Patents

Literature

116results about How to "Not easy to drip" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

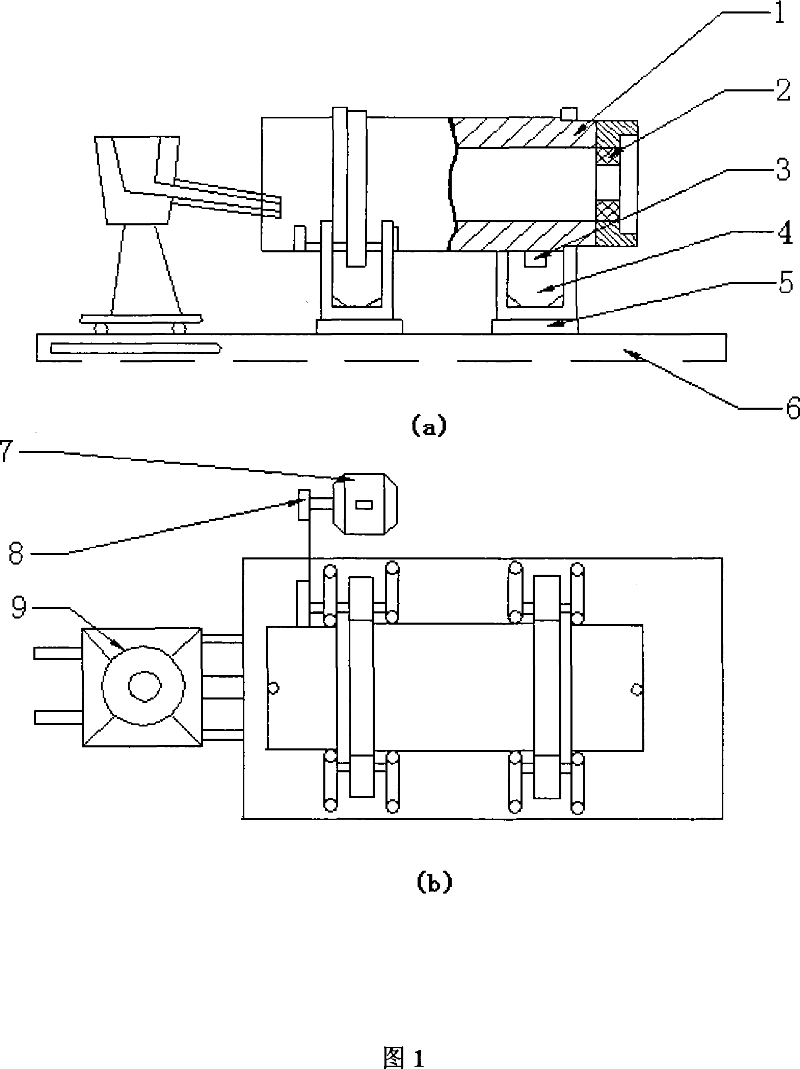

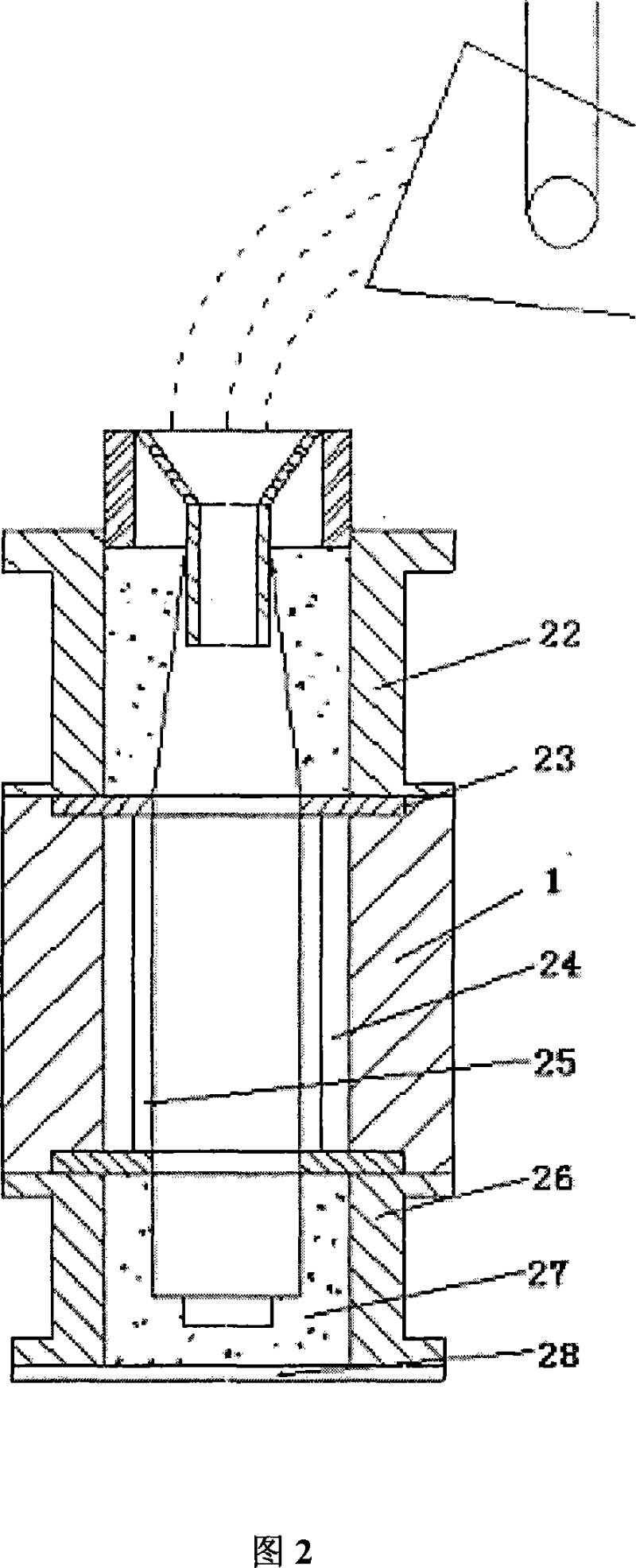

Low-aliquation high-speed steel roll and the preparing method

The invention discloses a low segregation centrifugal casting high speed steel roll and the method. The roll is constituted by high speed steel roll body and alloy ductile ion roll core. The roll is produced by electric furnace. The high speed steel roll body is cast on horizontal centrifuge. As the liquid steel is cast iron powder suspension concentrate with 4%-6% by weight of liquid steel is added. After the liquid steel is cast glass waste sludge is added and then it is cooled by spraying water to form the model. Meanwhile the rotate speed of casting model is changed continuously and finally the ductile ion roll core is cast at the top statically. There is no obvious element segregation in radial section of high speed steel roll manufactured in invention. The macro hardness of roll is high and can achieve 63-65HRC. The difference of roll face hardness is less than 2HRC. The hardness fall of roll along the radial direction is small. The tensile strength of roll body is more than 600MPa and the elongation of roll core is more than 3%. The service life is improved by 5-8 times than high chromium cast iron roll and is improved by 35%-48% than common high speed steel roll. It can decrease the producing cost of rolling steel and prolong roll changing period.

Owner:XI AN JIAOTONG UNIV

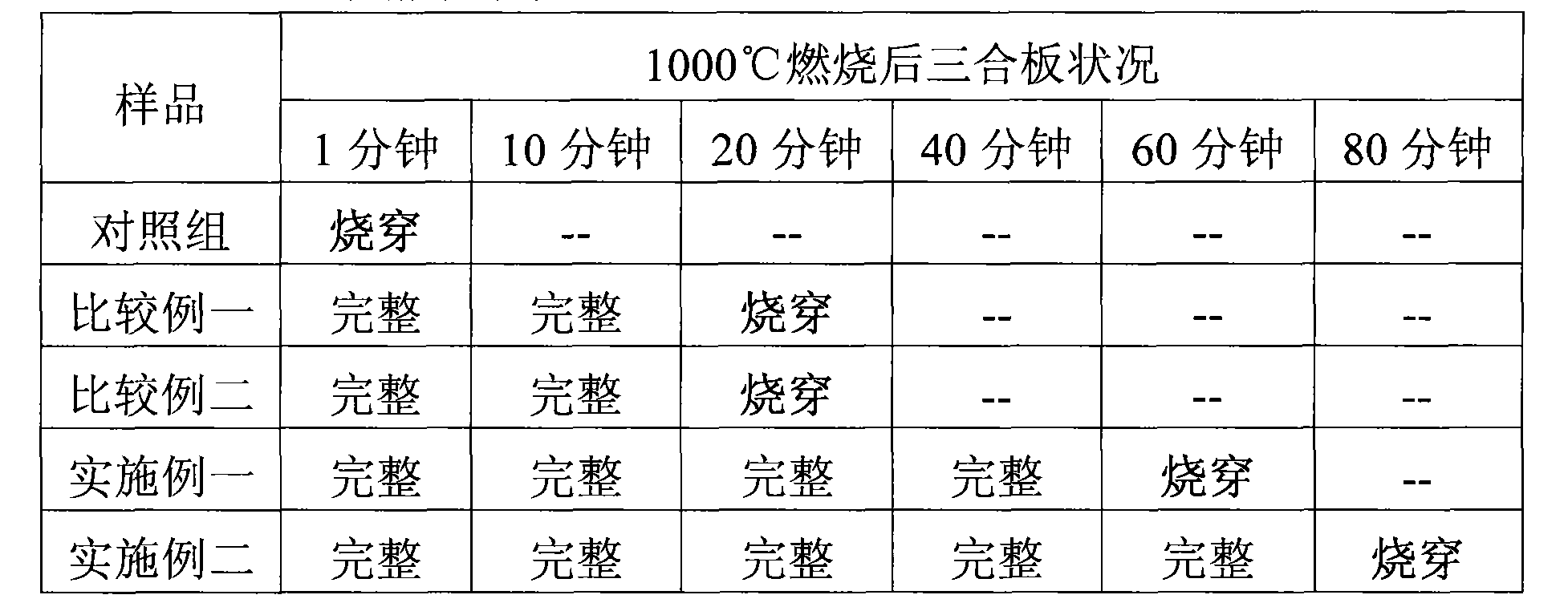

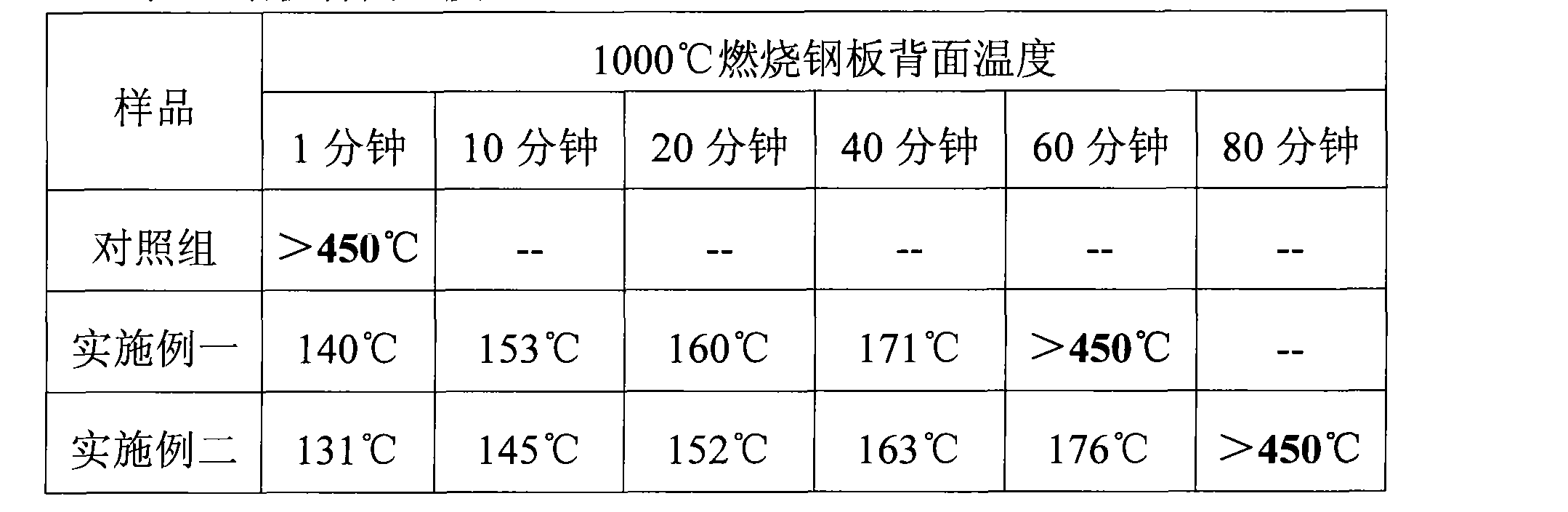

Transparent halogen-free fire-resisting paint constituent

InactiveCN101434760AImprove toughnessNot easy to crackFireproof paintsPolyurea/polyurethane coatingsSolventChemistry

The invention provides a transparent halogen-free fire-retardant paint composition, which consists of 100phr (Parts per Hundred of Resin) of adhesive, 50-400phr of solvent, 50-300phr of foaming agent, 10-200phr of carburetant, 1-100phr of carbonizing promoter and 0-100phr of auxiliary additive; wherein, the carbonizing promoter is a phosphorus-containing compound with reaction functional groups. A coat formed by the transparent halogen-free fire-retardant paint composition nearly generates no smoke when being heated but instantly generates an expanding layer of high toughness. The expanding layer is not likely to crack, does not melt, drop and droop and moreover, is capable of effectively obstructing oxygen and heat to fulfill fire-retardant effect. The paint composition has excellent compatibility and dispersibility among the ingredients, therefore has eminent transparency and can be used for the fire prevention of various buildings, furniture or in decoration without damaging the original appearance view thereof.

Owner:CHINA GENERAL PLASTICS

Carbon nano tube/chitosan mesoporous spherical composite material as well as preparation method thereof

ActiveCN103933949AWon't fall offEasy separationOther chemical processesAlkali metal oxides/hydroxidesCarbon nanotubeSpherical form

The invention relates to a carbon nano tube / chitosan mesoporous spherical composite material as well as a preparation method thereof. The preparation method of the spherical composite material comprises the following steps: (1) carrying out acid treatment and dispersion treatment on carbon nano tube raw materials; (2) preparing a chitosan solution with the degree of deacetylation of 80-100%; (3) adding the carbon nano tube which is treated by the step (1) into the chitosan solution obtained by the step (2), and mixing uniformly so as to a spherical liquid; (4) dissolving alkaline solute into water so as to obtain a solidified liquid; (5) dropwise adding the spherical liquid into the solidified liquid so as to prepare a composite sphere; (6) placing the composite sphere generated by the step (5) into a crosslinking agent solution to crosslink, and stirring so as to obtain a crosslinking composite sphere; (7) refrigerating and drying the crosslinking composite sphere obtain by the step (6) so as to obtain the carbon nano tube / chitosan mesoporous spherical composite material. The carbon nano tube / chitosan mesoporous spherical composite material disclosed by the invention is nontoxic, and has favorable adsorption performance.

Owner:梁吉 +1

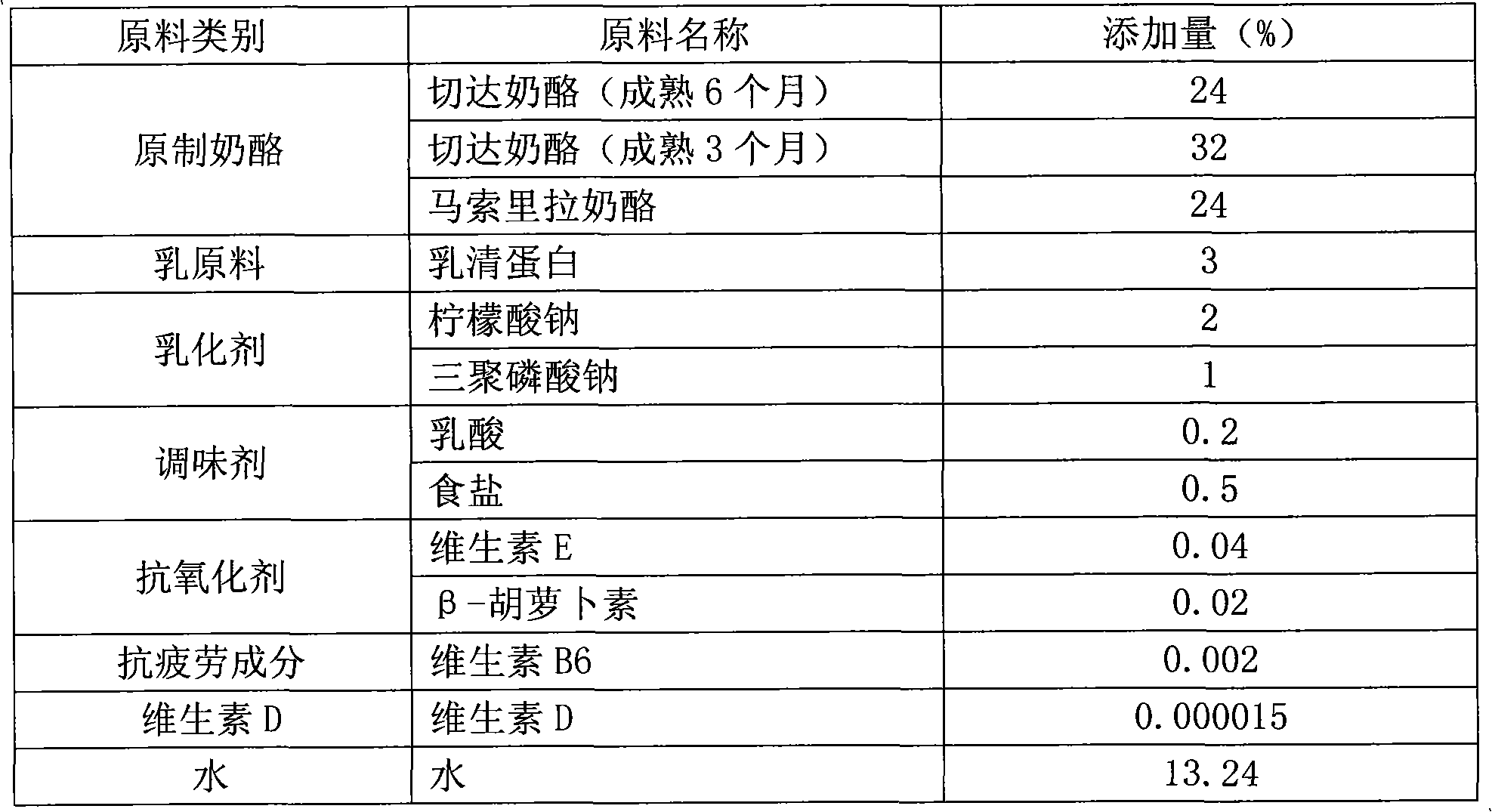

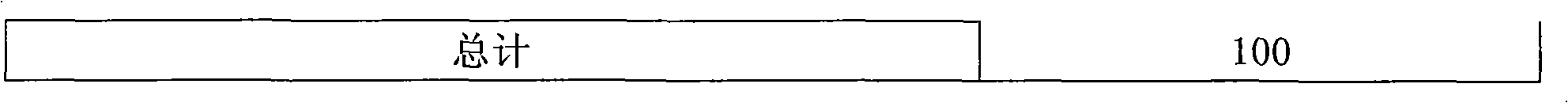

Special processed cheese for astronauts and production method thereof

ActiveCN102100259AMeeting nutritional needsExtended working hoursCheese manufactureBiotechnologyAntioxidant

The invention discloses a special processed cheese for astronauts and a production method thereof. The special processed cheese for astronauts comprises the following components in percentage by weight: 50 to 80 percent of raw cheese, 3 to 16 percent of milk raw materials, 1 to 3 percent of emulsifying agent, 0.1 to 2.0 percent of antioxidant, 0.000010 to 0.000025 percent of vitamin D, 0.002 to 0.4 percent of anti-fatigue component and 10 to 30 percent of water. The processed cheese is specially designed for the astronauts to eat in the space, can meet the special nutrition requirements of the astronauts during working and living in the space, and contains high-quality protein, calcium source, vitamin D, antioxidant and anti-fatigue component; and the adopted special processing technologyensures that the product has stable quality and is safe and reliable.

