Molecular sieve tunnel type microwave drying device continuously adjustable in power

A microwave drying and molecular sieve technology, used in progressive dryers, heating devices, drying solid materials, etc., can solve the problems of reduced efficiency, shortened life of the magnetron of the microwave source, and increased system energy consumption to achieve heating efficiency. High, prolong the life of the magnetron, the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

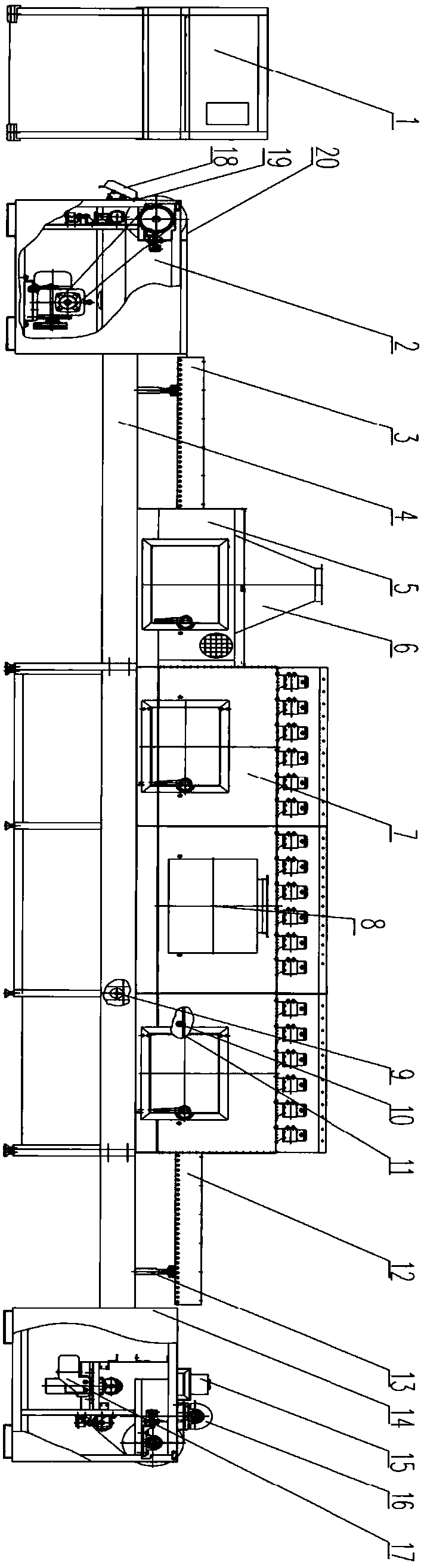

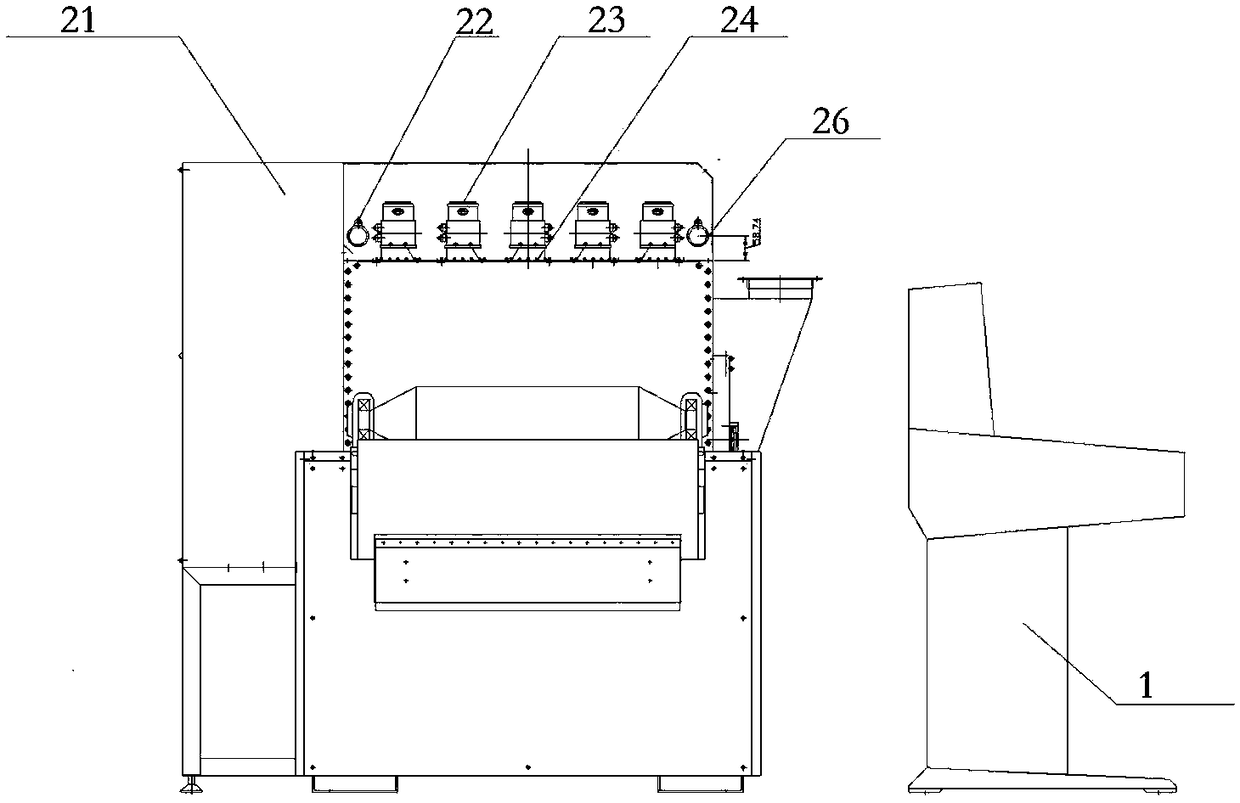

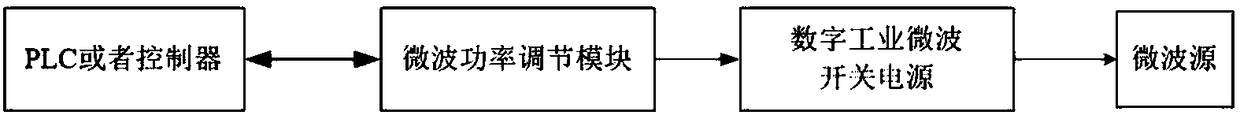

[0032] see figure 1 and figure 2 , This embodiment provides a molecular sieve tunnel microwave drying device with adjustable power. It mainly consists of material conveying system, microwave source and microwave power adjustment device, microwave heating resonant cavity, microwave suppression system, dehumidification and cooling system, temperature measurement system and electric control system, etc. The electric control system is a vertical console 1, and the temperature measurement system It is an infrared thermometer, and its details are as follows:

[0033] In this embodiment, the main body of the material conveying system is the power frame assembly 2, which is mainly divided into a feed end system and a discharge end system. 14. The upper roller 16 of the blanking trough and the photoelectric automatic deviation correction mechanism 17, the discharge end system includes a blanking tray assembly 18 and a blanking scraper 19, wherein the conveyor belt is a glass fiber P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com