Patents

Literature

258results about How to "Improve lubrication efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

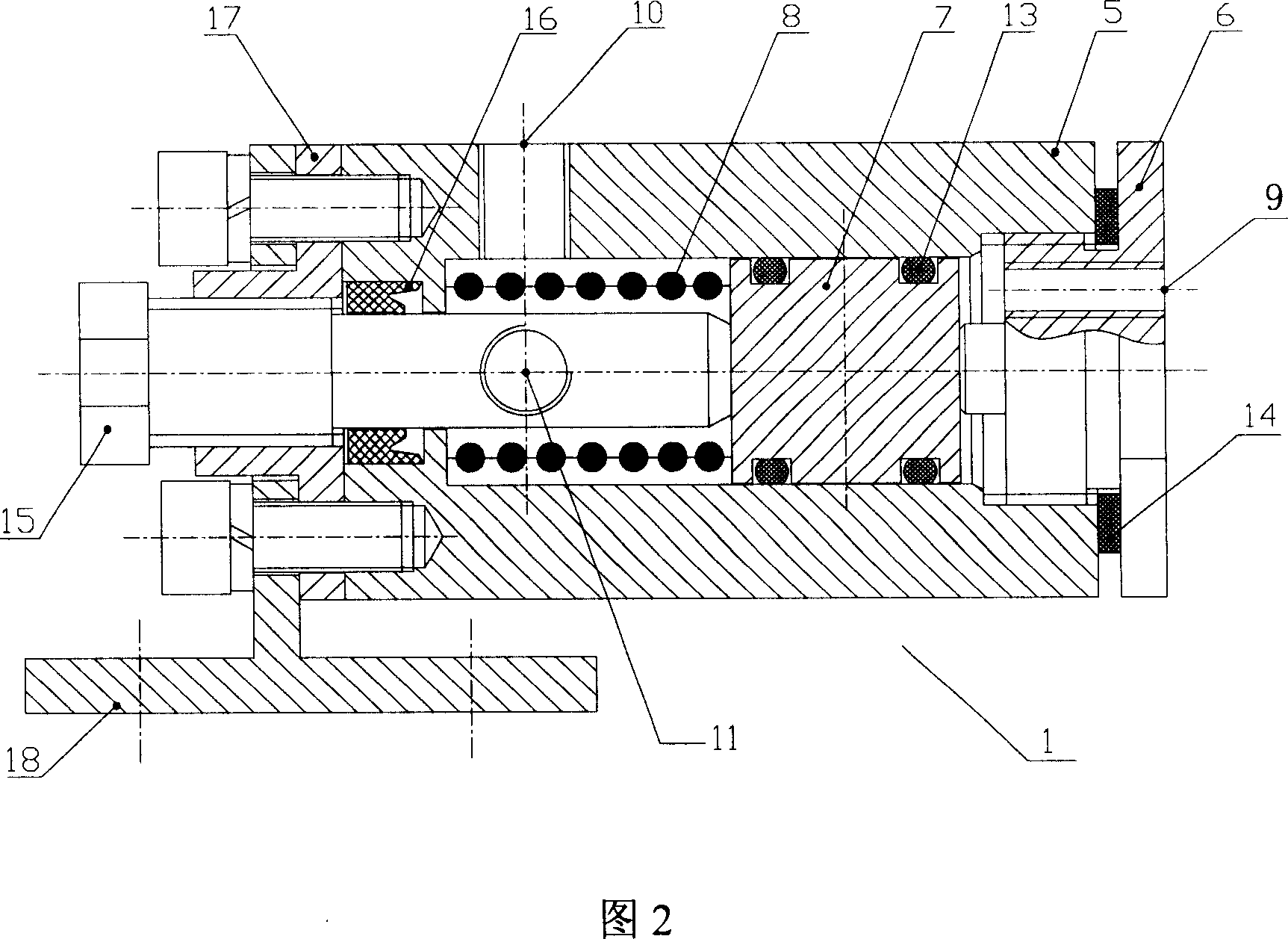

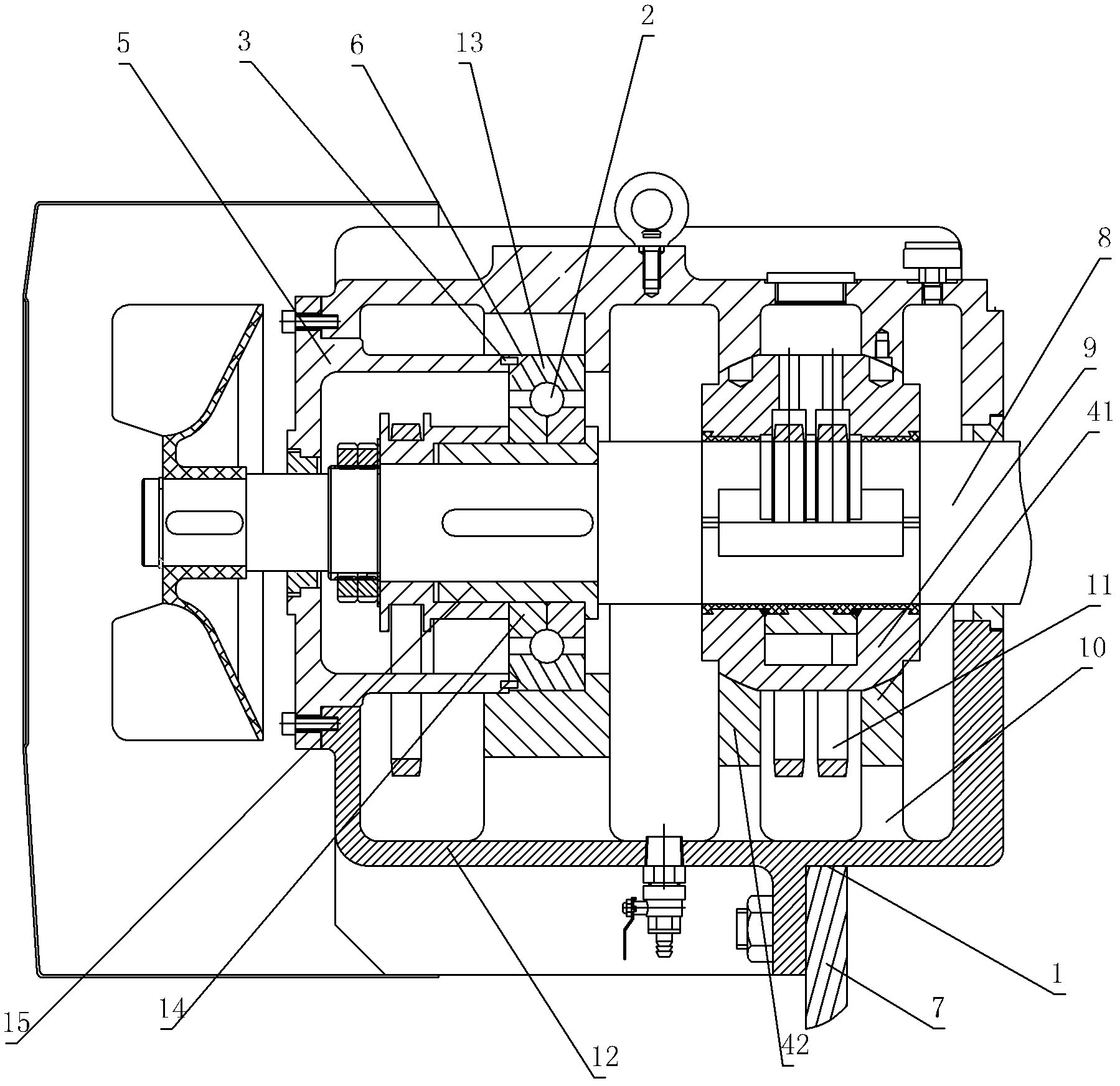

High-speed lower lubricating device for bearing ring

InactiveCN104747602ACause delay in deliveryEfficient collectionBearing componentsEngineeringPetroleum engineering

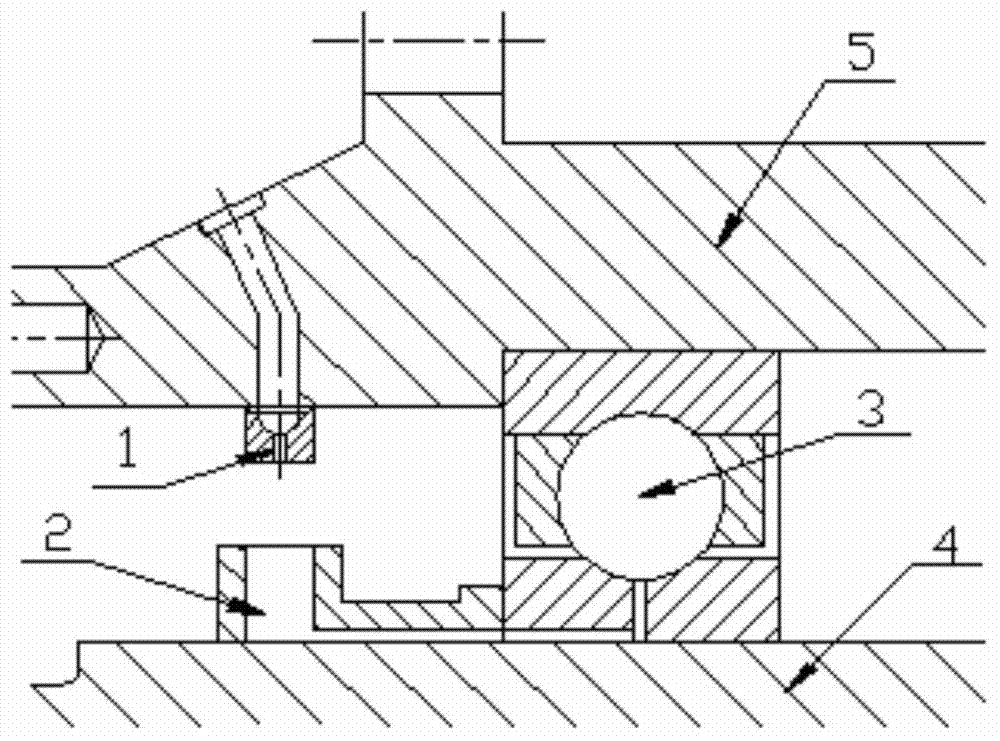

The invention discloses a high-speed lower lubricating device for a bearing ring. The high-speed lower lubricating device comprises an oil gathering sleeve, wherein an inner ring of a bearing and the oil gathering sleeve rotate synchronously; the inner wall of the inner ring of the bearing is respectively provided with a lubricating oil groove in an axial direction and a radial oil hole in a radial direction; one end of the radial oil hole is communicated with the lubricating oil groove, and the other end of the radial oil hole is communicated with a raceway of the inner ring of the bearing; the oil gathering sleeve and the inner ring of the bearing coaxially and fixedly sleeve a main shaft; the oil gathering sleeve is divided into two parts along the axial direction, the inner part of one part is provided with axial oil grooves butted with the lubricating oil groove, and the other part is radially provided with oil gathering passages which are in one-to-one butt joint with the axial oil grooves; the oil gathering passages are separated by a plurality of oil gathering blades distributed in the radial direction; an outer ring of the bearing is fixedly arranged on a shaft shell; the parts, which correspond to the oil gathering passages, of the shaft shell are provided with nozzles connected with a lubricating oil system. The high-speed lower lubricating device is capable of improving the bearing lubricating efficiency, reducing the lubricating oil quantity, further reducing the internal friction heat of the bearing and ensuring that sufficient oil film thickness exists in the raceway during high-speed rotation of the bearing.

Owner:CENT SOUTH UNIV

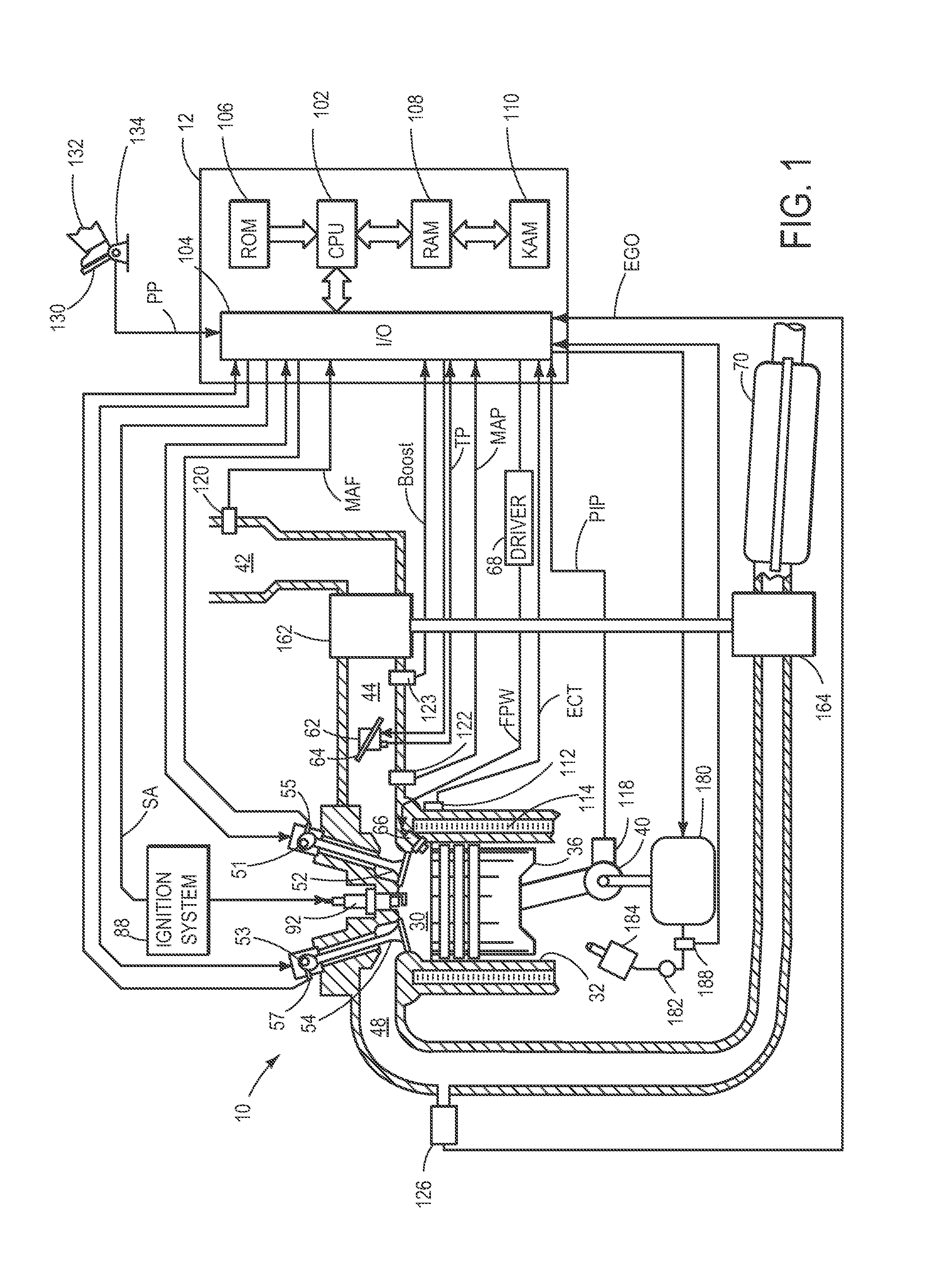

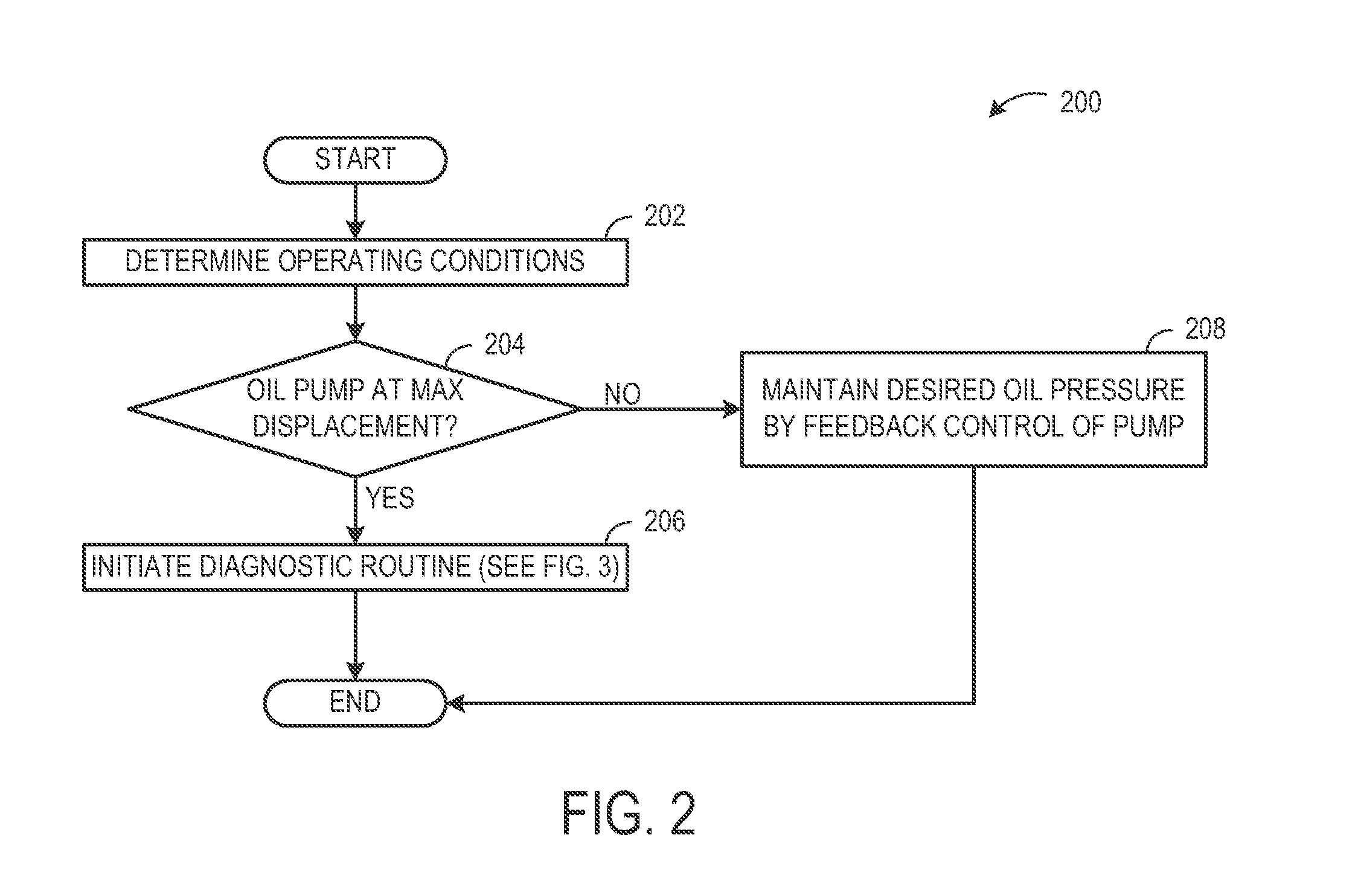

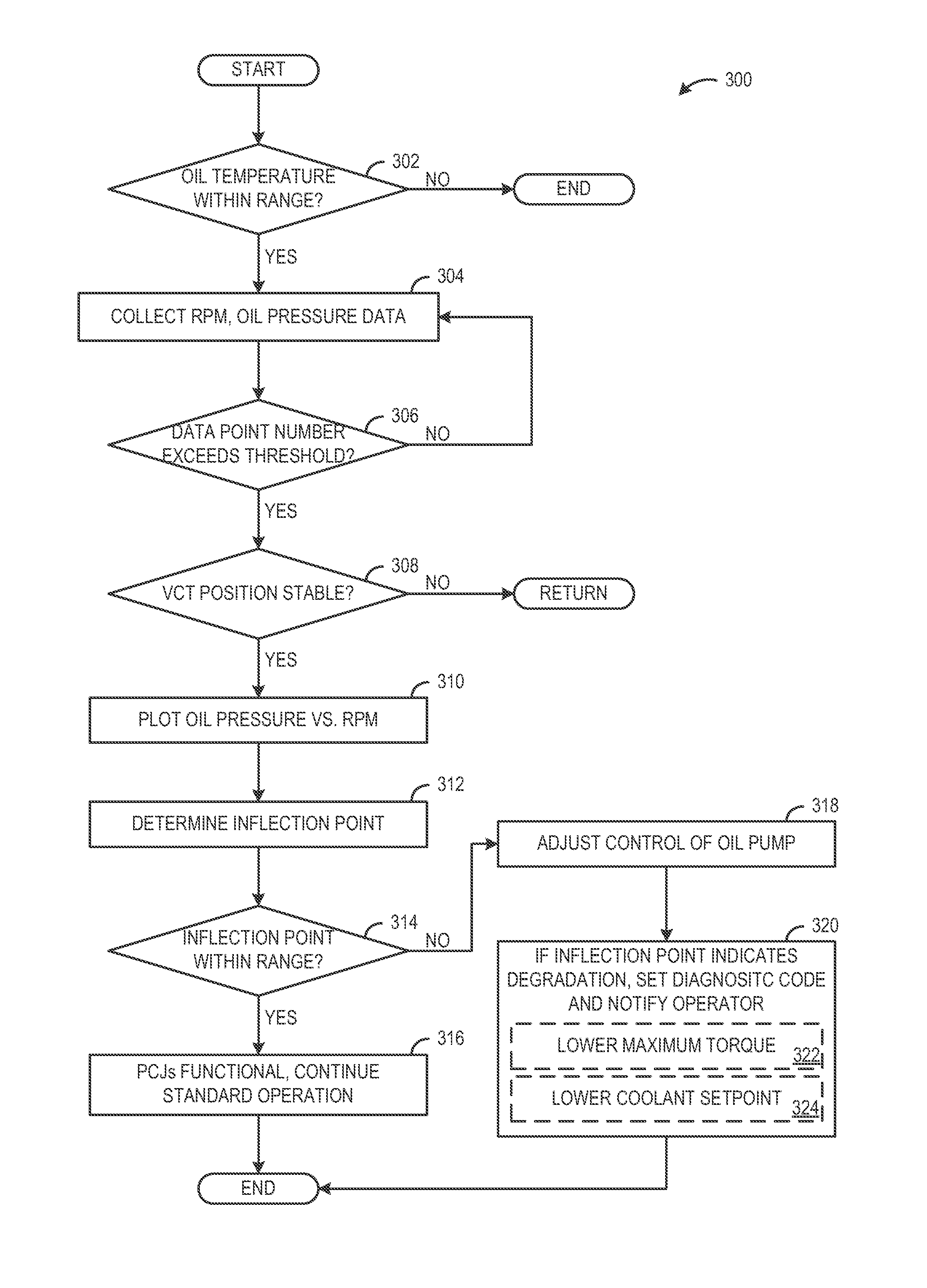

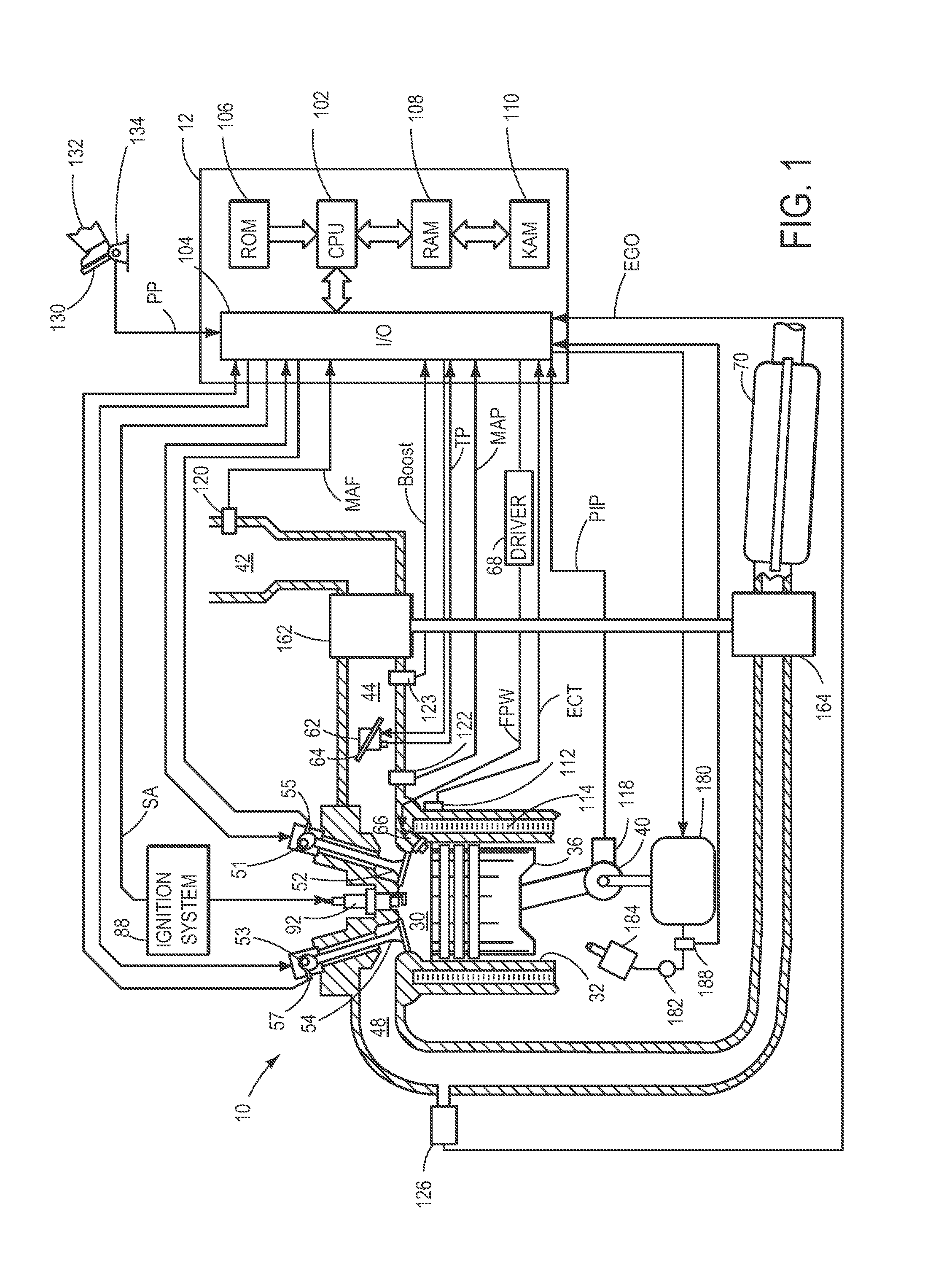

Variable oil pump diagnostic

ActiveUS20130192545A1Enhanced piston coolingEfficient engine operationLiquid coolingInternal-combustion engine testingPistonOil pressure

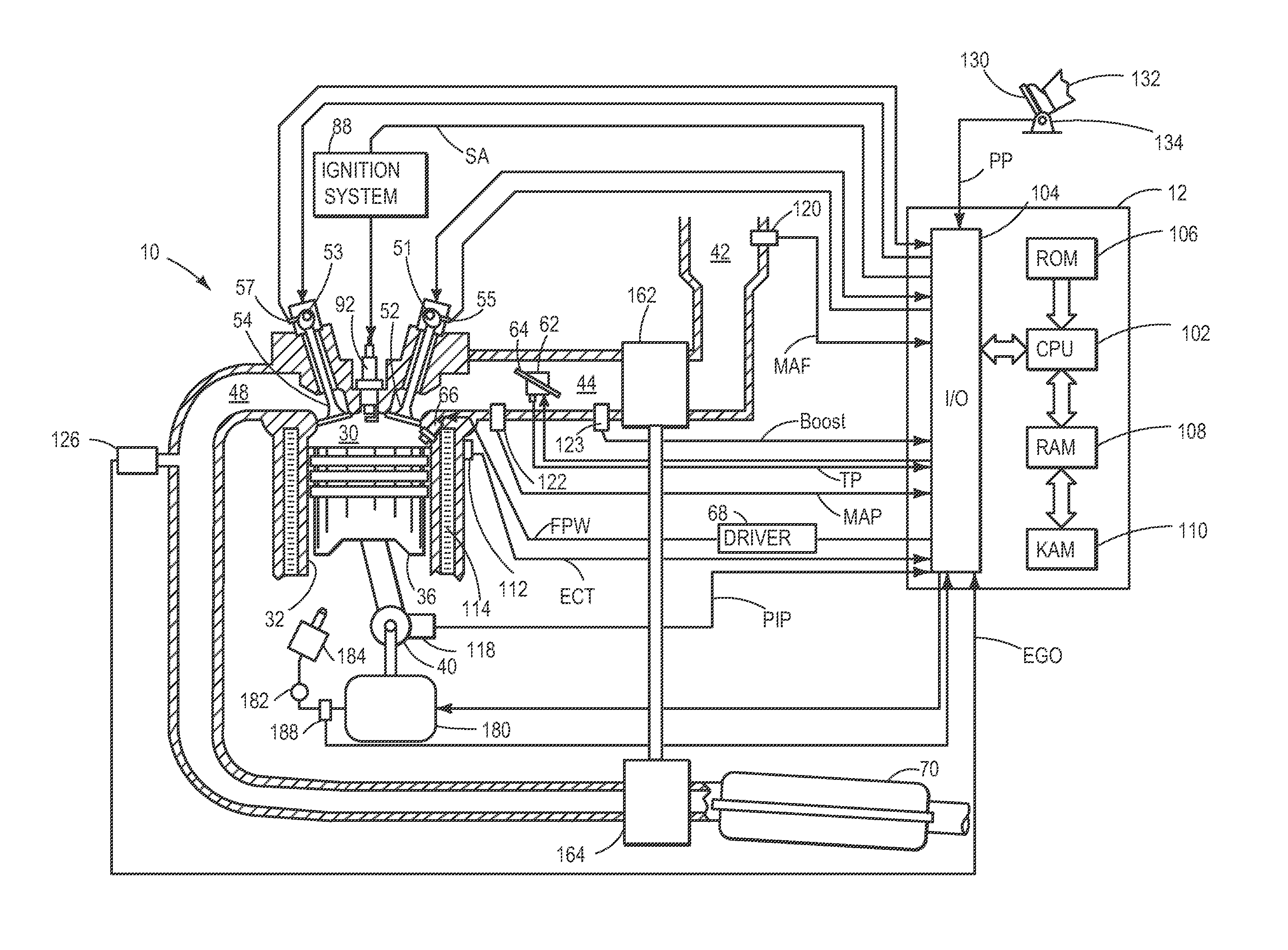

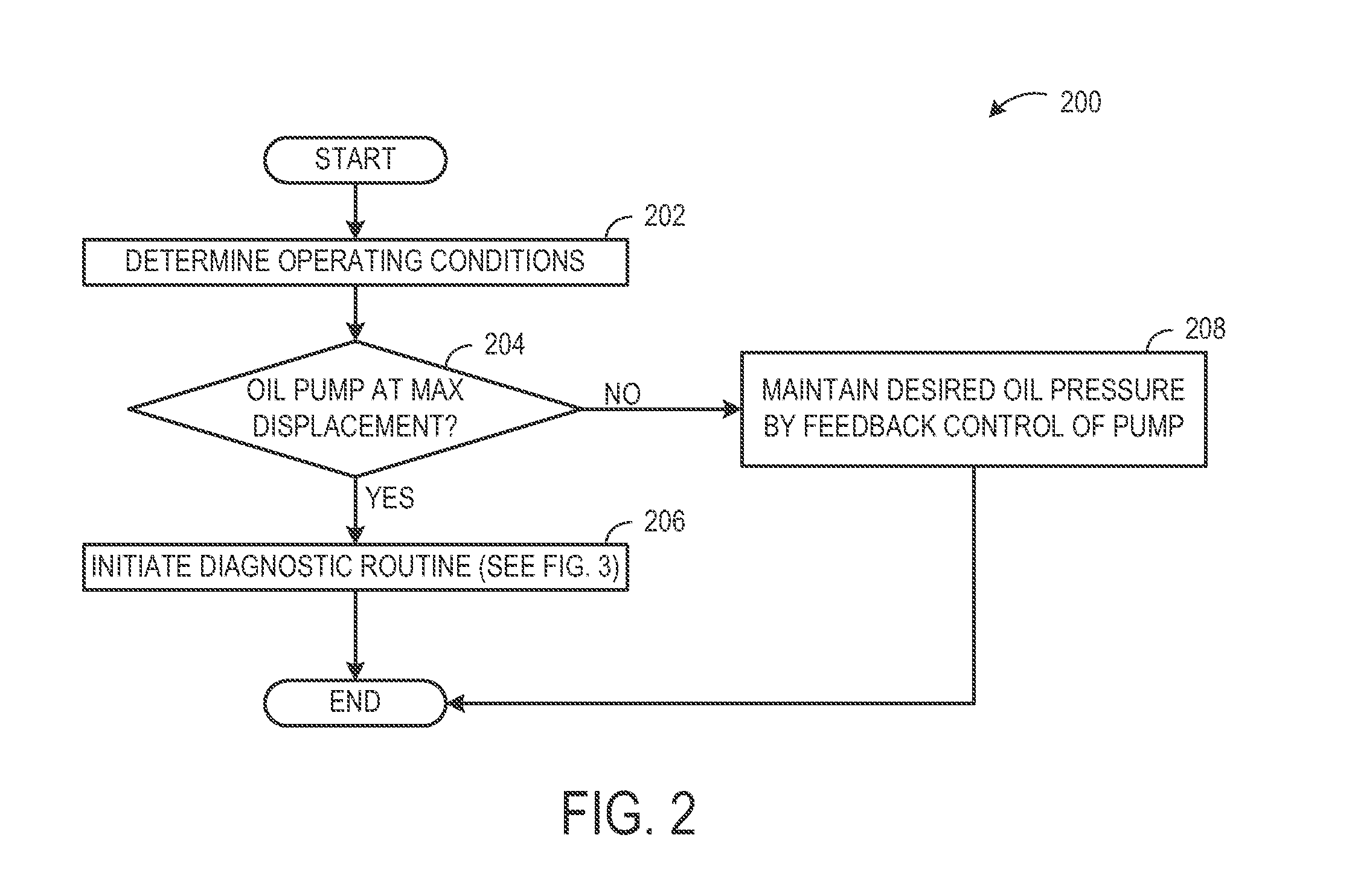

Embodiments for indicating degradation of a piston-cooling jet system are provided. In one example, an engine method comprises indicating degradation of a piston-cooling jet system in response to a relationship between engine speed and oil pressure at maximum oil pump displacement conditions. In this way, engine operation may be adjusted in response to an indicated degradation.

