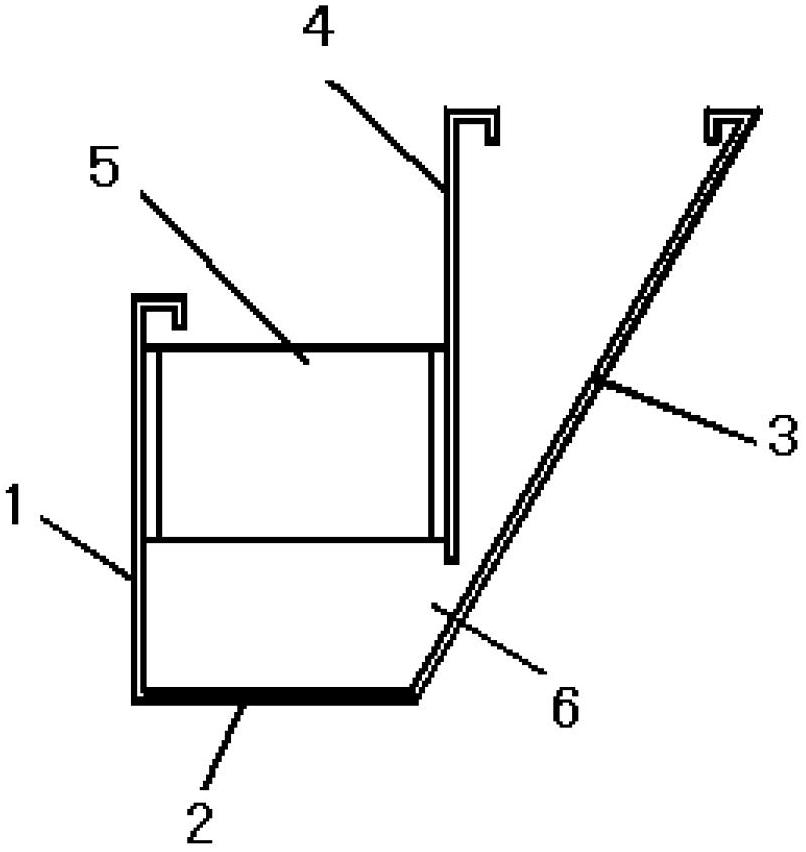

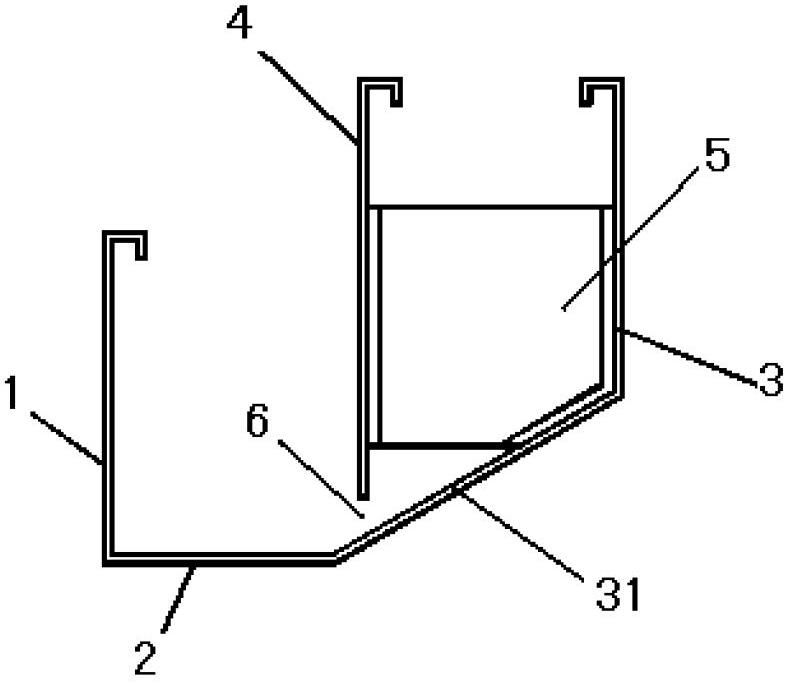

Multi-overlaid-layer gating system and technology for casting

InactiveCN104985128AImprove efficiencyReduced pouring timeFoundry mouldsFoundry coresEngineeringIron content

The invention discloses a multi-overlaid-layer gating system and technology for casting. The multi-overlaid-layer gating system is characterized in that the multi-overlaid-layer gating system comprises multiple layers which are overlaid, riser channels and spures are arranged in the gating system, and in each layer of the gating system, the upper end and the lower end of the riser channel and the upper end and the lower end of the spure are provided with risers and pouring gates respectively; a riser cup and a pouring gate cup are fastened to the riser and the pouring gate on the top layer of the gating system respectively; the riser and the pouring gate of the upper end of the next layer of the gating system are tightly sleeved with the riser and the pouring gate of the lower end of each upper layer of the gating system respectively; the riser and the pouring gate of the bottom layer of the gating system are sealed, cross gates are arranged between the riser channels and the spures, inner pouring gates are arranged on one sides inside the riser channels, the cross gates are communicated with the inner pouring gates, and the inner pouring gates are communicated with a product sand mold cavity. By means of the multi-overlaid-layer gating system, a multi-layer product sand mold cavity is cast, casting production efficiency is improved, casting time is shortened, the molten iron content in multi-overlaid-layer casting is guaranteed, temperature balance is guaranteed, and casting product quality is guaranteed.

Owner:HUBEI YAGANG METAL MFR

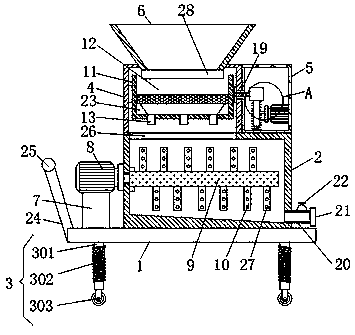

Feed feeding and mixing device with function of screening impurities for pig breeding industry

InactiveCN108854662AImprove safety and qualityImprove practicalityFeeding-stuffRotary stirring mixersPig breedingEngineering

The invention discloses a feed feeding and mixing device with a function of screening impurities for the pig breeding industry. The feed feeding and mixing device comprises a bottom plate; the top ofthe bottom plate is fixedly connected with a mixing box; the four corners of the bottom of the bottom plate are separately and fixedly connected with a mixing structure. The feed feeding and mixing device is provided with the bottom plate, the mixing box, the moving structures, supporting legs, springs, roller wheels, a first transmission case, a second transmission case, a feed chute, a support pillar, a first motor, a stirring column, stirring blades, a screen box, a sieve plate, blanking pipes, a second motor, a cam, a driving plate, a sliding chute, reset spring, a transmission column, a discharge pipe, a sealing cover, a regulating valve, a guide block, a push rod, an anti-slip sleeve, an open slot, through holes and a material limiting port which are cooperatively used, thus improving the safety and quality of pork and enhancing the practicality; the feed feeding and mixing device with the function of screening impurities for the pig breeding industry has the advantage of screening the impurities of feed, so that the practicality of the mixing device is improved.

Owner:芜湖市玉农生态农业有限公司

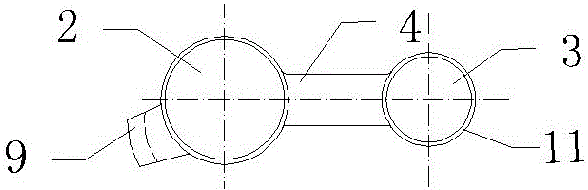

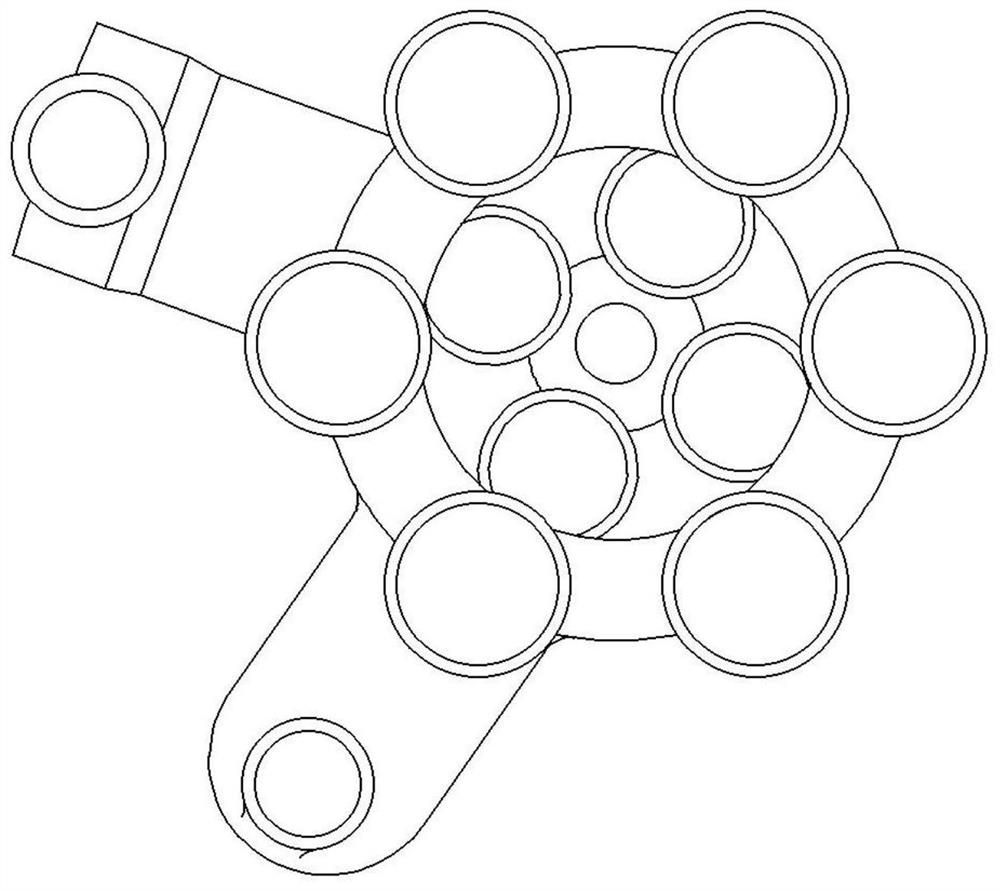

Bottom gating system with ingate in circular cross section

The invention discloses a bottom gating system with an ingate in circular cross section, which belongs to the technical field of casting, the existing gating system is not applicable to gating large casts, high in rejection rate and easy to lead the casts to produce stress and porosity so as to cause the high rejection rate of the casts. The bottom gating system comprises a mold cavity and a main sprue, a runner, a sub-sprue and a sub-runner in sequential connection, and is characterized in that the sub-runner is connected to the bottom part of the mold cavity via the ingate in the circular cross section. The bottom gating system can reduce the volume of a sand box, reduce the consumption of molding sand and further greatly reduce the production cost by adopting the ingate in the circular cross section; the bottom gating system can further lead molten metal to flow into the mold cavity smoothly, effectively prevent oxidizing slag which is produced by turbulent flow of the molten metal from being entangled into the mold cavity, prevent the production of slag inclusion in the cast, and further improve the quality of the cast; as molten iron enters into the mold cavity through the ingate in the circular cross section, the bottom gating system is difficult to produce temperature difference, and can reduce the production of the porosity and ensure the quality of the cast; and the operation is convenient.

Owner:ZHEJIANG JIALI WIND POWER TECH

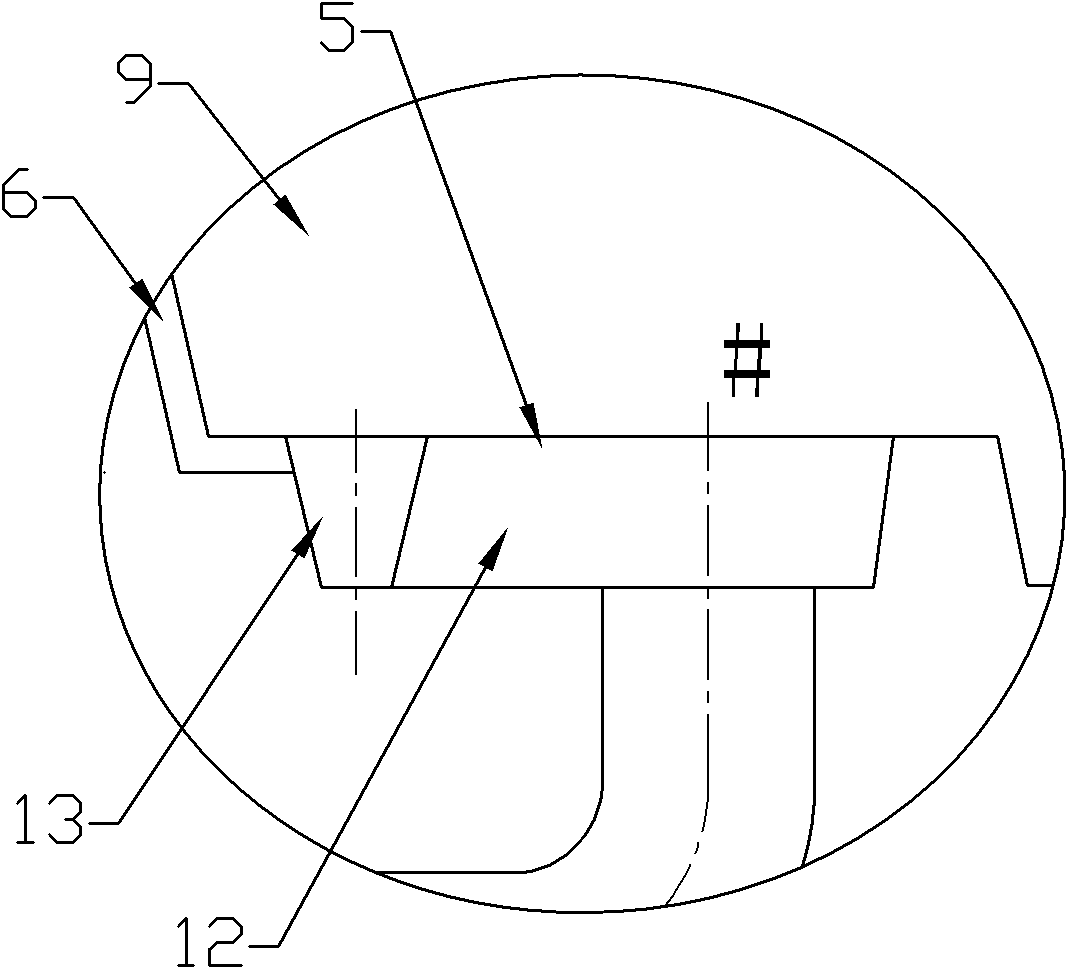

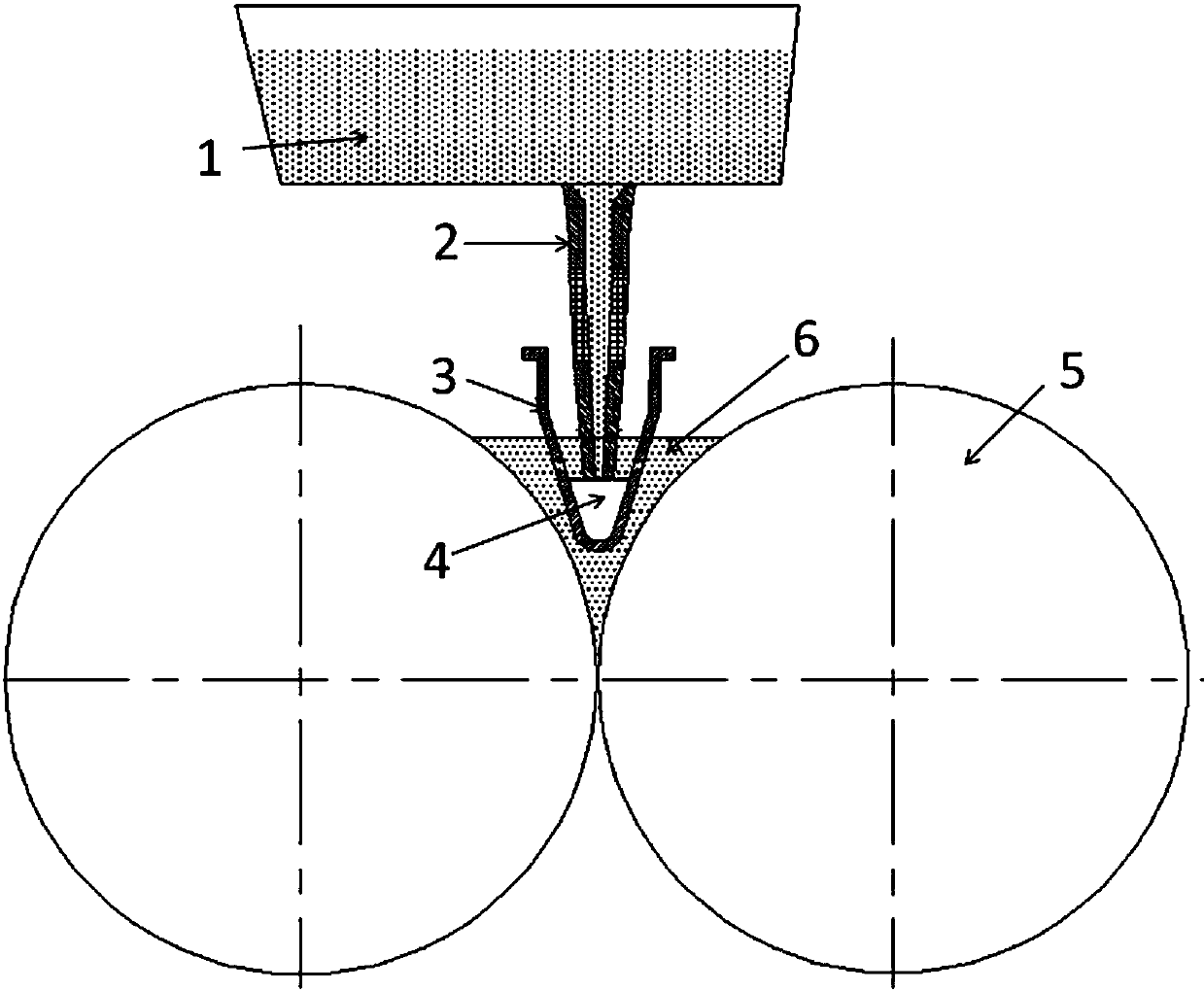

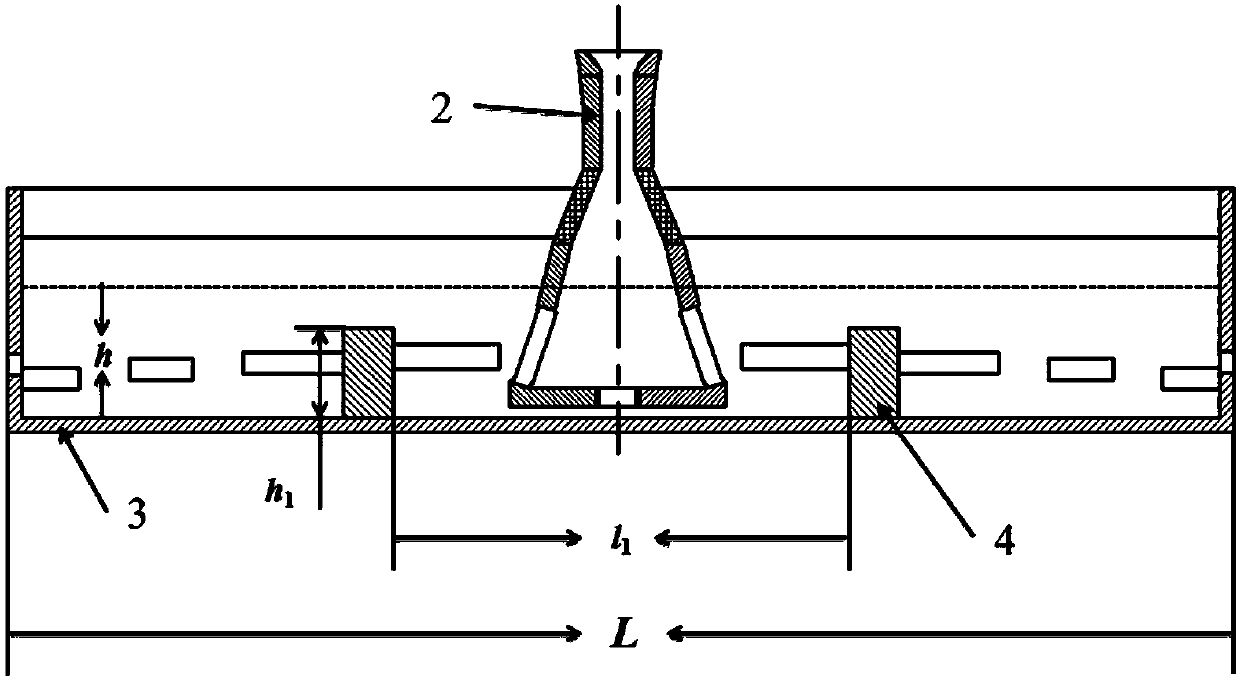

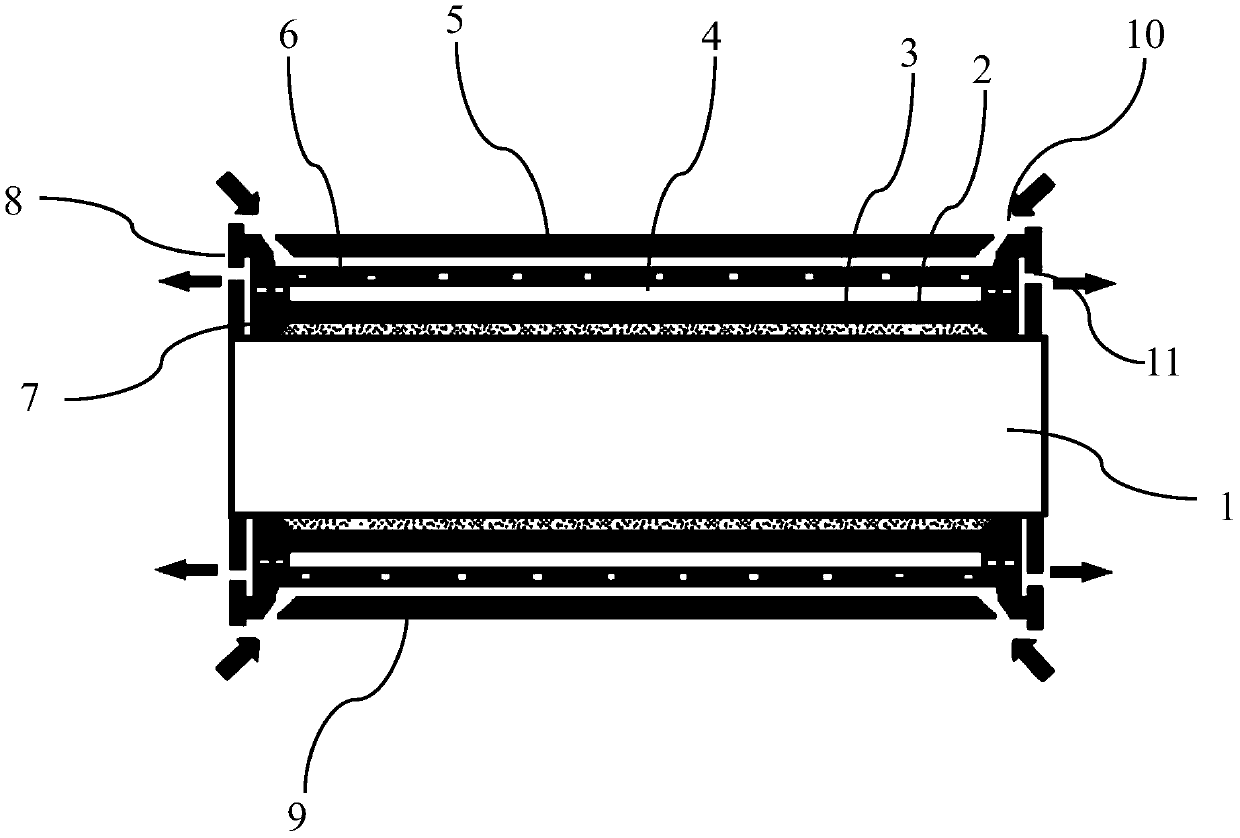

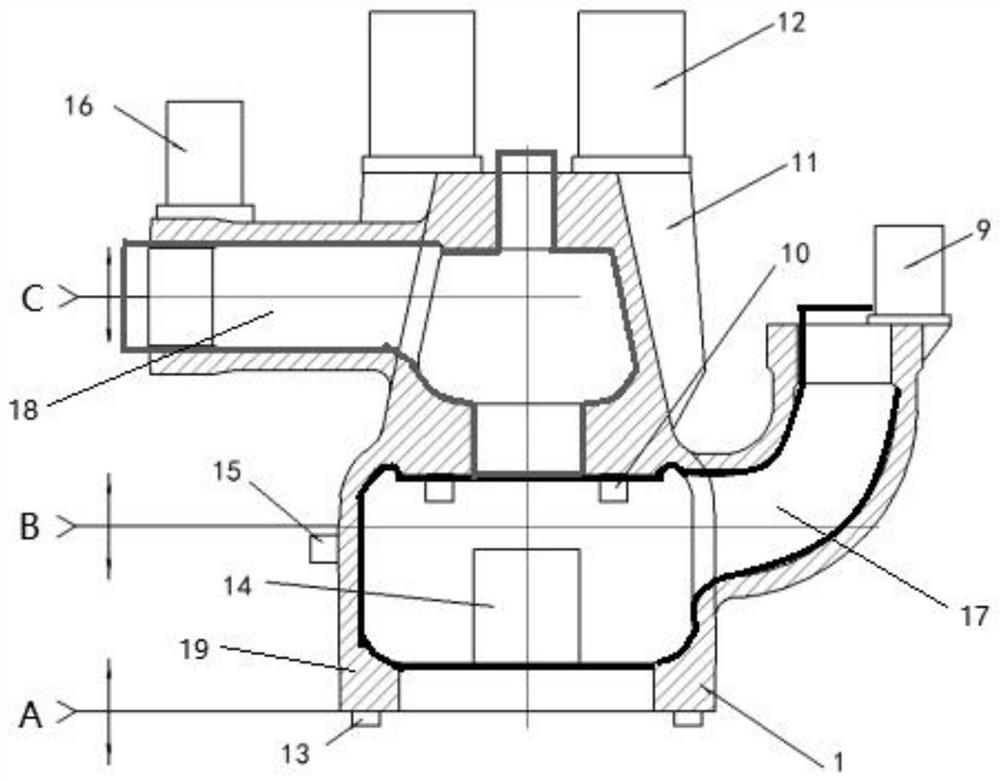

Casting system used for twin-roll thin strip continuous casting and use method thereof

The invention relates to a casting system used for twin-roll thin strip continuous casting and a use method thereof, and belongs to the technical field of thin strip continuous casting. The system comprises a submerged flow distribution water gap and a flow distributor, wherein the submerged flow distribution water gap consists of an inflow section, a transition section and an outflow section; the outflow section is divided into a contraction section and an expansion section from top to bottom; and the expansion section is in a fan-shaped and wedge-shaped flat shape and is provided with steel outlets. A use method comprises the steps that the submerged flow distribution water gap and the flow distributor are arranged under a tundish; liquid steel flows into the submerged flow distribution water gap, enters the flow distributor, and enters the gap between two casting rolls from flow distribution holes in the flow distributor; and the two casting rolls are started to move in opposite directions, the liquid level of a molten bath is kept to be higher than the upper edge of each steel outlet and each flow distribution hole, and the liquid steel is formed into thin strip steel after being cast-rolled by the casting rolls. Two times of flow distribution are realized for the liquid steel by the fan-shaped and wedge-shaped flat expansion section, the multi-hole flow distributor and flow guide dams of the multi-hole flow distributor, the fluctuation of the liquid steel level is reduced, and the smooth going of a cast rolling process and the quality of thin strips are guaranteed.

