Patents

Literature

48results about How to "Adjust the wind speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Near-wall air device for preventing high-temperature corrosion of water-cooled wall of power station boiler

InactiveCN101706110AReduce resistanceOvercome the shortcoming of fast wind speed attenuationCasings/liningsAir volumeCombustor

The invention discloses a near-wall air device for preventing the high-temperature corrosion of the water-cooled wall of a power station boiler, which comprises an air duct, a regulating valve, a near-wall air box, near-wall air unit nozzles, a fuel component on-line monitor and a speed measuring device, wherein the direction of the near-wall air is parallel to the axis of a pipe of the water-cooled wall, the resistance along the course is small and the air speed reduction is slow; only one layer of near-wall air nozzles is required to be arranged in a burner area and the system structure is simple; and the nozzles are flexibly arranged, the nozzle cooling condition is good, the operational air volume is small and the stability is high. Thus, the device is suitable to be promoted for preventing the high-pressure corrosion of the water-cooled walls of power station boilers.

Owner:XI AN JIAOTONG UNIV +1

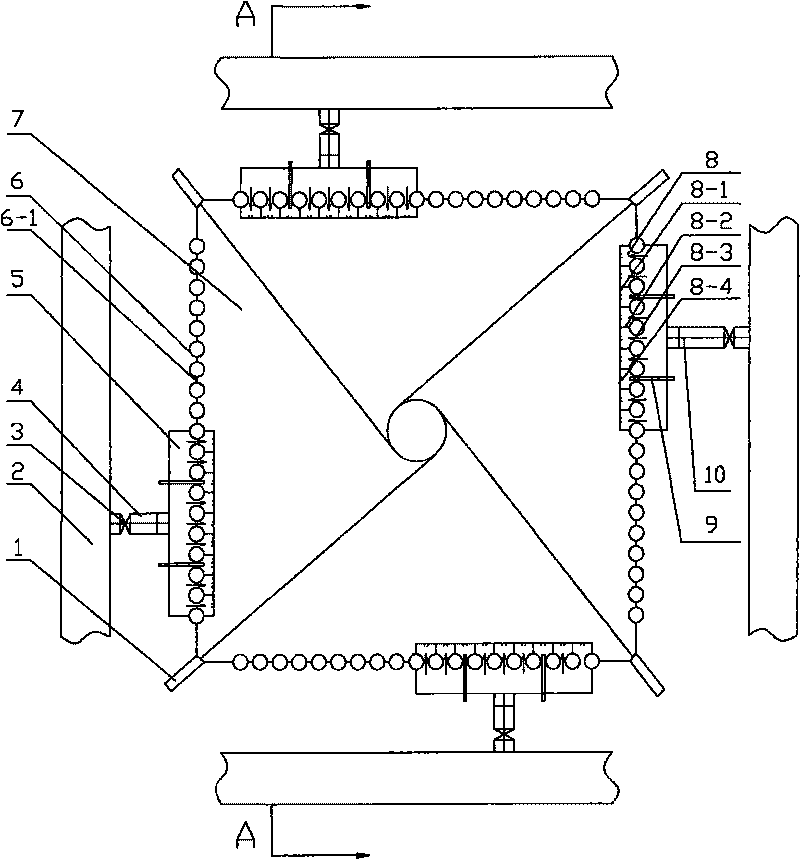

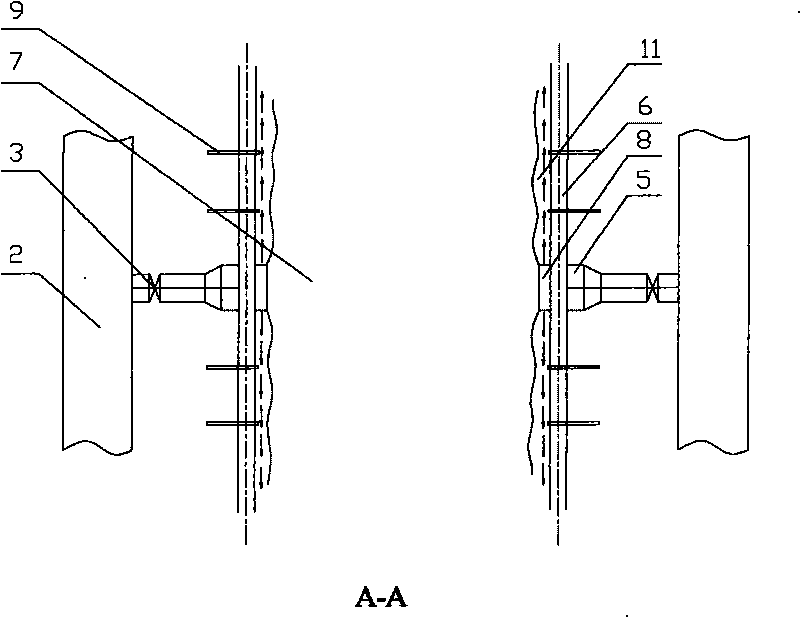

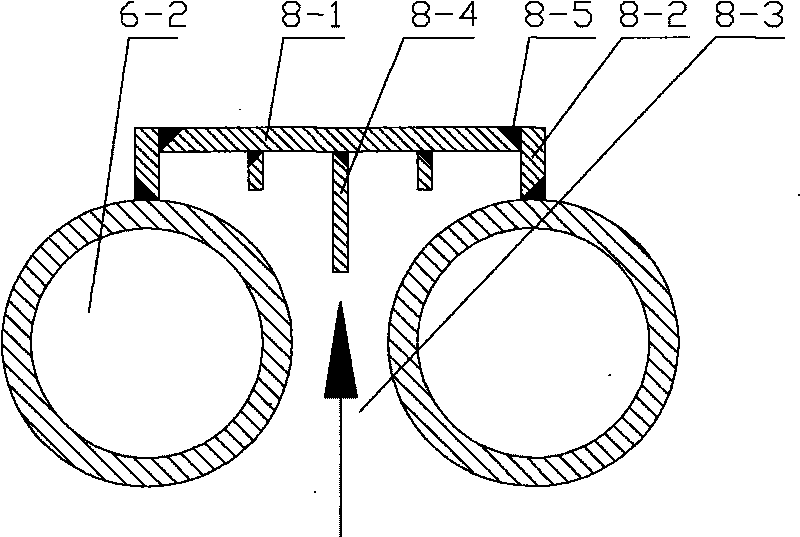

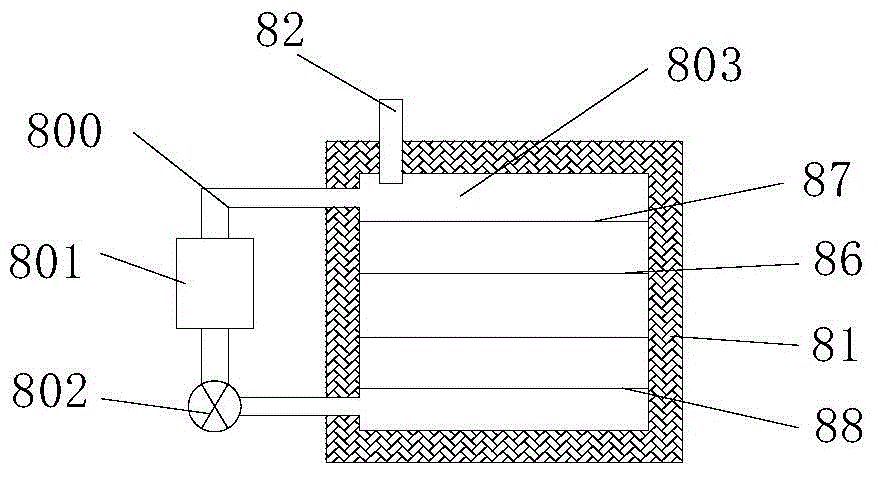

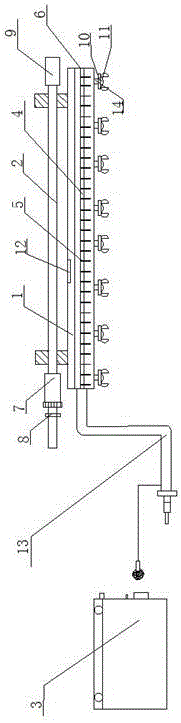

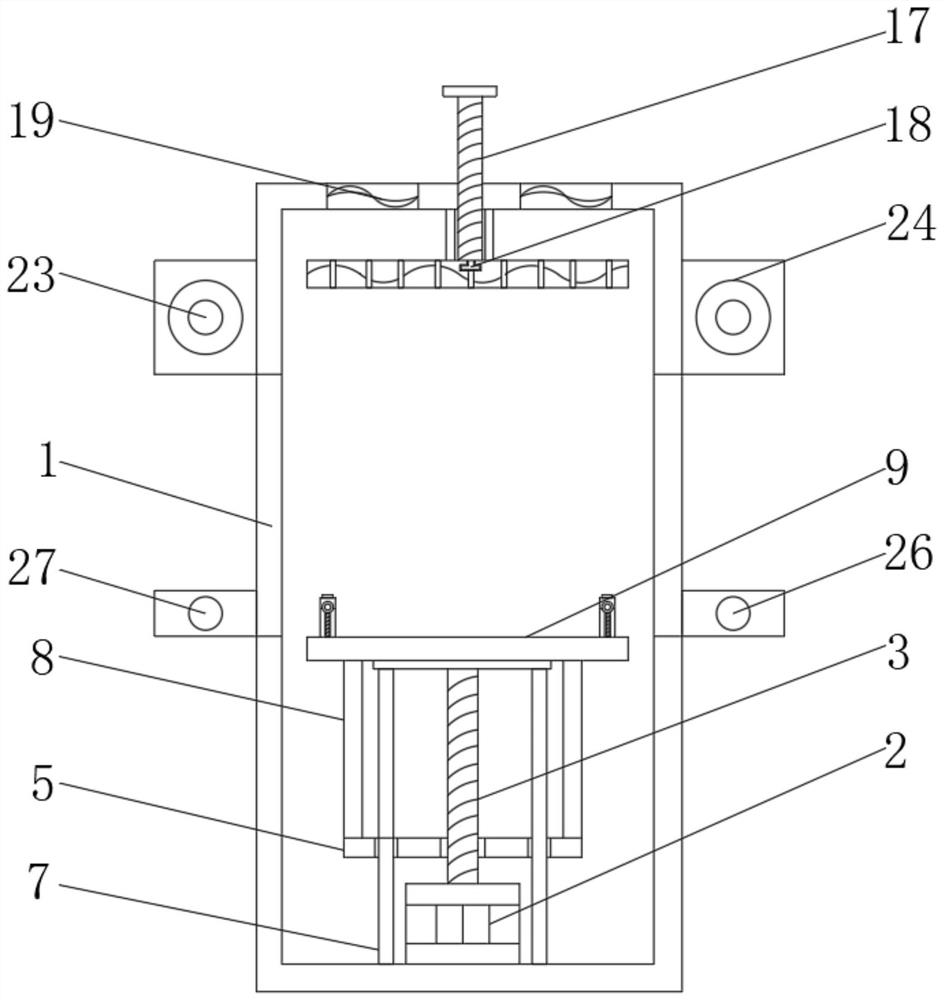

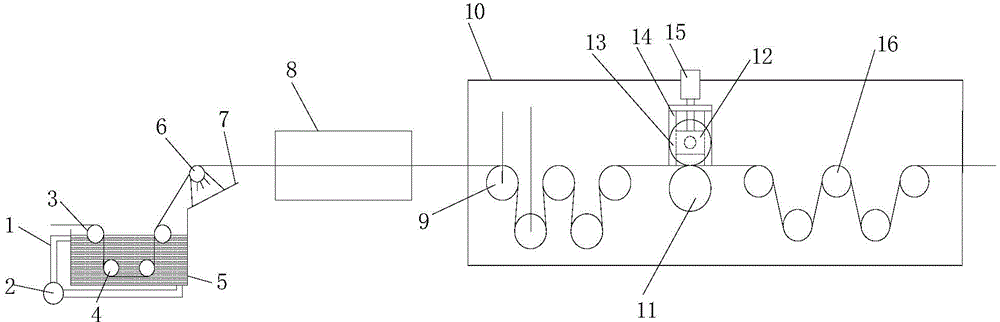

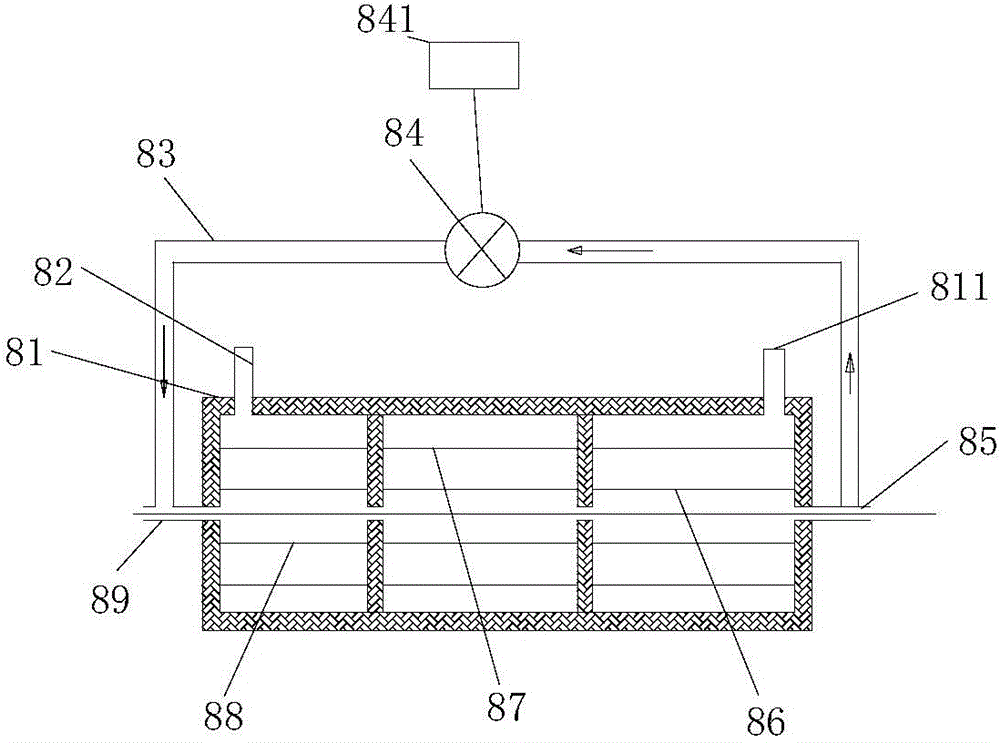

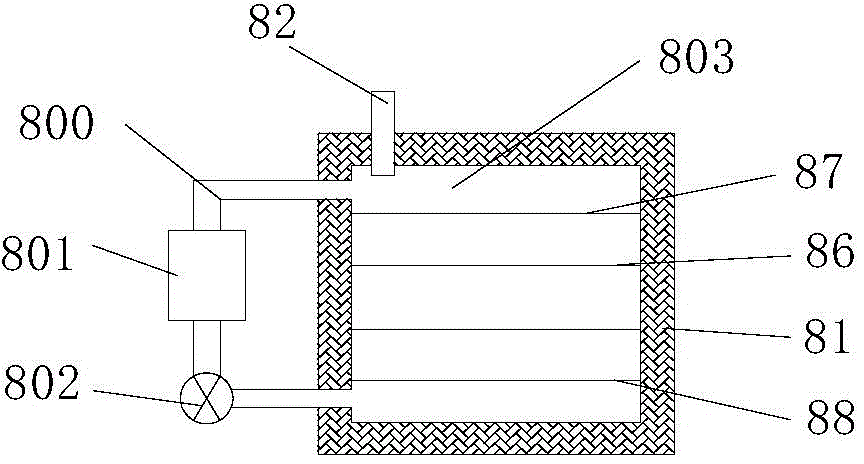

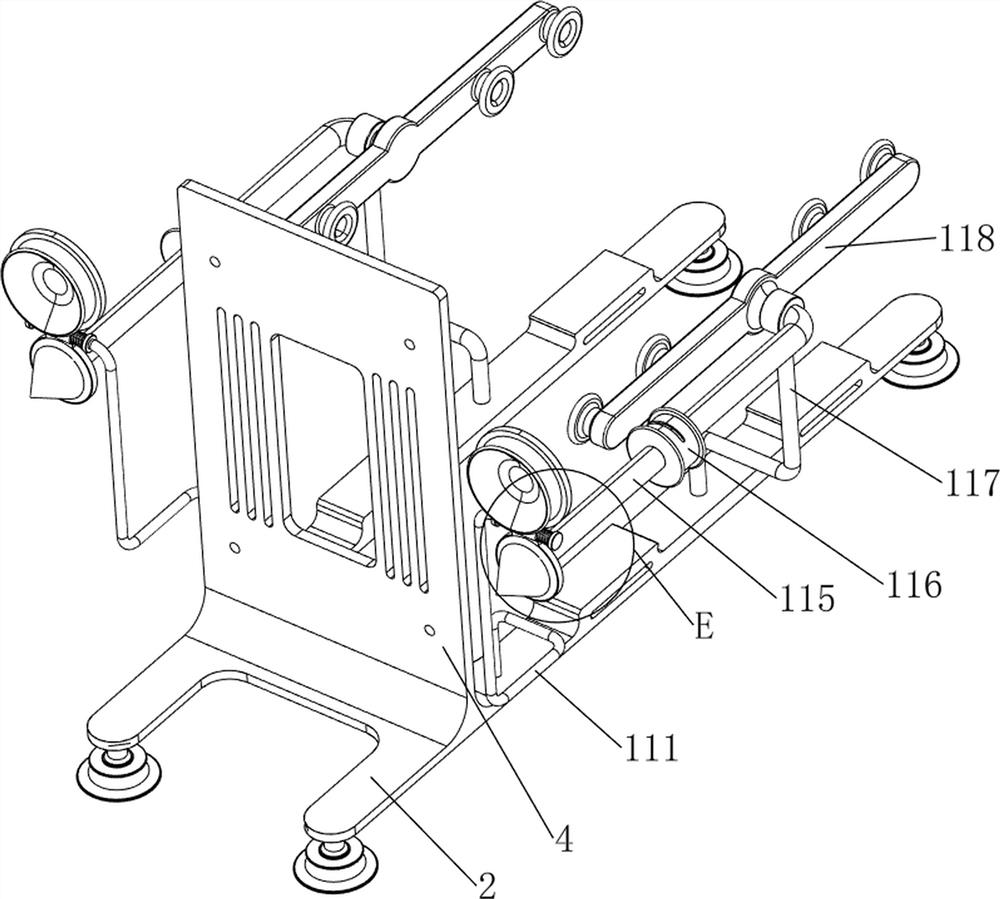

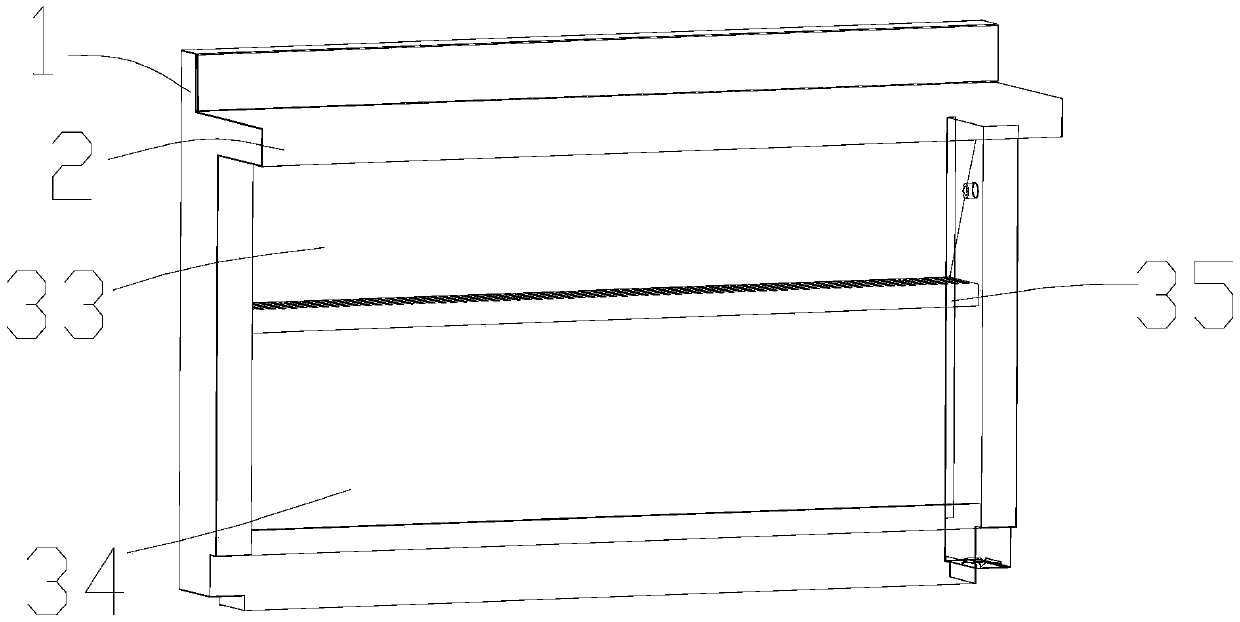

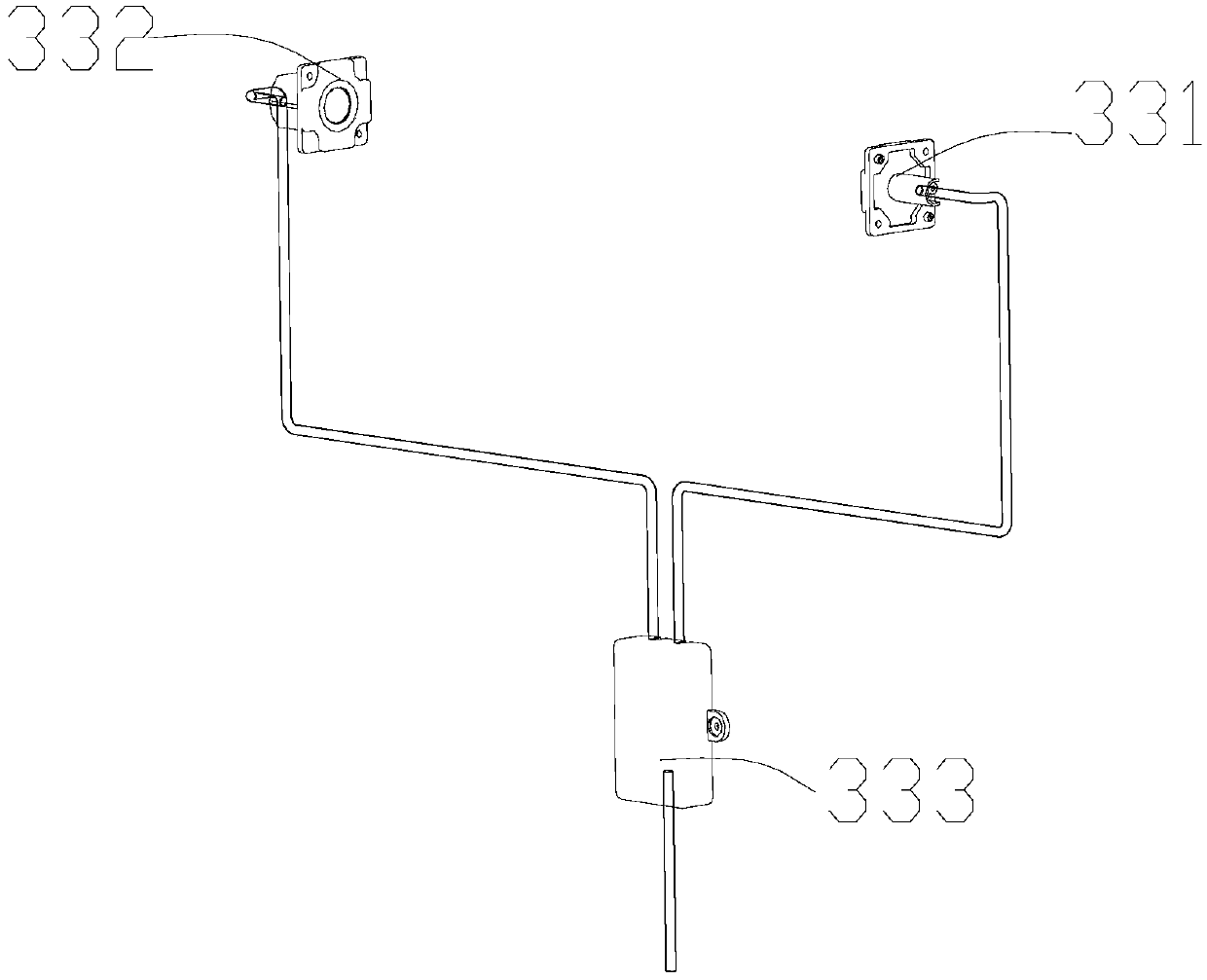

Sizing, drying and shaping device for polyacrylonitrile-based carbon fiber

ActiveCN103334246AGuaranteed uniformityImprove uniformityHeating/cooling textile fabricsLiquid/gas/vapor removal by gas jetsCarbon fibersWorking environment

The invention belongs to a generation device for a polyacrylonitrile-based carbon fiber and particularly relates to a sizing, drying and shaping device for the polyacrylonitrile-based carbon fiber. The sizing, drying and shaping device comprises a sizing device for sizing a carbon fiber, a drying device for the sized carbon fiber as well as a shaping device for shaping the dried carbon fiber, wherein the sizing device comprises a sizing groove for accommodating slurry; a circulating pipeline is arranged on the outer side of the sizing groove; one end of the circulating pipeline is connected with the bottom of the sizing groove; the other end of the circulating pipeline is connected with the upper edge of the sizing groove; a circulating pump is arranged on the circulating pipeline; a guiding roller which is partially immersed in the slurry and an immersing roller which is completely immersed in the slurry are arranged in the sizing groove; a reflowing plate which is arranged in an extending manner is arranged on the outlet edge of the sizing groove; and an air purge device is fixedly arranged above the reflowing plate. According to the sizing, drying and shaping device disclosed by the invention, the sizing is uniform, the shape of tows is good; the pollution of air to the carbon fiber is reduced in the sizing and drying; and meanwhile, the work environment is improved and the work comfortableness of workers is improved.