Owner:FORD GLOBAL TECH LLC

Variable oil pump diagnostic

ActiveUS8739746B2Guaranteed uptimeImprove fuel efficiencyInternal-combustion engine testingLubrication of auxillariesPistonOil pressure

Embodiments for indicating degradation of a piston-cooling jet system are provided. In one example, an engine method comprises indicating degradation of a piston-cooling jet system in response to a relationship between engine speed and oil pressure at maximum oil pump displacement conditions. In this way, engine operation may be adjusted in response to an indicated degradation.

Owner:FORD GLOBAL TECH LLC

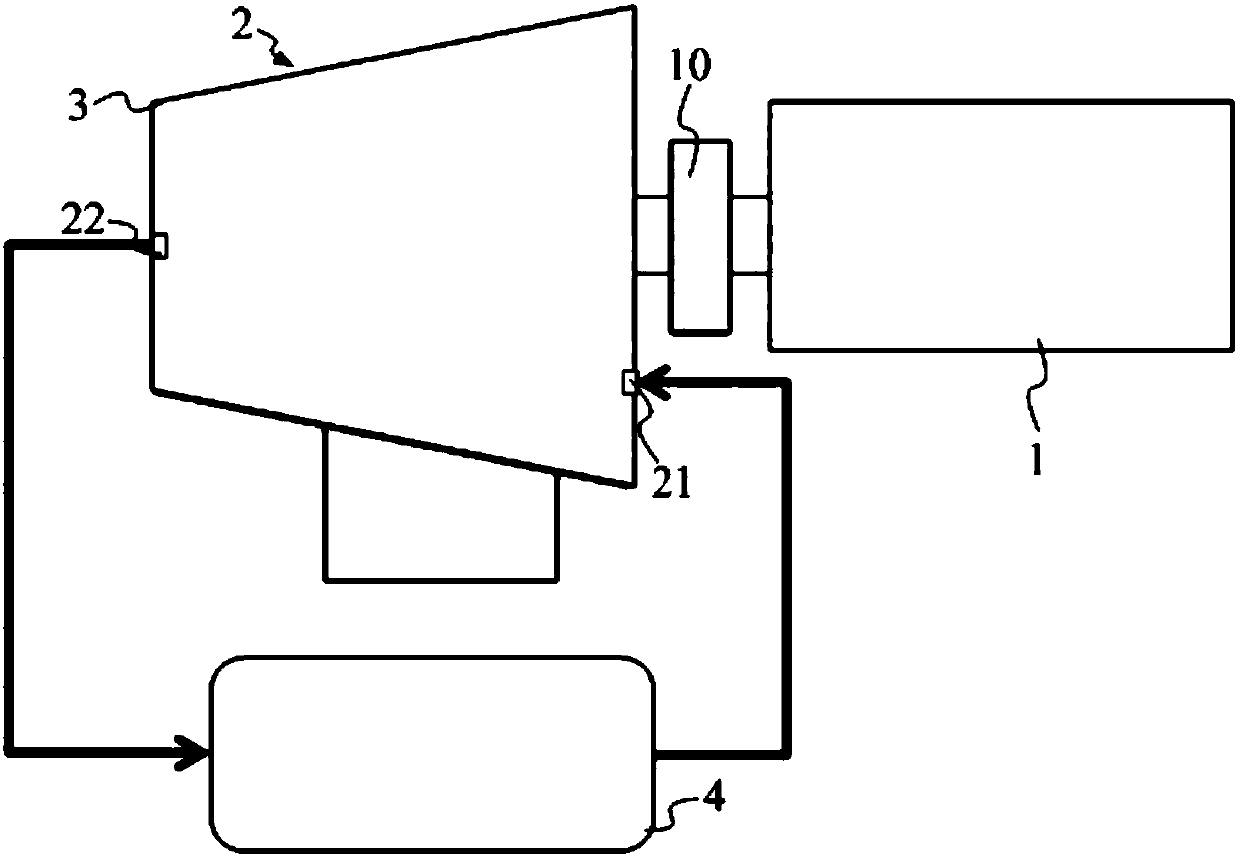

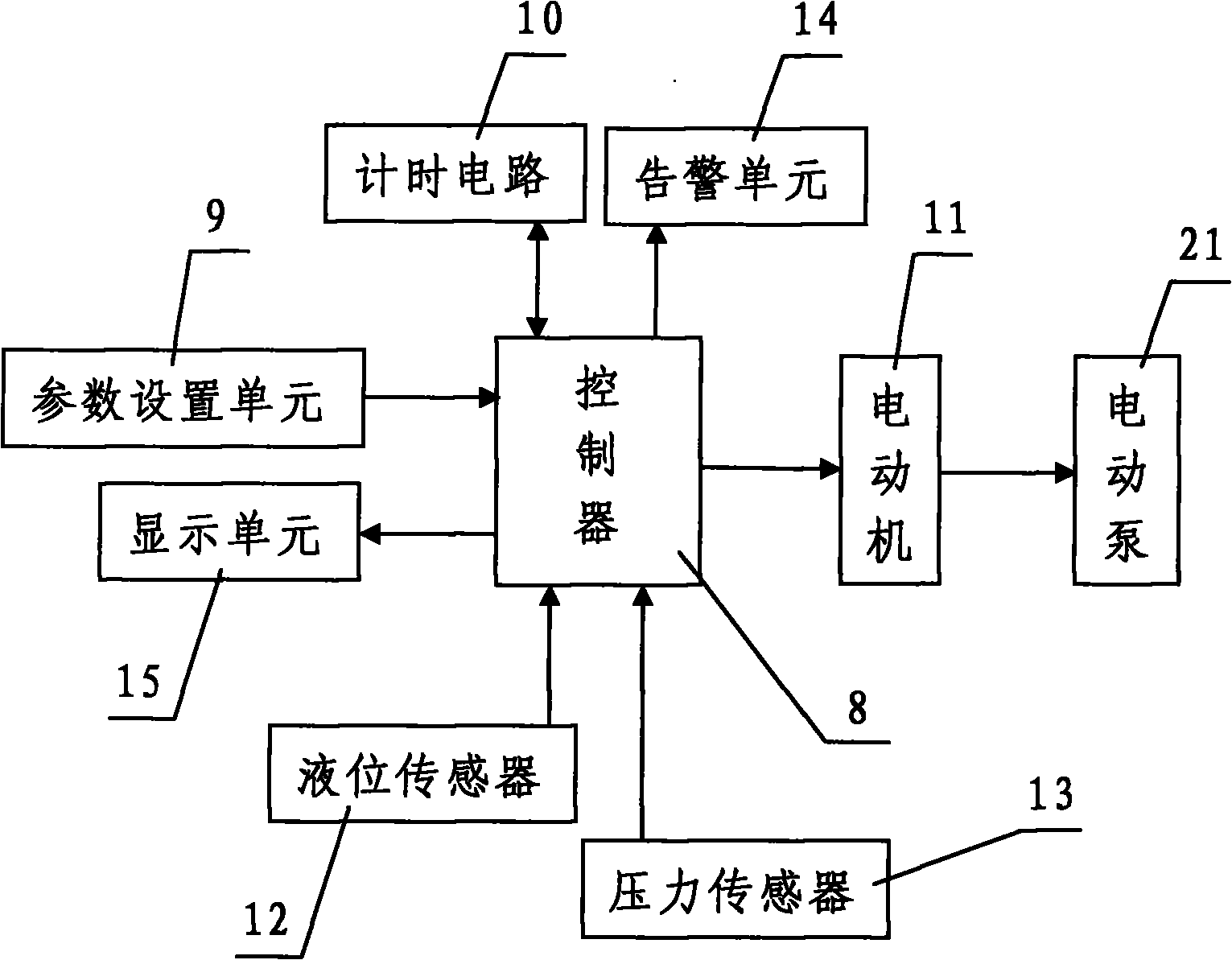

Engine oil processing system

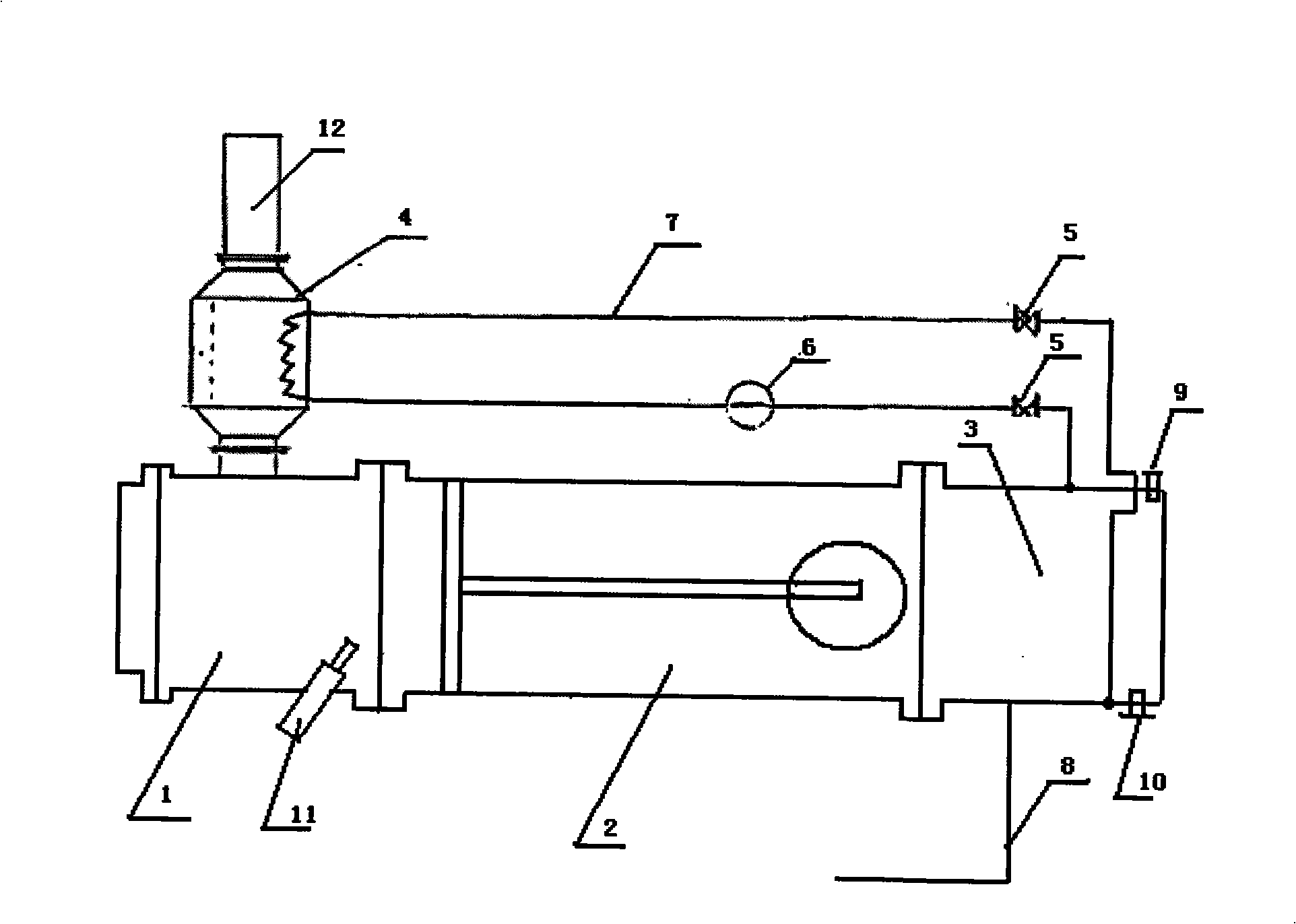

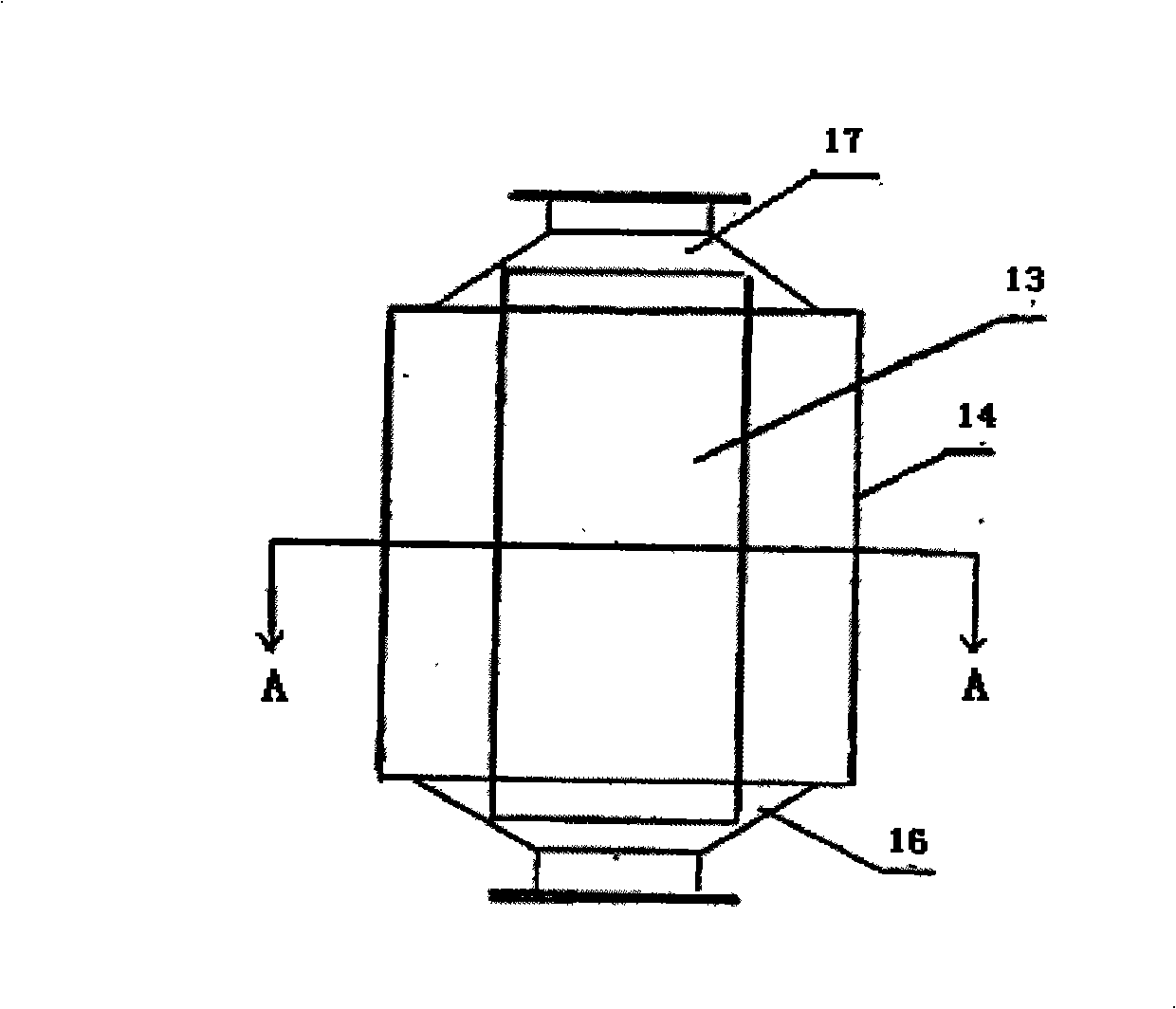

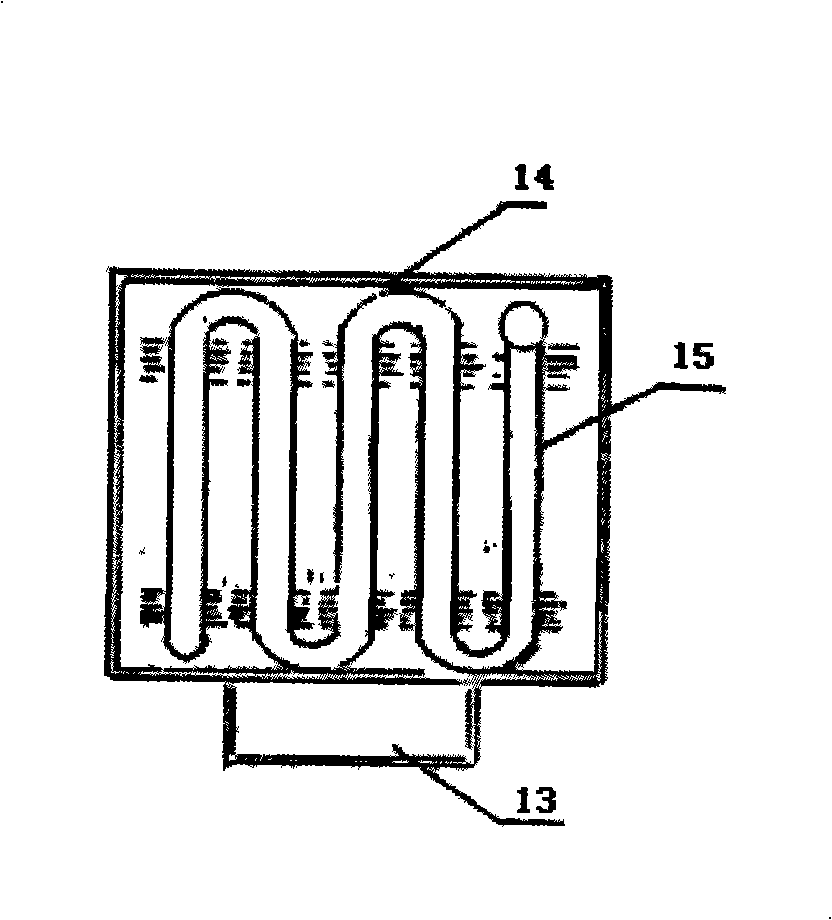

ActiveCN101270682AExtend oil change intervalsExtend engine lifeMachines/enginesLubrication temperature controlAutomotive engineeringBoiling point

The invention relates to a processing system aiming at the dilution problem of engine oil. The processing system comprises a heat exchanger, the engine oil, an insulating tube, an oil pump, an oil pressure sensor, an oil temperature sensor, an oil way switch and a vent pipe used for recycling fuel. When the engine is in operation, if oil pressure valve is below limiting value, an exhaust manifold is used to heat the insulating tube. The engine oil of a control pipeline and the fuel in an oil sump are used to exchange heat to lead bulk temperature to the boiling point of the fuel, thus separating the fuel from lubricant. The separated fuel goes through ventilation system and enters burning system again.

Owner:CHERY AUTOMOBILE CO LTD

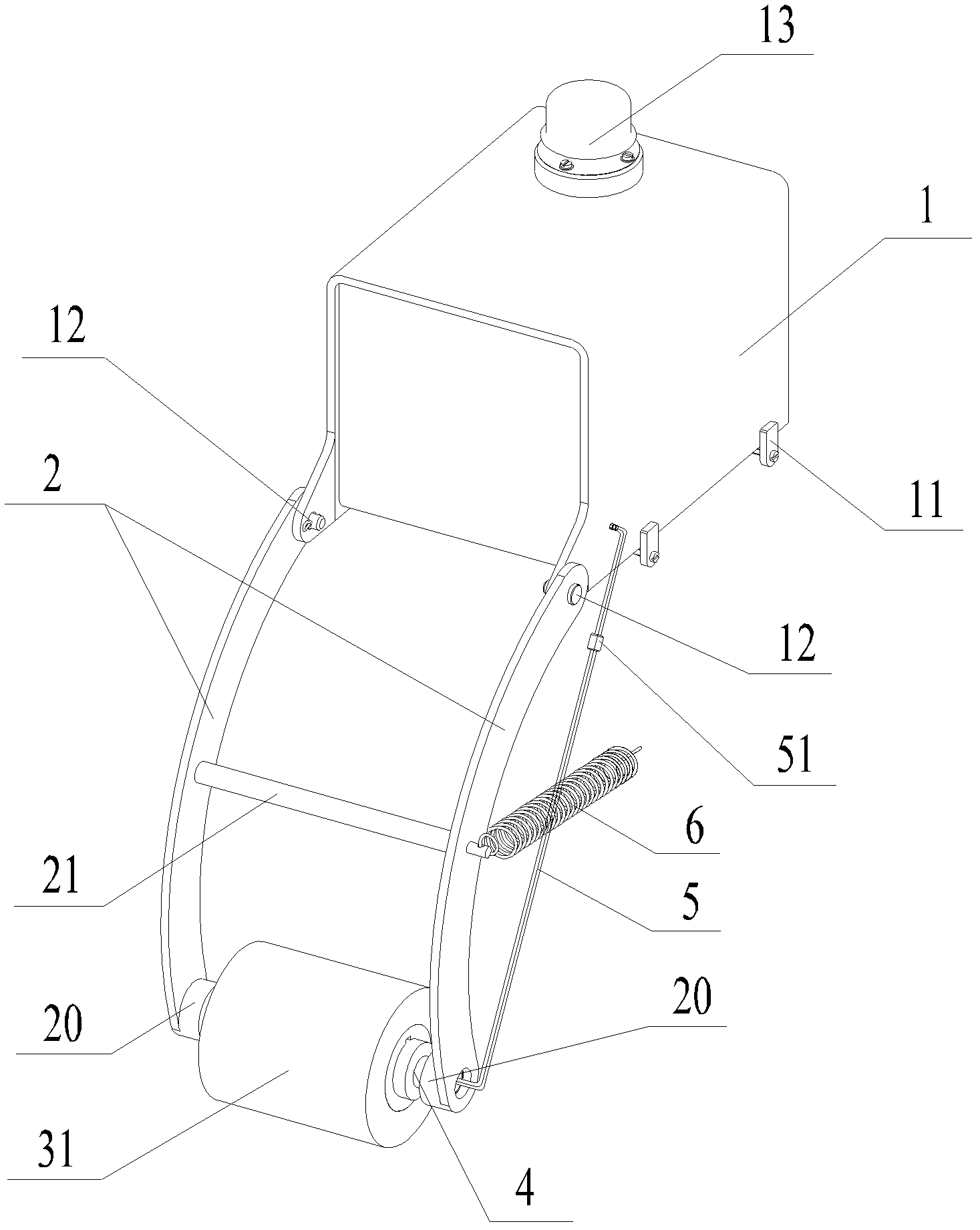

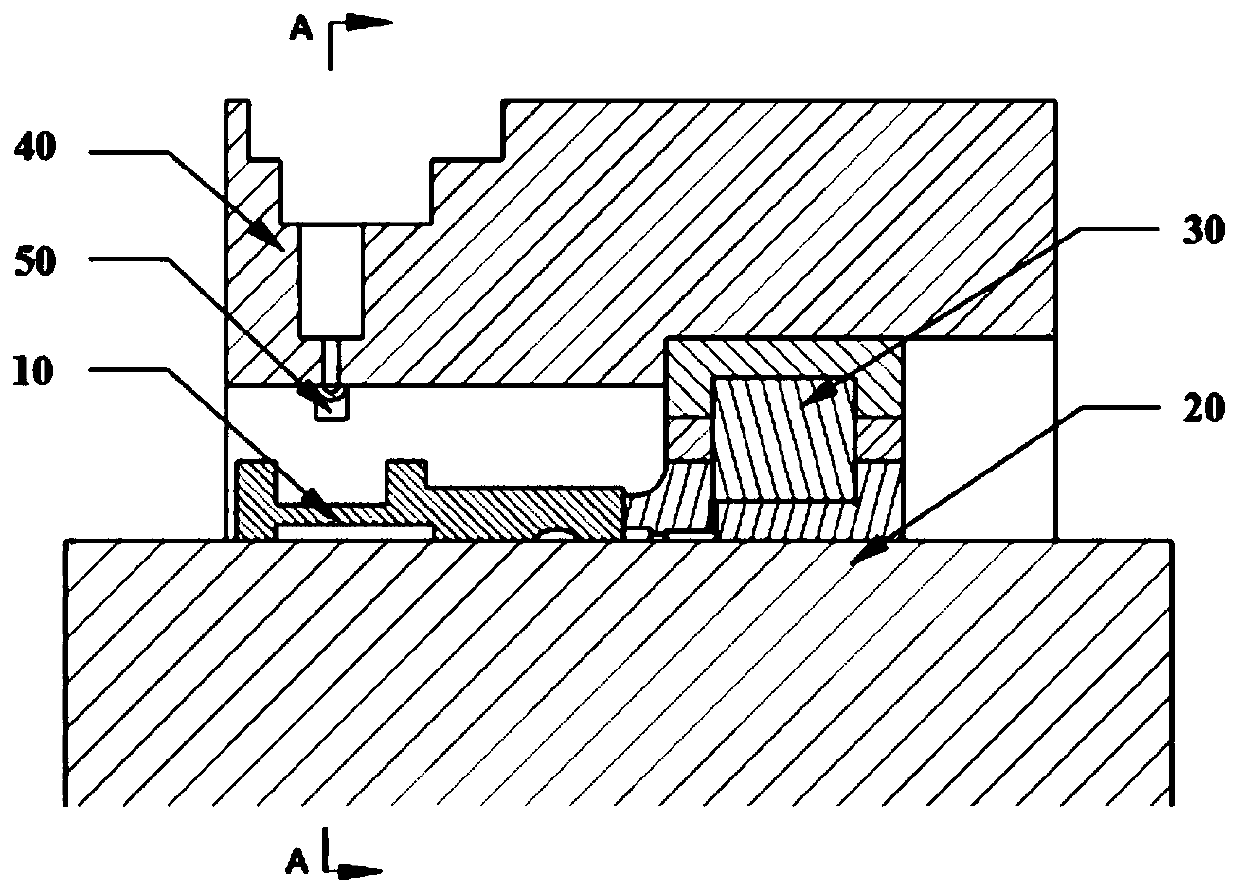

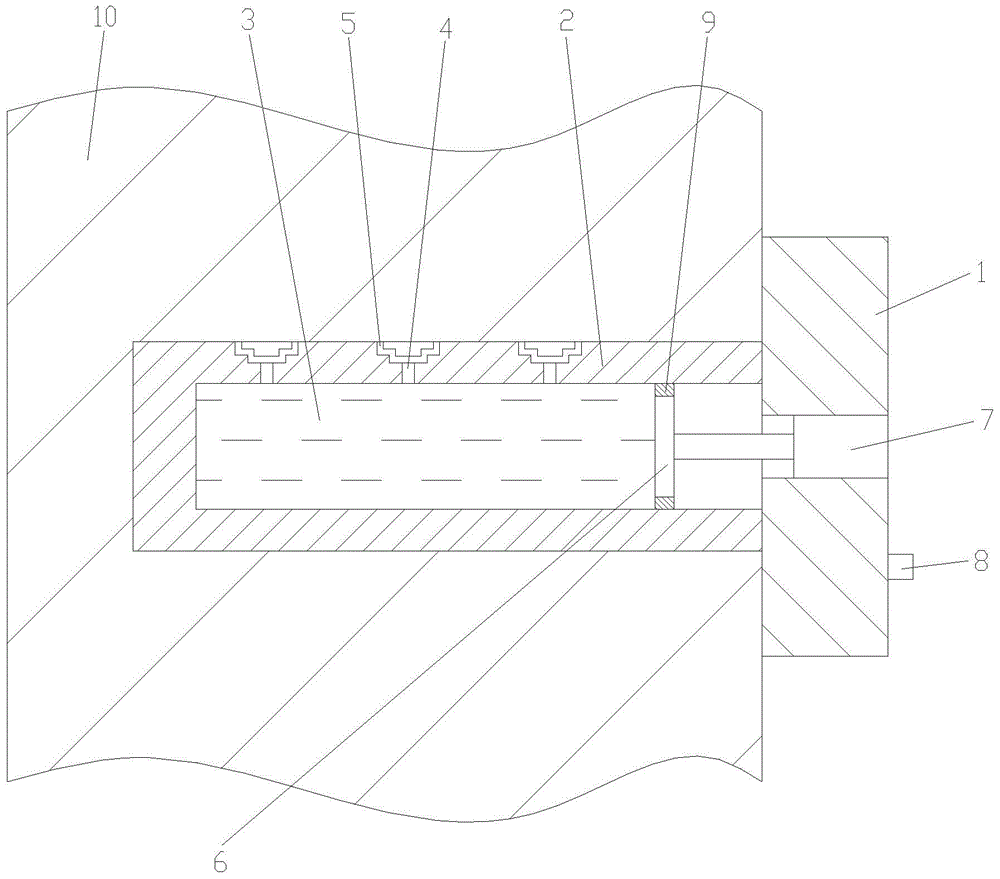

Automatic-lubricating drawing die

The invention discloses an automatic-lubricating drawing die used for automatic lubricating for drawing in the workpiece cold working process. The top end of a guide sleeve of an upper die base of the die is sealed through a sealing plug, a guide pillar is inserted from the bottom end of the guide sleeve, and therefore a changeable sealed pressure cavity is formed inside the guide sleeve. The pressure cavity is respectively communicated with a lubricating oil tank and a lubricating oil cavity through an oil inlet pipeline and an oil outlet pipeline, and the lubricating oil cavity is communicated with the upper surface of a cavity of a drawing female die. An oil inlet one-way valve is arranged on the oil inlet pipeline and makes oil be in an only-in-no-out state. An oil outlet one-way valve is arranged on the oil outlet pipeline and makes the oil be in an only-out-no-in state. On the basis of a drawing die, in combination with a plunger pump principle, the guide sleeve and the guide pillar are used for achieving linkage between drawing work and lubricating oil injecting of the die, automatic lubricating is achieved without shutdown, the system is simple, cost is low, and the lubricating effect is good.

