A self-radiating rare earth permanent magnet synchronous motor

A rare earth permanent magnet, synchronous motor technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of reduced heat sink effect, inconvenient disassembly and installation, limited gap between the machine compartment and front and rear covers, etc., to improve self-heating effect, improve self-heat dissipation capacity, improve the effect of heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

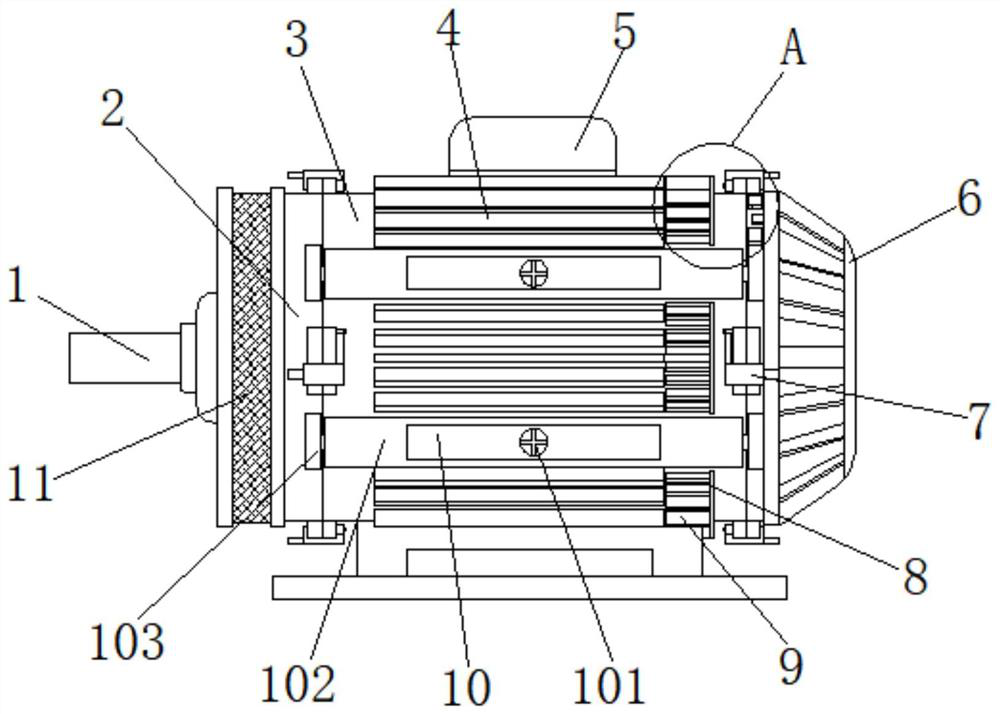

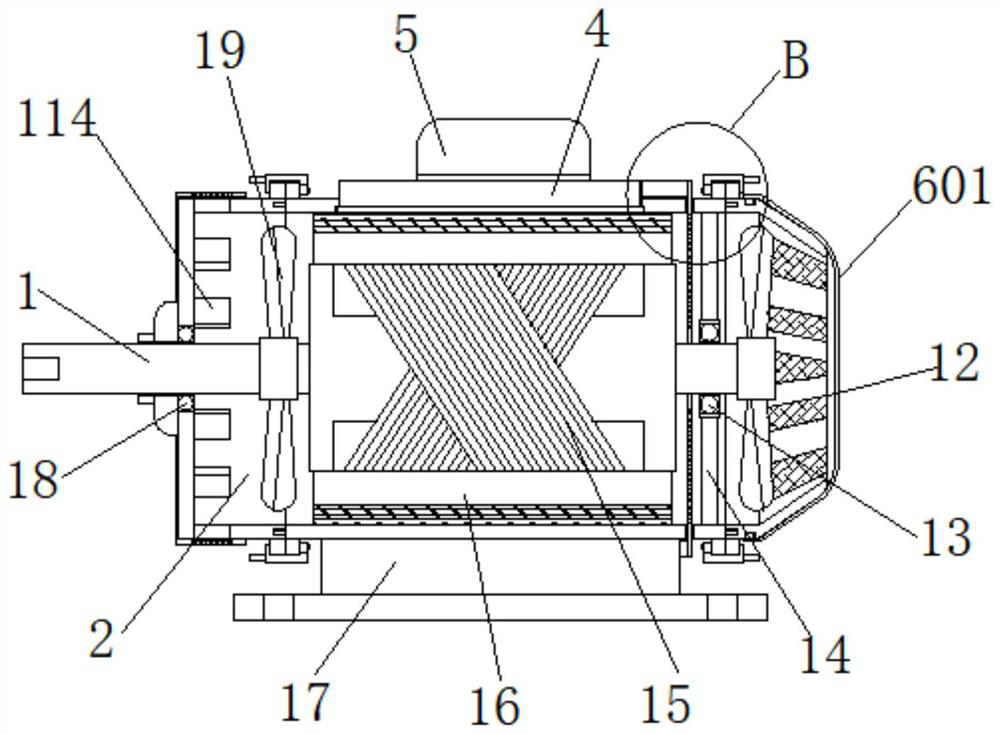

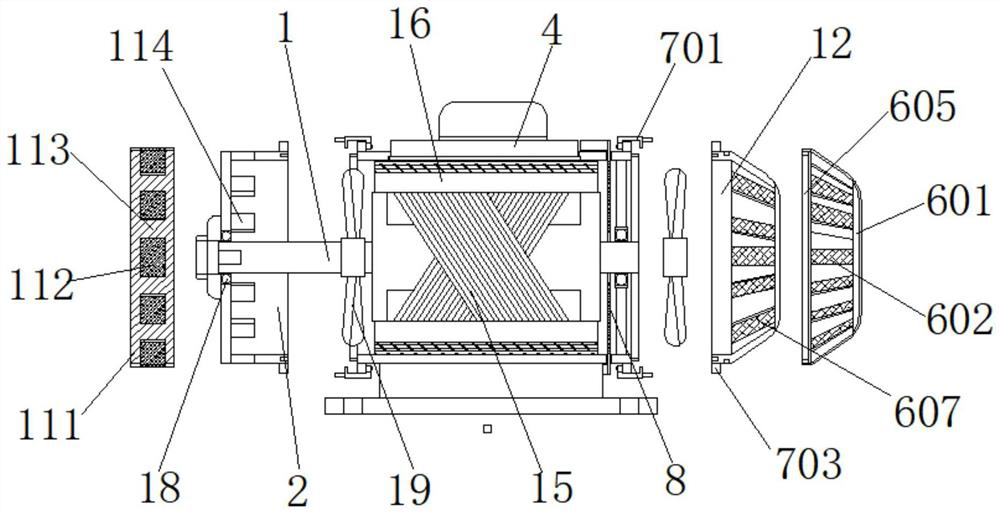

[0034] Example 1, such as Figure 1-3 As shown, when the external air sucks the chassis 3, it is necessary to turn the inner thread ring 113 such that the pass groove A111 and the pass groove B114 can be coincident, thereby enabling the outside air through the filter B112 filtered, after passing After passing through the groove A111 and the pass groove B114, it enters the interior of the chamber 3, and then rotates the outer cover 601 such that the outer cover 601 and the strip through hole 602 on the rear cover 12 are coincident with each other, and the air inside the cabinet 3 is from the strip The shaped hole 602 flows out into an external environment.

Embodiment 2

[0035] Example 2, such as figure 1 , 5 As shown, when the rare earth permanent magnet synchronous motor is needed, the four sets of bolts 101 are first united, and since the elastic recovery force of the spring 105 forces the mounting plate 104 and the plurality of sets of lasers 