Patents

Literature

232results about How to "Good drying effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Efficient drying and quality-improving device and method for brown coal

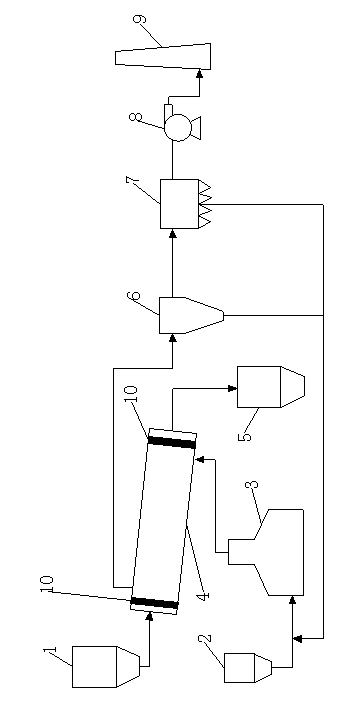

The invention relates to an efficient drying and quality-improving device and method for brown coal. In the prior art, no efficient drying and quality-improving device or method for brown coal, which is used for improving the utilization value of the brown coal, exists. The efficient drying and quality-improving device is characterized by comprising a coal storage bin, a fuel bin, a hot blast stove, a cylinder-type dryer, a product bin, a cyclone dust collector, an electrical dust collector and a plurality of pipelines, wherein both the product bin and the coal storage bin are connected with the cylinder-type dryer; the cylinder-type dryer is connected with the cyclone dust collector; and the cyclone dust collector, the electrical dust collector, the fuel bin are all connected with the hot blast stove. The method is characterized in that the raw material of the brown coal is conveyed into the cylinder-type dryer from the coal storage bin; the hot blast stove generates high-temperature flue gas at the temperature of 700-900 DEG C, and the flue gas is conveyed into the cylinder-type dryer; the raw material of the brown coal is dried by the high-temperature flue gas and conveyed into the product bin from the cylinder-type dryer for sealing and cooling, so that the finished product of the brown coal is obtained after cooling. According to the device and the method, the moisture in the brown coal can be reduced substantially, and a part of ash content in the brown coal can also be reduced, so that the utilization value of the brown coal can be improved.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Plastic particle drying machine

InactiveCN104044226AGood drying effectImprove heat utilizationDrying machines with non-progressive movementsHeating arrangementEngineeringExhaust pipe

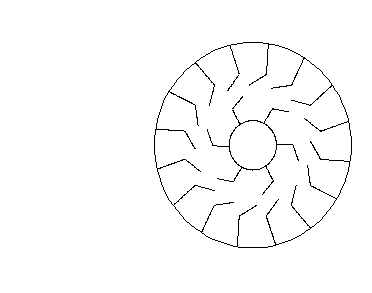

The invention discloses a plastic particle drying machine. The plastic particle drying machine comprises a stand, wherein a cylindrical material barrel is axially and rotationally mounted on the stand; a charging port is formed in one end of the material barrel; a feeding device is mounted at the charging port; a lamp box which extends into the material barrel from the charging port and can emit light to heat a material is mounted on the stand; a fan is further arranged on the stand; an air exhaust pipe which is communicated with the material barrel to exhaust air in the material barrel is connected to the fan; a limiting device which is used for limiting the axial position of the material barrel is arranged at each of two ends of the material barrel; a discharging port is formed in the barrel wall of the material barrel; a cover plate is mounted at the discharging port and is driven to close or open the discharging port by a cover plate driving device. The plastic particle drying machine can be used for drying plastic particles, and is good in complete drying effect, high in heat energy utilization rate, and stable and reliable to work.

Owner:ZHANGJIAGANG LIANDA MACHINERY

Preparation method of phosphogypsum-based sludge drying agent and application of preparation method in drying sludge

ActiveCN104045298ANo secondary pollutionIncrease profitSludge treatment by de-watering/drying/thickeningCement productionSlagPhosphogypsum

The invention relates to a preparation method of a phosphogypsum-based sludge drying agent, comprising the following steps: using phosphogypsum as a basic raw material, adding blast furnace slag, steel slag and a clinker, stirring for 30-45 min to uniformly mix the above materials, and adding a chemical exciting agent to prepare a cementing material which is the phosphogypsum-based sludge drying agent. The phosphogypsum-based sludge drying agent is poured into dewatered sludge, and stirring is carried out for 3-10 min to prepare a mixture. the mixture is placed in a sealed container and is maintained at the temperature of 20 DEG C+ / -1 DEG C and at humidity of being greater than or equal to 95% for 3-14 days, and moisture in the sludge is removed so as to further dry the sludge. The phosphogypsum-based sludge drying agent has advantages of large reduction extent of water content, short drying time and obvious drying effect; raw materials are mainly wastes; cost is low; energy consumption is low; there is no secondary pollution to the environment; and problems such as high water content of municipal sludge, high drying cost and the like can be solved.

Owner:武汉湖振煜环境科技有限公司

Coal ash drying device

InactiveCN101377379AGood drying effectReasonable structureDrying gas arrangementsDrying machines with non-progressive movementsInlet temperatureFlue gas

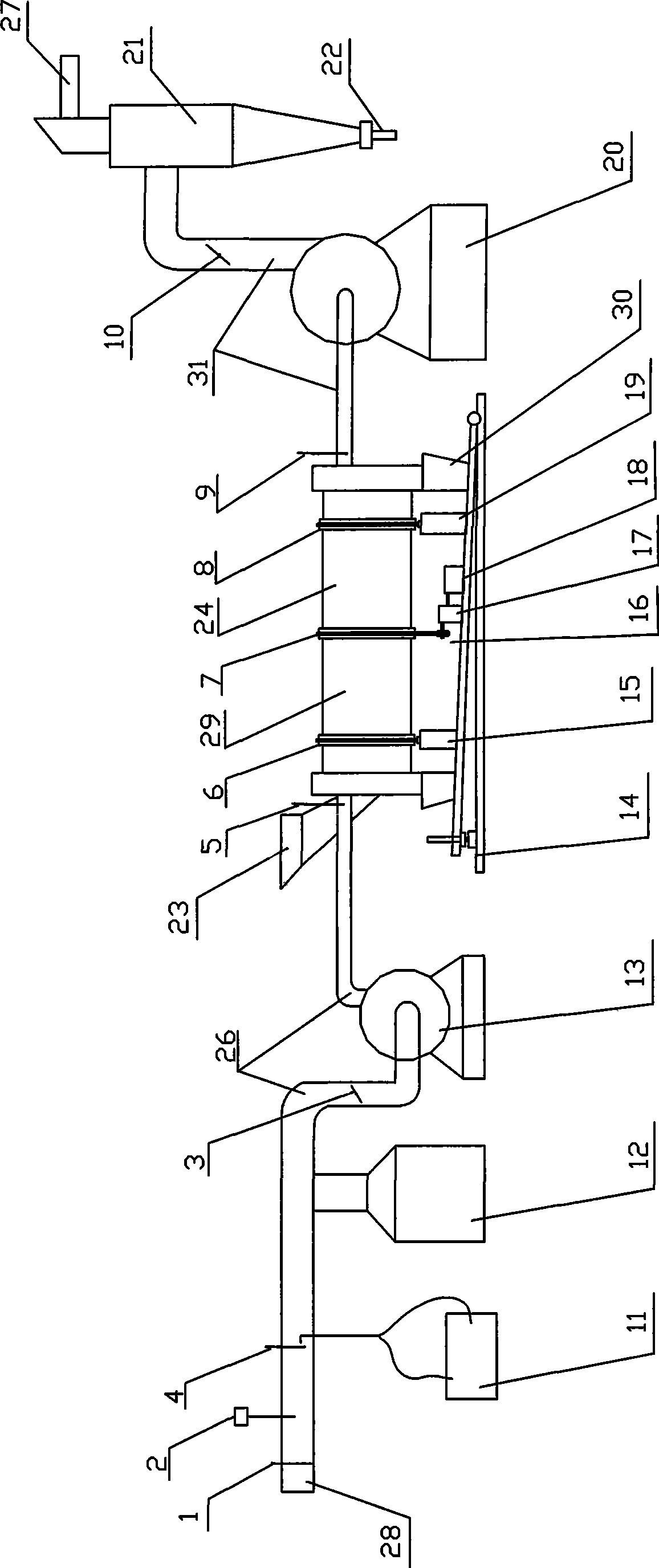

The invention provides a fly ash drying device, which is characterized by comprising a revolving barrel type dryer communicated with a heat supply pipe, wherein, the hot flue gas inlet of the heat supply pipe is provided with an air shutter; the heat supply pipe is provided with a fan; the heat supply pipe of the air inlet of the fan is provided with a butterfly bamper; the feed pipe connected with the revolving barrel type dryer is provided with a draft fan; a cyclone separating device is arranged at the end of the feed pipe; the butterfly bamper is arranged at the feed pipe between the draft fan and the cyclone separating device; the heat supply pipe is connected with an auxiliary heating furnace; the hot flue gas inlet of the heat supply pipe is provided with a hot flue gas inlet temperature sensor and a smoke volume measurement device; the heat supply pipe is provided with a smoke volume sensor; a revolving barrel type dryer inlet temperature sensor is arranged at a hot flue gas inlet of a revolving barrel type dryer of the heat supply pipe, while the outlet of the revolving barrel type dryer of the feed pipe is provided with a revolving barrel type dryer outlet temperature sensor. The device of the invention has the advantages of reasonable structure, good drying effect, and energy-saving.

Owner:NORTHEAST DIANLI UNIVERSITY

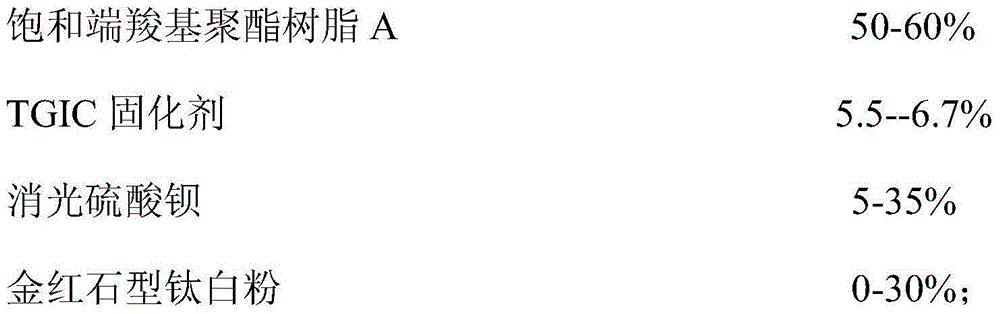

Three-dimensional simulative wood grain powder coating for aluminum profile and preparation method for three-dimensional simulative wood grain powder coating for aluminum profile

ActiveCN105038526AGood weather resistanceGood drying effectPowdery paintsPolyester coatingsWeather resistanceSpray method

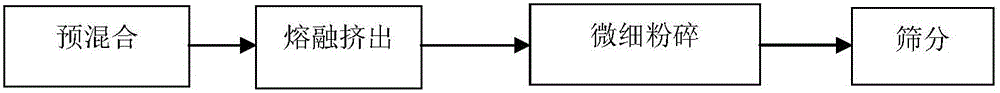

The invention discloses a three-dimensional simulative wood grain powder coating for an aluminum profile and a preparation method for the three-dimensional simulative wood grain powder coating for the aluminum profile as well as a spraying method of the powder coating. The powder coating is composed of type A body powder and type B surface powder. The powder coating comprises saturated end carboxyl polyester resin, a TGIC curing agent, an HAA curing agent, acrylic resin and the like. The preparation method for the powder coating comprises: firstly pre-mixing the raw materials of the body powder and the surface powder, respectively; and carrying out melt extrusion, tabletting and cooling, crushing, fine crushing and sieving on the mixed raw materials to prepare the powder coating. A construction technology of the powder coating comprises: firstly spraying the body powder; after simply curing body powder, then spraying the surface powder to form a pattern; and finally curing and forming the powder coating. According to the coating film, not only is a decorative pattern effect on the surface ensured, but also the weather resistance of the coating is greatly improved compared with that of a common heat transfer printing coating, so that the cost performance of the aluminum profile is greatly increased.

Owner:广东华江粉末科技有限公司

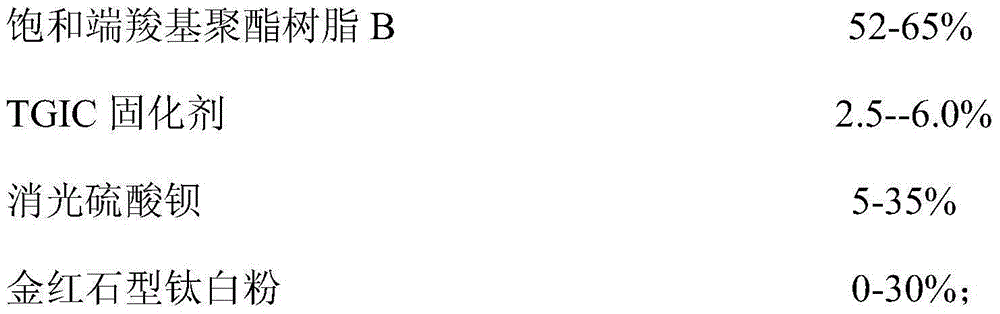

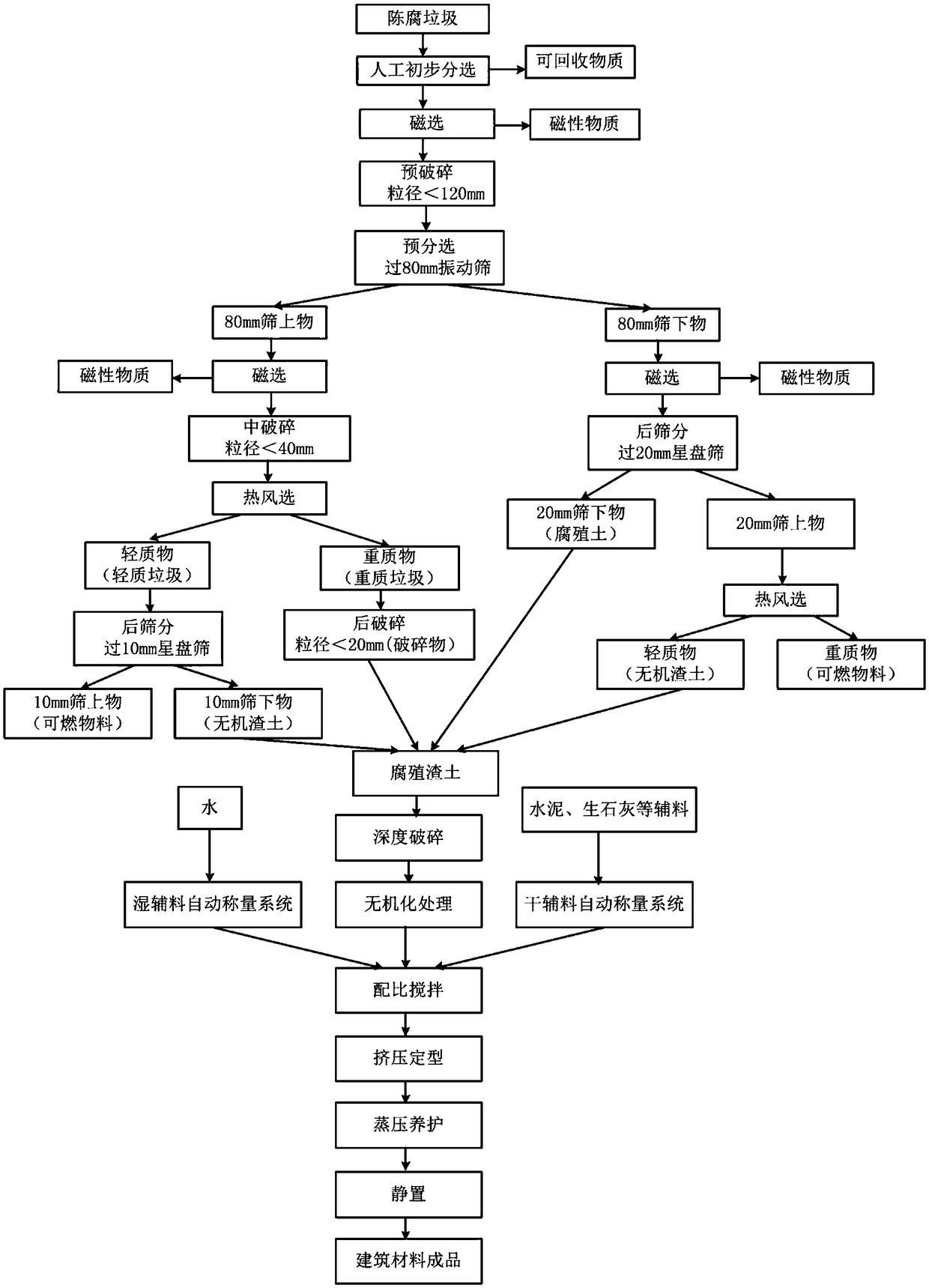

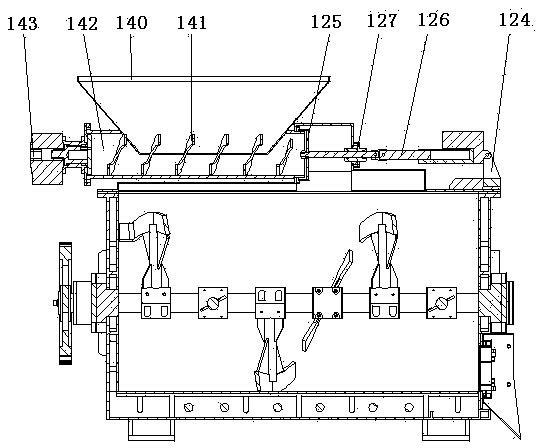

Method and system for manufacturing building materials by using stale garbage

ActiveCN108746152AEfficient separationAccurate sortingSolid waste disposalEnvironmental resistanceSocial benefits

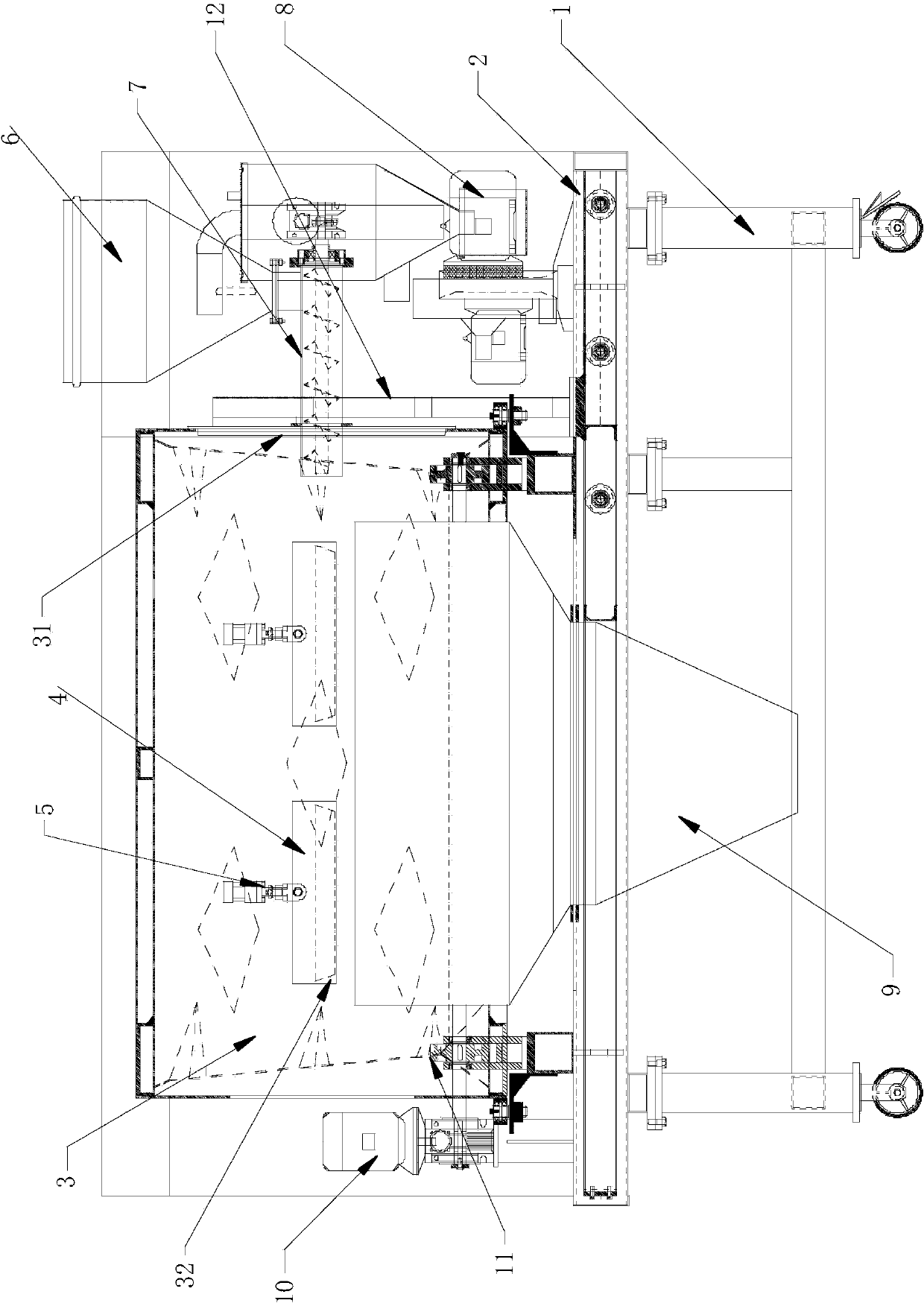

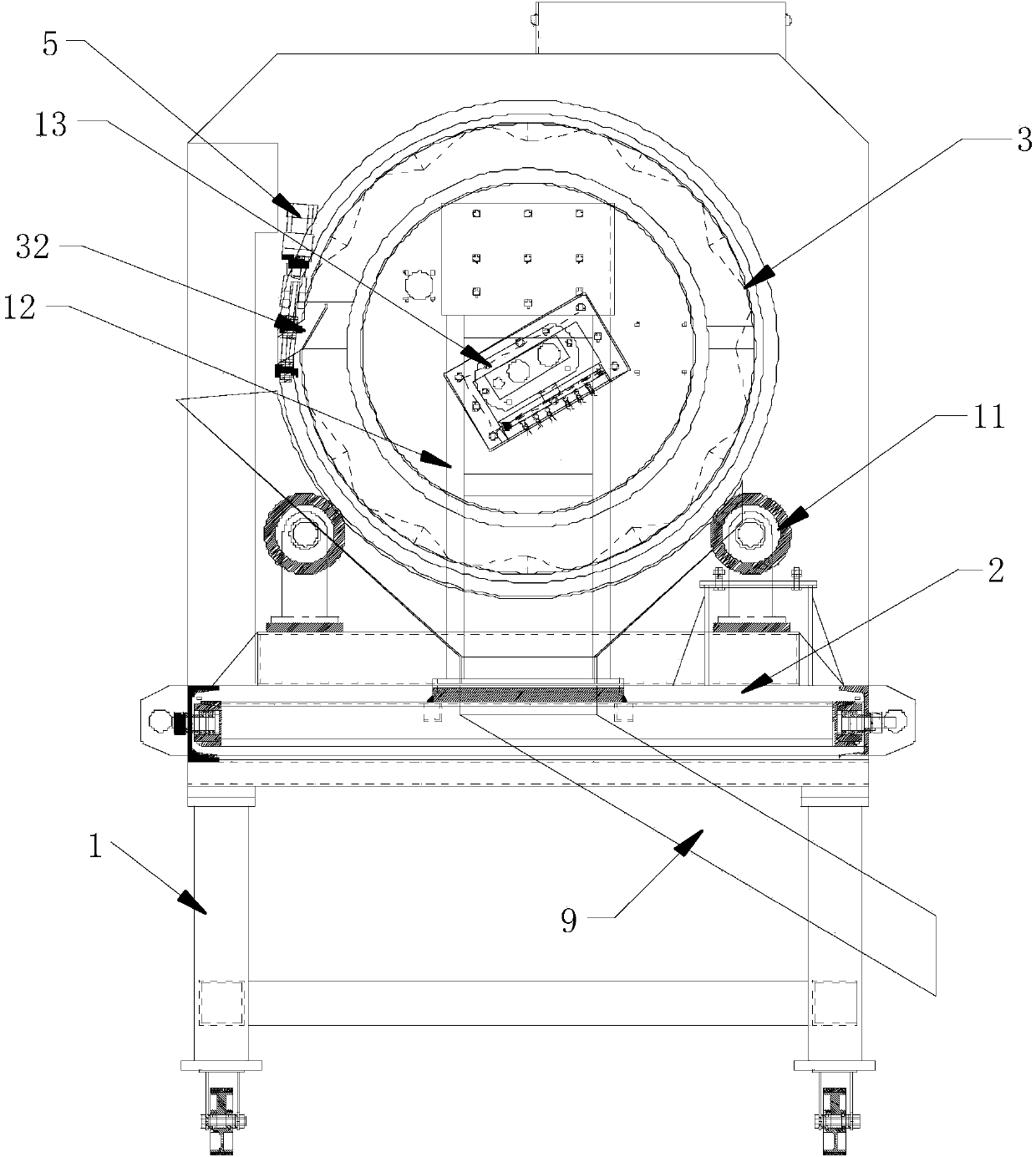

The invention discloses a method and a system for manufacturing building materials by using stale garbage. According to the method, the building material is prepared by taking humic muck screened outfrom the stale garbage as a raw material, and compared with sorting of different components of the stale garbage in the prior art, the method has the advantage that the accuracy is higher so that theresidual value of available resources in the garbage can be fully played; according to the system, manual sorting, magnetic separation, hot air separation, screening and crushing devices are combined, the process is well-organized, high-efficiency separation of magnetic substances, combustibles, the humic muck, large plastic blocks, large rubber blocks and other recyclable objects in the stale garbage can be achieved, so that accurate sorting and highly recovery of recyclable resources in the stale garbage can be realized; and meanwhile, due to the fact that the content of the humic muck in the stale garbage is extremely high, the muck is regenerated into the building material, a large amount of soil taking land can be saved every year, and the extremely good environmental protection benefit and social benefit are achieved.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

