Positive-pressure direct-firing pulverizing system based on segmented temperature control and control method thereof

A segmented control and pulverizing system technology, applied in the direction of combustion control, combustion method, block/powder fuel preparation, etc., can solve the problems of mixing pulverizing system, sacrificing boiler operation economy, etc., to ensure drying output , prevent burnout of the nozzle, and ensure the effect of ventilation output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

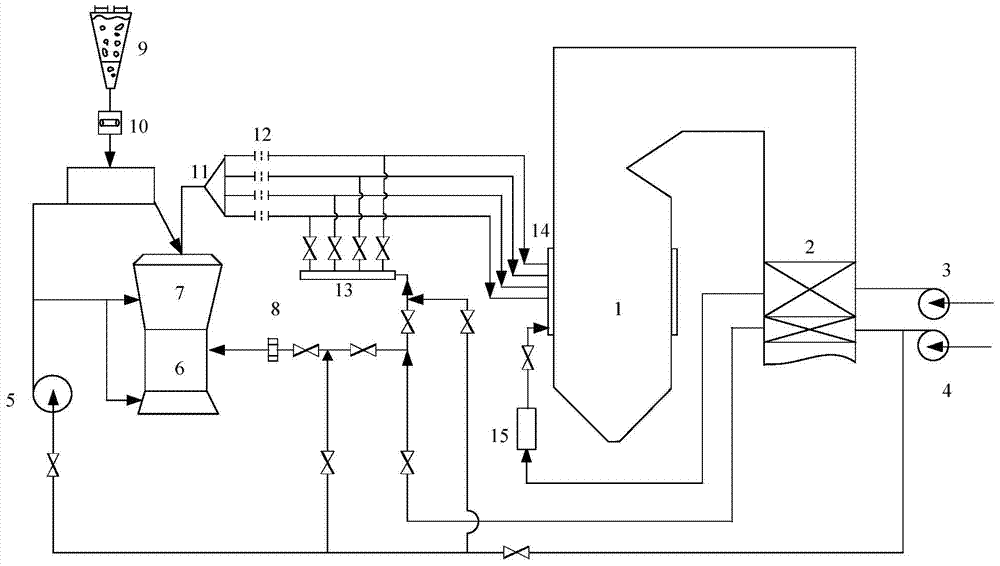

[0024] see figure 1 , the present invention is based on the positive pressure direct-blown pulverization system controlled by temperature segments, including an air preheater 2, a blower 3, a primary fan 4, a sealing fan 5, a coal mill 6, a coarse powder separator 7, and an air volume measuring device 8. Raw coal hopper 9, coal feeder 10, pulverized coal distributor 11, isolation door 12, powder feeding system regulating air box 13, pulverized coal burner 14 and secondary air box 15.

[0025] Wherein, the raw coal hopper 9 is used to supply coal for the coal feeder 10, the outlet of the coal feeder 10 is connected to the raw coal inlet of the coal mill 6, and the pulverized coal outlet of the coal mill 6 is connected to the entrance of the coarse powder separator 7, and the coarse powder is separated The outlet of the device 7 is connected to the inlet of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com