Drying structure for dish-washing machine liner

A dishwasher liner and drying technology, which is applied in the direction of tableware washing machine/rinsing machine, tableware washing machine/rinsing and rinsing machine parts, sustainable buildings, etc., can solve the problem of low condensation efficiency, long drying time, unfavorable and other problems, to achieve the effect of remarkable drying effect, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

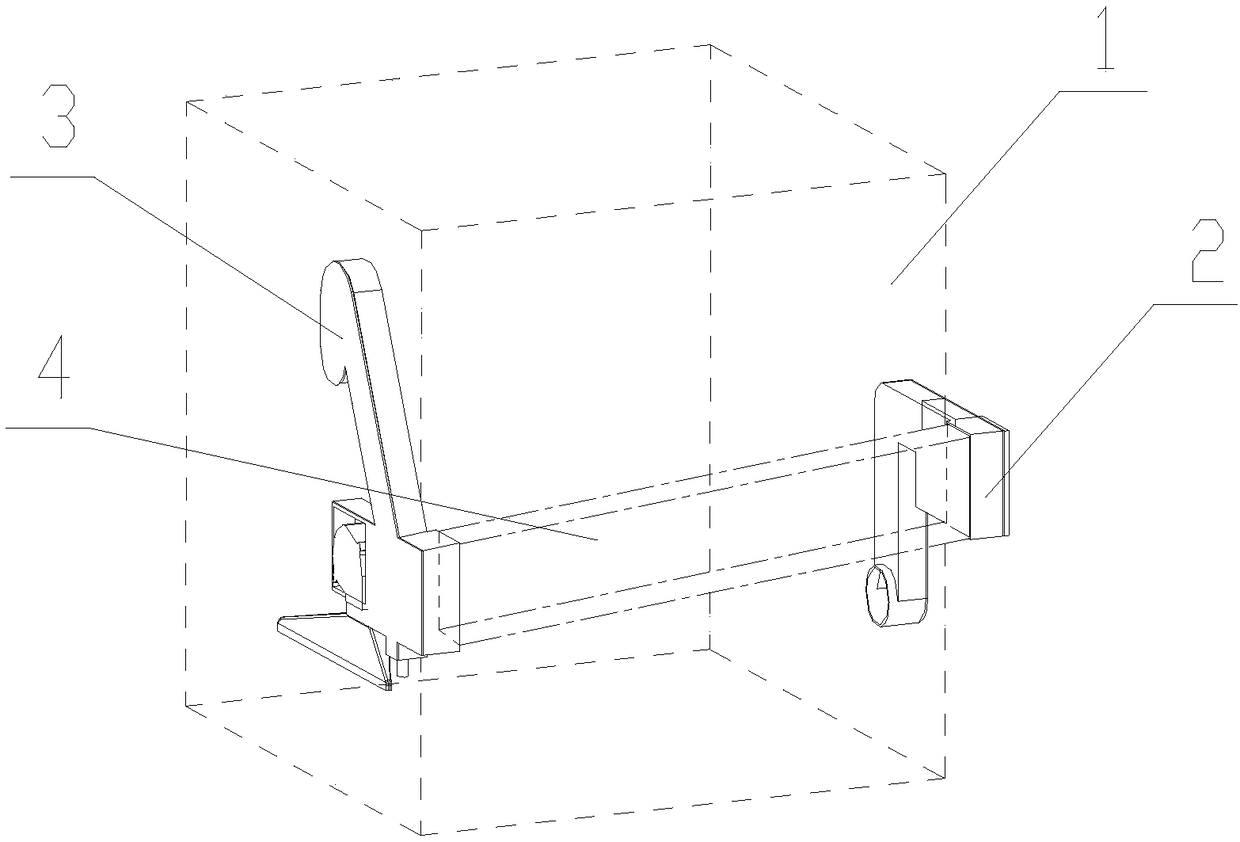

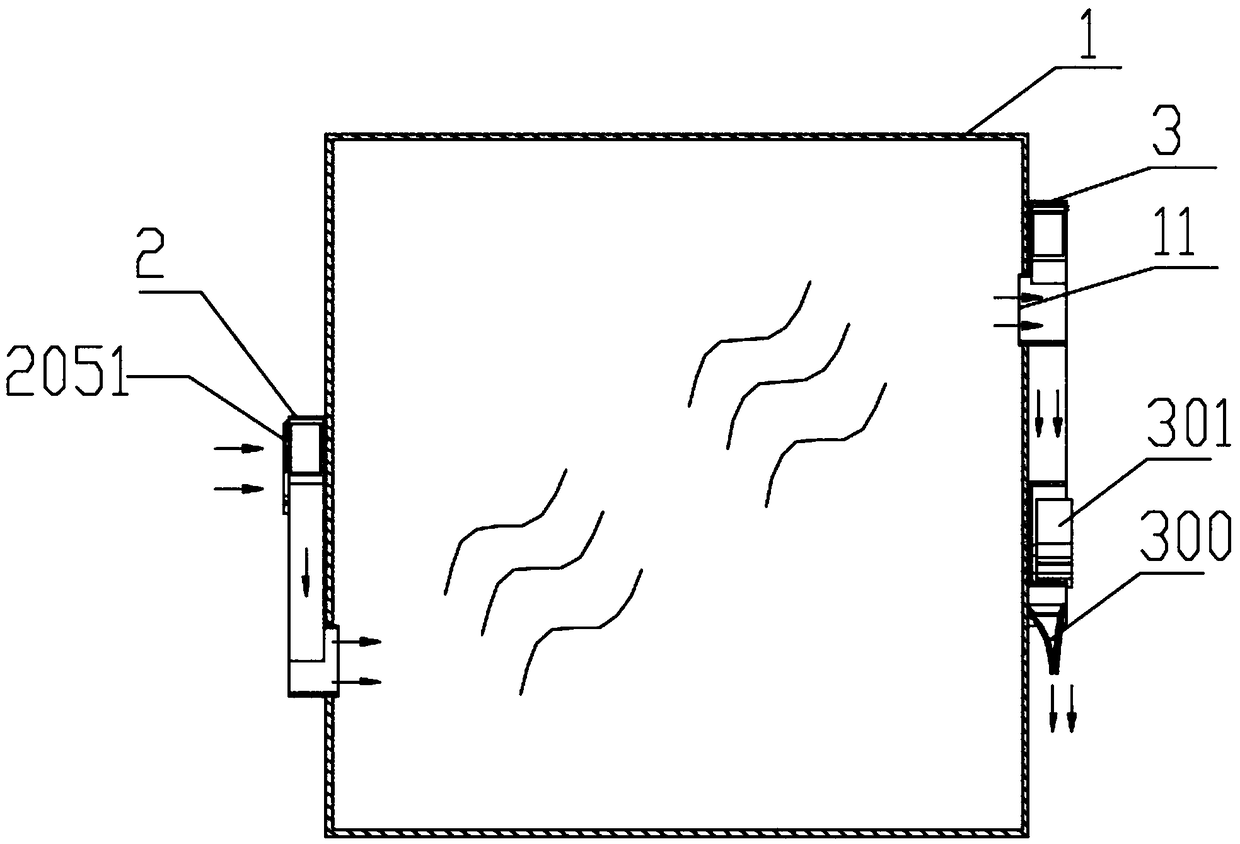