Owner:ZHONGJIAN TECH CO LTD

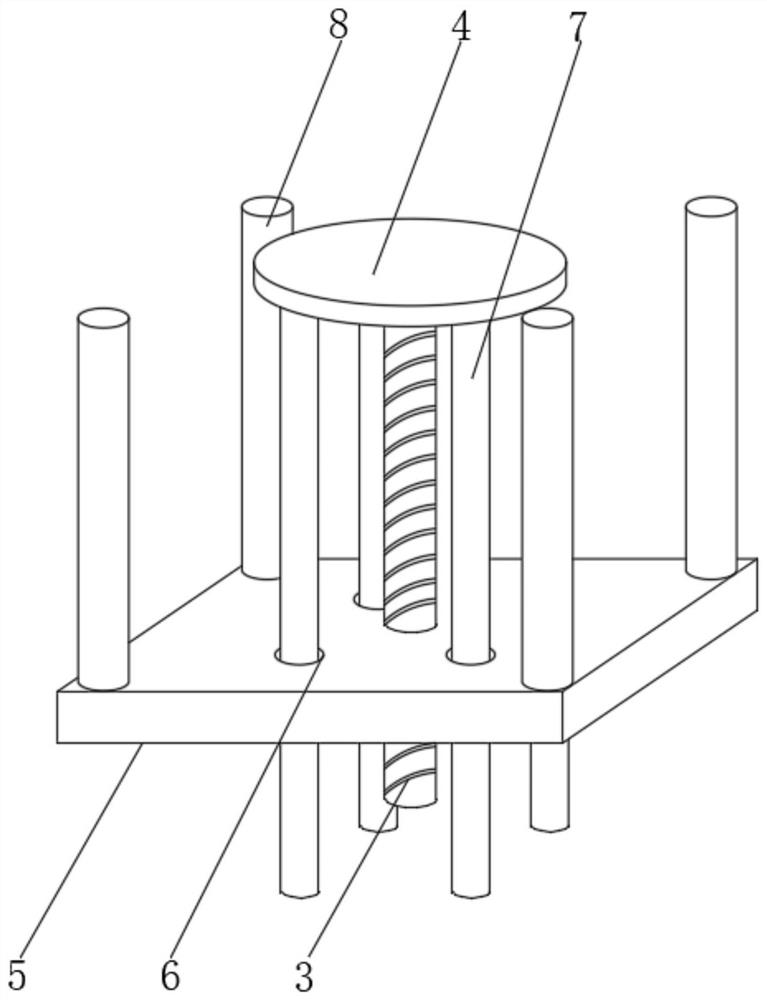

Ionic wind radiating device

ActiveCN105283046AConduct heatAdjust the wind speedCooling/ventilation/heating modificationsIonizationEngineering

The invention provides an ionic wind radiating device, which is characterized by comprising an insulated shell body and an ionic wind generator, wherein the shell body is composed of a bottom surface and a plurality of sliding rails in vertical connection with the bottom surface; an emitter of the ionic wind generator is fixed to free ends of the sliding rails, and is opposite to the bottom surface of the shell body; the emitter is connected with a positive electrode or a negative electrode of a power supply; the peripheral edge of a receiver of the ionic wind generator is provided with a plurality of sliding blocks, and the sliding blocks are installed on the sliding rails; the receiver is electrically connected with a ground wire, and an insulated thermal conducting substrate is fixed to the back surface of the receiver; the thermal conducting substrate is fixed to the bottom surface of the shell body and is fixedly connected with the bottom surface; and the surface of the receiver is coated with an ozone filtering coating. Through the structural design, the ionic wind generator has three functions of generating an ionic wind, effectively conducting heat and removing ozone generated in the ionization process. The ionic wind radiating device can adjust the distance between the receiver and the emitter of the ionic wind generator, so as to adjust wind speed of the ionic wind.

Owner:JIANGSU UNIV

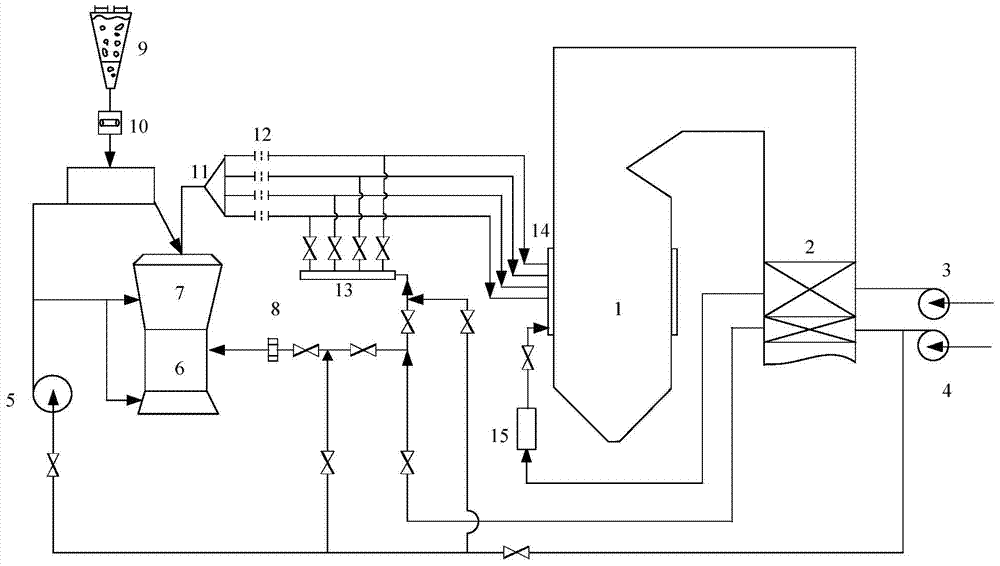

Positive-pressure direct-firing pulverizing system based on segmented temperature control and control method thereof

ActiveCN103925607AGuaranteed drynessGuaranteed ventilation effectAir supply regulationIndirect carbon-dioxide mitigationAir preheaterPositive pressure

The invention discloses a positive-pressure direct-firing pulverizing system based on segmented temperature control and a control method of the positive-pressure direct-firing pulverizing system. The positive-pressure direct-firing pulverizing system comprises an air preheater, an air feeder, a primary air fan, a seal air fan, a coal mill, a tailing separator, a raw coal hopper, a coal feeder, a pulverized coal distributor, an isolation door, a pulverized coal feeding system adjustment bellows, a pulverized coal burner and a secondary bellows. According to the control method, an inlet and an outlet of the coal mill are taken as a segment, an inlet and an outlet of a pulverized coal feeding system are taken as another segment, cold air and hot air are fed into the corresponding inlets of the two segments through corresponding pipelines, the temperatures of the two segments are monitored respectively, and then segmented control over the temperature of the pulverizing system is achieved. By means of the control method, the temperature of the pulverizing system and the temperature of the pulverized coal feeding system can be independently controlled, the air speed of the pulverized coal feeding system is kept not decreased under the condition that the air quantity of the pulverizing system is changed, and the demands for conveying pulverized coal and preventing a nozzle from being burnt out are met.

Owner:XIAN TPRI BOILER ENVIRONMENTAL PROTECTION ENG CO LTD +1

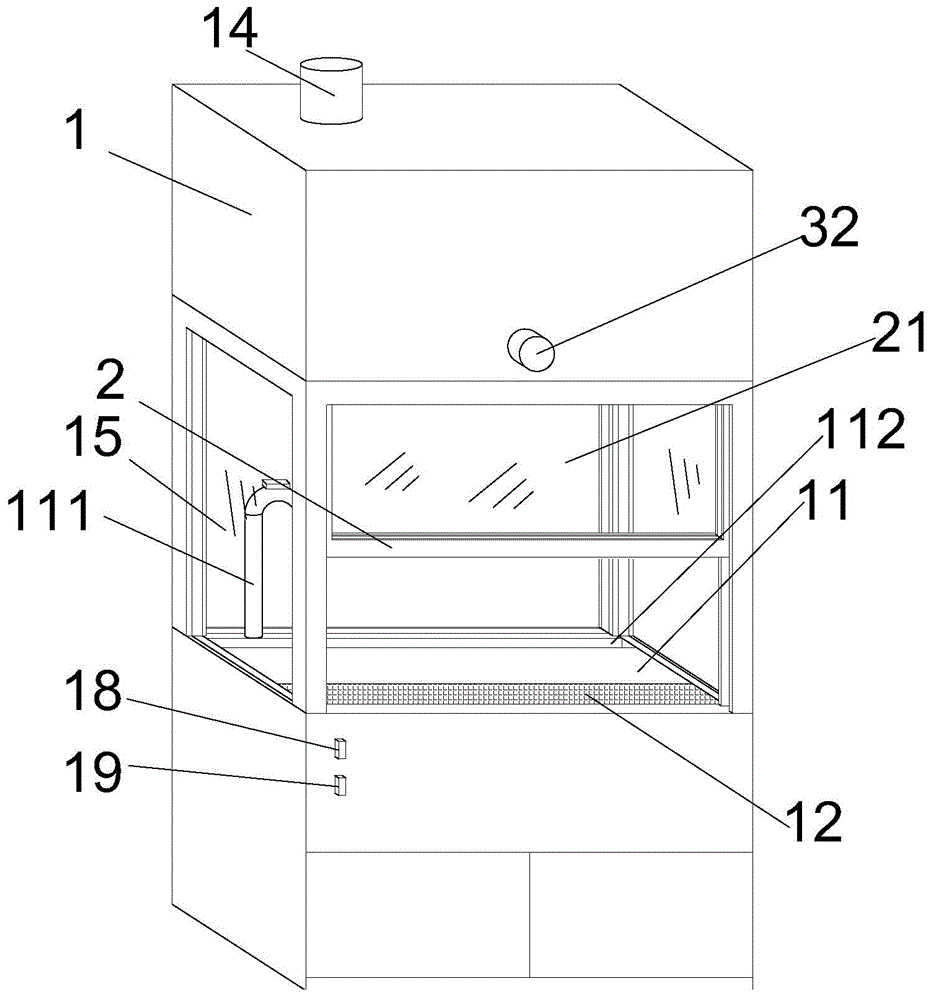

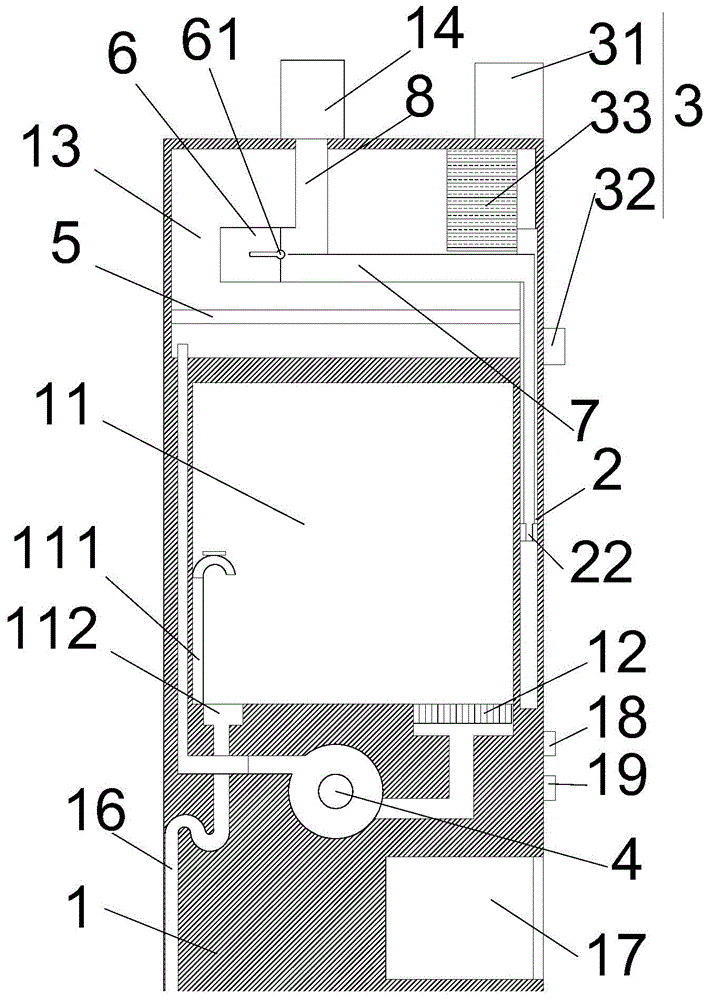

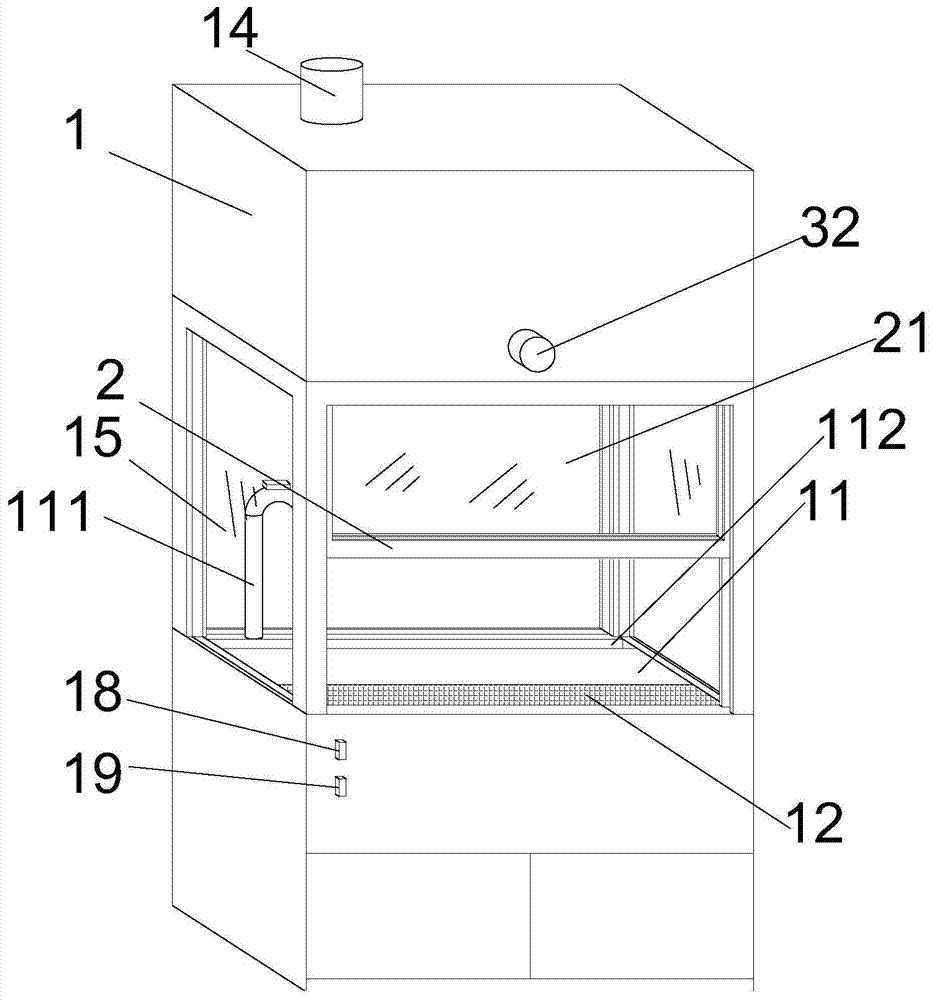

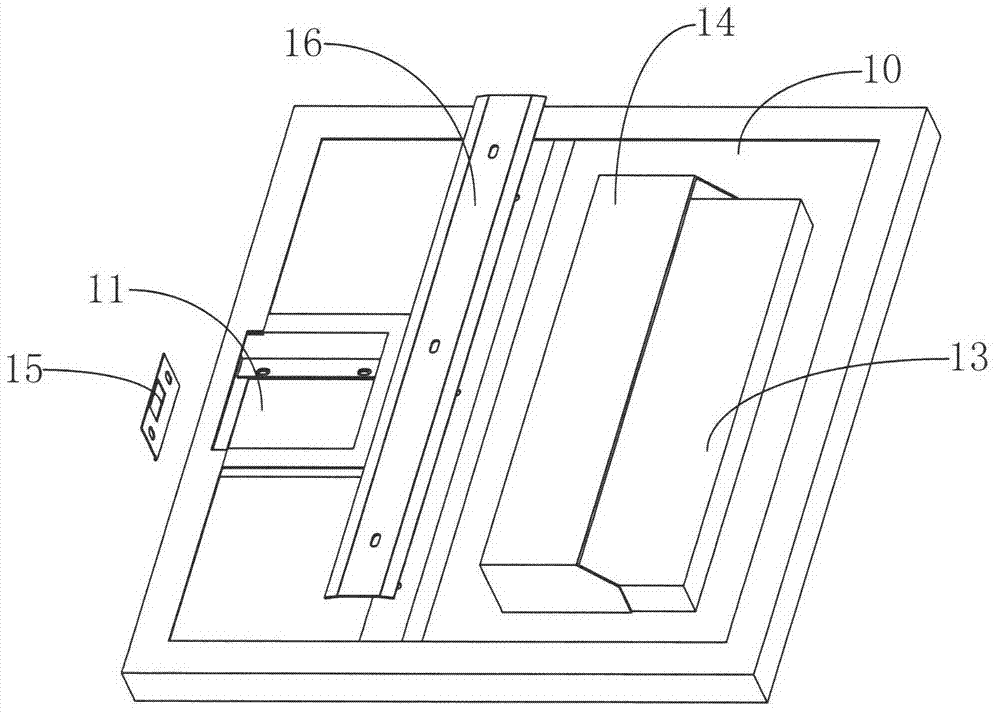

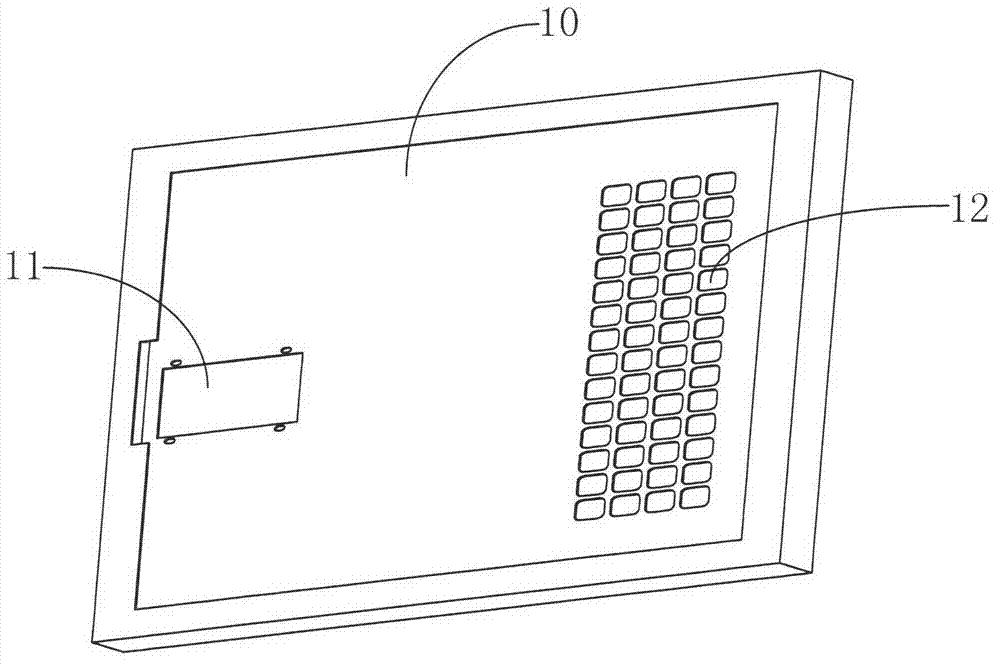

Fume cupboard for laboratory

The invention provides a fume cupboard for a laboratory. The fume cupboard comprises a cupboard body, a cupboard door and a control mechanism. A fan, a filter net, a flow distribution pipe, a first air guide pipe and a second air guide pipe are installed in the cupboard body. An operation room, an air inlet channel and a filter cavity are formed in the cupboard body. The cupboard door is provided with a first observation window. The bottom of the cupboard door is provided with a first air outlet channel, and the top of the cupboard body is provided with a second air outlet channel. An air outlet of the flow distribution pipe is communicated with the first air outlet channel through the first air guide pipe and communicated with the second air outlet channel through the second air guide pipe. A flow distribution valve is installed in the flow distribution pipe in a rotatable mode. The control mechanism comprises a control device, an infrared sensing device and a driving device. The driving device is in driving connection with the cupboard door. The control device is in communication connection with the infrared sensing device, the driving device and the fan. According to the fume cupboard for the laboratory, harmful gas can be effectively prevented from being inhaled by the human body, experimental operation is convenient, operation objects are almost not affected by the wind speed in the experiment process, and meanwhile energy can be saved.

