Patents

Literature

230results about How to "Achieve the purpose of drying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

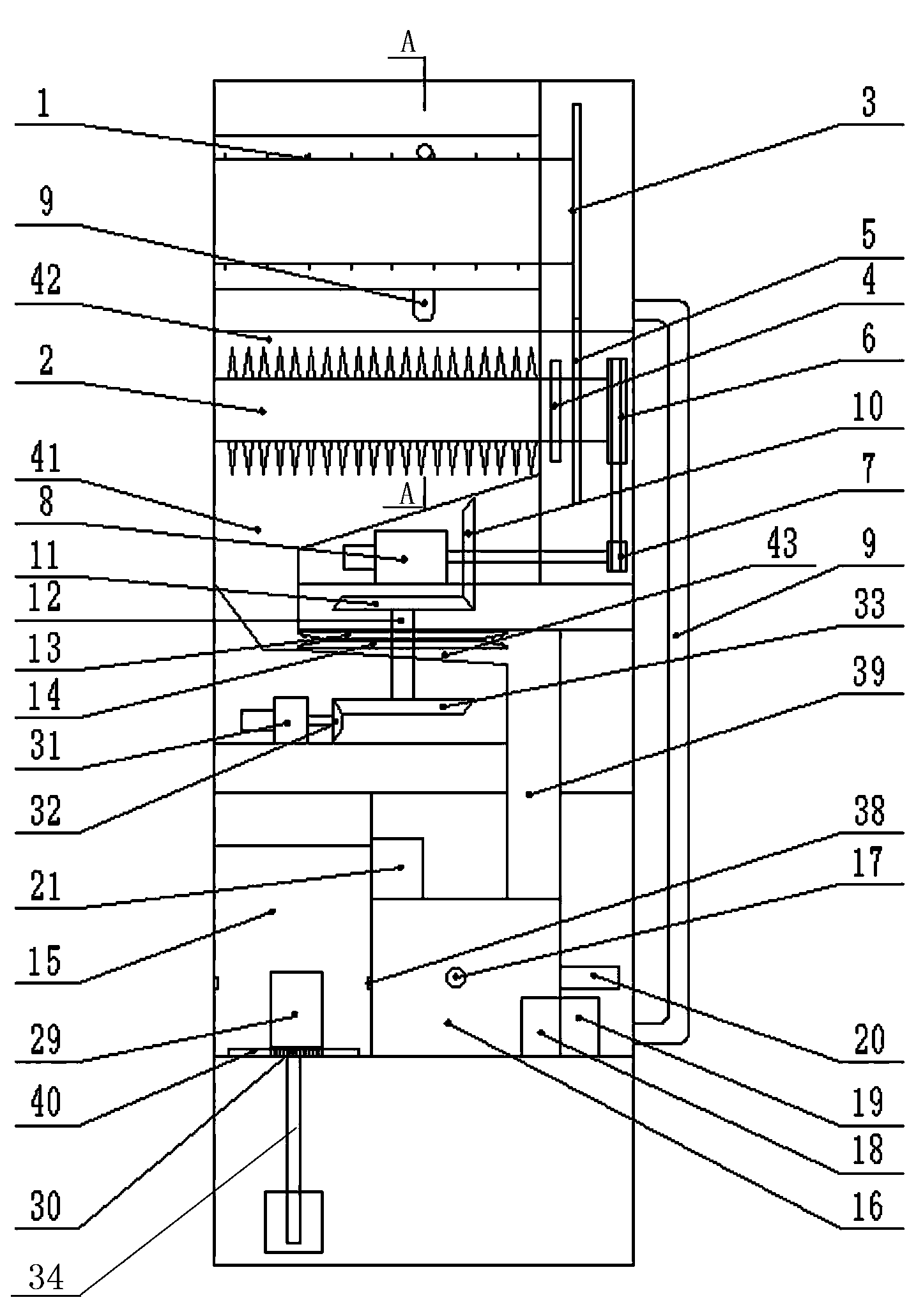

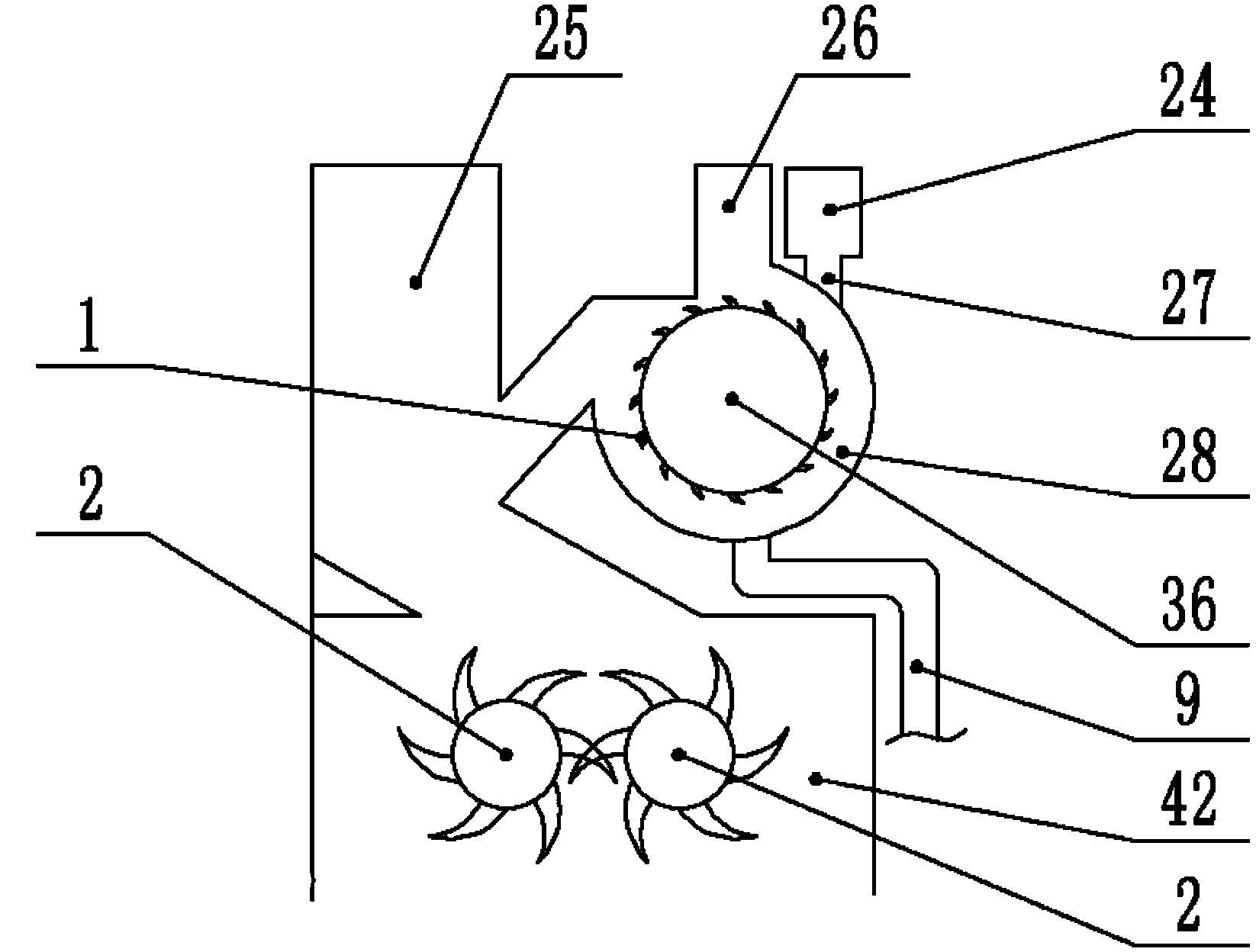

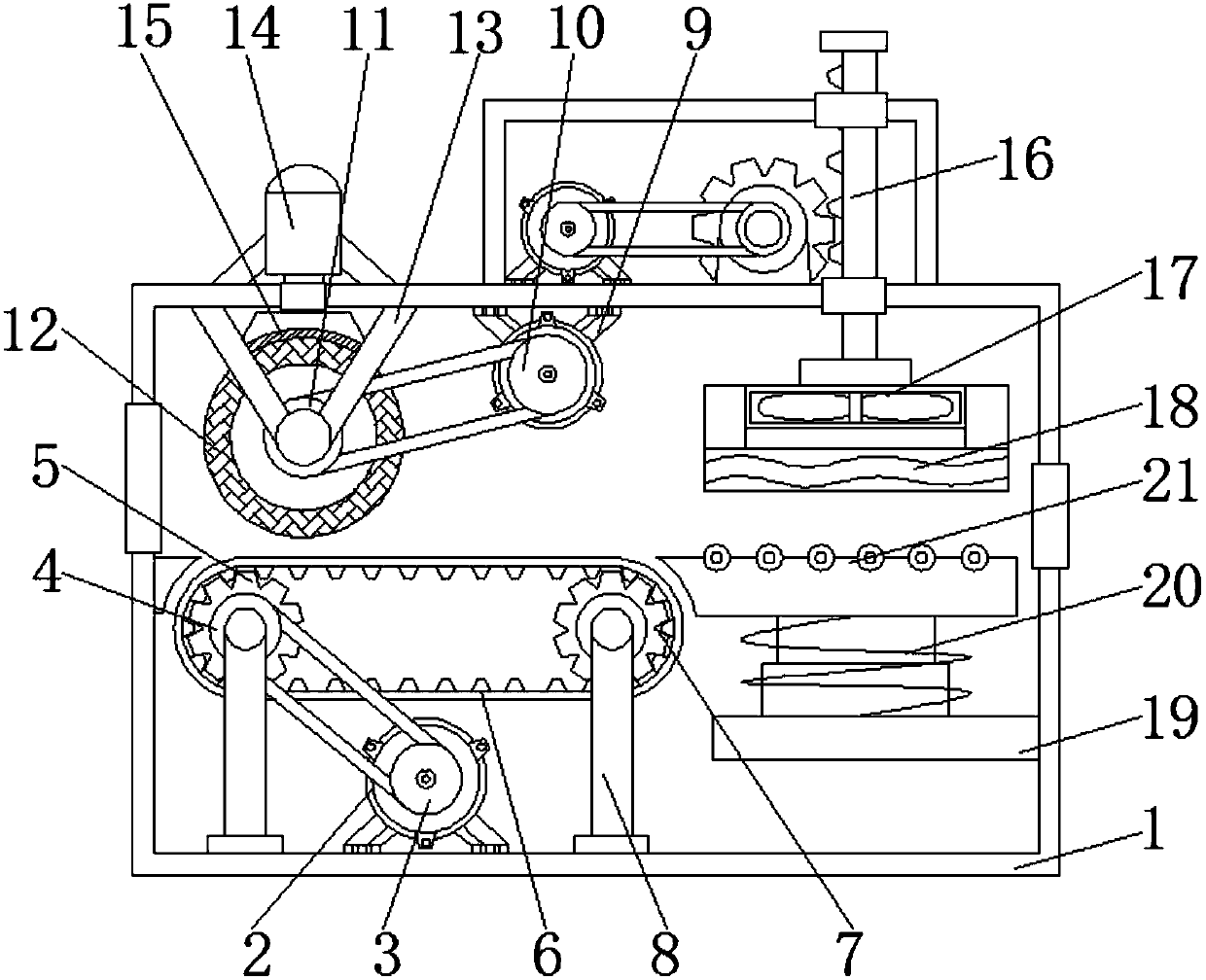

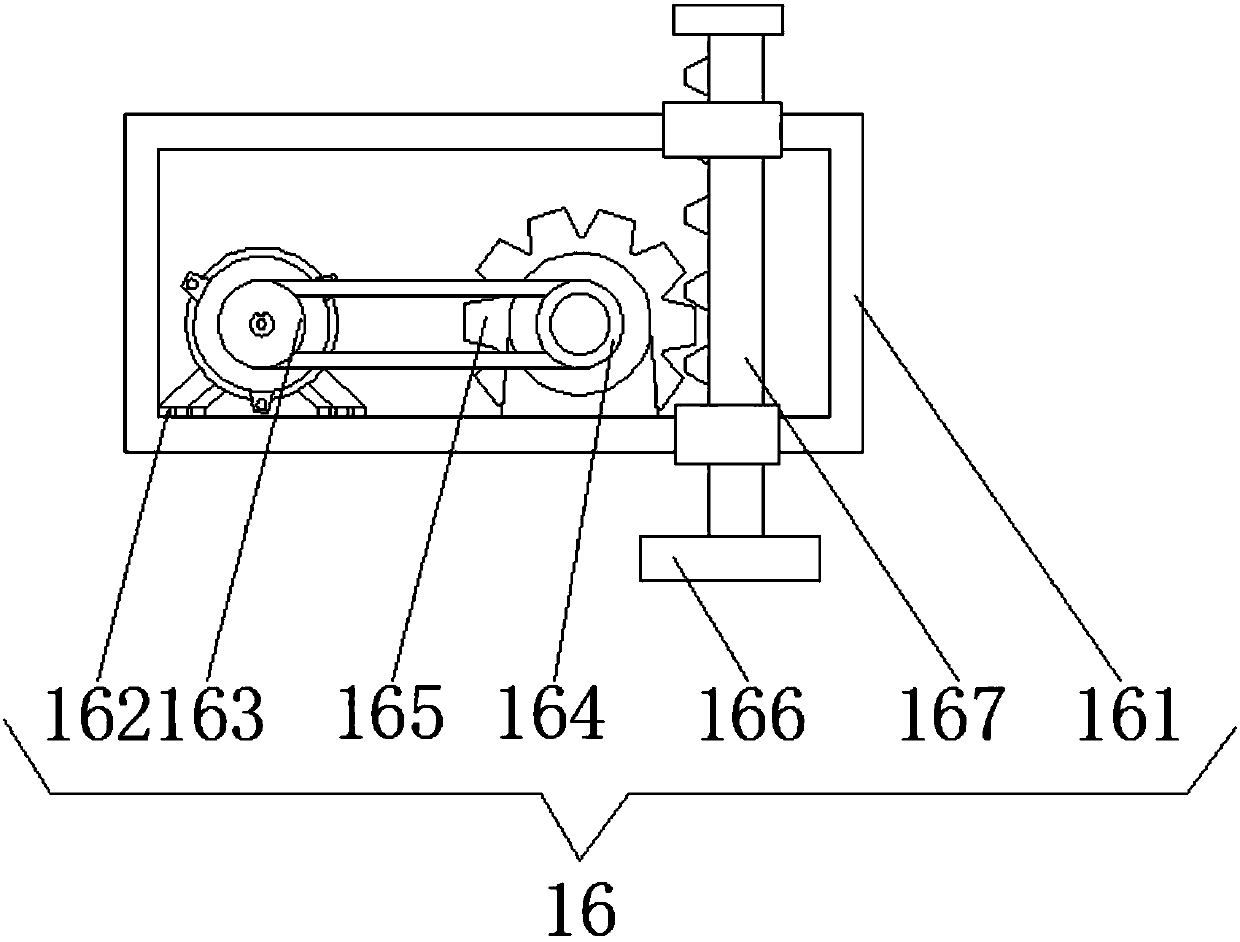

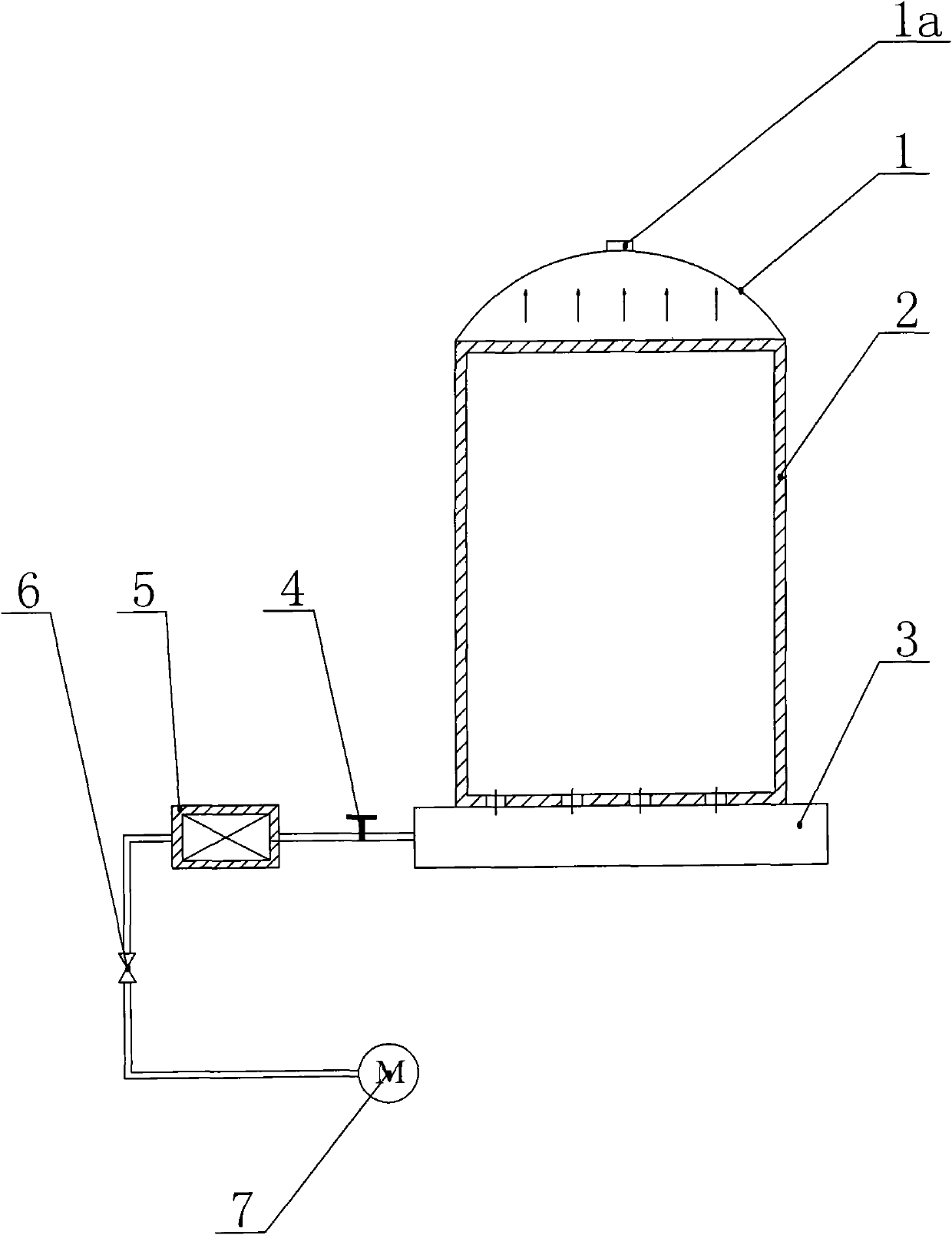

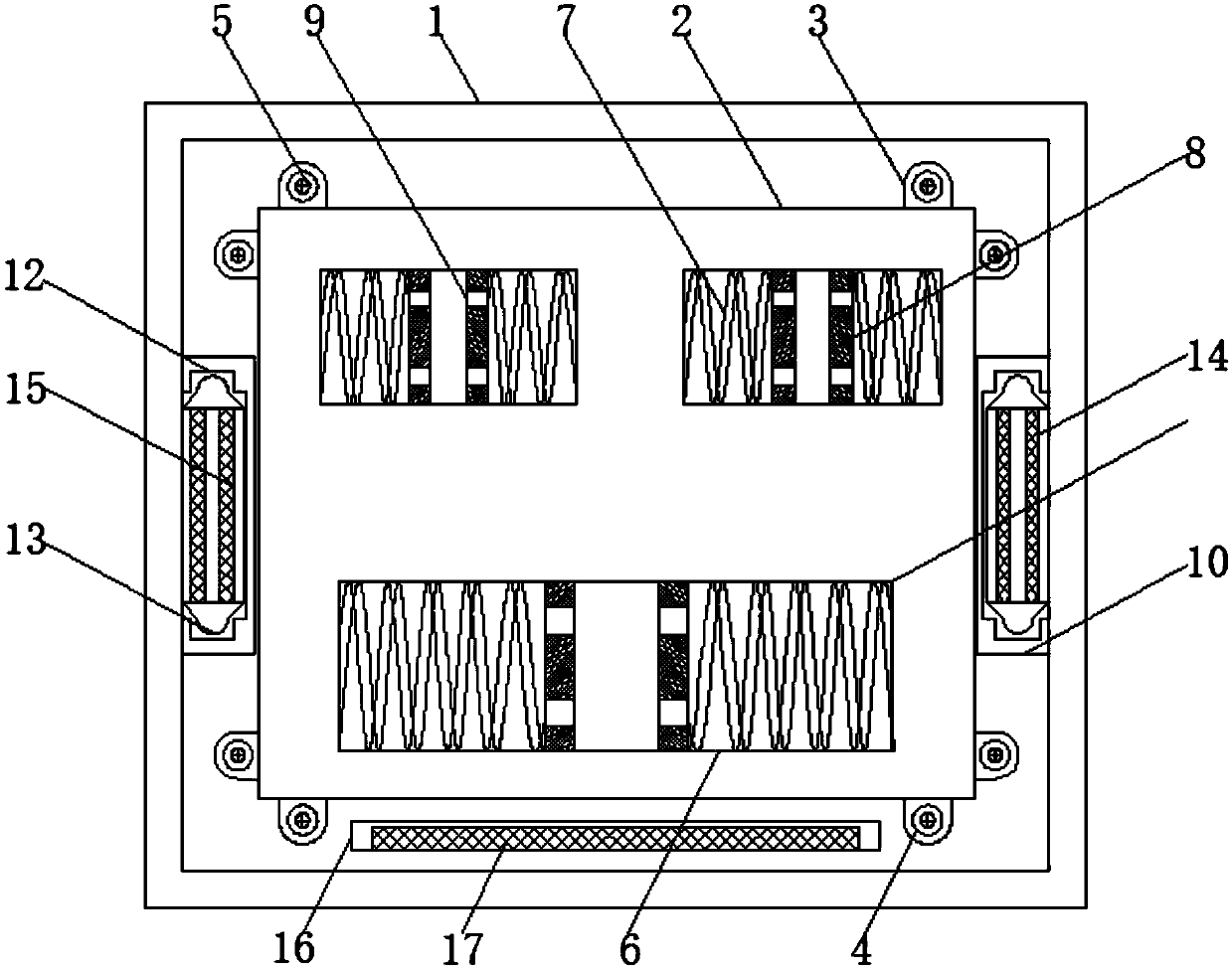

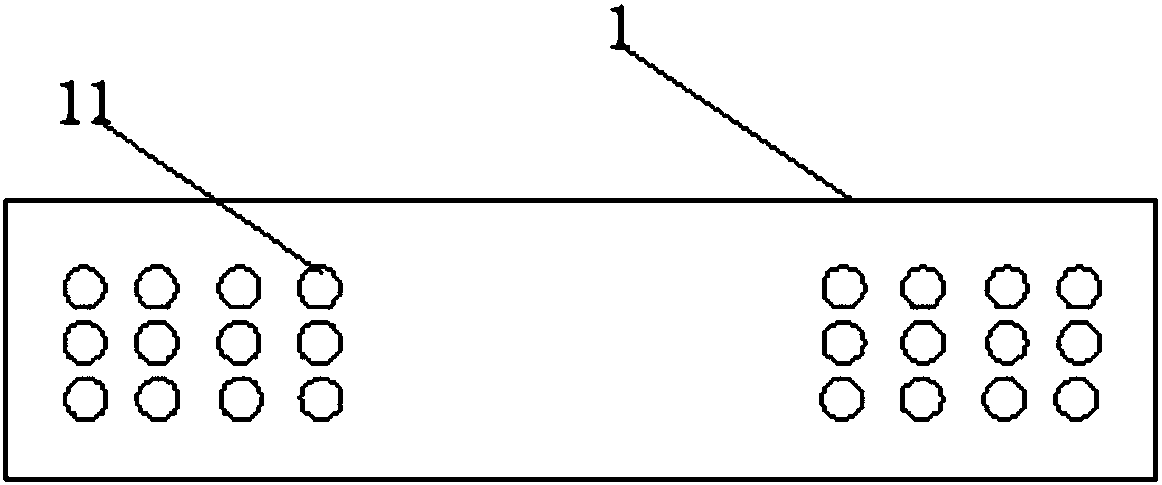

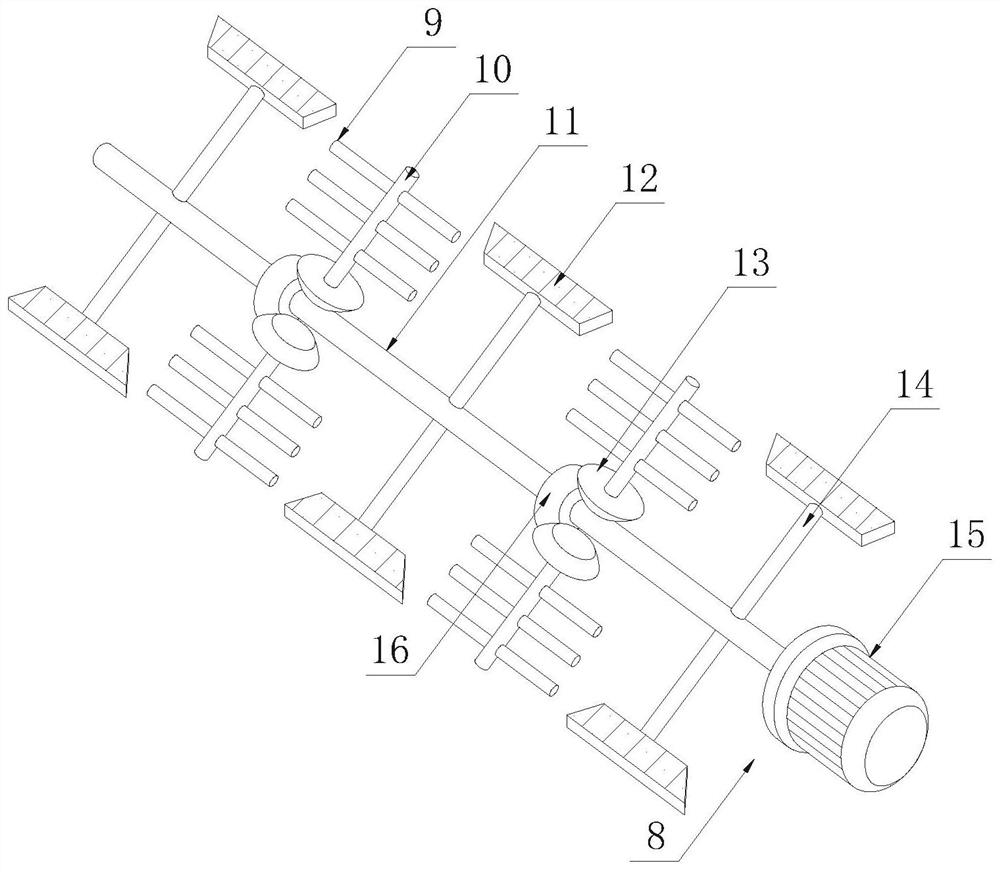

Grinding and painting equipment of locks for metal doors and windows

InactiveCN107497629AGuaranteed position changeReach spray paintLiquid surface applicatorsGrinding machinesWorking environmentArchitectural engineering

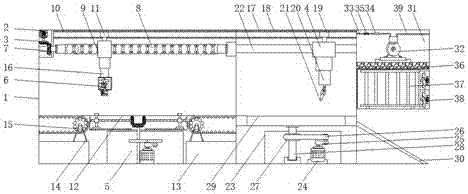

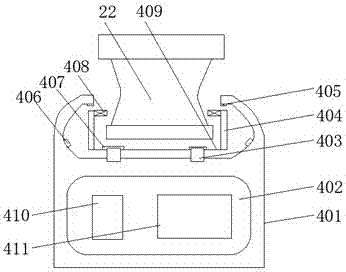

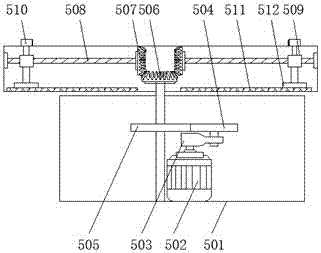

The invention discloses a polishing and painting equipment for metal door and window locks, which includes a frame, a first motor is fixedly connected to the top of the inner wall of the frame, and a first cone wheel is fixedly connected to the output shaft of the first motor through a flat key. , the bottom of the first conical wheel is fixedly connected with a second conical wheel, the second conical wheel is fixedly connected with a threaded rod through a flat key, and the top of the inner wall of the frame is fixedly connected with an auxiliary sliding track, the auxiliary An auxiliary slider is slidably connected to the inner wall of the sliding track, and the bottom of the auxiliary slider is fixedly connected to the slider through a connecting rod. The invention relates to the technical field of metal door and window lock processing. The grinding and painting equipment for metal doors and windows locks solves the problem of clamping and grinding workpieces, and can be positioned in different positions. The grinding device can change positions, ensuring the quality and accuracy of grinding and the adaptability to multiple working environments. After grinding The problem of painting and drying the workpiece.