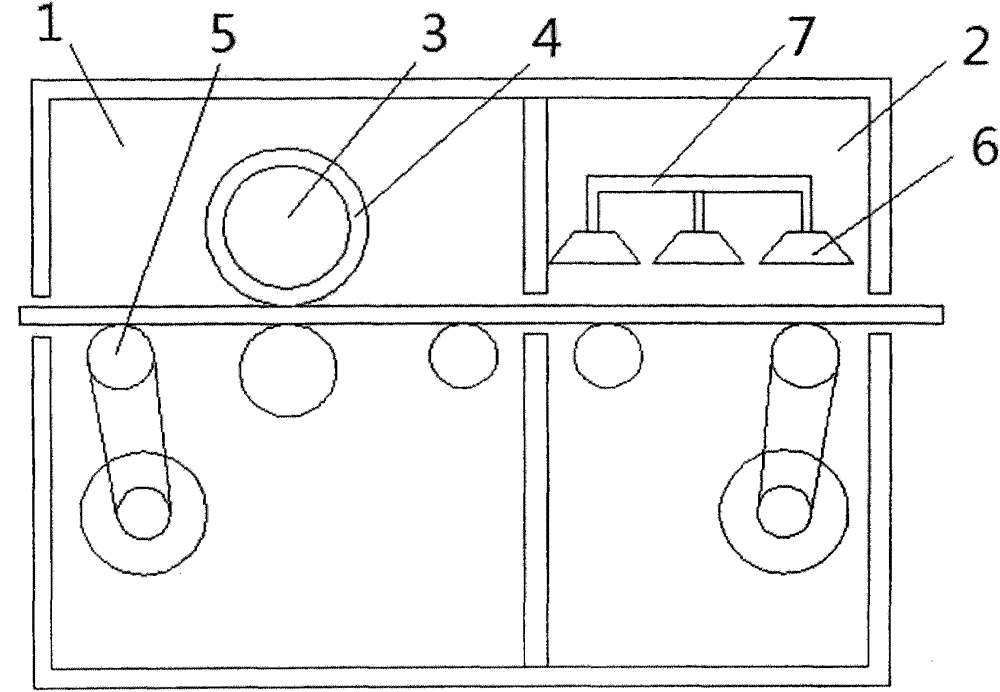

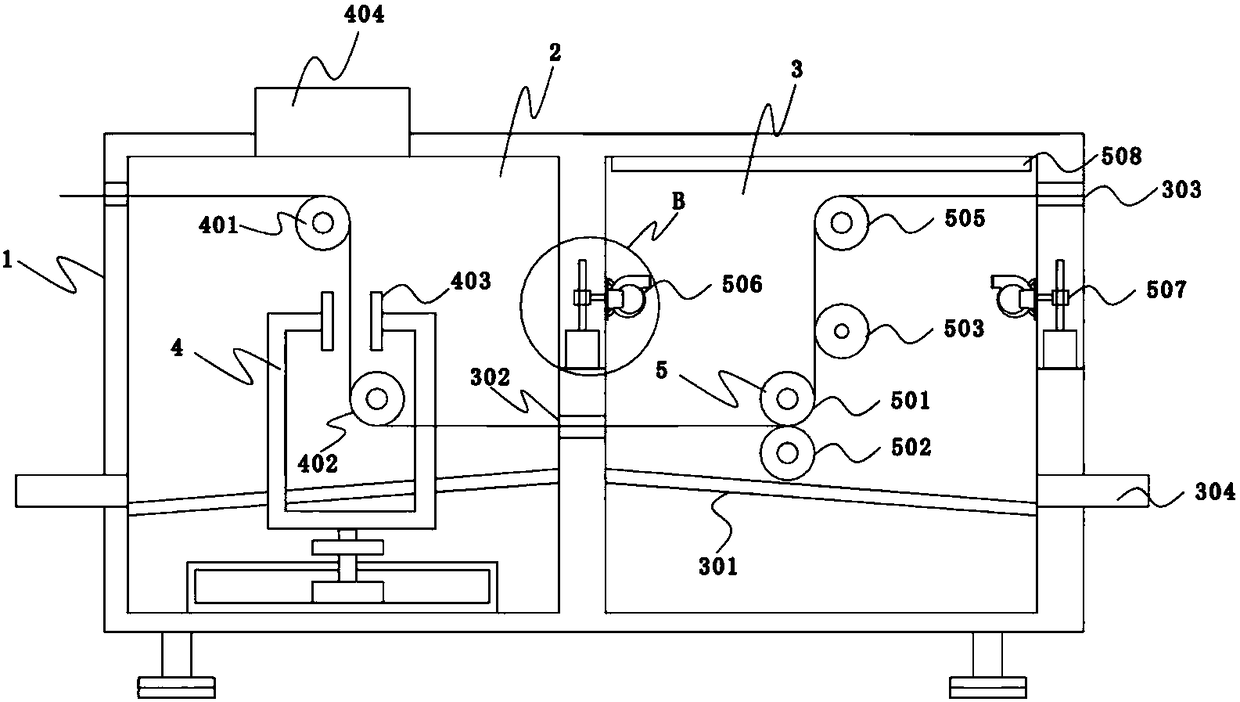

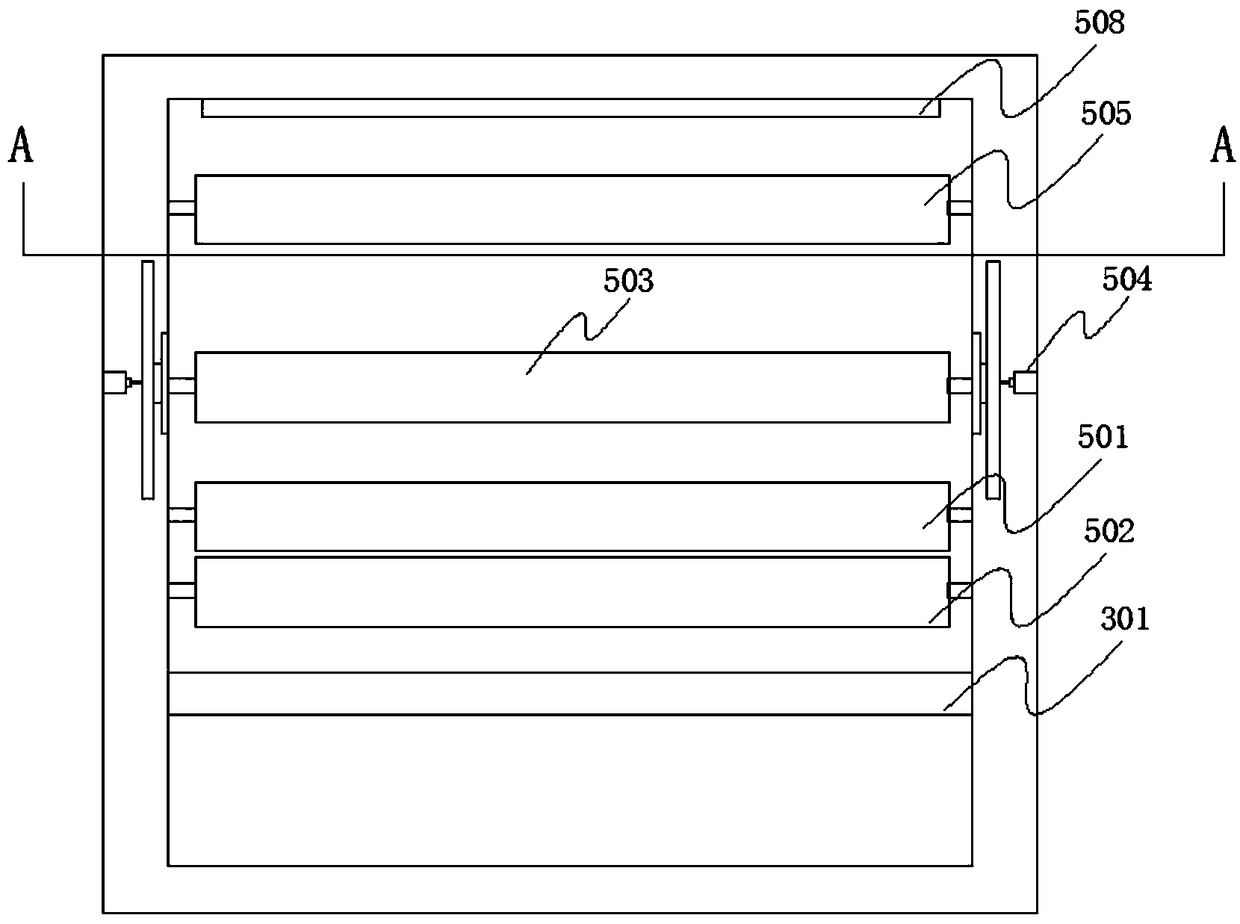

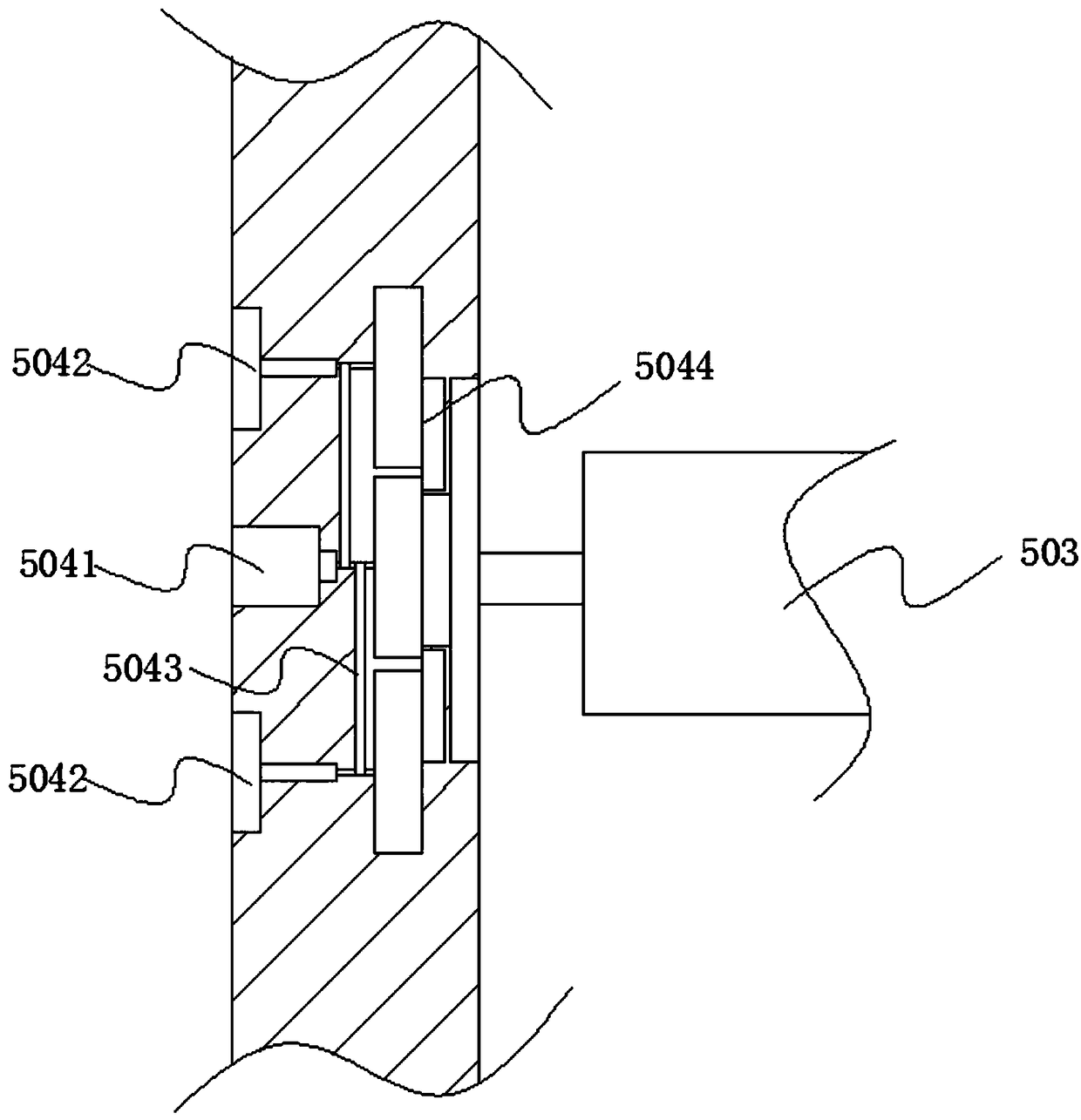

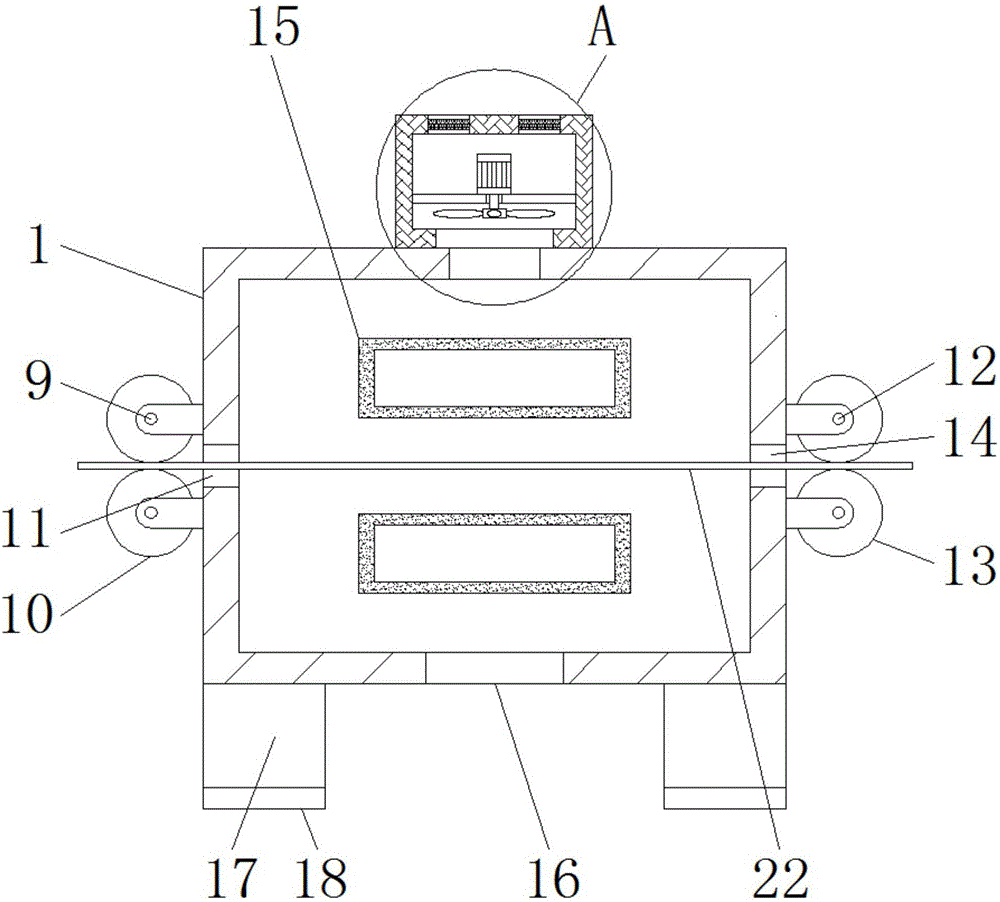

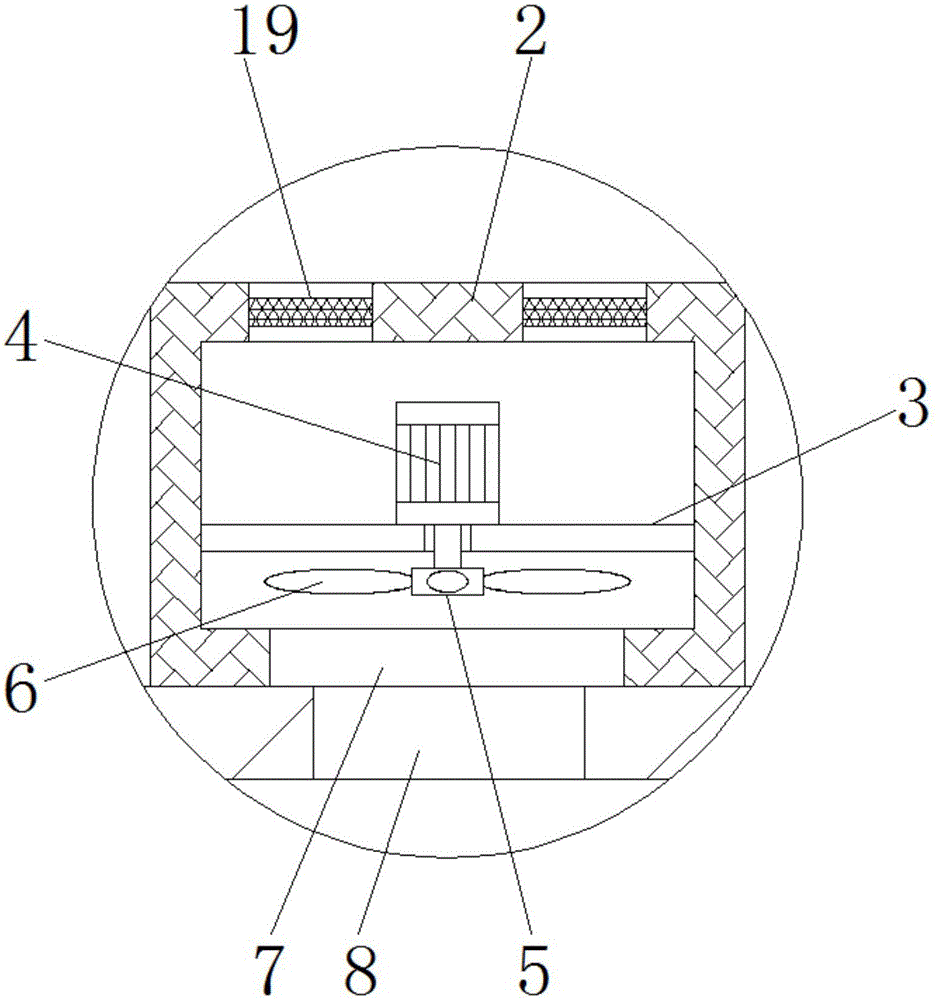

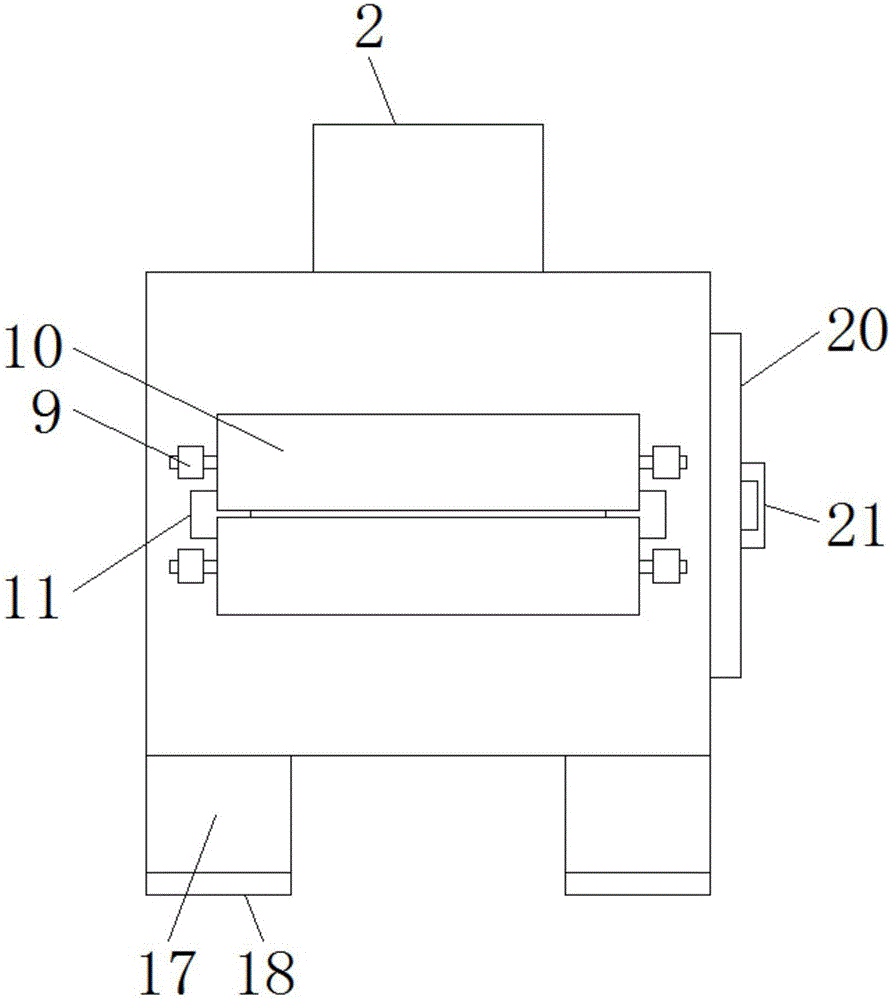

Corrugated paper printing and drying equipment

InactiveCN104890361ASimple structureGood drying effectPrinting press partsEngineeringPulp and paper industry

The invention discloses corrugated paper printing and drying equipment. The corrugated paper printing and drying equipment comprises a printing chamber and a drying chamber, wherein a printing roller and a printing plate arranged on the surface of the roller are arranged in the printing chamber; multiple drying lamp sets are arranged in the drying chamber; the drying lamp sets are connected through brackets, and comprise lamp housings; multiple drying lamps are uniformly arranged in the lamp housings; and conveying devices are respectively arranged in the printing chamber and the drying chamber. The corrugated paper printing and drying equipment is simple in structure, excellent in drying effect and convenient to be used and maintained.