Owner:HUNAN AGRICULTURAL UNIV

Chain lubrication device and forklift

InactiveCN102616553ANot easy to dripEasy to cleanCleaningStacking articlesLubricationPetroleum engineering

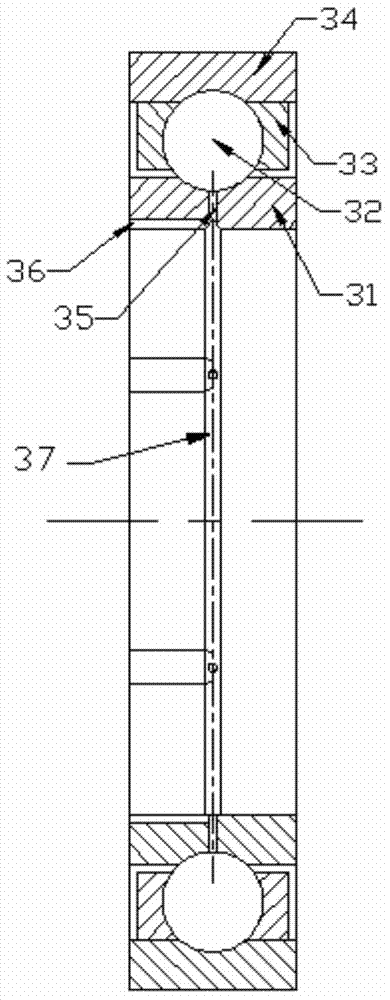

The invention provides a chain lubrication device and a forklift. The chain lubrication device comprises a bracket, a central shaft and an oil sucking felt ring. The central shaft is supported by the bracket, the oil sucking felt ring is used for pressing and contacting with a chain and sleeved on the central shaft, a first oil guiding channel is disposed on the central shaft, an oil inlet of the first oil guiding channel is arranged on an end surface of the central shaft, the first oil guiding channel is communicated with a pressure lubricating oil source via an oil inlet pipe, and an oil outlet of the first oil guiding channel corresponds to the oil sucking felt ring. By the aid of the chain lubrication device, the chain can be automatically lubricated, lubrication efficiency is high, and cost is low. The invention further provides the forklift comprising the chain lubrication device.