Owner:ZHEJIANG DEQING DETAI DOOR IND

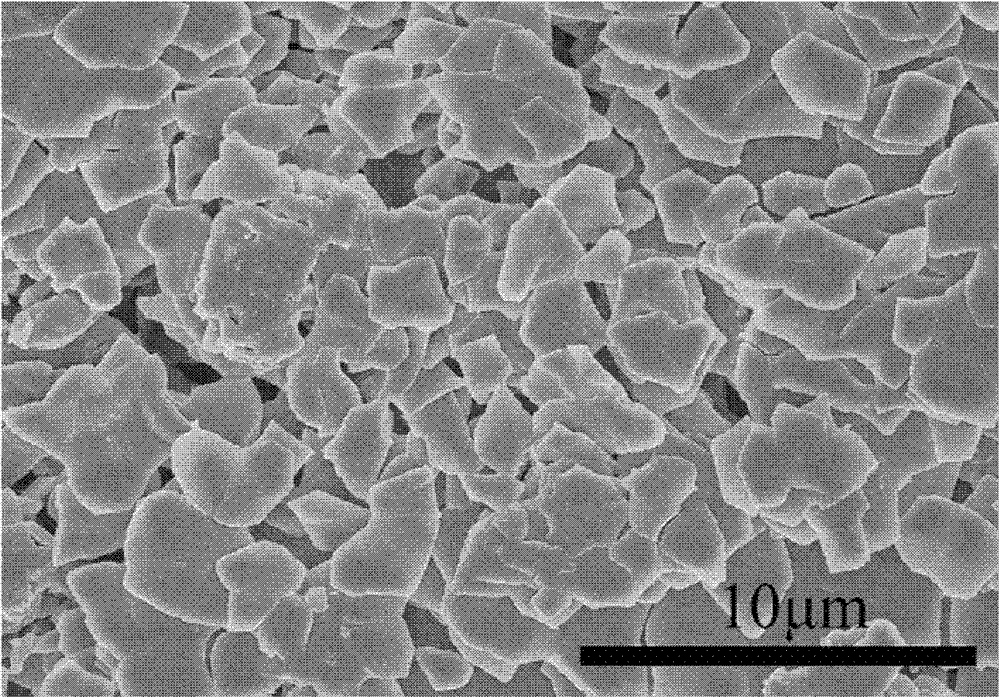

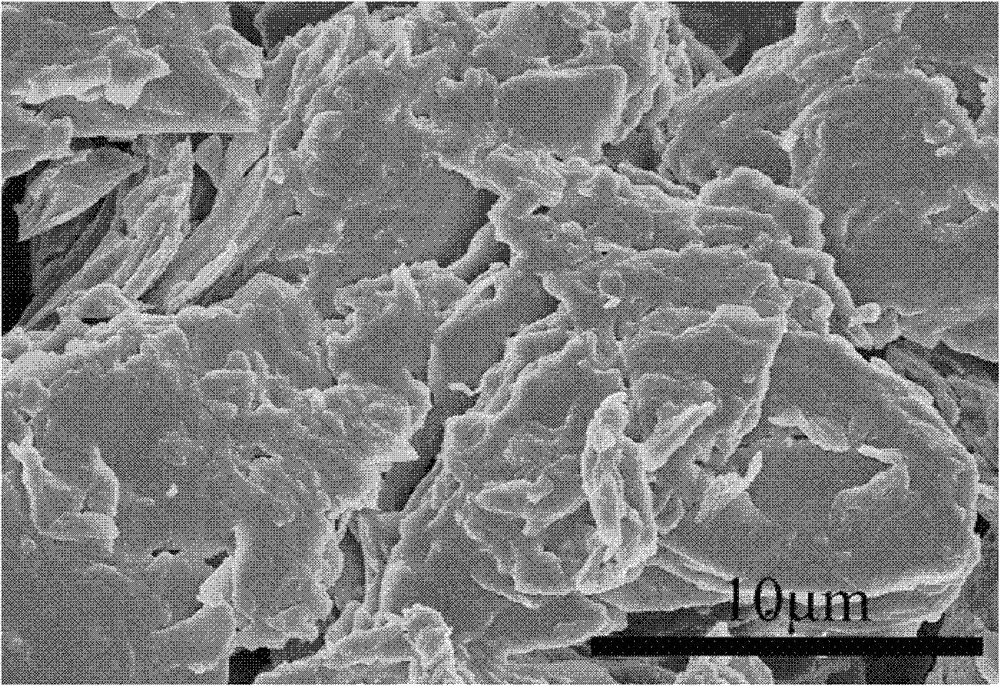

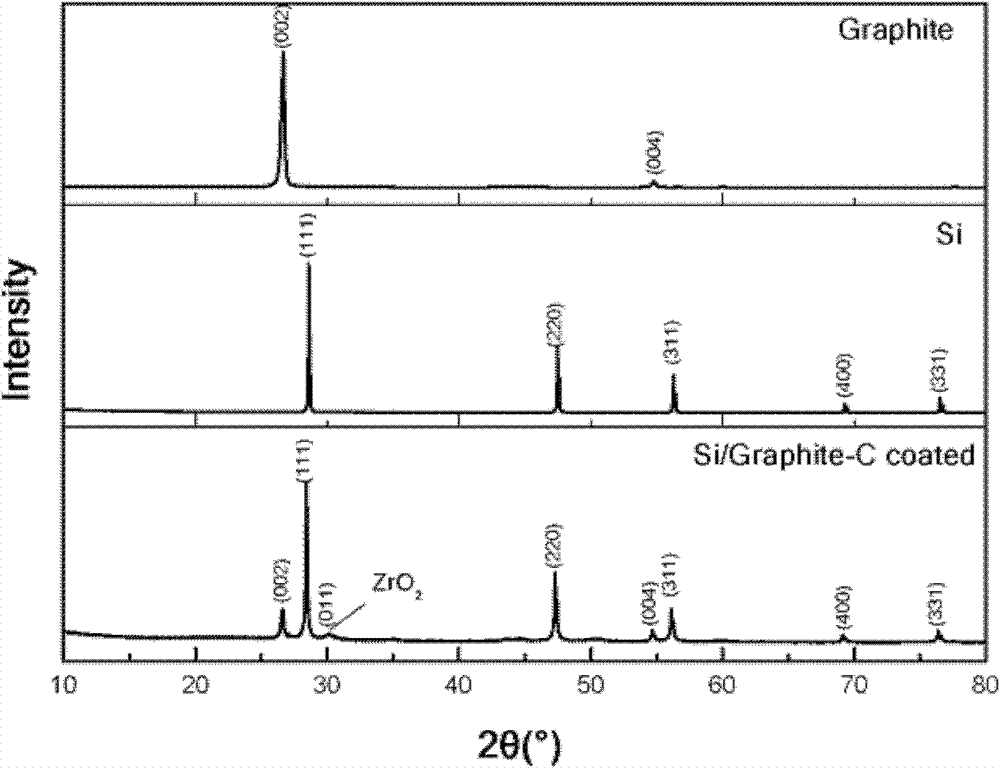

Preparation method of silicon carbon lithium ion battery cathode material

ActiveCN102790204AImprove cycle performanceIncrease capacityCell electrodesSurface oxidationFreeze-drying

The invention provides a preparation method of a silicon carbon lithium ion battery cathode material, which comprises the following steps: a) mixing a polymer solution, silicon powder and graphite to obtain a mixed solution; b) performing freeze drying of the mixed solution to obtain a solid mixture; c) sintering the solid mixture to obtain the silicon carbon lithium ion battery cathode material. The invention adopts freeze drying instead of a common drying method; the freeze drying means freezing the material, allowing the solvent component to rapidly become a solid state and to directly sublime under a vacuum condition so as to reach the drying purpose. With the process, the composite material and a carbon source can rapid coagulate within a short period, which avoids the problems of surface oxidation of the silicon material caused by normal temperature drying or high temperature drying, and non-uniform coating caused by settlement of the composite material powder. The obtained carbon-coated material has improved recycle performance and capacity when compared with materials obtained by common drying.

Owner:宁波富理电池材料科技有限公司

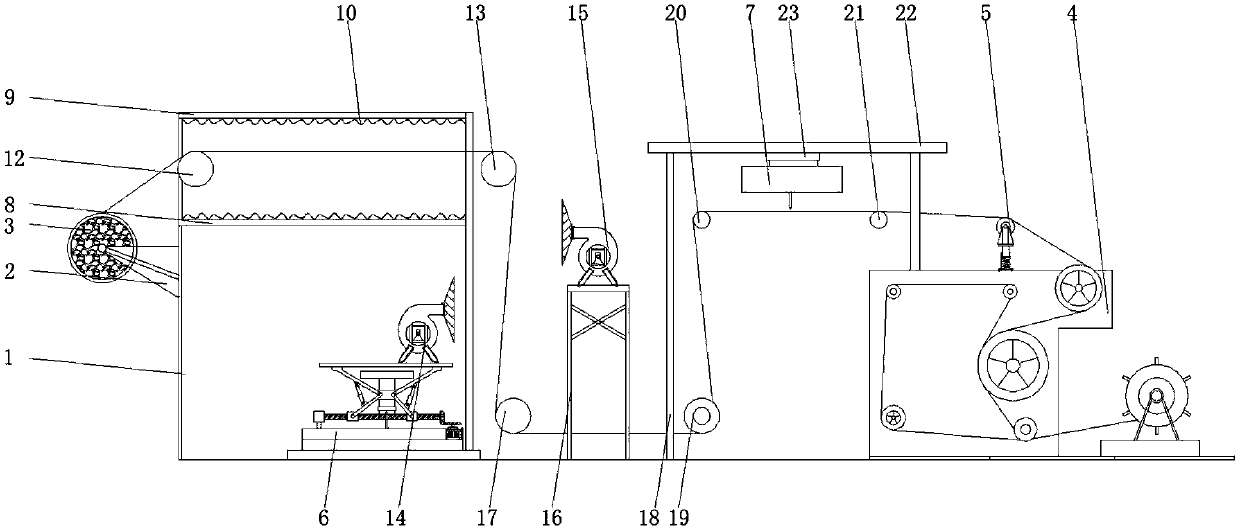

Small energy-saving paper brick machine

ActiveCN104069928AReasonable designEasy to recyclePaper article packagingGrain treatmentsBrickDesiccant

The invention discloses a self-heating type closed shaping paper brick machine. The paper brick machine comprises three parts, namely a paper feeding part, a grinding part and a packing press part, wherein the paper feeding part comprises a dry paper feeding part and a damp paper feeding part, and the damp paper feeding part is used for drying the damp paper through the heat produced by the self-heating and a chemical drying agent; the paper grinding part comprises a coarse grinding part and a fine grinding part, the coarse grinding is performed through a spiral cutter, and the fine grinding is performed through a grinding wheel, and a small cylinder is arranged on the surface of the grinding wheel to increase the friction force in process of grinding the paper so as to increase the production of the heat, and the damp paper can be dried. The ground paper enters a paper pressing cavity through a channel, and then compressed twice to form bricks, and the bricks are convenient to store and transport after being packed in a packing cavity.

