Patents

Literature

121results about How to "Avoid affecting the printing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

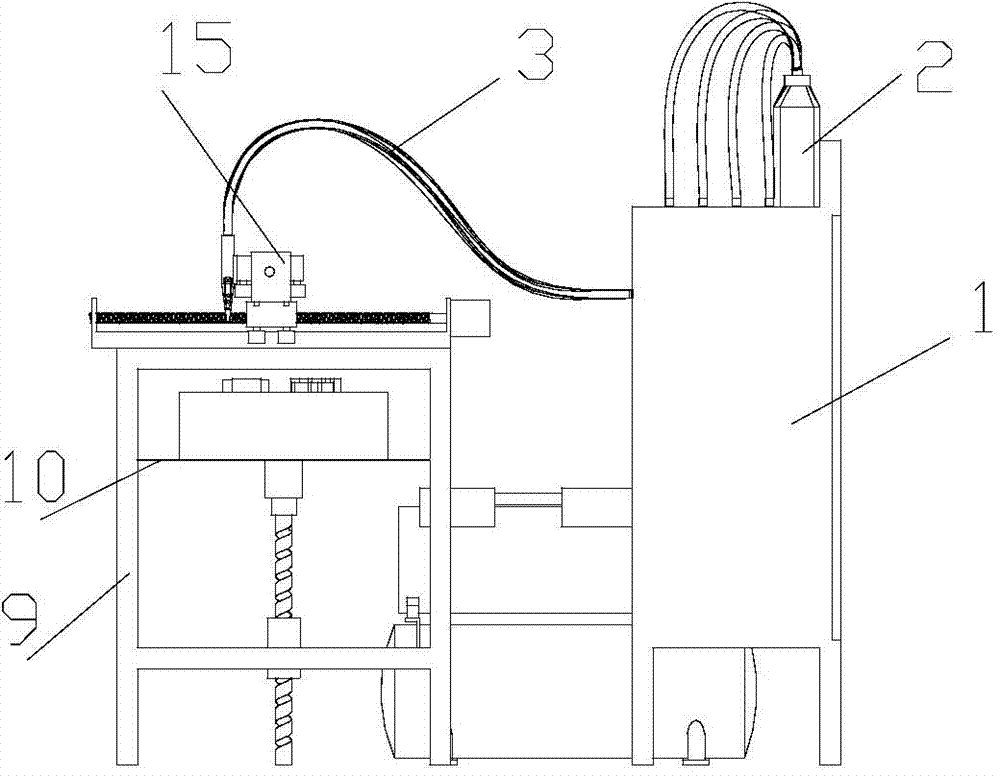

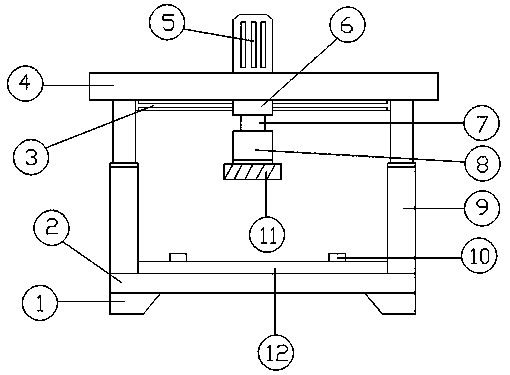

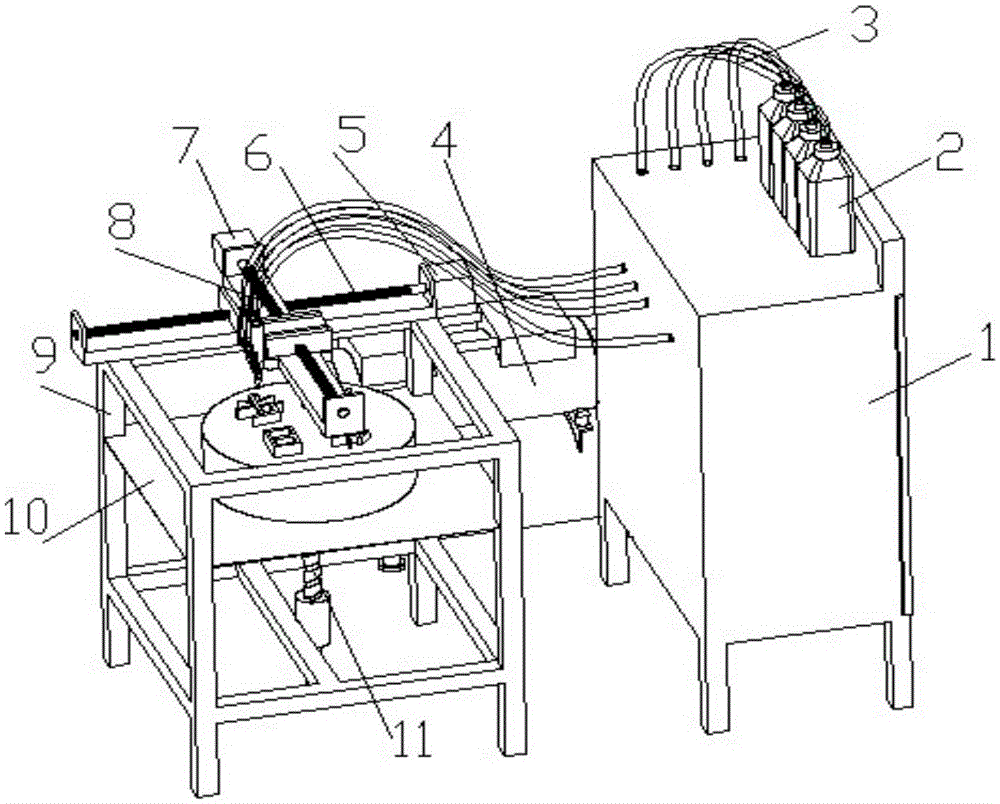

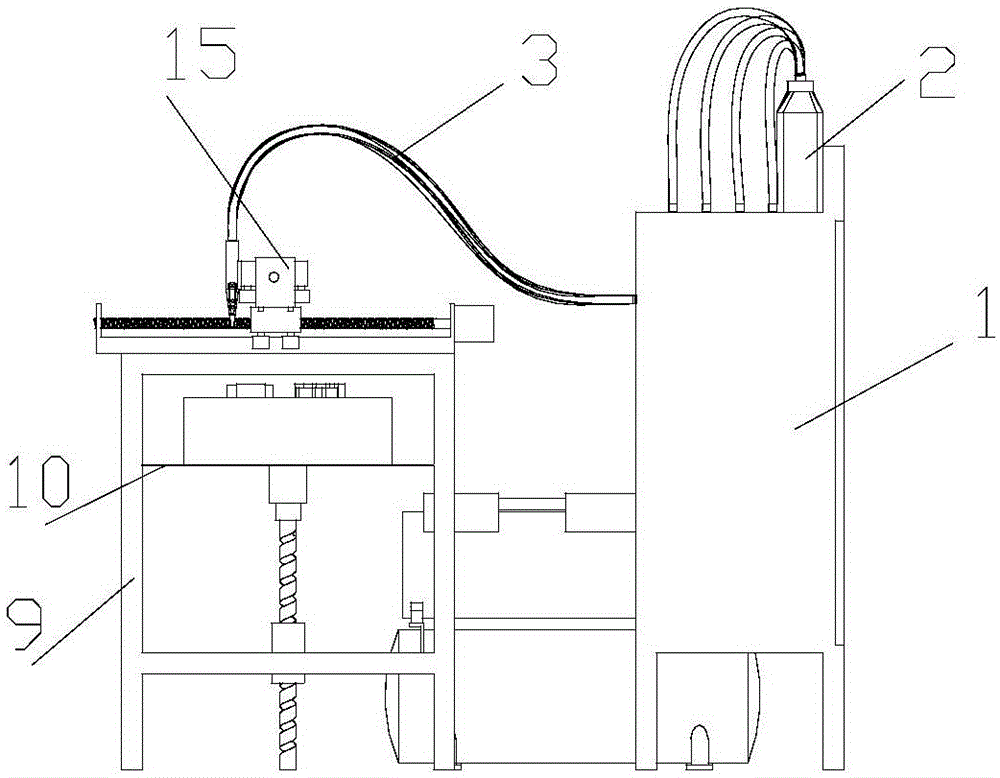

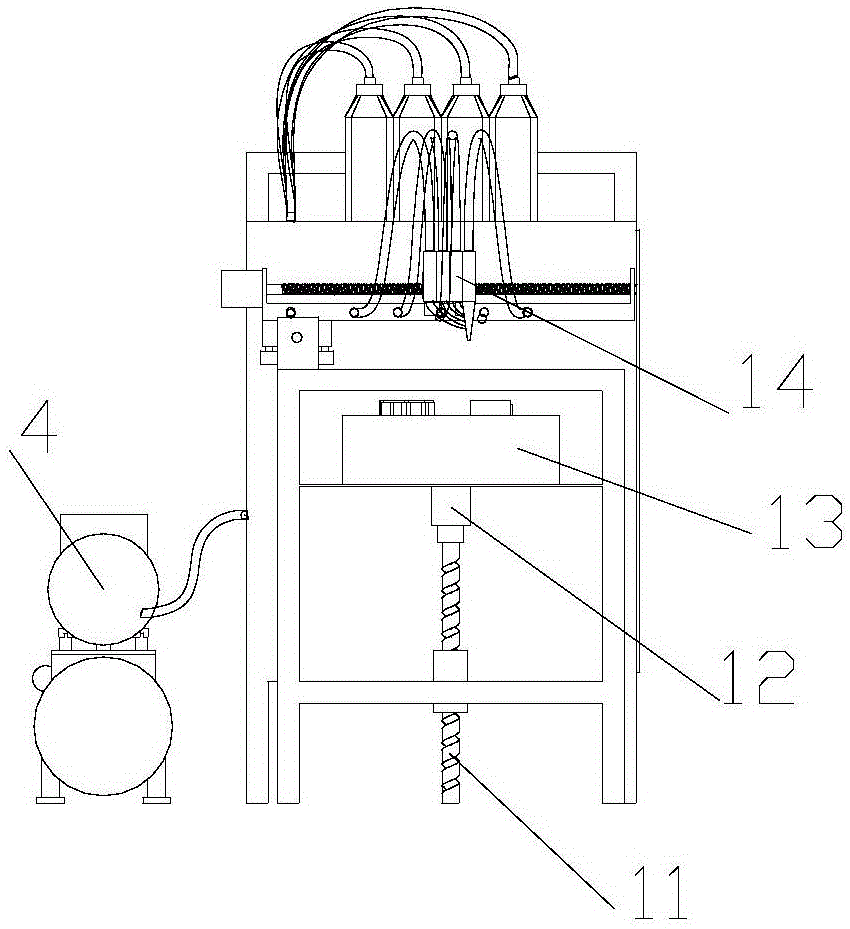

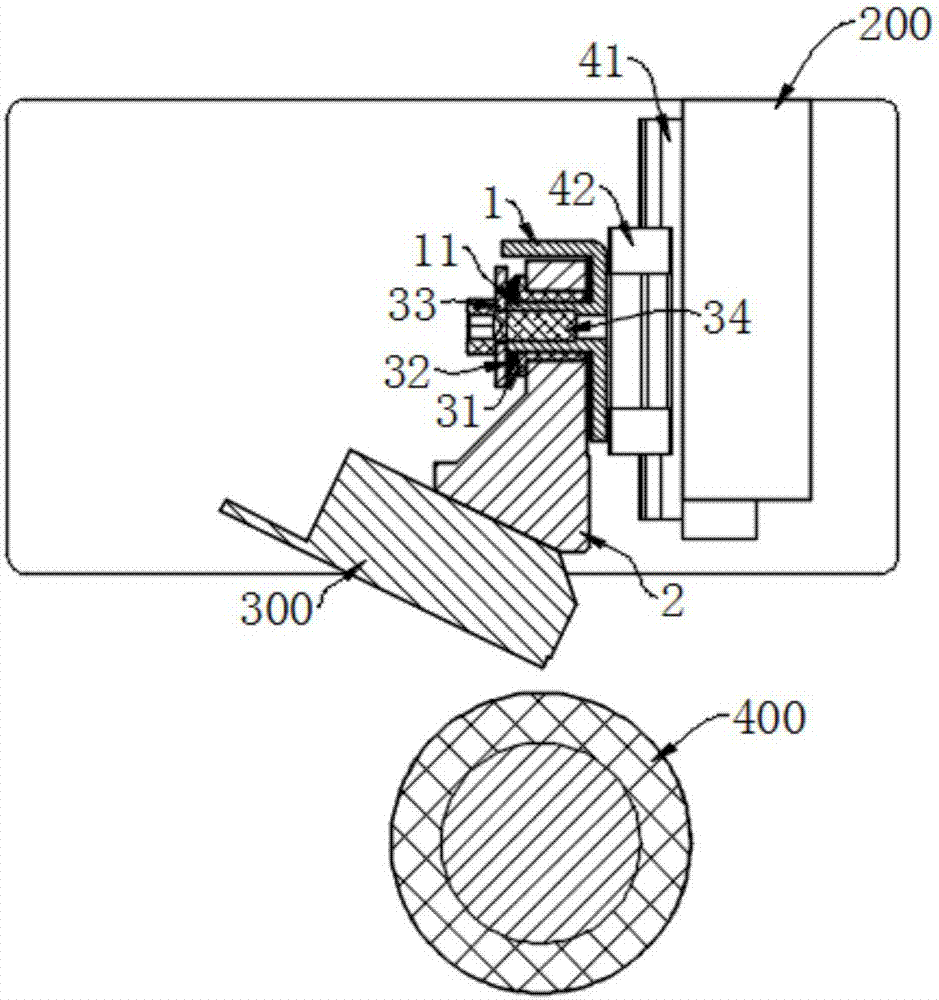

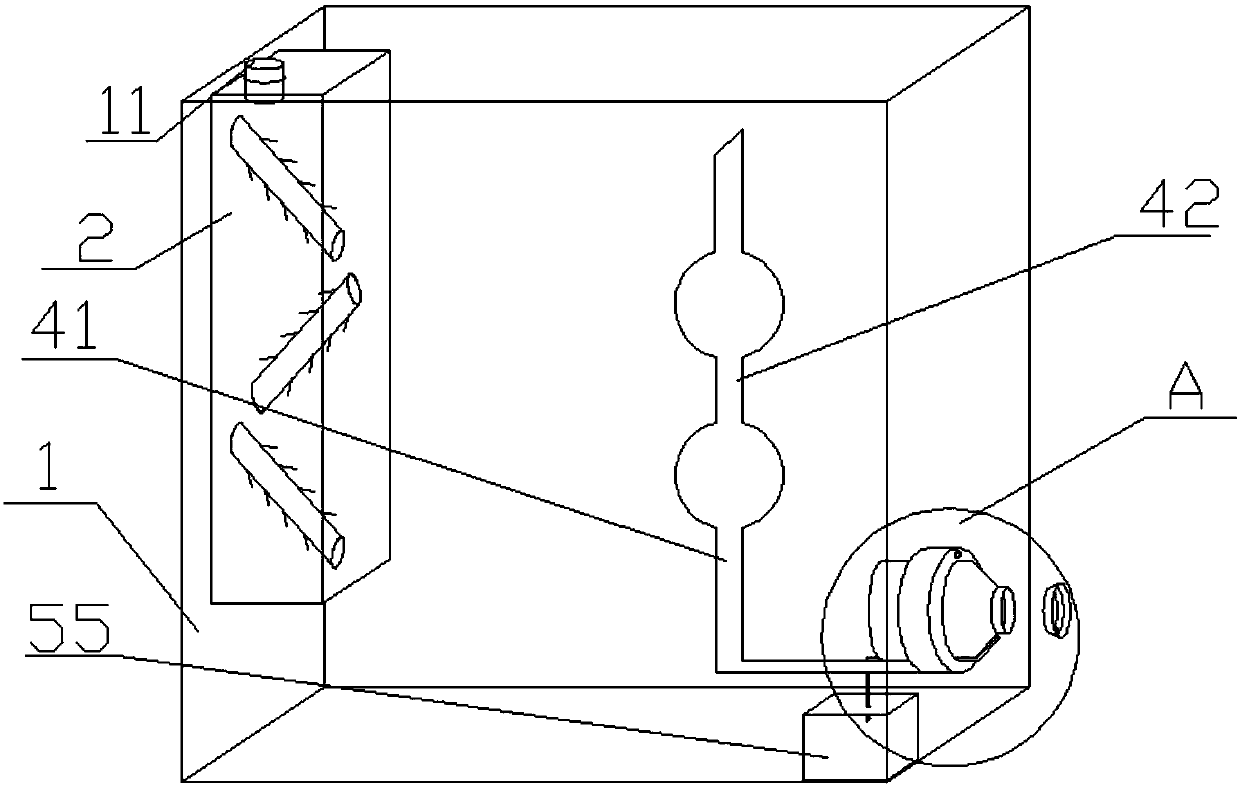

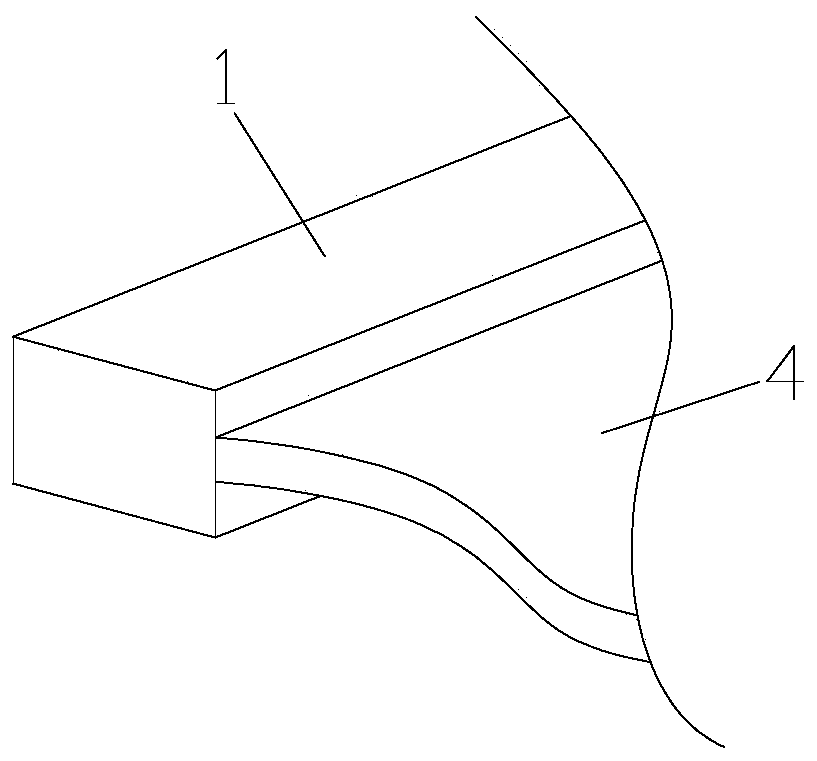

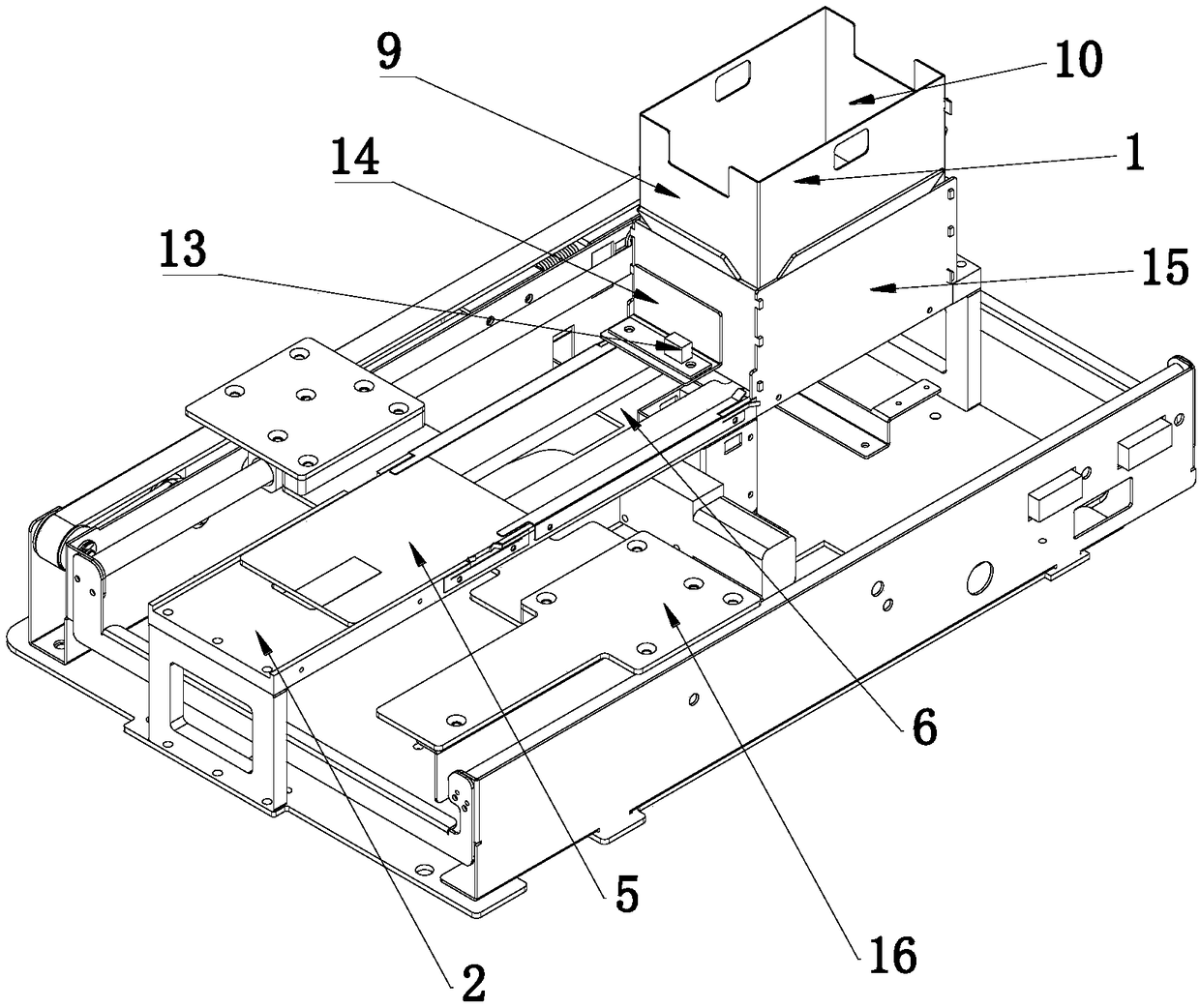

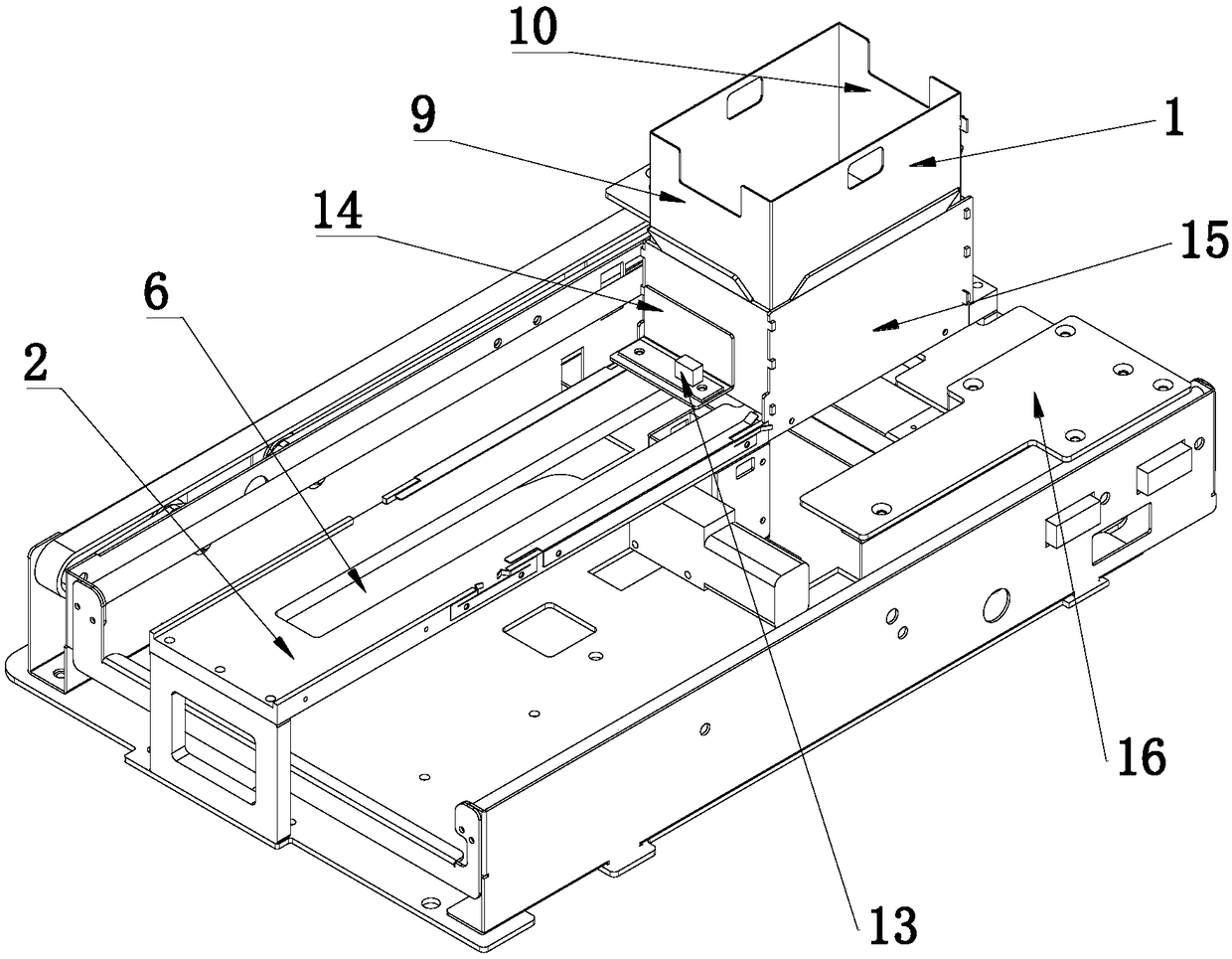

Printing device for three-dimensional biological structure and printing method

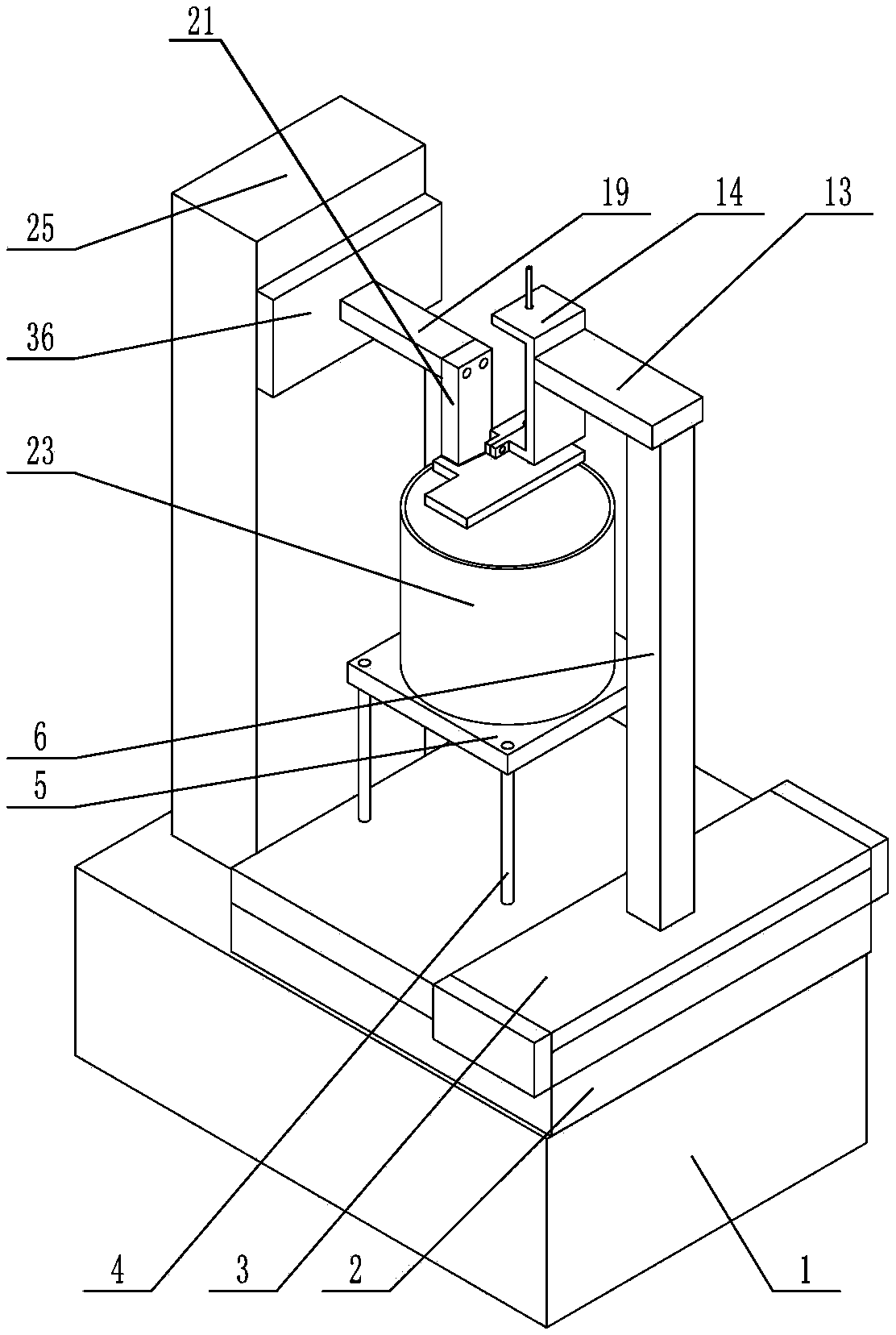

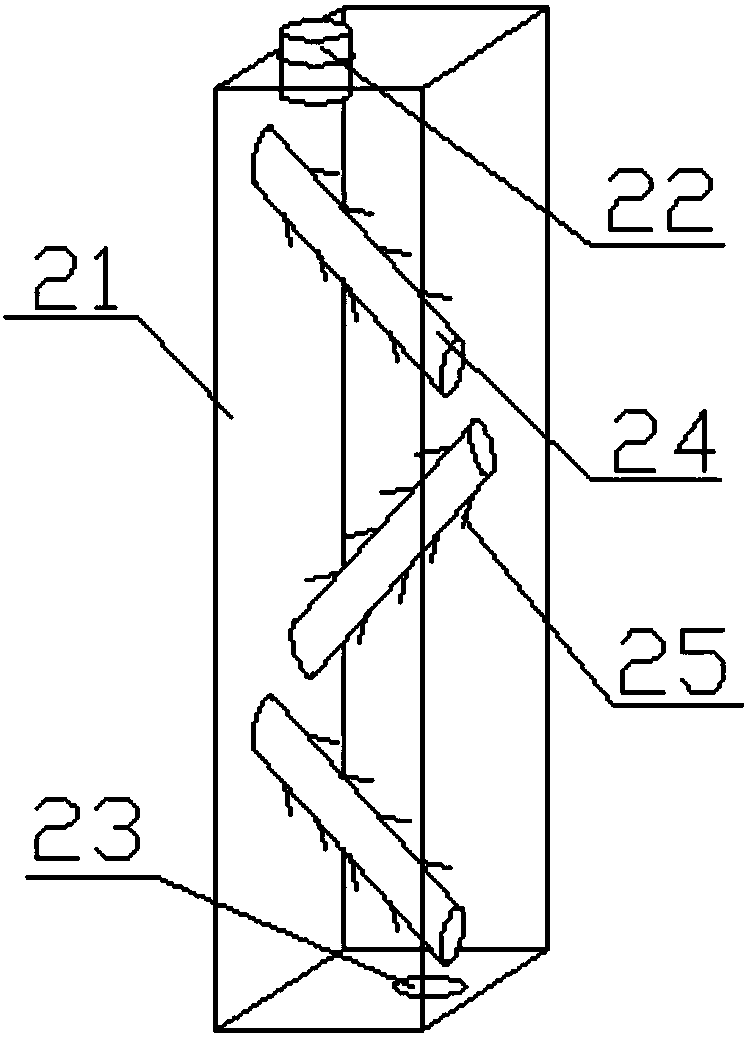

The invention discloses a printing device for a three-dimensional biological structure. The printing device comprises an execution unit with a liquid supply system, and a control unit, wherein the liquid supply system comprises an air compressor, an air capacitor communicated with an air outlet of the air compressor, and a liquid storage tank; a liquid outlet of the liquid storage tank is communicated with a liquid inlet of a spray head; a liquid inlet of the liquid storage tank is communicated with an air outlet of the air capacitor; a pressure reducing valve is arranged on a pipeline between the liquid storage tank and the air capacitor; the opening degree of the pressure reducing valve can be adjusted, and thus liquid drops at a spray nozzle of the spray head are enabled to not drop off; the height of the liquid storage tank can be adjusted, and thus the lowest end of a liquid level at the spray nozzle of the spray head is leveled with the spray nozzle of the spray head. The printing device disclosed by the invention can be widely applied to forming of biological scaffolds with various shapes, can be used for printing vascular structures and has the advantages of high printing precision, simpleness in operation, low cost and the like. Due to the adoption of the design of a replaceable clamp, a replaceable working face and a replaceable Z-shaped mounting plate, the printing device can be used for printing biological structures with different sizes and different tissue materials.

