Fused and deposited 3D printer capable of rapidly changing a printing nozzle

A technology of 3D printers and printing nozzles, which is applied in the field of 3D printing, can solve problems such as complex structure and difficult rapid replacement of nozzles, and achieve the effects of avoiding oxidation and decomposition, shortening the test cycle, and facilitating rapid replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

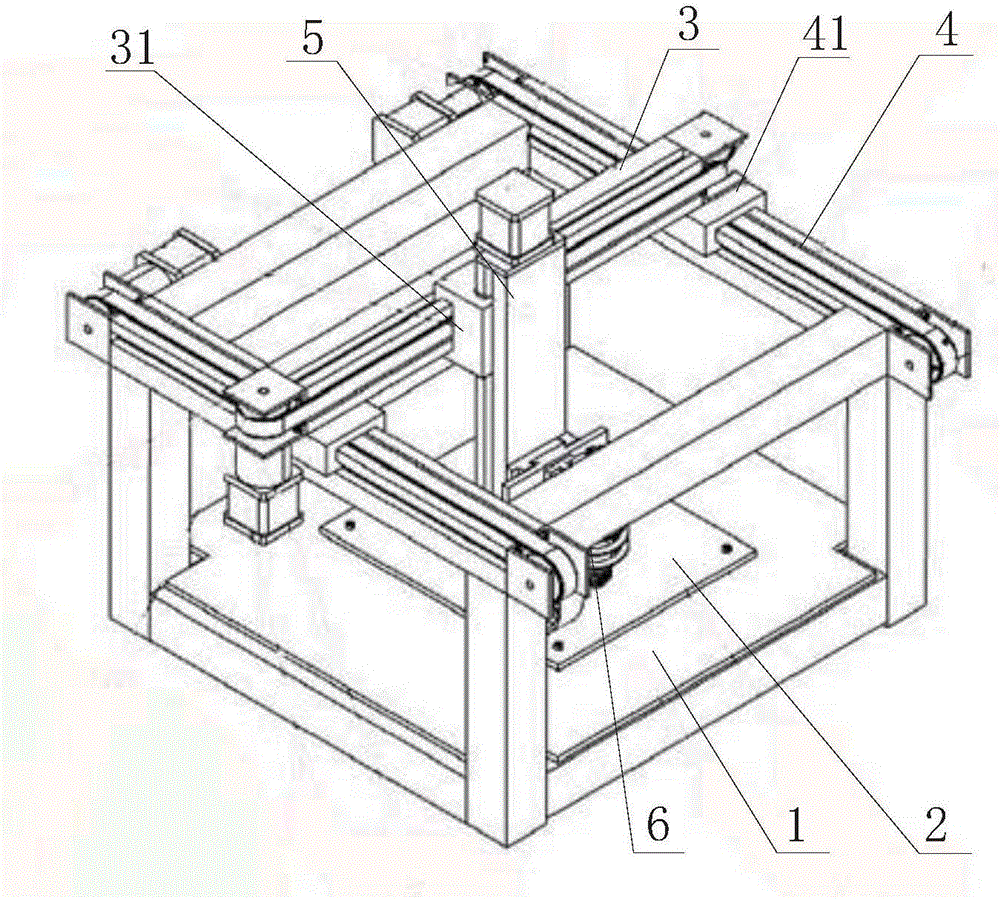

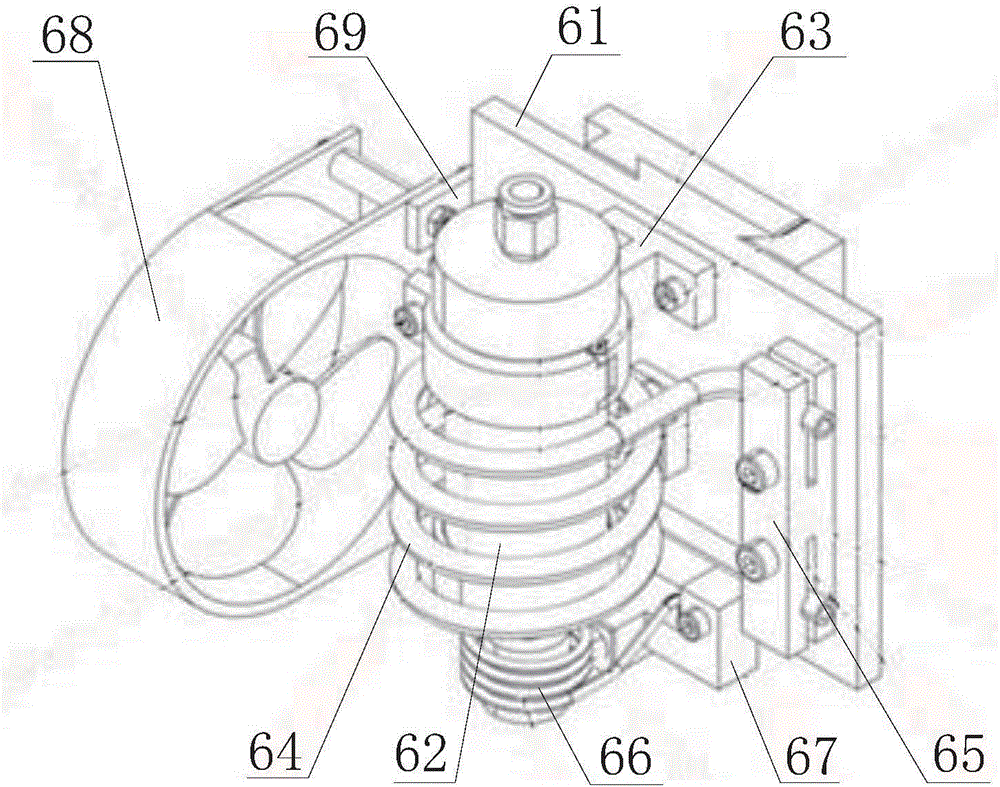

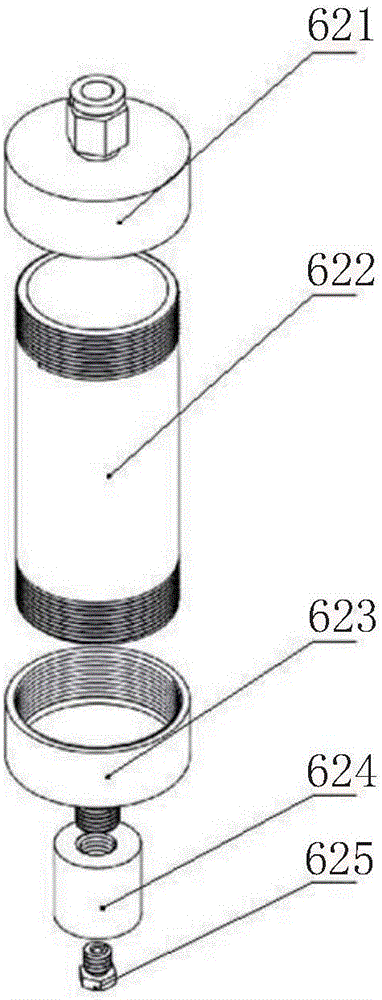

[0058] Such as figure 1 As shown, the fused deposition type 3D printer that can quickly replace the printing nozzle of the present invention includes a base plate 1 at the bottom, a printing frame, a printing head 6, and a driving printing head 6 mounted on the printing frame along the directions of the X axis, the Y axis and the Z axis. As for the moving kinematic mechanism, in this embodiment, the Z-axis direction is the vertical direction, and the X-axis, Y-axis, and Z-axis are perpendicular to each other.

[0059] Also include a gas compressor (not shown in the figure) to provide positive pressure for the barrel;

[0060] Vacuum pump (not shown in the figure), provides negative pressure for barrel;

[0061] The control unit (not shown in the figure) is electrically connected with the gas compressor and the vacuum pump, and controls the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com