Owner:BRIGHT DAIRY & FOOD CO LTD

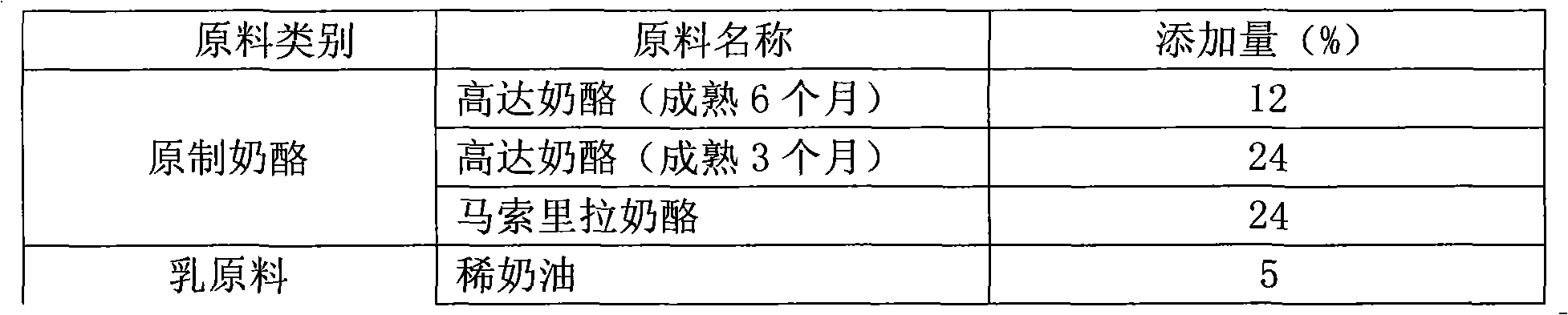

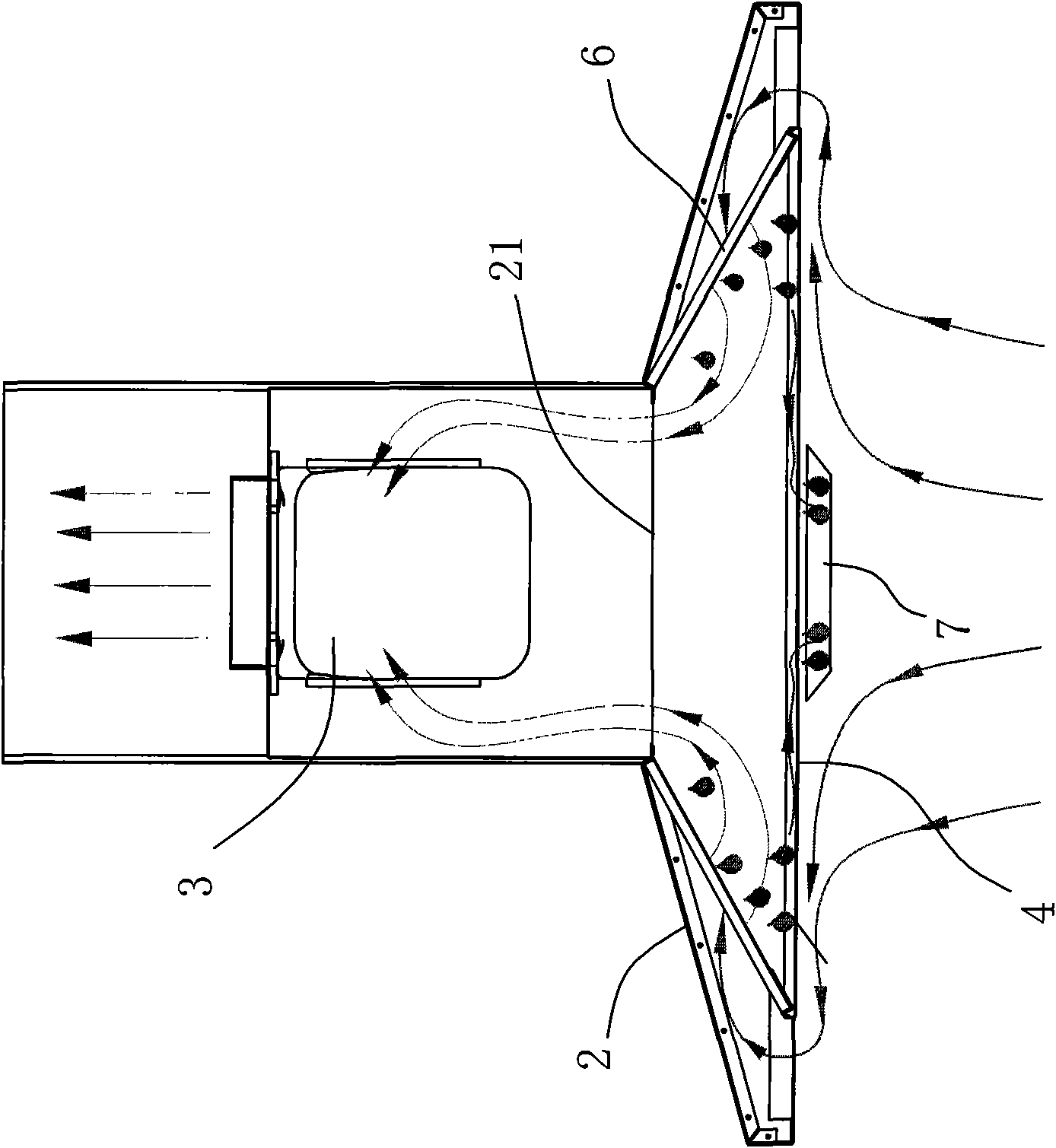

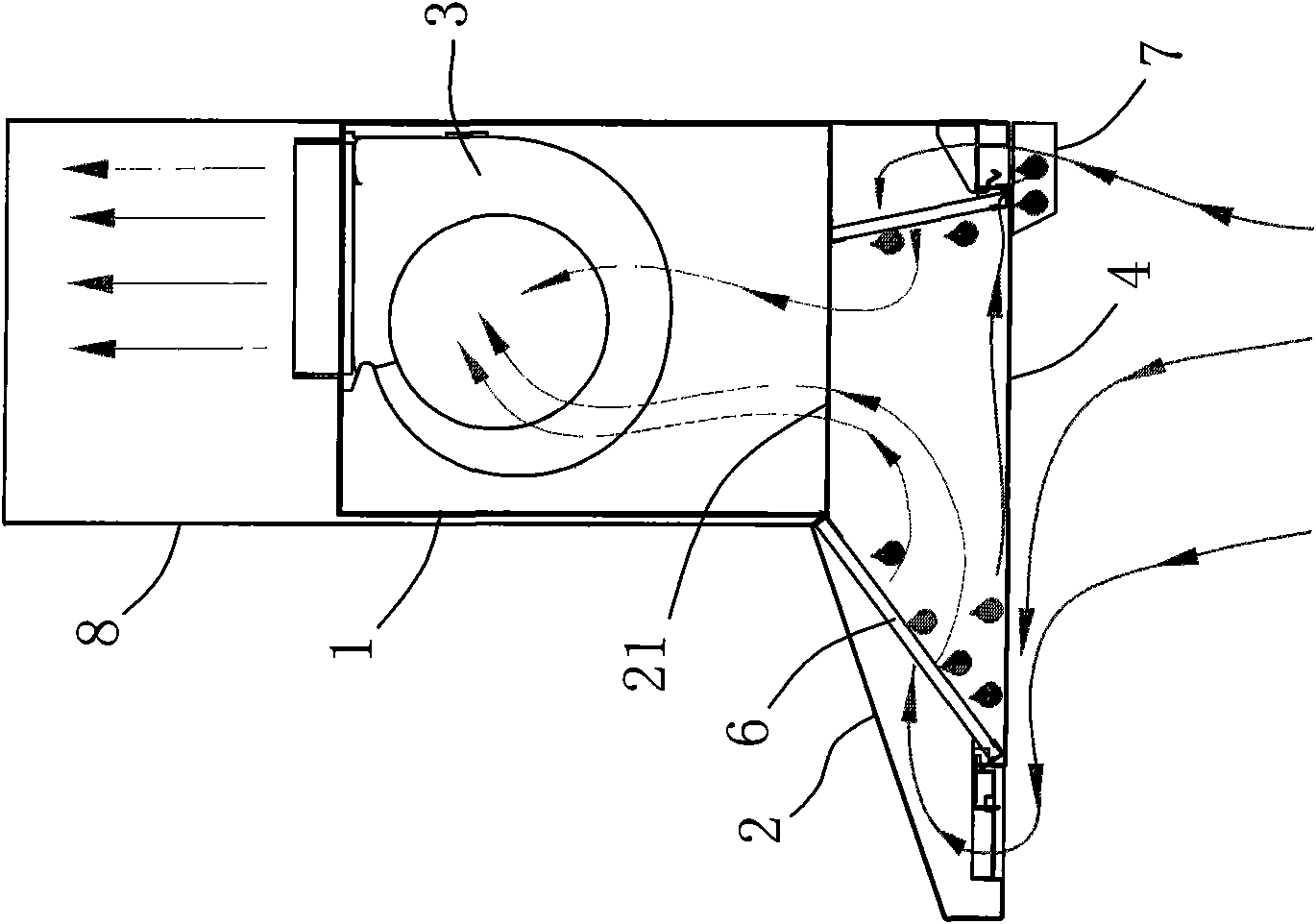

Range hood unsusceptible to residing oil stain on filter device

InactiveCN101592352AIncrease the areaGood oil filterDomestic stoves or rangesDispersed particle filtrationEngineeringFume hood

The invention discloses a range hood unsusceptible to residing oil stain on a filter device, which comprises a fan body and a fume collecting hood arranged below the fan body. The fume hood is provided with an air inlet which is provided with an oil fume filter device. The range hood is characterized in that an oil deflector which reserves a preset distance with the end face of the air inlet of the fume collecting hood is arranged below the air inlet; the oil fume filter device is arranged between the air inlet and the oil deflector; and the oil fume filter device is of a shape with a large upper part and a small lower part. A filter screen is insusceptibility to oil accumulation, thereby enlarging the area of wind field, improving the oil fume adsorption effect, effectively reducing noise of entire machine and achieving core filtering and low emission. The range hood is particularly suitable for a household range hood.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

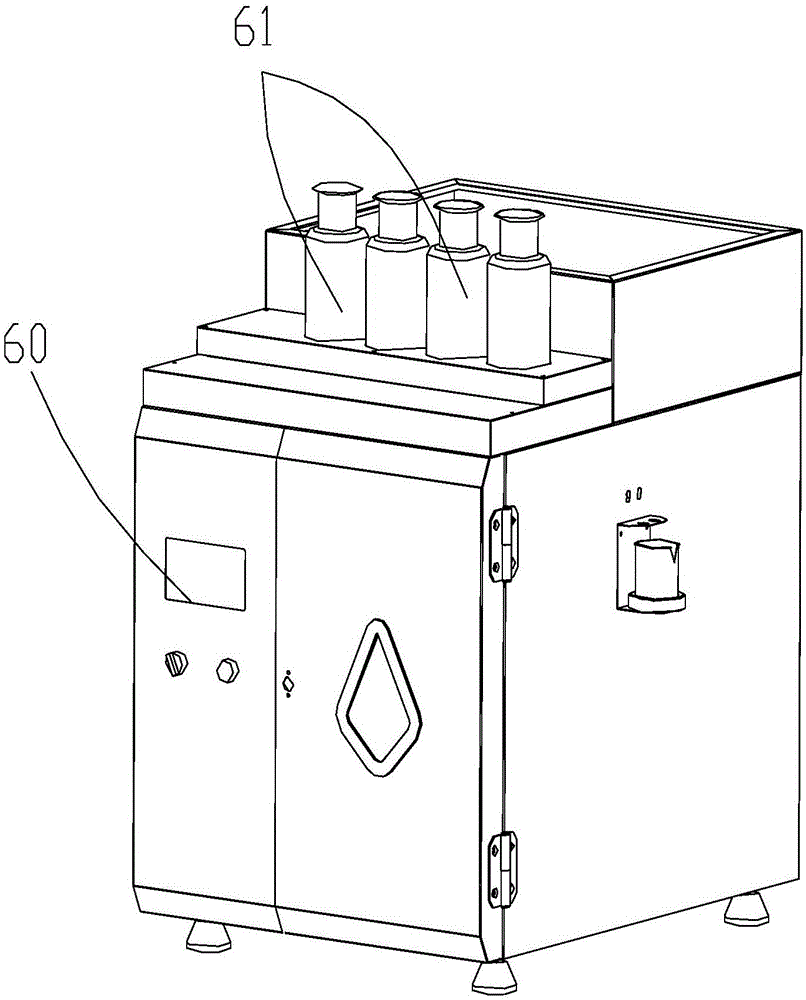

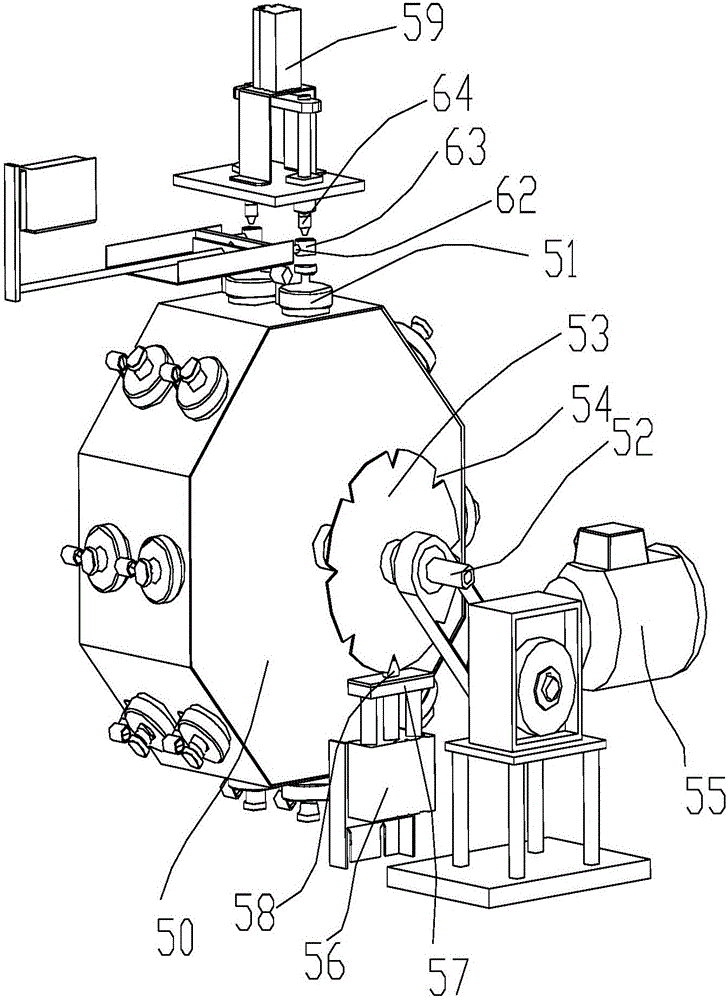

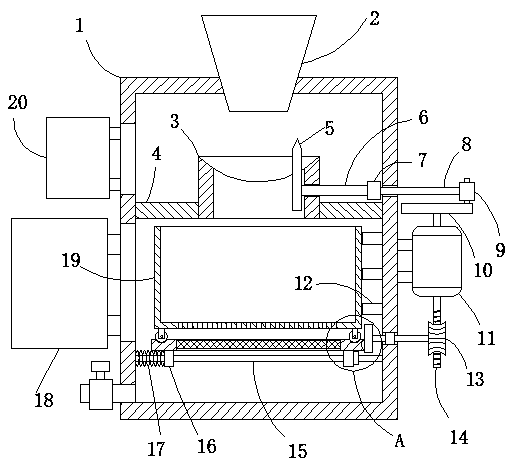

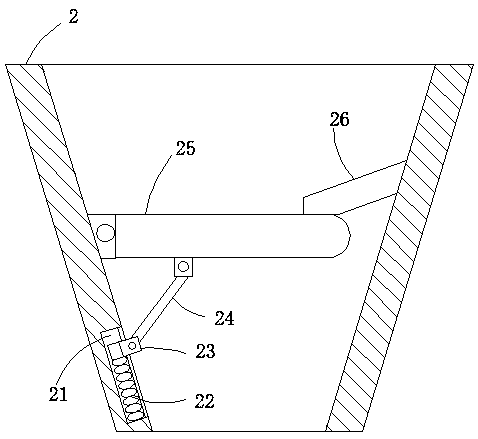

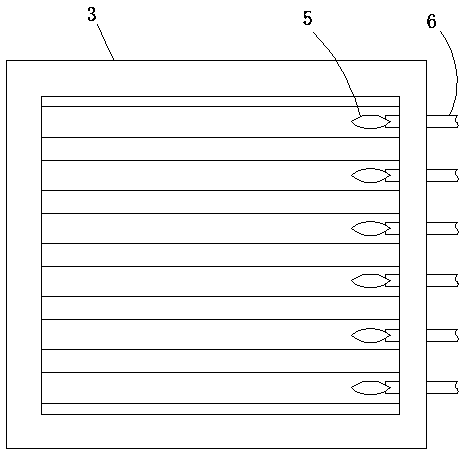

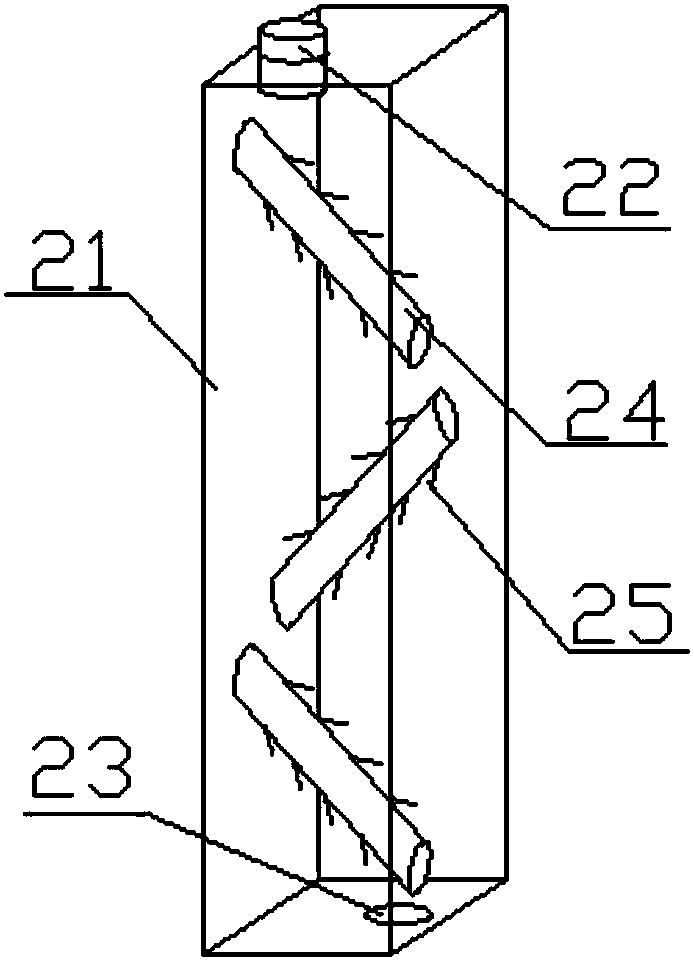

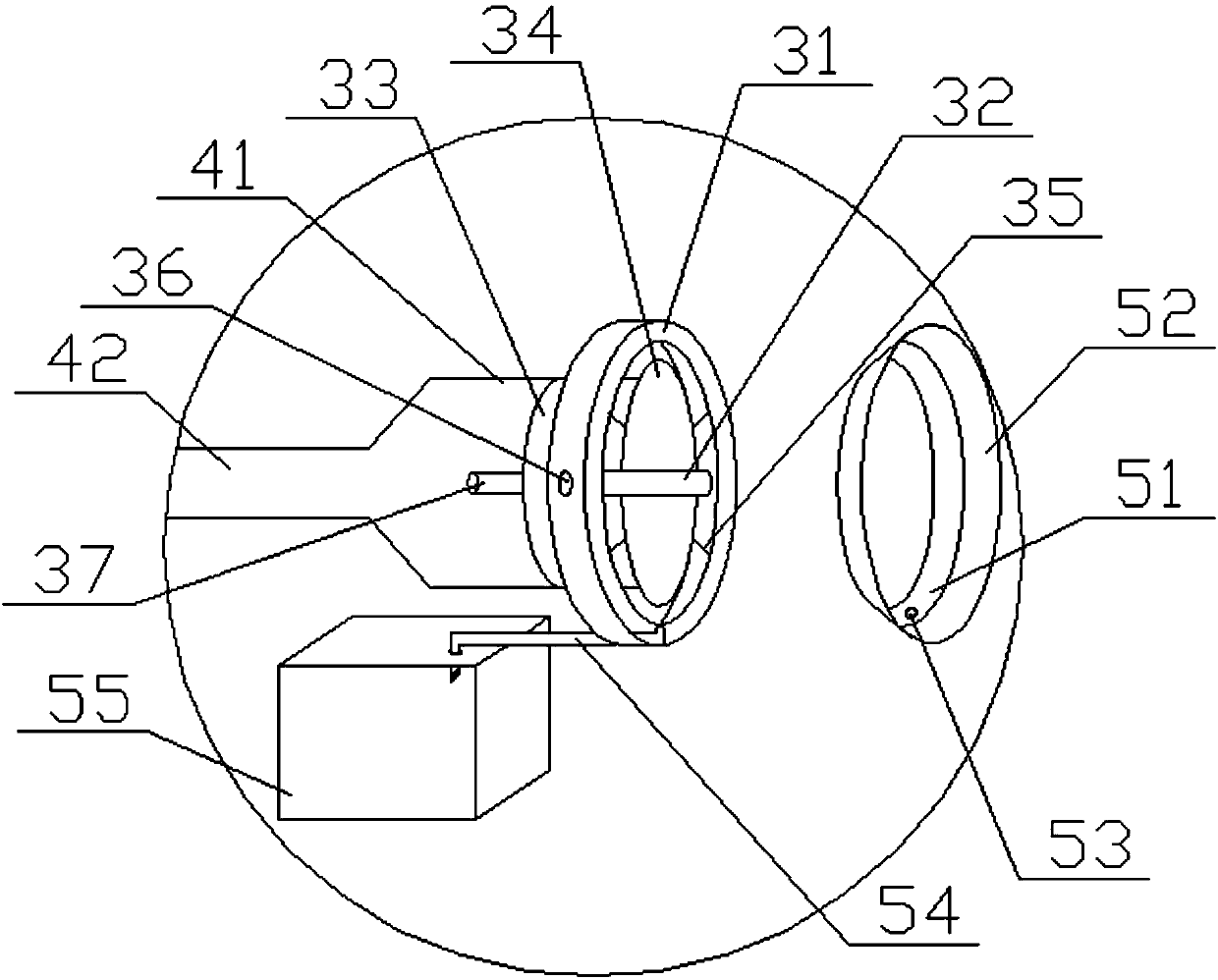

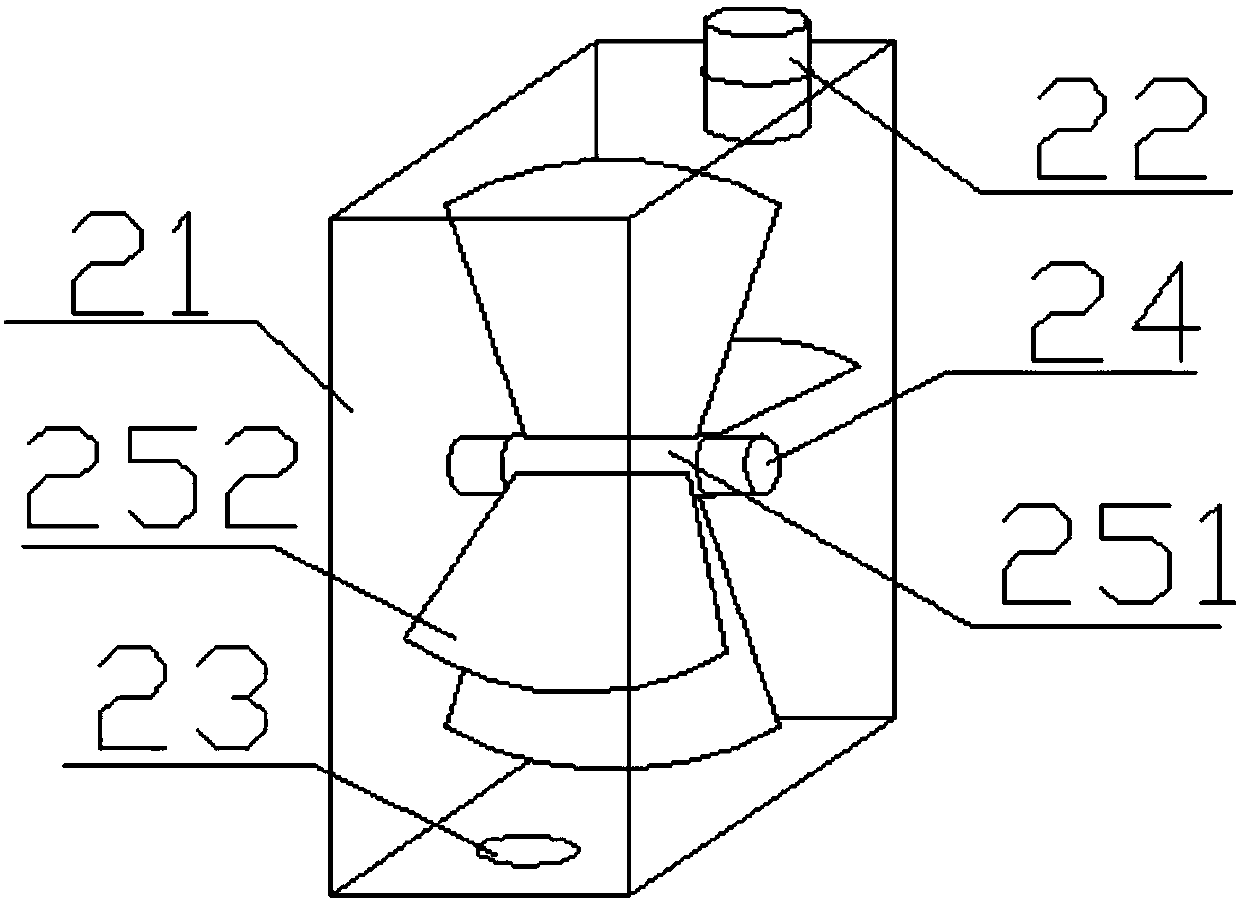

Color testing machine capable of achieving automatic charging and using method thereof

ActiveCN105970529AImplement auto-joinReduce human errorTextile treatment dyeing devicesEngineeringHuman error

The invention discloses a color testing machine capable of achieving automatic charging. The color testing machine comprises a shell, a rotating mechanism, dyeing cups, an auxiliary charging mechanism and a data processor; a containing cavity is formed in the shell; the rotating mechanism comprises a rotating cage and a power mechanism, the rotating cage is a three-dimensional component formed by drawing a n-regular polygon, and the side walls of the rotating cage are each provided with internally-concaved containing grooves; the dyeing cups are arranged in the containing grooves; each cup lid comprises a movable shaft which can vertically move, and each movable shaft is provided with a charging port and discharging ports; each material injecting cup is provided with holes and connected with the bottom wall of the corresponding cup lid; cup bodies are connected with the cup lids in a matched mode; when the movable shafts are pressed, the discharging ports of the movable shafts enter the material injecting cups; the auxiliary charging mechanism comprises a flow pump and a first air cylinder, the flow pump is connected with sample charging needles which are opposite to the charging ports, and the first air cylinder is used for pushing the movable shafts; the rotating mechanism and the auxiliary charging mechanism are both controlled by the data processor. According to the color testing machine capable of achieving automatic charging, automatic auxiliary charging is achieved, human errors are reduced, and dyeing defects cannot be generated.