Owner:ZHEJIANG UNIV

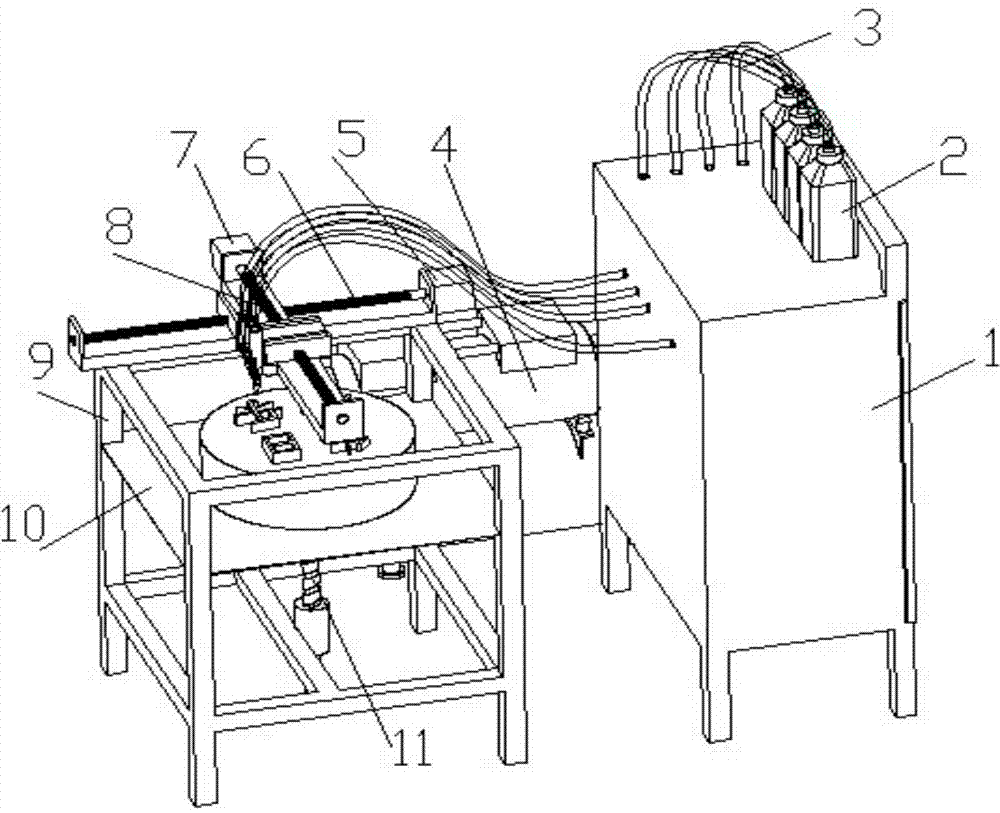

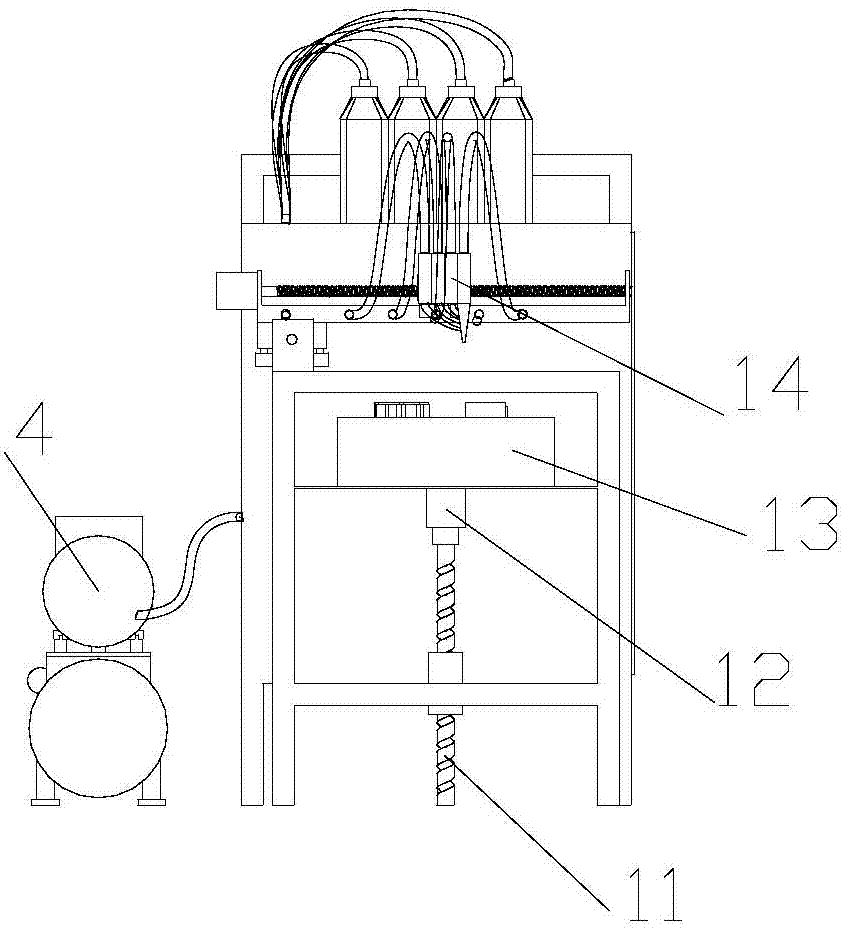

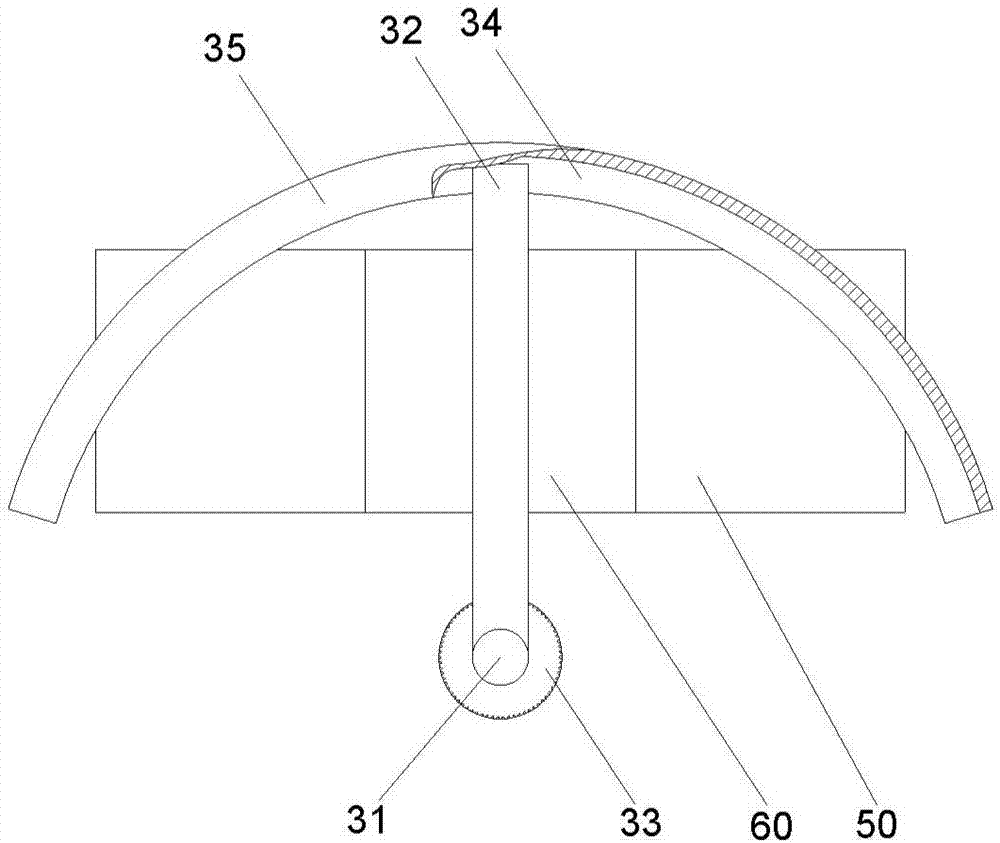

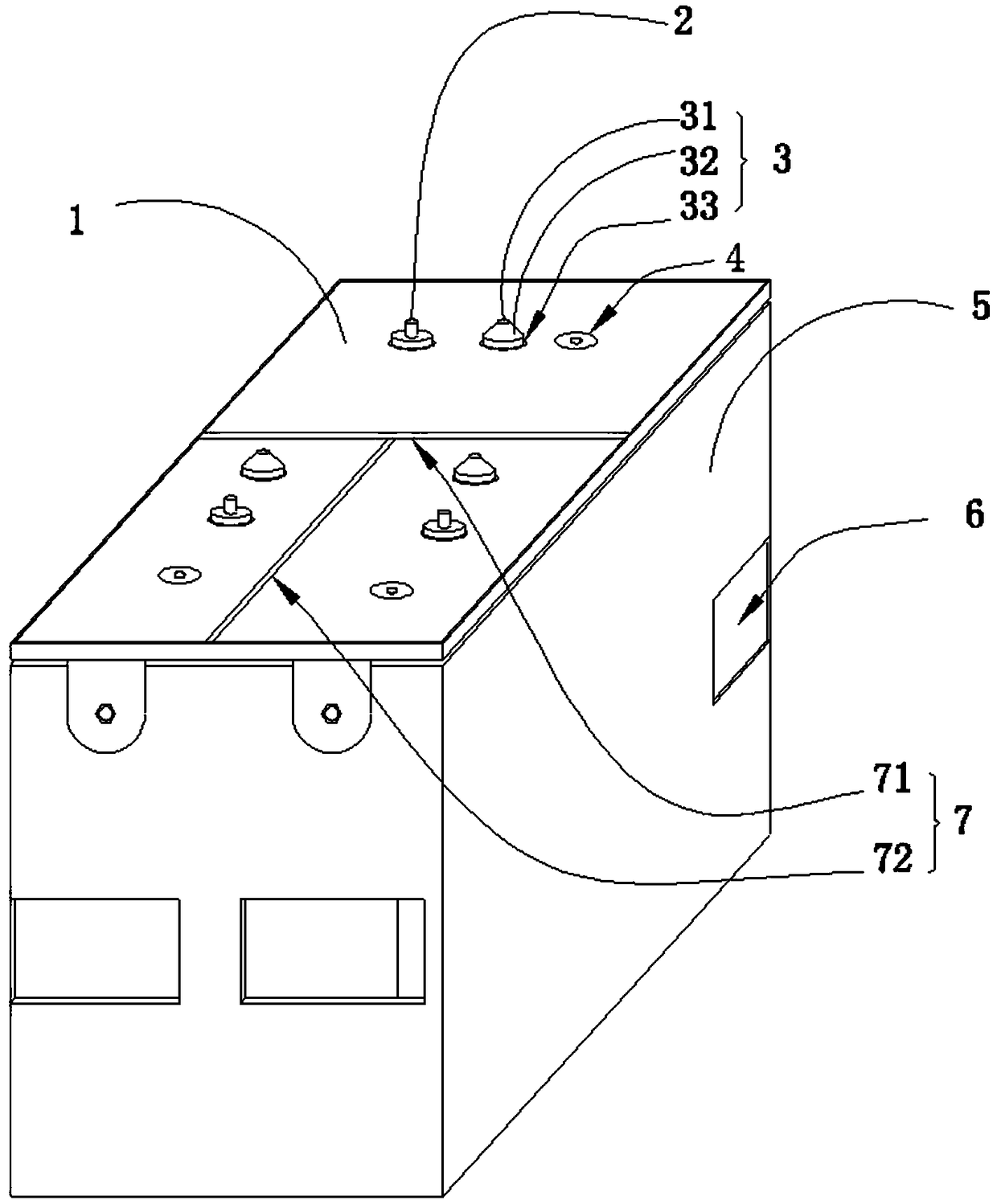

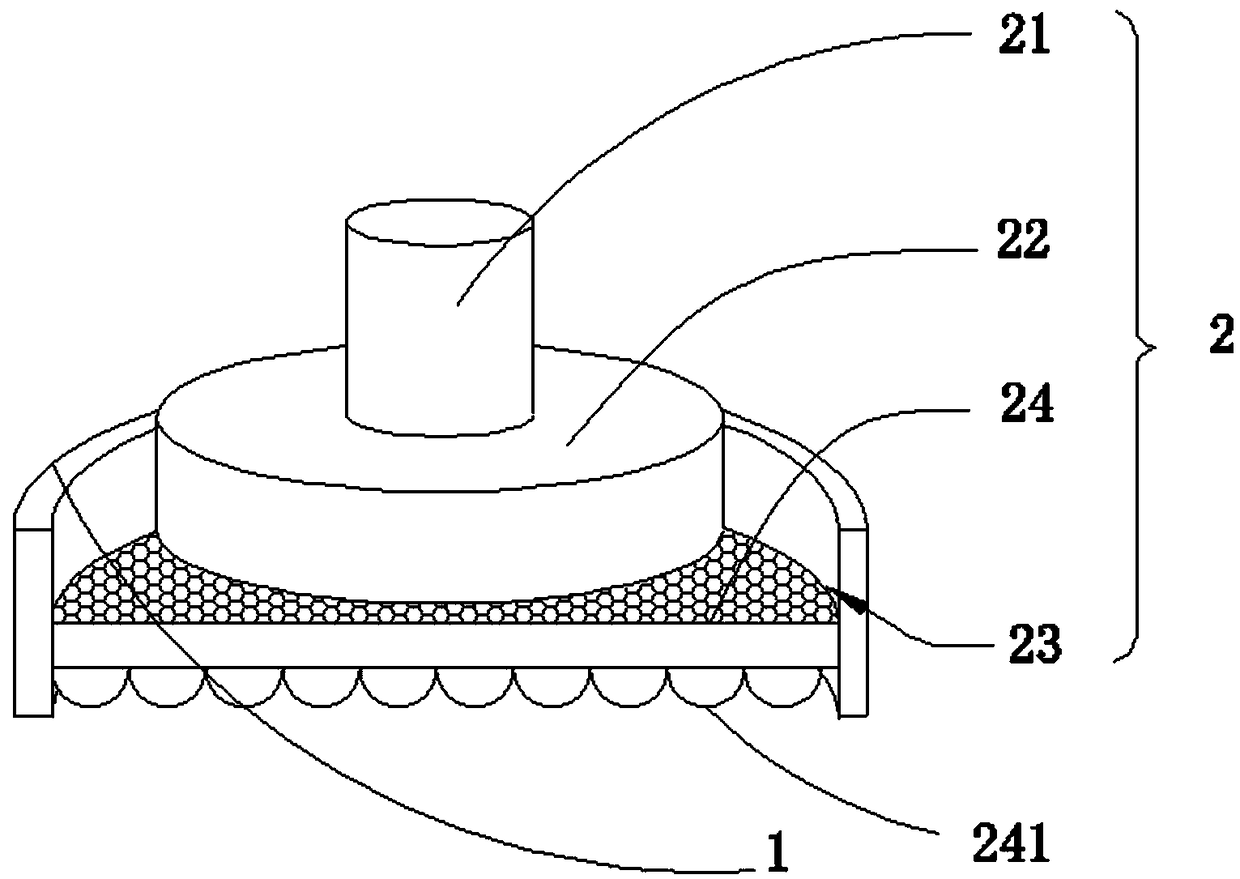

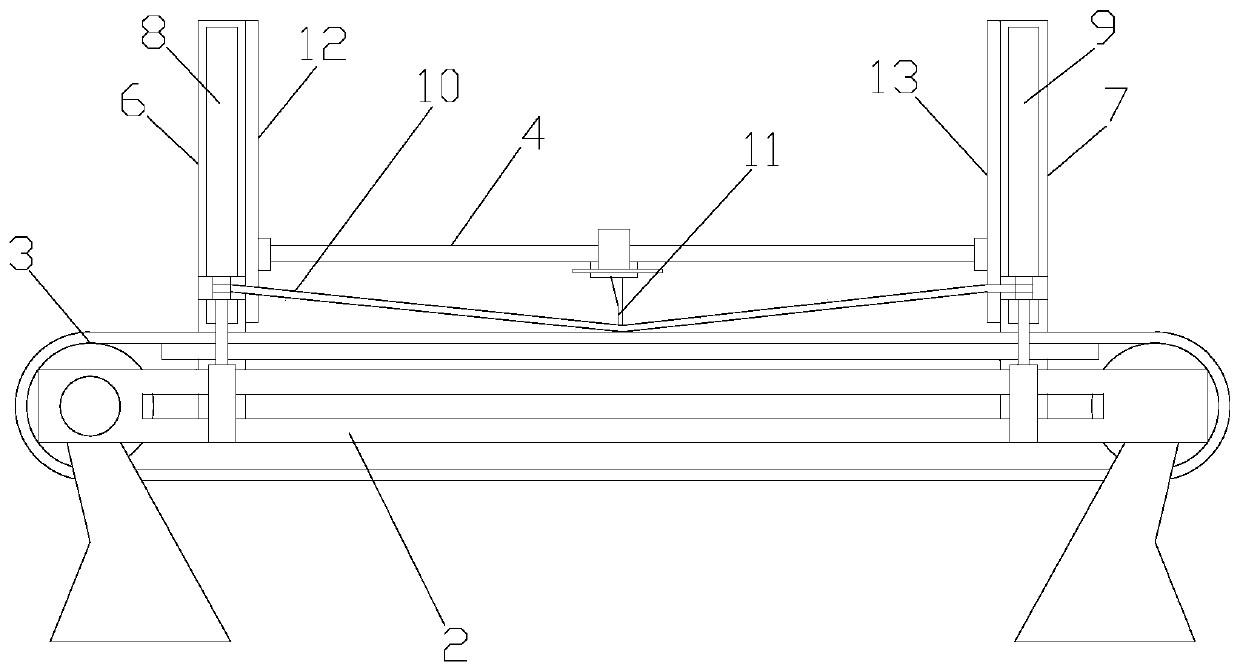

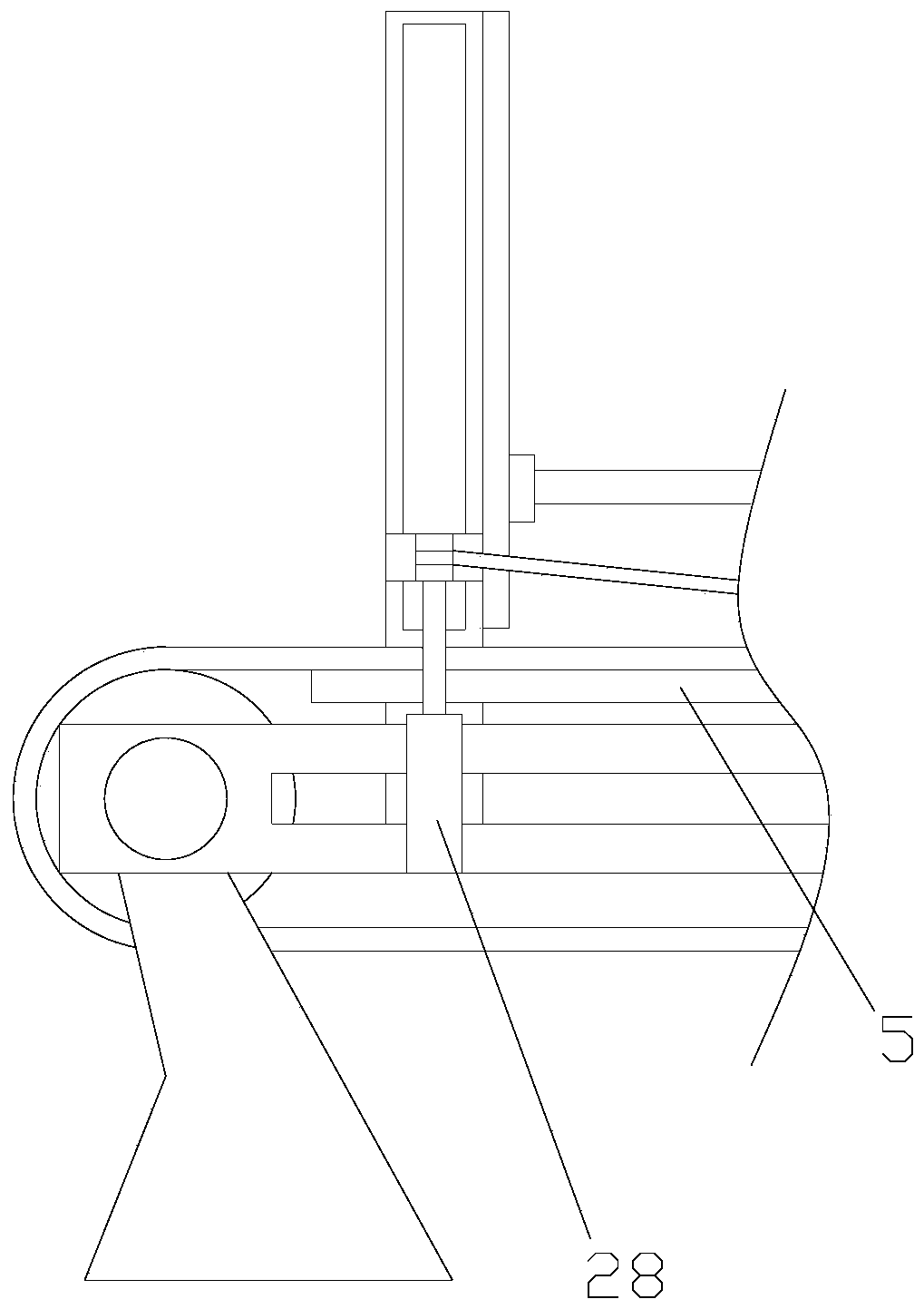

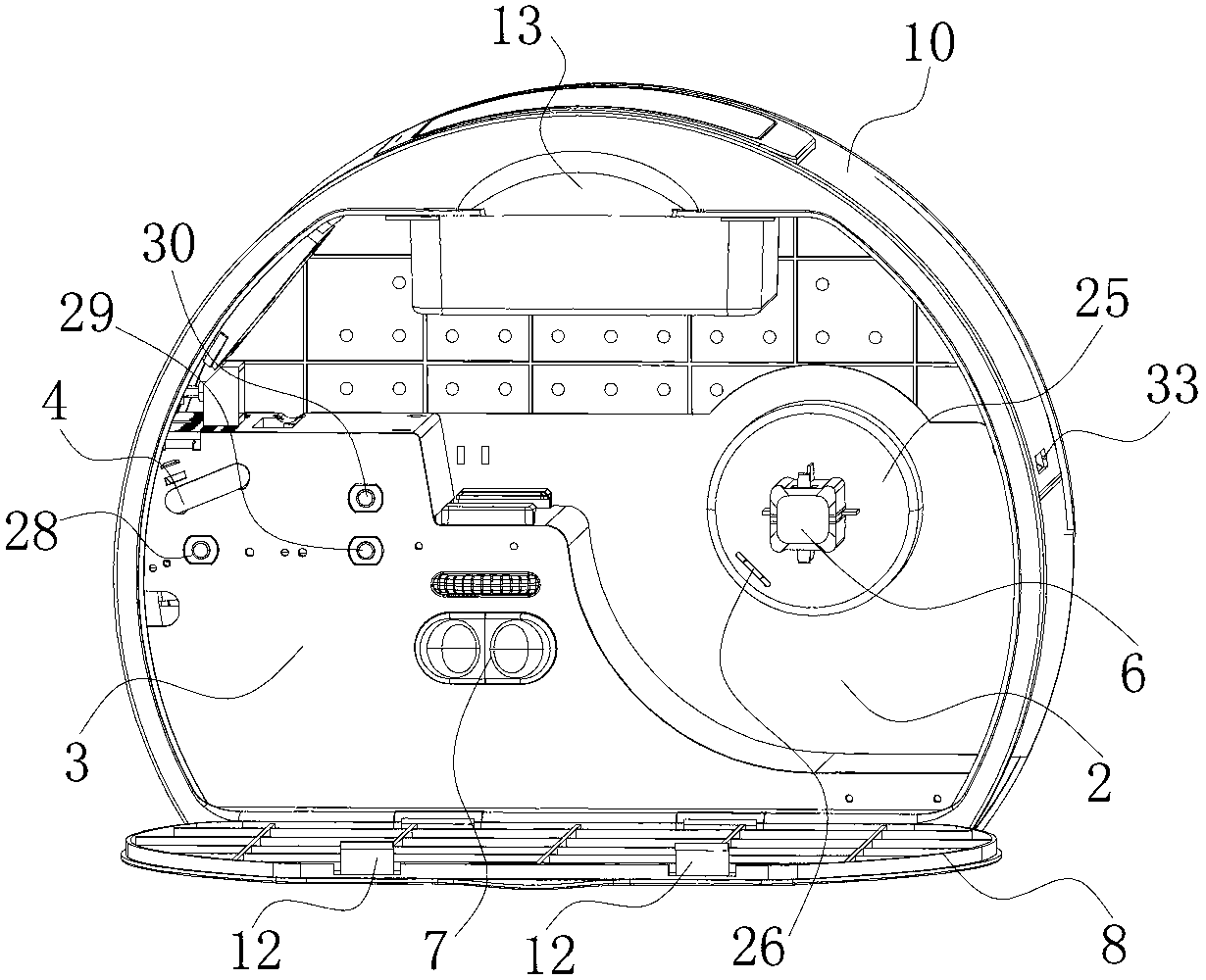

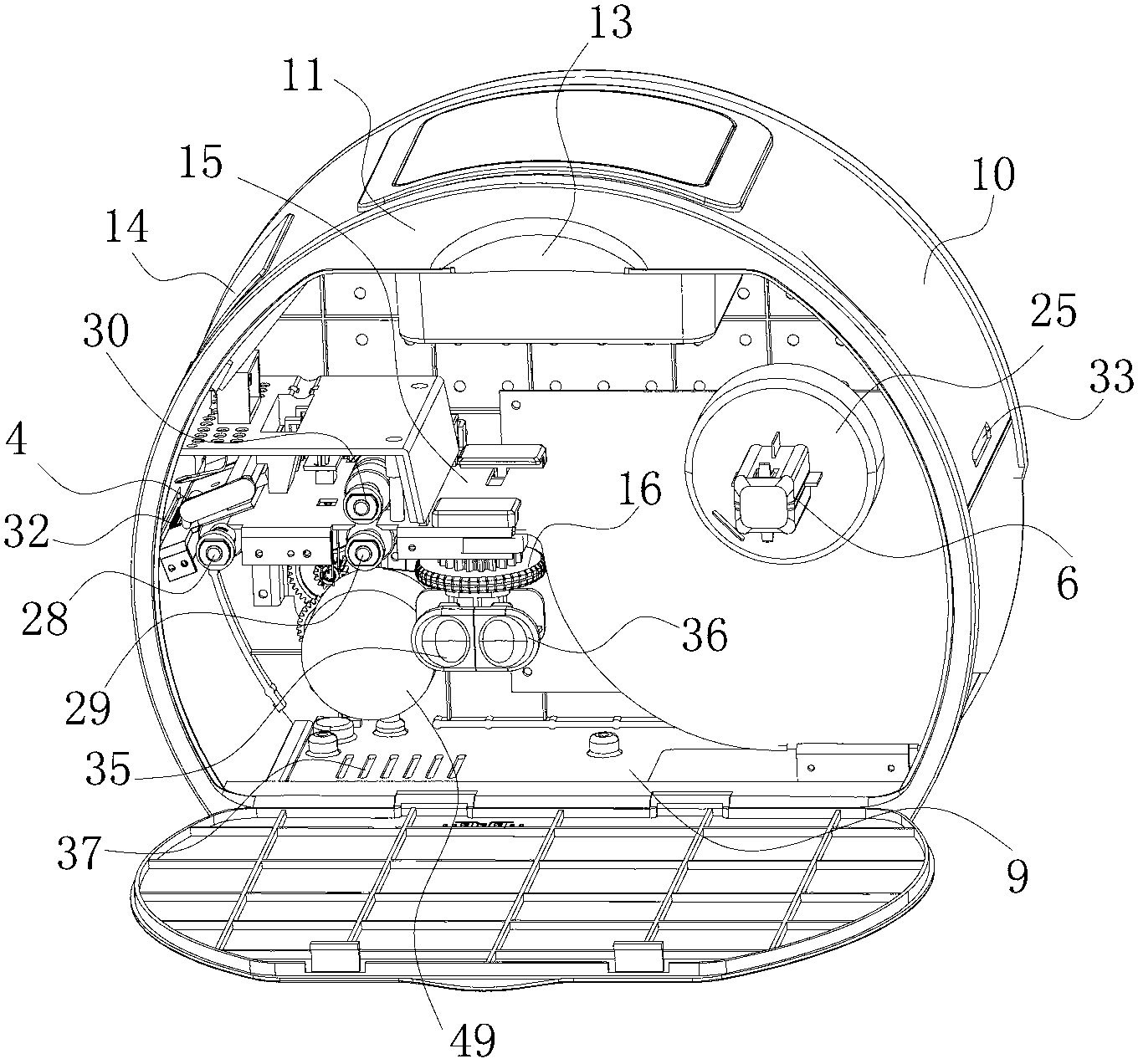

Color printing device for mounting patterns on cakes and control method of color printing device

ActiveCN104255850ASimple structureSimple and efficient operationBaked articles handlingColor printingAutomatic control

The invention discloses a color printing device for mounting patterns on cakes and a control method of the color printing device. A complete picture is dispersed into a vector diagram consisting of limited points according to certain resolution ratio by virtue of a discrete and fused technical ideal of 3D printing, and the discrete points are printed by adopting a rapid forming method so as to realize automatic printing and forming of patterns mounted on cakes. The color printing device for mounting patterns on the cakes integrates image processing, data acquisition and analysis, motor control and automatic spraying control and is simple in structure, reasonable in control scheme and is capable of substituting for manual operation of workers in the prior art so as to realize standard and industrial production, the labor intensity of the workers is greatly reduced and the working efficiency is improved. The color printing device can also be appropriately refitted in combination with related prior art so as to be used for surface spraying of murals and models, drawing of cartoon patterns on surfaces of toys, and the like.