Owner:GUIZHOU AXILIXI E COMMERCE

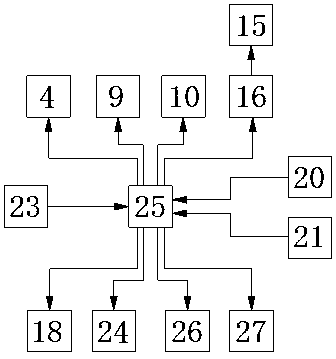

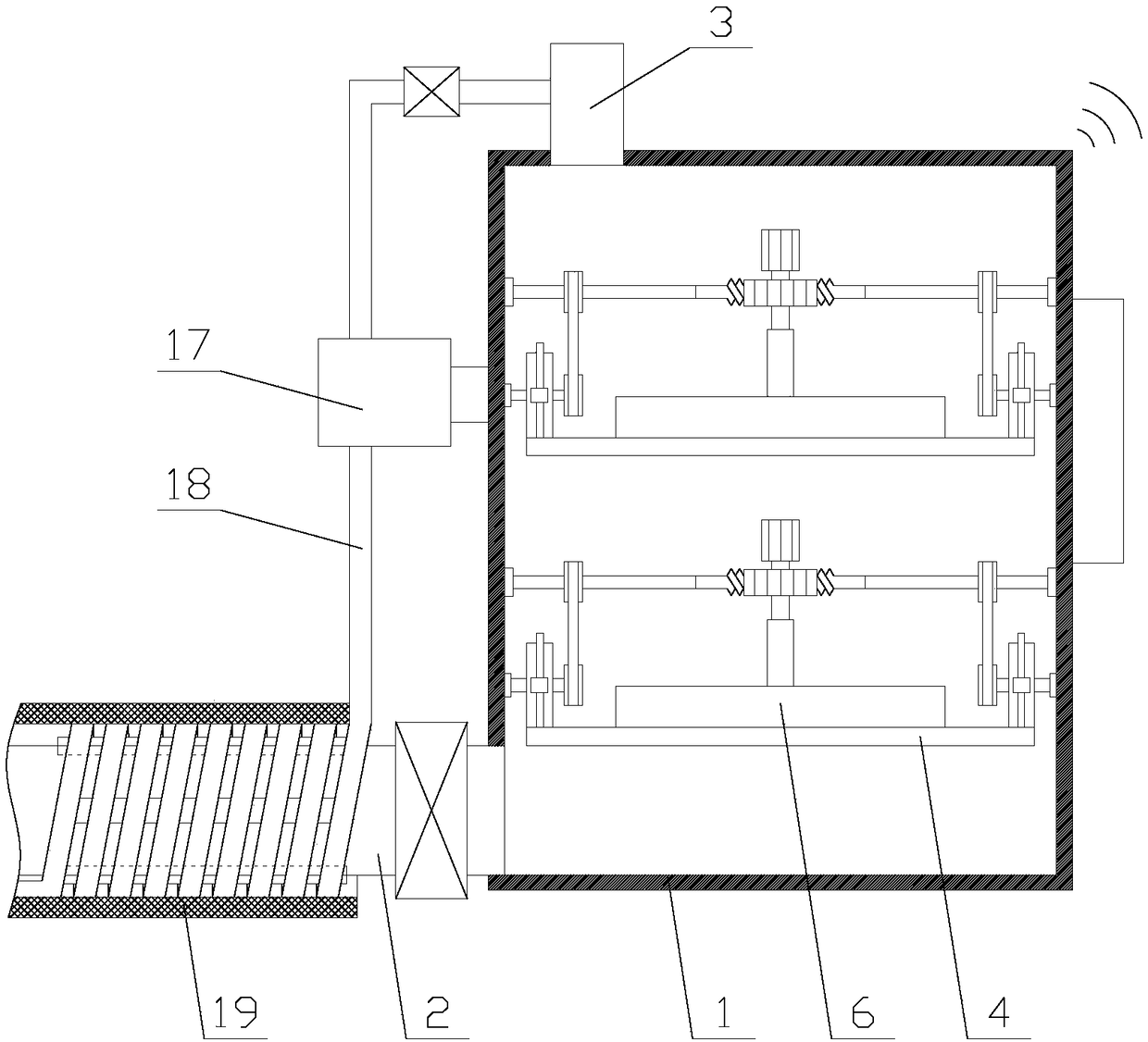

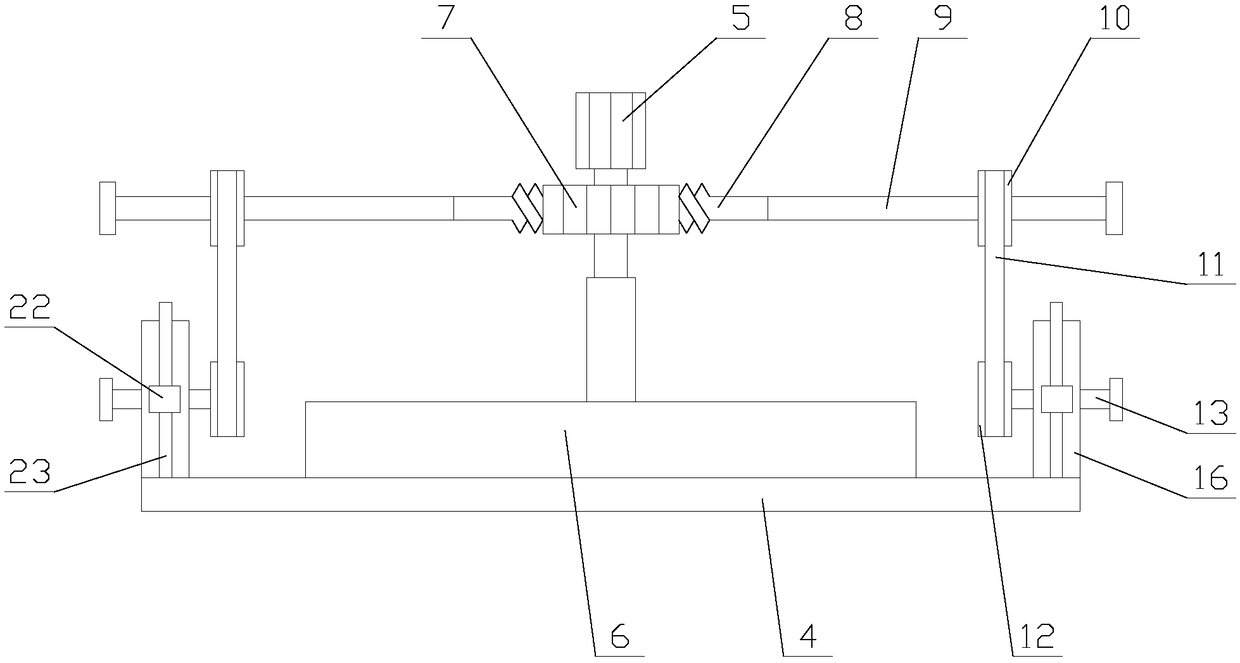

Tea drying device with reciprocating material turnover

InactiveCN107836536AGood drying effectGuaranteed cleanlinessPre-extraction tea treatmentDrying gas arrangementsAgricultural engineeringMoisture

The invention discloses a tea drying device with reciprocating material turnover. The device comprises a drying box; the drying box is fixedly arranged on the ground through supporting frames; the front side wall of the drying box is provided with an opening; the opening is hinged with a box door; the inner bottom of the drying box is rotationally connected to two pairs of roller wheels which arebilaterally and symmetrically arranged through supports; the roller wheels rotationally support a turnover box; the turnover box is arranged in the drying box; the side wall of the turnover box is provided with ventilating nets; a third rotating shaft which is rotationally connected to the left and right walls of the drying box is arranged in the drying box; a plurality of turnover plates are fixed arranged on the third rotating shaft in a connected mode. In the drying process, the turnover box rotates positively and negatively so as to drive tea leaves in the turnover box to roll, and the tealeaves are heated more thoroughly and uniformly, and drying effect and drying speed are improved. Meanwhile, the turnover plates rotate to turn over the tea leaves in the turnover box and to dispersethe tea leaves, so that hot air can conveniently flow between the tea leaves, and the tea is heated more uniformly, and simultaneously the discharge of moisture is facilitated.

Owner:雷晓琴

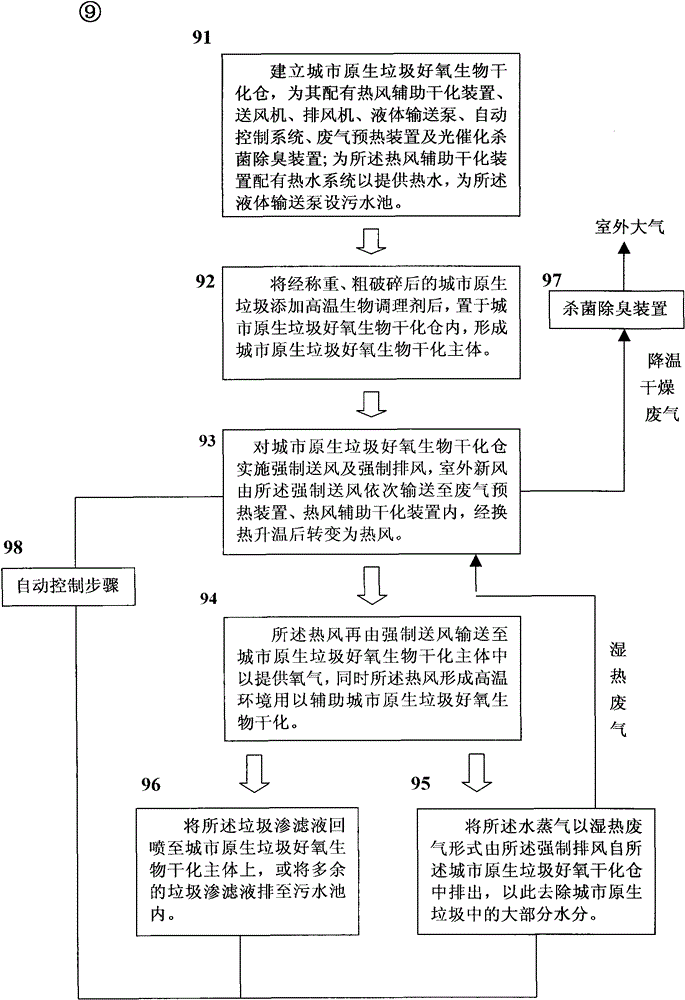

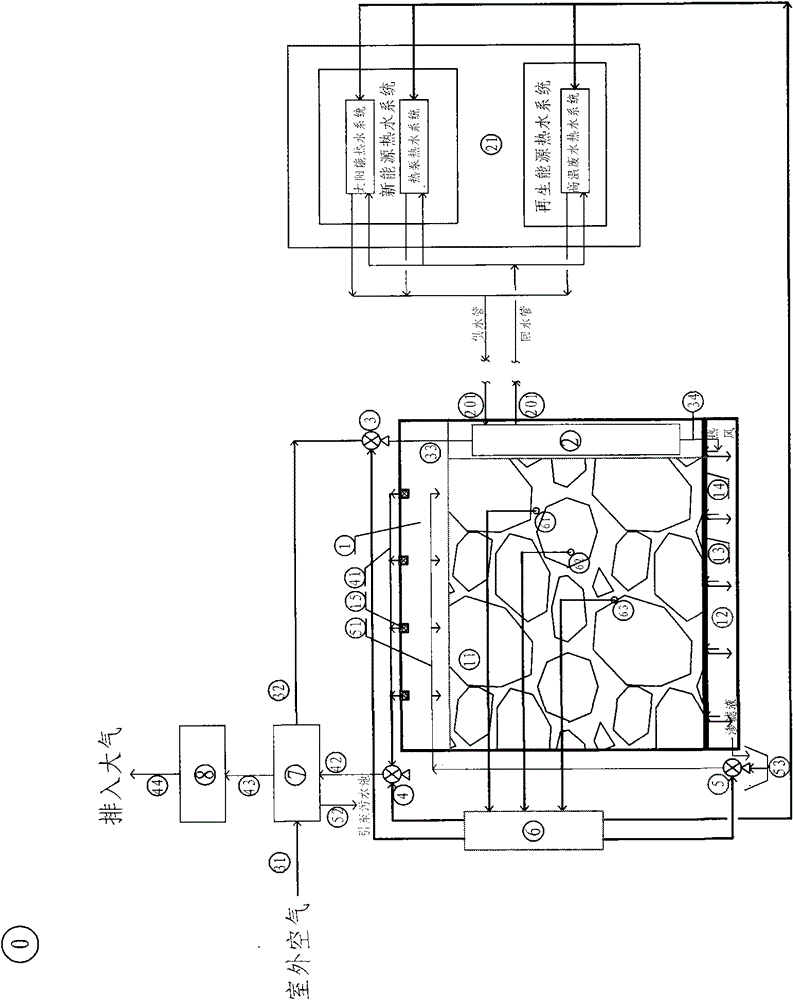

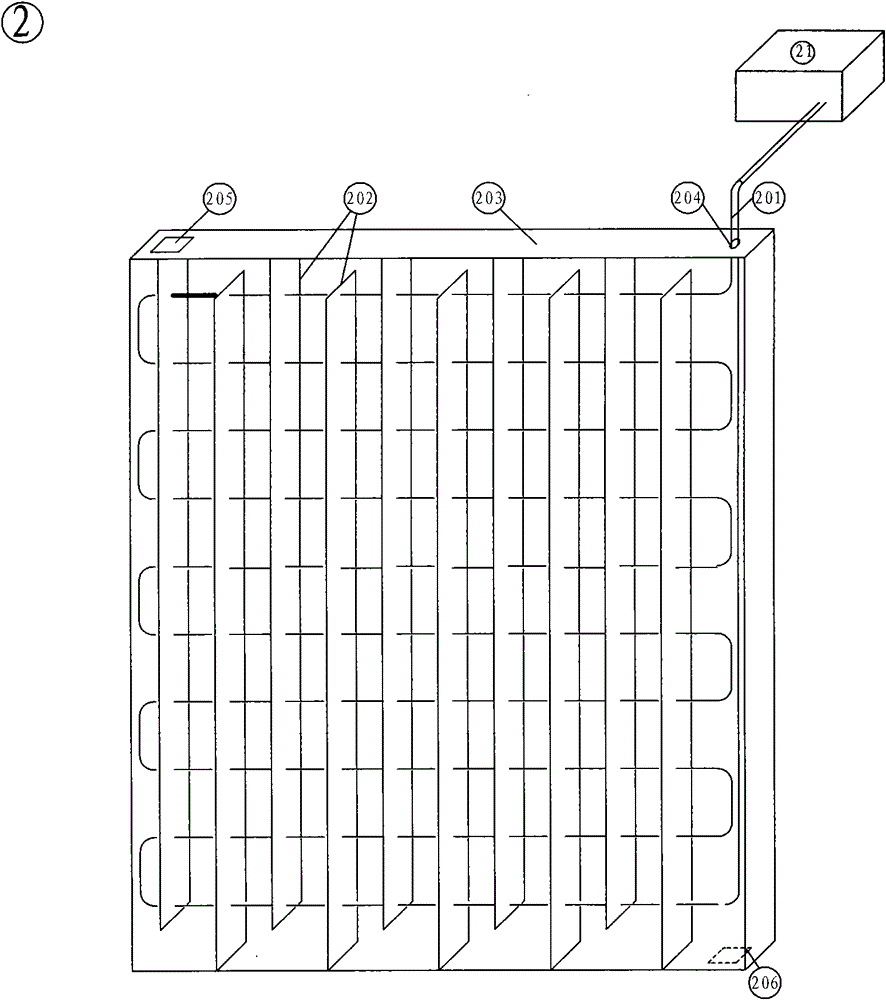

Method and system for drying aerobic organisms in urban raw garbage by aid of hot air

InactiveCN102716894AHigh degree of decompositionLarge amount of water evaporationSolid waste disposalAutomatic controlDecomposition

The invention provides a method and a system for drying aerobic organisms in urban raw garbage by the aid of hot air. Organic matters in the urban raw garbage are decomposed into moisture and other inorganic matters by the aerobic microorganisms in the urban raw garbage with high-temperature biological conditioners by the aid of oxygen provided by the hot air and a formed high-temperature environment, heat is released, most of the moisture is heated and evaporated into steam by the high-temperature environment and the heat, the steam is exhausted in a wet and hot waste gas form, garbage leachate is formed by an additional part of the moisture and drained, and the purpose of drying the aerobic organisms in the urban raw garbage is achieved. The system comprises an urban raw garbage aerobic organism drying bin, a hot-air auxiliary drying device, an air feeder, an exhaust fan, a liquid delivery pump and the like. The method and the system further can be optimized by means of automatic control, waste gas preheating, photocatalytic sterilization and deodorization and the like. The method and the system for drying the aerobic organisms by the aid of the hot air have the advantages that the decomposition degree of the organic matters in the urban raw garbage and moisture evaporation capacity are high, a drying process is short, a drying effect is obvious, and the garbage is treated in a harmless, reducing and stable manner.