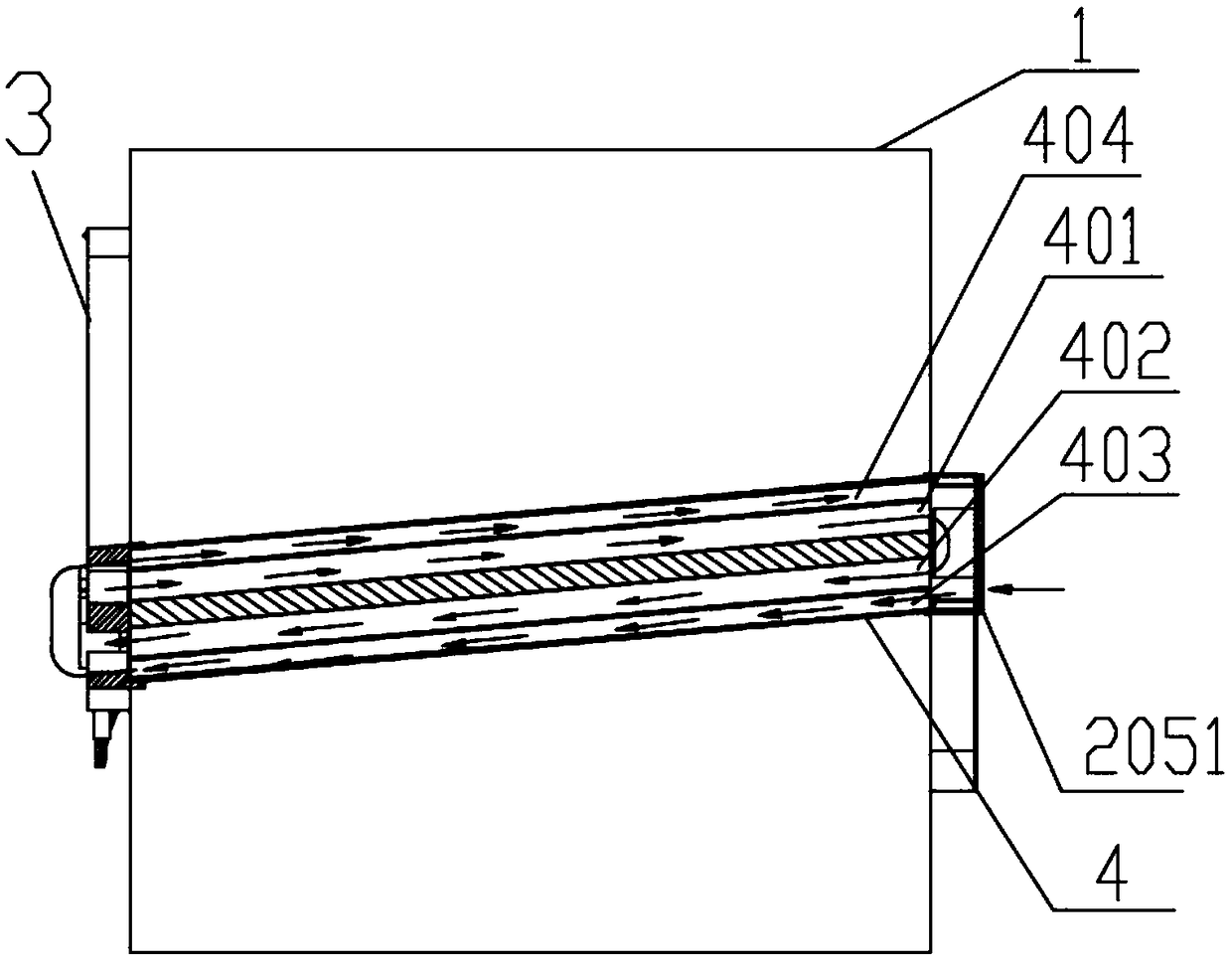

[0025] The specific structure of the present invention is as Figure 1-5 As shown, a drying structure of a dishwasher inner container 1 includes an air outlet assembly 3 and an air intake assembly 2 arranged on the inner container 1. Specifically, the outer wall of the dishwasher inner container 1 is provided with an air outlet assembly 3 The dishwasher liner 1 has an air outlet 11 communicating with the air outlet assembly 3, the other side wall of the dishwasher liner 1 is provided with an air intake assembly 2, and the dishwasher liner 1 has an air inlet 10 connected to the air inlet The lower ends of the gas components 2 communicate. Through the air intake fan 202 arranged on the air intake assembly 2 and the air outlet fan 301 of the air outlet assembly 3, the air intake fan 202 is used to deliver air to the dishwasher liner 1 through the air intake assembly 2, in other words During the drying process, external low-humidity air is forcibly introduced into the inner tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com