Near-wall air device for preventing high-temperature corrosion of water-cooled wall of power station boiler

A technology for high-temperature corrosion and power plant boilers, applied in combustion methods, combustion chambers, outer covers/linings, etc., can solve problems such as high heat load, burnout of nozzles, large total air volume of wall-attached wind, etc., and achieve small resistance and attenuation of wind speed slow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

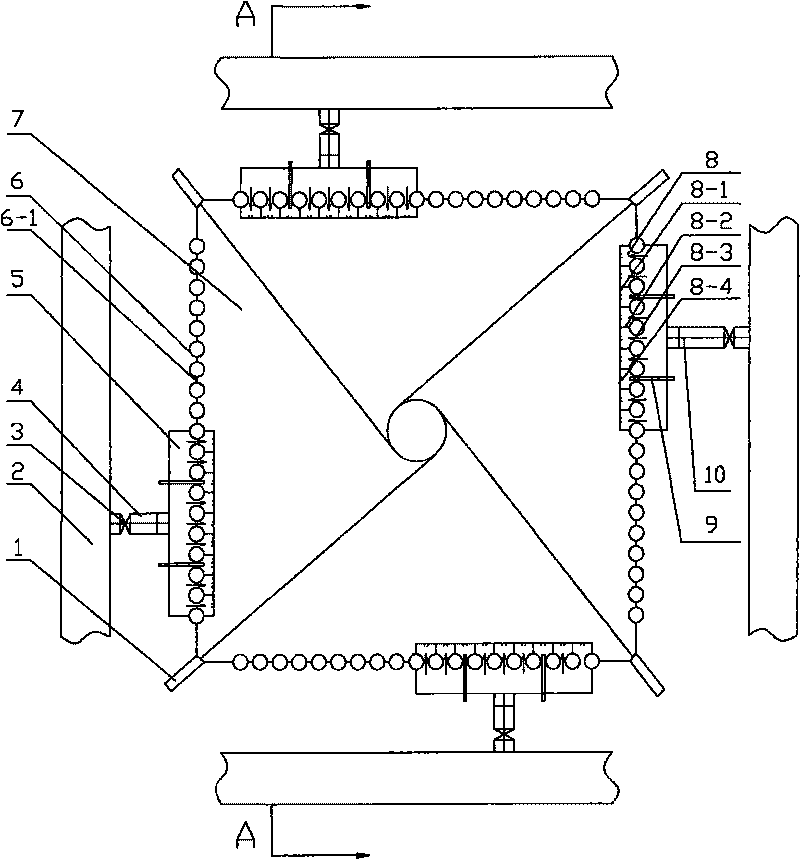

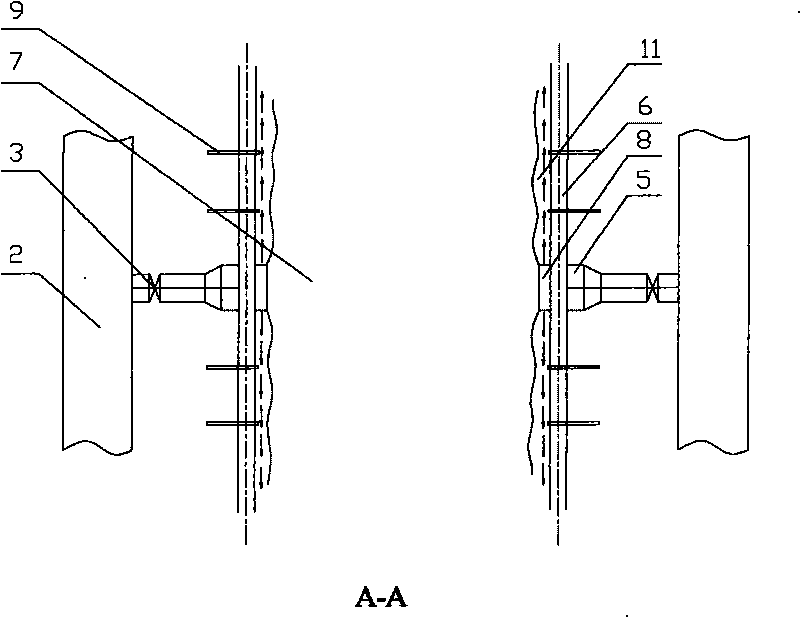

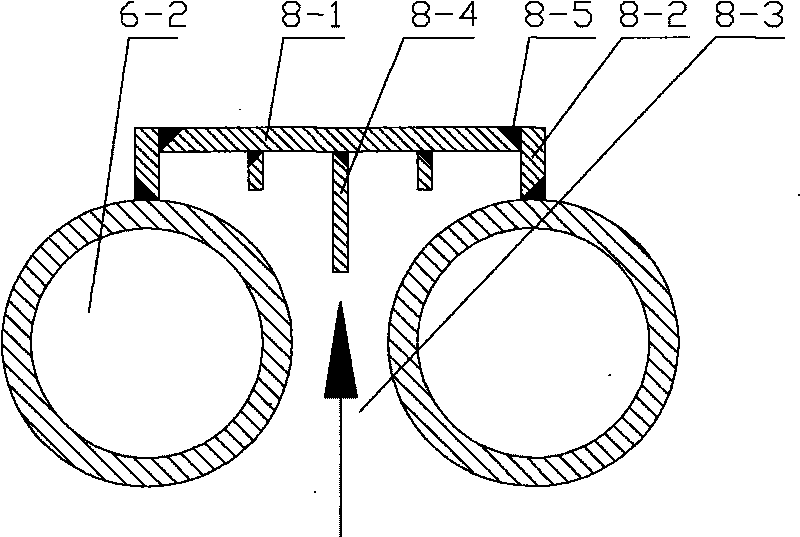

[0030] The present invention is described in further detail below in conjunction with accompanying drawing:

[0031] see figure 1 , 2 , 3. A wall-mounted air device for preventing high-temperature corrosion of the water wall of a power plant boiler, including an air duct 4, a wall-mounted wind box 5, a wall-mounted air unit nozzle 8, an online flue gas component monitor 9, and a velocity measuring device 10 ; One end of the air duct 4 communicates with the secondary air main pipe 2 through the damper 3, and the other end is connected with the wall-mounted wind box 5; the wall-mounted wind unit spout 8 includes a baffle 8-1, a fin Sheet 8-2, slit 8-3 and vortex plate 8-4; one end of the fin 8-2 is welded to the water wall tube 6-2, the other end is welded to the baffle plate 8-1, and the vortex plate 8-4 is connected to the The baffle plate 8-1 is connected by welding, the baffle plate 8-1, the fins 8-2 and the vortex plate 8-4 are all corrugated plates, and the membrane wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com