Owner:ANHUI YUAN LAB EQUIP

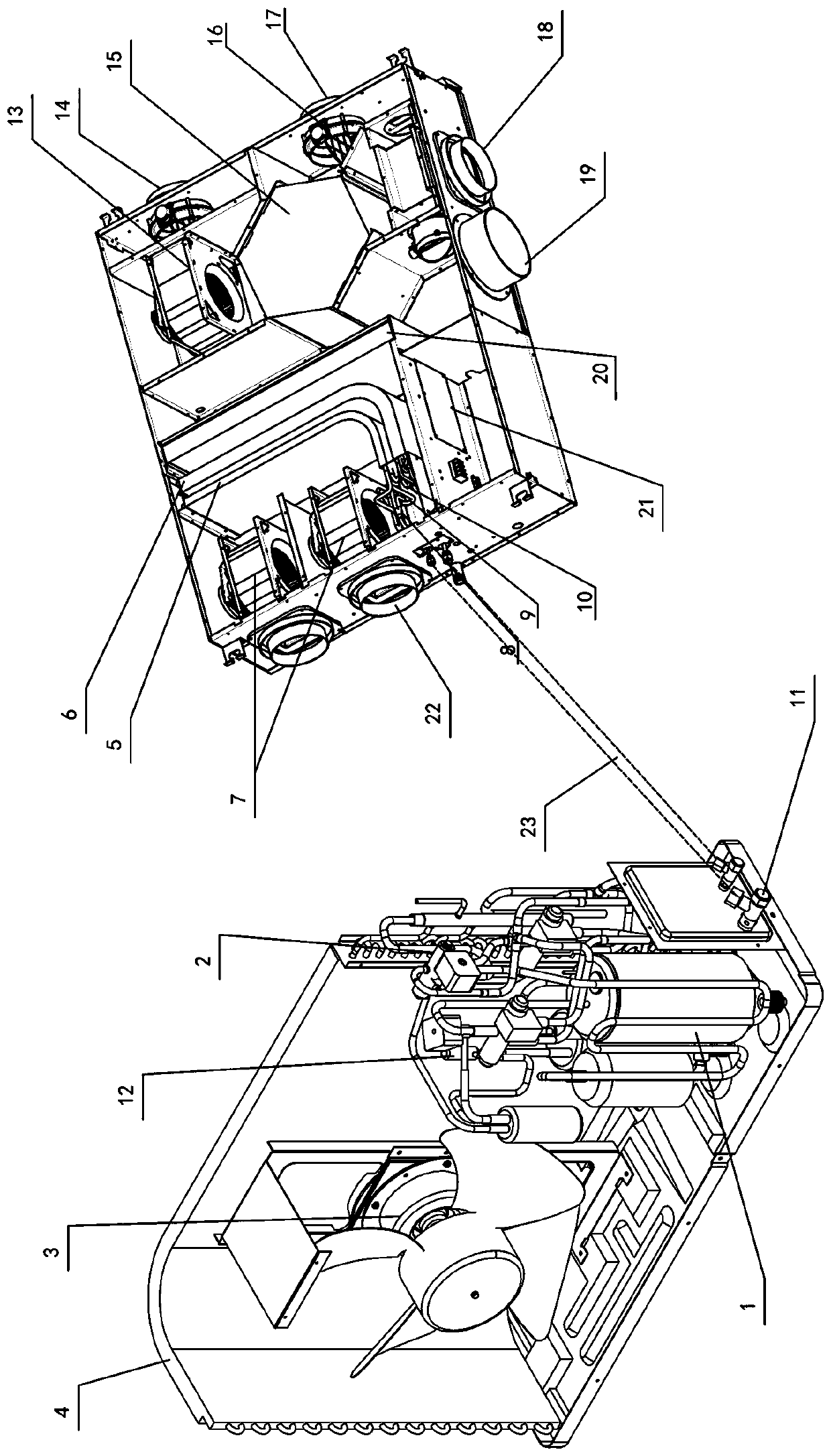

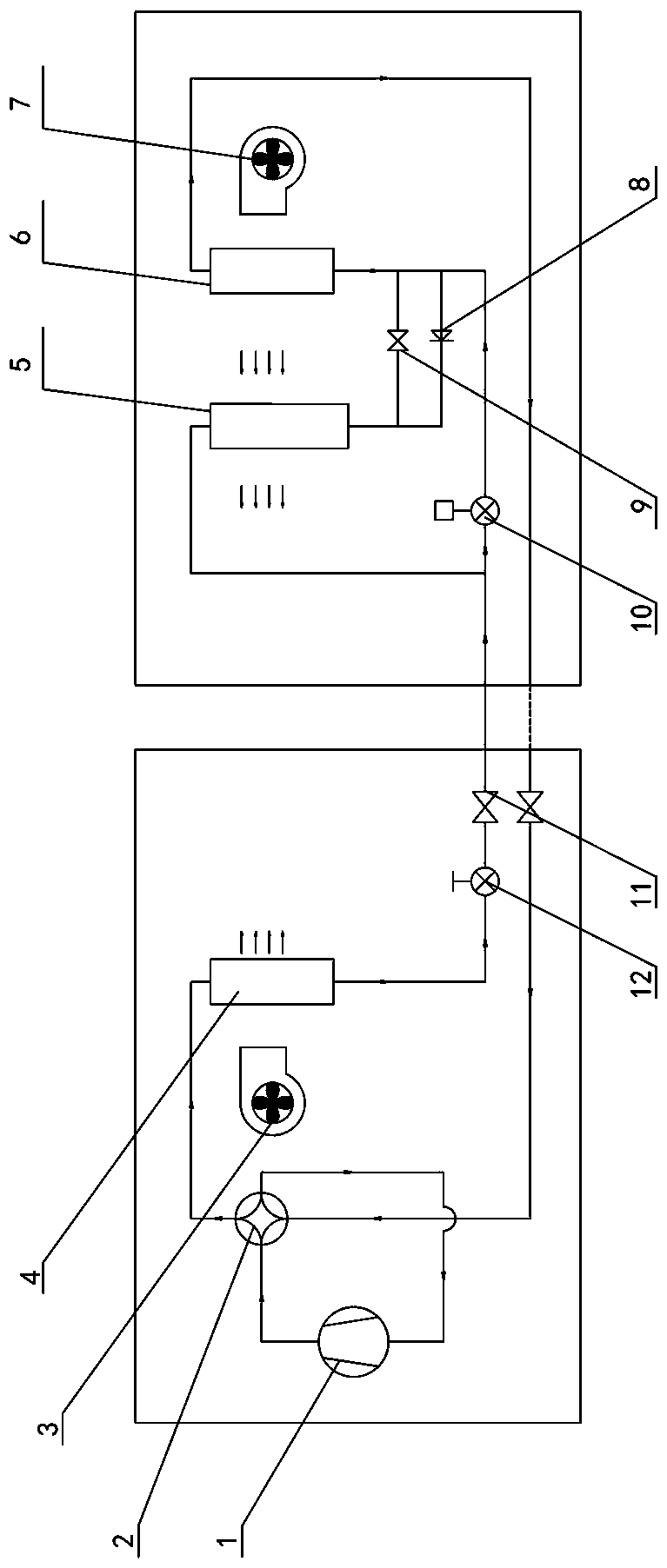

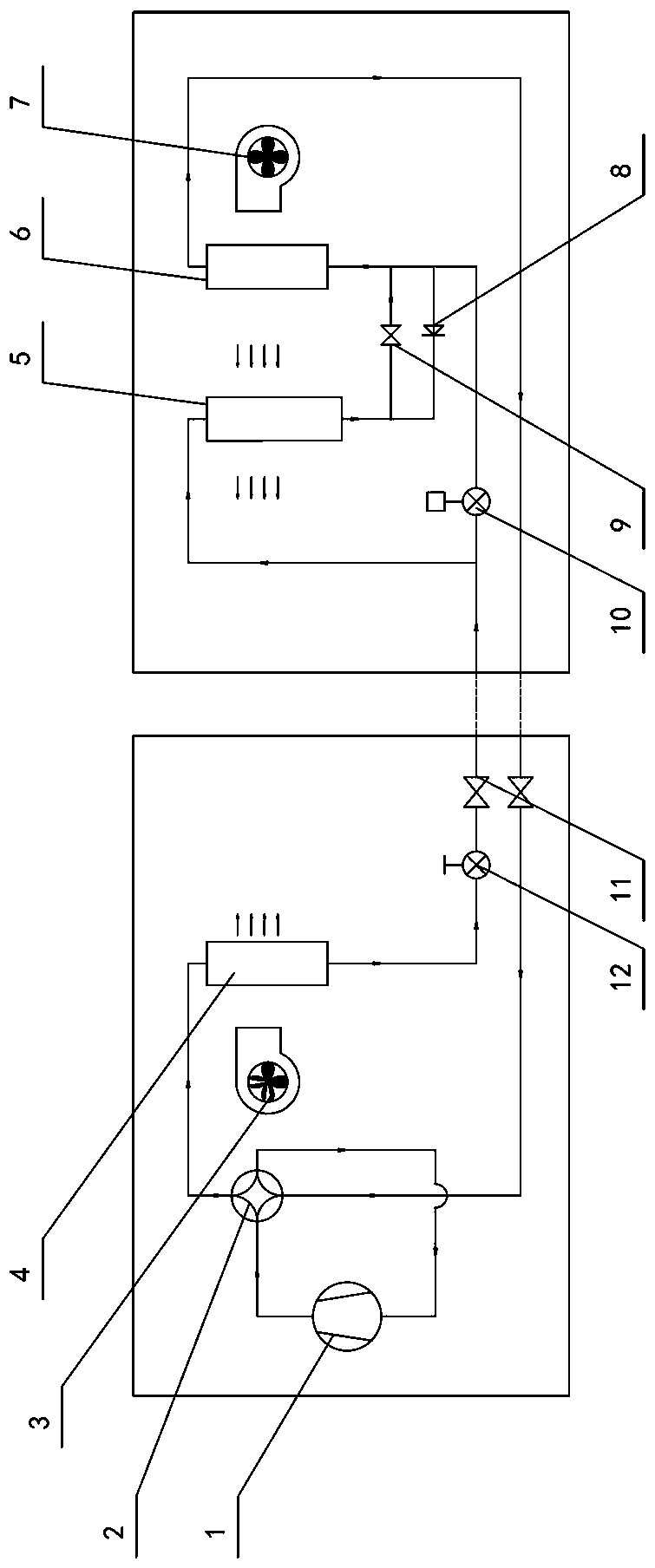

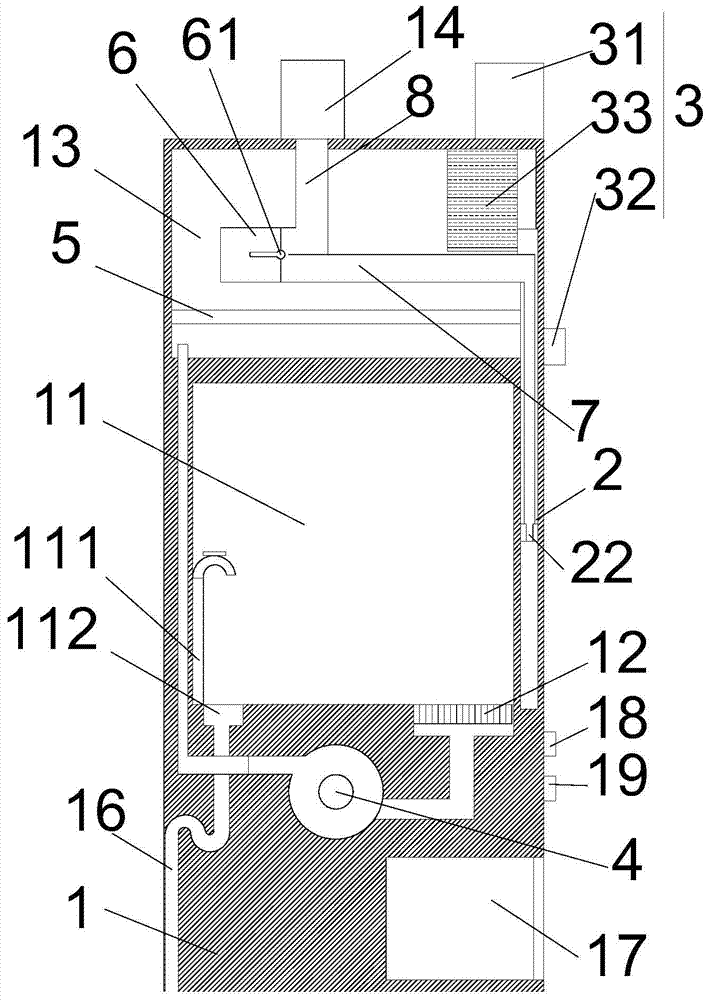

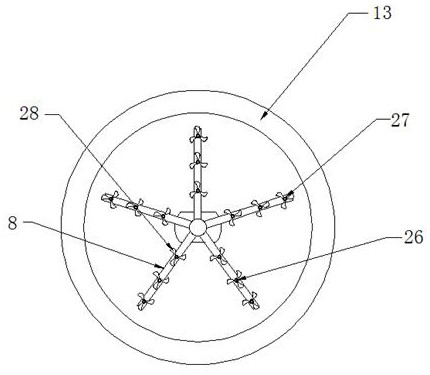

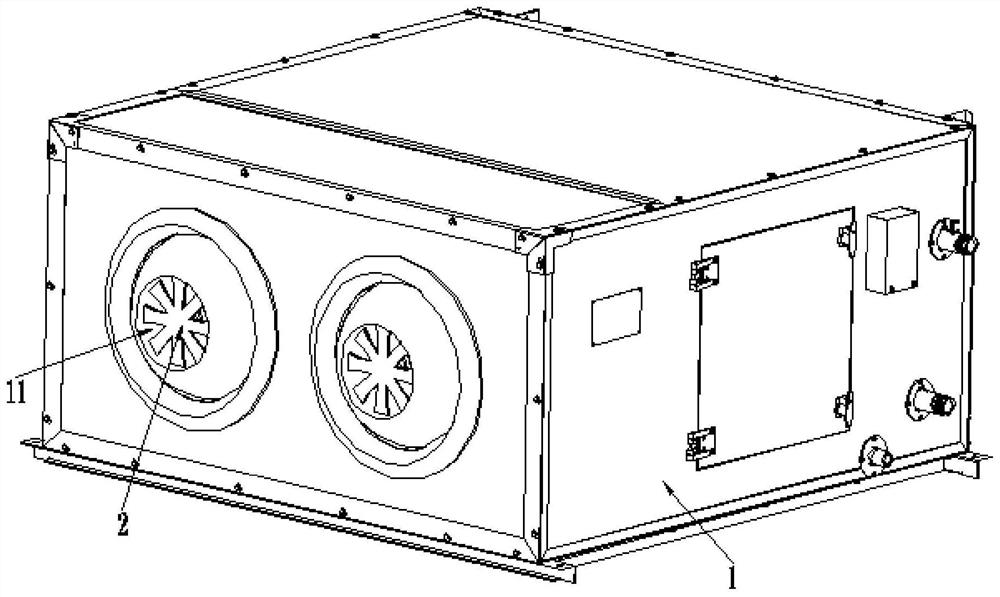

Total-heat fresh air exchange equipment with isothermal or temperature-rise dehumidification function

PendingCN110986206AAdjust the wind speedEnergy recovery in ventilation and heatingMechanical apparatusFresh airEngineering

The invention discloses total-heat fresh air exchange equipment with an isothermal or temperature-rise dehumidification function. The total-heat fresh air exchange equipment comprises an outdoor unitand an indoor unit which are connected by a copper pipe, and is characterized in that the outdoor unit is internally provided a compressor, a four-way valve, an outdoor fan, an outdoor condenser and an outdoor electronic expansion valve, the indoor unit is internally provided with a reheat condenser, an indoor evaporator, an indoor fan, a one-way valve, a dehumidification throttling device, a solenoid valve, a stop valve, an exhaust fan, a total-heat exchange core, an air filter net and a controller, an exhaust air outlet, a fresh air inlet and fresh air outlets are formed in cases on the leftside and the right side of the indoor unit correspondingly, and an exhaust air inlet and a circulating air inlet are formed in a case on the front side of the indoor unit. The temperature of a refrigerant outlet of the outdoor condenser is controlled by the controller to control the heat dissipation ratio of the outdoor condenser and the indoor reheat condenser, so that the temperature of indooroutlet air is controlled to be higher than or equal to the temperature of return air, an isothermal or temperature-rise effect is achieved, and a living environment with the suitable temperature and humidity is provided.

Owner:浙江普瑞泰环境设备有限公司

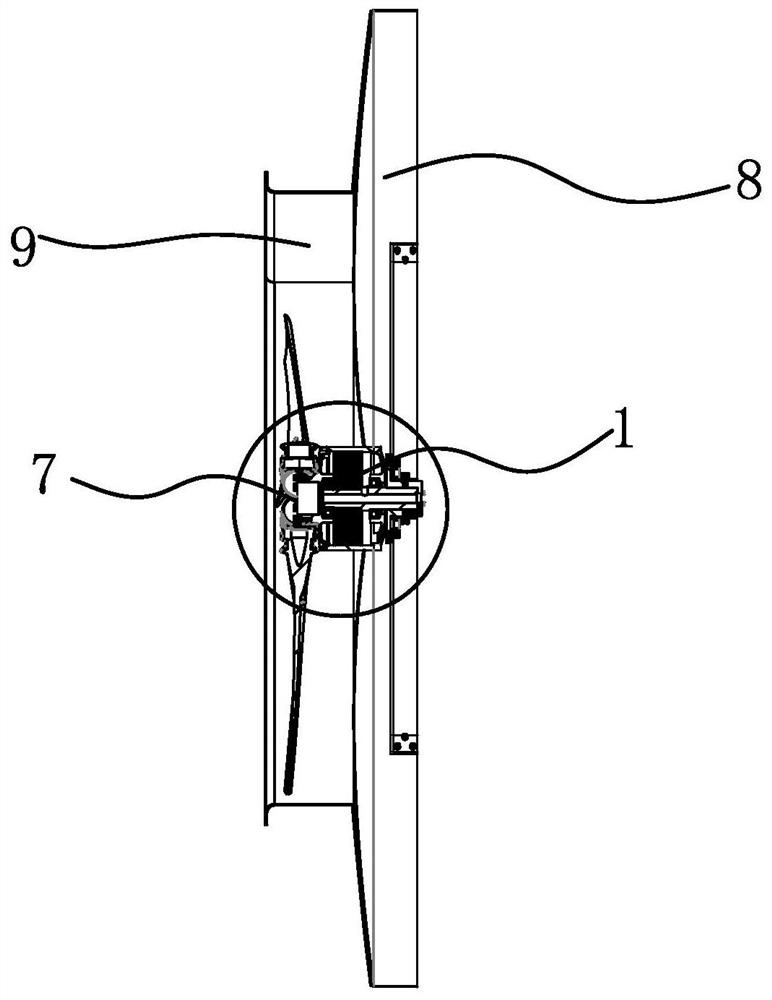

Air curtain isolating device

InactiveCN105135589AAvoid enteringAvoid harmSpace heating and ventilation safety systemsLighting and heating apparatusStraight tubeEngineering

The invention discloses an air curtain isolating device, and belongs to the technical field of air curtain devices. The air curtain isolating device is installed on one side of a door frame, and the door frame comprises two stand columns which are arranged oppositely and a cross beam which is erected at the top ends of the stand columns; the air curtain isolating device comprises a mechanical valve which is installed on one of the stand columns and fixed on the face, opposite to the other stand column, of the stand column, the middle of the cross beam is provided with a tee joint, two transverse connectors of the tee joint are each connected with one end of an air curtain short pipe which is horizontally arranged, the other end of each air curtain short pipe is connected with the top end of an air curtain long pipe, each air curtain long pipe is vertically installed on one stand column, and the bottom ends of the air curtain long pipe are closed; a longitudinal connector of the tee joint is connected with one end of a straight pipe, the other end of the straight pipe is communicated with an air outlet of the mechanical valve through a metal hose, and an air inlet of the mechanical valve is connected with an externally air supply device through a metal hose. According to the air curtain isolating device, harmful components can be prevented from entering an office area along with opening of an isolation door.

Owner:中船环境工程有限公司

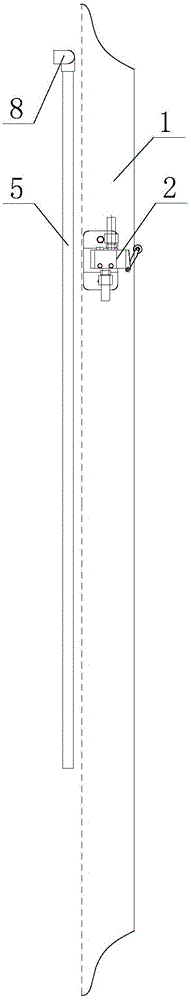

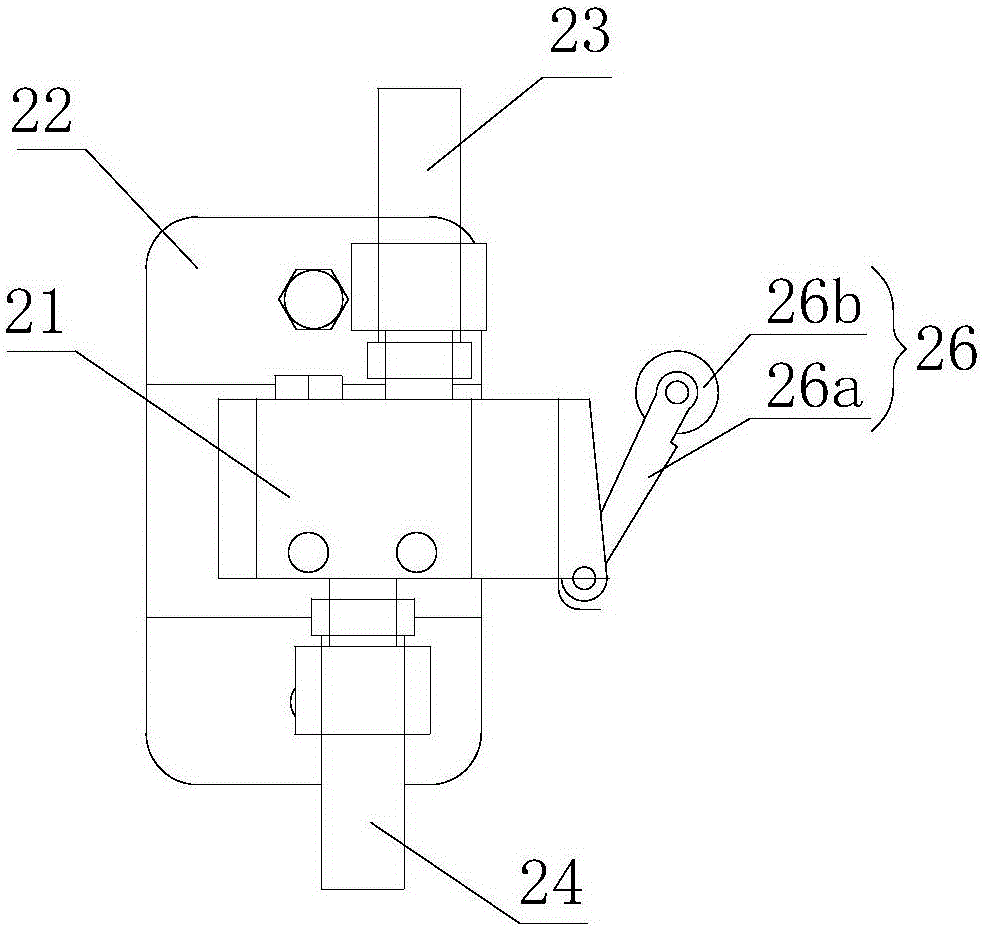

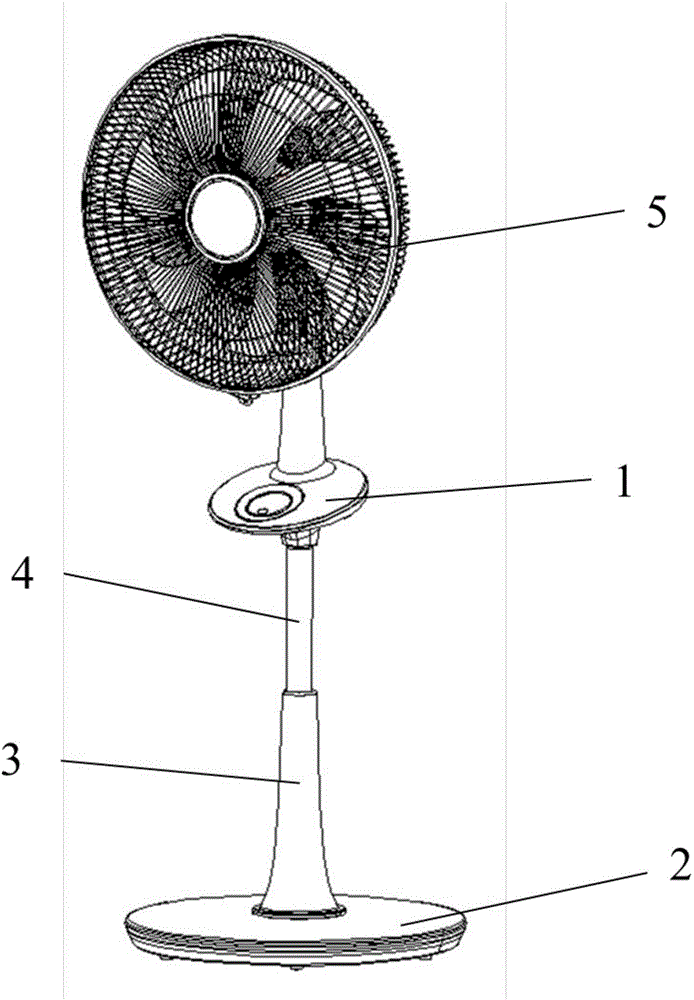

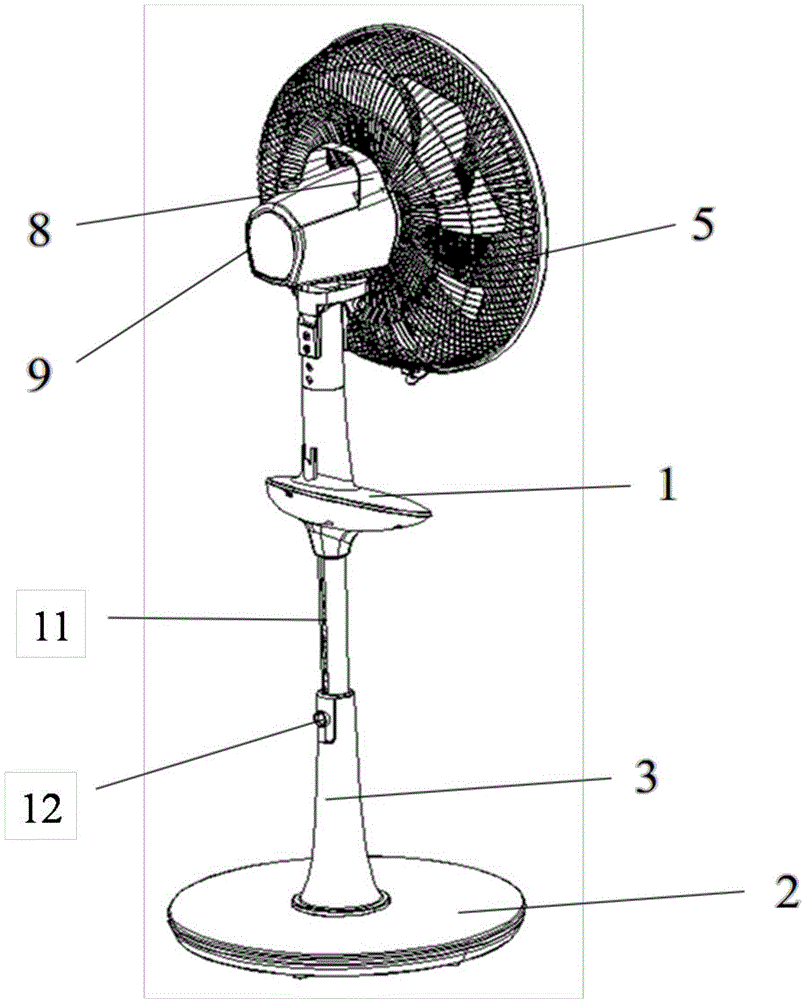

Novel electric fan

InactiveCN104373363AEasy to operateHumanized designPump componentsPump controlElectricityEmbedded system