109, the latch 109 is separated. The pin 108 is inside, and then manually pulls the multi-group U-shaped cassette 701, and then pulls the front cover 2 and the rear cover 12 toward one end of the trainer 3 so that the front cover 2 and the rear cover 12 The plug 107 gradually extracts from the inside of the slot 102, thereby completing the removal of the front cover 2 and the rear cover 12, followed by re-installed the front cover 2 and the rear cover 12 after being overhaul inside the motor.

Embodiment 3

[0036] Example 3, such as figure 2 , 3 4, 6, and 7, when the rare earth permanent magnet synchronous motor is used, the motor shaft 1 drives the two sets of fan 19 to rotate, during the operation of the motor, the rotor 15 and the stator winding 16 gradually produce a large amount of heat, the stator The heat of the outer side of the winding 16 gradually passes to the multi-group heat sink A4, and the heat dissipation area is improved by the portion of the heat sink A4, and the heat dissipation effect is improved. The fan 19 rotates so that the outside air is entered from the pass groove A111 into the charm 3 The inside, then the wind blows down on the surface of the rotor 15 and the stator winding 16, and the air with the temperature is passed through the annular thermal conductive sheet 8, and a portion of the heat is transmitted to the outer side of the cabinet 3 on the outer side of the cabinet 3. Thus, the heat transferred by the ring thermally conductive sheet 8 quickly disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com