Owner:NORTHEASTERN UNIV

Gas mixing and distributing structure of double-chamber or multi-chamber thin film deposition equipment

InactiveCN103122456ASimple structureSmall footprintChemical vapor deposition coatingProcess engineeringProduct gas

The invention belongs to the field of semiconductor thin film deposition equipment and in particular relates to a gas mixing and distributing structure of double-chamber or multi-chamber thin film deposition equipment. The gas mixing and distributing structure comprises a gas mixing chamber, gas inlet pipelines, at least two gas outlet pipelines and a gas intake baffle, wherein the bottom surface of the gas mixing chamber is connected with the first gas inlet pipeline and the second gas inlet pipeline, the gas intake baffle which is arranged on the bottom surface of the gas mixing chamber is arranged above the first gas inlet pipeline and the second gas inlet pipeline, and the inlet of the first gas inlet pipeline and the inlet of the second gas inlet pipeline are respectively positioned below the gas intake baffle; and at least two gas outlet pipelines are symmetrically connected to two opposite side surfaces of the gas mixing chamber. According to the gas mixing and distributing structure, various process gases can be sufficiently mixed, gases among chambers are uniformly distributed, and therefore a same process state can be kept among the chambers; and in addition, the gas mixing and distributing structure is simple in structure, low in cost, small in size and convenient to install and maintain.

Owner:PIOTECH CO LTD

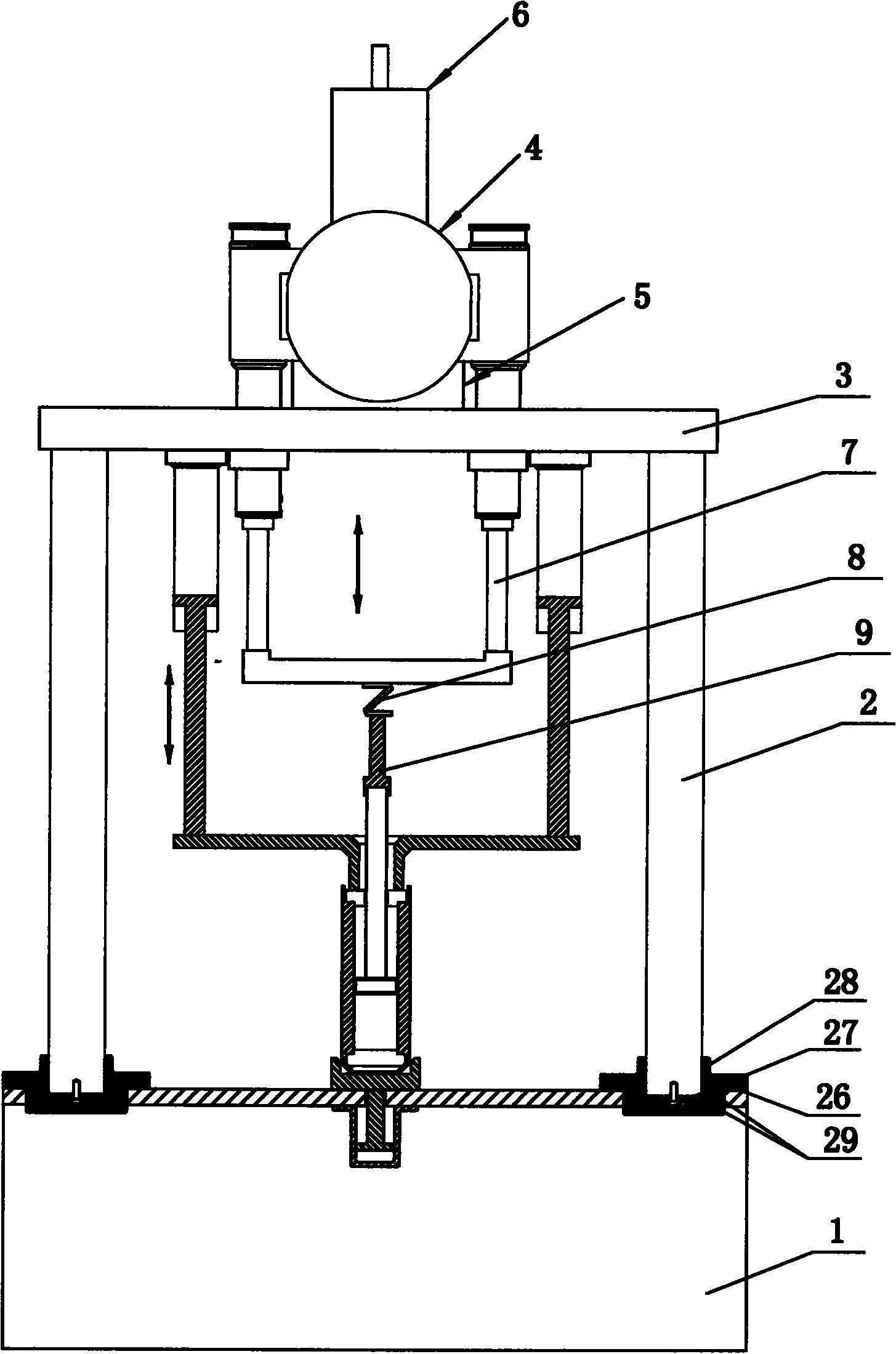

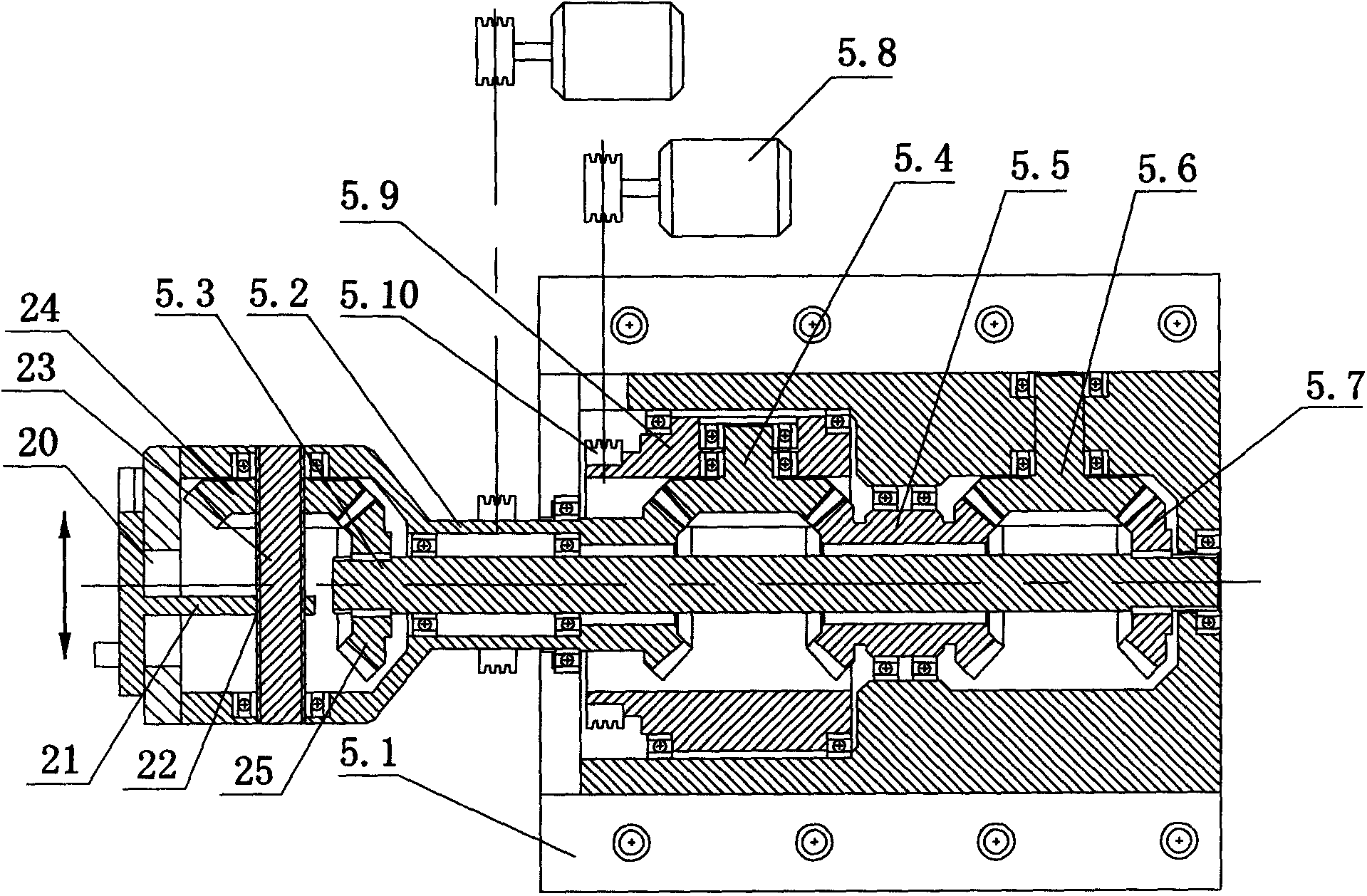

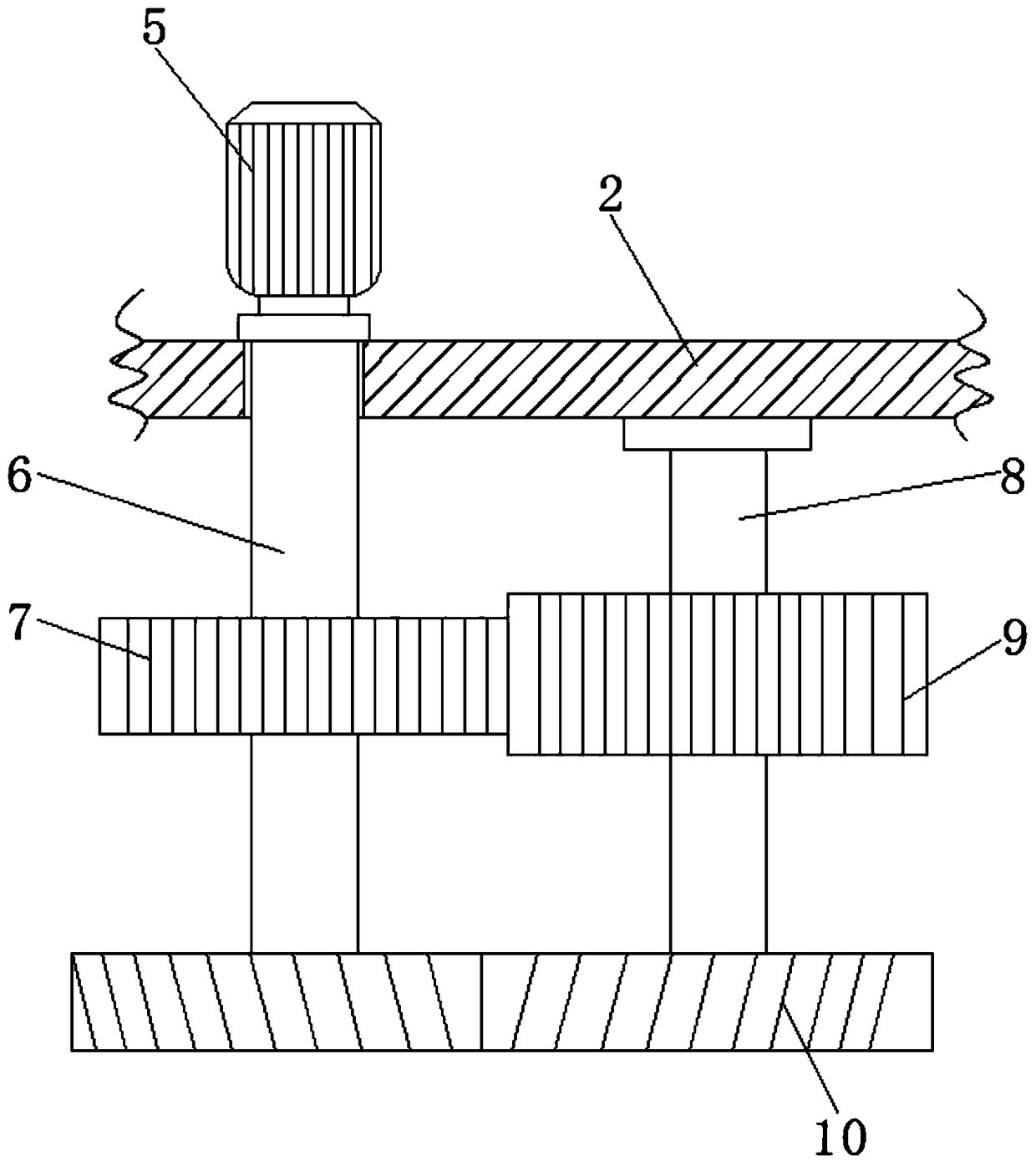

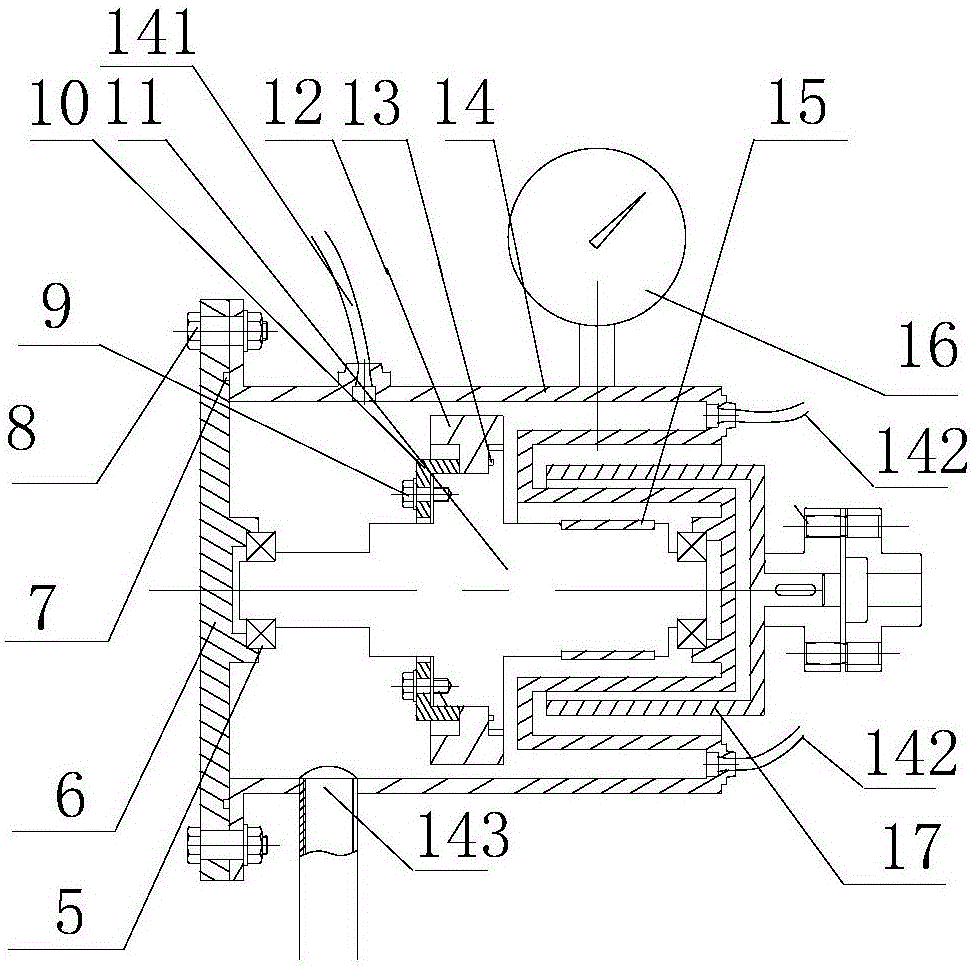

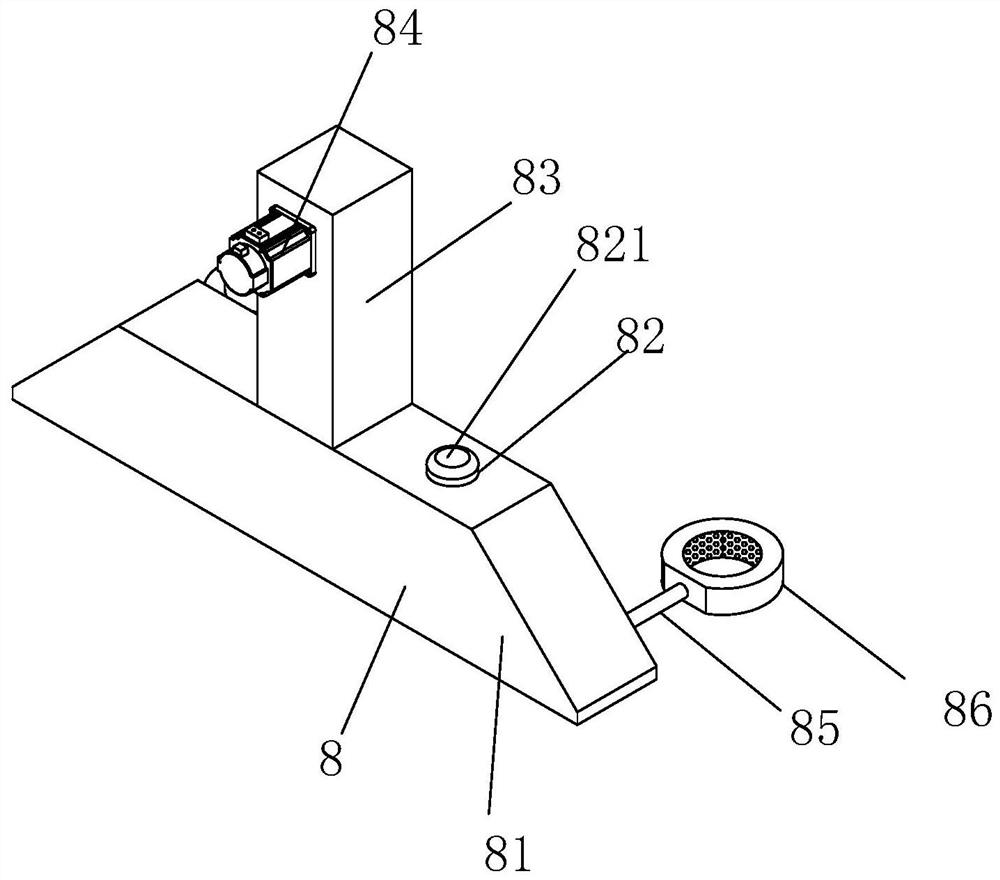

Overhead-type excitation displacement velocity force value relation curve detection equipment

ActiveCN103837353AHigh adjustment accuracyEliminate vibrationMachine part testingVehicle suspension/damping testingMechanical engineeringForce sensor

Overhead-type excitation displacement velocity force value relation curve detection equipment comprises a base (1), a stand column (2), a base plate (3) and a crank mechanism (4) and further comprises a concentric shaft rotation angle difference adjustment mechanism (5) and a gap eliminating mechanism (6), wherein the base plate (3) is connected with a test shaft (7) in a sliding mode, the lower end of the test shaft (7) is connected with a force sensor (8) and an upper clamp (9), the crank mechanism (4), the concentric shaft rotation angle difference adjustment mechanism (5) and the gap eliminating mechanism (6) are all connected to the base plate (3), the gap eliminating mechanism (6) is connected with the crank mechanism (4) which is in transmission connection with the test shaft (7), the crank mechanism (4) comprises an automatic counter weight assembly, and the concentric shaft rotation angle difference adjustment mechanism (5) is connected with the automatic counter weight assembly. Compared with the prior art, the equipment has the advantages that the crank mechanism is in the overhead type, the angle difference can be adjusted in real time, detection efficiency is high, detection precision is good and use flexibility is good.

Owner:宁波互生元机电科技有限公司

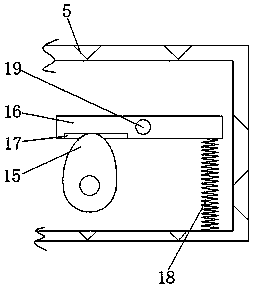

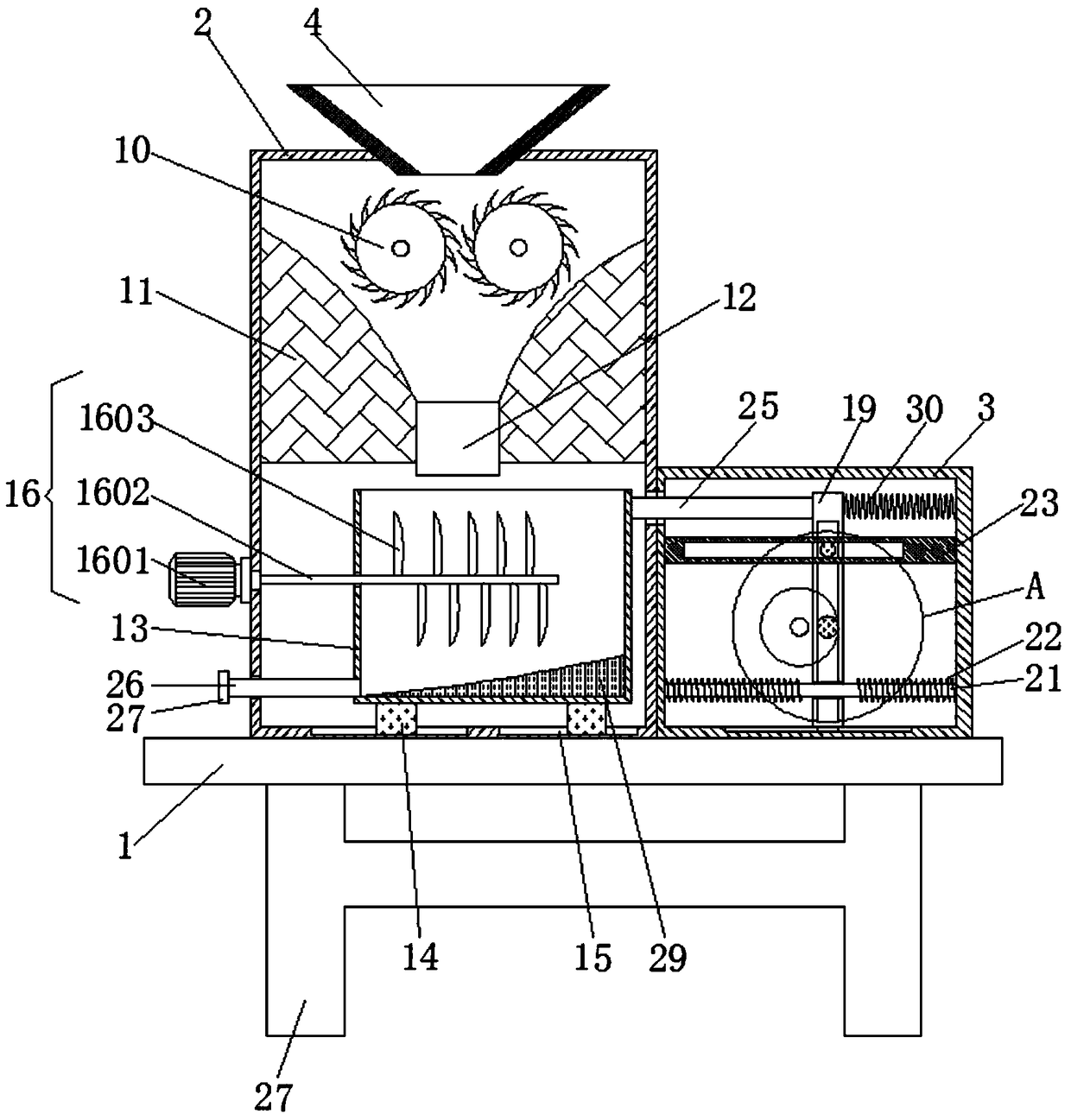

Civil construction engineering construction waste treating device

InactiveCN108855363AImprove practicalityImprove crushing efficiencyGrain treatmentsArchitectural engineeringConstruction waste

The invention discloses a civil construction engineering construction waste treating device. A first smashing box is fixedly connected to the left side of the top of a workbench. According to the civil construction engineering construction waste treating device disclosed by the invention, the workbench, the first smashing box, a transmission box, a feeding groove, a first motor, a first rotating column, a first gear, a second rotating column, a second gear, a smashing wheel, a flow limiting block, a blanking pipe, a second smashing box, a sliding block, a sliding groove, a stirring and smashing device, a third motor, a stirring rod, a smashing cutting blade, a second motor, a transmission disk, a first transmission frame, a transmission pin, a transmission column, a spring, a second transmission frame, a sliding pin, a transmission rod, a discharging pipe, a sealing cover, an H-shaped supporting frame, a guiding block and a return spring are matched and used; thus, the problem that anexisting smashing device cannot completely smash waste when smashing the waste is solved. The civil construction engineering construction waste treating device has the advantage of completeness in smashing, the practicability of the smashing device is enhanced, and the smashing efficiency of the smashing device is enhanced.