Owner:SKYRUN ELECTRIC SUZHOU

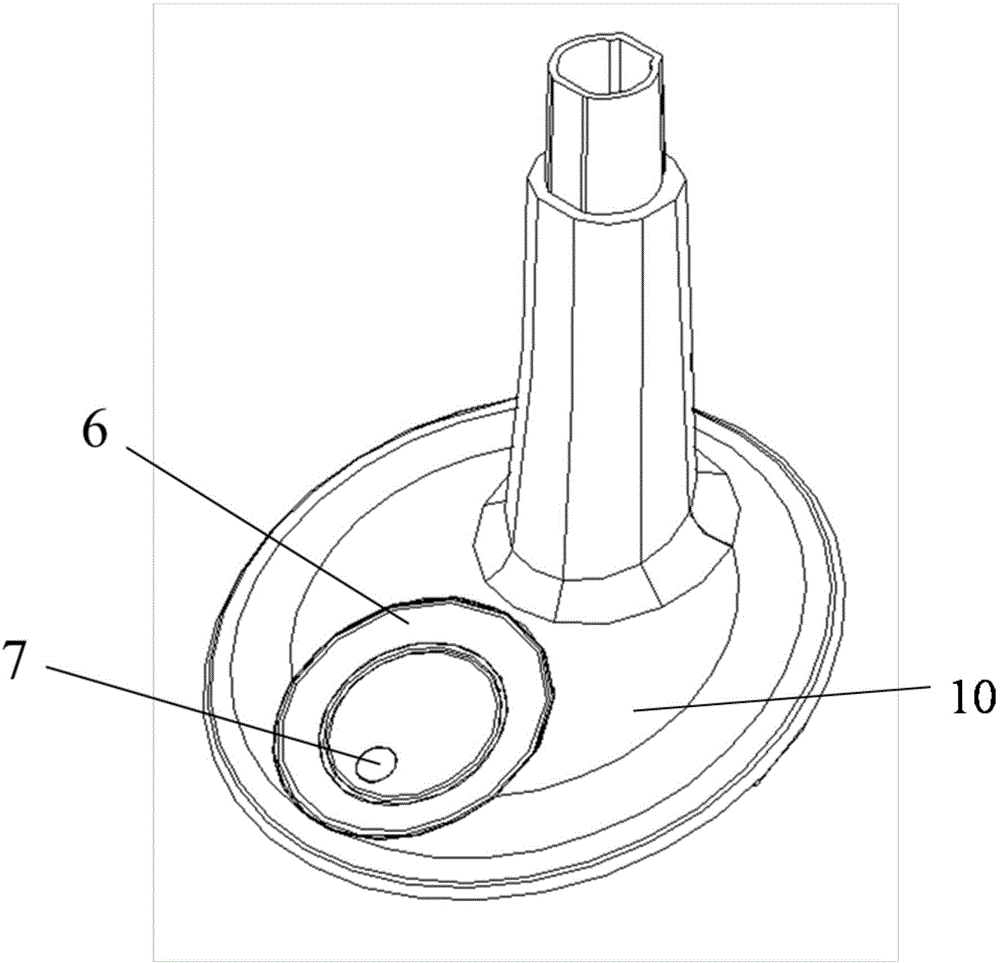

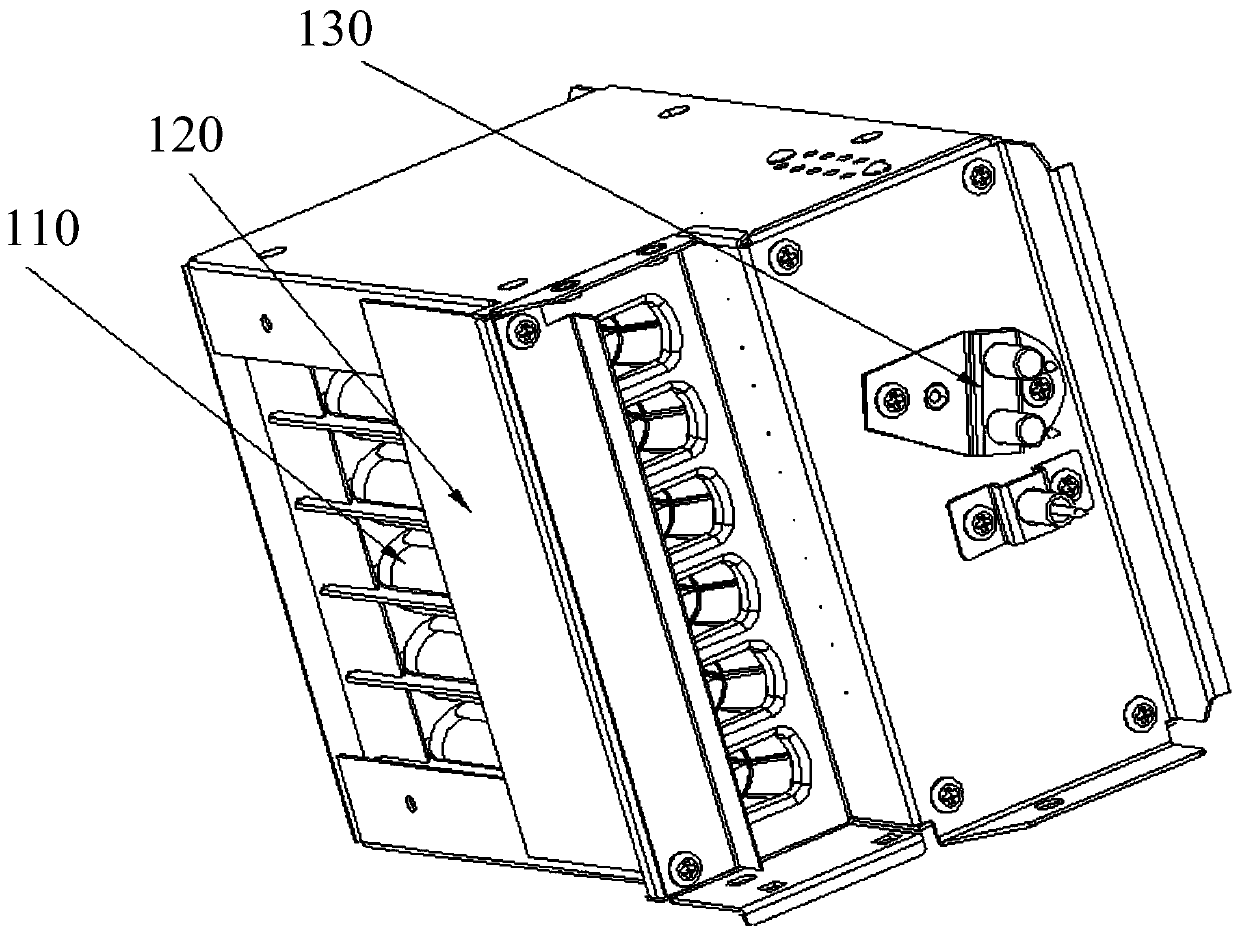

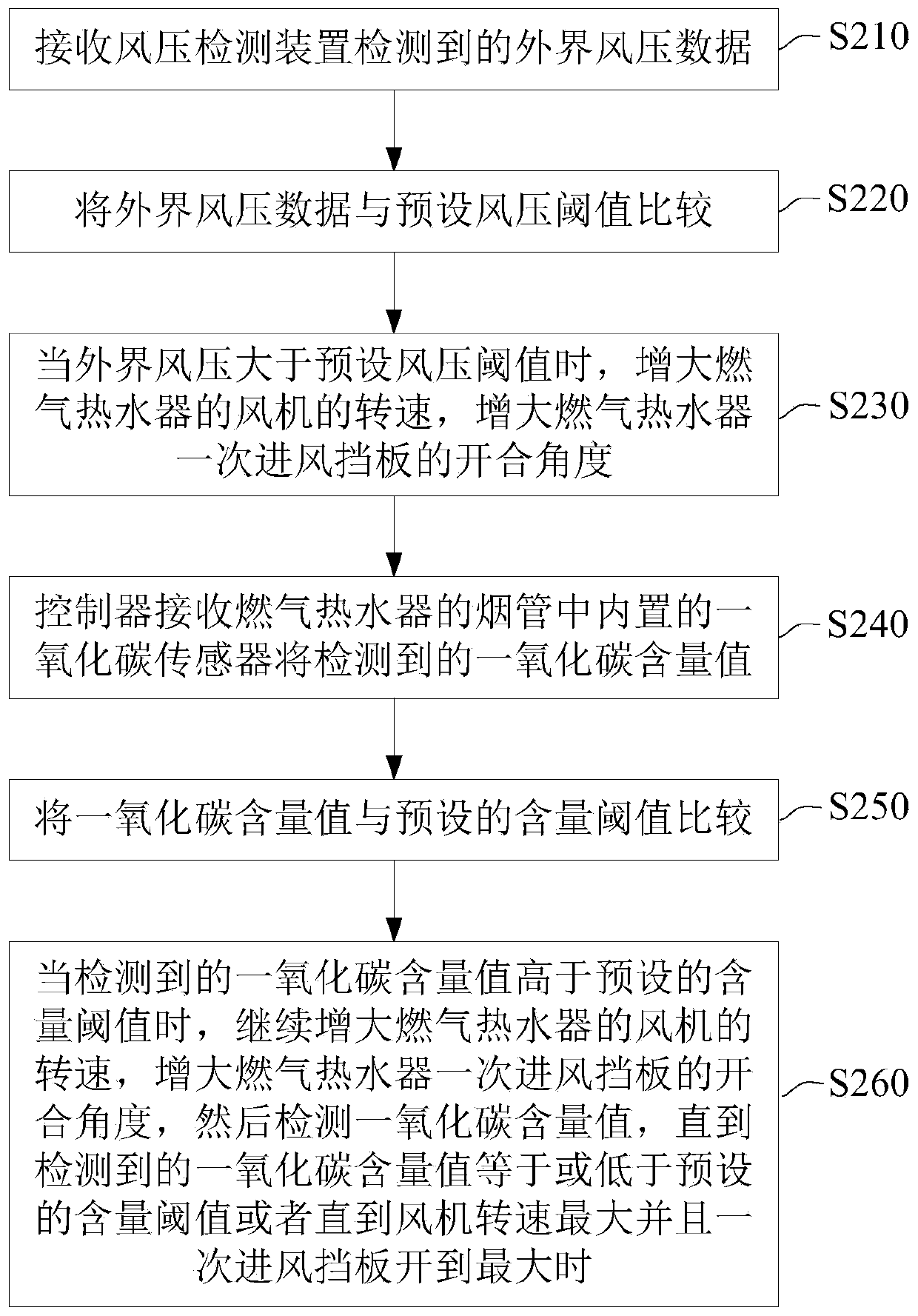

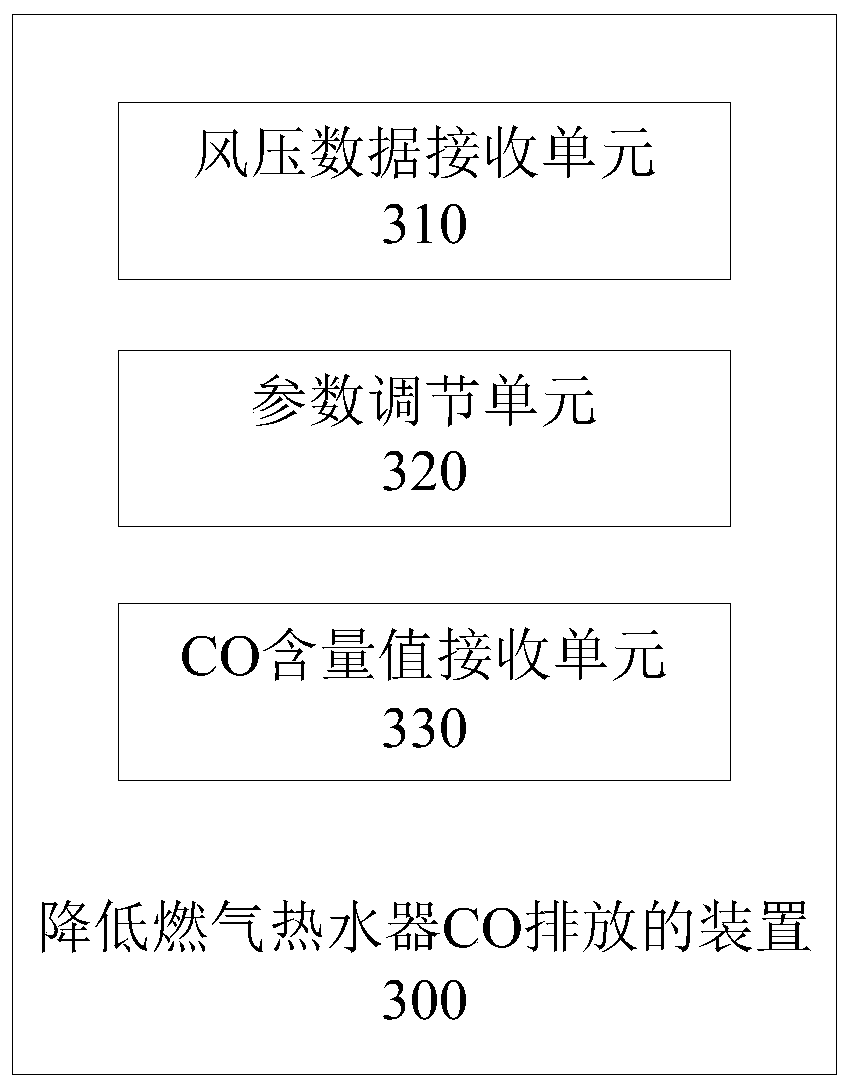

Method and device for reducing carbon monoxide emission of gas water heater

ActiveCN110595074AAdjust combustion conditionsAdjust the wind speedFluid heatersEngineeringPressure threshold

The invention discloses a method and device for reducing carbon monoxide emission of a gas water heater. The method includes the steps that external wind pressure data detected by a wind pressure detection device are received; when the external wind pressure is larger than the preset wind pressure threshold value, the rotating speed of a draught fan of the gas water heater is increased, and the opening and closing angle of a primary air inlet baffle of the water heater is increased; a controller receives the CO content value detected by a CO sensor arranged in a smoke tube in the gas water heater; when it is detected that the CO content value is higher than the preset content threshold value, the rotating speed of the draught fan of the water heater is increased continuously, the opening and closing angle of the primary air inlet baffle of the gas water heater is increased, and then the CO content value is detected till the detected CO content value is equal to or lower than the presetcontent threshold value or till the rotating speed of the draught fan is the maximum and the primary air inlet baffle is opened to the maximum degree. By means of the method and device, the problem of increasing of the CO content in bad conditions is solved, the CO content of the water heater in the normal use condition is reduced, and the heat efficiency in the bad conditions is improved.

Owner:GREE ELECTRIC APPLIANCES INC

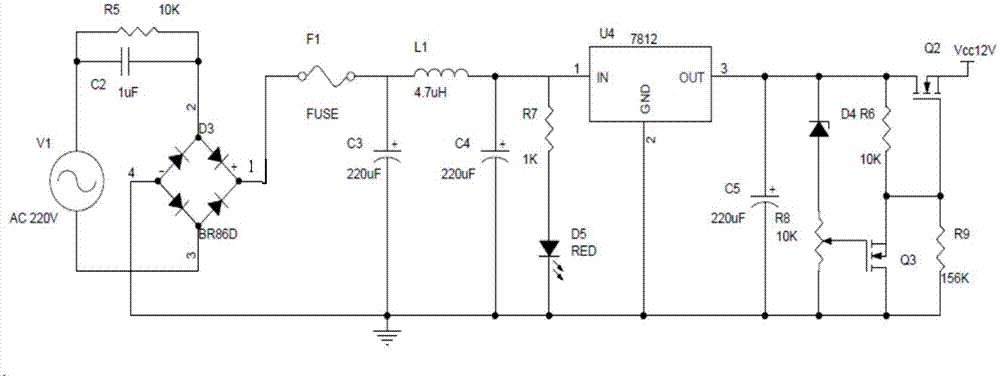

Output-amplifier-stage temperature control intelligent exhaust system

InactiveCN107882764ASimple structureHigh degree of intelligenceEngine controlPump controlCapacitanceCathode electrode

The invention discloses an output amplification stage temperature-controlled intelligent exhaust system, which is characterized in that it includes a power supply module, a temperature sensor U1, a fan M, a field effect tube Q4, a field effect tube Q5, and a front-end processing unit connected to the temperature sensor U1 Circuit, the capacitor C8 connected in series between the gate and drain of the field effect transistor Q4, the resistor R10 connected in parallel with the capacitor C8, the positive electrode is connected to the source of the field effect transistor Q4, and the negative electrode is connected to the GND pin of the temperature sensor U1 Connected polarity capacitor C7 and so on. The invention can automatically adjust the wind speed of the fan according to the temperature in the workshop, so as to intelligently cool down the temperature in the workshop, has a simple structure, high intelligence, and is suitable for wide use. The invention has the function of overvoltage protection to avoid damage to the system caused by high voltage.

Owner:四川新驱科为科技有限公司

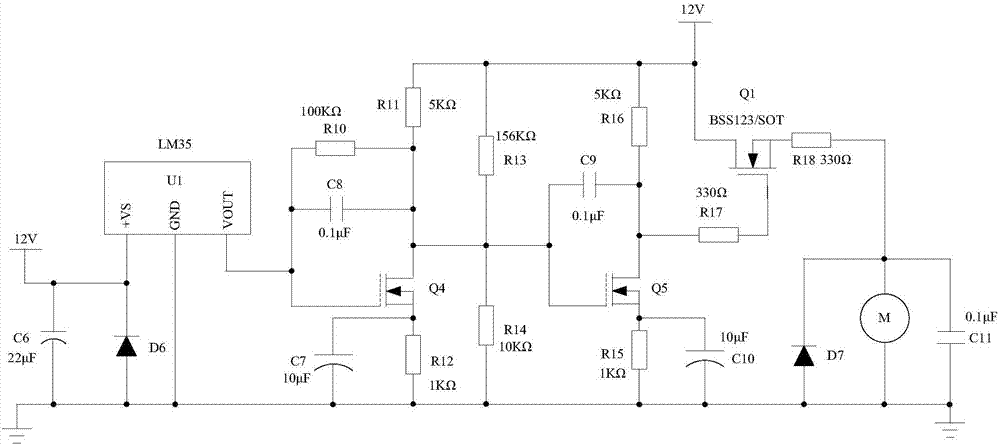

Process for recycling waste concrete aggregate and cementing material

ActiveCN108373280AAchieving High Level UtilizationImprove qualitySolid waste managementMaterials scienceConstruction aggregate

The invention relates to a process for recycling waste concrete aggregate and a cementing material and belongs to the technical field of concrete waste. The process includes: 1), separating through anexternal-circulation vertical mill: adopting the external-circulation vertical mill to process waste concrete to realize separation of aggregate and cement hydrate; 2), performing combined separatingpowder selection: adopting a static powder selector and a dynamic powder selector for separating powder selection, using the static powder selector to separate coarse aggregate and powder after goingthrough the external-circulation vertical mill, and using the dynamic powder selector to separate coarse powder and fine powder; 3), using an eccentric vibromill to correct circularity of aggregate selected out by the static powder selection and to further remove the cementing material attacked on the surface of the aggregate; 4), grading and washing: grading and washing the aggregate after beingtreated by the eccentric vibromill through a grading sieve to obtain coarse aggregate and fine aggregate. By the process, the aggregate and the cement hydrate are recycled to maximum extent, and an environment-friendly idea of cyclic utilization is realized.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

Ionic wind rod capable of removing static electricity

The invention provides an ionic wind rod capable of removing static electricity. The ionic wind rod capable of removing static electricity comprises a rod body, a high-pressure air pipe, a high-pressure generator and a spraying device. The high-pressure air pipe is connected at the upper end of the rod body, one side of the rod body is connected with the high-pressure generator through a high-pressure output line, a rod core is arranged in the rod body, a plurality of discharging needles are evenly distributed on the rod core, a plurality air outlets are evenly formed in the lower end of the rod body, spraying devices are installed at the lower ends of the air outlets, and the high-pressure air pipe, the discharging needles and the spraying device are matched. The ionic wind rod capable of removing static electricity is simple in structure and convenient to operate, static electricity ions on a product can be effectively removed, the air inlet speed and the air outlet speed can be effectively adjusted, the stability in the working process is guaranteed, the treating effect is improved, and the quality of the product is guaranteed; meanwhile, assembling, disassembling and maintaining are convenient, single maintaining and replacing can be achieved, and the service life of the ionic wind rod is prolonged.