Owner:TAIYUAN UNIV OF TECH

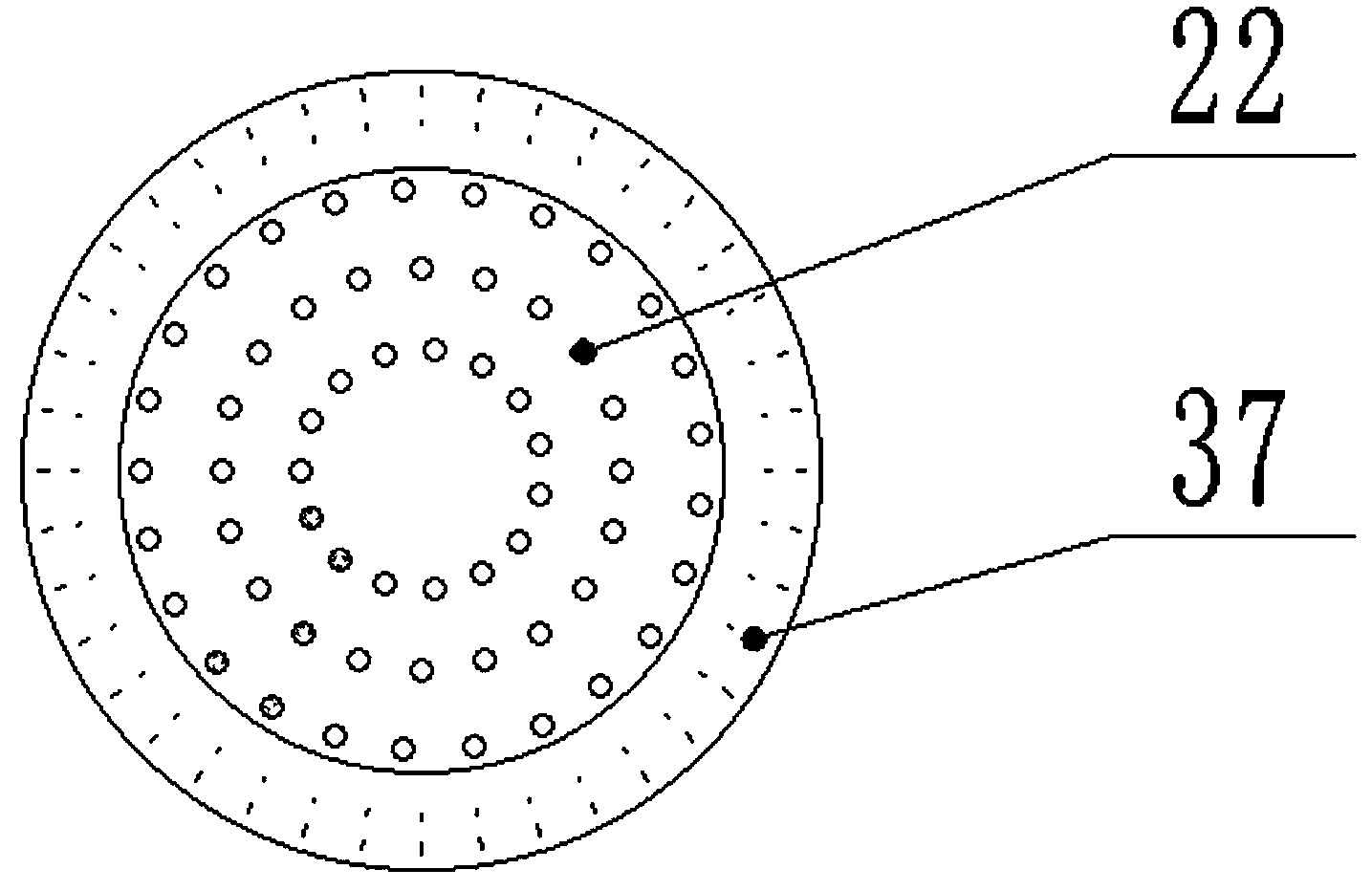

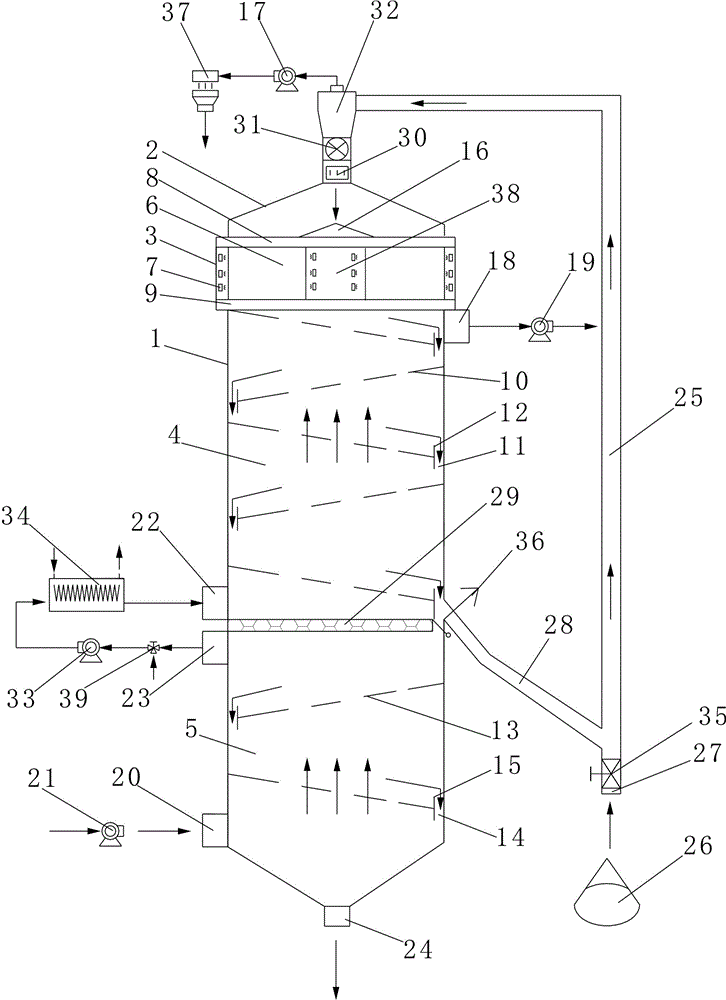

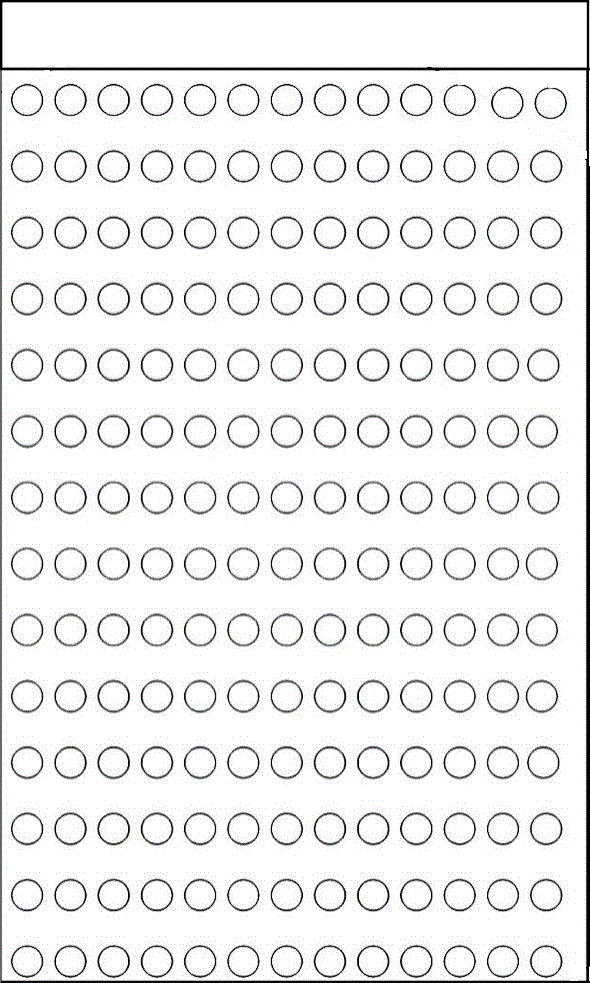

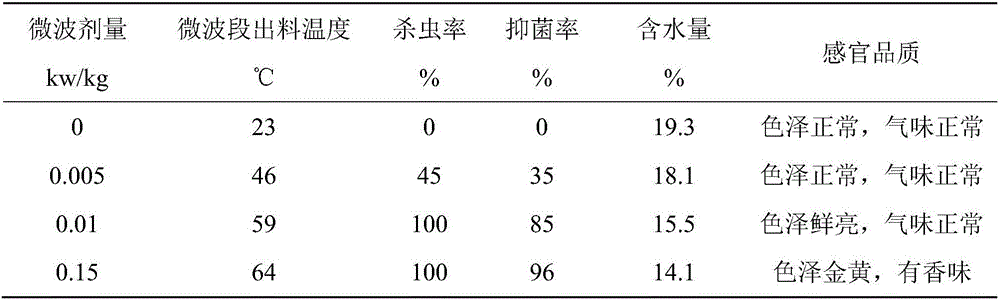

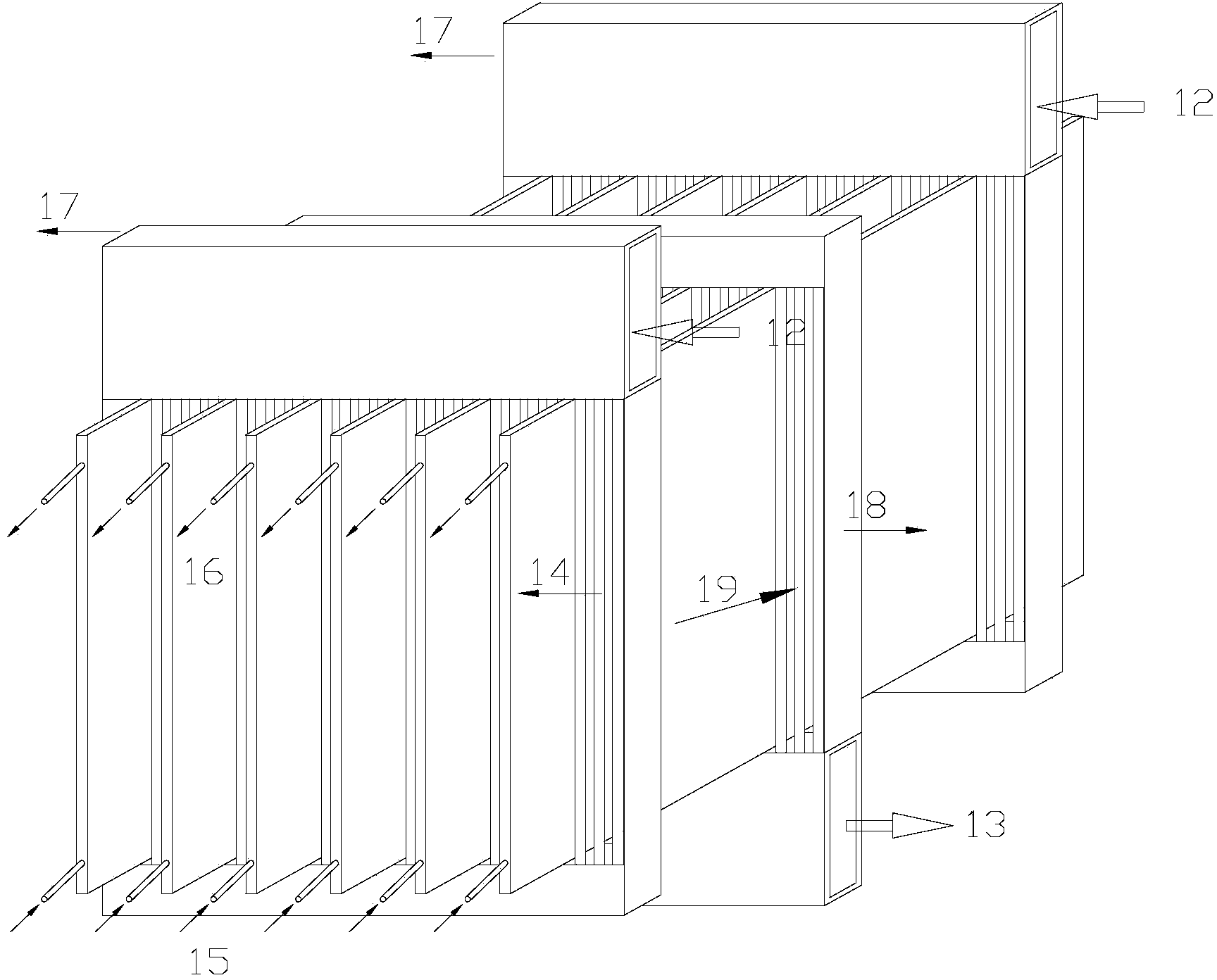

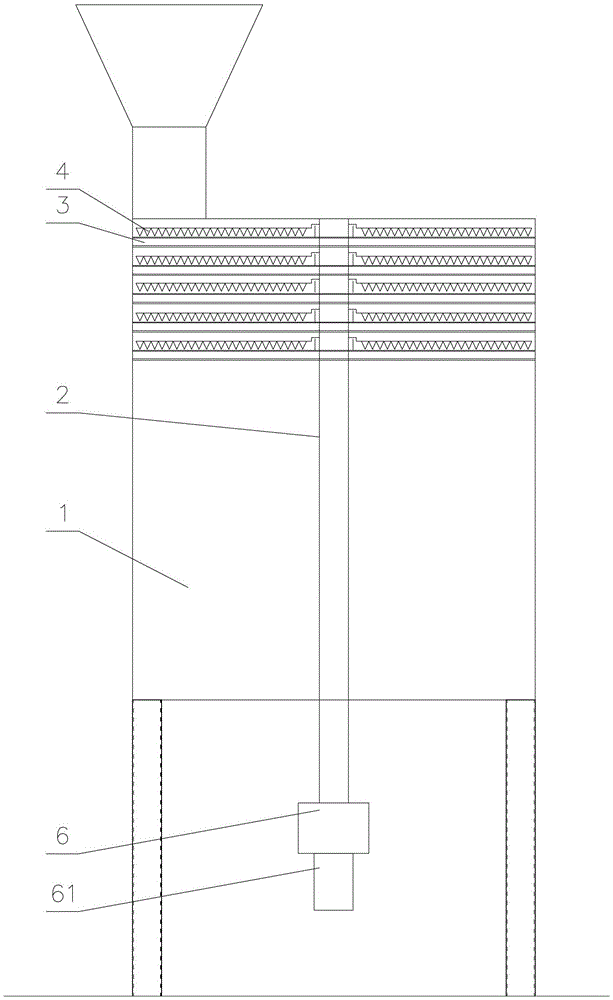

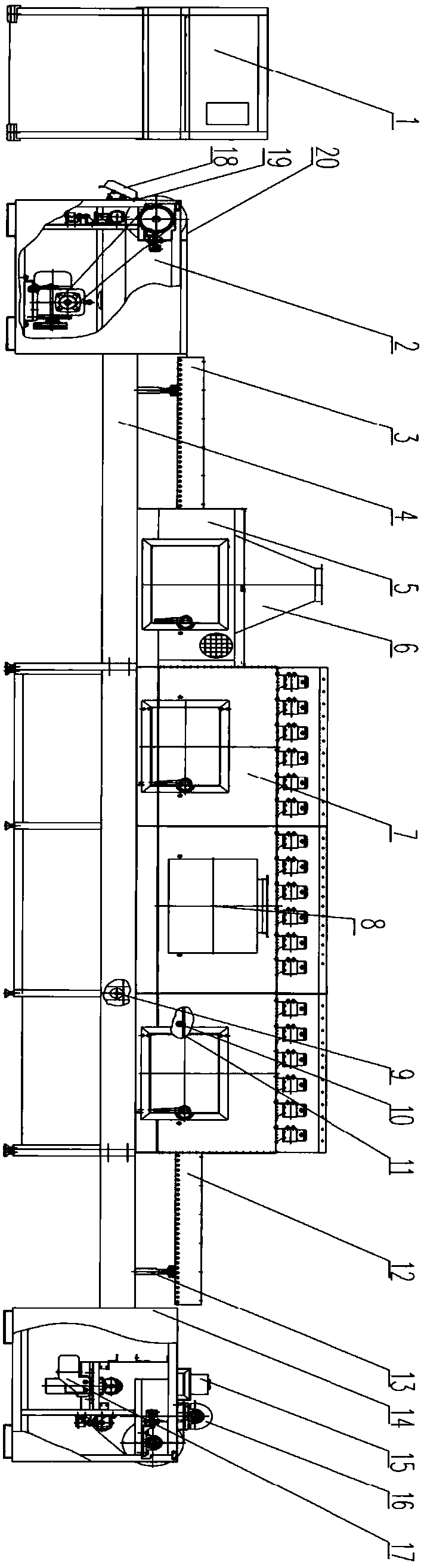

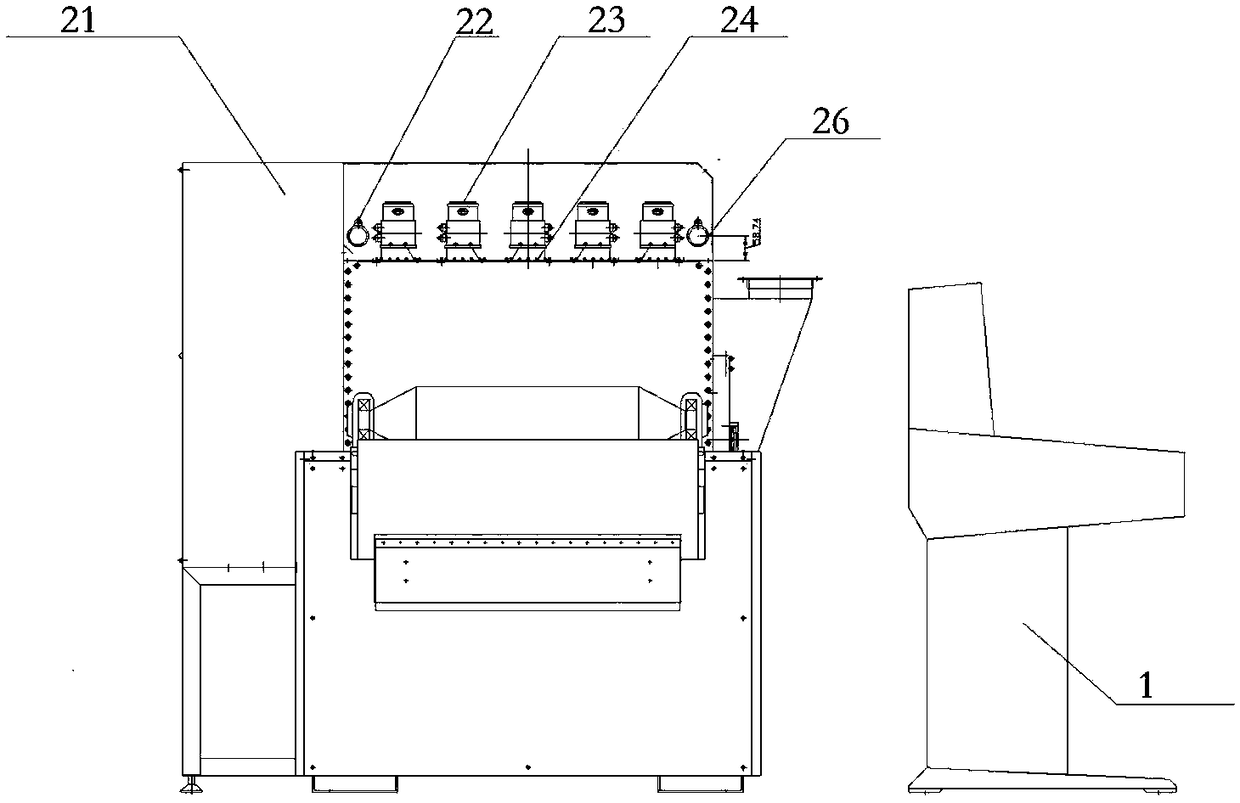

Grain microwave and fluidization combined drying equipment, drying method and application

ActiveCN105928323AReach killEfficient killingDrying solid materials with heatDrying gas arrangementsMicrowaveEngineering

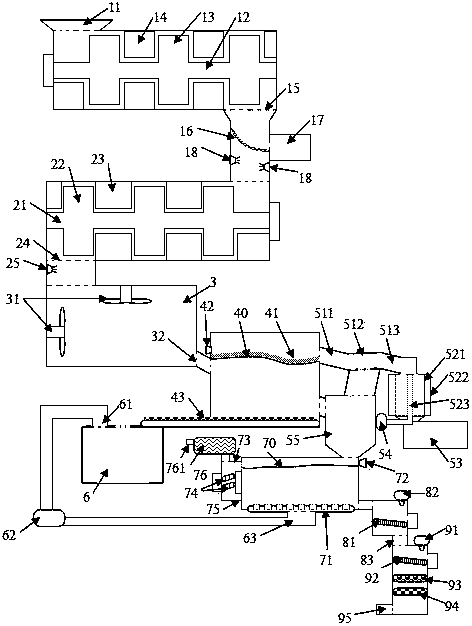

The invention discloses grain microwave and fluidization combined drying equipment, a drying method and application. The equipment comprises a tower body; and the tower body is provided with a buffer bin, a microwave section, a drying section and a cooling section in sequence from top to bottom. The drying section and the cooling section respectively include multiple fluidization plates staggered on upper and lower layers; one ends of the fluidization plates are fixedly connected with the tower body, and baffle plates are mounted at the other ends; and overflow channels are formed between the baffle plates and the tower body. An exhaust port of the cooling section communicates with a hot air intake ports of the drying section via a hot air fan and a heat exchanger; hot air exhausted by the cooling section is leaded into the drying section; and afterheat thereof is fully used to save the energy. The drying method comprises three steps of microwave preheating, fluidization drying and fluidization cooling. The drying equipment and the drying method use the microwave and fluidization combined drying, have the characteristics of high drying efficiency and uniform drying, can realize functions of insecticide and bacteriostasis, and can be used for drying such grains with good fluidity as paddy, wheat and corn.

Owner:HUAZHONG AGRI UNIV

Drying process of gelcasting large-sized and complex-shaped silicon carbide ceramic biscuit

The invention provides a drying process of gelcasting large-sized and complex-shaped silicon carbide ceramic biscuit, which belongs to the field of ceramic drying technology and solves the shortcomings of easily cracking of and deformation of green bodies by adopting the existing ceramic wet green drying process. The process provided by the invention firstly prepares liquid ethanol and deionized water into drying solution with different concentration, then puts the SiC wet green into the bottom of a drying tank, respectively adds drying solution obtained by the step one into the drying tank for soaking to obtain the contracted SiC green body, and finally puts the contracted SiC green body in a drying oven for drying. The drying process provided by the invention greatly reduces the drying difficulty of large-sized and complex-shaped SiC biscuit, and achieves the non-defect drying of 1.5m-magnitude SiC ceramic biscuit prepared by a gelcasting process.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Microwave drying method for preparation of pitaya flower tea

InactiveCN104920731AKeep the original colorImprove qualityTea substituesDrying gas arrangementsCold airMicrowave oven

The invention discloses a microwave drying method for preparation of pitaya flower tea. The method is as below: drying fresh pitaya flowers a microwave oven; heating 3-5 times, after each heating, taking the fresh pitaya flowers from the microwave oven, rapid cooling by cold air to 25-30 DEG C, and then placing the fresh pitaya flowers into the microwave oven for the next drying; successively reducing the output power of the microwave oven and then carrying out several times of alternate heating and rapid cooling; when the water content of the pitaya flowers is no higher than 5%, taking the pitaya flowers out of the microwave oven, drying by cold air and cooling to obtain the pitaya flower tea. The method not only can maintain the shape and color of pitaya flower, and but also better retains the active ingredients, reaches good flavor, texture and reconstitution property, and improves the quality of the pitaya flower tea.

Owner:GUIZHOU FRUIT INST

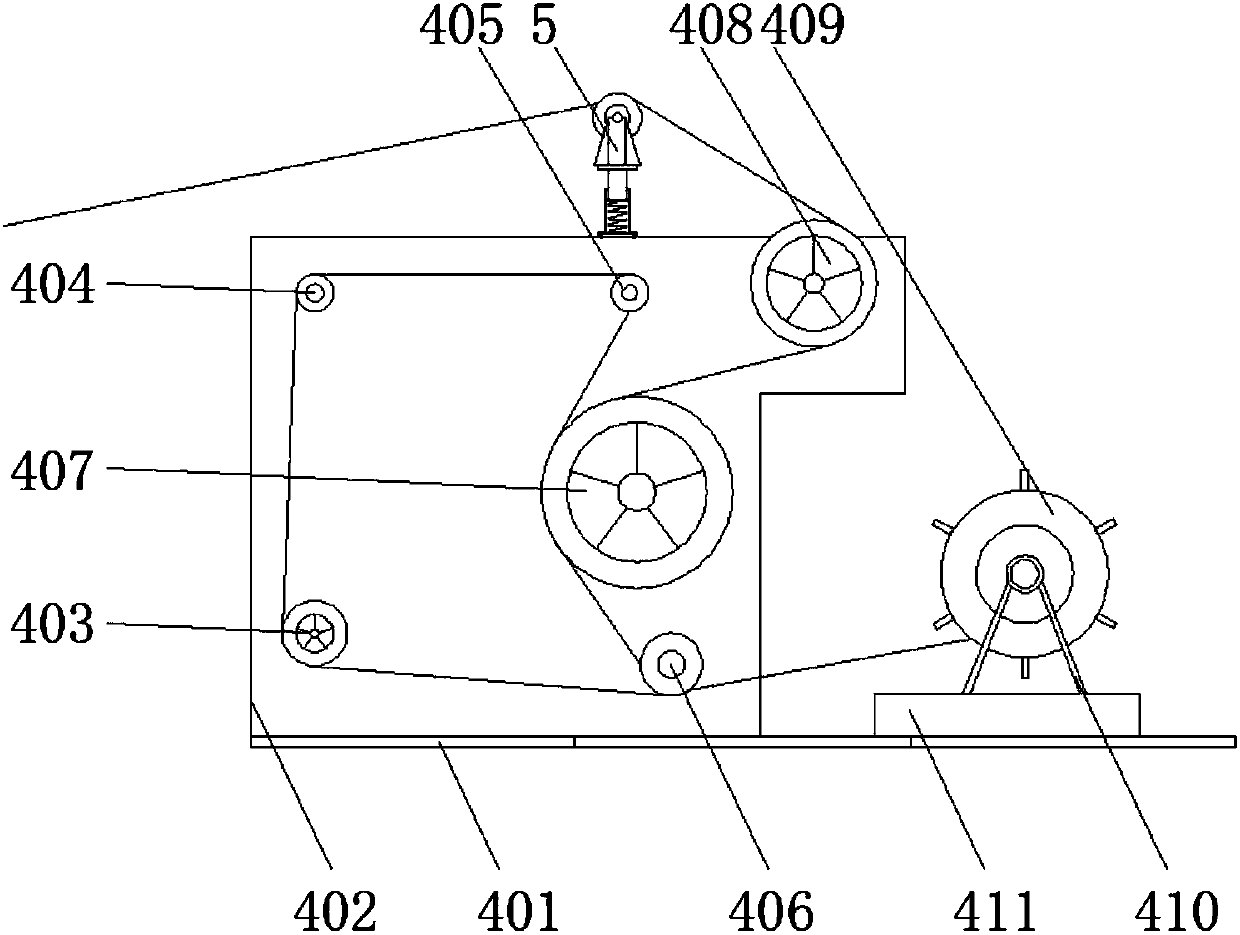

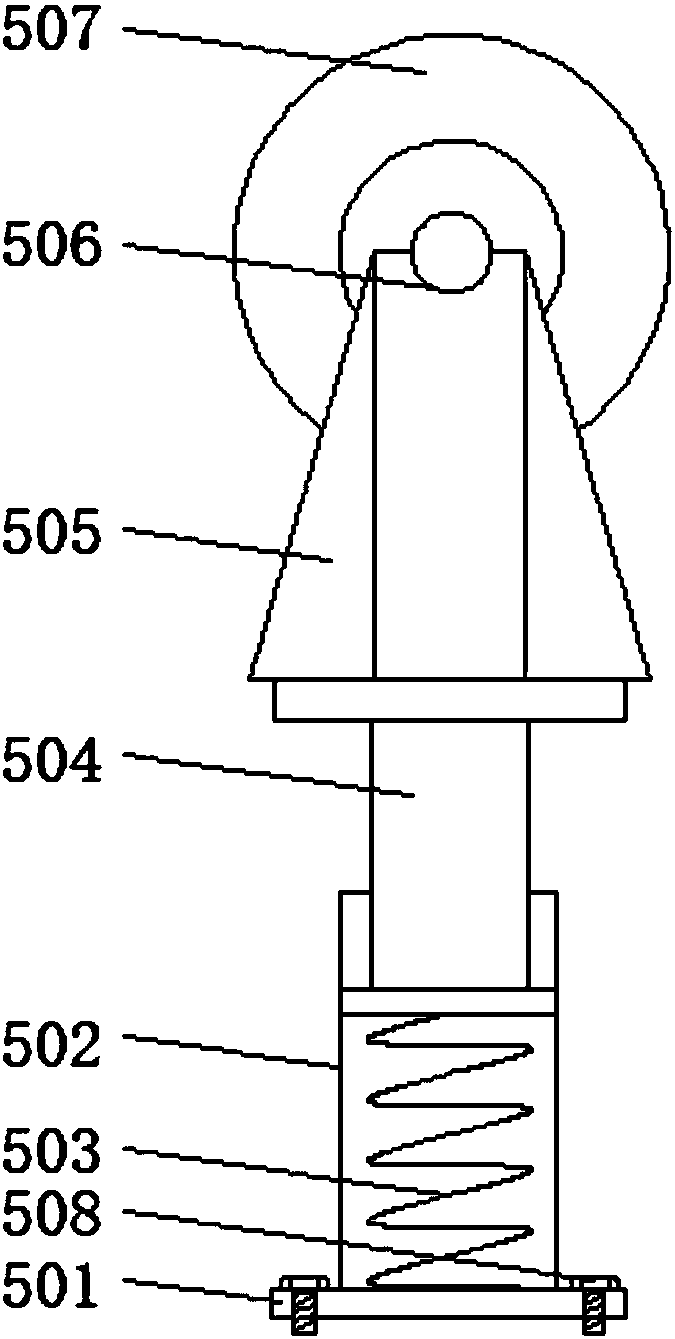

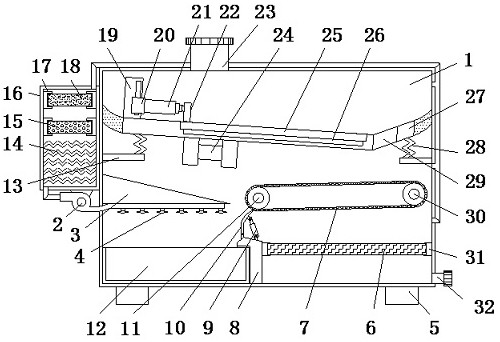

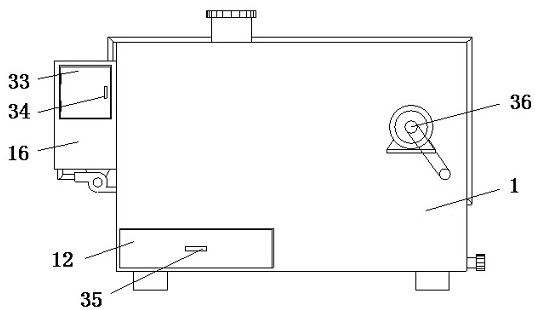

Automatic chemical fabric drying, tailoring and rolling machine

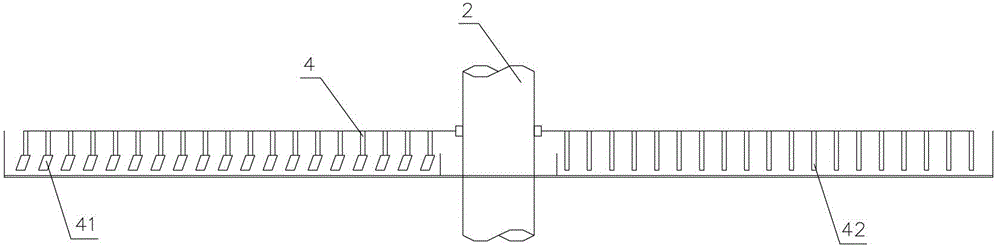

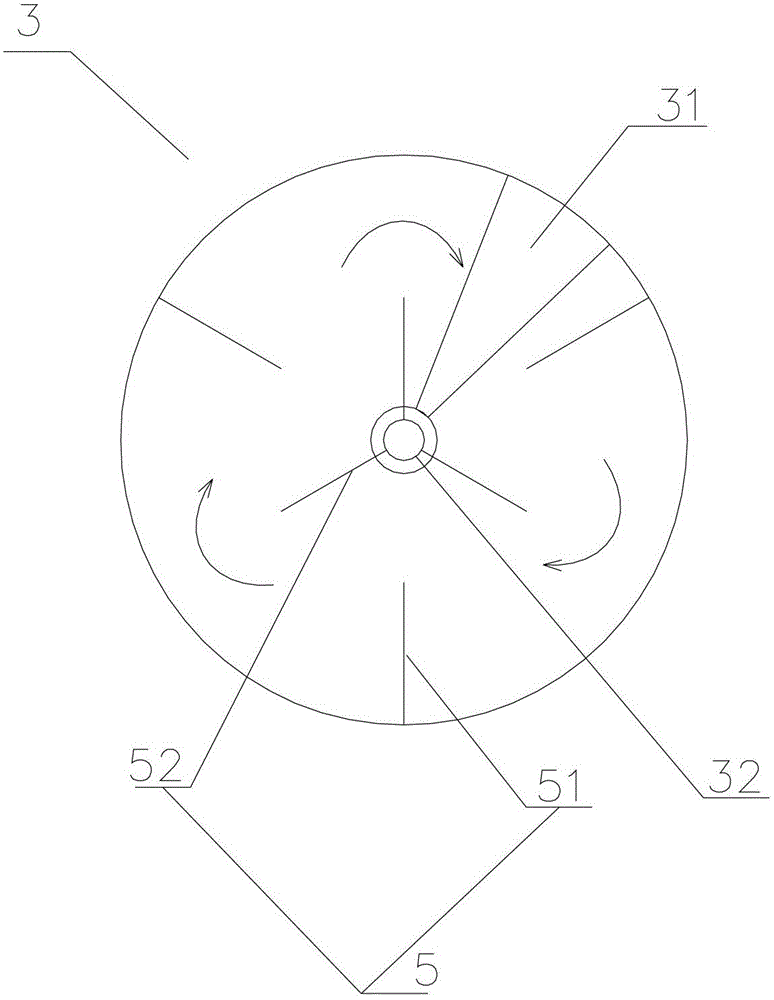

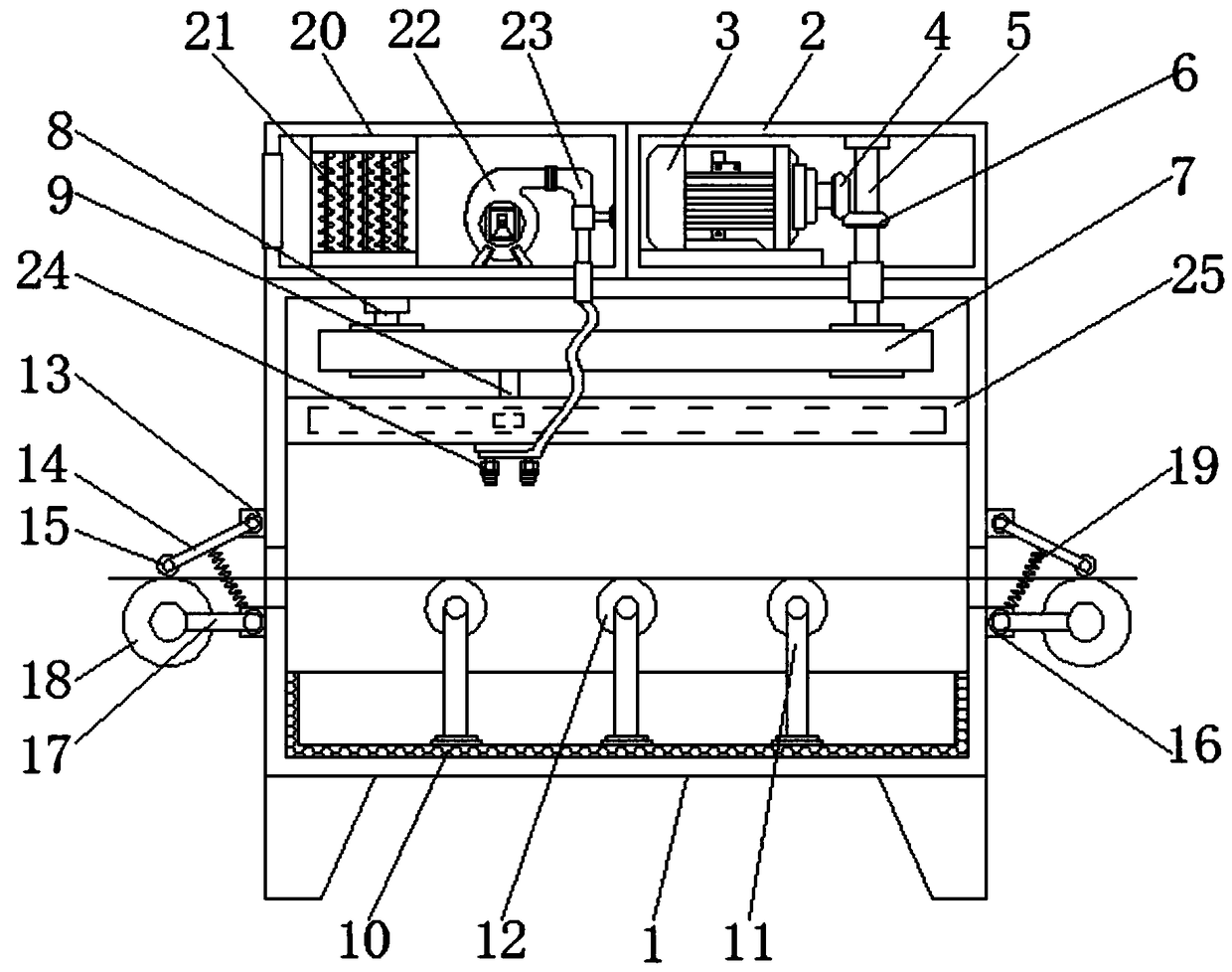

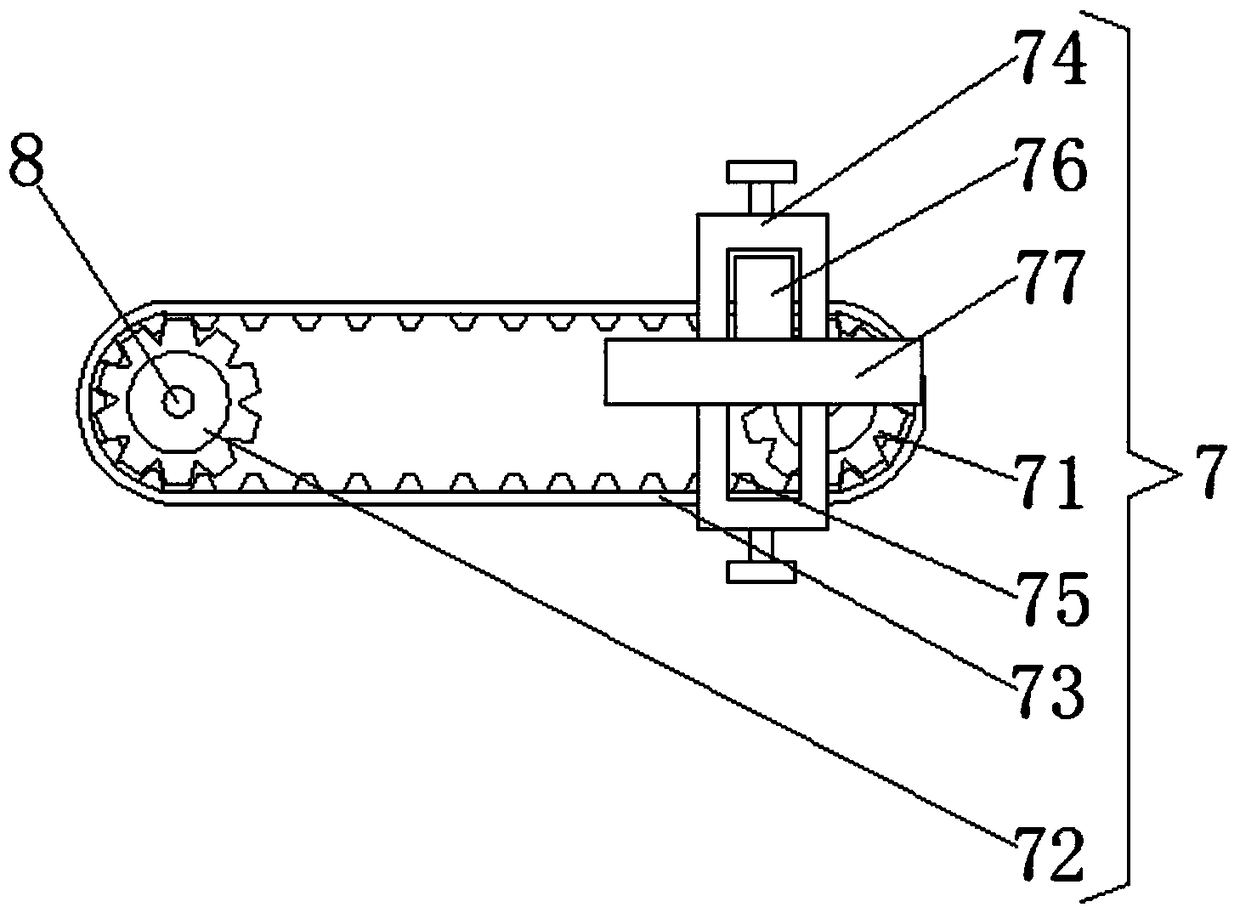

ActiveCN107558153AAchieve the purpose of dryingQuality assuranceDrying gas arrangementsSevering textilesElectrical resistance and conductancePulp and paper industry

The invention discloses an automatic chemical fabric drying, tailoring and rolling machine which comprises a drying box. A rotating roller installation frame is fixedly connected with one side of theouter wall of the drying box. The top end of the rotating roller installation frame is rotationally connected with a rotating roller through a rotating shaft. An upper drying fixed connection plate isfixedly connected with the top of the inner wall of the drying box. A lower drying fixed connection plate is fixedly connected with the two sides of the upper portion of the inner wall of the dryingbox. The inner wall of the upper drying fixed connection plate and the inner wall of the lower drying fixed connection plate are each provided with a drying resistance wire. The invention relates to the technical field of textile machinery. The automatic chemical fabric drying, tailoring and rolling machine has the advantages that chemical fabric is dried and cooled through an air blower, the quality of the dried chemical fabric is ensured, the workload of workers can be reduced through the automatic integrated design, the dried chemical fabric is automatically tailored and automatically rolled, and the tailoring and rolling automatic integrated stable running is ensured.

