Film squeezing machine

A squeeze dryer and film technology, applied in the direction of dryer, drying, drying solid materials, etc., can solve the problems of large floor area, high maintenance cost, high noise, etc., and achieve small floor space and good drying effect Good, easy maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The film squeeze dryer of the present invention will be further described in detail through specific examples below.

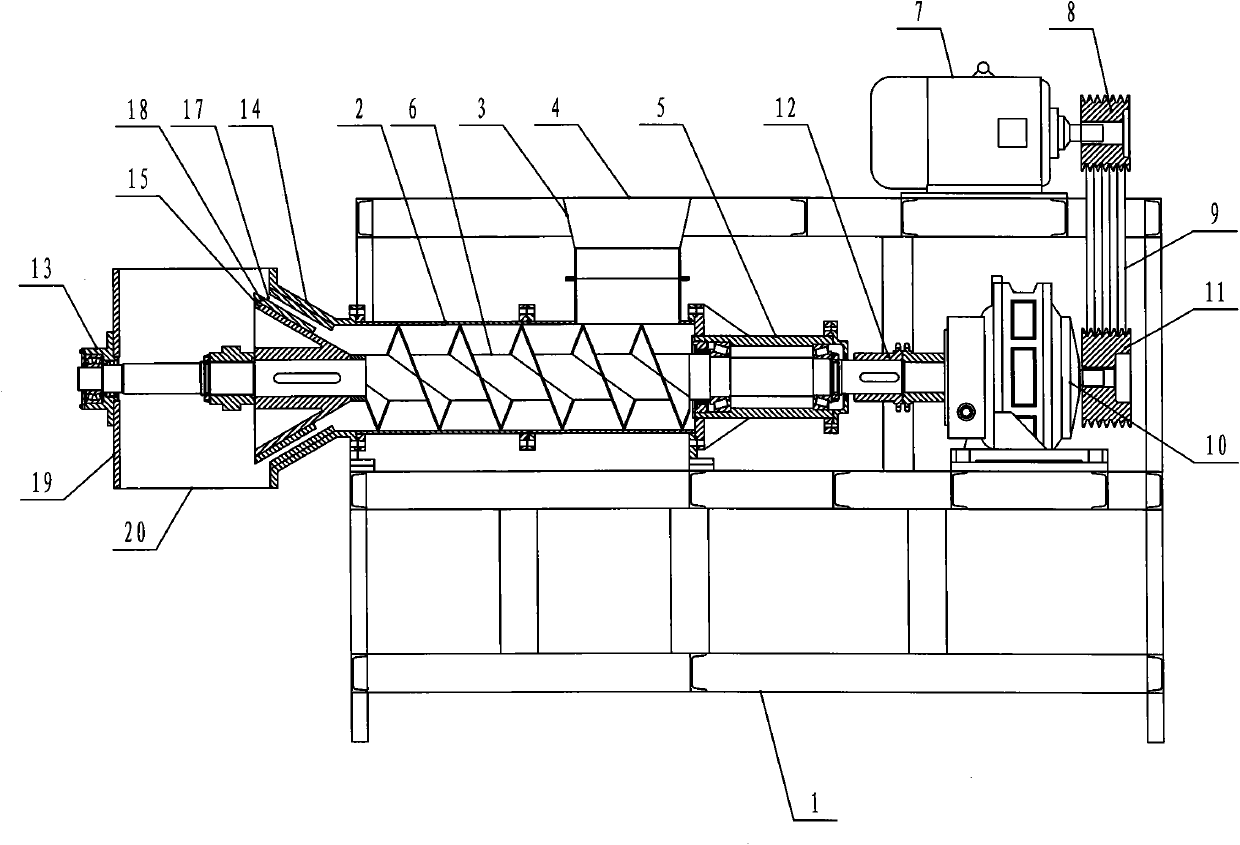