Owner:SKYLINE DALIAN ENVIRONMENTAL HIGH TECH +1

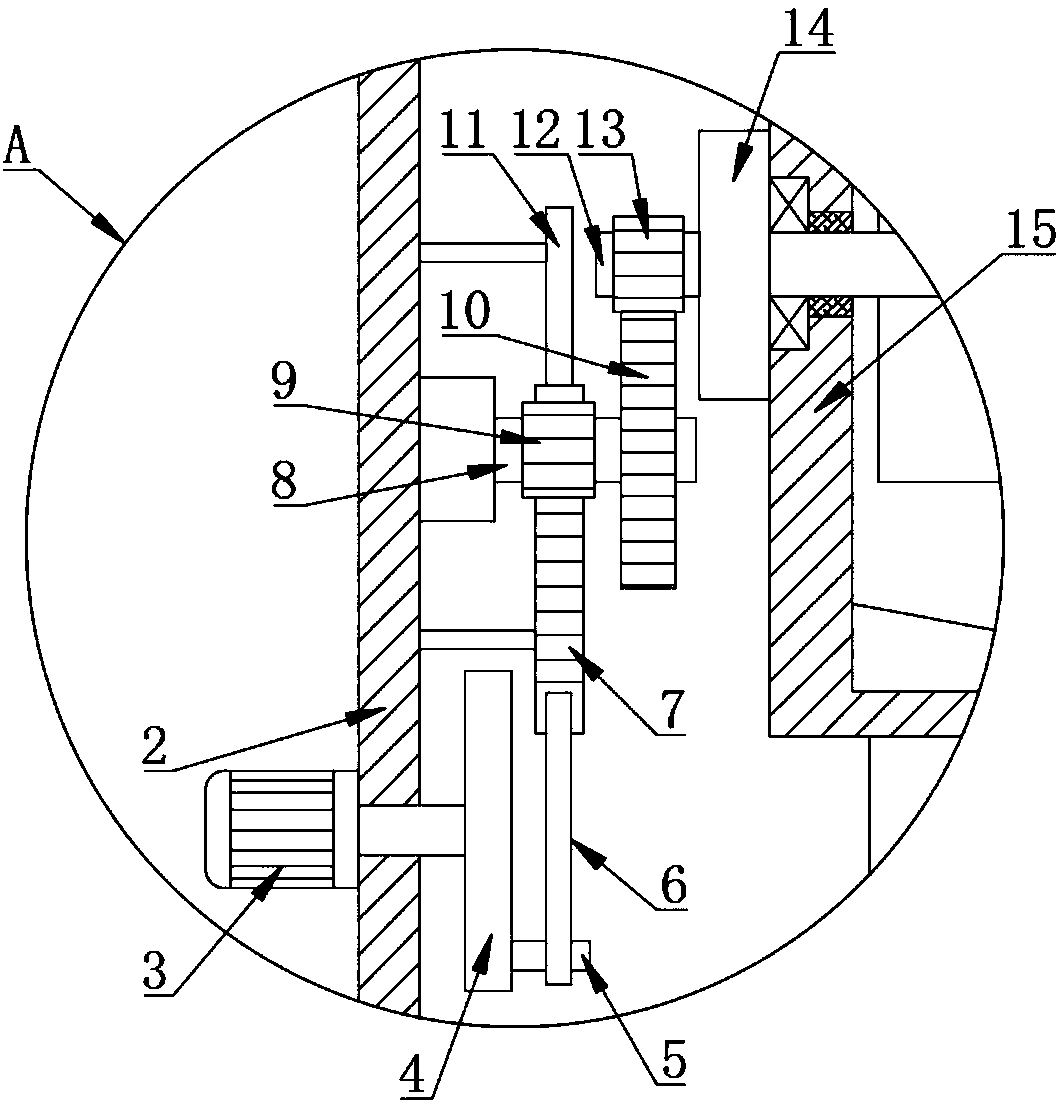

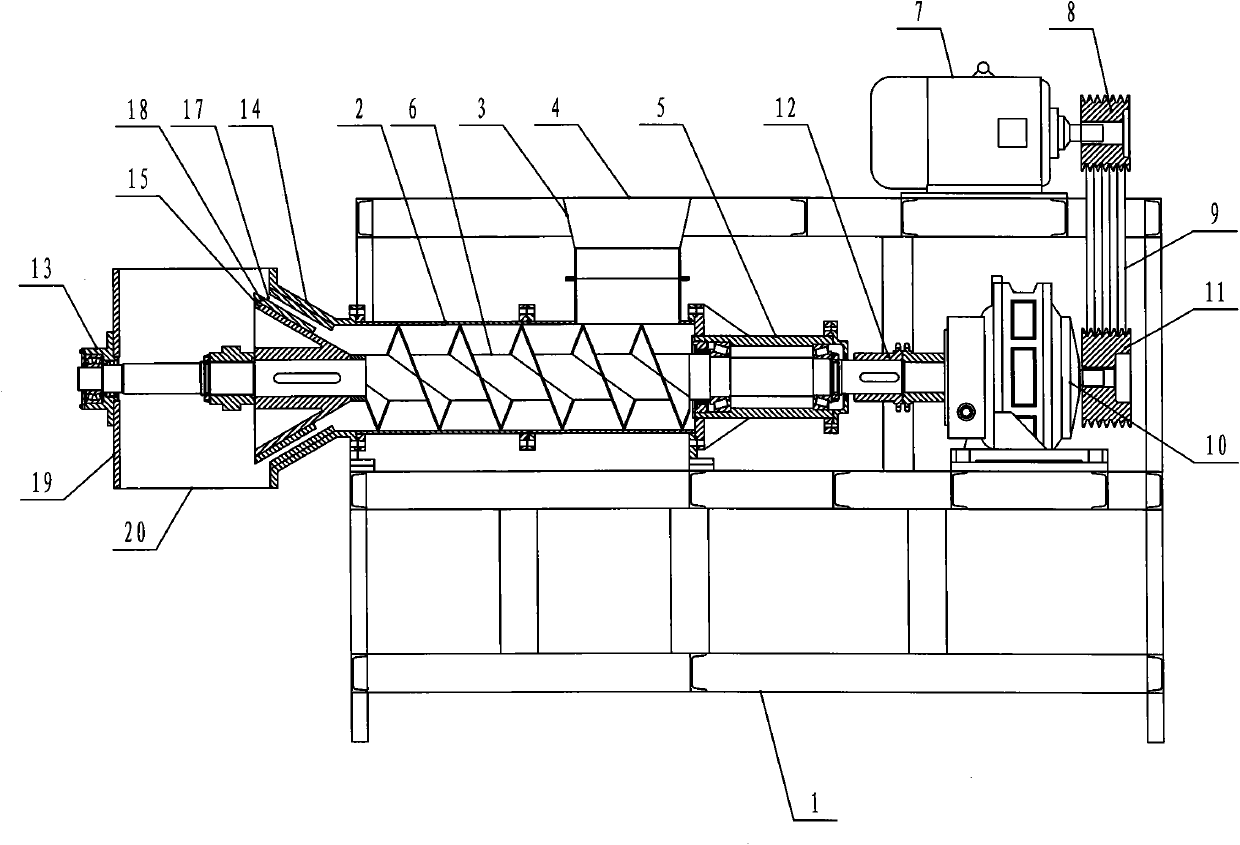

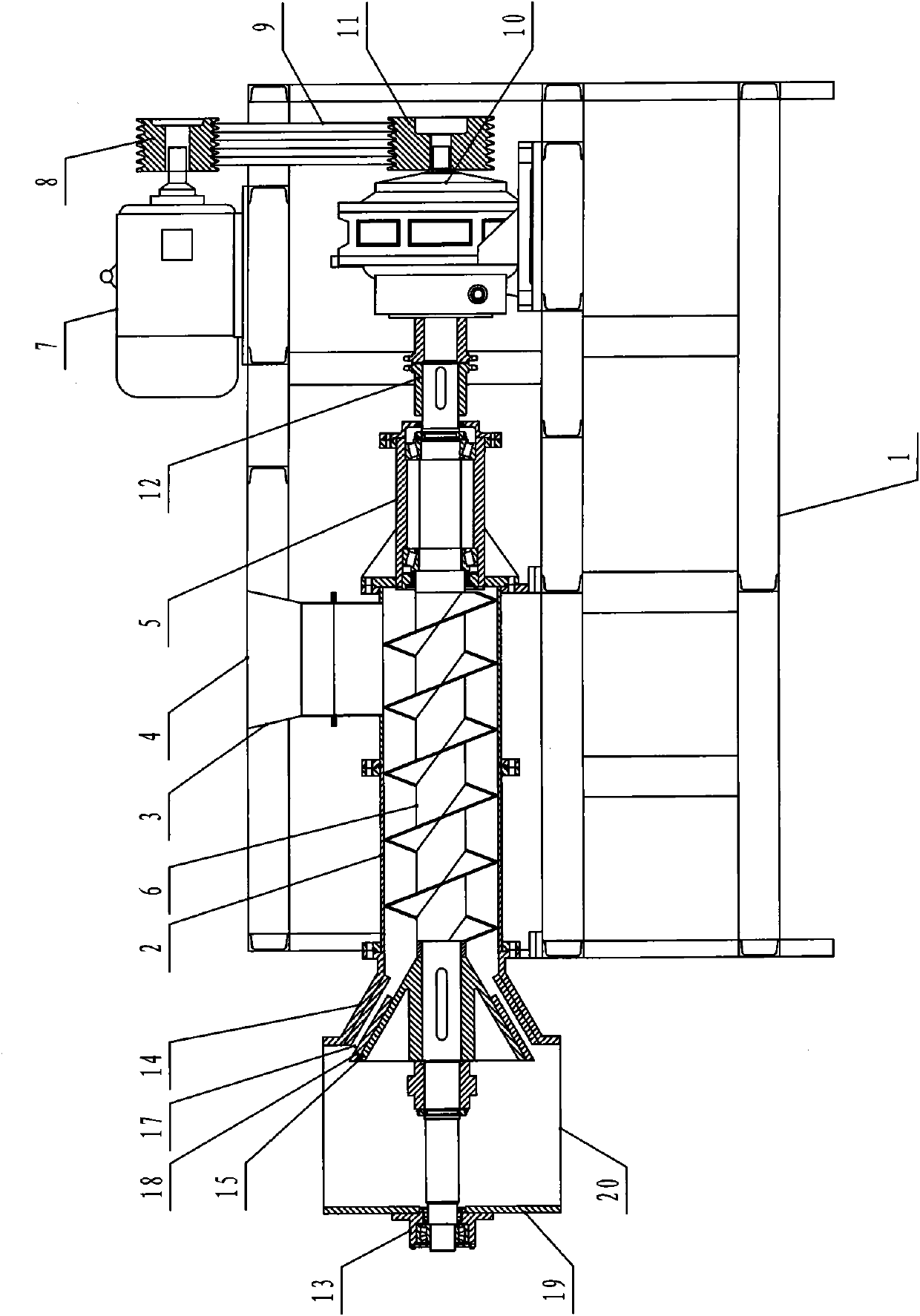

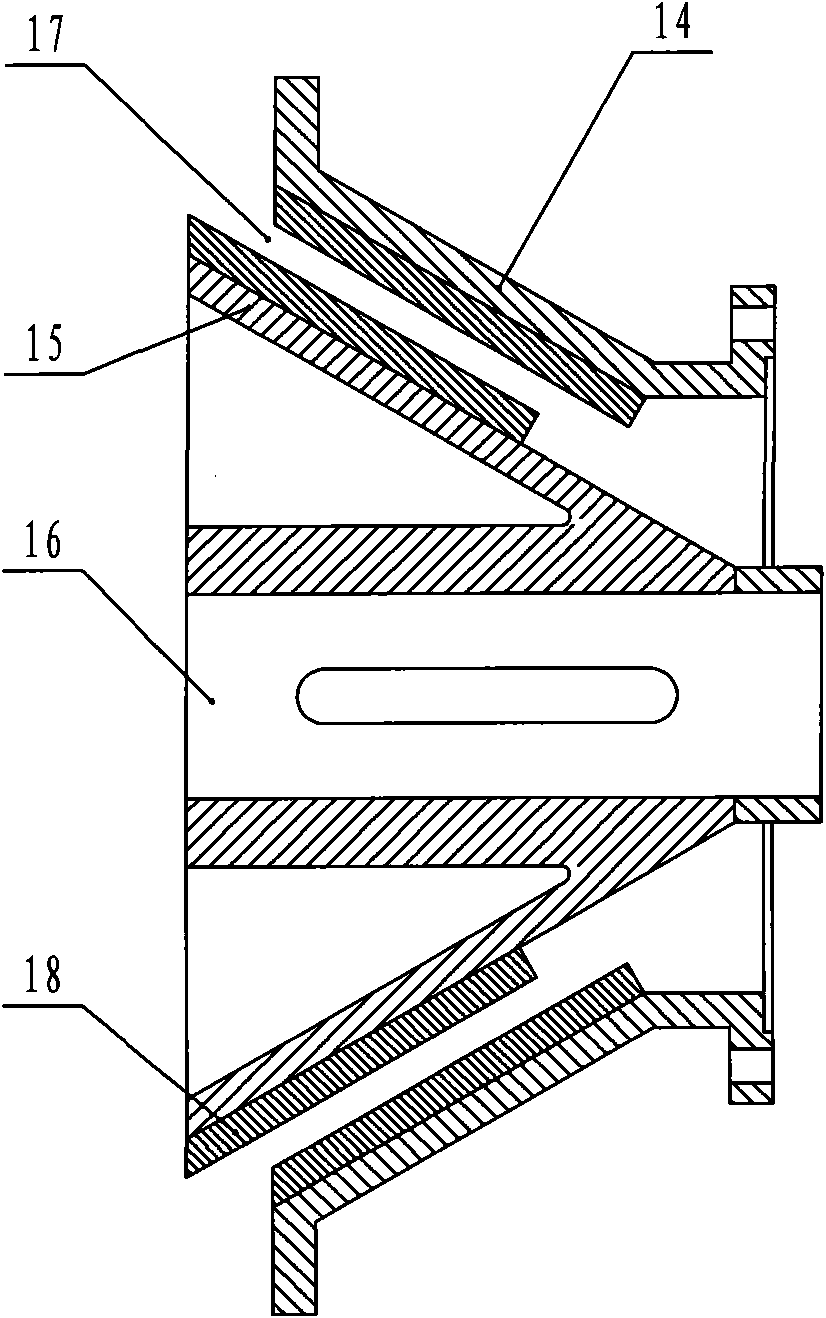

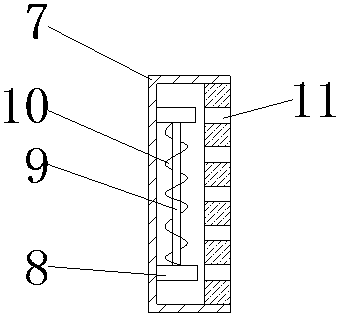

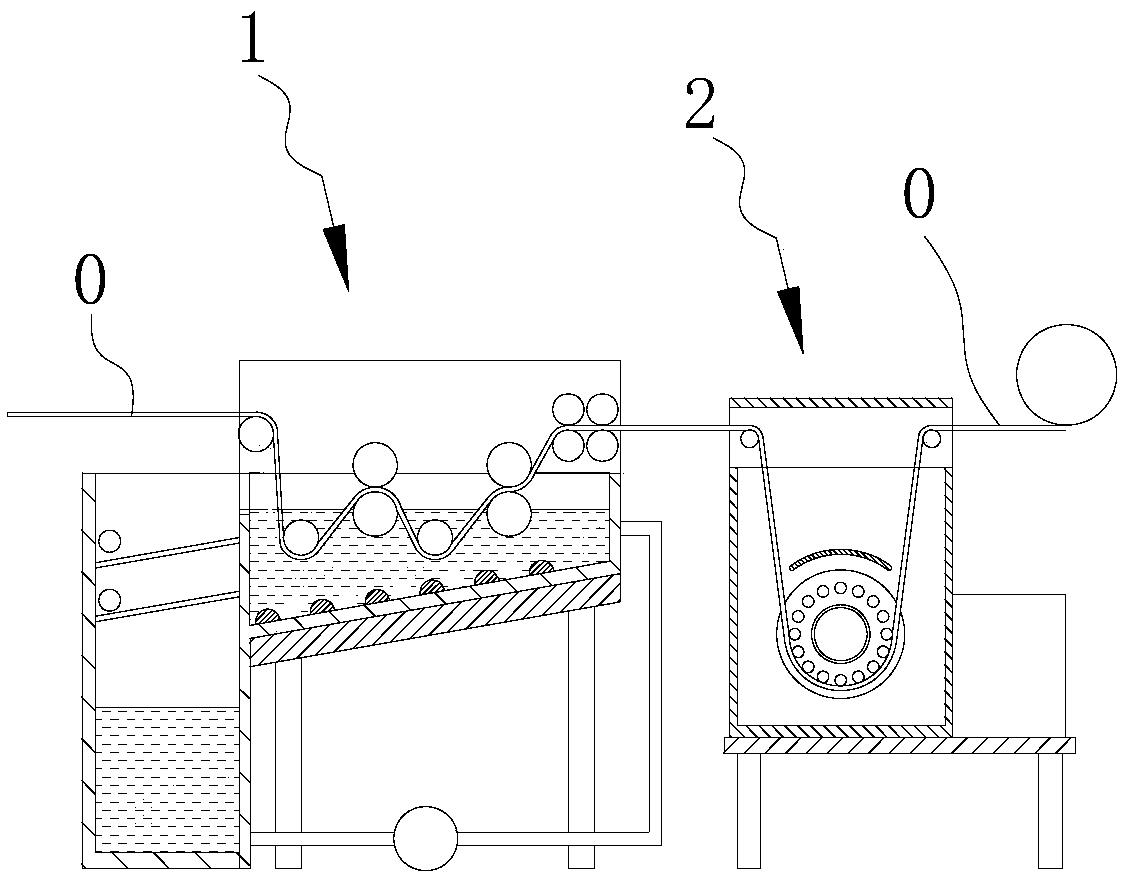

Film squeezing machine

InactiveCN101907388AGood drying effectReduce energy consumptionDrying solid materials without heatPlastic recyclingPlastic filmEngineering

The invention relates to a film squeezing machine, comprising a stand. A machine barrel is arranged on the machine frame. A material inlet is arranged on the machine barrel. The wall of the machine barrel is provided with water exhaust holes. The interior of the machine barrel is movably provided with a screw rod. One end of the screw rod is connected with a driving device, and the other end is movably connected with the machine frame though a bearing. One end of the machine barrel is connected with a material blocking friction outer disc. The material blocking friction outer disc is a hollow truncated cone structure, and the interior of the material blocking friction outer disc is provided with a material blocking friction inner disc. The material blocking friction inner disc is a cone structure and is sleeved and fixed on the screw rod. A passage is formed between the inner wall of the material blocking friction outer disc and the outer wall of the material blocking friction inner disc. Both ends of the passage are respectively communicated with the machine barrel and a material outlet, and the interior of the passage is provided with at least two friction blocks. The friction blocks are respectively arranged on the inner wall of the material blocking friction outer disc and the outer wall of the material blocking friction inner disc. The invention is suitable for dewatering and drying plastic films.

Owner:ZHANGJIAGANG LIANDA MACHINERY

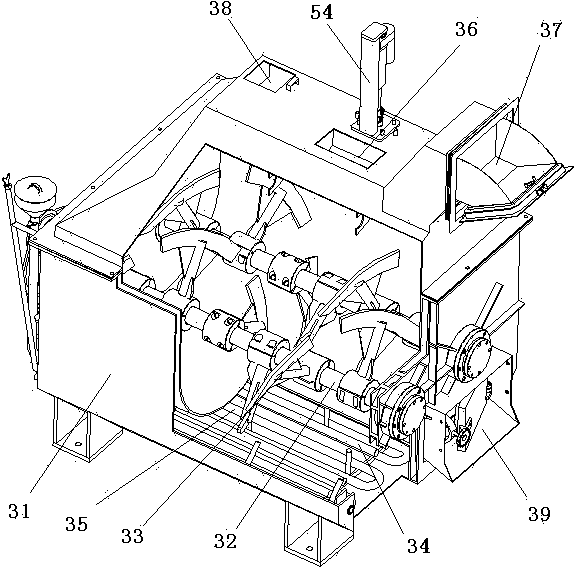

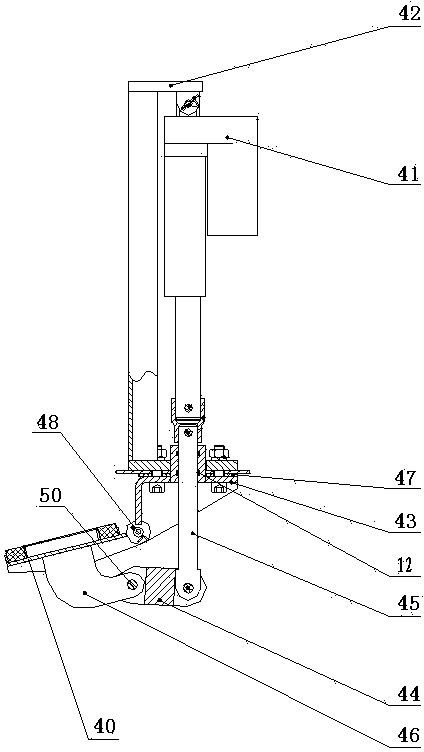

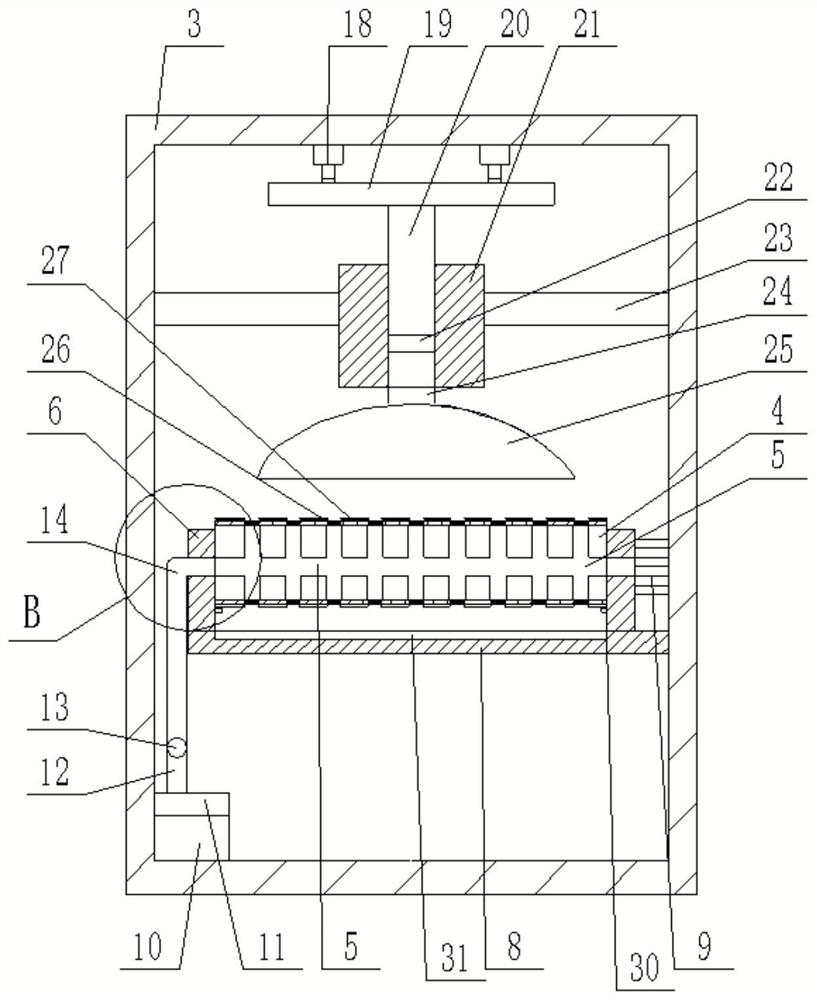

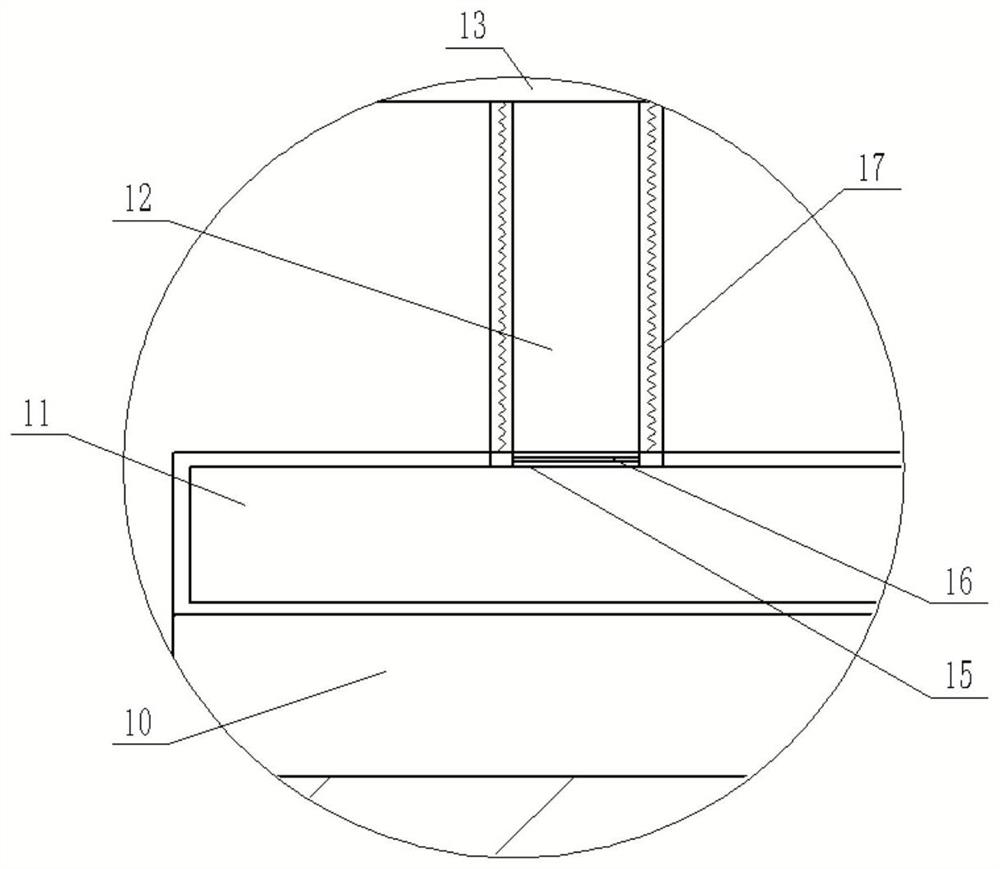

Fermentation drying device used for treating kitchen wastes

ActiveCN103464452AIncrease steam flow rateGood drying effectSolid waste disposalElectric machineryProcess engineering

The invention relates to the technical field of environmental protection equipment, and in particular relates to a fermentation drying device used for treating kitchen wastes. The fermentation drying device is characterized by comprising a fermentation tank, a stirring shaft, a temperature sensor, a heating element and an automatic door closing device, wherein the stirring shaft is arranged in the fermentation tank, a feeding port and a bacteria inlet are formed in the top surface of the fermentation tank, the heating element is arranged at the bottom of the fermentation tank, one side wall of the fermentation tank is provided with an exhaust port and the temperature sensor, a discharging port is formed in the side surface of the lower part of the fermentation tank, the feeding port corresponds to a kitchen waste outlet in the lower end of a sorting device, the bacteria inlet is provided with a sealing door, the discharging port is provided with a discharging door, the feeding port is provided with the automatic door closing device, the stirring shaft is provided with stirring blades, two ends of the stirring shaft are respectively and fixedly connected with the fermentation tank through a bearing and a bearing seat, and the stirring shaft is driven by a stirring motor. The fermentation drying device has the advantages of simple structure, high treatment speed, uniform fermentation, high heating speed, automatic oxygen filling, automatic feeding, automatic discharging, environmental protection without pollution and the like.

Owner:北京名流环保节能科技有限公司

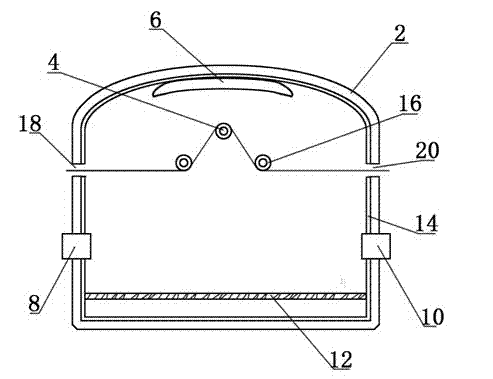

Drying box used for spinning

InactiveCN103542700ASimple structureGood drying effectDrying chambers/containersDrying machines with progressive movementsEngineeringTextile

The invention discloses a drying box used for spinning. The drying box comprises a box body, and is characterized in that the top of the box body is of an arc-shaped structure, the lower portion of the top of the box body is provided with an arc-shaped heating device, multiple rotating rollers distributed in a triangular shape are arranged below the heating device, the surfaces of the rotating rollers are further provided with heating layers respectively, and the positions, on the two sides of the rotating rollers, of the box body are provided with a cloth inlet and a cloth outlet respectively. According to the drying box used for spinning, the top of the box body is provided with the arc-shaped structure, the lower portion of the top of the box body is provided with the heating device, and accordingly the drying effect of textiles is good; due to the multiple rotating rollers distributed in the triangular shape below the heating device, the textiles can be dried evenly; the surfaces of the rotating rollers are provided with the heating layers, so that the drying effect is good, and a wire net is used for collecting debris falling in the drying process of the textiles; and the drying box used for spinning has the advantages of being simple in structure, good in drying effect, low in cost and the like.