Owner:钟乘凤

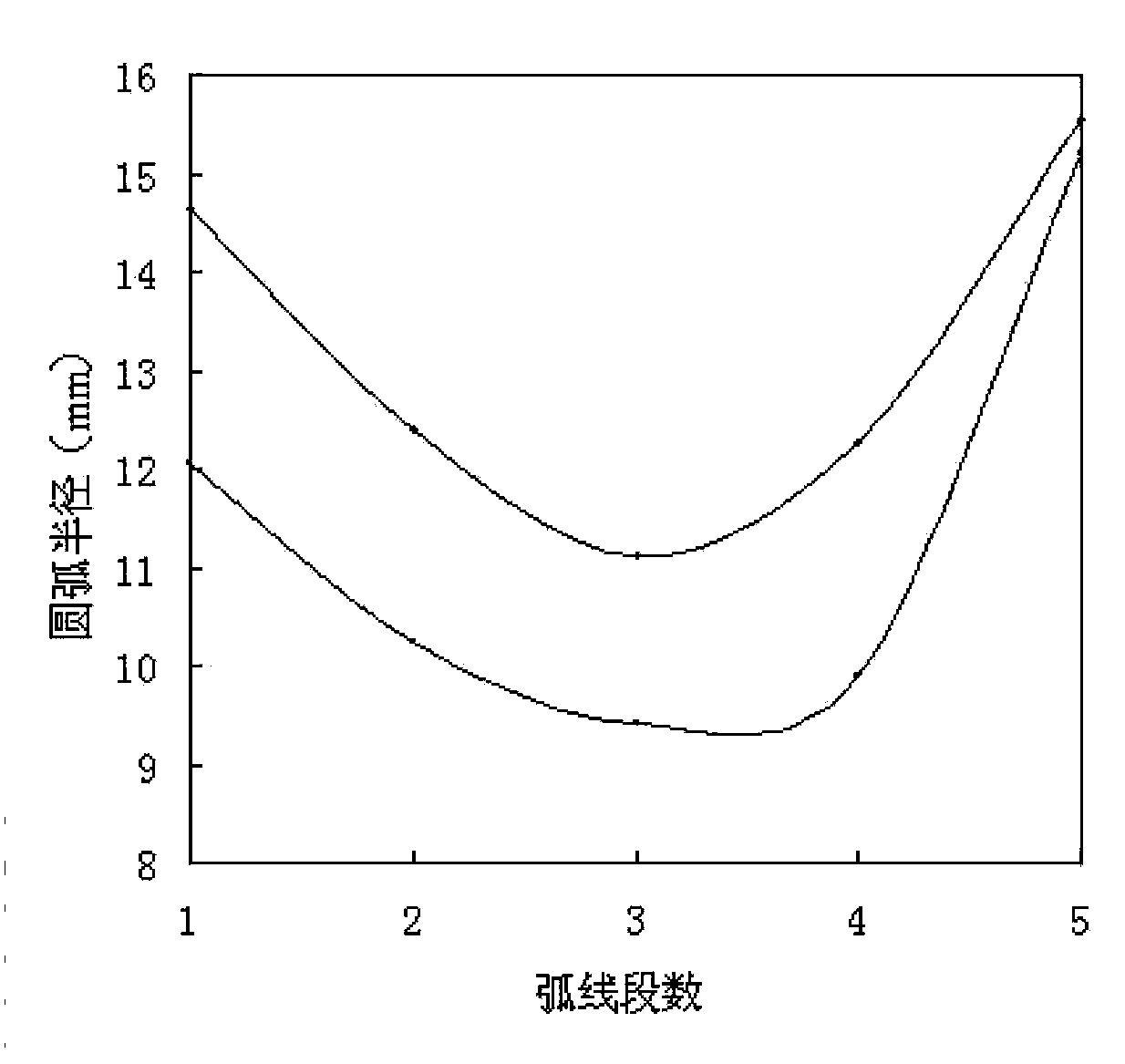

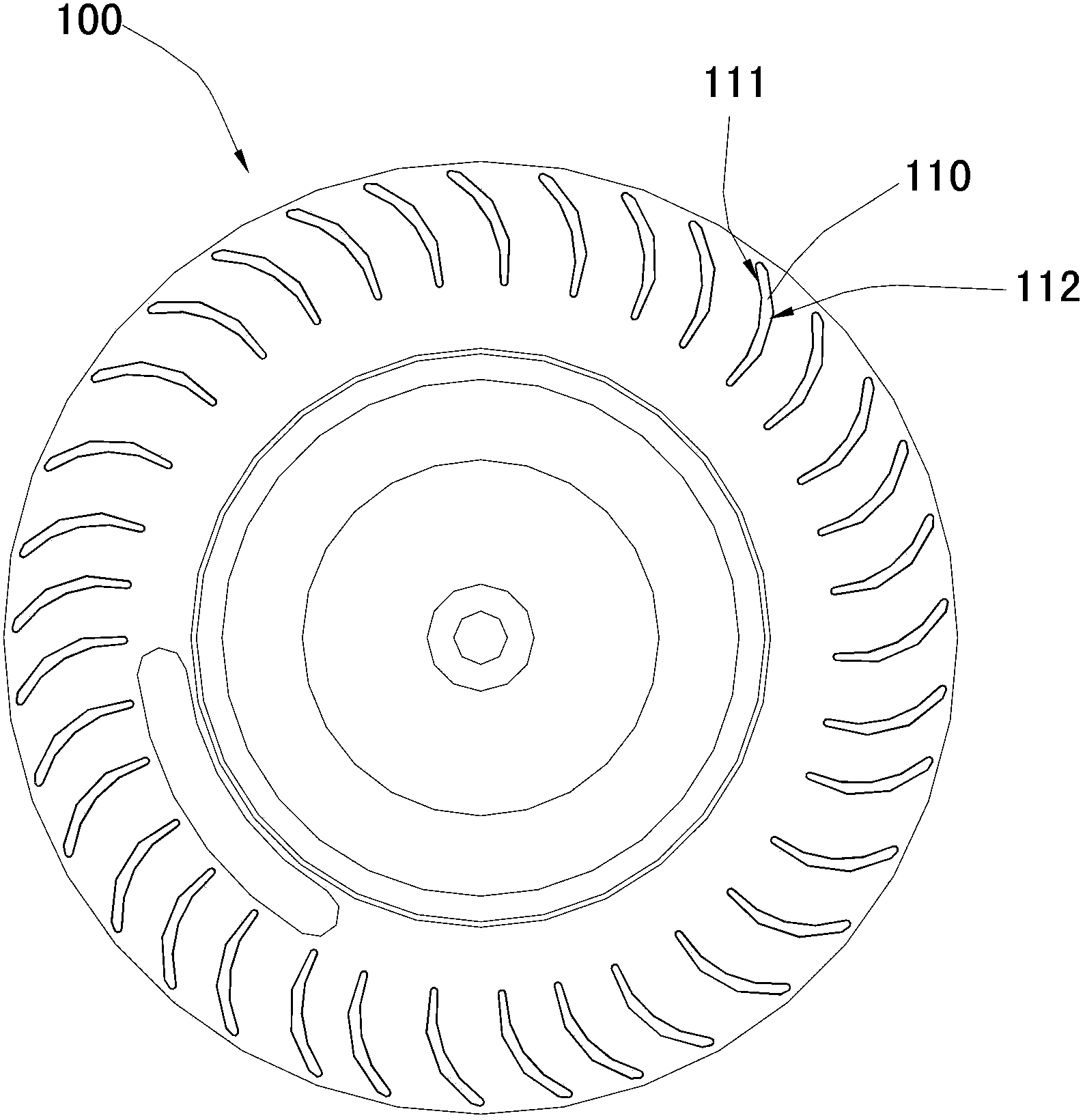

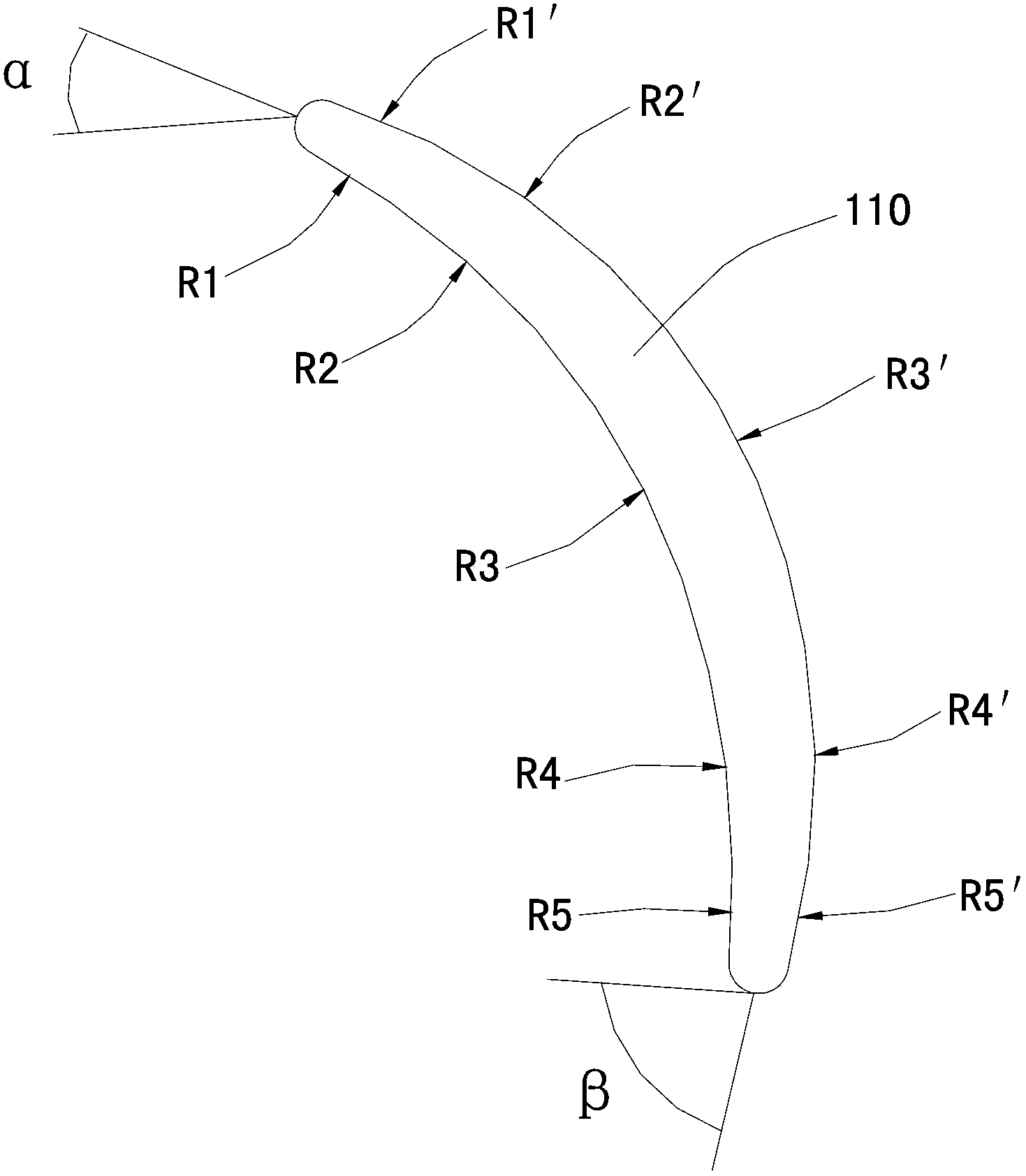

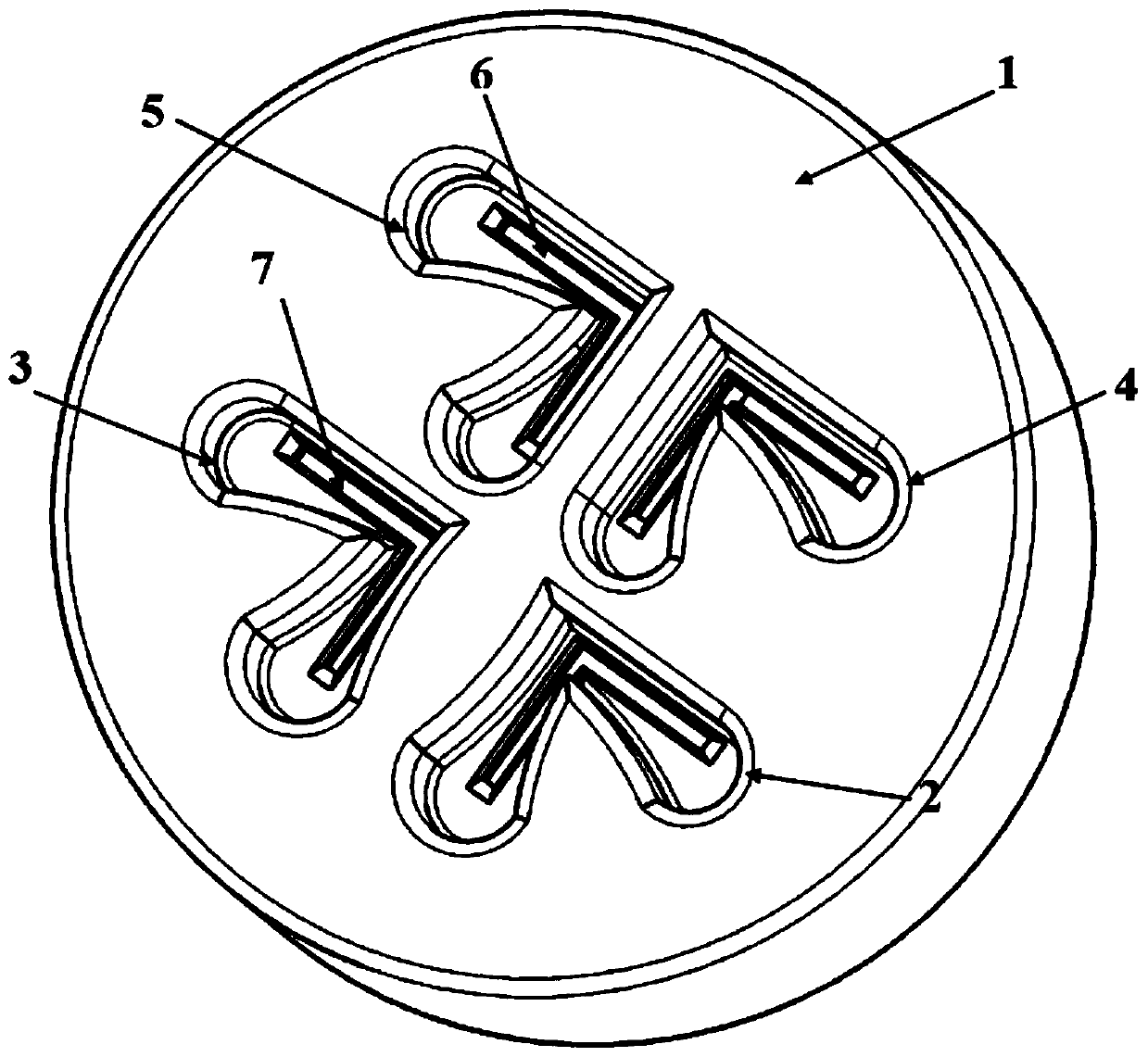

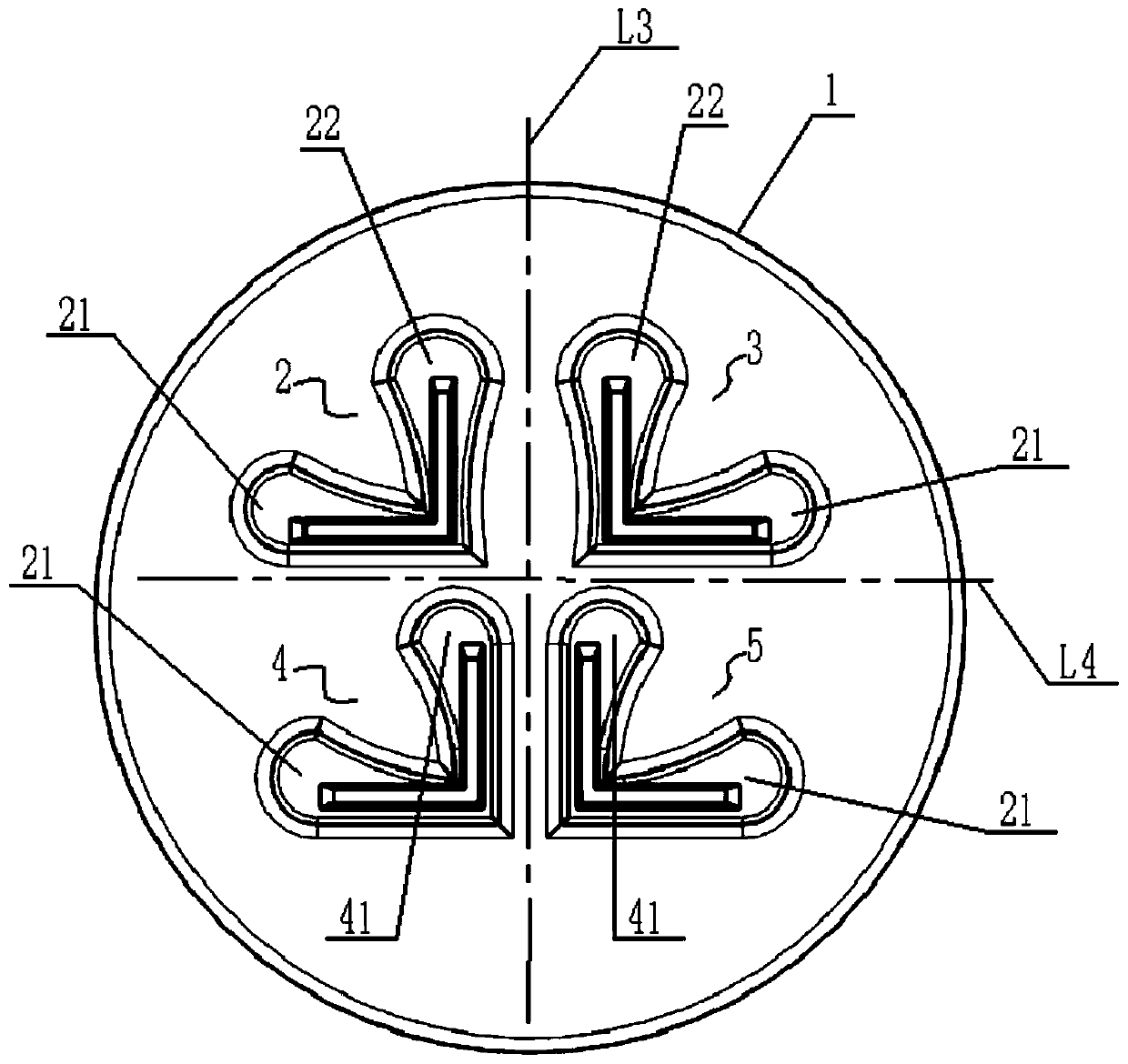

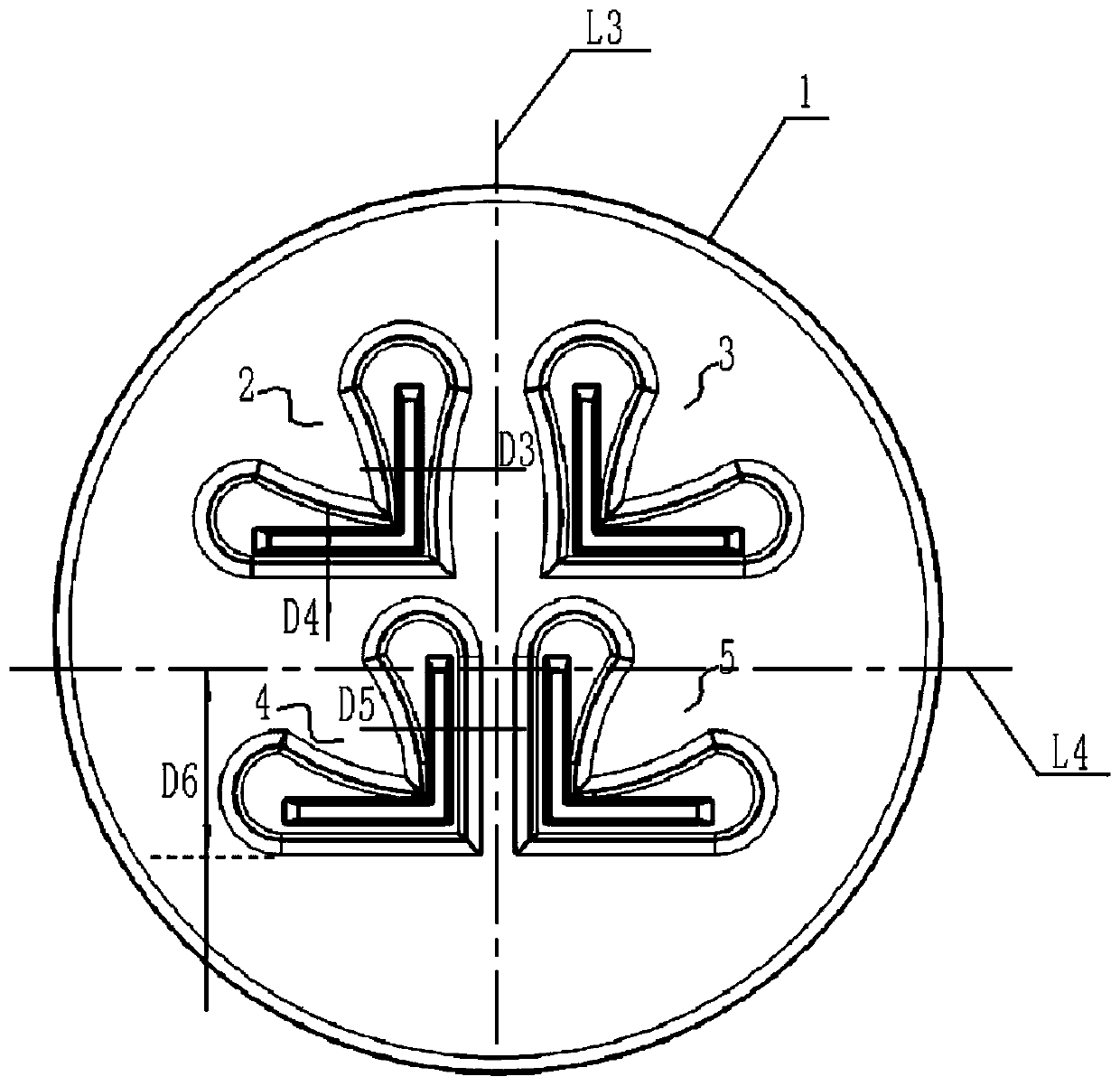

Cross-flow impeller, cross-flow fan and wall-mounted air conditioner

The invention discloses a cross-flow impeller, a cross-flow fan and a wall-mounted air conditioner. The cross-flow impeller comprises a plurality of blades arranged in the peripheral direction at intervals, each blade is provided with a pressure surface and a suction surface, a profile of each pressure surface is a concave curve, a profile of each suction surface is a concave profile, and curvature radiuses of the middles of the profile of each pressure surface and / or the profile of each suction surface are smaller than curvature radiuses of two ends. Since the pressure surface and / or the suction surface of each blade are designed into the curves different in curvature radius, traditional single-circular-arc curve design of existing blades is changed, airflow separation of a blade flow passage is reduced, aerodynamic noise caused by flow separation and secondary flow is effectively lowered, airflow is enabled to flow through a blade lattice more smoothly on the basis of guarantee of power capability, vortexes in the blade lattice are prevented from falling off, the aerodynamic noise is reduced, and comfort in use of the air conditioner is improved.

