Blast cooling equipment for platinum channel

A platinum channel and cooling device technology, applied in glass manufacturing equipment, glass furnace equipment, feeding troughs, etc., can solve the problem of low flexibility and achieve good air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is described in further detail below in conjunction with accompanying drawing:

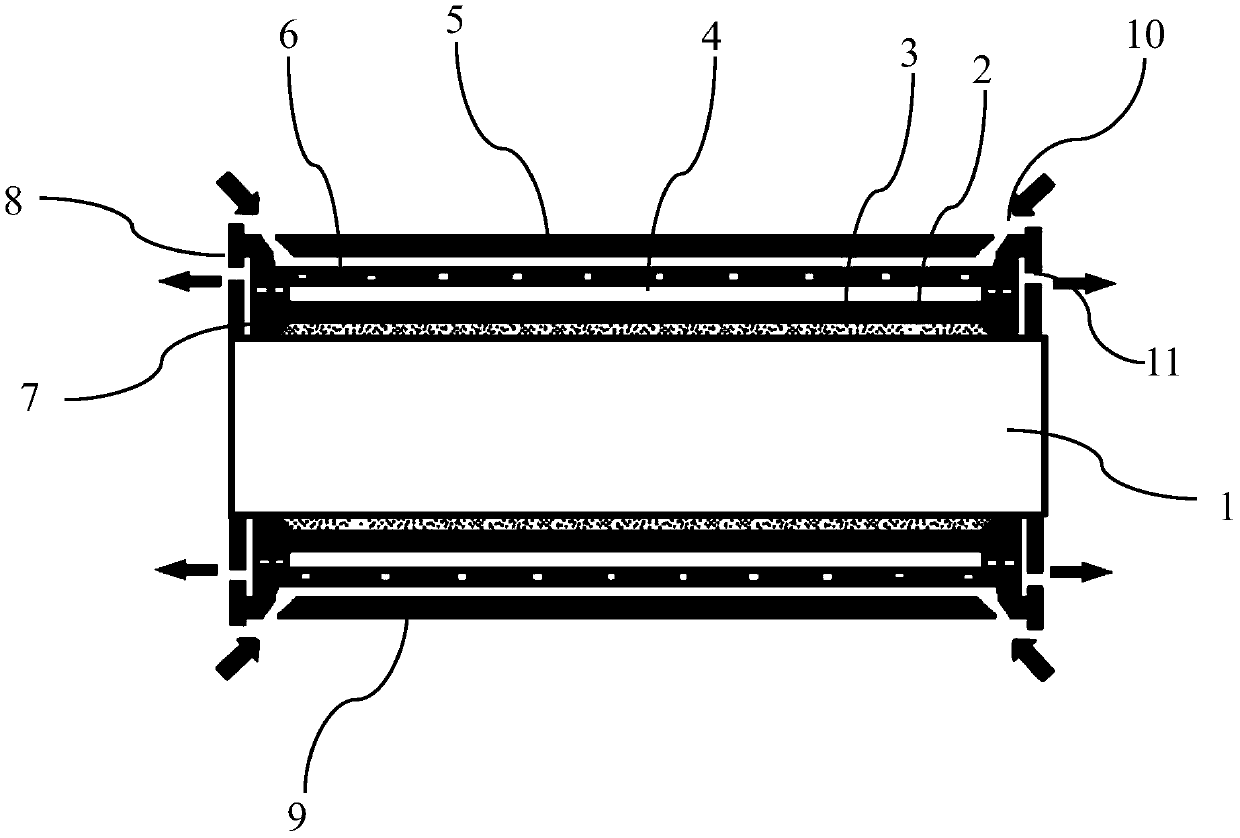

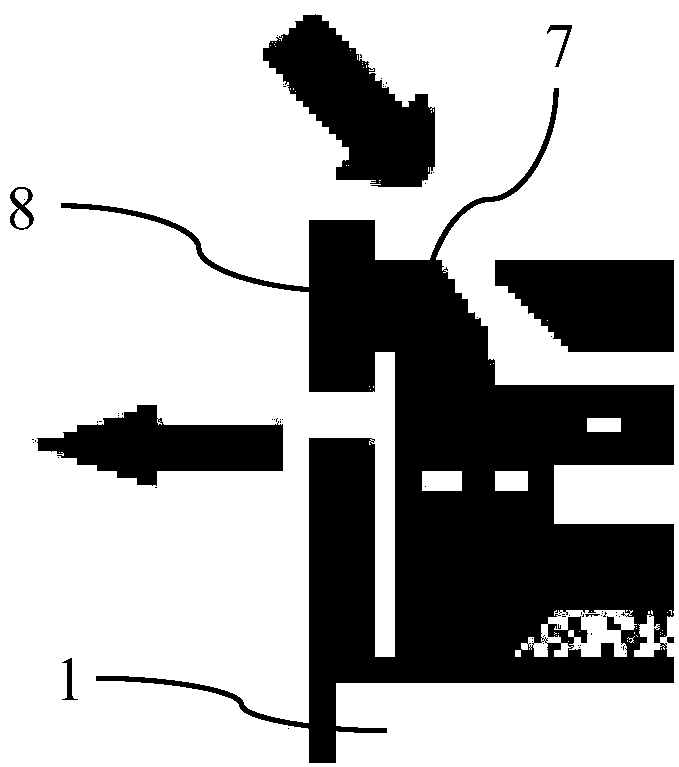

[0034] see figure 1 , the invention discloses a blast cooling device for a platinum channel; the device is installed outside the platinum channel, and the platinum channel includes a tubular platinum channel body 1 and an inner ring brick 3; the space