Owner:SANY GRP

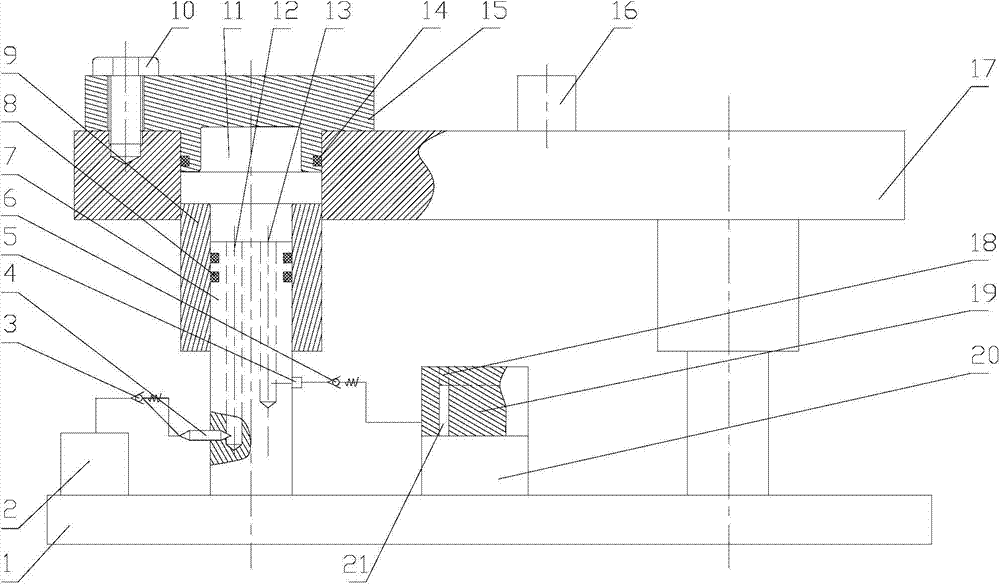

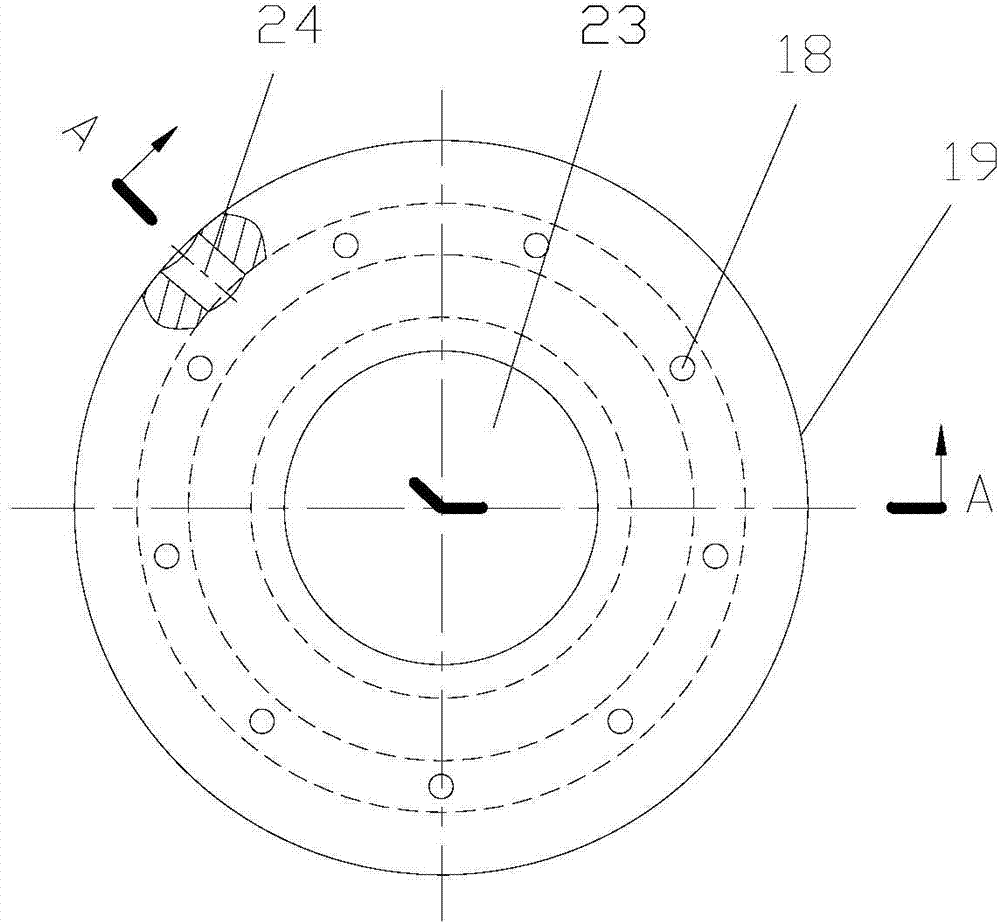

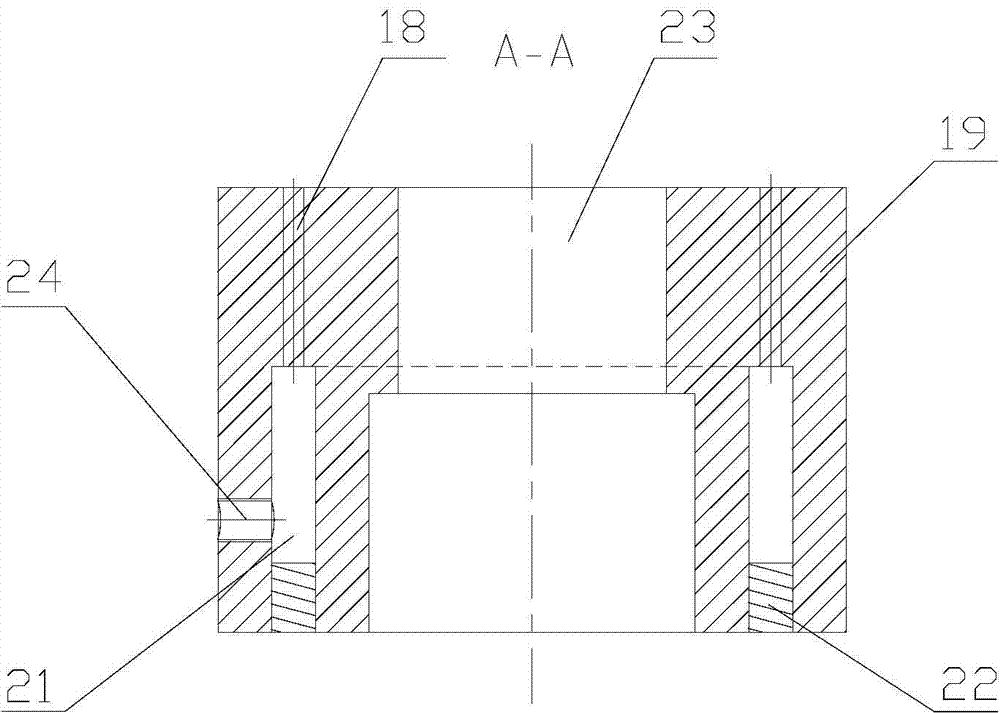

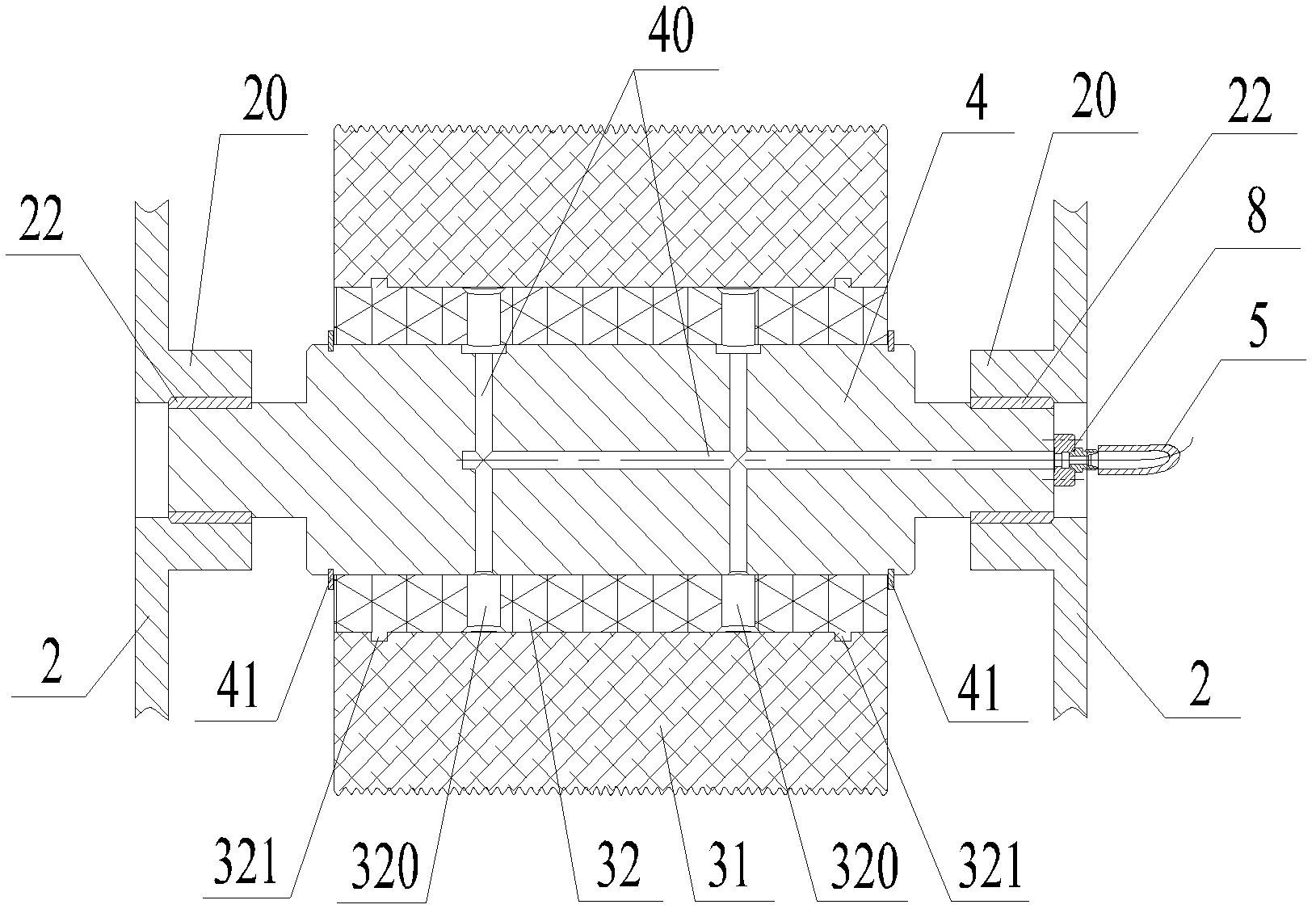

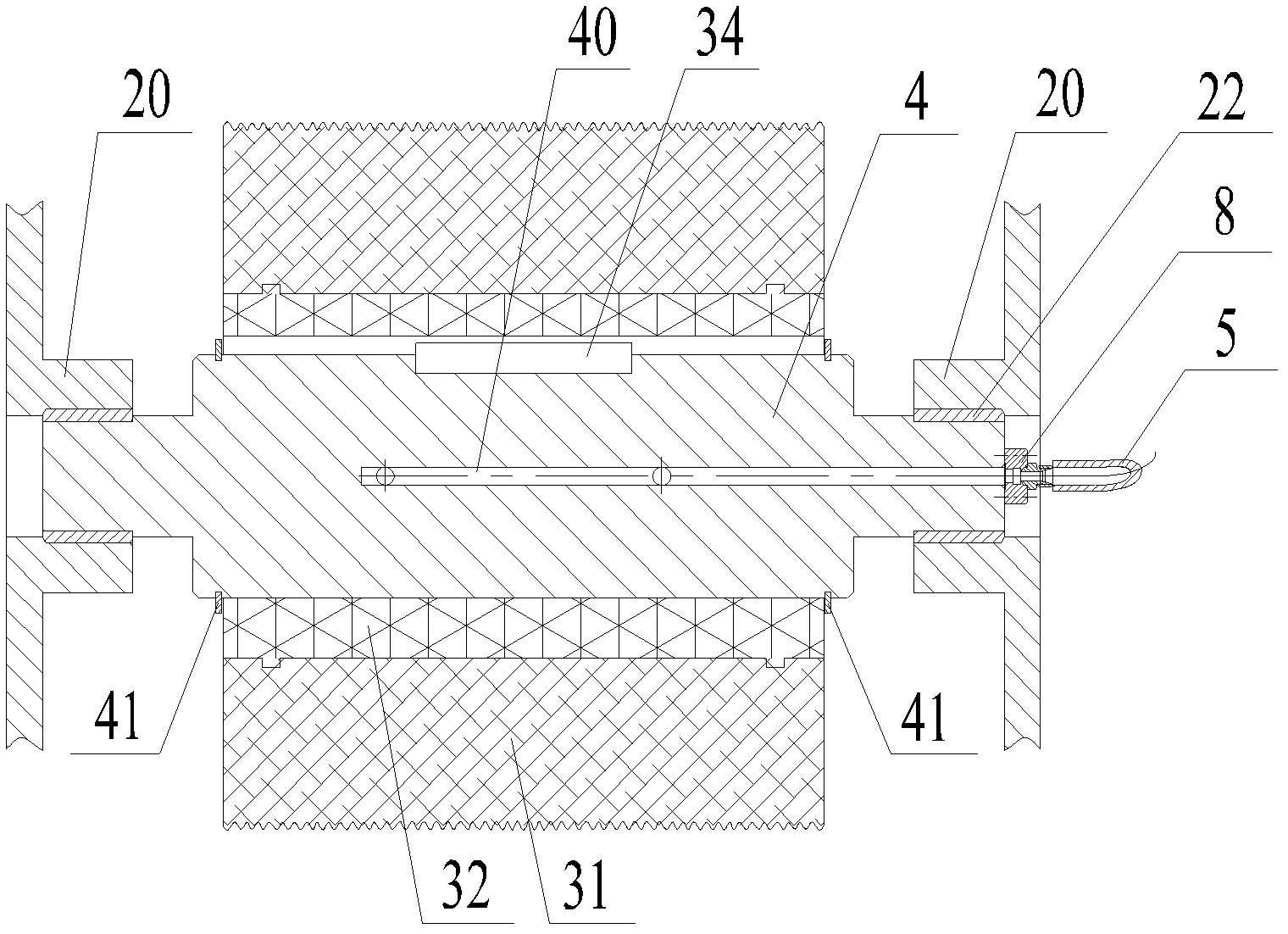

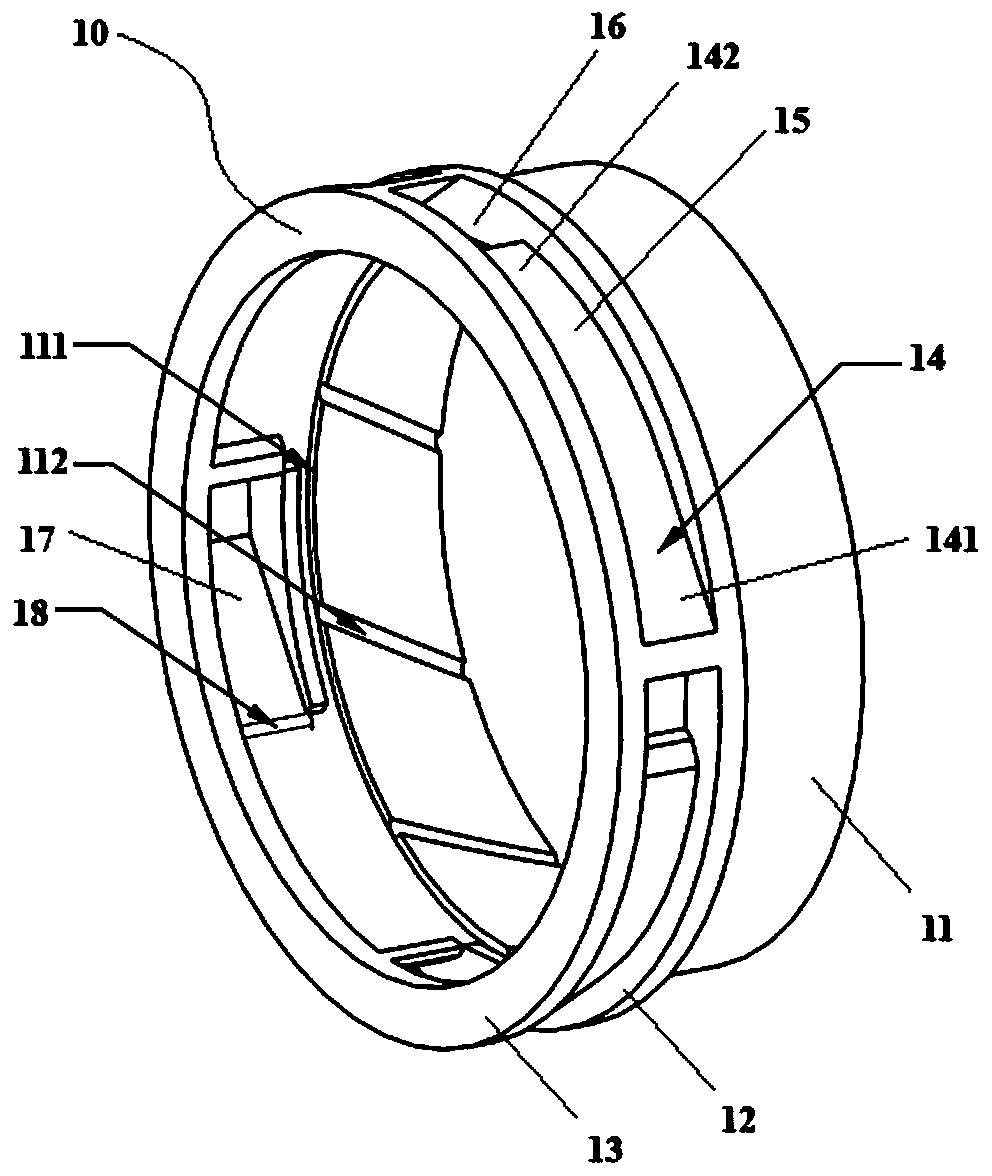

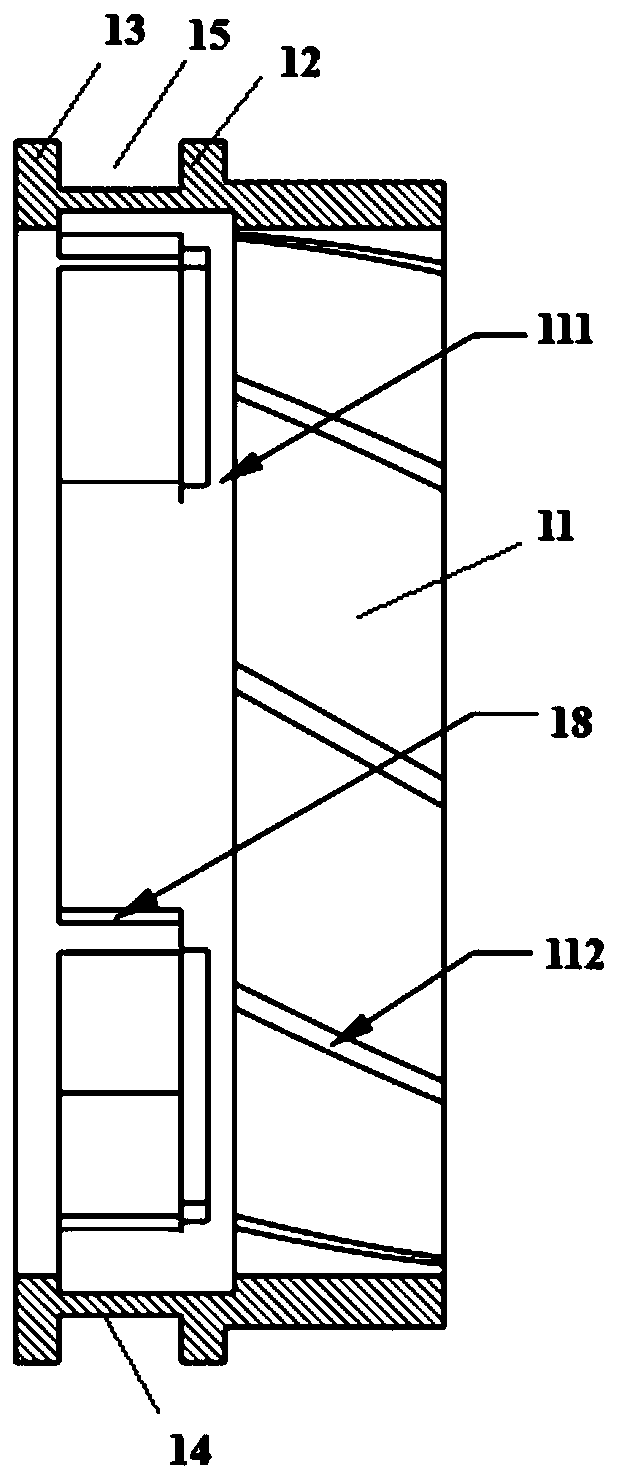

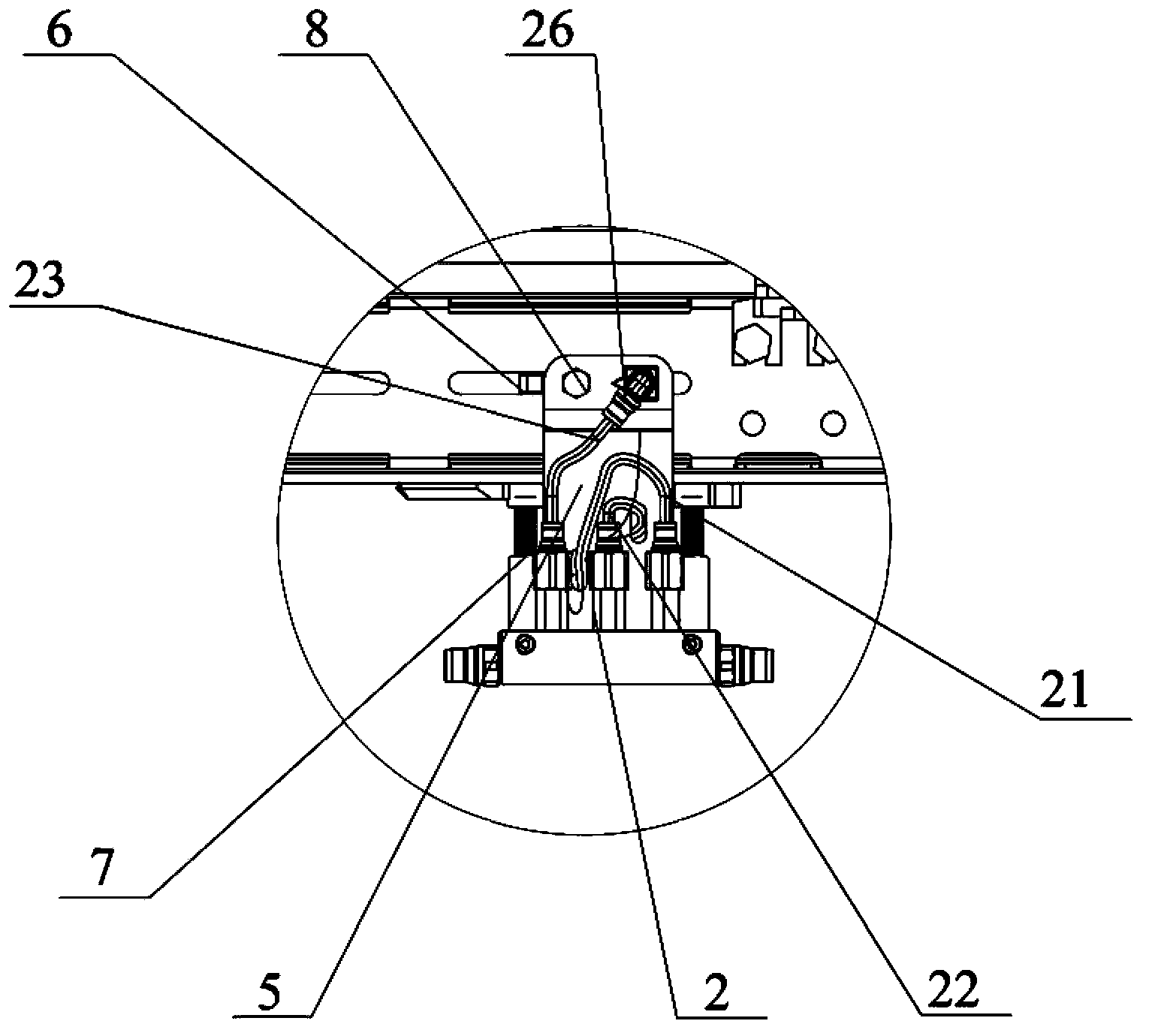

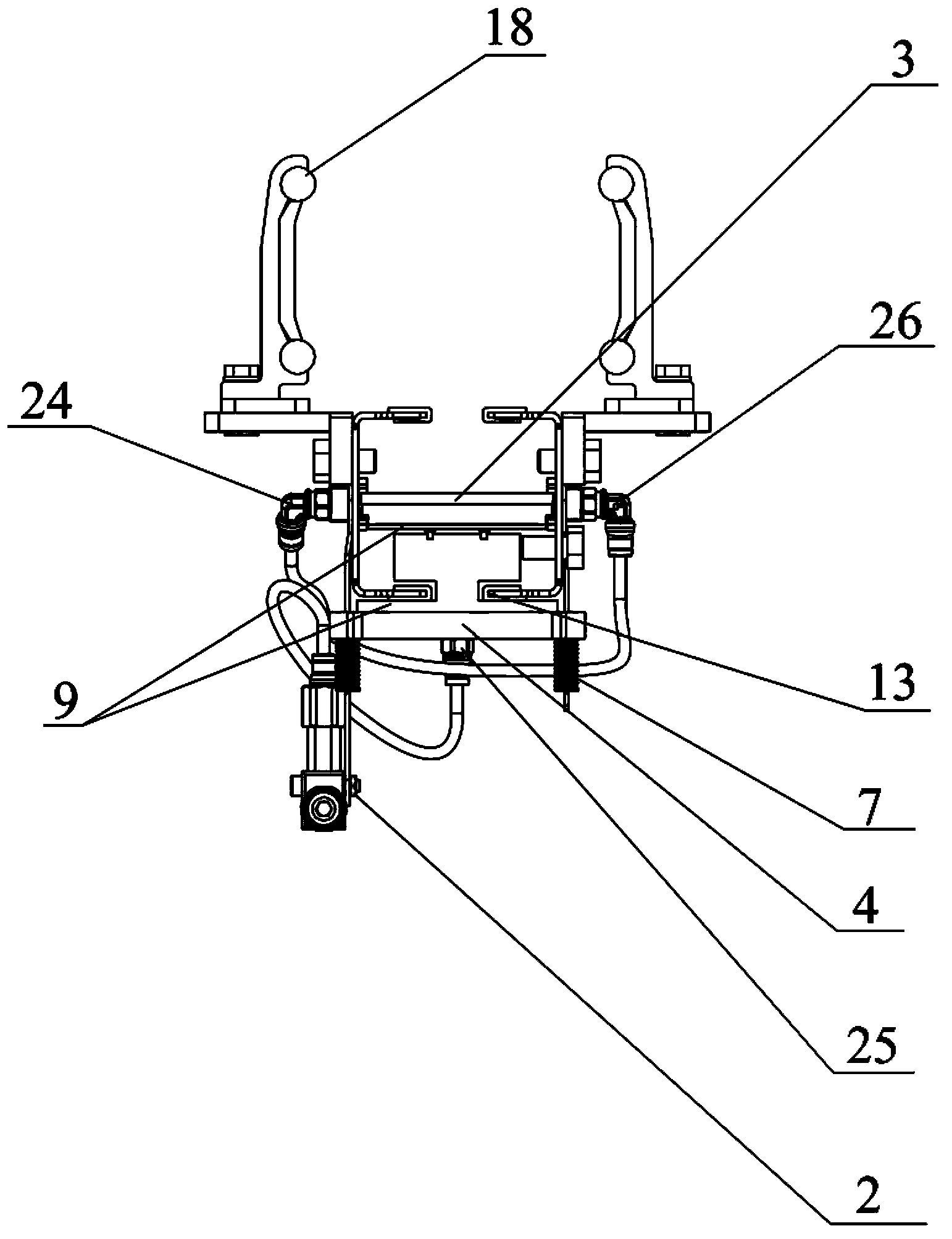

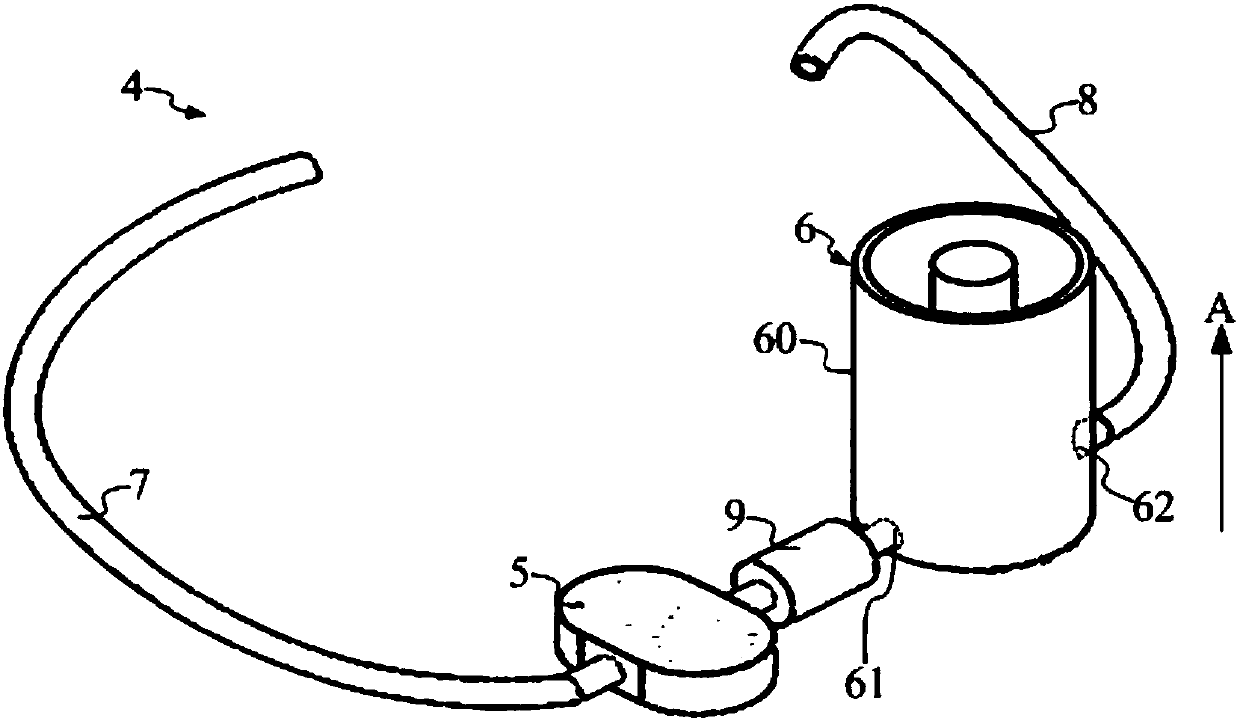

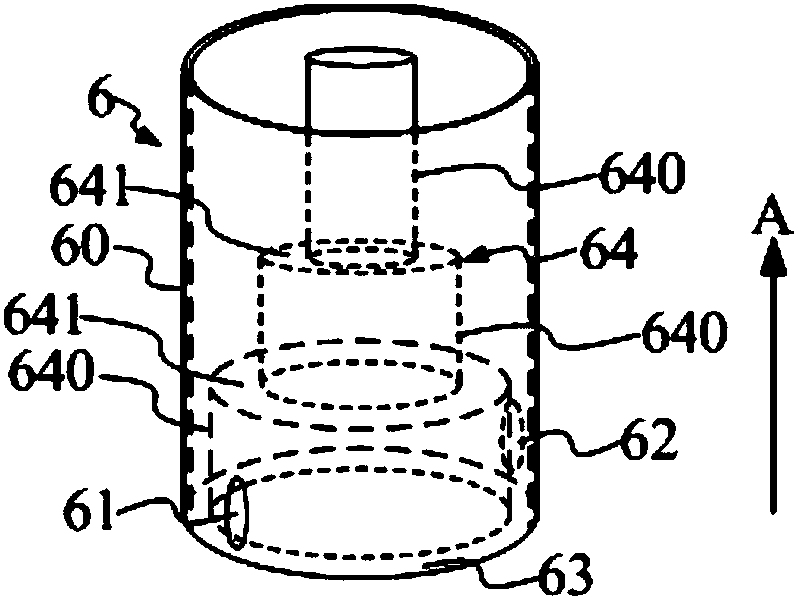

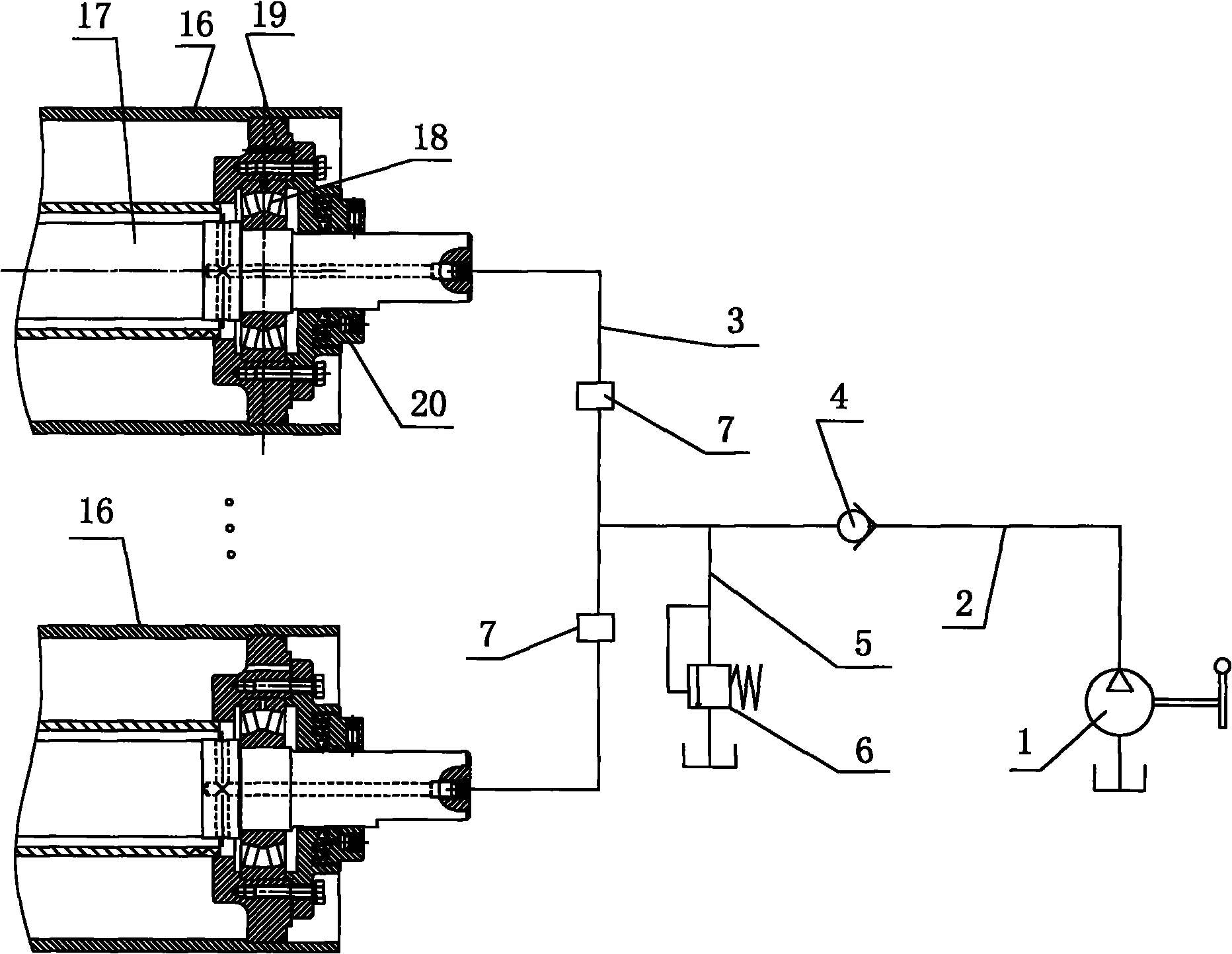

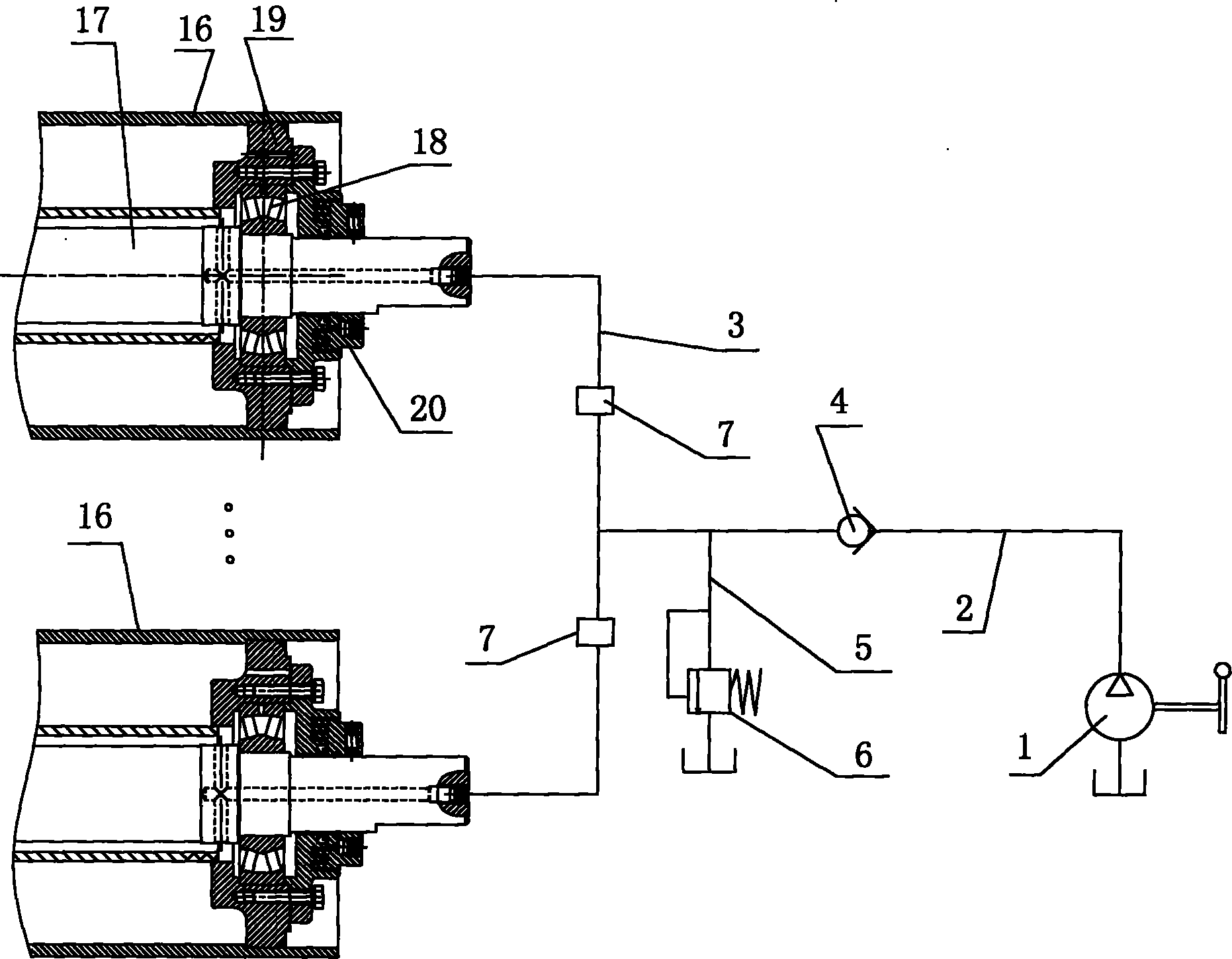

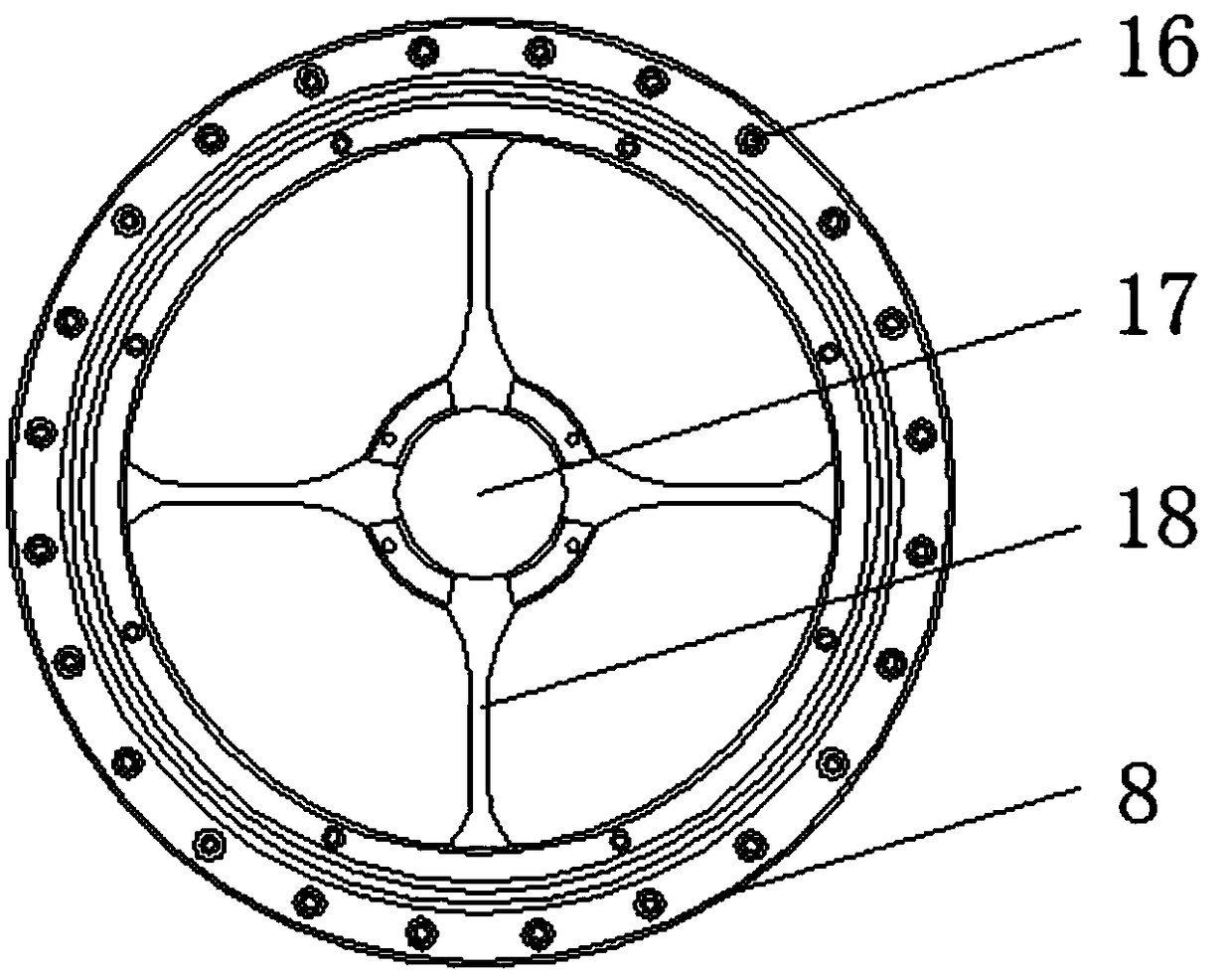

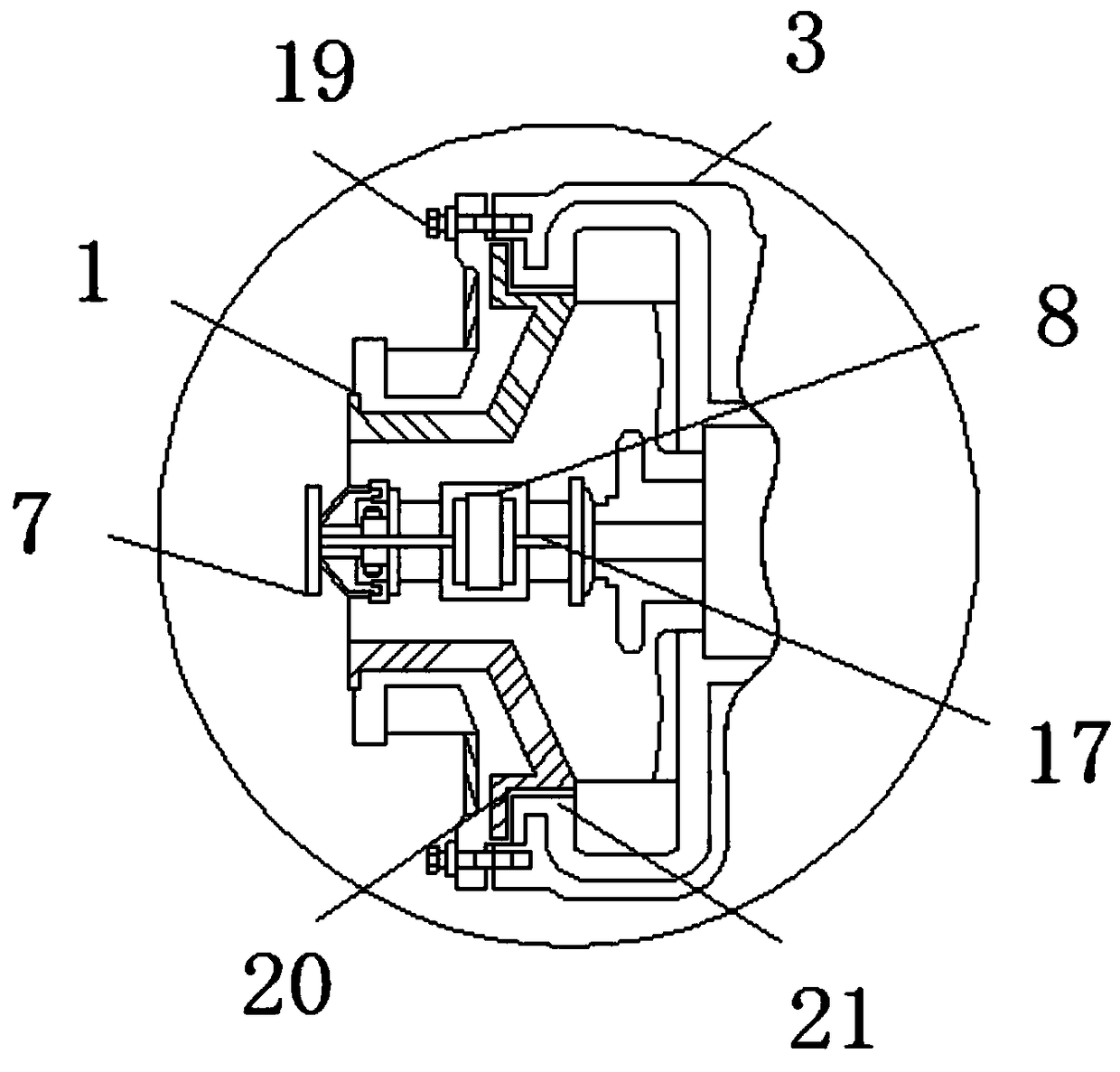

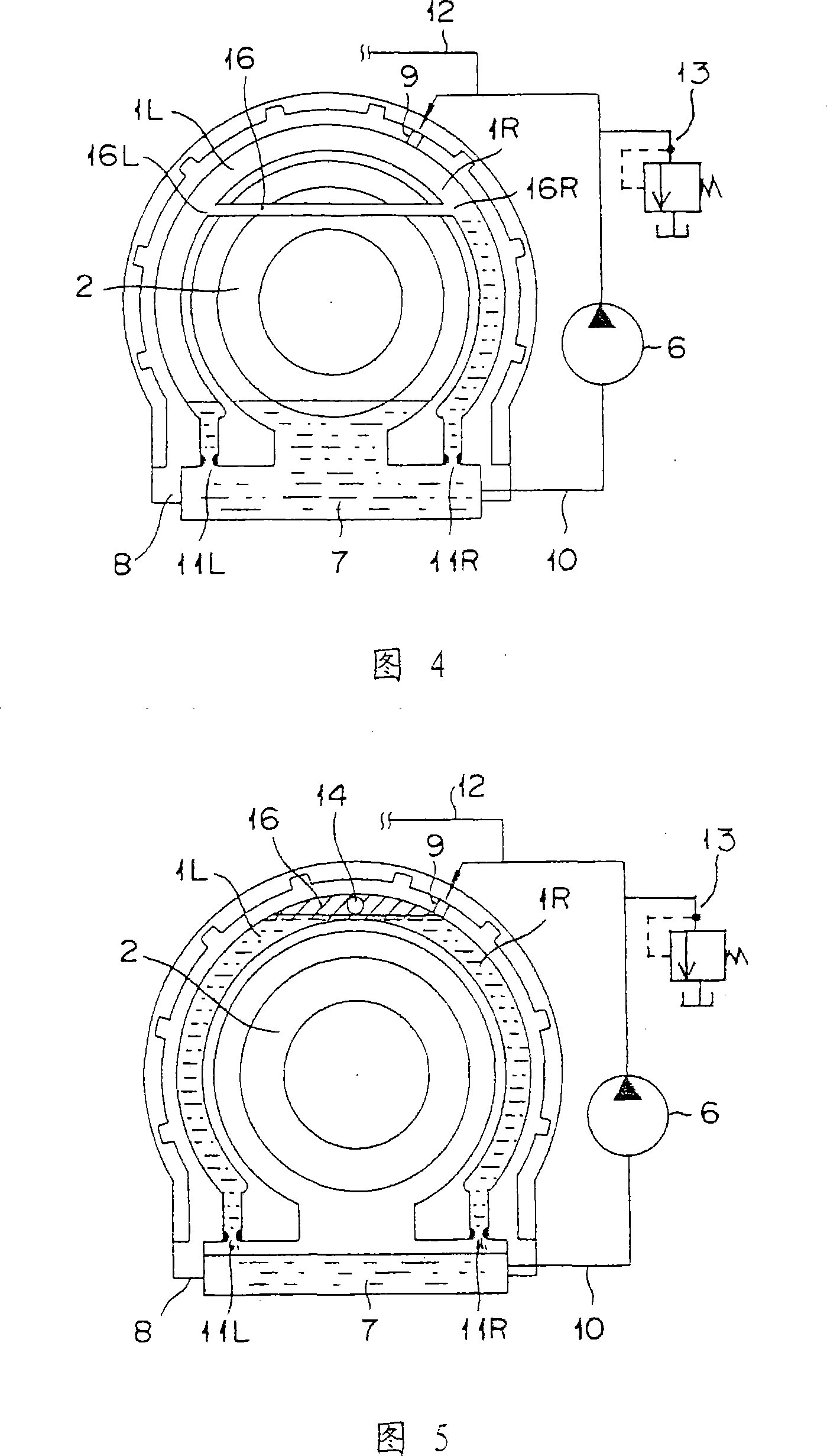

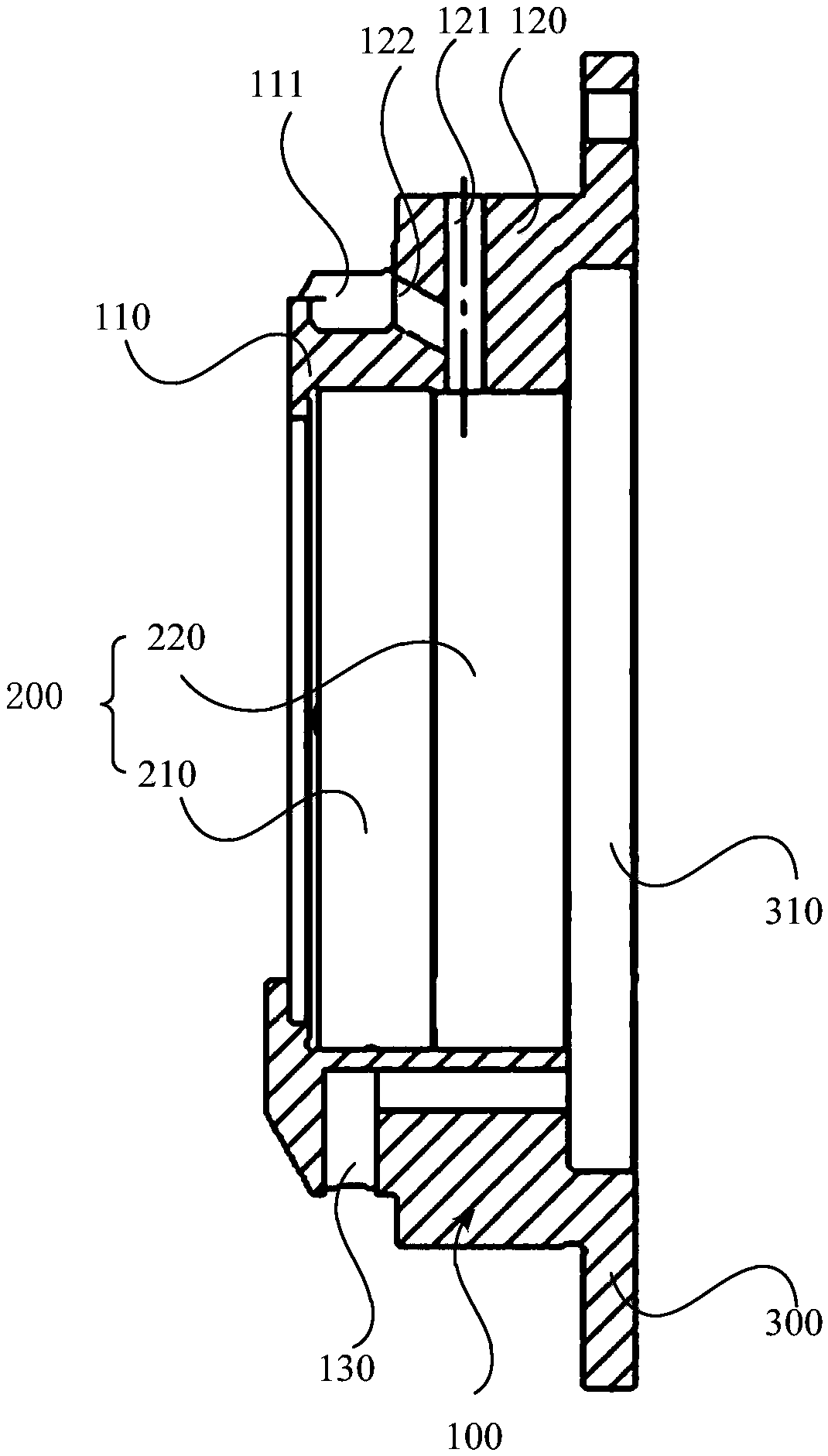

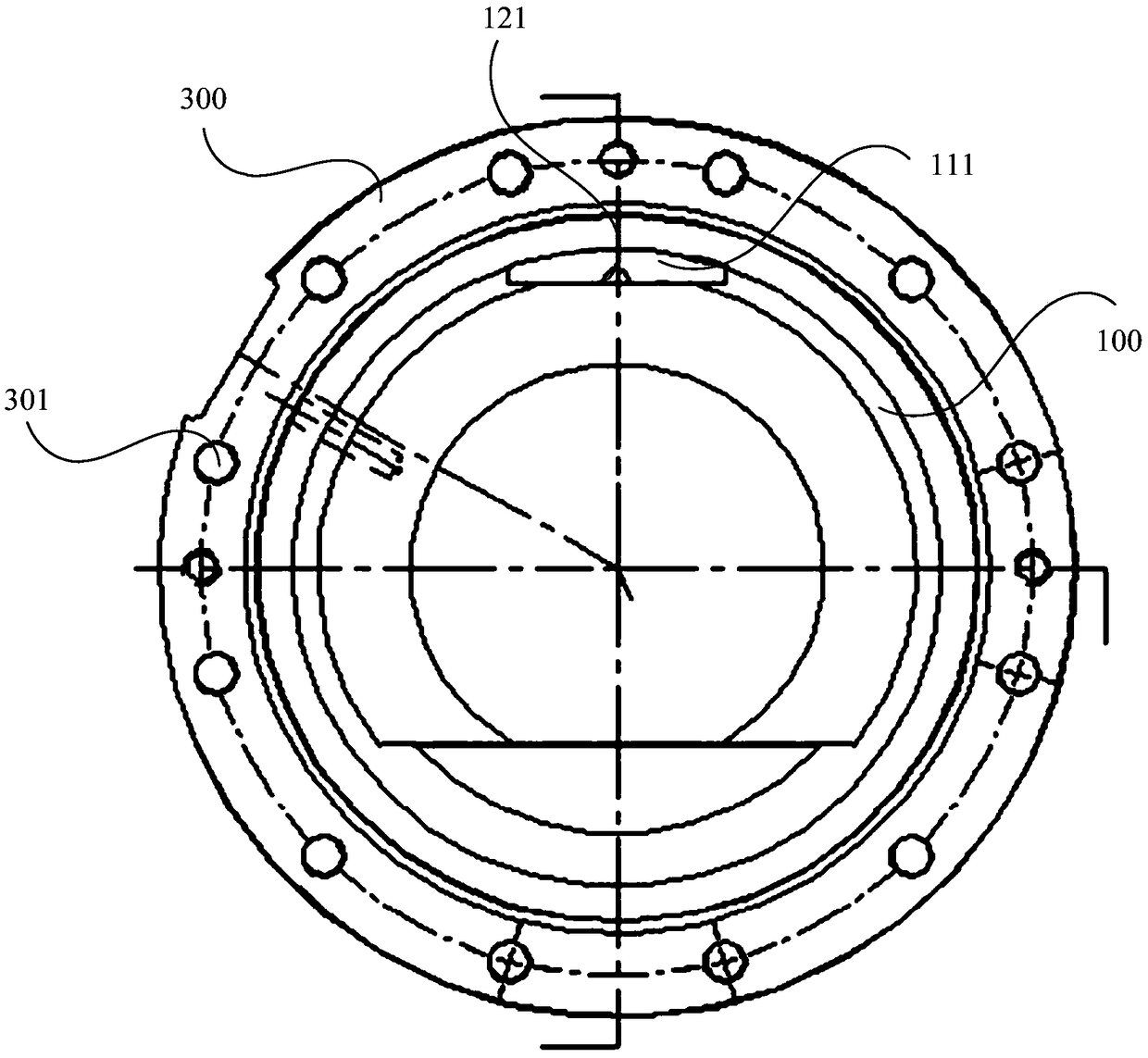

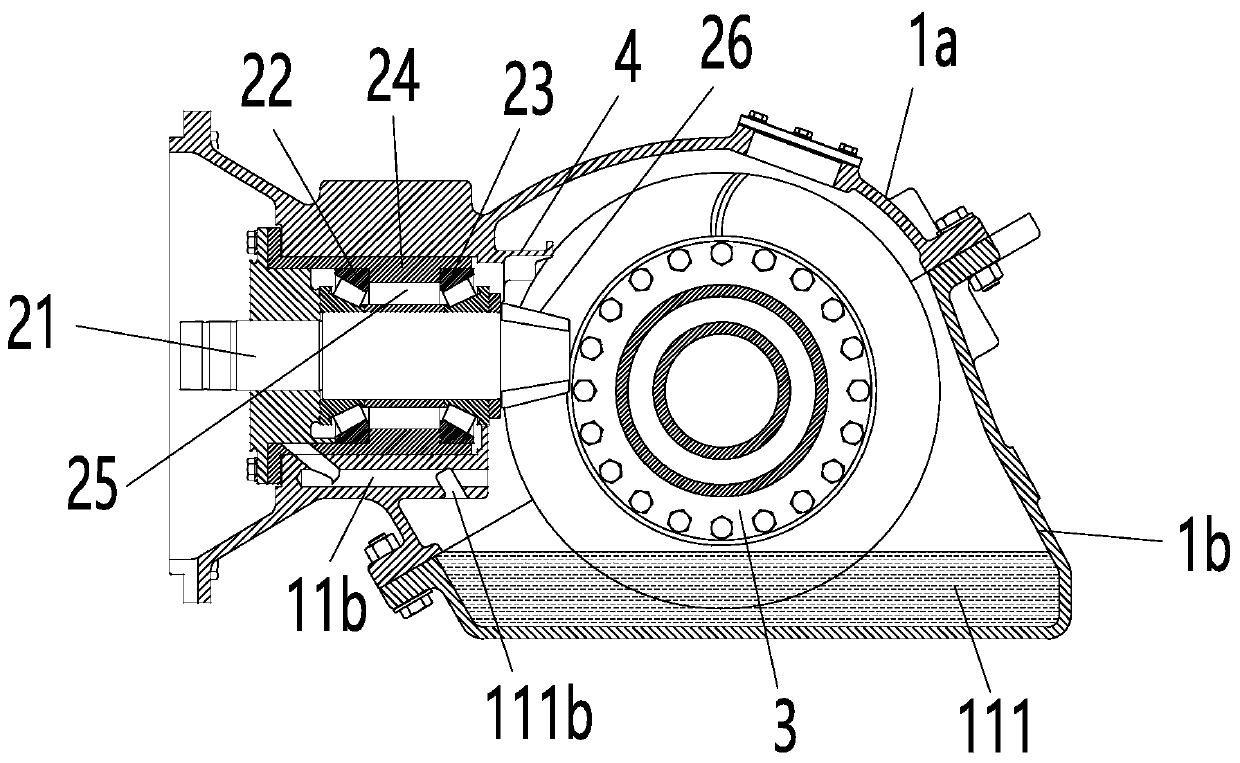

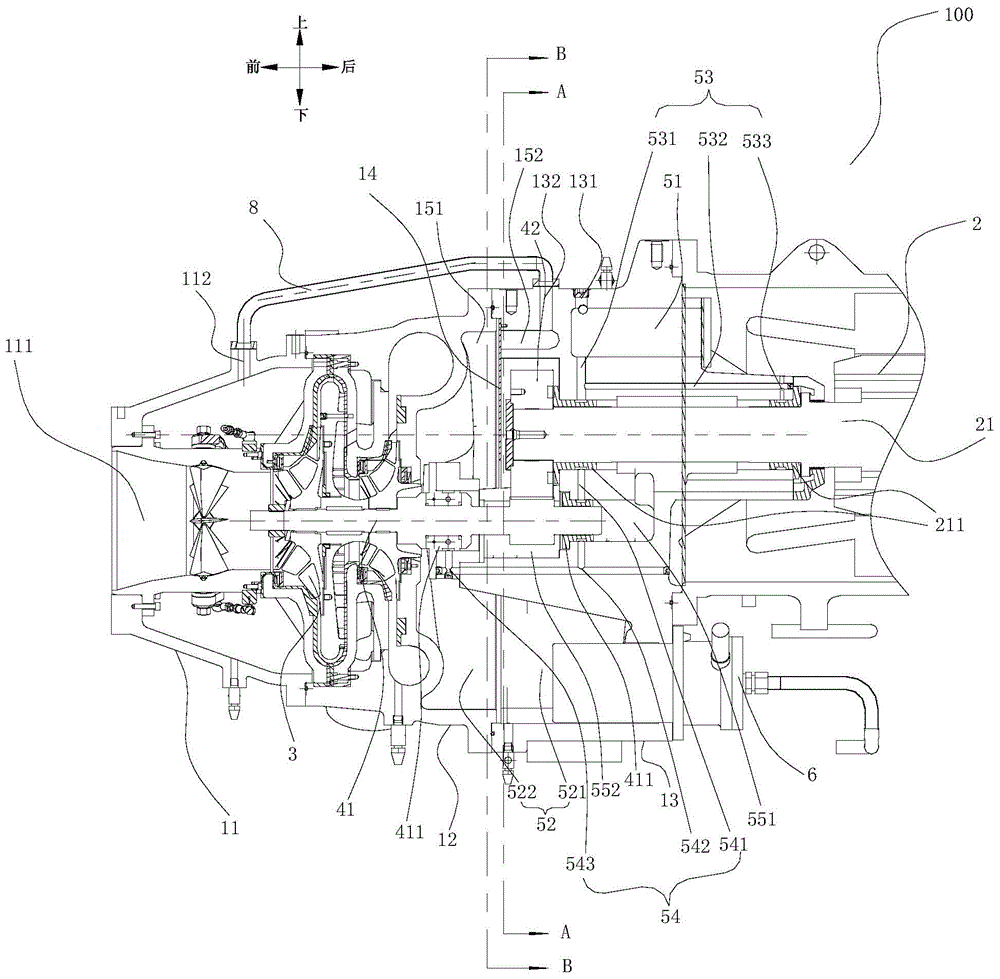

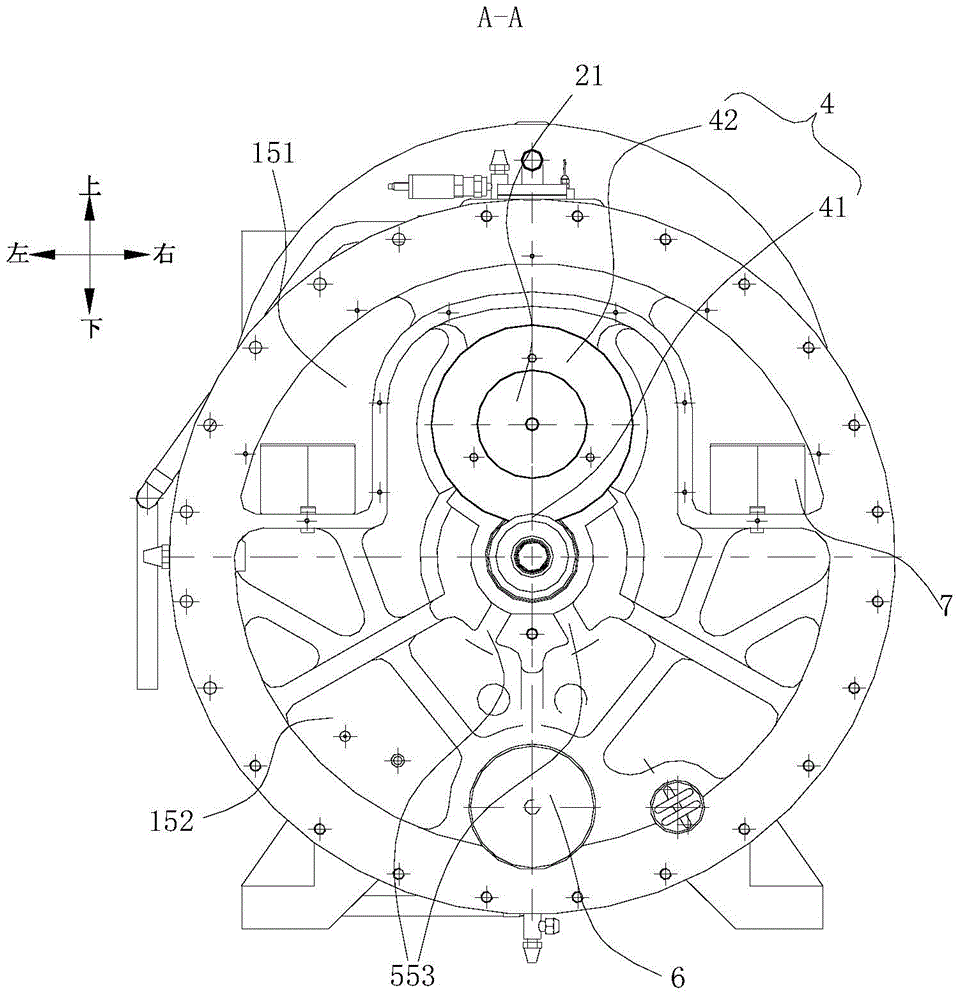

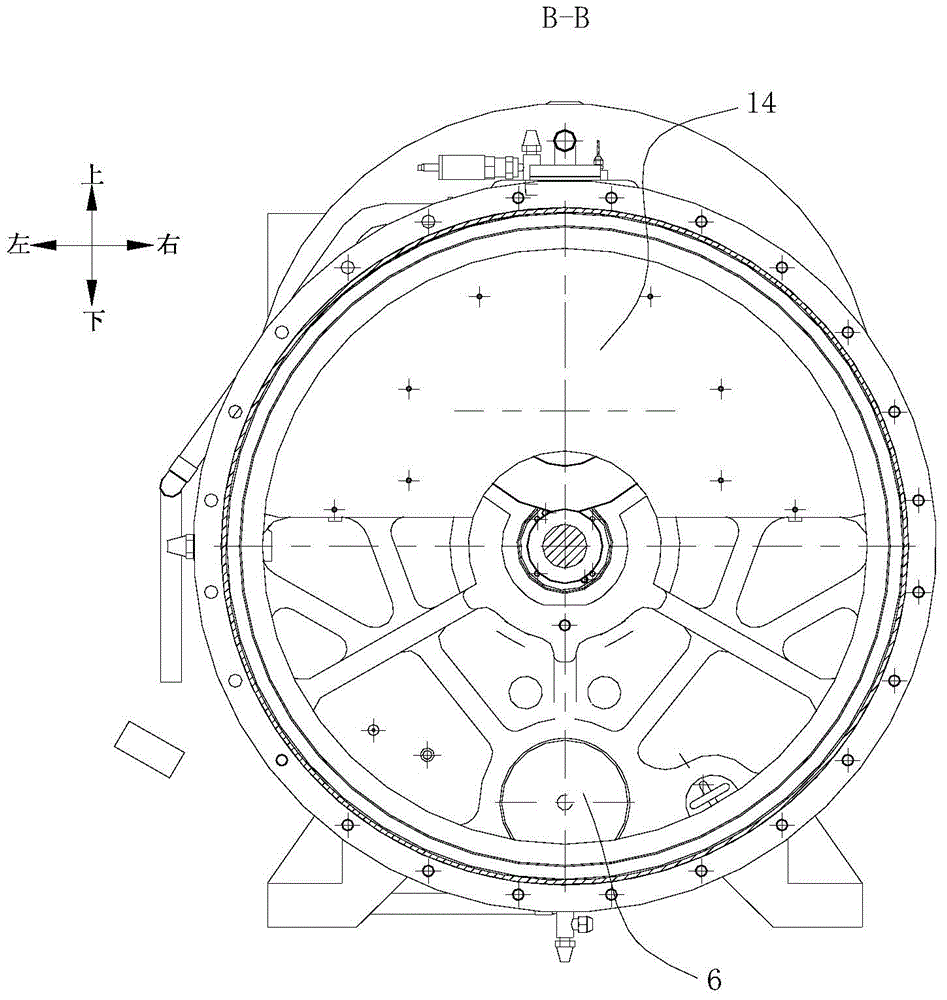

Radial oil collecting ring and under-ring oil supply lubricating device and method

ActiveCN110714987AImprove the lubrication effectImprove cooling effectBearing coolingHeavy loadOil supply

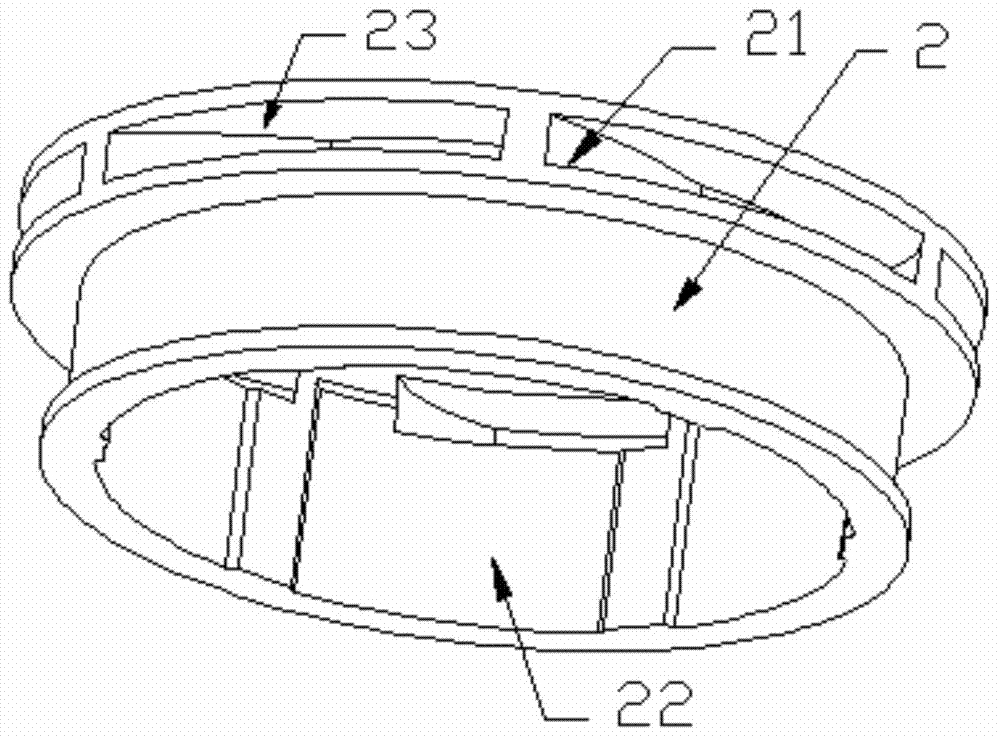

The invention provides a radial oil collecting ring and an under-ring oil supply lubricating device and method. The radial oil collecting ring comprises a cylindrical wall, a first annular retaining wall arranged at the end part of the cylindrical wall and coaxial with the cylindrical wall, a second annular retaining wall parallel and opposite to the first annular retaining wall, and a plurality of oil collecting blades connected between the first annular retaining wall and the second annular retaining wall. The under-ring oil supply lubricating device comprises the radial oil collecting ring,a main shaft, a bearing sleeving the main shaft, a bearing base sleeving the bearing, and an oil supply nozzle arranged on the bearing base and connected with an oil supply way, wherein the oil supply nozzle penetrates into the bearing base, and is aligned to an oil collecting tank; the radial oil collecting ring sleeves the main shaft, and can synchronously rotate with the main shaft; and one end, provided with an oil conveying chute, of the radial oil collecting ring is tightly bonded with the bearing. The radial oil collecting ring can greatly improve the oil collecting efficiency; and theoil collecting quantity can satisfy the bearing lubricating and cooling requirements under the conditions of high speed, high temperature and heavy load to guarantee long-time stable work of the bearing.

Owner:西安瑞谱捷特动力技术有限公司

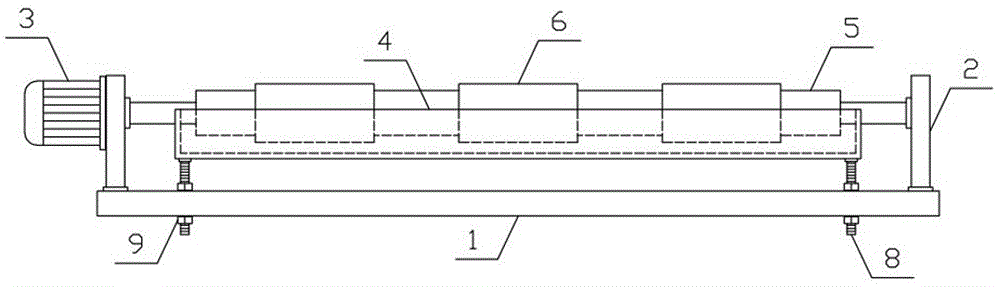

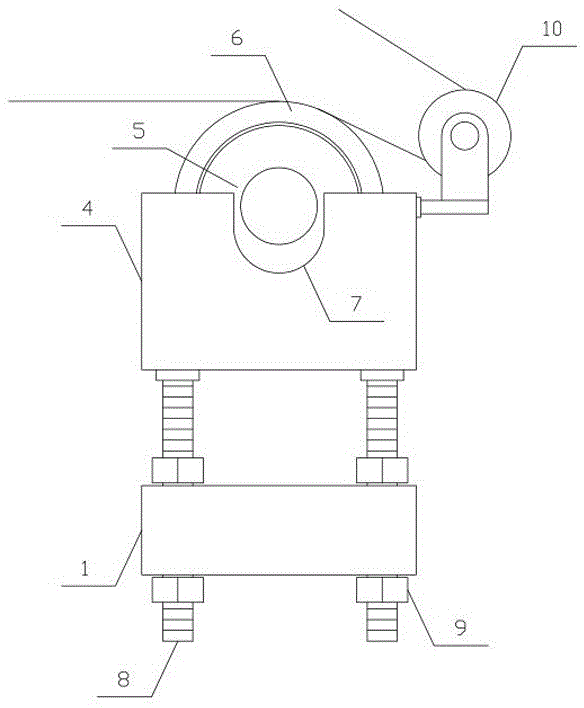

Automatic lubrication mechanism for conveyor chain

An automatic lubricating mechanism for the conveying chain is composed of a gas and liquid combined cylinder consisting of cylinder body with oil inlet and outlet, cylinder cover with vent, piston and restoring part, electromagnetic valve communicated with said vent via gas channel, sensor connected electrically with said electromagnetic valve, and pipeline connected to said oil outlet.

Owner:BYD CO LTD

Self-lubrication device for conveying production line

The invention discloses a self-lubrication device for a conveying production line. The conveying production line comprises a conveying chain, wherein the conveying chain is connected to a frame and is provided with continuous flat top surfaces. The self-lubrication device comprises a lubricant supply mechanism, a bottom lubrication mechanism and a fixing mechanism. The fixing mechanism comprises an elastic unit connected to the bottom lubrication mechanism. The bottom lubrication mechanism is installed in a working area, at the bottom of the frame, of the conveying chain. A lubricant supply pipeline reaches the working surface of the bottom lubrication mechanism. The working surface of the bottom lubrication mechanism is pressed on the working surface of the conveying chain below the bottom lubrication mechanism through the elastic unit with appropriate retention force so that the working surface of the conveying chain can be coated with a lubricant. The self-lubrication device can be adjusted in a self-adaptive mode according to the movement characteristic of the conveying chain. The self-lubrication device for the conveying production line has the main advantages of saving lubrication liquid and being convenient to install and free of manual intervention in self-adaptive adjustment of a lubrication position.

Owner:奥利伟·迪泰特

Yarn conveying lubrication device

