Downward pressing structure special for building steel bar cutter

A technology for building steel bars and cutting machines, which is applied in the field of steel bar cutting machine accessories, can solve the problems of labor-intensive oil injection, increased friction, and reduced work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

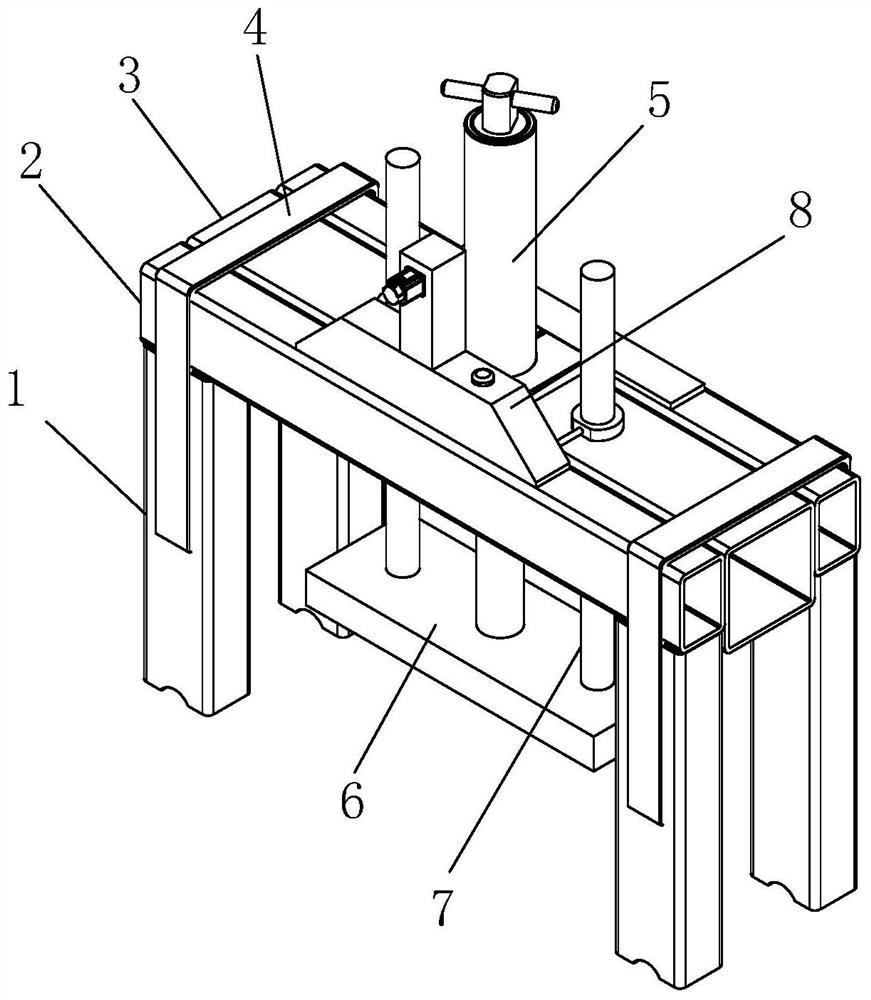

[0029] see figure 1 , the present invention provides a special press-down structure for a building steel bar cutting machine through improvement, including pillars 1, four sets of pillars 1 are provided, and the front and rear ends of the top of the four sets of pillars 1 are fixed with ejector rods 2, and the inner sides of the ejector rods 2 Fixed with the fixed plate 3, the top of the fixed plate 3 is respectively fixed with the pillar 1 and the ejector rod 2 through the guard 4, and the middle part of the top of the fixed plate 3 is installed with a hydraulic cylinder 5. 6. A guide rod 7 is fixed vertically at the left and right ends of the top, and the top of the guide rod 7 runs through the fixed plate 3, and a lubricating device 8 is provided at the front end of the top of the ejector rod 2 .