Owner:海安荣祥化纤有限公司

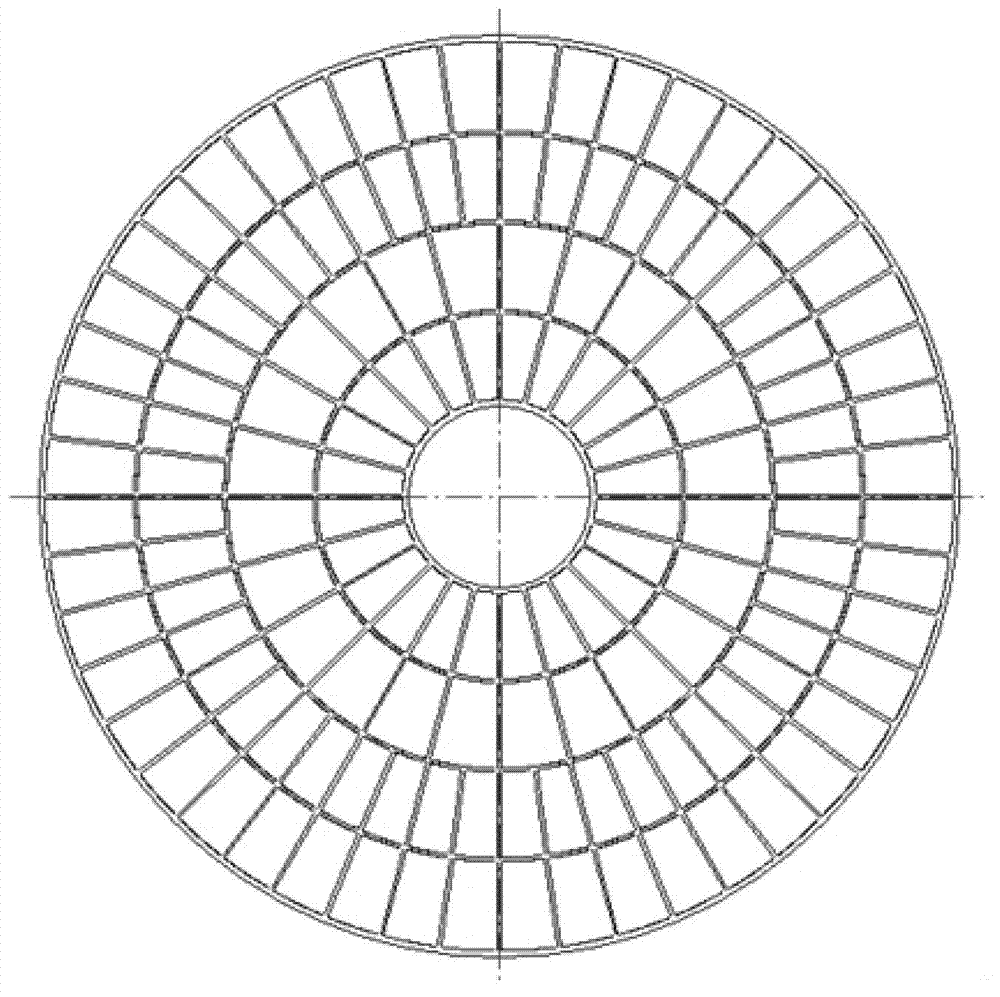

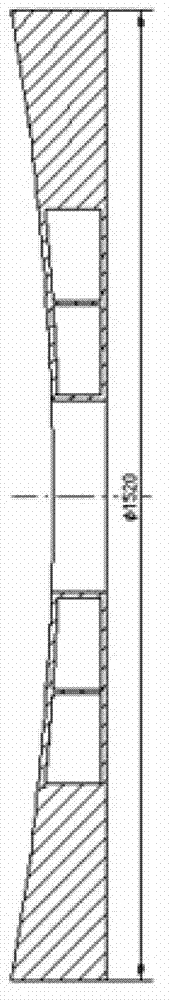

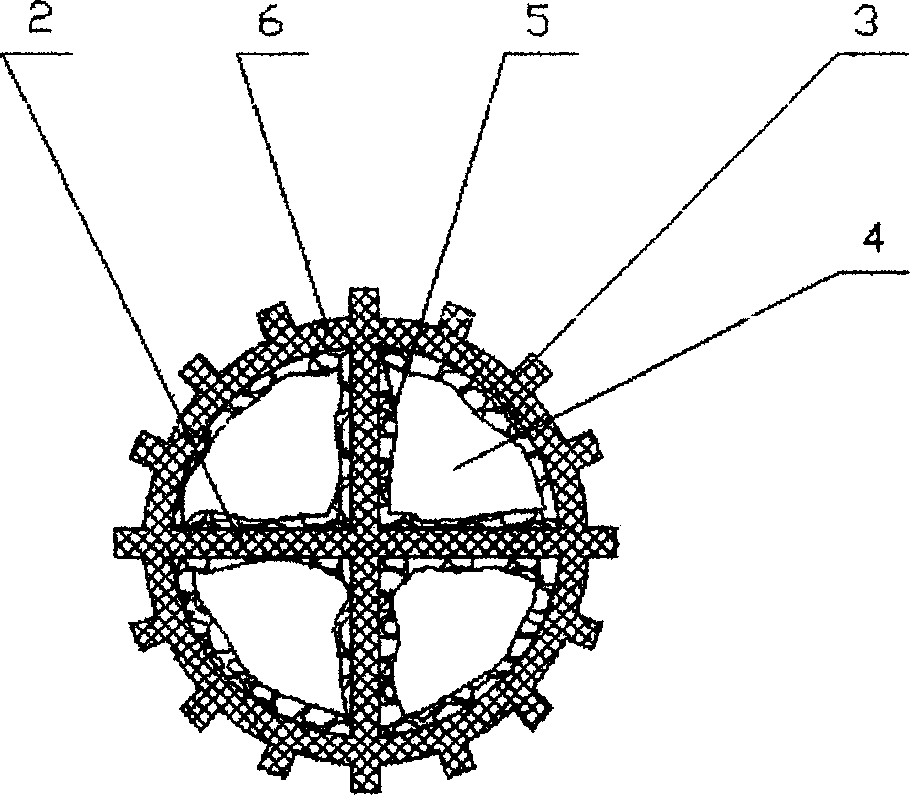

Suspension carrier of biomembrane

InactiveCN1785842APromote degradationImprove adhesionSustainable biological treatmentBiological water/sewage treatmentActive componentBiological membrane

The present invention relates to a biological membrane suspension carrier of biological membrane moving bed biochemical system applicable to sewage treatment engineering. It is made up by using composite material composed of high-molecular resin and inorganic active component. It adopts circular tube structure, and said structure is formed from the following components: cross-reinforcing rib, internal cavities, several flow deflectors and accilimatized membrane, etc.

Owner:大连雅希科技有限公司

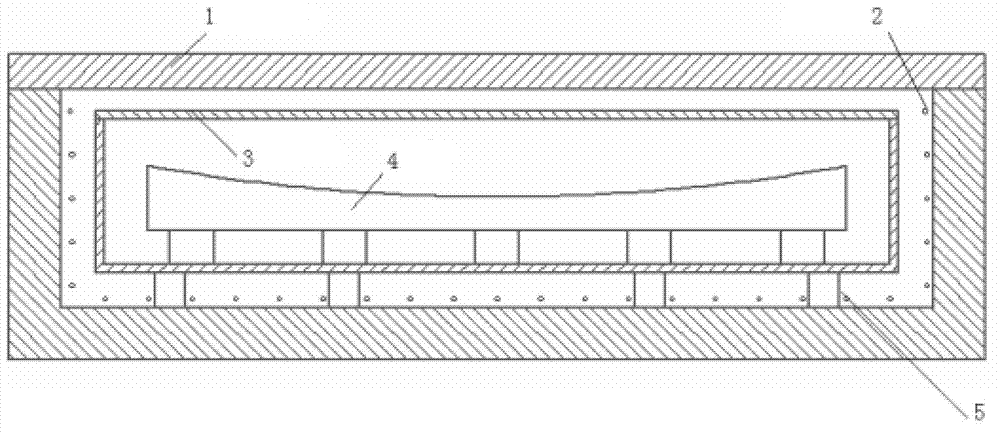

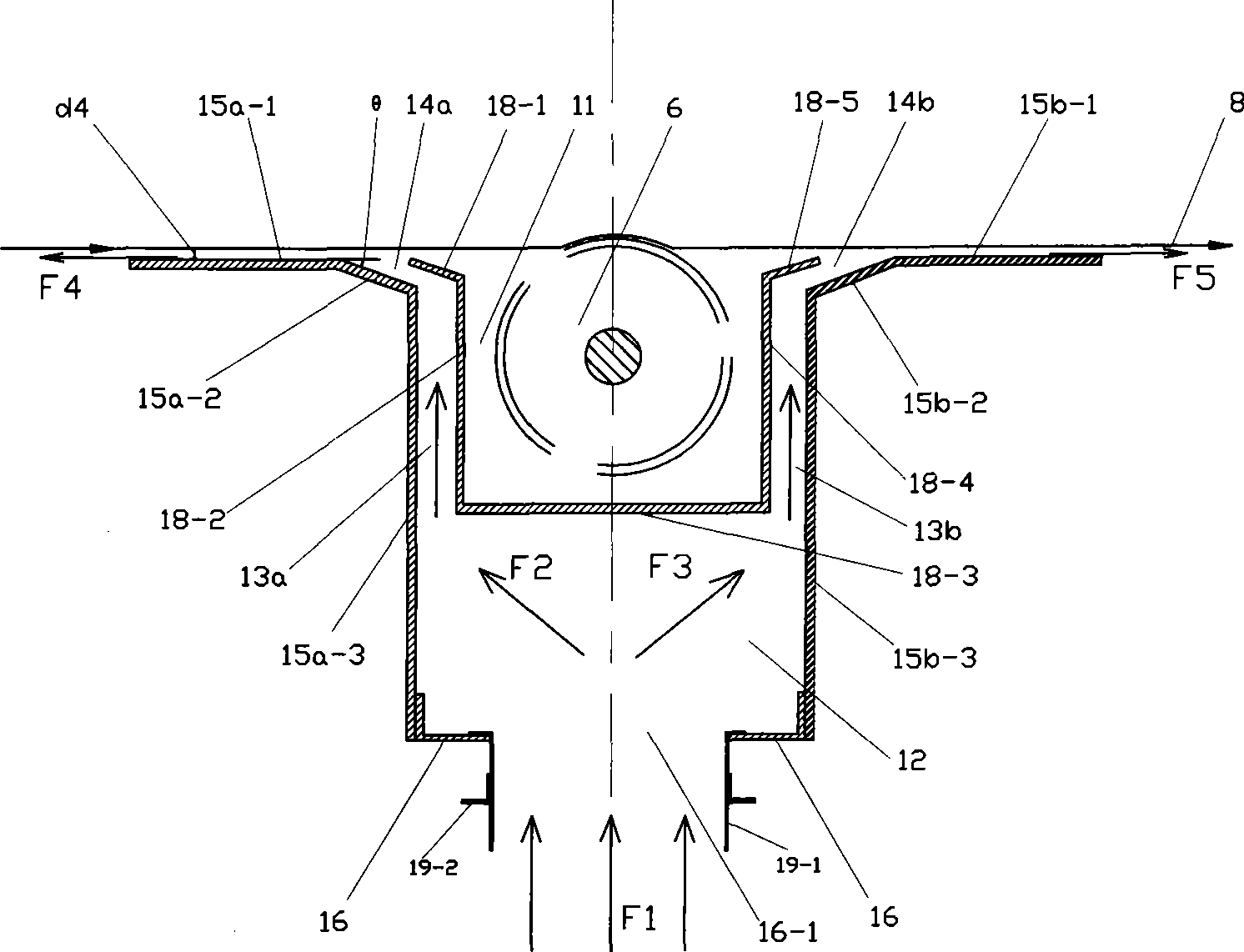

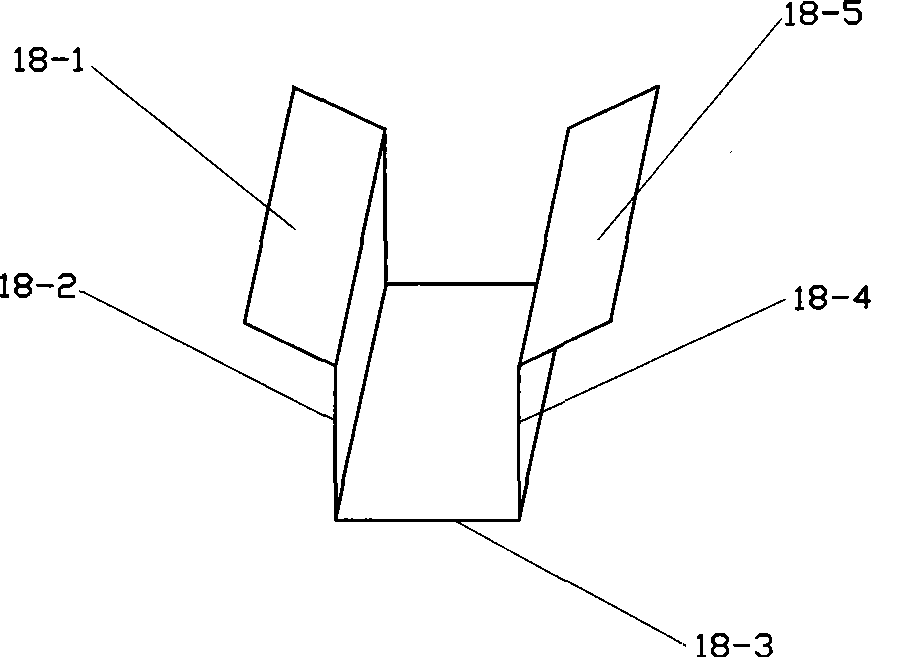

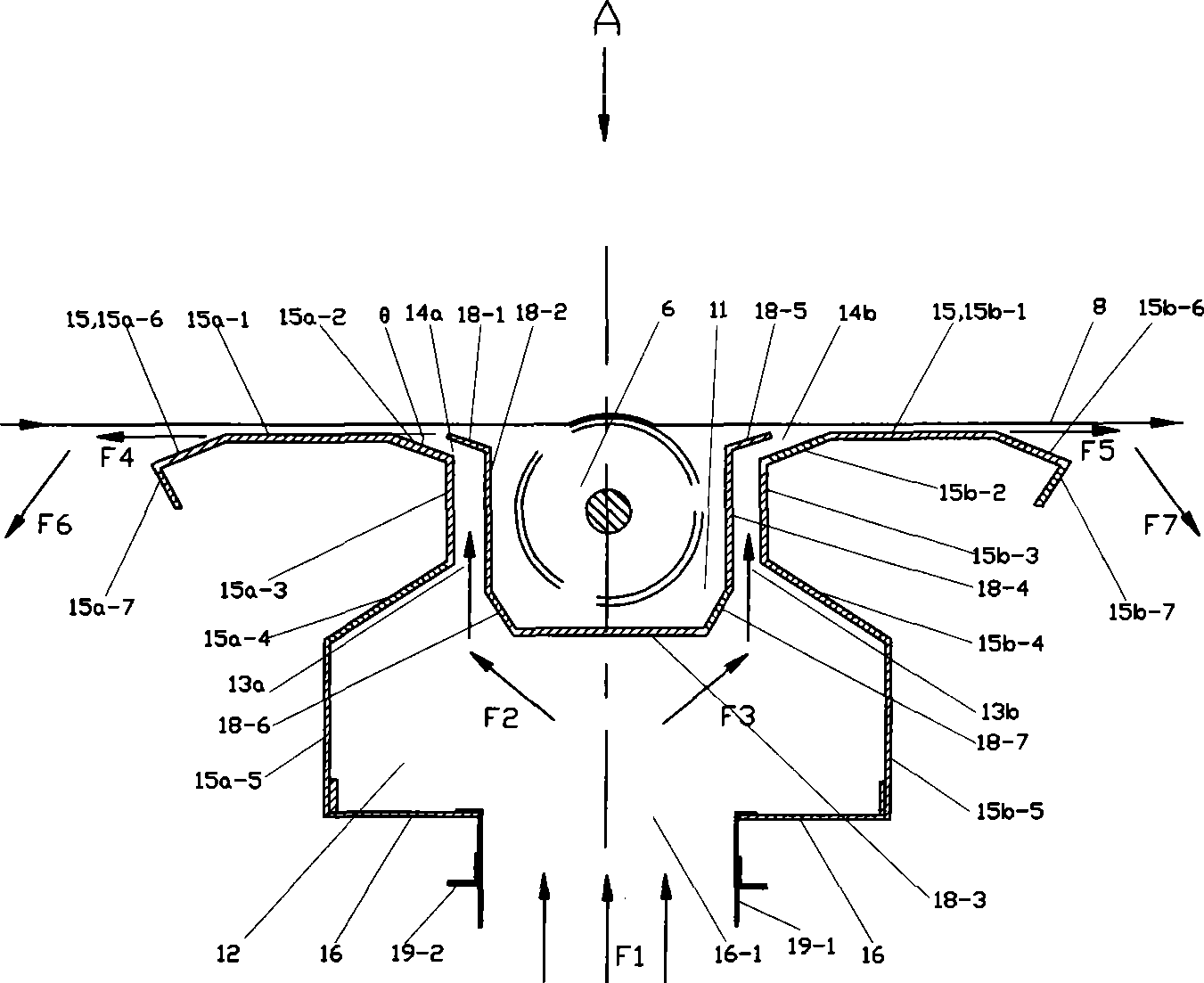

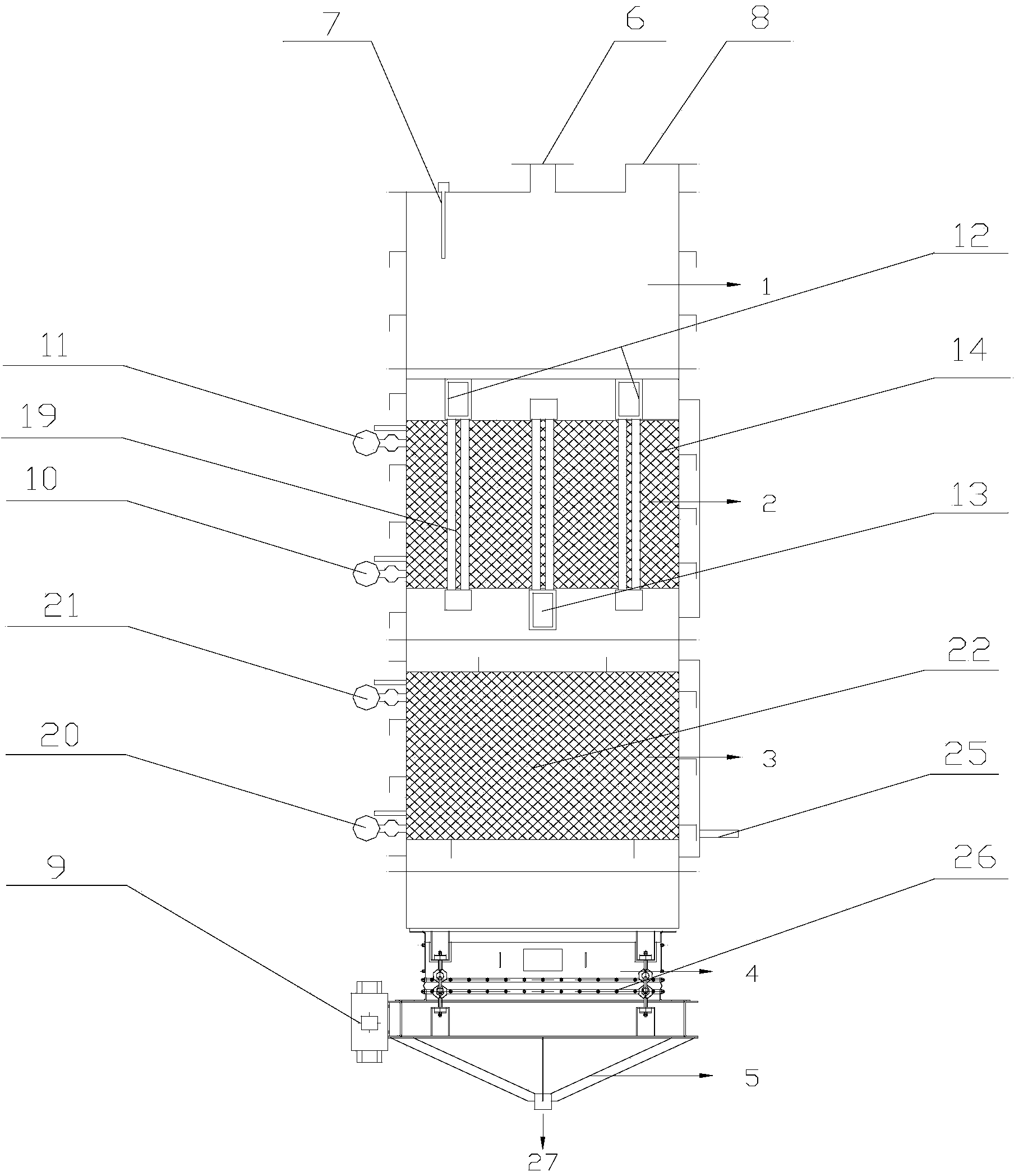

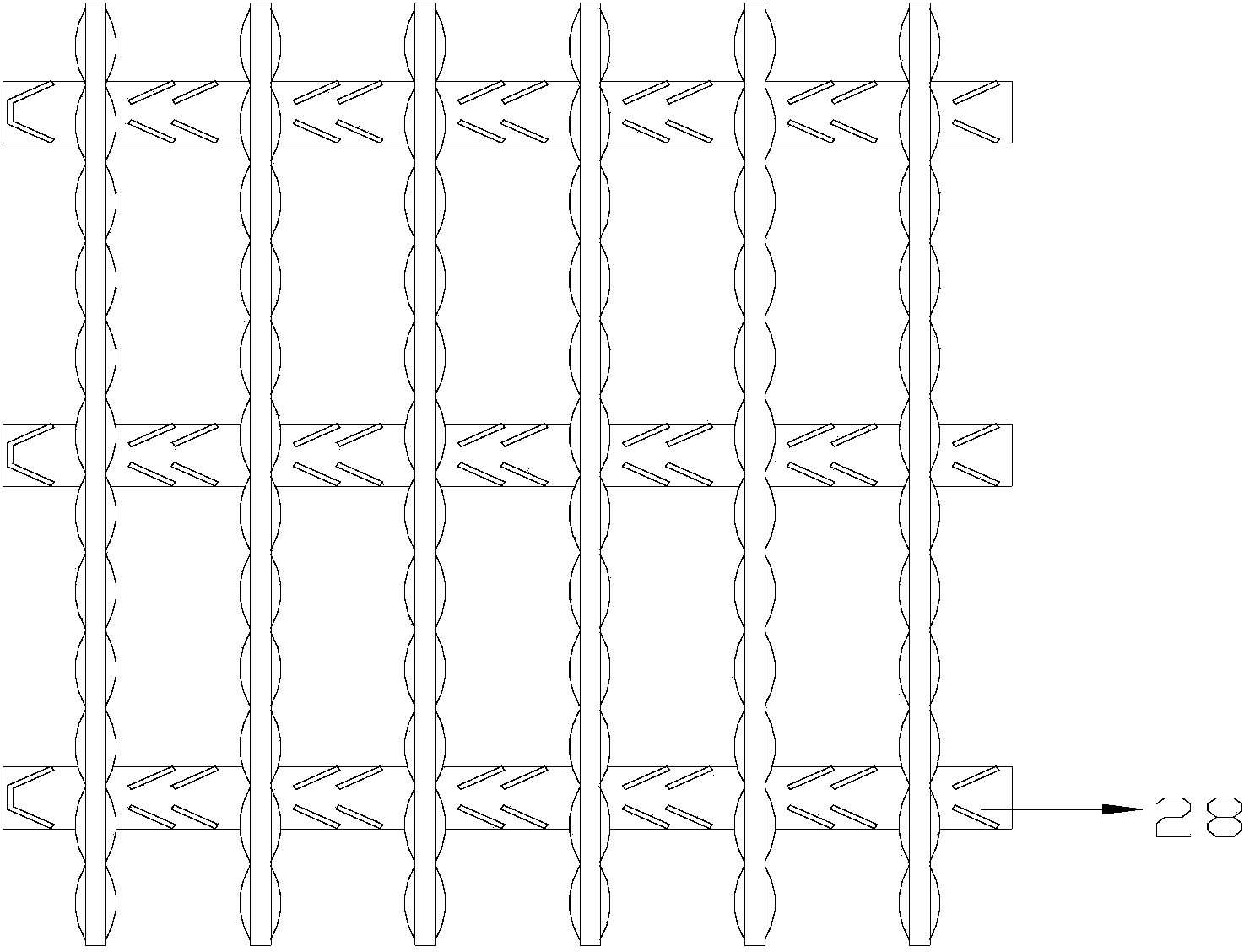

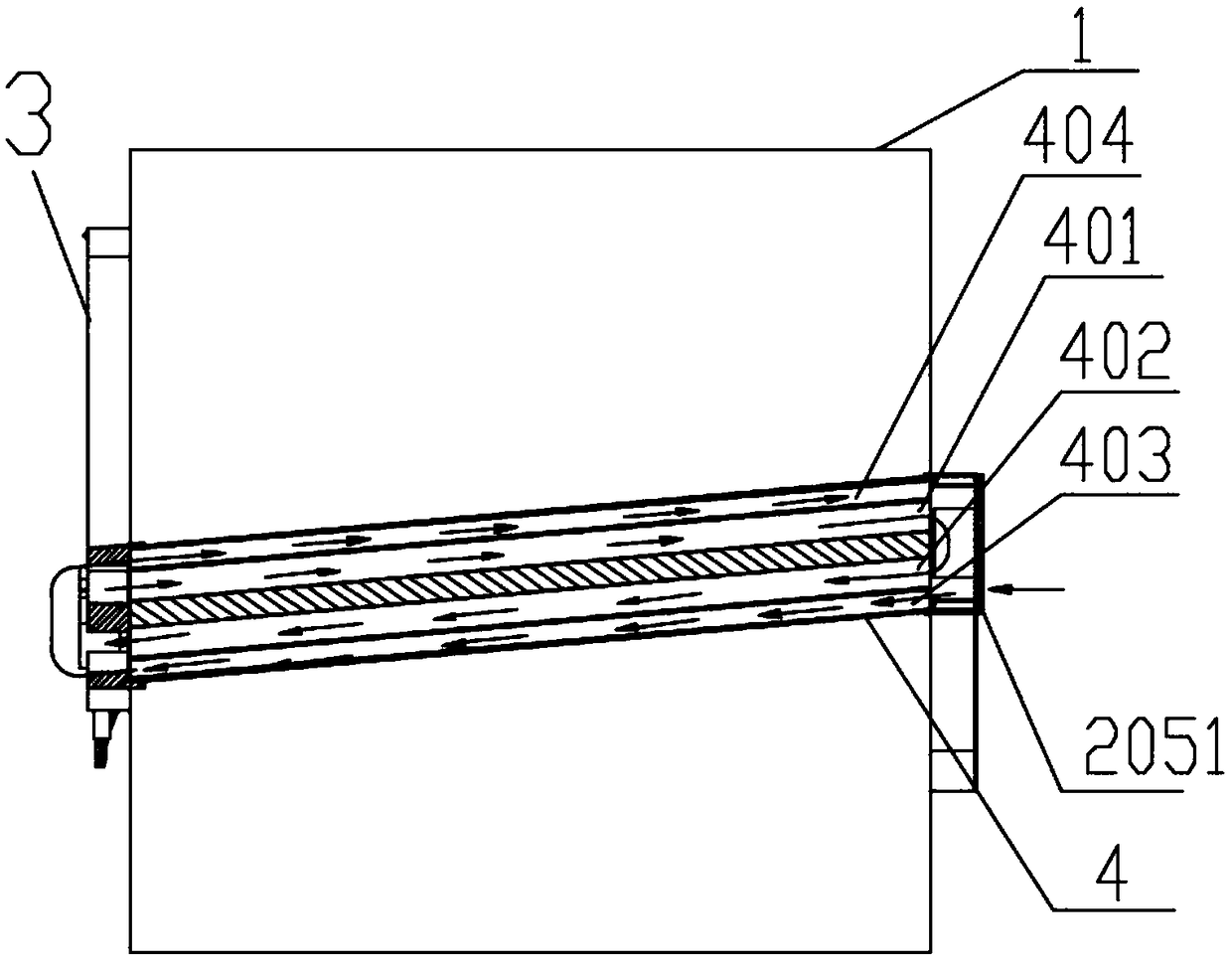

Air-flow type drying oven for drying coating layer of radiate material and blast nozzle parts thereof