Owner:GREE ELECTRIC APPLIANCES INC

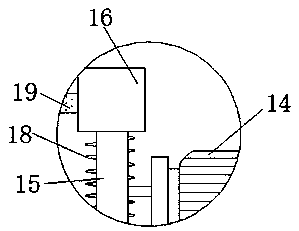

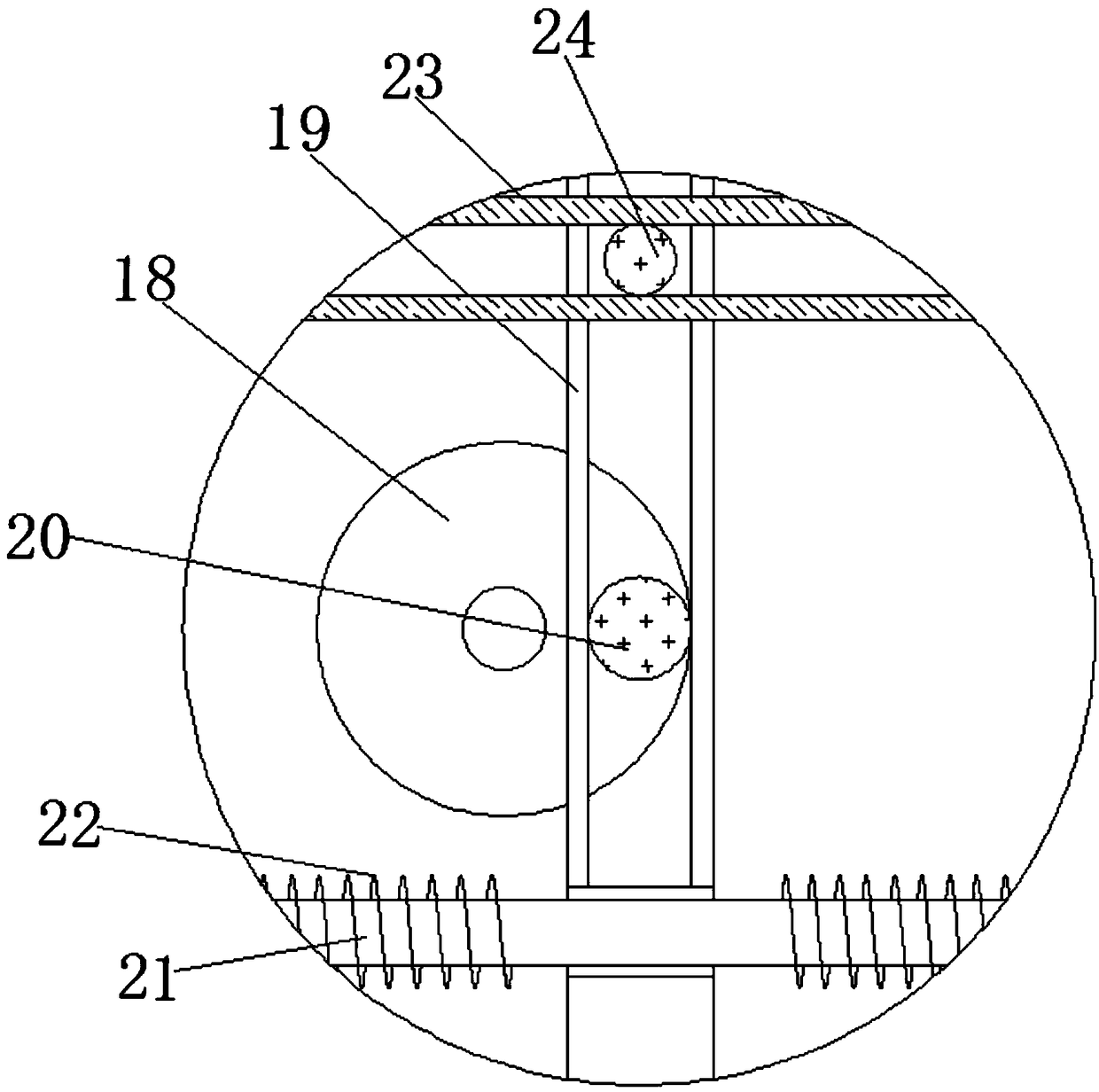

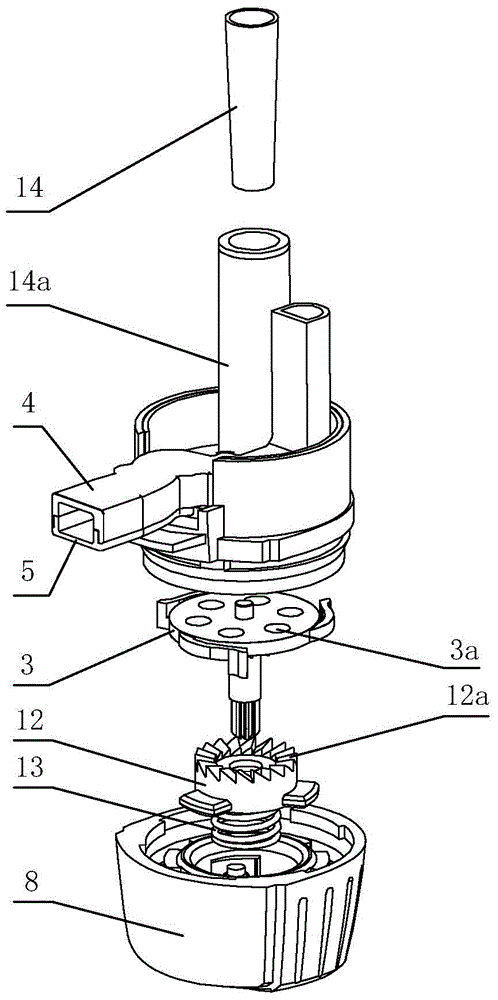

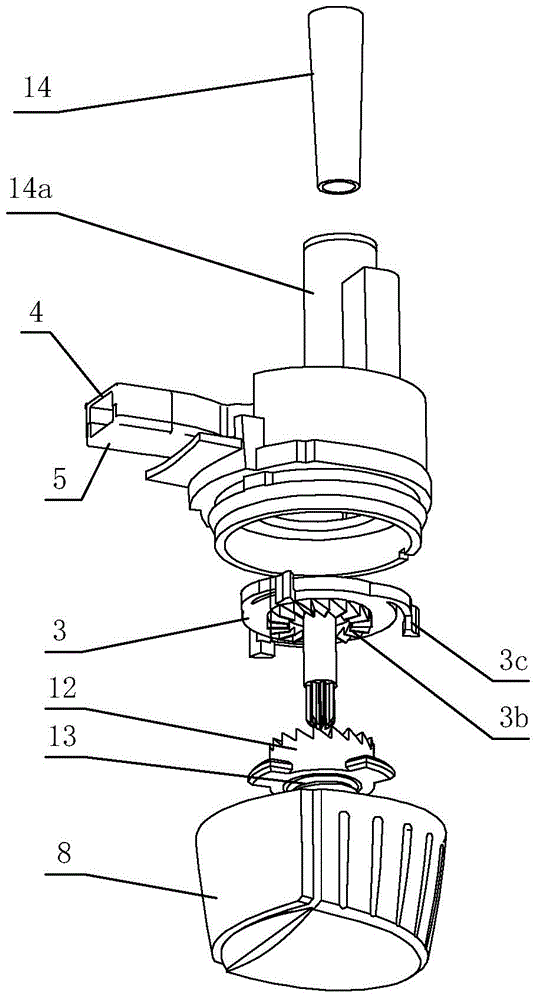

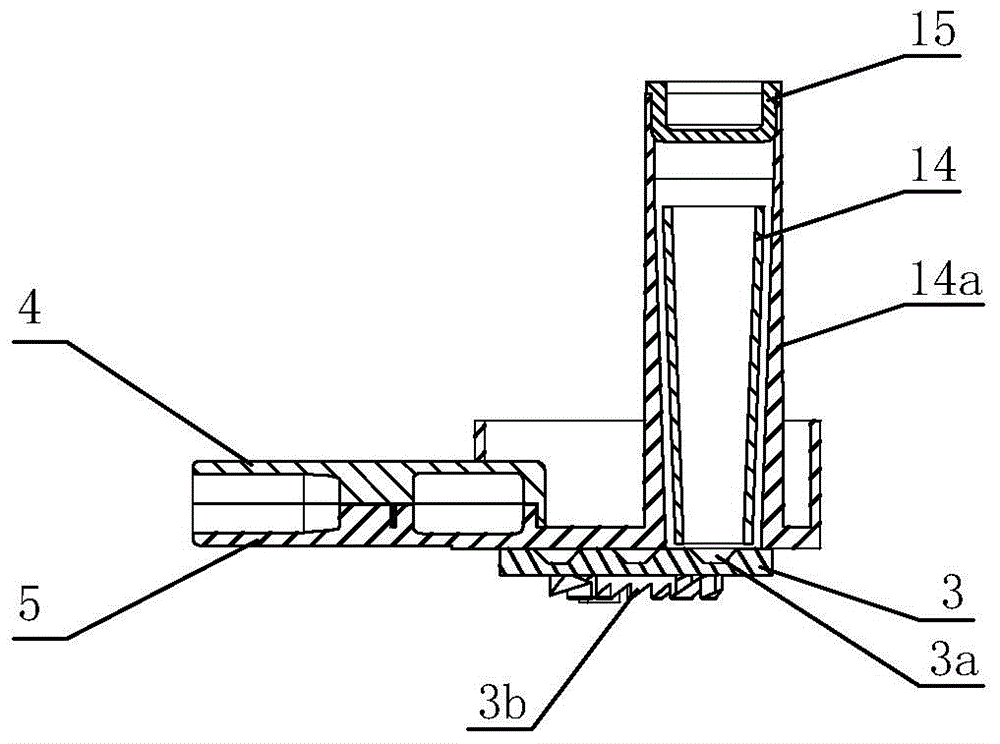

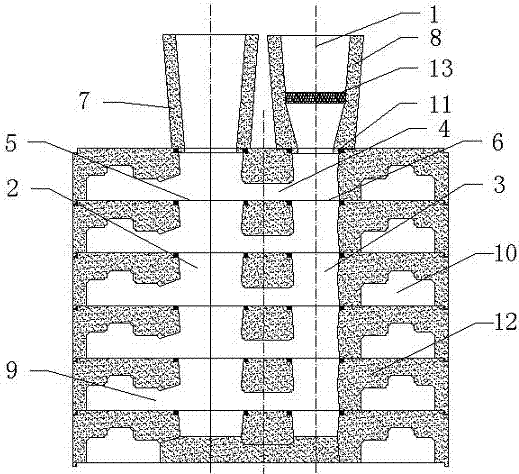

Vibrating medicine storage unit for dry powder inhalation dosing device

The invention relates to a vibrating medicine storage unit for a dry powder inhalation dosing device and belongs to the field of inhalation type dosing instruments. A turning cover, a spring, a vibration gear, a turntable and an external medicine drum arranged on a flow channel lower component form the vibrating medicine storage unit for the dry powder inhalation dosing device. While impact vibration is performed on a medicine powder storage container of the medicine storage unit, a second vibrating component, namely an internal medicine drum, which can synchronously freely vibrate, is also arranged in the medicine powder storage container, so as to perform compound vibration on medicine powder in the medicine powder storage container, so that the metering accuracy of the medicine powder dose provided by the medicine storage unit in the process of medicine dosing by the whole dry powder inhalation dosing device each time is guaranteed better, the mechanical structure design change workload needed for the variation of varieties of filling medicine powder can also be reduced, and the good adaptability of the dry powder inhalation dosing device for the powder medicine varieties in a large range is improved. The vibrating medicine storage unit can be widely suitable for the fields of design and manufacture of dry powder inhalation dosing devices of various specifications.

Owner:SHANGHAI CHENPON PHARMA TECH

A casting multi-layer pouring system and process

InactiveCN104985128BImprove efficiencyImprove utilizationFoundry mouldsFoundry coresThermodynamicsProcess engineering

The invention discloses a casting multi-layered pouring system and process, which is characterized in that: the pouring system is multi-layered and stacked respectively, the pouring system is respectively provided with a riser channel and a sprue, each layer of the pouring system, a riser The upper and lower ends of the sprue and the sprue are respectively provided with a riser and a gate. The top riser and the gate of the gating system are respectively fastened with a riser cup and a sprue cup. The riser and the gate at the lower end of each layer of the gating system are respectively tight. Set on the riser and gate at the upper end of the gating system of the next layer, the riser and gate at the bottom of the gating system are sealed separately, a horizontal runner is provided between the riser channel and the sprue, and a The ingate, the runner leads to the ingate, and the ingate communicates with the cavity of the product sand model. The present invention casts multi-layer product sand mold cavities by setting a multi-layer pouring system, improves the production efficiency of castings, shortens the pouring time, ensures the composition and temperature balance of multi-layer pouring molten iron, and guarantees the quality of pouring products.

Owner:HUBEI YAGANG METAL MFR

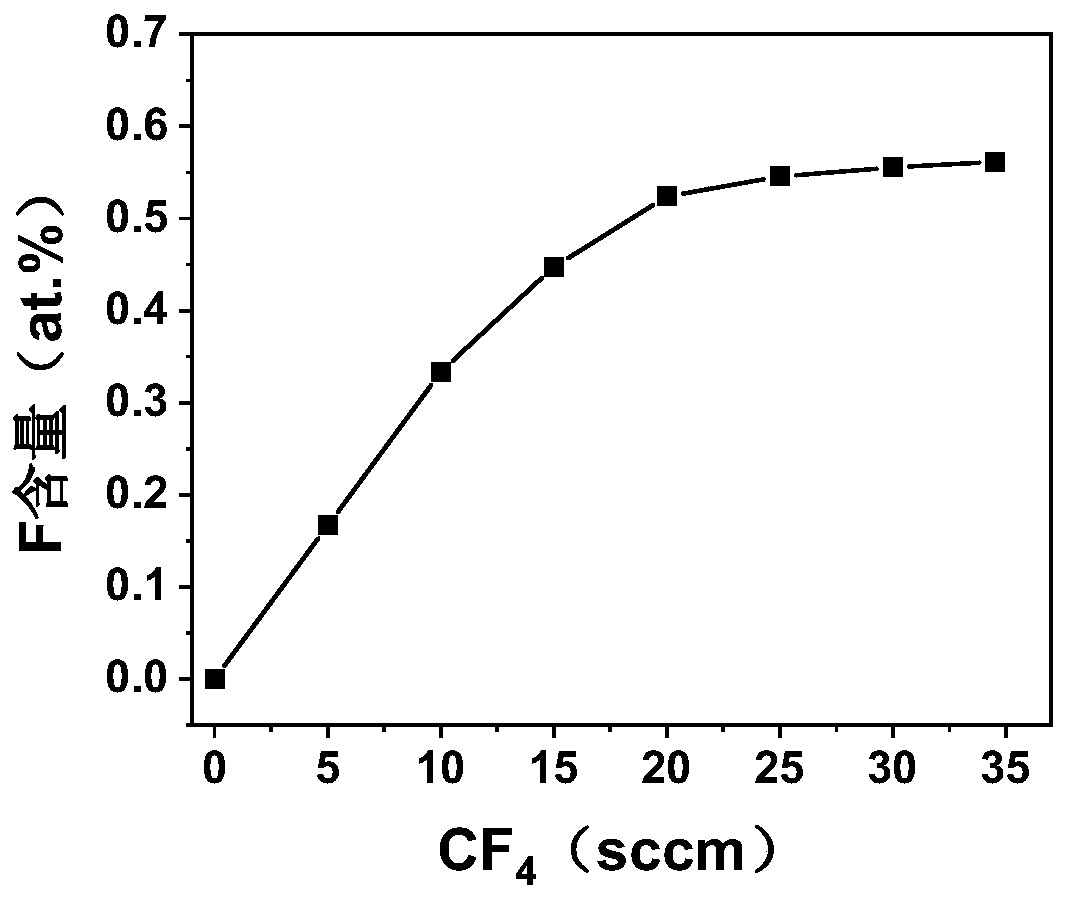

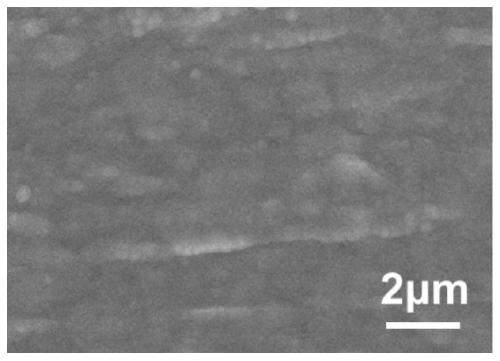

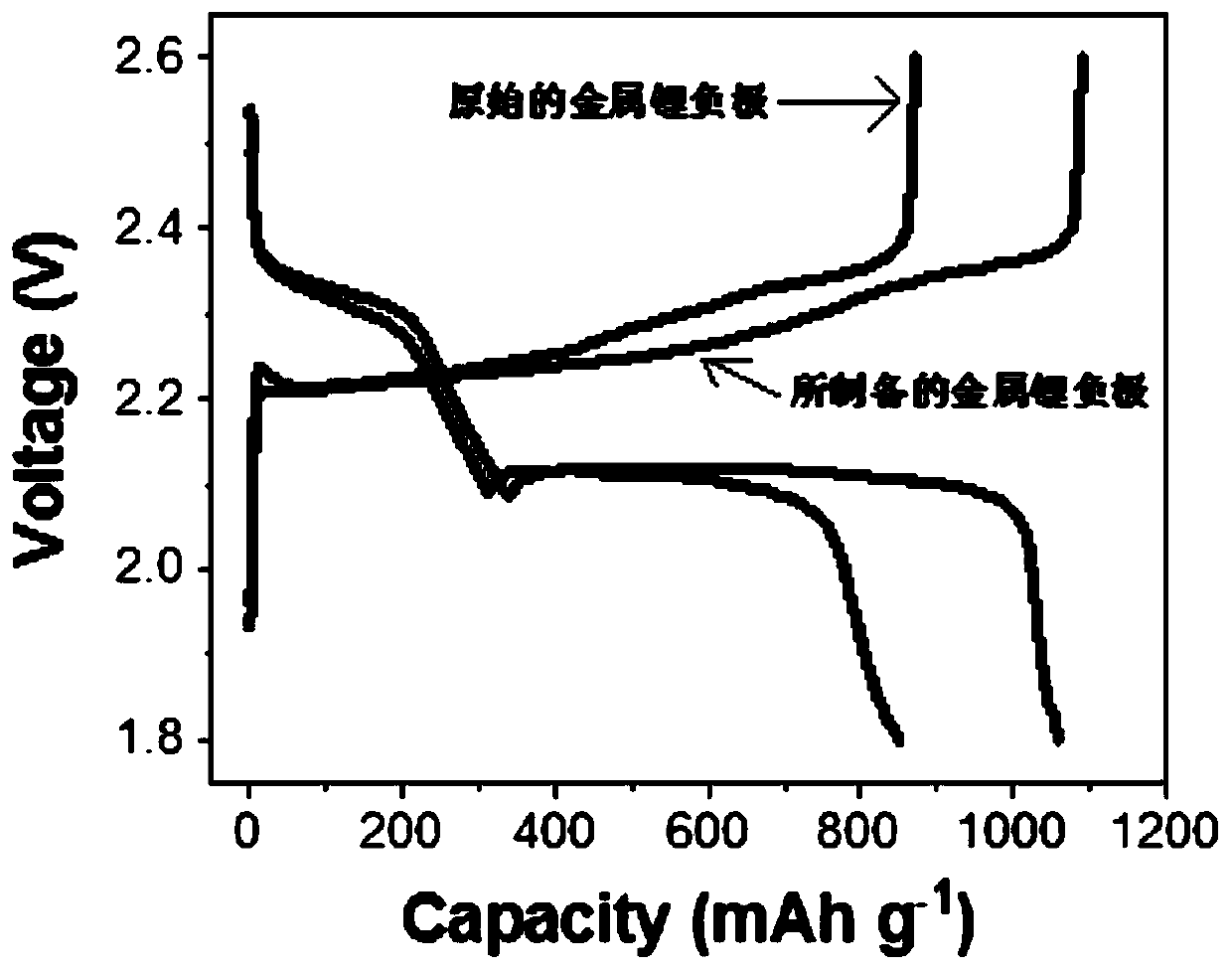

Preparation method of metal lithium negative electrode, metal lithium negative electrode, battery and application

InactiveCN111430713AUniform compositionInhibit corrosion reactionFinal product manufactureLi-accumulatorsMetallic lithiumElectrical battery

The invention provides a preparation method of a metal lithium negative electrode, the metal lithium negative electrode, a battery and an application, wherein the preparation method of the metal lithium negative electrode comprises the steps of depositing a carbon fluoride film layer on the surface of a metal lithium sheet by utilizing a direct-current pulse plasma vapor deposition method, etc. According to the preparation method of the metal lithium negative electrode, the protective layer is formed on the surface of the metal lithium sheet to form the stable metal lithium negative electrode,the lithium negative electrode does not easily generate dendrites in the charging and discharging process, the potential safety hazards are avoided, and the metal lithium negative electrode has the excellent cycle performance.

Owner:TIANMU LAKE INST OF ADVANCED ENERGY STORAGE TECH CO LTD

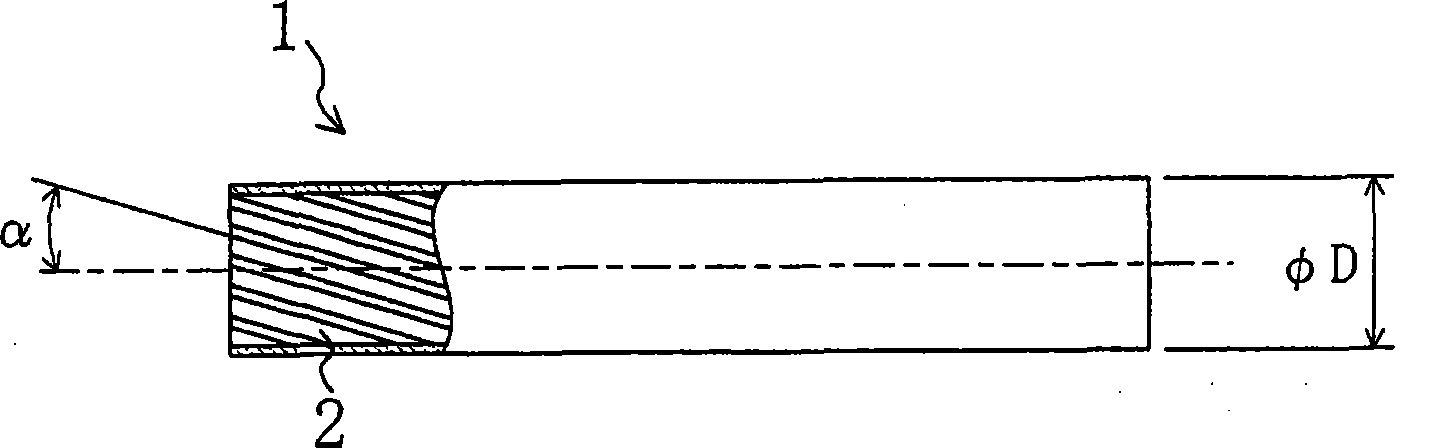

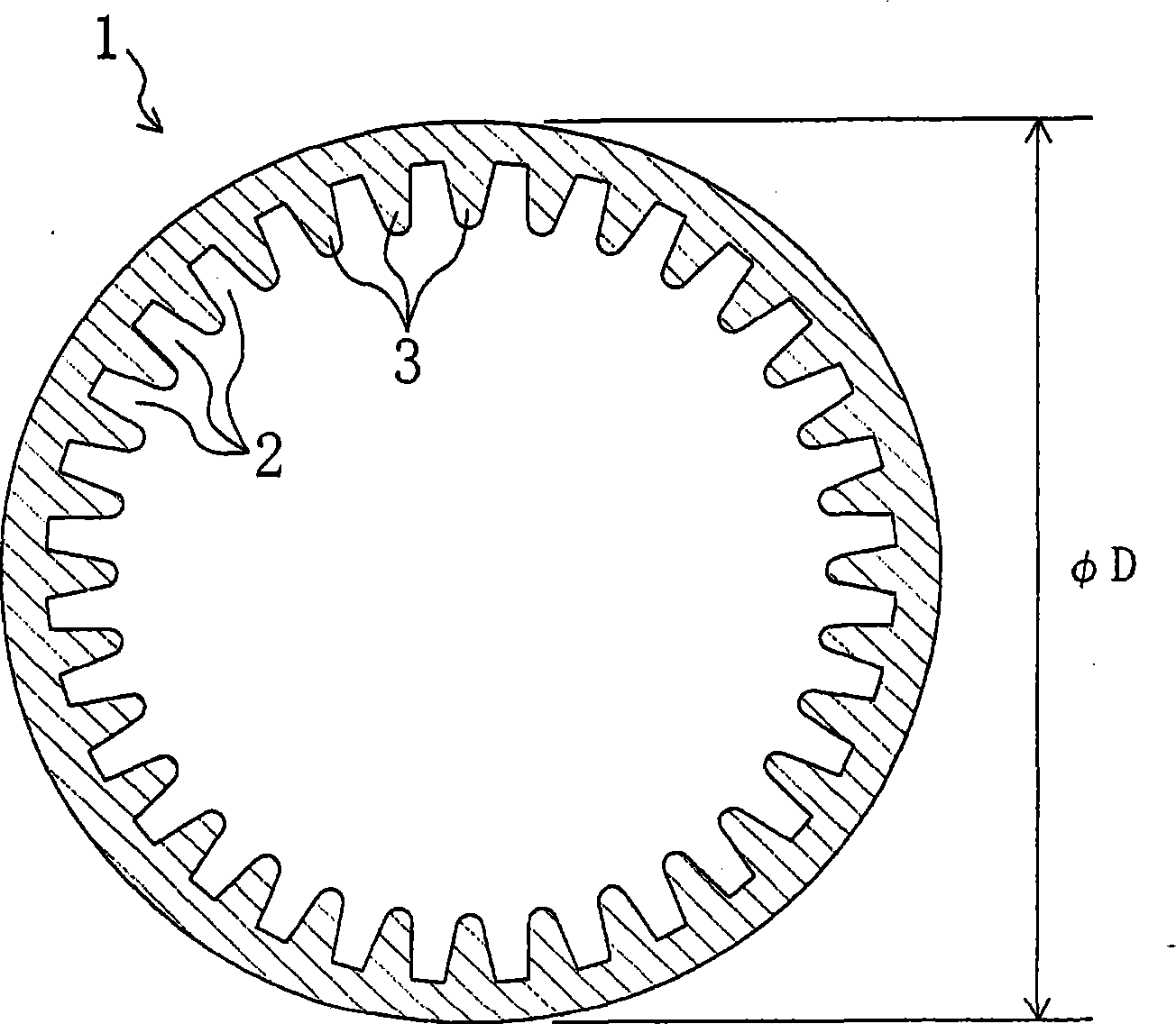

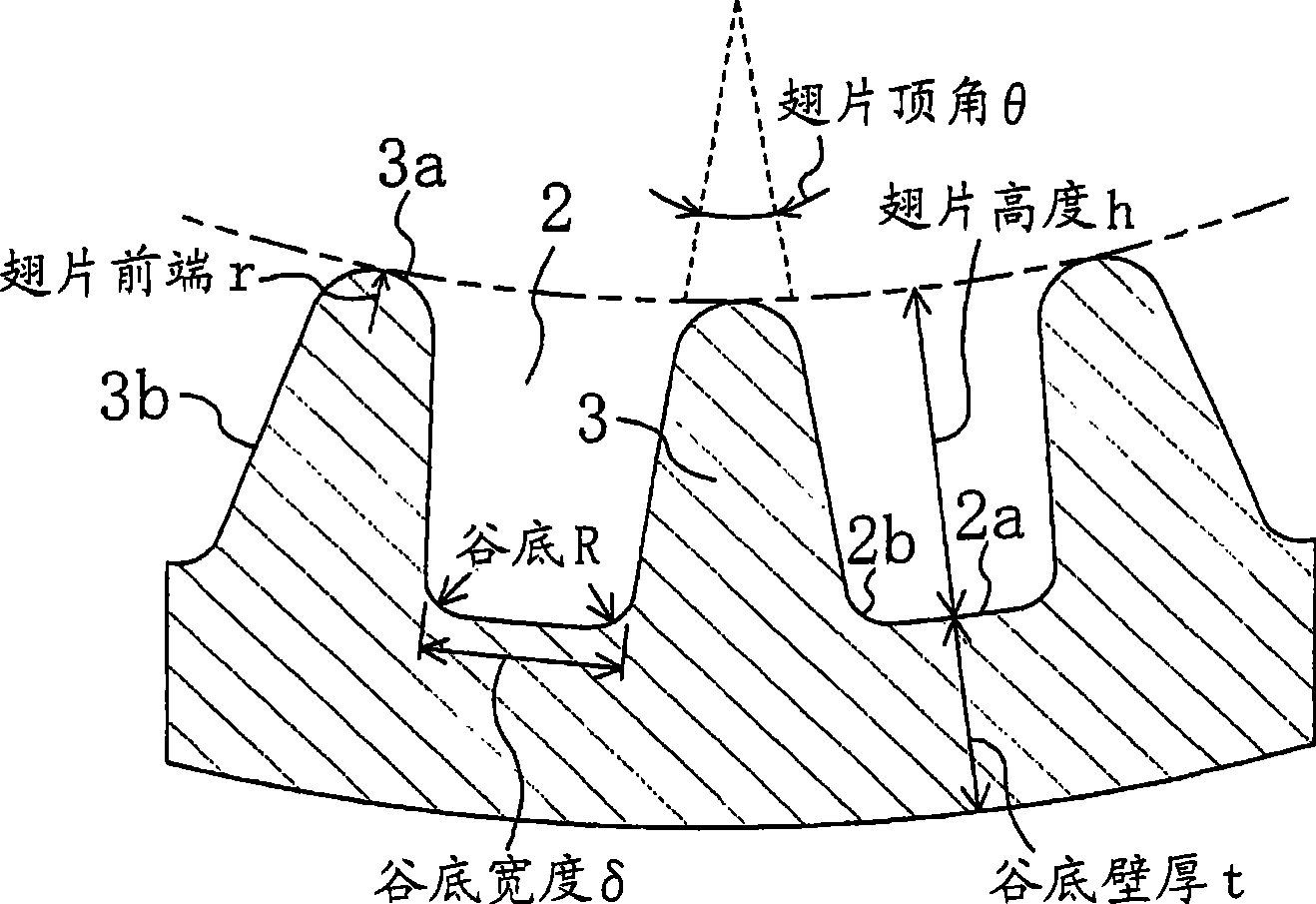

Tube with grooves on inner surface and its manufacturing method, and fluted plug

InactiveCN101416016AImprove reliabilityReduce liquidityDrawing mandrelsTubular elementsEngineeringRidge

The invention provides a tube with grooves formed in an inner surface thereof, a method of producing the tube and a grooved plug. The tube having grooves formed in its inner surface. The grooves are formed in a reverse trapezoidal cross section, and the corners at the root of each groove have a circular arc shape and the ratio (R / delta) of the radius R (mm) of each corner to the width delta (mm) of the groove is not less than 0.10 and not more than 0.25. A grooved plug having ridges and grooves formed on the outer peripheral surface of the plug is inserted into a blank tube, and the outer peripheral surface of the blank tube is pressed. This causes a blank tube material to flow into the grooves of the plug to form grooves in the inner surface of the blank tube. In this process, the blank tube material can easily flow into the grooves of the plug, so that cracks of the grooves and fins can be prevented.

