Patents

Literature

66results about How to "Not easy to weather" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Artificial float stone and its manufacturing method

The invention relates an approach to produce artificial pumice. It is burned by nether materials: inorganic material, sodium hydroxide, borax, Paris white, carbon dust and isinglass. Thereinto, inorganic material is selected from minerals or clay. It follows nether steps: mixing above materials in terms of given ratio, cracking blending to 60-200 items and loading into a module to bake.

Owner:郭勇

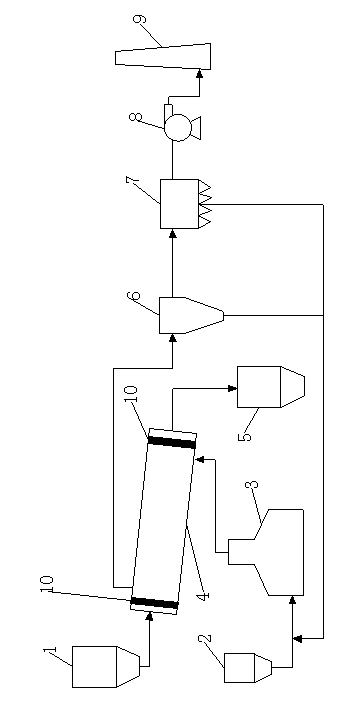

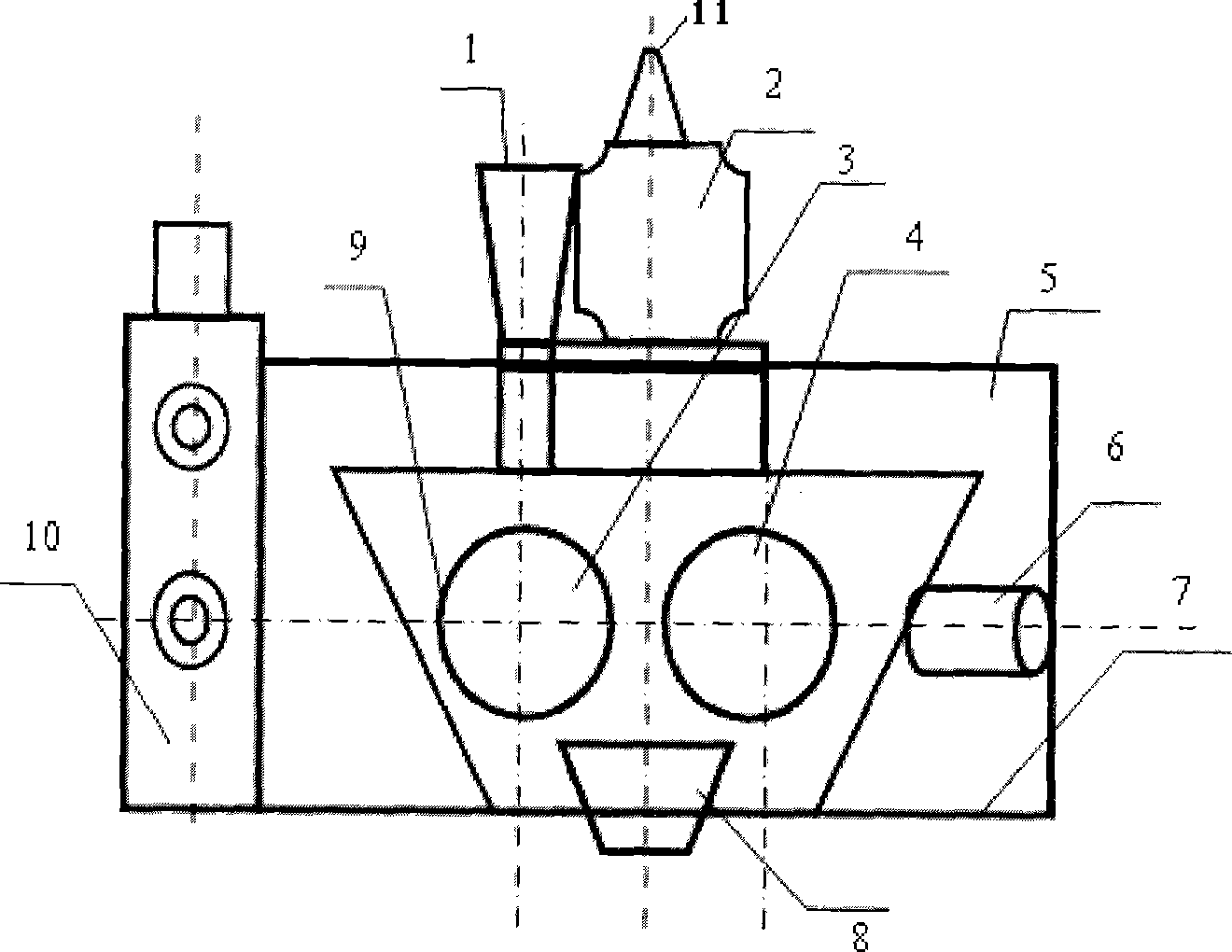

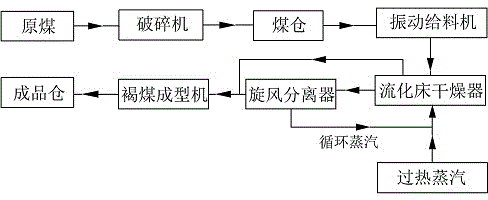

Efficient drying and quality-improving device and method for brown coal

The invention relates to an efficient drying and quality-improving device and method for brown coal. In the prior art, no efficient drying and quality-improving device or method for brown coal, which is used for improving the utilization value of the brown coal, exists. The efficient drying and quality-improving device is characterized by comprising a coal storage bin, a fuel bin, a hot blast stove, a cylinder-type dryer, a product bin, a cyclone dust collector, an electrical dust collector and a plurality of pipelines, wherein both the product bin and the coal storage bin are connected with the cylinder-type dryer; the cylinder-type dryer is connected with the cyclone dust collector; and the cyclone dust collector, the electrical dust collector, the fuel bin are all connected with the hot blast stove. The method is characterized in that the raw material of the brown coal is conveyed into the cylinder-type dryer from the coal storage bin; the hot blast stove generates high-temperature flue gas at the temperature of 700-900 DEG C, and the flue gas is conveyed into the cylinder-type dryer; the raw material of the brown coal is dried by the high-temperature flue gas and conveyed into the product bin from the cylinder-type dryer for sealing and cooling, so that the finished product of the brown coal is obtained after cooling. According to the device and the method, the moisture in the brown coal can be reduced substantially, and a part of ash content in the brown coal can also be reduced, so that the utilization value of the brown coal can be improved.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

