Tube with grooves on inner surface and its manufacturing method, and fluted plug

An inner surface, grooved technology used in tubular elements, lighting and heating equipment, mandrels, etc., to solve problems such as fin shedding, fin chipping or cracking, and poor fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Hereinafter, embodiments of the present invention will be described in detail based on the drawings.

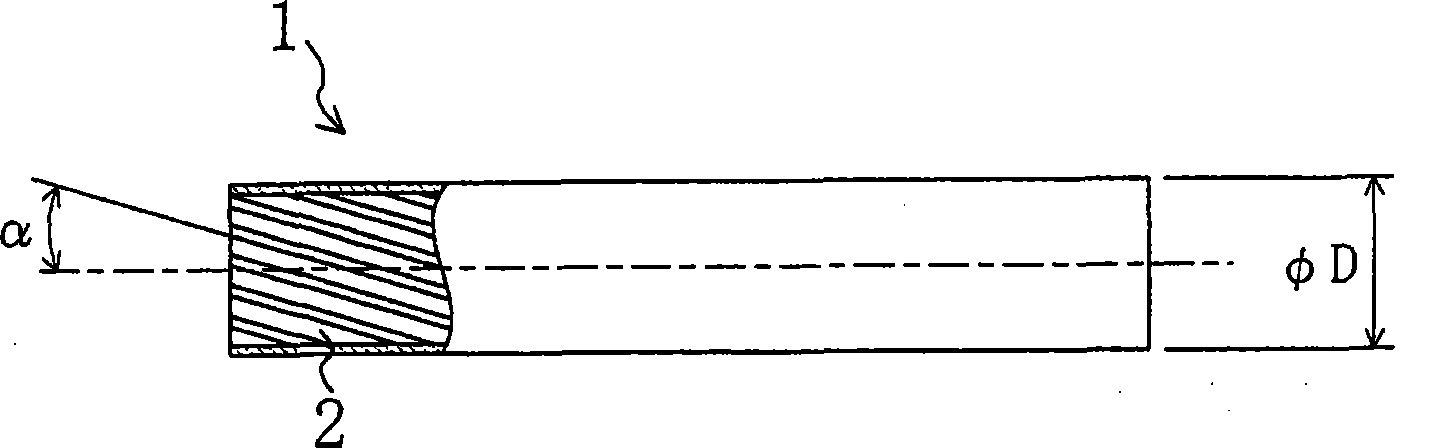

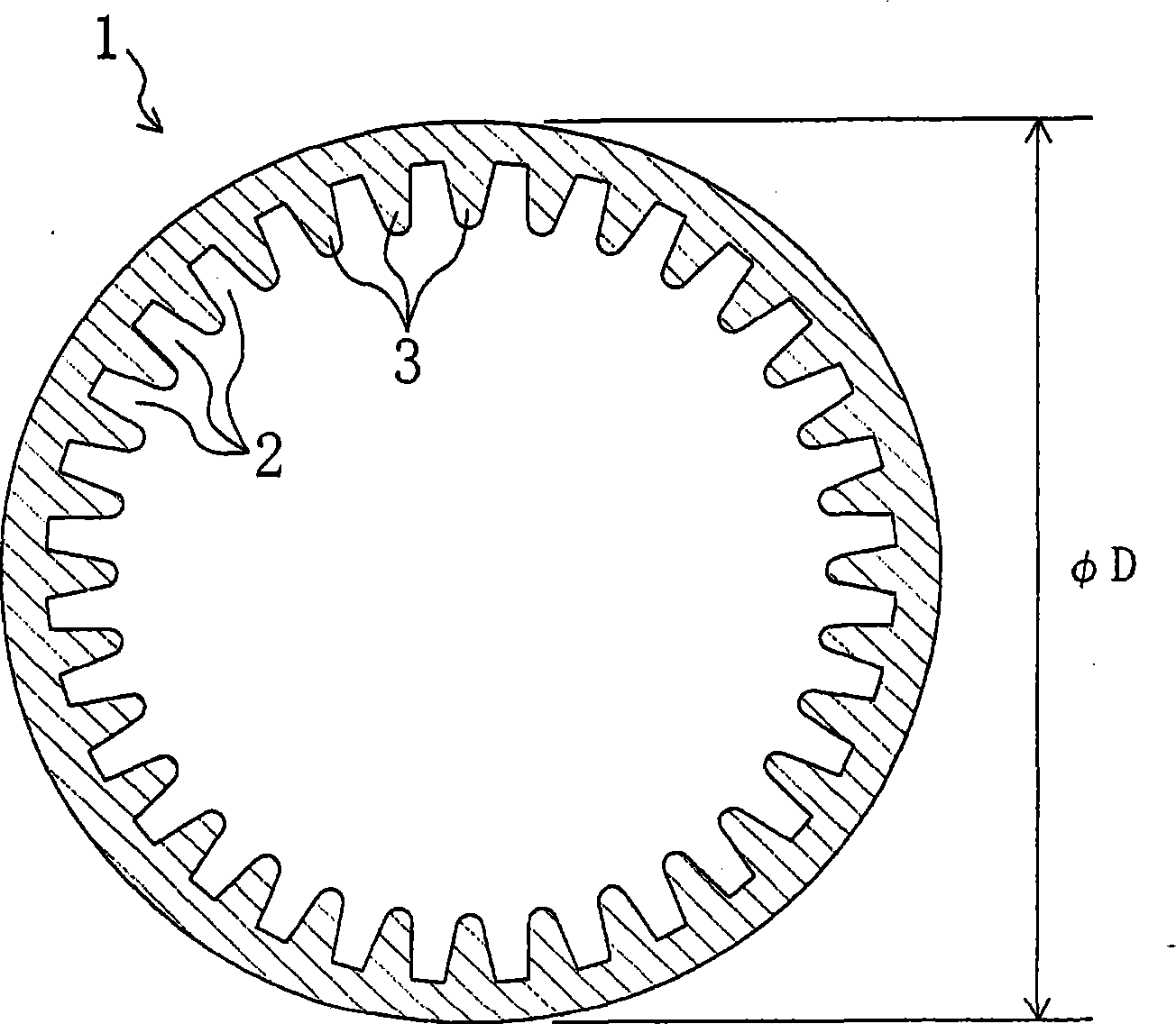

[0055] The inner grooved tube of the present embodiment is used as a heat transfer tube of a heat exchanger (so-called finned tube heat exchanger) provided in a refrigeration device or the like, and a refrigerant flows inside the