The invention discloses a yarn conveying lubrication device and belongs to the field of textile processing machinery and equipment. The device comprises a fixing bracket, lubrication brackets, lubrication motors and an oil storage tank, wherein the lubrication brackets are vertically and symmetrically arranged on the two sides of the upper part of the fixing bracket; each lubrication motor is horizontally arranged on one side of each lubrication bracket; a lubrication roller is horizontally and rotationally connected to the lubrication bracket; a plurality of lubrication rubber sleeves are uniformly arranged on the outer side of the lubrication roller in sequence; the oil storage tank is horizontally arranged on the lower side of the lubrication roller; clamping grooves matched with the lubrication rollers are formed in the two sides of the oil storage tank respectively; two adjustment screw rods are vertically and uniformly arranged on the two sides of the lower part of the oil storage tank respectively and penetrate through the fixing bracket vertically and downwards; adjustment nuts are in threaded connection with the adjustment screw rods on the upper and lower sides of the fixing bracket; and a plurality of yarn guide wheels corresponding to the lubrication rubber sleeves are vertically and rotationally connected to one side of the oil storage tank. The device is simple in structure and can quickly and efficiently lubricate yarns in a conveying process to meet the needs of production and use.

Owner:JIAXING TUHUANG CASHMERE CO LTD

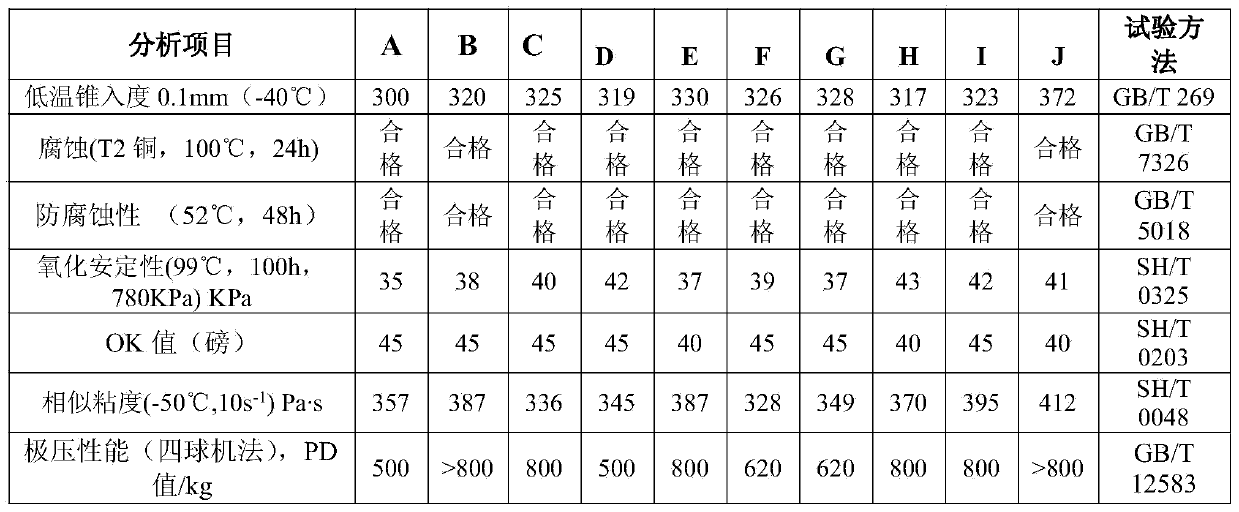

Lubricating grease composition for gears of electric shovel and preparation method thereof

ActiveCN104194873AGood low temperatureImprove water resistanceLubricant compositionAntioxidantHydroxystearic Acid

The invention provides a lubricating grease composition for gears of an electric shovel and a preparation method thereof. A thickening agent is prepared from reactants of 12-hydroxy stearic acid, hexanedioic acid, salicylic acid and lithium hydroxide; and additives comprise polyacrylic acid copolymer, an extreme pressure agent, an antirust agent, a restoring agent and an antioxidant. The preparation method comprises the following steps: adding 12-hydroxy stearic acid, salicylic acid and polyacrylic acid into base oil, mixing, and heating to 60-90 DEG C; adding lithium hydroxide monohydrate containing hexanedioic acid, saponifying and compounding for 1.5-2 hours; heating to 185-190 DEG C in 2 hours, and keeping the temperature for 1.5 hours; continuously heating to 220-240 DEG C, and naturally cooling to a temperature below 120 DEG C; sequentially adding the extreme pressure agent, the antirust agent, the restoring agent and the antioxidant; pressing oil for three times by virtue of a three-roller machine after the temperature is reduced to 40-60 DEG C, and then canning. The lubricating grease can be widely applied to mineral mechanical industry, and is capable of reducing abrasion and prolonging the cycle for changing grease.

Owner:CHINA PETROLEUM & CHEM CORP

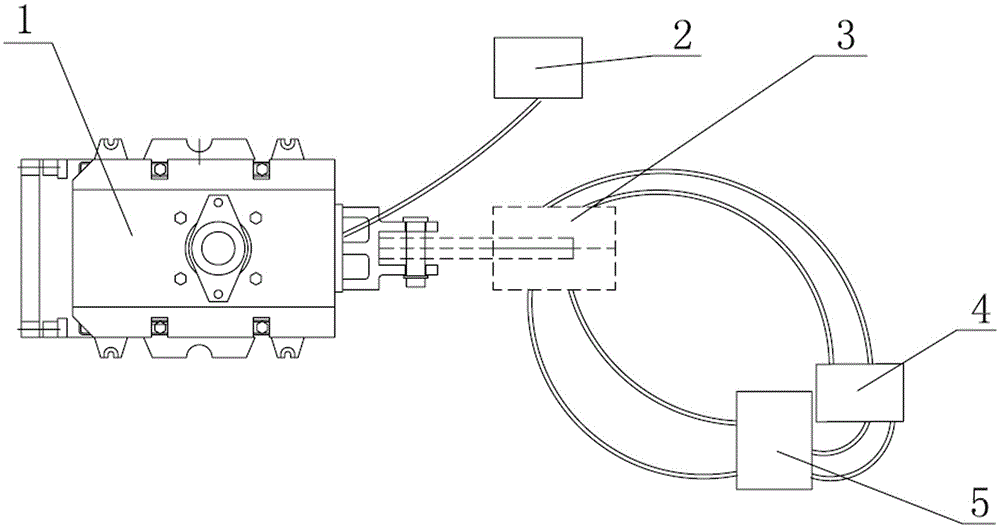

Gearbox lubricating test device and measuring device for lubricating oil injection quantity

InactiveCN107687946APlay a lubricating effectOptimal Solution for Filling VolumeMachine gearing/transmission testingCapacity measurement calibrationPetroleum engineeringVariator

Owner:SAIC MOTOR

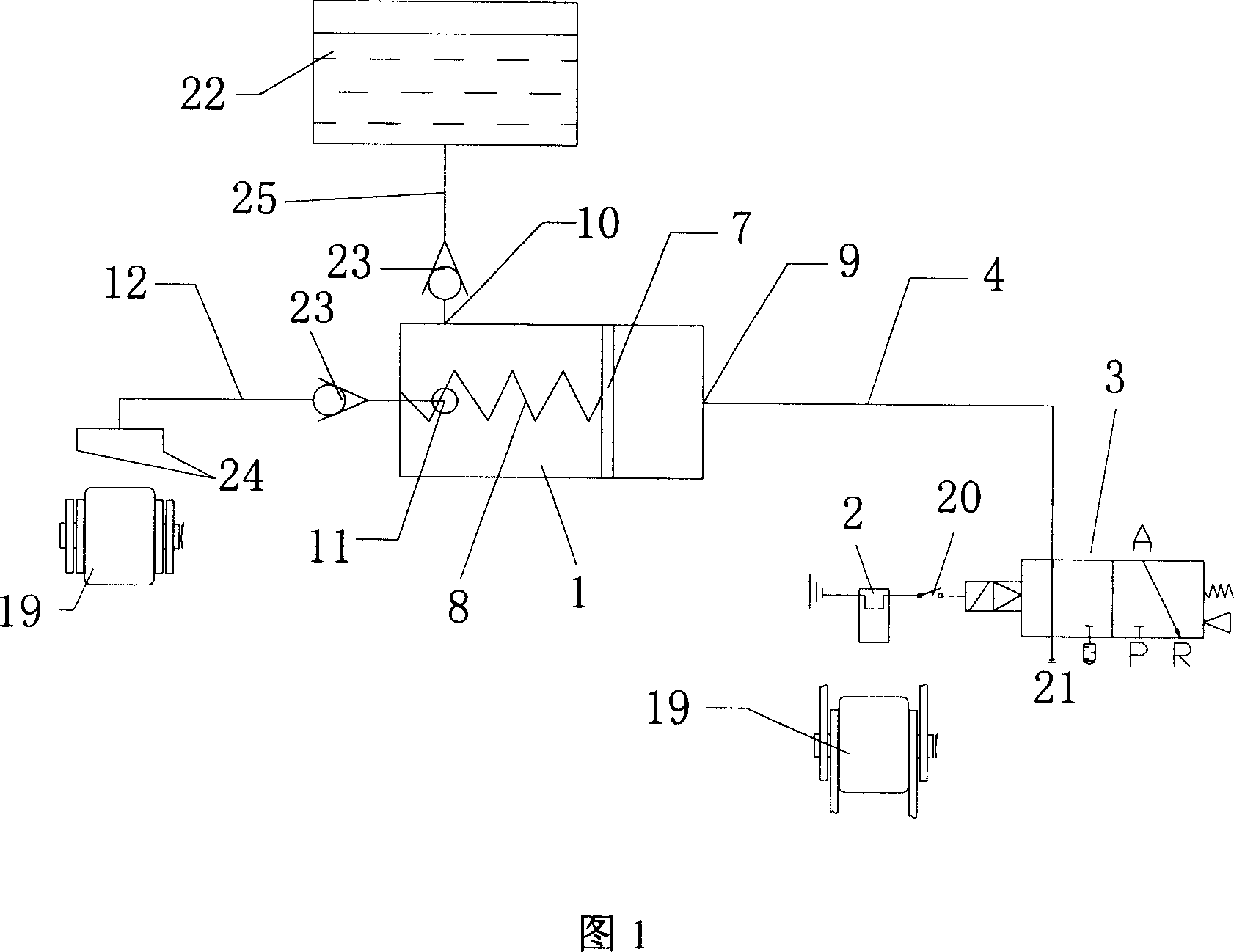

Machine head and machine tail centralized lubricating system of belt conveyor

The invention discloses a machine head and machine tail centralized lubricating system of a belt conveyor, comprising a main oil supply pipeline, a lubricant pump, a one-way valve, a plurality of oil supply branches, a plurality of oil feed distributors, an oil return pipeline and an overflow valve, wherein the lubricant pump continuously injects lubricating grease inside an oil storage tank into the main oil supply pipeline; the one-way valve is arranged on the main oil supply pipeline; the plurality of oil supply branches are respectively connected with an oil outlet of the main oil supply pipeline; the plurality of oil feed distributors are respectively arranged on the plurality of oil supply branches; the oil return pipeline is communicated with the main oil supply pipeline; the overflow valve is arranged on the oil return pipeline; an oil inlet of the main oil supply pipeline is connected with an oil injection orifice of the lubricant pump; the oil outlets of the plurality of oil supply branches are connected with the lubricating positions of the machine head and the machine tail of the belt conveyor, wherein the lubricating positions need to be lubricated; and the oil outlet of the oil return pipeline is connected into the oil storage tank. The invention has the advantages of reasonable design, easy operation, safe and reliable work and good lubricating effect, can also realize the centralized lubrication of a plurality of lubricating points and effectively overcomes the defects and the shortages of nonuniform and discontinuous lubrication, poor lubricating reliability, low lubricating efficiency, and the like of the traditional lubrication mode.

Owner:SHAANXI PUBAI SANTONG

Yaw gear ring lubrication system

PendingCN108036048AReduce maintenance costsImprove lubrication efficiencyGear lubrication/coolingLubricationOil transportation

The embodiment of the invention discloses a yaw gear ring lubrication system including a lubricating pump, a main oil pipeline and a distributor group. The lubricating pump is connected with the distributor group through the main oil pipeline, the distributor group includes a plurality of oil transportation openings, and each oil transportation opening of the oil transportation openings is used toconnect with a yaw gear ring. The lubrication efficiency is improved, and the maintenance cost of the lubricating pump is saved.