Owner:TAICANG HUAHAO INFORMATION TECH CO LTD

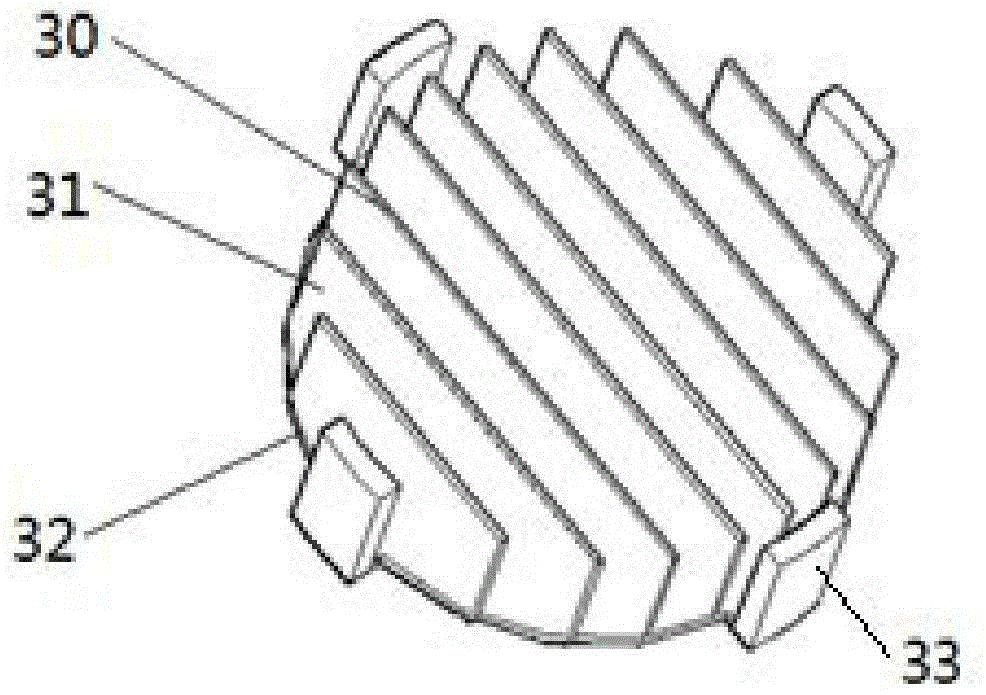

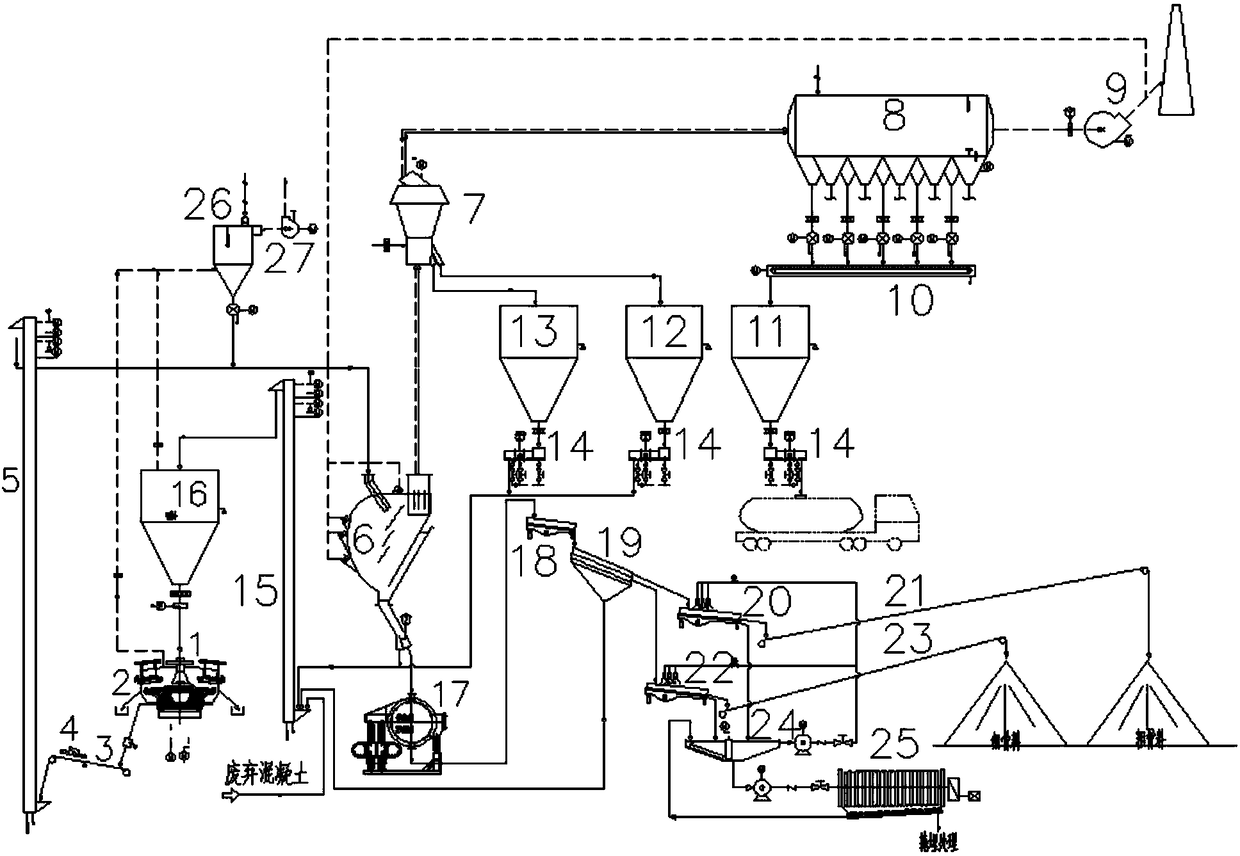

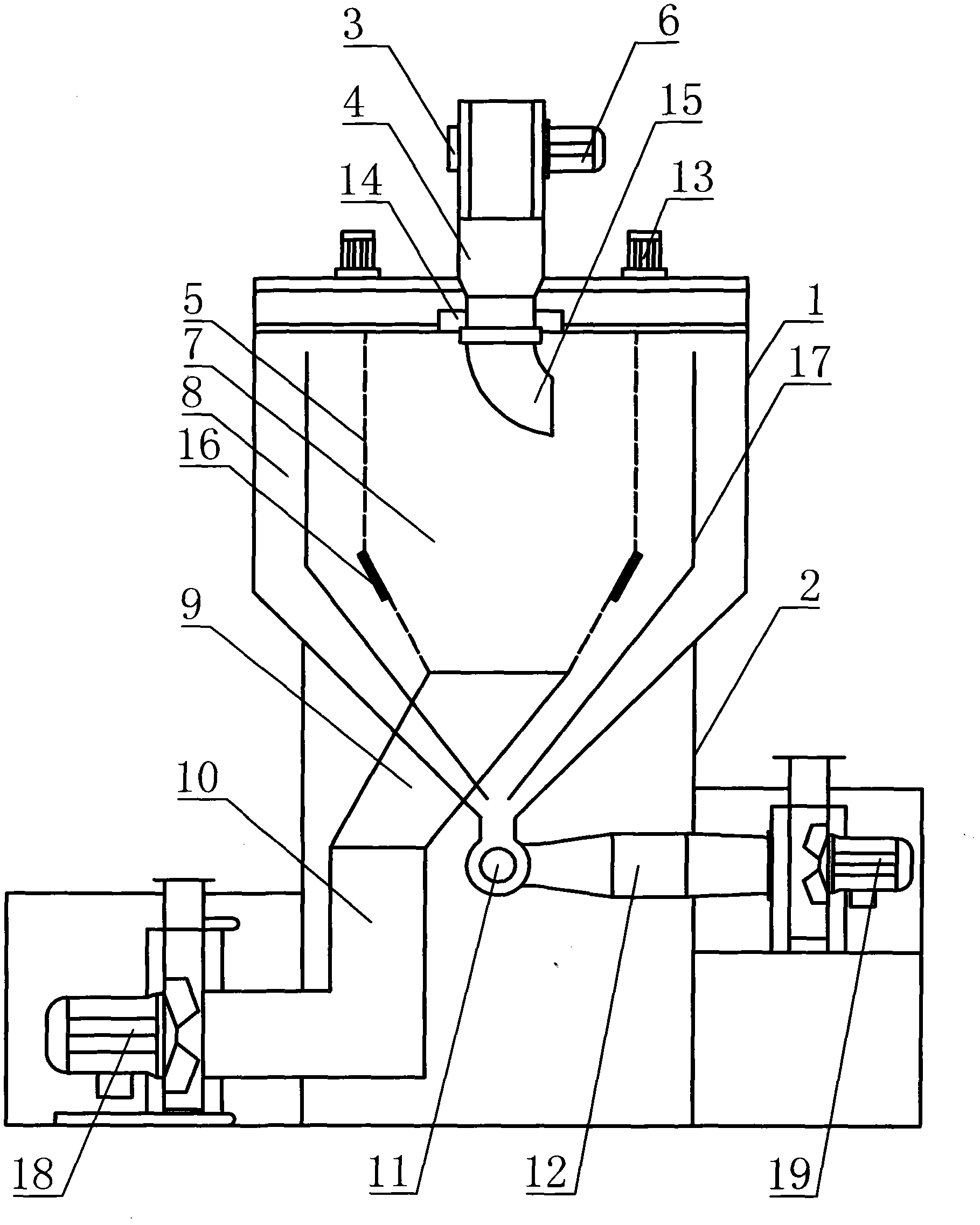

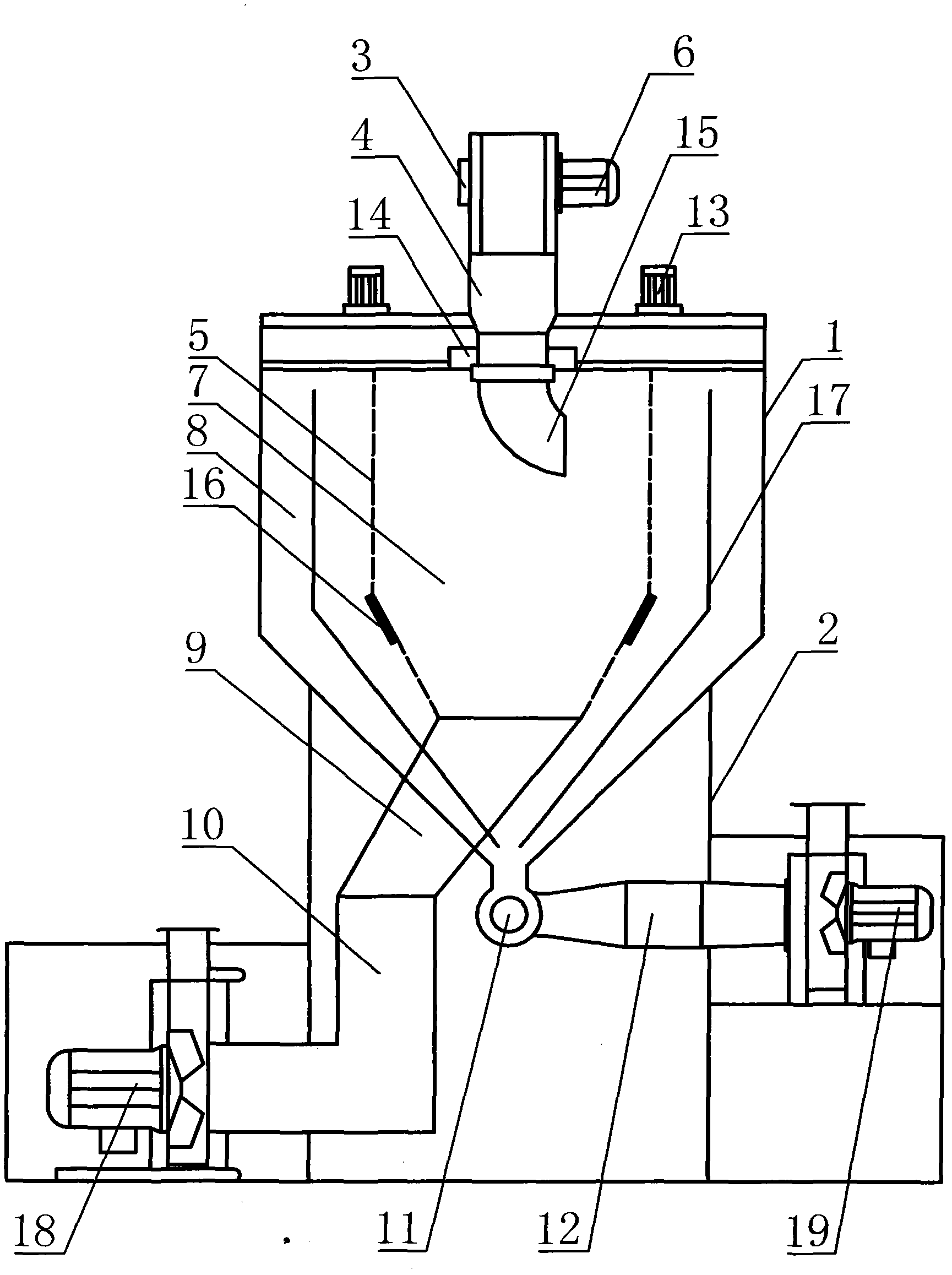

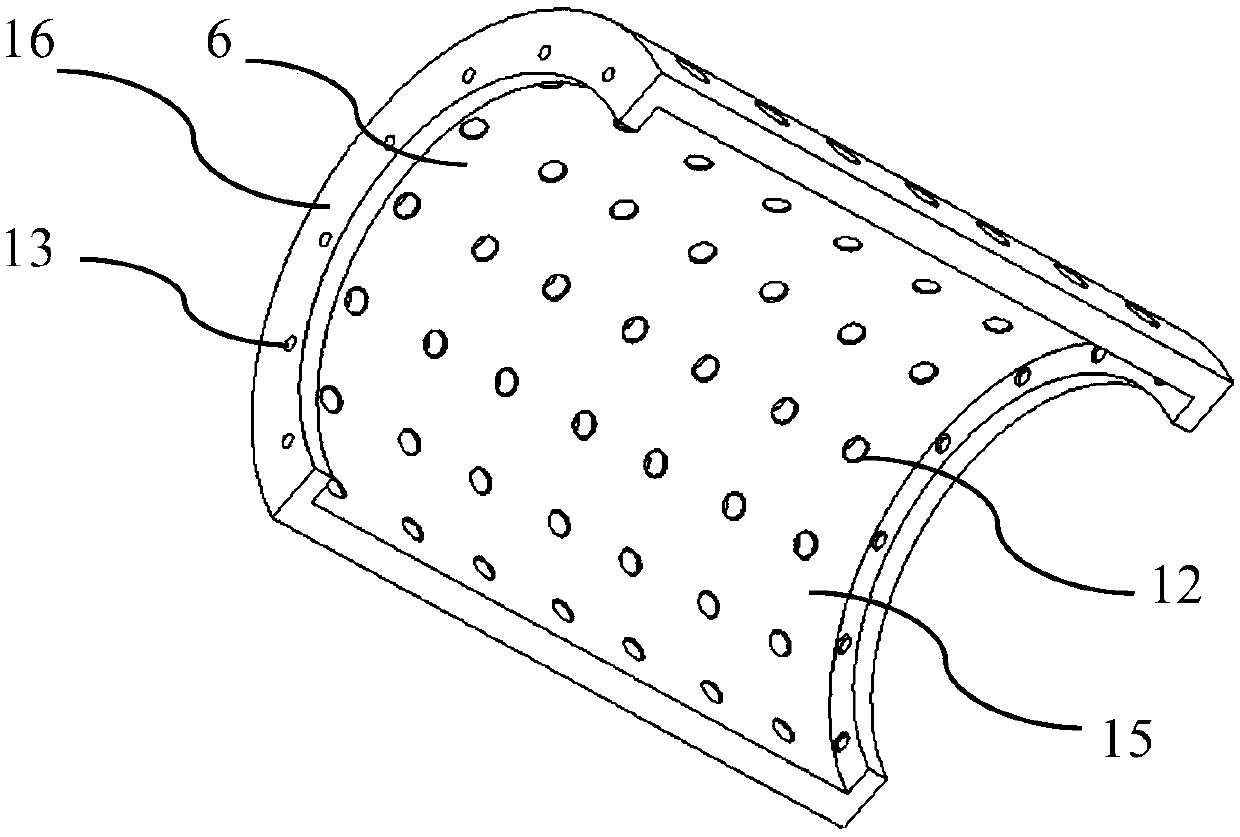

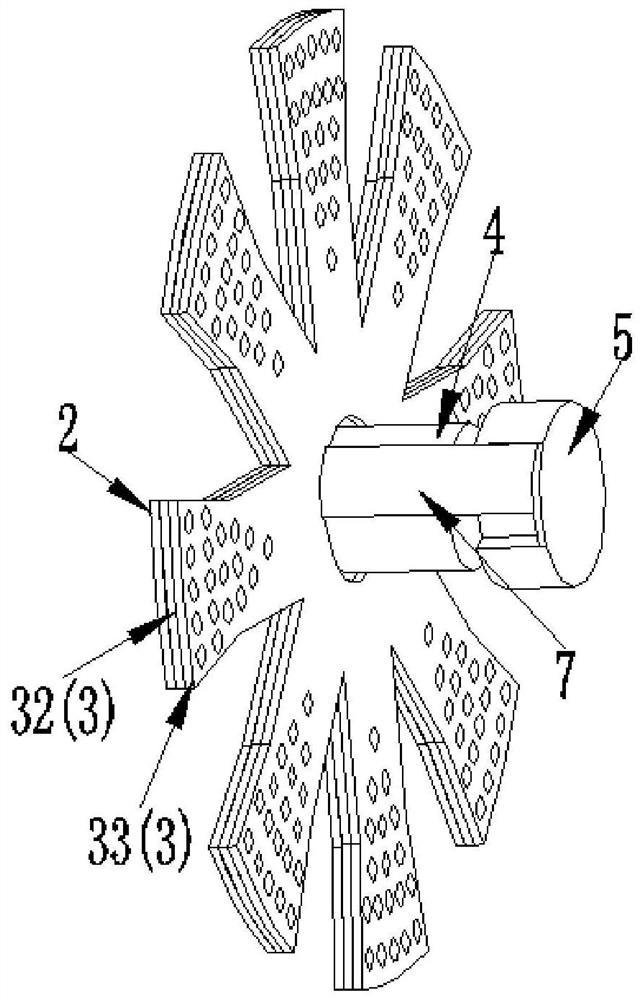

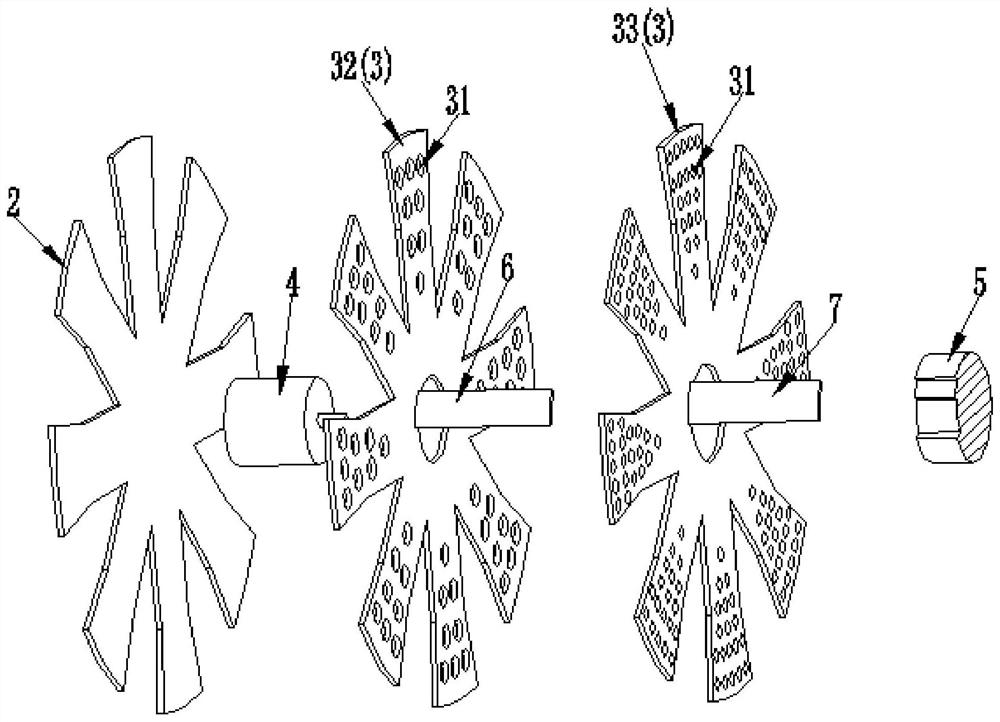

Cage type cotton removing and tiny dust removing machine

InactiveCN102618971AEfficient and full dust removalReduce in quantityFibre cleaning/opening machinesEngineeringCOTTON WOOL

The invention relates to the technical field of textile machines, in particular to a cage type cotton removing and tiny dust removing machine, which has a good tiny dust removing effect and is high in cotton discharging quality and low in failure rate. The machine comprises an upper box body (1), wherein a raw cotton inlet pipe (4) of which one side is provided with a raw cotton inlet (3) is arranged in the center of the top of the upper box body, and a dust removing cage (5) which is communicated with the top of the upper box body (1) is arranged in the internal center of the upper box body; a cotton inlet fan (6) is arranged on one side of the raw cotton inlet pipe (4); a port at one end of the raw cotton inlet pipe, which is extended into the upper box body, is provided with a rotating device; a tiny dust filtering chamber (7) is formed in an internal space of the dust removing cage (5); a tiny dust collecting chamber (8) is formed between the tiny dust filtering chamber (7) and the inner wall of the upper box body (1); a middle section cotton collecting chamber (9) which is connected with the tiny dust filtering chamber (7) is formed on the top of a lower box body (2); and a cotton discharging pipe (10) connected with the outlet of the middle section cotton collecting chamber (9), a dust collecting groove (11) connected with the outlet of the tiny dust collecting chamber (8) and a dust discharging air pipe (12) connected with the outlet of the dust collecting groove (11) are arranged at the bottom of the lower box body (2).

Owner:刘伟

laboratory fume hood

Owner:ANHUI YUAN LAB EQUIP

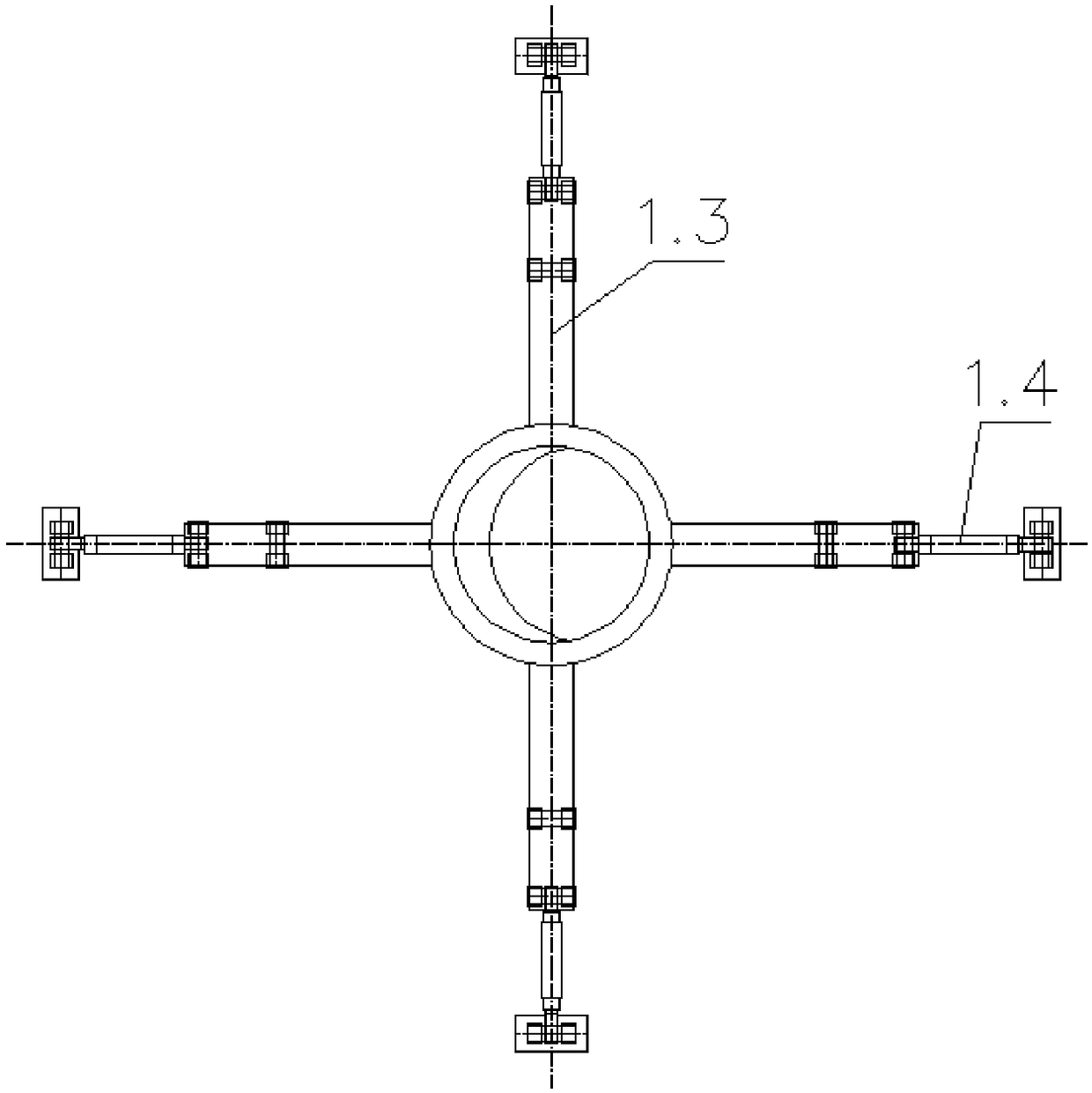

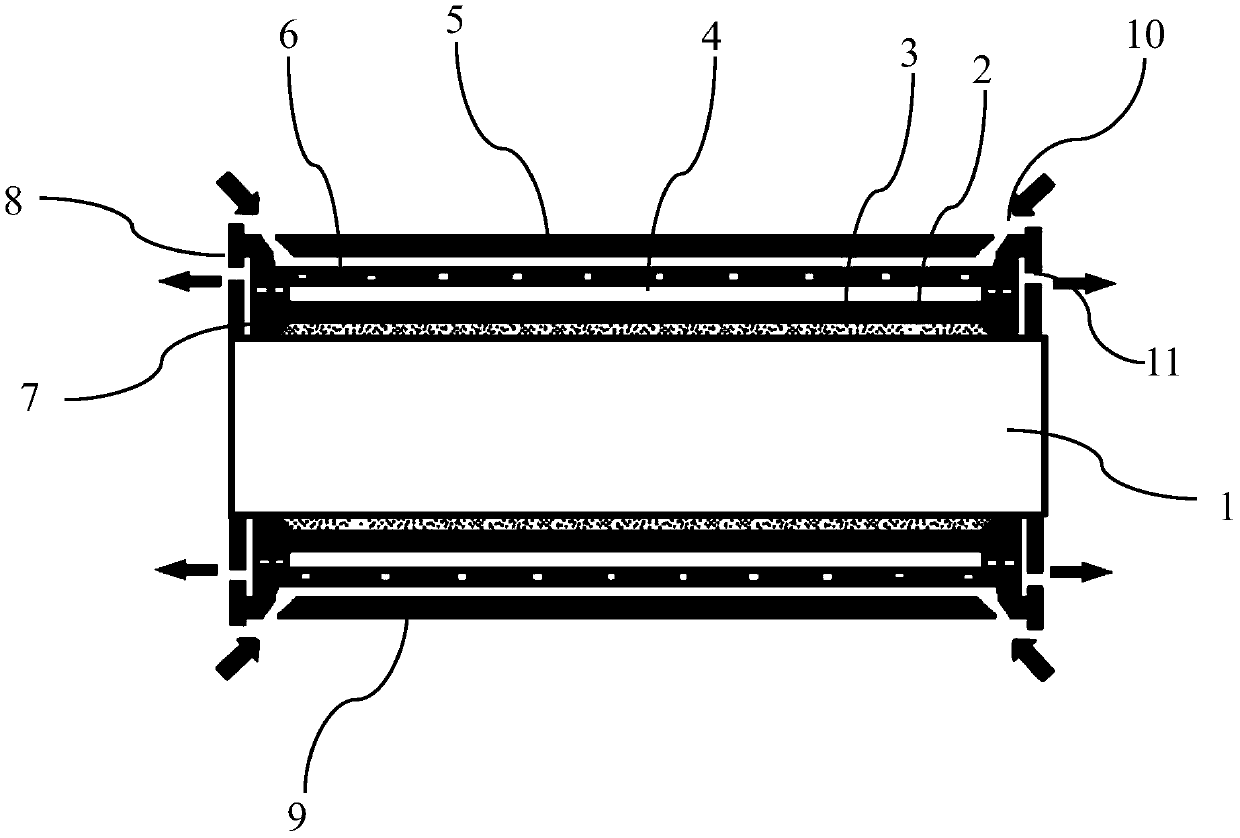

Blast cooling equipment for platinum channel

ActiveCN109608023AEasy to installIncrease flexibilityForehearthsGlass furnace apparatusPlatinumAir volume

The invention discloses blast cooling equipment for a platinum channel. The blast cooling equipment is divided into two space areas including a cooling chamber and a blast chamber by semi-circular-annular air leakage bricks, ventilation holes are uniformly distributed in each semi-circular-annular air leakage brick, and a set of supporting bricks and a structure of air inlets and air outlets are installed at two modified ends. According to the equipment disclosed in the invention, after cooling air enters the blast chamber from an air supply opening, the air is uniformly dispersed after passing through ventilation openings, the dispersed air enters the cooling chamber, the cooling air cools the outer wall of the platinum channel while moving quickly towards inner air outlets and outer airoutlets located at two sides, thereby indirectly cooling molten glass in the platinum channel, and the purpose of cooling is achieved by the repeated cycle cooling; and at the same time, the cooling equipment can be installed in any place that needs to be cooled, of the platinum channel, the air supply volume and speed of the cooling air are adjusted according to cooling range of the molten glassin the platinum channel, and the equipment has high flexibility, and realizes precise cooling of the molten glass.

