Central baffle, pressurized hollow fiber separation membrane module comprising same, and method for washing same

A fiber membrane, pressure type technology, applied to the central baffle and the pressure type hollow fiber membrane module containing it and its cleaning field, can solve the problems of concentrated water bottleneck, congestion, pressure increase, etc., to reduce membrane fouling, membrane use long time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

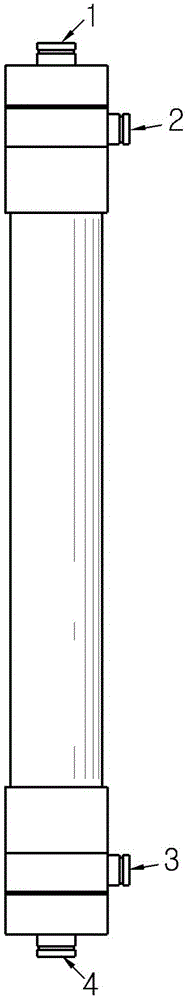

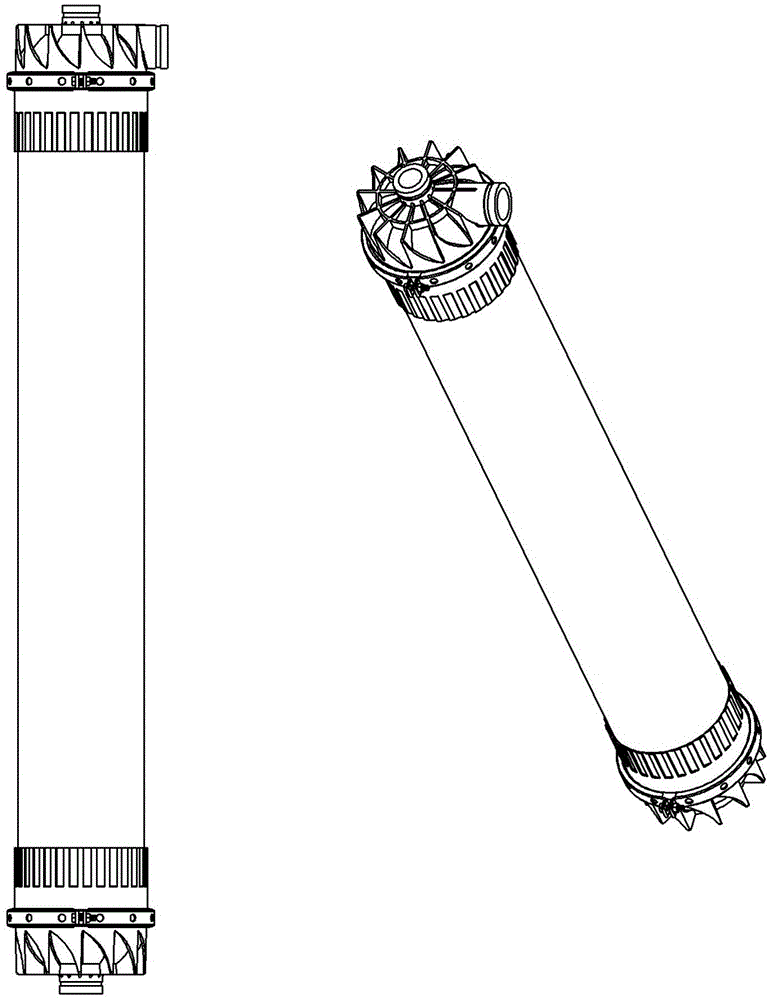

[0062] By connecting a cylindrical pressure-type module with a central baffle to the backwash water line, backwash air line, and drain line, the pressure-type membrane module device such as image 3 Medium structure. The amount of backwash water and backwash air flowing through the pressure type membrane module is adjusted by electrically driven valves and pumps.

[0063] 1. Measurement method based on backwash time

[0064] 1) Construct a pressure type membrane module device.

[0065] 2) Determine the total backwash time according to the nature of the raw water, and the backwash time is divided at equal ratios (50:50). The total backwash process time can be determined considering the process recovery rate in the range of 30-90 seconds.

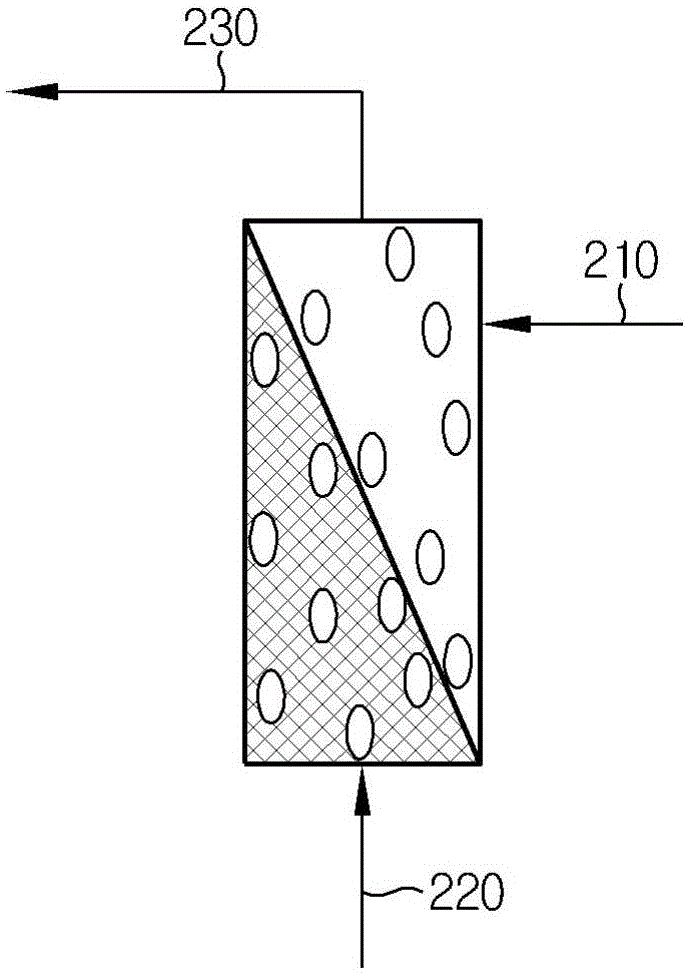

[0066] 3) In the period of the first stage of the total backwash time, use 2Q, that is, the water volume twice as high as that of the pressure membrane module and 200L / min (LPM), that is, up to the traditional backwash air 2 / 3 of the volu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com