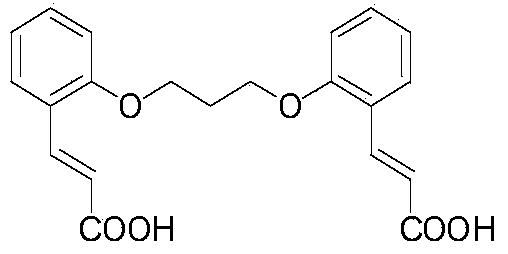

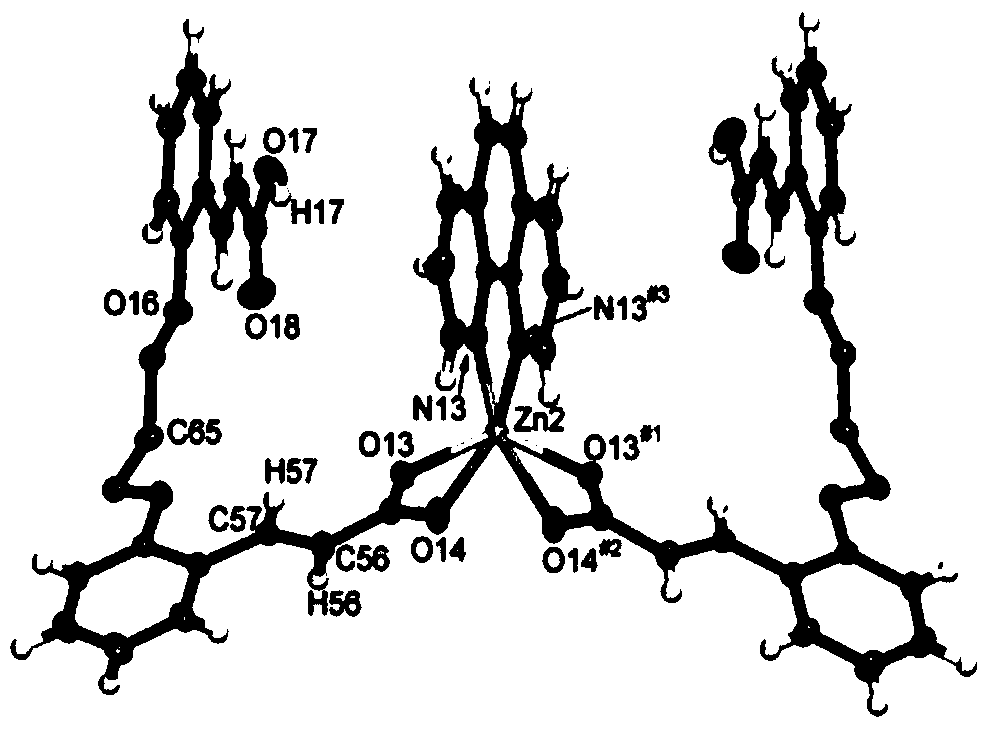

Luminescent material Zn(phen)(HL)2 and preparation method thereof

ActiveCN103524539ANot easy to weatherExcellent foundation for developmentLuminescent compositionsZinc organic compoundsLuminescent materialCoordination complex

The invention belongs to the technical field of luminescent materials, and concretely relates to a luminescent material Zn(phen)(HL)2 and a preparation method thereof. A technical problem to be solved is to provide a luminescent material. A technical scheme in the invention is characterized in that the molecular structure of a luminescent complex Zn(phen)(HL1)2 is shown in the specification. The invention also provides the preparation method of the complex Zn(phen)(HL)2. The invention provides a new blue luminescent material.