Owner:WUJIANG QIANQIANHE TEXTILE

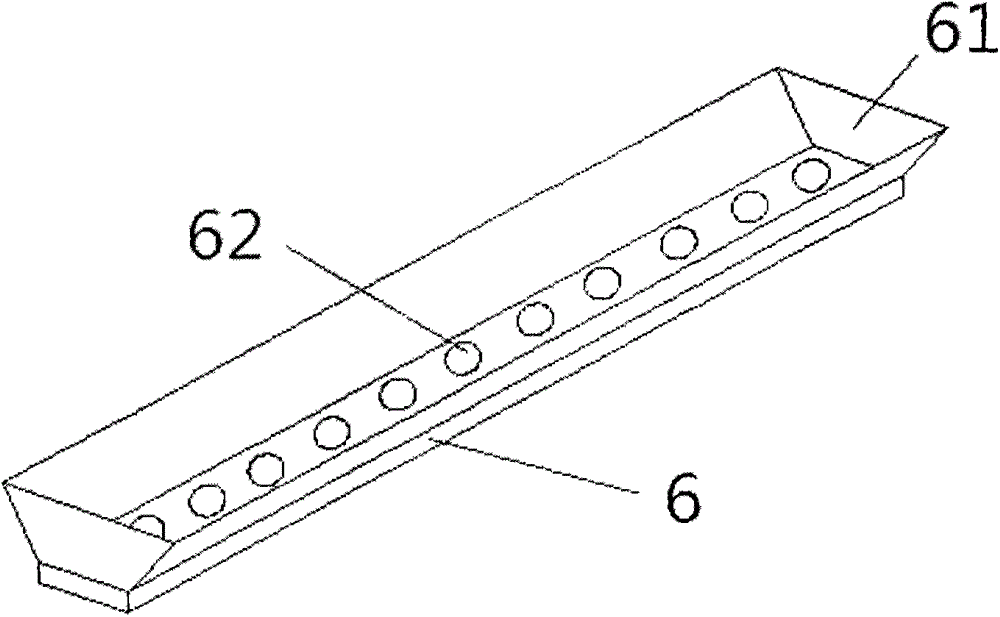

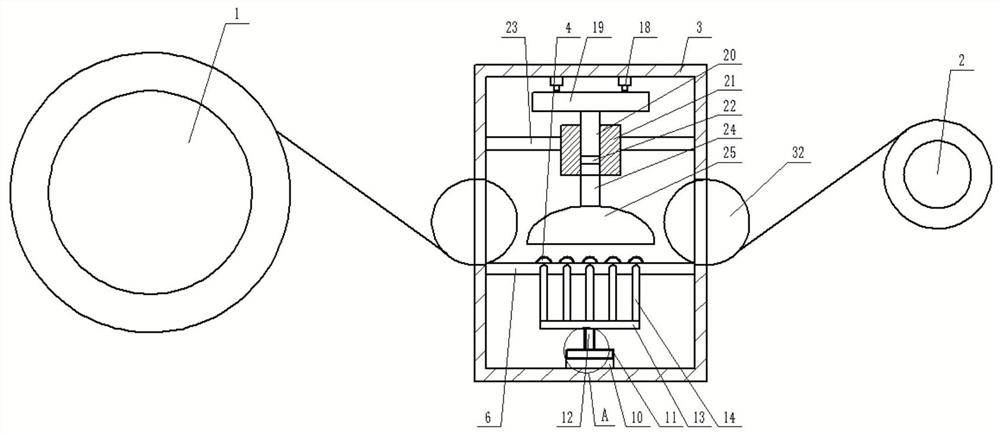

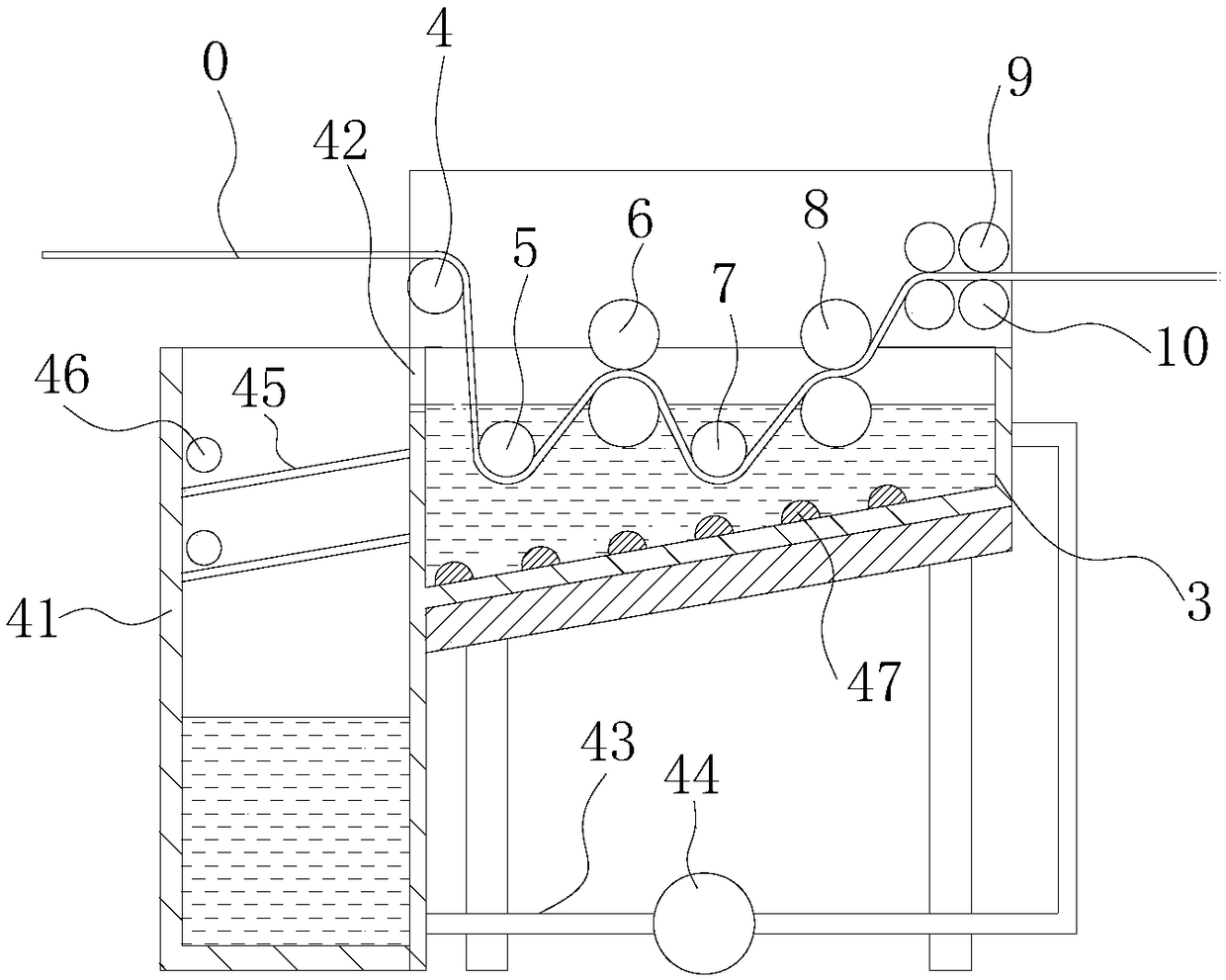

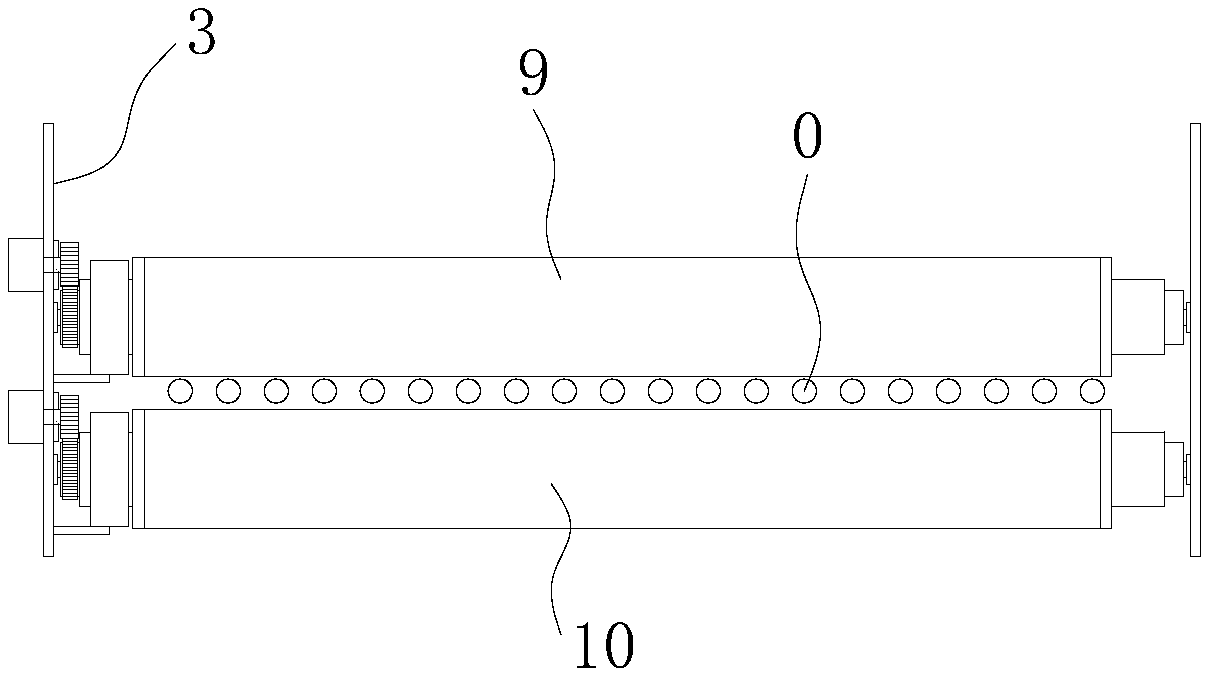

Electrolytic copper foil drying device

ActiveCN111707077AGood drying effectImprove the effectDrying gas arrangementsDrying machines with progressive movementsCopper foilEngineering

The invention discloses an electrolytic copper foil drying device. The electrolytic copper foil drying device comprises an unwinding roll and a winding roll. A box is arranged between the unwinding roll and the winding roll. A guide mechanism is arranged in the box. An air inlet mechanism is arranged at the bottom of the guide mechanism. A waste heat treatment mechanism is arranged at the top of the guide mechanism. A driving mechanism is arranged on one side of the guide mechanism. A friction mechanism is arranged on the guide mechanism. The friction mechanism comprises a plurality of rollersarranged on the guide mechanism. The driving mechanism drives the rollers to rotate. The rotating direction of the rollers is opposite to the driving direction of electrolytic copper foil. Each roller is internally provided with a through cavity. The surface of each roller is provided with a plurality of rows of exhaust hole sets sequentially arranged at intervals. Hot air is supplied into the cavities through the air inlet mechanisms. The hot air is discharged from the exhaust hole sets and collected through the waste heat treatment device. The waste heat treatment device cyclically discharges the collected hot air to the electrolytic copper foil in a pressurization mode. The electrolytic copper foil drying device can dry water stain on the surface of the electrolytic copper foil to prevent secondary rusting and oxidation.

Owner:GUANGDONG FINE YUAN SCI TECH CO LTD

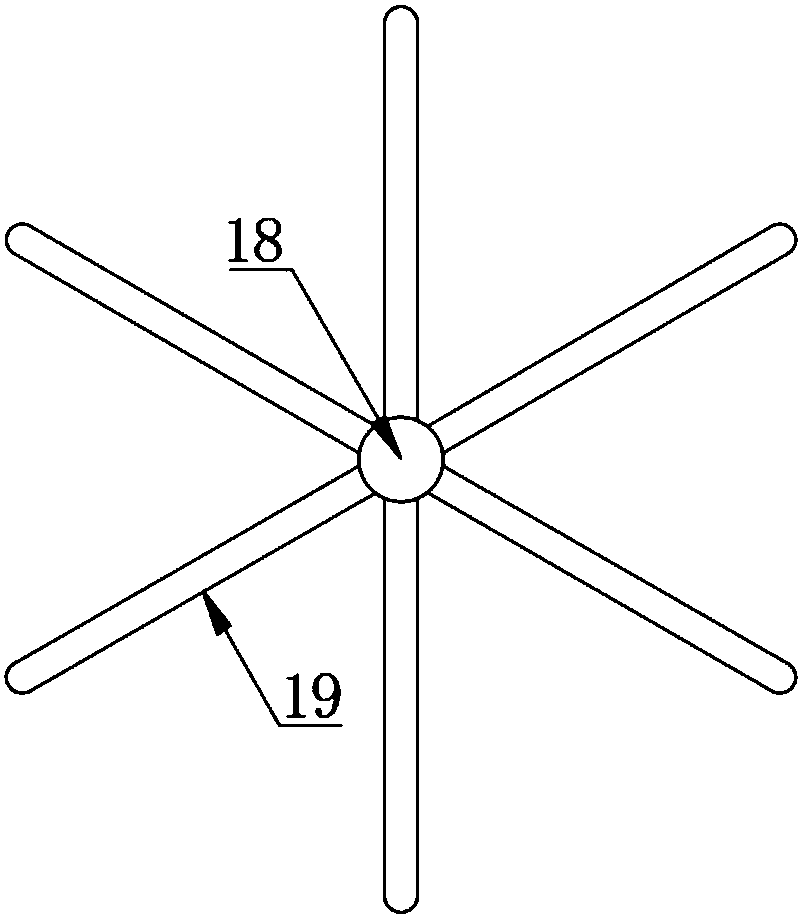

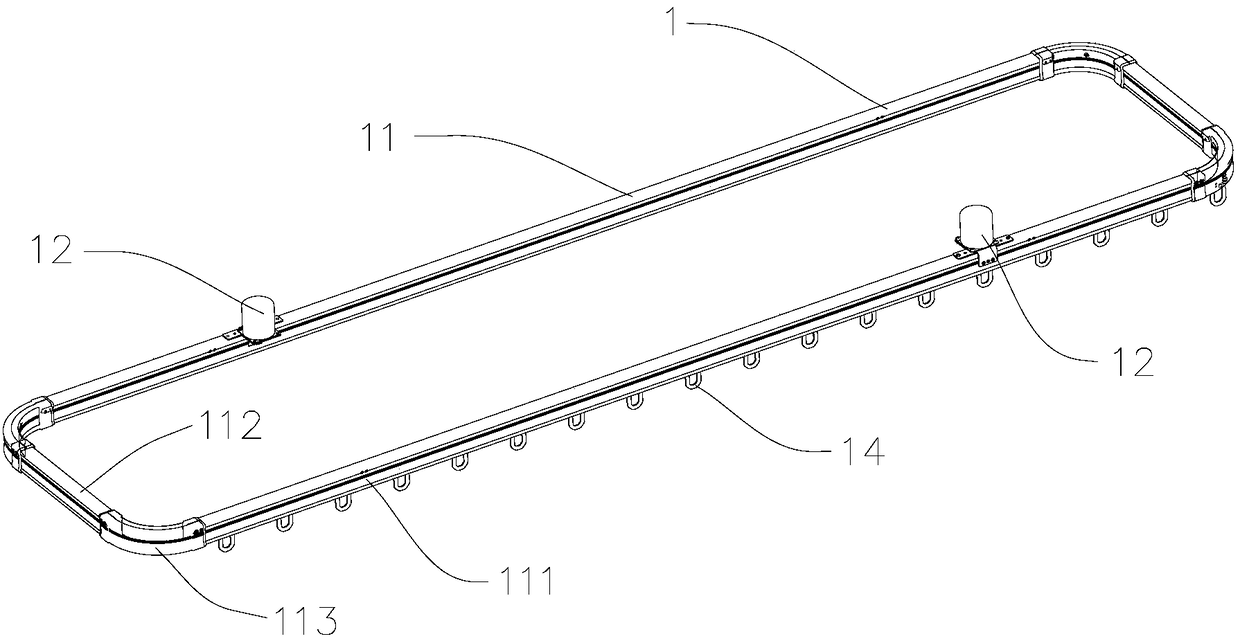

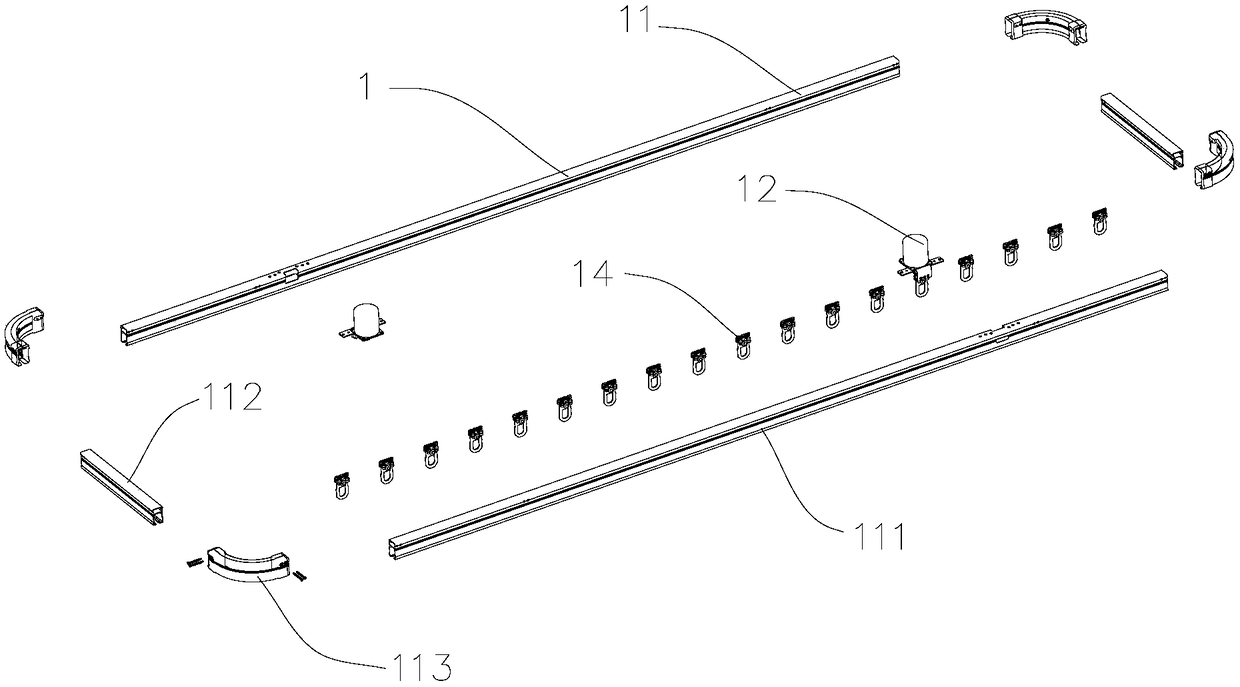

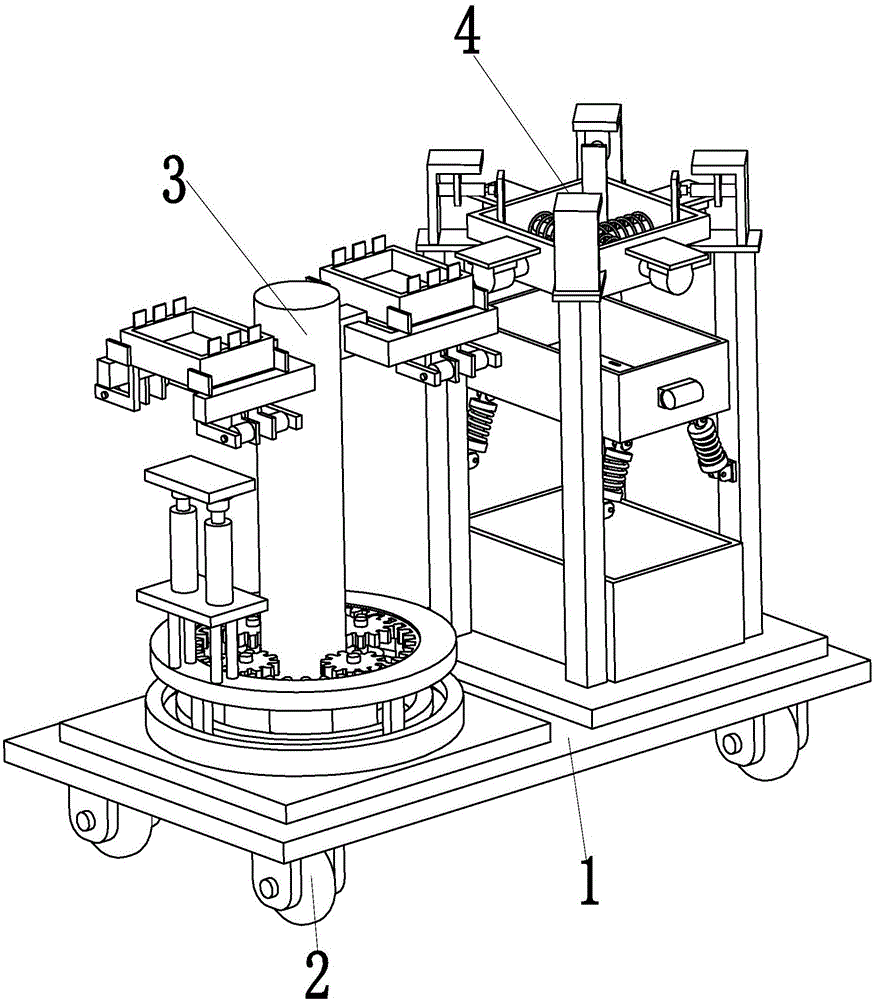

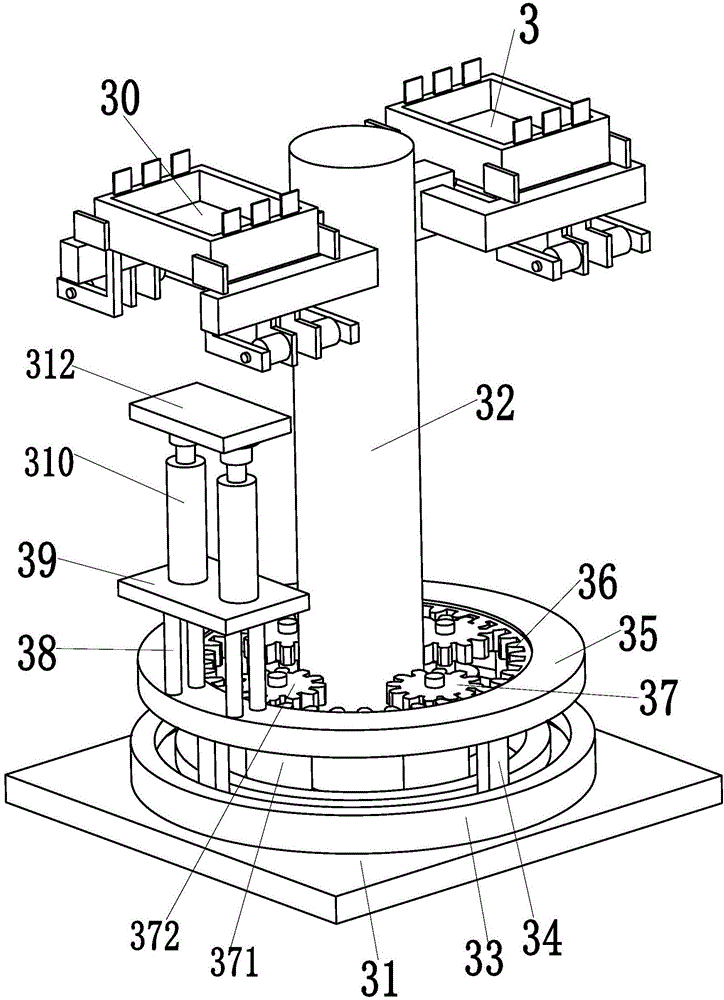

Annular laundry rack and intelligent laundry rack

PendingCN108193453AGood drying effectReduce frictionOther drying apparatusTextiles and paperLaundrySprocket

The invention provides an annular laundry rack and an intelligent laundry rack. The annular laundry rack comprises a laundry rack body, motors, a transmission mechanism and clothes hook components andis characterized in that the laundry rack body is provided with an annular rail, and the bottom end of the laundry rack body is provided with an opening communicated with the rail; the motors are arranged on the laundry rack body, and the output shafts of the motors extends into the rail; the transmission mechanism comprises sprockets and a chain, the sprockets sleeve the output shafts, and the chain is annularly arranged along the rail and meshes with the sprockets; each clothes hook component comprises a clothes hook; the top end of each clothes hook is fixed to the chain, a clothes hangingring is formed at the bottom end of each clothes hook, and each clothes hanging ring extends out of the laundry rack body from the opening. The annular laundry rack has the advantages that a complexclothes hook pushing device is not needed, the chain is driven by the motors to rotate along the laundry rack body so as to drive the clothes hook components to slide relative to the laundry rack bodyto regulate the directions of airing clothes to allow the clothes to be evenly irradiated by sunlight, and a good airing effect is achieved.