ActiveCN101417276AUniform heating on the surfaceIncrease the direct contact areaPretreated surfacesSpray nozzlesEngineeringAirflow

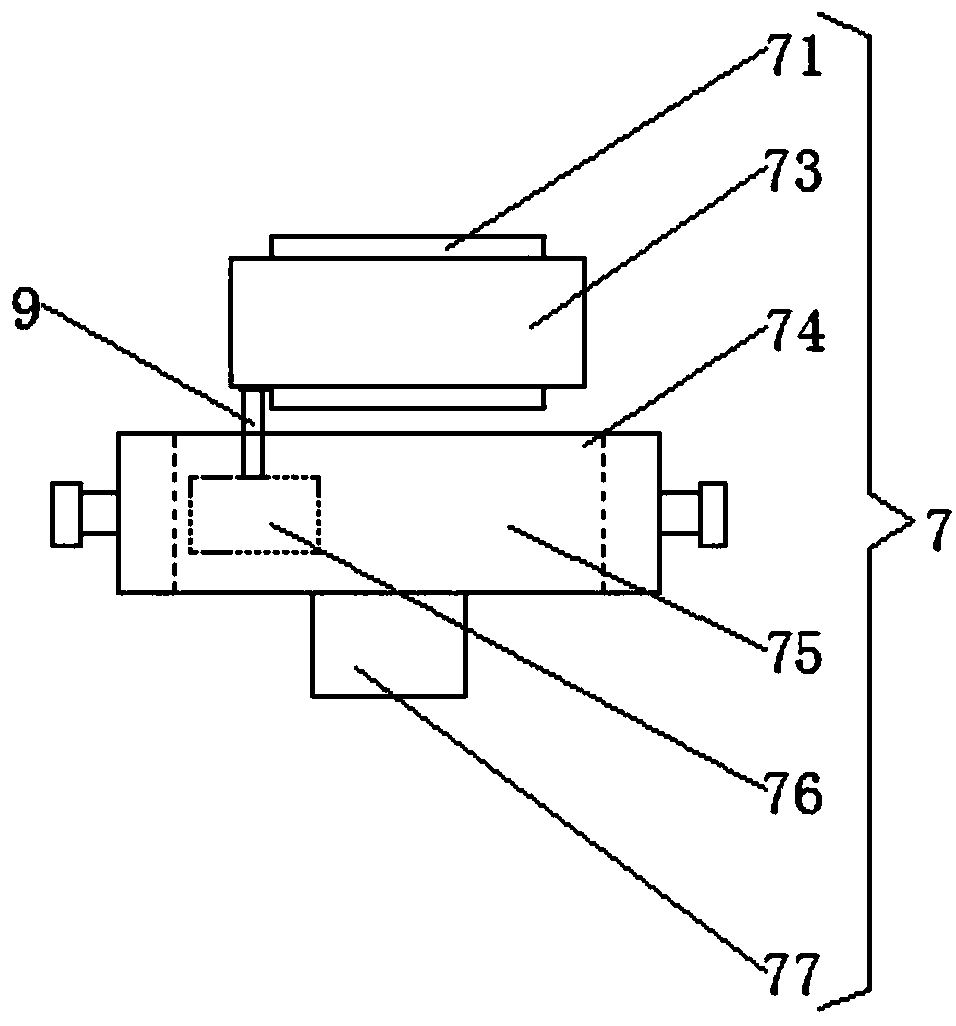

The invention discloses an air flow drying oven for drying the coating of a radiate material and a blast nozzle part thereof. The blast nozzle part is a case, the lower part of which is provided with an air inlet. The middle of the upper part of the case is provided with a guide roller groove, and the case is provided with an inner cavity at the lower part and a left air duct and a right air duct which are positioned at the left side and the right side of the upper part and directly communicated with the inner cavity. An air outlet of the left air duct is a left parallel air flow blast nozzle which inclines towards the left, and the air outlet of the right air duct is a right parallel air flow blast nozzle which inclines towards the right. When the blast nozzle part is used in the drying oven, the left and right blast nozzles accelerate the flow flowing to the left and right sides of the blast nozzle part, and a left horizontal supporting plate and a right horizontal supporting plate lead the air flow to form parallel wind which is parallel to the radiate material, thus increasing the direct contact area between the wind and the radiate material, leading the radiate material surface to be heated evenly and the heat exchange between the parallel hot wind and the radiate material to be more sufficient, improving the heat exchange efficiency and having better drying quality due to even heating.

Owner:CHANGZHOU YONGSHENG NEW MATERIALS EQUIP CO LTD

Powder material drying and cooling integrated device

ActiveCN104132525AAvoid secondary pollutionReduce energy consumptionDrying solid materialsHeating arrangementPipingEngineering

The invention relates to a powder material drying and cooling integrated device which is designed to solve the problems that drying and cooling of powder materials are finished in different devices, and accordingly energy consumption is high and the area occupied by the devices is large. The powder material drying and cooling integrated device is of a vertical structure and sequentially comprises a feeding box, a drying box, a cooling box and a discharging box from top to bottom. The top of the feeding box is provided with a feeding inlet, the drying box is provided with a heating fluid inlet pipe, a heating fluid outlet pipe, a transverse flow air inlet pipe, a transverse flow air outlet pipe and drying box heat exchange sheets which heating fluids flow through. The cooling box is provided with a cooling water inlet pipe, a cooling water outlet pipe and cooling box heat exchange sheets which cooling water flows through. The discharging box is provided with a discharging port. The powder material drying and cooling integrated device can meet the requirements for drying and cooling of the powder materials in the heat exchange sheets, and is small in occupied area and high in heat exchange efficiency.

Owner:北京广厦环能科技股份有限公司

Printing device with drying function

PendingCN107599624AAchieve the purpose of dryingAvoid damagePrinting press partsCardboardPrinting ink

The invention discloses a printing device with a drying function. The printing device comprises an outer frame, wherein a first motor is fixedly connected to the bottom part of the inner wall of the outer frame, one end of an output shaft of the first motor is fixedly connected with a first belt wheel, and the surface of the first belt wheel is in transmission connection with a second belt wheel through a belt. The invention relates to the technical field of printing devices. According to the printing device with the drying function, printing is carried out conveniently, the printing effect isimproved, meanwhile, continuous printing can be achieved, time is saved, working efficiency is improved, and the burden of workers is relieved; later-stage processing can carried out conveniently, the position of drying can be adjusted to prevent a paper board from being damaged, so that practicability of the device is improved; the paper board can be conveniently discharged, and can be stabilized conveniently in the drying process, so that printing effect is prevented from being influenced; and printing ink is conveniently brushed onto the surface of a printing roller, so that printing is achieved, discharging and feeding of the device are convenient, and use by people is convenient.

Owner:安吉腾新印刷厂

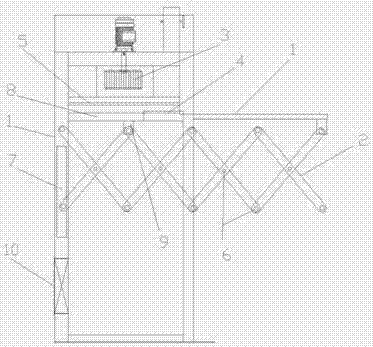

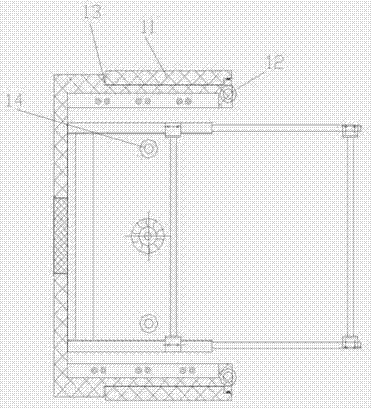

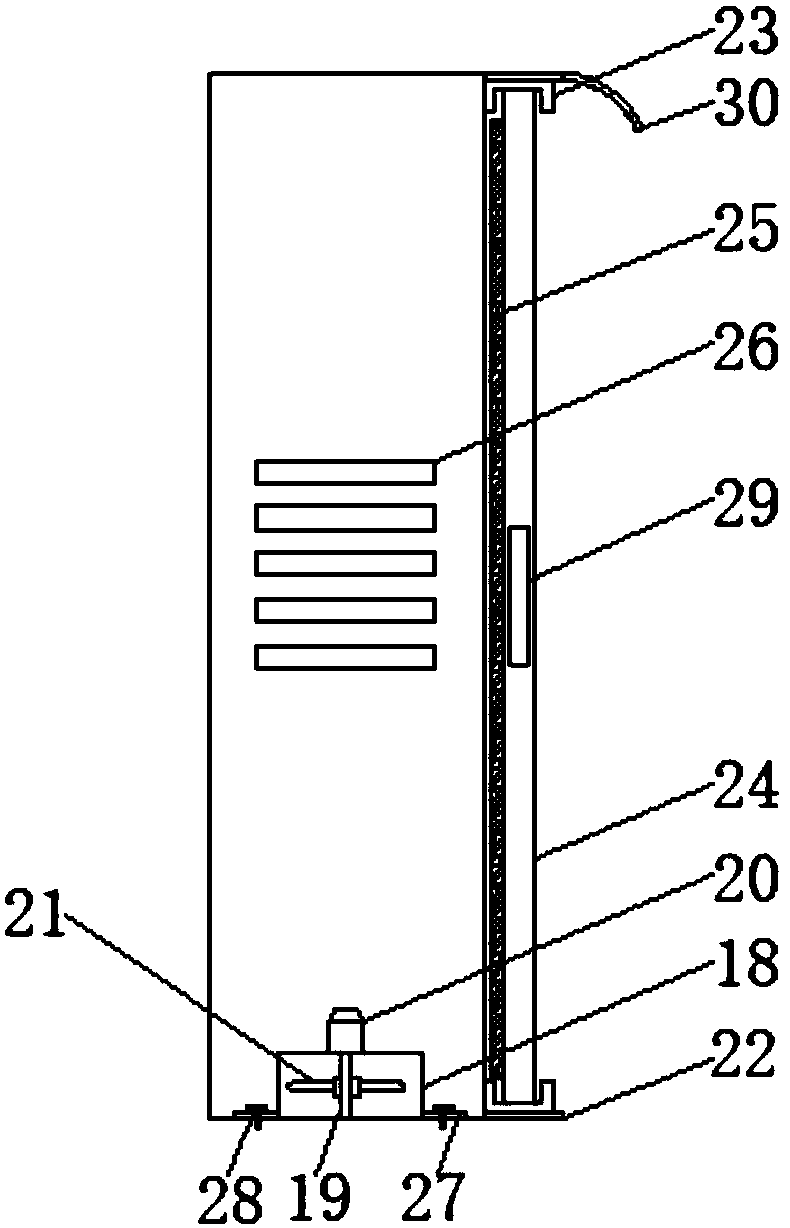

Automatic clothes hanging wardrobe

InactiveCN107099984ACompact structureAchieve the purpose of dryingWardrobesTextiles and paperEngineeringClothes hanger

The invention belongs to the technical field of smart household appliance, and particularly relates to an automatic clothes hanging wardrobe. The automatic clothes hanging wardrobe comprises a wardrobe body, shear forked type telescopic frames, a blower and electric push rods; the blower is installed at the front part of the wardrobe body, and the lower part of the blower is provided with an electric heating pipe; there are two sets of shear forked type telescopic frames arranged in parallel, a hanging rod is connected to the middle of moving joints of two shear forked type telescopic frames; the upper part of one end of each shear forked type telescopic frame is hinged with the inner part of the wardrobe body, and the lower part of one end thereof is glidingly connected with a chute on the inner wall of the wardrobe body; the inner part of the wardrobe body is provided with two slide rails, and the slide rails are in slide fit with slide sleeves; the slide sleeves are connected with moving joints at the upper parts of the shear forked type telescopic frames, and the upper part of the slide rails are equipped with the electric push rods; the telescopic rods of the electric push rods are connected with the moving joints at the upper parts of the shear forked type telescopic frames. The device can be used as the wardrobe as well as a clothes hanger; the automatic clothes hanging wardrobe has the advantage of being simple and compact in structure.

Owner:李怡萱

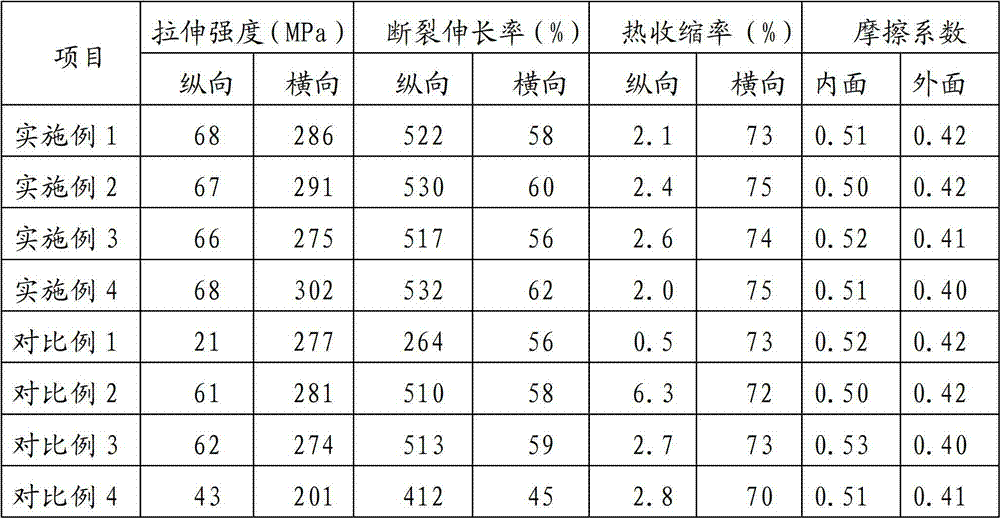

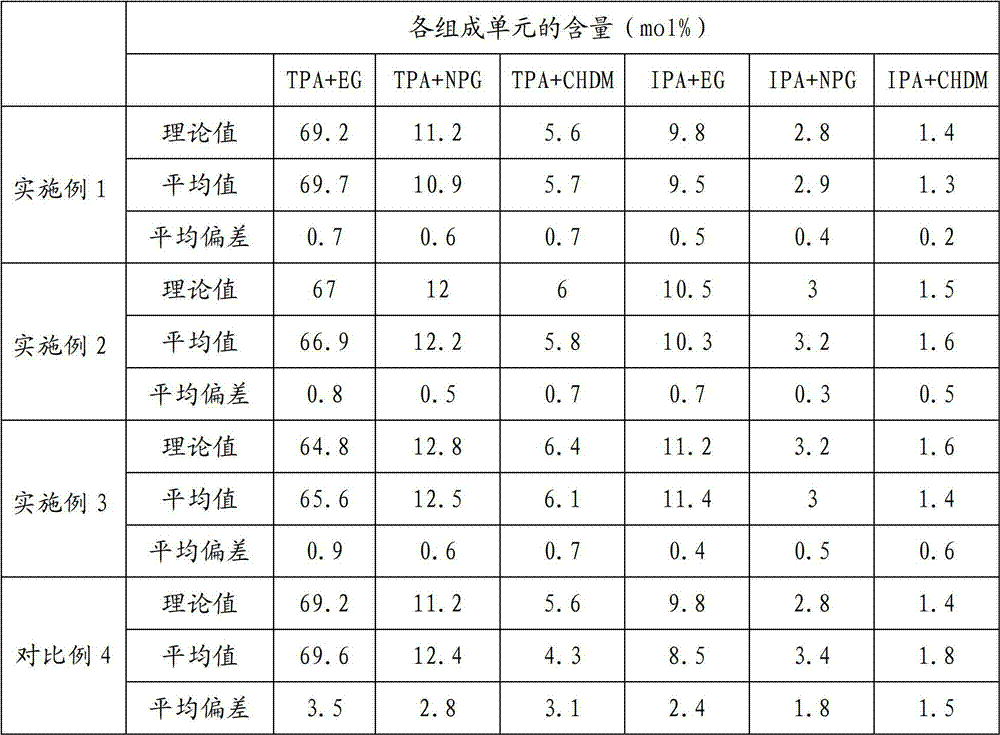

Thermoshrinkable polyester film and preparation method thereof

The invention discloses a thermoshrinkable polyester film and a preparation method thereof. The preparation method comprises steps as follows: various polyester raw materials subjected to dust removal respectively enter storage bins, are respectively metered by an agravic weigher according to the proportion, simultaneously enter an inlet of a double screw extruder, are subjected to melt extrusion by a sandwich layer double screw extruder and two surface layer double screw extruders, and form a casting piece through a three-layer co-extrusion die head; the casting piece is respectively subjected to longitudinal stretching and lateral stretching, wherein the longitudinal stretching comprises a preheating zone, a stretching zone, a thermal setting zone and a cooling zone, and the thermal setting zone of the lateral stretching is more than 15m long; and the casting piece is subjected to traction rolling to obtain the thermoshrinkable polyester film. By adopting the proportioning mode of directly feeding after accurate metering by people, the instantaneous addition error range of various materials is at most 1%; and the material is biaxially stretched, so that the produced film has the advantages of greatly higher density, strength and uniformity, lower longitudinal shrinkage and lateral low-temperature shrinkage, and especially higher ductility and thermoshrinkable uniformity.

Owner:SHANDONG SHENGHE PLASTIC DEV

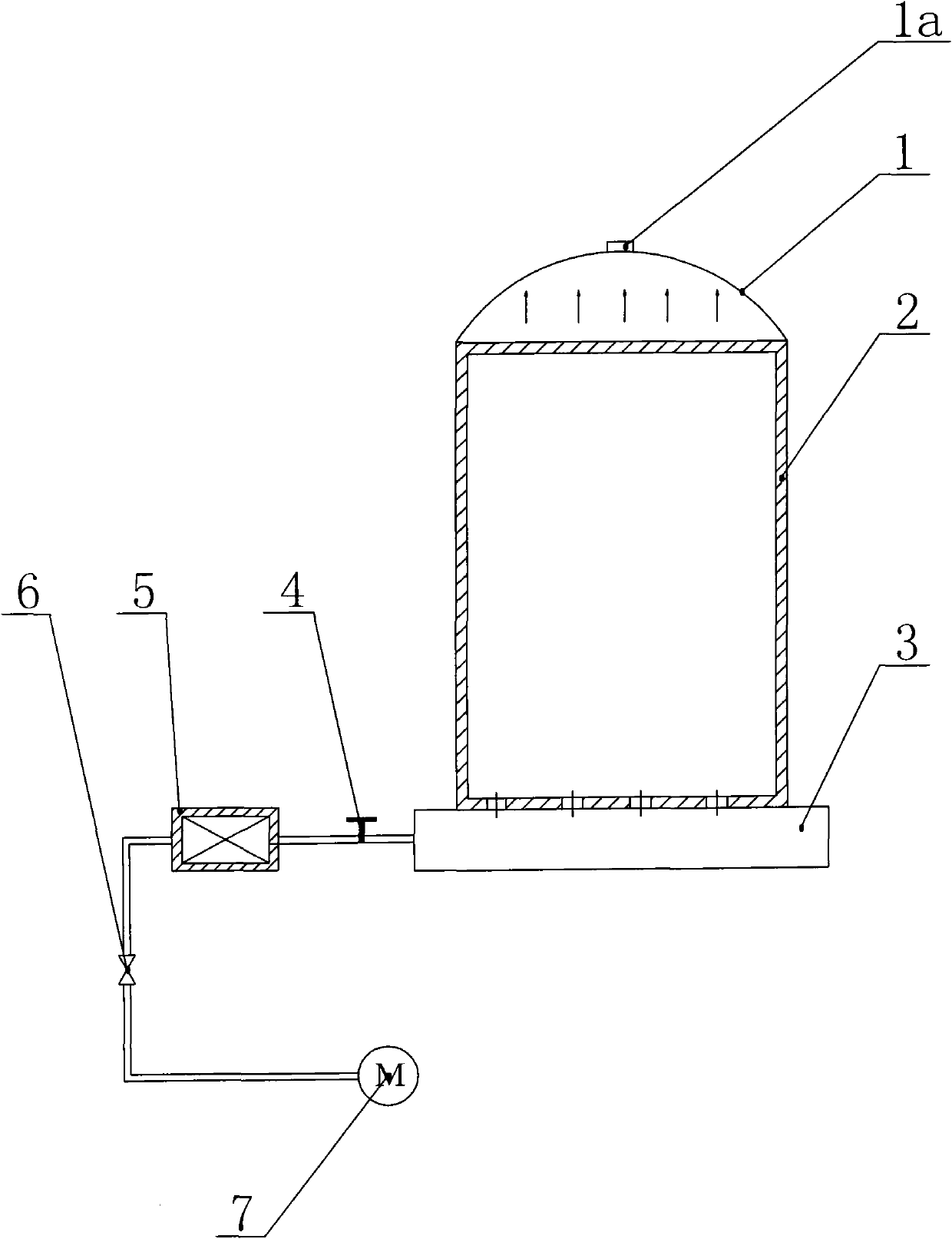

Insect-preventive drying system for barn

InactiveCN102564099AAchieve the purpose of dryingTo achieve the purpose of pest controlEdible seed preservationDrying gas arrangementsNitrogenEngineering

The invention discloses an insect-preventive drying system for a barn, which is used in the field of barn drying devices and comprises a cylindrical barn body, an arched barn top and an air compressor. The barn top is provided with a vent hole, an output end of the air compressor is connected with a nitrogen-oxygen separation device for separating oxygen and nitrogen, the separation device is provided with a nitrogen outlet and an oxygen outlet, the nitrogen outlet is connected with a vent duct at the bottom of the barn, and a seal valve is arranged between the nitrogen outlet and the vent duct. The problem that existing drying devices cannot kill insects is solved, and fodder and materials can be well preserved. The insect-preventive drying system is applicable to storage of feed in barns.

Owner:王诚本

Numerically-controlled machine tool chip removal device

InactiveCN112276655AAvoid scratchesEasy dischargeDrying gas arrangementsDrying machines with non-progressive movementsNumerical controlHEPA

The invention discloses a numerically-controlled machine tool chip removal device which comprises a collecting box and a heating box. Supporting plates are fixedly connected to the upper ends of the left side and the right side of an inner cavity of the collecting box, and first partition plates are movably connected to the tops of the supporting plates through a plurality of springs distributed at equal intervals. The left ends of the tops of the first partition plates are fixedly connected with a sliding base with the right side slidably connected with a slider, and the right side of the slider is movably connected with a push plate through a first electric telescopic rod. The device is provided with the supporting plates, the springs, the first partition plates, a vibration motor, a heating plate, the sliding base, the slider, the first electric telescopic rod, the push plate, a driven wheel, a glass fiber filter screen plate, a driving wheel, a conveying motor, a second clamping seat, a KDF filter layer, a heating box, a heating wire, a pipeline, a fan, a spray head, a first clamping seat, an HEPA filter screen and an activated carbon filter layer, so that the device can have the functions of chip collection, chip drying and cutting fluid collection, and therefore great convenience is brought to use of people.

