Cage type cotton removing and tiny dust removing machine

A technology for fine dust and cotton cleaning, applied in the direction of fiber opening and cleaning machine, etc., can solve the problems of high drop loss rate of spinnable fibers, inability to remove fine dust, poor dust removal effect, etc., to achieve efficient and sufficient dust removal work, saving Maintenance cost, effect of reducing quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

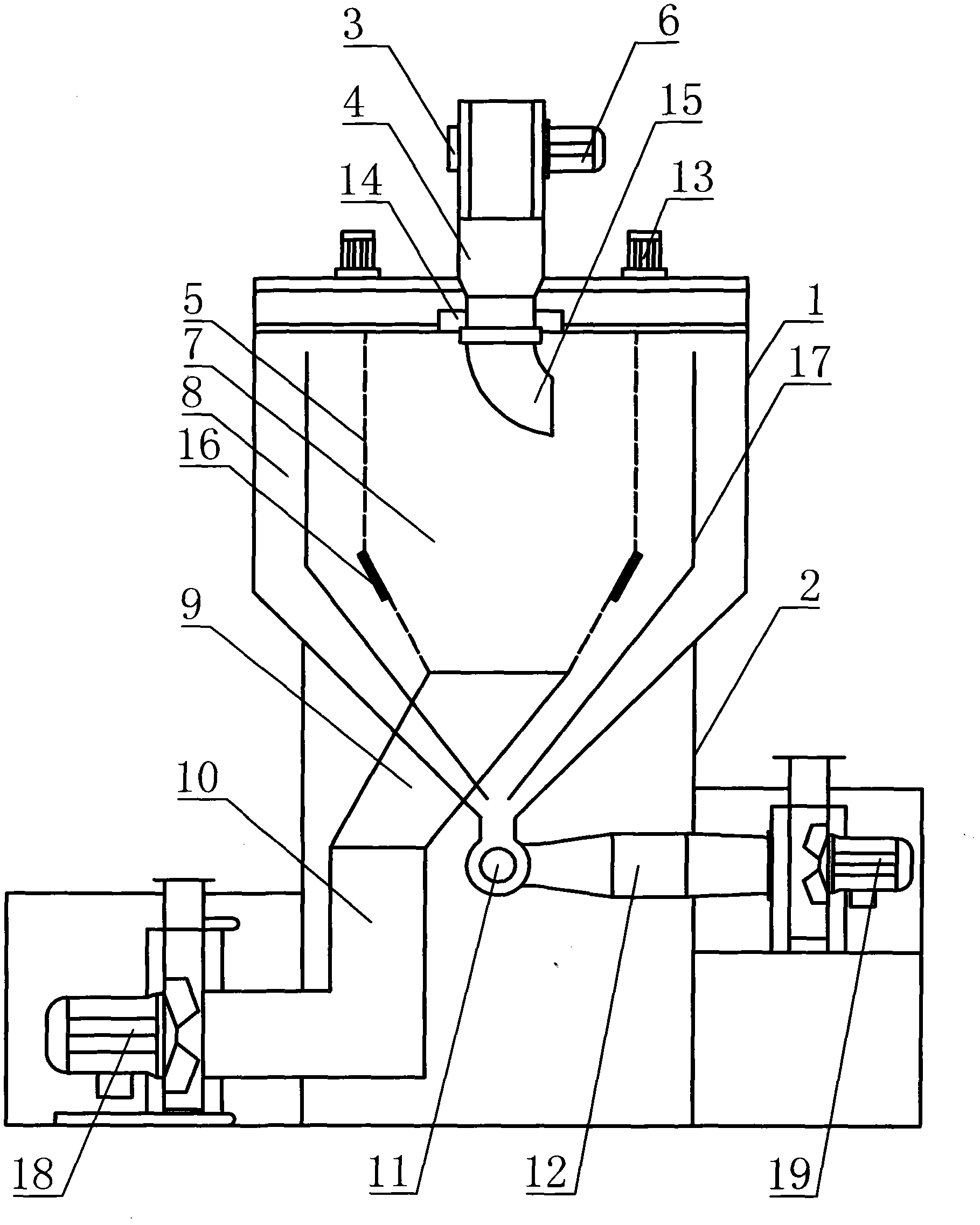

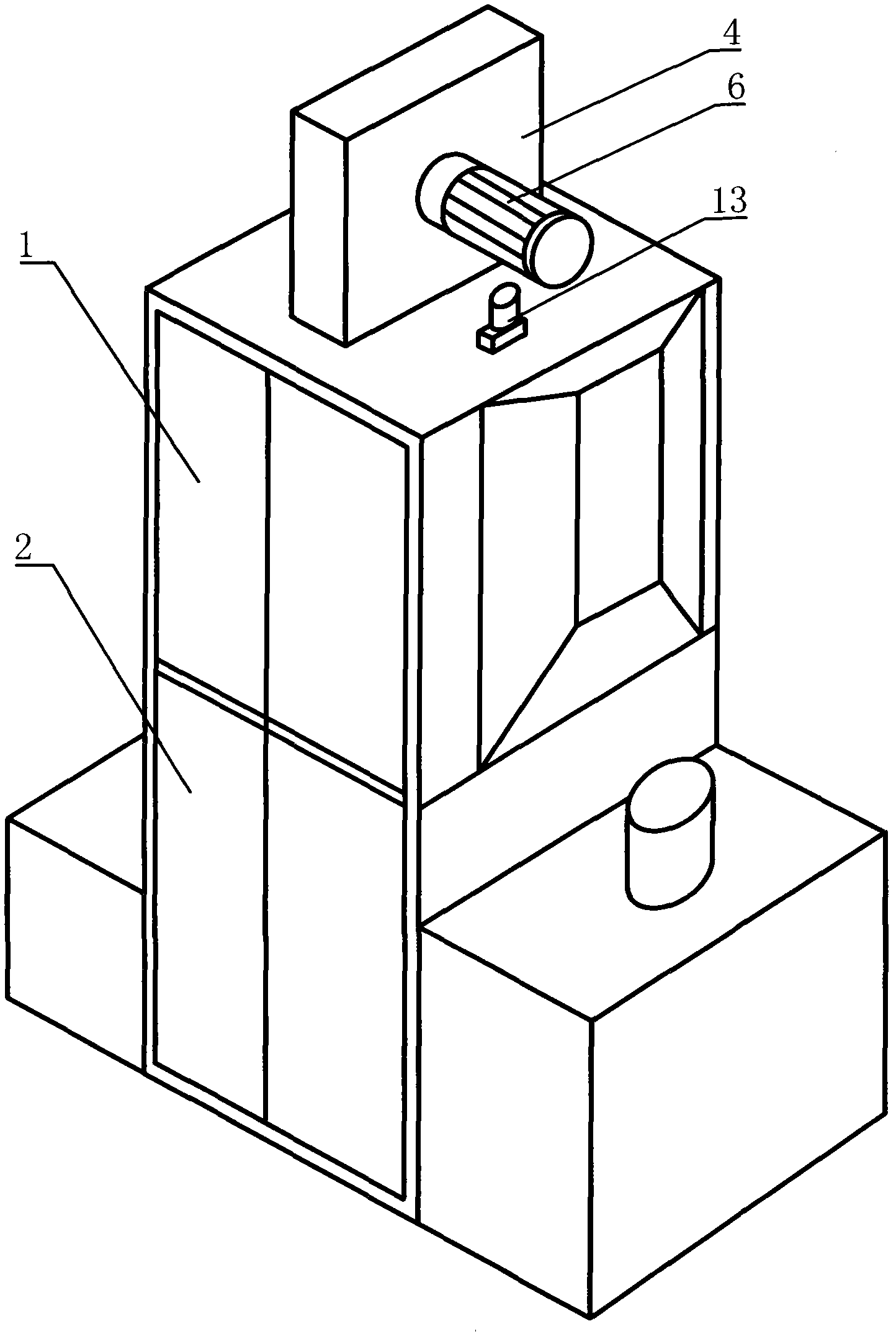

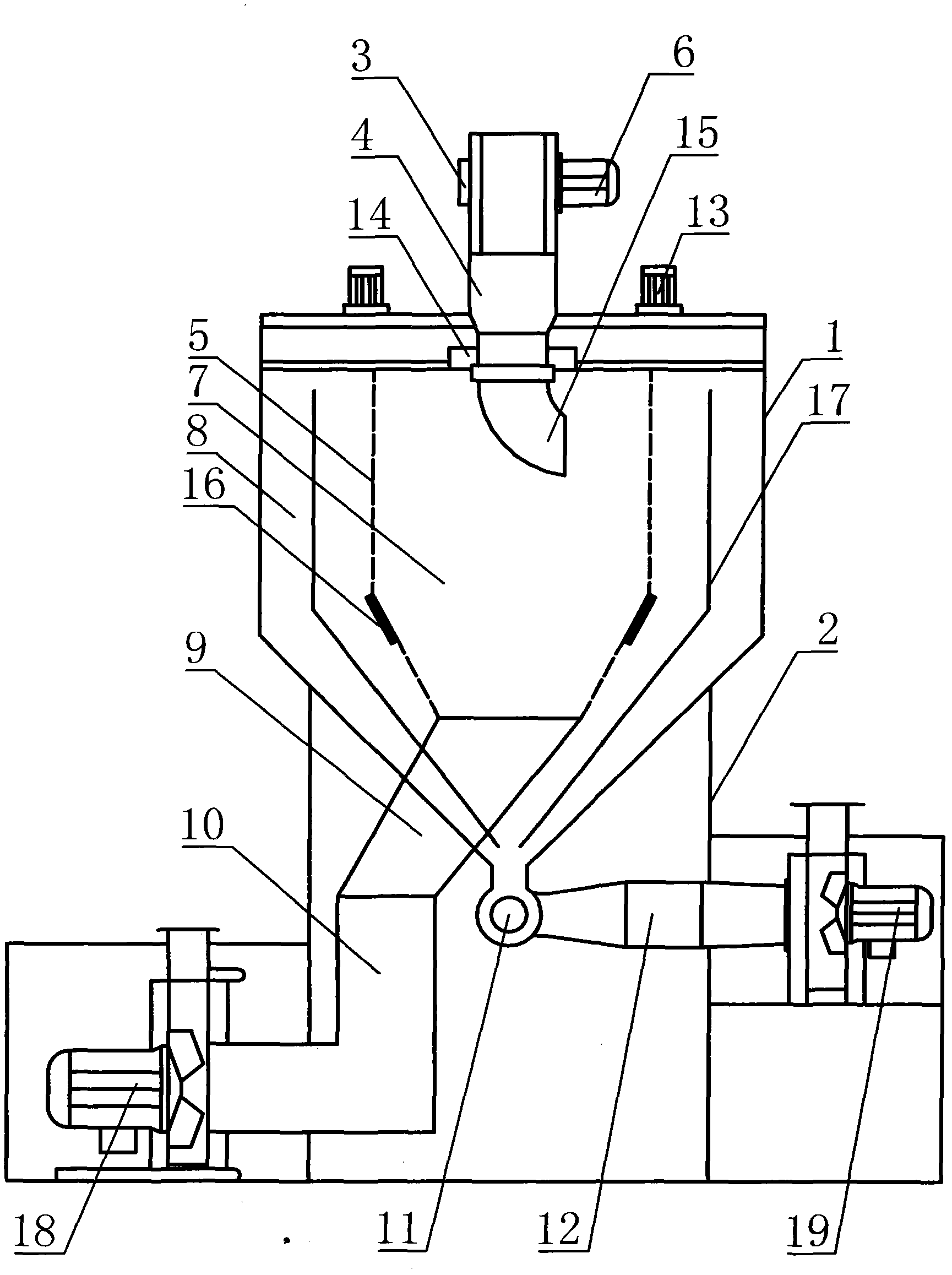

[0019] The cage-type cotton cleaning and dust removal machine of the present invention includes a box body, and the box body is divided into upper and lower parts, the upper part is the upper box body 1, and the lower part is the lower box body 2; the raw cotton tube 4 is arranged on the