Owner:广东顶固集创家居股份有限公司

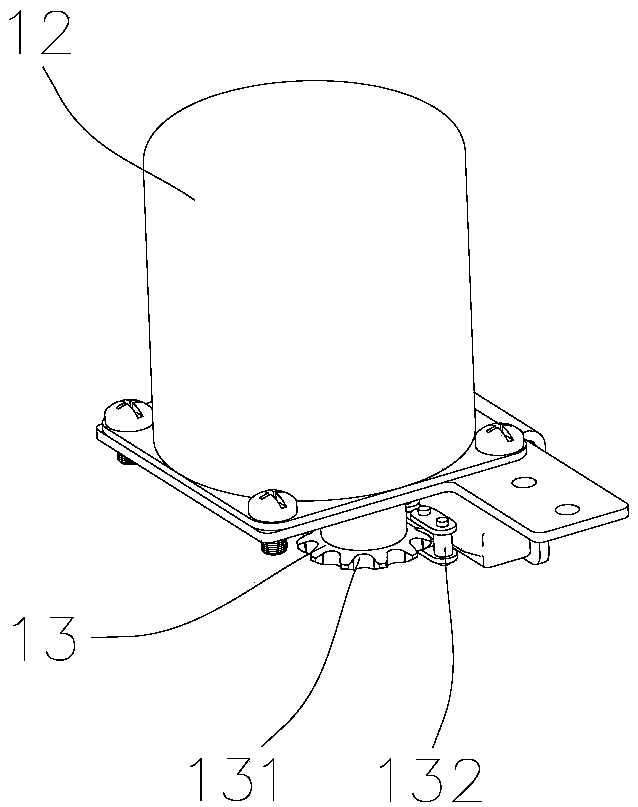

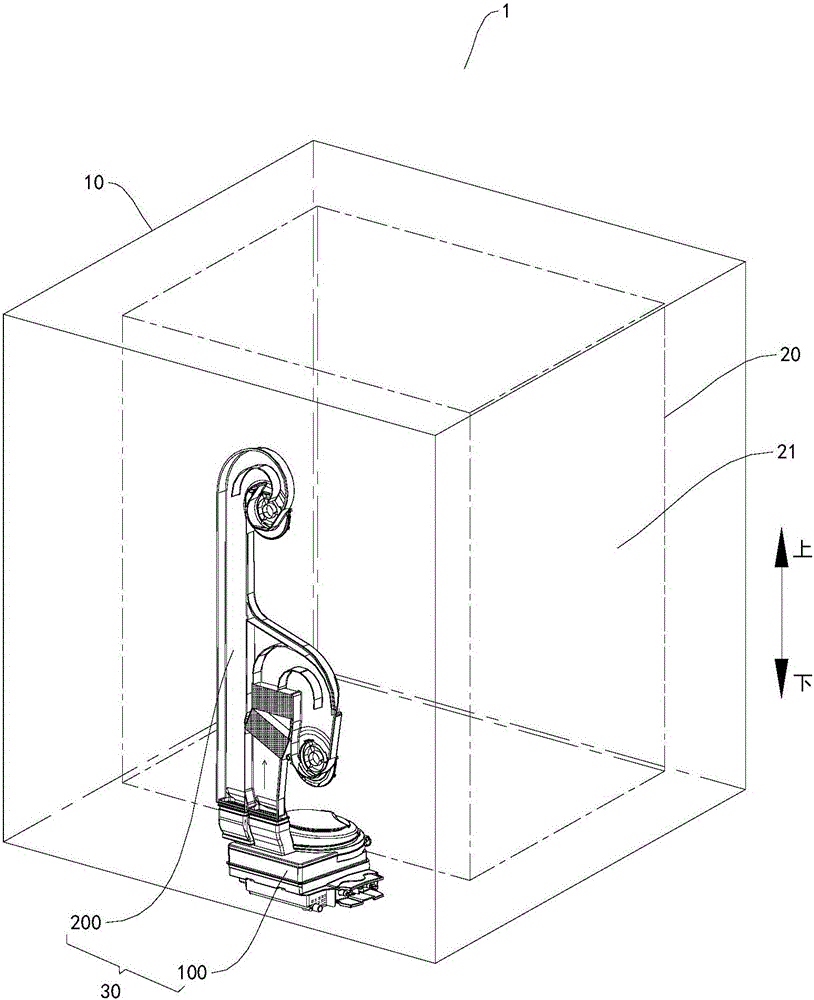

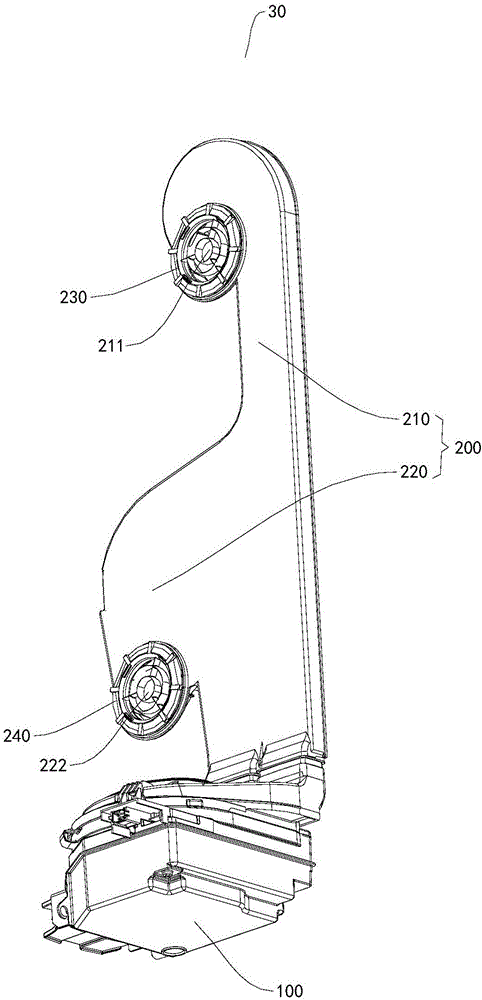

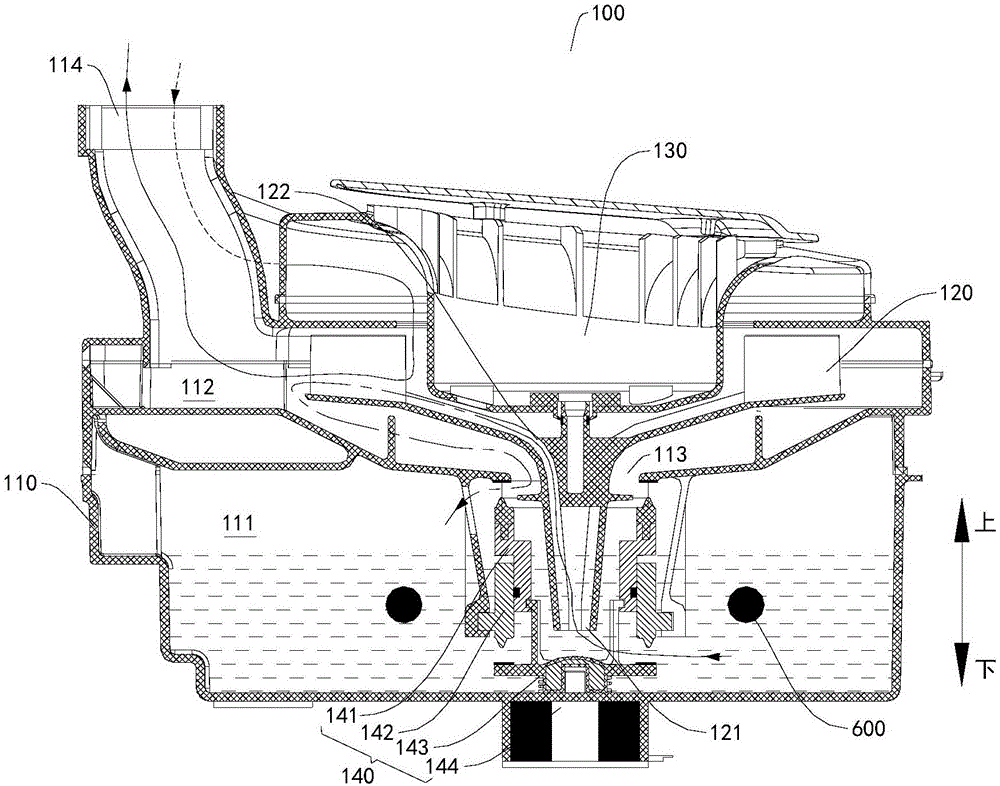

Drying system and dish washer with same

ActiveCN106562737AGood drying effectEnergy saving and clean environmentTableware washing/rinsing machine detailsHigh energyMoisture

The invention discloses a drying system and a dish washer with same. The drying system comprises the components of a dehumidifier device which is used for accommodating moisture absorbing solution, wherein the dehumidifier device is provided with an air inlet and an air outlet, The dehumidifier device comprises a heating device which is used for heating the moisture absorbing solution for realizing regeneration of the moisture absorbing solution; and an air channel assembly which is internally provided with an air inlet channel and an air outlet channel, wherein the air inlet channel is provided with an incoming air inlet and an incoming air outlet which is communicated with the air inlet, and the air outlet channel is provided with an outgoing air outlet and an outgoing air inlet that is communicated with the gas outlet. The drying system provided by an embodiment of the invention has advantages of high drying effect, high energy saving effect, benefit for environment cleaning, etc.

Owner:SANHUA AWECO APPLIANCE SYST WUHU CO LTD

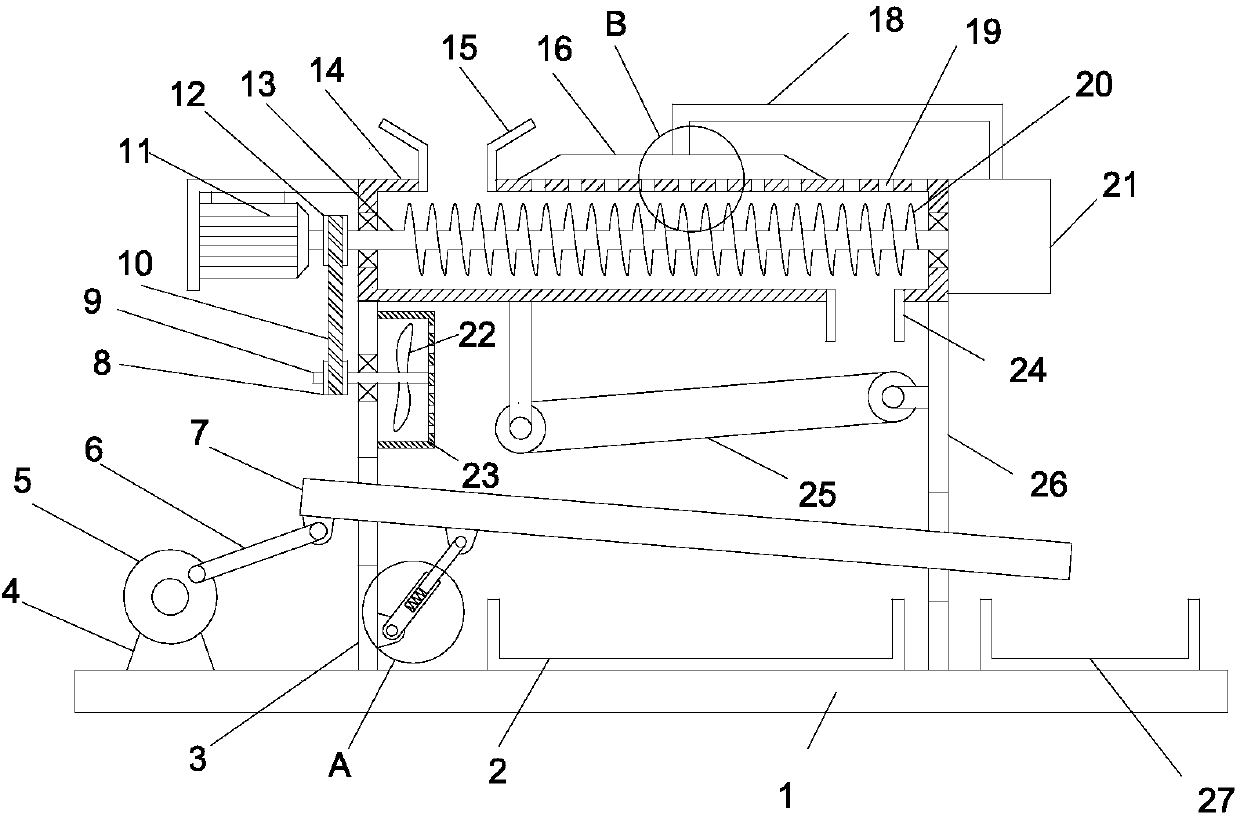

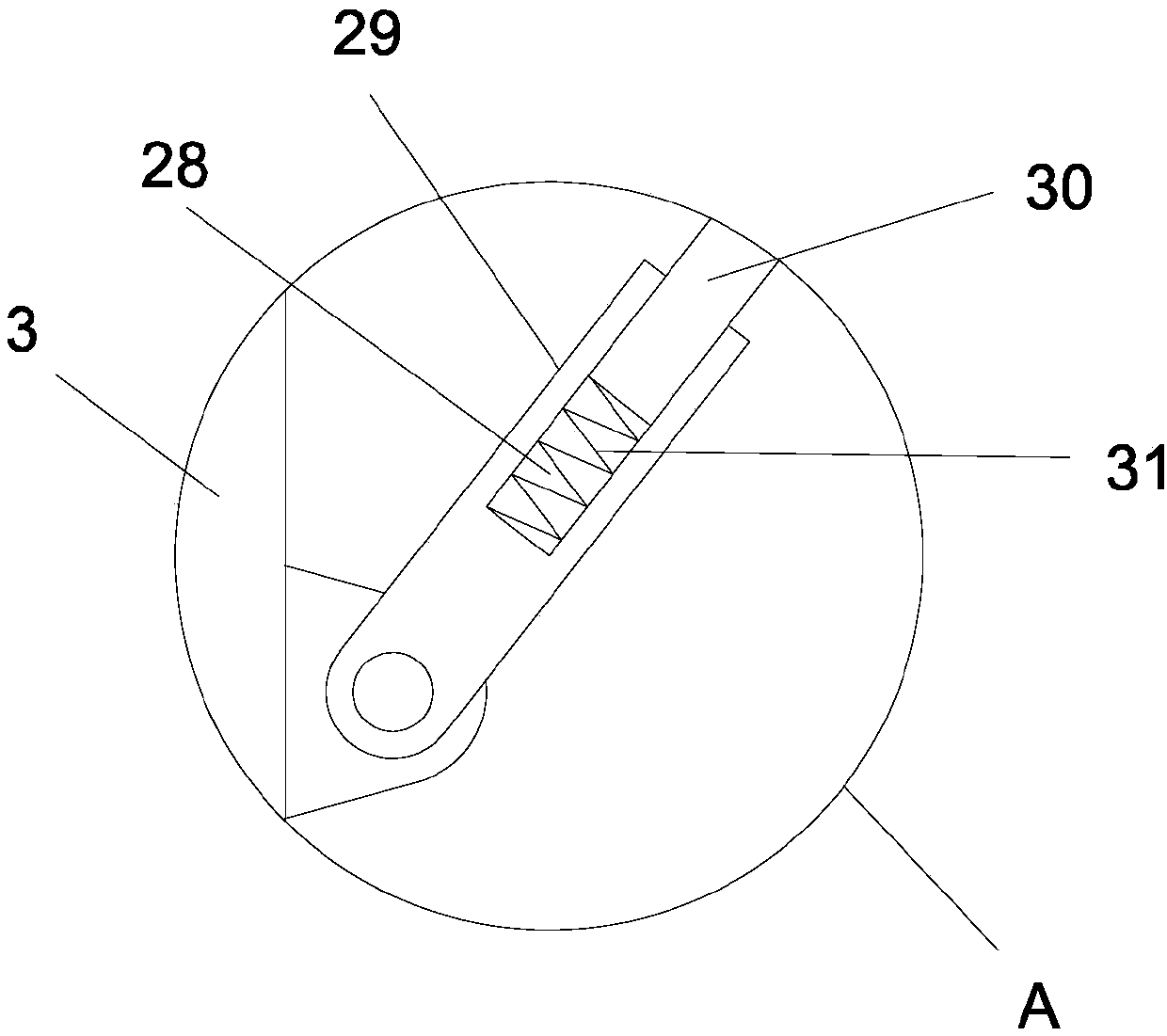

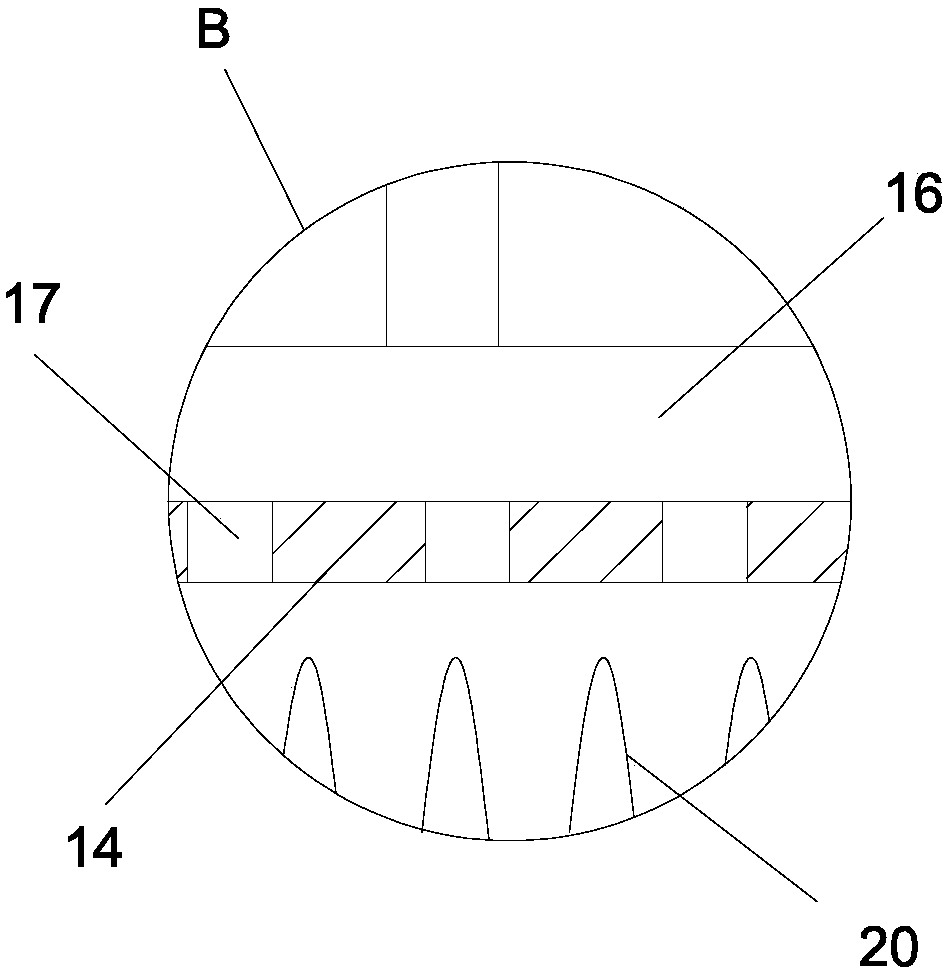

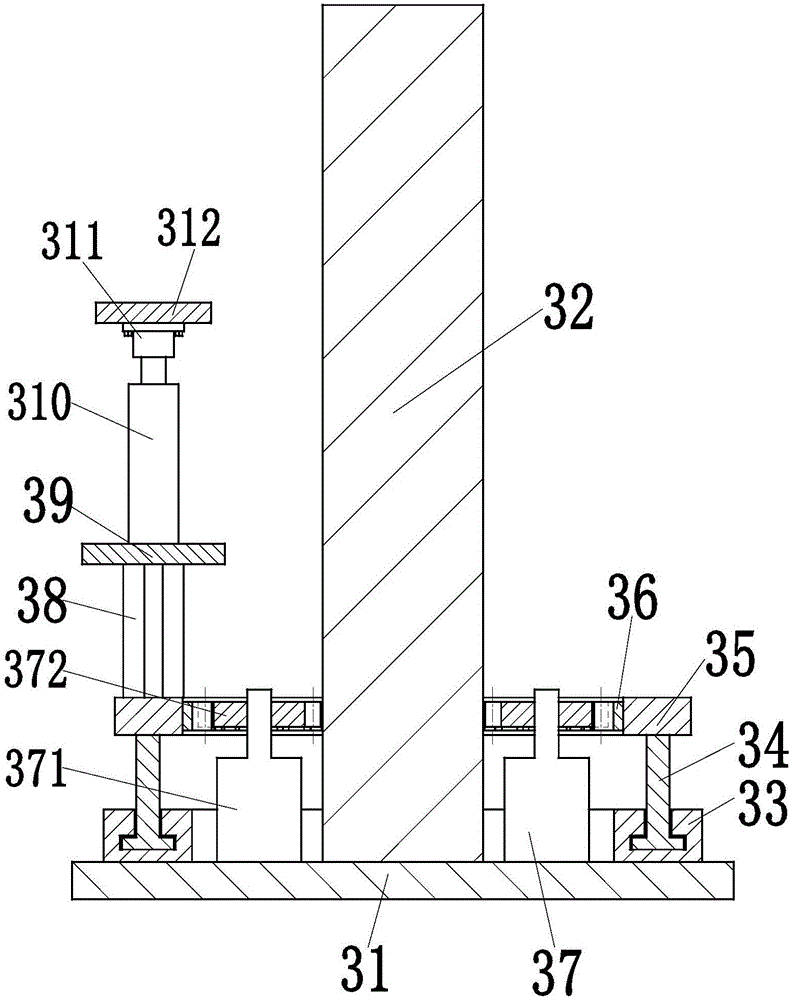

Corn seed screening device for agricultural breeding

InactiveCN107812707AImprove drying effectGood drying effectSievingScreeningAgricultural engineeringAgriculture

The invention discloses a corn seed screening device for agricultural breeding. The corn seed screening device comprises a bottom plate. A left vertical plate and a right vertical plate are verticallyare fixedly installed on the bottom plate; a driven belt wheel is arranged and fixedly installed on a driven shaft in a sleeving mode; a driving belt wheel and the driven belt wheel are sleeved witha transmission belt; a screening basket movably penetrates between the left vertical plate and the right vertical plate in a mode of being inclined towards the lower-right portion; the upper end of aconnecting rod is hinged to the lower-left bottom face of the screening basket; and a first collecting groove is fixedly formed in the lower portion of the screening basket. A hot air machine conductshot air drying on corn seeds in a housing through an air supply pipe and an air collection cover; a driving shaft drives a spiral blade to turn over the corn seeds rotationally, so that hot air and the corn seeds can make full contact, and the drying effect is greatly improved; meanwhile, the corn seeds conveyed on a conveying belt are subjected to secondary air-blowing drying of fan blades and can be spread on the conveying belt, and thus the drying effect is better; and vibration of the screening basket to the corn seeds is facilitated through swinging of the screening basket, and thus thescreening rate is increased.

Owner:雷晓琴

Industrial material drying device

InactiveCN104819626AReasonable structural designGood drying effectDrying gas arrangementsDrying machines with non-progressive movementsElectric heatingEngineering

Owner:DONGZHI OASIS ENVIRONMENTAL PROTECTION CHEM

Textile cloth cleaning device

InactiveCN108505252AGood drying effectFully dryLiquid/gas/vapor removal by squeezing rollersLiquid/gas/vapor removal by gas jetsEngineeringAir drying

The invention discloses a textile cloth cleaning device. The device comprises a box body, a first containing cavity, a second containing cavity, a cleaning mechanism and a drying mechanism, wherein the first containing cavity and the second containing cavity are formed in the box body, the cleaning mechanism is disposed in the first containing cavity, and the drying mechanism is disposed in the second containing cavity. The drying mechanism comprises a drying component, a first lifting device matched with the drying component, a guiding roller disposed above the drying component, air drying components disposed on the side walls of the second containing cavity respectively, second lifting devices matched with the air drying components and a heating member disposed on the top of the second containing cavity. Firstly, cloth is squeezed and dewatered by squeezing rollers; secondly, the cloth is more fully dried by the arranged drying mechanism and an air drying mechanism, and through the arranged lifting devices, the cloth is dried in a large area, so that the effect of drying the cloth is better.

Owner:绍兴市柯桥区则有五金有限公司

Potassium chlorate drying device

PendingCN107677072AImprove work efficiencyGood drying effectDrying gas arrangementsDrying machines with non-progressive movementsElectric machineryHot blast

The invention discloses a potassium chlorate drying device comprising a drying box. The right side of the top of the drying box is movably connected with a feeding pipe. The bottom of the drying box is movably connected with a discharging pipe. The top of the drying box is movably connected with a motor. The bottom of a rotating shaft penetrates through the drying box and extends to an inner cavity of the drying box. Through matching of the drying box, the feeding pipe, the discharging pipe, the motor, the rotating shaft, stirring blades, a heating box, heating bases, a heating pipe, an electric heating wire, heat conducting sheets, a bottom plate, a connecting plate, a supporting plate, a hot air blower, a power frequency modulator, a hot air guide pipe, a vacuum pipe, an exhaust pipe, atemperature sensor, a humidity sensor, a control panel and a single chip microcomputer, the problems that a traditional potassium chlorate drying device is slow in drying process and does not have a smashing function, potassium chlorate needs to be smashed through a smashing machine after being dried, and consequently production cost is increased for enterprises are solved.