Owner:孙嘉悦

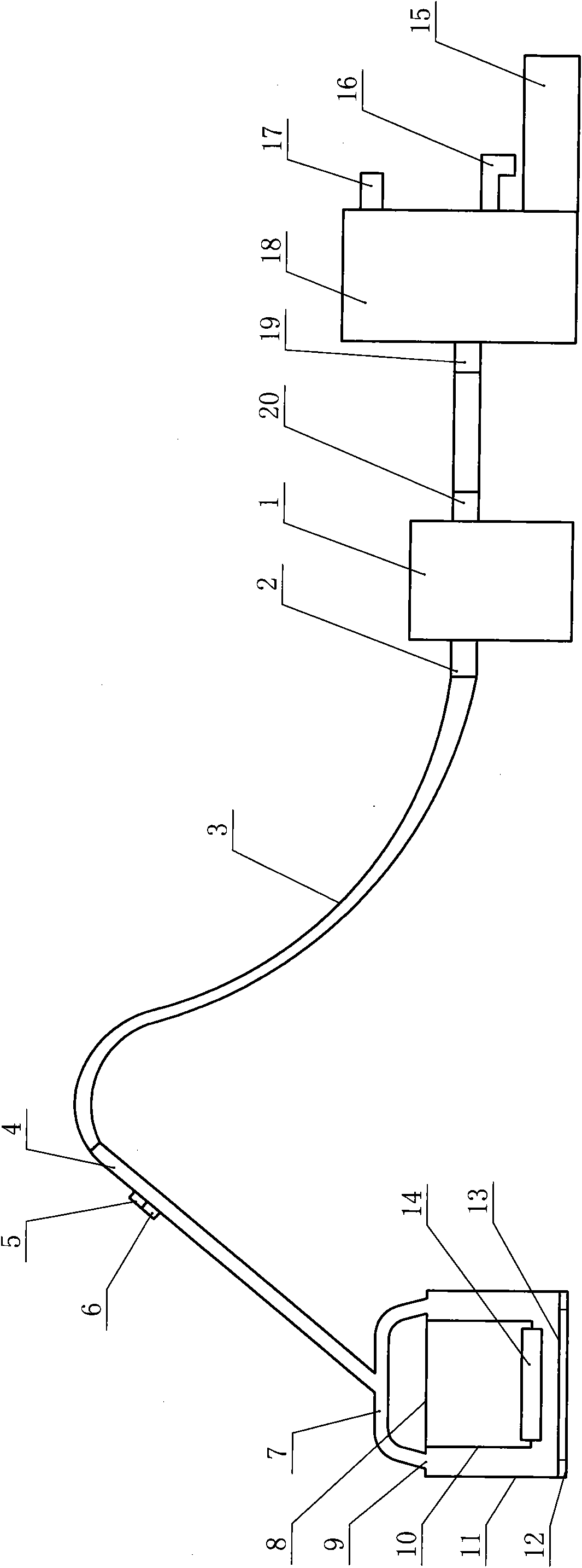

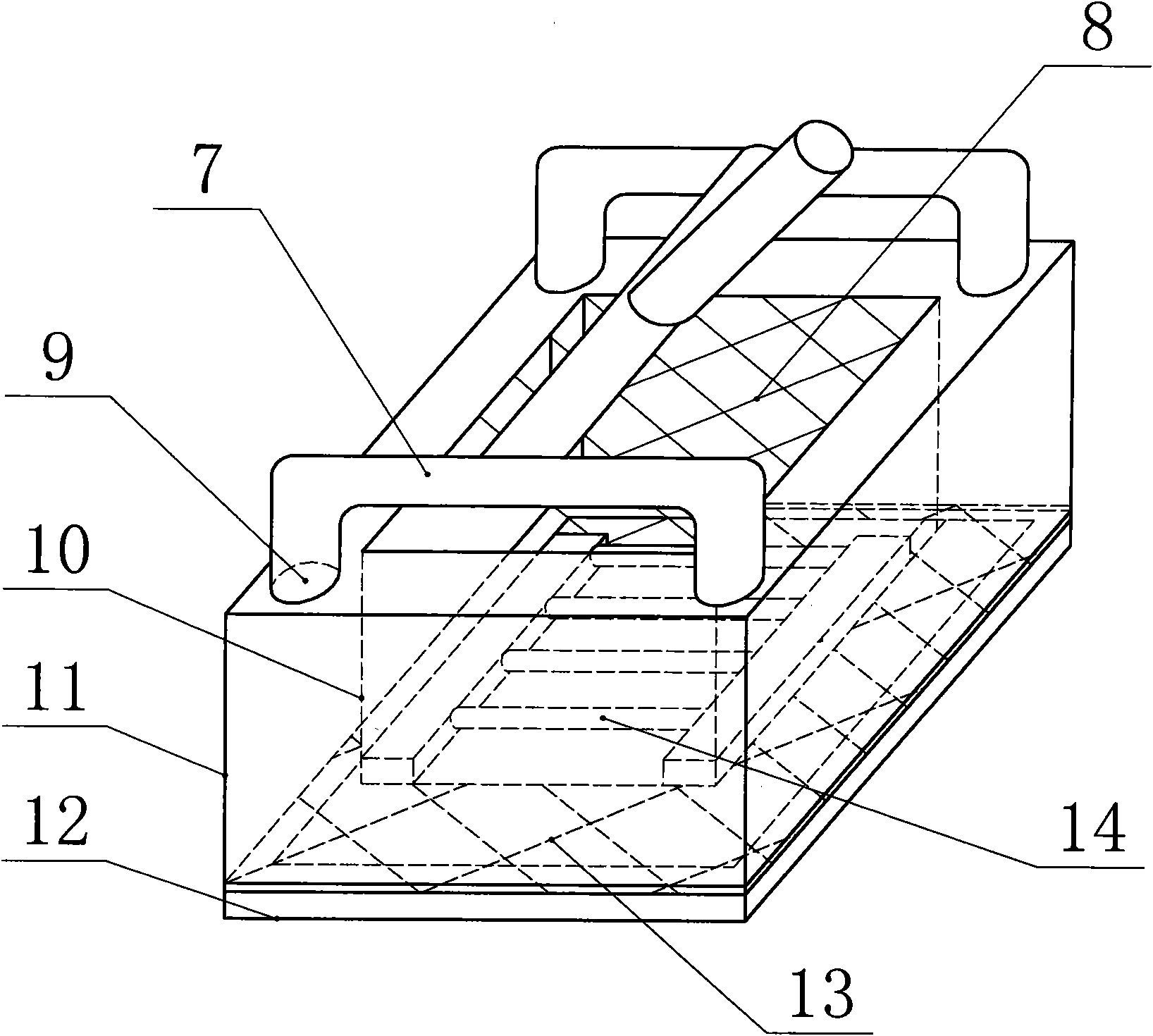

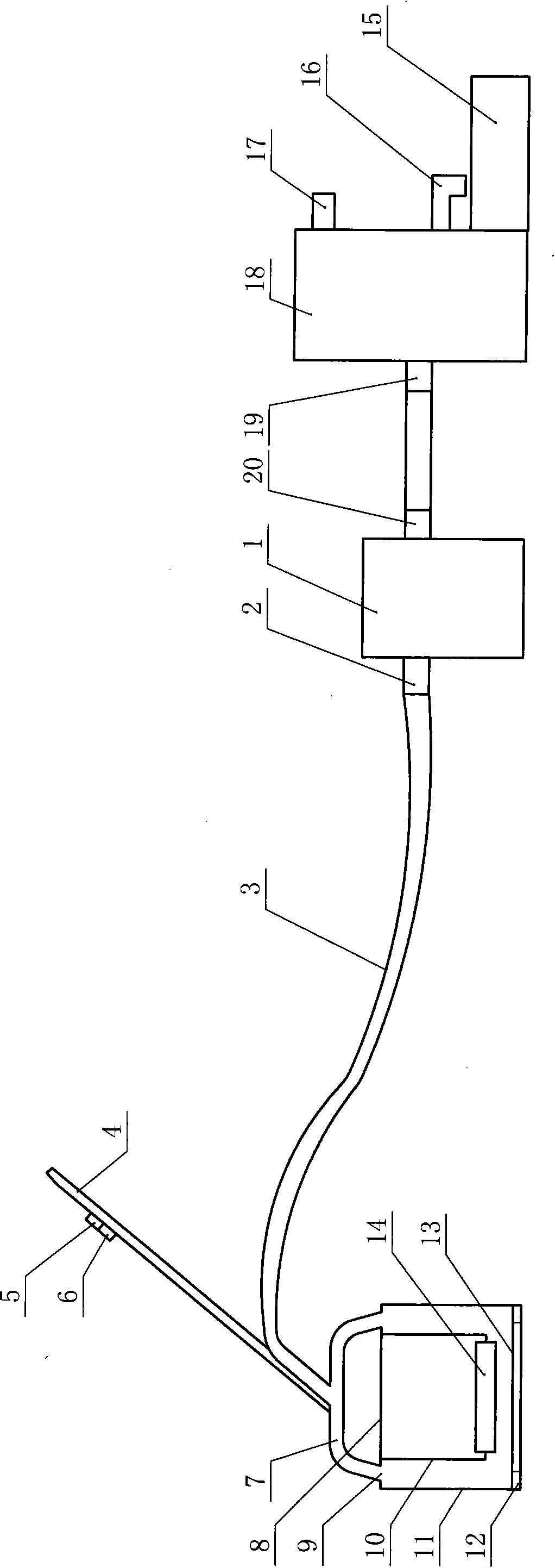

Movable baking and drying machine

InactiveCN101829476AEasy to dryAchieve the purpose of dryingDrying solid materials with heatDispersed particle separationCooking & bakingWater storage tank

The invention discloses a movable baking and drying machine, mainly comprising an electric baking device, a gas pumping and drainage device, a water and gas separation device and an operation device. The air inlet of the gas pumping and drainage device is communicated with a through hole of the electric baking device, and an air outlet is communicated with a gas inlet of the water and gas separation device; a water outlet of the water and gas separation device is provided with a water storage tank; the operation device is connected with the electric baking device; and the electric baking device comprises an outer shell, an inner shell arranged in the outer shell, an electrical heating tube arranged at the lower part of the inner shell, and a sealing bar arranged at the lower end of the outer shell. The distance between the lower end face of the inner shell and the lower end face of the outer shell is from 0.5 to 1.5 cm. A hollow interlayer is arranged between the outer side of the inner shell and the inner side of the outer shell, the upper end face of the interlayer is sealed, and the upper end ace of the interlayer is provided with a through hole which is communicated with the air inlet of the gas pumping and drainage device through a pipeline. The invention has the advantages of simple structure, low energy consumption, low cost, convenient operation, capability of drying ground and wall face rapidly and good humidity removal effect.

Owner:陈平

Sludge drying device and sludge treatment system

ActiveCN102875002AReduce pollutionAvoid direct contactSludge treatment by de-watering/drying/thickeningEngineeringMoisture

The invention discloses a sludge drying device and a sludge treatment system. The sludge drying device comprises a drying chamber, a rotating shaft, a driving device, a heat transfer air box and a stirrer, wherein the heat transfer air box is hollow shell-shaped; a smoke chamber, an air inlet and an air outlet which are communicated with the smoke chamber are arranged in the heat transfer air box; the upper surface of the heat transfer air box is used for receiving and drying sludge; the heat transfer air box is provided with a discharge hole which extends from the upper surface to the lower surface of the heat transfer air box; a discharge partition plate which extends from the upper surface to the lower surface of the heat transfer air box is also arranged in the heat transfer air box; the smoke chamber of the heat transfer air box is isolated from the discharge hole by the discharge partition plate; and the stirrer is provided with a scraper. In a drying process, hot smoke enters the smoke chamber of the heat transfer air box through the air inlet, the heat of the hot smoke is supplied to the heat transfer air box, and the sludge is heated on the upper surface of the heat transfer air box to evaporate moisture so as to fulfill the aim of drying; and thus, the sludge can be prevented from being directly contacted with the hot smoke, and the pollution of the hot smoke is reduced.

Owner:湖南省益能环保科技有限公司

Rapid and uniform drying device for textile fabric

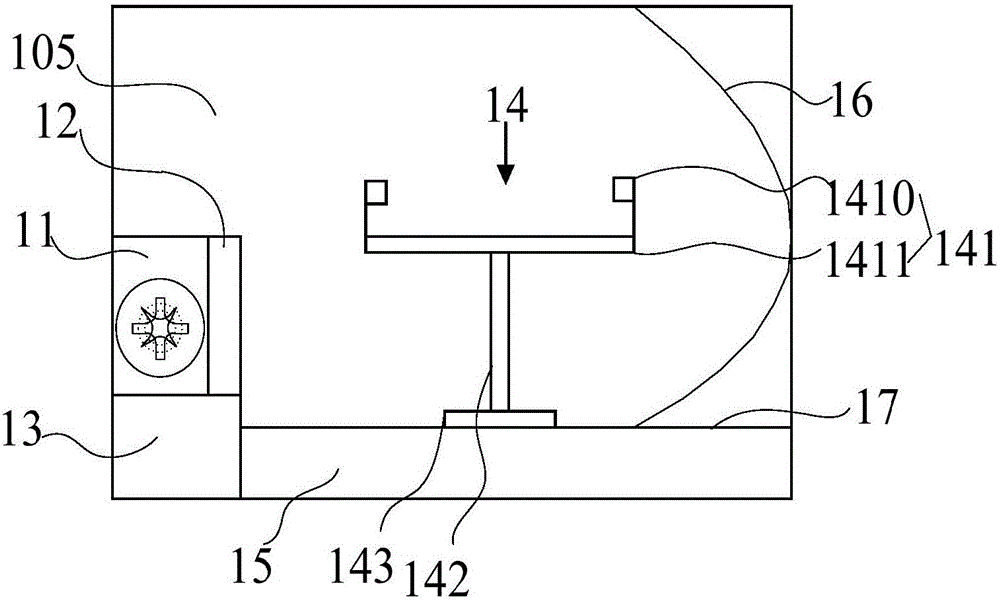

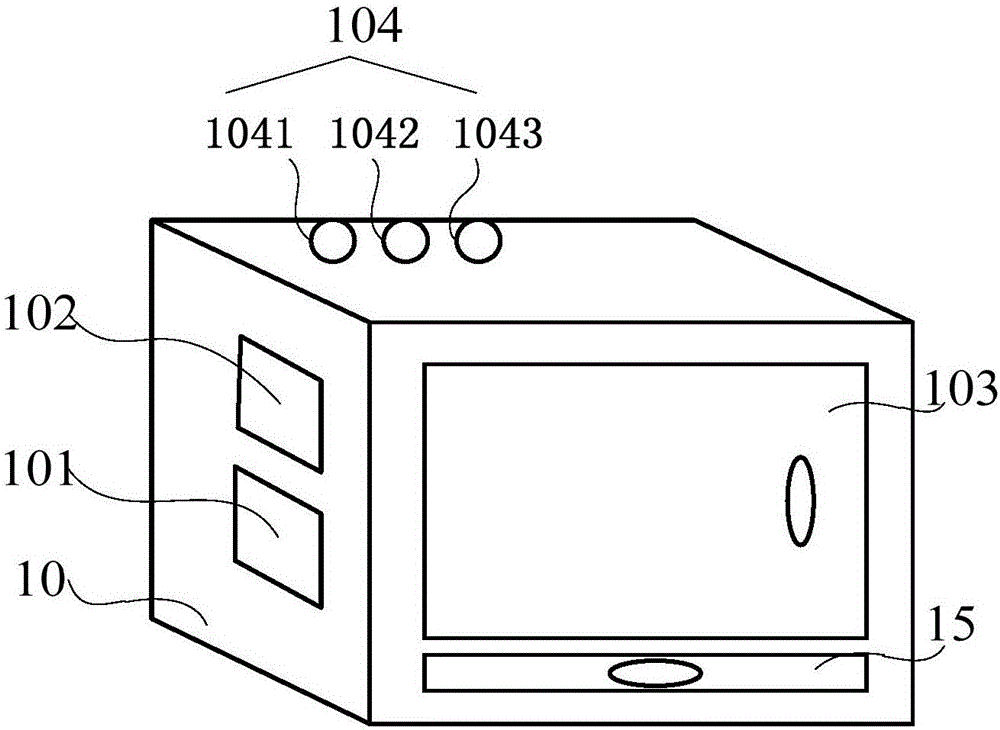

InactiveCN108106379AAchieve the purpose of dryingFail to meet production requirementsDrying gas arrangementsDrying machines with progressive movementsEngineeringDrying time

The invention discloses a rapid and uniform drying device for textile fabric, and relates to the technical field of textile machinery equipment. The rapid and uniform drying device comprises a box body, a motor box is fixedly connected to the right side of the top of the box body, and a motor is fixedly connected to the bottom of the inner wall of the motor box; a first bevel gear sleeves the surface of an output shaft of the motor, a first rotating rod is rotationally connected to the top of the inner wall of the motor box, a second bevel gear sleeves the surface of the first rotating rod, and the surface of the second bevel gear is meshed with the surface of the first bevel gear; and the bottom end of the first rotating rod sequentially penetrates through the motor box and the box body to extend into the interior of the box body, and a reciprocating device is fixedly connected to the surface of the part, extending into the interior of the box body, of the first rotating rod. According to the rapid and uniform drying device for the textile fabric, the problem that the textile fabric can not meet the production requirement due to incomplete drying is solved, the drying efficiency of the textile fabric is improved, the drying time of the textile fabric is saved, and the efficiency of the whole processing program is improved.

Owner:宁波市鄞州智伴信息科技有限公司

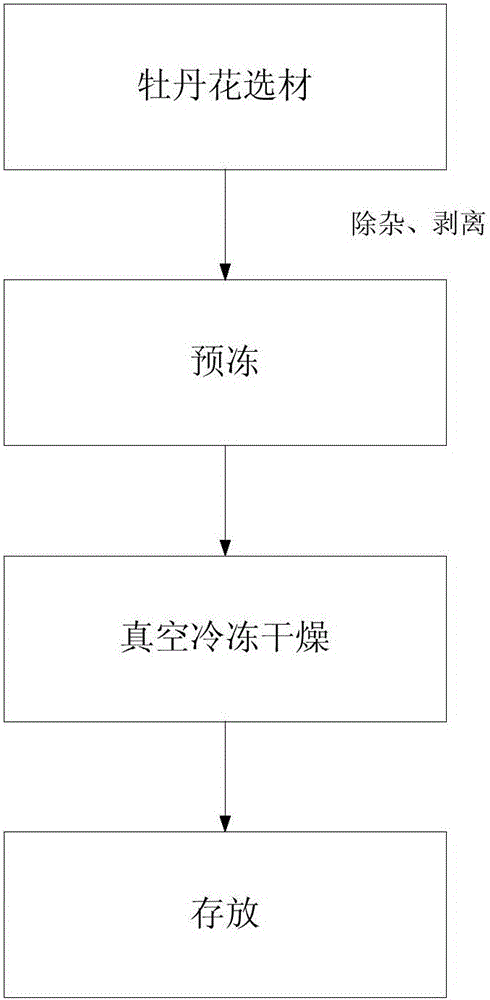

Drying method of flower materials in peony flower tea preparation technology

The invention discloses a drying method of flower materials in a peony flower tea preparation technology. The drying method includes the following steps that fresh peony flowers are picked; outermost petals of the peony flowers are stripped off, dirt is removed, and the integrity of petals is kept; the treated peony flowers are put into a cryogenic refrigerator in the optimum form to be pre-cooled; the pre-cooled peony flowers are rapidly put into a vacuum freezing dryer, the freezing temperature, the vacuum degree of a drying chamber, the temperature of a heating plate and the thickness of the material are set, and freezing drying is carried out; the dried peony flowers are stored in a sealed shady place. The dried peony flowers obtained through the drying method hardly shrink, the original color and flavor are kept basically, and the dried peony flowers have the advantages of being high in phenolic substance content and high in oxidation resistance, can serve as a high-quality raw material of peony flower tea and also have high ornamental value. According to the drying method, on the basis of vacuum freezing drying, the drying time is short, the process is simple, no contamination is caused, the product is good in sensory quality, high in nutrient retention rate and good in rehydration property, and the defects of high time consumption and labor consumption, low efficiency and the like of a traditional drying method are overcome.

Owner:NORTHWEST A & F UNIV

Household garbage centralized processor

ActiveCN109647860AAvoid pollutionImplement primary classificationCombination devicesSolid waste disposalDensity ratioEnvironmental engineering

The invention relates to a household garbage centralized processor. The household garbage centralized processor comprises a rough breaking chamber, a fine breaking chamber, a mixing chamber, a densityseparation chamber, a plastic removal chamber, an incinerator, a bubble forming chamber, an acid treatment chamber and a composite processing filter chamber. According to the processor, the householdgarbage is broken firstly, mixed with water, and then divided into floating matter, sediment and water-soluble matter or matter easy to mix with water according to the density ratios different from water; the sediment is burned into metal and inorganic non-metal to be separated; after the plastic is removed, the floating matters leave as fibrous substances; and the liquids can be purified by steps of bubble forming, filtering, absorption and the like. Thus, deep treatment and partial recycling of the household garbage are achieved.

Owner:蚌埠新业环境服务有限公司

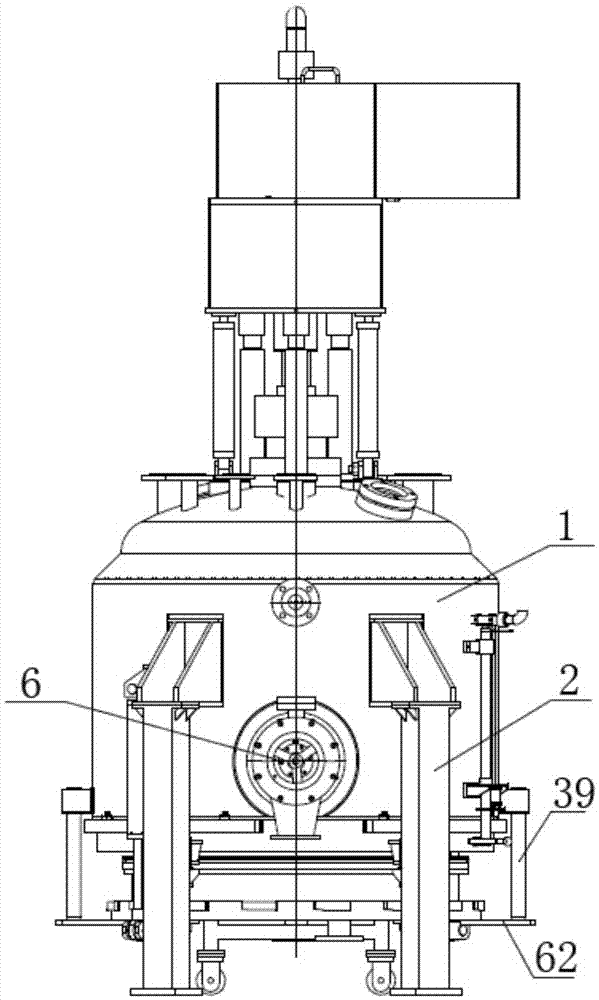

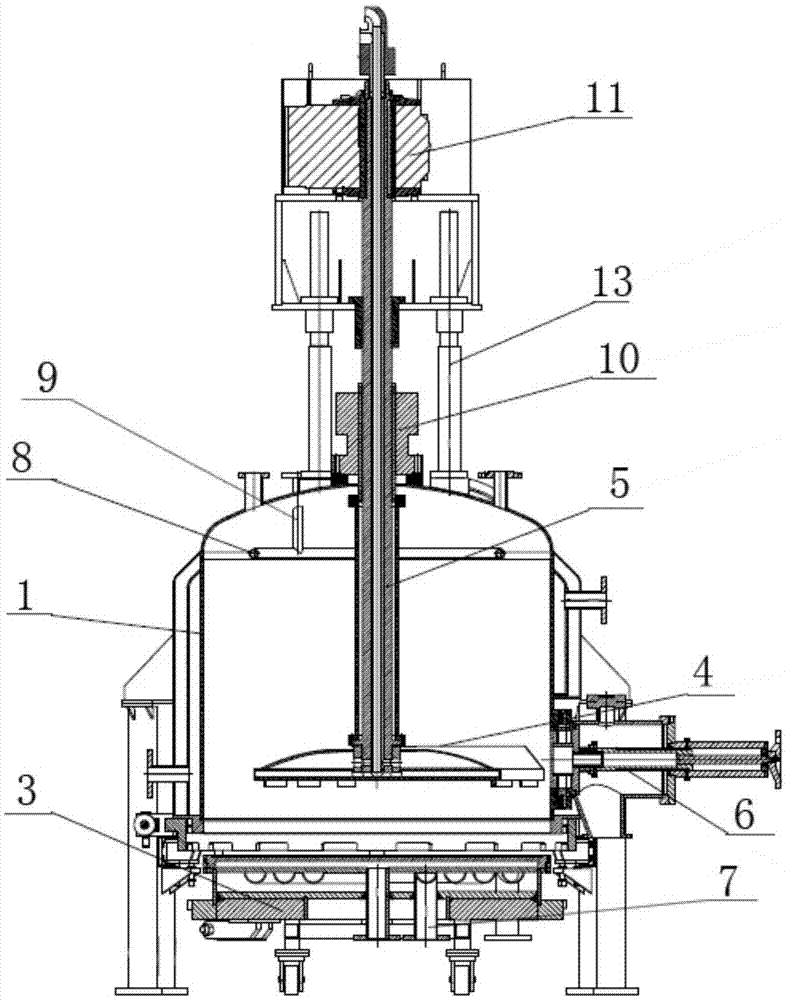

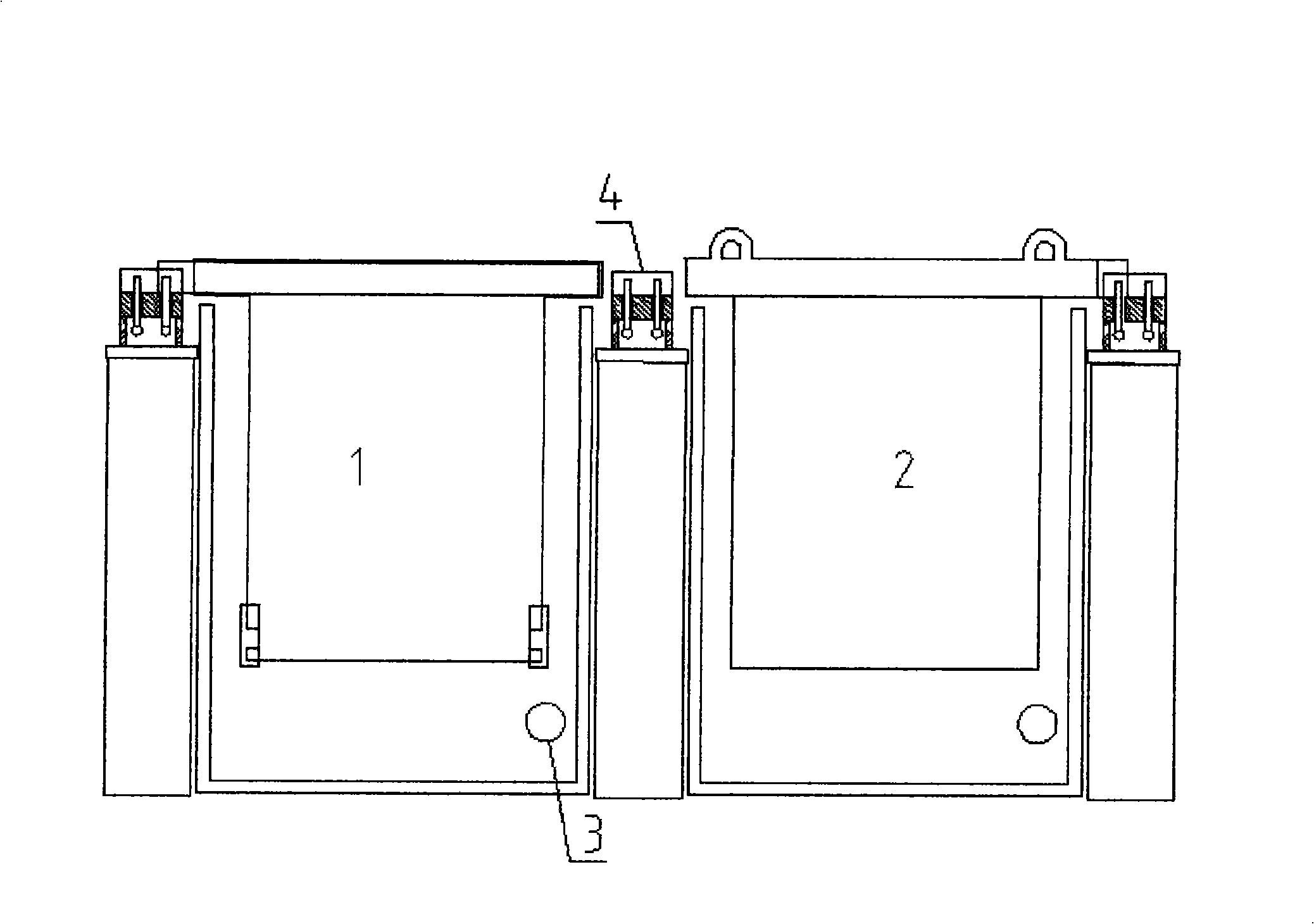

Three-in-one kettle structure

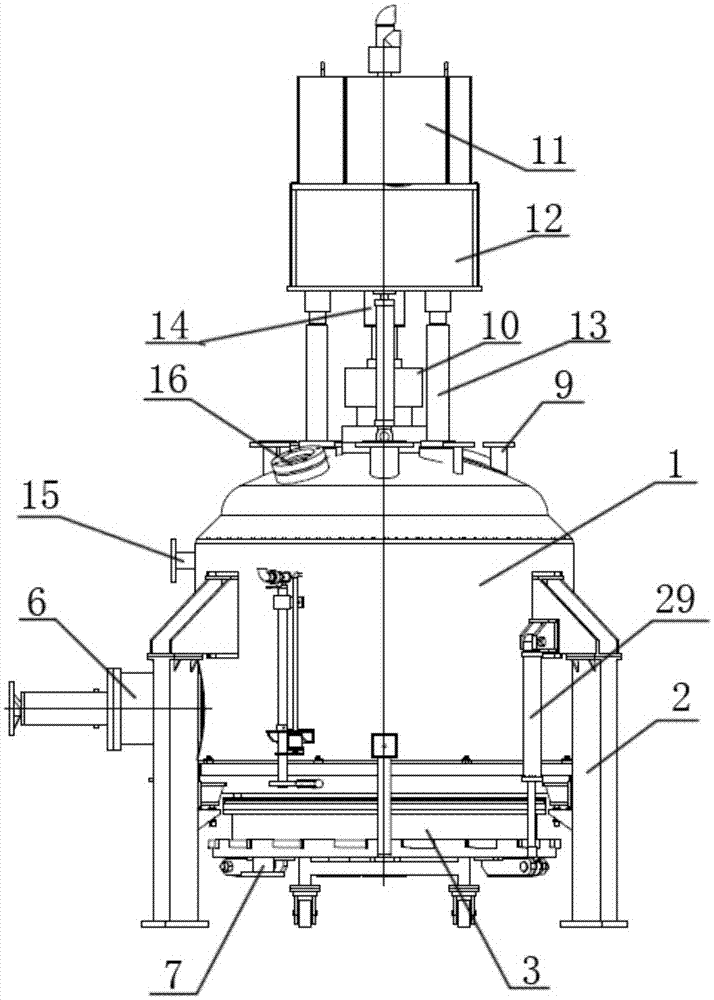

InactiveCN105435502AImprove filtration efficiency and qualityImprove heat transfer coefficientMembrane filtersStationary filtering element filtersFiltrationWater source

The invention provides a three-in-one kettle structure. According to the three-in-one kettle structure, internal cleaning and material slurry washing can be realized in a container, when materials are dried, the turning distance is short, the crystal destruction is less, the agglomeration is difficult, and the heat transfer coefficient is high. The three-in-one kettle structure comprises a kettle body, wherein a plurality of vertically arranged support legs are arranged on the outer side of the kettle body, a lower end cover is arranged just below the bottom end surface of the kettle body, a stirring blade is arranged in the kettle body, a stirring shaft penetrates through the top of the kettle body and then is fixedly connected to the center of the stirring blade, and a discharging mechanism is arranged on the middle lower part of the kettle body. The three-in-one kettle structure is characterized in that a suction filtration opening is formed in the lower end cover which is a filter heating chassis, a spray device is arranged on the upper part of an inner cavity of the kettle body, the spray device is externally connected with an external water source through a connecting pipe, a sealing device is arranged between the stirring shaft and the top of the kettle body, a stirring motor is externally connected to the top of the stirring shaft, and the stirring motor is supported on a motor base.