Owner:华润电力风能(汕头濠江)有限公司

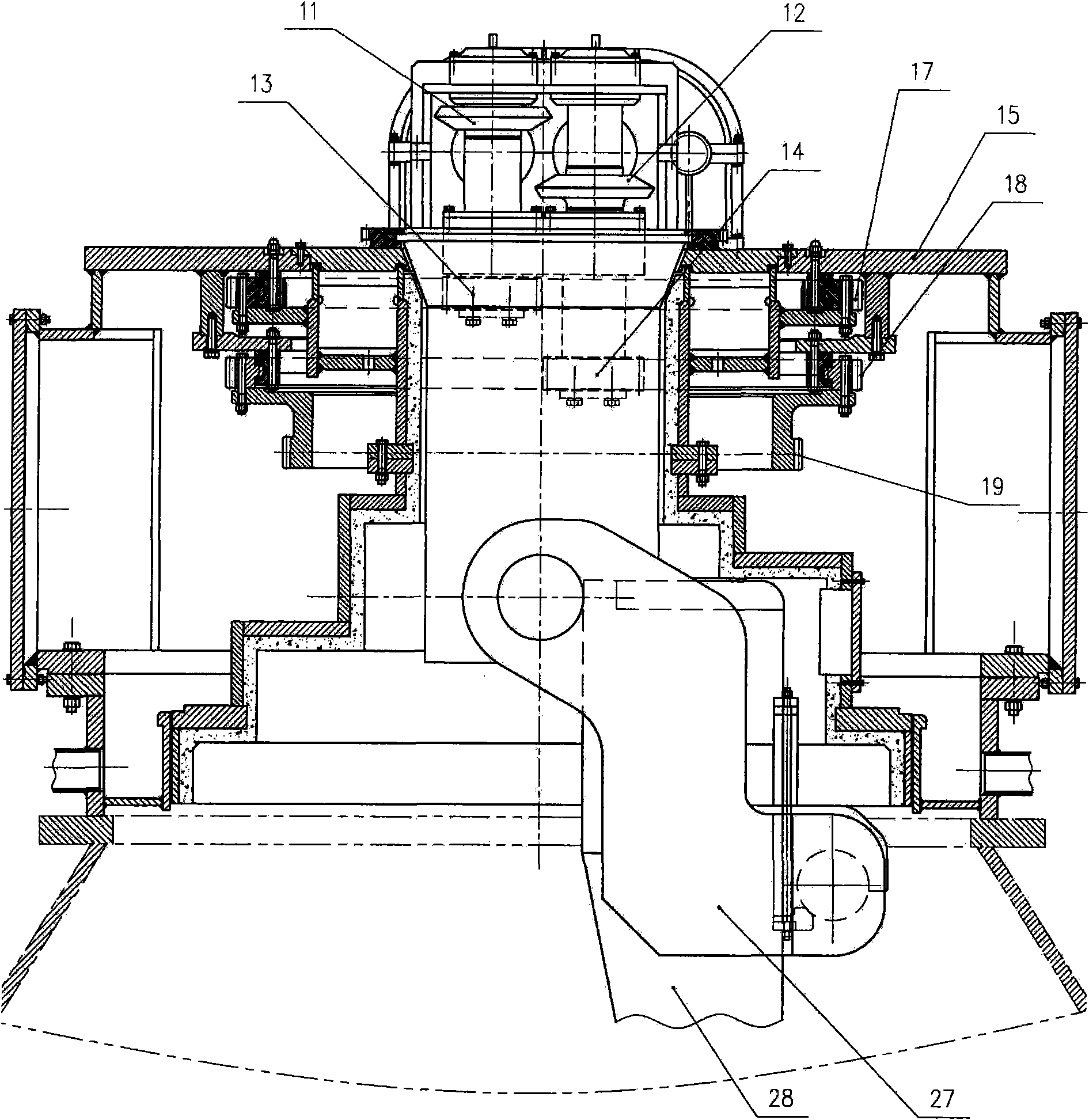

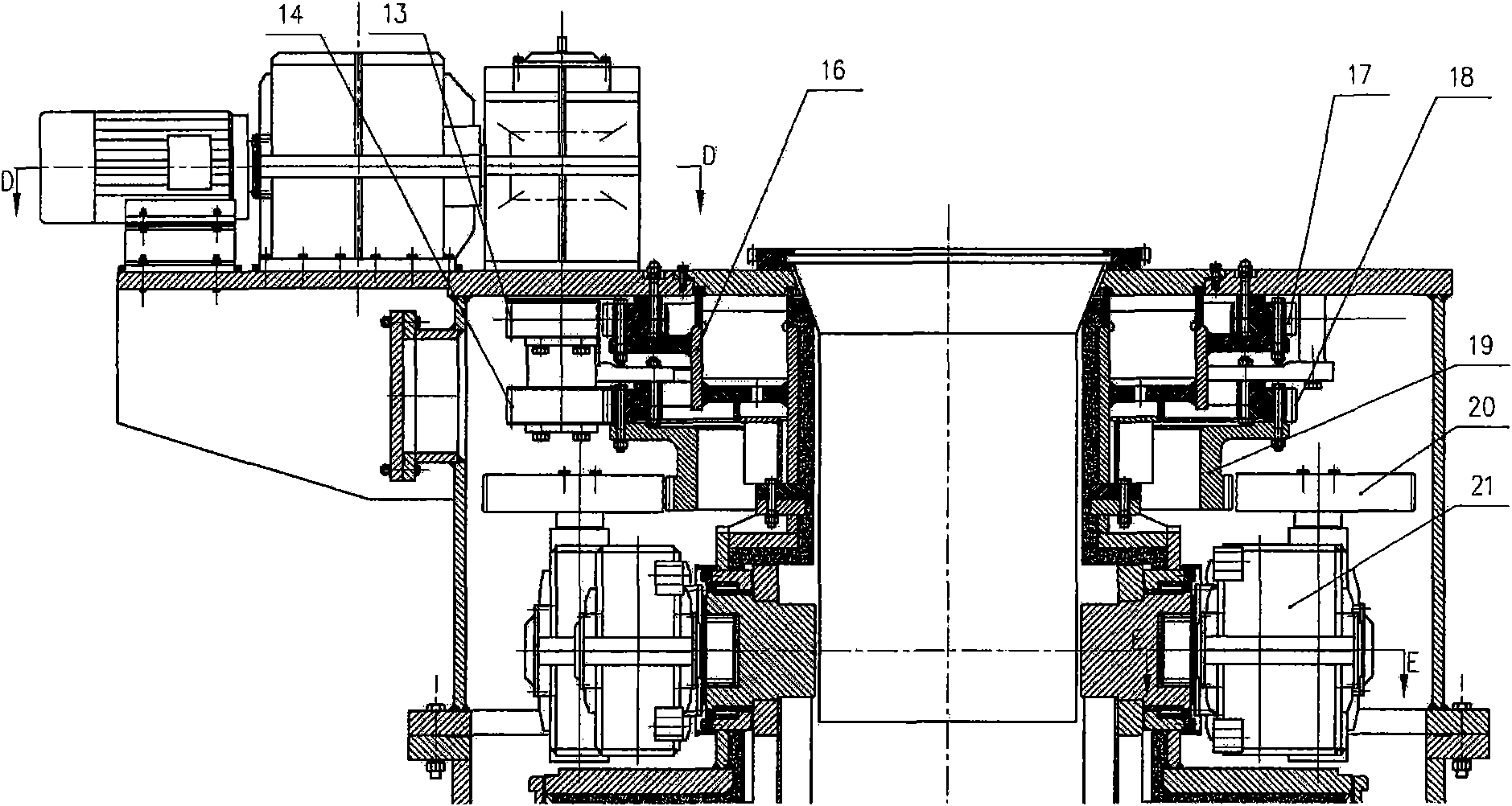

Furnace top distributing gear

ActiveCN101580885ACompact structureSmooth transmissionBlast furnace componentsBlast furnace detailsEngineeringGear drive

The invention discloses a furnace top distributing gear for distributing materials on the top of an iron-fining furnace, belonging to the technical field of mechanical engineering. A rotating motor and a tilting motor are independently driven by a set of differential mechanisms, wherein differential mechanism drive and previous-stage drive adopt all-gear drive, the previous-stage drive of a central sun wheel of the differential mechanism adopts gear drive with common drive ratio, and a furnace pot is tilted by a three-ring speed reducer. The furnace top distributing gear can realize the functions of furnace pot tilting, furnace pot rotation and furnace pot tilting and rotation, has the advantages of compact structure, reliable drive, stable work, high drive efficiency, long service life, little maintaining workload and convenient furnace pot replacement, can be used for blast furnace engineering of various types or other places where loose unpacked materials are delivered.

Owner:CISDI ENG CO LTD

Sea water pump with anti-corrosion function

The invention discloses a sea water pump with anti-corrosion function, which comprises a cover body, a water inlet pipe, a pump shell and a base, wherein the middle position of the top end of the baseis provided with the pump shell, one end of the pump shell is provided with the cover body, a pump shaft is arranged at the central position of one end in the pump shell, close to the cover body, thepump shaft extends transversely through the cover body, one end of the pump shaft, away from the cover body, is evenly provided with balance wings, a pulley flat key is arranged at one end of the pump shaft, close to the cover body. The pump shaft of the pulley flat key, close to the balance wings, is provided with an oil guide plate. A sealing cavity is arranged at the central position of one end in the pump shell, away from the cover body, and a storage battery is arranged inside the sealing cavity. According to the invention, through arranging the cover body, the pump shell, a reserved block, a reserved groove and a fixing bolt, the whole device is convenient to disassemble and assemble, so that personnel can overhaul and clean the inner part of the device, and the functionality of thedevice is enhanced.

Owner:WUHU JINGDA MACHINERY MFG CO LTD

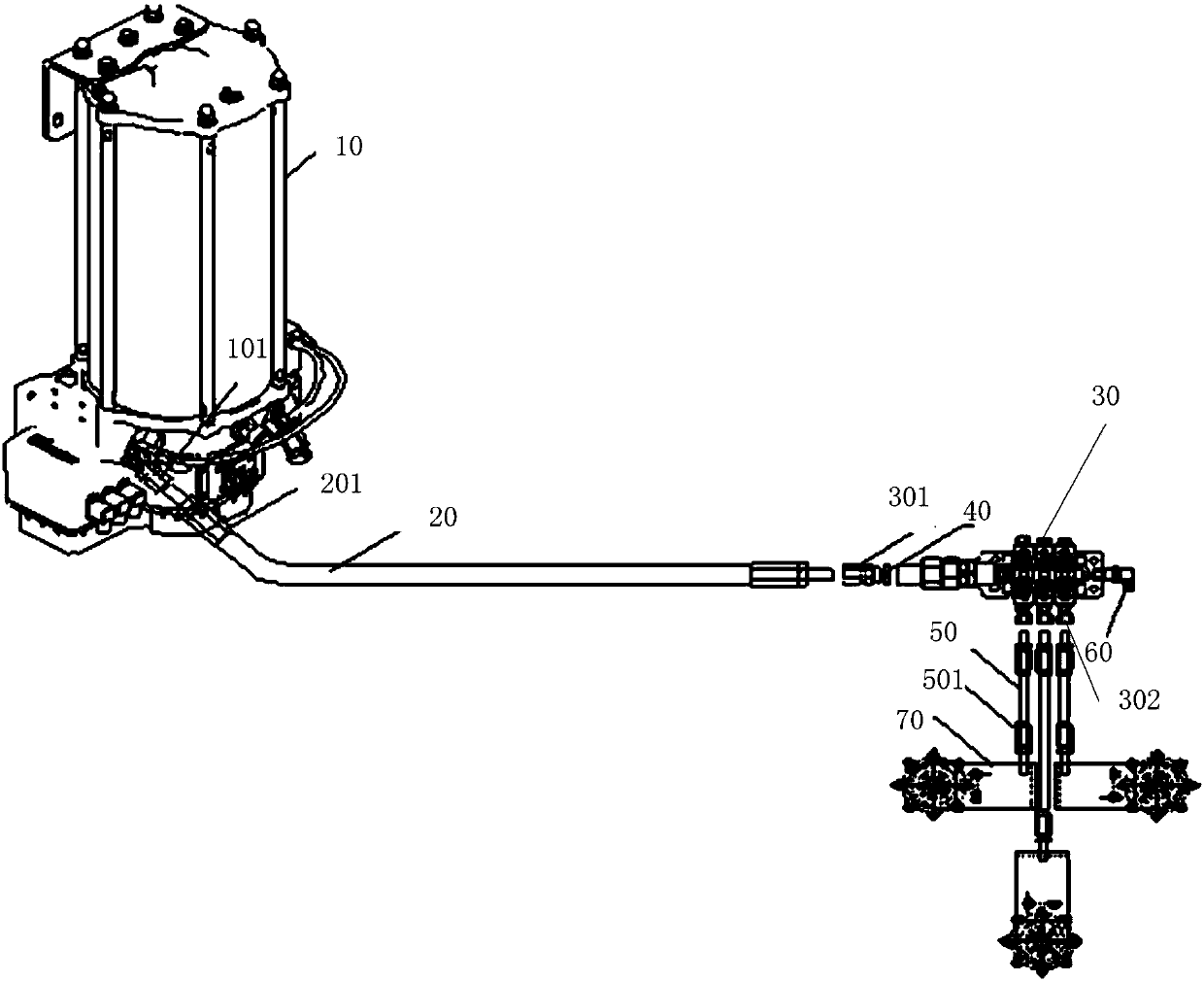

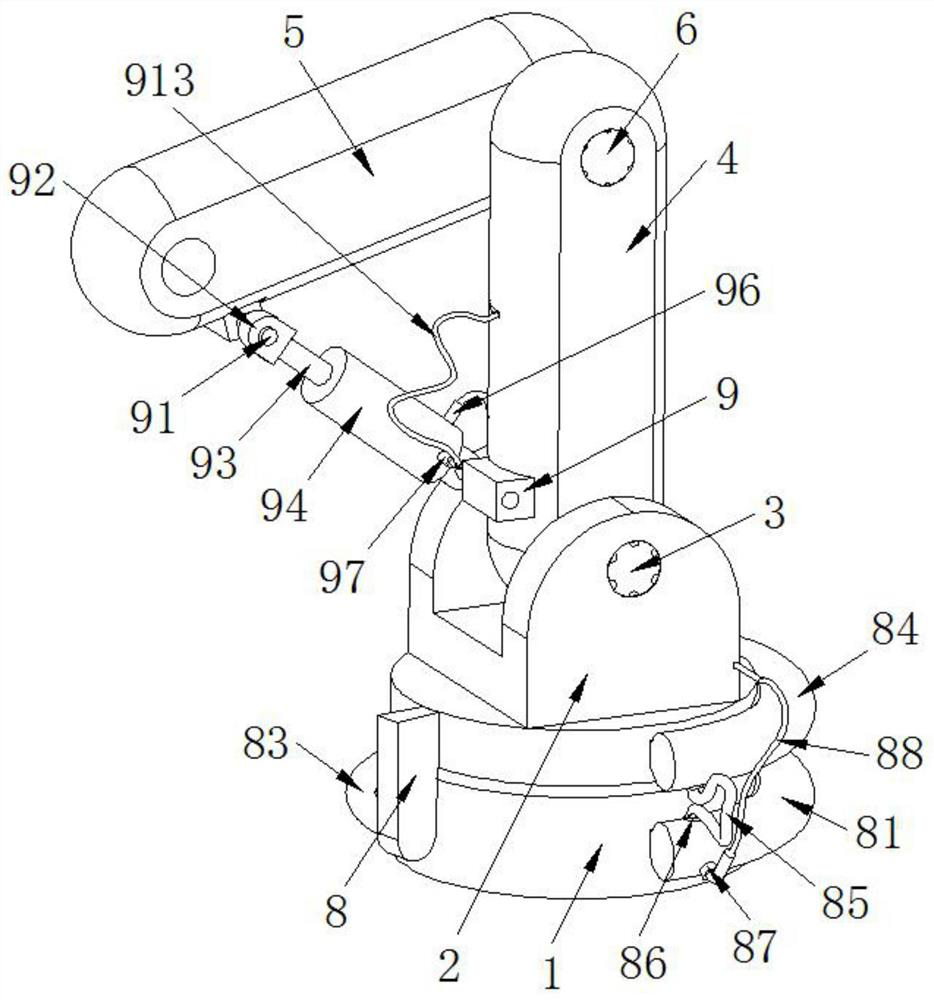

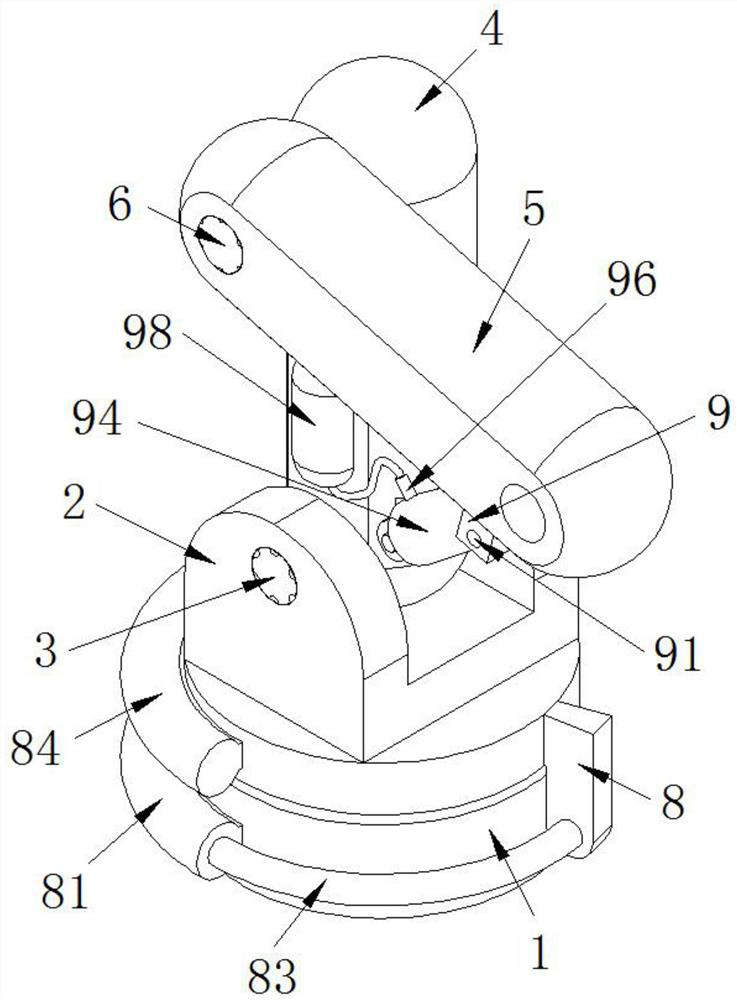

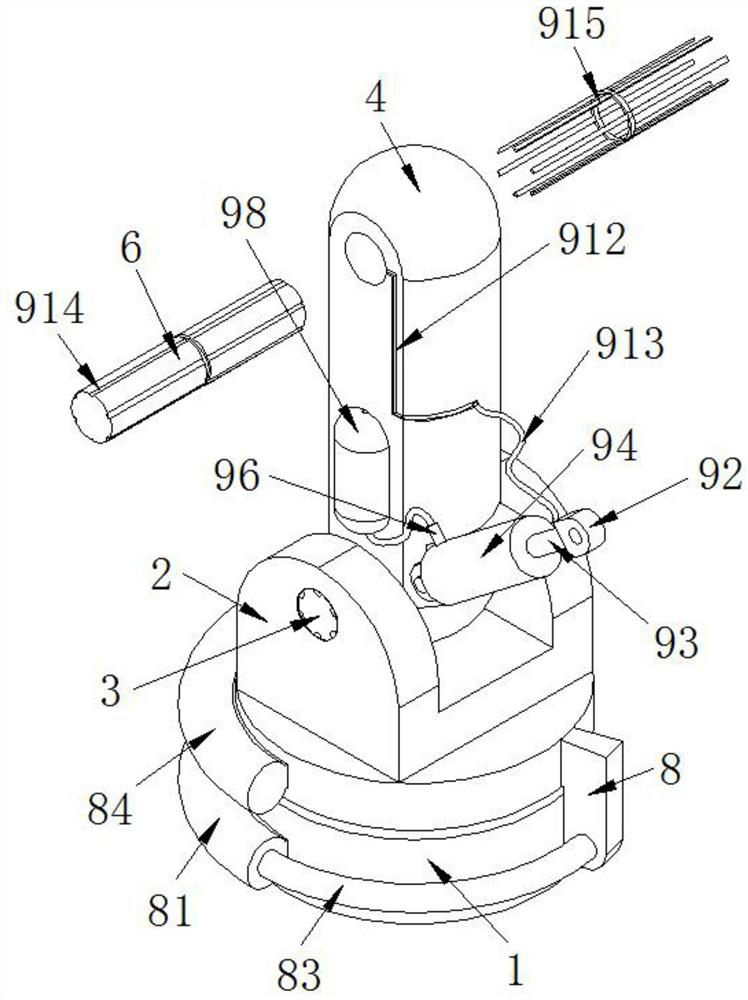

Industrial robot joint automatic lubricating system

The invention belongs to the technical field of industrial robot joint equipment, and particularly relates to an industrial robot joint automatic lubricating system. The system comprises a chassis, a rotating disc seat, a rotating disc shaft, a first joint, a second joint and a joint shaft in hinged rotation, and a rotating shaft is fixedly mounted at the bottom of the rotating disc seat. According to the automatic lubricating system for the joints of the industrial robot, by arranging a first automatic lubricating mechanism and a second automatic lubricating mechanism, a first push rod and a second push rod are driven to work when the rotating disc seat rotates or the first joint and the second joint rotate; the interior of a first lubricating pipe and the interior of a second lubricating pipe are controlled to generate suction force or pressure, lubricating oil in a first oil storage pipe and a second oil storage pipe is automatically controlled to flow out of a first smearing pipe and a second smearing pipe, the rotating disc shaft and the joint shaft are smeared, the lubricating oil can be injected in time, the lubricating efficiency is improved, joint abrasion is avoided, and the service life is prolonged.

Owner:NANJING YUQUN COMM TECH CO LTD

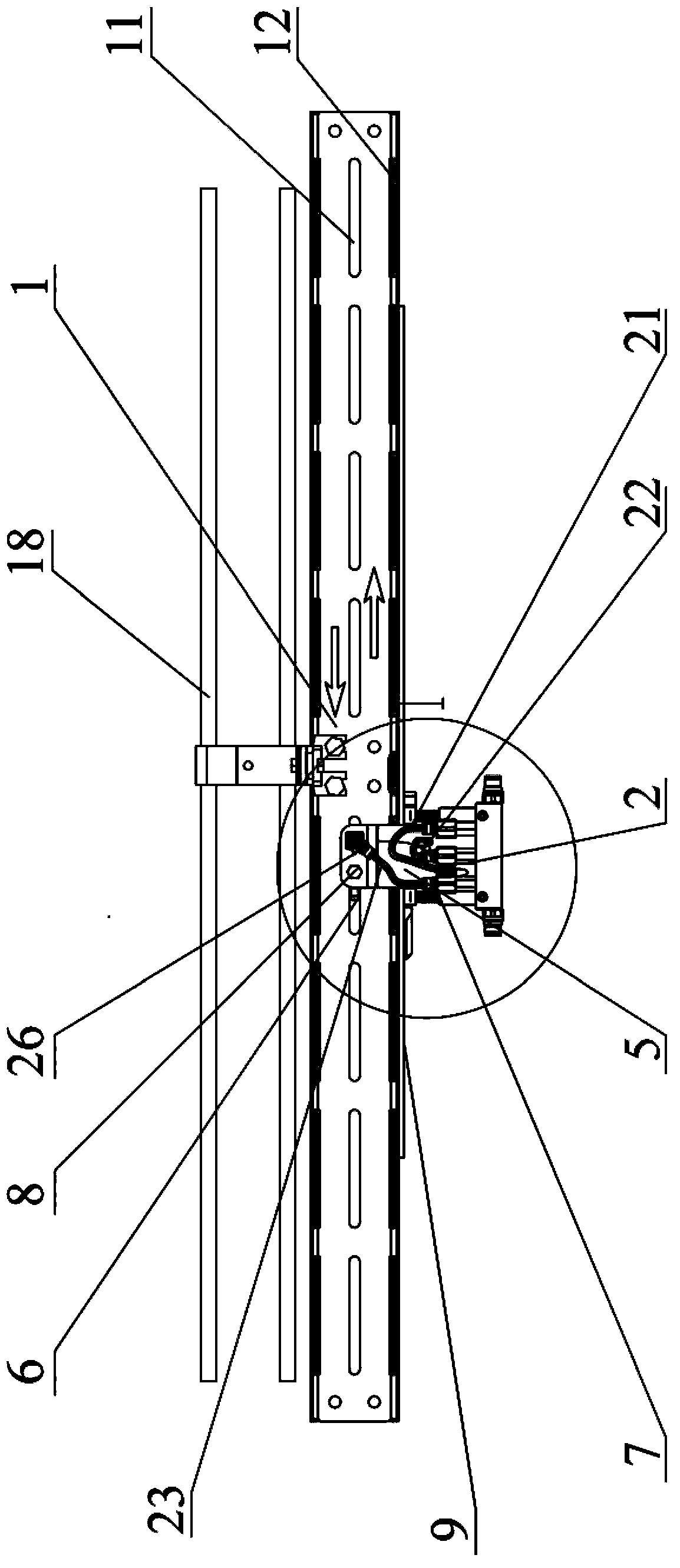

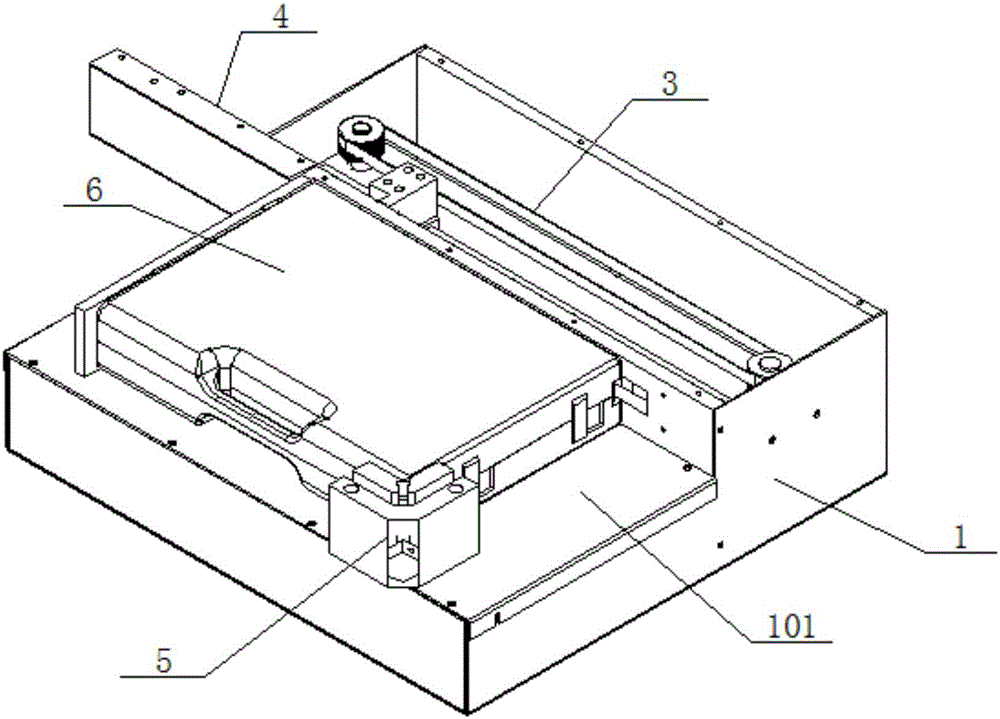

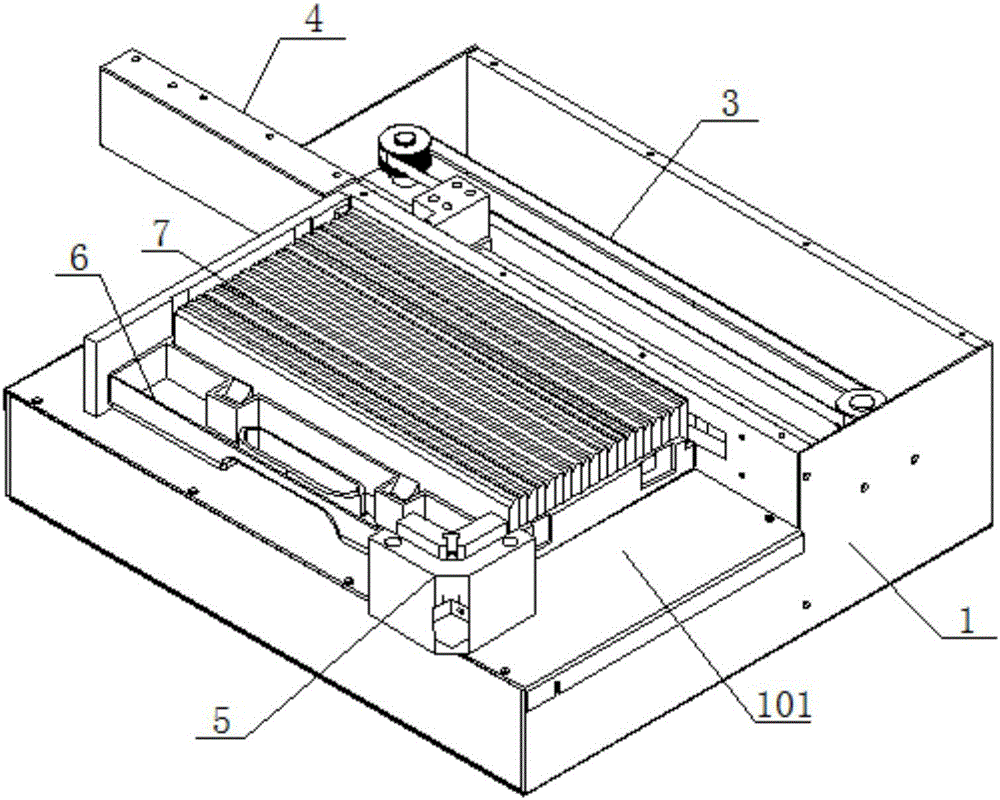

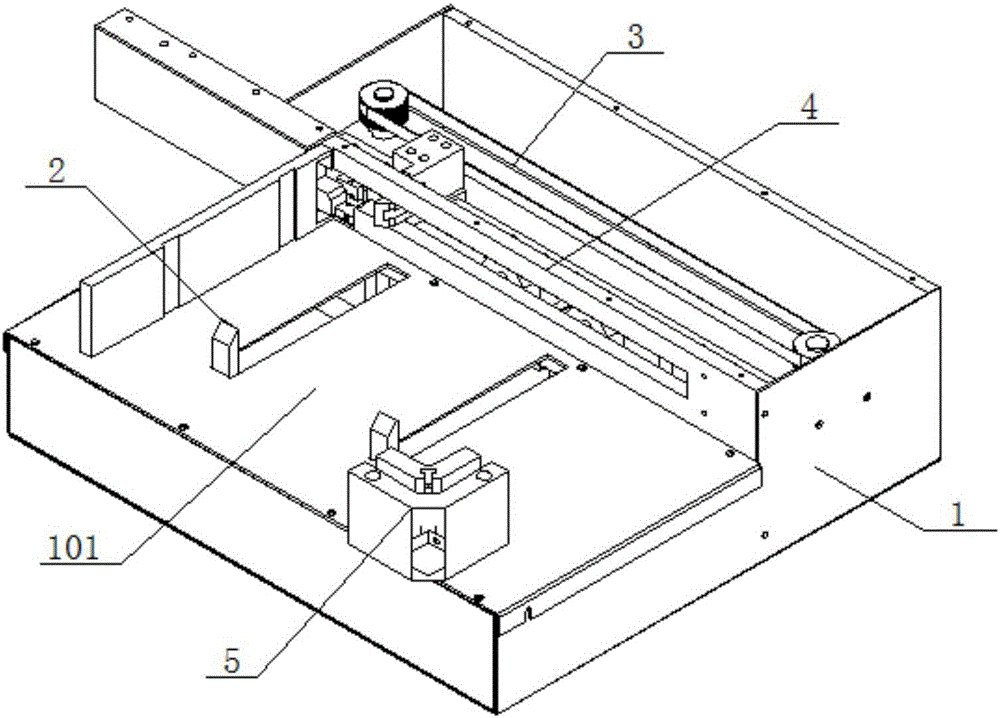

Automatic barstock feeding mechanism

ActiveCN106626116ASave human effortImprove lubrication efficiencyFeeding devicesGripping devicesLubricationEngineering

The invention discloses an automatic barstock feeding mechanism which comprises a shell, a longitudinal pushing mechanism arranged at the bottom of the shell, a transverse pushing mechanism arranged on one side of the shell, a material box arranged on the shell, a discharging mechanism arranged between the material box on the shell and the transverse pushing mechanism, and a material box clamping device arranged on the shell and used for fixing the material box. The automatic barstock feeding mechanism can automatically and continuously push lubricating barstock onto a cutting saw web for realizing automatic lubrication of the saw web, and manual operation is not needed during the lubricating process, so that manpower is saved, possible danger caused by manual operation is also avoided, the lubricating efficiency is improved, and the workshop environment is not polluted; and the automatic barstock feeding mechanism is reasonable and skillful in structure, long in service life and excellent in working stability.