Owner:CHONGQING NORMAL UNIVERSITY

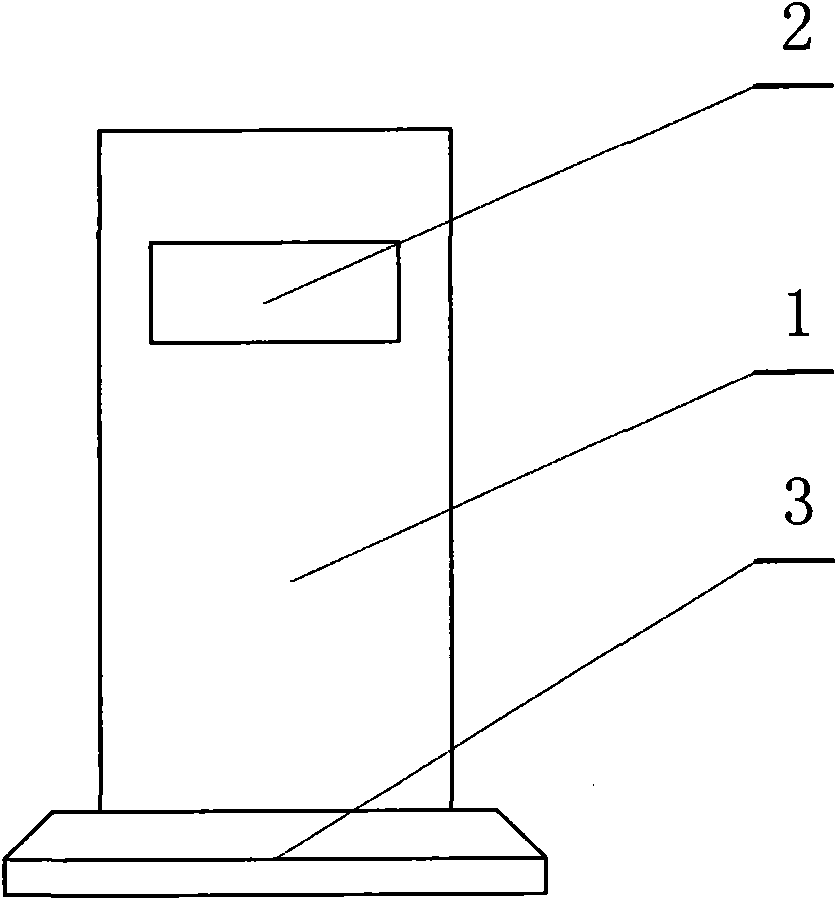

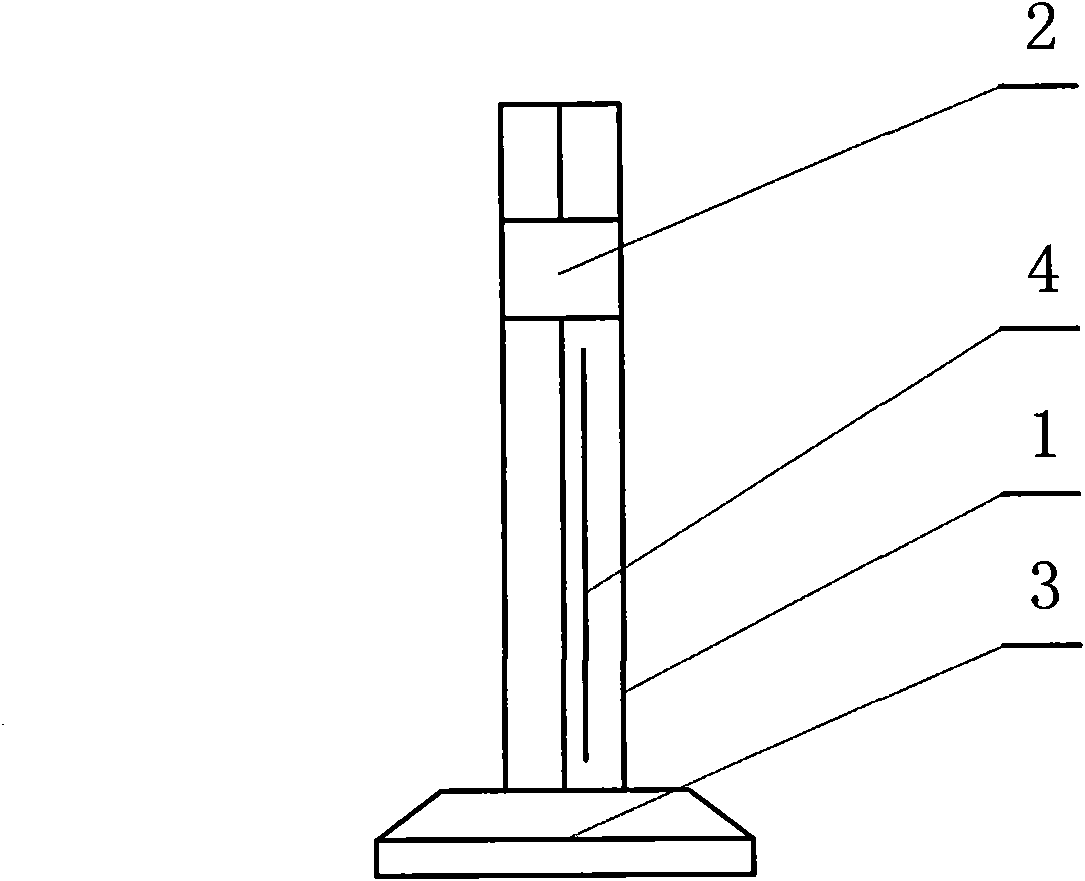

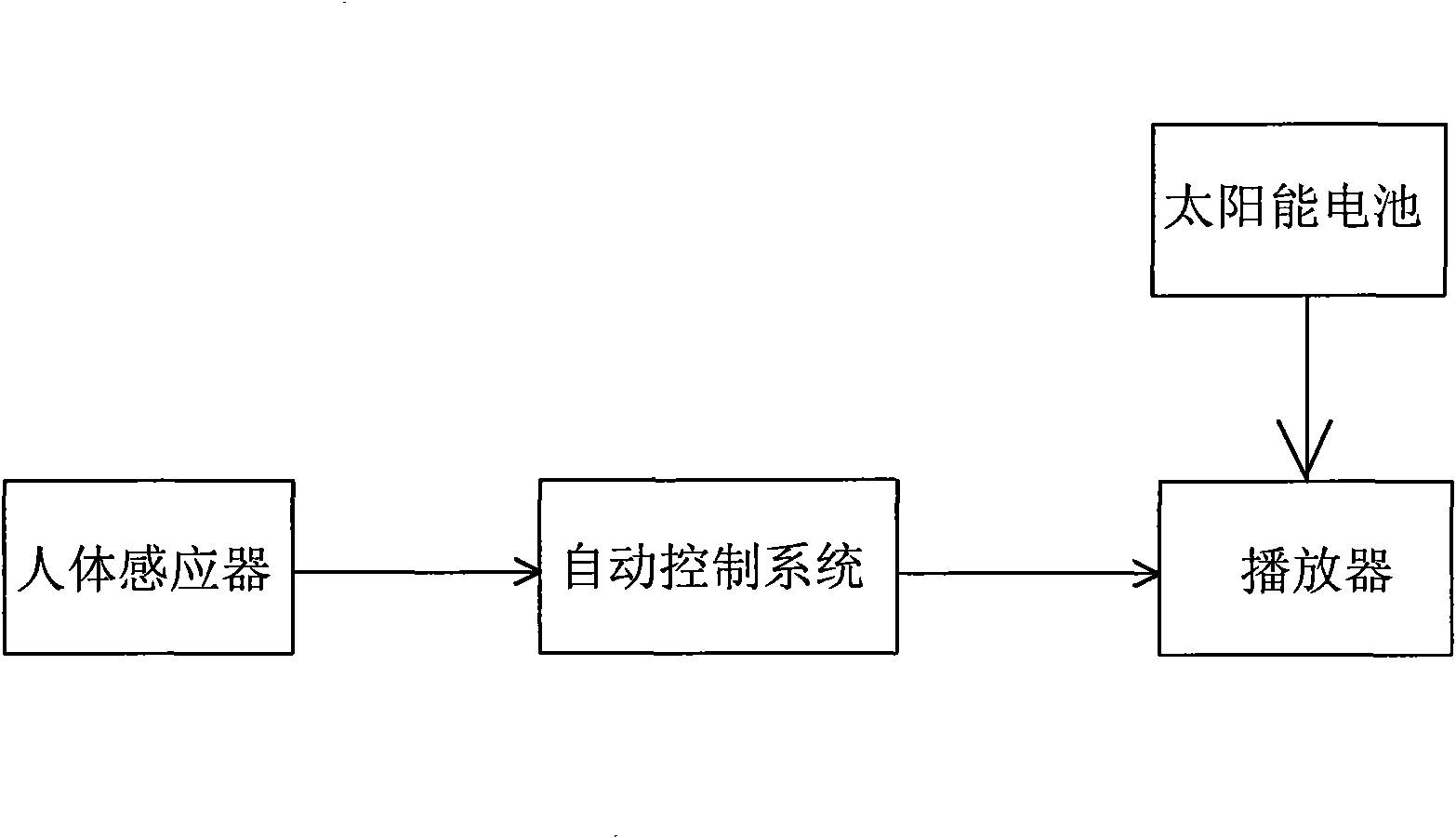

Intelligent electronic grave monument

InactiveCN101876214AAvoid replacementNot easy to weatherBurial vaultsMonumentsAutomatic controlControl system