Owner:广州市鸿通机械有限公司

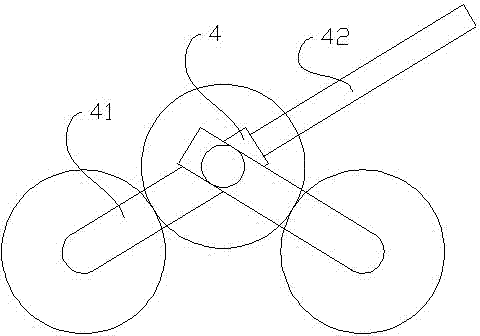

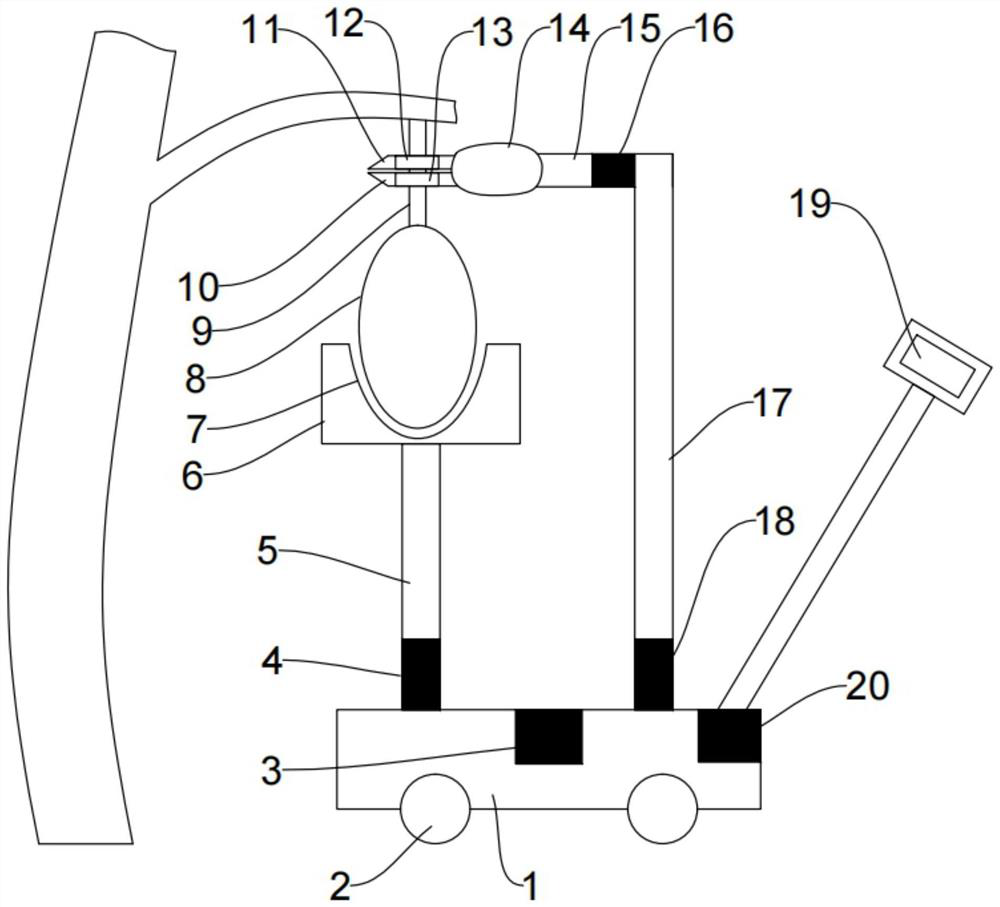

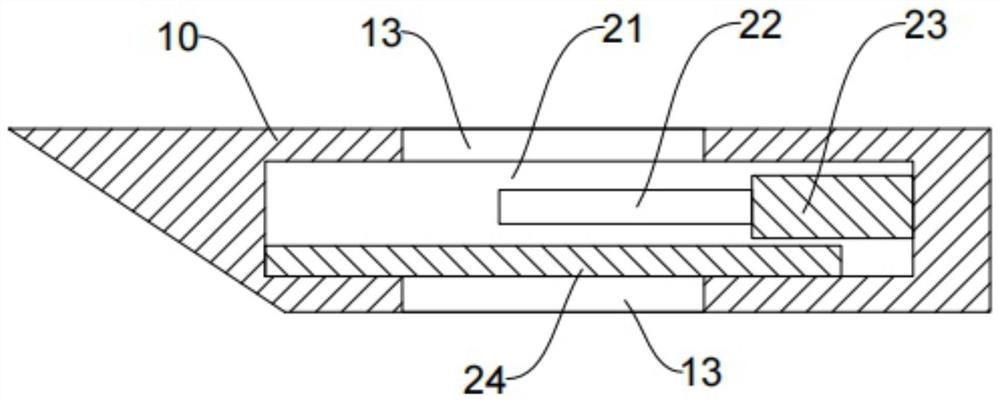

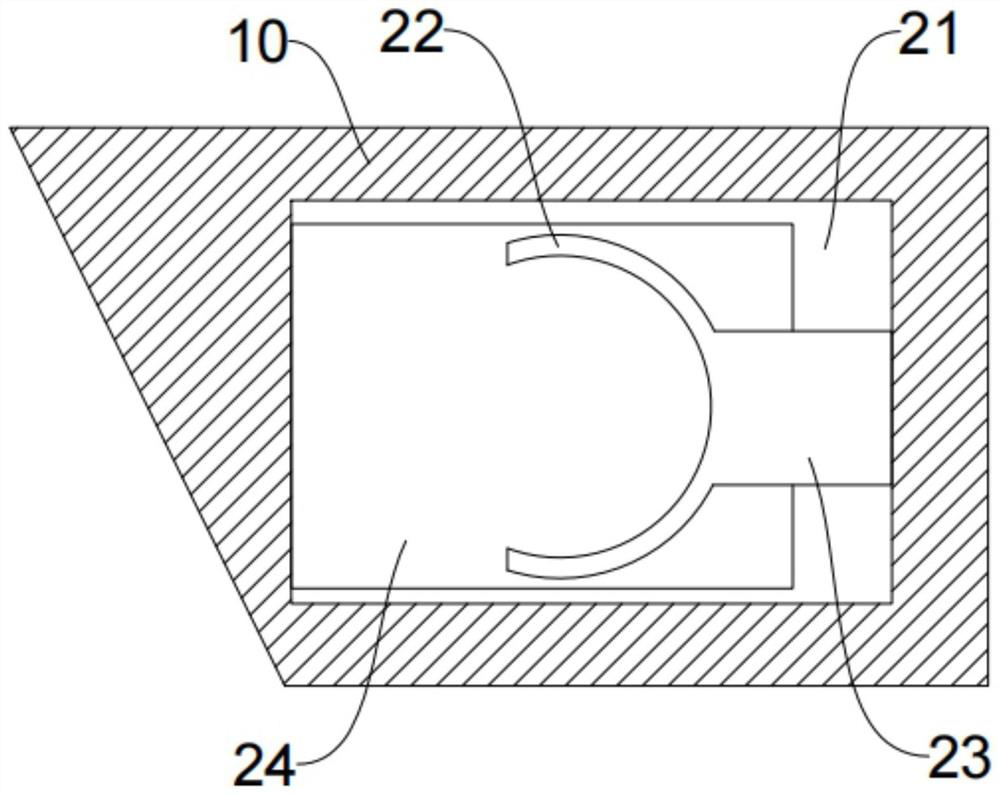

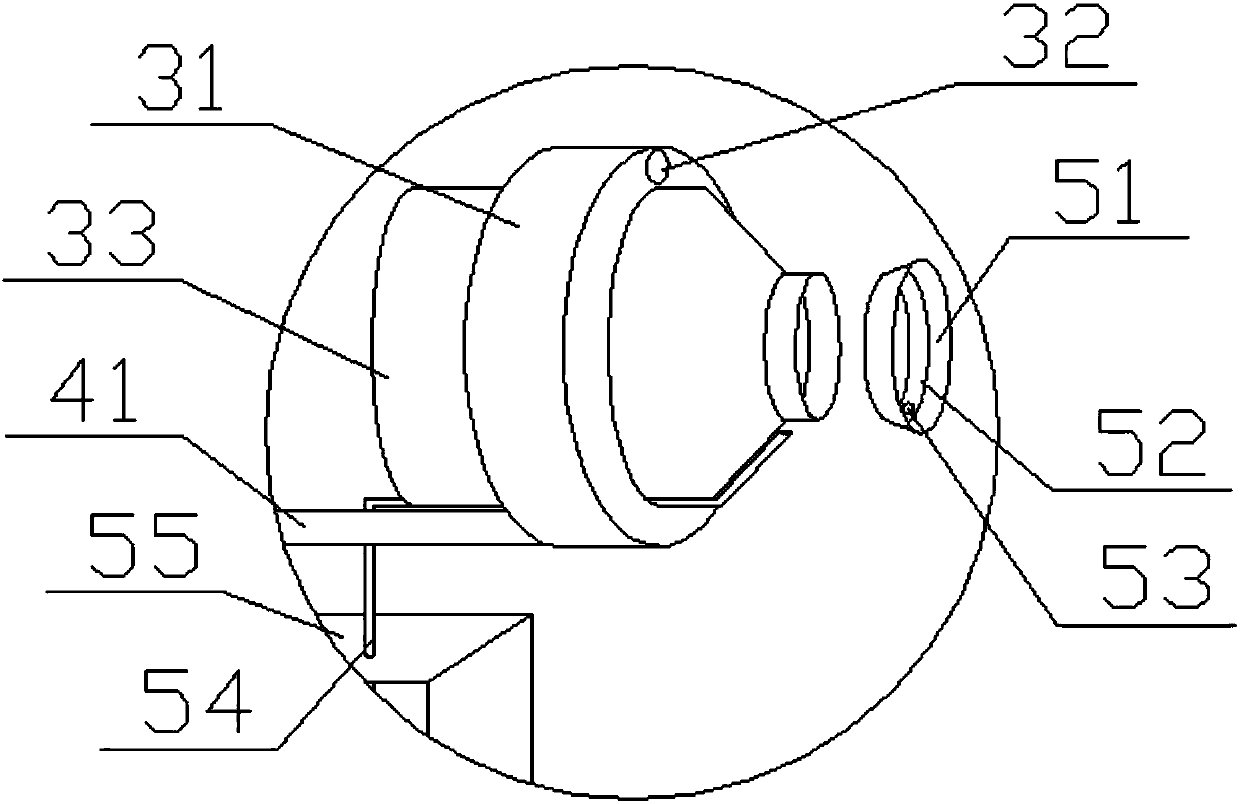

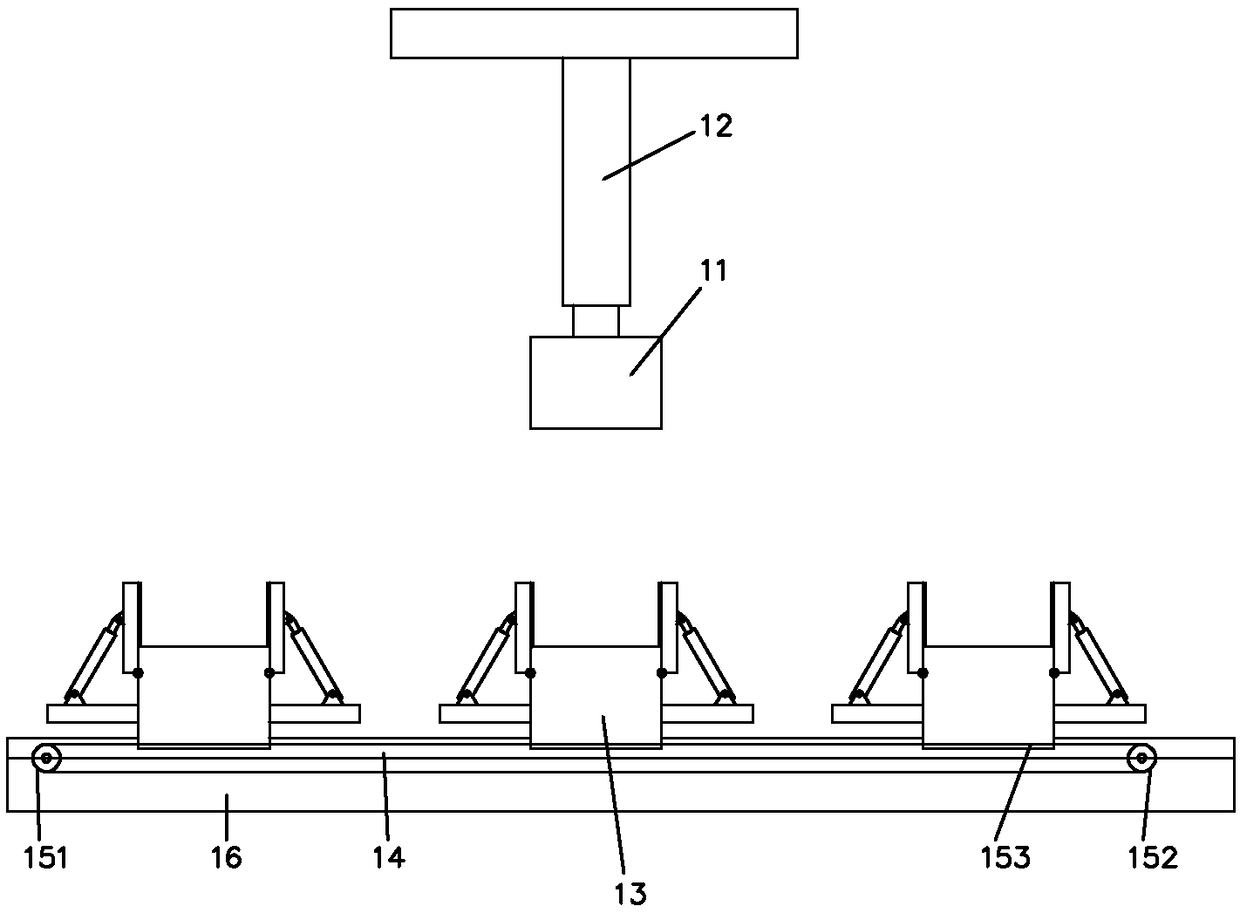

Chain lubrication device and forklift

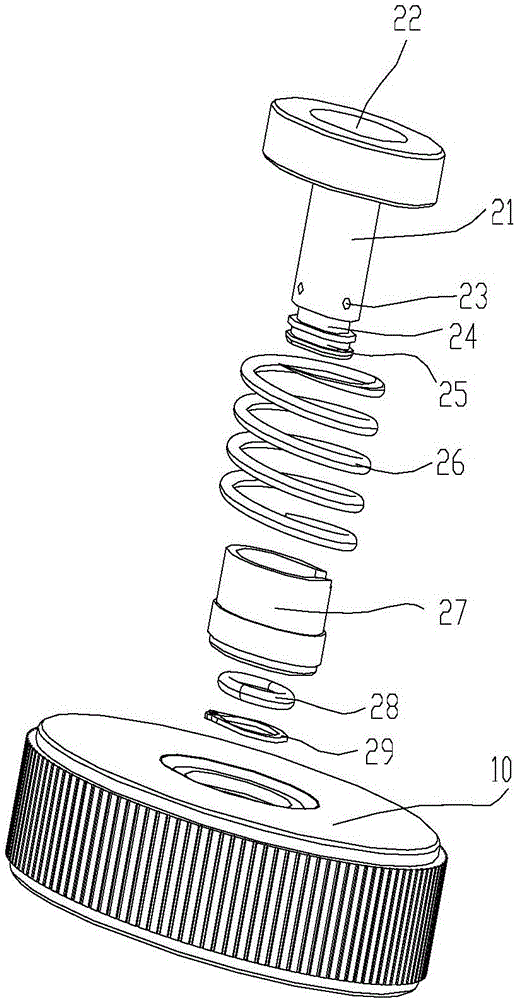

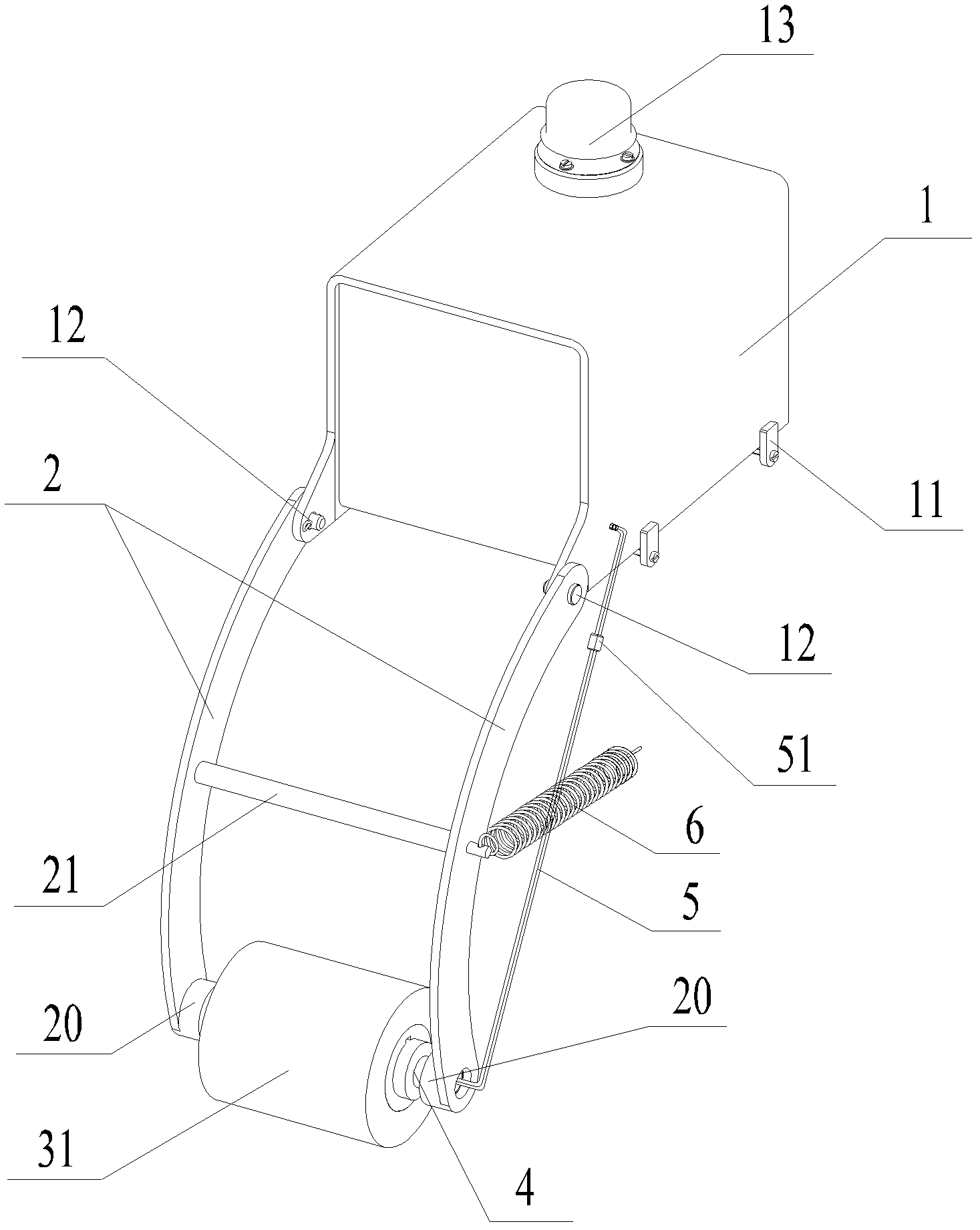

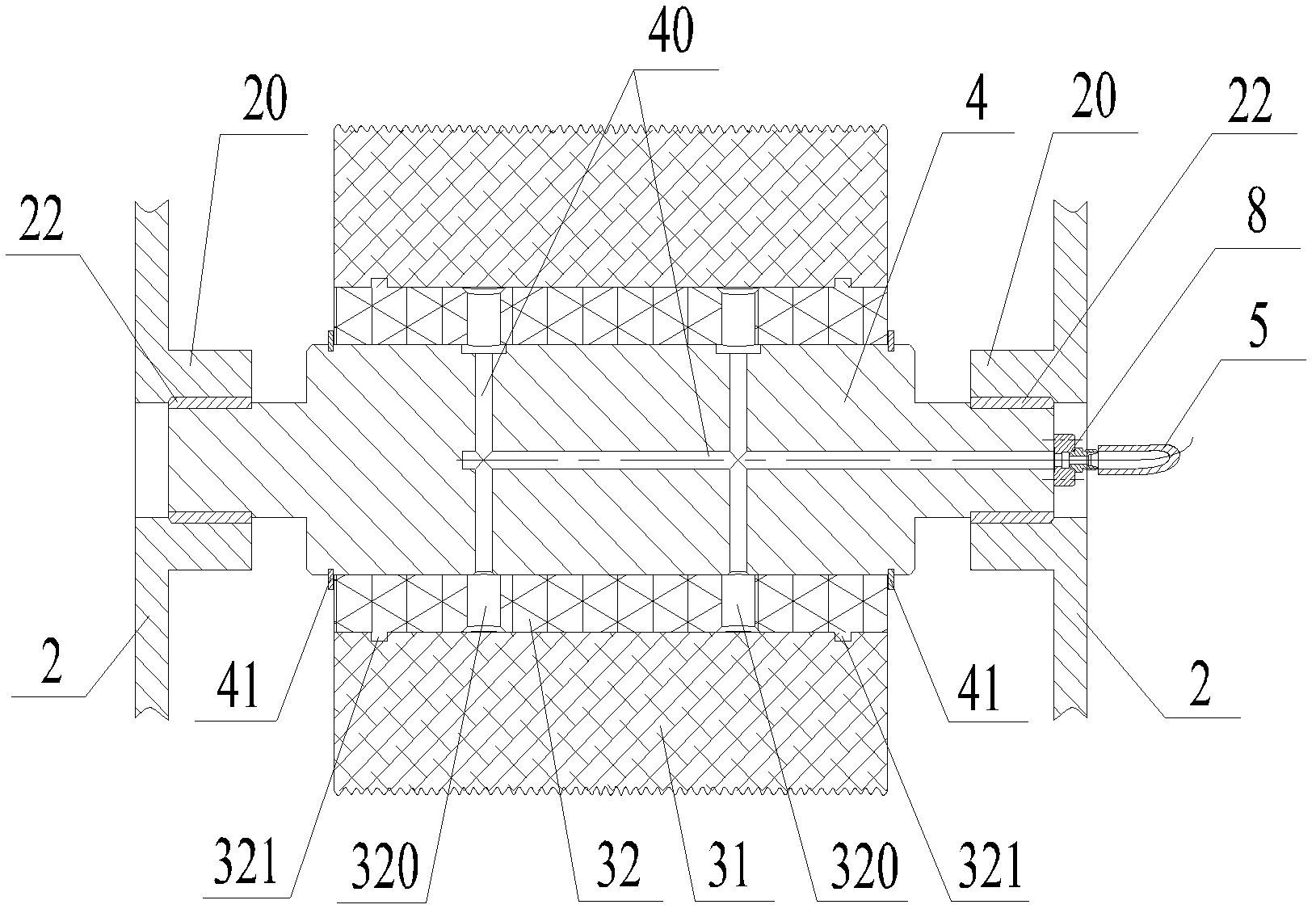

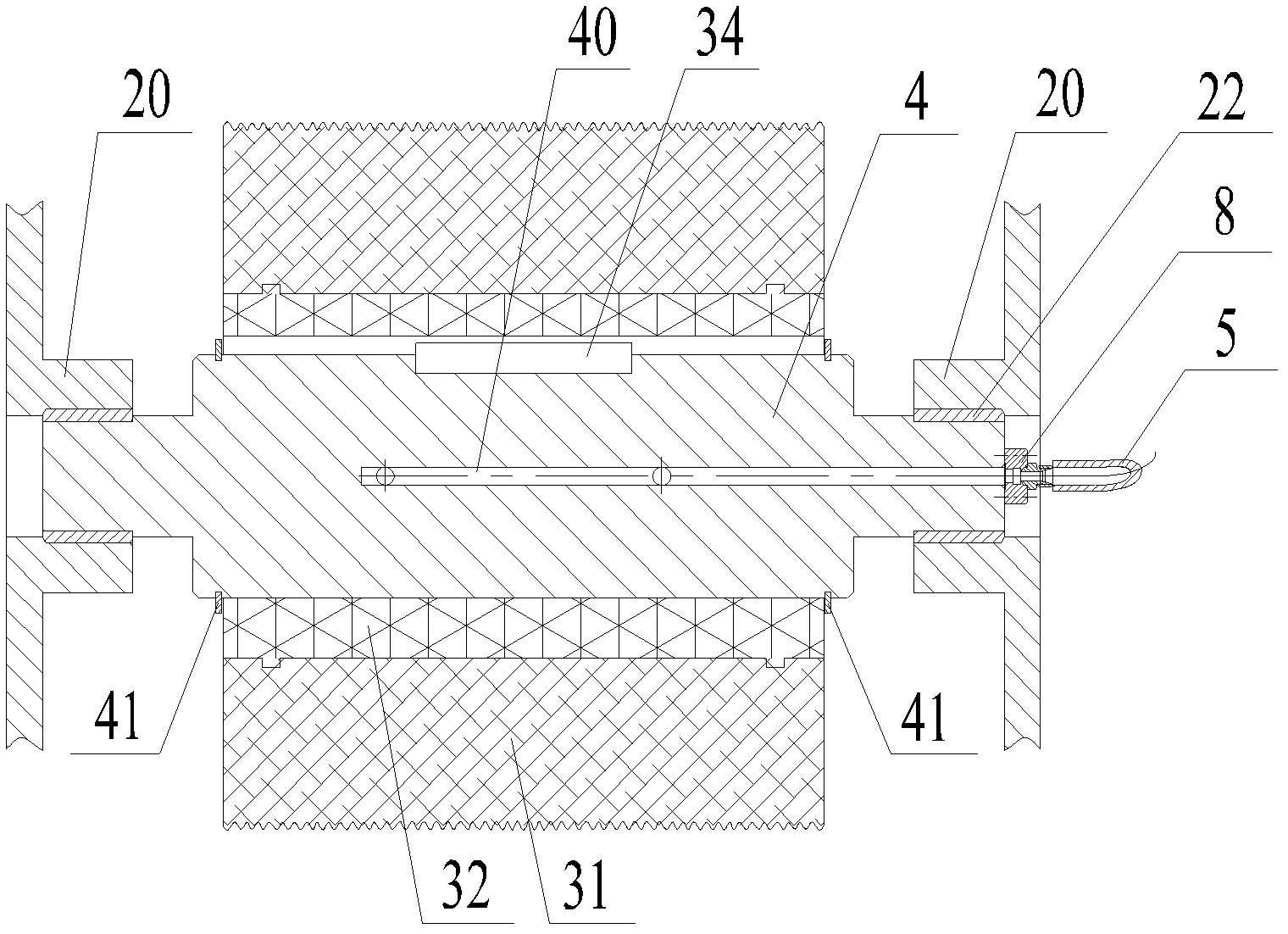

InactiveCN102616553ANot easy to dripEasy to cleanCleaningStacking articlesLubricationPetroleum engineering

The invention provides a chain lubrication device and a forklift. The chain lubrication device comprises a bracket, a central shaft and an oil sucking felt ring. The central shaft is supported by the bracket, the oil sucking felt ring is used for pressing and contacting with a chain and sleeved on the central shaft, a first oil guiding channel is disposed on the central shaft, an oil inlet of the first oil guiding channel is arranged on an end surface of the central shaft, the first oil guiding channel is communicated with a pressure lubricating oil source via an oil inlet pipe, and an oil outlet of the first oil guiding channel corresponds to the oil sucking felt ring. By the aid of the chain lubrication device, the chain can be automatically lubricated, lubrication efficiency is high, and cost is low. The invention further provides the forklift comprising the chain lubrication device.

Owner:SANY GRP

125 DEG C radiation-crosslinked, halogen-free, low-smoke, flame-retardant oil-resistant and cold-resistant cable material and preparation method thereof

InactiveCN108586908AHigh strengthHigh hardnessPlastic/resin/waxes insulatorsLow-density polyethyleneElastomer

The invention provides a 125 DEG C radiation-crosslinked, halogen-free, low-smoke, flame-retardant oil-resistant and cold-resistant cable material and a preparation method thereof. The cable materialcomprises the following components in parts by weight: 65 parts of base resin A, 35 parts of base resin B, 12-17 parts of a compatilizer, 150-190 parts of a flame retardant, 15-25 parts of methyl vinyl silicone rubber, 0.8-1.6 parts of an antioxidant, 0.4-0.8 part of a lubricant, 1.4-3 parts of a coupling agent, 15-20 parts of a reinforcing agent and 0.4-1 part of a crosslinking agent, wherein thebase resin A is a combination of ethylene-vinyl acetate (EVA) and a polyolefin elastomer (POE); the base resin B is a combination of the ethylene-vinyl acetate (EVA) and linear low-density polyethylene (LLDPE). The cable material provided by the invention has the characteristics of good temperature resistance, oil and cold resistance, aging resistance, superior mechanical properties and the like.The invention further provides the preparation method of the cable material.