Owner:SHANDONG UNIV OF SCI & TECH

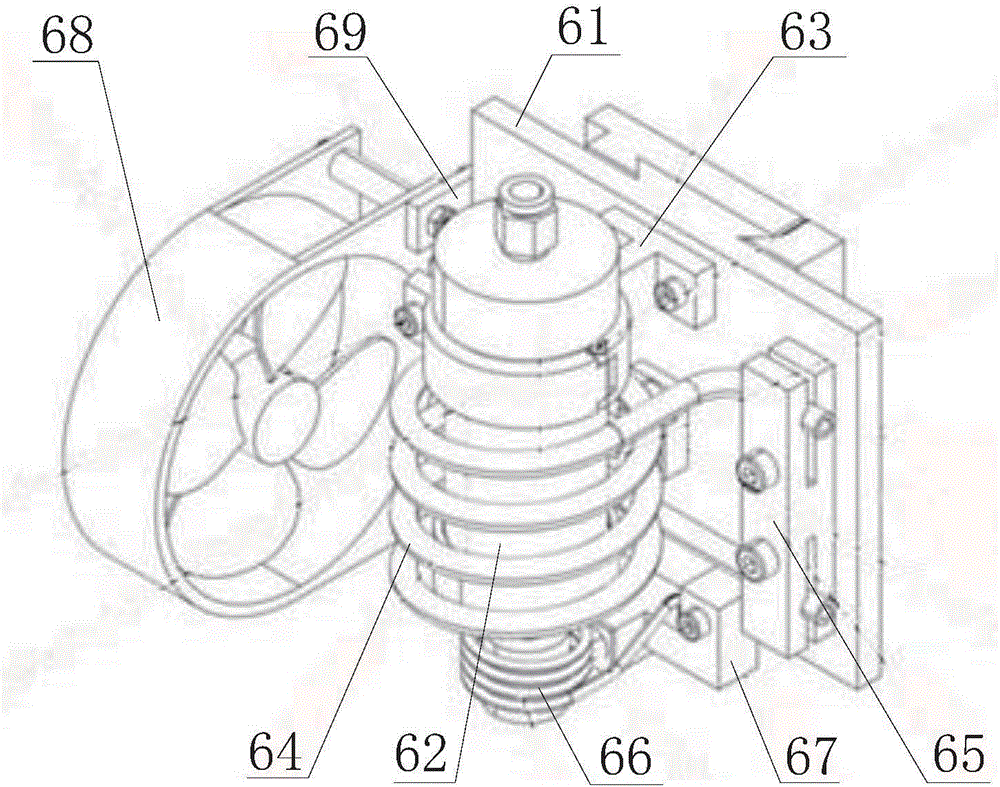

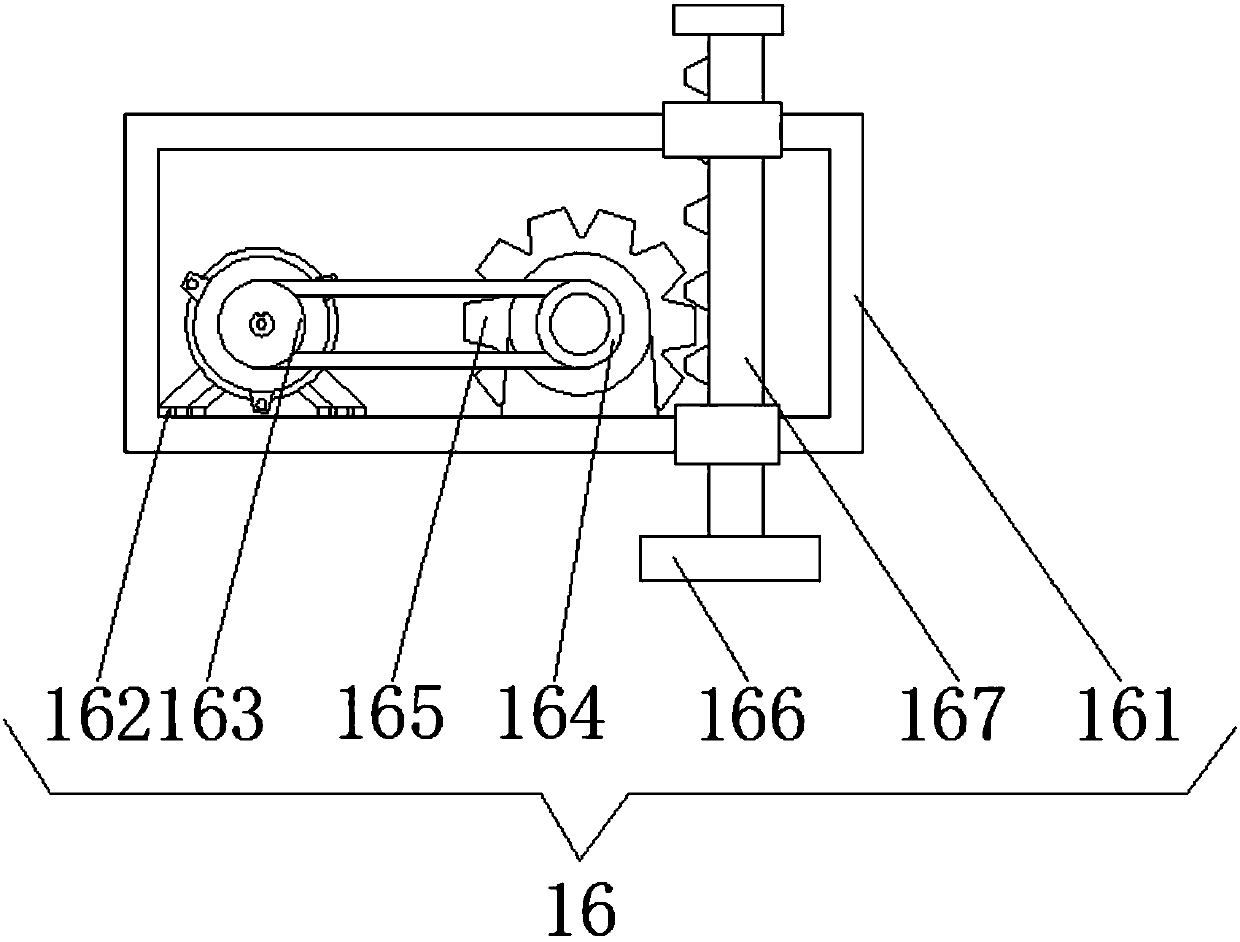

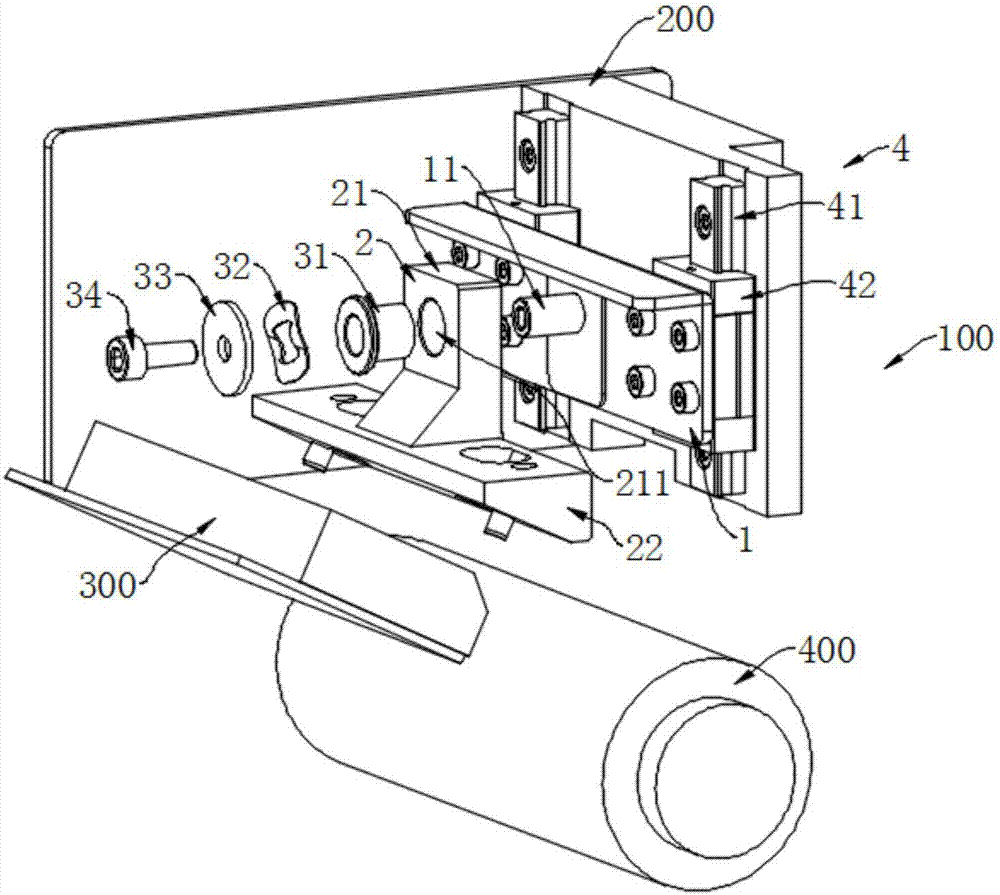

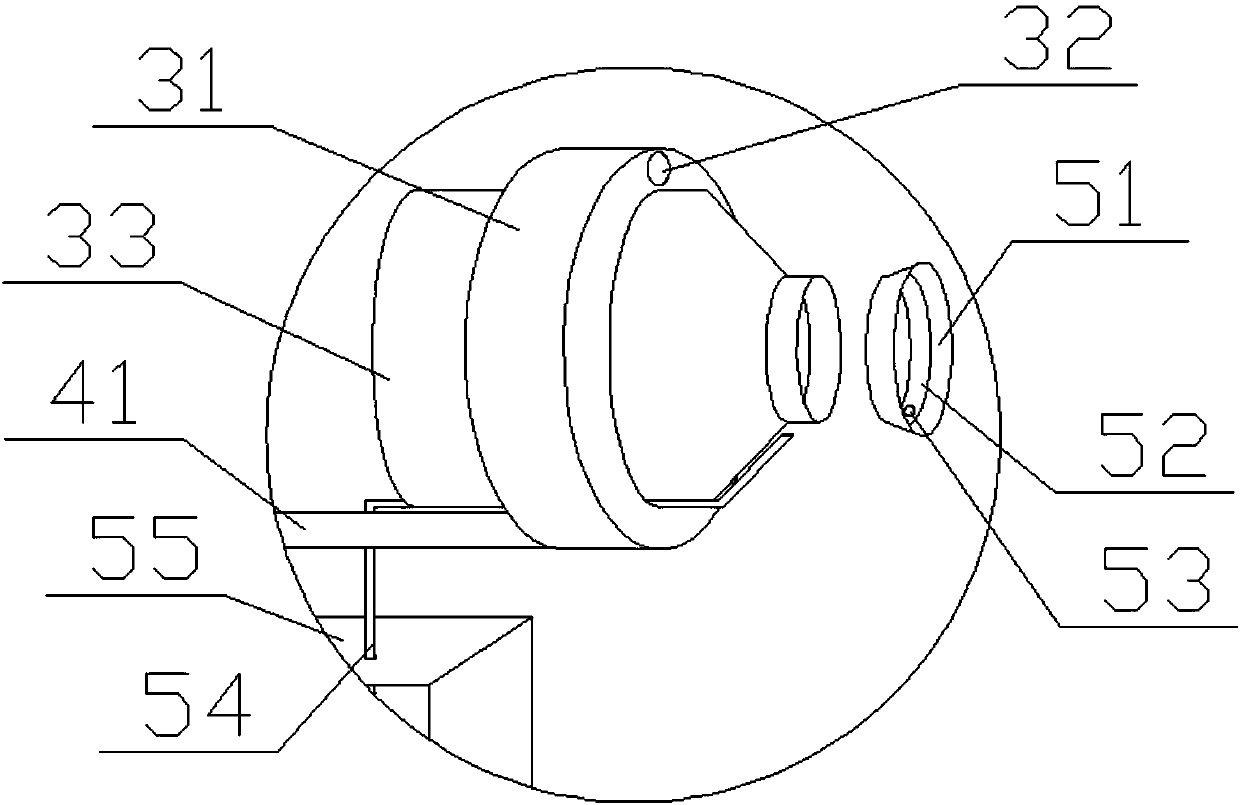

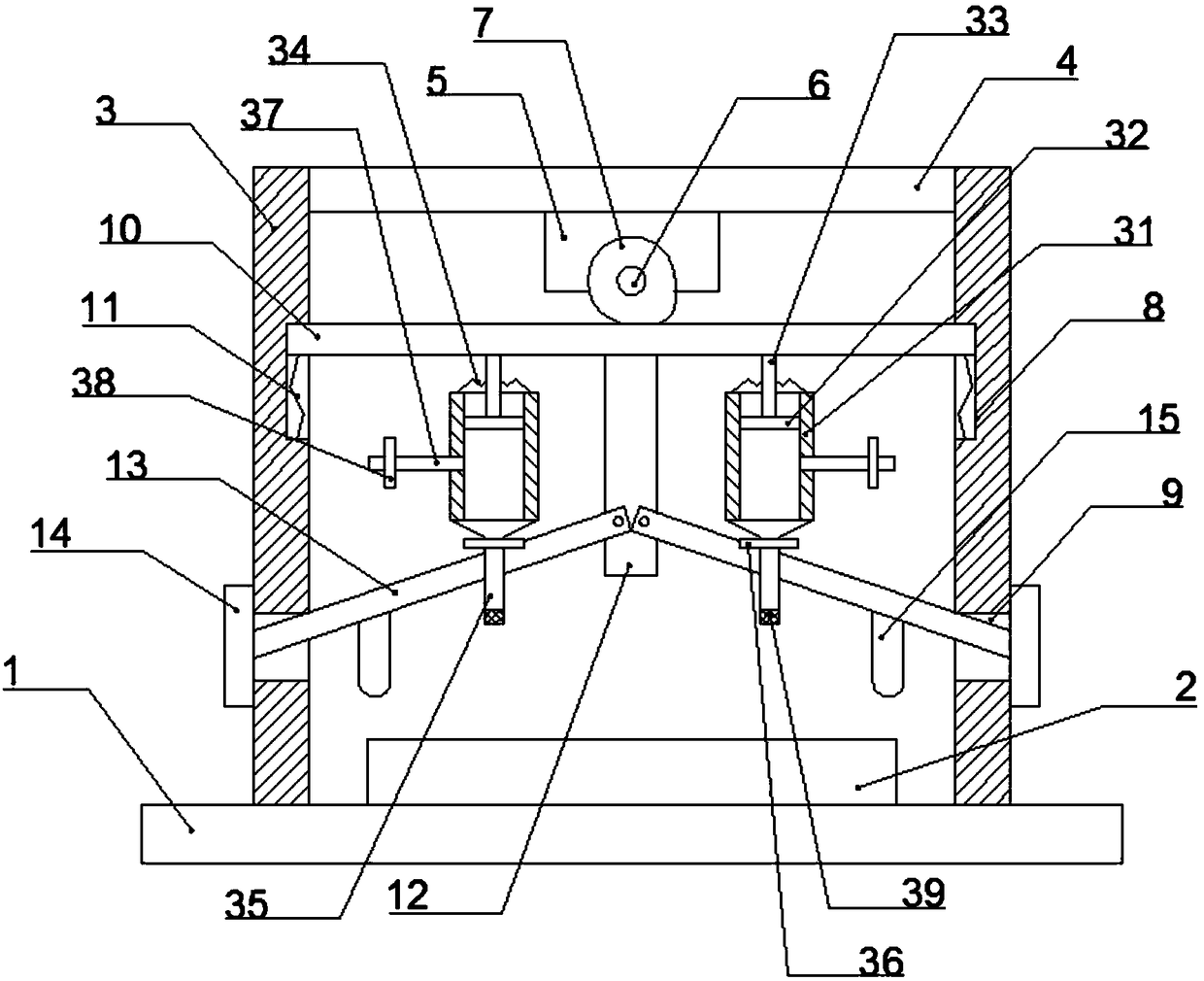

Fused and deposited 3D printer capable of rapidly changing a printing nozzle

ActiveCN106493941AQuick changeEasy to disassembleManufacturing heating elements3D object support structuresMetallic materialsControl circuit

The invention discloses a fused and deposited 3D printer capable of rapidly changing a printing nozzle, which comprises a printing table and a printing head, wherein the printing head comprises: a supporting plate; a printing nozzle made of a metal material and fixed on the supporting plate via a stand of the printing nozzle; a heating device, comprising an electromagnetic induction coil, the electromagnetic induction coil sleeving the printing nozzle and fixed on the supporting plate via a stand of the coil; a cooling device, used for cooling the printing nozzle, and fixed on the supporting plate via a cooling stand; and a control circuit, electrically connected to the electromagnetic induction coil to provide an alternating voltage for the electromagnetic induction coil. The heating mechanism and the printing nozzle mechanism of the fused and deposited 3D printer are separated from each other to facilitate rapid change of the printing nozzle.