Owner:DAIKIN IND LTD

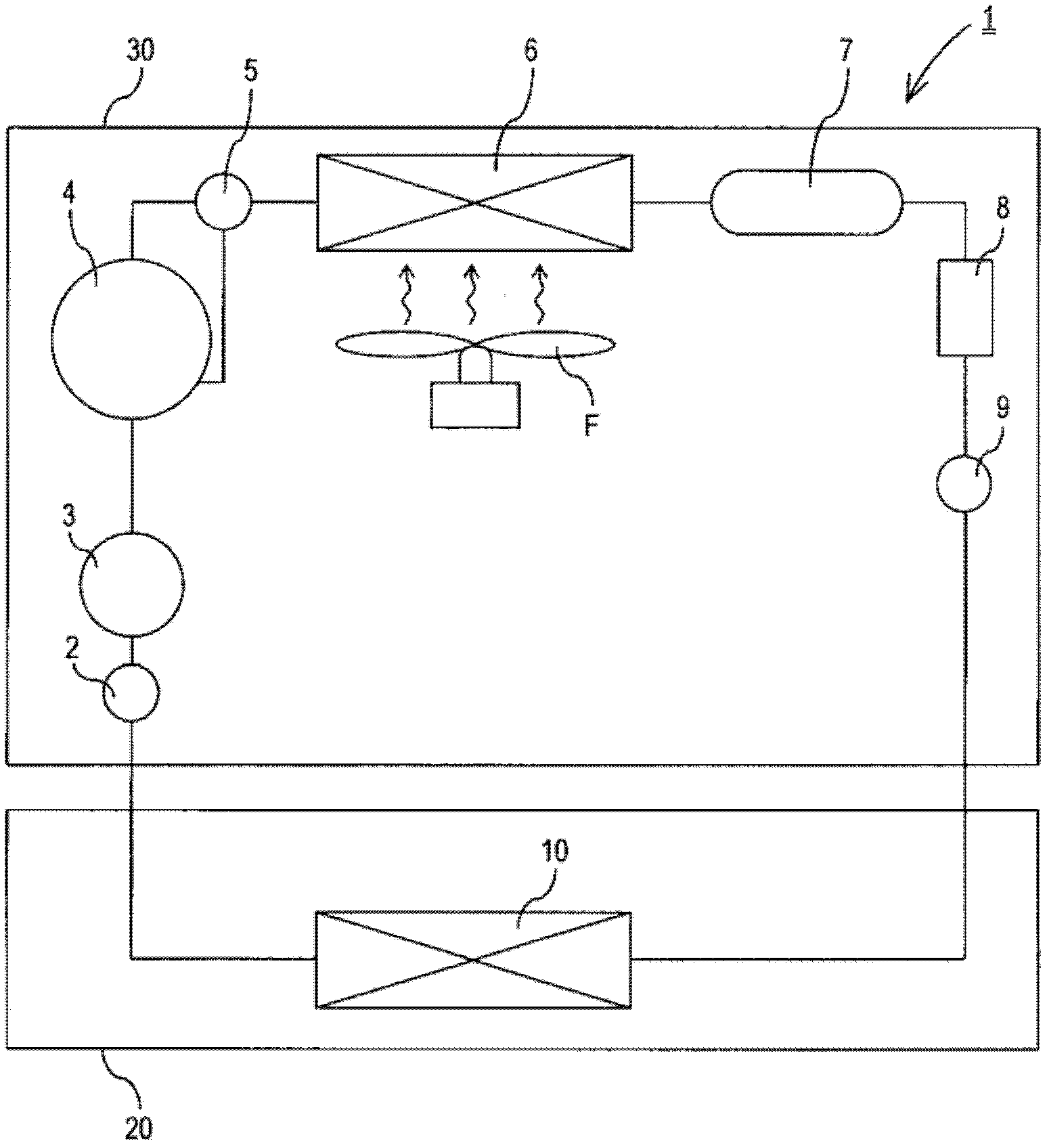

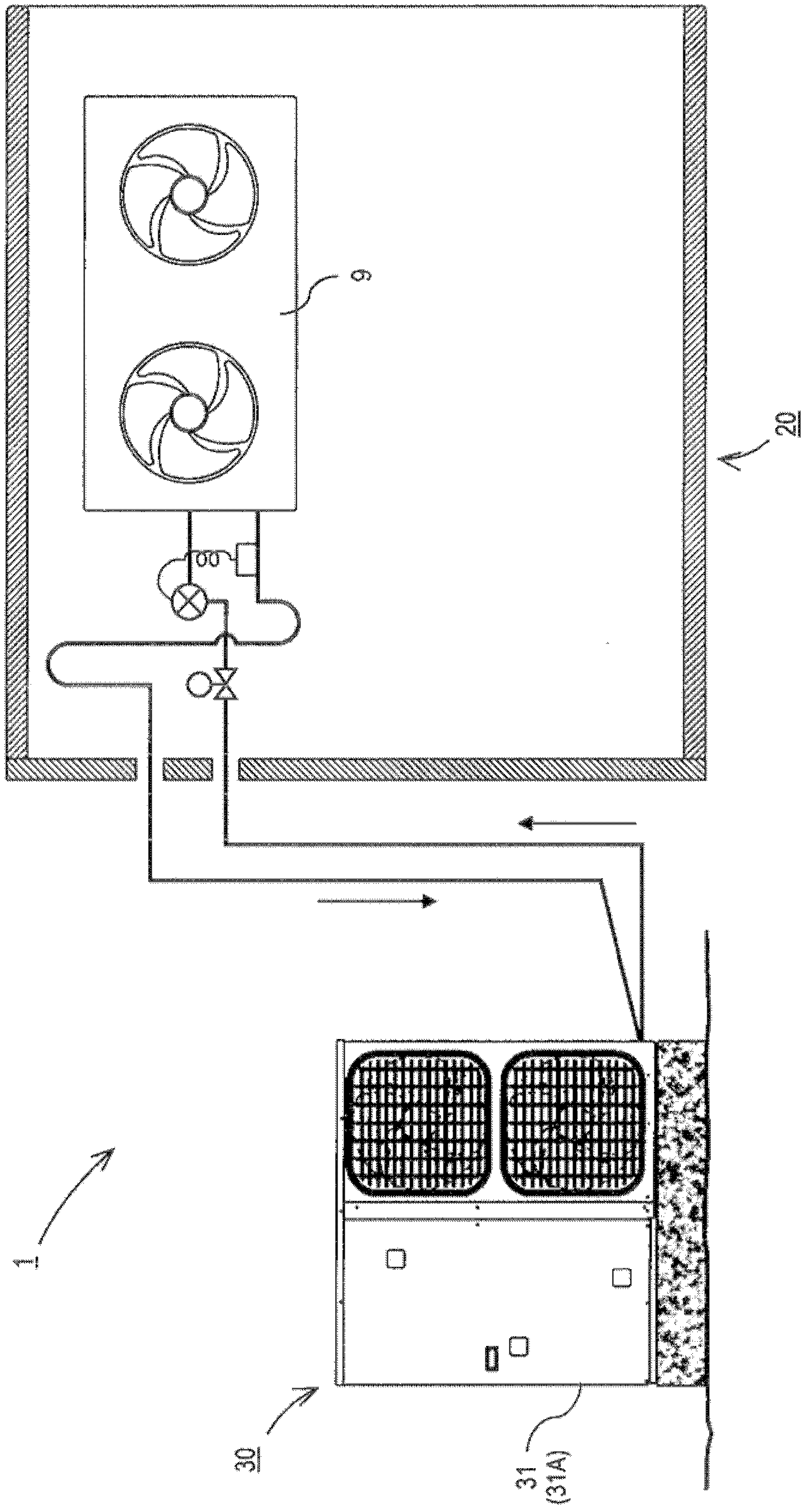

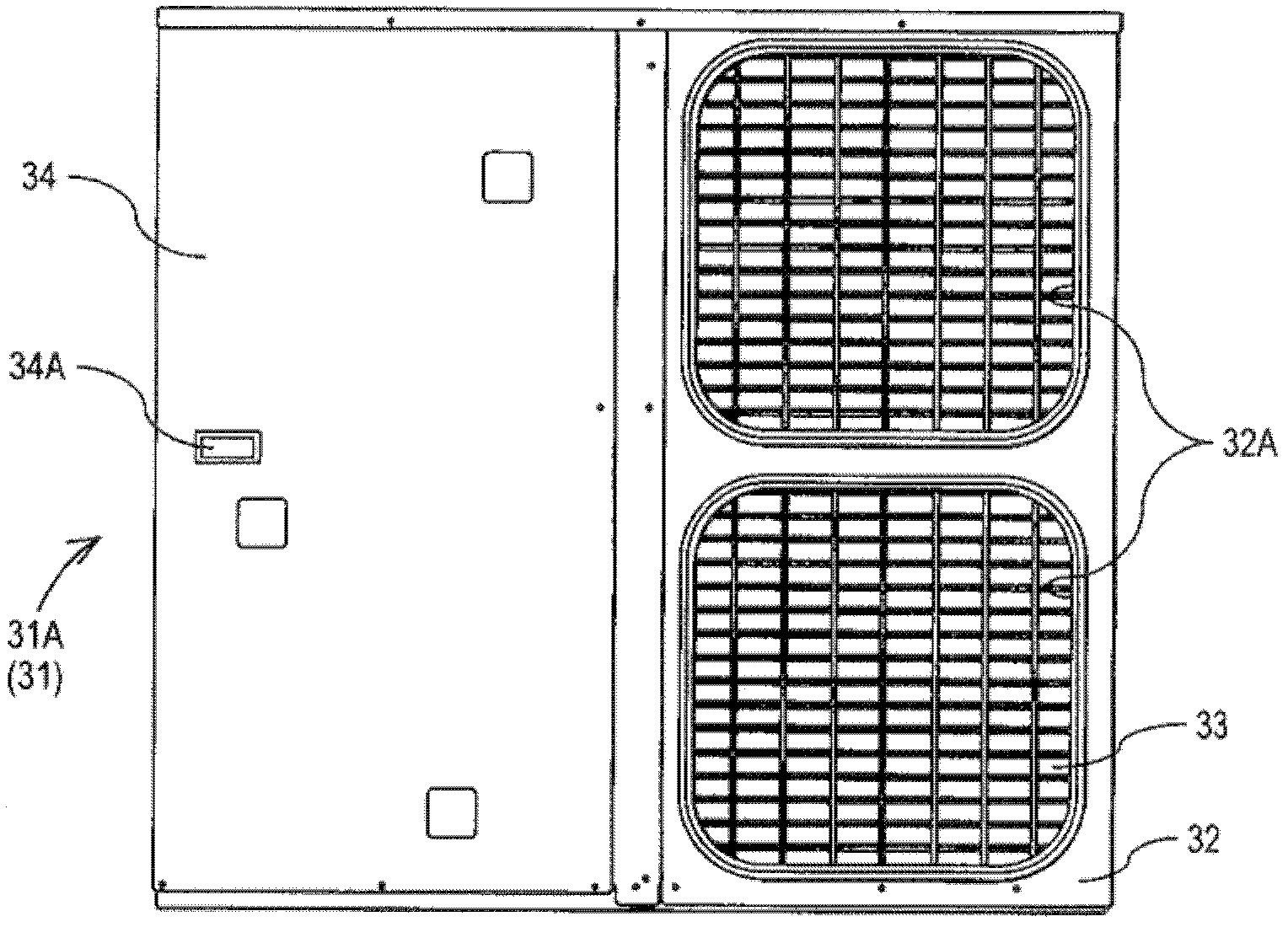

Outdoor unit and refrigerating device

InactiveCN102759212ADoes not lead to largeImprove cooling effectCompression machines with non-reversible cycleElectricityEngineering

The invention provides an outdoor unit and a refrigerating device. The heat dissipation effect can be achieved with low cost and without upsizing of a shell even a special heat dissipation device is not installed additionally. The inside of the shell (31) is provided with a fan chamber (A) which comprises an evaporator (10) and fans (F) for cooling the evaporator, a mechanical chamber (B) which at least comprises a compressor (4) and an accumulator (3), and an electric fitting chamber which is disposed in the upper space of the upper side of the mechanical chamber across a rack and receives various electric fitting components including a converter used for controlling operation of the compressor. The mechanical chamber and the electric fitting chamber are isolated from the fan chamber through a separator horizontally; external air sucked in from an external air suction hole disposed in a back panel of the shell and is an area facing the accumulator is cooled and flows out to the fan chamber through a rainproof exhaust part of the separator after finally flowing through the converter disposed in the innermost part of the electric fitting chamber.

