Sizing, drying and shaping device for polyacrylonitrile-based carbon fiber

A technology of polyacrylonitrile carbon fiber and setting device, which is applied in the direction of textiles and papermaking, heating/cooling fabric, fabric surface trimming, etc. It can solve the problems of carbon fiber pollution, affecting the production environment, and high energy consumption, and achieves long flow mileage, The effect of maintaining the drying effect and improving the uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further explained below in conjunction with the accompanying drawings.

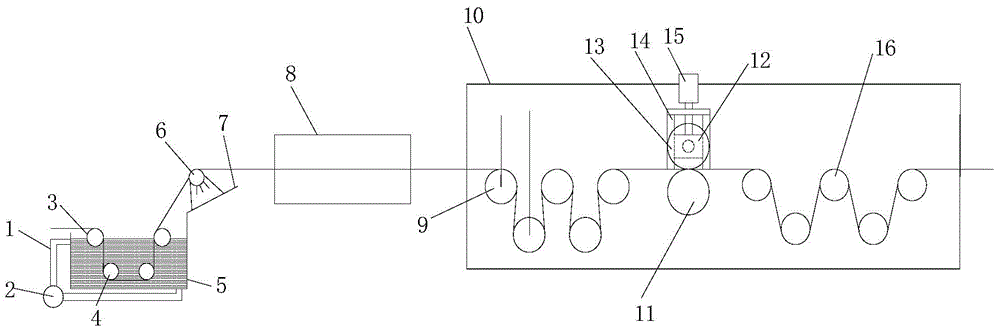

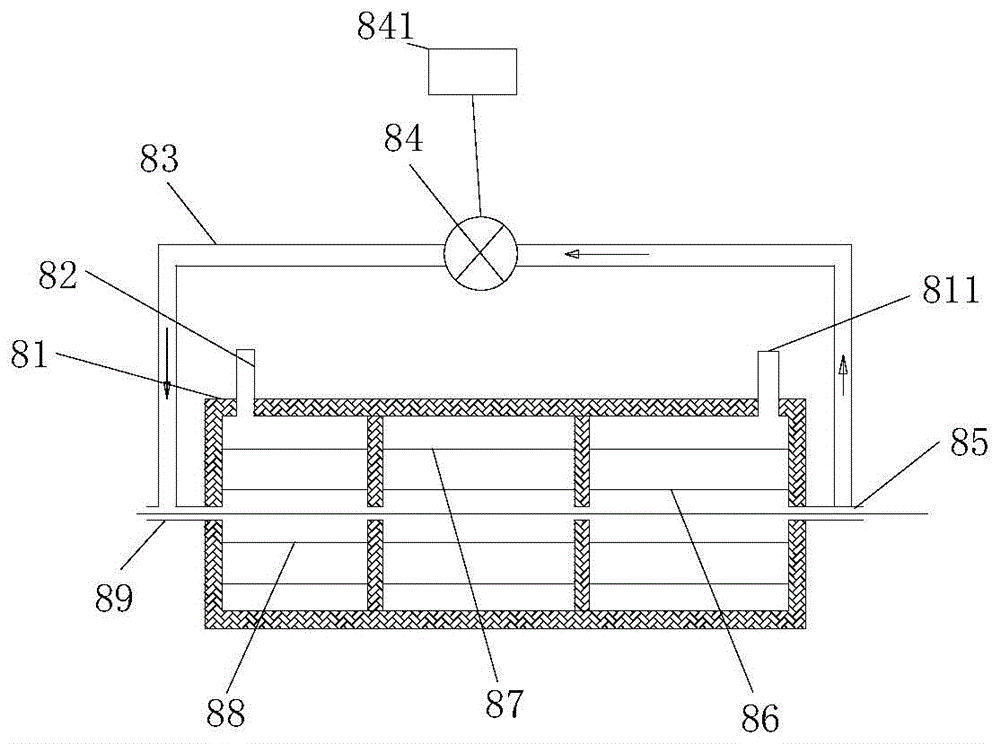

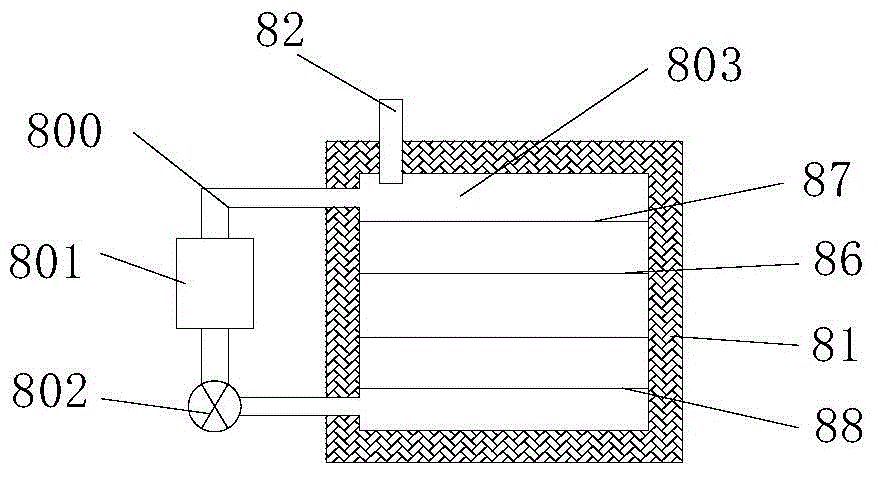

[0031] like figure 1 The shown polyacrylonitrile carbon fiber sizing, drying and sizing device is characterized in that: it includes a sizing device for sizing carbon fibers, a drying device for drying carbon fibers after sizing, and a sizing device for sizing the dried carbon fibers. The sizing device includes a sizing tank 5 containing the sizing liquid. A circulation pipeline 1 is arranged on the outside of the sizing tank 5. One end of the circulation pipeline 1 is connected to the bottom of the sizing tank 5, and the other end is connected to the upper edge of the sizing tank 5. The circulation pipe A circulating pump 2 is arranged on the road 5; a guide roller 3 partially immersed in the slurry and a submerged roller 4 completely immersed in the slurry are arranged in the sizing tank 5; An air sweeper 6 is fixed above the return plate 7 mentioned above.

[0032...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com