Owner:山东仁科测控技术有限公司

Rail-side solid-liquid-solid lubricating material and manufacturing method thereof

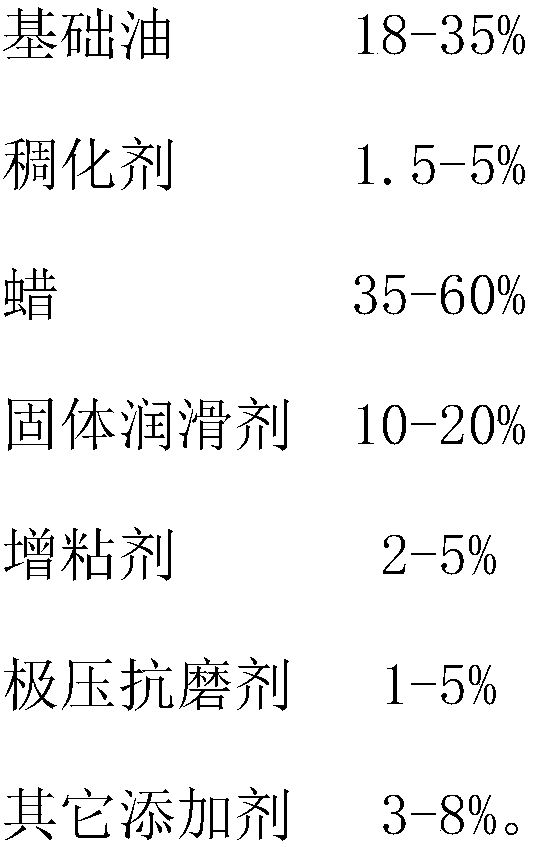

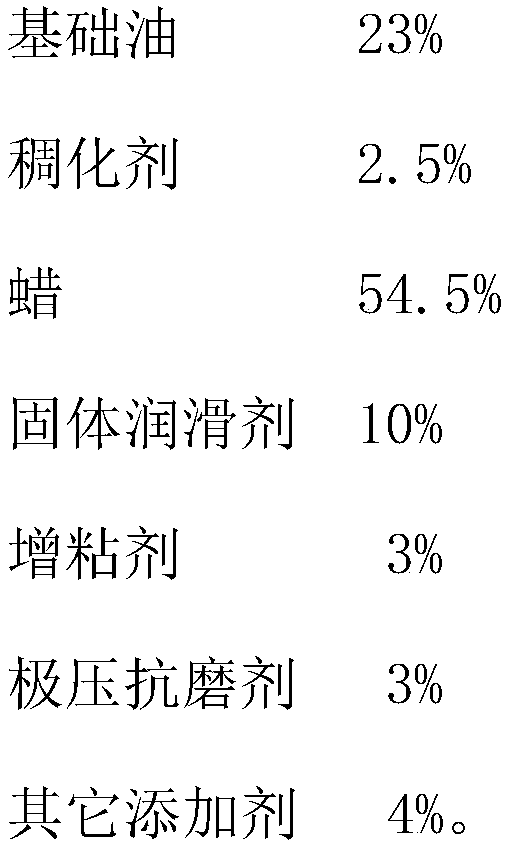

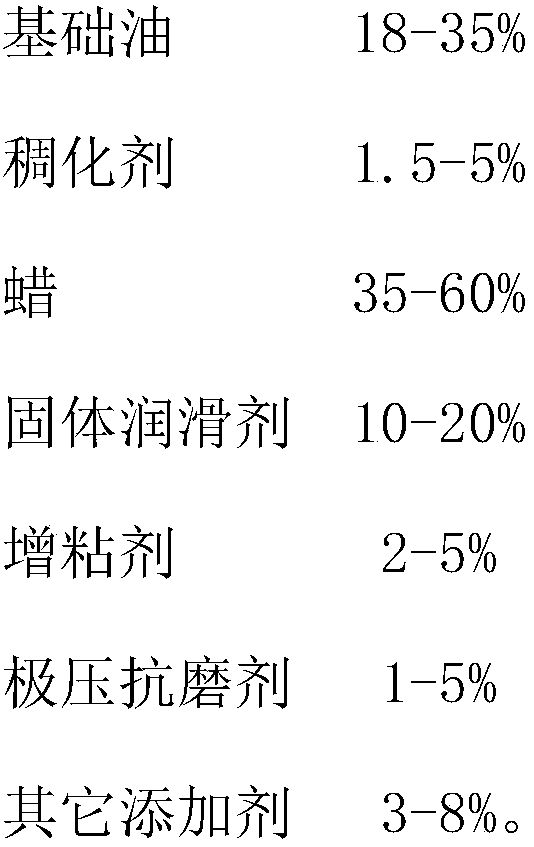

InactiveCN107603700AAvoid the disadvantages of high oil content and easy oil separationImprove the lubrication effectLubricant compositionWaxBase oil

The invention discloses a rail-side solid-liquid-solid lubricating material and a manufacturing method thereof. The solid-liquid-solid lubricating material is prepared from the following raw materialsin percentage by weight: 18-35% of base oil, 1.5-5% of a thickening agent, 35-60% of wax, 10-20% of a solid lubricant, 2-5% of a tackifier, 1-5% of an extreme-pressure antiwear agent and 5-8% of other additives. According to the rail-side solid-liquid-solid lubricating material and the manufacturing method thereof, the solid-liquid-solid lubricating material has a low friction coefficient and relatively strong adhesion to a steel rail, can solve the problem that a lubricating material cannot adhere under the working condition of having water, has a low oil separating rate and certain degradation capacity, can effectively relieve the pollution of the lubricating material to the environment along a railway, and can reduce problems generated by a steel rail oil wedge.

Owner:ZHEJIANG BAOSHENG RAILWAYNEW MATERIALS TECH

High-strength converter tapping slag stopping mechanism capable of improving operating efficiency and processing technology thereof

ActiveCN105063275AAvoid security risksAvoid stickingManufacturing convertersFurnace typesSlagHigh intensity

The invention relates to a high-strength converter tapping slag stopping mechanism capable of improving operating efficiency and a processing technology thereof and belongs to the technical field of cast iron processing. The high-strength converter tapping slag stopping mechanism capable of improving the operating efficiency comprises a slag stopping mechanism body, a mechanism cooling system, an oil cylinder, a hydraulic system and a hydraulic cooling system. The mechanism cooling system is communicated with the slag stopping mechanism body through a pipeline. The output end of the oil cylinder is connected with the slag stopping mechanism body and used for driving the slag stopping mechanism body. The oil cylinder, the hydraulic system and the hydraulic cooling system are sequentially communicated through pipelines and form a loop. The sliding face of a sliding mold frame is in an oil groove type horizontal sliding mode. Compared with other similar slag stopping mechanisms, the safety risks caused by roller abrasion and axle fracturing of an axle-roller type slag stopping mechanism are eliminated completely.

Owner:华东瑞泰科技有限公司

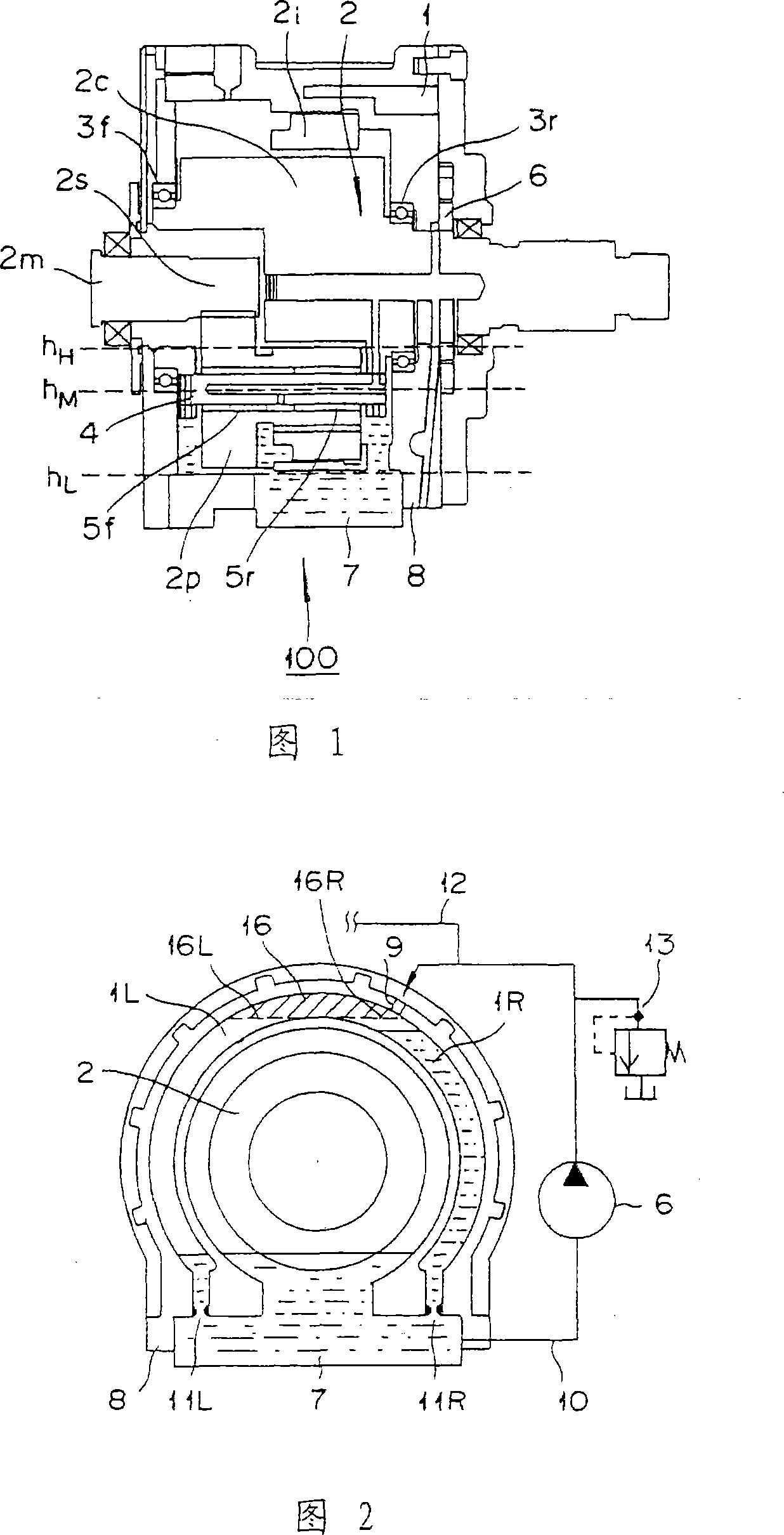

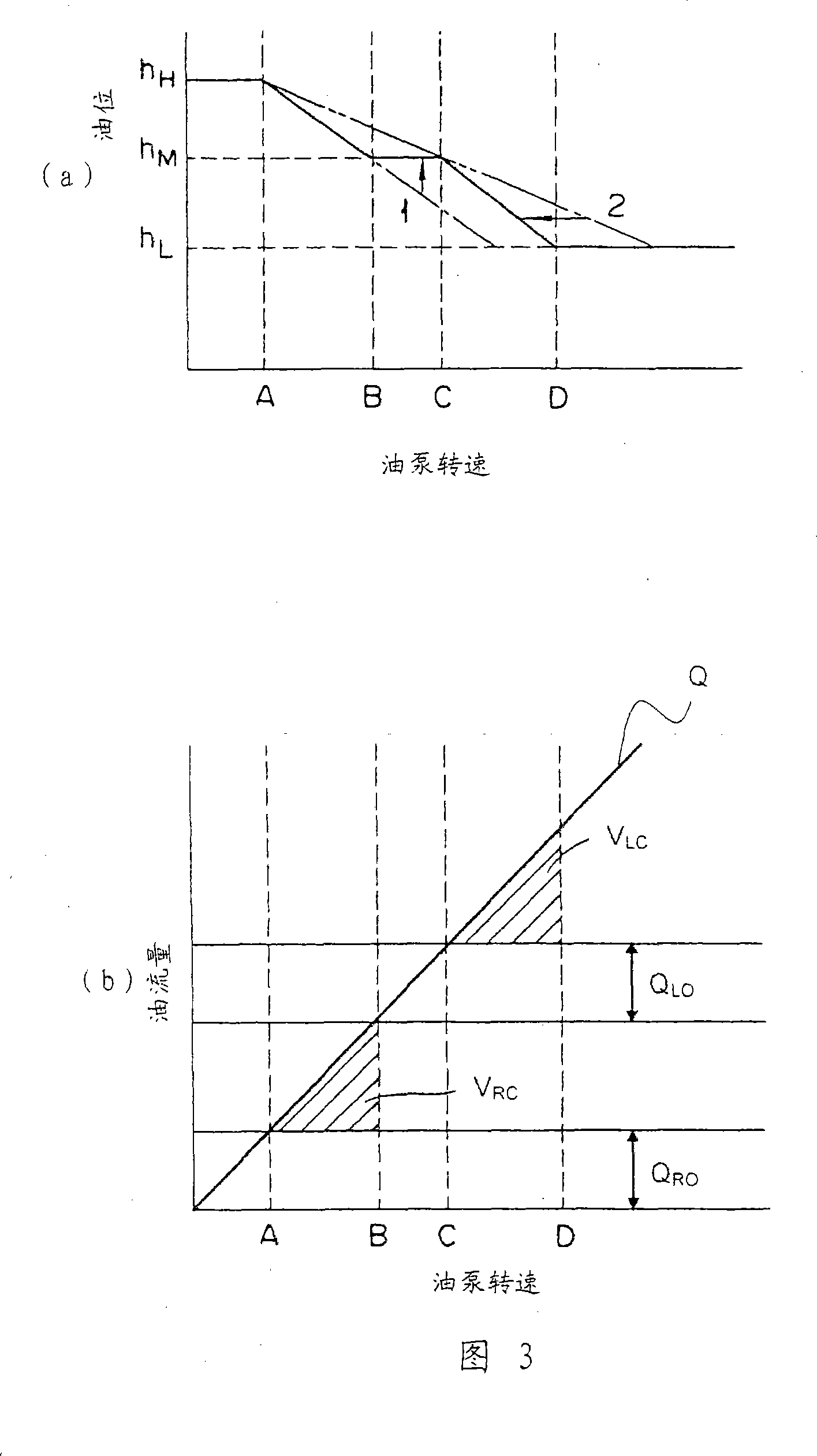

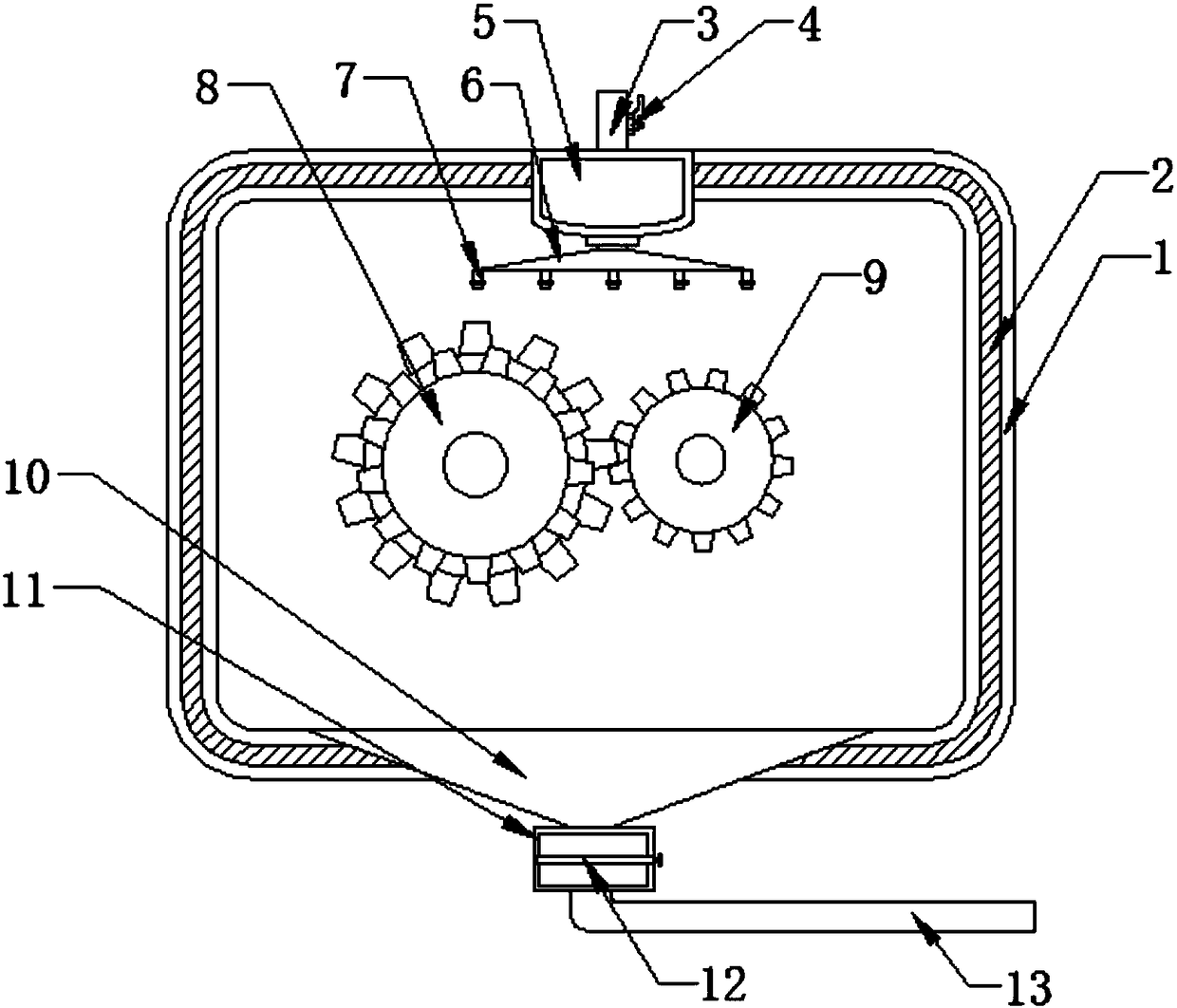

Power transmission device

InactiveCN101126443AImprove lubrication efficiencyImprove mechanical efficiencyGear lubrication/coolingWaste managementPower transmission

A power transmission device is provided with a gear mechanism, a case, an oil pump and an oil tank. The gear mechanism is arranged to operate in coordination with a drive source. The case houses the gear mechanism and stores oil for lubricating the gear mechanism. The oil pump is arranged to operate in coordination with the drive source so as to pump the oil stored in the case to lubricate the gear mechanism. The oil tank is arranged to collect a portion of the oil pumped from the oil pump. The oil tank includes a first discharge outlet arranged to discharge the oil collected in the oil tank to the case and a second discharge outlet arranged to discharge collected oil to the case when an amount of the oil collected in the oil tank is equal to or larger than a prescribed amount.

Owner:NISSAN MOTOR CO LTD

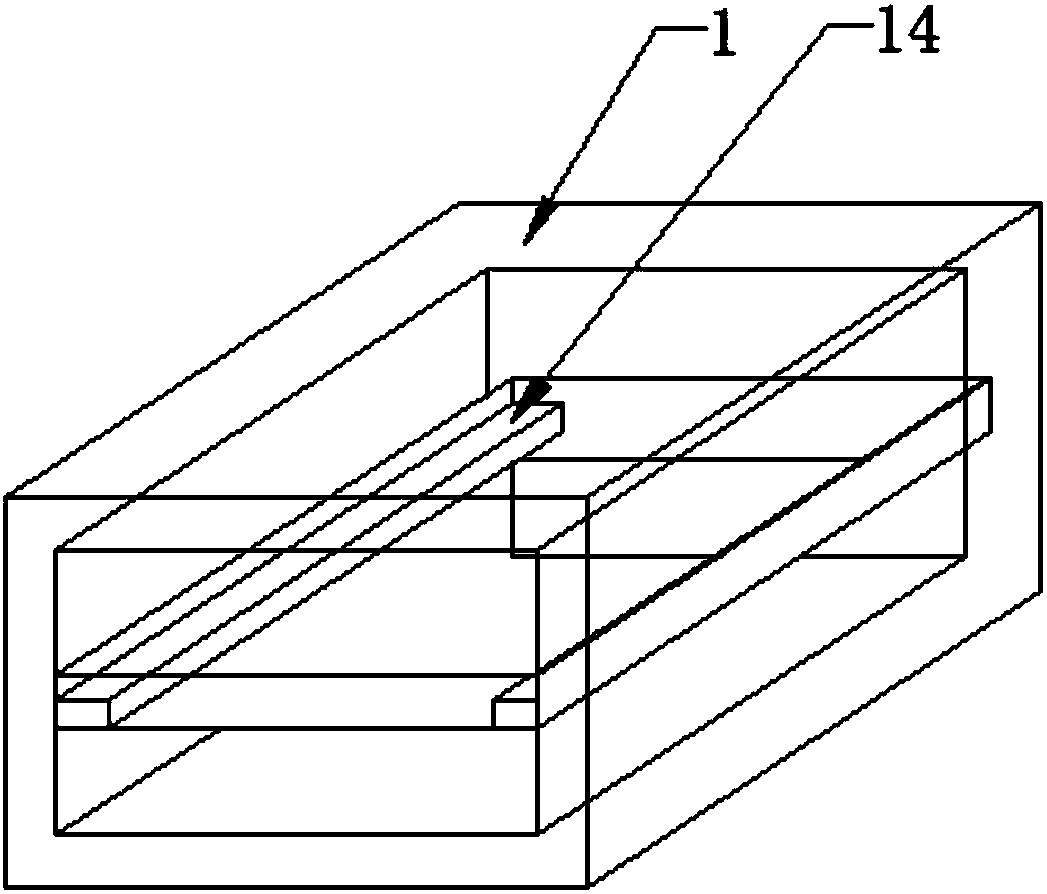

Transmission box with lubricating function

InactiveCN108331909AImprove lubrication efficiencyHigh lubrication efficiency and relatively uniformGear lubrication/coolingEngineeringOil storage

The invention discloses a transmission box with a lubricating function. The transmission box comprises a shell. An oil storage mechanism is fixedly arranged at the top end inside the shell, the top end of the oil storage mechanism communicates with the outside world through an oil filling pipe arranged in the middle of the top end of the shell, a manual valve is arranged in the middle of the oil filling pipe, and the two edge sides of the shell are rotatably connected with two rotating shafts through bearings correspondingly. According to the transmission box with the lubricating function, byarranging the oil storage mechanism, lubricating oil is stored, when needing to be used, the lubricating oil inside a storage chamber is discharged out, and then lubricating can be completed; the lubricating oil is sprayed out through spraying heads, multiple positions of internal parts are lubricated, thus the lubricating efficiency is high, and lubricating is uniform; the lubricating oil used during lubricating is recycled through a recycling mechanism, the lubricating oil is filtered through a filter net, and the cleanliness of the lubricating oil is improved; and by forming a sound insulation groove, noise generated in working of the transmission box is insulated, and the working quality of workers is improved.

Owner:湖州诺诚低温设备有限公司

Bearing sleeve, gear case and rail vehicle

PendingCN109185346AImprove lubrication efficiencyReduce manufacturing difficultyBearing componentsMechanical engineering

Owner:BEIJING NANKOU RAILWAY TRANSIT MACHINERY

Traction gear box and rail vehicle

InactiveCN110886833AIncrease oil volumeImprove lubrication efficiencyGear lubrication/coolingGear wheelControl theory

The invention relates to the technical field of a rail vehicle transmission system, and discloses a traction gear box and a rail vehicle. The traction gear box comprises a gear box body, a driving gear assembly, a driven gear assembly and an oil accumulation tank, wherein an accommodation cavity is constructed inside the gear box body; the driving gear assembly is arranged in the accommodation cavity; the driven gear assembly is meshed with the driving gear assembly; an oil pool for containing lubricating oil is constructed at a position in the accommodation cavity, which corresponds to the lower part of the driven gear assembly; the lower end of the driven gear assembly is infiltrated in the lubricating oil in the oil pool; the oil accumulation tank is formed on the inner wall of the gearbox body and positioned above the driving gear assembly; the oil accumulation tank is used for bearing the lubricating oil shaken by rotation of the driven gear assembly; an oil inlet passage is constructed inside the driving gear assembly; and the oil inlet passage is communicated with the oil accumulation tank through an oil inlet hole formed on the gear box body. The traction gear box has theadvantages of high lubricating efficiency and good lubricating effect.

Owner:CRRC QINGDAO SIFANG CO LTD

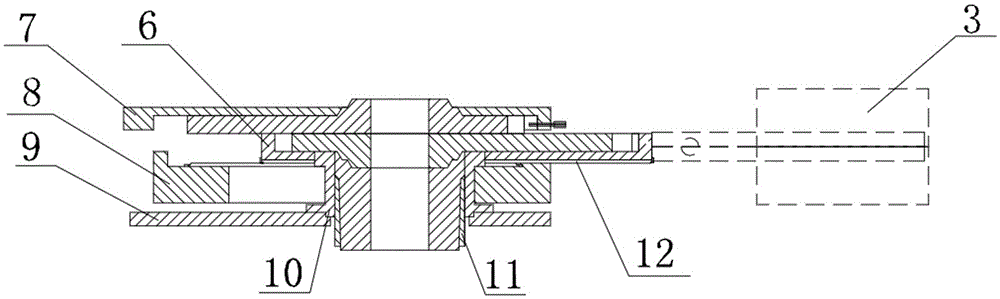

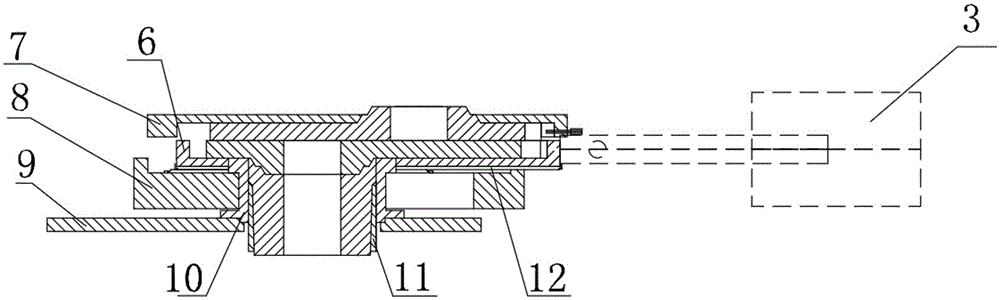

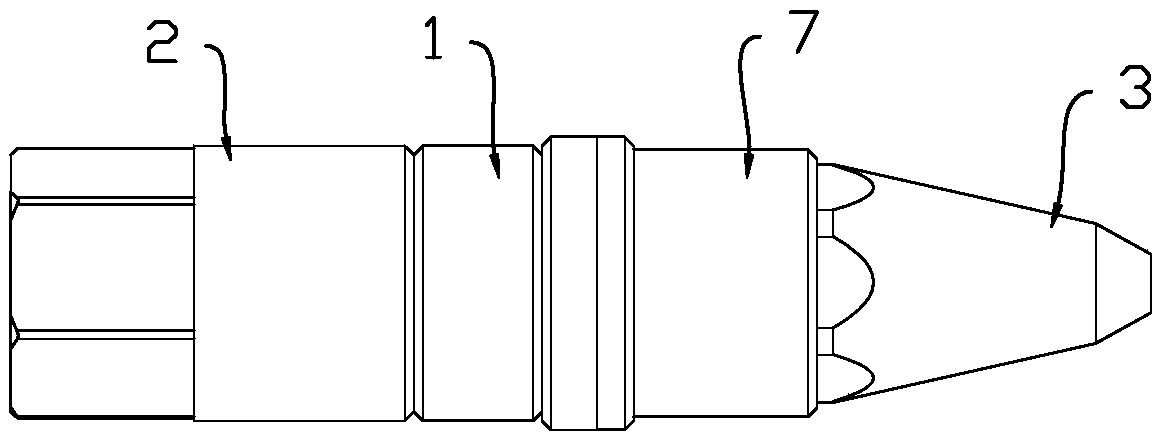

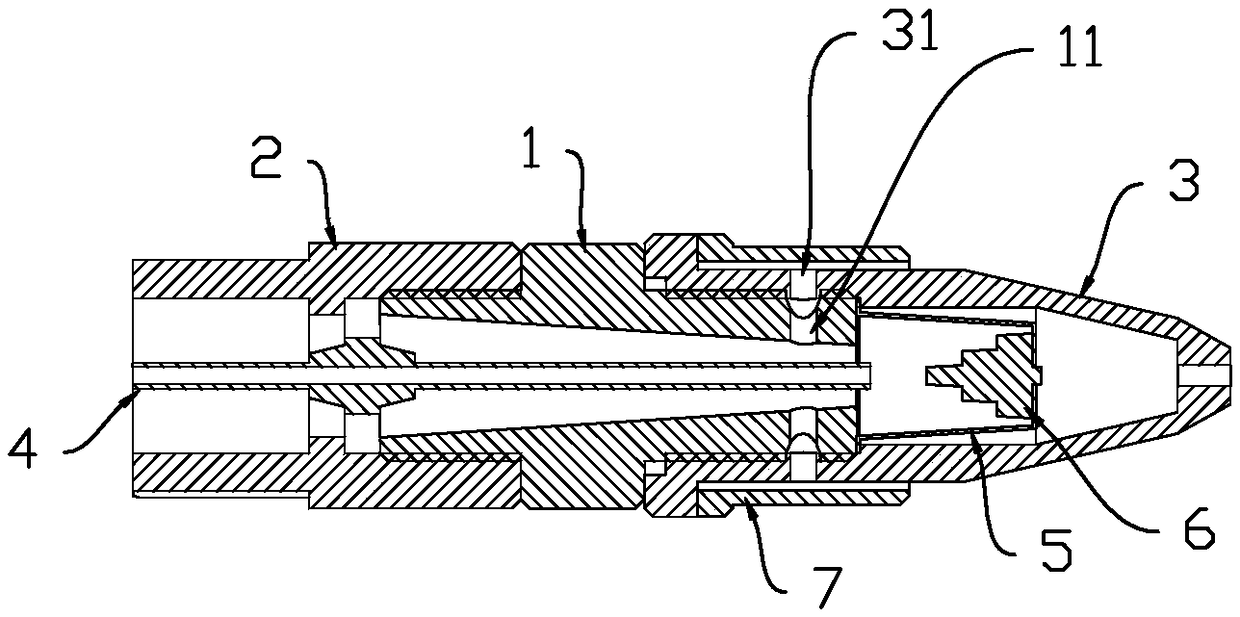

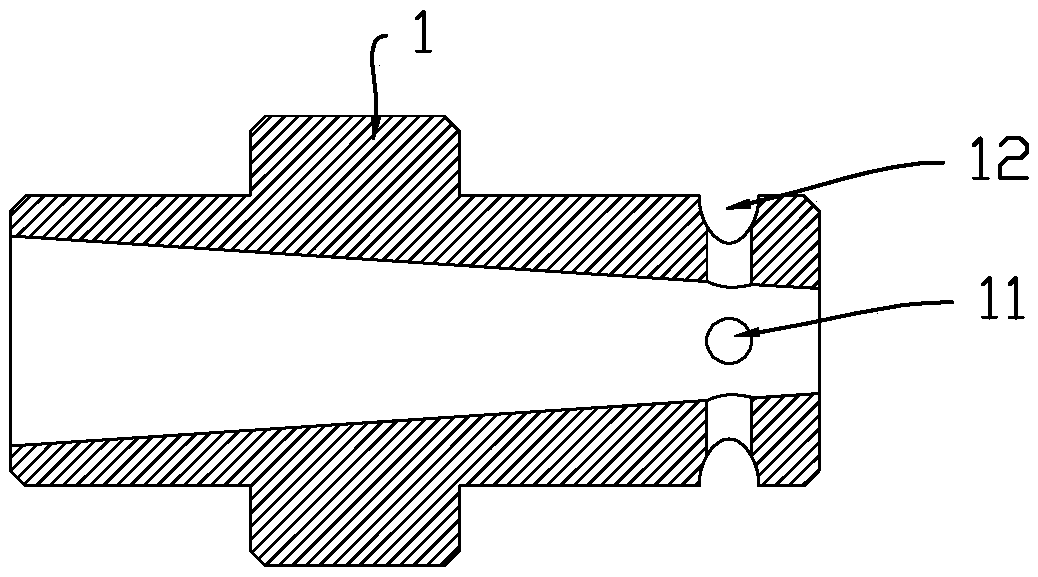

Airflow constraint type fine oil mist nozzle device

PendingCN108745676ASmall particlesImprove the lubrication effectLiquid spraying apparatusSpray nozzleHigh pressure

The invention discloses an airflow constraint type fine oil mist nozzle device. The airflow constraint type fine oil mist nozzle device comprises a nozzle main body which is internally provided with ahigh-pressure airflow passage, two ends of the nozzle main body are provided with a nozzle connection pipe for introducing high-pressure airflow and a nozzle sleeve outputting oil mist in a sleevingmanner correspondingly, the nozzle sleeve is provided with a mist spray mouth, the nozzle main body is internally provided with an oil pipe for conveying oil liquid, the nozzle sleeve is internally provided with a support with elasticity, and the support is provided with an atomizing cone facilitating the oil liquid to be atomized. According to the airflow constraint type fine oil mist nozzle device, in the working process, the high-pressure airflow is injected into the high-pressure airflow passage from the nozzle connection pipe, lubricating oil flows from the oil pipe into the nozzle sleeve, the high-pressure airflow impacts the lubricating oil and then hits the atomizing cone to make the atomizing cone and the support with elasticity generate high-frequency oscillation, so that the oilmist is generated and sprayed out from the mist spray mouth, the oil mist with small particles is obtained, the lubrication efficiency is improved, and the airflow constraint type fine oil mist nozzle device is used for the field of lubricating and cooling.