Owner:ZHEJIANG UNIV

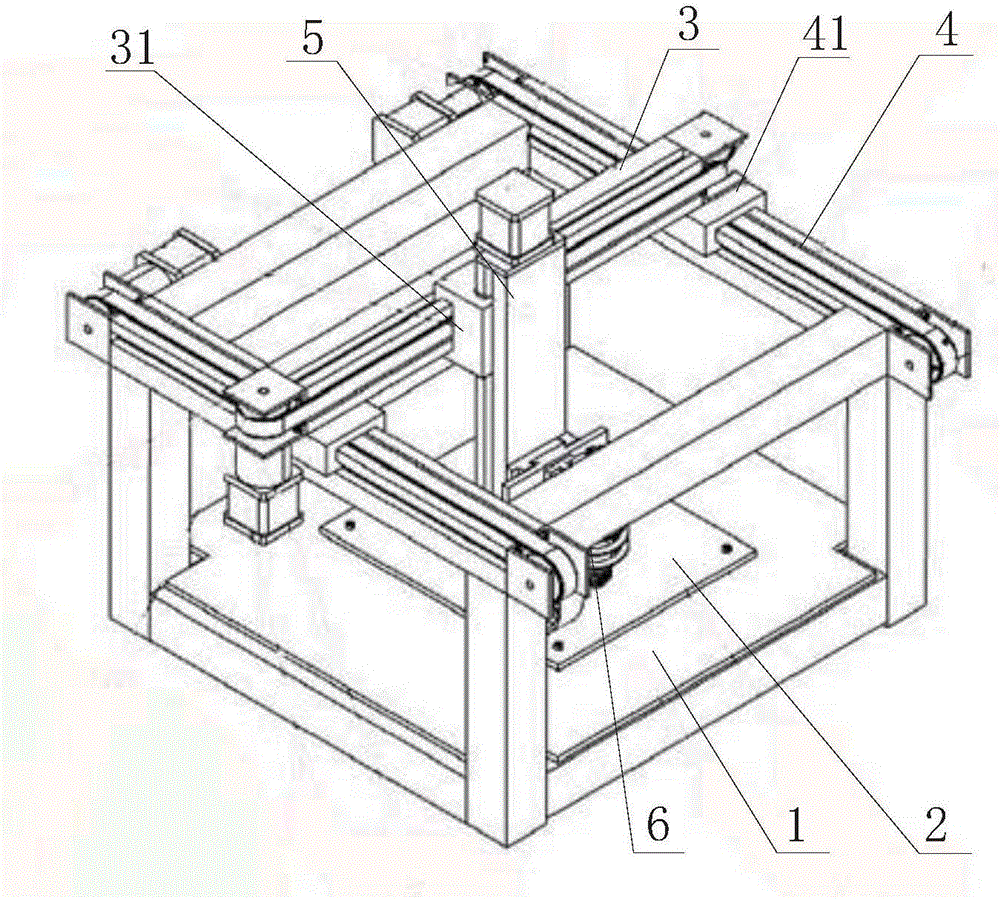

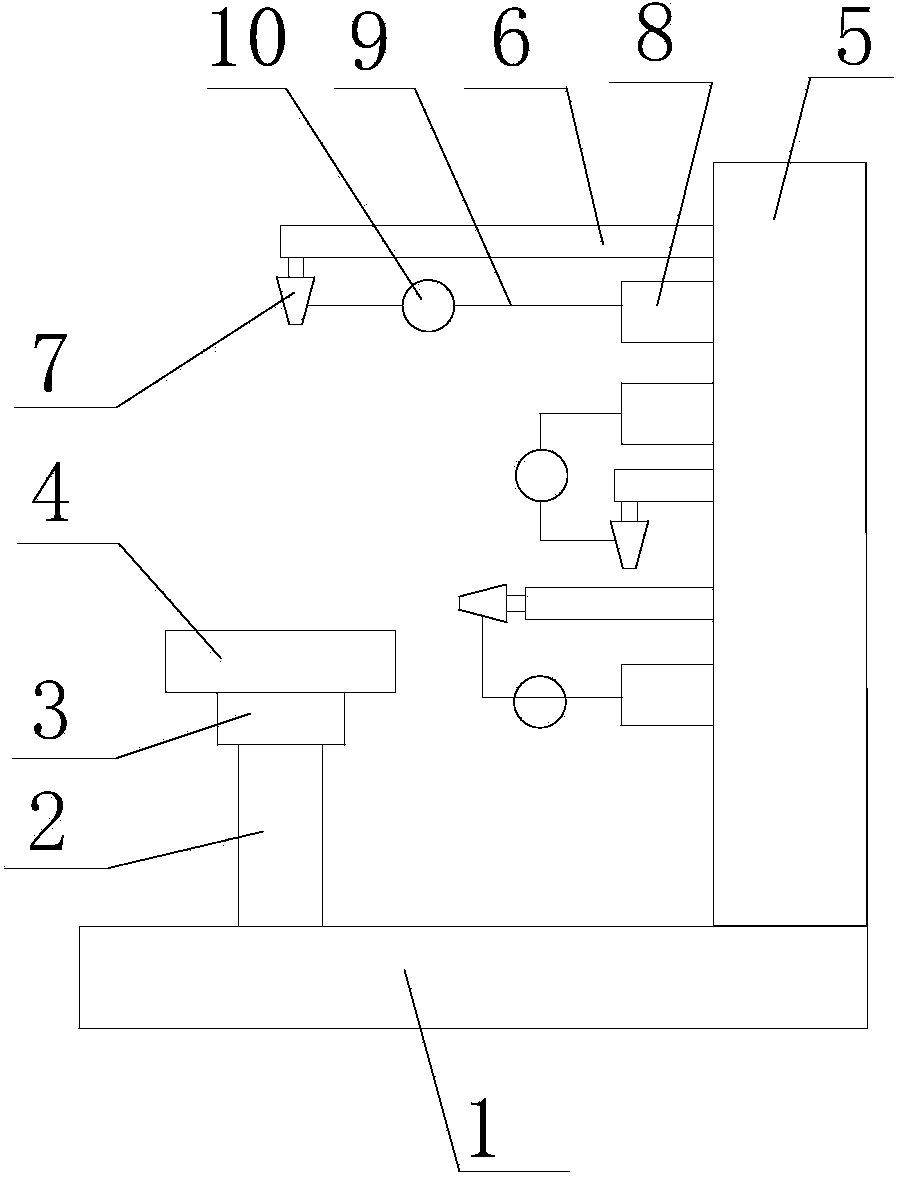

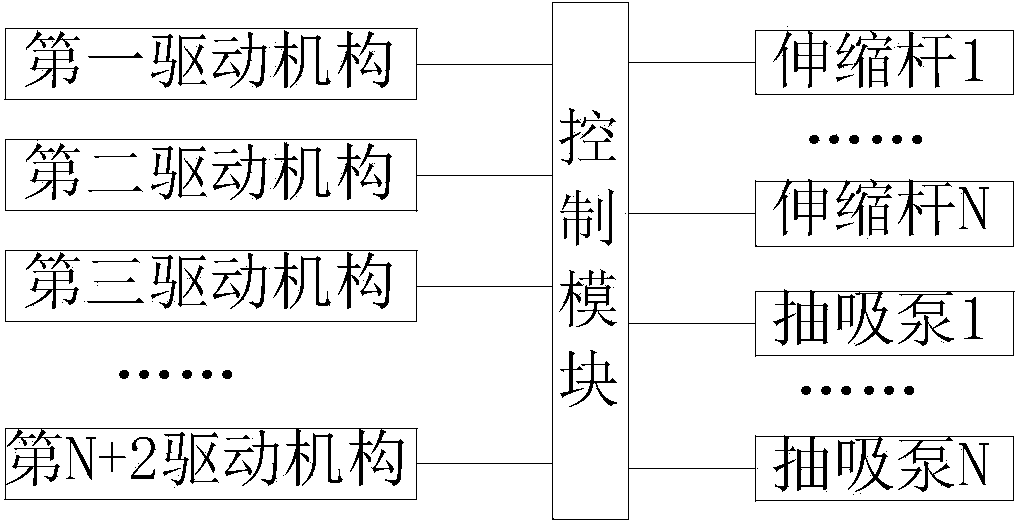

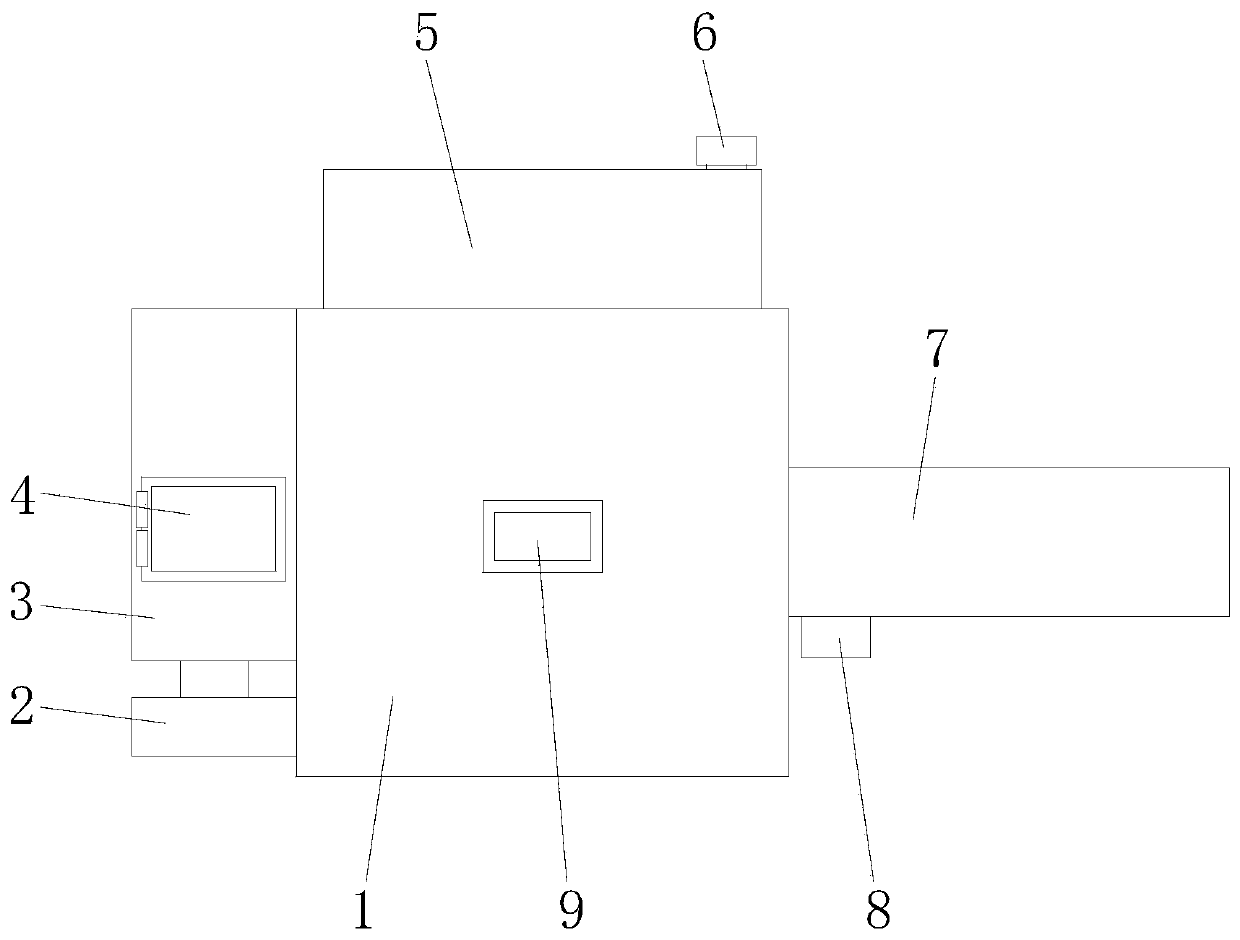

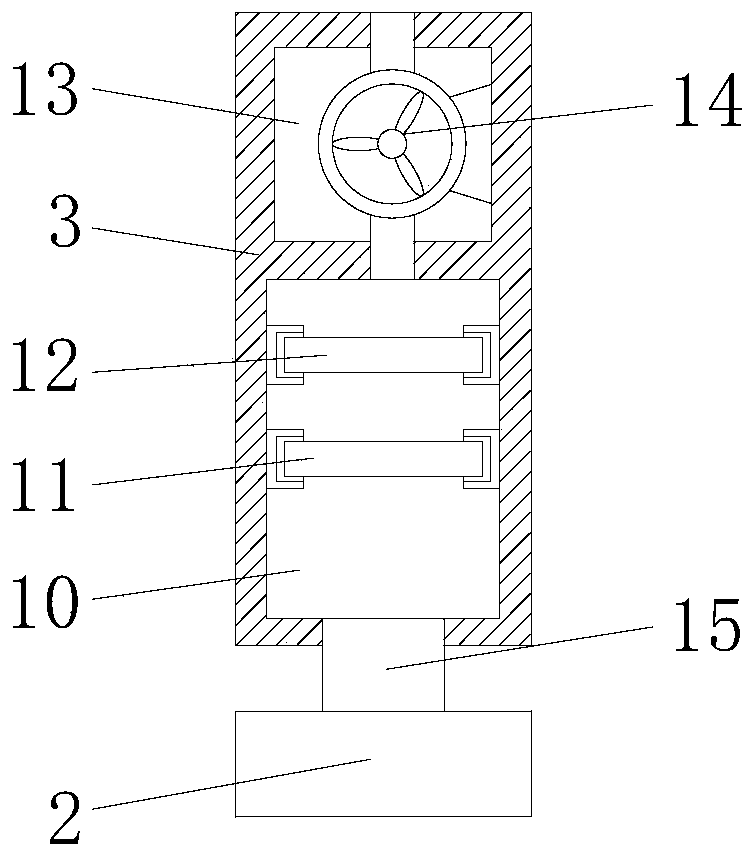

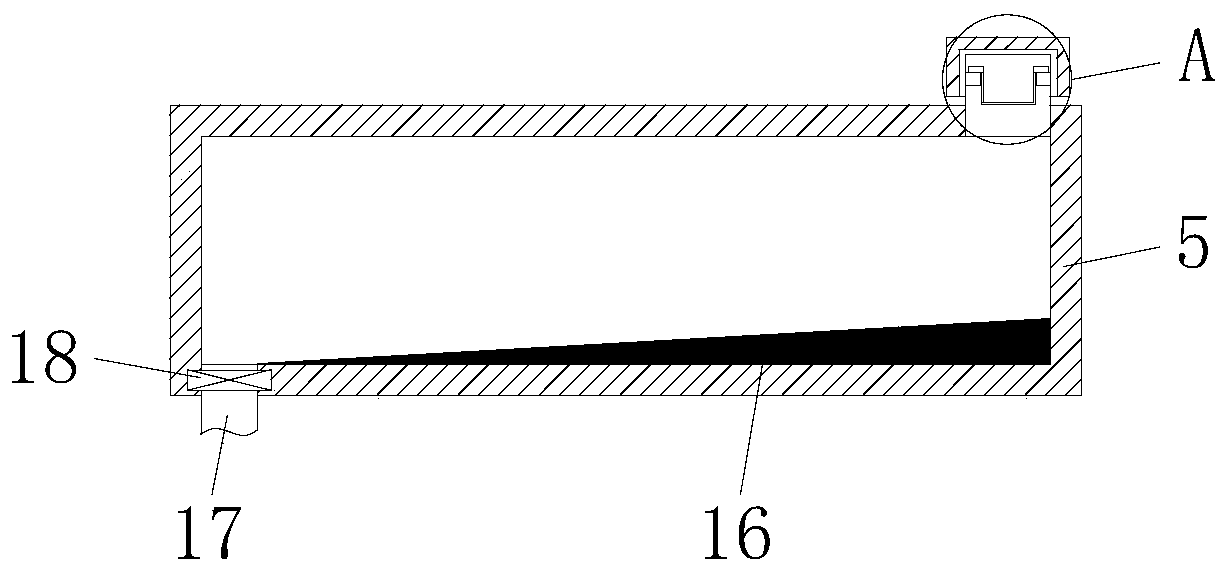

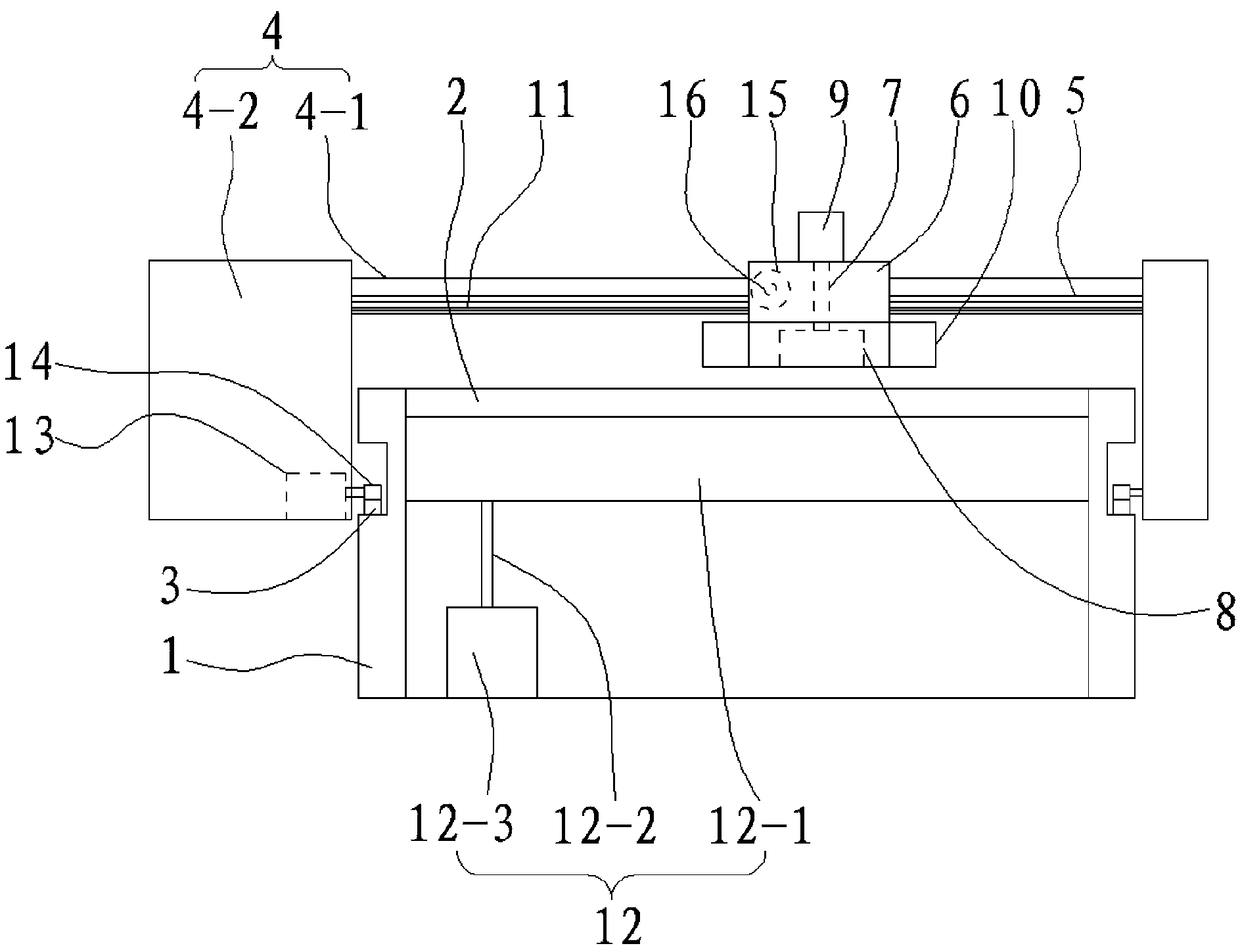

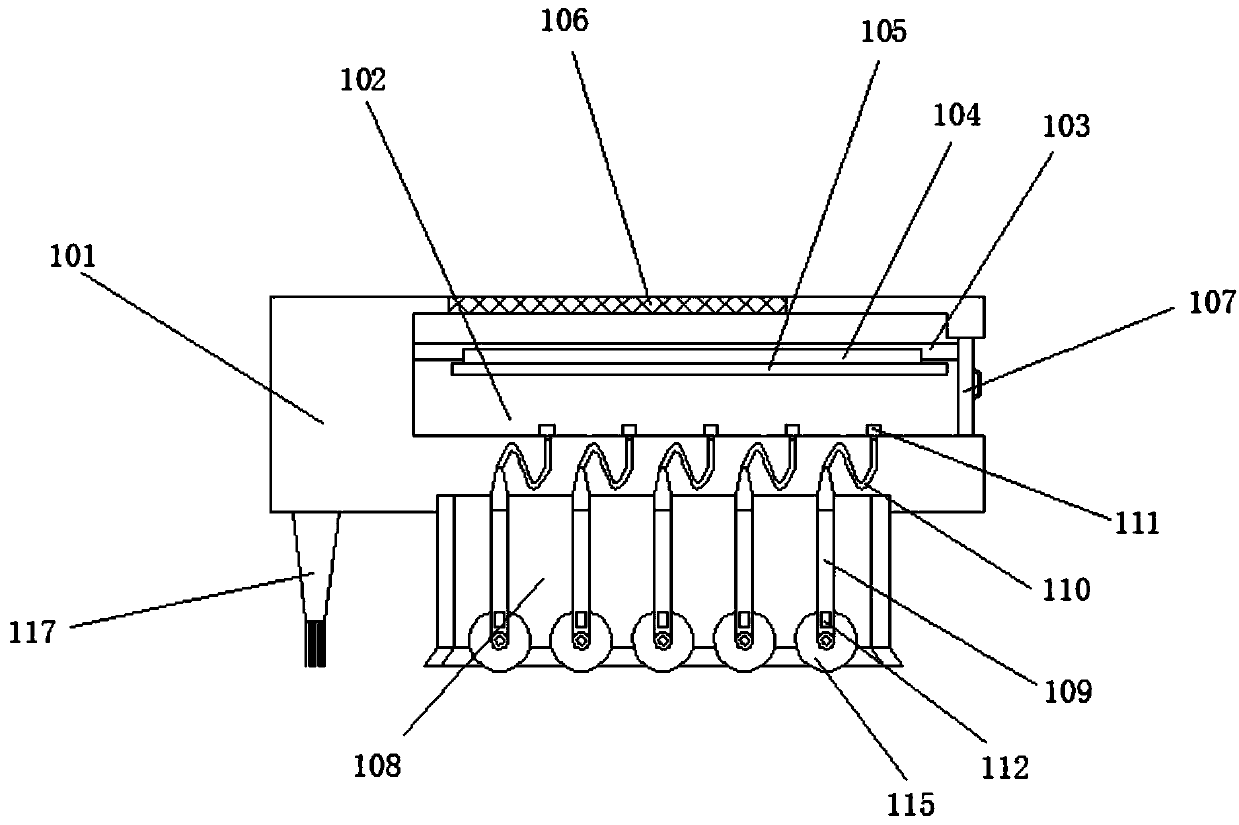

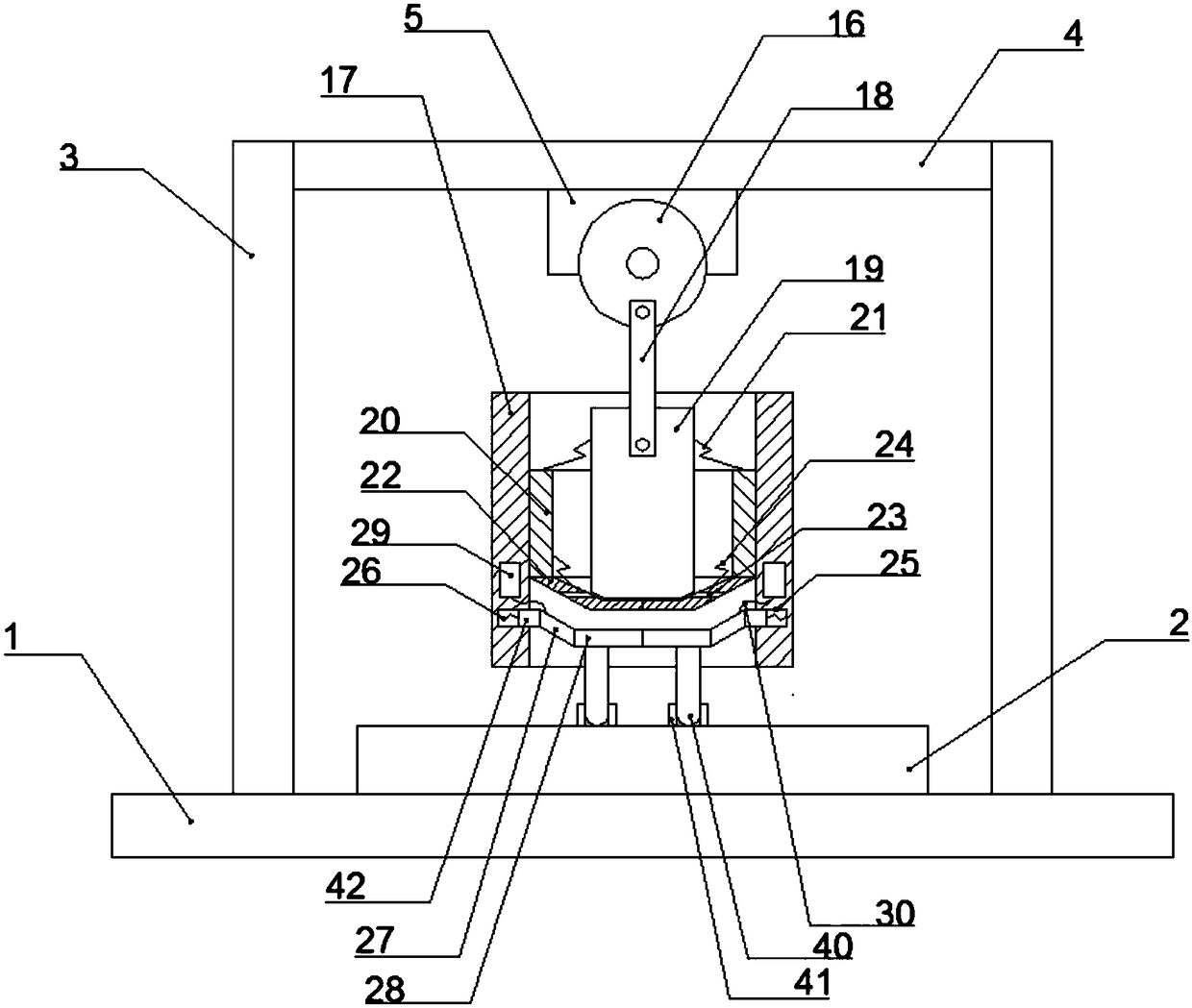

Rapid color three-dimensional printer

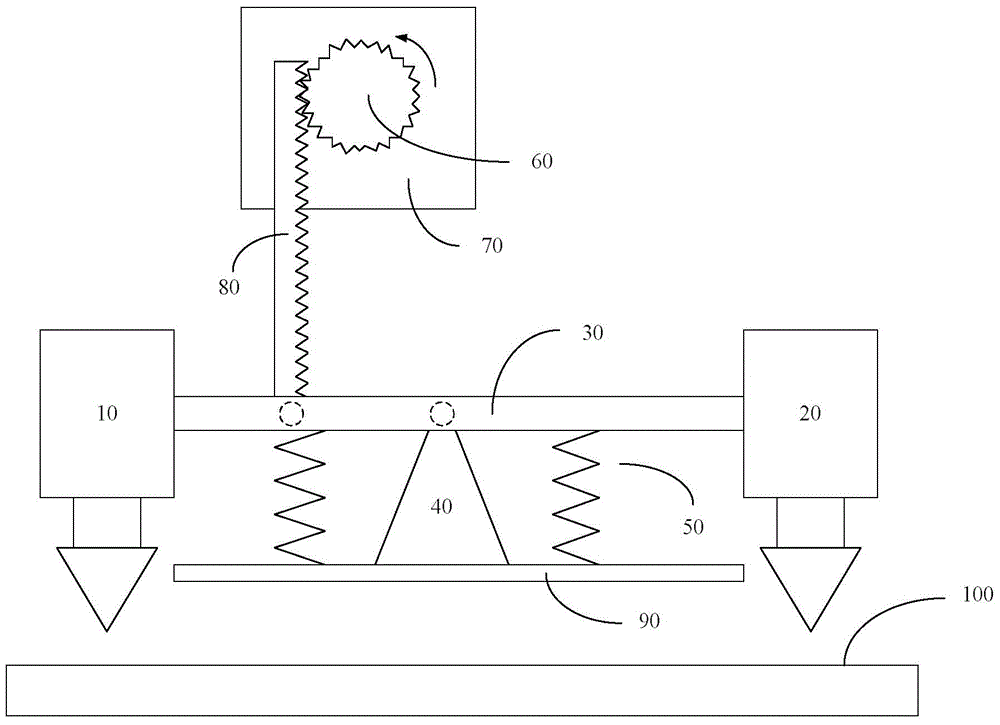

ActiveCN104249456AAvoid the hidden danger of surface color difference reducing surface qualityAvoid affecting the printing effectColor printingEngineering

The invention provides a rapid color three-dimensional printer including a base, a telescopic bracket, a rotating shaft, a worktable, a supporting seat, N telescopic rods, N print spray heads, N storage tanks, N connection pipes, N suction pumps, N + 2 driving mechanisms and a control module; the support the seat is arranged on the base, the N telescopic rods are movably, horizontally and parallelly arranged on the supporting seat and is located one side close to the worktable, the N print spray heads are respectively arranged on the N telescopic rods, distance between the N print spray heads and the worktable can be adjusted by stretching of the N telescopic rods, the N storage tanks at least comprises one a base material storage tank, and the rest of color material storage tanks, the base material storage tank is used for storing a base material, the color material storage tanks are used for storing color printing materials, the N print spray heads are respectively connected with the N storage tanks through the N connection pipes, and the N suction pumps are arranged on the N connection pipes. The rapid color three-dimensional printer is provided with a plurality of spray heads, is conducive to improving the printing speed, and can avoid surface chromatic aberration.

