Preparation method of metal lithium negative electrode, metal lithium negative electrode, battery and application

A technology of metal lithium and metal lithium sheets, applied in the field of chemical power sources, can solve problems such as unstable mechanical properties, potential safety hazards, thermal runaway, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A kind of preparation method of metal lithium negative pole, concrete steps are as follows:

[0029] In a drying room with a dew point lower than -40°C, a DC pulsed plasma vapor deposition system was used, with metal lithium sheets as substrates, and CH 4 and CF 4 The mixed gas is the reaction gas, and the carbon fluoride film is deposited on the metal lithium sheet by using a DC pulsed plasma vapor deposition system.

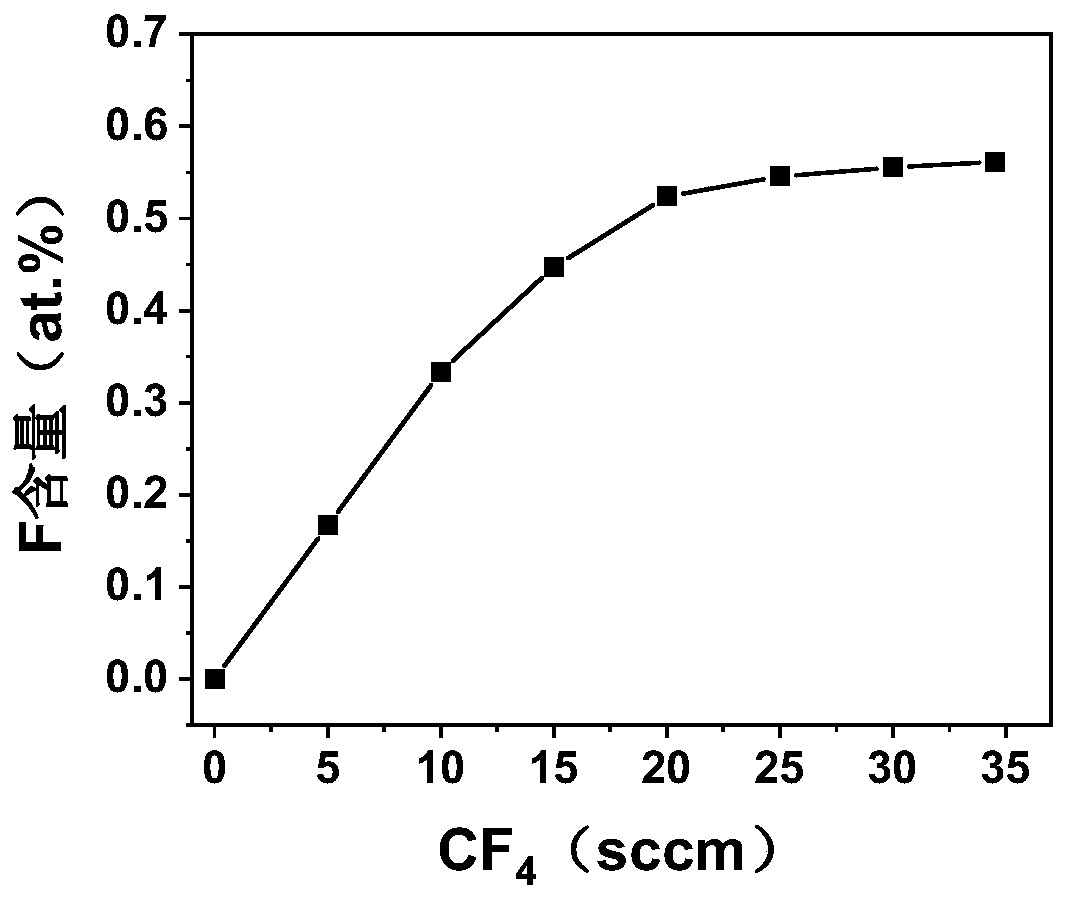

[0030] Prior to deposition, pump down the vacuum chamber to 10 -4 Below Pa, then for, through Ar + The substrate was etched for 30 minutes under a negative bias of 500V to remove surface impurities such as oxides, and then different proportions of CH 4 and CF 4 Reactive gas with a total flow rate of 40 sccm. The DC bias voltage on the negative plate is -700V, the upper stage adopts DC pulse auxiliary electrode, the DC bias voltage is 400V, the pulse frequency is 60KHz, and the duty cycle is 50%. During the deposition process, the substrate temperat...

Embodiment 2

[0033] The preparation method of metal lithium negative pole is the same as embodiment 1, just CH 4 Gas and CF 4 The gas volume flow ratio is fixed at 1:1, corresponding to CF 4 The flow rate is 20 sccm, the thickness of the carbon fluoride film is controlled by controlling the deposition time, the deposition rate is 1.67nm / min, and the thickness of the carbon fluoride film corresponding to 30 minutes of deposition is 50nm.

[0034] Assembling a symmetrical lithium metal battery: both the positive and negative electrodes use the prepared metal lithium sheets, and a PP separator is added in the middle, which is placed in a button battery case. The electrolyte is 1M LiTFSI DOL:DME (v:v=1:1), assembled into After the CR2032 button battery is sealed in a special sealing machine, a symmetrical metal lithium battery is obtained. After the battery was left standing for 24 hours, the internal resistance of the battery was measured with a CHI660e electrochemical workstation produced ...