Owner:SANYO ELECTRIC CO LTD

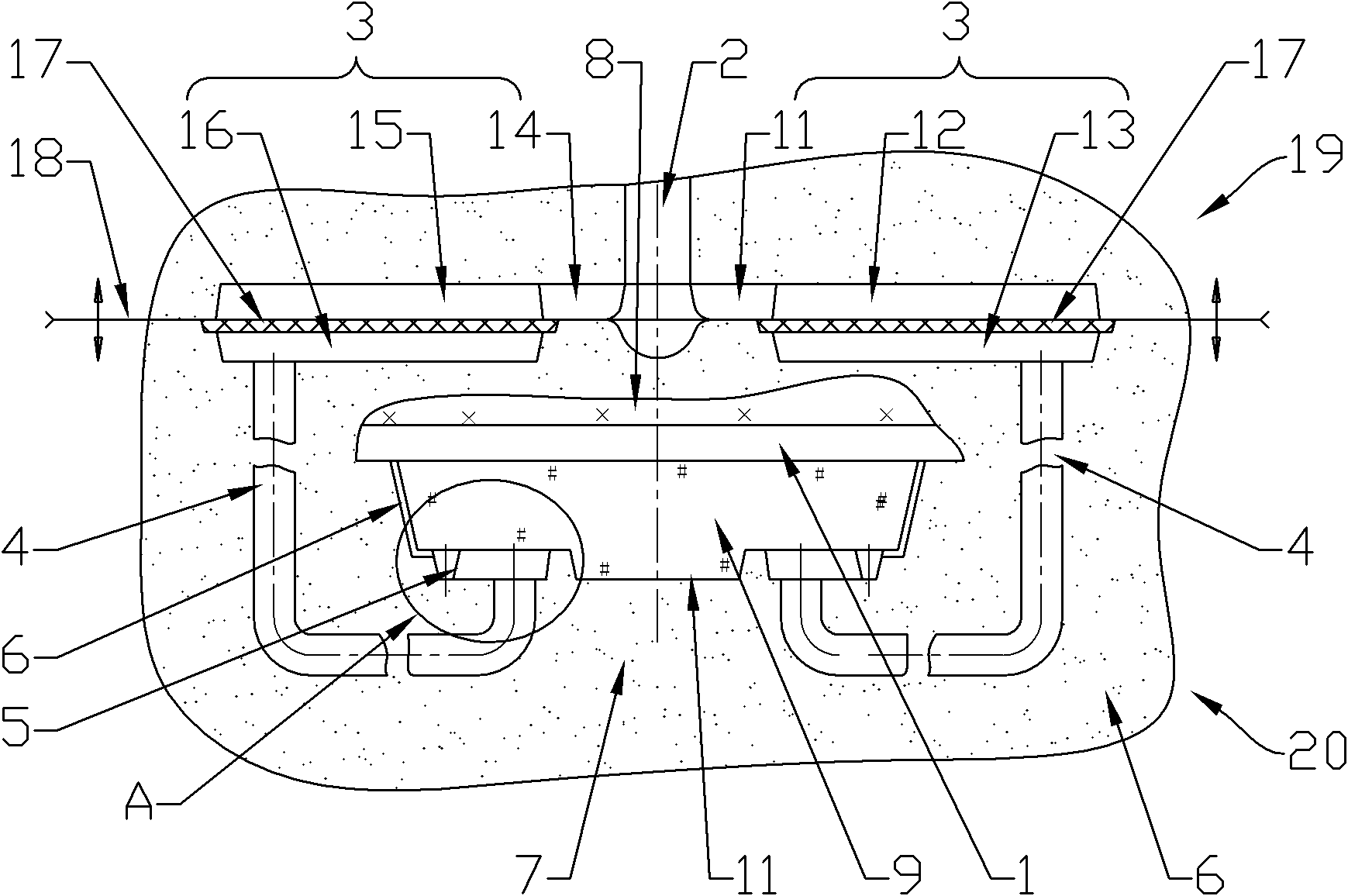

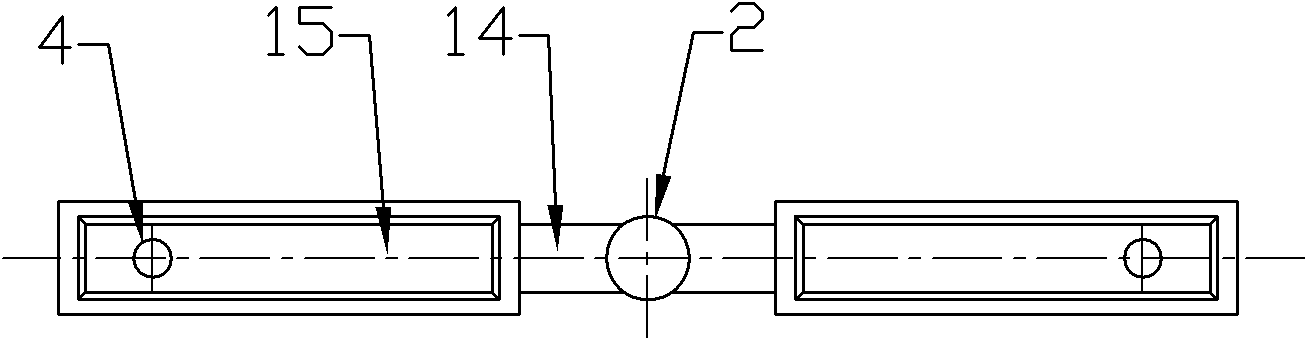

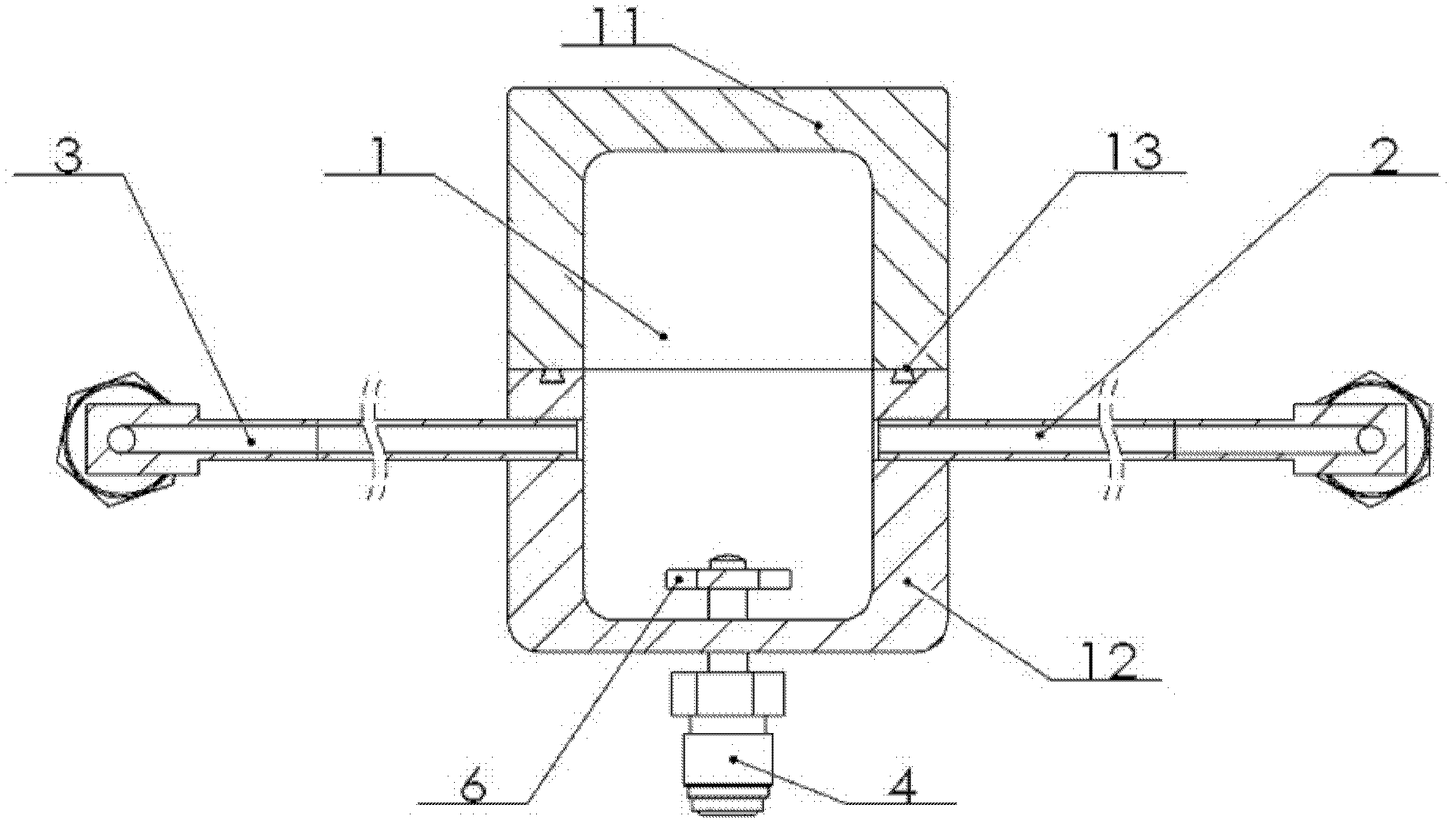

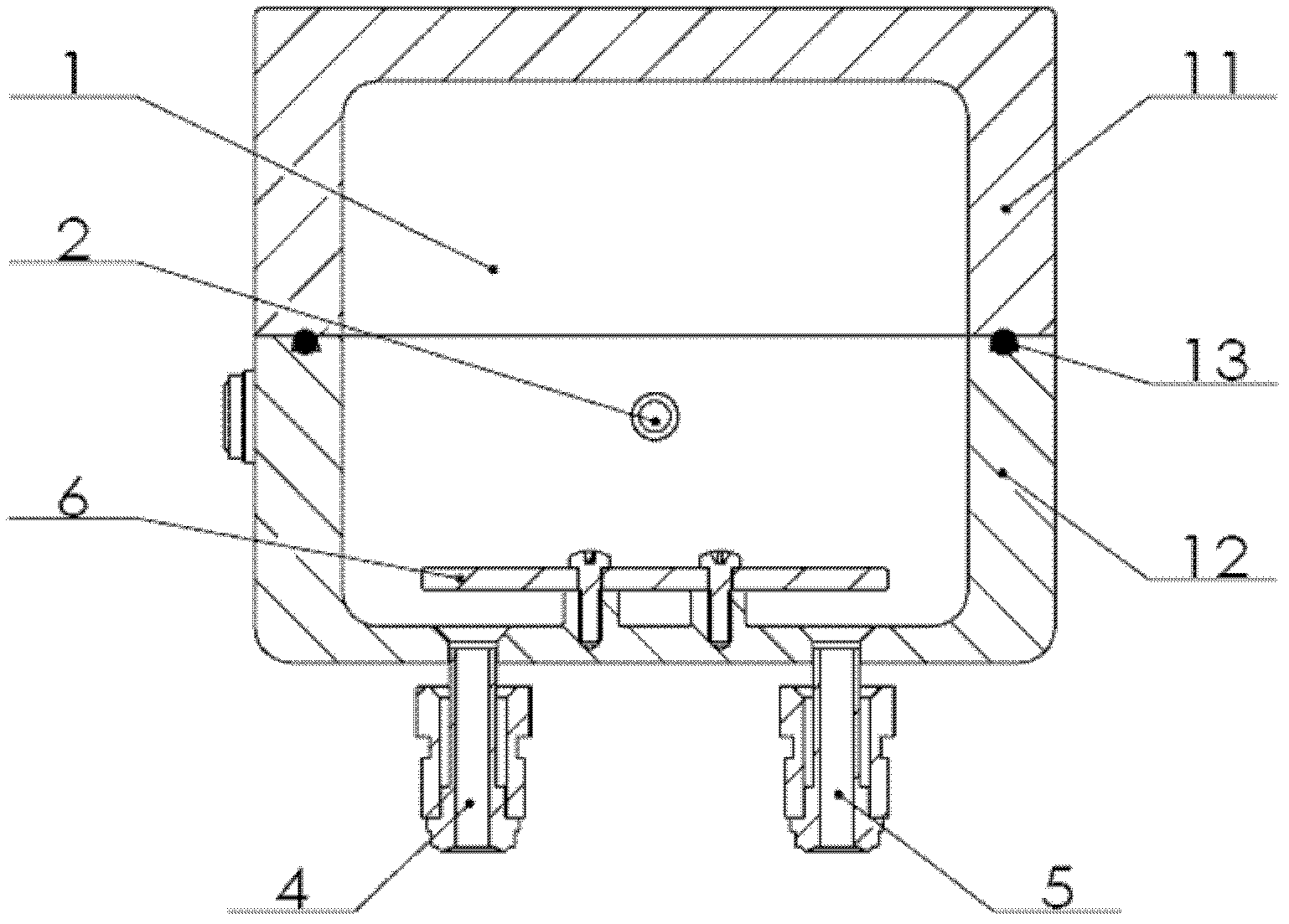

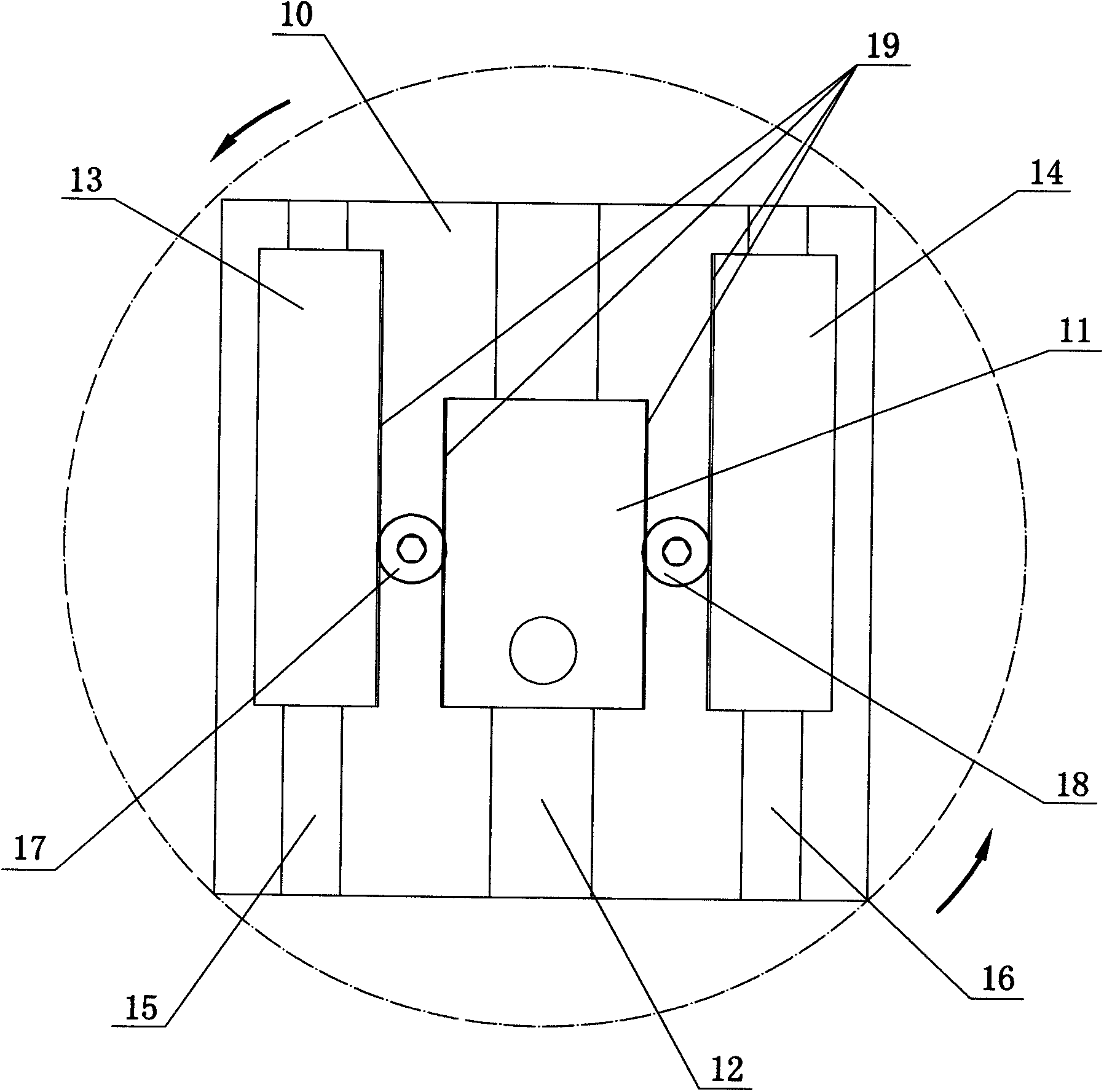

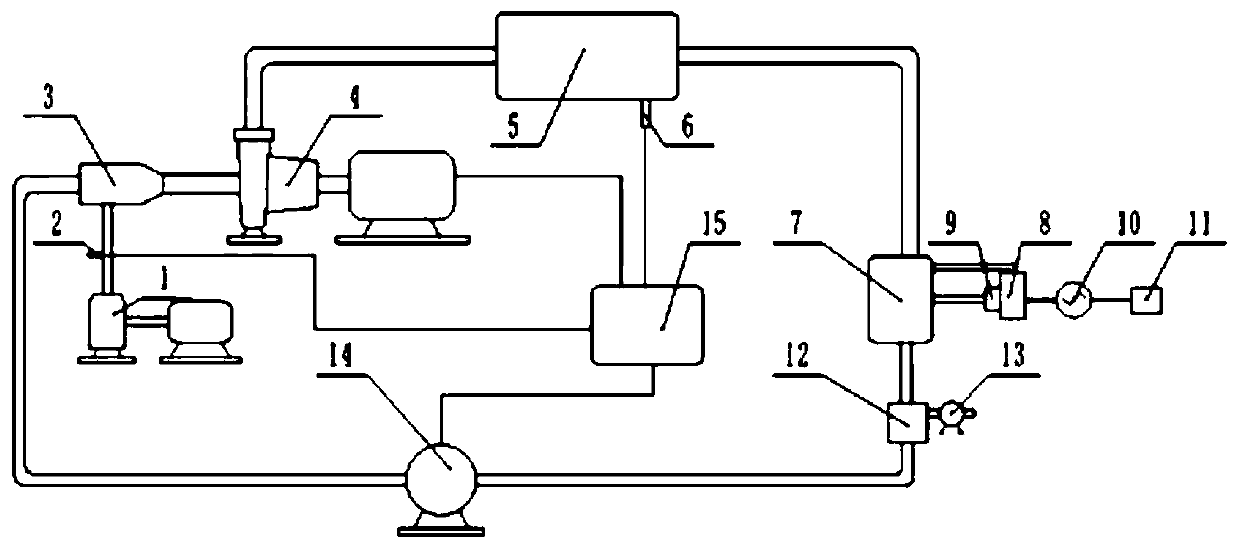

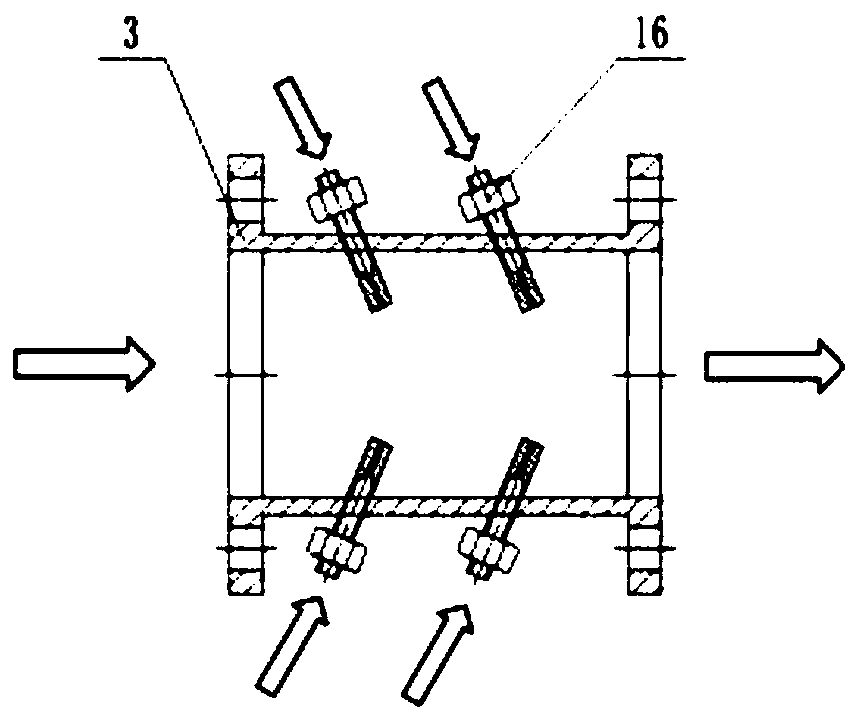

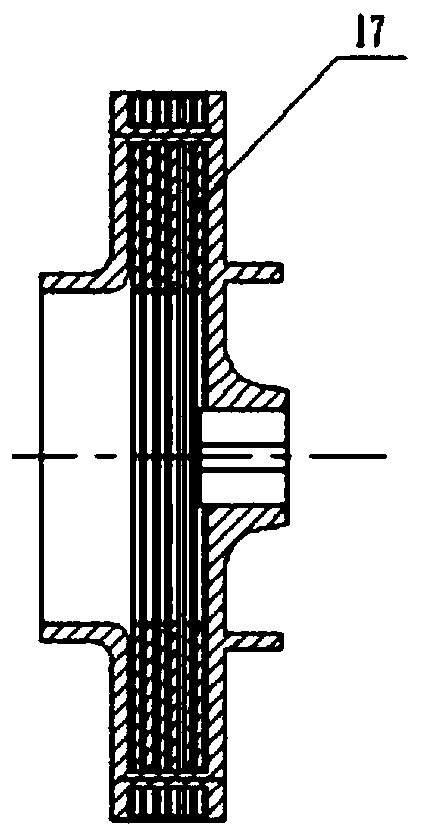

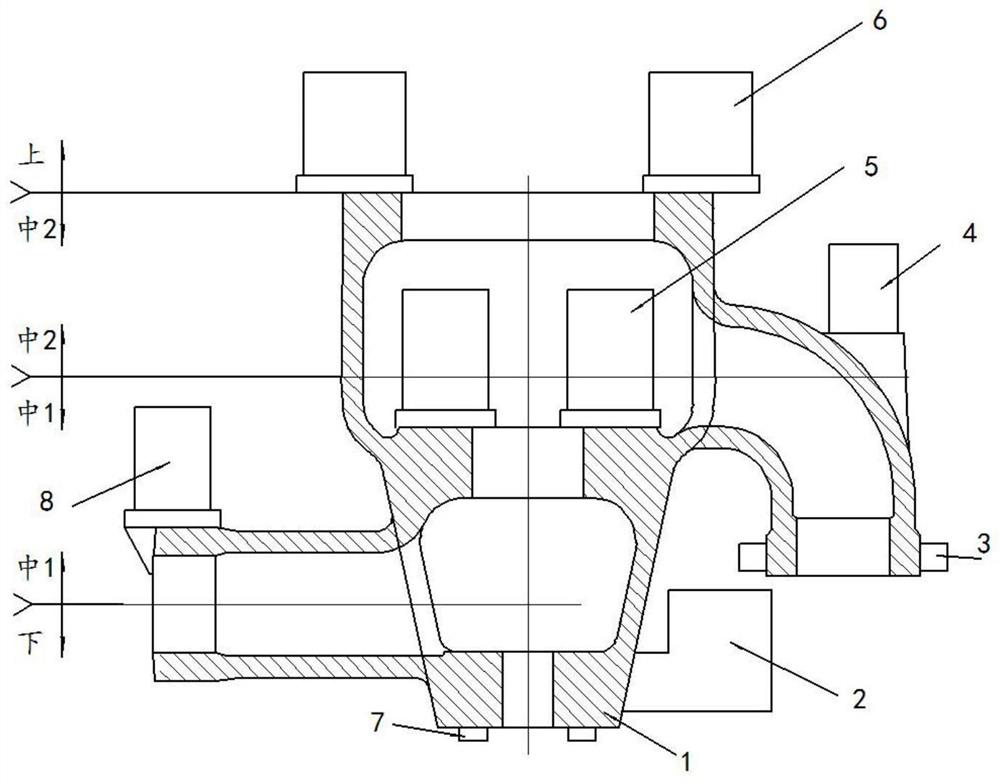

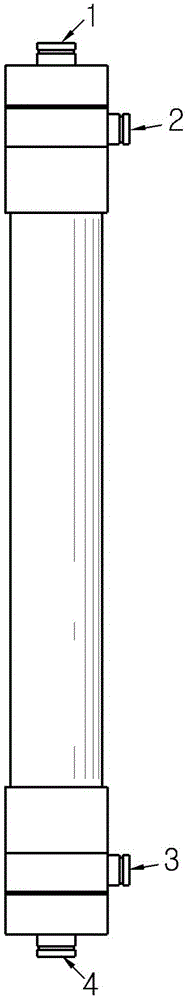

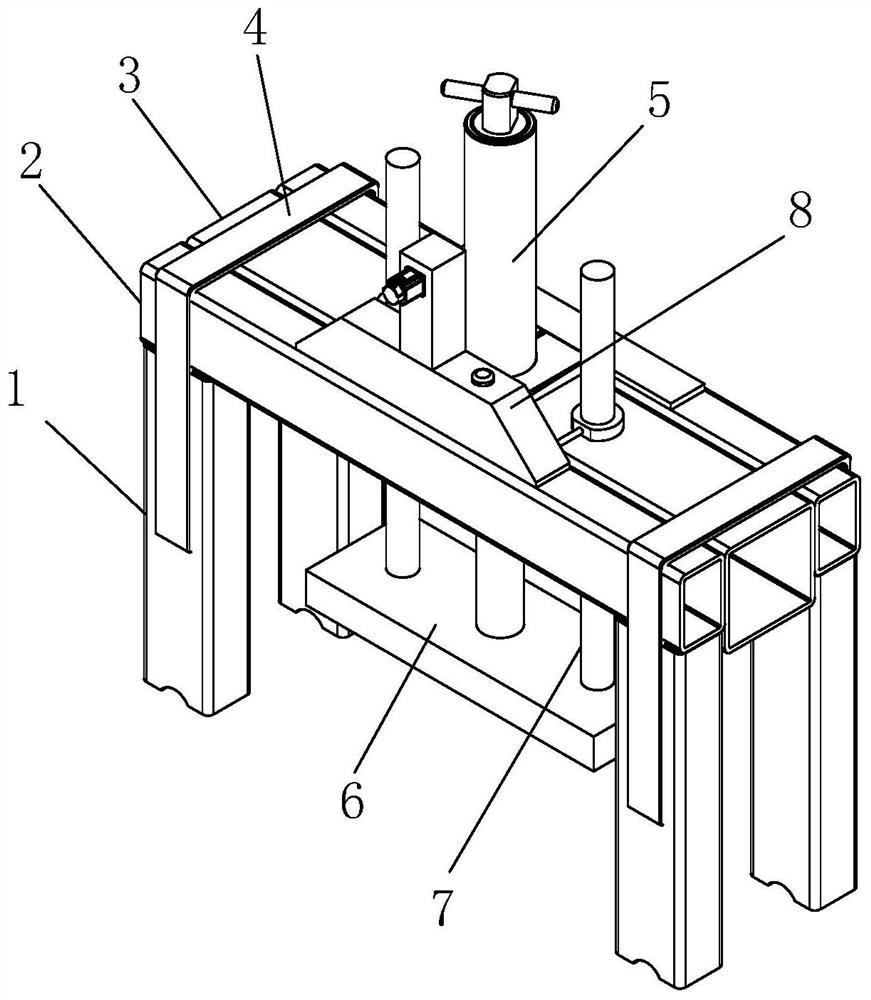

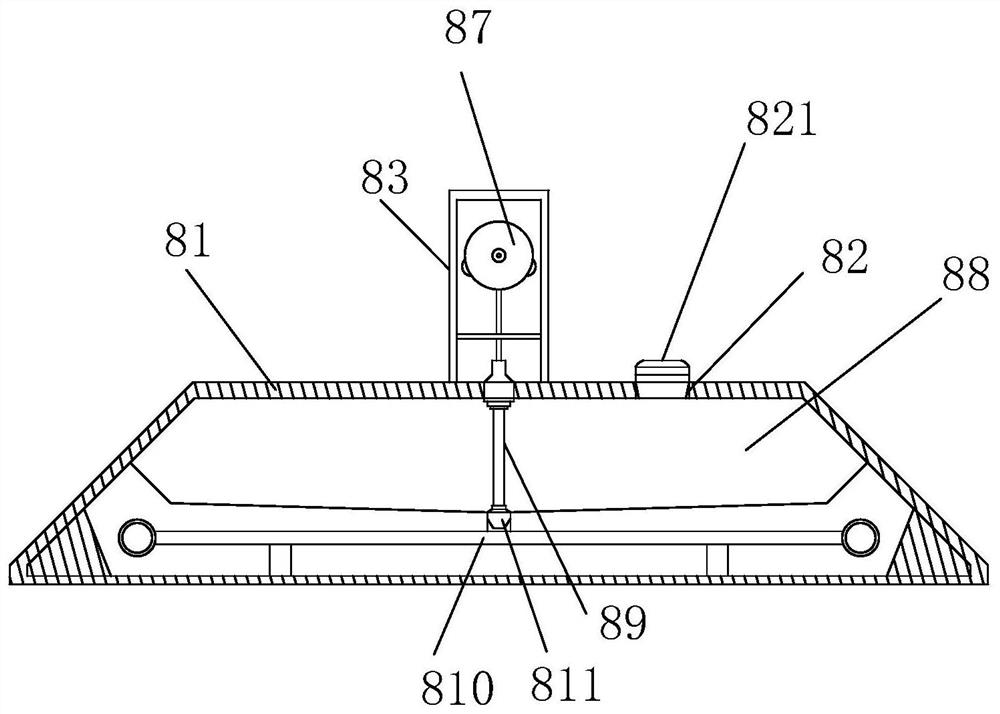

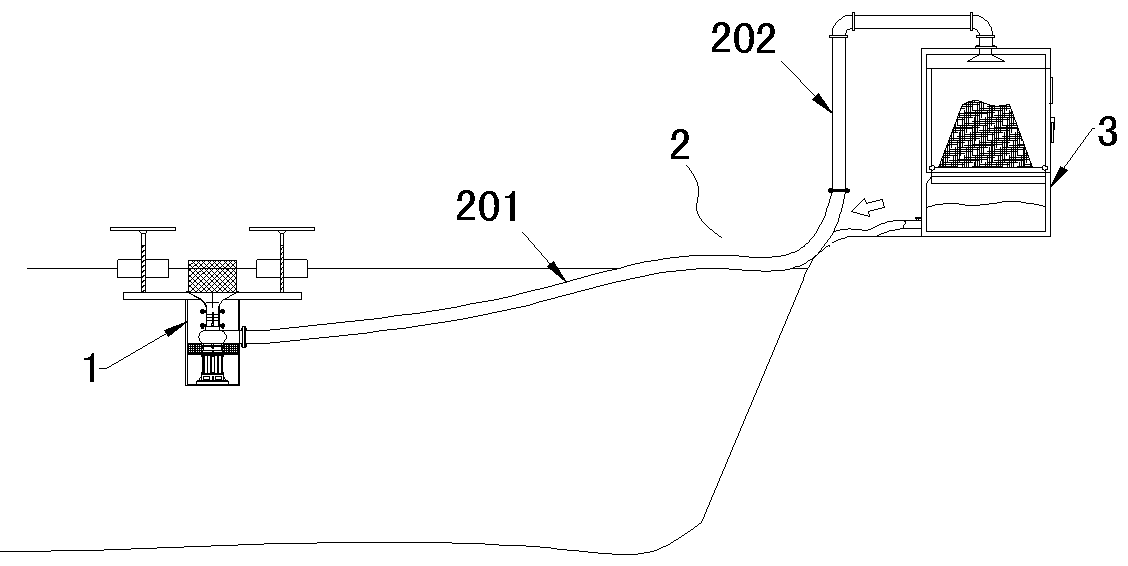

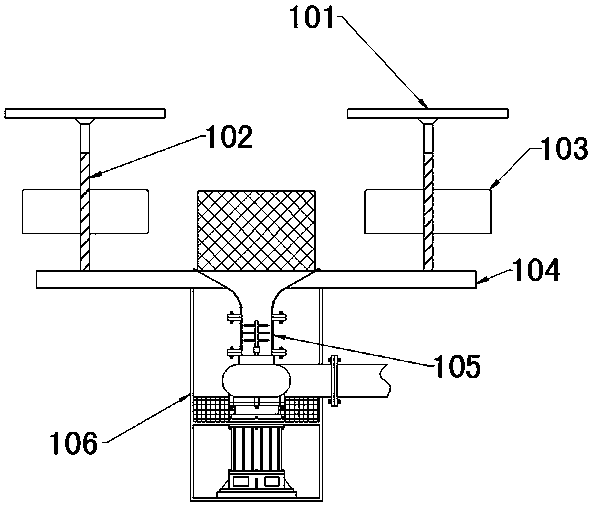

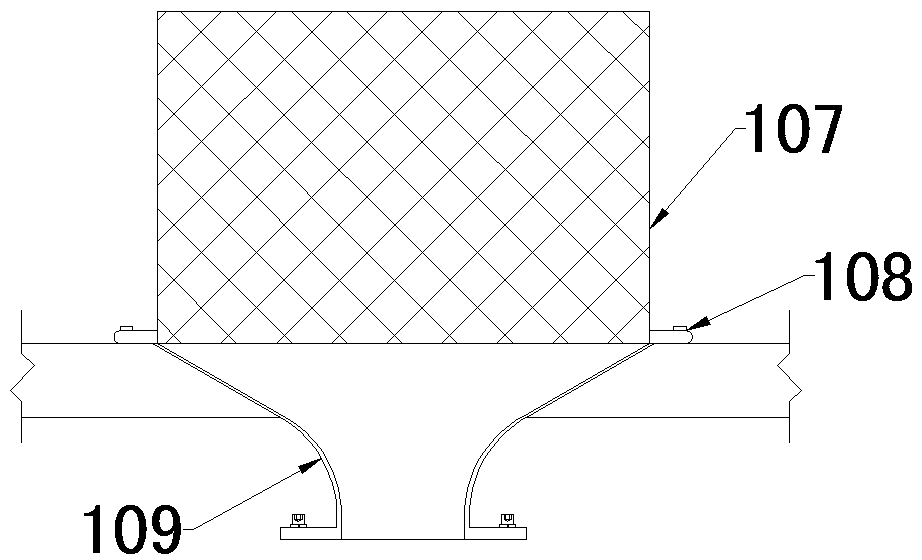

Universal centrifugal pump wear ring test bed

ActiveCN106678056ASmooth inflowAvoid interferencePump controlNon-positive displacement fluid enginesEngineeringCentrifugal pump

The invention discloses a universal centrifugal pump wear ring test bed comprising a wear ring test unit, a fluid medium supply unit, a leaking liquid collection unit and a test table. The fluid medium supply unit, the wear ring test unit and the leaking liquid collection unit are installed on the test table. The fluid medium supply unit communicates with an inlet of a seal cavity of the wear ring test unit. An outlet of the seal cavity of the wear ring test unit communicates with the leaking liquid collection unit through a pipeline. The universal centrifugal pump wear ring test bed has the beneficial effects that the universal centrifugal pump wear ring test bed can be suitable for measuring leaking amounts of wear rings of different wear ring gaps, different wear ring lengths and different wear ring types; and operation is quite convenient, only the test wear rings need to be replaced when experiments are done on different samples, and most structures do not need to be detached. Measurement results are accurate, the medium leakage amounts are accurately measured through complete sealing of a rotor part and the difference method, the experiment precision is greatly improved, and reliability of the results is ensured.

Owner:ZHEJIANG UNIV OF TECH

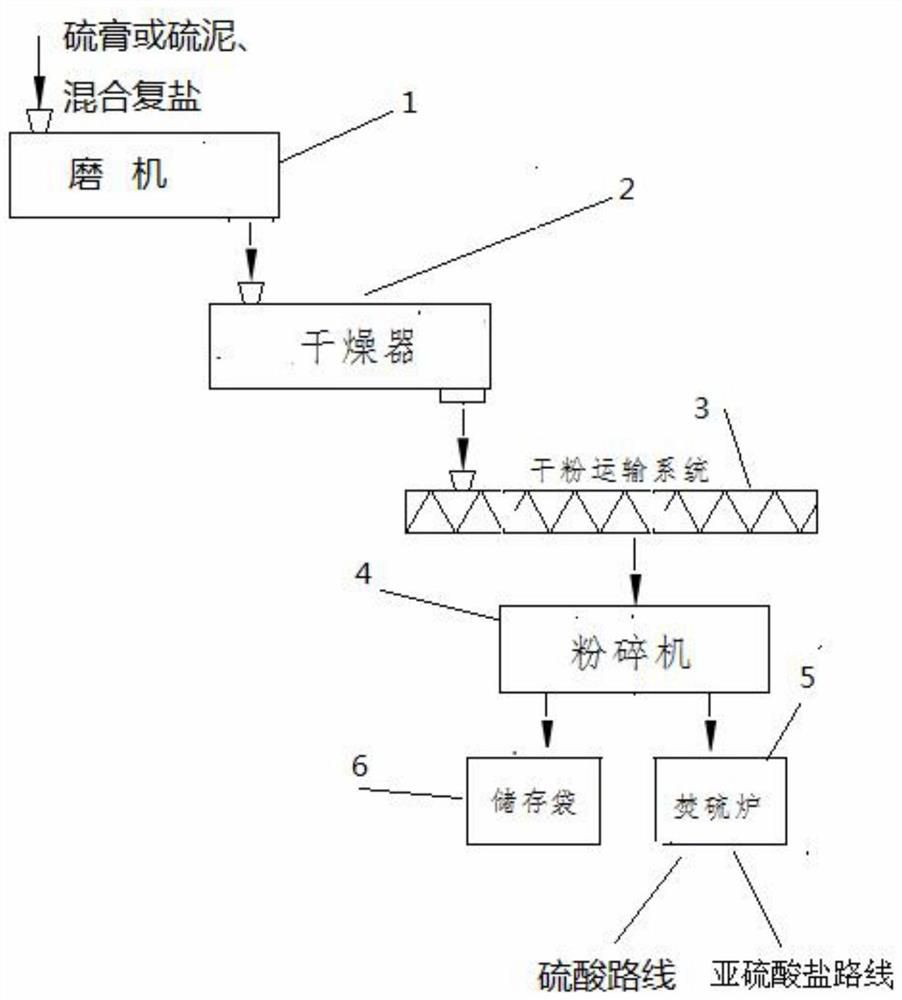

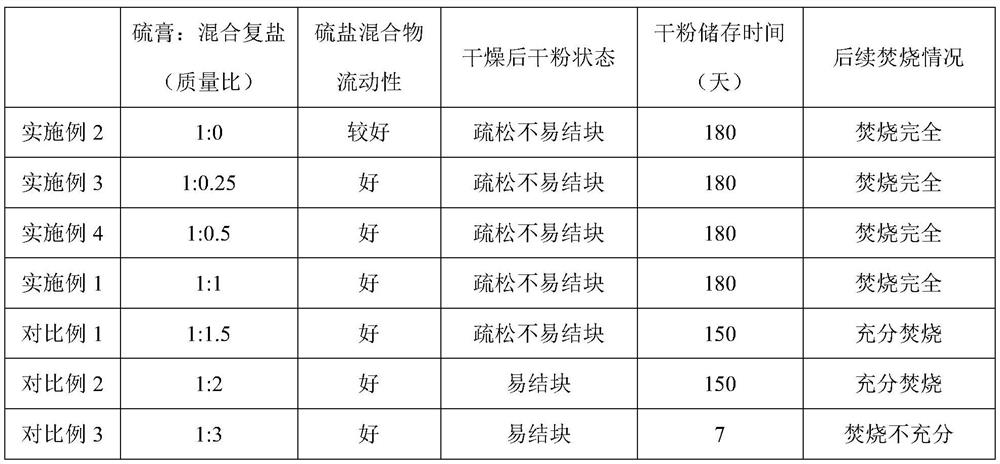

Treatment method of desulfurization solid waste

PendingCN112238126AHigh yieldEnergy saving and emission reduction recyclingSolid waste disposalTransportation and packagingDouble saltEnvironmental chemistry

The invention discloses a treatment method of desulfurization solid waste. The treatment method comprises the following steps that a, sulfur paste or sulfur mud is taken to be mixed with mixed doublesalt to obtain a sulfur salt mixture; b, a sulfur-fixing agent is added into the sulfur salt mixture obtained in the step a, water is added, uniform stirring is carried out to obtain a sulfur salt mixed slurry; c, drying treatment is carried out on the sulfur salt mixed slurry obtained in the step b to obtain sulfur-containing powder; and d, storing or combustion treatment are carried out on the sulfur-containing powder obtained in the step c. According to the treatment method, thte sulfur paste or sulfur mud difficult to treat in a coking plant and mixed double salt can be mixed together to be treated at the same time, the solid waste problem of the coking plant is solved, the obtained sulfur-containing powder is loose, not prone to caking and free of caking after being stored for more than half a year, the sulfur-containing powder can be completely incinerated in the subsequent sulfuric acid or sulfite production process, energy conservation and emission reduction are achieved, meanwhile, the effect that resources are recycled is realized, and better economic benefits are brought to enterprises.