between the platinum channel body 1 and the inner ring brick 3 is filled with There is grouting material 2; the platinum channel body 1, grouting material 2 and inner ring brick 3 are the original structure of the platinum channel; at present, the diameter of the platinum channel cooling section of the G6 substrate production line is 190mm, the length is ≤2600mm, and the thickness of the filling material is 20mm.

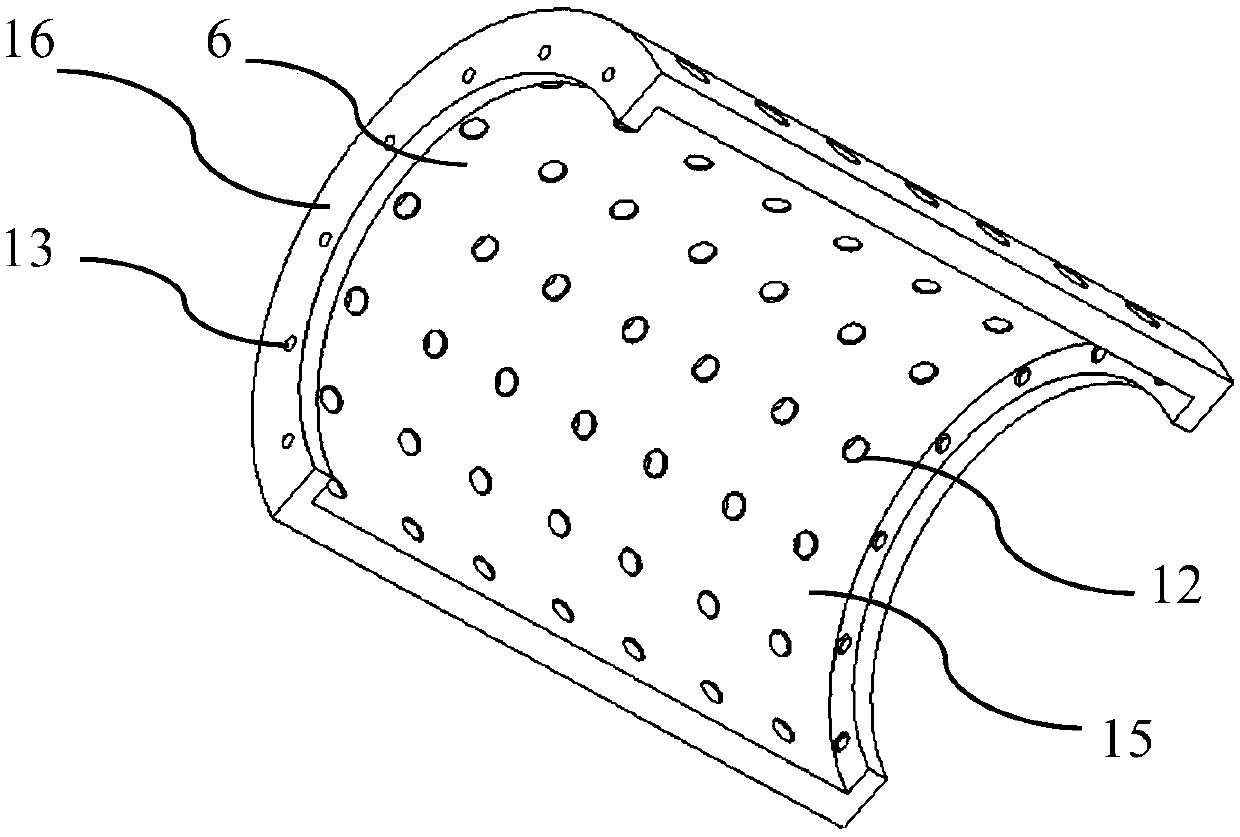

[0035] see figure 1 and image 3, the outer side of the inner ring brick 3 is provided with a semi-circular air-leakage brick 6, the sides of the two semi-circular air-leakage bricks 6 are fixedly connected ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com