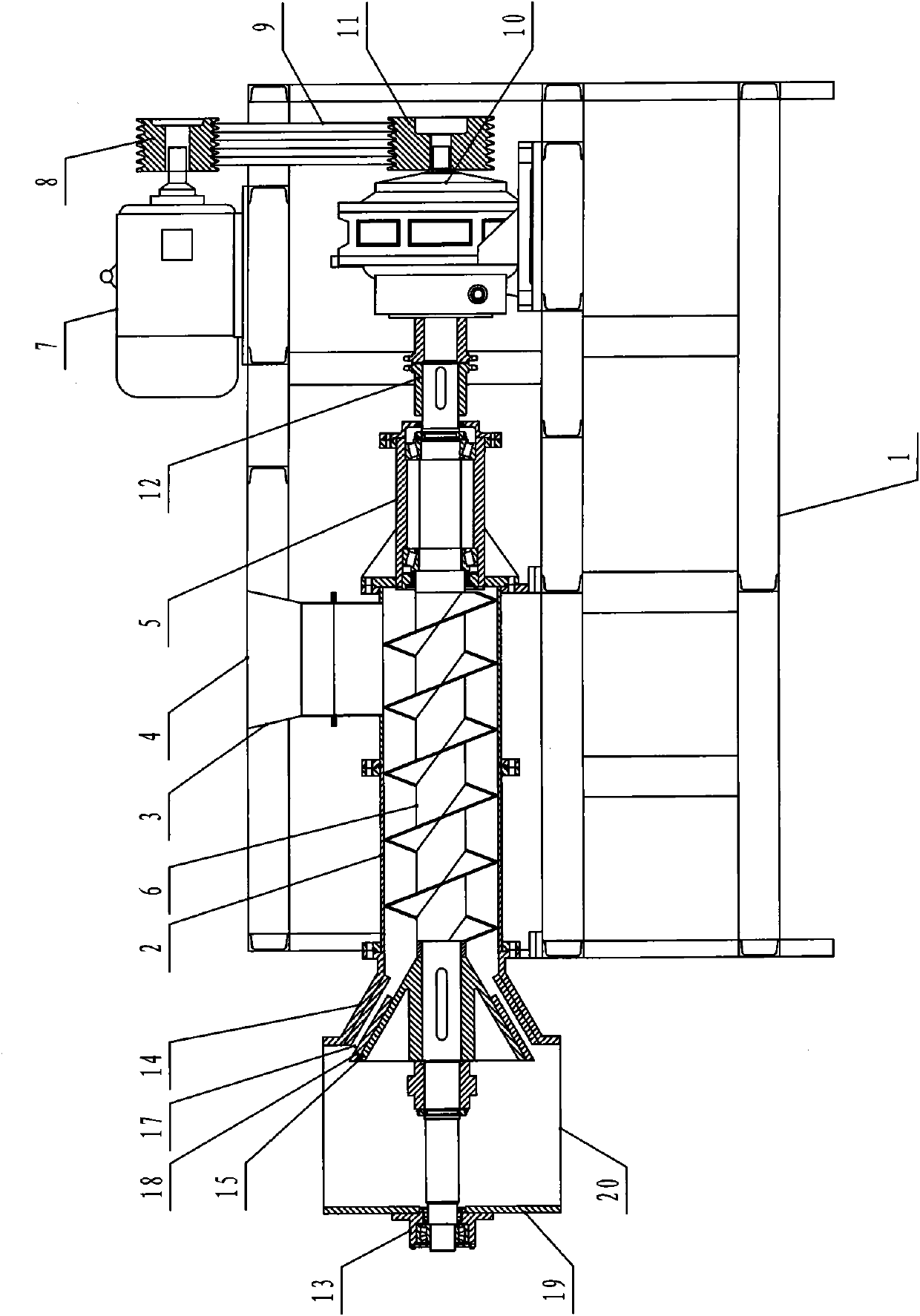

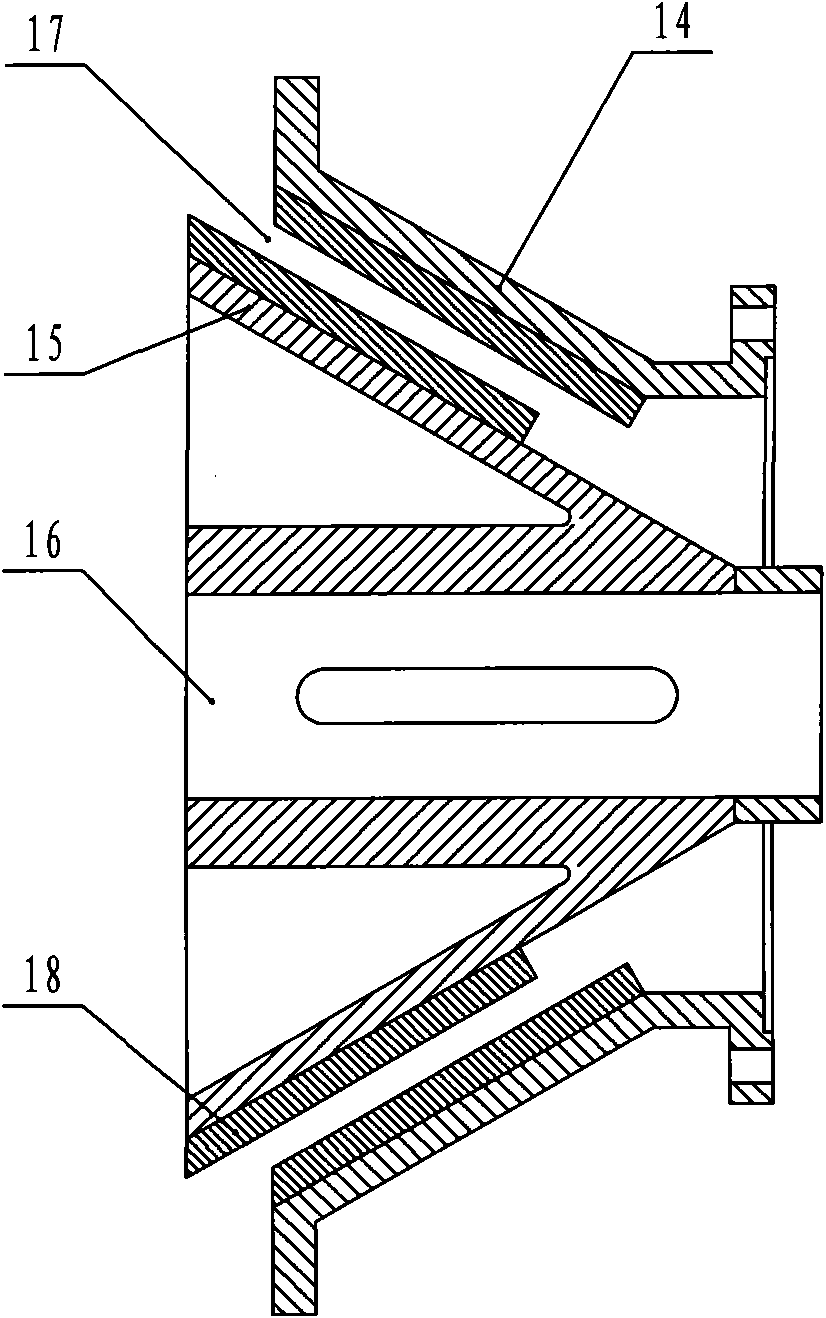

[0013] Such as figure 1 As shown, the film squeezer includes a frame 1, an organic barrel 2 is arranged on the frame, and drainage holes are densely covered on the wall of the barrel 2, and a feeding hopper 3 is arranged on the barrel 2, and the upper part of the feeding hopper 3 is an inlet. The feed port 4, one end of the barrel 1 is connected with the bearing seat 5, the bearing seat 5 is fixedly connected with the frame 1, the inner part of the barrel 2 is provided with a screw 6, and one end of the screw 6 is movably arranged in the bearing seat 5, and is connected with the driving device located outside the bearing seat 5, the driving device includes a motor 7 fixed on the frame 1, the output shaft of the motor 7 is provided with a driving pulley 8, and the driving pulley 8 passes through the belt 9 Connect with the driven pulley 11, the driven p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com