upper At the center of the top of the box body 1, one side is provided with a raw cotton inlet 3, and the side corresponding to the raw cotton inlet 3 is installed with 4 cotton feeding fans 6, and a rotating device is installed at one end port extending into the upper box body 1; dust cage 5 Set in the center of the upper box 1 and communicate with the top of the upper box 1, the inner space forms a dust filter chamber 7; the dust collection chamber 8 is formed between the inner wall of the upper box 1 and the dust removal cage 5; the middle section collects cotton The chamber 9 is installed on the top of the lower box 2 and connected with the dust filter chamber 7; the cotton outlet pipe 10 i...

example 2

[0022] Cage type cotton cleaning and dust removal machine of the present invention, as figure 1 , figure 2 As shown, the rotating device includes a rotating motor 13, a rotating bearing 14, a rotating elbow 15, and a rotating nozzle. The rotating motor 13 is symmetrically installed on both sides of the top of the upper box body 1; the rotating elbow 15 rotates The tube bearing 14 is installed at the outlet end of the raw cotton tube 4; the rotary nozzle is arranged on the rotary elbow 15. When the raw cotton enters the raw cotton pipe 4, turn on the rotating motor 13 to drive the rotating elbow 15 to rotate 360°, and spray the raw cotton evenly to the dust removal cage 5 through the rotating nozzle while rotating. This method is conducive to efficient and sufficient removal. It works with fine dust, and can effectively reduce the number of neps, realize the effect of evenly distributing raw cotton, and improve the utilization rate of the dust removal cage.

[0023] The dedu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com