Owner:LEIYANG JINYUE SCI & TECH DEV

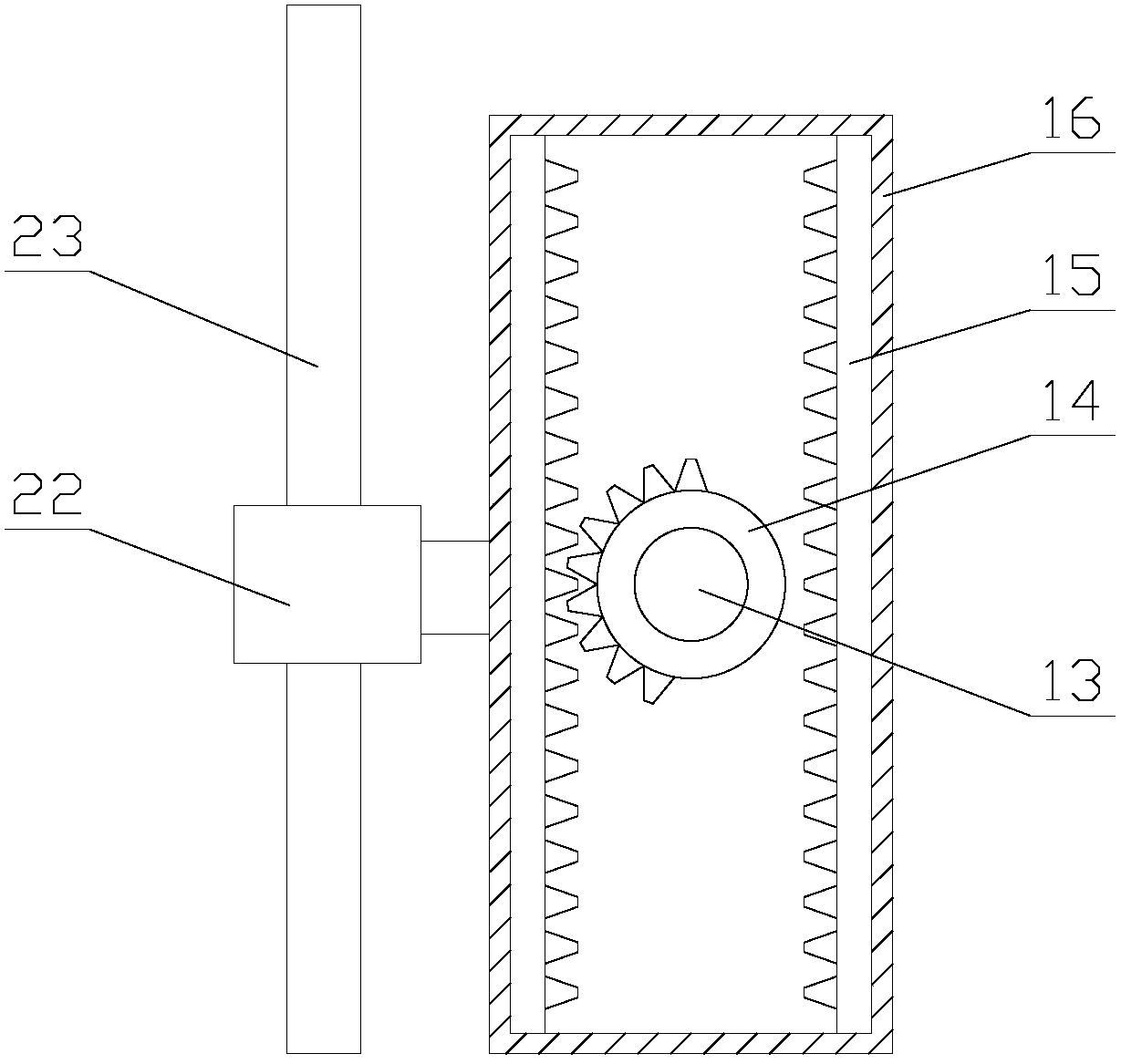

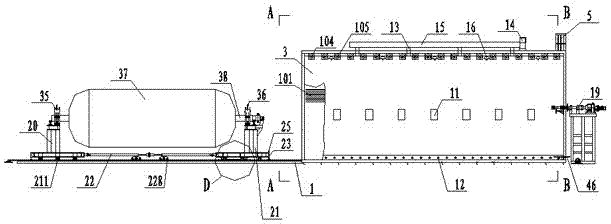

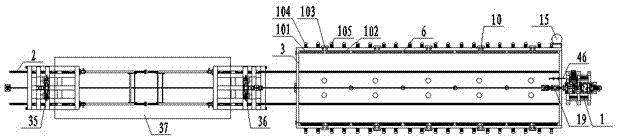

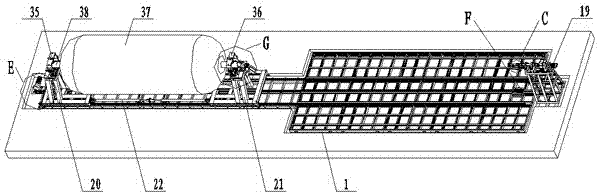

Drying equipment for novel material treatment with good using effect

InactiveCN108397996AImprove drying effectGood drying effectDrying gas arrangementsDrying chambers/containersExhaust heatWaste heat

The invention relates to drying equipment for a novel material treatment with a good using effect. The drying equipment comprises a main body, an air inlet pipe and an exhaust pipe and also comprisesa treatment mechanism and a preheating mechanism, wherein the treatment mechanism comprises a tray, a motor, a stirrer, a cylindrical gear, a worm and two mobile assemblies; the preheating mechanism comprises a connecting pipe, an air pump, a heat-dissipating pipe and a sleeve. According to the drying equipment for the novel material treatment with the good using effect provided by the invention,all surfaces of the material can be mixed fully with hot air through the treatment mechanism, so that the drying effect is improved, the drying effect is better, and follow-up processing and treatmentare prevented from being affected as the material is not uniformly dried. Waste hot air in the main body heats fresh air in the air inlet pipe through the preheating mechanism to play a pre-heating role, so that the heat waste in the drying process is reduced to play a role of recovering waste heat; the drying efficiency is improved greatly, the drying equipment is more energy-saving and environment-friendly, and the practicality and reliability of the drying equipment are improved greatly.

Owner:合肥广能新材料科技有限公司

Extra-large drying oven structure provided with carbon fiber barrel

InactiveCN107192239ACompact structureGood drying effectDrying gas arrangementsDrying chambers/containersTuyereFiber

The invention discloses an extra-large drying oven structure provided with a carbon fiber barrel. The structure comprises a rack and sliding rails arranged in the rack. A drying oven is arranged at the upper end of the rack. A drying cavity is formed in the drying oven. A ladder is arranged on the drying oven. Heated air circulation side air ducts are symmetrically formed in the two sides of the interior of the drying oven. The upper ends of the two heated air circulation side air ducts communicate with each other through a heated air circulation upper air duct formed in the upper end of the drying oven. The lower ends of the heated air circulation side air ducts are provided with heated air circulation air outlets communicating with the drying cavity. A heated air circulation air return port communicating with the drying cavity is formed in the middle of the heated air circulation upper air duct. A plurality of heating units are uniformly arranged in the positions, at the upper ends of the heated air circulation side air ducts, of the drying oven correspondingly.

Owner:JIANGSU GUANGSHENGYUAN TECH DEV

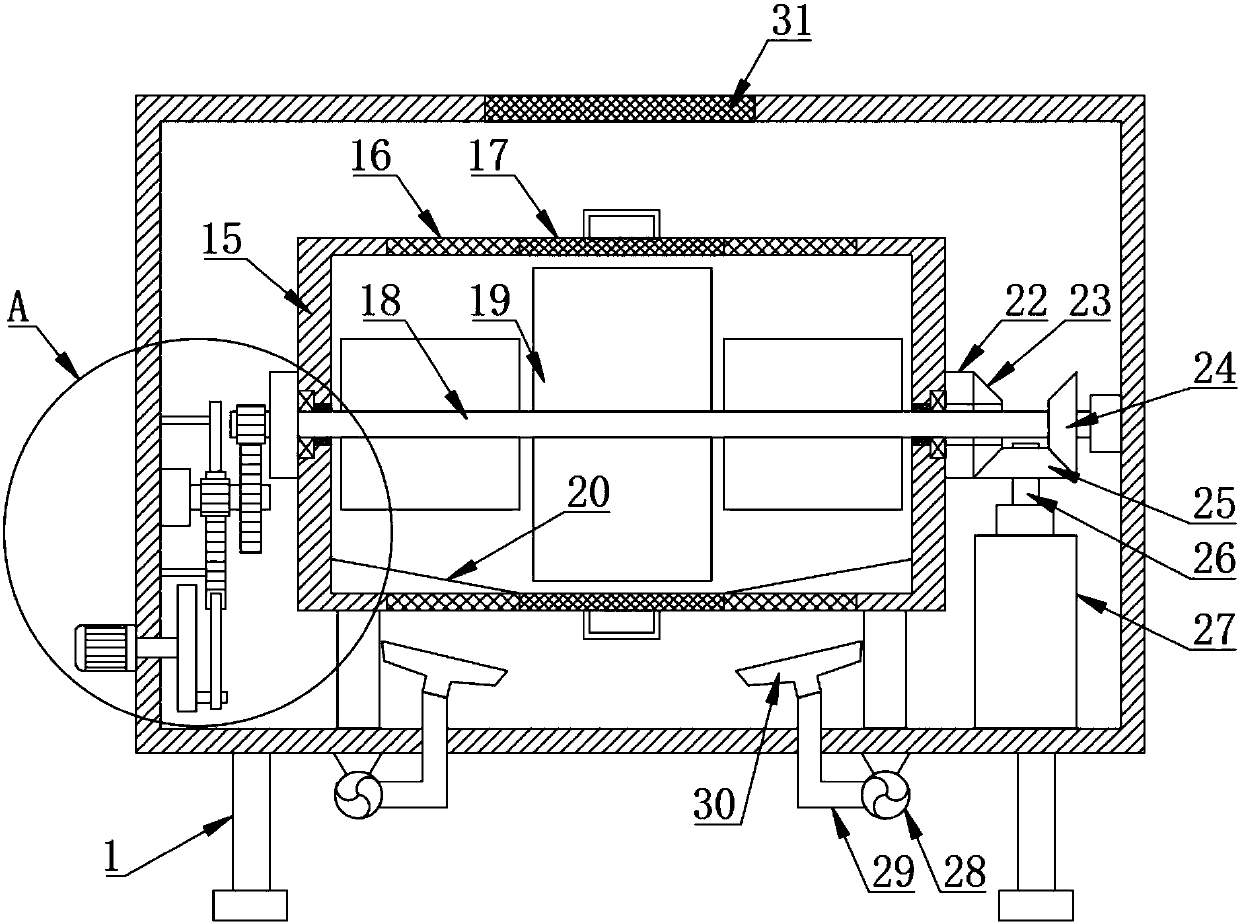

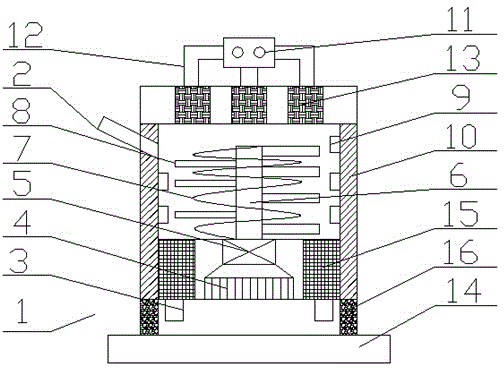

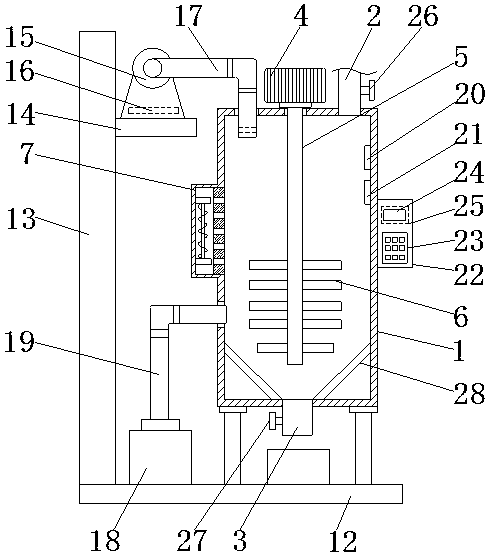

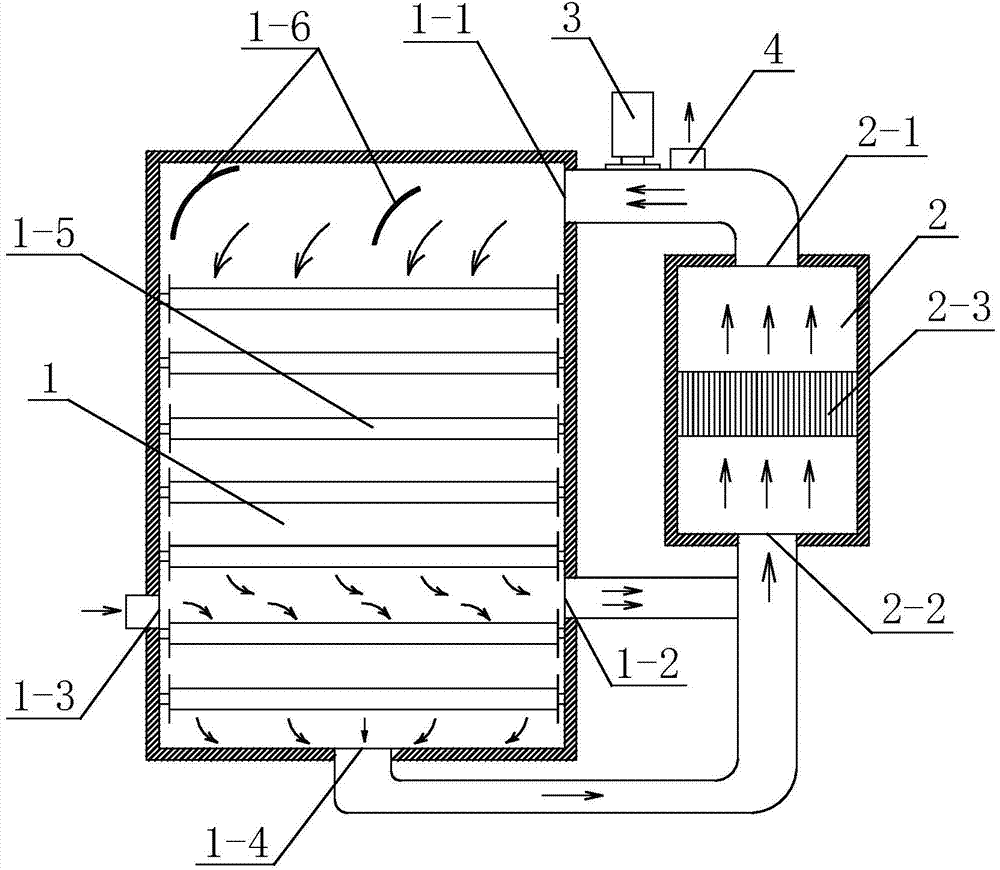

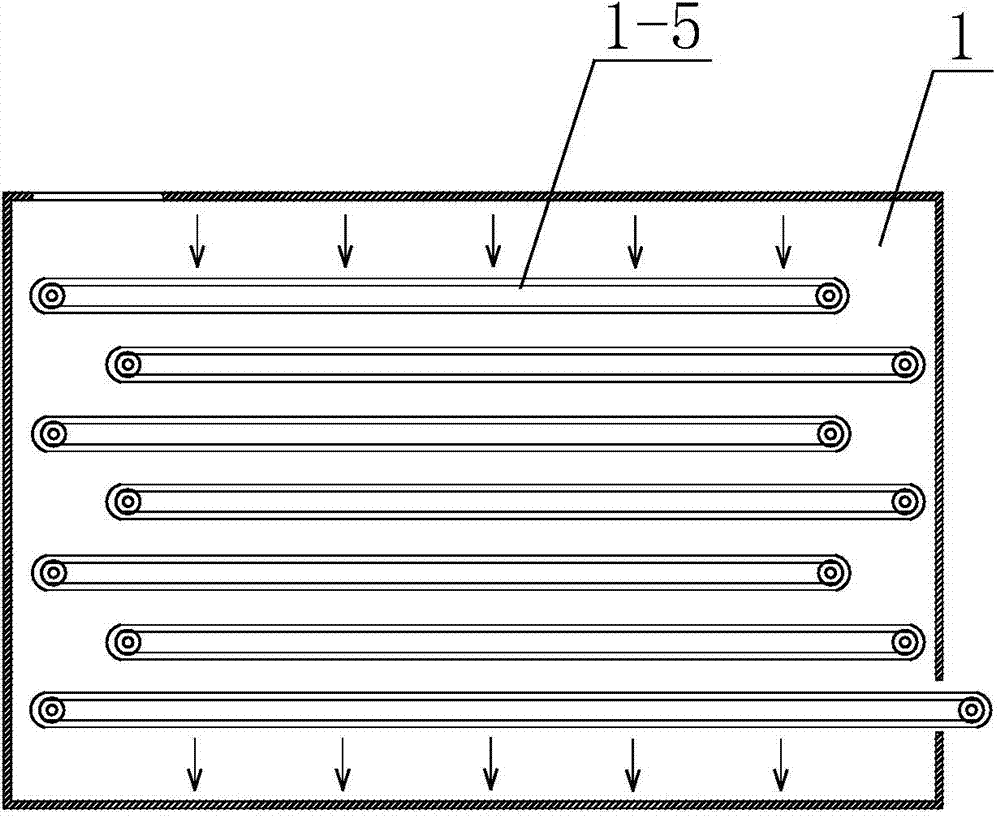

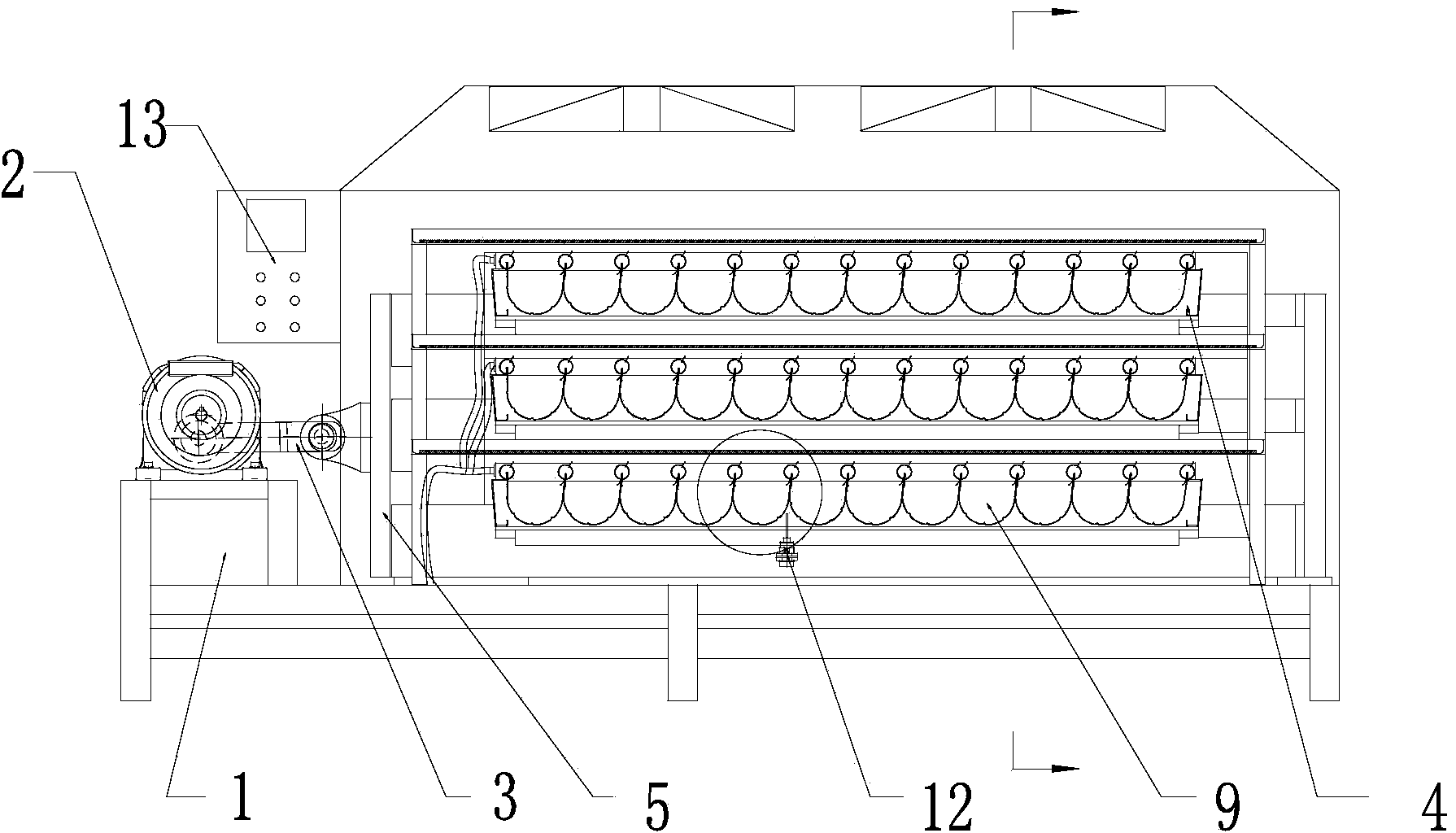

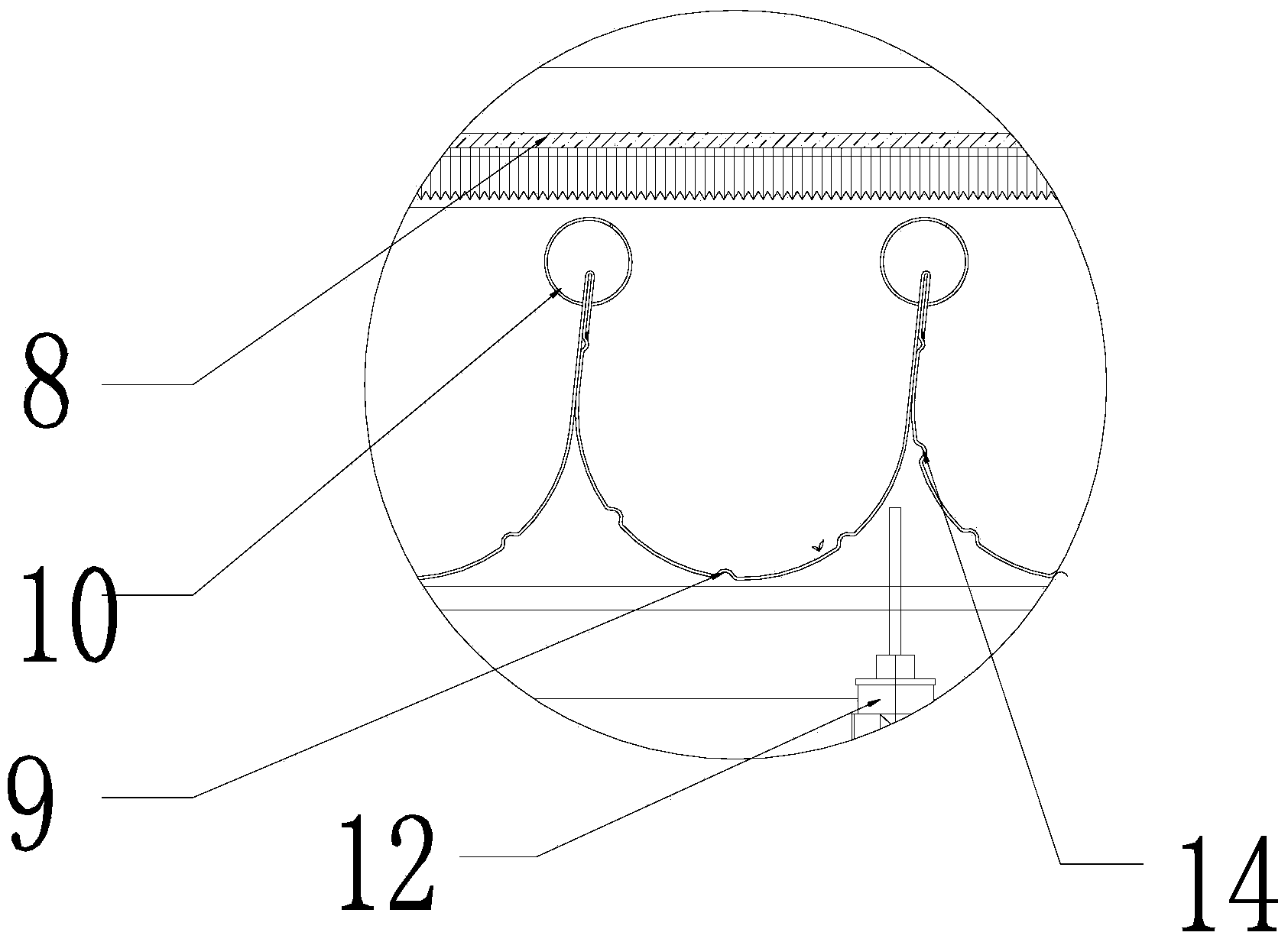

Sludge dryer

InactiveCN103693837AShort processing cycleImprove efficiencySludge treatment by de-watering/drying/thickeningSludgeSafe operation

The invention relates to a sludge dryer which comprises a drying chamber and a circulating air heating chamber, wherein a hot air inlet is arranged at the top of the drying chamber, a circulating air outlet and a supplementary air inlet are arranged in positions close to the bottom of the drying chamber, a supplementary air outlet is arranged at the bottom of the drying chamber, and multiple layers of stainless steel mesh-belt conveyer tables are arranged in the drying chamber; a hot air outlet is arranged at the top of the circulating air heating chamber, a mixed air inlet is arranged at the bottom of the circulating air heating chamber, and a heat exchanger connected with a heat source is arranged in the circulating air heating chamber; the hot air outlet of the circulating air heating chamber and the hot air inlet of the drying chamber are communicated through an air duct provided with a draught fan and a waste discharge port; the circulating air outlet and the supplementary air outlet of the drying chamber are respectively communicated the mixed air inlet at the bottom of the circulating air heating chamber through air ducts. The sludge dryer can continuously operate to perform batch drying treatment on municipal domestic sludge, and has the remarkable advantages of short treatment cycle, high efficiency, good drying effect, stable and safe operation, environment friendliness, low energy consumption, high automation degree and the like, thus having excellent popularization and application prospects.