Owner:萍乡市新安环保工程有限公司

Energy recovery gas-liquid two-phase circulating cooling system

PendingCN111336717ASmooth inflowReduce vibration and noiseSteam engine plantsRefrigeration safety arrangementElectric energyElectric generator

The invention discloses an energy recovery gas-liquid two-phase circulating cooling system which comprises a first compressor, a gas flow controller, an atomizing pump, a cooling area, a temperature sensor, a fin tube heat exchanger, a second expansion machine, an electric generator, a storage battery, a gas-liquid separator, an air pump, a liquid delivery pump and a controller. A micropore in thesurface of the impeller outlet of the atomizing pump atomizes low temperature gas-liquid two-phase flow into a low temperature high-pressure gas-liquid mixture, and the low temperature high-pressuregas-liquid mixture can be in direct contact with the cooling area for heat dissipation; the fin tube heat exchanger absorbs the heat of high-temperature high-pressure gas-steam mixture for power generation, and the generated electric energy is stored in storage battery to be used by power generation equipment in the cooling system; after heat dissipation and pressure drop of the high-temperature high-pressure gas-steam mixture in the fin tube heat exchanger, the high-temperature high-pressure gas-steam mixture enters the gas-liquid separator; after gas-liquid separation, deionized water entersthe liquid delivery pump, the air flows into the external environment, and the operation condition of the entire system is adjusted by the controller.

Owner:JIANGSU UNIV +1

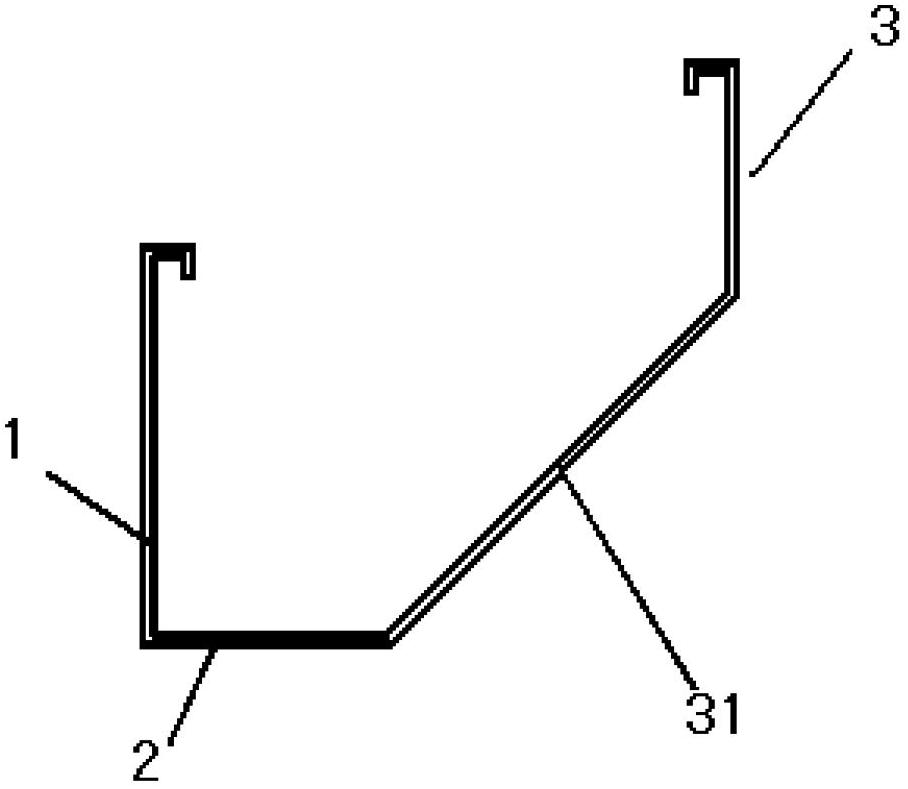

Automatic blanking manger for feeding domestic fowls

The invention relates to an automatic blanking manger for feeding domestic fowls. The automatic blanking manger is characterized in that the manger comprises a strip manger body formed by an inner baffle, a soleplate connected with the inner baffle, and an outer baffle which is arranged opposite to the inner baffle and is connected with soleplate; a tilted segment slanting inward is arranged at the joint of the lower part of the outer baffle and the soleplate; a clapboard is vertically arranged along the length direction of the manger body between the inner baffle above the tilted segment and the outer baffle; a gap is left between the bottom of the clapboard and the tilted segment; and a plurality of support plates connected with the manger body are arranged on the clapboard at intervals. The automatic blanking manger can be widely used in the feeding process of raised domestic fowls.

Owner:CHINA AGRI UNIV

Blast cooling equipment for platinum channel

ActiveCN109608023AEasy to installIncrease flexibilityForehearthsGlass furnace apparatusPlatinumAir volume

The invention discloses blast cooling equipment for a platinum channel. The blast cooling equipment is divided into two space areas including a cooling chamber and a blast chamber by semi-circular-annular air leakage bricks, ventilation holes are uniformly distributed in each semi-circular-annular air leakage brick, and a set of supporting bricks and a structure of air inlets and air outlets are installed at two modified ends. According to the equipment disclosed in the invention, after cooling air enters the blast chamber from an air supply opening, the air is uniformly dispersed after passing through ventilation openings, the dispersed air enters the cooling chamber, the cooling air cools the outer wall of the platinum channel while moving quickly towards inner air outlets and outer airoutlets located at two sides, thereby indirectly cooling molten glass in the platinum channel, and the purpose of cooling is achieved by the repeated cycle cooling; and at the same time, the cooling equipment can be installed in any place that needs to be cooled, of the platinum channel, the air supply volume and speed of the cooling air are adjusted according to cooling range of the molten glassin the platinum channel, and the equipment has high flexibility, and realizes precise cooling of the molten glass.

Owner:IRICO DISPLAY DEVICES

Novel casting method of steam turbine combined steam valve shell steel casting

ActiveCN111940675APrecise positioningLower center of gravityFoundry mouldsFoundry coresSlagMold filling

The invention provides a novel casting method of a steam turbine combined steam valve shell steel casting. The outer contour of the steam turbine combined steam valve shell steel casting is formed bya lower casting mold, a first middle casting mold, a second middle casting mold and an upper casting mold, and three parting surfaces are designed from the bottom to the top of the casting molds, namely, the large-diameter end surface of a conical main body serves as a first parting surface, the horizontal plane passing through the diameter of an opening of a bent pipe serves as a second parting surface, and the horizontal plane passing through the diameter of an opening of a straight pipe serves as a third parting surface; and a bottom pouring system is adopted for mold filling of the castingmolds to form the steam turbine combined steam valve shell steel casting, and pouring from the large opening end to the small opening end of the steam turbine combined steam valve shell steel castingis achieved. The large opening end of the steam turbine combined steam valve shell steel casting faces downwards, and the small opening end of the steam turbine combined steam valve shell steel casting faces upwards, so that a sand core is accurate in positioning, low in gravity center without skew and accurate in size, hot spots are prevented from being generated at the small opening end, the bent pipe is continuously and stably filled with molten steel along with rising of the molten steel in the casting process, the molten steel falling phenomenon is avoided, the slag inclusion rate of thesteam turbine combined steam valve shell steel casting is reduced, and the quality of the finished steam turbine combined steam valve shell steel casting is ensured.

Owner:SICHUAN JINLEI CASTING

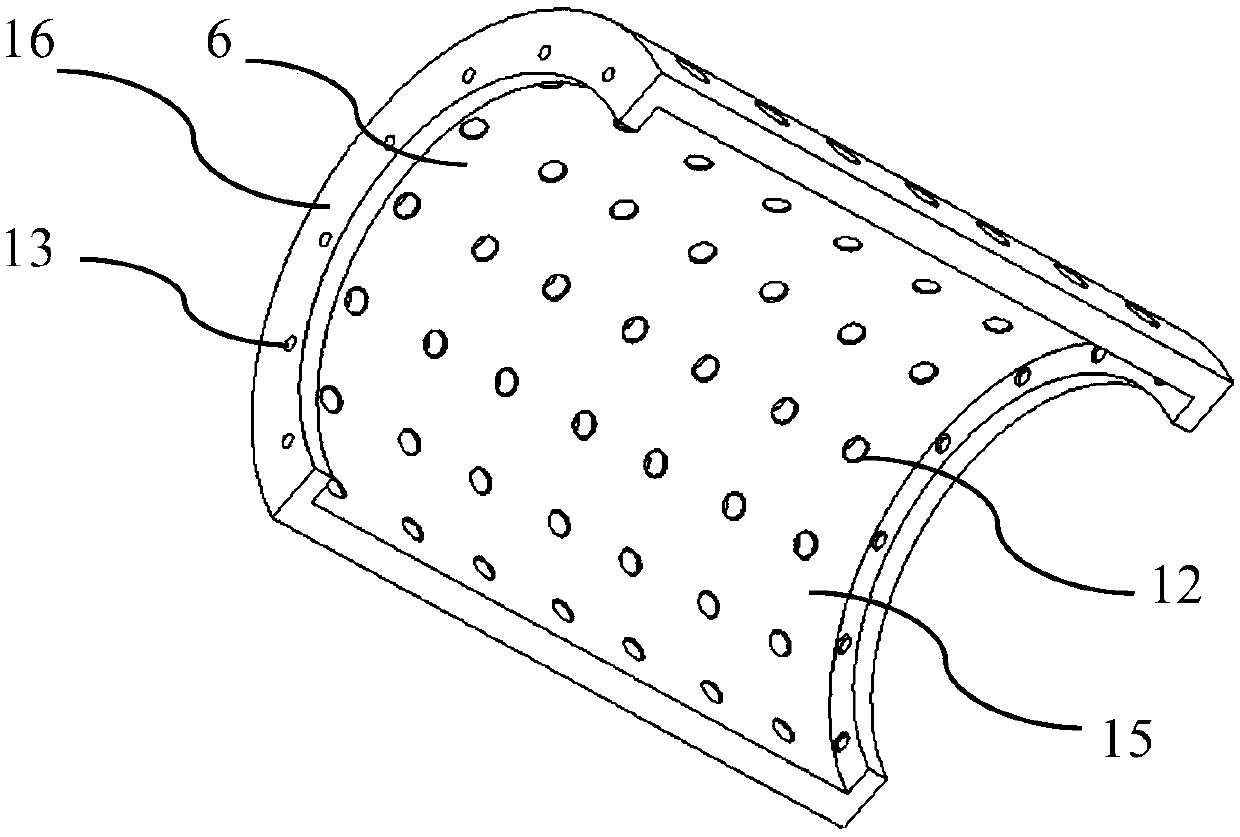

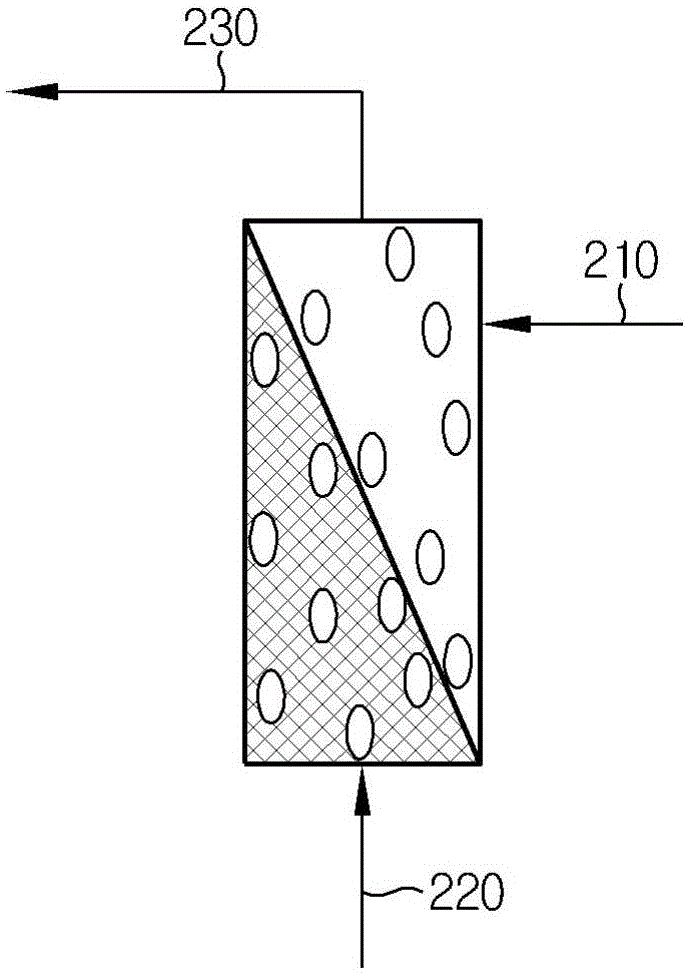

Central baffle, pressurized hollow fiber separation membrane module comprising same, and method for washing same

InactiveCN105163836ASolve bottlenecksReduce pollutionSemi-permeable membranesMembranesFiberCleaning methods

The present invention relates to the structure of a pressurized hollow fiber separation membrane module, and a method for washing the same. In particular, a central baffle of a cylindrical shape having a hollow is installed inside the pressurized hollow fiber separation membrane module, wherein the central baffle comprises: an air zone including, on the outer periphery thereof, at least one back washing hole which is regularly or irregularly formed in a penetrating manner; and a water zone including at least one back washing hole which is regularly or irregularly formed in a penetrating manner. The central baffle is installed in the center of the pressurized hollow fiber separation membrane module on the same axis as a concentration part so as to allow concentrated water and cleaning air to uniformly flow in all directions of a housing and to improve an increase of the pressure and linear velocity or a stagnating phenomenon, or the like, which may occur in the conventional modules, thereby increasing the effect of physical washing and decreasing contamination of the separation membrane.

Owner:爱科利态株式会社

Elevator traction sheave mould

The invention relates to an elevator traction sheave mould. A traction sheave comprises a tabular body and a continuous wheel rim arranged around an edge of the body, wherein the wheel rim is vertical to a plane of the body; an axial concentric wheel cylinder is arranged in the center of the body; and the mould comprises an upper steel mould and a lower steel mould for molding an outer surface of the traction sheave, and a concave sand mould for molding an upper end face and a lower end face of the traction sheave. The elevator traction sheave mould is characterized in that a columnar inner bore sand mould for forming an inner cavity of the wheel cylinder is arranged between the upper steel mould and the lower steel mould; the upper steel mould, the lower steel mould, the concave sand mould and the inner bore sand mould enclose to form a traction sheave molding cavity; a casting liquor pouring channel is arranged in the lower steel mould; and the channel is communicated with the molding cavity and a mould outer casting liquor storage tank. The elevator traction sheave mould is provided with a bottom pouring channel structure so as to facilitate casting liquor to flow into the mould molding cavity smoothly and uniformly, and the casting quality is improved. A fixed nut in threaded connection is arranged on the upper end of the inner bore sand mould, so that an axial position of the inner bore sand mould is favored to be fixed, and the fixed nut can also be unscrewed conveniently so as to beneficial to demoulding.

Owner:WUJIANG XINYI PRECISION HARDWARE

Profile porous self-bending extrusion die

The invention relates to a profile porous self-bending extrusion die, and belongs to the technical field of dies. The technical problem that the cross section is prone to deforming due to large stressborn by the outer side surface of a profile existing in the prior art is solved. According to the profile porous self-bending extrusion die, because the two ends of a first semicircular cavity wall are connected to the first end of a first straight cavity wall and the first end of a first curved surface cavity wall correspondingly, the metal flow can be adjusted so as to enable metal to flow intoa material inlet opening more steadily and enable the metal to flow unevenly, so that a bent part is directly extruded, the profile is not subject to transverse moment force, and the outer side of the profile is reduced or the cross-sectional deformation is prevented.

Owner:山东松竹铝业股份有限公司 +1

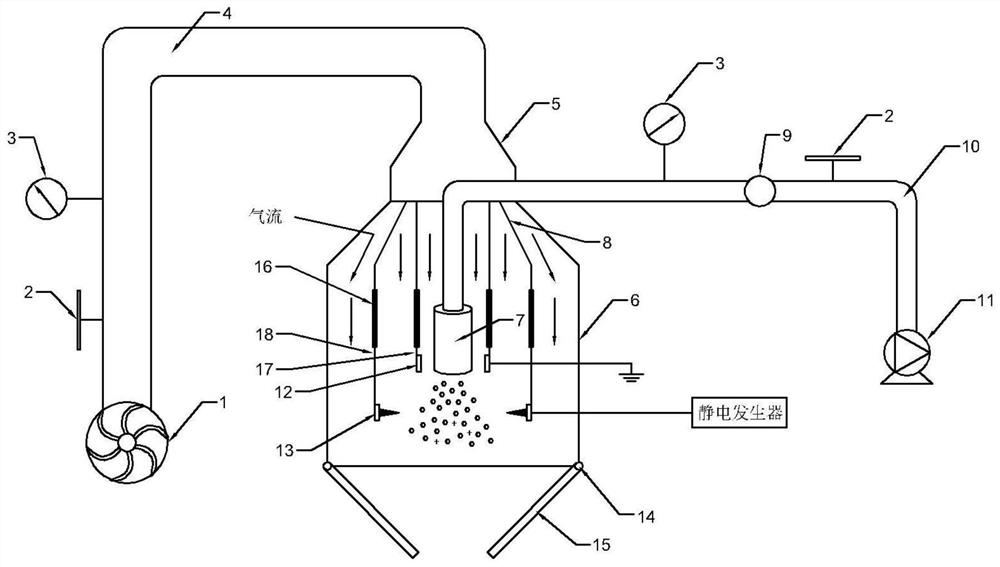

Gas-assisted double-fluid electrostatic atomization device in desulfurization tower

The invention discloses a gas-assisted two-fluid electrostatic atomization device in a desulfurization tower. The device comprises an atomization generation chamber, the atomization generation chambercomprises an insulating air duct, the upper end of the insulating air duct is connected with an outlet of a flow dividing and stabilizing pipeline, a one-way conduction plate is hinged to the bottomof a cylindrical section, the spray inlet pipeline and the nozzle are arranged in the insulating air duct along the central axis, flow deflectors are sleeved outside the outlet section of the spray inlet pipeline and are divided into an inner flow deflector and an outer flow deflector, the inner flow deflector and the outer flow deflector extend downwards from the outlet of the flow dividing and stabilizing pipeline, the inner walls and the outer walls of the inner flow deflector and the outer flow deflector are hydrophobic coatings, a grounded first copper ring is arranged on the edge of theinner wall of the bottom of the inner flow deflector, a second copper ring connected with a high-voltage electrostatic generator is arranged on the edge of the bottom inner wall of the outer flow deflector, a grounding copper ring is used as an adjusting electrode, the problem that the surface of the electrode is prone to entrainment of water mist in the charged spraying process of the induction charged nozzle is effectively solved, and meanwhile high-humidity gas can be prevented from flowing back into the nozzle to wet the electrode.

Owner:JIANGSU UNIV

Downward pressing structure special for building steel bar cutter

The invention discloses a downward pressing structure special for a building steel bar cutter. The downward pressing structure comprises a supporting column, an ejector rod, a fixing plate, a protecting piece, a hydraulic cylinder, a pressing plate, a guide rod and a lubricating device; the lubricating device is installed at the top of the ejector rod, an oil bin is installed inside the lubricating device and can store lubricating oil, the lubricating oil is discharged through a branch pipe at the bottom and then enters a fixing sleeve through an oil pipe, namely, the position of the guide rodcan be lubricated, the effect is good, and the lubricating efficiency is high. A reciprocating mechanism is installed in the lubricating device and controlled by an independent driving motor, so thata fixing plug at the bottom is moved out of a bottom outlet of the oil bin, the lubricating oil can stably flow into the branch pipe at the bottom, excessive manual operation is not needed, and the automation effect is good; the oil absorption cotton is installed in the fixing sleeve and absorbs the lubricating oil discharged from the oil pipe, and then the lubricating oil seeps out through a permeation ring on the inner side of the fixing sleeve, so that the contact position of the guide rod and the fixing plate is continuously and stably lubricated.

Owner:赖路玉

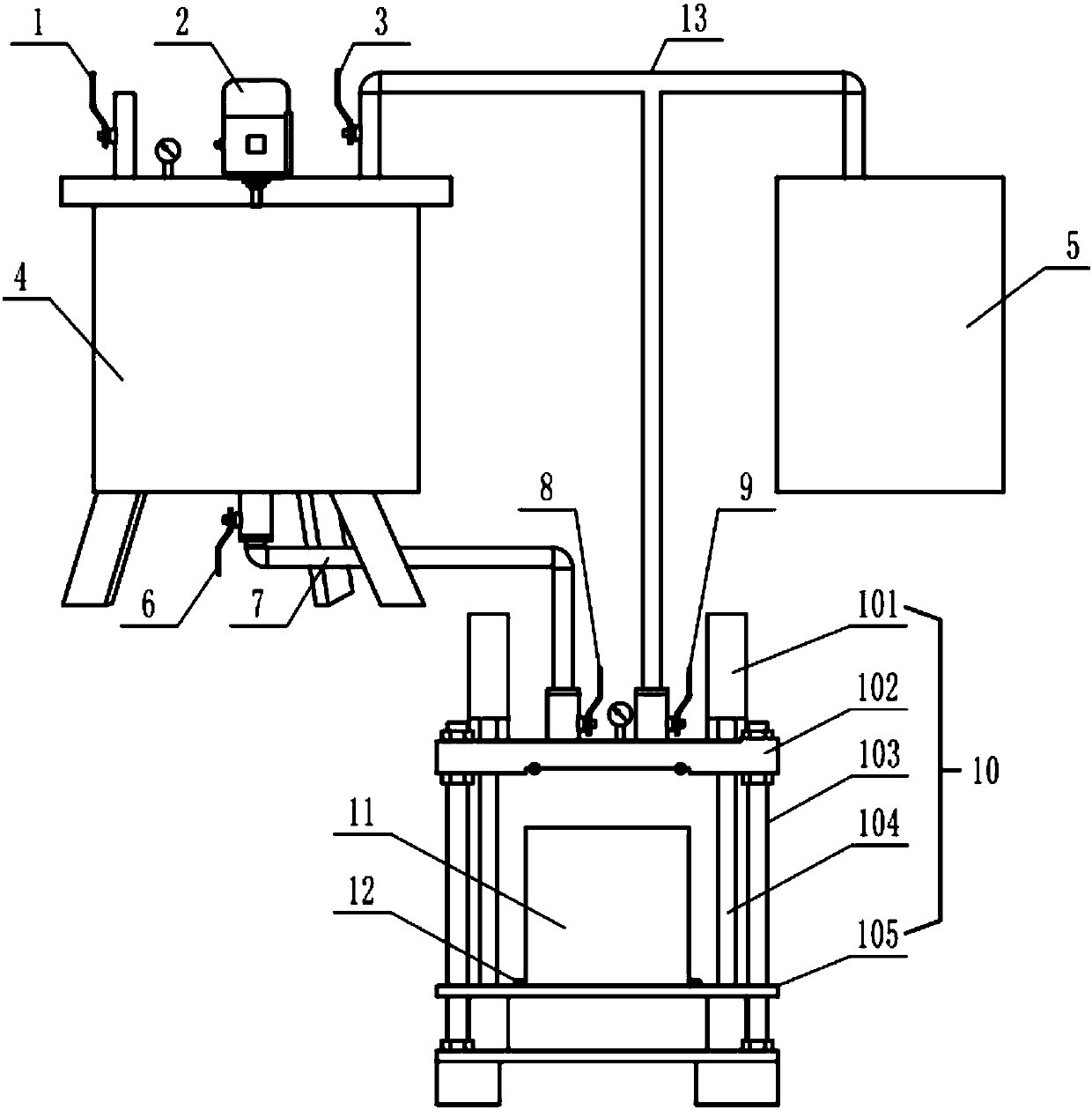

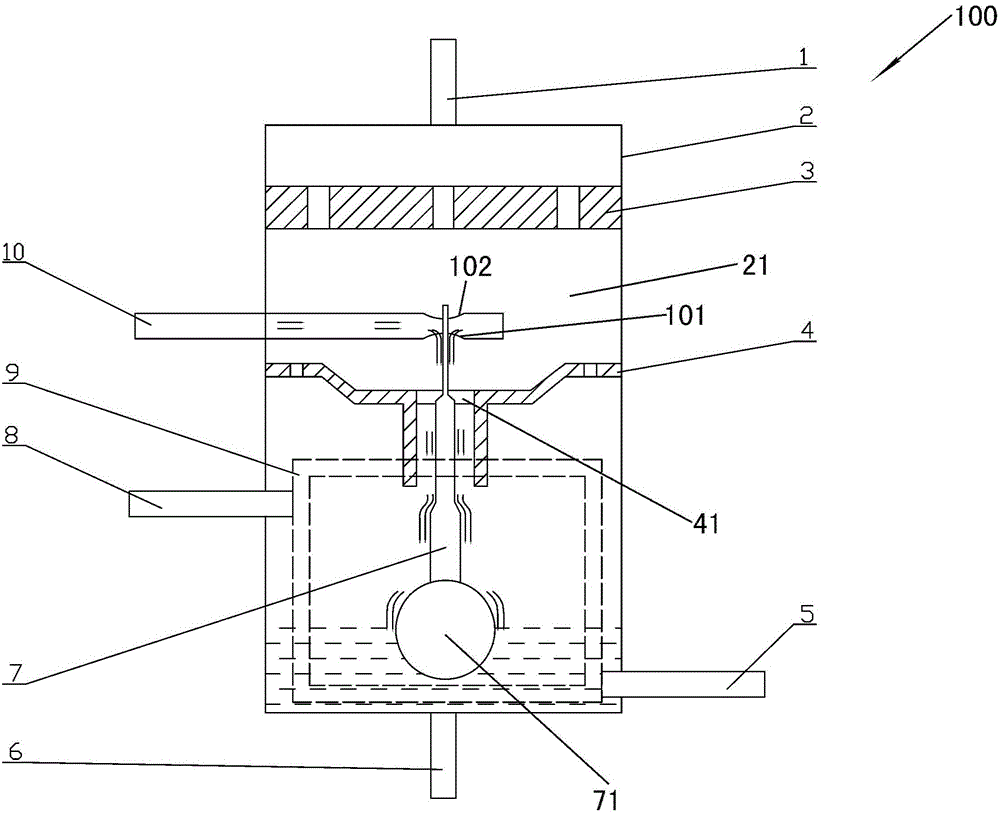

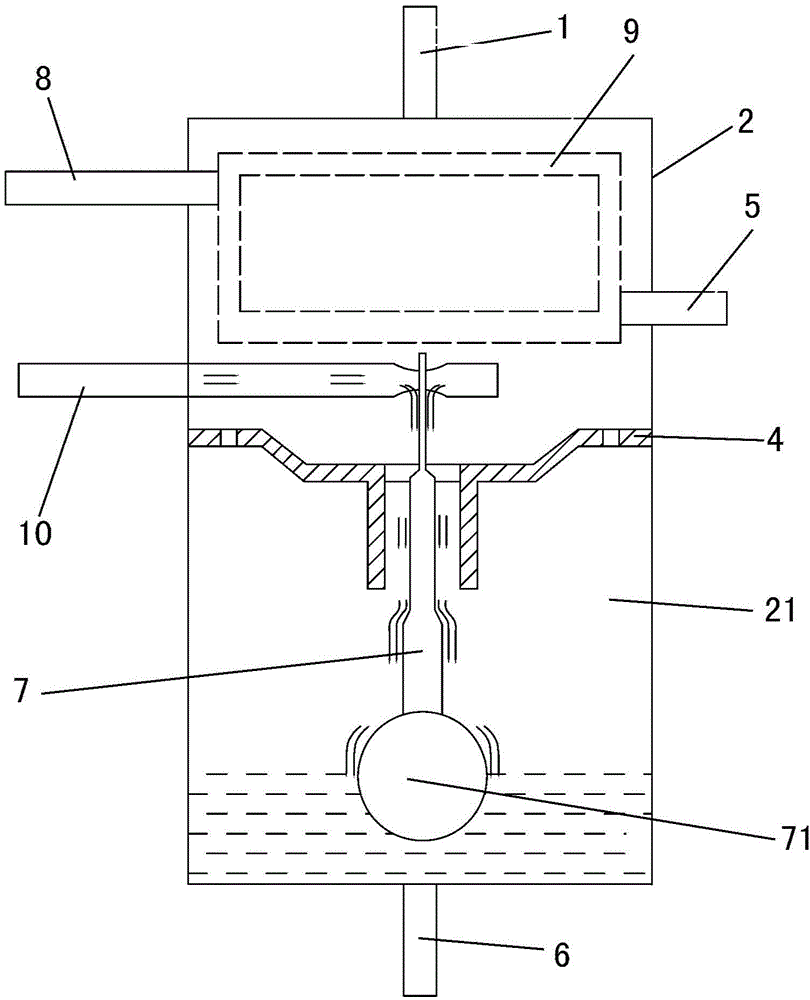

Vacuum gel casting device

InactiveCN108015882ASimple structureSmall footprintFeeding arrangmentsAuxillary shaping apparatusMold fillingPulp and paper industry

The invention relates to a vacuum gel casting device. The vacuum gel casting device comprises a vacuum stirring bucket, a vacuum pump and a casting tank. A stirring motor is arranged on the upper portion of the vacuum stirring bucket. The casting tank comprises a tank body. A lifting platform is arranged in the tank body. An end cover is arranged at the top of the tank body. Lifting air cylindersare arranged on the upper portion of the end cover and are connected with the lifting platform through guide columns arranged in the tank body. The vacuum stirring bucket and the casting tank are connected with the vacuum pump through vacuumizing pipes. The vacuum stirring bucket is connected with the end cover through a flow guide pipe, and a discharging control valve is arranged at the joint ofthe vacuum stirring bucket and the flow guide pipe. The height of the bottom of the vacuum stirring bucket is larger than the height of the end cover. The vacuum gel casting device is simple in structure, small in occupied space, convenient to operate, high in grouting efficiency and high in casting quality, a manufactured blank is full in mold filling, uniform and free of bubbles, and the requirement for close-size prefabricated members in the precision machine production process can be met.