Embodiment 3

[0039] The preparation method of metal lithium negative pole is the same as embodiment 1, just CH 4 Gas and CF 4 The gas volume flow ratio is fixed at 1:1, corresponding to CF 4 The flow rate is 20 sccm, and the thickness of the prepared carbon fluoride film on the metal lithium negative electrode is 50 nm.

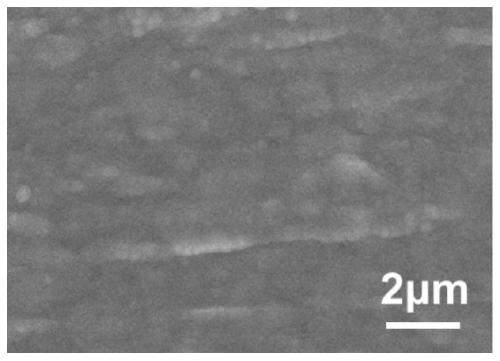

[0040] figure 2 This is the SEM picture of the surface of the prepared metal lithium negative electrode. It can be seen from the figure that the carbon fluoride film is very uniformly covered on the surface of the metal lithium negative electrode without pinholes, cracks and other defects, which can effectively isolate the metal lithium from the electrolysis. liquid.

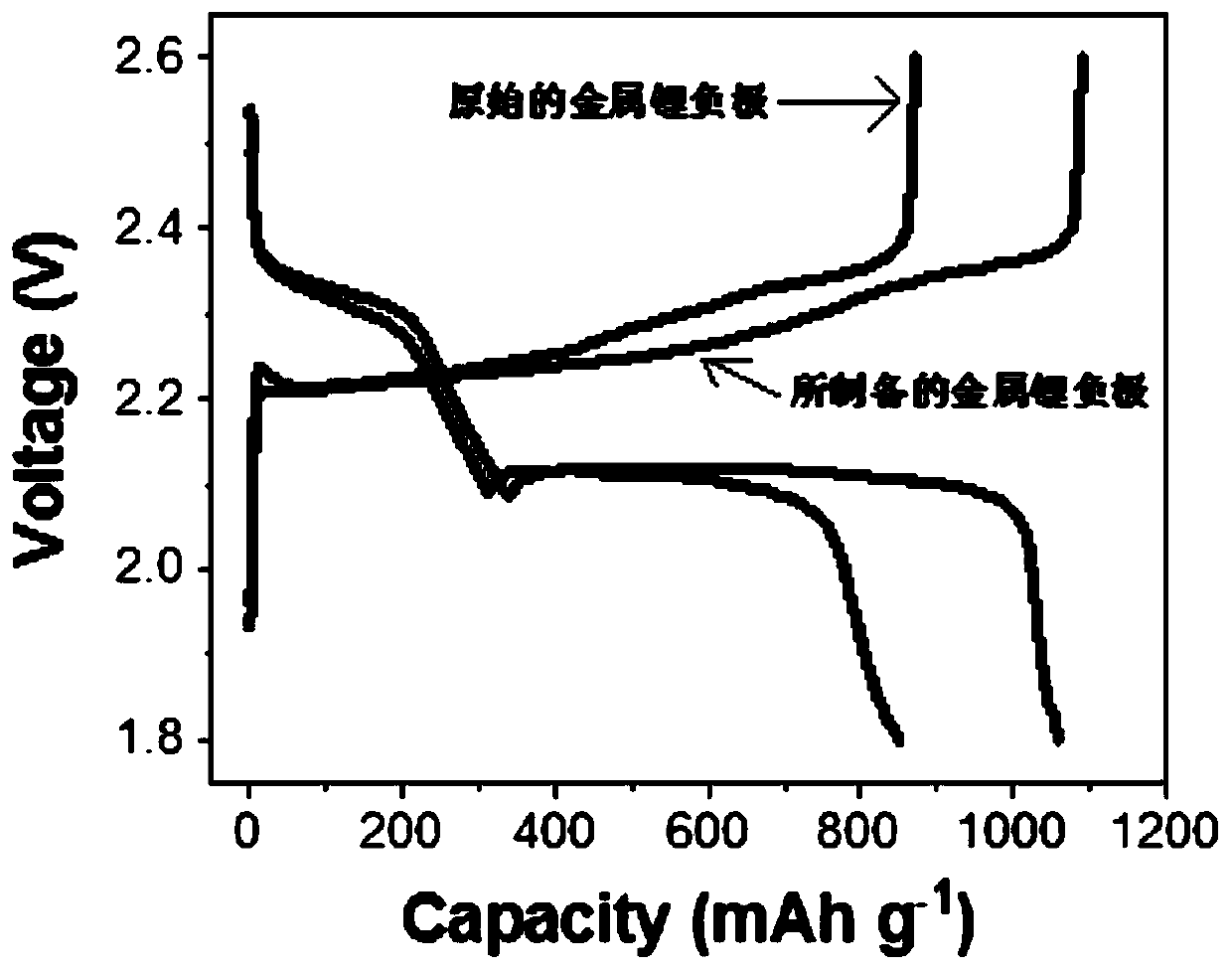

[0041] (1) Assembling lithium-sulfur batteries:

[0042]The prepared metal lithium sheet is used as the negative electrode, the sulfur-carbon electrode sheet is used as the positive electrode, and a PP diaphragm is added in the middle, which is placed in a button battery shell, and an appropriate amoun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com