Owner:WUHU LINYI ELECTRONICS SCI & TECH

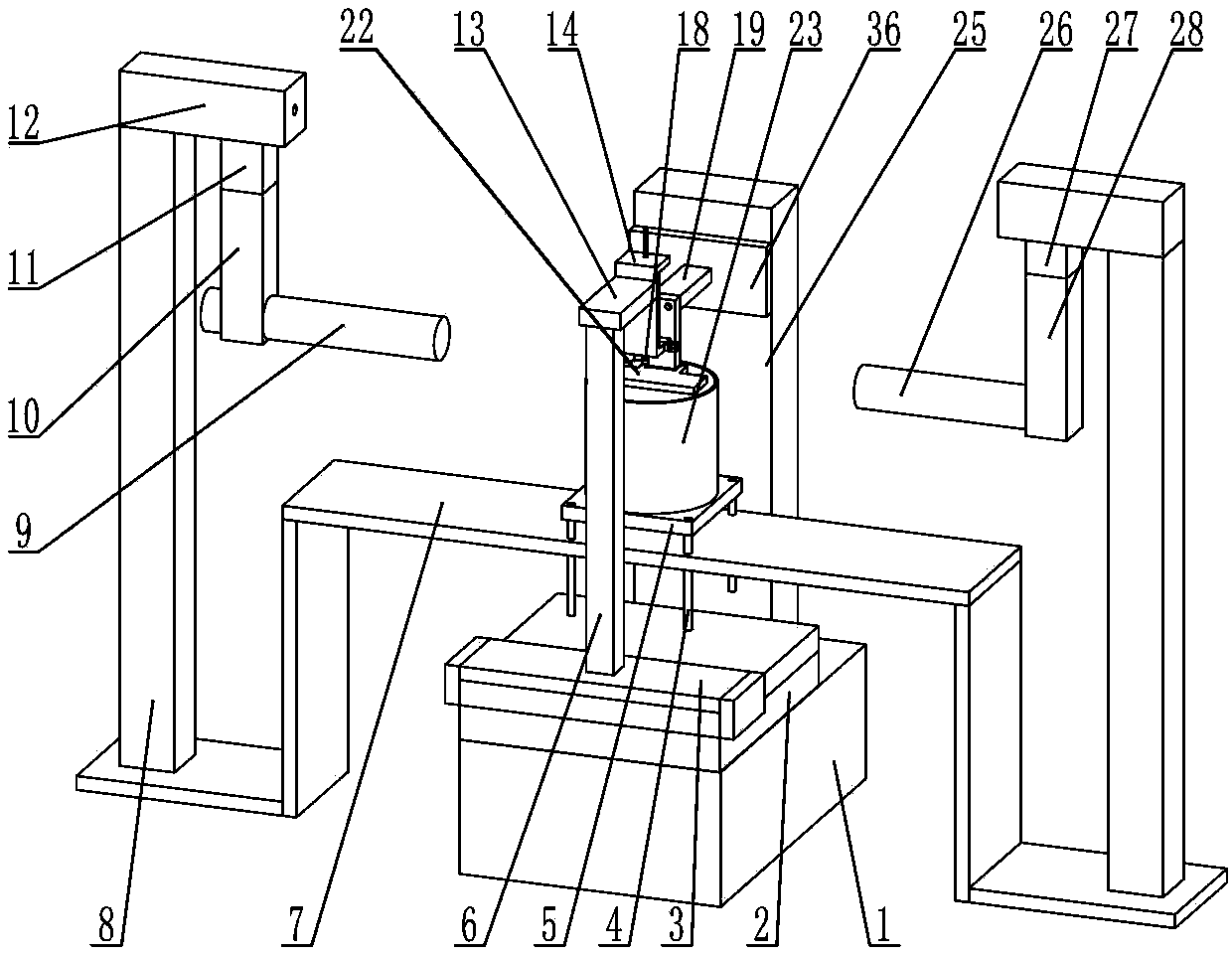

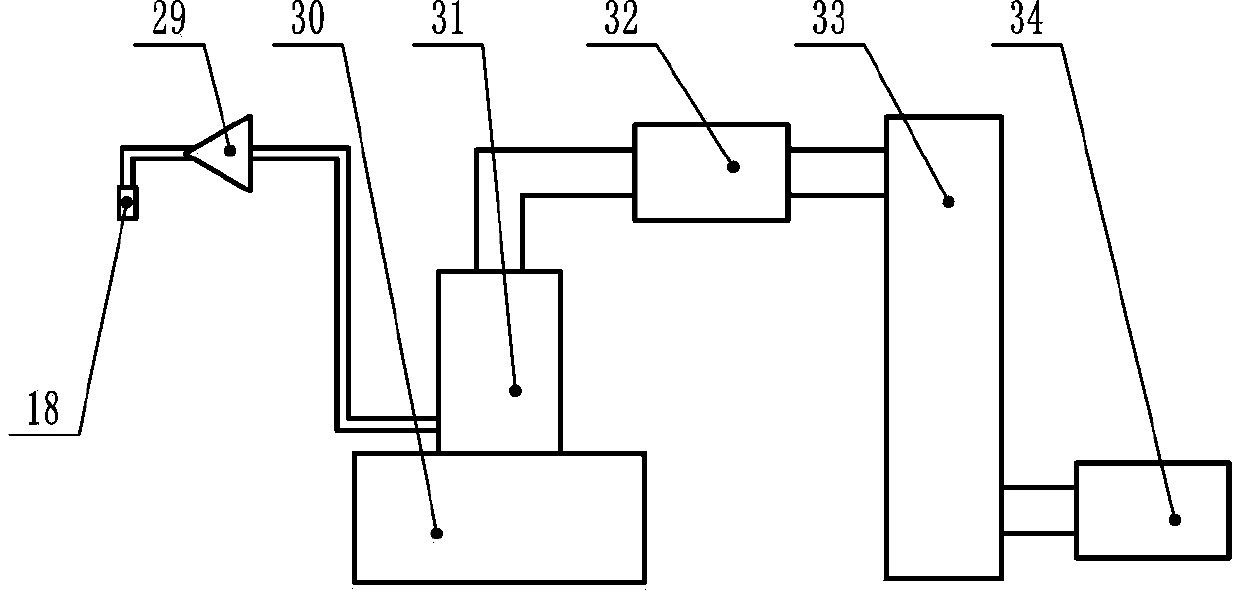

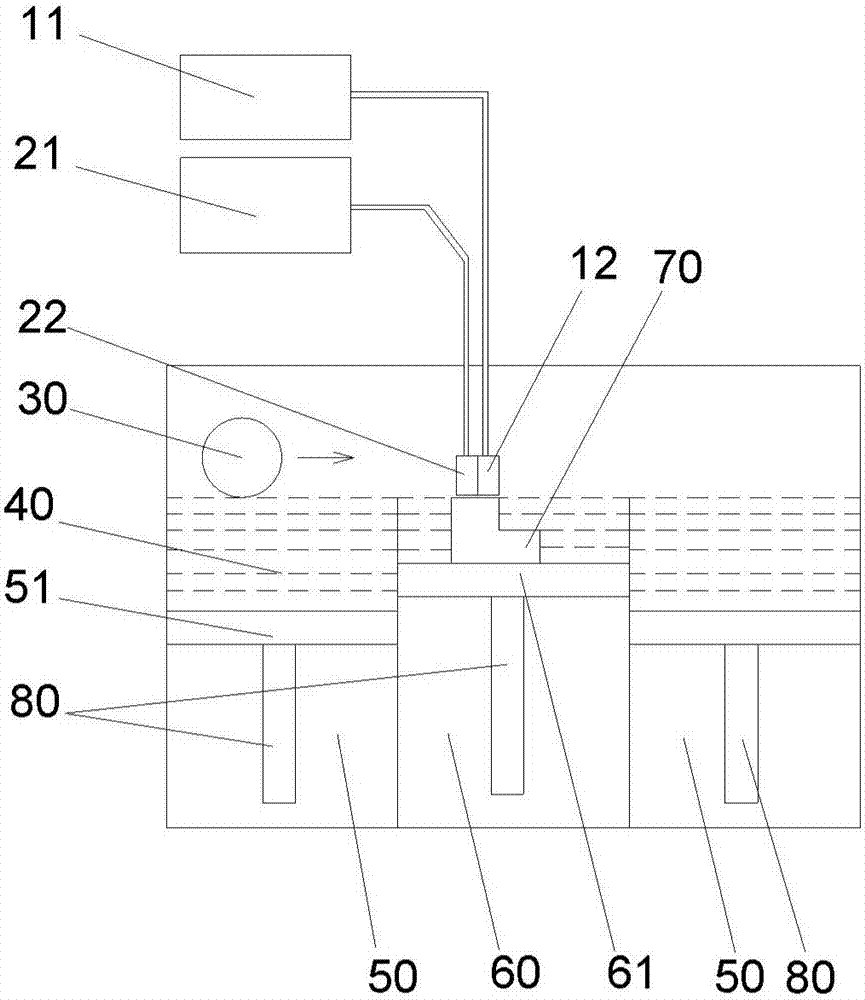

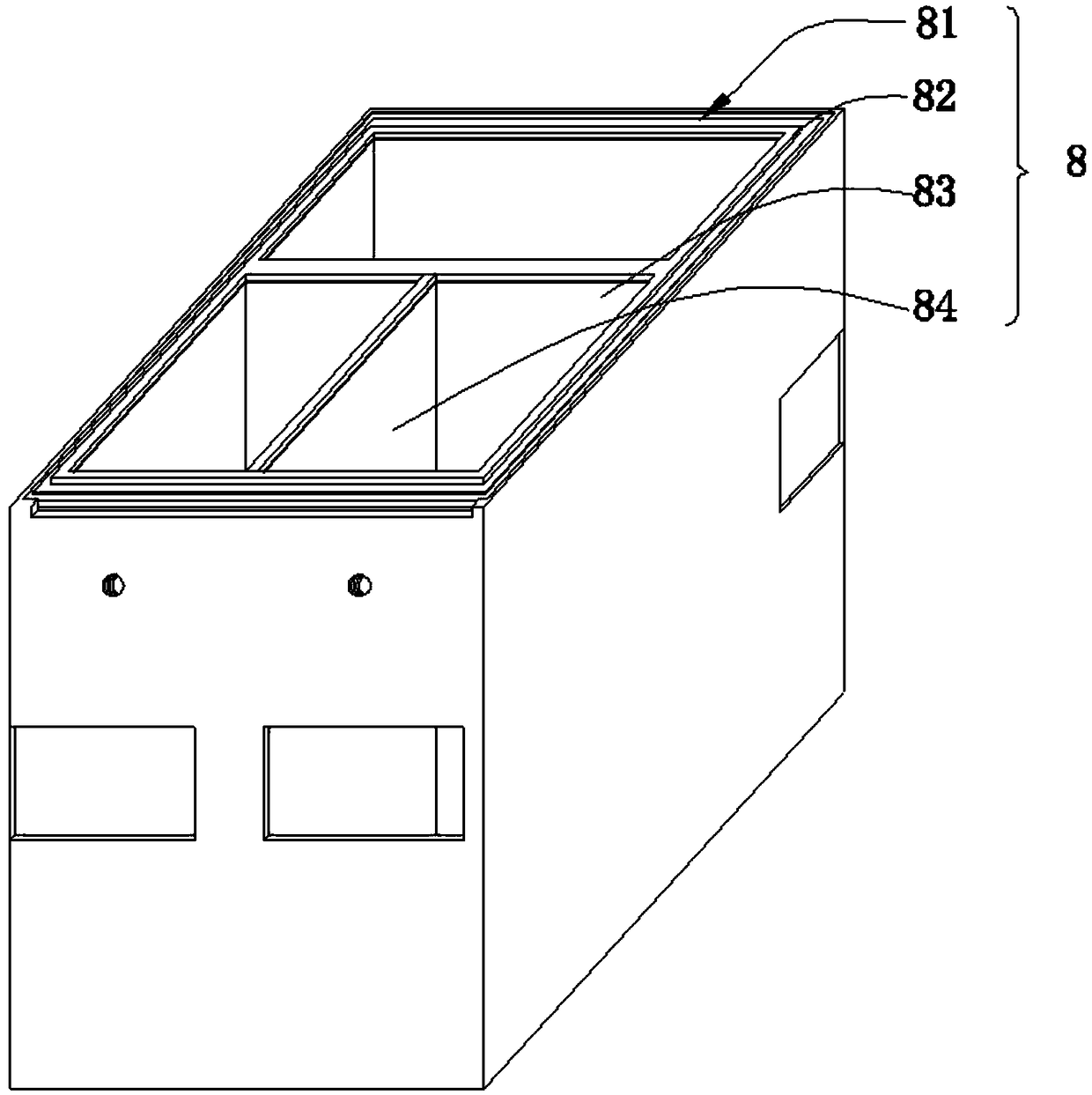

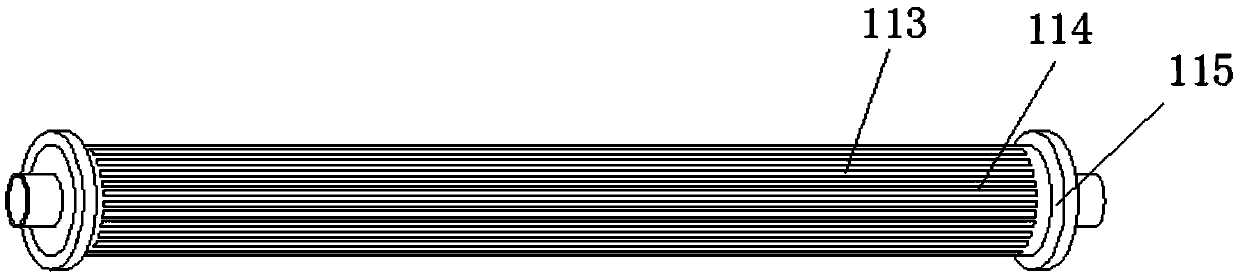

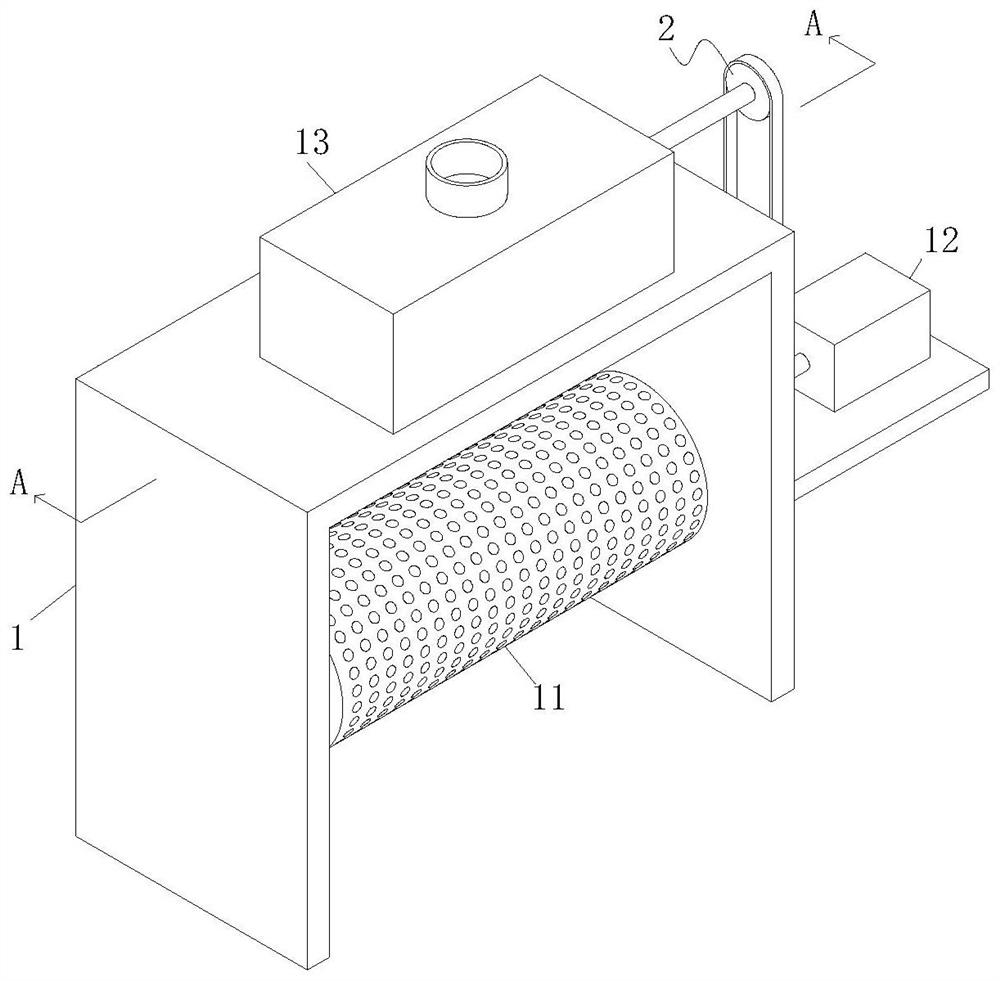

UV photo-cure 3D rapid forming system and printing method thereof

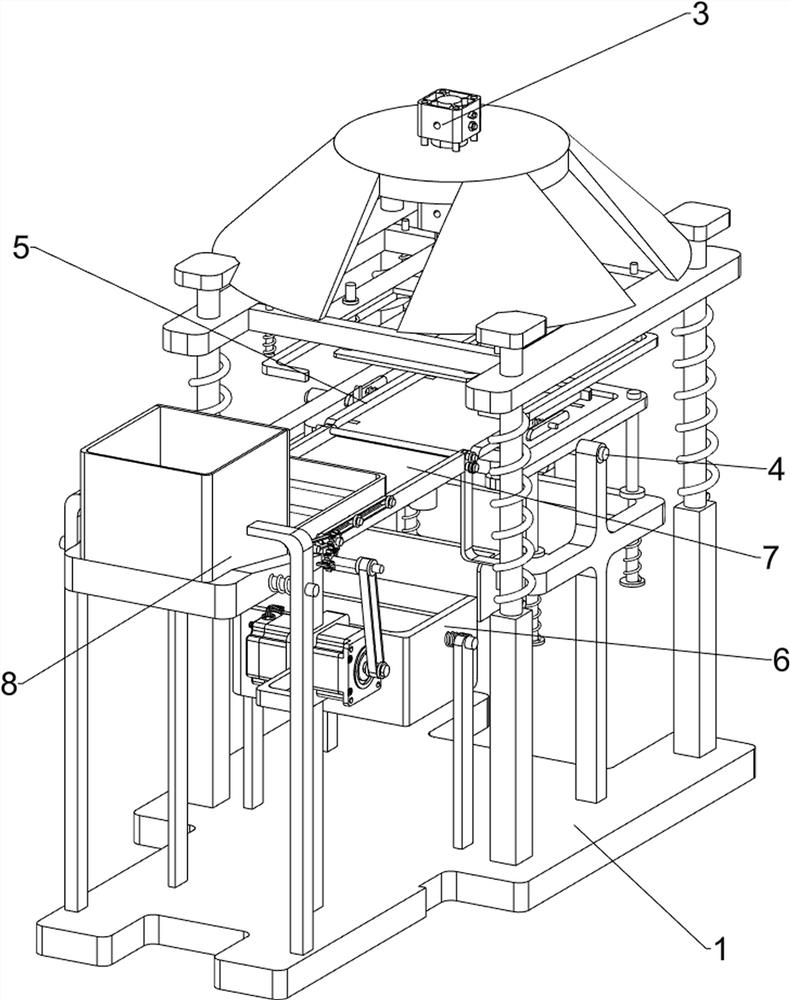

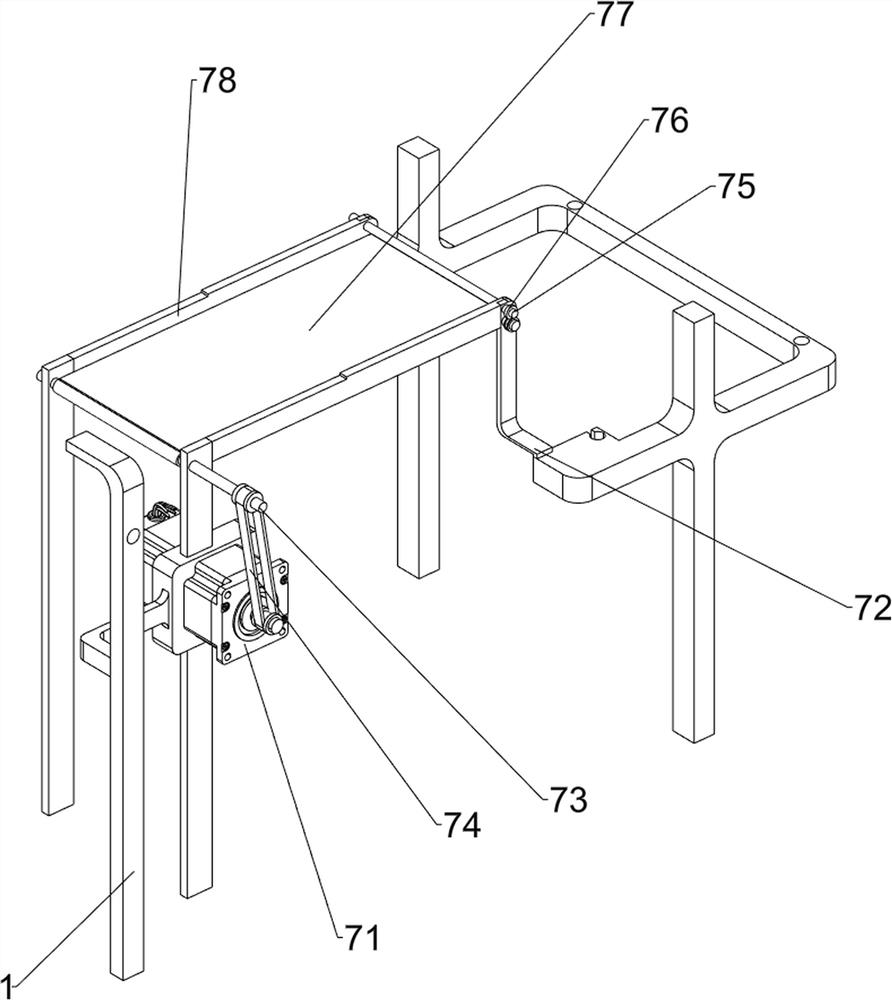

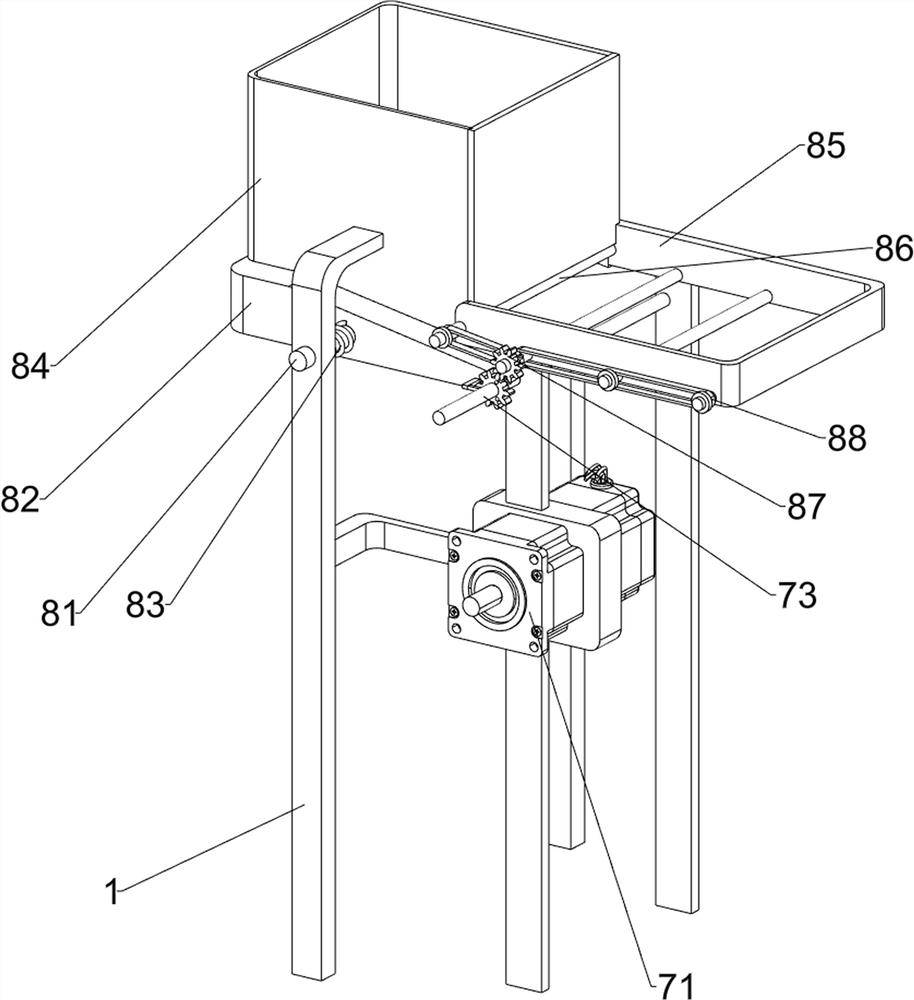

InactiveCN107415239AAvoid affecting the printing effectLow input costAdditive manufacturing apparatus3D object support structuresUV curingEngineering

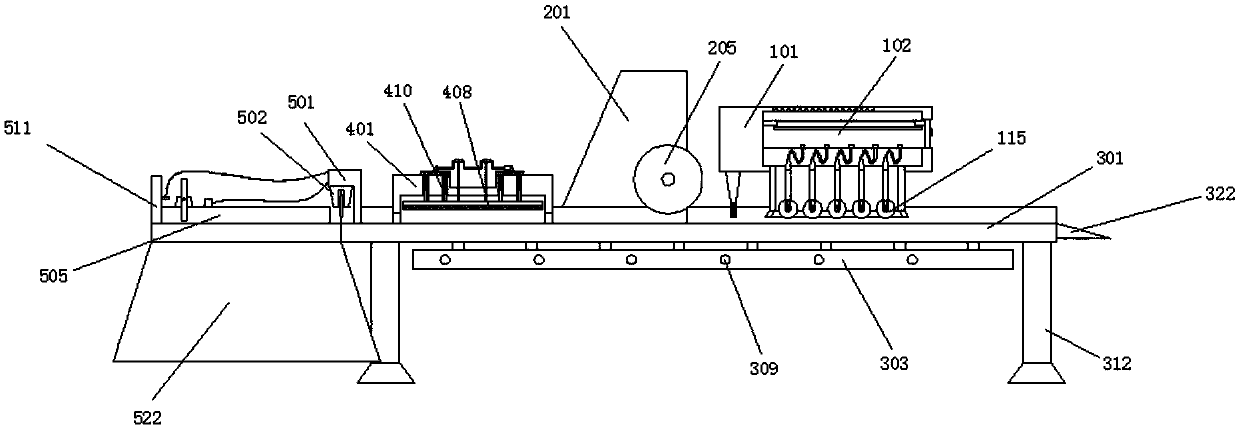

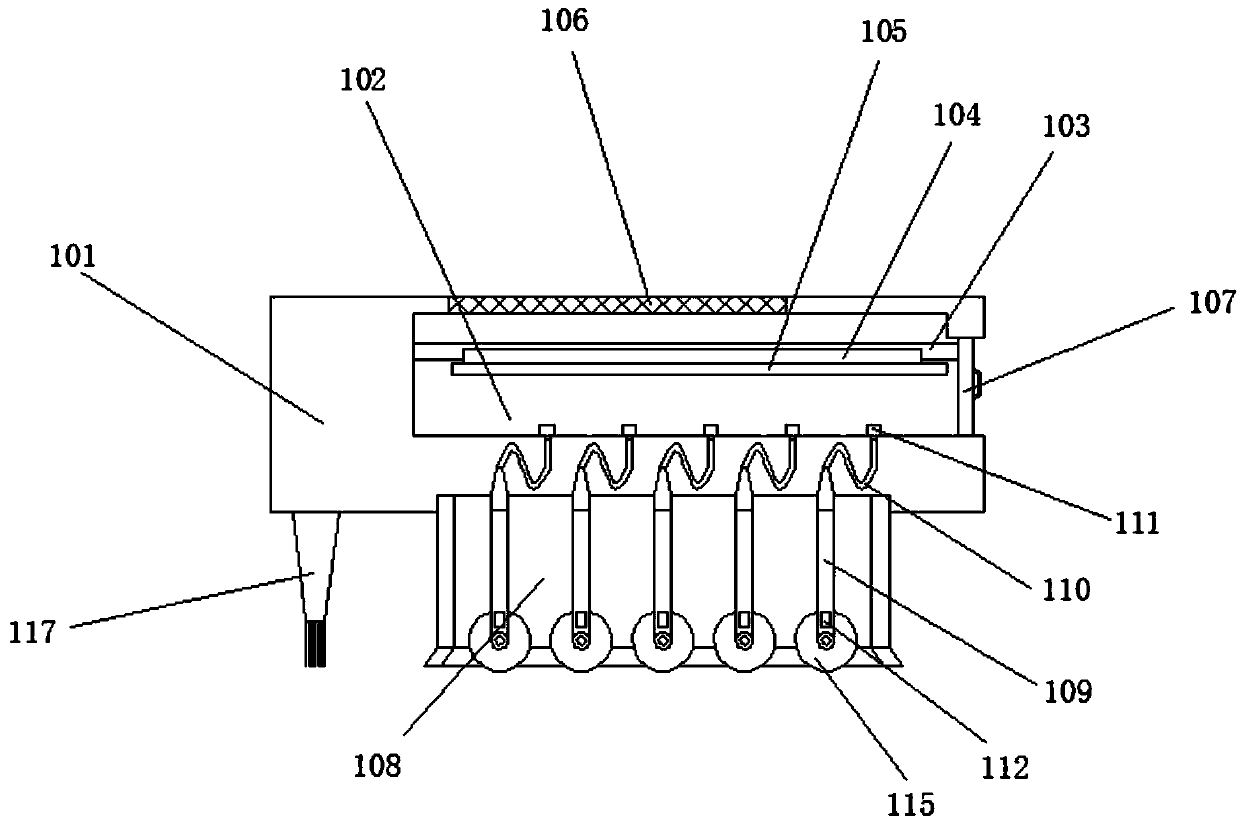

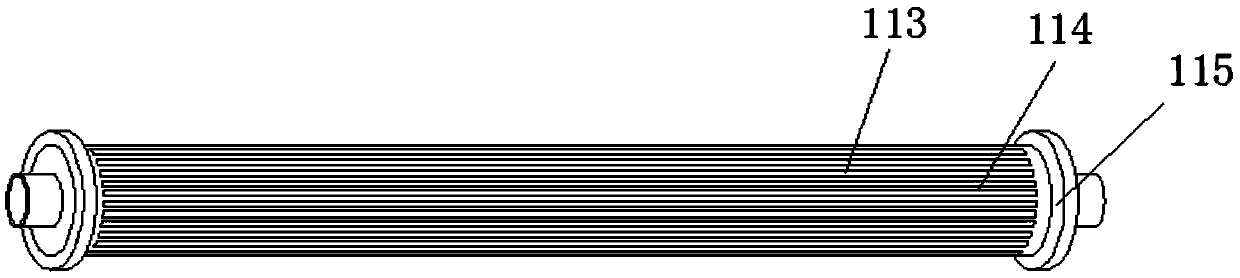

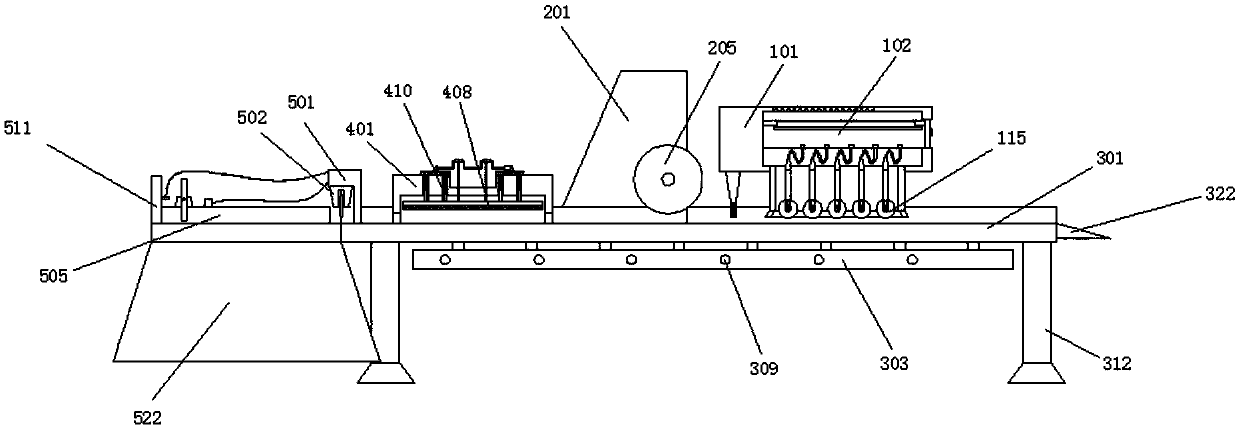

The invention provides a UV photo-cure 3D rapid forming system and further provides a printing method of the UV photo-cure 3D rapid forming system. The UV photo-cure 3D rapid forming system comprises a printing curing device, a printing bin and a powder supply device. The printing curing device comprises a UV lamp curing unit and a UV glue bonding unit, the printing bin is provided with a work table for bonding and curing forming of printing powder, and the powder supply device is used for storing and conveying the printing powder to the printing bin and comprises a powder supply bin body and a powder laying roller. The UV photo-cure 3D rapid forming system and the printing method thereof have the advantages that according to the system, the UV photo-cure technology is applied to three-dimensional printing, the problems that a three-dimensional-printing forming workpiece is low in strength and needs secondary curing aftertreatment, for example, the workpiece is steeped by glue again are solved, the input cost is reduced, the production period is shortened, and the production efficiency is improved; operation is convenient, and the powder laying efficiency is high; and a powder layer is subjected to primary curing before UV curing and thus is better in supporting intensity than loose powder, the supporting effect on the subsequent cured workpiece is better, and forming is facilitated.

Owner:NANTONG INST OF TECH

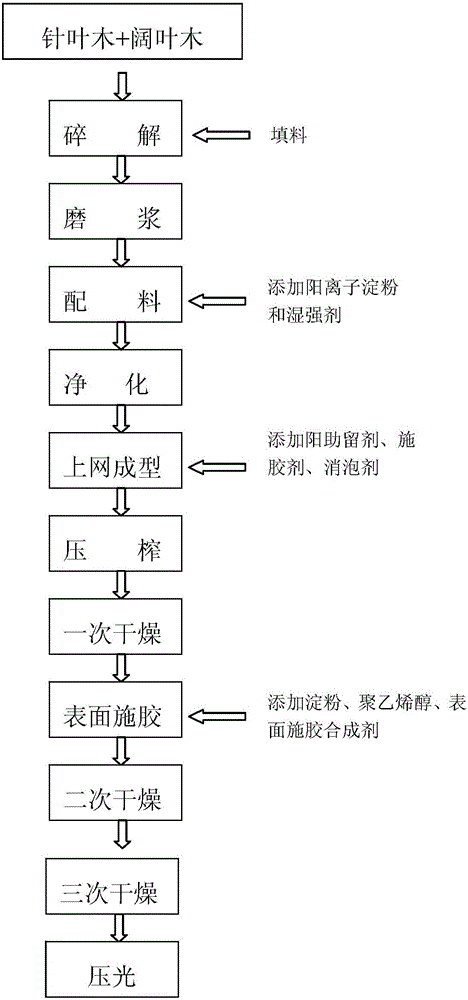

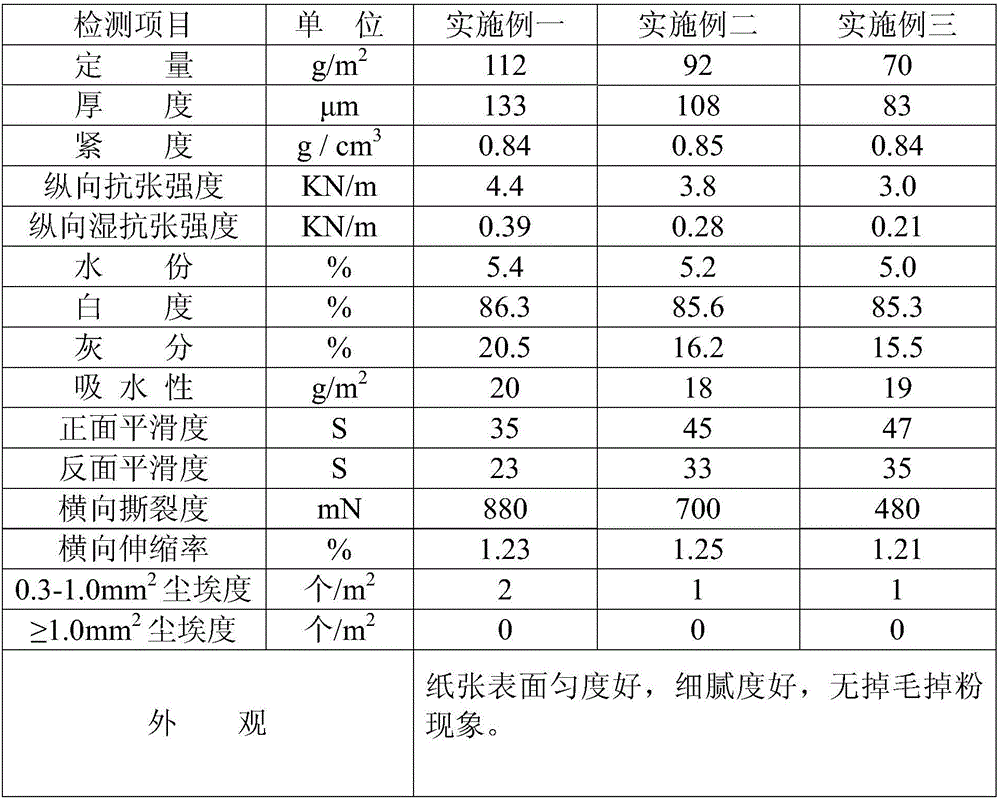

Process for producing thermal dye sublimation raw paper

InactiveCN105951498AImprove surface smoothnessImprove uniformityWater-repelling agents additionDryer sectionFiberPapermaking

A process for producing raw paper by thermal dye sublimation is related to the technical field of papermaking and includes: pulping coniferous wood and broad-leaved wood in a mass ratio of 15:85-30:70 through a pulper, and adding a filling material, the mass ratio of plant fiber to the filling material being 70:30-85:15; subjecting obtained pulp to pulp grinding under controlled beating degree of 25-35 degrees SR, and adding a cationic starch and a wet strength agent respectively into the pulp; performing dilution purification, web-forming and pressing, and subjecting obtained wet paper sequentially to primary drying, surface gluing, secondary drying and tertiary drying to obtain the thermal dye sublimation raw paper. Indexes of the thermal dye sublimation raw paper such as tear, uniformity, shrinkage, tensile strength and smoothness can be effectively controlled, preventing the problems occurring during use of raw paper produced by traditional process, such as picking, poor printing effect, wrinkling during printing, and proneness to breakage during printing.

Owner:SHANDONG TIANYANG PAPER

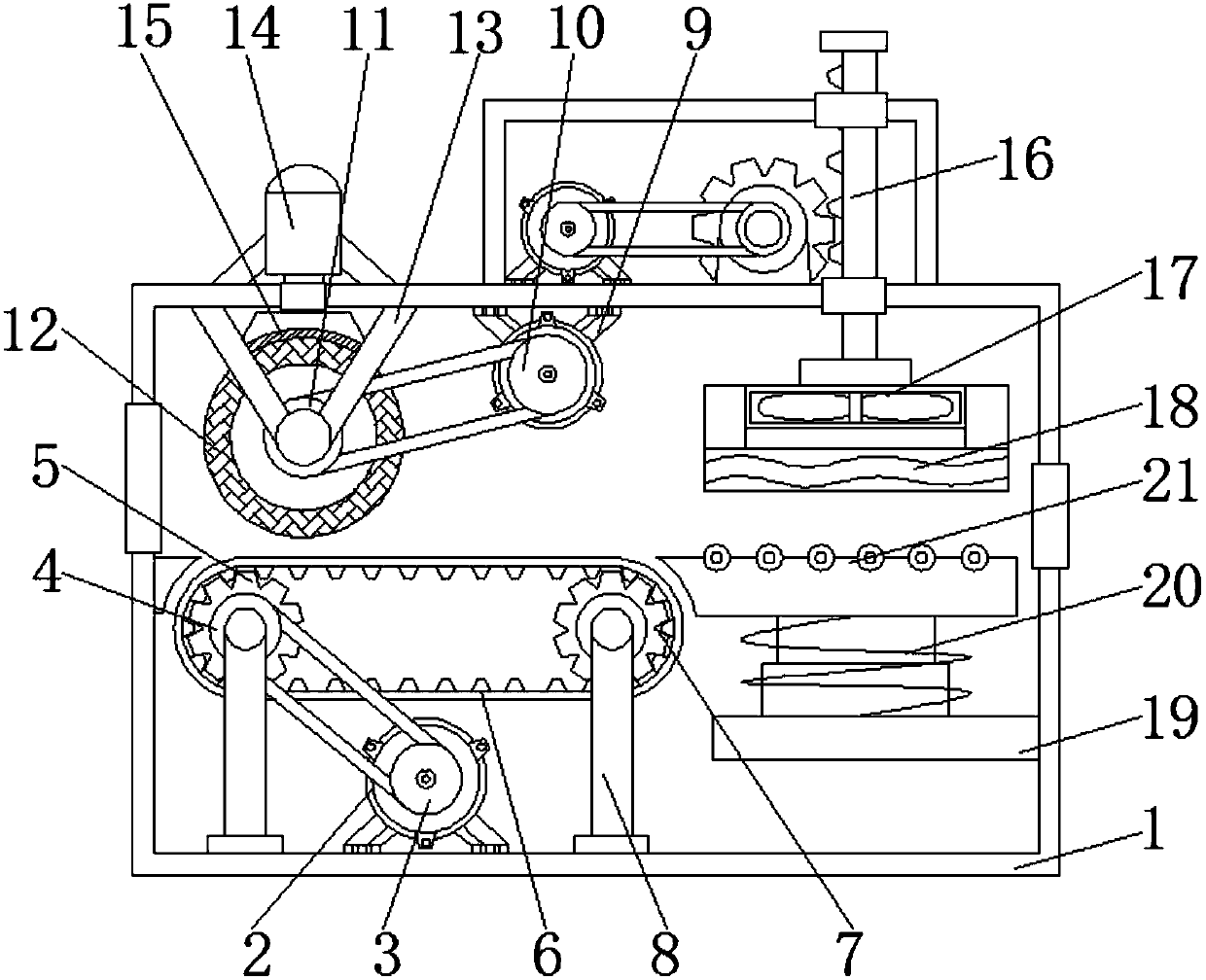

Printing device with drying function

PendingCN107599624AAchieve the purpose of dryingAvoid damagePrinting press partsCardboardPrinting ink

The invention discloses a printing device with a drying function. The printing device comprises an outer frame, wherein a first motor is fixedly connected to the bottom part of the inner wall of the outer frame, one end of an output shaft of the first motor is fixedly connected with a first belt wheel, and the surface of the first belt wheel is in transmission connection with a second belt wheel through a belt. The invention relates to the technical field of printing devices. According to the printing device with the drying function, printing is carried out conveniently, the printing effect isimproved, meanwhile, continuous printing can be achieved, time is saved, working efficiency is improved, and the burden of workers is relieved; later-stage processing can carried out conveniently, the position of drying can be adjusted to prevent a paper board from being damaged, so that practicability of the device is improved; the paper board can be conveniently discharged, and can be stabilized conveniently in the drying process, so that printing effect is prevented from being influenced; and printing ink is conveniently brushed onto the surface of a printing roller, so that printing is achieved, discharging and feeding of the device are convenient, and use by people is convenient.