Owner:IRICO DISPLAY DEVICES

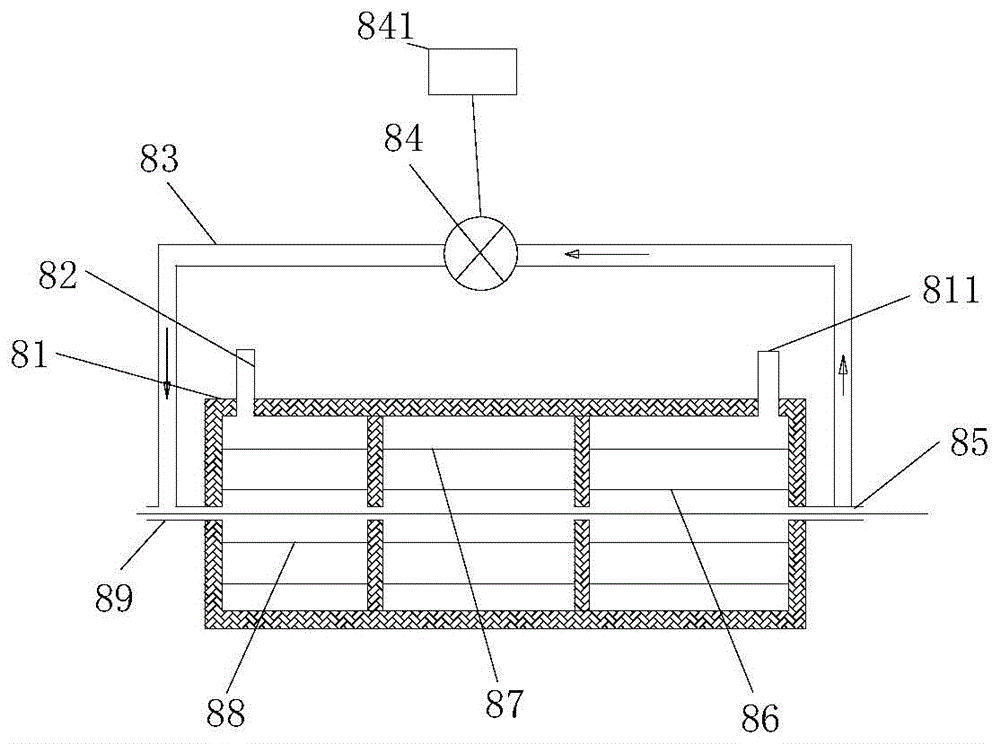

Cloth drying equipment for textile production

ActiveCN111623615BAdjust the wind speedGood adjustment functionDrying gas arrangementsDrying machines with progressive movementsElectric machineryStructural engineering

The invention discloses a fabric drying equipment for textile production, which comprises a main body, a lifting motor is fixedly installed in the middle of the bottom end of the main body, a threaded shaft is installed on the upper end of the lifting motor, and a threaded shaft is sleeved on the outer surface of the threaded shaft. Lifting plate, the upper surface of the lifting plate is penetrated with a limiting hole, the inner bottom of the main body is fixedly installed with a limiting rod near the outside of the lifting motor, the upper end of the limiting rod is fixed with a baffle plate, and the upper surface of the lifting plate is close to Push rods are fixedly installed at the corner positions, and a placement plate is fixedly installed on the upper end of the push rod, and a heating plate is arranged directly above the placement board. The cloth drying equipment can prevent the cloth from being damaged or the drying time is slow due to excessively high or low heat and wind speed. Dry unevenly, play a very good limit effect.

Owner:山东远腾环保设备有限公司

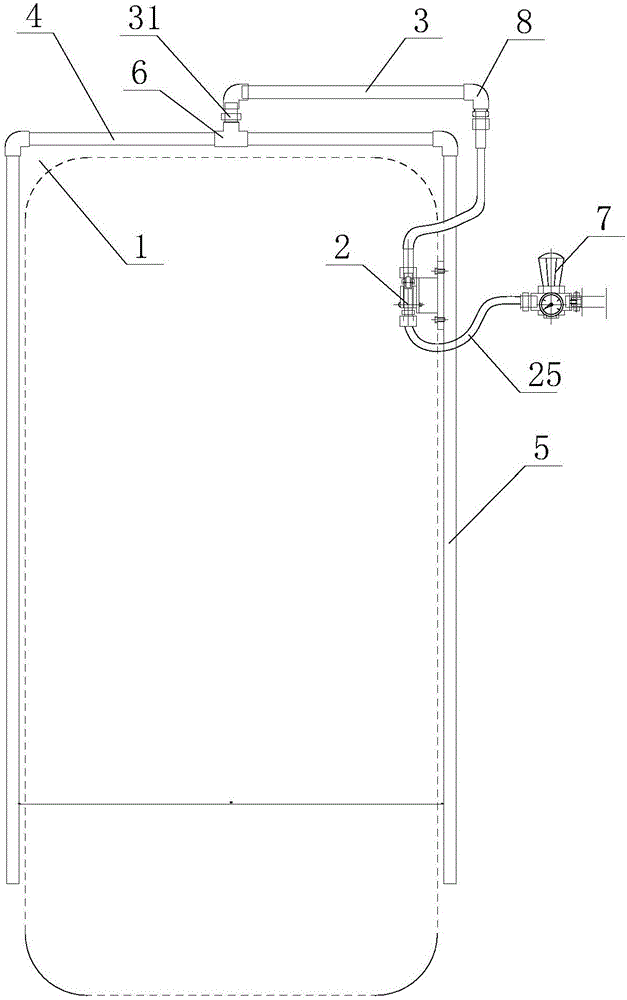

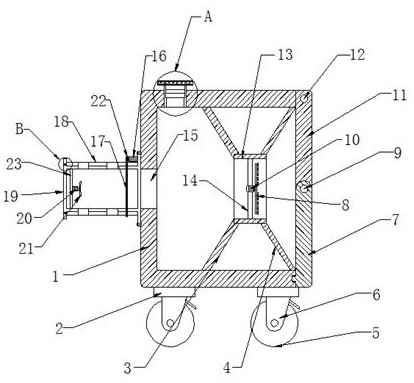

Fresh air device, control method thereof and air conditioner

PendingCN112032844AAdjust the wind speedAdjust the air volumeMechanical apparatusCondensate preventionAir volumeAir velocity

The invention discloses a fresh air device, a control method of the fresh air device and an air conditioner. The fresh air device comprises a shell, an air valve and a driving device. The shell is provided with an air inlet and an air outlet, the air valve is movably arranged at the air inlet, the driving device is connected with the air valve, and the driving device is used for adjusting the position of the air valve so as to adjust the opening degree of the air inlet. According to the fresh air device, the opening degree of the air inlet can be adjusted by adjusting the position of the air valve, so that the air inlet speed and the air inlet volume can be adjusted, and the anti-condensation effect can be achieved under the condition that the fresh air device is kept started to operate.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

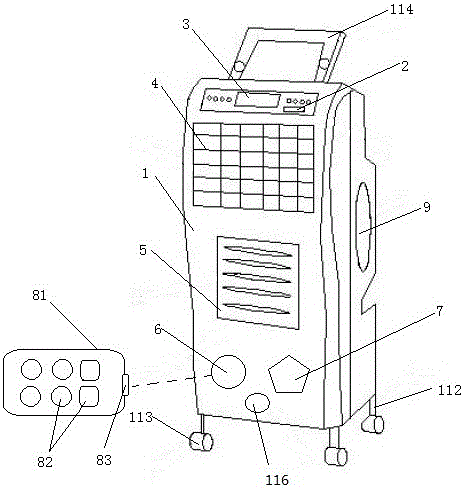

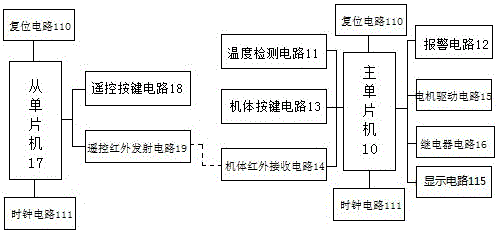

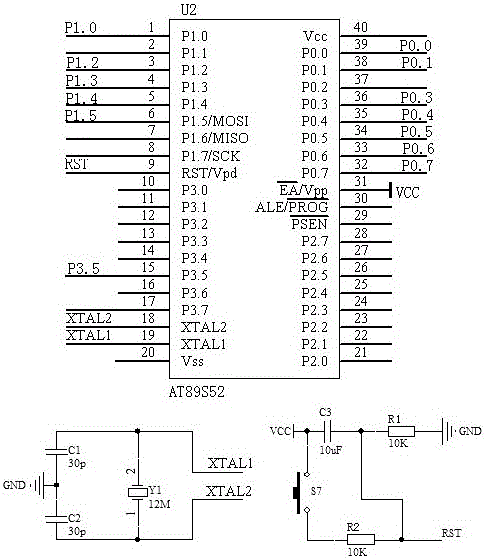

Infrared remote control intelligent fan heater

InactiveCN105737254ASimple structureImprove securityNon-electrical signal transmission systemsLighting and heating apparatusInfraredRemote control

The invention discloses an infrared remote control intelligent fan heater. The intelligent fan heater comprises a machine body, and a machine body key switch, a display screen, an exhaust plate, an indicating lamp, an infrared receiver, a buzzer and a temperature sensor arranged on the machine body from top to bottom; a machine body circuit board in circuit connection with the machine body key switch, the display screen, the indicating lamp, the infrared receiver and the buzzer is arranged in the machine body; and the machine body circuit board includes a machine body control circuit. The intelligent fan heater further comprises an infrared remote controller; the remote controller is packed by a shell; the shell is provided with a remote control key and an infrared transmitting tube; a remote control circuit board connected with the remote control key and the infrared transmitting tube is arranged in the shell; and the remote control circuit board includes a remote control circuit. The intelligent fan heater is simple in structure and high in safety, prevents the scald, is excellent in heating effect, and can be remotely controlled through infrared rays.

Owner:SUZHOU INST OF INDAL TECH

Sizing, drying and shaping device for polyacrylonitrile-based carbon fiber

ActiveCN103334246BGuaranteed uniformityImprove uniformityHeating/cooling textile fabricsLiquid/gas/vapor removal by gas jetsCarbon fibersWorking environment

Owner:ZHONGJIAN TECH CO LTD

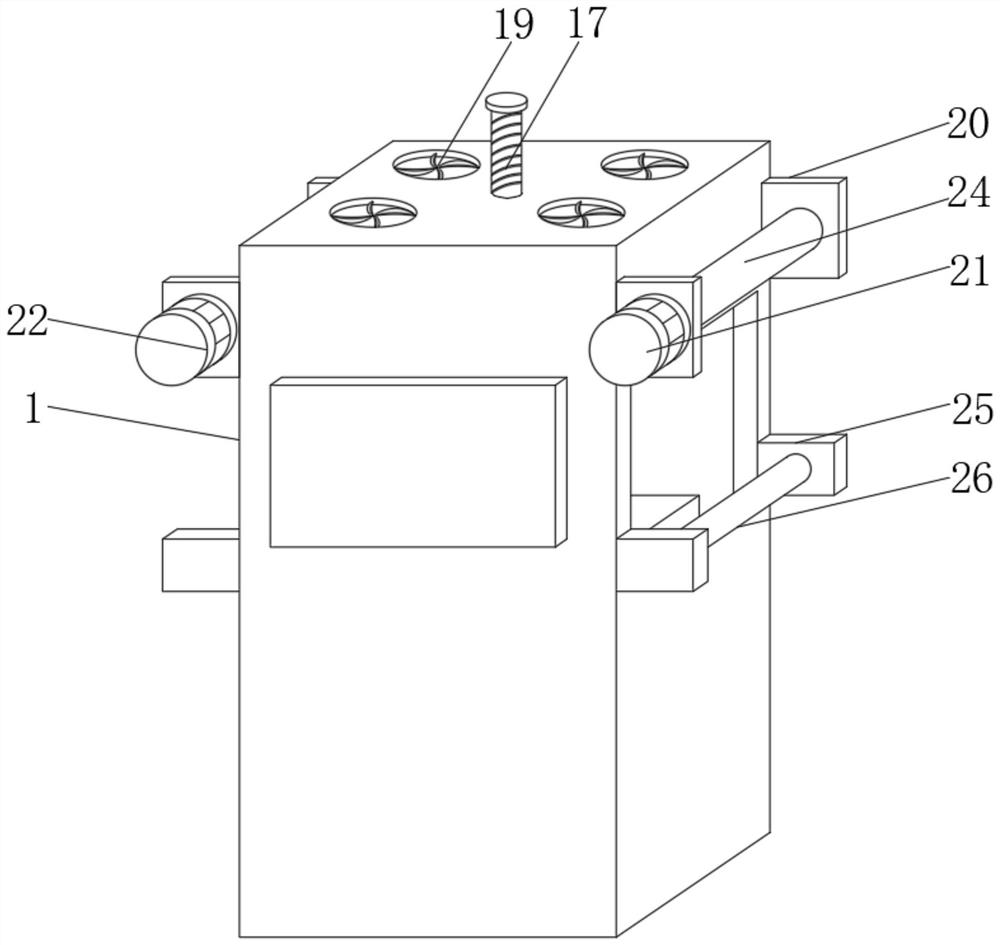

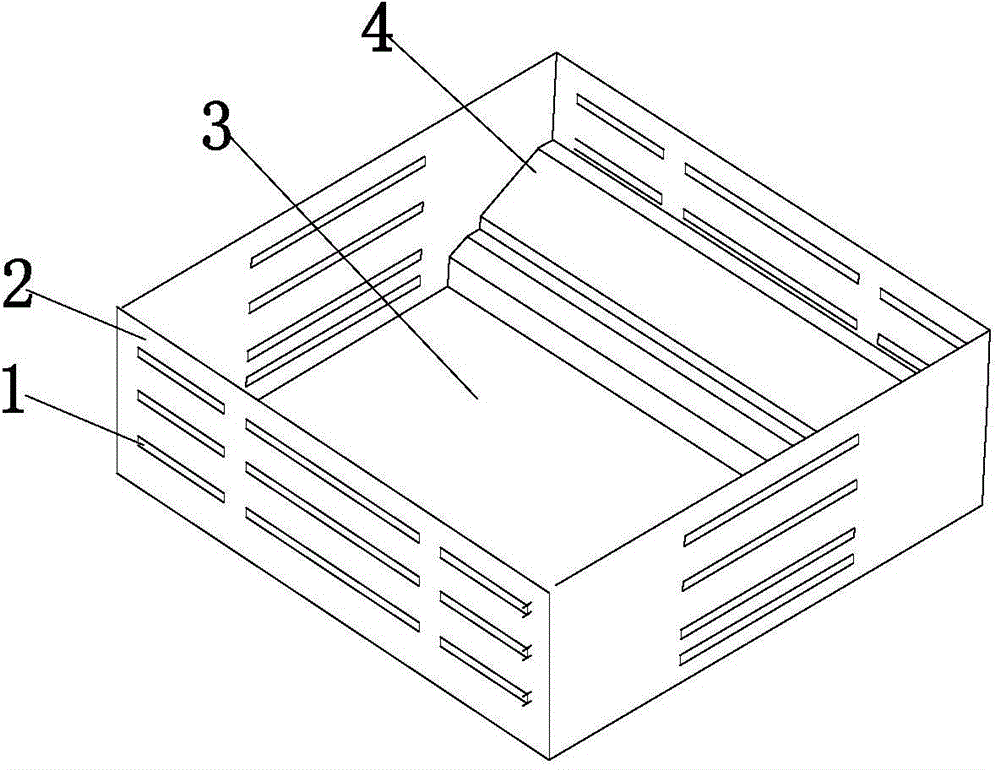

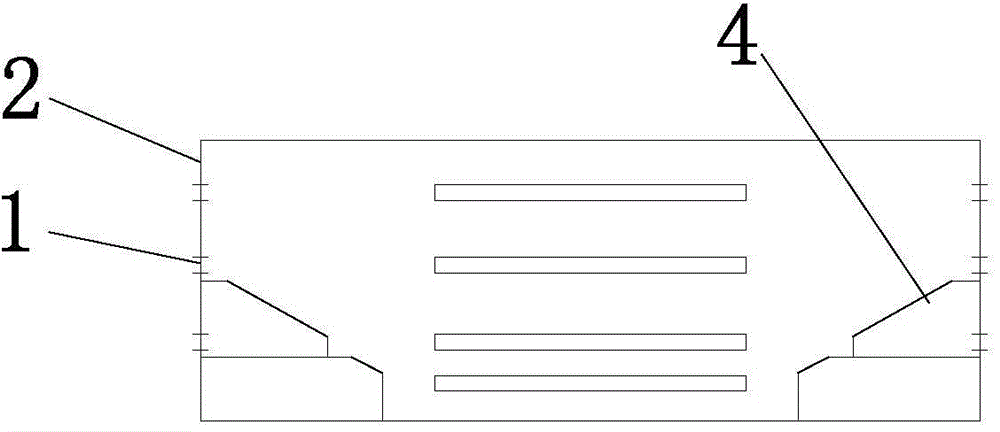

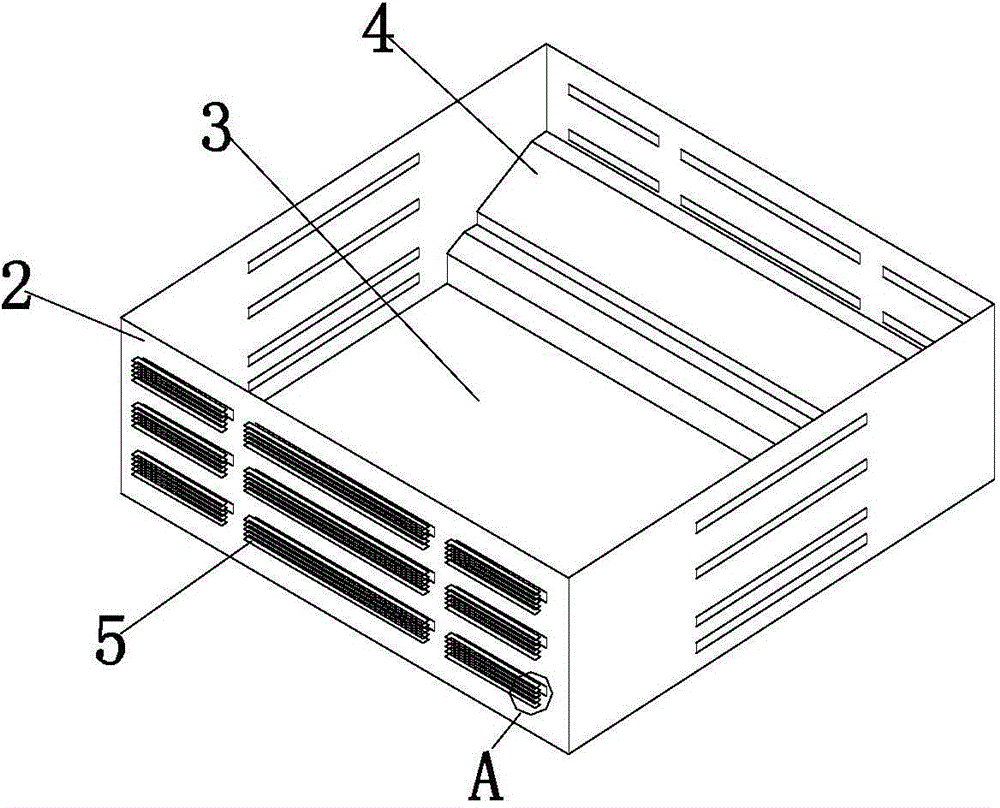

Air supply piece and energy storage container

PendingCN113437401AMeet temperature uniformity requirementsSmall temperature differenceSecondary cellsCell component detailsThermodynamicsAir volume

The invention provides an air supply piece and an energy storage container, relates to the technical field of energy storage, and is used for reducing the temperature difference of batteries in the energy storage container, so that the temperature difference of the batteries can meet the requirement of the energy storage container for the temperature uniformity of the batteries. The air supply piece comprises a body, the body comprises a bottom plate and a side wall extending upwards from the bottom plate, an air cavity allowing air to flow is defined by the side wall and the bottom plate, at least one part of the side wall is an arc-shaped air guide plate, the arc-shaped air guide plate protrudes out of the air cavity, an air inlet is formed in the side wall and used for being communicated with an air conditioner, and a plurality of air outlets are formed in the bottom plate. According to the air supply piece, the arc-shaped flow guide plate is used for guiding air and adjusting the air speed in the air cavity, so that the air outlet amount of each air outlet is more uniform, the temperature difference of the environment where a battery cluster below each air outlet is located is reduced, the battery temperature difference of the whole energy storage container is reduced, and the requirement of the energy storage container for battery temperature uniformity is met.