Owner:杭州万瑞达新材料有限公司

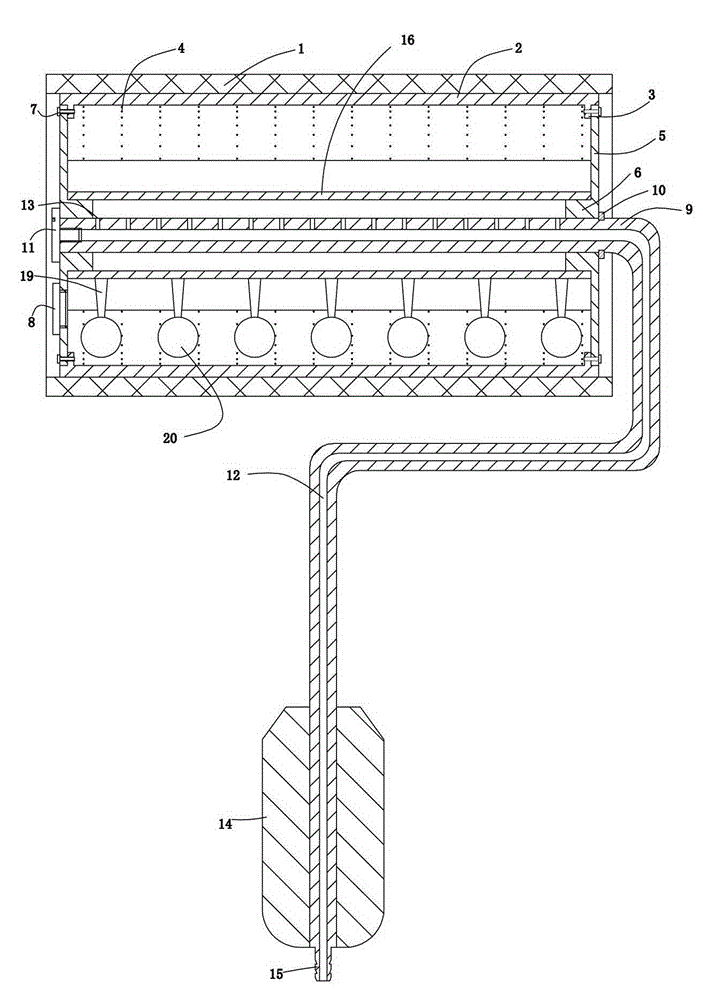

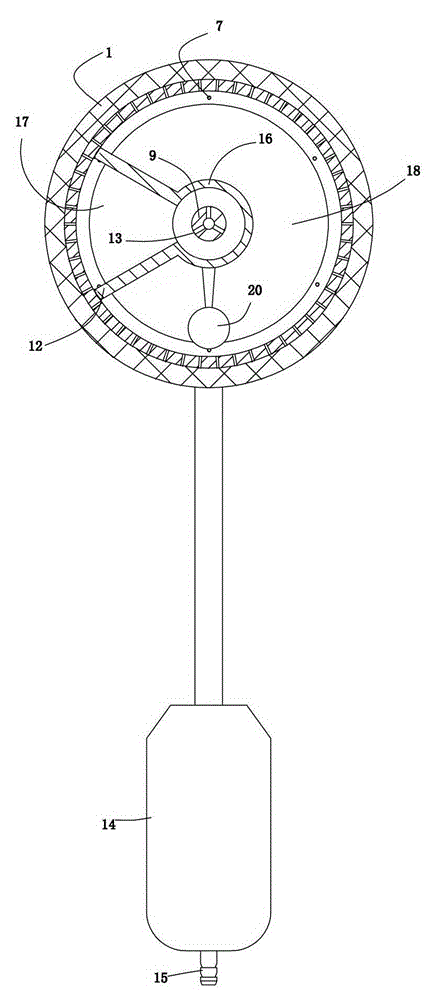

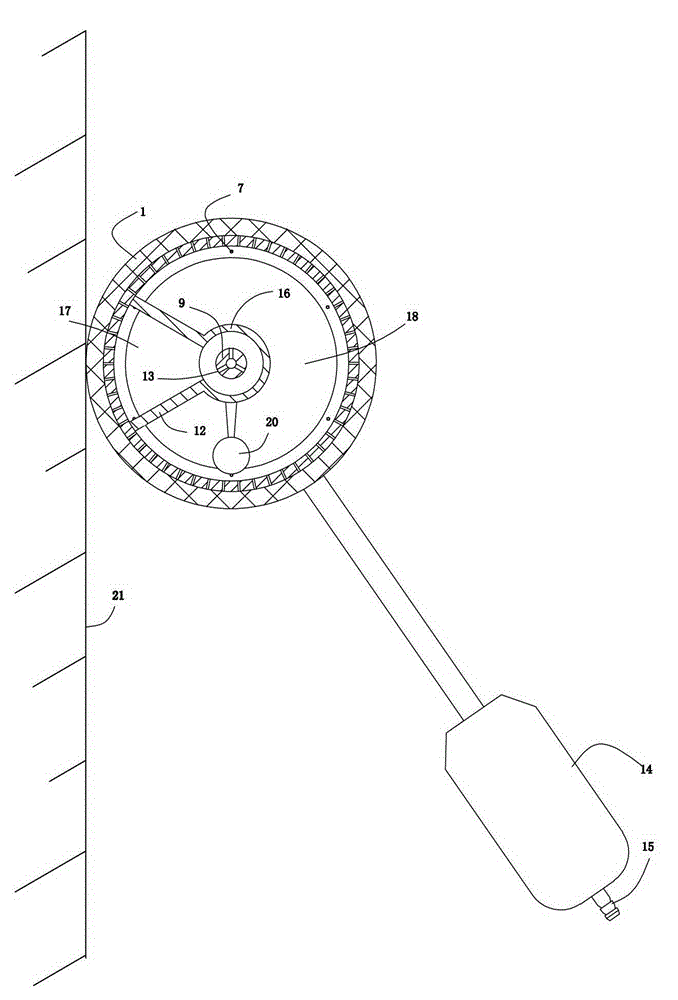

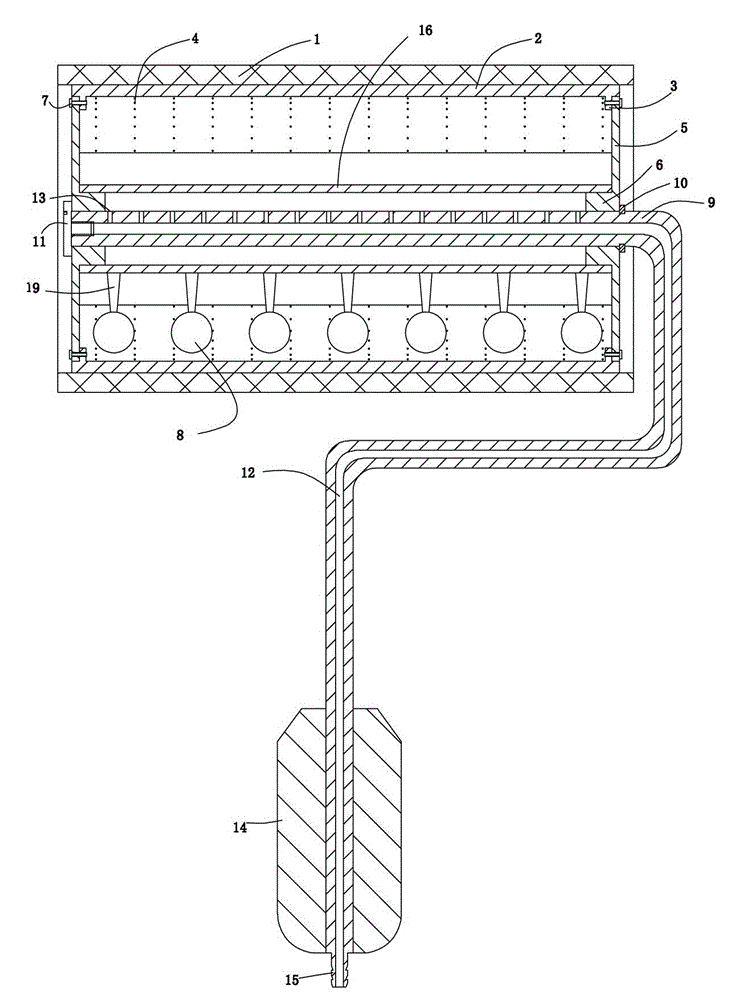

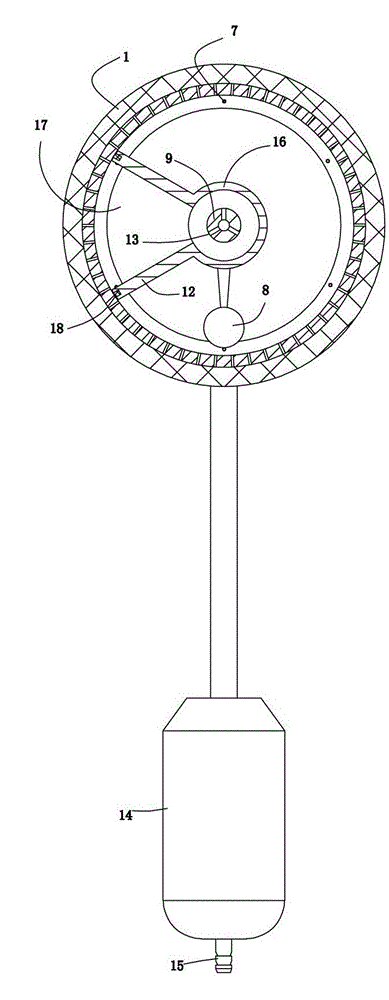

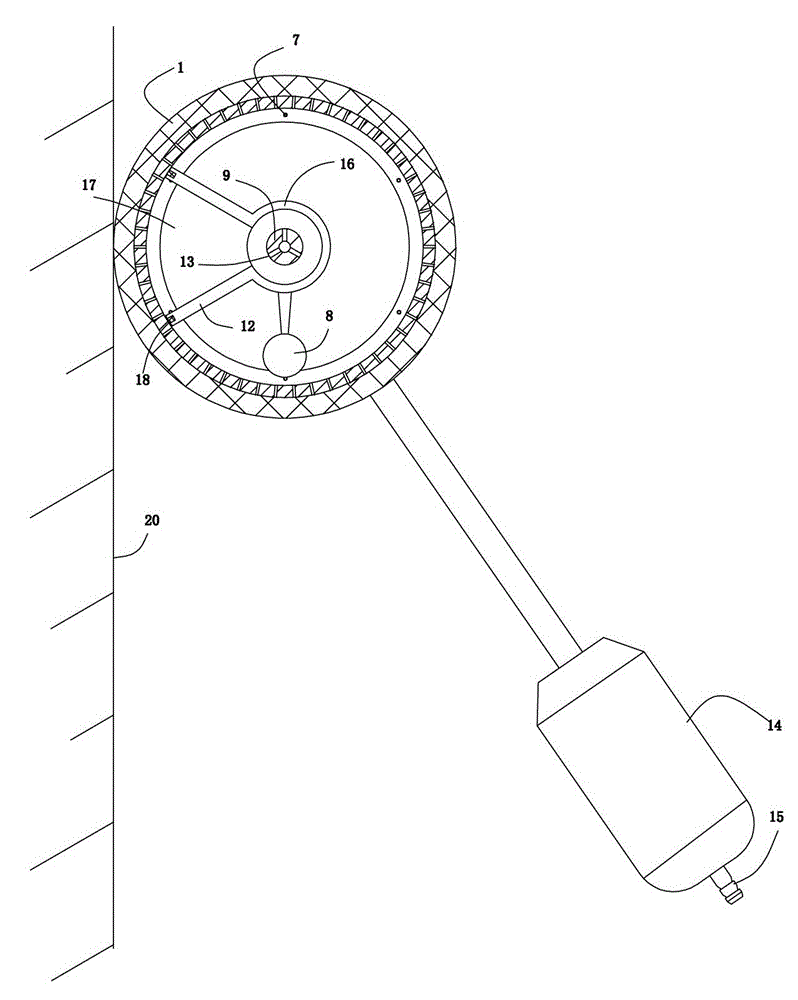

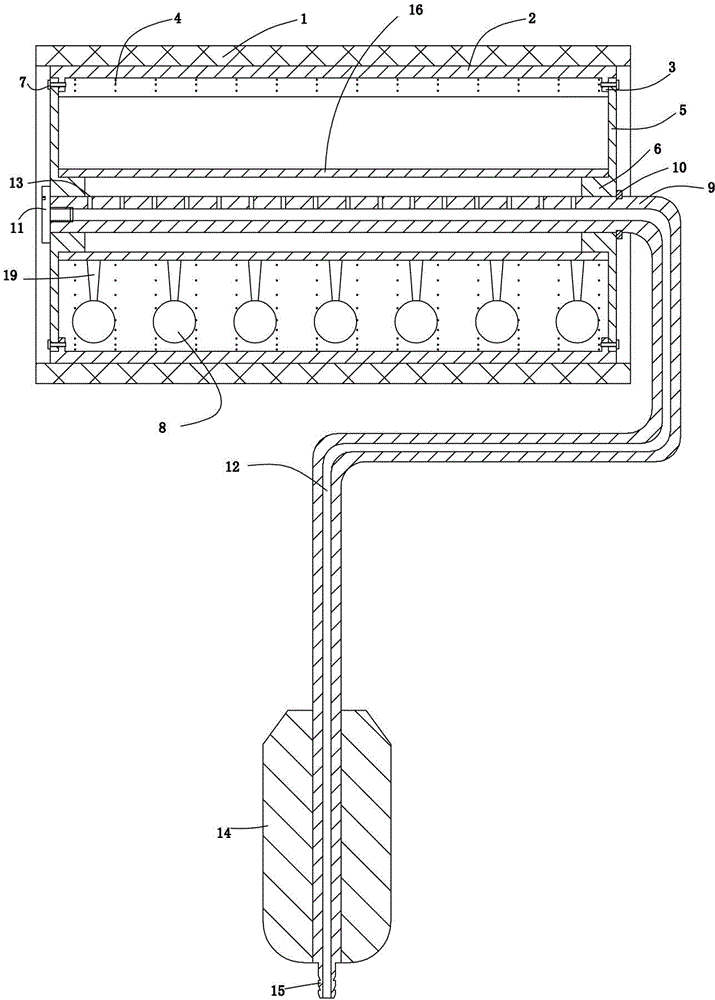

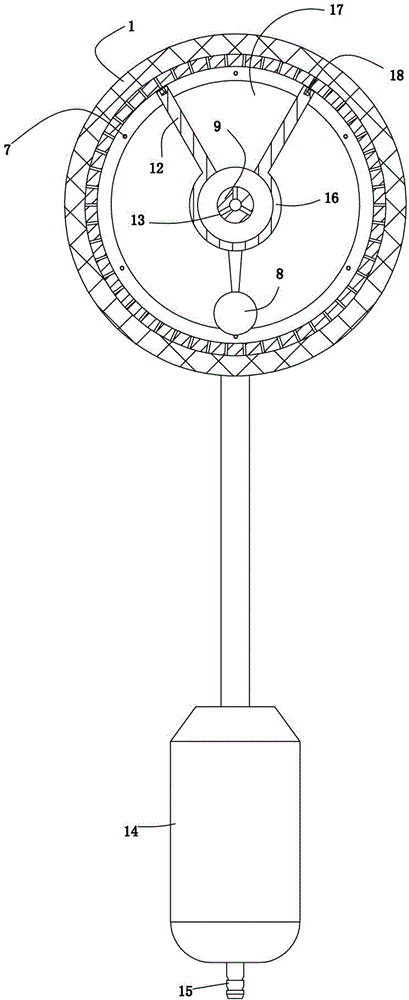

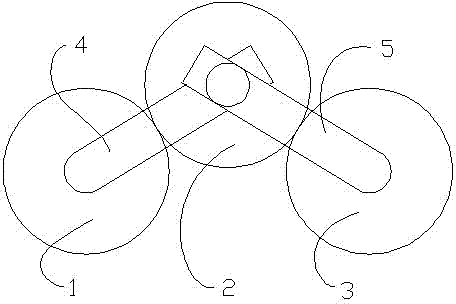

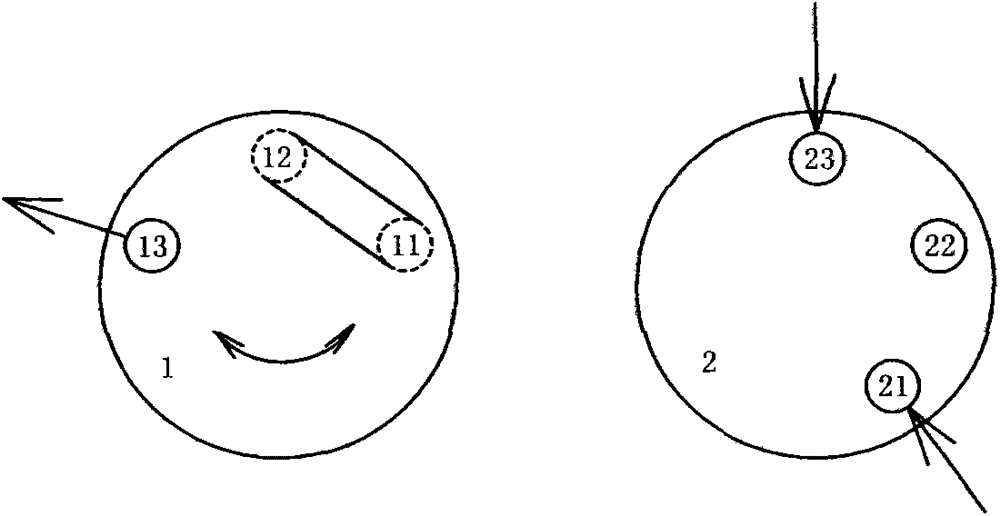

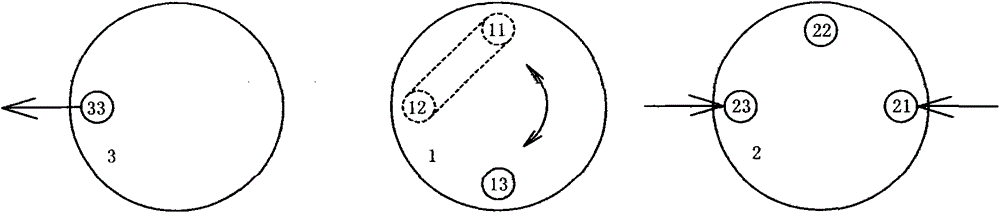

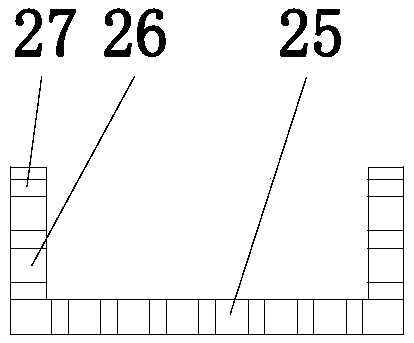

Wall coating roller brush

The invention discloses a wall coating roller brush. The wall coating roller brush can supply materials in a directional mode, and brushes a wall uniformly, and coating cannot drip or leak easily. A roller is arranged in the roller brush; a storage cavity is formed in the roller; through discharging holes are densely distributed in a wall of the roller; two ends of the roller are respectively provided with fixing rings and end caps; a shaft hole is formed in the center of each end cap; a center shaft is a hollow shaft, is positioned on the inner sides of the end caps and is provided with a plurality of air outlet holes along the longitudinal direction; step shafts are respectively arranged at opposite positions of inner sides of center holes of the end caps; the excircle of each step shaft is matched with an air flow guiding sleeve of which the cross section is in the shape of a C-shaped opening; guiding plates are respectively arranged at two ends of the C-shaped opening of each air flow guiding sleeve, and are in the shape of a horn mouth; and a counter weight is arranged on the lower portion of each air flow guiding sleeve. When a user brushes the wall by rotating the roller, air flows through the horn mouths and then is blown to the wall, coating is supplied in a directional mode, sagging caused by the reason that the amount of supplied coating is excessive is avoided, the wall is brushed uniformly, and the coating cannot drip or leak easily.

Owner:安徽省正翔防腐防水有限责任公司

Wall paint roller brush for feeding in fixed direction

The invention discloses a wall paint roller brush for feeding in a fixed direction, and aims at providing the wall paint roller brush which can conduct feeding in the fixed direction and is uniform in painting and not prone to paint leakage. A roller is arranged in a brush cylinder. Through discharge holes are densely distributed in the cylinder wall of the roller. The two ends of the roller are each provided with a fixing ring and an end cover. A shaft hole is formed in the center of each end cover. A central shaft is a hollow shaft. A plurality of air outlets are longitudinally formed in the portion, inside the end covers, of the central shaft. The opposite positions of the inner sides of the central holes of the end covers are each provided with a step shaft. An air flow guide sleeve with the section opened in a C shape is arranged on the outer circle of each step shaft in a matched manner. The two ends of the C-shaped opening of each air flow guide sleeve are each provided with a guide plate. The guide plates are each in a horn mouth shape. A heavy hammer is arranged at the lower portion of each air flow guide sleeve. When the roller is rotated to conduct painting, air is blown onto a wall after passing through horn mouths, paint is fed in the fixed direction, sagging caused by a too large feed amount is avoided, painting is more uniform, and meanwhile the paint is not prone to leakage.