Owner:HUNAN HANGTIAN CHENGYUAN PRECISION MACHINERY

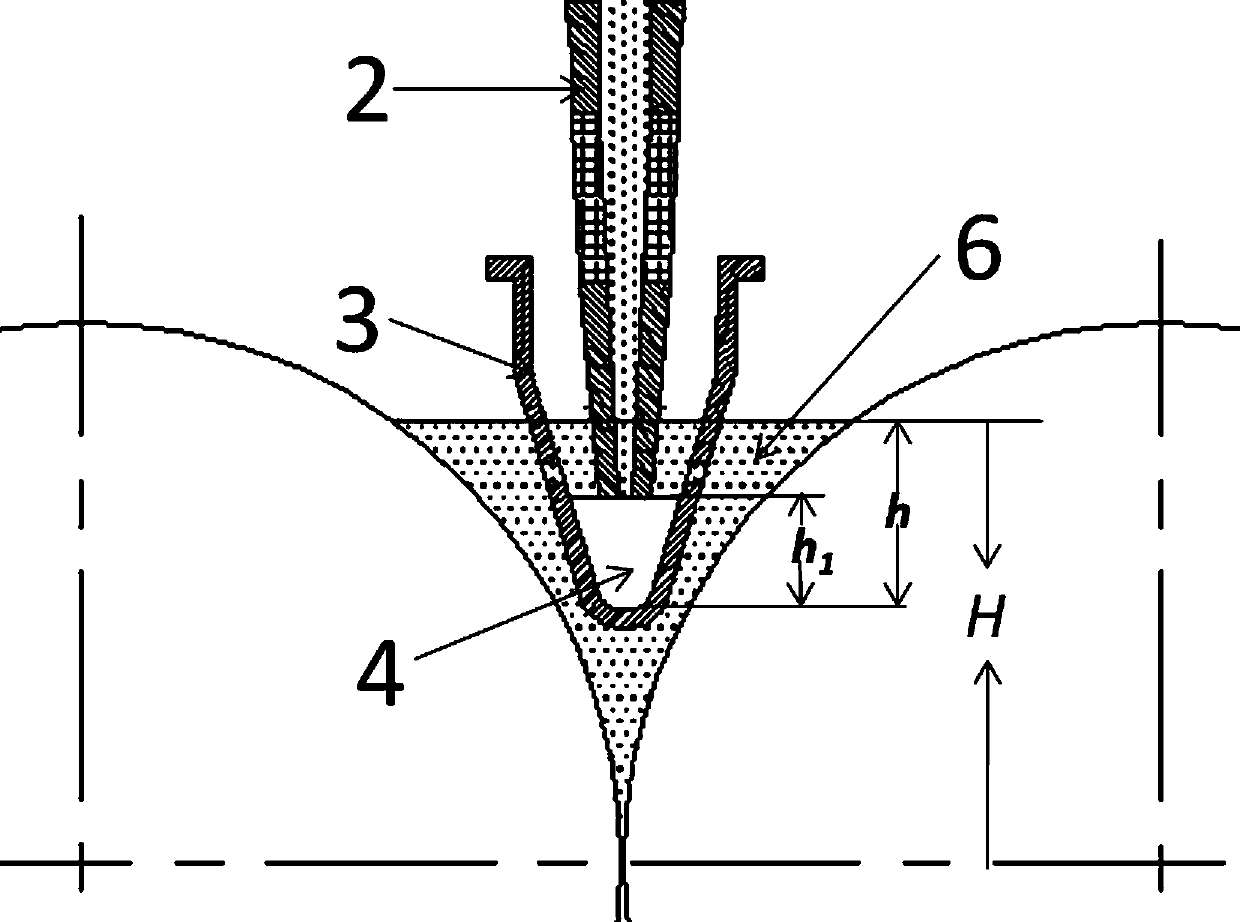

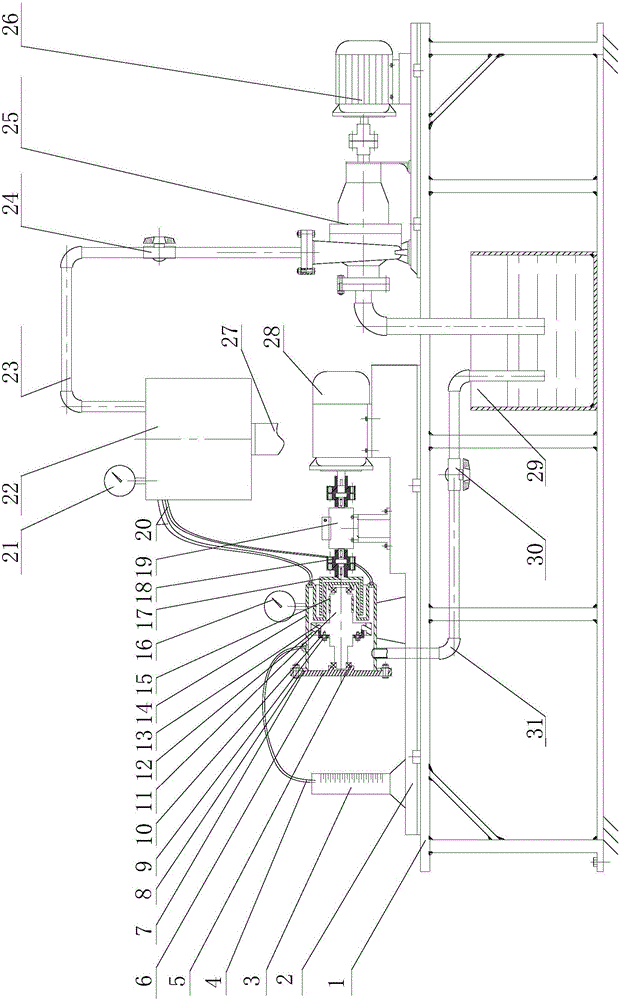

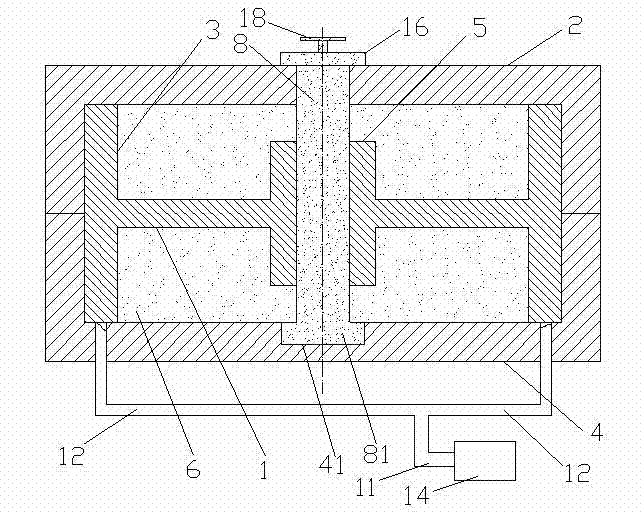

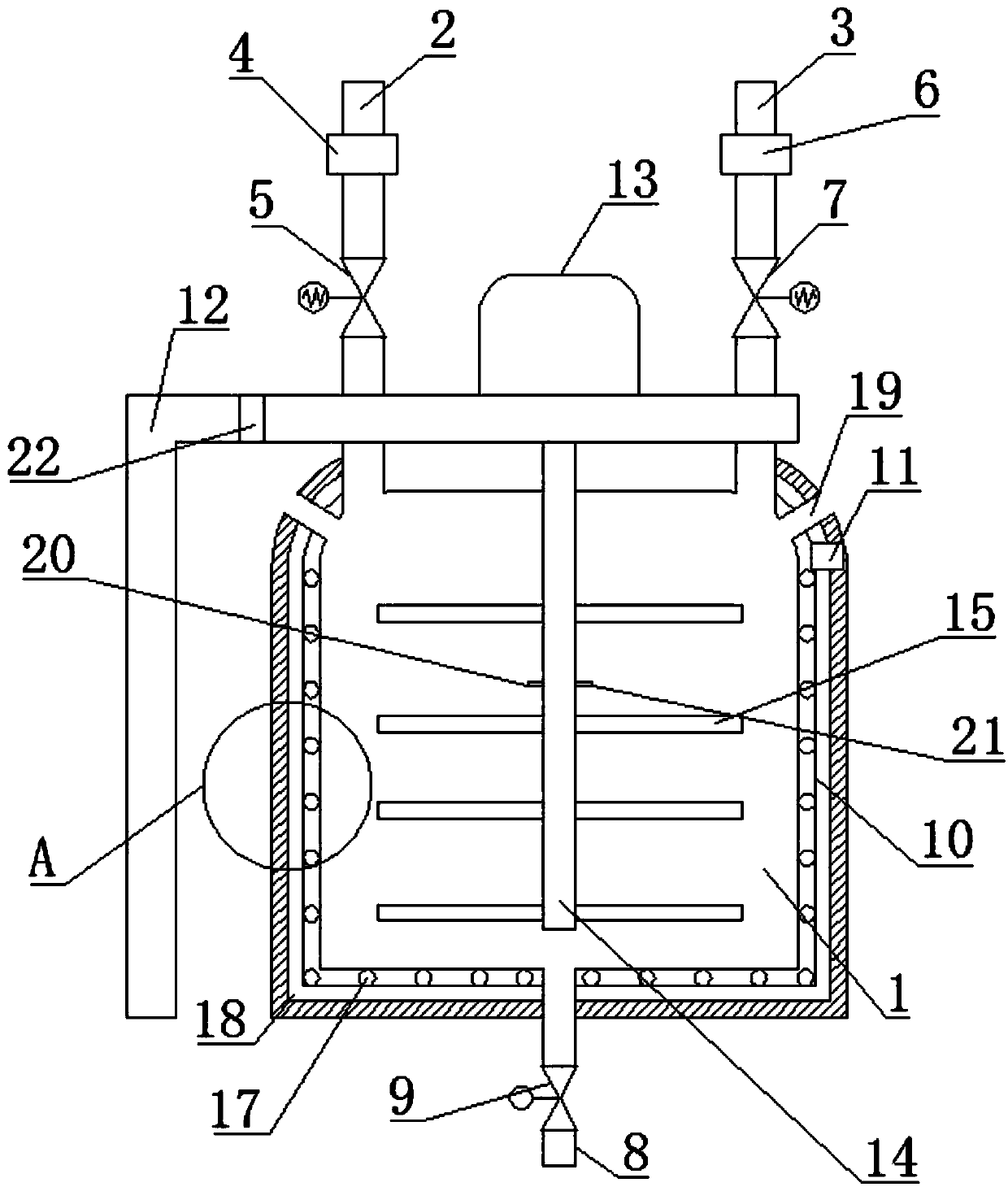

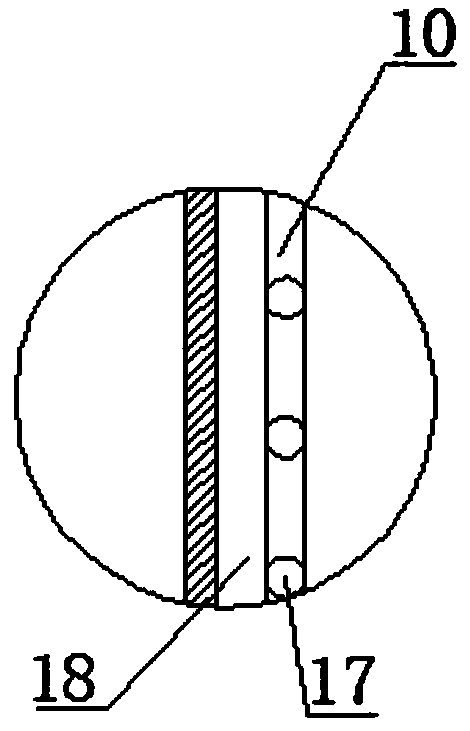

Automatic temperature control type water-reducing agent production device

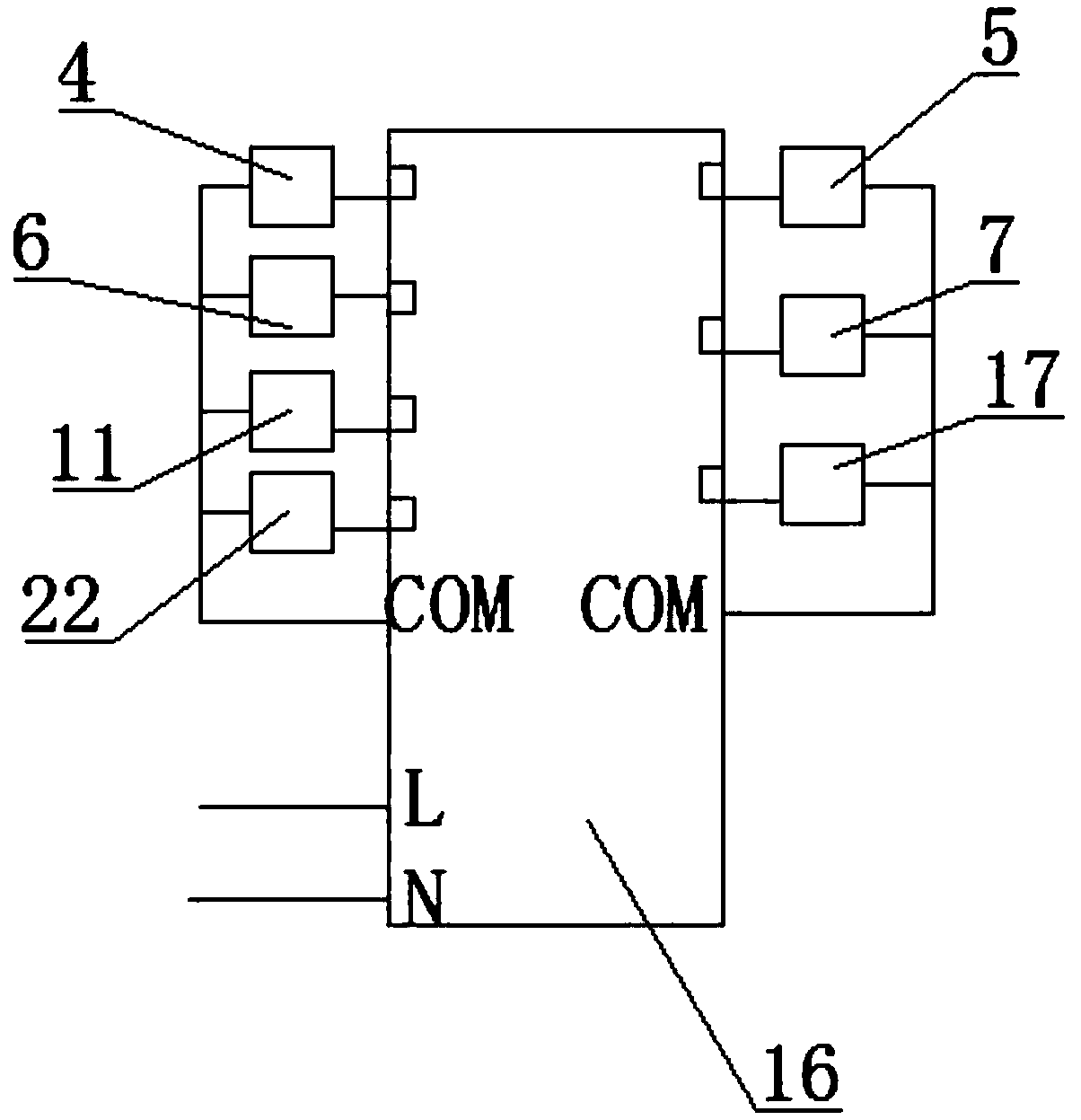

InactiveCN107754747ARealize automatic controlReduce churnProcess control/regulationChemical/physical/physico-chemical stationary reactorsTemperature controlAutomatic control

The invention discloses an automatic temperature control type water-reducing agent production device which comprises a reaction tank (1); a first material supply pipe (2) and a second material supplypipe (3) are arranged at the top of the reaction tank (1); a flow inductor A (4), a solenoid valve A (5), a flow inductor B (6) and a solenoid valve B (7) are respectively arranged on each of the twomaterial supply pipes; a discharging pipe (8) is arranged at the bottom of the reaction tank (1), and a discharging valve (9) is arranged on the discharging pipe (8); a heating layer (10) is arrangedin the side wall of the reaction tank (1), and a temperature inductor (11) is arranged outside the heating layer (10); a fixed frame (12) is mounted outside the reaction tank (1), and a motor (13) ismounted on the fixed frame (12); a stirring shaft (14) is connected with the motor (13), and a stirring rod (15) is arranged on the stirring shaft (14); and a PLC (16) is arranged outside the reactiontank (1). The automatic temperature control type water-reducing agent production device disclosed by the invention not only can improve the temperature control efficiency, but also has the advantagesof being small in error probability and convenient to operate.

Owner:ZHEJIANG DADONGWU GROUP CONSTR OF THE NEW MATERIAL

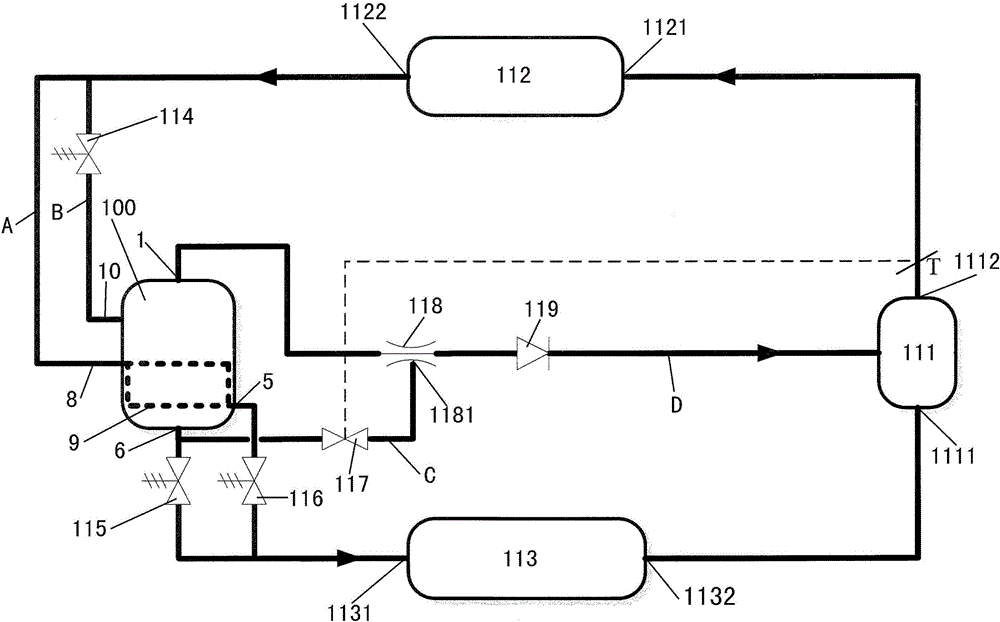

Flash tank and refrigeration system with same

InactiveCN105466090AMulti-capability outputImprove COPRefrigeration componentsRefrigerantEngineering

The embodiment of the invention discloses a flash tank and a refrigeration system with the same. The flash tank comprises a leading-in pipeline, a first flow regulation part and a floatable component. The leading-in pipeline is used for leading a medium into a cavity and provided with a medium inlet located in the cavity. The first flow regulation part can seal at least one part of the medium inlet of the leading-in pipeline to adjust the flow area of the medium inlet of the leading-in pipeline. The floatable component is connected with the lower end of the first flow regulation part, so that the first flow regulation part moves up and down according to the liquid level of the liquid medium in the cavity. When the liquid level is raised to make the first flow regulation part move upwards, the flow area of the medium inlet of the leading-in pipeline is decreased. While when the liquid level is lowered to make the first flow regulation part move downwards, the flow area of the medium inlet of the leading-in pipeline is increased. Through the flash tank, the inflow state of a refrigerant can be controlled more stably, and automatic regulation of the liquid level can be achieved without the aid of an electric control mode.

Owner:DANFOSS (TIANJIN) CO LTD

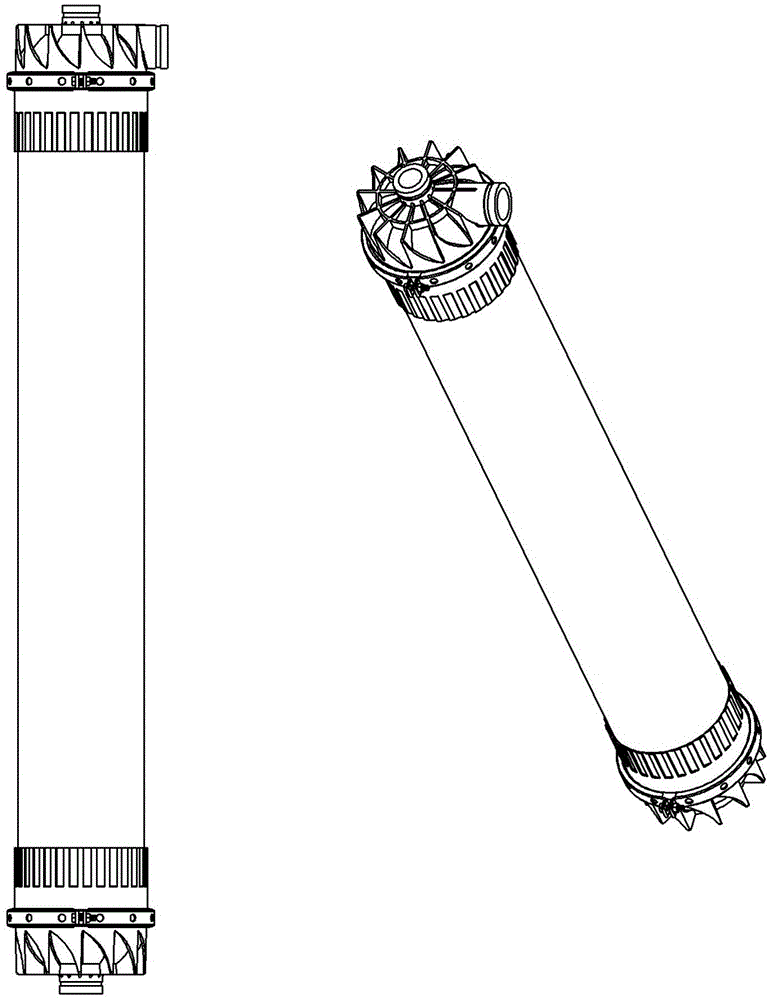

Submersible type portable aqua-plant fishing equipment

PendingCN111226582AIncrease contact areaAvoid cloggingWater cleaningMowersEnvironmental geologyMechanical engineering

The invention relates to submersible type portable aqua-plant fishing equipment. The equipment comprises an aqua-plant collecting and cutting device, a delivery pipeline and an aqua-plant separation device, wherein the aqua-plant collecting and cutting device has a vertical structure and is totally divided into three layers by using upper and lower two supporting plates as boundaries; a solar cellpanel, a cylindrical buoy and an impurity filter screen are arranged on the upper layer of the aqua-plant collecting and cutting device; a water absorption horn, an aqua-plant cutter and a delivery pump are arranged on the middle layer of the aqua-plant collecting and cutting device; a motor matched with the delivery pump is arranged on the lower layer of the aqua-plant collecting and cutting device; and one end of the delivery pipeline is connected with the water outlet of the delivery pump, and the other end of the delivery pipeline is connected with the water inlet of the aqua-plant separation device. The submersible type portable aqua-plant fishing equipment with the submersible type design is simple and reasonable in structure and convenient to use and operate, has high fishing efficiency and relatively high automatic degree, can overcome the defect that floating equipment has a large size and needs on-board manual work, and is used for cleaning fine aqua-plants which cannot be fished by a traditional aqua-plant fisher.

Owner:WATER CONSERVANCY PROJECT MANAGEMENT OFFICE OF HONGZE LAKE OF JIANGSU PROVINCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com