Output-amplifier-stage temperature control intelligent exhaust system

An amplified and intelligent technology, applied in the direction of pump control, engine control, automatic disconnection emergency protection device, etc., can solve the problem of low intelligence of the exhaust system, achieve good adjustment, avoid damage, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

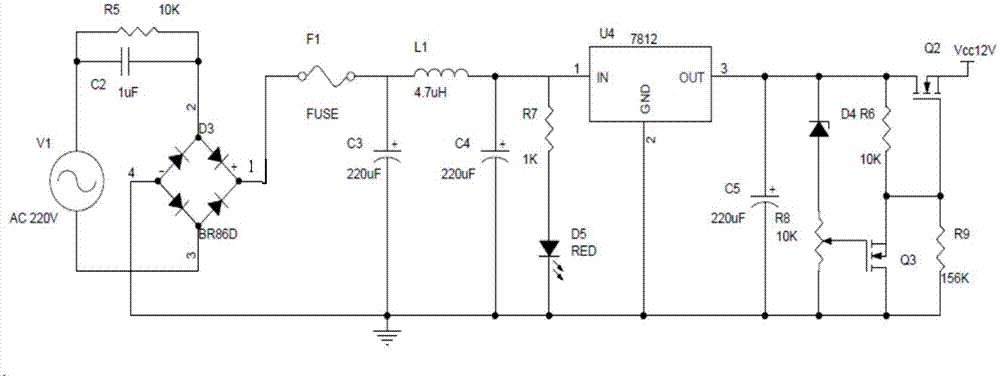

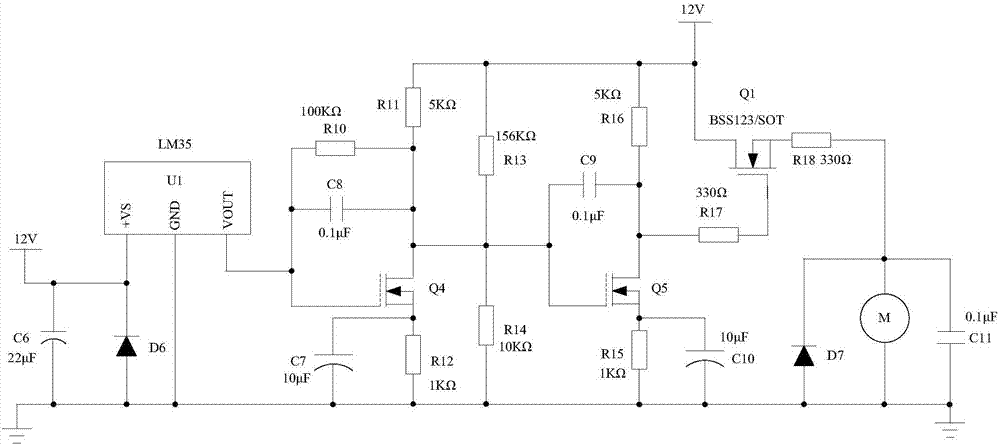

[0017] Such as figure 1 , 2 As shown, the output amplification stage temperature control intelligent exhaust system of the present invention includes a power supply module, a temperature sensor U1, a fan M, a field effect transistor Q4, a field effect transistor Q5, and a front-end processing circuit connected to the temperature sensor U1, connected in series The capacitor C8 between the gate and the drain of the field effect transistor Q4, the resistor R10 connected in parallel with the capacitor C8, the positive electrode connected to the source of the field effect transistor Q4, and the negative electrode connected to the GND pin of the temperature sensor U1 The polar capacitor C7, the resistor R12 connected in parallel with the polar capacitor C7, one end connected to the drain of the field effect transistor Q4, and the other end connected to the drain of the field effect transistor Q5 through the resistor R16, and the resistor R11 connected in series The resistor R13 bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com