Owner:安吉腾新印刷厂

Improved ink cartridge

InactiveCN108839441ANo need to discard frequentlyRealize automatic ink fillingPrintingEngineeringElectromagnet

The invention relates to the technical field of printer equipment, and discloses an improved ink cartridge. The improved ink cartridge comprises a main ink cartridge and an auxiliary ink cartridge. Anink outlet is formed in the main ink cartridge, an ink guide pipe is arranged between the main ink cartridge and the auxiliary ink cartridge in a communicating mode, a valve is arranged on the ink guide pipe, a wedge block is fixedly connected to the valve, and a first spring is connected between the wedge block and the ink guide pipe. The main ink box is internally provided with a first slidinggroove and a second sliding groove, the length of the second sliding groove is greater than the length of the first sliding groove, slide blocks are slidably connected into the first sliding groove and the second sling groove, filter plates are fixedly connected between the slide blocks, floating balls are fixedly connected to the filter plates, and wedge bars are hinged to the filter plates. Theslide blocks are provided with magnets, the bottoms of the first sliding groove and the second sliding groove are fixedly connected with electromagnets, the main ink cartridge is provided with a switch, the main ink cartridge is provided with a impurity outlet, the impurity outlet communicates with a waste box, a baffle is slidably connected into the main ink cartridge, a transmission rod is fixedly connected to the baffle, and a second spring is connected between the transmission rod and the main ink cartridge. The improved ink cartridge can automatically add ink and remove impurities.

Owner:贵州省仁怀市西科电脑科技有限公司

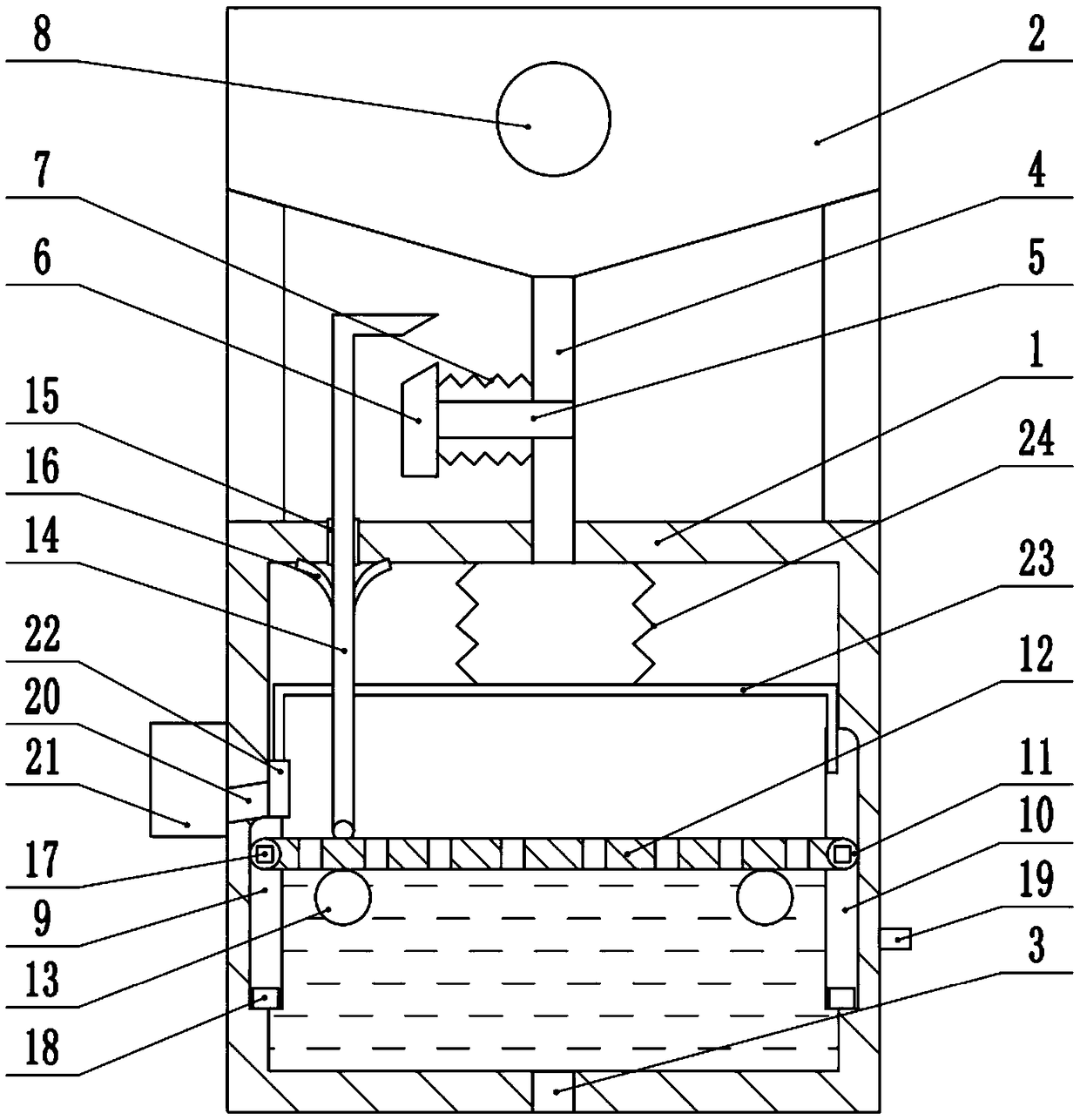

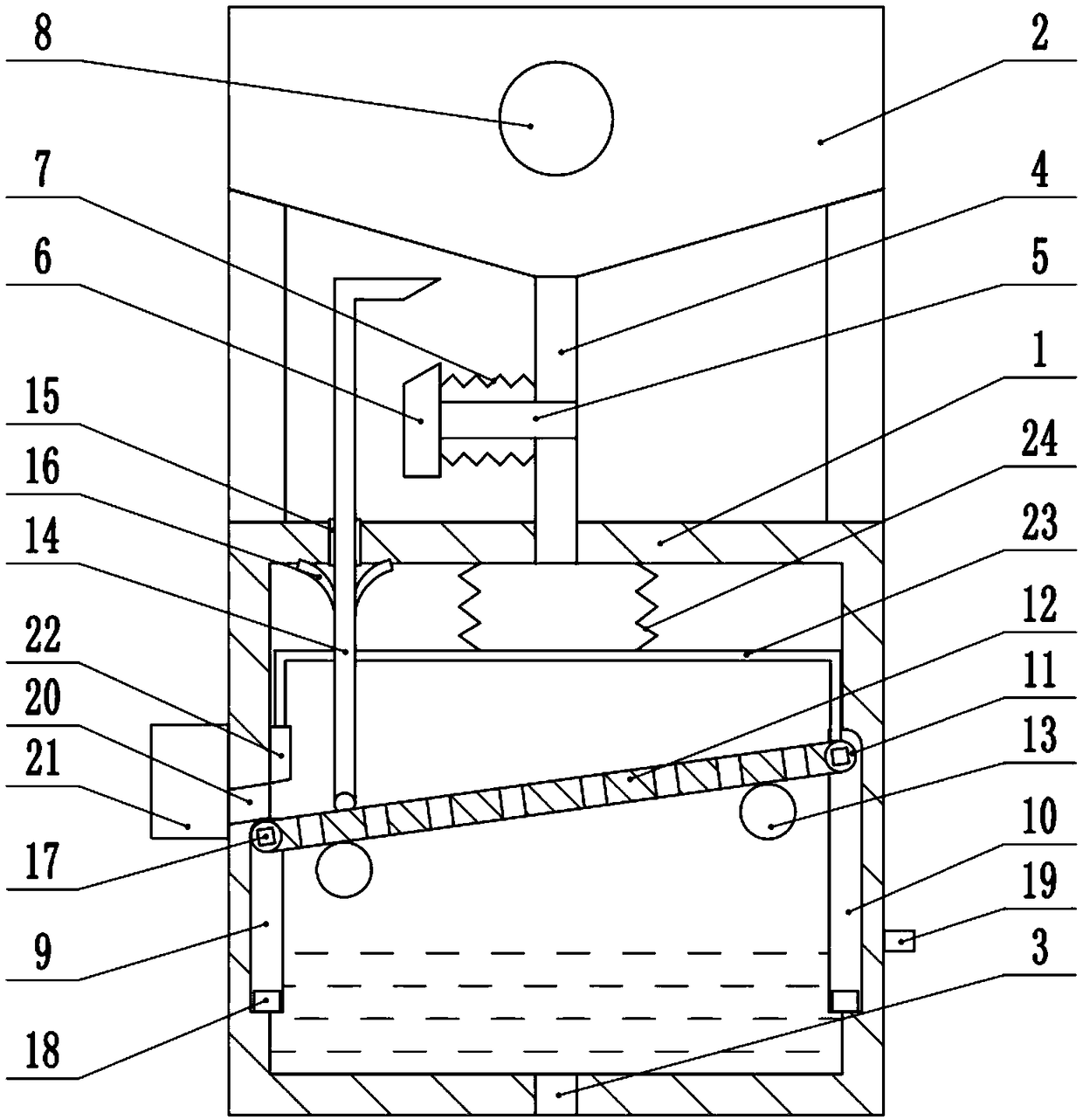

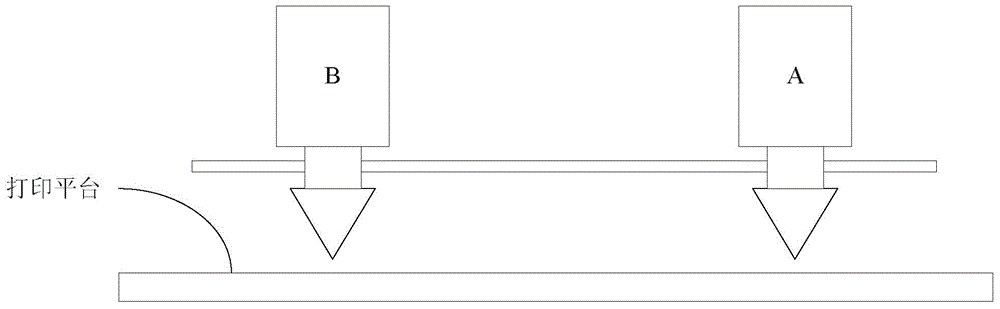

3D printer and 3D printing method

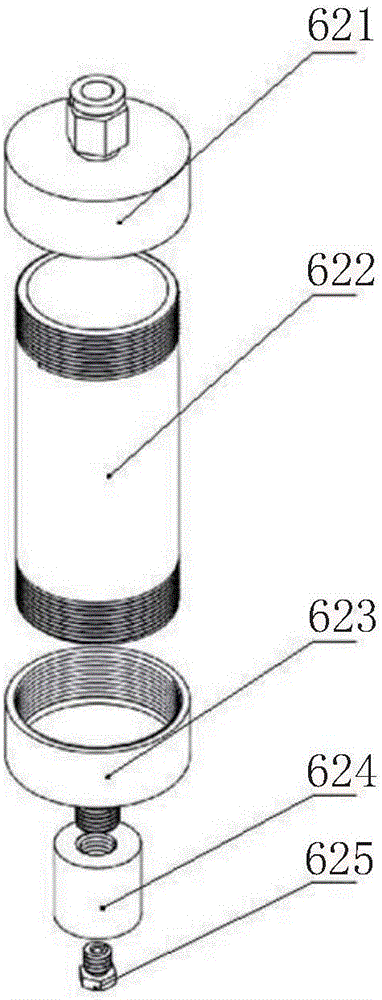

ActiveCN104608381AAvoid affecting the printing effectAdditive manufacturing apparatusEngineering3D printing

The invention discloses a 3D printer which comprises a plurality of nozzles and a height adjusting device connected with the nozzles, wherein the height adjusting device is used for adjusting the nozzles so as to position the nozzles at different heights. When one nozzle works, other nozzles can be in a state of being higher than the working nozzle. The invention further discloses a 3D printing method. When the working nozzle of the 3D printer moves leftwards and rightwards, the other nozzles are far away from a printing plane, so that the situation that the non-working nozzles scrap the printing plane and the printing effect is affected is avoided.

Owner:INVENTECSHANGHAI TECH +2

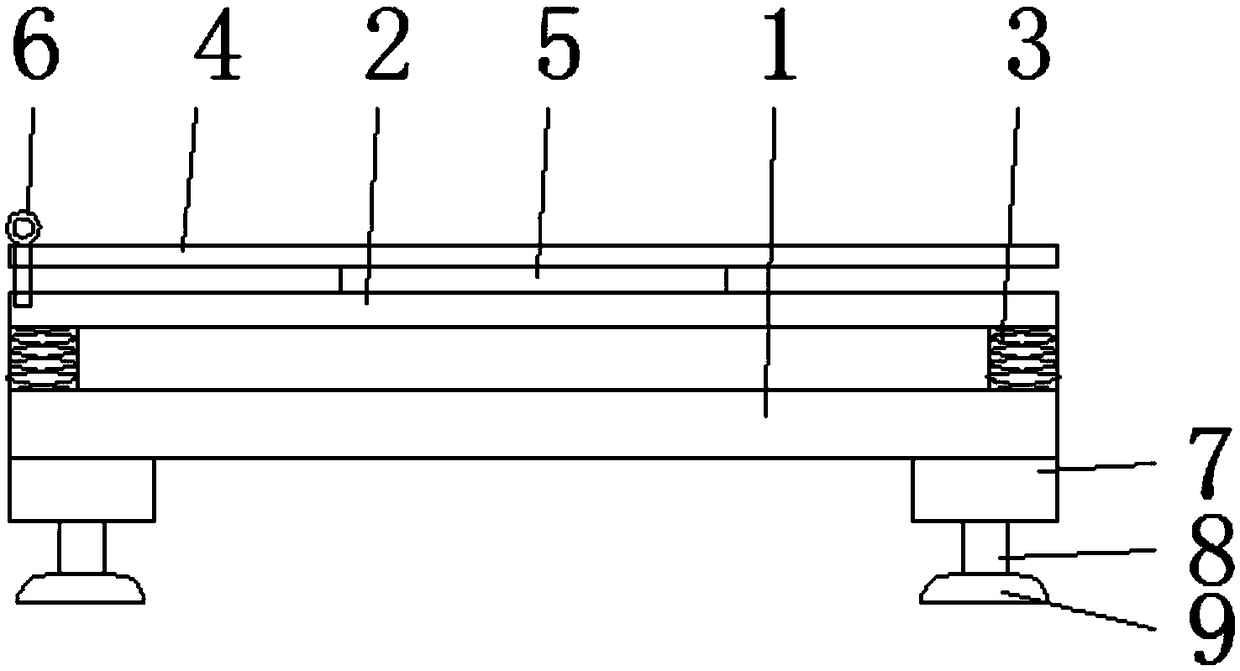

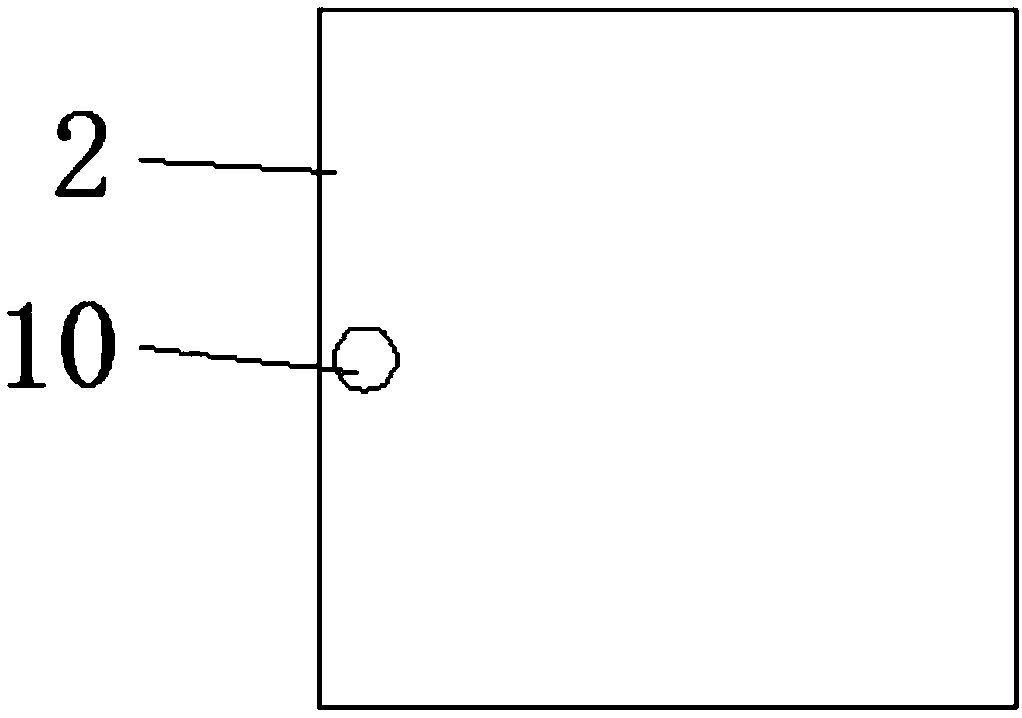

Adjustable positioning conveying table for plastic extruding plate machining device

InactiveCN109573540AStable deliveryReduce frictional resistanceRotary pressesConveyor partsPrinting inkEngineering

The invention discloses an adjustable positioning conveying table for a plastic extruding plate machining device. The adjustable positioning conveying table comprises a conveying table body, and a dust removal cavity, a printing table, a drying bin and a beam frame are sequentially and fixedly installed on the top side of the conveying table body from right to left; a clamping and positioning mechanism is arranged on the conveying table body, a cutting knife rest is movably installed on the lower side of the beam frame, and an automatic discharging mechanism is fixedly installed on the left side of the conveying table body. According to the adjustable positioning conveying table, the surface of the plastic extruding plate can be subjected to dust removal treatment, the printing ink is prevented from being printed onto dust during printing, and therefore the printing effect is influenced; a printing roller can be adjusted and rotated, the distance and the position of printing can be changed, and then a printing pattern is changed, and the effect of air drying during printing is achieved; redundant ink of the corrugated board can be adsorbed and cleaned through adsorption cotton after the printing, meanwhile, hot air plays a role in drying the surface, the automatic quantitative automatic cutting and discharging are realized, the full-automatic machining operation is simple and accurate, the manual labor is reduced, and the adjustable positioning conveying table is easy to popularize and apply.

Owner:张磊

Handheld bar code machine convenient to use

PendingCN110978791AAvoid nozzle cloggingAvoid cloggingTypewritersOther printing apparatusBarcodeEngineering

The invention discloses a handheld bar code machine convenient to use. The handheld bar code machine convenient to use comprises a machine body. The lower portion of the left side of the machine bodyis fixedly connected with a gas collecting hood, the left side of the machine body is fixedly connected with a box body, a purification groove is formed in an inner cavity of the box body, the bottomof an inner cavity of the purification groove is fixedly connected with a short pipe, the other end of the short pipe is fixedly connected with the gas collecting hood, the upper portion of the innercavity of the purification groove is slidingly connected with a dust screen through a sliding groove, and the portion, on the upper portion of the dust screen, of the inner cavity of the purificationgroove is slidingly connected with an activated carbon filter plate through a sliding groove. Through mutual cooperation of the gas collecting hood, an ink storage box, the dust screen, the activatedcarbon filter plate, a draught fan, the short pipe, a long pipe, an electromagnetic valve and a filter drum, the problems that an existing handheld code sprayer does not have a gas purification function, physical health of operators is easily affected, after ink is used up, an ink box needs to be detached to be replaced, and the operation is very troublesome are solved.

Owner:苏州嘉荣兴信息科技有限公司

Ink jet proofing device

PendingCN109291664AConstant distanceEasy to operateTypewritersPower drive mechanismsMechanical engineeringOffset printing

The invention relates to the technical field of printing equipment, in particular to an ink jet proofing device. The ink jet proofing device comprises a rack; a printing platform is disposed on the rack; longitudinal movement sliding rails which are horizontally disposed are disposed at the two side edges of the rack; a base is disposed above the printing platform; the two ends of the base are disposed on the two longitudinal movement sliding rails in a sliding manner; a transverse movement sliding rail is disposed on the base; a sliding block is disposed on the transverse movement sliding rail in a sliding manner; an ascending-descending rod which is vertically disposed is arranged on the sliding block; a printing mechanism is fixedly connected to the bottom end of the ascending-descending rod; and an ascending-descending servo motor which is used for driving the ascending-descending rod to ascend and descend is disposed on the sliding block. The ink jet proofing device has the beneficial effects that by accurately controlling the ascending-descending servo motor, control over ascending and descending of the printing mechanism is achieved, the effect that the distance between theprinting mechanism and a printed material is constant is guaranteed, thus the ink jet proofing device can serve as an all-purpose printer which can print various materials and is convenient to operate, and the industry problems that the period of offset printing proofing is long, and the cost is high can be solved.

Owner:CHONGQING HONGJIN PRINTING

Full-automatic efficient positioning printing machine for production

InactiveCN112406284AGood effectImprove printing effectRegistering devicesRotary pressesPrinting pressIndustrial engineering

The invention relates to a positioning printing machine, in particular to a full-automatic efficient positioning printing machine for production. The full-automatic efficient positioning printing machine for production integrates automatic feeding, precise positioning and automatic discharging. The full-automatic efficient positioning printing machine for production comprises a bottom plate, and apressing mechanism is arranged on the bottom plate; and a pressure bearing mechanism arranged on the bottom plate, wherein the pressure bearing mechanism is connected with the pressing mechanism andlocated below the pressing mechanism. A rubbing plate is driven by a mounting plate to move downwards, a printing material can be rubbed when the rubbing plate touches paper, in order to achieve a better and clearer printing effect, an air cylinder continues to extend to enable a fixing plate to continue to slide along a first sliding rod and a second sliding rod, and the effect that the rubbing plate efficiently prints the paper and other materials is achieved.

Owner:钟源

Ink box of printing machine

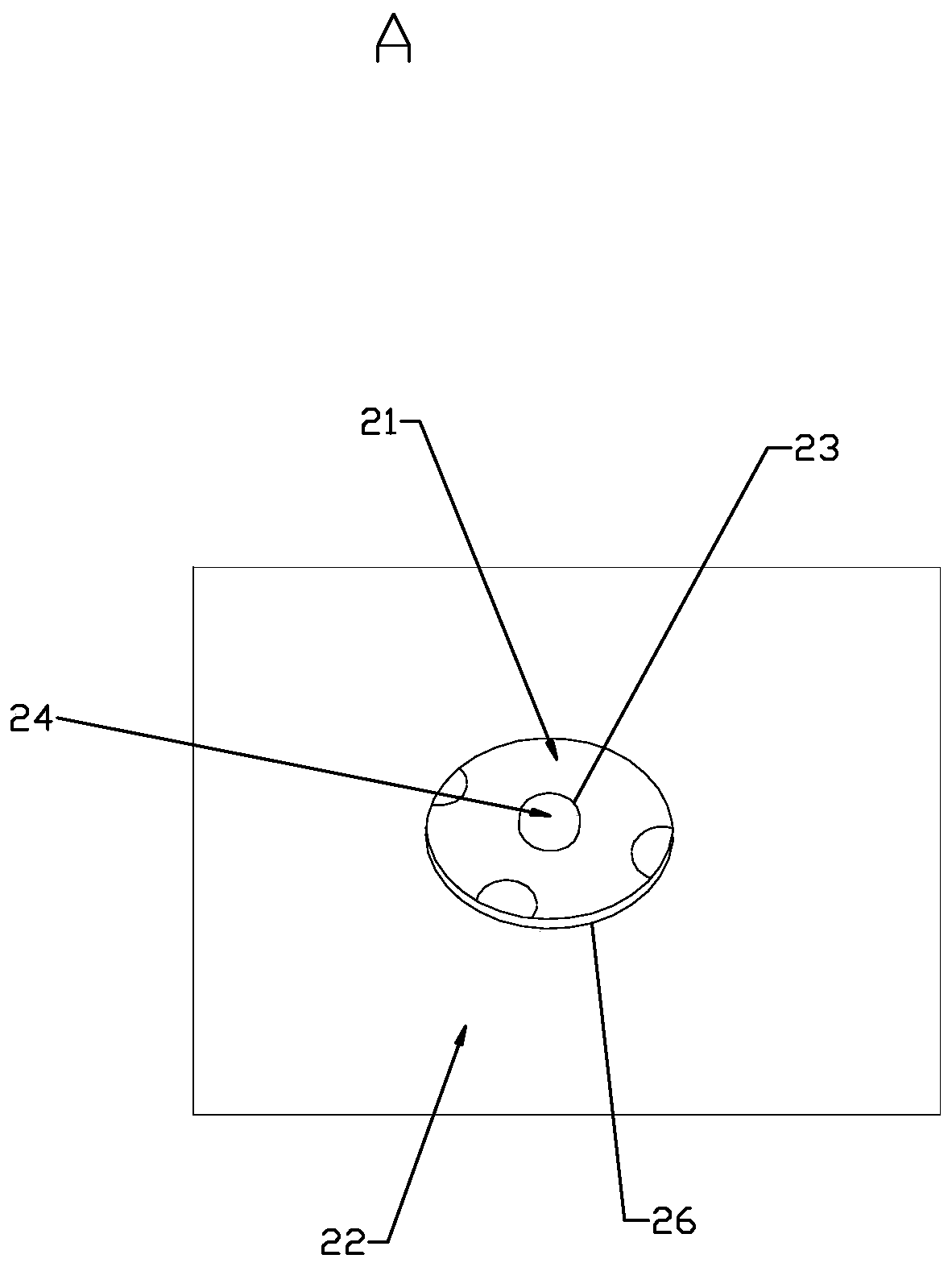

The invention relates to the field of printing machine ink box treatment, in particular to an ink box of a printing machine. The ink box comprises a box cover, ink adding mechanisms, cleaning mechanisms, vent holes, a box body, a mark mechanism and a sealing mechanism. Filter screens are mounted at the top of the box cover, and ink dripping heads are arranged at the bottoms of the filter screens.The ink dripping heads distributed in a circumferential array manner can guarantee that uniform ink dripping is achieved in the ink adding process, and meanwhile impurities of ink added into the box body can be filtered out conveniently. A rubber ring is mounted at the top of the box body, and the situation that different kinds of ink in the box body are mixed due to poor sealing performance, andthe printing effect is influenced is avoided. Meanwhile, the sealing mechanism is arranged between the box body and the box cover, and a good sealing effect is achieved. A groove is formed in the topof the box body, a convex block is mounted at the bottom of the box cover, and the side face of the groove and the convex block are in clamped connection. The sealing performance of secondary utilization of the ink box can be increased conveniently.

Owner:绍兴韵足针纺织有限公司

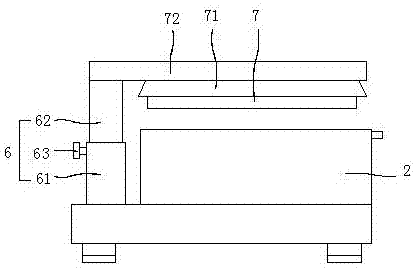

Automated printing equipment

InactiveCN109334228AFlexible connectionAvoid affecting the printing effectRotary pressesPrinting press partsEngineeringAutomation

The invention discloses automated printing equipment. The automated printing equipment comprises a base, a bottom plate, a slide rail, a cover plate, a motor, a sliding block, a suction pump, a liquidstorage box, lifting cylinders, limiting blocks, a printing head and a working plate. The automated printing equipment is characterized in that the base is placed at the very bottom of the whole structure, the sliding block is arranged on the slide rail, the liquid storage box is arranged at the bottom of the suction pump, and the printing head is arranged at the bottom of the liquid storage box.According to the automated printing equipment, the upper bottom plate is supported by the base, and the lifting cylinders move vertically under the action of pressure and can be adjusted to the mostsuitable positions according to the actual size of a product, so that the printing quality is improved, and a wide application range is achieved; the sliding block is driven by the slide rail to movein the horizontal direction, and then the printing head is driven to move, so that the product can be completely printed; the suction pump is used for transporting raw materials in the liquid storagebox to the printing head, the automation level is high, and the labor consumption is reduced; and the automated printing equipment further has the characteristics of low manufacturing cost, simple structure, convenient operation, firmness and durability and flexible connection of all components.

Owner:滁州千字文印务有限公司

Drying device of inkjet printer

InactiveCN107471835AAdjust the drying heightAvoid affecting the printing effectOther printing apparatusEngineering

The invention discloses a drying device of an inkjet printer. The drying device comprises a drying base, a drying shell, a support rod, a drying lamp, a cabinet door and a rubber mat, the drying shell is arranged on the upper side of the drying base, a drying chamber is arranged inside the drying shell, a drying platform is arranged inside the drying chamber, a corona wire and an anode plate are installed on two sides of an inner wall of the drying chamber, the support rod is arranged on one side of the upper end of the drying base, a cross rod is arranged on the upper end of the support rod, the drying lamp is arranged on the lower side of the cross rod through a lampshade, supporting feet are arranged on the four corners of the lower side of the drying base, the cabinet door is connected with one side of the drying base in a hinged mode, and the support rod is composed of a first telescopic rod and a second telescopic rod. According to the drying device of the inkjet printer, the corona wire and the anode plate are arranged on the two sides of the inner wall of the drying chamber, electrostatic dust removal can be carried out while drying, dust is prevented from sticking on a printed paper, and the printing effect is affected.