Owner:广东金华城建设集团有限公司

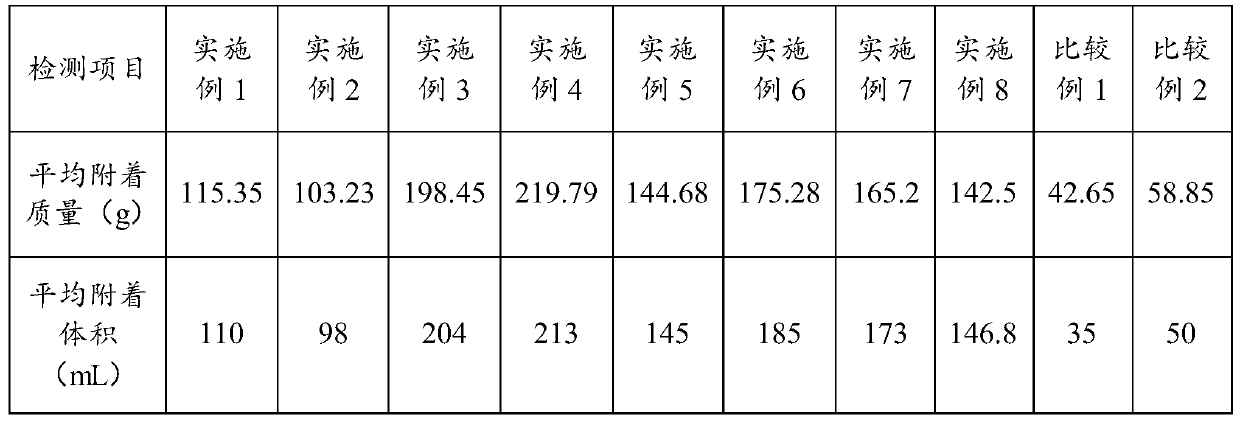

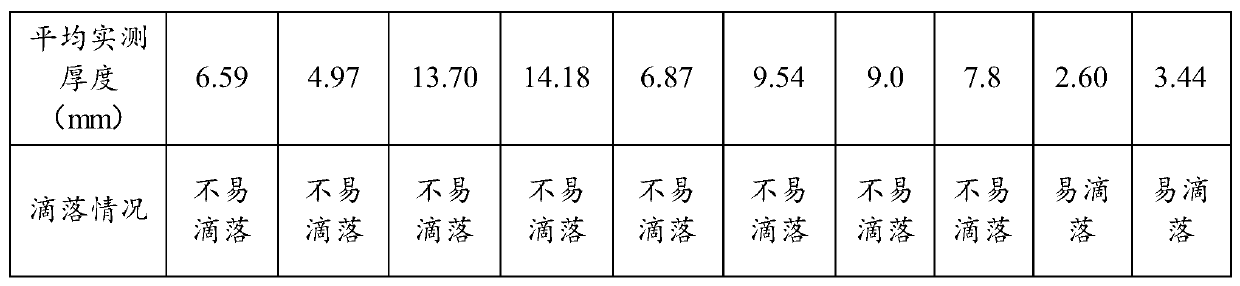

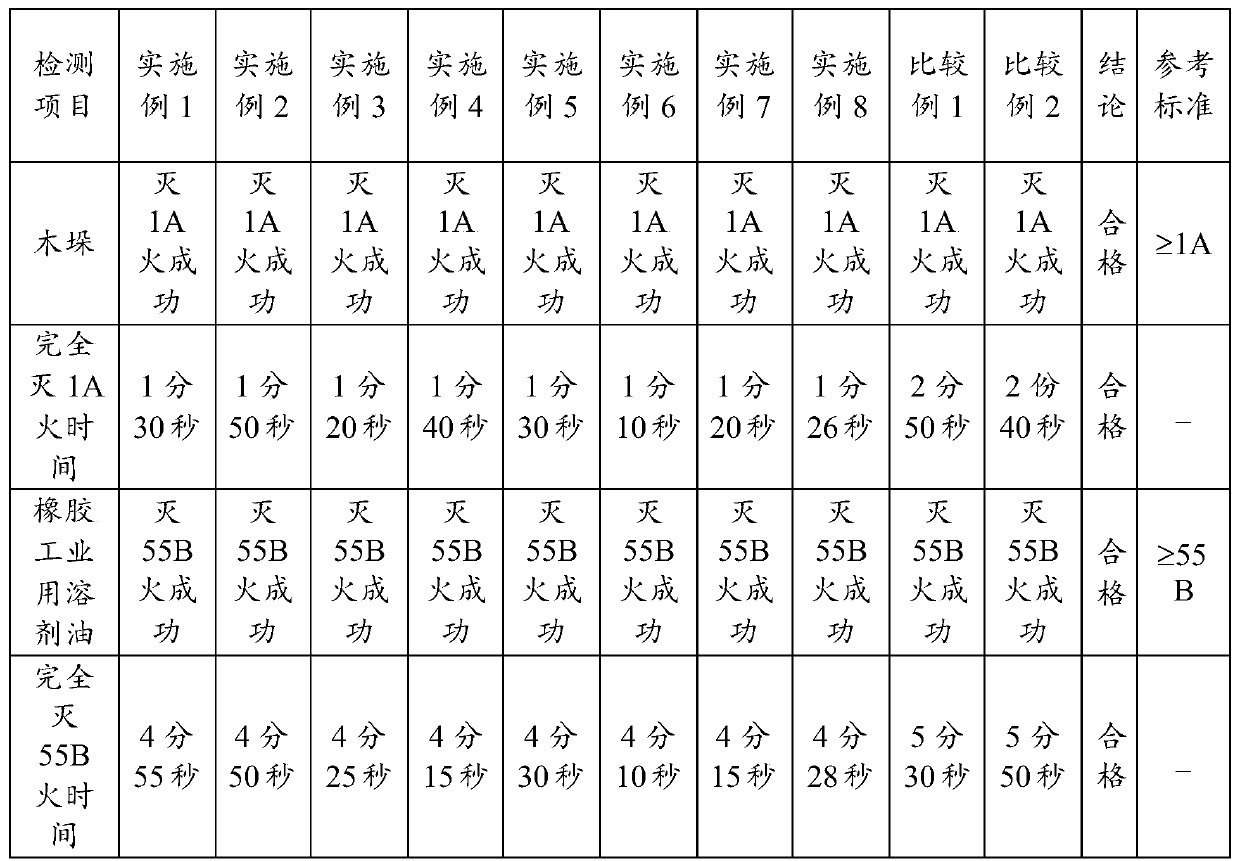

Polymer hydrogel fire extinguishing agent and preparation method thereof

ActiveCN109966688AGood chemical stabilityIncrease the thickness of the attachmentFire extinguisherSuper absorbentPolymer chemistry

The invention relates to the technical field of polymer fire extinguishing materials, particularly to a polymer hydrogel fire extinguishing agent and a preparation method thereof. The polymer hydrogelfire extinguishing agent comprises: 0.1-0.5 wt% of polyacrylate type super absorbent resin and / or an acrylate-acrylamide copolymer, and 0.01-0.5 wt% of inorganic nanoparticles, with the balance beingwater. The inorganic nanoparticles have excellent chemical stability, thermal stability and compatibility. The inorganic nanoparticles are added into the specific super absorbent resin to increase viscosity of the specific super absorbent resin, thus improving the thickness of attachment of the hydrogel fire extinguishing agent, effectively improving fire extinguishing effect of the polymer hydrogel fire extinguishing agent, and allowing the fire extinguishing agent to have good timeliness. Accordingly, the provided fire extinguishing agent has excellent adhesion ability, can have good adhesion ability even on the vertical surface of an object, can cover the surface of the object without falling, and has excellent fire extinguishing effect.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

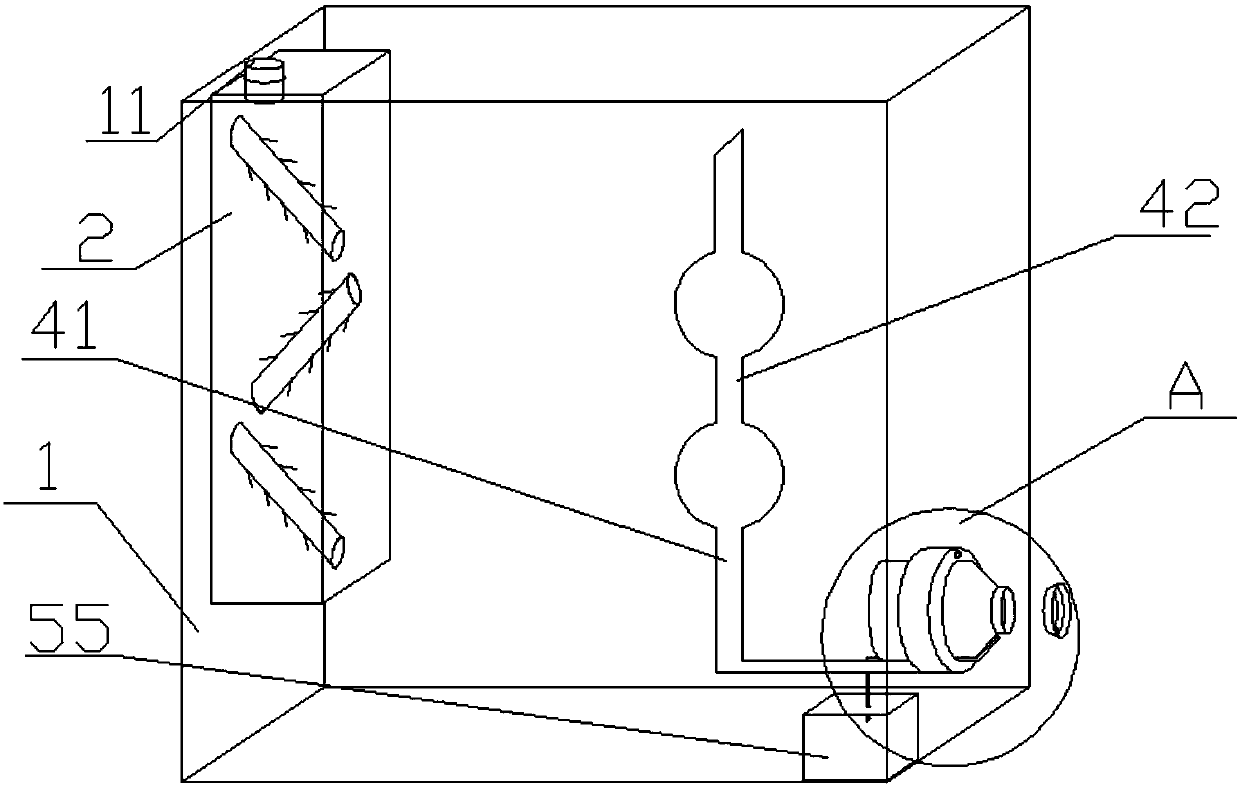

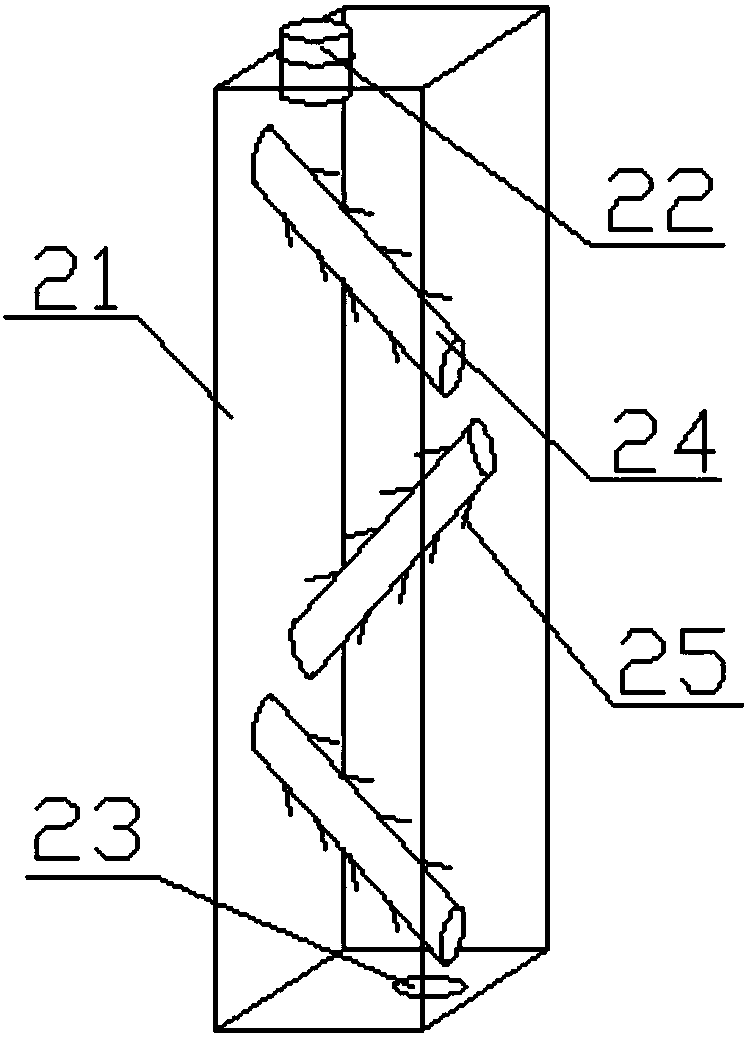

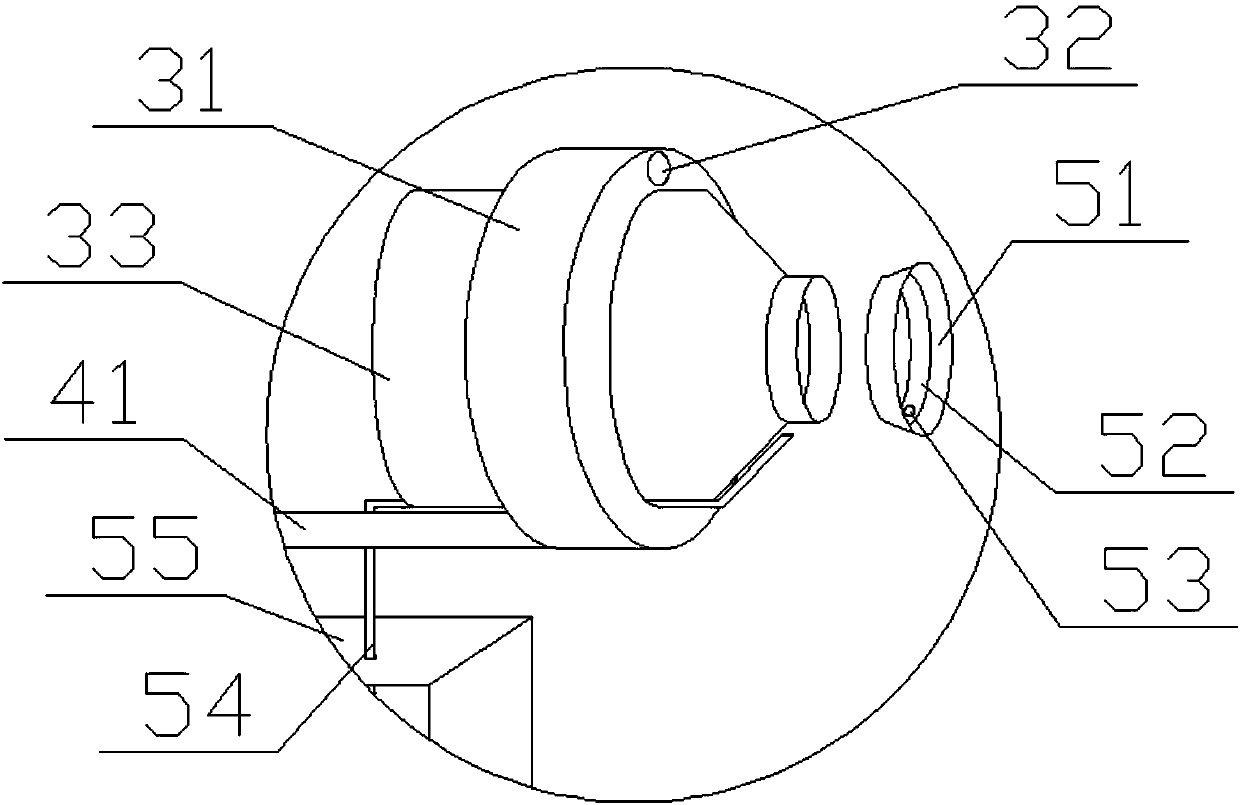

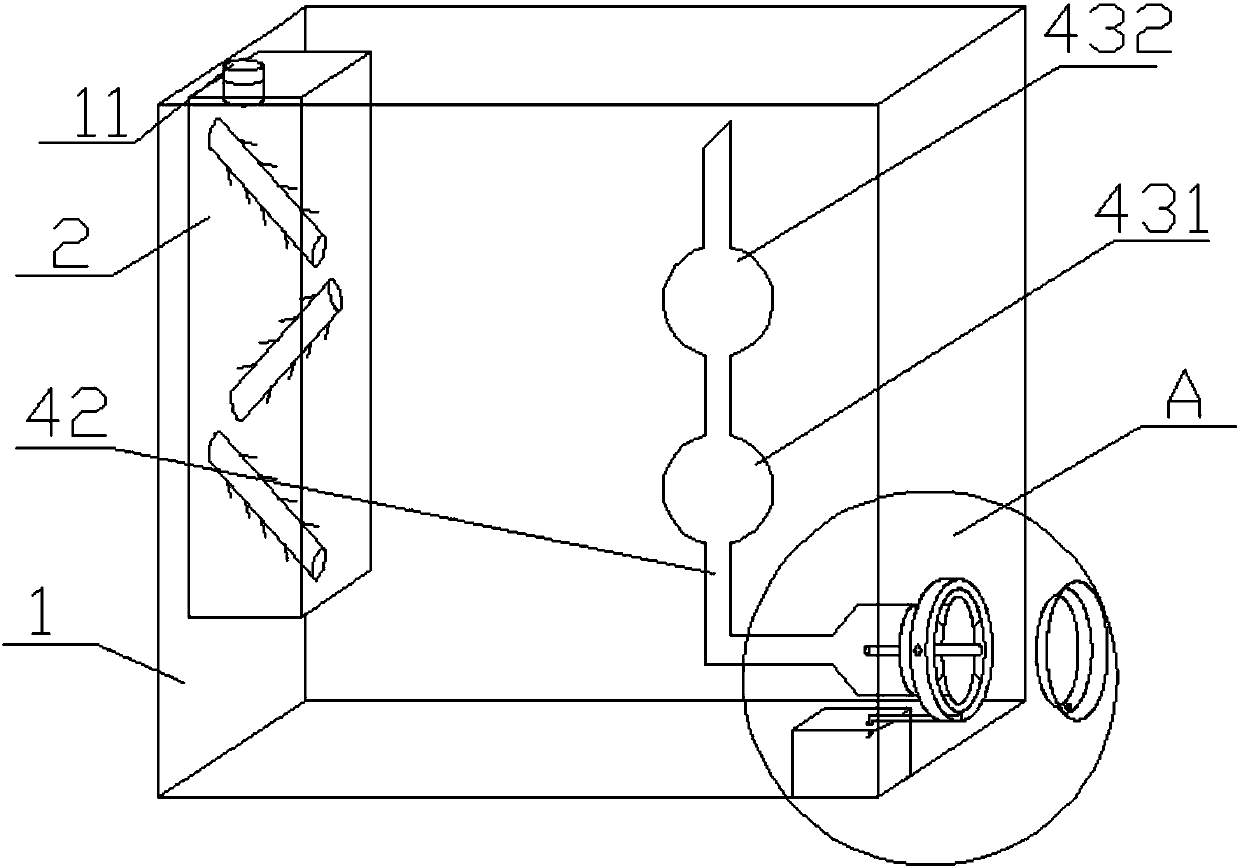

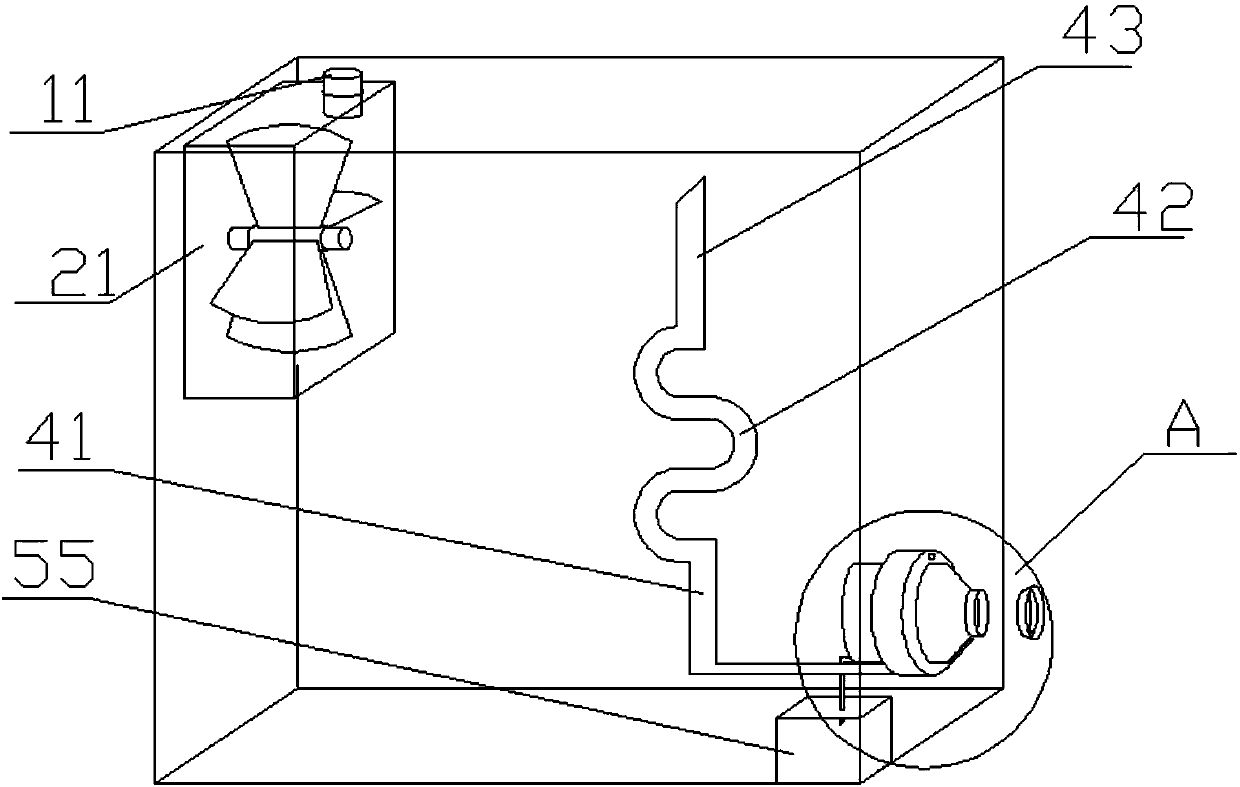

Automatic waste recovery device with recognition and classification functions

InactiveCN110606294AEasily brokenFast Classification ProcessingWaste collection and transferRefuse receptaclesLiquid wasteThrough transmission

The invention relates to the technical field of waste recovery and discloses an automatic waste recovery device with recognition and classification functions. The device comprises a box, a feeding hopper and an inductor assembly arranged in the feeding hopper. The center of the upper end of the box is fixedly connected with the side wall of the feeding hopper through a mounting port. The inductorassembly is fixedly connected with the inner wall of the right side of the feeding hopper. A T-shaped sliding groove is formed in the inner wall of the left side of the feeding hopper. A sealing mechanism is connected into the T-shaped sliding groove. A transverse plate is fixedly connected into the box. The center of the transverse plate is fixedly connected with a rectangular block through a rectangular through hole. An arc-shaped groove is formed in the upper end of the rectangular block. A plurality of openings are formed between the groove bottom of the arc-shaped groove and the lower endof the rectangular block in a penetrating mode. Crushing blades are connected into the multiple openings through transmission mechanisms correspondingly. According to the automatic waste recovery device with the recognition and classification functions, solid and liquid waste can be effectively separated, liquid in the waste is not prone to dripping down to the road surface during transporting, and recyclable waste resources can be further separated out.

Owner:HEBEI UNIV OF ENVIRONMENTAL ENG

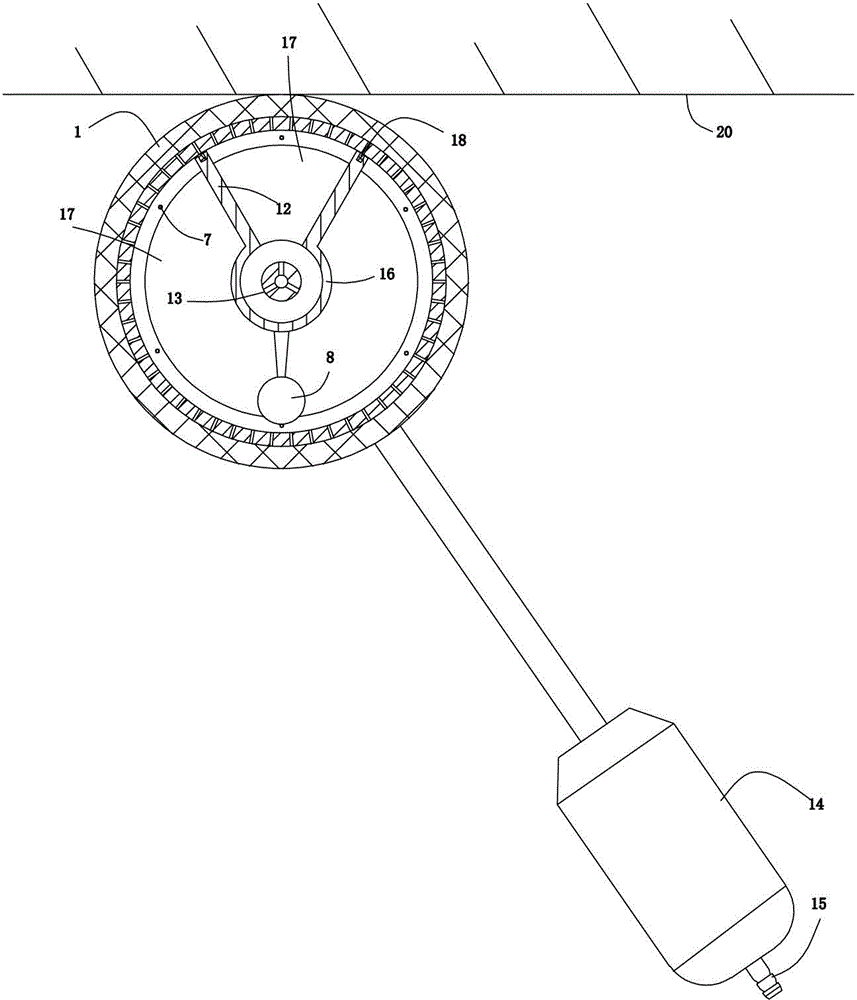

Directionally feeding type ceiling paint roller brush

ActiveCN104858112ANot easy to dripEvenly paintedLiquid surface applicatorsCoatingsPaint rollerAirflow

The invention discloses a directionally feeding type ceiling paint roller brush and aims to provide the directionally feeding type ceiling paint roller brush, according to which, a material can be directionally fed, the painting is uniform and paint is unlikely to drip down. A roller is arranged in a roller brusher body; multiple through material outlets are densely formed in the wall of the roller; a fixing ring and an end cover are separately arranged at two ends of the roller; an axial hole is formed in the central position of the end cover; a central shaft is hollow; multiple vent holes are longitudinally formed in the central shaft, at the inner side of the end cover; a step shaft is arranged at the opposite position of the inner side of the central hole of the end cover; an air flow guide sleeve the section of which is provided with a C-shaped opening is adaptively arranged on the excircle of the step shaft; a guide plate is arranged at each of the two ends of the C-shaped opening of the air flow guide sleeve; the guide plate is horn opening-shaped; a heavy hammer is arranged at the lower end of the air flow guide sleeve. When the roller rotates to paint, air is blown towards a wall through the horn-shaped opening, so that the paint is directionally fed, the sagging caused by over feeding is avoided, the painting is relatively uniform and the paint is unlikely to drip down.