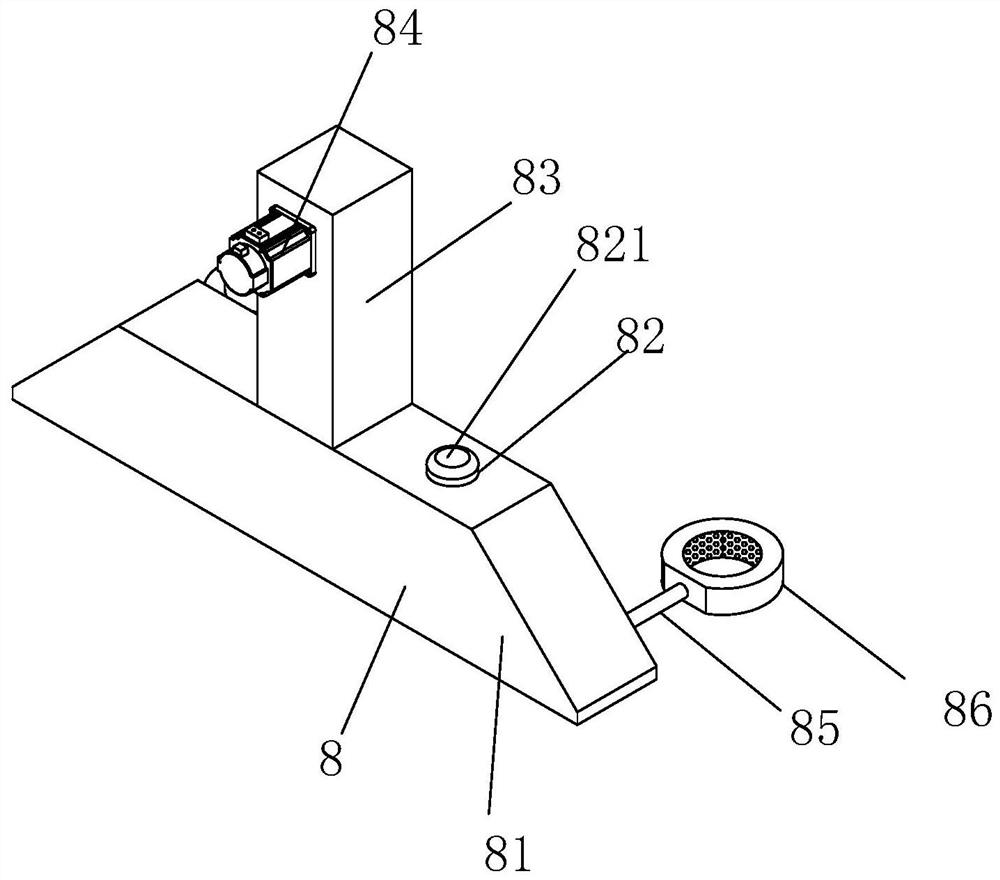

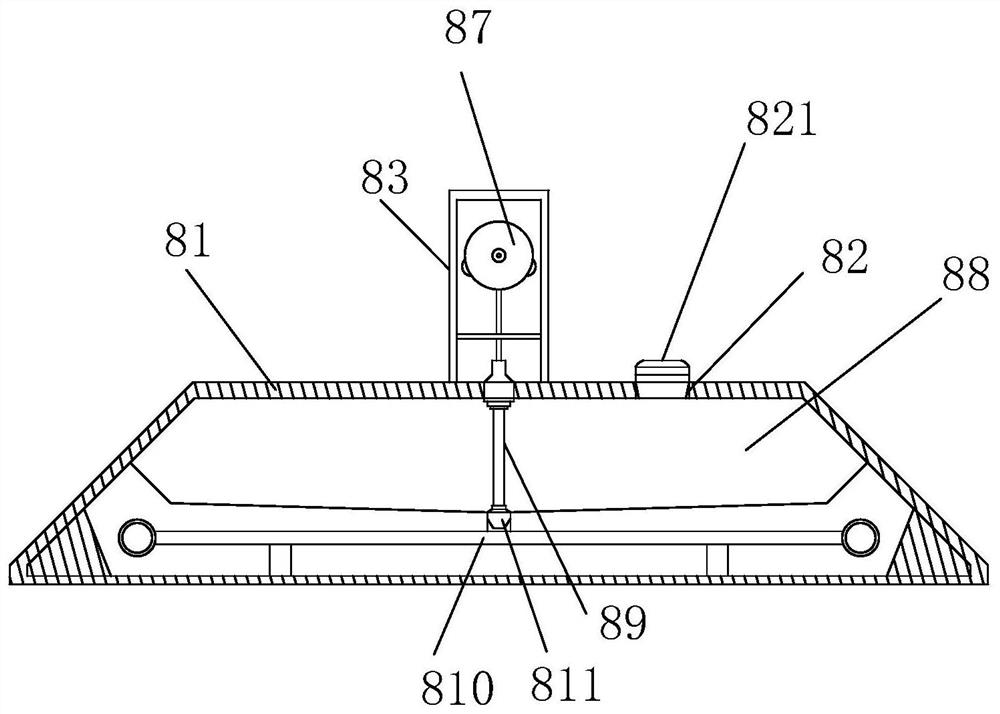

[0030] see figure 2 and image 3 , the present invention provides a special pressing structure for a building steel bar cutting machine through improvement. The lubricating de...

Embodiment 2

[0035] The present invention provides a special pressing structure for building steel bar cutting machine through improvement. The housing 81 is trapezoidal, and the back of the housing 81 is provided with a sealing cover. The sealing cover and the housing 81 are fixed by bolts, which is convenient for users to Internal inspection and maintenance are carried out; the oil pipe 85 is flexible, which is convenient for oil filling and has a long service life; both ends of the oil pipe 85 are bonded with a layer of silica gel, which effectively improves the sealing performance and prevents leakage.

[0036] The present invention provides a special pressing structure for a building steel bar cutting machine through improvement, and its working principle is as follows;

[0037] First, when the pressing structure needs to be used, the pressing structure is first installed on the steel bar cutting machine, and then the user connects the hydraulic cylinder 5 with the external hydraulic e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com