Agricultural drying machine for rice type small-size particle grain

A technology for grain dryers and rice grains, applied in dryers, drying, grain drying, etc., can solve the problems of long drying time, low drying efficiency, and simple structure, so as to improve efficiency, ensure drying effect, and improve The effect of production and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

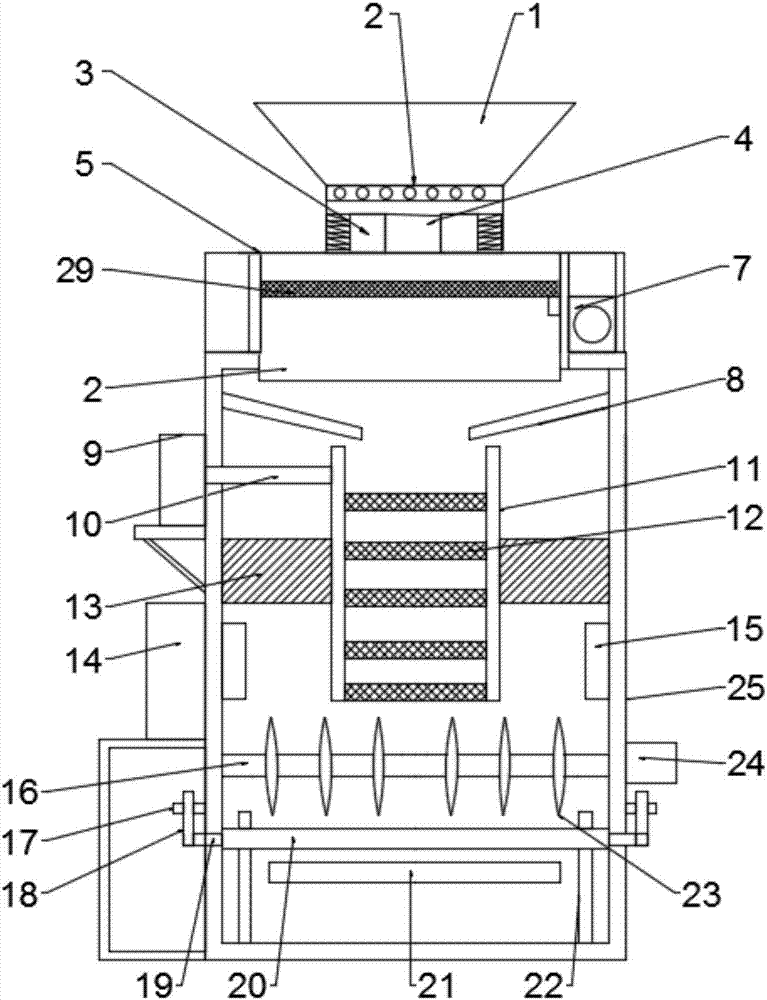

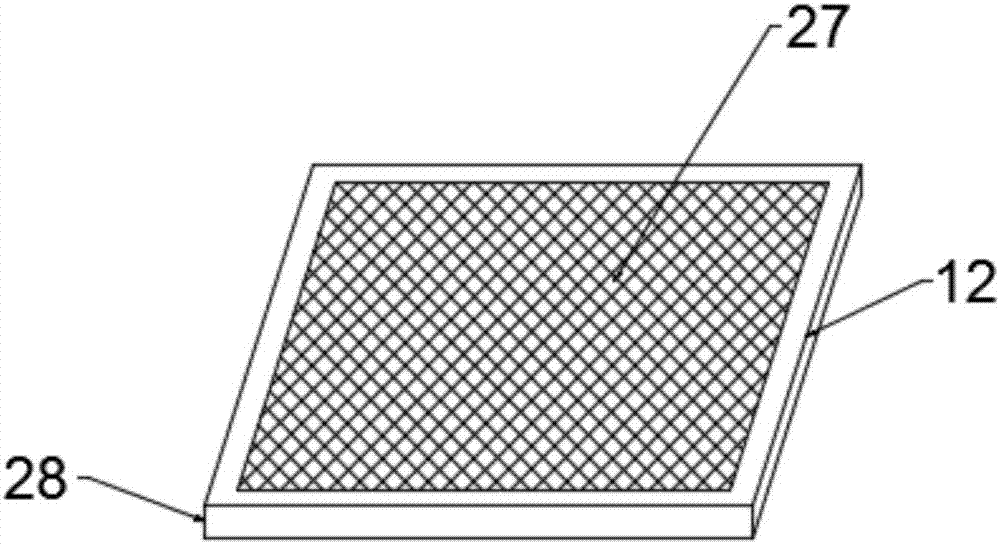

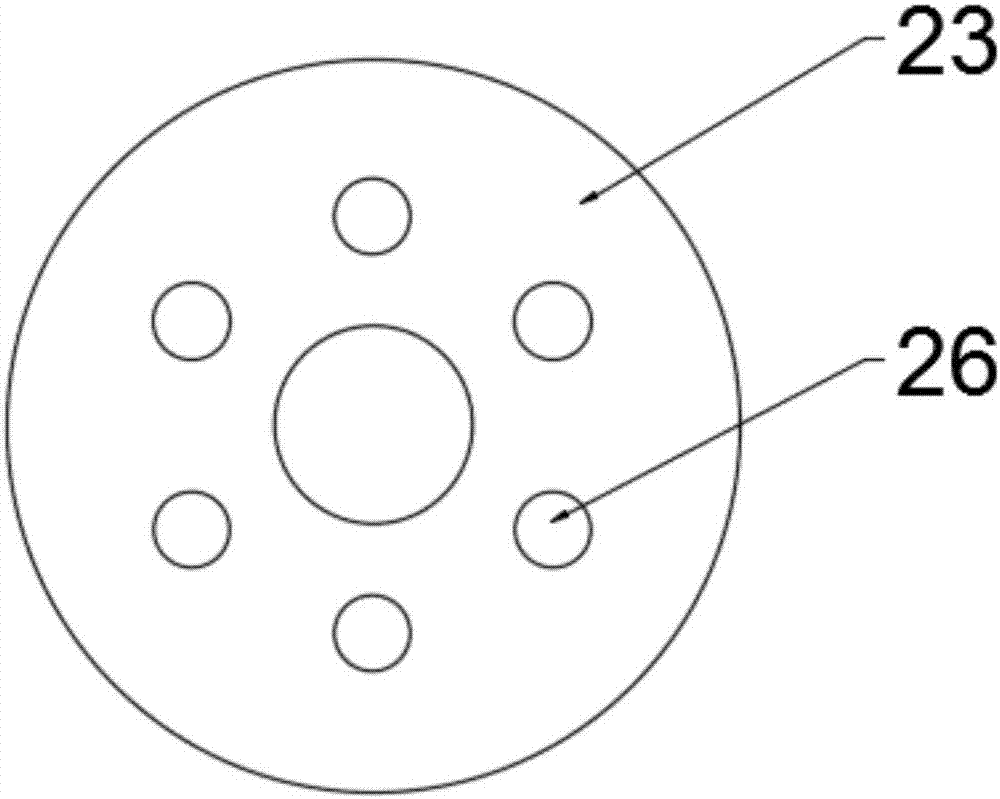

[0021] see Figure 1~3 , a small-diameter grain dryer for agricultural rice and cereals, including a machine housing 25, the top of the machine housing 25 is provided with a primary sieve feed mechanism; the primary sieve feed mechanism includes an upper feed hopper 1 and is docked with the upper feed hopper The screening chamber 5, the bottom end of the screening chamber 5 is connected to the discharge port 29, the feeding hopper 11 is in a Y shape, the upper vertical section of the feeding hopper 1 is provided with a pulverizer 2, and the lower end of the upper feeding hopper 1 passes through The feeding pipe 4 communicates with the screening chamber 5, and the inner cavity of the feeding pipe 4 is provided with a feed controller 3, and one side of the screening chamber 5 is connected to the impurity removal door through several hinges, and a scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com