Owner:BEIJING HYPERSTRONG TECH

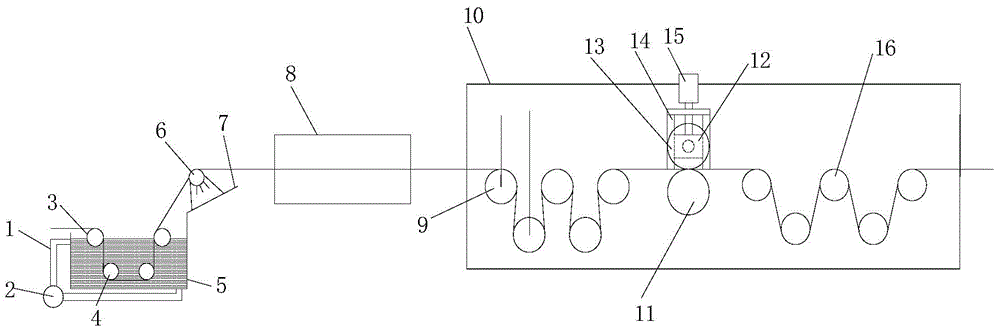

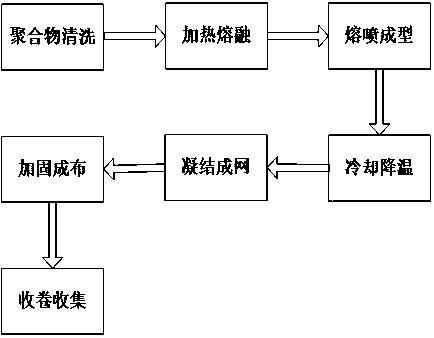

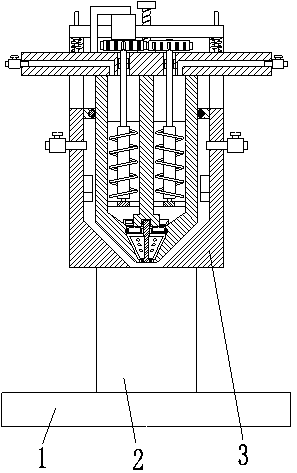

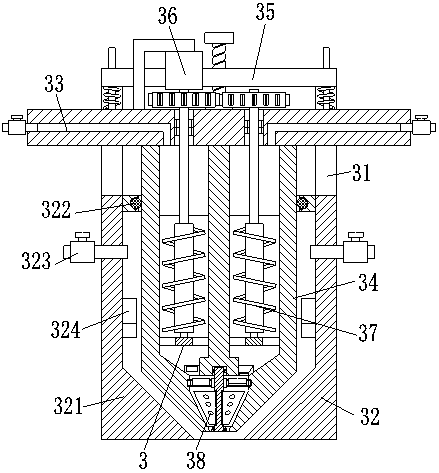

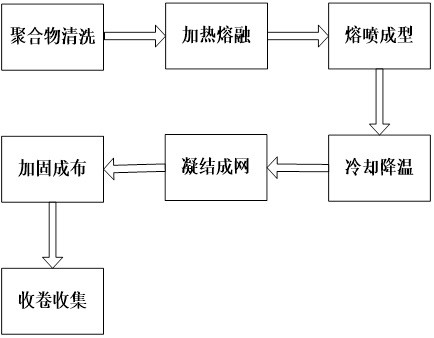

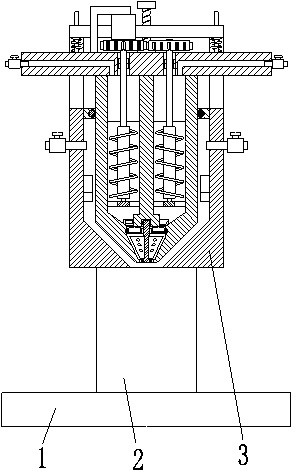

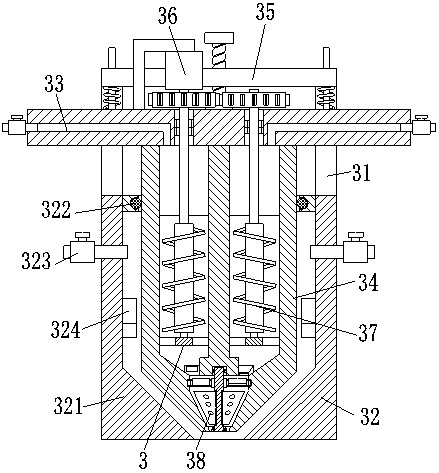

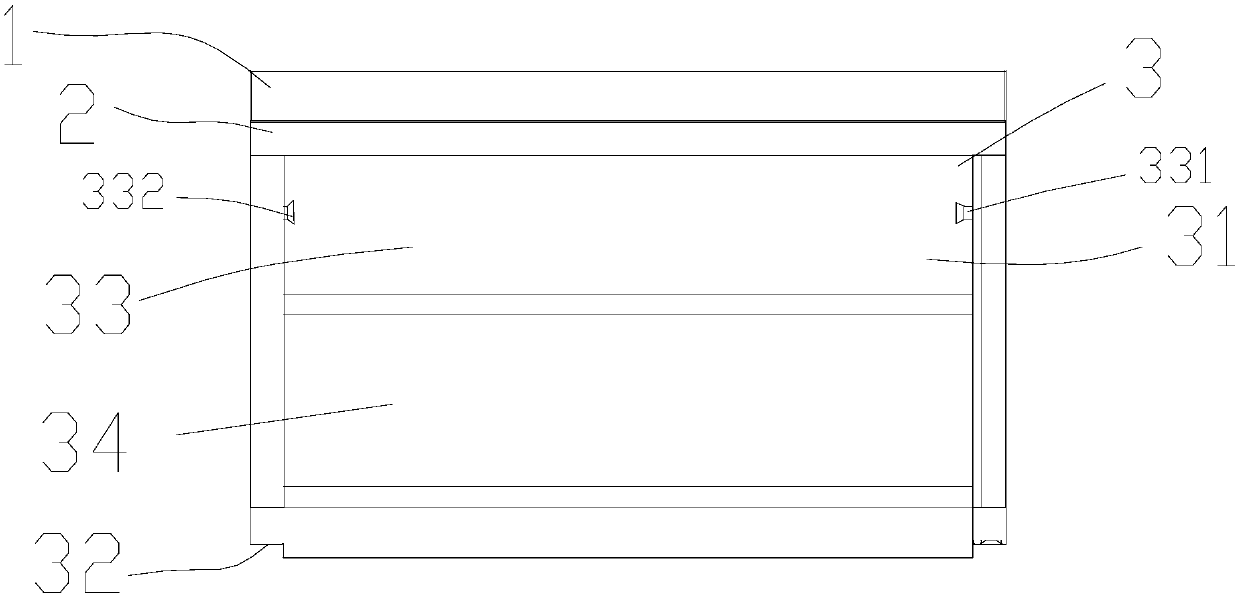

Production and processing method of medical melt-blown non-woven fabric

ActiveCN111593488AUniform distribution of fiber thicknessImprove processing efficiencySpinning head liquid feederMelt spinning methodsWoven fabricMelt blowing

The invention relates to a production and processing method of medical melt-blown non-woven fabric. The production and processing method of the medical melt-blown non-woven fabric comprises a base plate, supporting frames and a melt-blowing device, wherein the supporting frames are symmetrically mounted at the upper end of the base plate, and the melt-blowing device is mounted between the upper ends of the supporting frames. By the adoption of the production and processing method of the medical melt-blown non-woven fabric, the problems that when an existing device is used for processing melt-blown non-woven fabric, the air speed during melt blowing cannot be accurately regulated generally, hot air cannot be effectively and uniformly dispersed during melt-blowing, and consequentially, the thickness distribution of fibers after melt-blowing is not uniform, and the subsequent usage effect of the non-woven fabric is affected; and meanwhile, when the existing device is used for processing the melt-blown non-woven fabric, melt-blown polymers cannot be effectively, uniformly and rapidly mixed generally, and consequentially, the melt-blown polymers are likely to be layered, and the qualityand effect of the non-woven fabric are affected are solved.

Owner:SHANGHAI MINGGUAN PURIFICATION MATERIALS

An ion wind cooling device

ActiveCN105283046BAdjust the wind speedWork efficiency impactCooling/ventilation/heating modificationsEngineeringIonization

Owner:JIANGSU UNIV

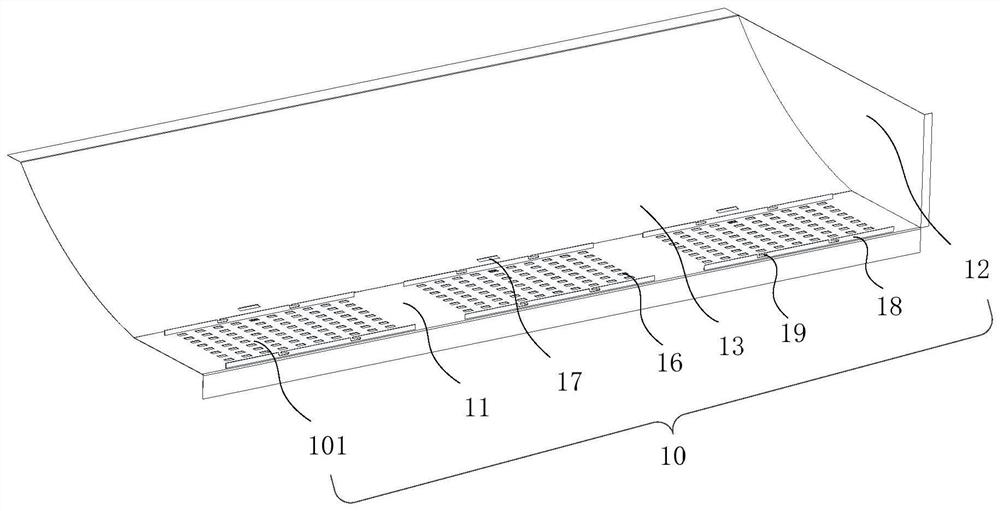

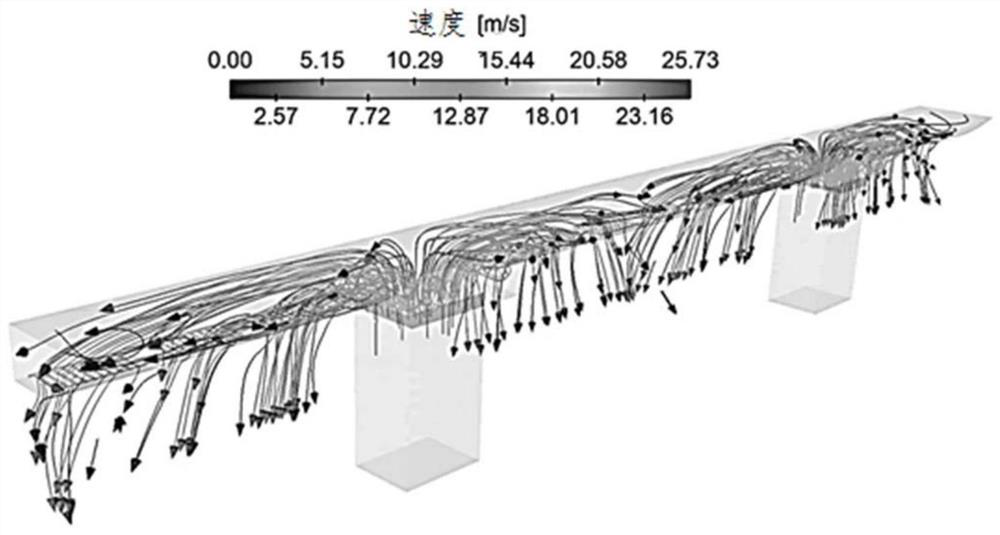

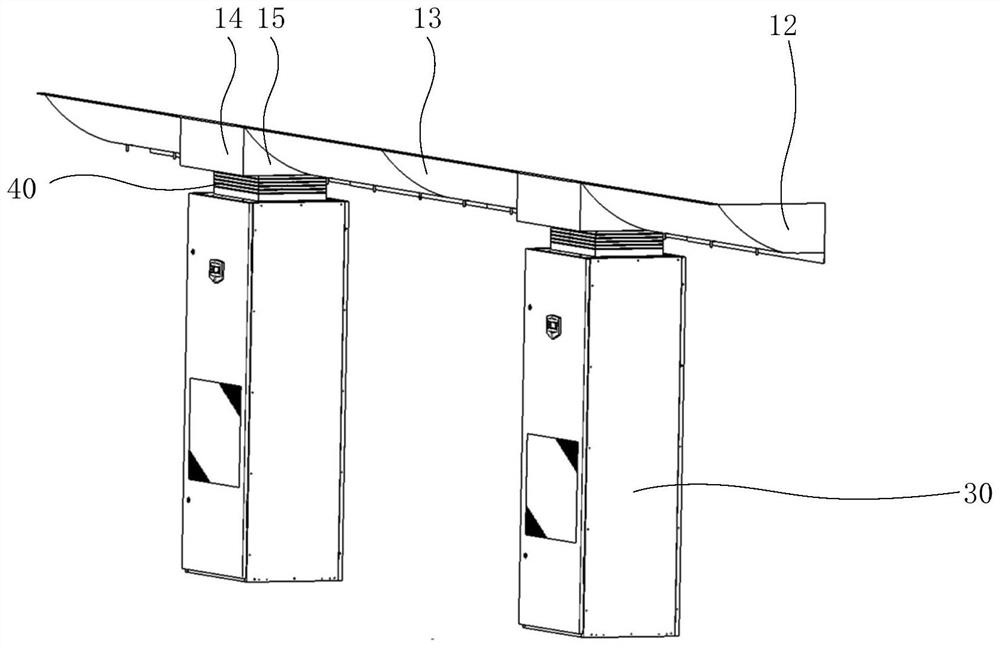

Sun louver capable of adjusting indoor air speed and indoor air direction of gymnasium

InactiveCN104864578AAdjust the wind directionAdjust the wind speedLighting and heating apparatusAir conditioning systemsNatural ventilationEngineering

The invention discloses a sun louver capable of adjusting the indoor air speed and the indoor air direction of a gymnasium. The inclination angle of blades of the sun louver are can be adjusted; the sun louver is right arranged on the outer side of an air inflow window of the southern facade of the gymnasium, and the distance between the sun louver and a southern facade wall is 0.7-1 time of the width of each blade; according to the inclination angle of the blades, the blades are horizontally arranged or arranged in an up-dip or down-dip mode, and the up-dip angle and the down-dip angle of the blades is 25-40 degrees. Due to the fact that the sun louver with the inclination angle of the blades adjustable is arranged a certain distance from the air inflow window, the air direction and the air speed of indoor natural ventilation can be adjusted; the purposes of saving energy, improving an indoor healthy air environment and meeting the using requirements of different functions are achieved; the requirements of training and competition of large balls such as basketballs and volleyballs, small balls such as table tennis and badmintons and various sporting events for an indoor environment can be met.

Owner:SOUTH CHINA UNIV OF TECH

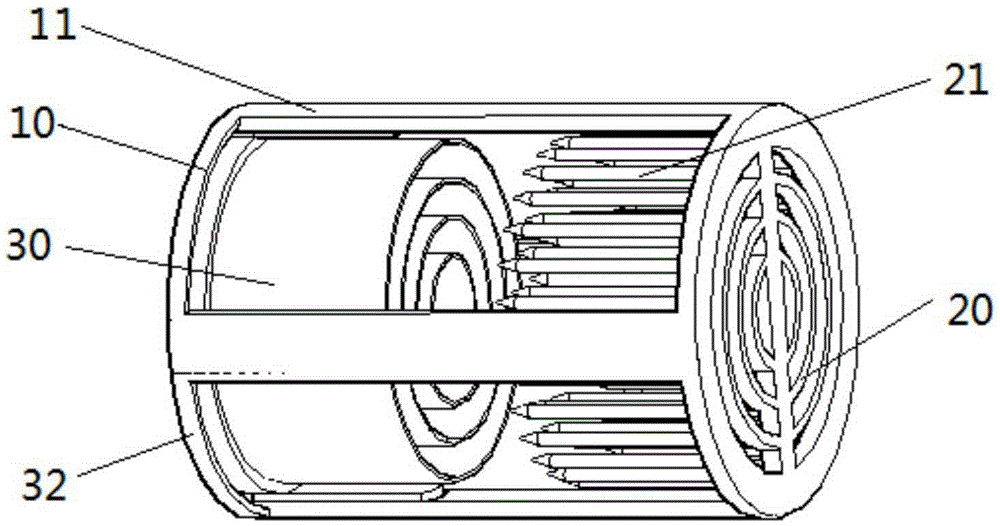

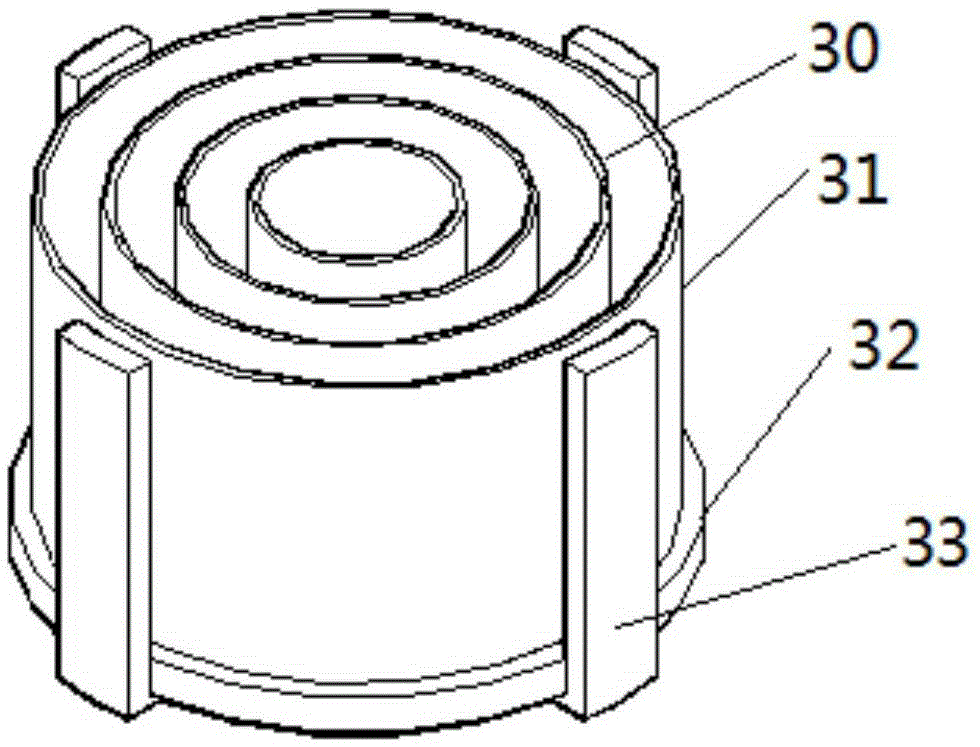

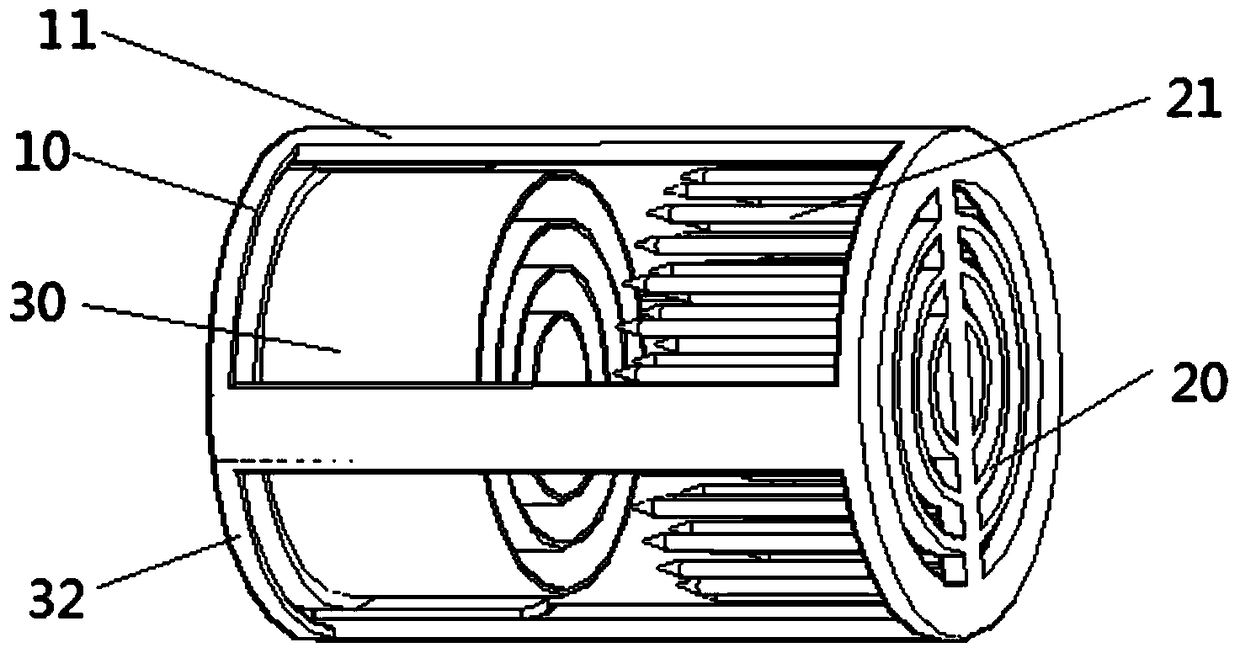

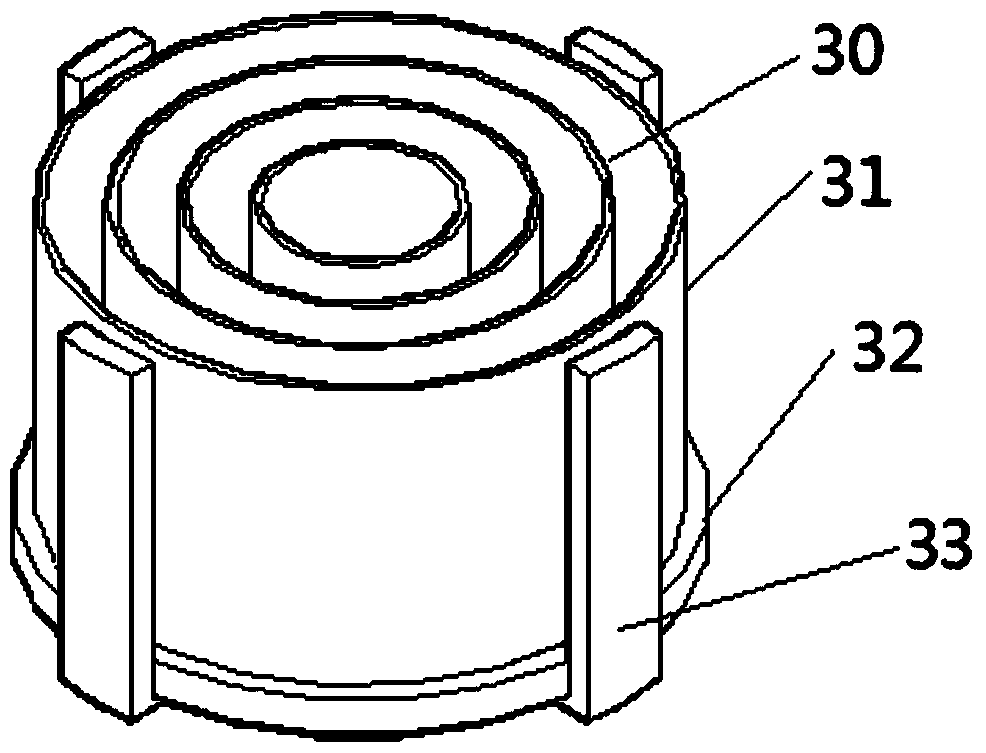

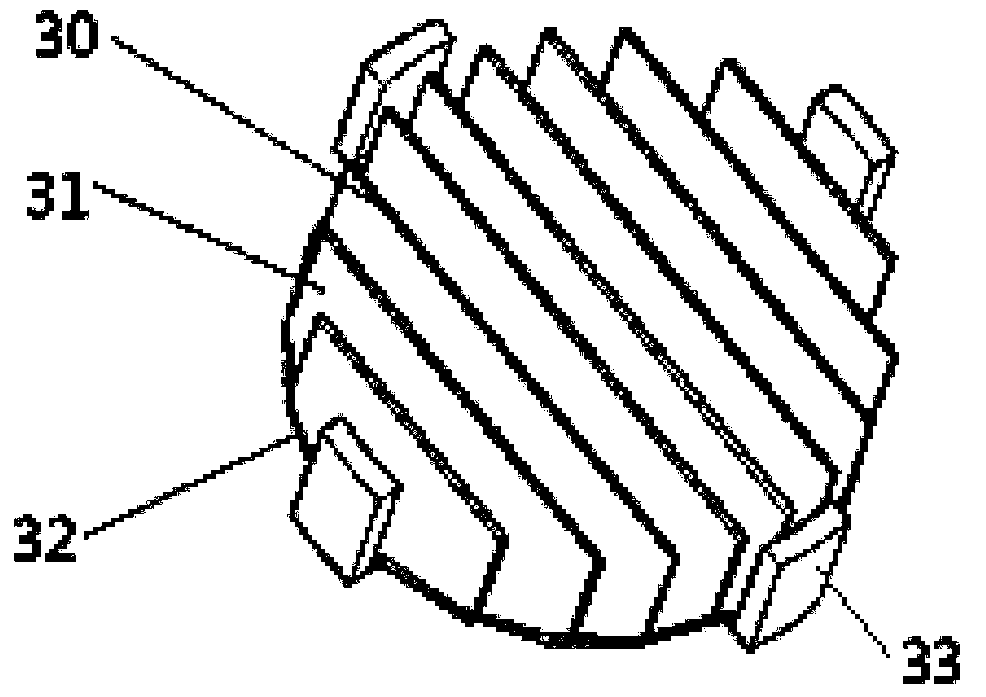

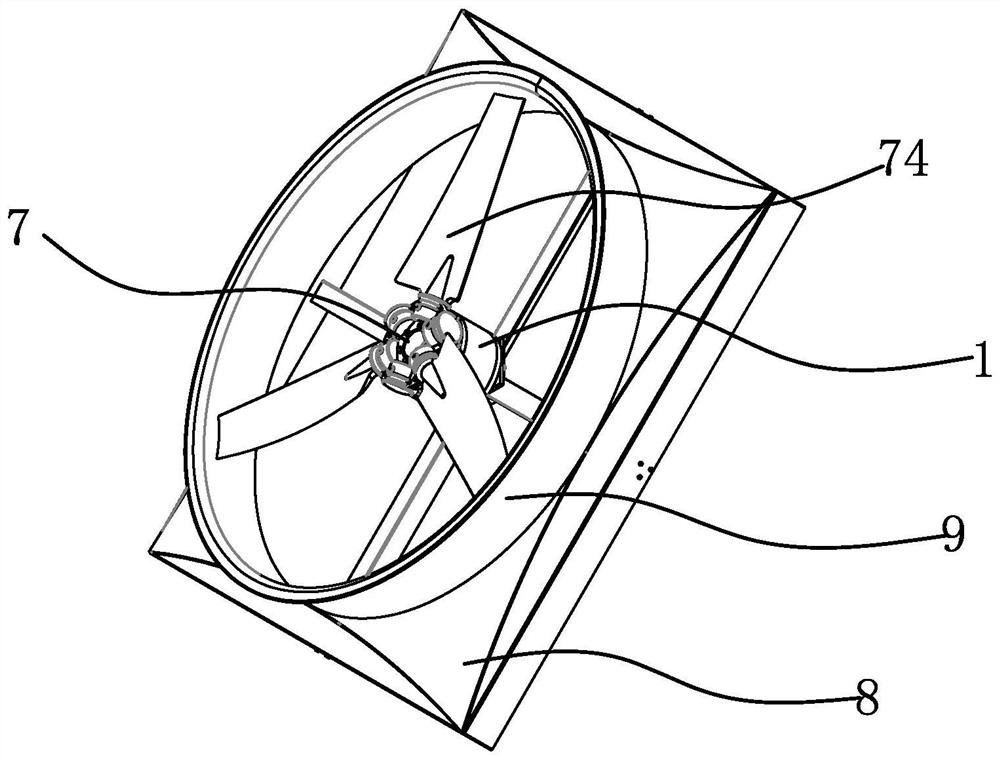

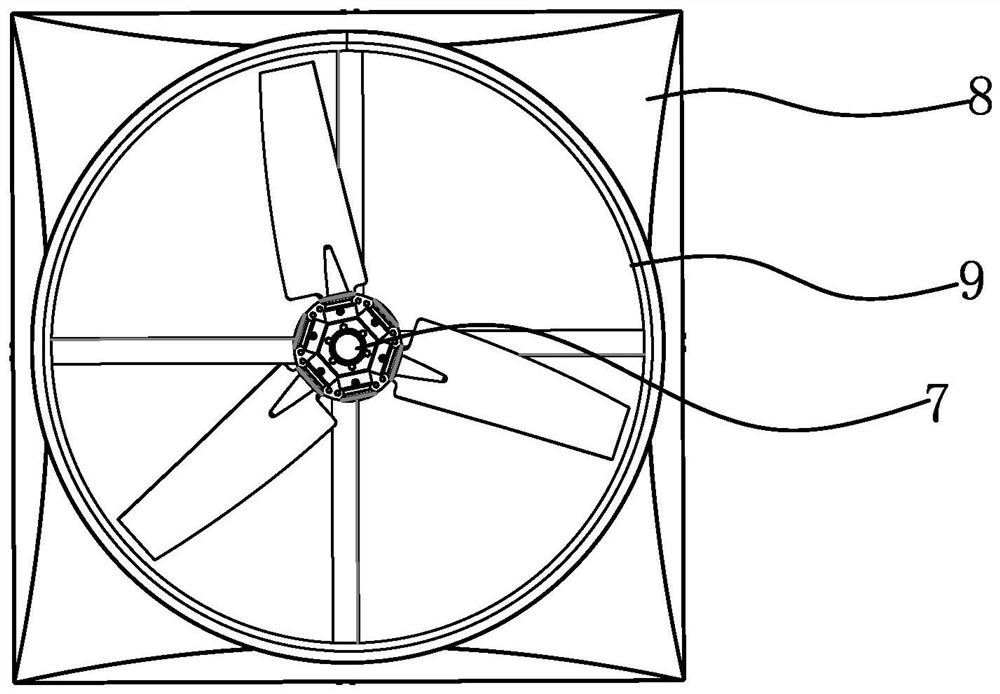

Outer rotor permanent magnet motor and fan using same

InactiveCN112383170AFrequency conversionAdjust the wind speedAssociation with control/drive circuitsMechanical energy handlingElectric machineStructural engineering

