A kind of production and processing method of medical melt-blown non-woven fabric

A melt-blown non-woven fabric and processing method technology, which is applied in the directions of melt spinning, non-woven fabrics, textiles and paper making, etc., can solve the problems of uneven distribution of fiber thickness, polymer layering, and inability to melt polymer mixing, etc. Achieve uniform distribution of fiber thickness, ensure quality effect, and improve processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be embodied in various ways of claims defined and covered.

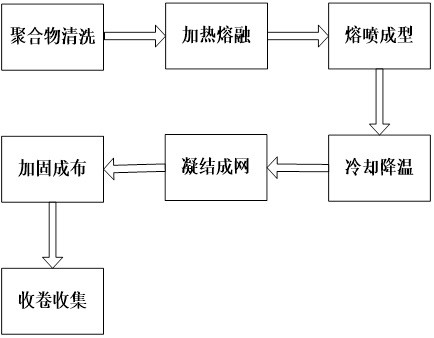

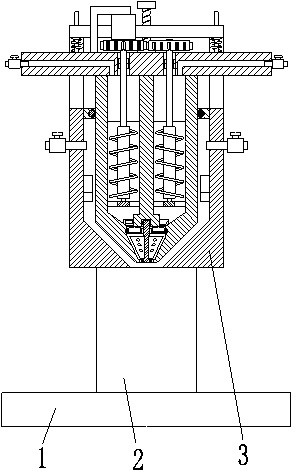

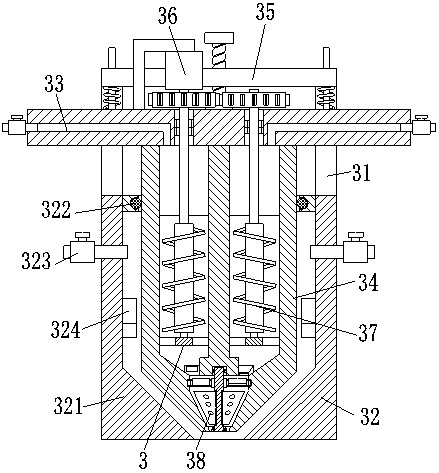

[0036]Such asFigures 1 to 7As shown, a medical meltblown non-woven fabric production method, the medical meltblown nonwoven fabric production method is used as follows, the processing equipment including the bottom plate 1, the support frame 2, and the meltblown device 3, the bottom plate 1 The upper end is configured with a support frame 2, and a meltblown device 3 is mounted between the upper end of the support frame 2.

[0037]The meltblown device 3 includes a connecting frame 31, a blowing air mechanism 32, a slider 33, a feed carrier 34, a modulating mechanism 35, a drive mechanism 36, a feed mechanism 37, and a meltblown mechanism 38, the upper end of the support frame 2. The connecting frame 31 is mounted, the connecting frame 31 is mounted directly, the upper end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com