Owner:MIYOU GROUP

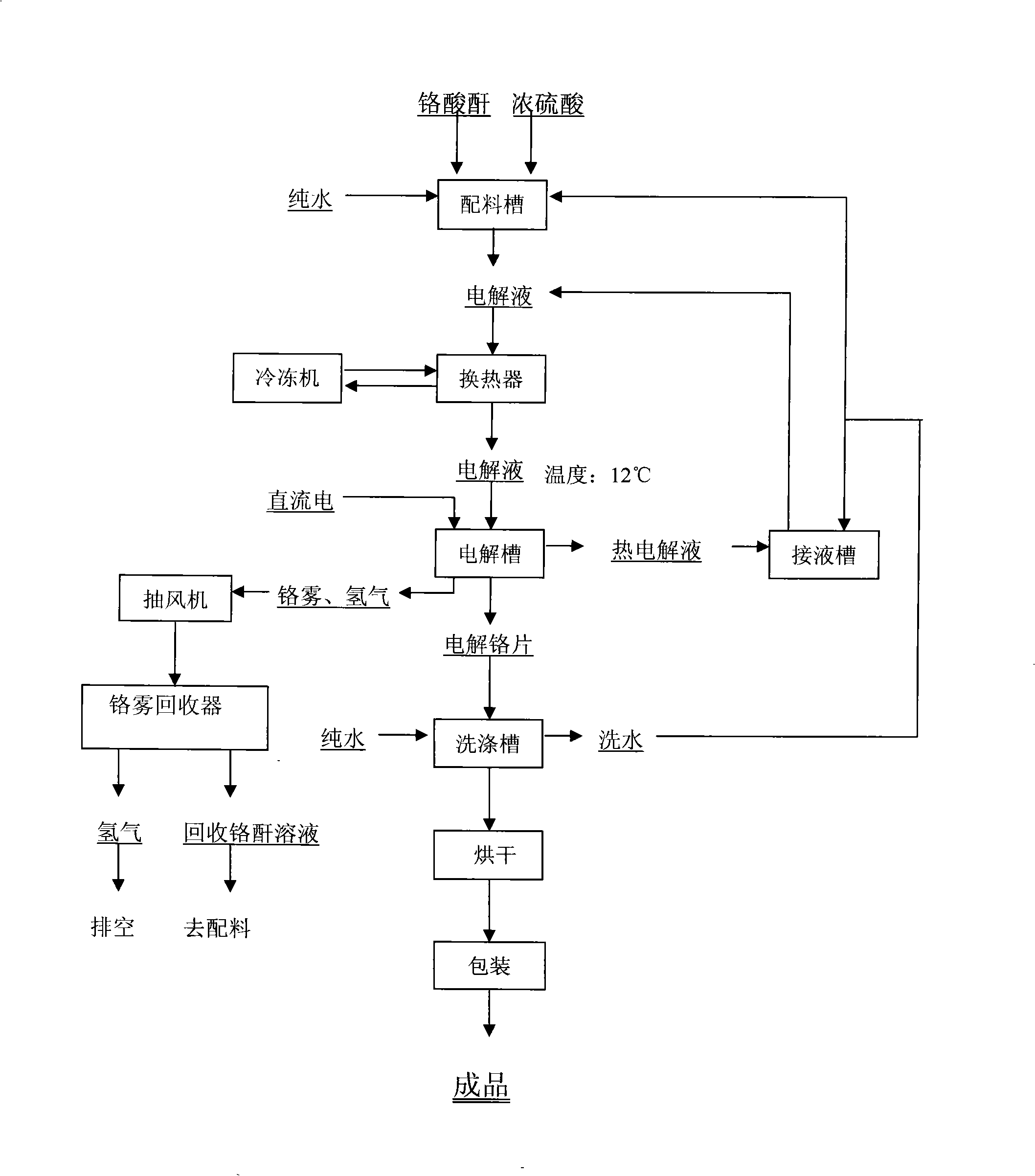

Method for producing high-purity metal chromium by electrolysis

ActiveCN101260537AAchieve the purpose of dryingPhotography auxillary processesProcess efficiency improvementLithium bromideMetal

The invention discloses a method for electrolytic production of high purity chromium metals, wherein, chromic anhydride and concentrated sulfuric acids are mixed into electrolytes according to a certain proportion which are thrown into a liquid receiving tank and then cooled by an acid-proof pump through a super stainless steel plate heat exchanger, and cooling water is provided by a steam lithium bromide refrigerating machine; the electrolytes after cooling are thrown into an electrolytic cell, pass through a liquid separation device in the cell and uniformly arrive between cathode plates and anode plates for electrolytic reaction; the electrolytes after electrolysis flow into the liquid receiving tank from an overflow weir of the electrolytic cell, and then the circulation is repeated to and fro. After the thickness of chromium plates reaches 1 to 2 millimeters through electrolysis of 24 hours or so, the cathode plates of the electrolytic cell are entirely moved out by a hanger frame through a pole plate switching device under the condition of no power failure, and then the electrolytic reaction is continued after replacement of a set of novel cathode plates. The chromium plates are knocked off manually from the replaced cathode plates, and the content of chromium can reach 99.99 percent after third-stage countercurrent washing and drying through a vibrated fluidized bed. The method reduces the cost and improves the production efficiency.

Owner:XINJIANG SING HORN GRP CO LTD

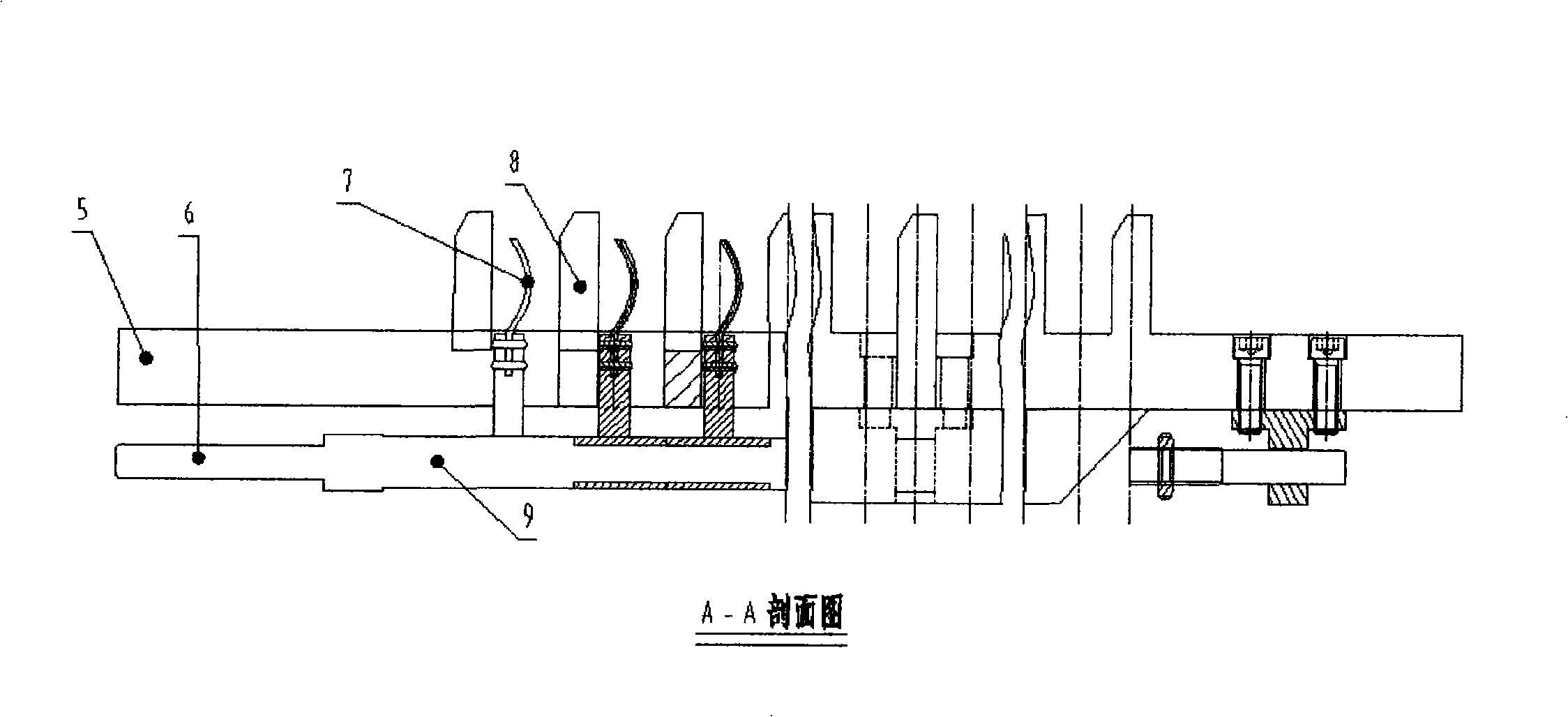

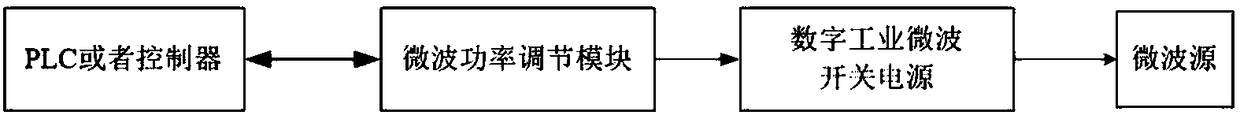

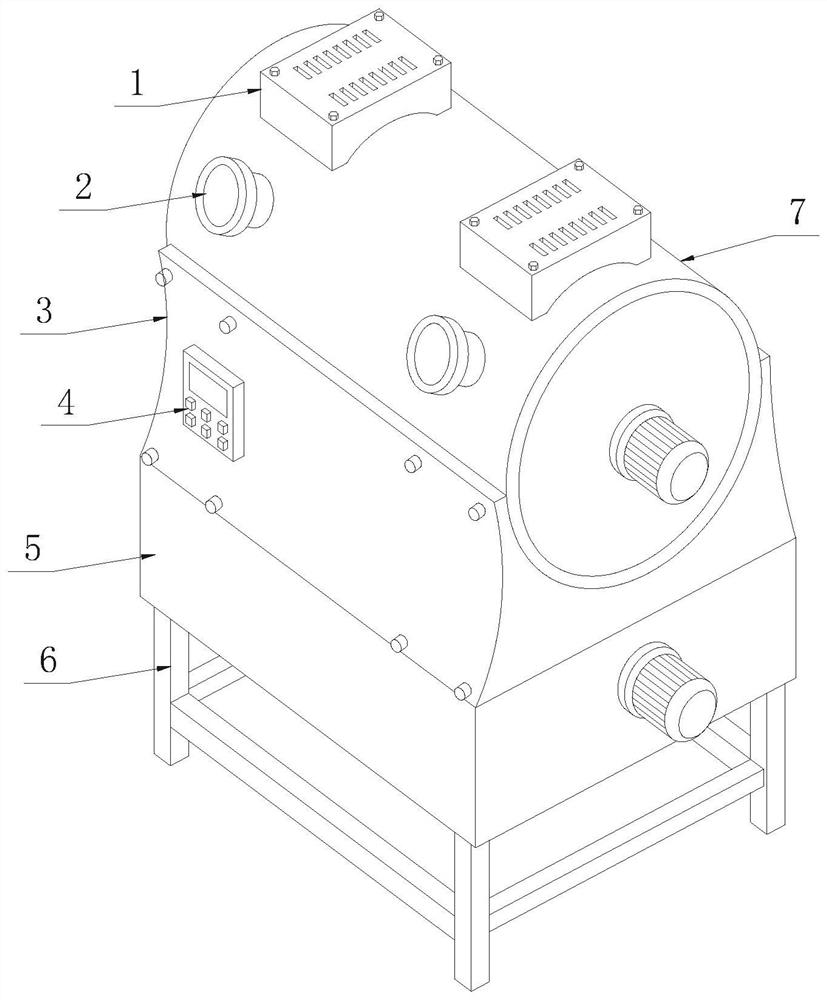

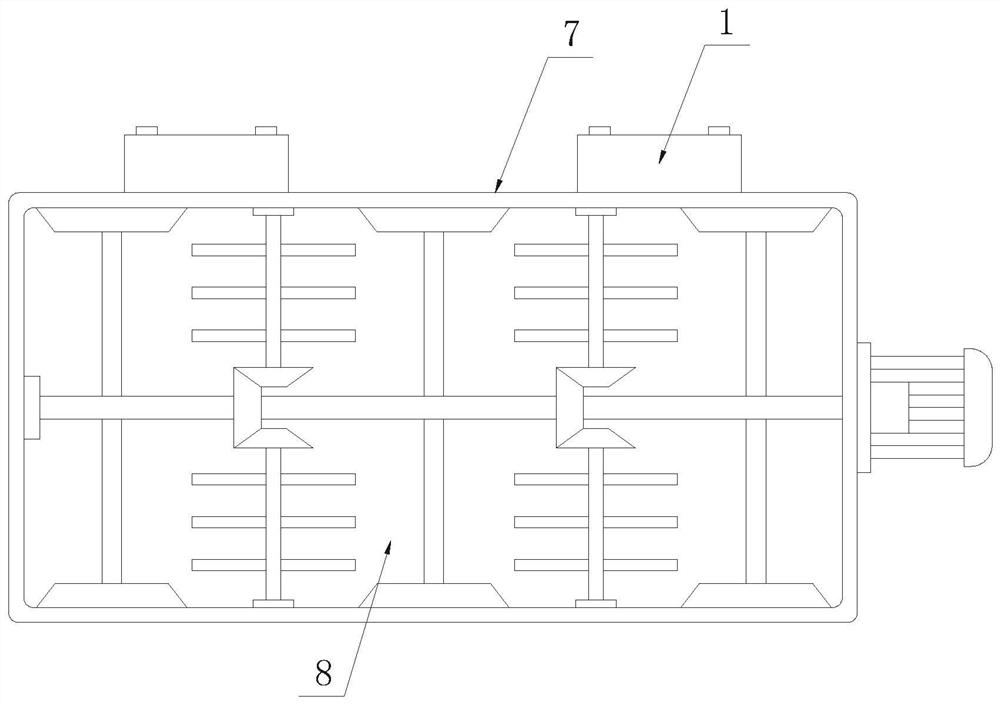

Molecular sieve tunnel type microwave drying device continuously adjustable in power

InactiveCN108106384AAchieve the purpose of dryingHeating evenlyDrying solid materials with heatDrying machines with progressive movementsMolecular sieveMicrowave cavity

The invention discloses a molecular sieve tunnel type microwave drying device continuously adjustable in power. The main body of the molecular sieve tunnel type microwave drying device is a microwavedrying furnace, and the molecular sieve tunnel type microwave drying device is provided with a feeding end and a discharging end, and further comprises microwave heating resonant cavities, a materialconveying system, a microwave source, a microwave power adjusting device, a microwave suppression system, a moisture exhaust and cooling system, an electric control system and a temperature measurement system. According to the molecular sieve tunnel type microwave drying device, a microwave device continuously adjustable in power is adopted to uniformly heat molecular sieve materials, and the temperatures of all portions of the molecular sieve materials in tunnel type microwave cavity bodies are measured through an infrared thermometer; if the temperatures are too high or too low, the temperatures of the molecular sieve materials in the microwave cavities are within an appropriate material heating temperature range by adjusting the microwave power; and compared with conventional microwavedrying devices constant in power, the molecular sieve tunnel type microwave drying device continuously adjustable in power has the advantages of being capable of prolonging the service life of a magnetron of the microwave source, low in energy consumption, high in heating efficiency and the like.

Owner:湖南景远微波科技有限公司

Smart photovoltaic lightning protection combiner box

InactiveCN107769015AEasy to openSolve the problem that it is inconvenient to open the box for maintenanceSubstation/switching arrangement cooling/ventilationPhotovoltaicsSoftware engineeringLightning

The invention discloses a smart photovoltaic lightning protection combiner box. The box includes a box body. An insulation board is connected to the front face of the inner side of the box body. A module box is fixedly connected to the front face of the insulation board. Springs are fixedly connected to two sides of the inner wall of the module box. A clamp board is fixedly connected to one side away from the inner wall side of the module box of each spring. A filtering box is fixedly connected to one side away from a slide chute of each slide block. A filter screen is arranged in an inner cavity of each filtering box. A drying box is fixedly connected to the bottom of the inner side of the box body. A heat dissipation box is fixedly connected to each of two sides of the bottom of the inner wall of the box body. According to the invention, through cooperative use of the box body, connection boards, necks, box doors and sealing gaskets, a problem of box opening inconvenience during combiner box maintenance is solved. Through cooperative use of the insulation boards, the module box, the springs, the clamp boards and clamp holes, a problem of dismounting convenience of inner parts ofthe combiner box is solved. Through cooperative use of the drying box and a drying bag, a problem of large humidity in the combiner box is solved.

Owner:江苏大浪电气集团有限公司

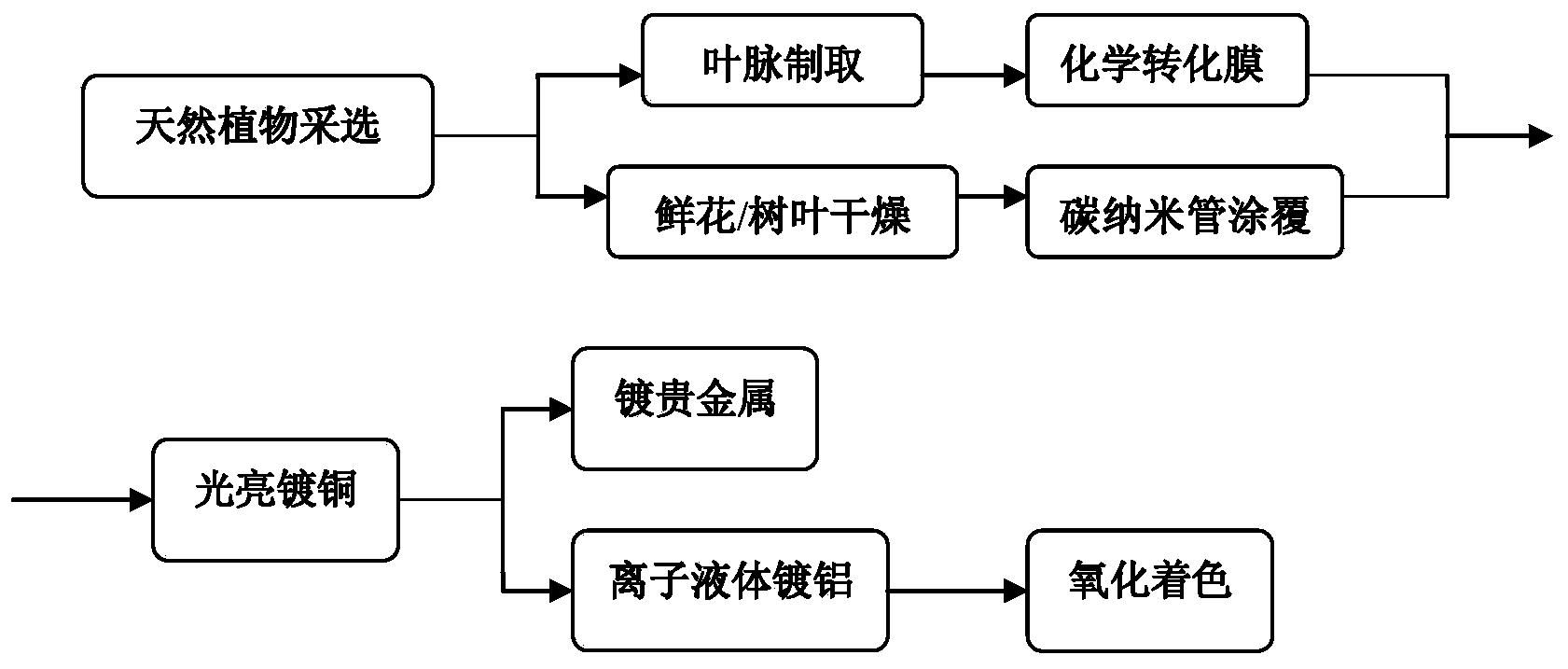

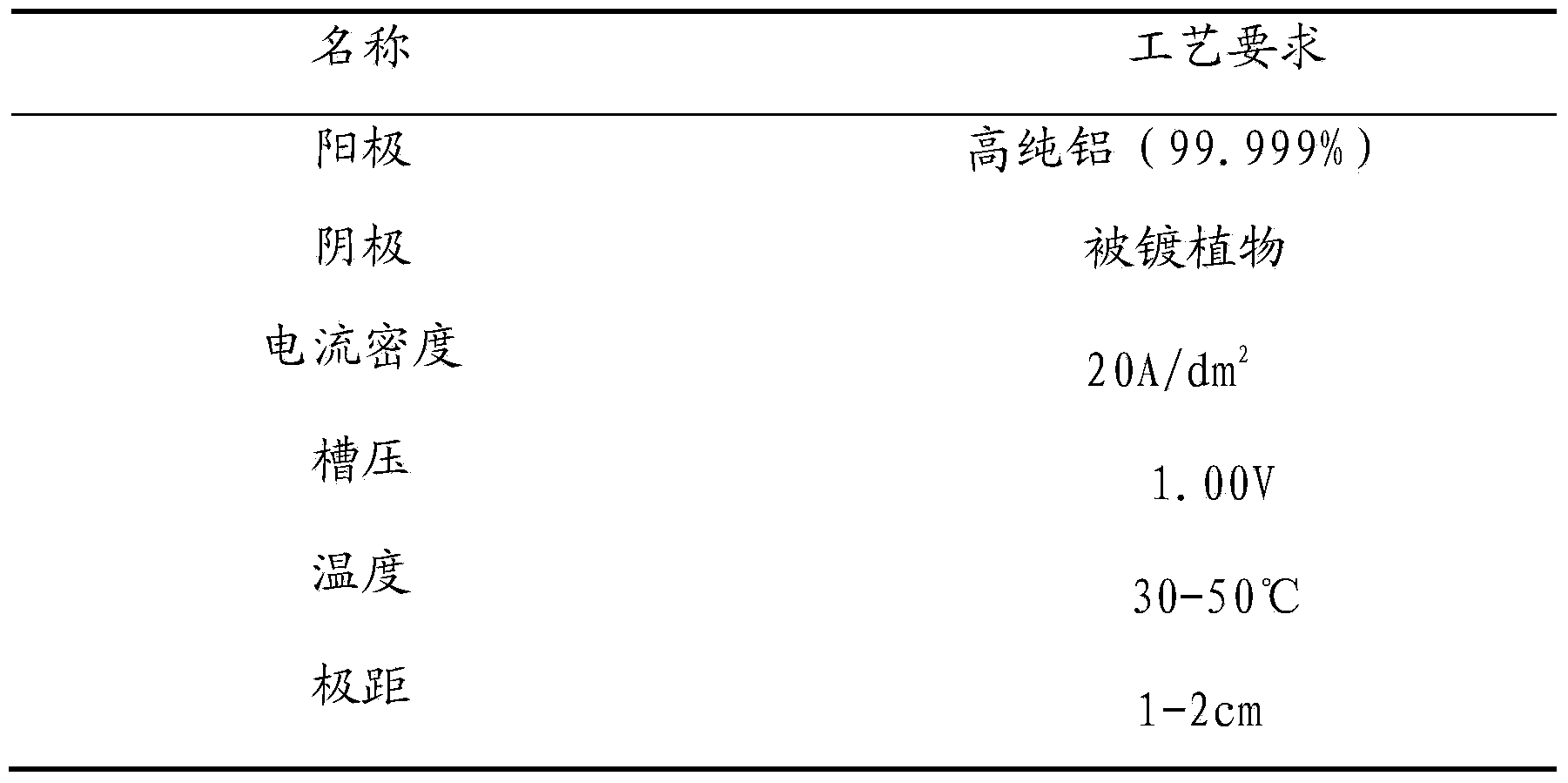

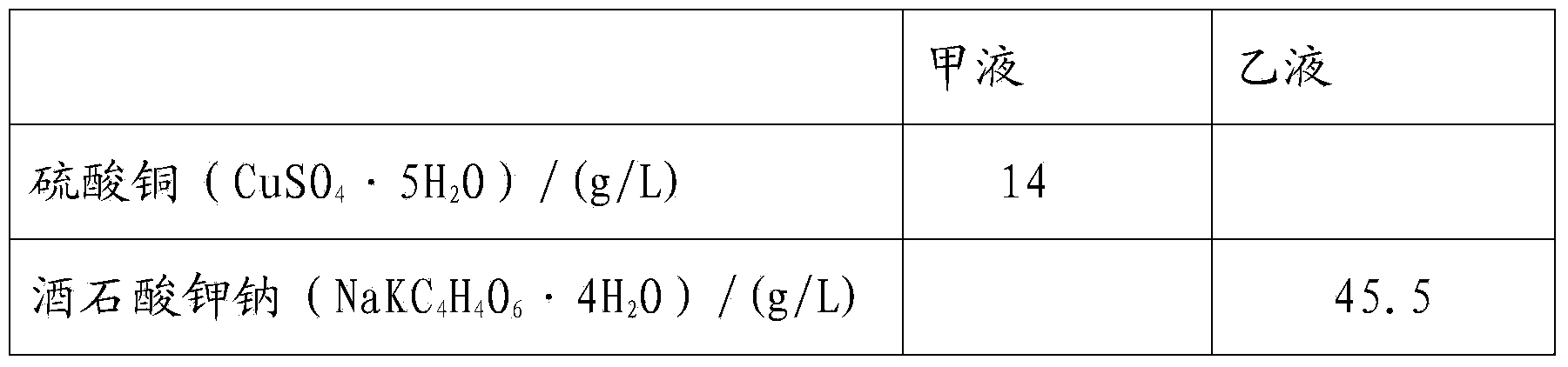

Natural plant electroplating and finishing technique

ActiveCN103882488AAvoid oxidation and blackeningGood oxidation coloringSpecial surfacesCoatingsVeinElectrical conductor

The invention discloses a natural plant electroplating and finishing technique and mainly solves the problems that the natural plant is soft in texture, easy to break, rot and go bad and the problems of an earlier stage processing method of the natural plant, a method for transforming a non-conductor to a conductor, selection and combination of electroplating liquid formulation. When drying the plant, an alkali liquor is used for cooking the plant, then mesophyll is lightly brushed away, and leaf vein is retained; when transforming the non-conductor, a method for mixing carbon nanotube powder with two-component polyester resin is used for coating a conductive layer; finally, noble metals or ionic liquid aluminum is plated by using a cyanide-free electroplating formulation. Through the technique, the natural plant, which is difficult to store, can be processed by a series of methods for drying, removing mesophyll, coating protection layers and electroplating, so that the natural form of the natural plant can be stored for a long time; the natural plant does not go bad and rot; meanwhile, the appreciation and collection value is greatly improved, thus giving the enjoyment of beauty to people.

Owner:SHENYANG NORMAL UNIV

Drying structure for dish-washing machine liner

PendingCN108742459ASimple structureEasy to operateTableware washing/rinsing machine detailsHome appliance efficiency improvementExhaust gasEnergy consumption

The invention discloses a drying structure for a dish-washing machine liner. An air inlet and an air outlet are formed in the liner, and a height difference exists between the air inlet and the air outlet. The drying structure also comprises an air inlet component, the air inlet component comprises an air inlet draught fan and a filter device, the air inlet component is communicated with the air inlet, and the air inlet component is used for sucking gas into the liner. The drying structure also comprises an air outlet component, the air outlet component is connected with the air outlet, the air outlet component is used for discharging gas inside the liner, and the air outlet component is internally provided with a condenser and an air outlet draught fan. A heat exchange device is connectedbetween the air outlet component and the air inlet component, so that gas entering into the liner is preheated, and in addition, the temperature of the exhaust gas of the liner can also be reduced; and the drying structure has the characteristics of simple structure and obvious drying effect, and has the advantage of being beneficial to reduction of energy consumption.