The invention provides an outer rotor permanent magnet motor and a fan using the same, and solves the problem of low structural stability of an outer rotor motor in the prior art. The motor comprisesa fixed shaft and a stator assembly fixedly connected with the fixed shaft, and a rotor is arranged on the outer side of the stator assembly. A front end cover and a rear end cover which are fixedly connected with the rotor are arranged on the two sides of the rotor, a front bearing and a rear bearing are arranged between the front end cover and the fixing shaft and between the rear end cover andthe fixing shaft respectively, the fixing shaft extends out of the rear end cover, a load connecting part is arranged on the front end cover, and the front end cover and the load connecting part are integrated. And the load connecting part is provided with a fan assembly. The installation stability of the fan is higher, the installation angle of the fan support can be set according to needs, and the operation stability is higher.

Owner:招国梅

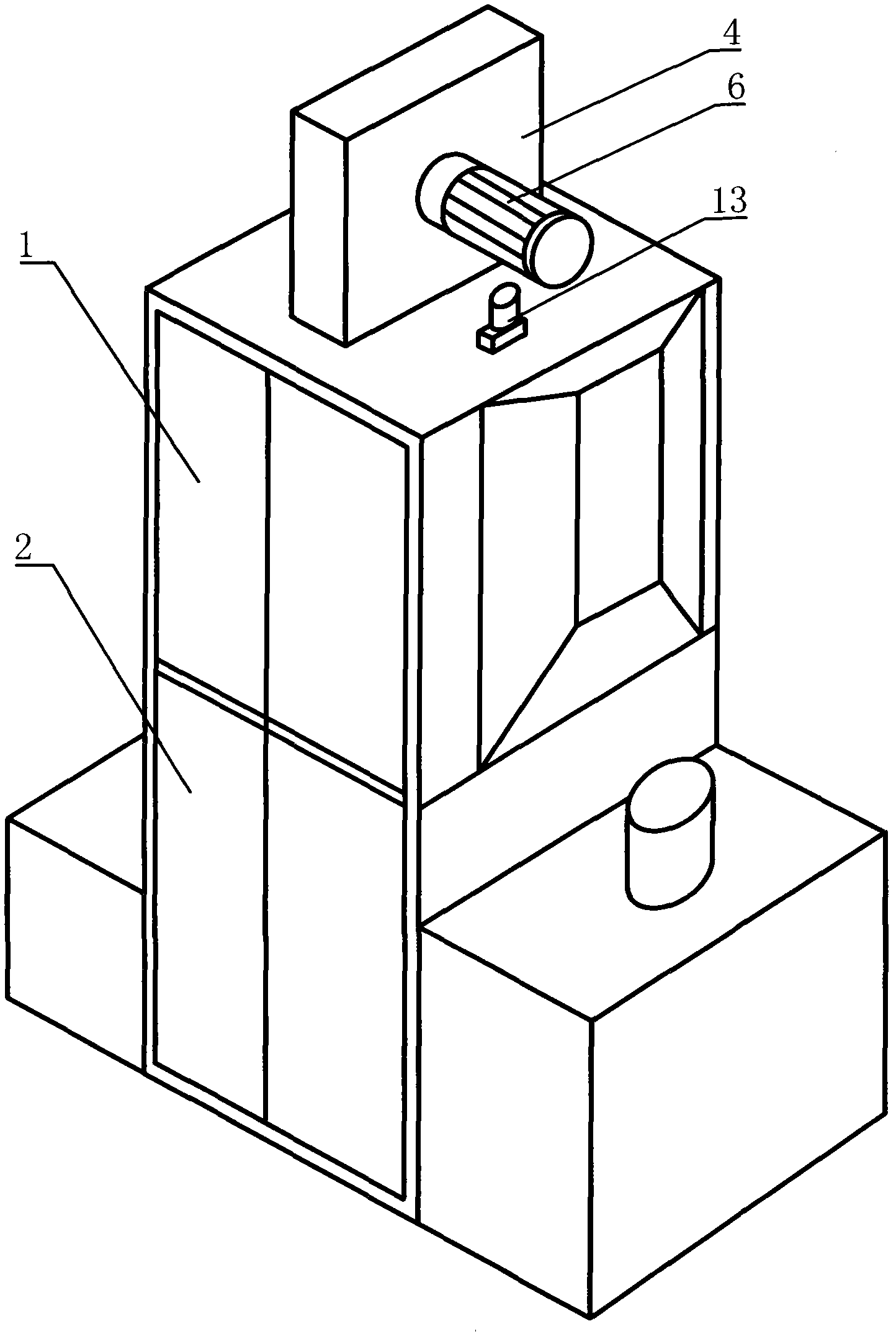

Door plate

InactiveCN102852433AAchieve ventilationAdjust the wind directionVentilation arrangementDoor leavesEngineeringWind direction

Owner:昆山西马克动力机械有限公司

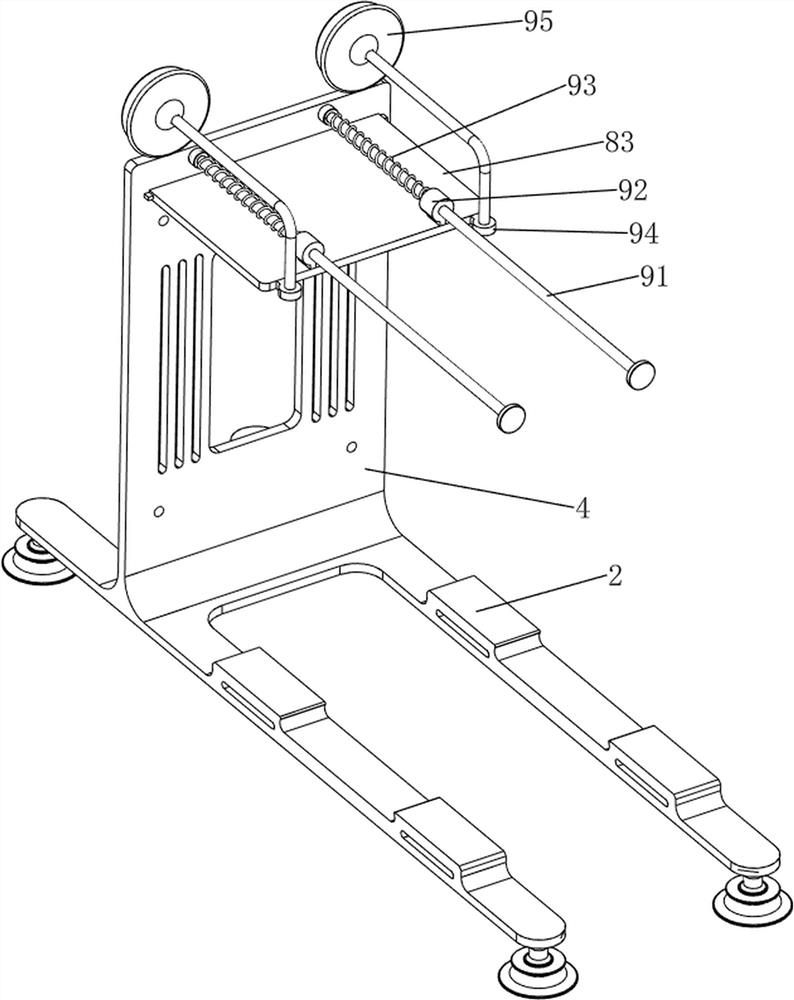

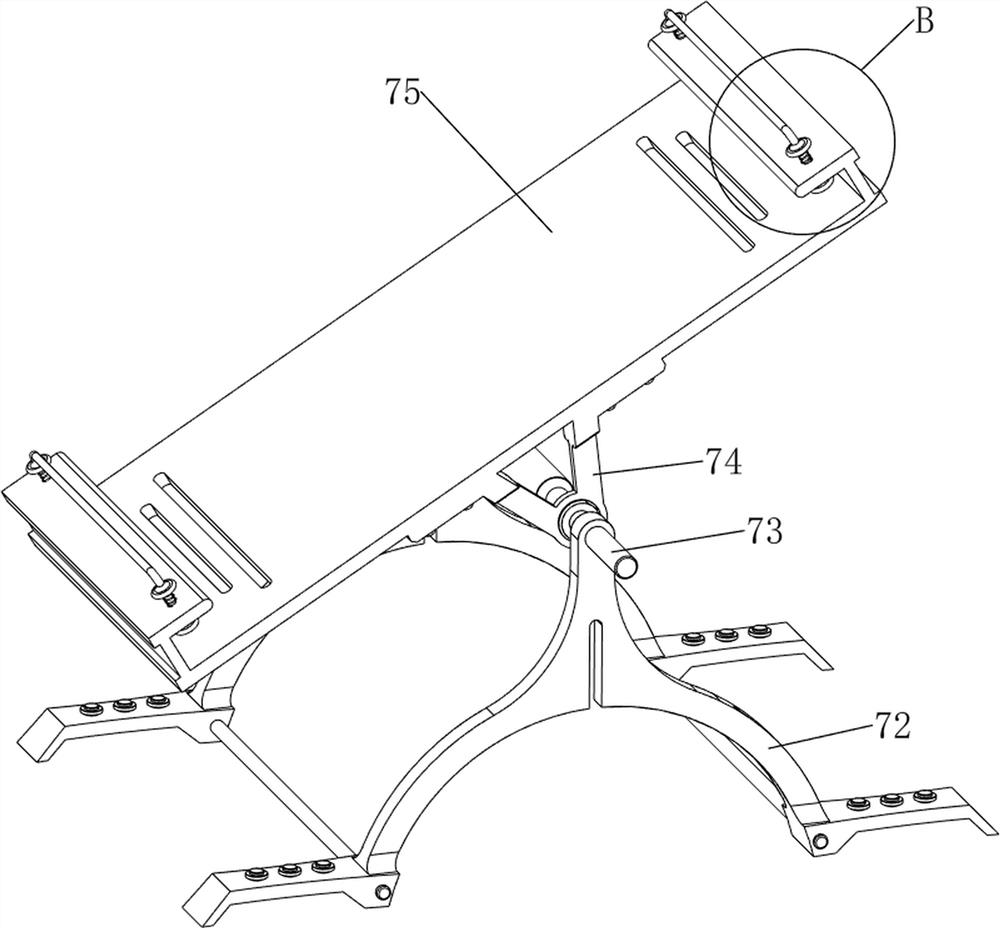

Wind-resistant protection device for photovoltaic power station

PendingCN113965151AProtection against lossNo lossPhotovoltaic supportsPhotovoltaic energy generationElectrical and Electronics engineeringRolling chassis

The invention relates to a protection device, in particular to a wind-resistant protection device for a photovoltaic power station. The technical problem is to provide the wind-resistant protection device for the photovoltaic power station, which can prevent an object from being blown by wind to smash a photovoltaic panel and can ensure that the receiving efficiency of the photovoltaic panel is not reduced. According to the technical scheme, the wind-resistant protection device for the photovoltaic power station comprises chassis, a mounting plate, a damping plate, a wind-resistant plate, first sliding rods and the like. The chassis are symmetrically arranged on the two sides of the bottom of the mounting plate, the number of the chassis is four, and the wind-resistant plate is arranged on one side of the top of the mounting plate. The first sliding rods are symmetrically arranged on the upper side and the lower side of the wind resisting plate in a sliding mode, and the damping plate used for reducing the wind speed is connected between the first sliding rods. According to the invention, under the action of the damping plate and the wind-resistant plate, wind cannot be completely blown to the photovoltaic panel, so that the photovoltaic panel can be effectively protected from loss.

Owner:张文芳

Ventilation equipment with air supplementing channel and using method thereof

InactiveCN112452059AImprove exhaust efficiencyImprove air qualityDispersed particle filtrationTransportation and packagingStructural engineeringBellows

Owner:江苏枂硕电子科技有限公司

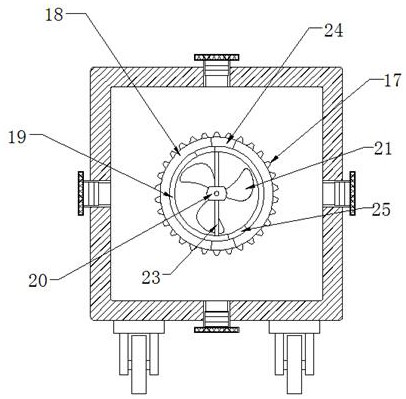

Gear shifter for jet flow air cabinet, jet flow air cabinet and air conditioning system

PendingCN112228957AChange sizeAdjust the wind speedLighting and heating apparatusAir conditioning systemsElectric machineryJet flow

The invention provides a gear shifter for a jet flow air cabinet, the jet flow air cabinet and an air conditioning system, relates to the technical field of air conditioners, and solves the technicalproblem that in the prior art, for a jet flow air cabinet with a fixed-frequency motor, a gear shifter for adjusting the air outlet speed does not exist at an air outlet of the jet flow air cabinet. The gear shifter is installed in an air outlet of the jet flow air cabinet and comprises air blocking pieces; and the size of the area, shielding the air outlet, of the gear shifter and / or the position, shielding the air outlet, of the gear shifter can be adjusted by adjusting the relative positions among the air blocking pieces. The gear shifter provided by the invention is used for adjusting theairflow flowing speed of the air outlet of the jet flow air cabinet and the size of an air column.

Owner:GREE ELECTRIC APPLIANCES INC

A kind of production and processing method of medical melt-blown non-woven fabric

ActiveCN111593488BGuarantee the effect of subsequent useSpread evenlySpinning head liquid feederMelt spinning methodsNonwoven fabricPolymer

Owner:SHANGHAI MINGGUAN PURIFICATION MATERIALS

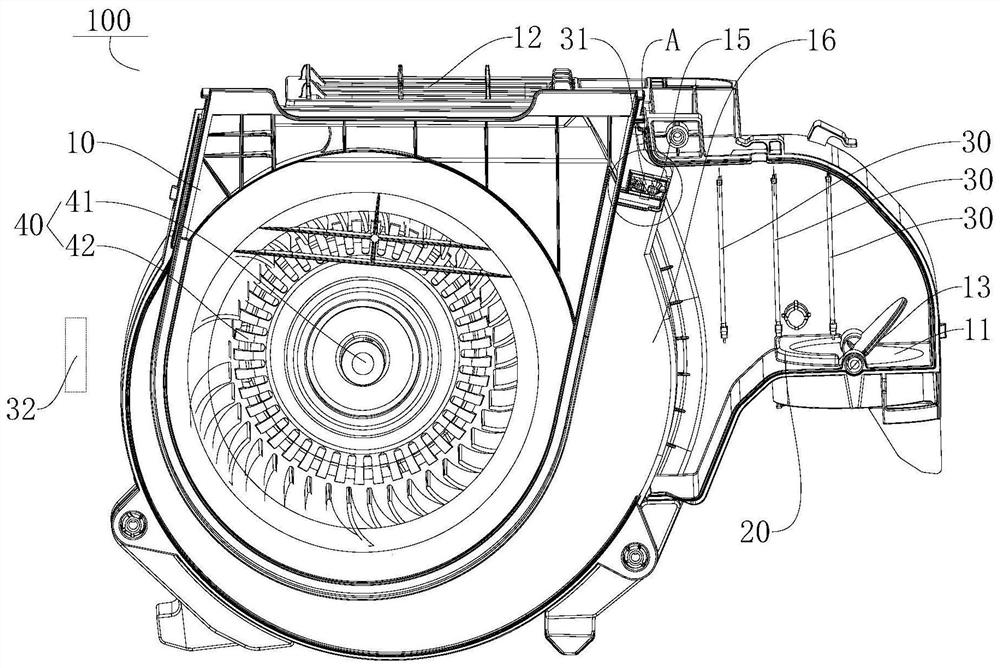

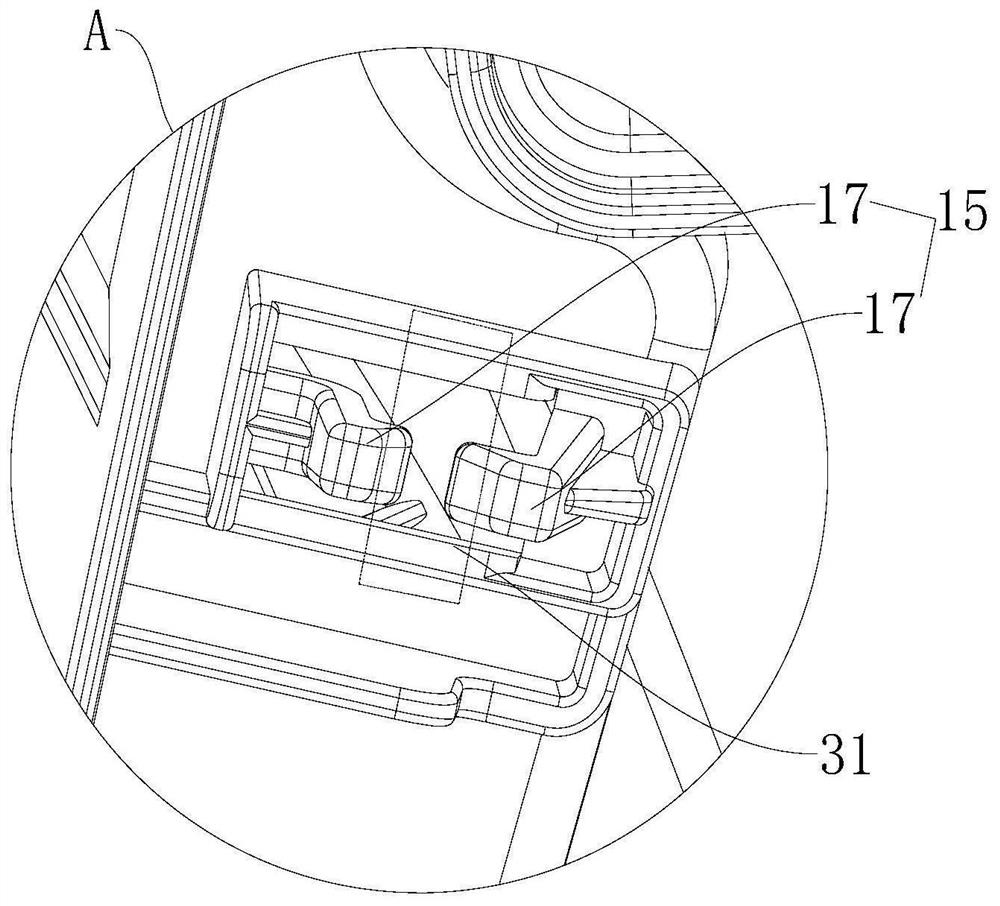

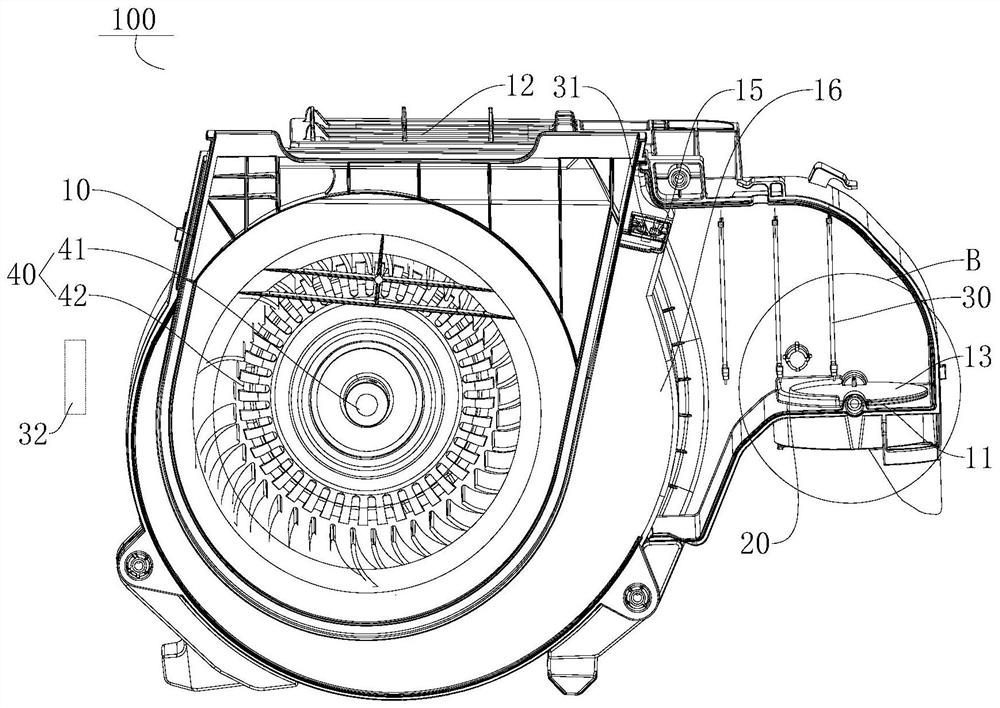

Structural module for controlling smoke by utilizing laser identification technology

PendingCN109654569AAdjust the wind speedEasy to produceDomestic stoves or rangesLighting and heating apparatusInterior spaceAir volume

The invention provides a structural module for controlling smoke by utilizing a laser identification technology, and the structural module is applied to a range hood. The range hood comprises a box body, wherein an inner space of the box body is provided with a semi-enclosed cavity body; the box body is provided with a panel assembly; the box body is also provided with a smoke inlet and a smoke exhaust hole; the inner space of the semi-enclosed cavity body of the box body is divided into a laser cavity and an electric control cavity; the smoke inlet communicates with the laser cavity; the smoke exhaust hole communicates with the electric control cavity; a partition plate is arranged at a joint of the laser cavity and the electric control cavity; and the structural module is arranged in thelaser cavity. The structural module comprises a laser emitting end and a laser receiving end; the laser emitting end and the laser receiving end are oppositely fixed to the inner walls of the two sides of the laser cavity through fixed screw holes; the inner part of the laser emitting end is used for emitting laser beams; the laser receiving end is used for receiving the laser beams emitted fromthe laser emitting end and sending laser signals to a laser electronic control module; and the controller is used for receiving a modulation command of the laser electronic control module and triggering a blower electronic control module to adjust air volume.

Owner:广东美集世智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com