Owner:南京银城建设发展股份有限公司

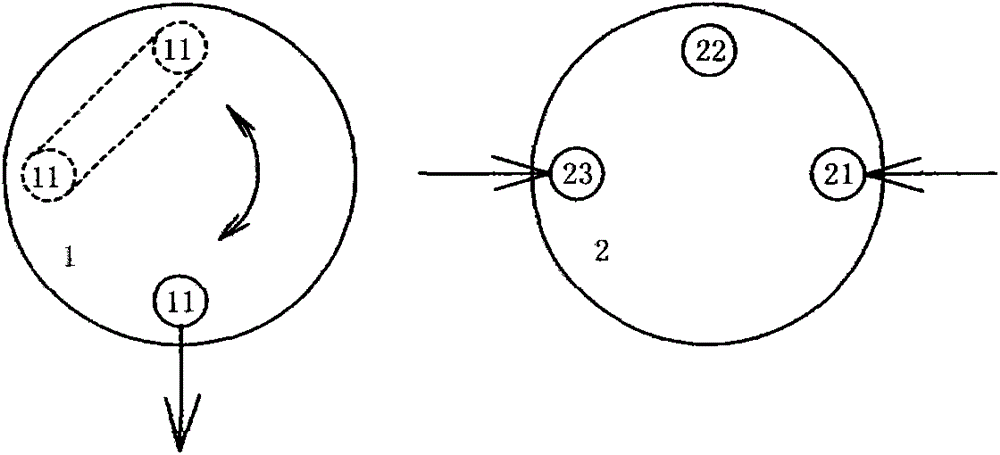

Three-roller grinding mill

The invention provides a three-roller grinding mill, which belongs to the technical field of grinding machinery. The three-roller grinding mill comprises a fixed roller, an adjusting roller, a passive adjusting roller, an active connecting mechanism and a passive connecting mechanism, and is characterized in that: one end of the active connecting mechanism is hinged with the fixed roller, the other end of the active connecting mechanism is connected with the adjusting roller, and the active connecting mechanism drives the adjusting roller to rotate around the axle center of the fixed roller; two ends of the passive connecting mechanism are respectively hinged with the adjusting roller and the passive adjusting roller. According to the invention, the three-roller grinding mill has a more stable structure, and since a discharging position of the adjusting roller is attached onto a top, ground materials do not easily fall onto a feeding position again, thereby improving efficiency of the grinding mill, reducing shaking and friction of the grinding mill and prolonging the service life of the grinding mill.

Owner:苏州冰心文化用品有限公司

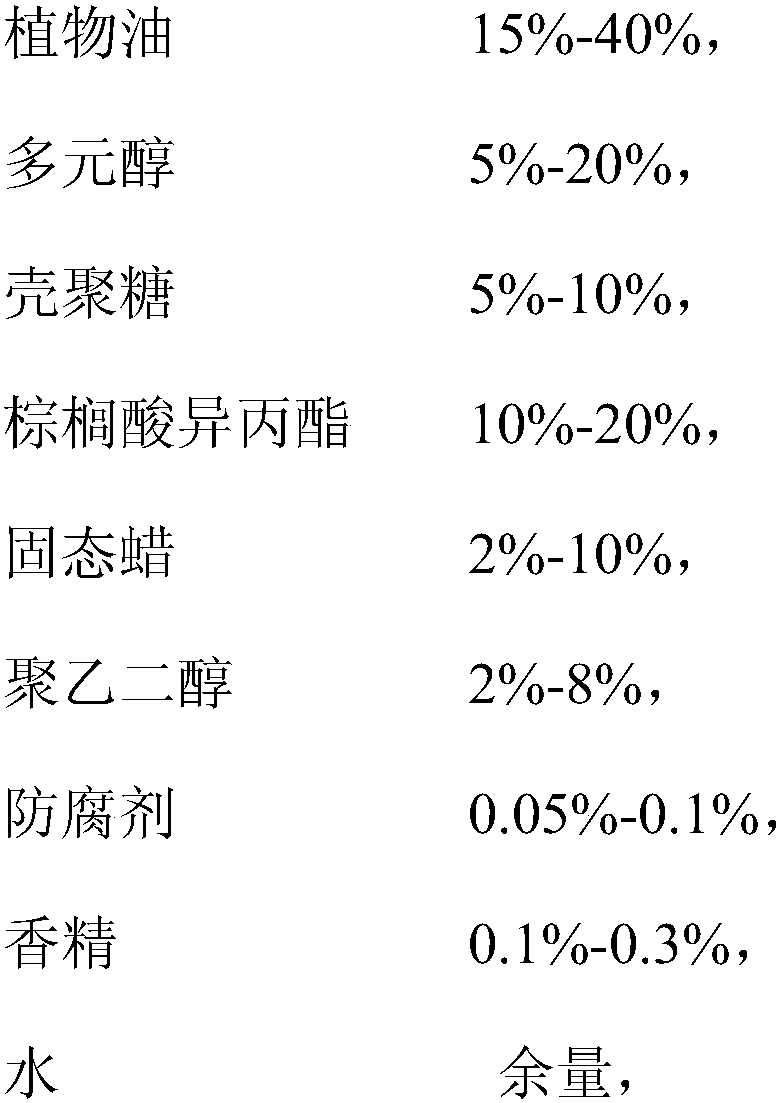

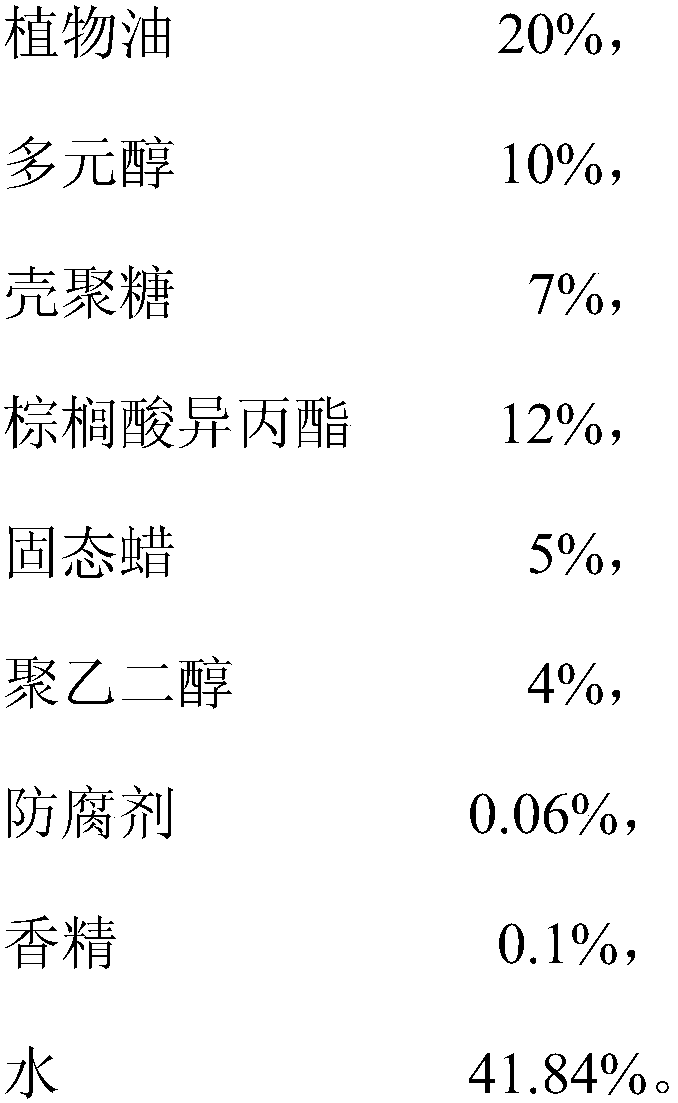

Cleansing cream containing chitosan and preparation method thereof

The invention discloses a cleansing cream containing chitosan and a preparation method thereof. The cleansing cream comprises the following raw material components by weight percentage: 15%-40% of vegetable oil, 5%-20% of polyol, chitosan 5%‑10%, 10%‑20% isopropyl palmitate, 2%‑10% solid wax, 2%‑8% polyethylene glycol, 0.05%‑0.1% preservative, 0.1%‑0.3% fragrance, Water balance, wherein, polyethylene glycol is not included in the polyhydric alcohol. At the same time, the invention also specifically discloses a preparation method of a cleansing cream containing chitosan. The chitosan-containing cleansing cream prepared by the above scheme is a compound mixture made of various raw materials through reasonable deployment and processing. , Purify pores, absorb metal residues from make-up and many other functions.

Owner:ZHEJIANG OCEAN UNIV

Dual-control water faucet with public water inlet pipeline valve body assembly device

ActiveCN104421461ASimplify the installation processNot easy to dripMultiple way valvesSlide valveEngineeringControl valves

The invention relates to a water treatment industry, in particular to the aspect of drinking water filtering. The invention discloses a dual-control water faucet with a public water inlet pipeline valve body assembly device. The dual-control water faucet comprises a cold and hot water switching control valve device, a pure water and mixed water outlet elbow, a public cold water inlet pipeline, a middle water inlet and outlet pipeline, the valve body assembly device with a dual-valve side-mounted structure and a water purification control valve device, wherein a water inlet and a middle water outlet, respectively hermetically butted to relevant water gaps of a controlled disk of the water purification control valve, of the dual-valve side-mounted structure extend to a water purification end and the lower part of the valve body assembly device; a water inlet formed in the butting side vertical surface of the water purification control valve is communicated with a cold water inlet formed in the butting side vertical surface of the cold and hot water switching control valve device to form a public water inlet pipeline; a control disk of the water purification control valve device is rotated to do reciprocating movement within a range of two equal switching positions so as to realize connection or disconnection between the water inlet of the controlled disk and the middle water outlet.

Owner:杜也兵

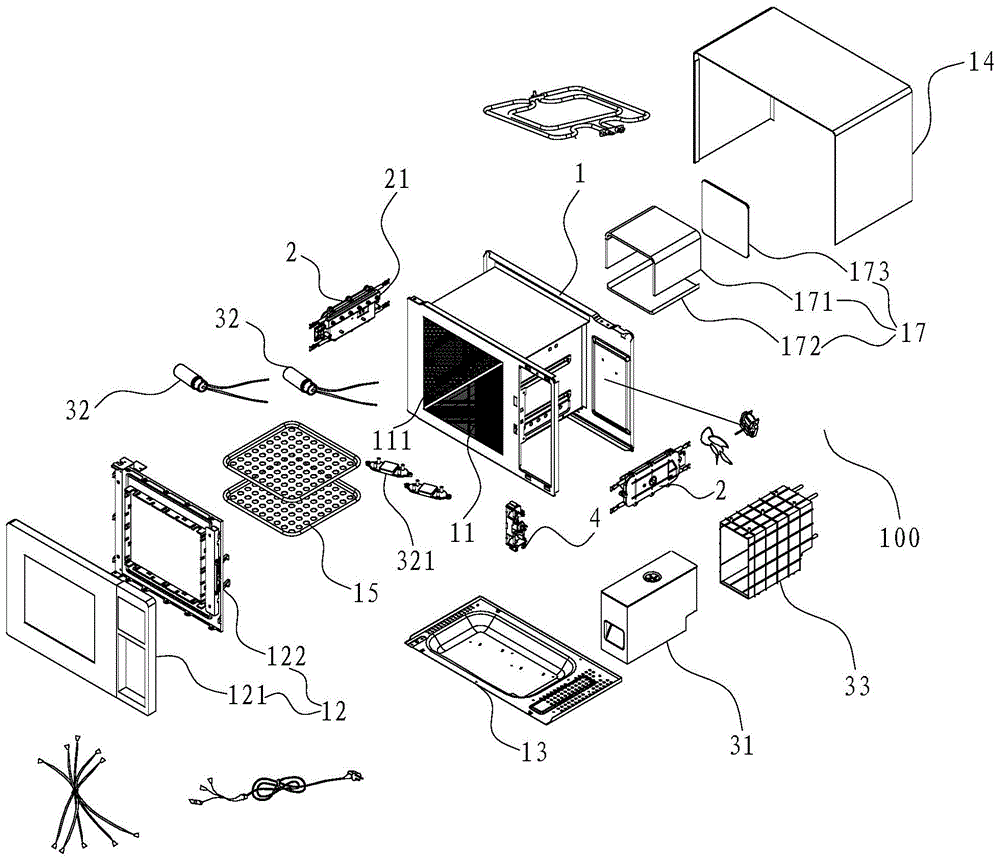

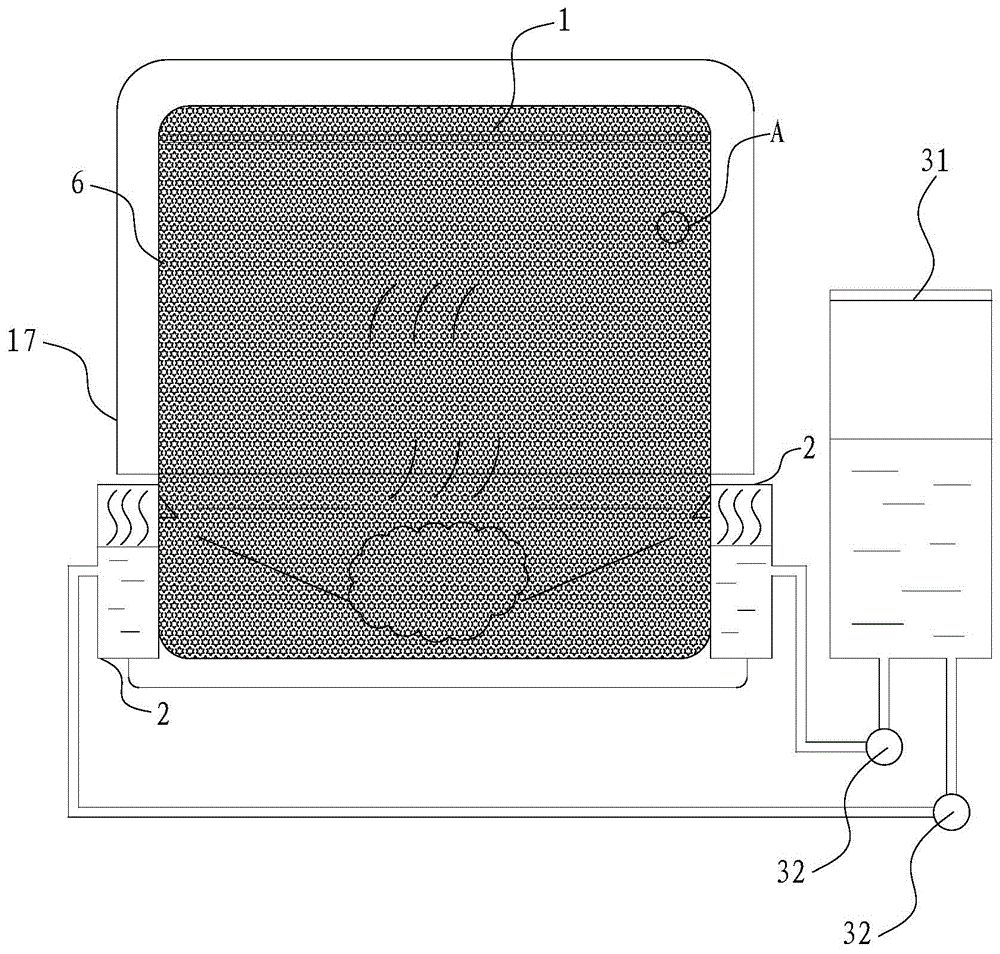

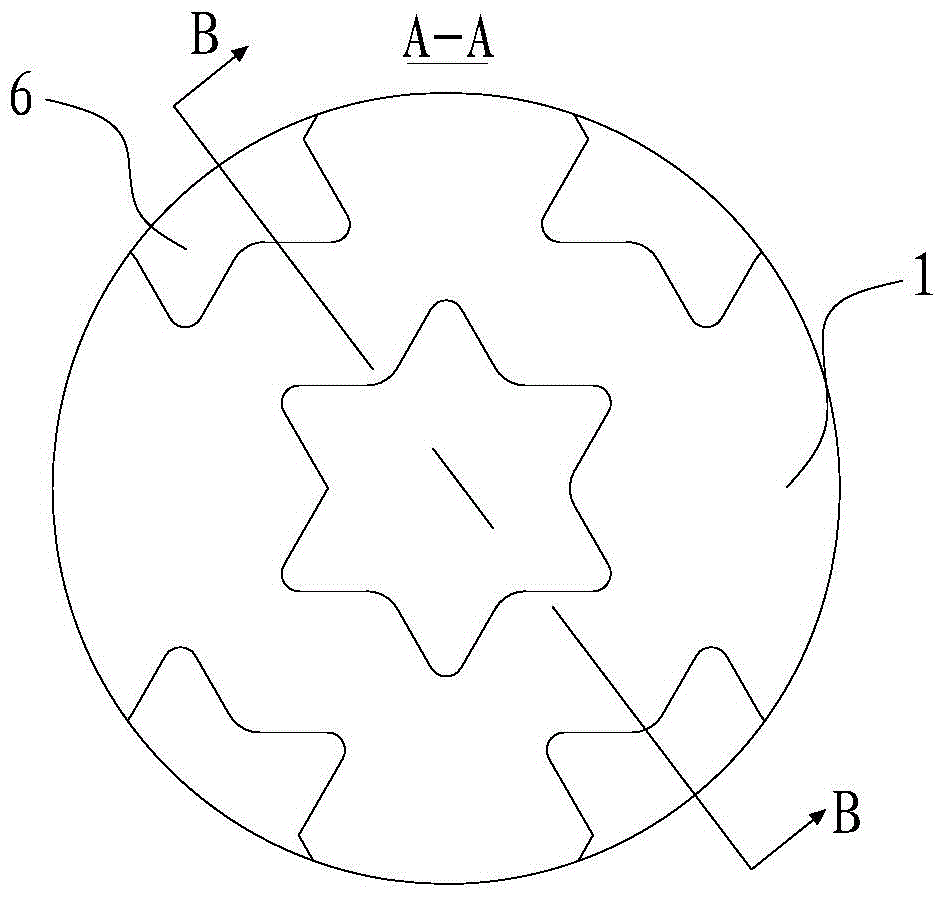

Steam cooking utensil

InactiveCN104622270AGood cooking effectReduces pooling together to form water dropletsSteam cooking vesselsSpray nozzleCondensed water

The invention discloses a steam cooking utensil which comprises a metal cavity, steam generators and a water supply device. A cooking cavity is formed in the metal cavity and protrusions protruding inwards are arranged on the circumferential wall of the cooking cavity. The steam generators are arranged outside the metal cavity and communicated with the cooking cavity through steam nozzles. The water supply device is connected with the steam generators through water pumps so as to supply water sources to the steam generators. By the adoption of the steam cooking utensil, due to the fact that the protrusions are arranged on the circumferential wall of the cooking cavity, the situation that water on the periphery is collected to form water drops by initially-condensed water due to the tension of the inner wall faces of the cooking cavity can be reduced, condensed water is not likely to drop onto food in the cooking cavity, and the steam cooking utensil is good in cooking effect and convenient to clean.

Owner:MIDEA GRP CO LTD +1

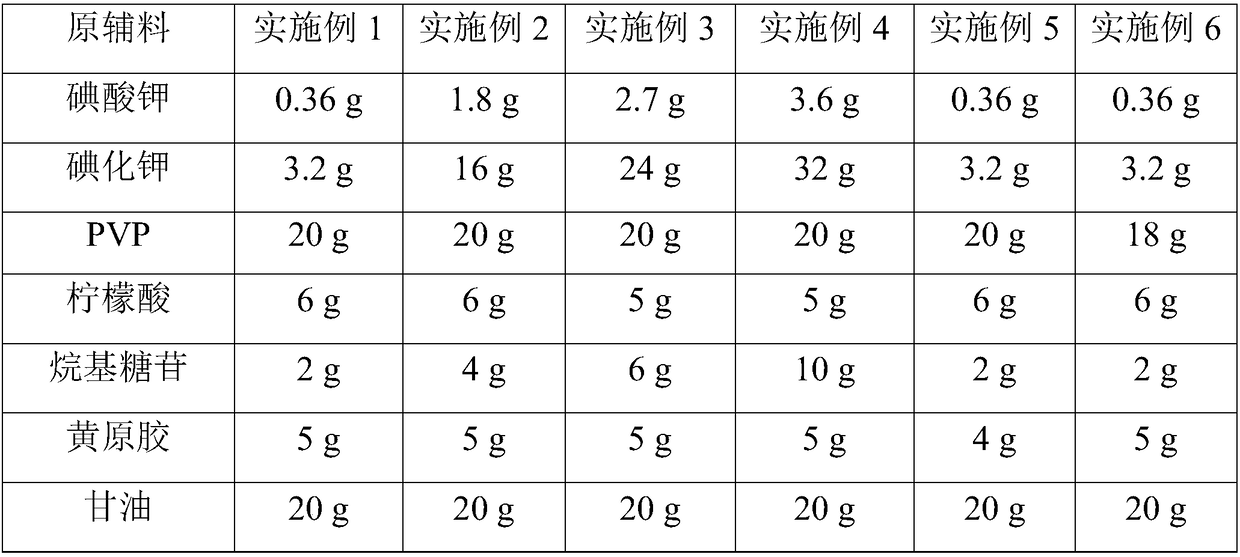

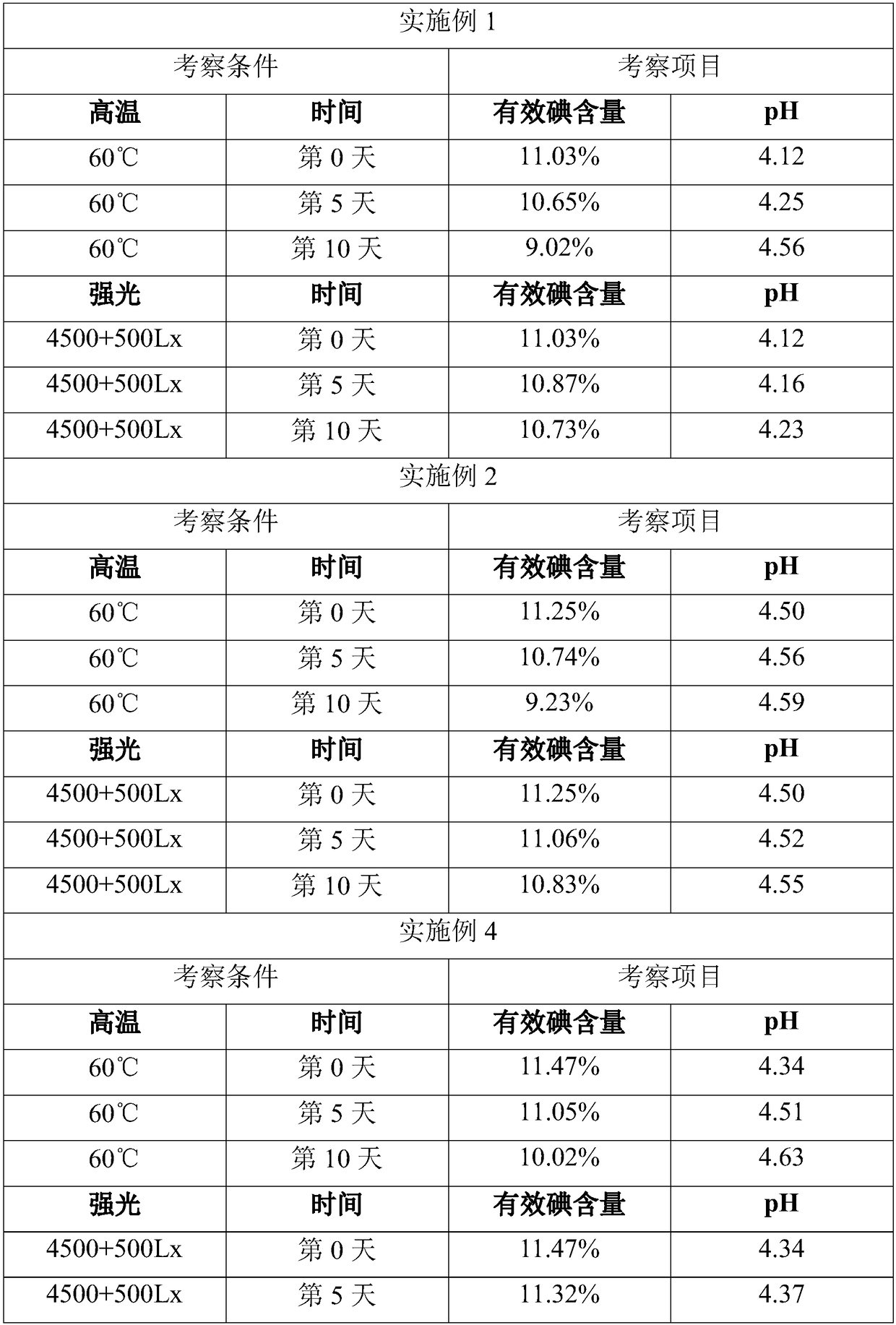

Anti-leaking povidone iodine solution and preparation method thereof

ActiveCN108653201AAvoid wastingNot easy to dripAntibacterial agentsAntisepticsSuspending AgentsPotassium iodine

The invention relates to an anti-leaking povidone iodine solution and a preparation method thereof. Each 1000g of anti-leaking povidone iodine solution is mainly prepared from the following raw materials in parts by weight: 0.3-5g of potassium iodate, 0.3-35g of potassium iodide, 10-25g of PVP (Polyvinyl Pyrrolidone), 2-10g of organic acid, 1-10g of surfactant, 0.5-10g of suspending agent, 18-30gof emollient and the balance of water and pH (Potential of Hydrogen) modifier, wherein the mass ratio of the PVP and the suspending agent is (3.5-5):1. The product has the advantages of good stability, less possibility of leaking, slow releasing, long-lasting pesticide effect, high antibacterial effect and skin protection, a great quantity of manpower and pharmacy cost can be saved, and the anti-leaking povidone iodine solution is suitable for extensive dairy farms.

