Rapid color three-dimensional printer

A 3D printer and color technology, applied in the field of 3D printing, can solve the problems of reducing the surface quality of color models, mixing multiple consumables, and easy to form color differences, etc., to avoid the time-consuming effect of changing the connection relationship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

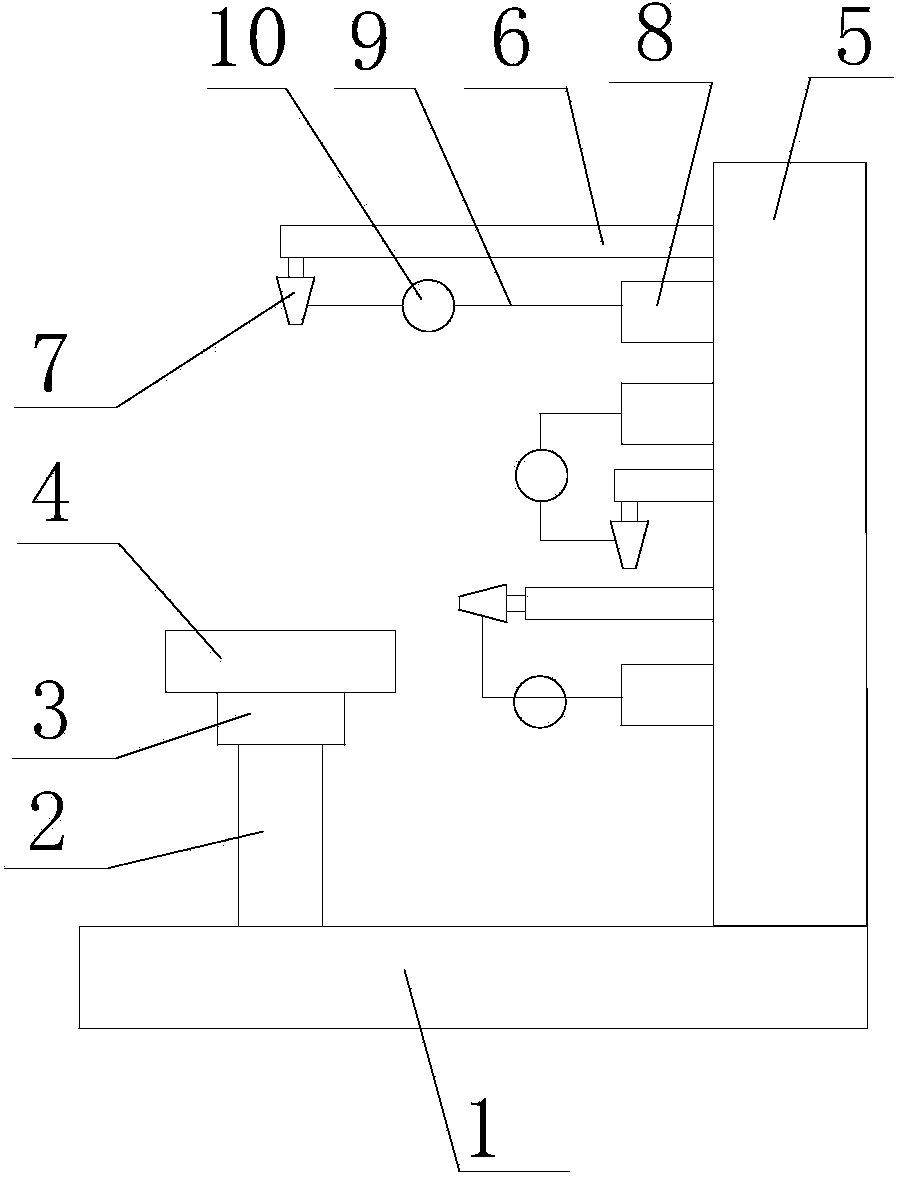

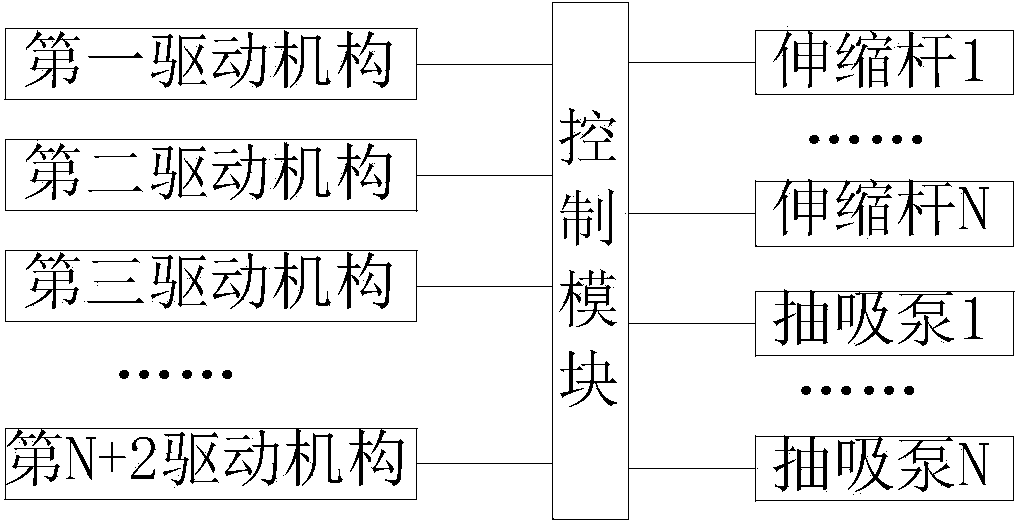

[0017] refer to figure 1 , figure 2 , a fast color three-dimensional printer proposed by the present invention, comprising: a base 1, a telescopic bracket 2, a rotating shaft 3, a workbench 4, a support seat 5, N telescopic rods 6, N print nozzles 7, and N storage boxes 8. N connecting pipes 9, N suction pumps 10, N+2 driving mechanisms and control modules, N≥2.

[0018] The telescopic support 2 is installed on the base 1, and the workbench 4 is installed on the telescopic support 2 through the rotating shaft 3. The first driving mechanism is used to drive the telescopic support 2 to expand and contract along the vertical direction so as to adjust the height of the workbench 4 , and the second drive mechanism is used to drive the rotating shaft 3 to rotate so as to drive the workbench 4 to rotate.

[0019] The support base 5 is installed on the base 1 . On the side of the support base 5 close to the workbench 4, there are N slideways parallel to each other along the horizo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com