Owner:WEIFANG HUAGUANG DIGITAL EQUIP

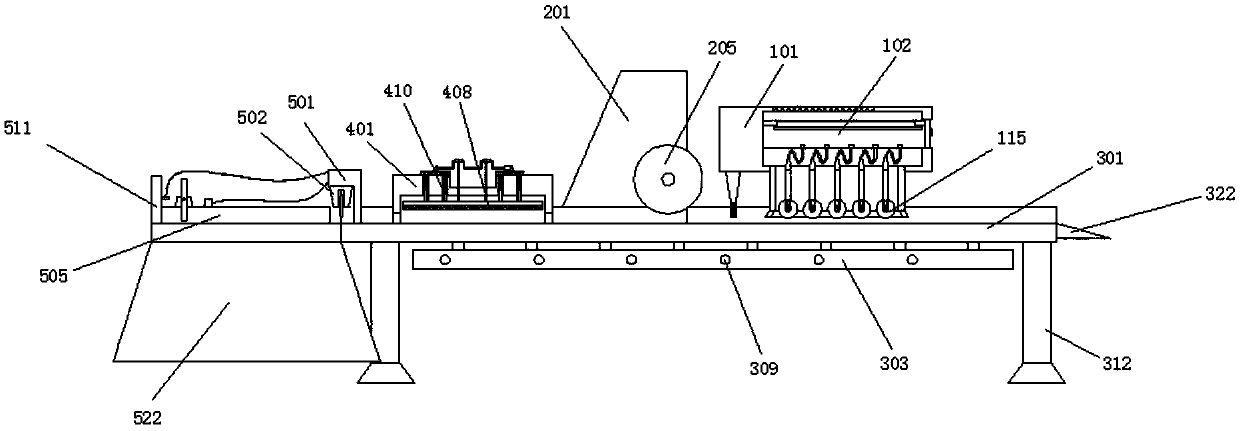

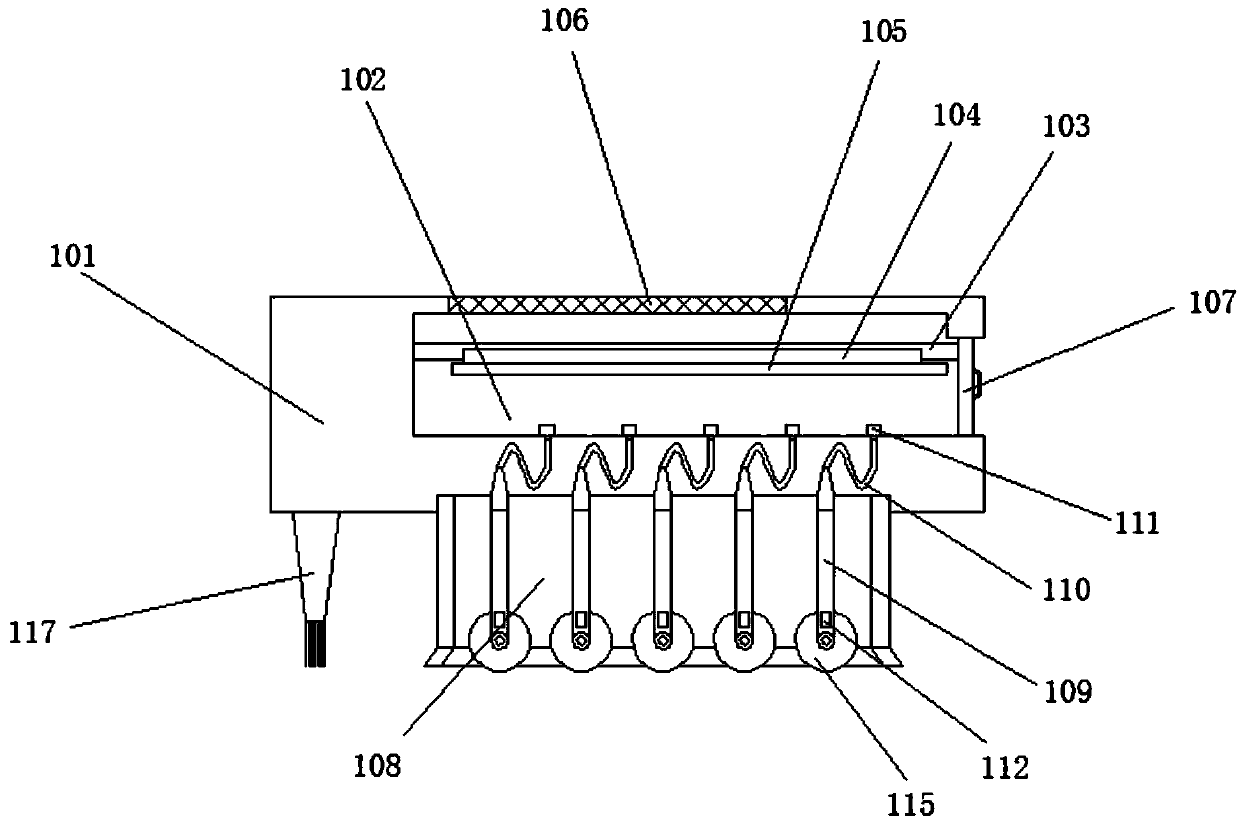

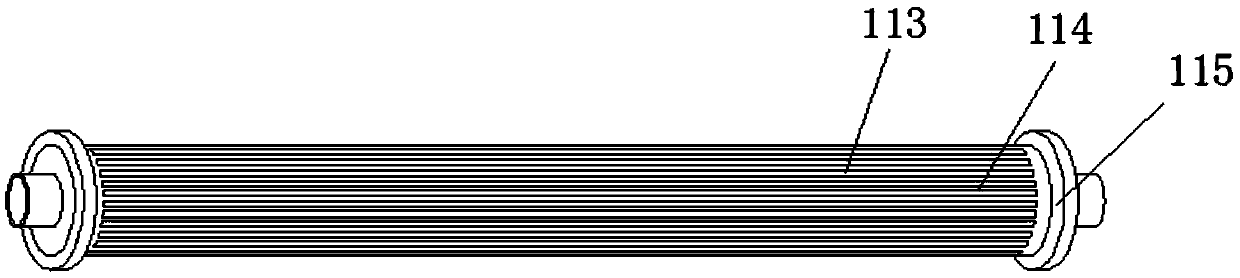

Cake decorating color printing device and control method thereof

ActiveCN104255850BRealize industrializationRealize standardized productionBaked articles handlingAutomatic controlColor printing

The invention discloses a color printing device for mounting patterns on cakes and a control method of the color printing device. A complete picture is dispersed into a vector diagram consisting of limited points according to certain resolution ratio by virtue of a discrete and fused technical ideal of 3D printing, and the discrete points are printed by adopting a rapid forming method so as to realize automatic printing and forming of patterns mounted on cakes. The color printing device for mounting patterns on the cakes integrates image processing, data acquisition and analysis, motor control and automatic spraying control and is simple in structure, reasonable in control scheme and is capable of substituting for manual operation of workers in the prior art so as to realize standard and industrial production, the labor intensity of the workers is greatly reduced and the working efficiency is improved. The color printing device can also be appropriately refitted in combination with related prior art so as to be used for surface spraying of murals and models, drawing of cartoon patterns on surfaces of toys, and the like.

Owner:SHANDONG UNIV OF SCI & TECH

Electrostatic dust removal mechanism for extruded sheet processing device

InactiveCN109551883AReduce frictional resistanceBetter and smoother deliveryRotary pressesPrinting press partsAutomatic processingPrinting ink

The invention discloses an electrostatic dust removal mechanism for an extruded sheet processing device. The electrostatic dust removal mechanism comprises a conveying table, wherein a dust removal cavity, a printing table, a drying bin and a beam frame are fixedly installed on the top side of the conveying table from right to left in sequence; a clamping and positioning mechanism is arranged on the conveying table; a cutting tool rest is movably installed on the lower side of the beam frame; and an automatic part discharging mechanism is fixedly installed on the left side of the conveying table. The electrostatic dust removal mechanism can carry out dust removal treatment on the surface of an extruded sheet, the situation that the printing effect is affected due to printing ink is printedon dust during printing is avoided, a printing roller can be adjusted and can be adjusted in a rotating mode, the distance and position of printing can be changed so as to change printing patterns, the function of air drying is achieved at the same time of printing, after printing is carried out, excess printing ink of corrugated cardboards can be adsorbed clean through adsorption cotton, meanwhile, the surface is dried through hot air, automatic quantitative automatic cutting and part discharging are realized, the full-automatic processing operation is simple and accurate, the labor force isgreatly reduced, and the electrostatic dust removal mechanism is easy to popularize and apply.

Owner:张磊

Hot-drying ink absorbing mechanism used after printing and used for plastic extruding plate processing device

InactiveCN109551886AStable deliveryReduce frictional resistanceRotary pressesPrinting press partsEngineeringPrinting ink

The invention discloses a hot-drying ink absorbing mechanism used after printing and used for a plastic extruding plate processing device. The hot-drying ink absorbing mechanism comprises a conveyingtable, a dust removal cavity, a printing table, a drying bin and a beam frame are sequentially and fixedly installed on the top side of the conveying table from right to left, a clamping and positioning mechanism is arranged on the conveying table, a cutting knife rest is movably arranged on the lower side of the beam frame, and an automatic discharging mechanism is fixedly installed on the left side of the conveying table. According to the hot-drying ink absorbing mechanism used after printing and used for the plastic extruding plate processing device, the surface of an plastic extruding plate can be subjected to dust removal treatment, so that printing ink is prevented from being printed onto dust during printing, and then the printing effect is prevented from being influenced; a printing roller can be adjusted, can be adjusted in a rotating mode, and can change the distance and the position of printing so as to change a printing pattern; and the effect of air drying during printingis also achieved, the redundant printing ink of a corrugated board can be adsorbed and cleared through adsorption cotton after printing, meanwhile, a drying effect on the surface is achieved through hot air, and automatic quantitation and automatic cutting and discharging are realized, so that the full-automatic machining operation is simple and accurate, moreover, the manual labor is reduced, andthe then the hot-drying ink absorbing mechanism is easy to popularize and apply.

Owner:张磊

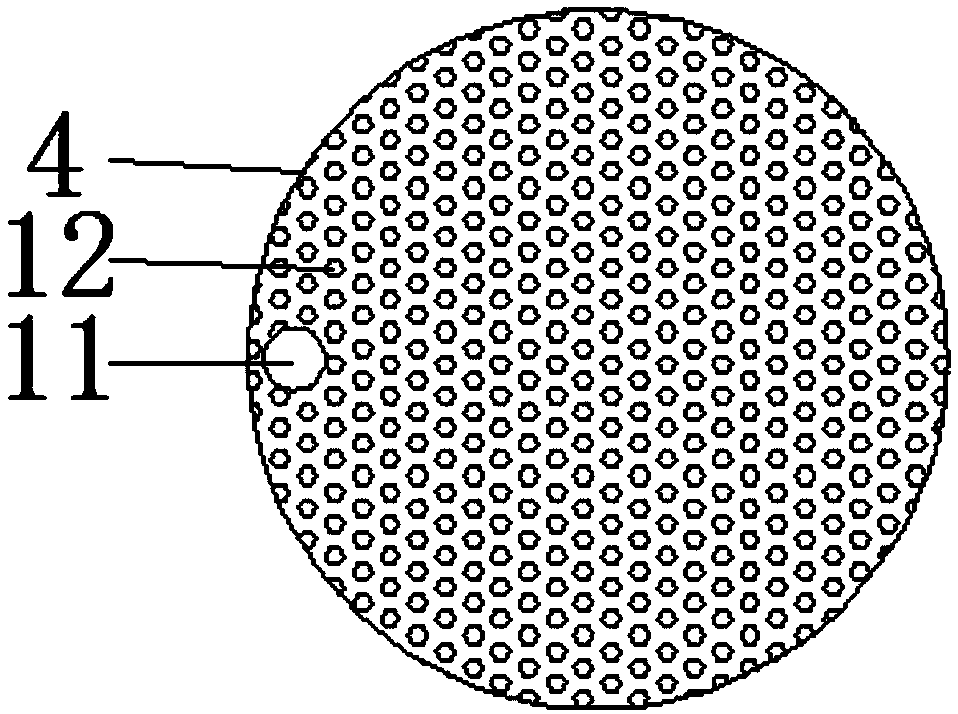

Printing machine roller

ActiveCN114434961APrevent glazingImprove work efficiencyRotary pressesPrinting press partsElectric machineryStructural engineering

The invention relates to the technical field of printing, in particular to a printing machine roller which comprises a roller frame, a roller is arranged on the front side in the roller frame, roller shafts on the left side and the right side of the roller are rotationally connected with a left side plate and a right side plate of the roller frame respectively, and the right side of the roller frame is fixedly connected with a motor through a rack. A roller shaft on the right side of the roller penetrates through a right side plate of the roller frame and is fixedly connected with an output shaft of the motor, and a cleaning mechanism is arranged on the rear side of the roller. The upper end face of the roller frame is fixedly connected with an ink box, and the lower end face of the ink box horizontally communicates with a plurality of ink conveying pipes at equal intervals. According to the printing machine roller, when the roller body rotates to the position of the collecting box, the magnet at the position of the feeding port of the collecting box can attract the punches in the micropores in the roller body, so that the punches eject impurities deposited in the micropores out of the micropores, and the impurities fall onto the material guiding plate under the scraping effect of the scraping plate and enter the material receiving groove along the material guiding plate; glazing caused by excessive accumulation of impurities in the micropores is avoided, meanwhile, cleaning can be carried out without shutdown, and the working efficiency is improved.

Owner:杭州名师文化传播有限公司

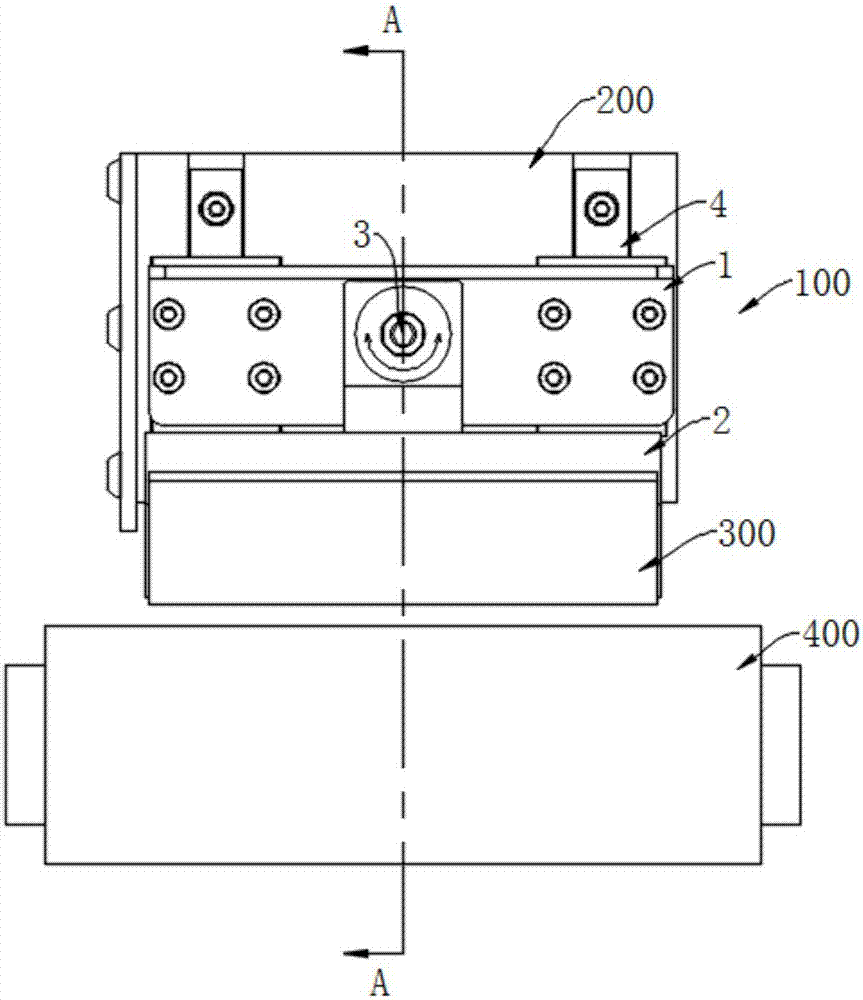

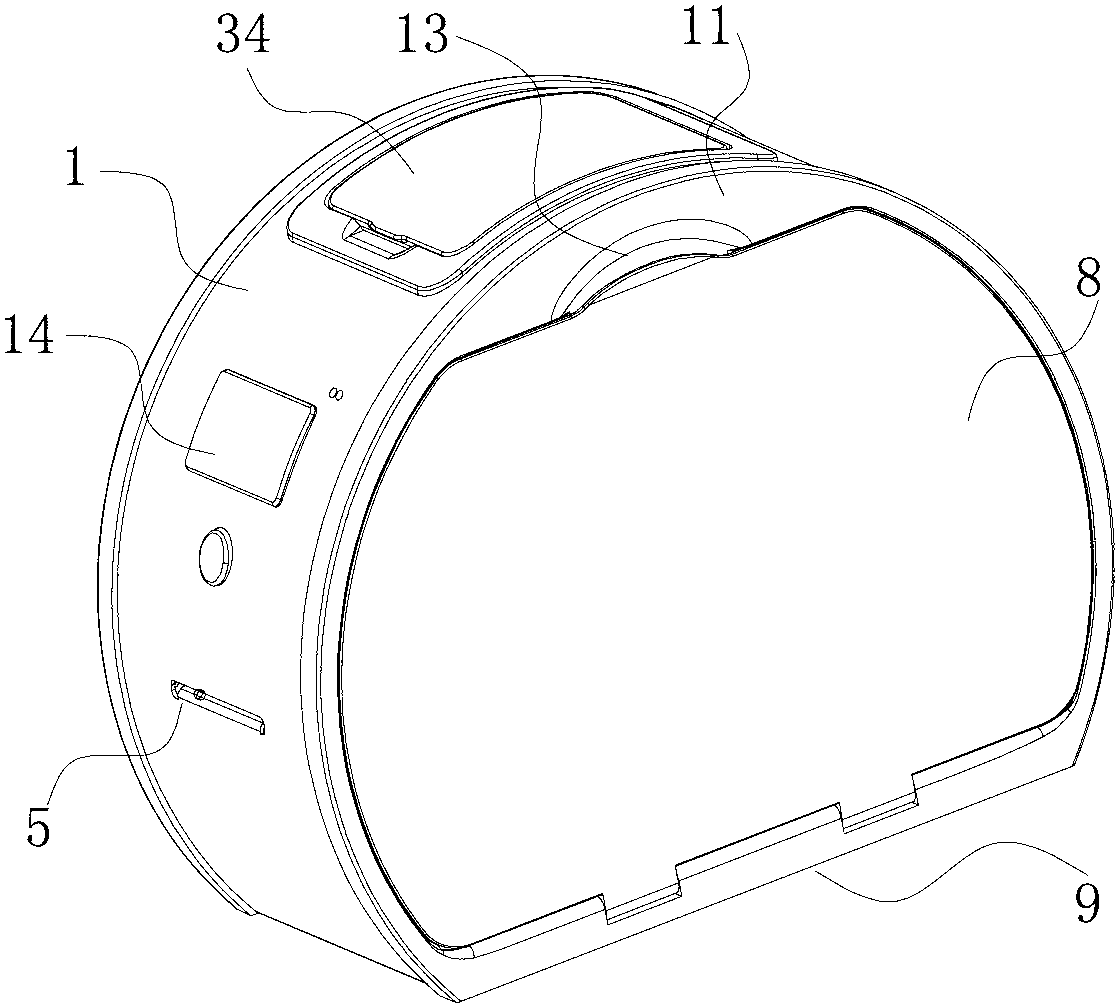

Printing head self-adaptive adjustment device and printer thereof

The invention provides a printing head self-adaptive adjustment device which comprises a fixing rack, a connecting rack and a connecting component; the fixing rack is arranged on a printer base; a printing head is arranged on the connecting rack; the connecting rack is connected with the fixing rack by the connecting component; the connecting rack has a locking state and a rotation adjustment state relative to the fixing rack; the connecting component comprises a connecting piece and an elastic piece; the connecting rack is connected with the fixing rack through the connecting piece; and the elastic piece generates pressure on the matching end faces of the connecting piece and the fixing rack. In a rotation adjustment state, the printing head deflects relative to a rubber roller, by this time, the pressure on the contact line of the printing head and the rubber roller is not balanced, and then torque driving the connecting rack to deflect is generated till the contact line of the printing head and the rubber roller is stressed uniformly. Self-adaptive adjustment on the parallelism degree of the printing head and the rubber roller is realized, the contact line of the printing head and the rubber roller is stressed uniformly, and thus the printing quality is improved.

Owner:XIAMEN HANIN ELECTRONICS TECH CO LTD

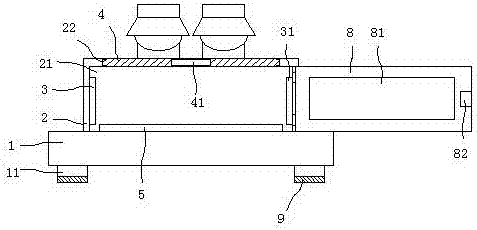

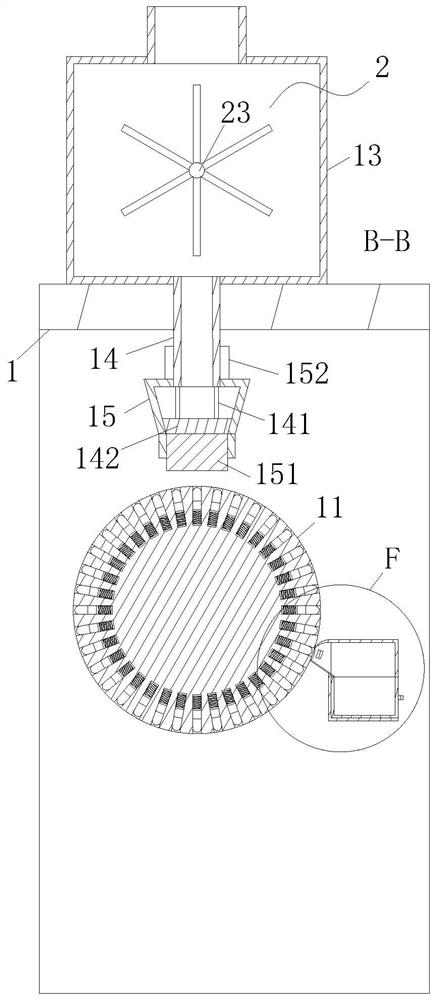

Rubber powder laser sintering 3D printing forming device and printing method

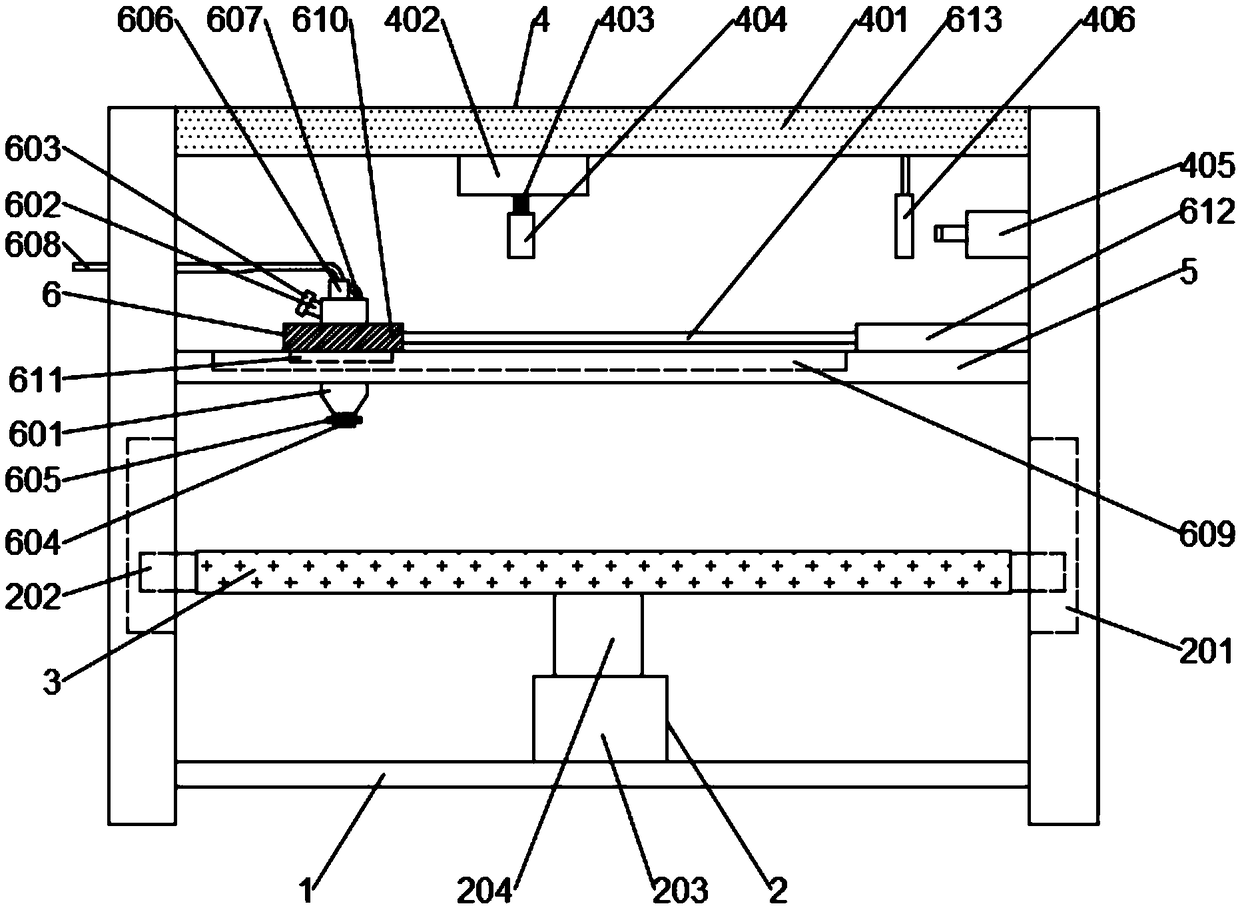

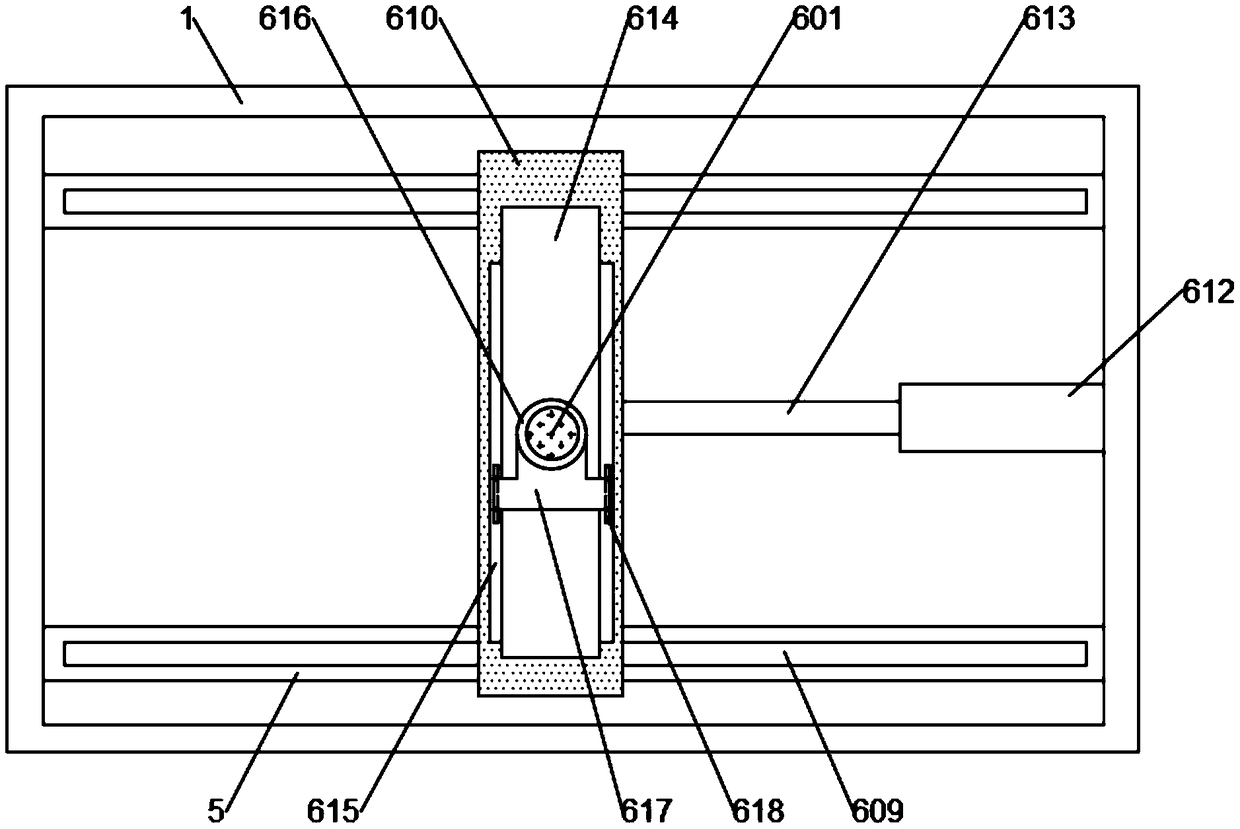

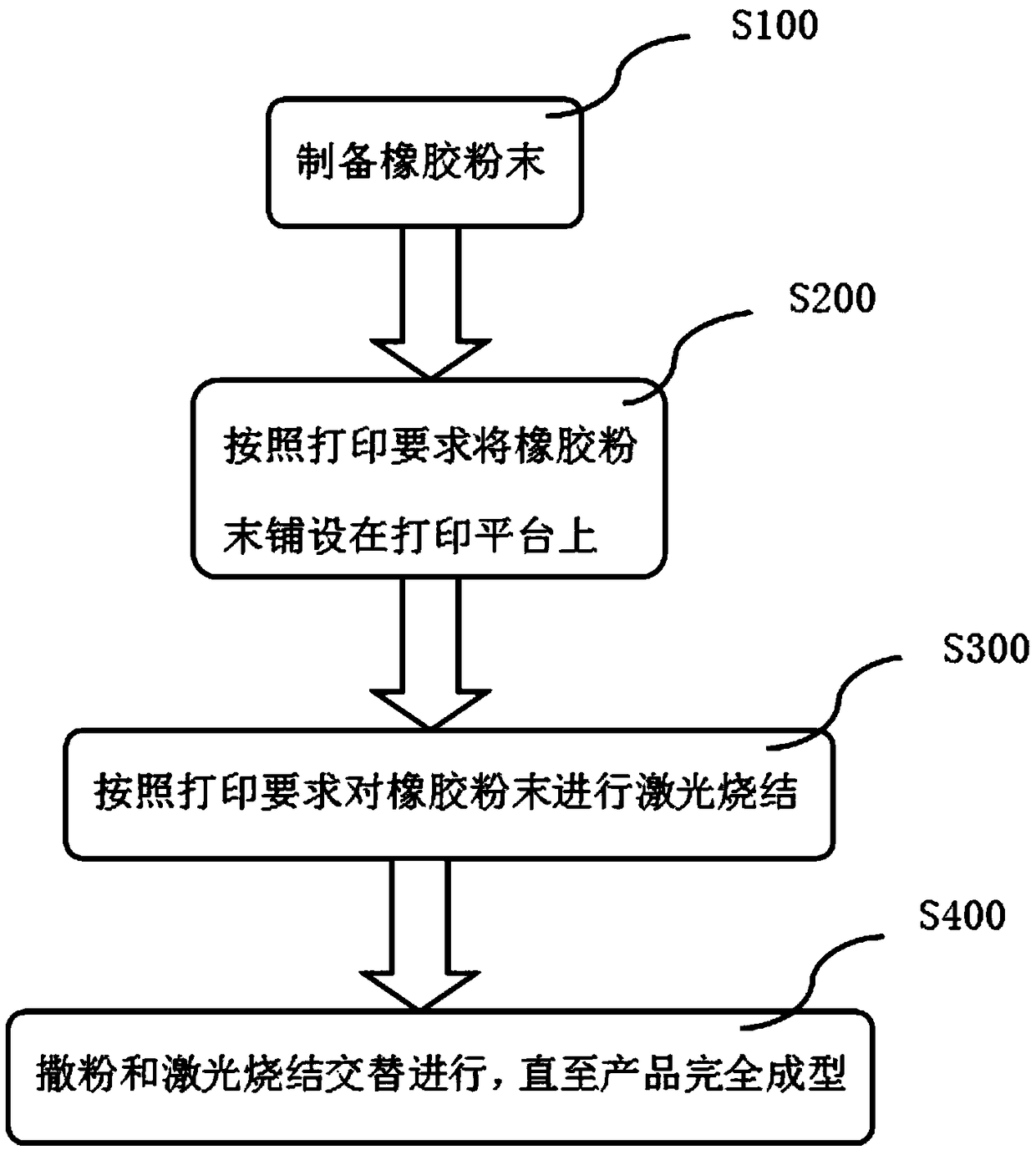

PendingCN109366985AHigh sintering precisionFully sinteredManufacturing platforms/substrates3D object support structuresScanning mirrorMaterials science

The invention discloses a rubber powder laser sintering 3D printing forming device and a printing method. A machine body is included, the bottom of the machine body is connected with a printing platform through a lifting structure, a sintering device is arranged at the top end of the machine body, supporting sliding rods fixed to the two sides of the machine body are arranged under the sintering device, the supporting sliding rods are provided with a powder spreading device, and the sintering device comprises a moving guide rail arranged at the top end of the machine body; and a first electricsliding block is mounted on the moving guide rail, the bottom end of the first electric sliding rod is connected with a scanning mirror through a rotating connecting member, a laser generator is arranged on the side of the scanning mirror, and a refractor assembly is arranged between the laser generator and the scanning mirror. The device is high in sintering precision and sufficient in sintering, does not affect surrounding materials, enables rubber powder to be more evenly spread, is higher in spreading precision, and avoids the position deviation of the rubber powder; and in addition, therubber powder prepared by the device has better quality, all components are more uniformly mixed, and the quality of products can be ensured.