Owner:FOSHAN NANHAI EASTERN ALONG PHARMA CO LTD

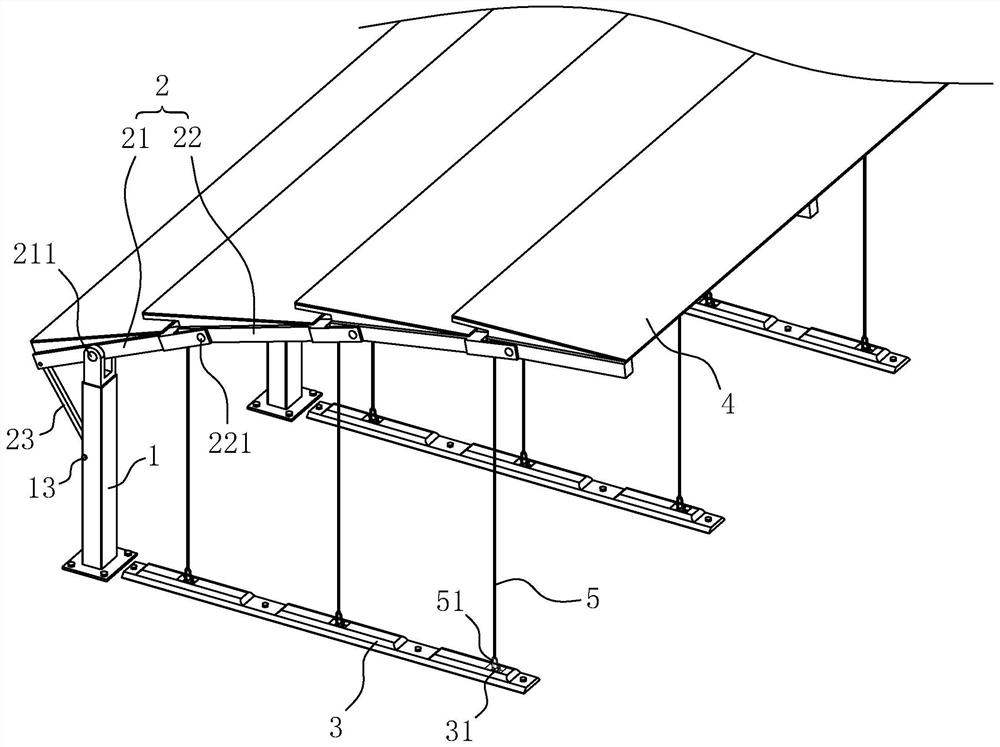

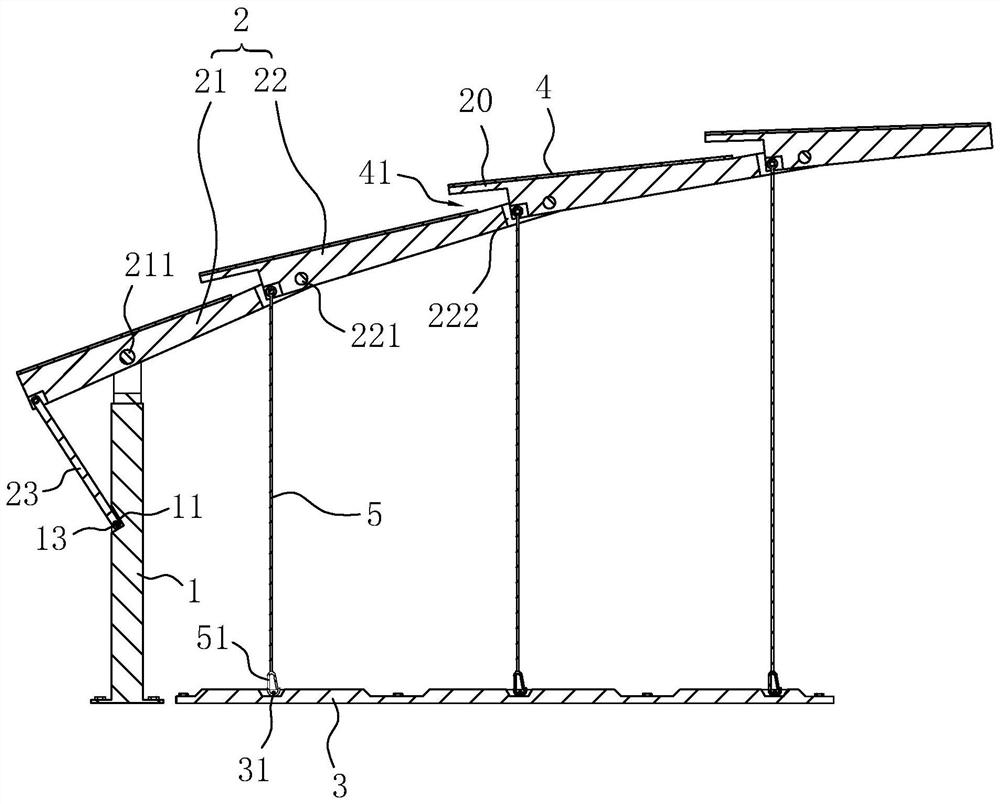

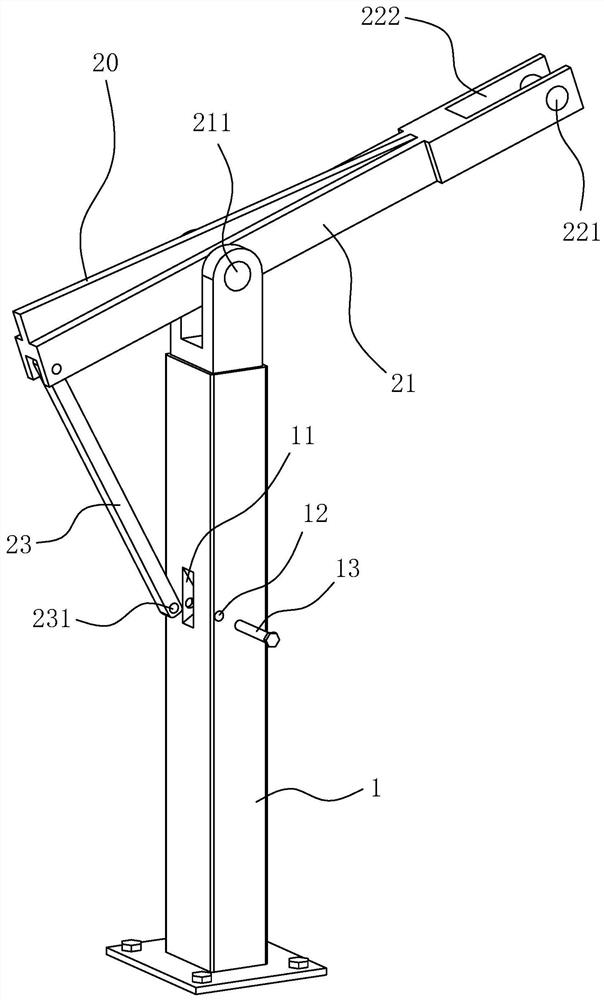

Municipal parking shed and mounting process thereof

ActiveCN111648630AReduce the possibility of rubbing against other carsStrong wind resistanceBuilding roofsParkingsHearing changeDriver/operator

The invention discloses a municipal parking shed and a mounting process thereof, and relates to the technical field of municipal engineering. According to the technical scheme, the municipal parking shed comprises multiple supporting columns which are arranged side by side and frameworks, a ceiling is mounted between the adjacent frameworks, partition strips which are fixed to the ground are further included, parking space is formed between the adjacent partition strips, each framework comprises a main frame and multiple auxiliary frames, the adjacent auxiliary frames are in hinged connectionthrough first hinge shafts, the first hinge shafts are located on the near ends, towards the main frames, of the auxiliary frames, the auxiliary frames are connected with pull ropes, one ends of the pull ropes are connected to the ends, towards the main frames, of the auxiliary frames, and the other ends of the pull ropes are connected to the partition strips. When vehicles rub the pull ropes, thepull ropes can generate deforming to enable the auxiliary frames and the ceiling to generate deforming, sounds can be sent out while deforming is achieved, visual and hearing changes can be fed backto a driver, the driver can be promoted to change the behavior, the possibility of rubbing other vehicles can be reduced, the wind resistance capacity of the ceiling is high, rainwater is not prone todropping to the parking space downwards, and the parking shed can be conveniently mounted.

Owner:ZHEJIANG DINGXING CONSTR

Double-agent-form foam hair-dyeing composition

The invention discloses a double-agent-form foam hair-dyeing composition. The double-agent-form foam hair-dyeing composition comprises a first agent containing an alkaline agent and a second agent containing hydrogen peroxide and is characterized in that the mixed liquid of the first agent and the second agent comprises, by weight percentage, 1-15% of ampholytic surfactant, 0.1-3% of cationic polymer, 0.1-10% of higher alcohol and 0.1-5% of polyol. The double-agent-form foam hair-dyeing composition has the advantages that the specific types of ampholytic surfactant, cationic polymer, higher alcohol and polyol of specific content are compounded to obtain the double-agent-form foam hair-dyeing composition which is good in foamability and stable and good in foam; when the hair-dyeing composition is used for dyeing hair, the hair-dyeing composition is non-irritant to the scalp, the foam of the hair-dyeing composition is stable, fine and smooth and less prone to dripping, and good hair-dyeing experience and effect are achieved.

Owner:HUAANTANG BIOTECH GRP CO LTD

Anti-bubble ink box

The invention discloses an anti-bubble ink box, which comprises: a casing, the upper part of which is provided with an ink supply port, and the lower part is provided with an ink outlet; an ink guiding mechanism, which includes an ink guiding box and a plurality of ink guiding rods; an air guiding mechanism , which includes a cylinder body, a first liquid guide tube and an air guide tube set sleeved inside the cylinder body; a liquid guide mechanism, which includes a protective cover, a second liquid guide tube and an ink storage box. The invention provides a separate path for air circulation by setting an air guide mechanism at the ink outlet, separates the air path from the liquid path, reduces the air in the ink, thereby reducing the generation of air bubbles in the printing process and improving the printing effect. Purpose: At the same time, set the flow path of dripping ink at the ink outlet, guide the dripping ink into the ink storage box, and store it in the sponge body, so as to avoid the pollution of the printer caused by the dripping ink that is not easy to clean, and completely solve the problem of ink dripping .

Owner:北海市天硌打印耗材有限公司

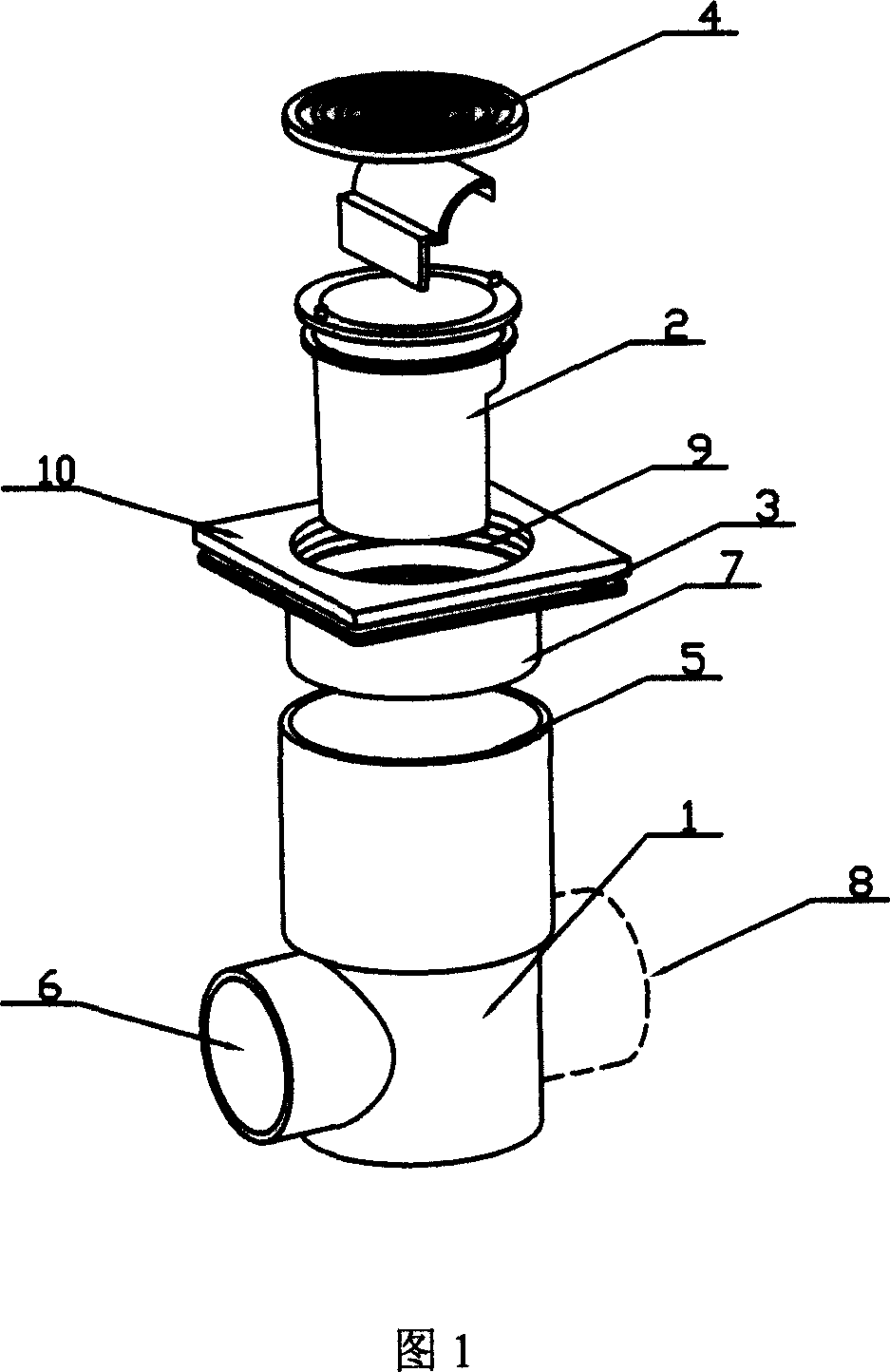

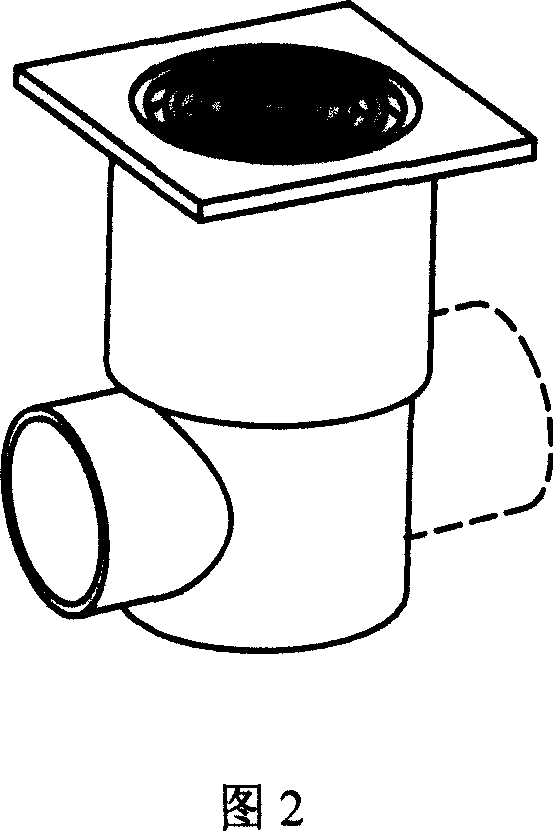

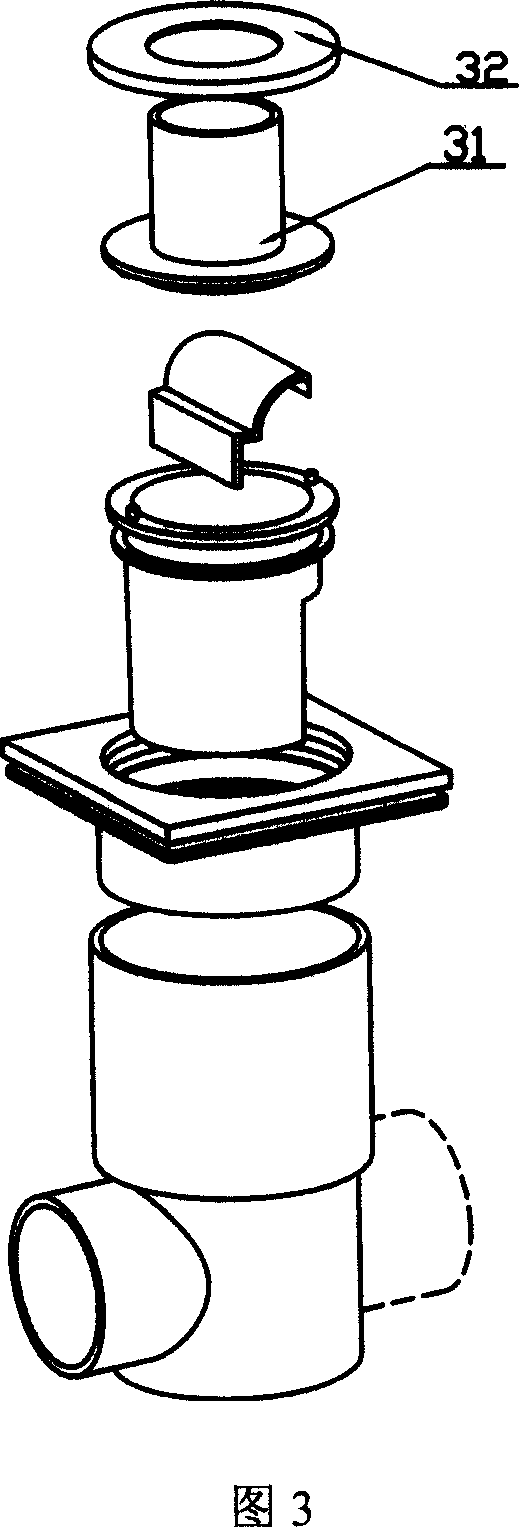

Multifunctional dismountable type floor drain

The present invention discloses a removable multifunctional floor drain used in the co-floor sewage discharge system. It includes the following several portions: external shell with internal cavity, removable water seal type floor drain combination body, panel and cover plate. The described external shell possesses an upwards-extended upper mouthpiece; one side of said external shell is equipped with a sewage outlet communicated with said internal cavity. Said panel has a downwards-extended lower mouthpiece, said lower mouthpiece is inserted into the above-mentioned upper mouthpiece, the removable water seal type floor drain combination body is mounted in the lower mouthpiece of said panel, and the opening of said cover plate is covered by said cover plate. Said floor drain also can be used as sewage discharge device of washing machine or other sanitary equipment.

Owner:陆正新

Jackfruit picking device

The invention discloses a jackfruit picking device.The jackfruit picking device comprises a base, a fixing mechanism, a picking mechanism, a driving mechanism, a controller, a first lifting rod, a second lifting rod, a first motor and a second motor, wherein the picking mechanism comprises electric scissors, a packaging film, an automatic strapping device, a telescopic rod and a third motor; the electric scissors comprise a base, an upper blade and a lower blade; an upper through hole is formed in the upper blade, and a lower through hole is formed in the lower blade; a cavity is formed in the lower blade, and the lower through hole penetrates through the cavity; the packaging film and the lower through hole are coaxially arranged, and the packaging film seals the lower through hole; the automatic strapping device is arranged in the cavity and located above the packaging film; and the controller is electrically connected with the electric scissors, the automatic strapping device, the driving motor, the first motor, the second motor and the third motor. The invention relates to the technical field of crop picking devices, and aims to solve the technical problems that existing jackfruit picking is high in difficulty and risk and mucus at fractures of fruit stems drips all around.

Owner:海南飞歌生态农业发展有限公司

Water saving type nut cleaning device

PendingCN109499969ANot easy to spillDissolves and softens quicklyCleaning using liquidsWater savingMechanical engineering

The invention discloses a water saving type nut cleaning device. A cleaning box, a plate chain, a driving rolling column, a driven rolling column, a partition plate, a steam pipe, a gas sucking channel and a water spraying pipe are included; the two sides of the cleaning box are provided with the driving rolling column and the driven rolling column correspondingly; the driving rolling column and the driven rolling column are sleeved with the plate chain; the two side walls of the cleaning box are provided with a feeding port and a discharging port correspondingly; the plate chain penetrates into the cleaning box from the feeding port and penetrates out of the discharging port; a material falling device is arranged above the feeding end of the plate chain; and the vertically arranged partition plate is arranged in the cleaning box. According to the water saving type nut cleaning device, due to the fact that the steam pipe is matched with the gas sucking channel, oil dirt on a nut can befast dissolved and softened, and can effectively drip, the amount of water for use is effectively saved, and the later water spraying pipe is used in cooperation so that the nut can be cleaned completely.

Owner:嘉兴光明科技股份有限公司

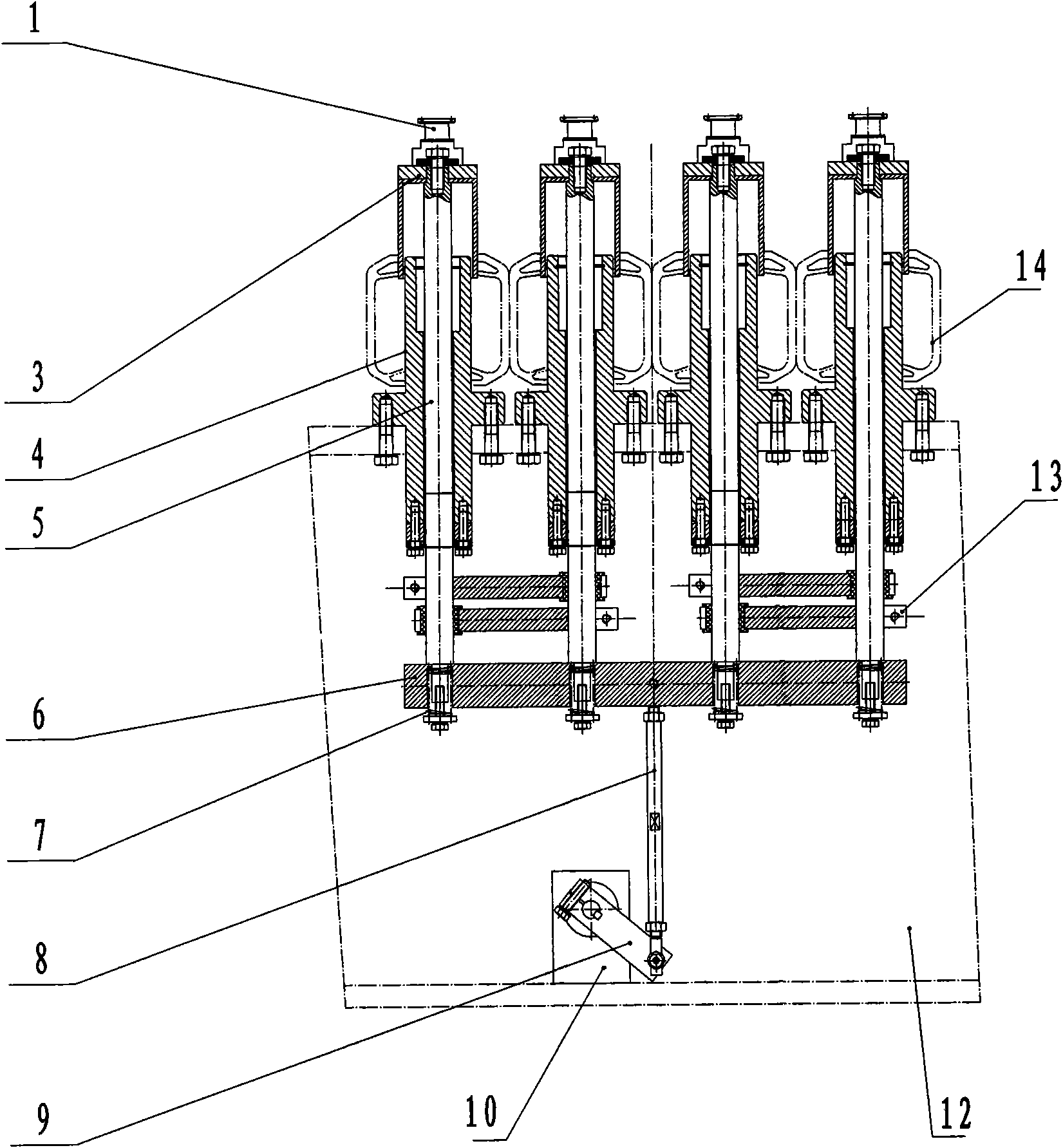

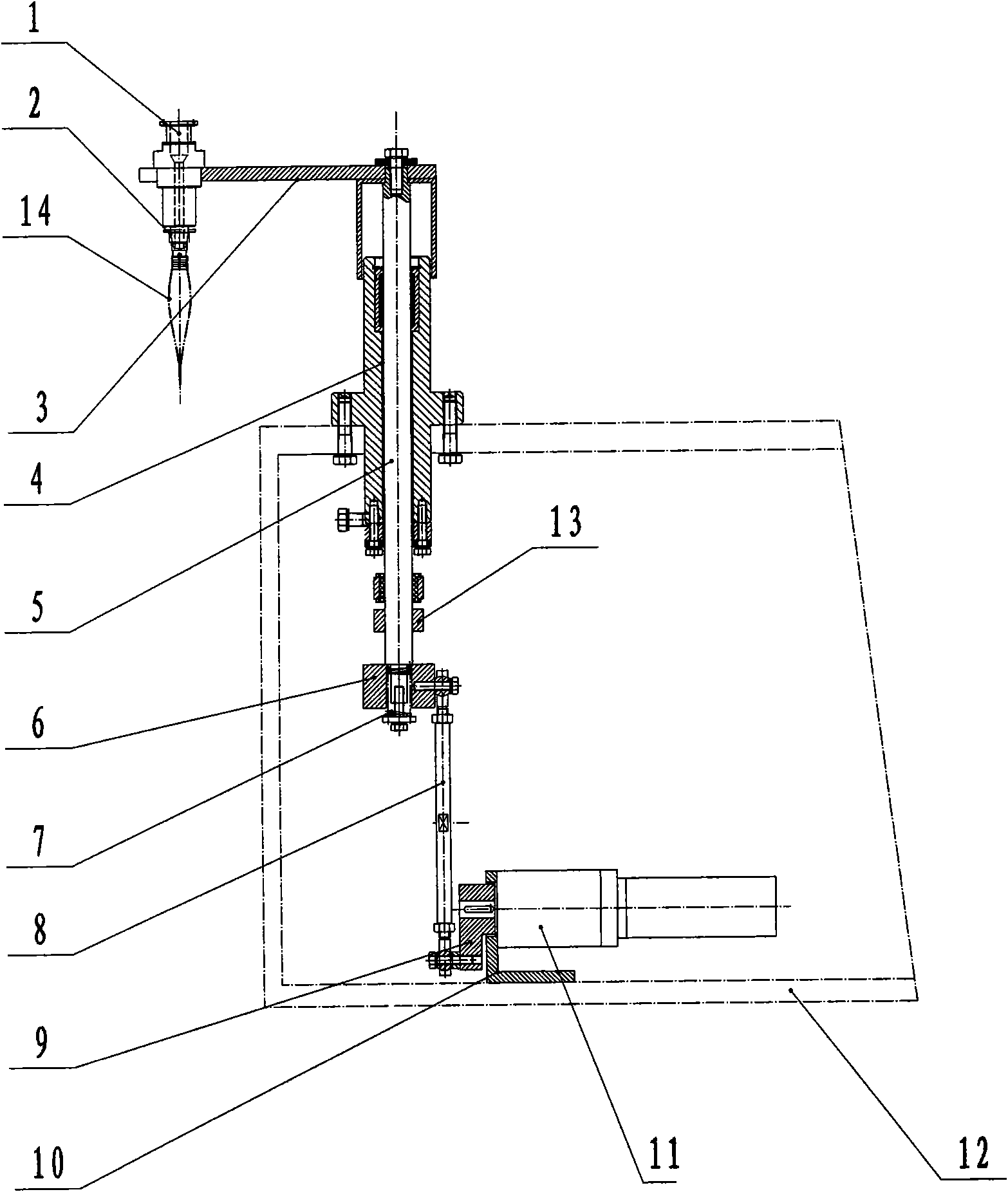

Filling head lifting device for big soft infusion bag production line

The invention discloses a filling head lifting device for a big soft infusion bag production line, comprising a driving mechanism, an oscillating arm, a lifting sliding shaft and a filling head; wherein, the output end of the driving mechanism is connected with the oscillating arm, the lifting sliding shaft is sleeved on a lifting base, the upper end of the lifting sliding shaft is provided with the filling head, and the lower end of the lifting sliding shaft is connected with the oscillating arm through a connecting rod. The filling head lifting device for big soft infusion bag production line of the invention has simple and compact structure, low cost and reliable use and is not easy to damage.