Owner:CONPROFE TECH GRP CO LTD +1

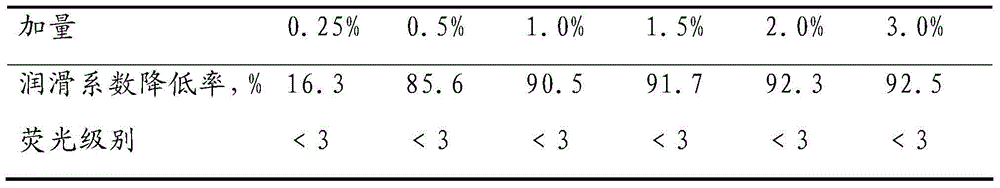

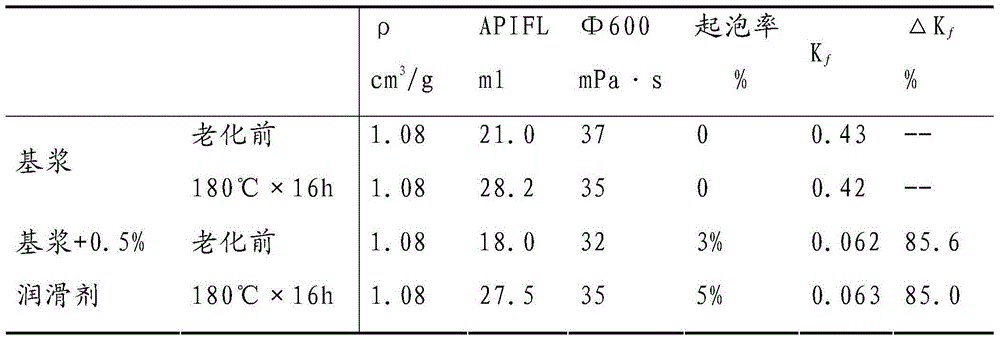

Low toxicity and low fluorescence lubricant for drilling fluid and preparation method thereof

ActiveCN104830292AReduce the impactImprove lubrication efficiencyDrilling compositionFluorescenceRoom temperature

The invention discloses a low toxicity and low fluorescence lubricant for drilling fluid. The lubricant consists of the following components by weight: 50-90 parts of base oil, 5-30 parts of an emulsifier, 2-5 parts of a penetrant, 1-5 parts of a condensation point modifier and 2-10 parts of an extreme pressure agent. The preparation method is as below: adding 50-90 parts of base oil into a reactor, stirring and heating to 40-50 DEG C, then adding 5-30 parts of an emulsifier for an emulsified reaction, stirring for 1 h, raising the temperature to 50-60 DEG C, adding 2-5 parts of penetrant, stirring for 30 min, then adding 2-10 parts of the extreme pressure agent, continuing stirring for 30 min, stopping heating, then adding 1-5 parts of the condensation point modifier, cooling with stirring to room temperature, and pouring the lubricant out of the reactor. The lubricant provided by the invention has the advantages of low toxicity, low fluorescence, high lubrication efficiency, high temperature toleration and no foaming, and can satisfy the requirements of different wells such as large displacement well.

Owner:TIANJIN BO XING ENG SCI & TECH LIMITED COMPANY OF CNPC +2

Split bearing bush seat type sliding bearing tank

InactiveCN102518680AEasy to installReduce bending momentBearing coolingBearing unit rigid supportBall bearingRolling-element bearing

The invention relates to a split bearing bush seat type sliding bearing tank, which comprises a tank body connected with a casing, a sliding bearing component and a rolling bearing component which are arranged in the tank body and used for supporting a shaft,; the sliding bearing component comprises a bearing bush, an oil ring and a bearing bush installation seat; the rolling bearing is a single four-point contact ball bearing; and a gravity support surface between the tank body and the casing is positioned at the lower part of the sliding bearing component. According to the invention, the technical problems of large volume, large weight and large bending moment of the current sliding bearing tank can be solved, the weight of the bearing tank can be reduced, the capacity of the lubricating oil can be raised, and the installation of the sliding bearing tank is more stable and reliable.

Owner:西安航天泵业有限公司

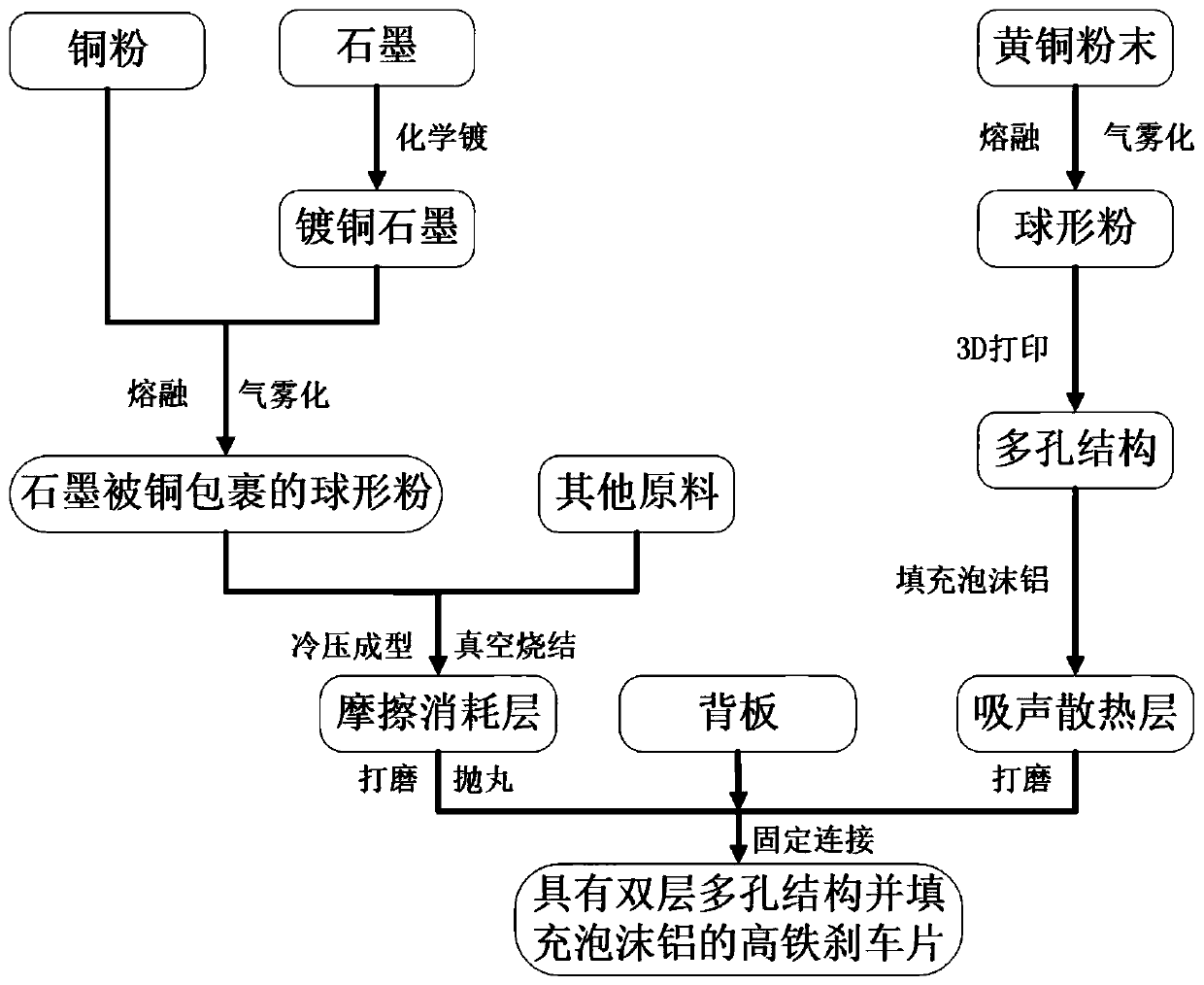

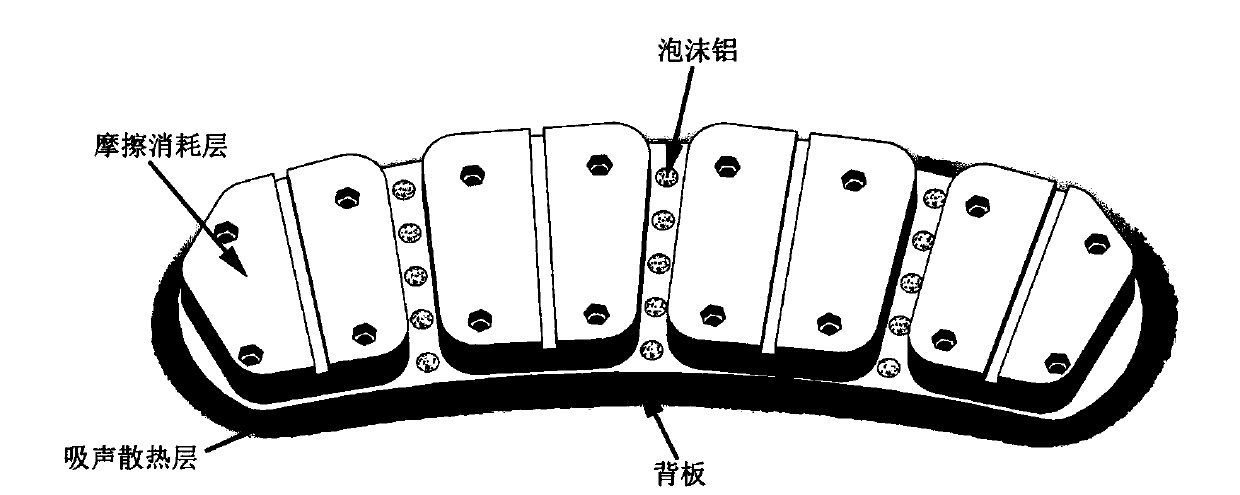

Environmentally-friendly low-dust and low-noise novel brake pad for high-speed railway and preparation method thereof

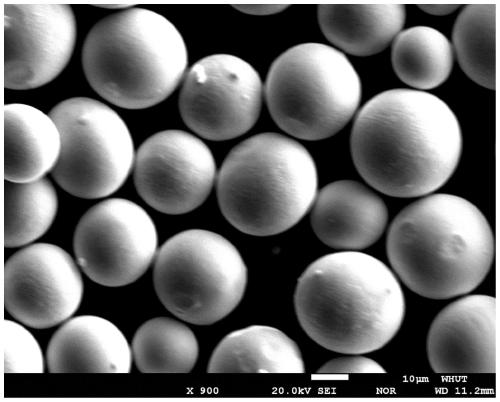

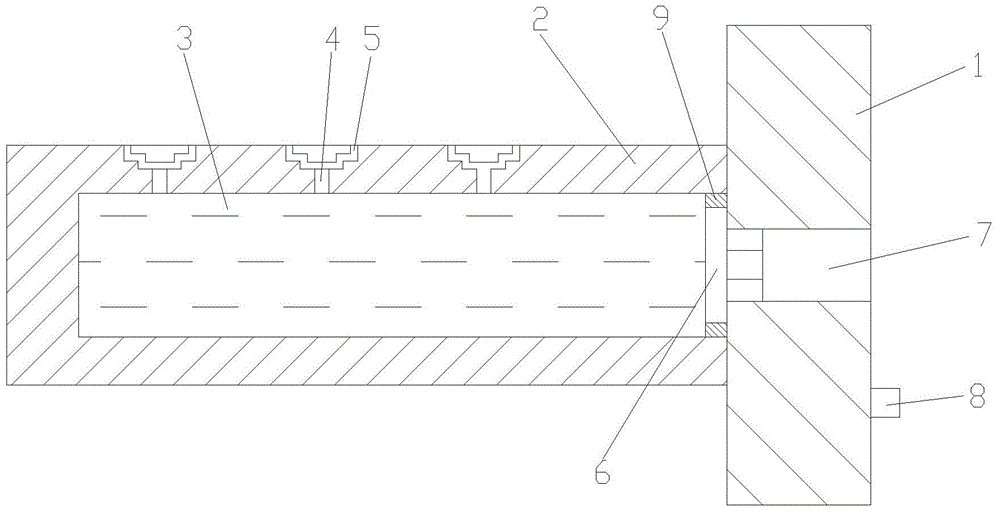

ActiveCN110375023AWith wear resistanceWith sound absorption and noise reduction performanceAdditive manufacturingTransportation and packagingLow noiseChemical plating

The invention discloses an environmentally-friendly low-dust and low-noise novel brake pad for a high-speed railway and a preparation method thereof. The novel brake pad for the high-speed railway comprises a friction consumption layer and a sound absorption heat dissipation layer and meanwhile has good wear resistance and sound absorption and noise reduction performances. The preparation method comprises the following steps that cold press molding is carried out on a raw material of the friction consumption layer, and vacuum sintering is carried out so as to obtain the friction consumption layer, wherein the existence state of graphite in the friction consumption layer is that copper plating is carried out on the surface of the graphite by adopting chemical plating, then composite spherical powder of copper and the copper-plated graphite is prepared through an aerosol powder preparation method, and the graphite is tightly combined with the copper; and an H62 copper alloy substrate ofa porous structure is obtained through the sound absorption and heat dissipation layer through a 3D printing technology, and then pores are filled with foamed aluminium, so that the effect of reducingthe noise pollution is achieved. The brake pad for the high-speed railway has the advantages of being simple in formula, high in production efficiency, small in dust pollution, low in brake noise andgood in heat dissipation performance.

Owner:WUHAN UNIV OF TECH

Automatic oil outlet bolt

The invention discloses an automatic oil outlet bolt which comprises a bolt body. A bolt head and a screw are connected with each other to form the bolt body, and an oil storage groove is formed inside the screw; the oil storage groove is filled with lubricating oil; oil outlet holes which are communicated with the oil storage groove are axially formed in the screw; the oil outlet holes comprise oil inlet flow channels and oil outlet flow channels; the oil inlet flow channels are communicated with the oil outlet flow channels; each oil outlet hole comprises the two corresponding labyrinth oil outlet flow channels; a piston is arranged at an opening of the oil storage groove; a cylinder is arranged in the bolt head; an end of a telescopic rod of the cylinder is connected with the piston; a switch for controlling the cylinder is arranged on the outer surface of the bolt head. The automatic oil outlet bolt has the advantages that the automatic oil outlet bolt is simple in operation, convenient to use and high in oil outlet and lubrication efficiency; each oil outlet hole comprises the two corresponding labyrinth oil outlet flow channels, accordingly, the lubricating oil can be prevented from leaking when stored in the oil storage groove, and lubrication effects of the lubricating oil can be guaranteed when the automatic oil outlet bolt is used.

Owner:SUZHOU SHUNYI HARDWARE

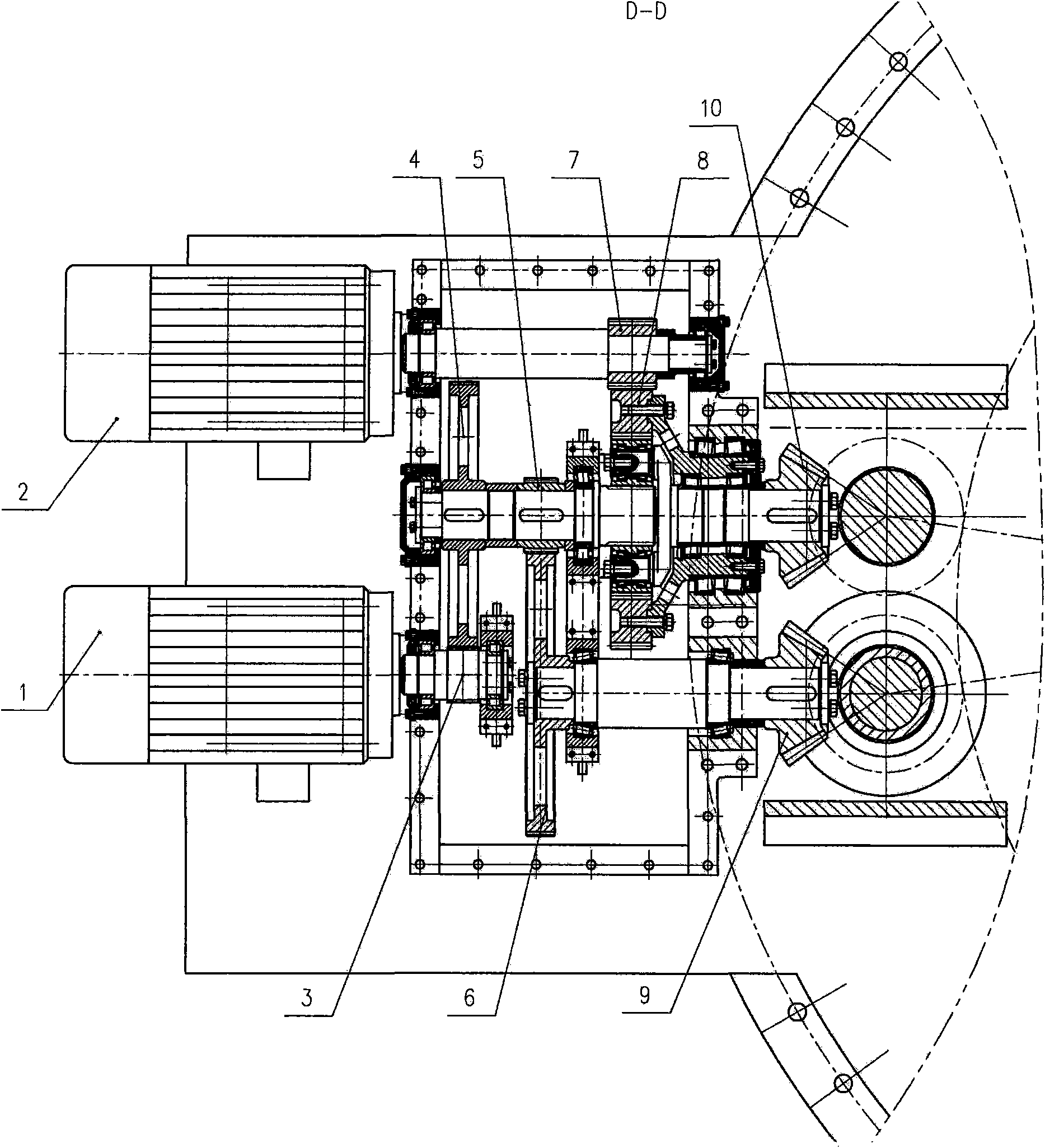

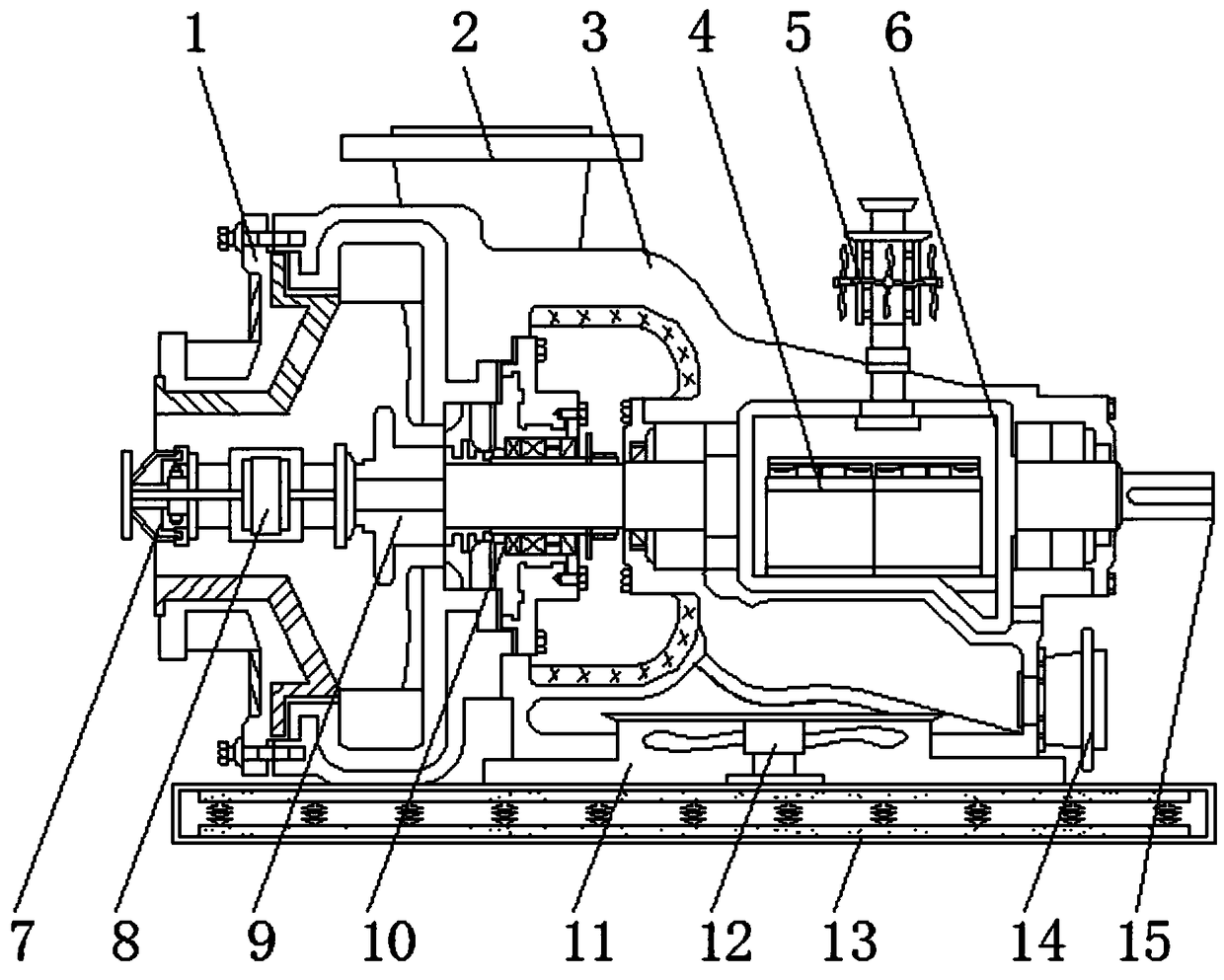

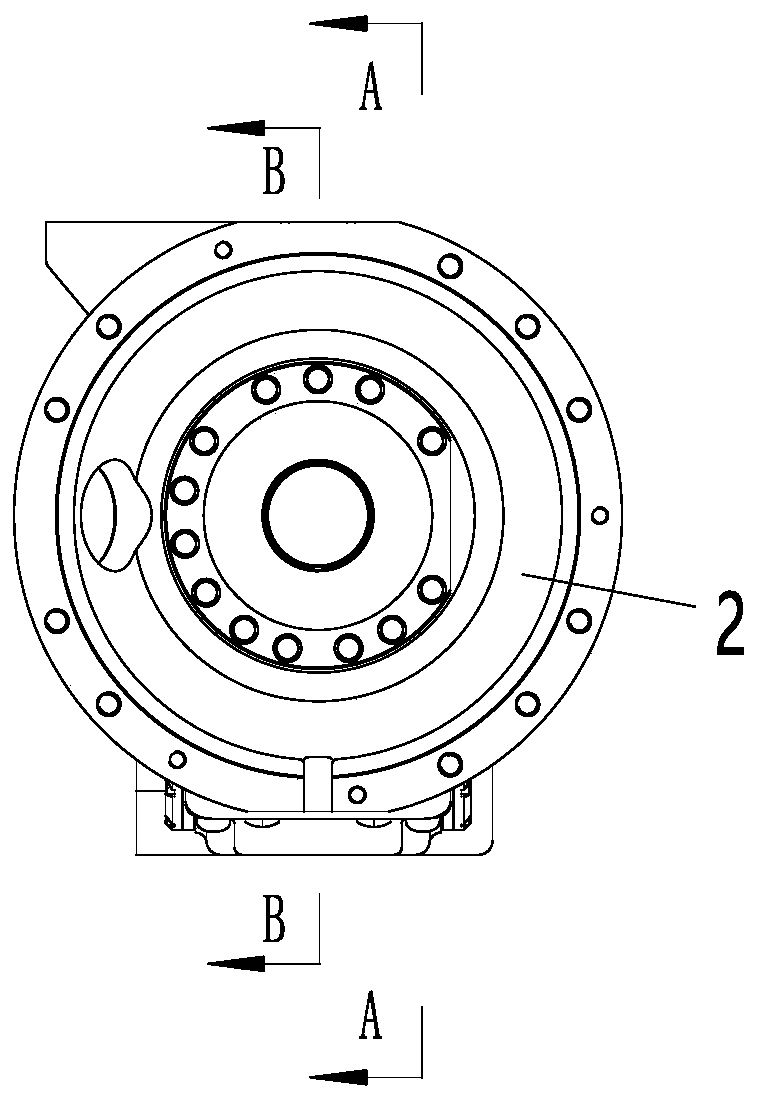

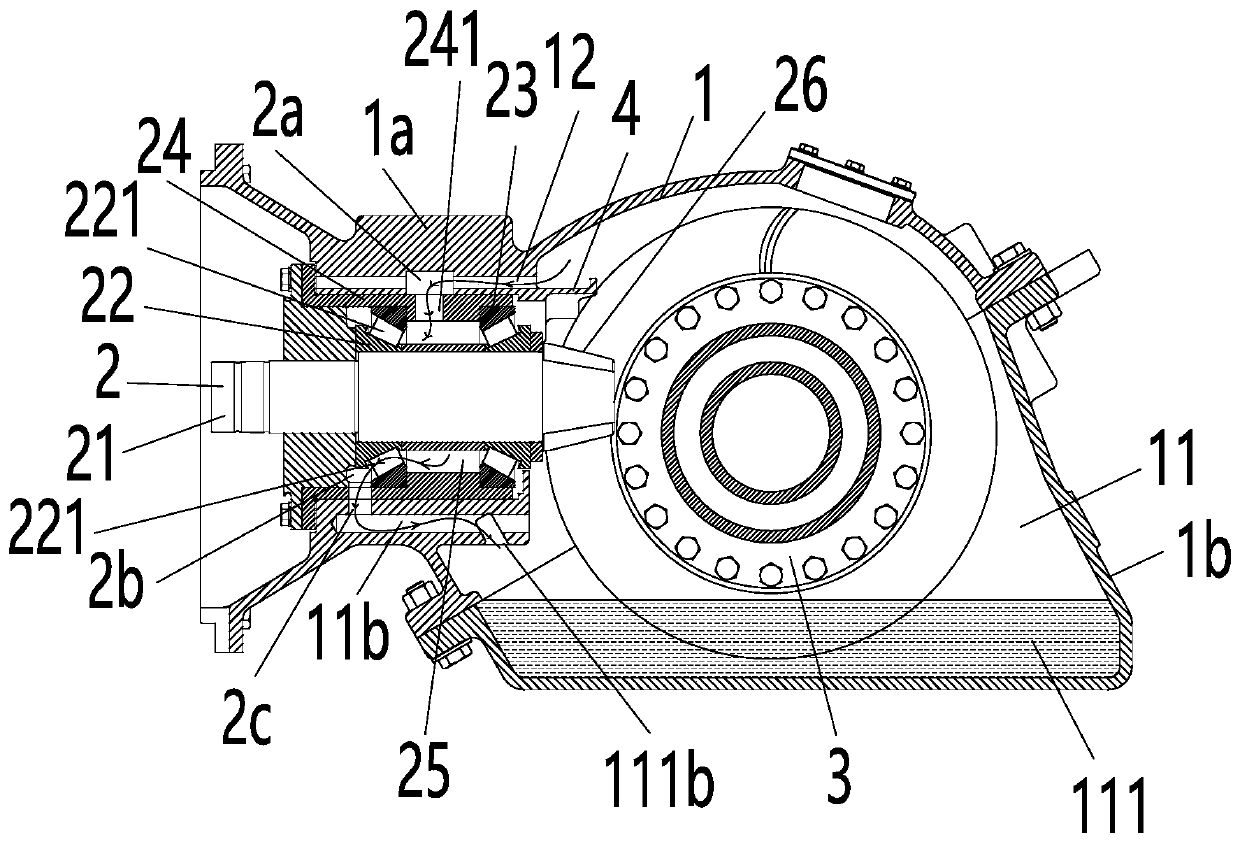

Cantilever centrifugal compressor

ActiveCN105298871AImprove stabilityCompact structurePump componentsPump installationsVertical planeDrive shaft

The invention discloses a cantilever centrifugal compressor which comprises a shell, a motor, an impeller driven by the motor to rotate, a transmission assembly and a lubricating oil way system symmetric about the vertical plane left and right. An output shaft of the motor is supported in the shell through two first bearings which are axially spaced. The transmission assembly is connected with the output shaft. A transmission shaft of the transmission assembly is supported in the shell through two second bearings which are axially spaced. The transmission shaft is sleeved with the impeller. The transmission shaft and the output shaft are located in the same vertical plane. The lubricating oil way system is arranged in the shell and used for lubricating the two first bearings and the two second bearings. According to the cantilever centrifugal compressor, the gravity center is located on the center plane, stability is high, the structure is compact, occupied space is small, the structure for supporting the shell is simple, the lubricating oil way system is simple, lubricating efficiency and reliability are high, the machining and assembling requirements of the transmission assembly are low, and cost is low.

Owner:CHONGQING MIDEA GENERAL REFRIGERATING EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com