Vibrating drying device for plate production and processing

A technology of board production and drying equipment, which is applied in the direction of progressive dryer, drying gas arrangement, and drying of solid materials without heating, etc. It can solve the problems of affecting wood drying efficiency, poor air flow, uneven drying of wood boards, etc. problems, to achieve the effect of ensuring the drying effect, reducing the drying time, and avoiding the dead angle of drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

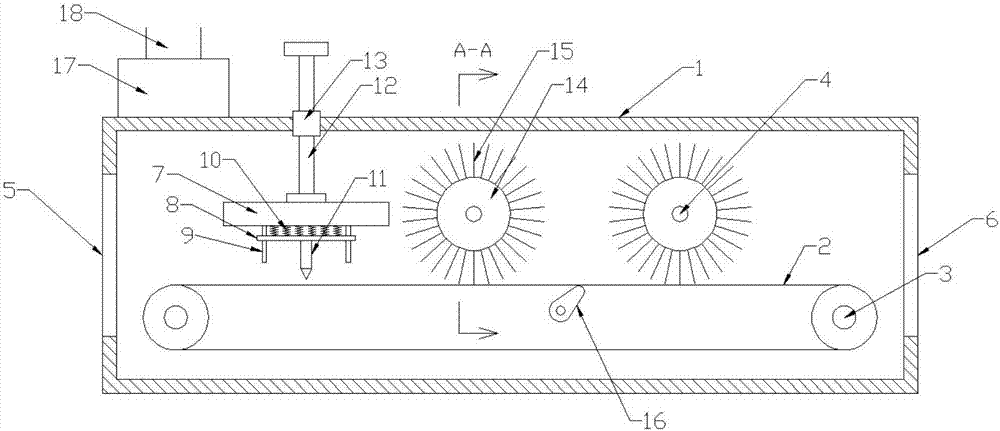

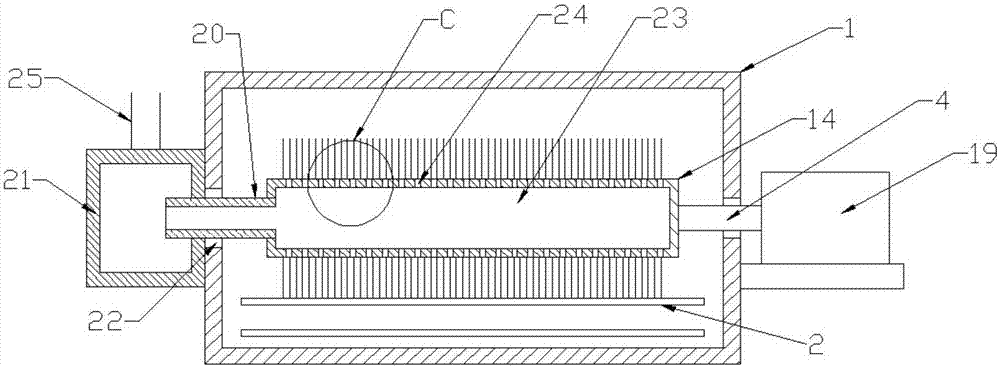

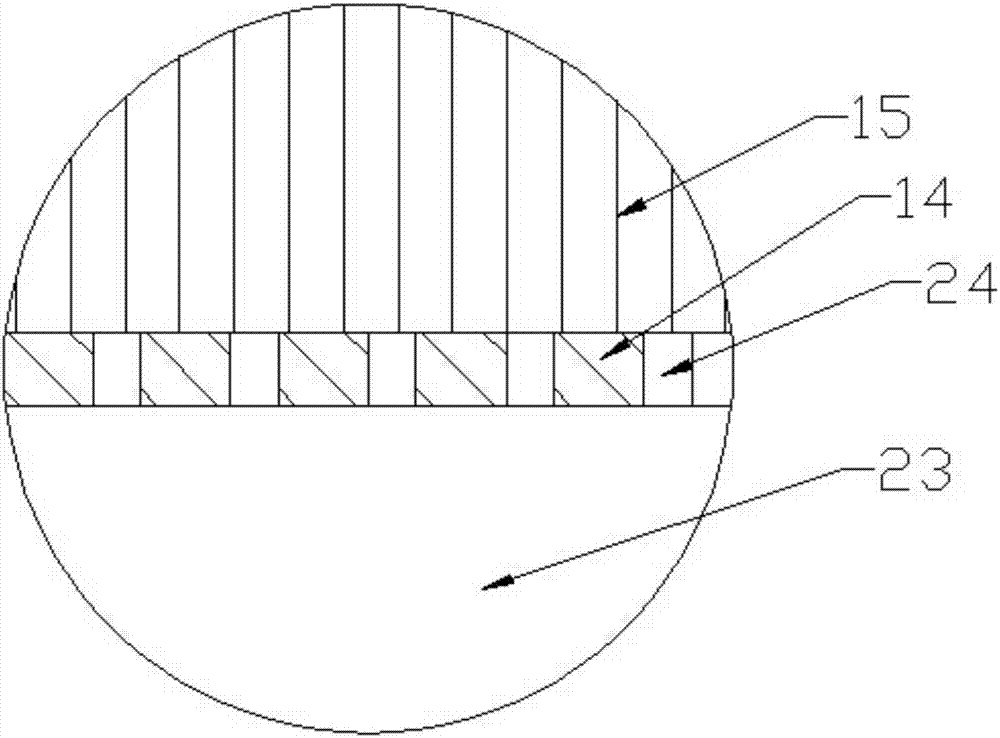

[0020] Please refer to the figure, in the embodiment of the present invention, a vibratory drying device for plate production and processing includes a box body 1, a conveyor belt 2, a transmission wheel 3 and a motor 19; the conveyor belt 2 is arranged in the box body 1, and conveys Both ends of the belt 2 bypass the drive wheel 3, and the drive wheel 3 is coaxially connected to the drive mechanism. The drive mechanism can be specifically a drive motor, which drives the conveyor belt 2 to move to realize sheet material conveyance; the left end of the conveyor belt 2 corresponds to There is a material inlet 5 on the box body 1, and a material outlet 6 is opened on the box body 1 corresponding to the right end. The plate enters from the material inlet 5, is transported by the conveyor belt 2, and finally sent out from the material outlet 6; the conveyor belt There are several protrusions 26 evenly distributed on the outer surface of 2. The height of the protrusions 26 is 5-10mm....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com