Tea drying plant

A technology for drying equipment and tea, applied in drying, drying machine, lighting and heating equipment and other directions, can solve the problems of inconsistent water loss speed and loss, unguaranteed uniformity, inconsistent drying effect of tea leaves, etc. To achieve the effect of good drying effect, moderate moisture and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

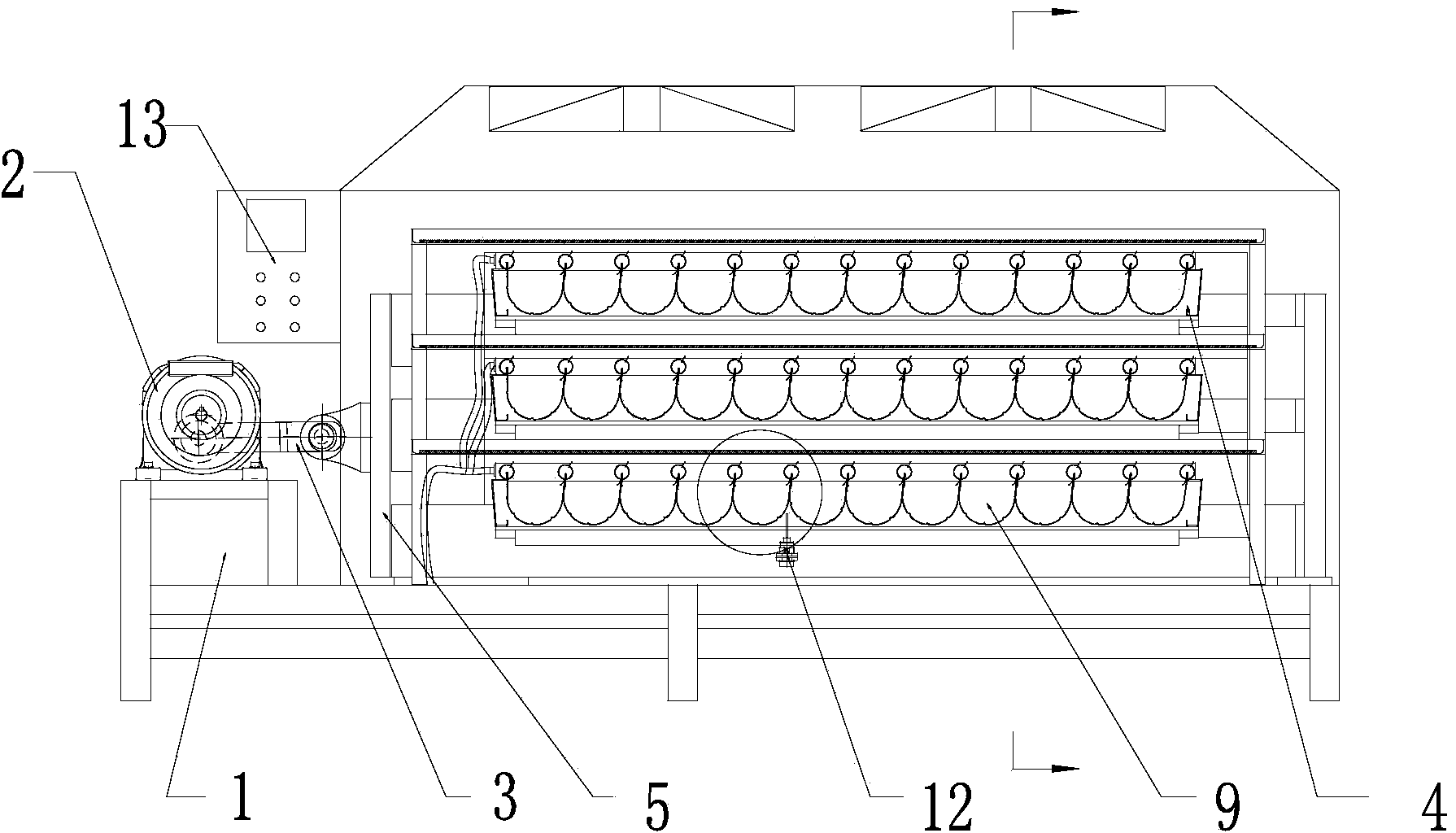

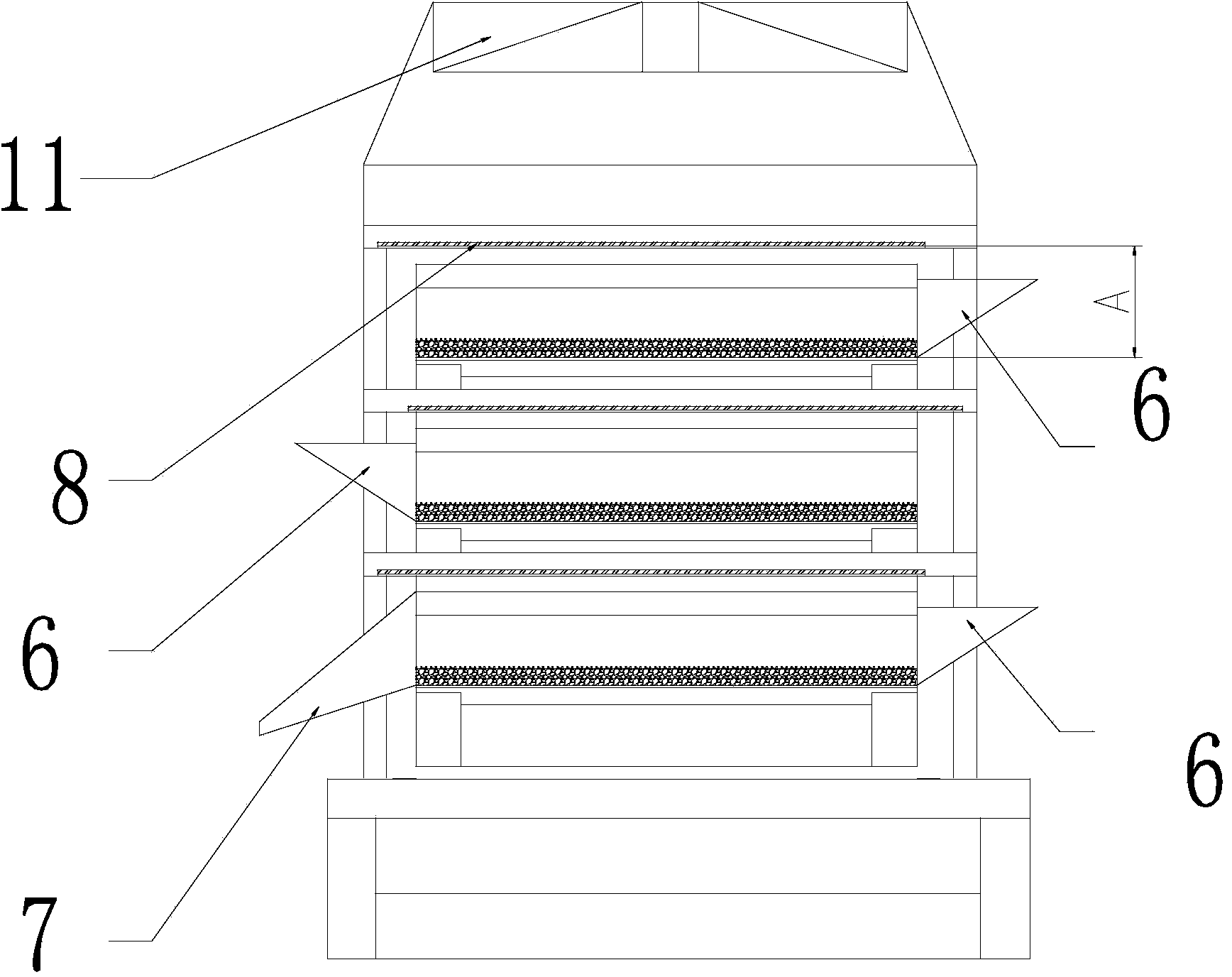

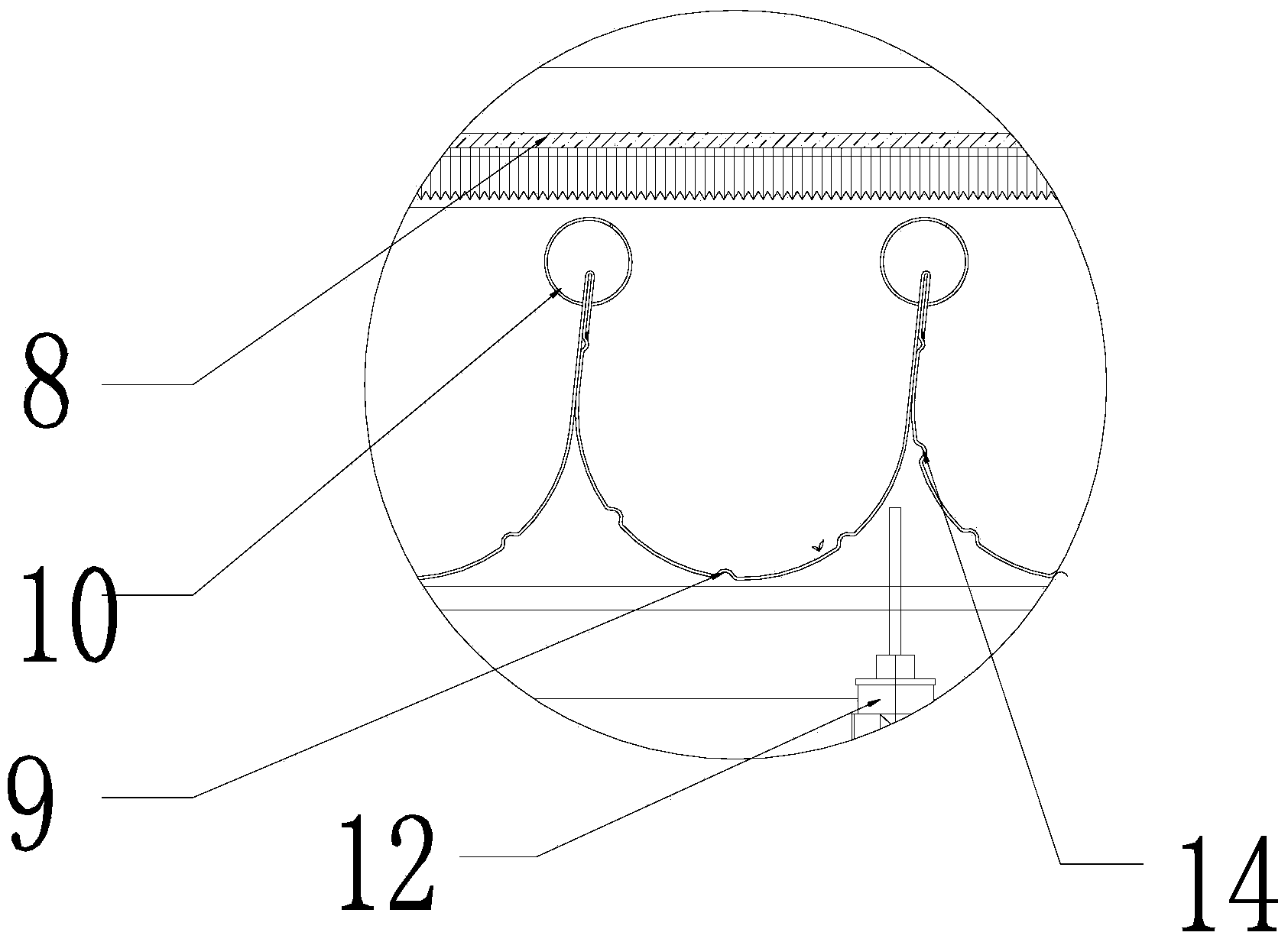

[0019] The present invention will be further described below in conjunction with accompanying drawing.

[0020] like figure 1 and figure 2 As shown, the tea drying equipment of the present invention includes a frame 1, a driving device 2, a transmission device 3, a drying and shaping pot 4, and a heating device. The transmission device 3 is installed on the frame 1, and the driving device 2 Connected to the transmission device 3, the shaping pot is connected to the transmission device 3, and also includes a drying chamber 5, the drying shaping pot 4 is two or more, and the drying shaping pot 4 is arranged in the drying chamber in layers 5; the drying and shaping pot 4 is provided with a feed position and a discharge level, and the feed level of the same layer of drying and shaping pot 4 is higher than the discharge level, and the feed level of the next layer of drying and shaping pot 4 is the same as The output level of the last layer of drying and shaping pot 4 is correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com