Three-dimensional simulative wood grain powder coating for aluminum profile and preparation method for three-dimensional simulative wood grain powder coating for aluminum profile

A powder coating, three-dimensional technology, applied in the direction of powder coatings, polyester coatings, coatings, etc., can solve the problems of monotonous texture, poor weather resistance, not vivid enough, etc., to achieve increased fluidity, mechanical properties and good weather resistance. The effect of dry effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

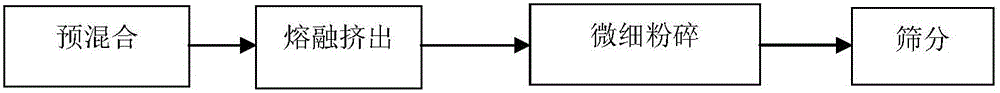

[0049] Prepare the three-dimensional simulation wood grain powder coating for aluminum profile according to the following steps:

[0050] In the first step, prepare the first spraying type A powder and the second spraying type B powder respectively; both of them are dry mixed powder coatings,

[0051] Wherein the A-type powder includes A1-type powder and A2-type powder, the weight ratio of the A1-type powder and A2-type powder is 1:1, according to the following formula, the A1-type powder is pre-mixed, and the A2-type powder is pre-mixed :

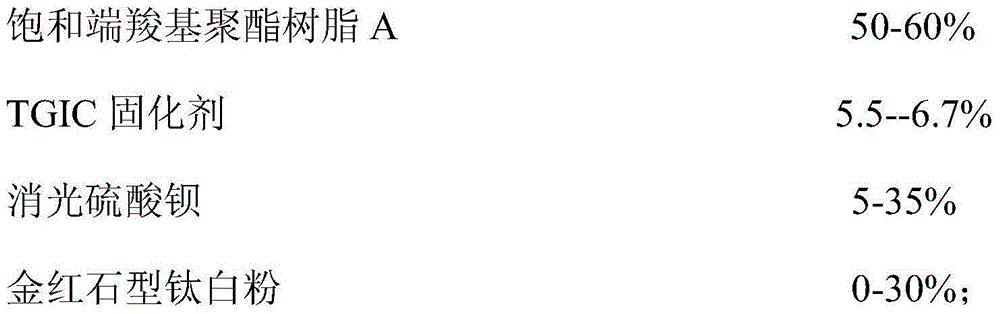

[0052] A1 type powder comprises the raw material of weight percent as follows:

[0053]

[0054]

[0055] A2 type powder comprises the raw material of weight percent as follows:

[0056]

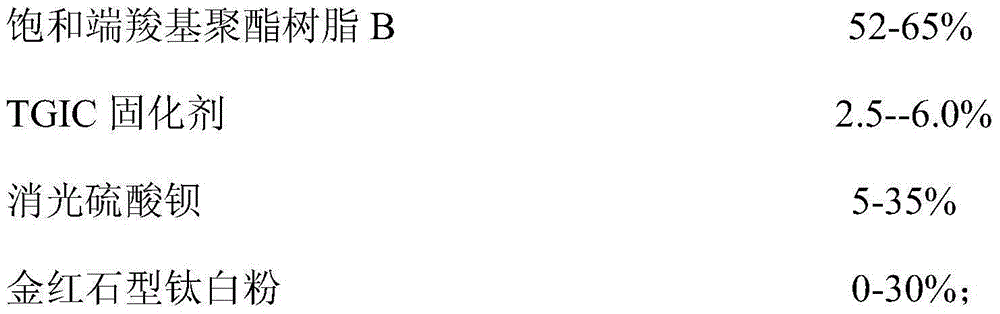

[0057] Wherein the B-type powder includes B1-type powder and B2-type powder, the weight ratio of the B1-type powder and B2-type powder is 1:1, according to the following formula, the B1-type powder is pre-mixed, and the B2-type powder is pre-m...

Embodiment 2

[0076] Prepare the three-dimensional simulation wood grain powder coating for aluminum profile according to the following steps:

[0077] In the first step, prepare the first spraying type A powder and the second spraying type B powder respectively; both of them are dry mixed powder coatings,

[0078] Wherein the A-type powder includes A1-type powder and A2-type powder, the weight ratio of the A1-type powder and A2-type powder is 1:1, according to the following formula, the A1-type powder is pre-mixed, and the A2-type powder is pre-mixed :

[0079] A1 type powder comprises the raw material of weight percent as follows:

[0080]

[0081] A2 type powder comprises the raw material of weight percent as follows:

[0082]

[0083]

[0084] Wherein the B-type powder includes B1-type powder and B2-type powder, the weight ratio of the B1-type powder and B2-type powder is 1:1, according to the following formula, the B1-type powder is pre-mixed, and the B2-type powder is pre-m...

Embodiment 3

[0098] Prepare the three-dimensional simulation wood grain powder coating for aluminum profile according to the following steps:

[0099] In the first step, prepare the first spraying type A powder and the second spraying type B powder respectively; both of them are dry mixed powder coatings,

[0100] Wherein the A-type powder includes A1-type powder and A2-type powder, the weight ratio of the A1-type powder and A2-type powder is 1:1, according to the following formula, the A1-type powder is pre-mixed, and the A2-type powder is pre-mixed :

[0101] A1 type powder comprises the raw material of weight percent as follows:

[0102]

[0103]

[0104] A2 type powder comprises the raw material of weight percent as follows:

[0105]

[0106] Wherein the B-type powder includes B1-type powder and B2-type powder, the weight ratio of the B1-type powder and B2-type powder is 1:1, according to the following formula, the B1-type powder is pre-mixed, and the B2-type powder is pre-m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com