Owner:TRUKING TECH LTD

Ink supply ink box

The invention discloses an ink supply ink box, which comprises: a shell with an ink supply port on the upper part and an ink outlet on the lower part; Through hole; ink guide mechanism, which includes a plurality of ink guide rods; installation body, which includes a plug ring, a cylinder sleeved inside the plug ring, and a disc arranged at the end of the cylinder body; an air guide mechanism, which includes the first The second pipe body, the third pipe body arranged vertically with the second pipe body and communicating with the contact part, and the air guide tube group; the liquid guide mechanism, which includes a protective cover, a liquid guide tube and an ink storage box. The invention can discharge the air in the ink delivered to the inside of the ink box, avoid the generation of a large number of air bubbles in the printing process, and can completely solve the problem of ink dripping at the ink outlet.

Owner:北海市天硌打印耗材有限公司

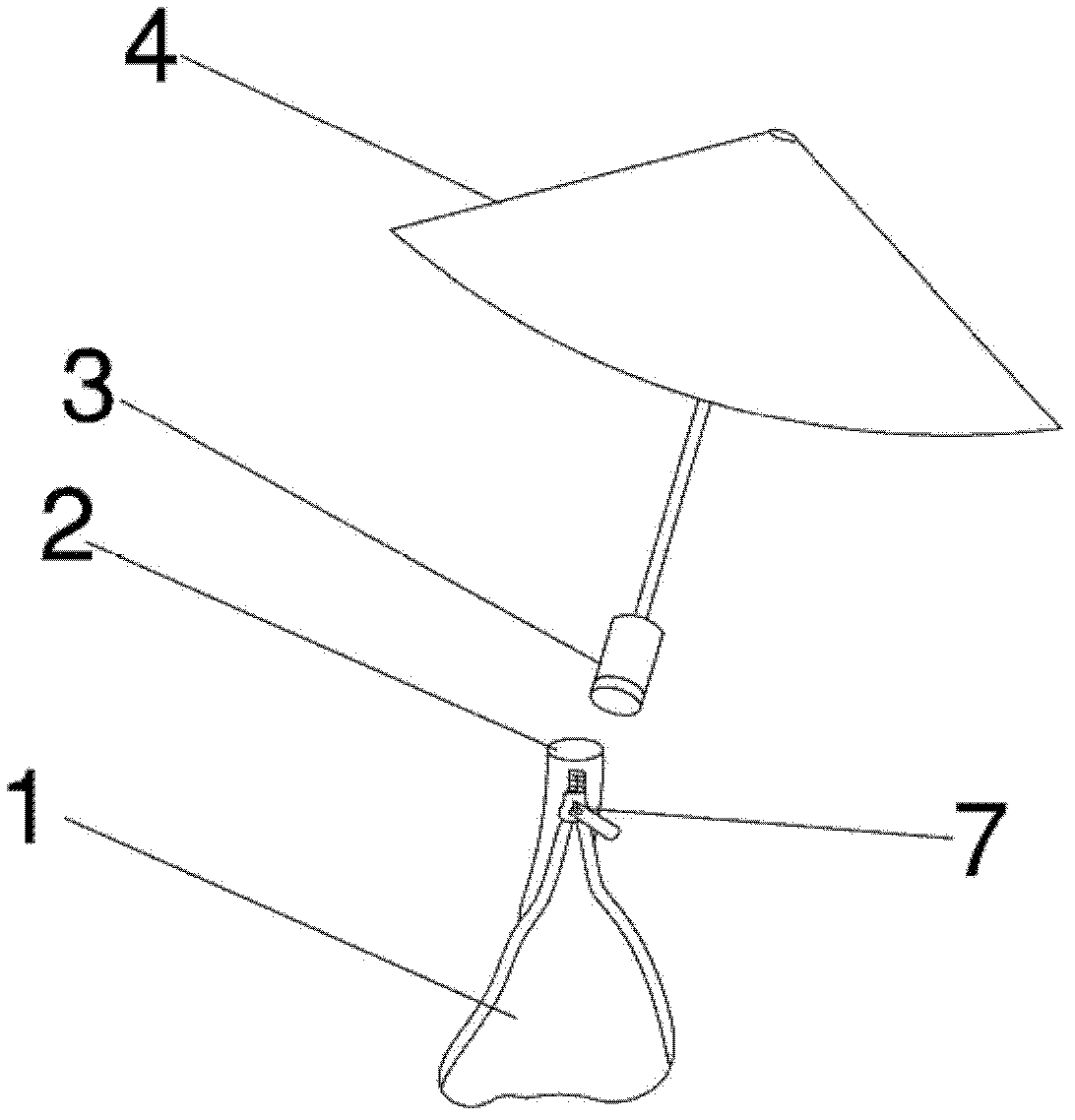

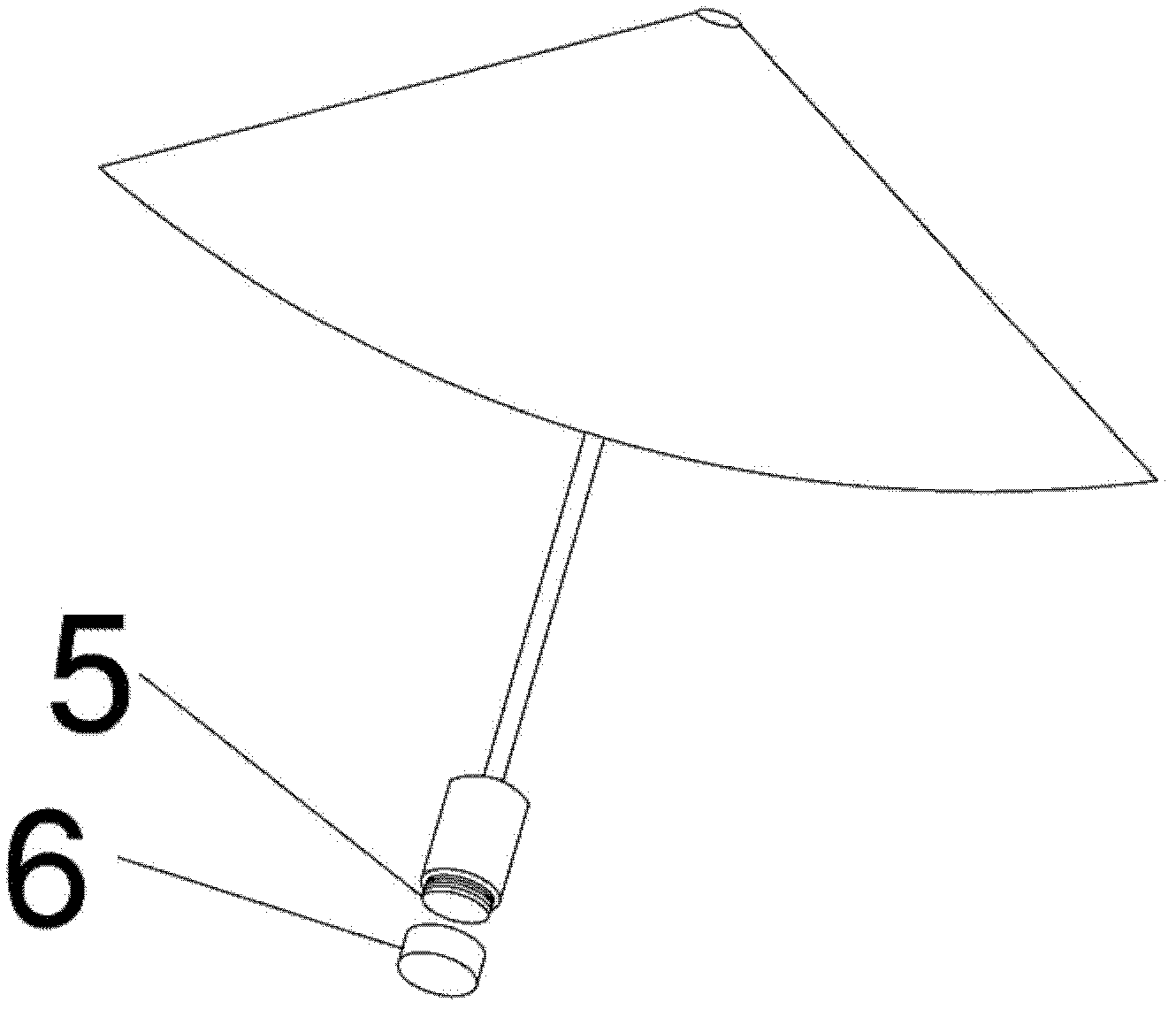

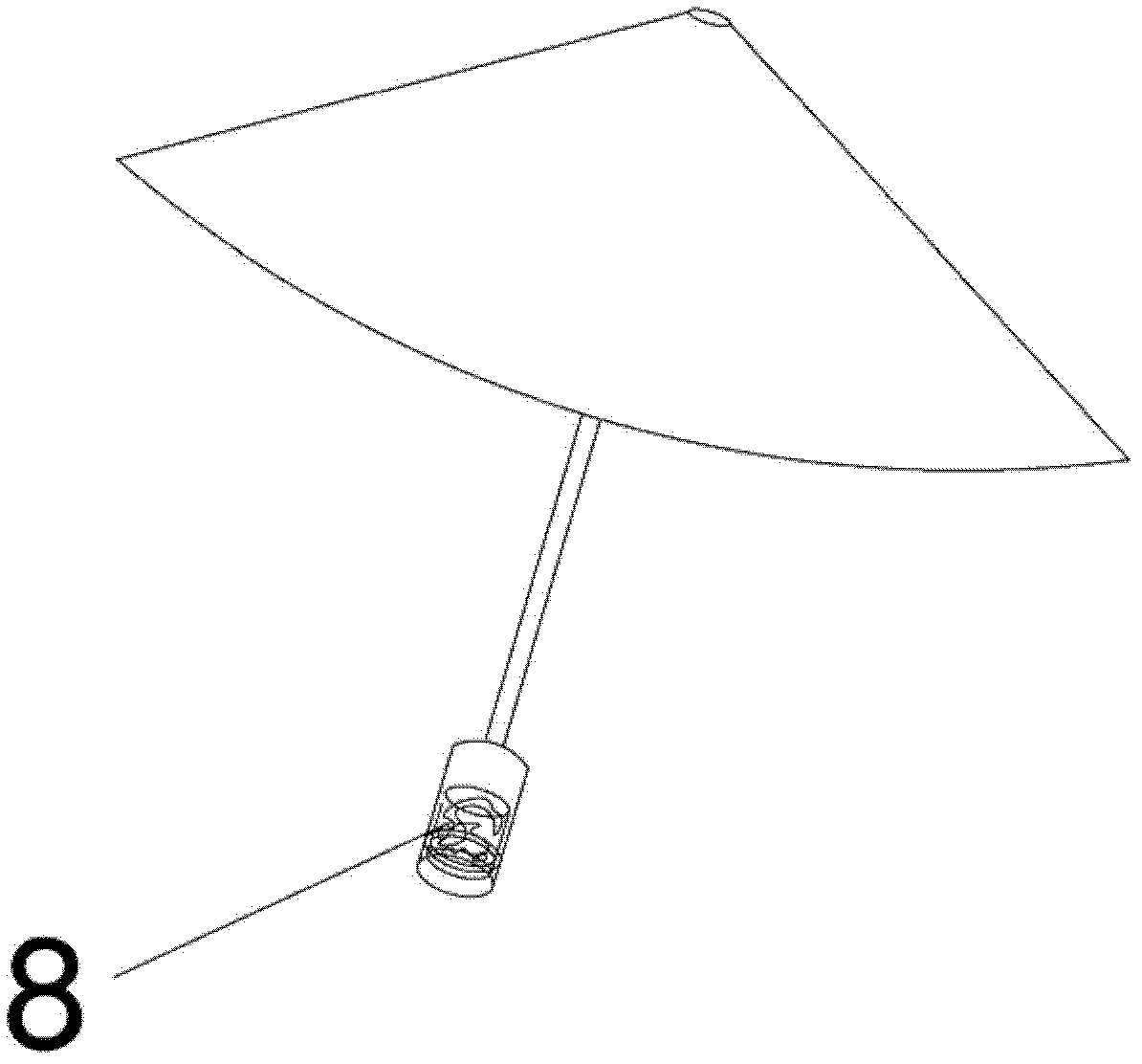

Umbrella cover structure for folding umbrella

The invention provides an umbrella cover structure for a folding umbrella. The umbrella cover structure comprises an umbrella cover and an umbrella handle, wherein the umbrella cover comprises an umbrella cover surface and an opening-closing device arranged on the umbrella cover surface; the umbrella handle is provided with a cavity for containing the umbrella cover; and the cavity comprises a cavity body and a cavity cover. The umbrella cover structure is reasonable in overall structural design and is convenient to use, and the ulbrealla cover structure and an folding umbrella can be carried together conveniently and beautifully.

Owner:TAICANG ZHETAITIAN PROD DESIGN

Ink cartridge for printer

InactiveCN107813612ASolve the hourglassAvoid affecting the printing effectPrintingImpellerEngineering

The invention discloses an ink box for a printer, which comprises: a casing; an ink guiding box, which is arranged inside the casing, and a fixed rod is arranged inside the said ink guiding box; body and a plurality of blades fixed on the curved surface of the first cylinder; the installation body, which includes the second cylinder and the first liquid guide tube; the air guiding mechanism, which includes the first part of the L-shaped tube body, the serpentine tube body The second part and the linear third part; the liquid guiding mechanism, which includes a protective cover, a second liquid guiding tube and an ink storage box. The present invention completely separates the liquid path of the ink in the ink cartridge from the air path of the air by designing an air guiding mechanism at the ink outlet, so as to avoid a large amount of air being dissolved into the ink when the air passes through the ink, causing Generation of large amounts of air bubbles.

Owner:北海市天硌打印耗材有限公司

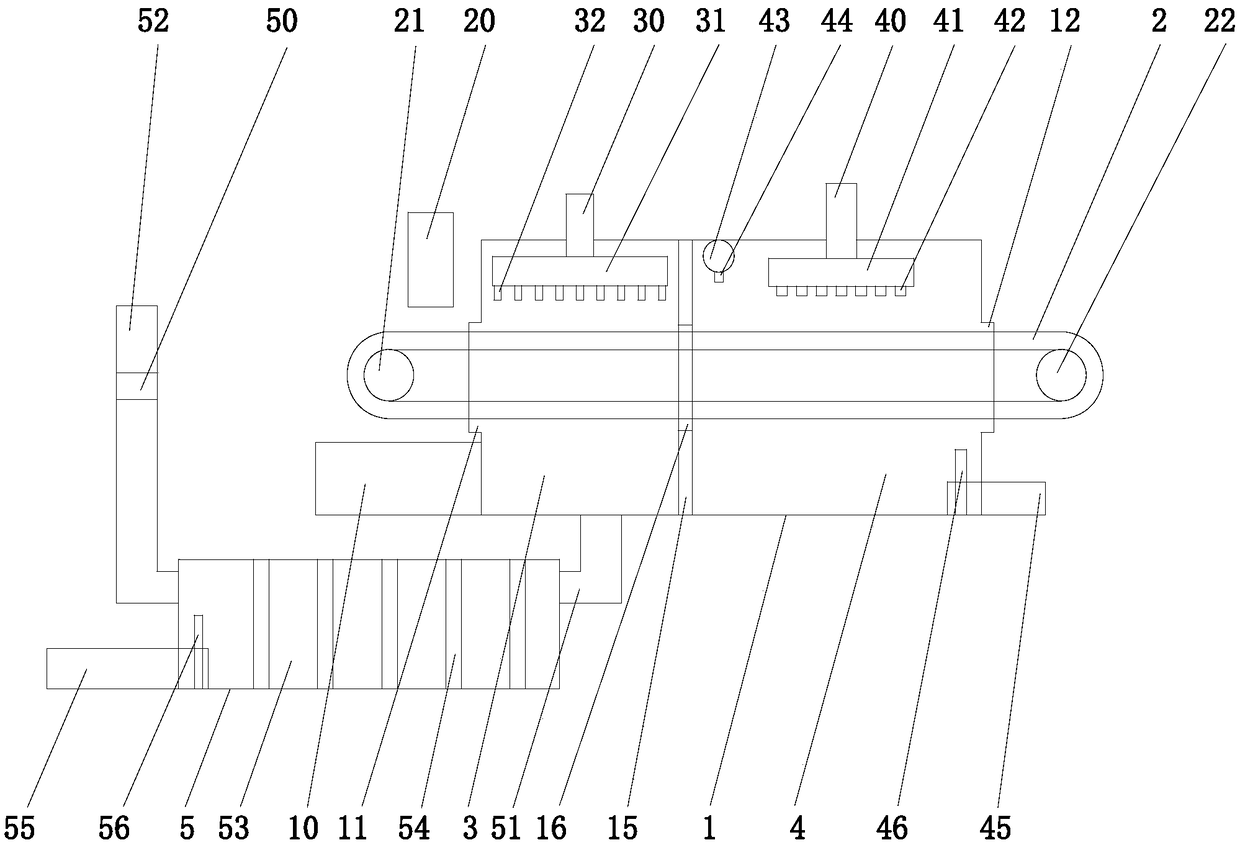

Continuous smooth cold press machine

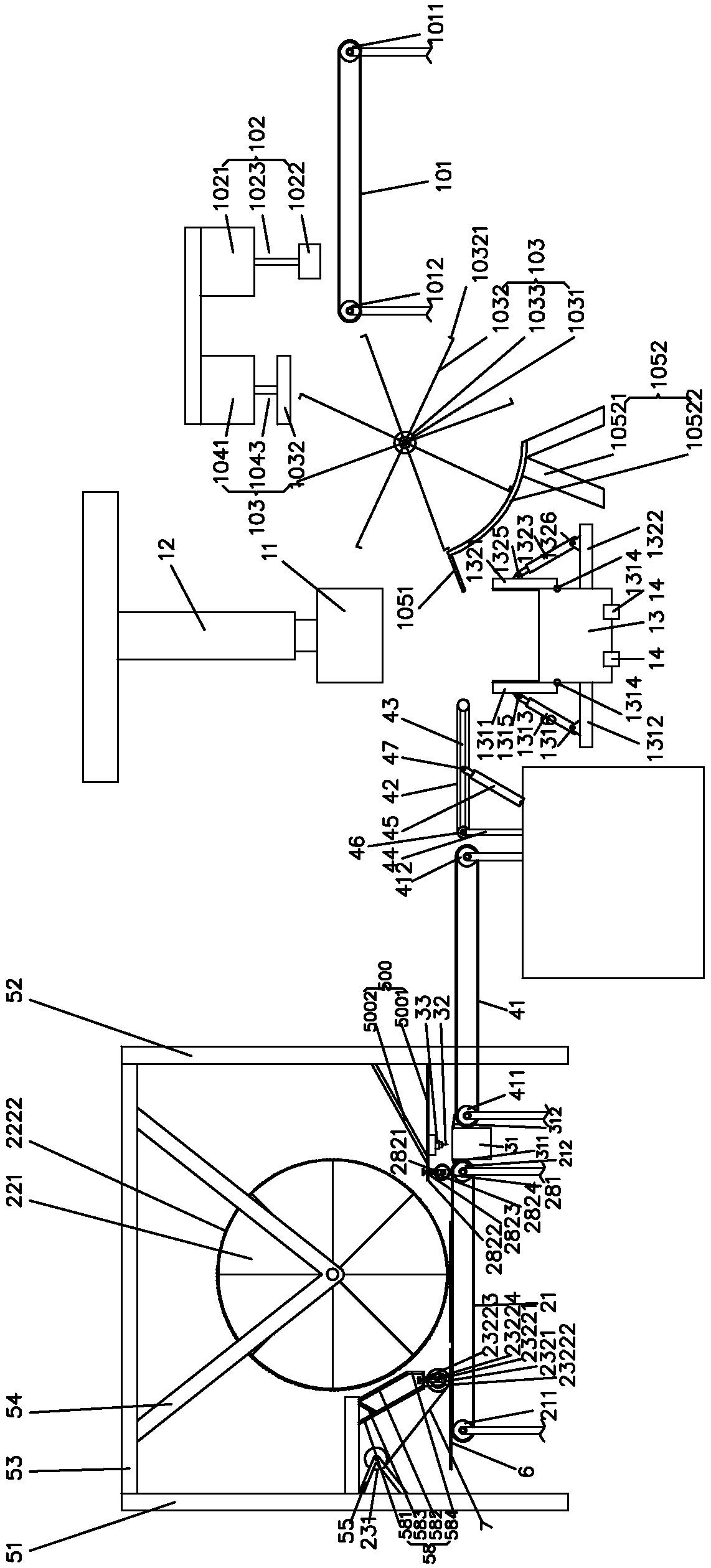

ActiveCN109049182AWon't flow outRealize automatic feedingPlywood pressesVeneer pressesProduction lineSurface layer

The invention provides a continuous smooth cold press machine. The structure form of a traditional plywood cold press machine is broken through. In the practical working process, under the control ofa master controller, brush coating is carried out on a template blank through a brush coating production line segment, brush coating template blocks are formed and conveyed to a cold press forming production line segment, a supply production line segment conveys an interlayer and an uppermost-layer template blank to the cold press forming production line segment, the uppermost-layer template blankis cushioned above the brush coating template blocks with the corresponding number to be used as a surface layer, the interlayer is cushioned above the uppermost-layer template blank to isolate the uppermost-layer template blank and the multiple brush coating module blocks which are located on the upper portion from the uppermost-layer template blank and the multiple brush coating module blocks which are located on the lower portion, cold press forming is carried out through the cold press forming production line segment finally, automatic feeding is achieved, and meanwhile multiple sheets ofplywood can be formed at a time. Compared with the prior art, cold press forming can be carried out on the template blank continuously and smoothly without interception, the mechanical degree is high, and the finished plywood is higher in strength.

Owner:漳州鑫华成机械制造有限公司

Preparation method of hot curing emulsion slurry for integration of rubber shoe upper and sole

ActiveCN102321440AImprove adhesionSmall fluctuationNatural rubber adhesivesNon-macromolecular adhesive additivesPolymer scienceVulcanization

The invention discloses a preparation method of hot curing emulsion slurry for the integration of a rubber shoe upper and a sole, which comprises the steps that: KOH solution, nekal BX solution, penetrant JFC solution and the mixture of stabilizer H and polyacrylamide are prepared and are uniformly mixed with natural rubber latex to prepare the hot curing emulsion slurry for the integration of the rubber shoe upper and the sole. Compared with traditional latex, the preparation method greatly improves the stability and improves the working efficiency and reduces the consumption of an emulsion slurry brush, so that the emulsion slurry brushing performance is improved, the slurry which is brushed on the upper is increased, the emulsion slurry is easier to dip by the emulsion slurry brush and the emulsion slurry cannot easily fall off, and the brushing heights are easier to maintain consistent, the applied slurry is increased and the attraction is improved; and the adhesion of the upper and the sole is significantly improved, so that the quality defect of the product that the glue of an enclosing strip is cracked when the product is in use is reduced.

Owner:JIHUA 3539 SHOE MAKING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com