Owner:VATTI CORP LTD

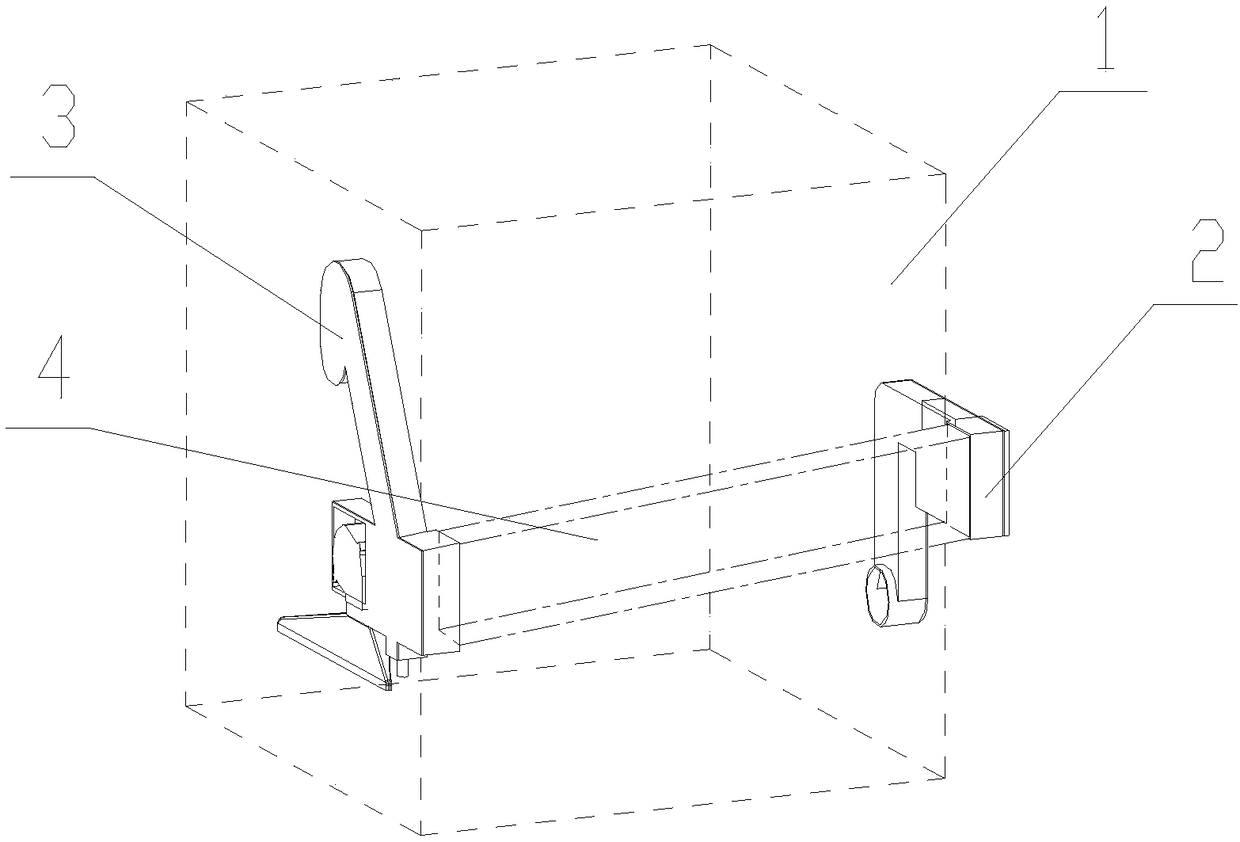

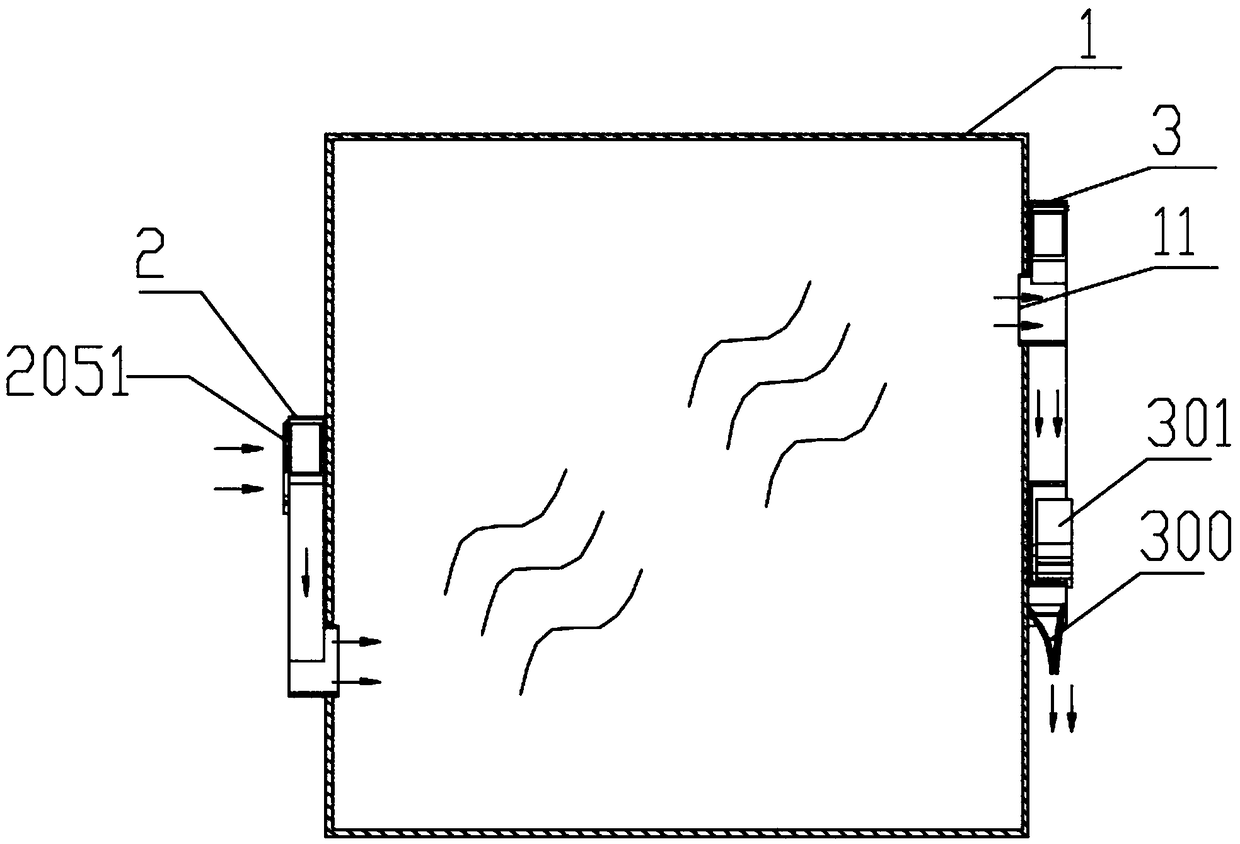

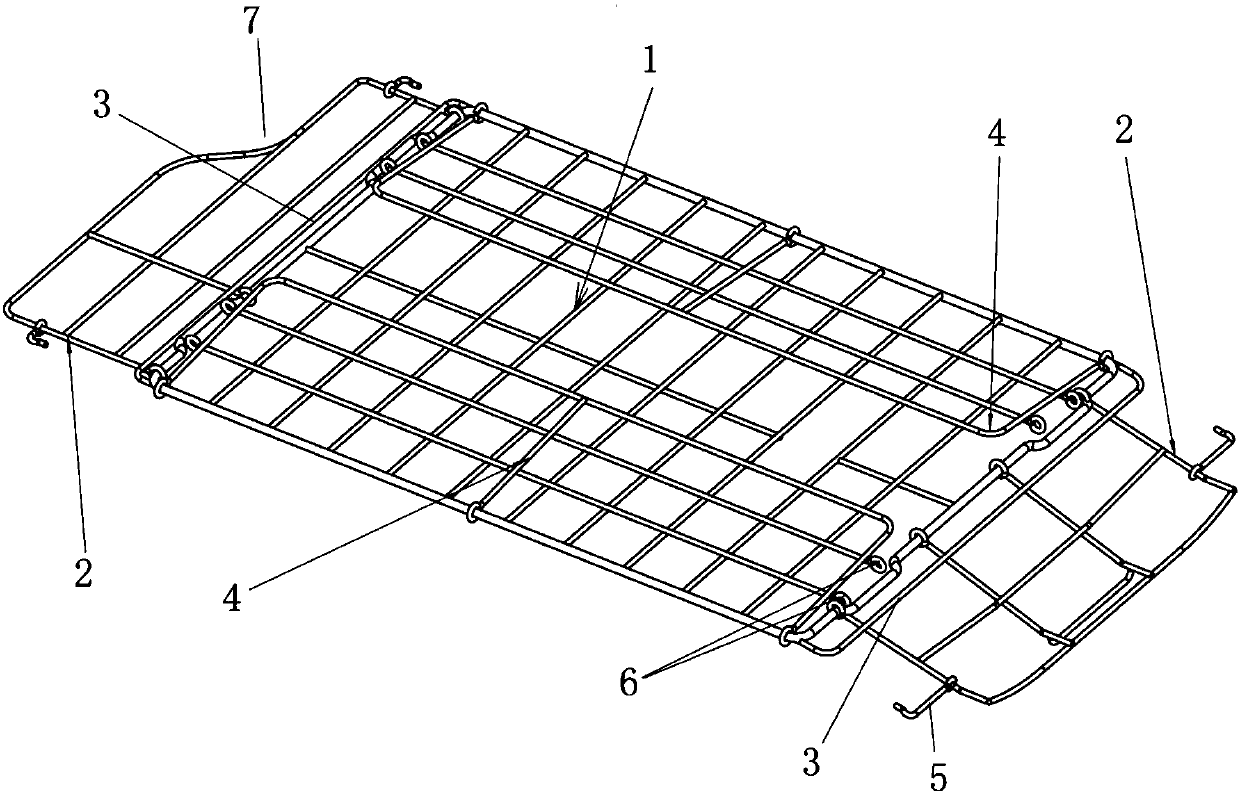

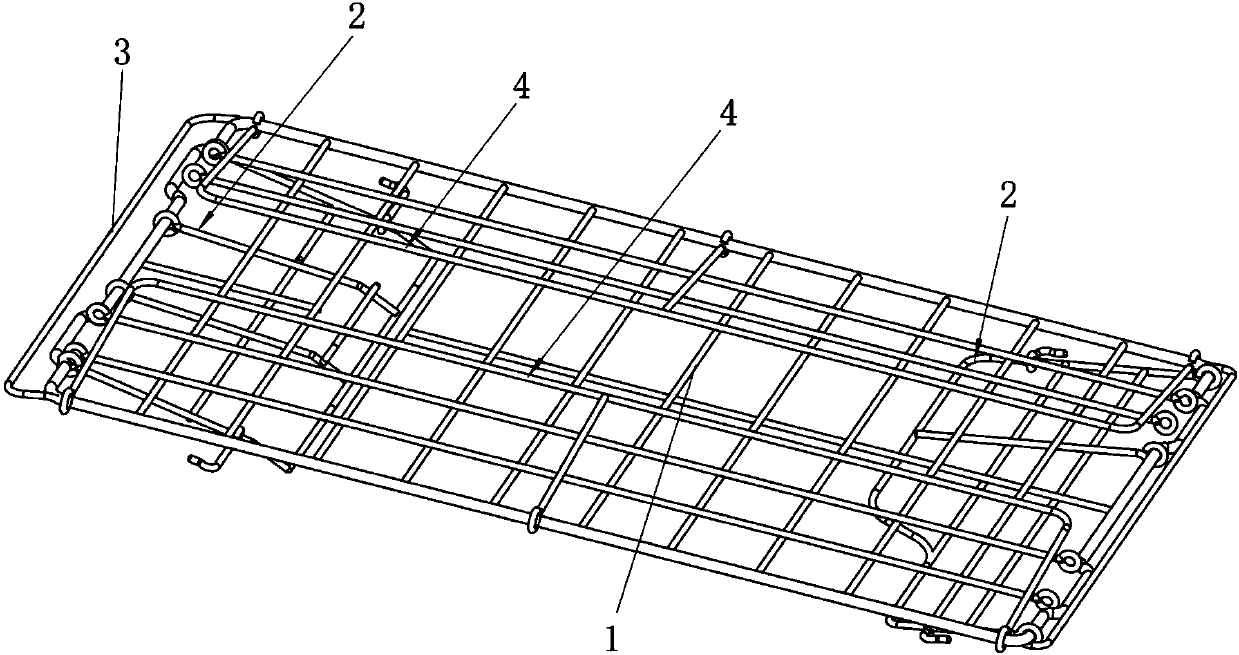

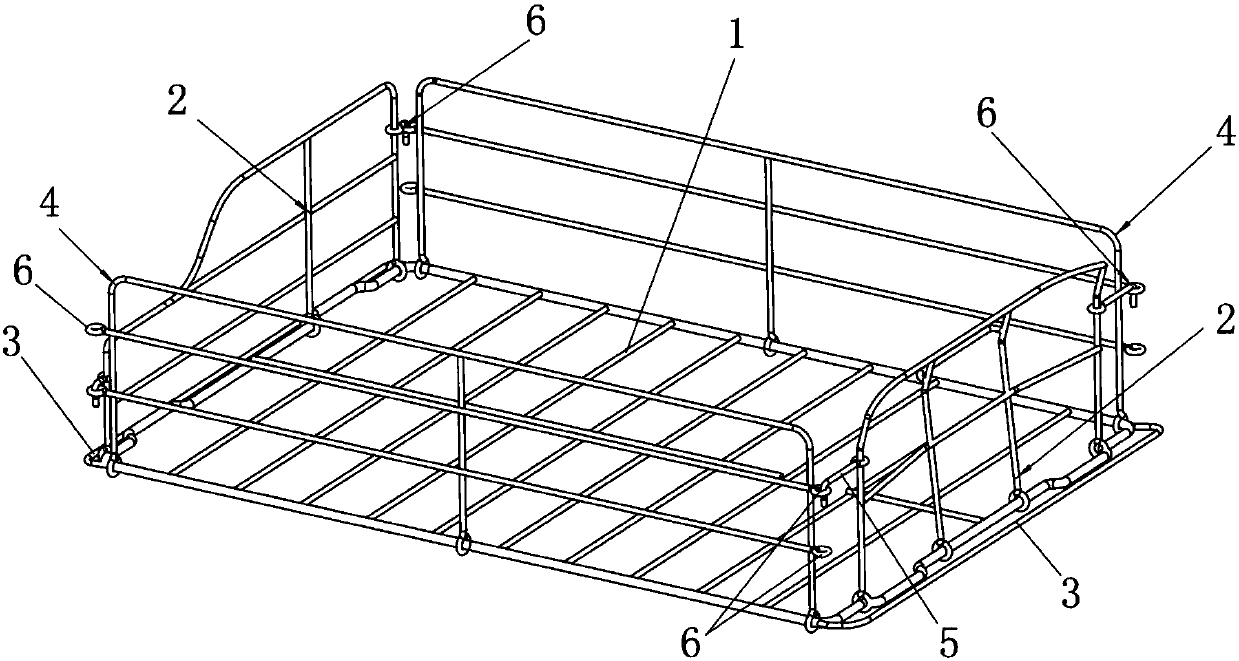

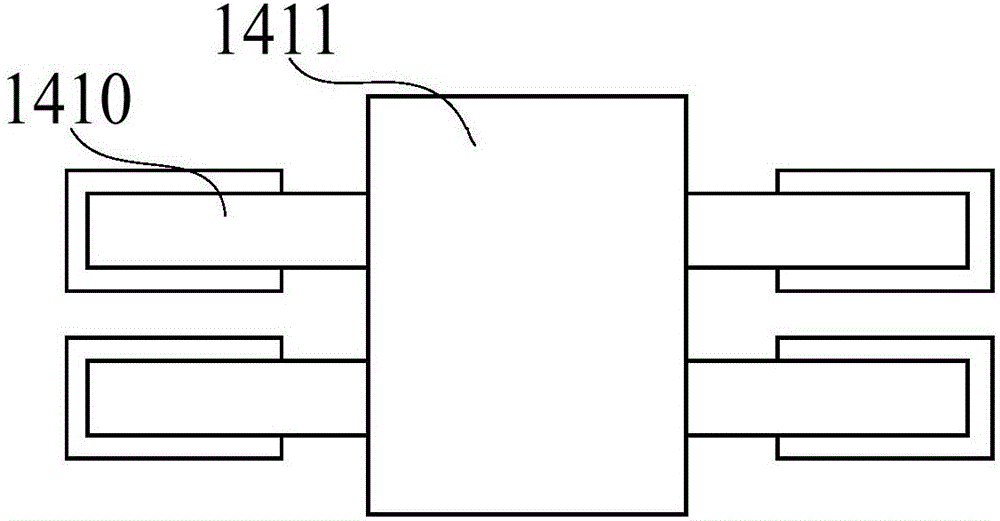

Article placing rack and drying machine or washing and drying integrated machine

ActiveCN107641938AImprove qualityImprove experienceOther washing machinesTextiles and paperMechanical engineering

The invention relates to the field of article drying technologies, and discloses an article placing rack and a drying machine or a washing and drying integrated machine. The article placing rack comprises a rack. Support components are connected onto the rack and can be repositioned relative to the rack, so that the connection lengths of the article placing rack can be adjusted. The article placing rack and the drying machine or the washing and drying integrated machine have the advantages that two opposite ends of the article placing rack need to be connected to positions between two externalsupport foundations when the article placing rack is used, for example, the two opposite ends of the article placing rack need to be lapped between the two external support foundations, and the support components can be repositioned relative to the rack, so that the connection lengths of the portions, which are used for being connected to the positions between the two external support foundations, of the article placing rack can be adjusted; only the connection lengths need to be adjusted, so that the article placing rack can be connected to the positions between the two external support foundations with different distances, articles can be placed, for example, the articles can be placed in barrels of different types of drying machines or washing and drying integrated machines, the to-be-dried articles can be statically placed on flat planes, the purpose of drying the articles can be achieved, the problem of noise can be solved, and the to-be-dried articles can be effectively protected.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

Drying device

PendingCN106839680AAchieve the purpose of dryingDegree of reductionDrying solid materials without heatDrying gas arrangementsThermodynamicsEngineering

The invention relates to the technical field of drying, and particularly relates to a drying device. The drying device comprises a box body, a drying mechanism and an object loading mechanism, wherein a drying cavity is formed in the box body; the object loading mechanism is fixed in the drying box and is used for fixing a to-be-dried object; the box body is provided with an air inlet and an air outlet; the drying mechanism comprises a fan; the fan is provided with an air outlet channel; the air outlet channel, the air inlet, the drying cavity and the air outlet are communicated with one another to form a drying path. Air supplied from the fan passes through the air inlet and then is in contact with the to-be-dried object, and then blows out through the air outlet, and so on, thereby achieving the drying target. According to the drying device, the artificial participation degree can be reduced, the drying efficiency is improved and equipment is prevented from being damaged.

Owner:SHENZHEN TINNO WIRELESS TECH

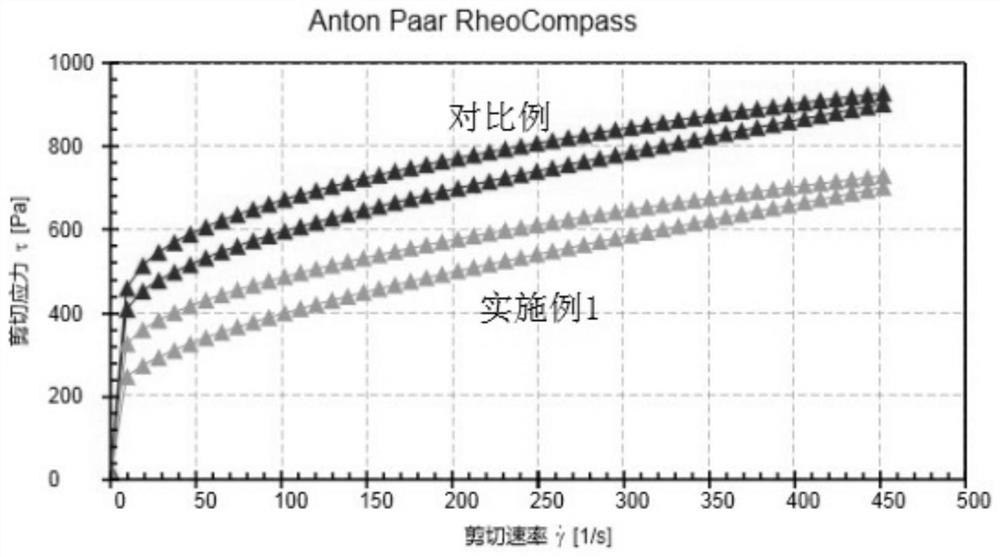

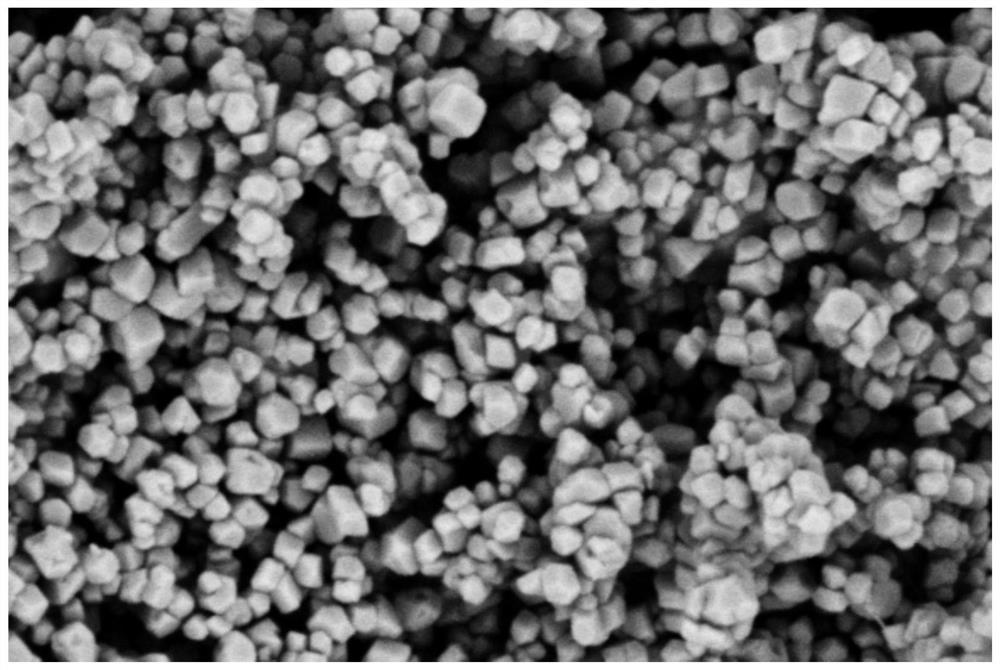

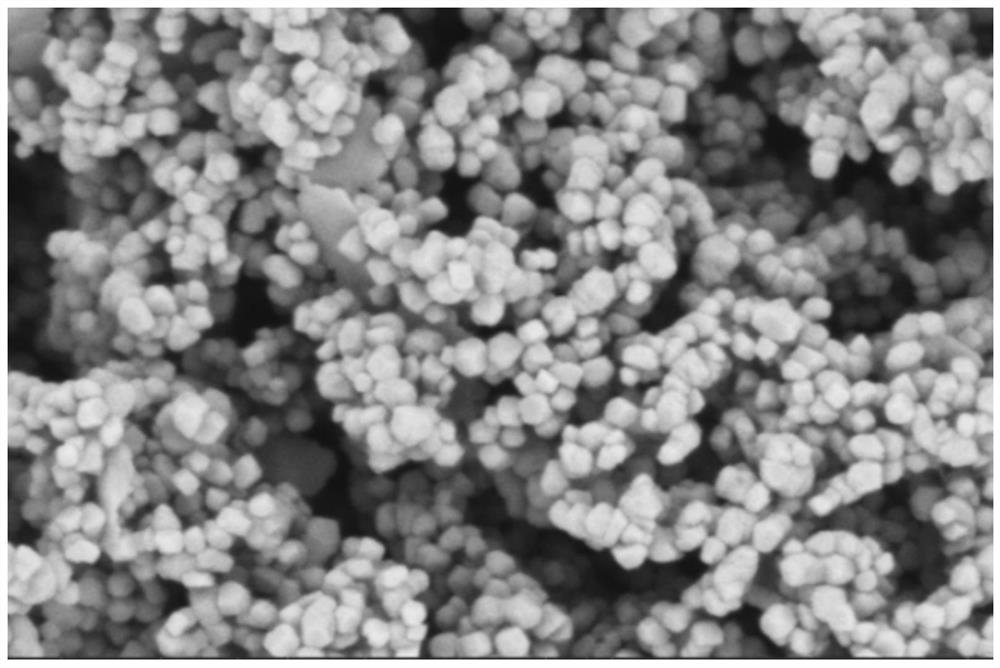

Surface treatment method of nano calcium carbonate for impact-resistant automobile chassis coating

ActiveCN112724708AHigh viscoelasticityImprove rheologyCalcium/strontium/barium carbonatesMaterial nanotechnologySodium stearateCarbonization

The invention discloses a surface treatment method of nano calcium carbonate for an impact-resistant automobile chassis coating, which comprises the following steps of diluting lime milk to obtain slurry, regulating the specific gravity, and carbonating the slurry in a carbonating tower, measuring conductivity through an instrument, adding a crystal form control agent at the lowest point of gelatinization conductivity at the initial stage of carbonization, and stirring to react until the pH value is less than or equal to 7 to obtain calcium carbonate suspension, carrying out oleophylic surface treatment on the calcium carbonate suspension, stirring, and adding a compound treatment agent consisting of a sodium stearate saponification solution and flaxseed gum, polyhexamethylene glycol, sodium dodecyl benzene sulfonate and isopropyl triisostearoyl titanate for surface treatment, and carrying out filter pressing, microwave vacuum drying and sieving to obtain the nano calcium carbonate. The nano calcium carbonate particles prepared through the method are regular in morphology, have the advantages of being good in stability, good in rheological property, high in impact resistance, low in moisture absorption capacity and the like, and can improve the impact resistance and sagging resistance of PVC paste when applied to filling of the automobile chassis coating PVC paste.

Owner:GUANGXI HUANA NEW MATERIALS TECH CO LTD

Environment-friendly drying and crushing integrated device for household garbage

InactiveCN112547197AQuick flipAchieve the purpose of dryingHollow article cleaningDrying machines with non-progressive movementsRotational axisControl switch

The invention relates to the technical field of household garbage treatment equipment, and discloses an environment-friendly drying and crushing integrated device for household garbage. A driving assembly is arranged in a drying box, an installation base is fixedly connected to the bottom of the drying box, a control switch is fixedly connected to the outer side of the installation base, and a crushing assembly is connected to the bottom of the installation base; and a supporting frame is fixedly connected to the bottom of the crushing assembly. The driving assembly can drive stirring rods andsecond rotating shafts to rotate while driving cleaning plates to rotate, garbage attached to the inner wall of the drying box can be removed through the rotating cleaning plates, and rapid stirringof the garbage in the drying box can be accelerated through transverse rotation of the stirring rods. The purpose of conducting drying within a short period of time is achieved conveniently, and the dried garbage can be crushed through the crushing assembly; and meanwhile, the distance between crushing teeth on two rotating rods in the crushing assembly is adjustable, and therefore the corresponding crushing precision can be adjusted according to actual requirements.

Owner:台州禾墨装饰设计有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com