Owner:QINGDAO UNIV OF SCI & TECH

Anti-bubble ink box

The invention discloses an anti-bubble ink box, which comprises: a casing, the upper part of which is provided with an ink supply port, and the lower part is provided with an ink outlet; an ink guiding mechanism, which includes an ink guiding box and a plurality of ink guiding rods; an air guiding mechanism , which includes a cylinder body, a first liquid guide tube and an air guide tube set sleeved inside the cylinder body; a liquid guide mechanism, which includes a protective cover, a second liquid guide tube and an ink storage box. The invention provides a separate path for air circulation by setting an air guide mechanism at the ink outlet, separates the air path from the liquid path, reduces the air in the ink, thereby reducing the generation of air bubbles in the printing process and improving the printing effect. Purpose: At the same time, set the flow path of dripping ink at the ink outlet, guide the dripping ink into the ink storage box, and store it in the sponge body, so as to avoid the pollution of the printer caused by the dripping ink that is not easy to clean, and completely solve the problem of ink dripping .

Owner:北海市天硌打印耗材有限公司

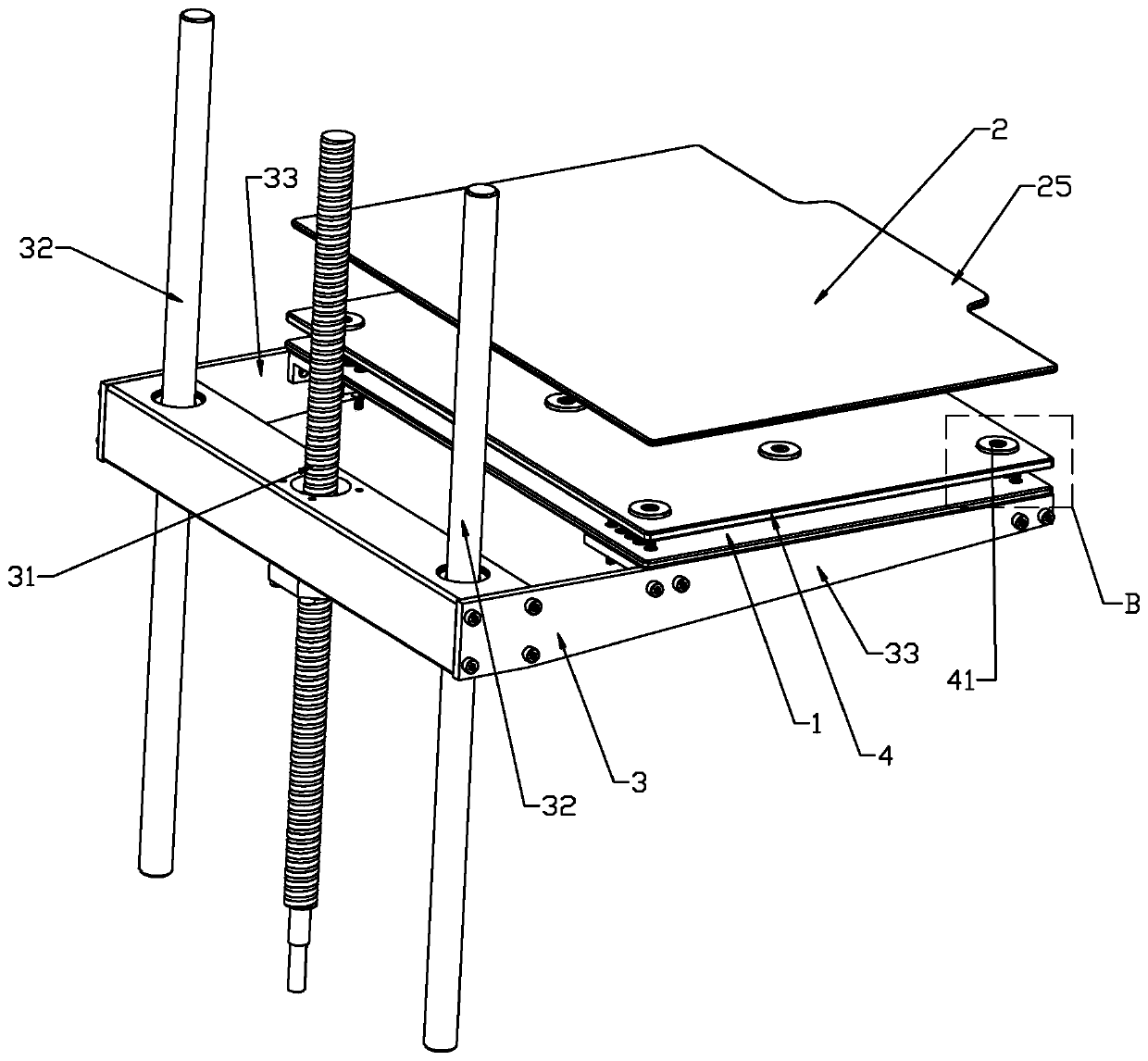

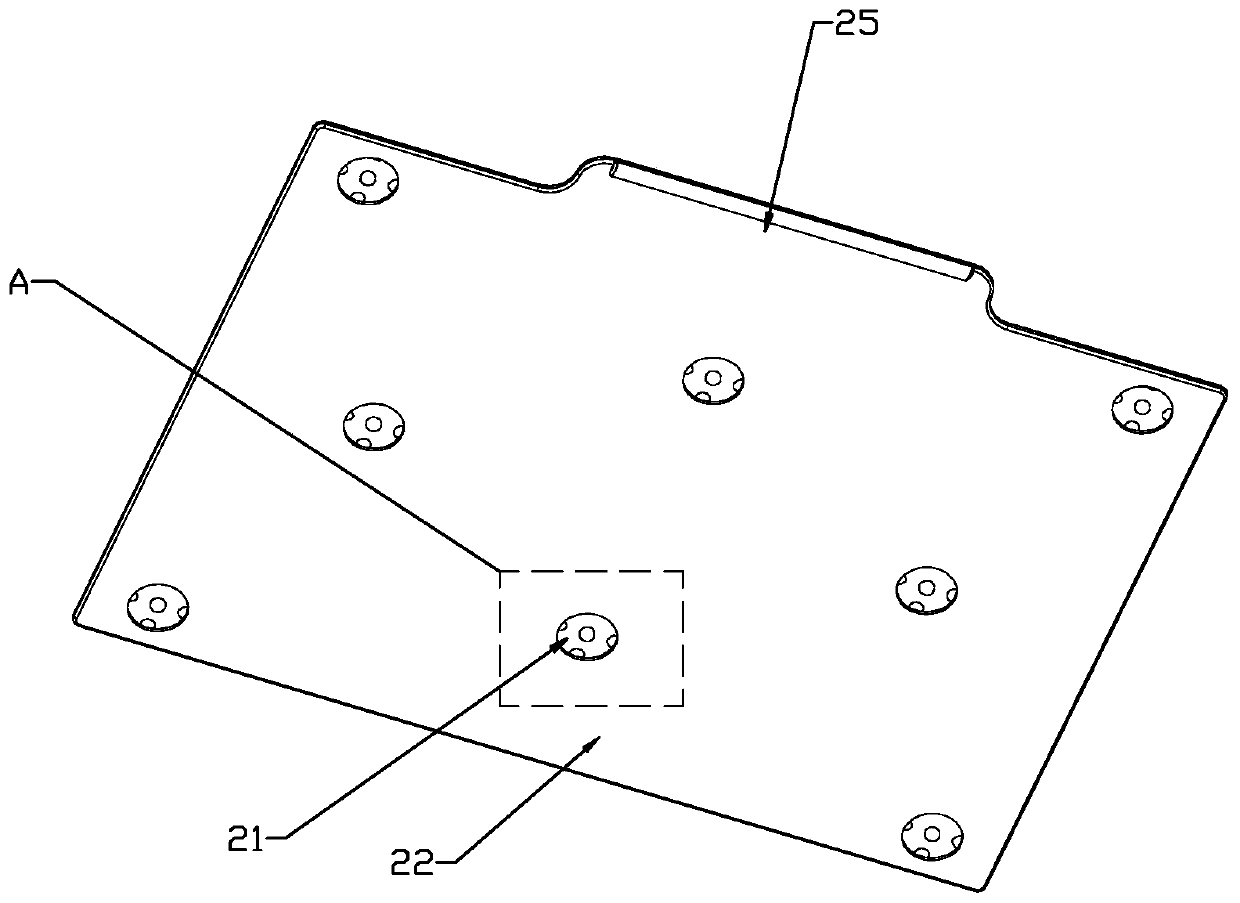

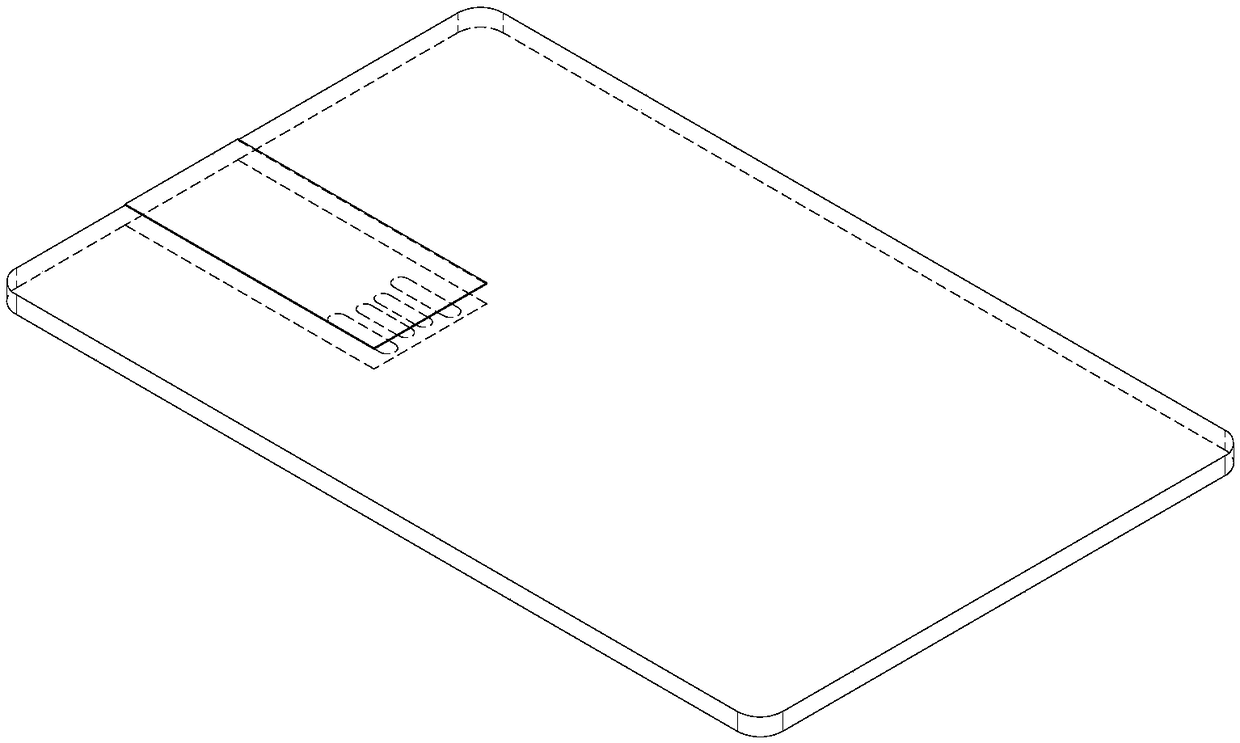

Magnetic modeling platform for 3D printer

PendingCN109693382AImprove placement accuracyEnhance the adsorption forceManufacturing platforms/substrates3d printBiochemical engineering

The invention relates to a magnetic modeling platform for a 3D printer. The magnetic modeling platform comprises a modeling platform body and a base plate allowing forming of printing materials, the base plate is placed above the modeling platform body, and is composed of an inner layer and an outer layer covering the outer side of the inner layer, the inner layer is made of magnetic metal attracted by an electric disk, the outer layer is made of plastic, and the modeling platform body is provided with a magnetic generating device for adsorbing the base plate to the modeling platform body through magnetism. According to the scheme, the magnetic modeling platform for the 3D printer is provided, wherein the magnetic modeling platform is simple in structure, facilitated locking and separationof the base plate, and has the high base plate strength.

Owner:安徽中科祥晟科技有限公司

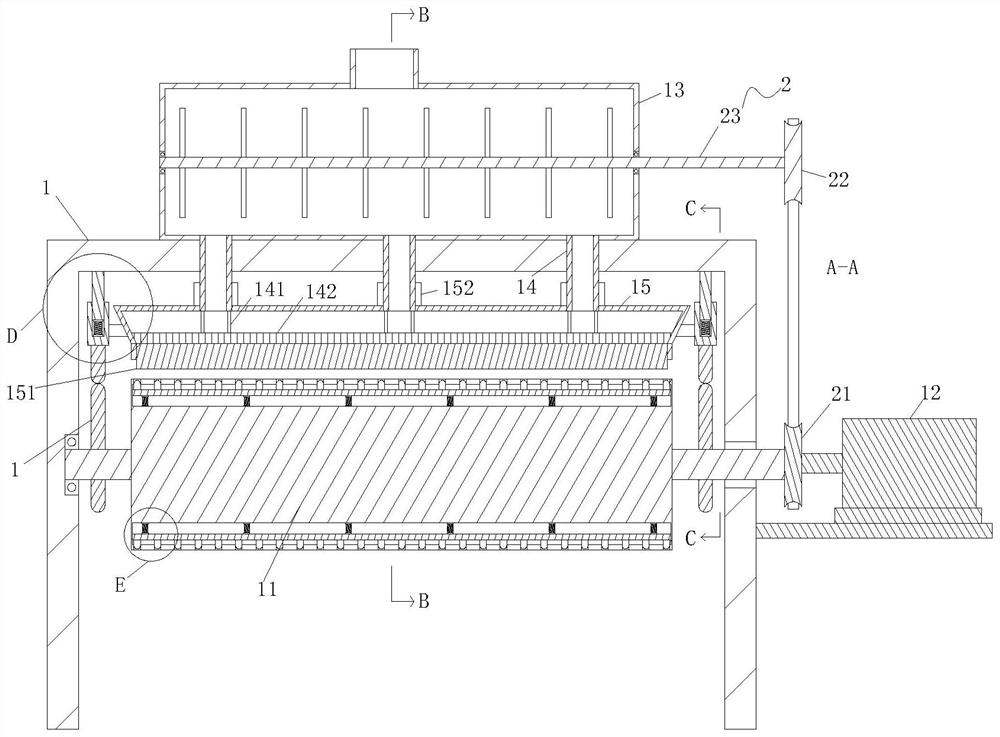

Screen printer

The invention discloses a screen printer. The screen printer comprises a net frame, a support frame, a conveyor and an electric linear guide rail, wherein a supporting plate used for supporting a conveyor belt is arranged on the supporting frame, the supporting plate is fixedly connected with the supporting frame, the conveyor is mounted on the support frame, the belt of the conveyor is clung to the supporting plate, a first connecting plate and a second connecting plate are arranged on the supporting frame, a first sliding guide rail and a second sliding guide rail are arranged on the front surface of the first connecting plate and the front surface of the second connecting plate respectively, clamps used for clamping the net frame is arranged on the first sliding guide rail and the second sliding guide rail, a net plate is arranged on the net frame, the net plate is located right above the supporting plate, the electric linear guide rail is mounted between the first connecting plateand the second connecting plate, and a scraping plate matched with the net plate is arranged on a slider of the electric linear guide rail. The screen printer can adjust the screen height so as to prevent the scraping plate from working under the condition of high load for a long time.

Owner:HUZHOU XINTIAN GREEN PACKAGE PRINTING CO LTD

Base for 3D printing equipment

InactiveCN108973127AEasy to removePrevent slippingManufacturing platforms/substratesManufacturing heating elementsHeat conductingBiochemical engineering

The invention provides a base for 3D printing equipment. The base comprises a printing platform, a heat conducting sheet and a heating wire, a supporting plate is arranged at the top of a fixing basebody through damping springs, a rotating bearing is arranged at the top of the supporting plate, the printing platform is arranged at the top of the rotating bearing, the heat conducting sheet is arranged in the middle of the interior of the printing platform, the heating wire is arranged at the bottom of the heat conducting sheet, the top of the printing platform is provided with micro grooves, screw mounting base bodies are arranged at the four corners of the bottom of the fixing base body, and adjusting screws are arranged at the bottoms of the screw mounting base bodies. According to the base, the horizontal of the fixing base body can be adjusted, so that the printing platform is in a horizontal state; the influence of vibration on the printing effect can be avoided; the heating wireand the heat conducting sheet are used cooperatively, so that the printing platform can be heated, and the phenomenon that a printed product adheres to the printing platform and cannot be easily takendown can be avoided; and through the cooperative use of the micro grooves, the printed product is prevented from slipping off from the printing platform.

Owner:浙江威步机器人股份有限公司

Printer

ActiveCN103009827AWith deceleration functionNo offsetOther printing apparatusPulp and paper industryControl circuit

The invention discloses a printer. The printer comprises a housing, wherein a paper roll placing cavity, a fixing frame and a control circuit are arranged in the housing, the fixing frame is provide with a printing head, a paper output port corresponding to the printing head is arranged on the housing, the paper roll placing cavity is provided with a winding shaft, the fixing frame is provided with an operation control portion, an operation open window is disposed on one side of the housing, a cover plate is arranged on the housing, the cover plate is matched with the operation open window, and after the cover plate covers the operation open window, the cover plate is opposite to the shaft end of the winding shaft and covers the operation control portion. The printer is convenient to operate, difficult to be damaged, and high in reliability when used to print.

Owner:B&B EXPORTING

Automatic pushing device for storage cards

ActiveCN108382899AImprove cleanlinessAvoid affecting the printing effectCoupling device detailsArticle feedersComputer science

Owner:SUZHOU NETZON INFORMATION STORAGE TECH

QR code printer for seed packing bag

PendingCN108501544AAvoid offsetSlow down ink outputTypewritersPower drive mechanismsCircular discElectric machinery

The application discloses a QR code printer for a seed packaging bag. The QR code printer comprises a base and a conveyor belt, wherein two supporting plates are arranged on the base and located at two sides of the conveyor belt respectively; a top plate is arranged between the two supporting plates; a motor is arranged on the top plate; a linkage shaft is arranged on an output shaft of the motor;a rectifying mechanism and a printing mechanism are sequentially arranged on the linkage shaft in a conveying direction of the conveyor belt; the rectifying mechanism comprises a cam fixedly connected to the linkage shaft and vertical grooves symmetrically formed in the supporting plates left and right; a pressing plate is connected between the two vertical grooves in a sliding manner; a first spring is arranged between the pressing plate and each vertical groove; a rectifying bar is arranged at the bottom of the pressing plate; the printing mechanism comprises a disc fixedly connected to thelinkage shaft and a guide cylinder fixedly connected to the two supporting plates; a linkage arm is hinged to an eccentric part of the disc; a printing head is arranged in the guide cylinder; the topof the printing head is hinged to the end, away from the disc, of the linkage arm; and an inking mechanism is further arranged in the guide cylinder. By adoption of the scheme, the problem that a conventional printer has a poor QR code printing effect is mainly solved.

Owner:重庆市飞龙种业有限责任公司

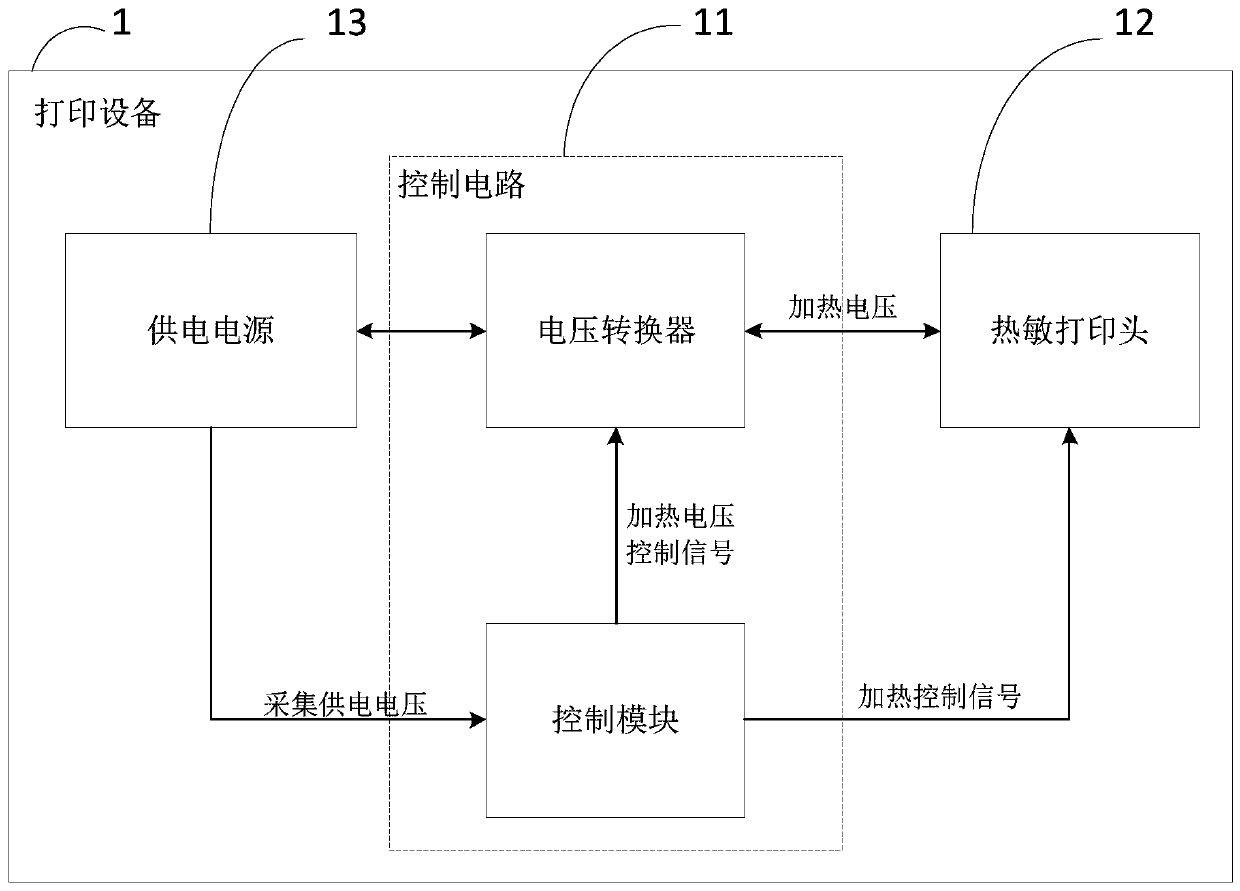

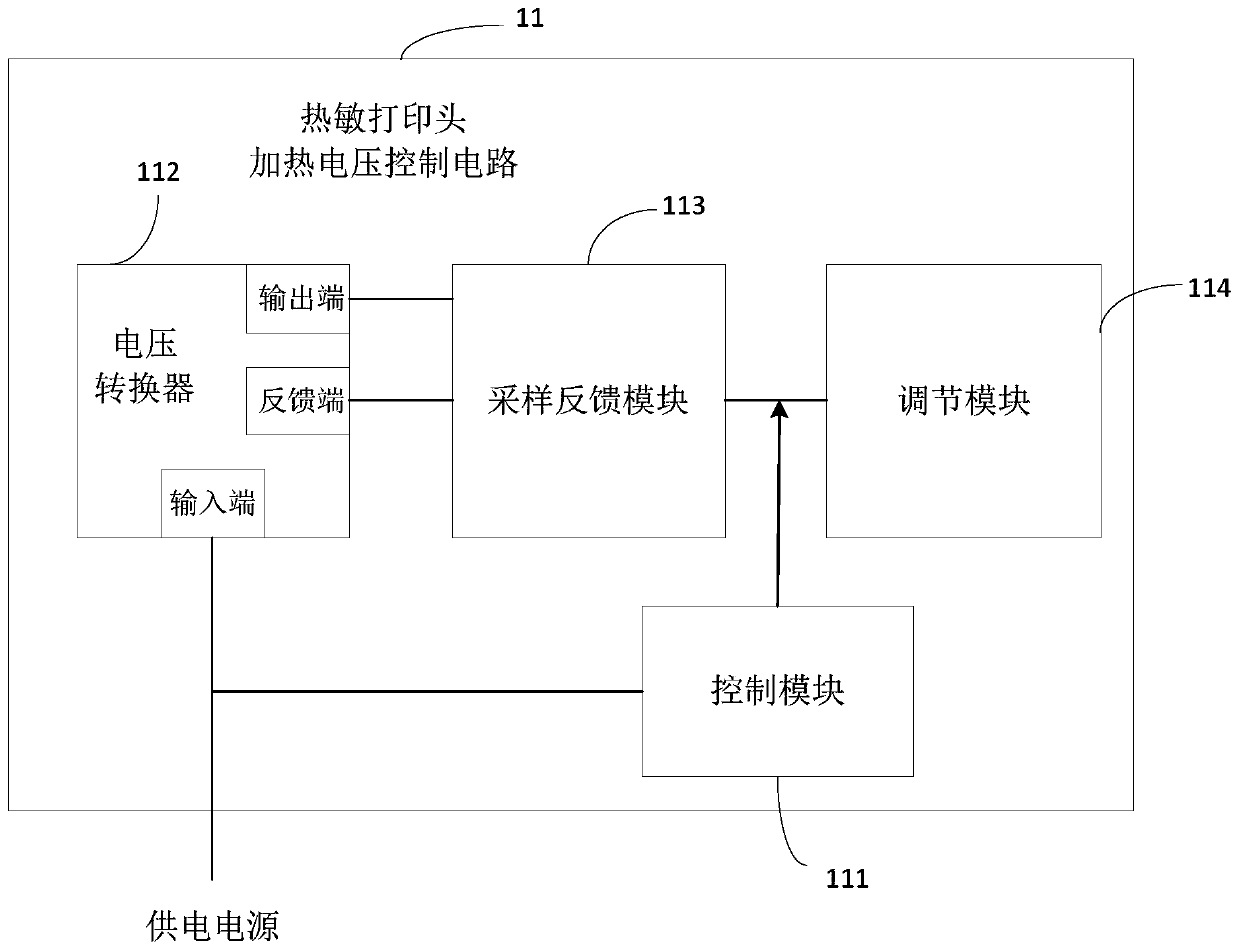

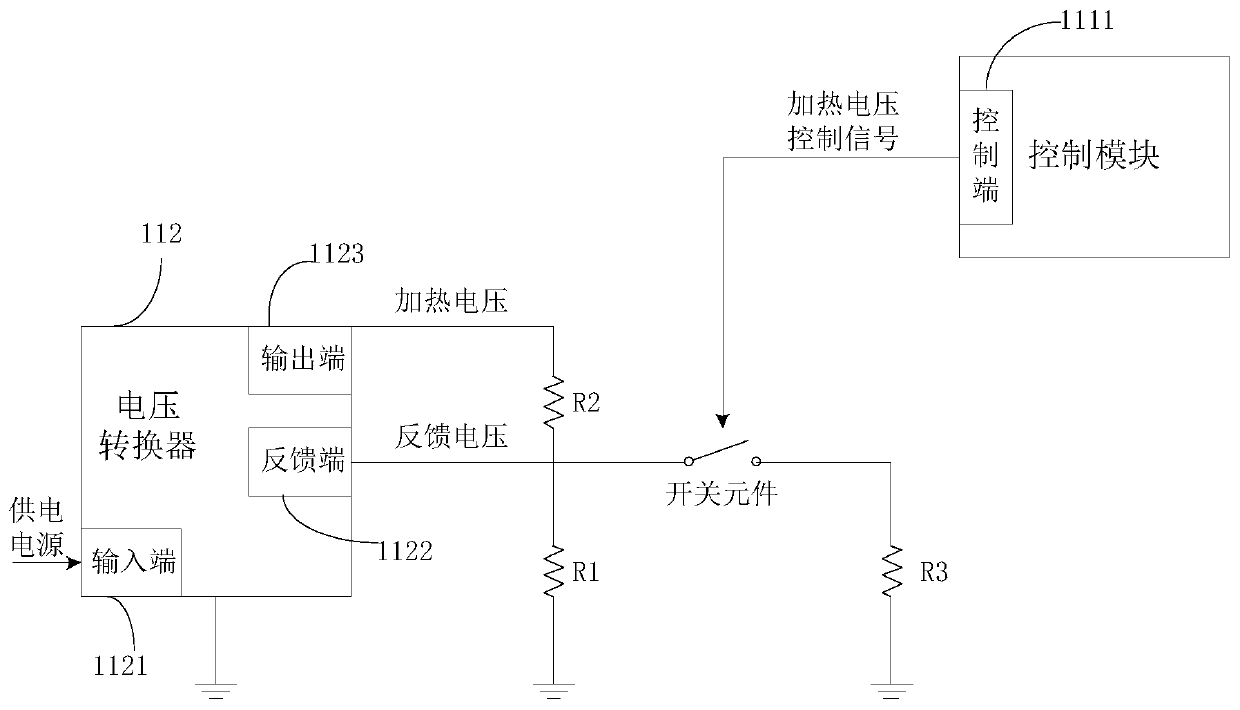

Thermosensitive printing head heating voltage control circuit and printing device

ActiveCN109849526AImprove printing efficiencyAvoid affecting the printing effectPrintingVoltage converterVoltage control

The invention provides a thermosensitive printing head heating voltage control circuit. The thermosensitive printing head heating voltage control circuit comprises a voltage converter, a sampling feedback module, a control module and an adjusting module; the voltage converter is connected with the sampling feedback module which is connected with the adjusting module; the control module is furtherconnected with the sampling feedback module and the adjusting module; the voltage converter is used for converting a power source voltage coming from a power supply and outputting a heating voltage; the sampling feedback module is used for acquiring the heating voltage; and the control module is also used for controlling the heating voltage according to the power source voltage through the adjusting module.

Owner:XIAMEN HANIN ELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com