Owner:CHANGZHOU XINGANG THERMOELECTRICITY

Integrated tea leaf tedding and screening machine

ActiveCN106269518AUniform transmission forceGood transmission effectSievingGas current separationScreening effectEngineering

The invention relates to an integrated tea leaf tedding and screening machine which comprises a bottom plate, four universal wheels are symmetrically installed on the lower end face of the bottom plate, the integrated tea leaf tedding and screening machine is moved to a processing position through the four universal wheels, a condensation tedding device is installed on the left side of the upper end face of the bottom plate and achieves the function of condensing light and rapidly tedding tea leaves, the tedding time is greatly shortened, the tedding speed is high, and the tedding effect is good; a multilevel screening device is installed on the right side of the upper end face of the bottom plate and achieves the function of automatically screening the tea leaves at multiple levels, the screening time is short, the screening speed is high, and the screening effect is good; the condensation tedding device comprises a tedding support plate installed on the left side of the upper end face of the bottom plate, an installation cylinder is welded at the middle part of the upper end face of the tedding support plate, and an annular limit groove is installed on the upper end face of the tedding bottom plate. The integrated tea leaf tedding and screening machine achieves the functions of integrally automatically tedding and screening the tea leaves, no manual operation is needed, the operation is simple and convenient, and the degree of automation is high.

Owner:岳阳县洞庭春纯天然茶叶有限公司

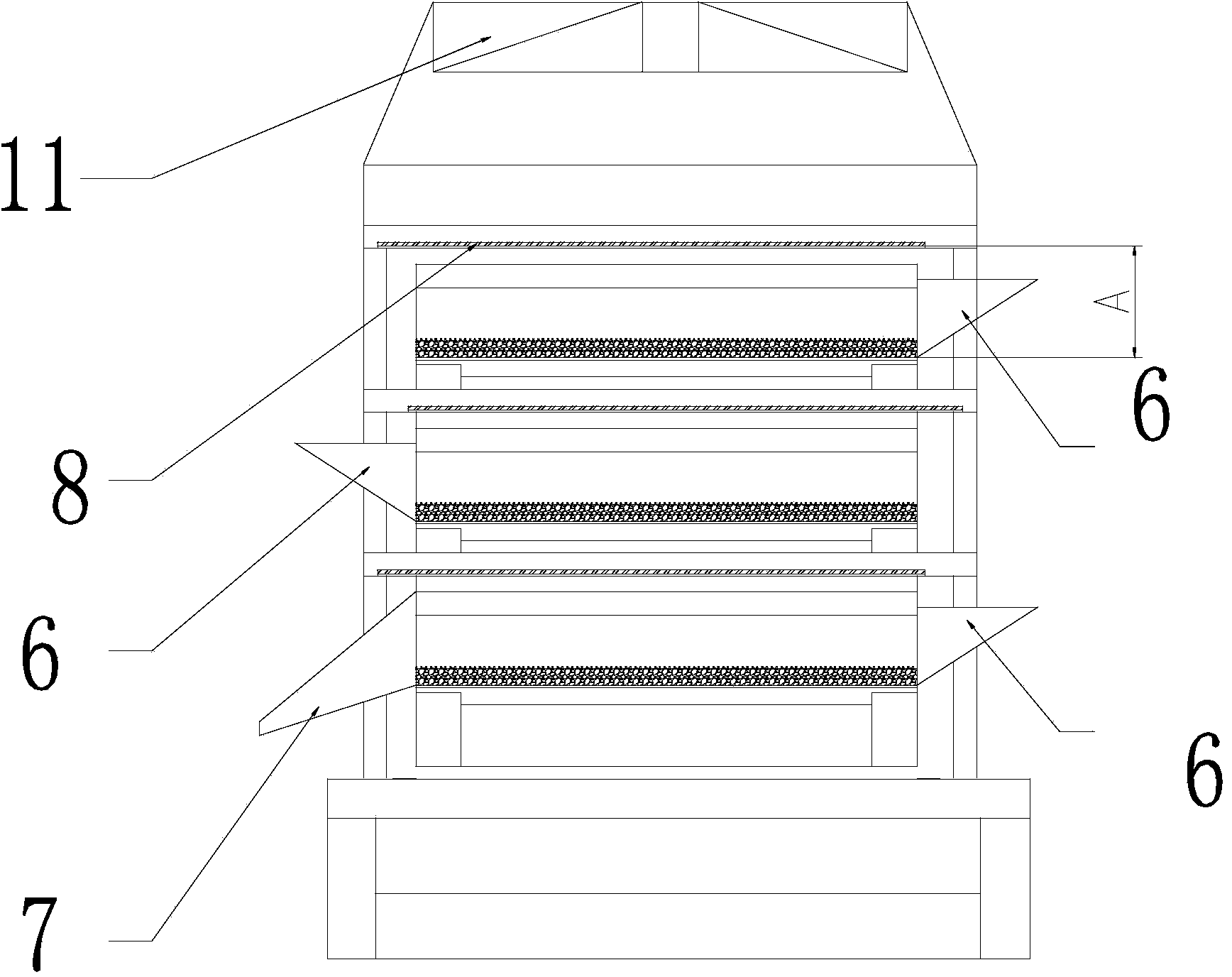

Tea drying plant

InactiveCN103954113AGood drying effectImprove qualityDrying solid materials with heatPre-extraction tea treatmentEngineeringEnergy consumption

The invention discloses a tea drying plant, and in particular to a tea drying plant for the field of tea processing. The tea drying plant provided by the invention can realize continuous drying of tea, strengthens the drying effect in the tea continuous drying process, improves the tea quality, reduces the energy consumption, and comprises a frame, a driving device, a transmission device, drying-shaping pots and a heating device, wherein the transmission device is mounted on the frame; the drying-shaping pots are arranged in a drying cavity in a layered manner; feeding positions and discharging positions are arranged on the drying-shaping pots; the feeding position is higher than the discharging position in the same layer of the drying-shaping pot. As the drying-shaping pots are arranged in the drying cavity in the layered manner, the tea to be dried and processed can be baked by the former layer of drying-shaping pot, and then processed tea is dropped to the next layer of the drying-shaping pot from a feeding hole, so that the tea can be continuously dried and processed in the drying cavity from top to bottom by passing through multiple layers.

Owner:SICHUAN NAT TEST MEASURING INSTR TECH

Efficient environment-friendly drying agent

InactiveCN105561923AStrong adsorption capacityGood drying effectOther chemical processesDispersed particle separationChemistryActive carbon

The invention discloses an efficient environment-friendly drying agent. The efficient environment-friendly drying agent is prepared from the following materials in parts by mass: 25-29 parts of active carbon, 15-17 parts of anhydrous magnesium chloride, 8-12 parts of zinc oxide, 15-18 parts of natural zeolite, 9-15 parts of lime, 6-8 parts of bentonite and 7-12 parts of aluminium hydroxide. The efficient environment-friendly drying agent is high in adsorption capability, is good in drying effect, can effectively prevent the problems of product damage caused by moisture and the like, is wide in applicable range, is low in cost, and is good in economy.

Owner:QINGDAO HONGYU ENVIRONMENTAL PROTECTION AIR CONDITIONING EQUIP

Textile drying machine with good drying effects

InactiveCN107435198AGood drying effectShorten drying timeTextile treatment containersLiquid/gas/vapor removal by gas jetsAirflowEngineering

The invention discloses a textile dryer with good drying effect, which comprises a box body, the center of the top of the box body is fixedly connected with a casing, and the inner cavity of the casing is fixedly connected with a support plate transversely, and the support plate A motor is fixedly connected to the top of the plate, the output shaft of the motor penetrates to the bottom of the support plate and is fixedly connected to a rotating shaft, and the surface of the rotating shaft is fixedly connected to fan blades. The present invention solves the problem that the existing textile dryer cannot quickly dry the wet textile cloth through the cooperative use of the box body, the shell, the support plate, the motor, the rotating shaft, the fan blade, the opening, the air inlet, the heating plate and the air outlet. Drying, the problem of poor drying effect, the textile dryer with good drying effect has the advantages of good drying effect, so that the textile cloth can be dried quickly by using hot air in the drying box, reducing the cost of textile The drying time of the cloth shortens the manufacturing cycle of the textile cloth, and the operation is simple and convenient for the user.

Owner:SUZHOU YUANLING TEXTILE CO LTD

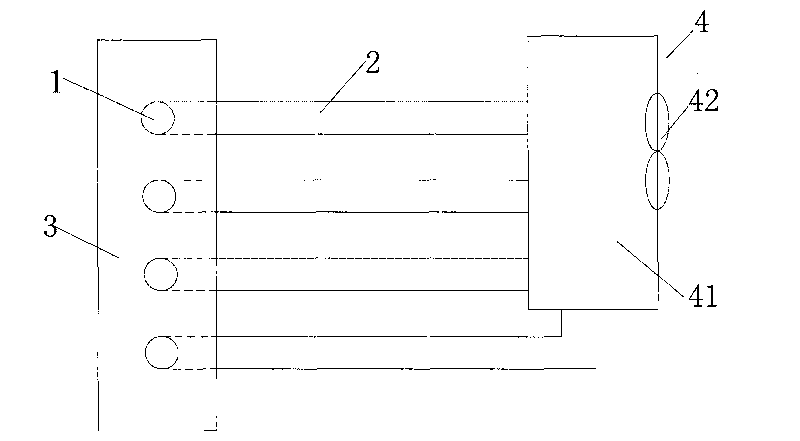

Sizing machine with great drying performance

ActiveCN109457419AGood drying effectGood uniformityLiquid/gas/vapor removal by suctionTextile treatment carriersYarnTextile

The invention relates to the technical field of textile and aims at providing a sizing machine with great drying performance. According to the adopted technical scheme, the sizing machine with the great drying performance comprises a sizing machine main body and a drying box, wherein the sizing machine main body and the drying box are sequentially arranged in a yarn conveying direction; the dryingbox comprises a box body, wherein the upper portion, facing one side of the sizing machine main body, of the box body is provided with a yarn inlet, the upper portion of the other side of the box body is provided with a yarn outlet, and the yarn inlet and the yarn outlet are provided with a yarn inlet guide roller and a yarn outlet guide roller respectively. The lower portion of the interior of the box body is also provided with a drying cage, and yarn sequentially bypasses the yarn inlet guide roller, the drying cage and the yarn outlet guide roller in an inverted zigzag pattern. According to the sizing machine, the yarn can be quickly dried in the drying box, and the drying effect is good.

Owner:叶德江

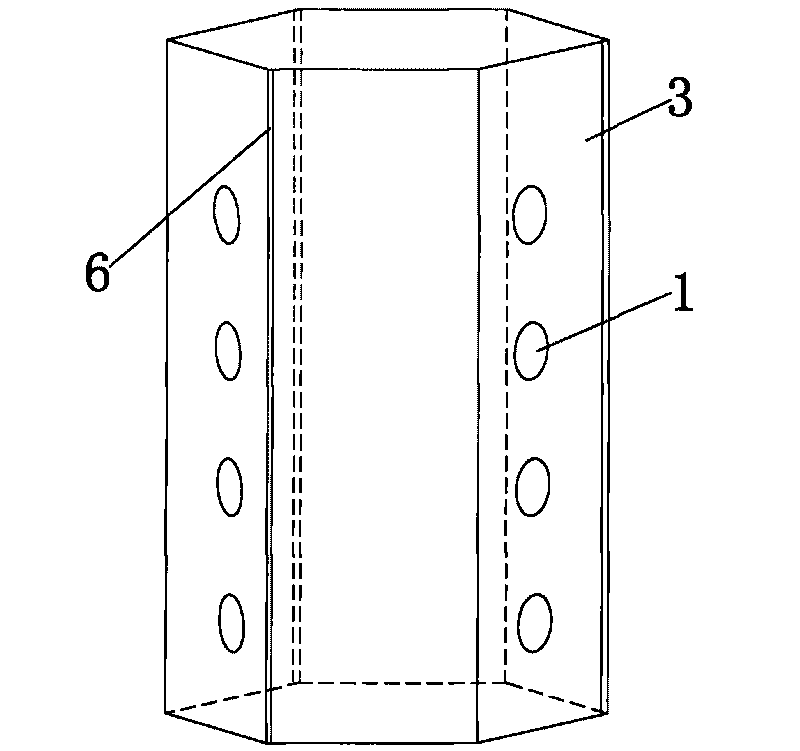

Body drying device

InactiveCN101721161AAvoid wastingAvoid the pitfalls of wind speed weakeningDomestic applicationsEngineeringProduct gas

The invention relates to a body drying device comprising a side wall and a plurality of air blowing holes which are arranged from top to bottom on the side wall, wherein each air blowing hole is connected with blast pipes respectively and independently connected to a dry gas supply air source. The body drying device has the advantages of small gas flow rate loss, good body drying effect and the like.

Owner:郑文芳 +1

Ultrasonic cleaner

ActiveCN103658103AGood drying effectPrevent affecting the final drying effectDrying gas arrangementsCleaning using liquidsHot blastEngineering

The invention relates to an ultrasonic cleaner which comprises a machine frame, a first spraying groove, an ultrasonic cleaning groove, a second spraying groove, a feeding mechanism and a wind cutting mechanism. The first spraying groove, the ultrasonic cleaning groove, the second spraying groove, the feeding mechanism and the wind cutting mechanism are arranged on the machine frame. The wind cutting mechanism comprises a hot wind cutting water channel, a hot wind drying chamber basically sealed, a heating box, a water cutting wind inlet pipe and a drying wind inlet pipe, and the water cutting wind inlet pipe and the drying wind inlet pipe are communicated with the heating box respectively. The feeding mechanism sequentially penetrates through the first spraying groove, the ultrasonic cleaning groove, the second spraying groove, the hot wind cutting water channel and the hot wind drying chamber in the conveying direction from front to back. The water cutting wind inlet pipe comprises a water cutting wind inlet which is located in the hot wind cutting water channel, and the drying wind inlet pipe comprises a drying wind inlet which is located in the hot wind drying chamber. The ultrasonic cleaner is even in hot wind distribution, and good in drying effect.

Owner:ZHANGJIAGANG KEYUXIN ULTRASONIC

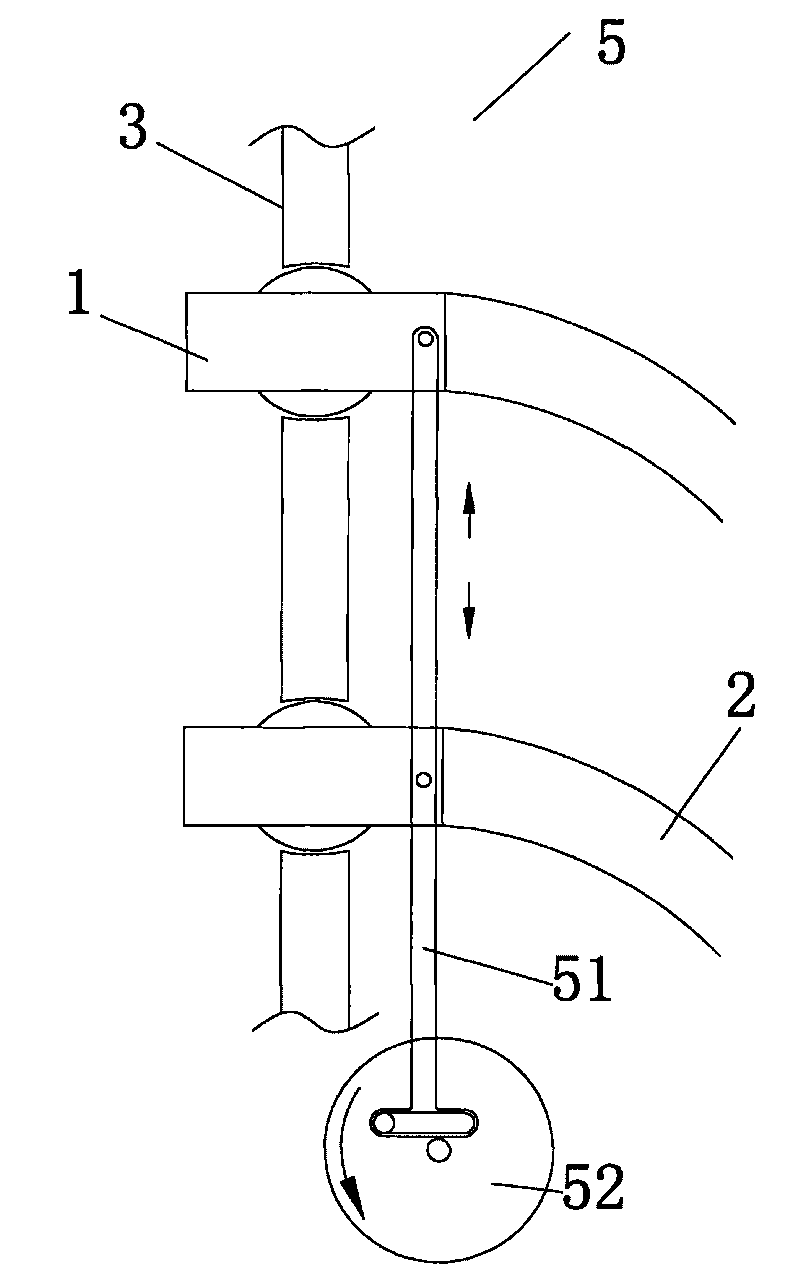

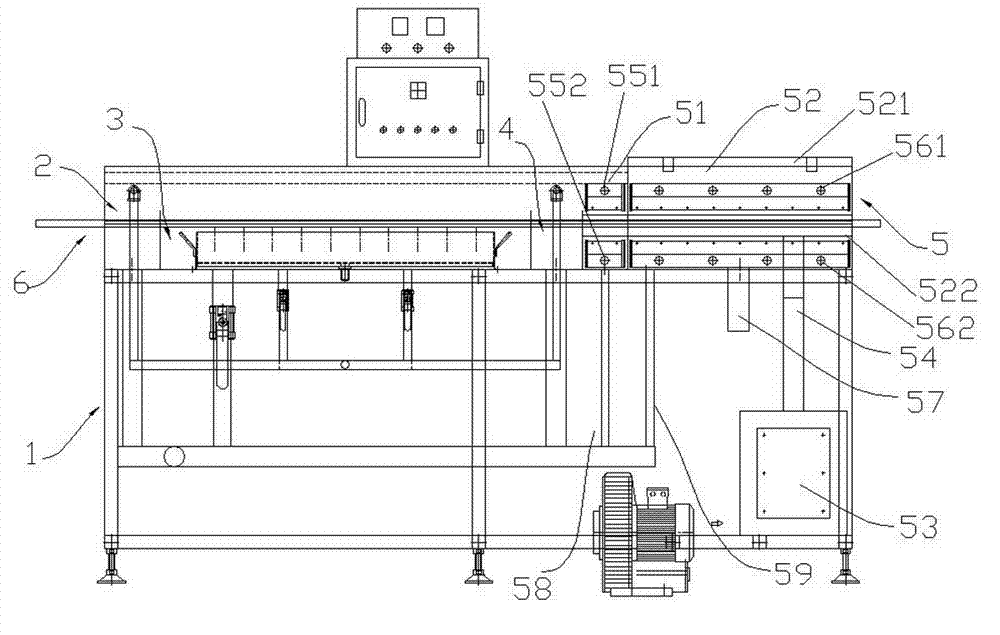

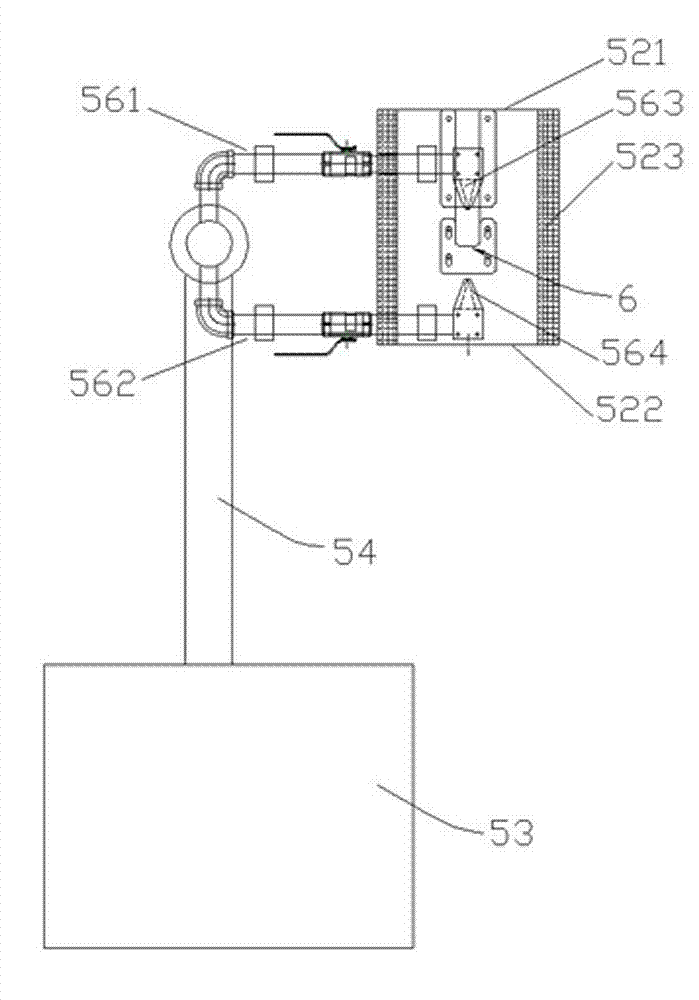

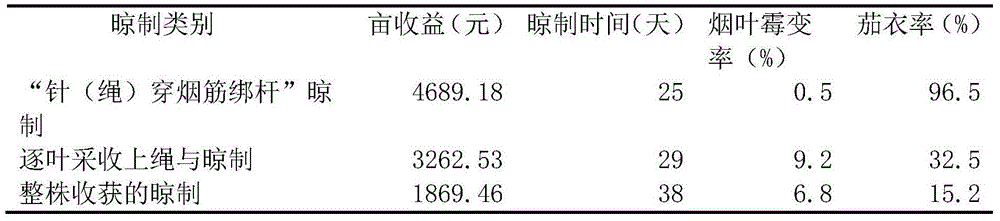

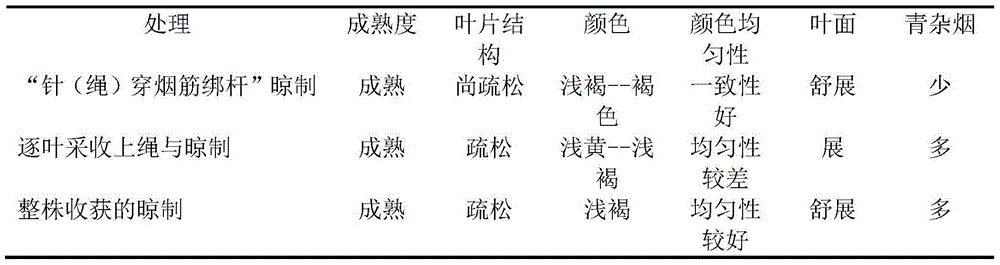

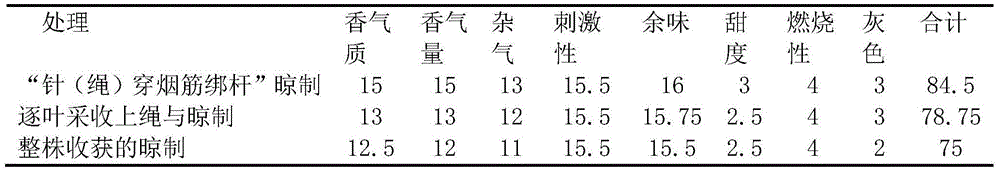

Needle rope threading, tobacco stem binding and airing method of cover of tobacco of cigar

The invention relates to a needle rope passing, tobacco stem binding and airing method of a cover of tobacco of cigar. The method comprises the steps of a, arranging in an airing room; b, picking tobacco; c, threading tobacco leaves; d, binding the tobacco stems; e, suspending; f. hanging to dry by the air; g, taking off. According to the method, the method of airing the cover of the tobacco of the cigar is changed; the method has a good airing effect; the surface and back of the aired tobacco are consistent in color; the produced cover is outstanding; the flavor is remarkable.

Owner:湖北省烟草公司恩施州公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com