inner grooved tube. The refrigerant flowing through the inner grooved tube evaporates or condenses by exchanging heat with air or water flowing around the tube. The material of the inner grooved tube of this embodiment (hereinafter referred to as the heat transfer tube 1 ) is copper or a copper alloy. In addition, the material of the pipe with grooves on the inner surface is not limited thereto, and may be aluminum or the like.

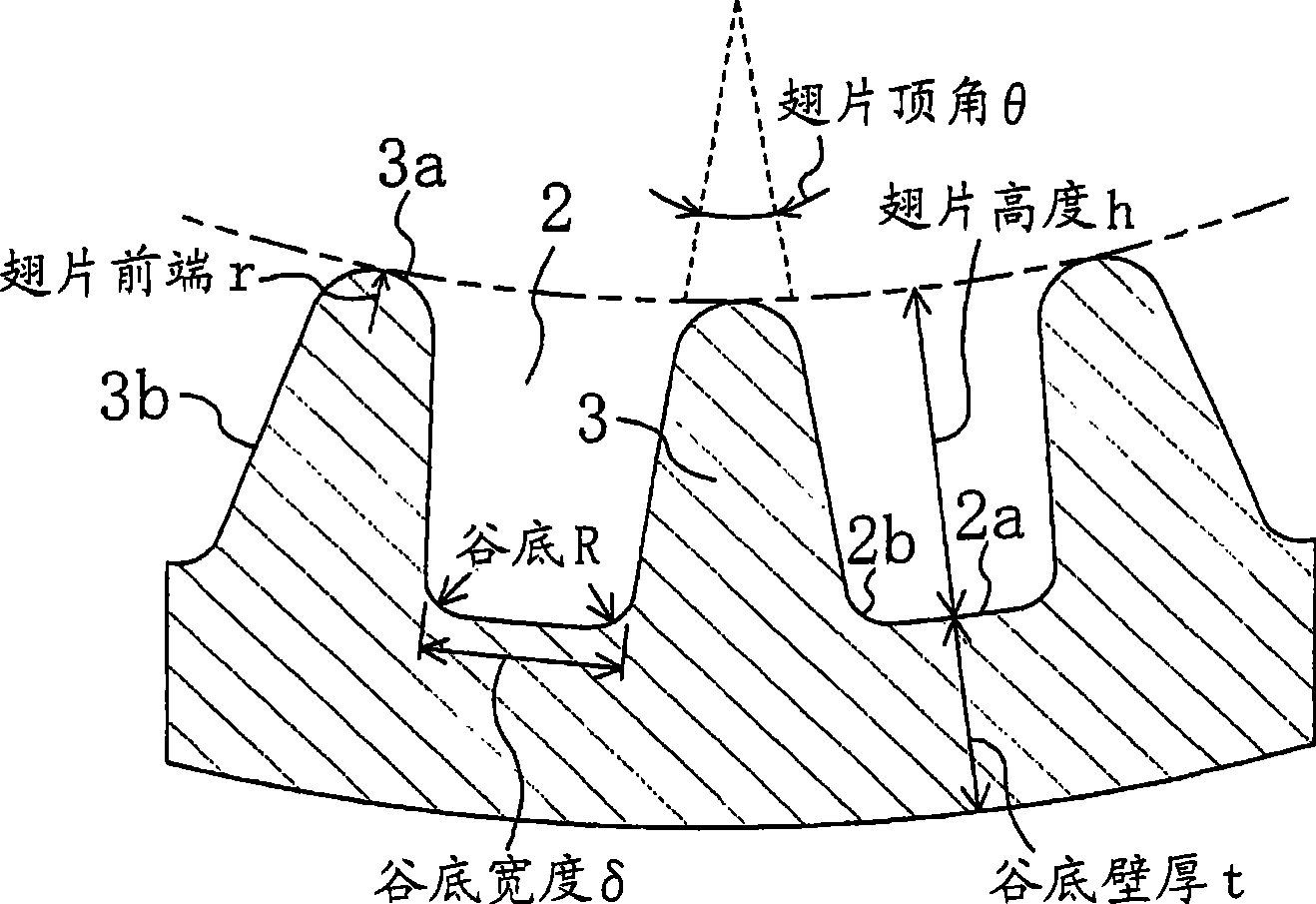

[0056] Such as Figure 1 ~ Figure 3 As shown, a plurality of fins 3 extending helically in the tube axis direction are formed on the inner surface of the heat transfer tube 1 . The fin 3 constitutes a ridge having ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com