The invention relates to an intelligent electronic grave monument, which comprises a monument board, music and video play equipment and a monument seat, wherein the monument seat is provided with a slot; the monument board is arranged in the slot of the monument seat, and is double-layer shading crystal glass; monumental writings and patterns are engraved on the inner layer of a monument board body; a hole is reserved over the monument board and is provided with the music and video play equipment; and the music and video play equipment comprises a solar battery, a human body induction detection switch, automatic control system software and a player. The intelligent electronic grave monument has the function of automatically identifying passers-by and worshipers, and has the characteristics of elegance, uniqueness, simple and convenient process manufacturing, high corrosion resistance and the capacity of realizing music and video automatic play.

Owner:江兰芳

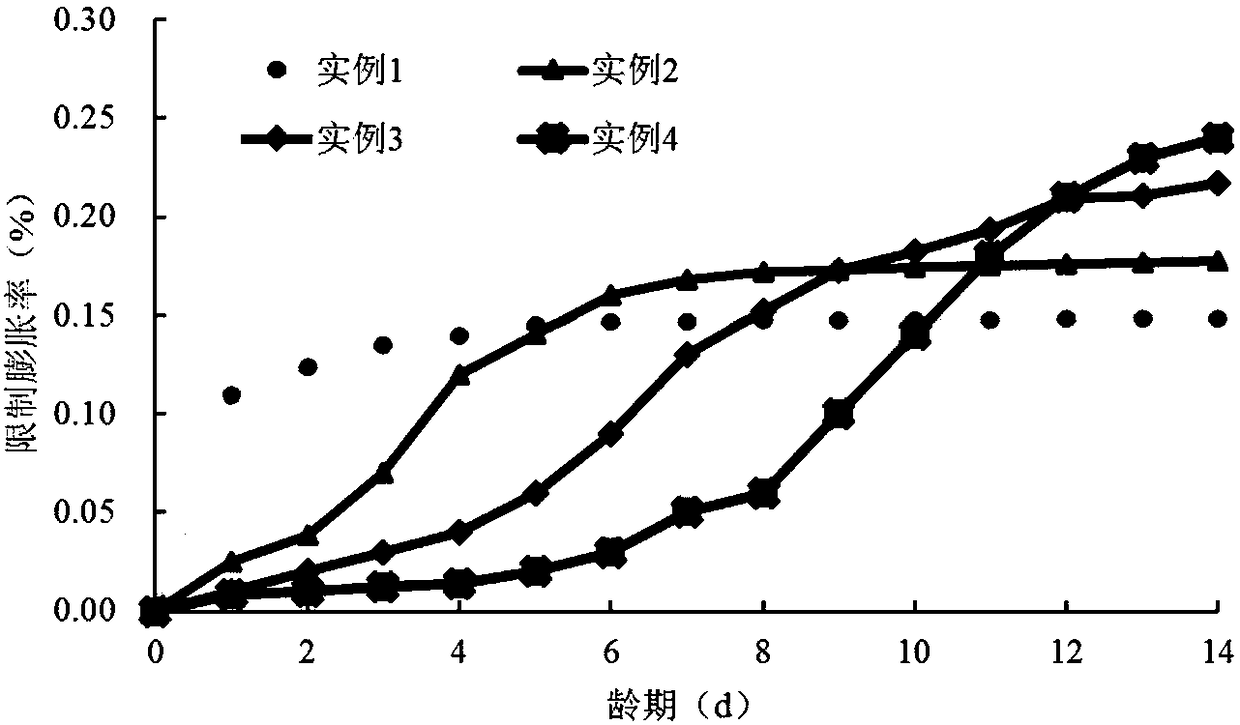

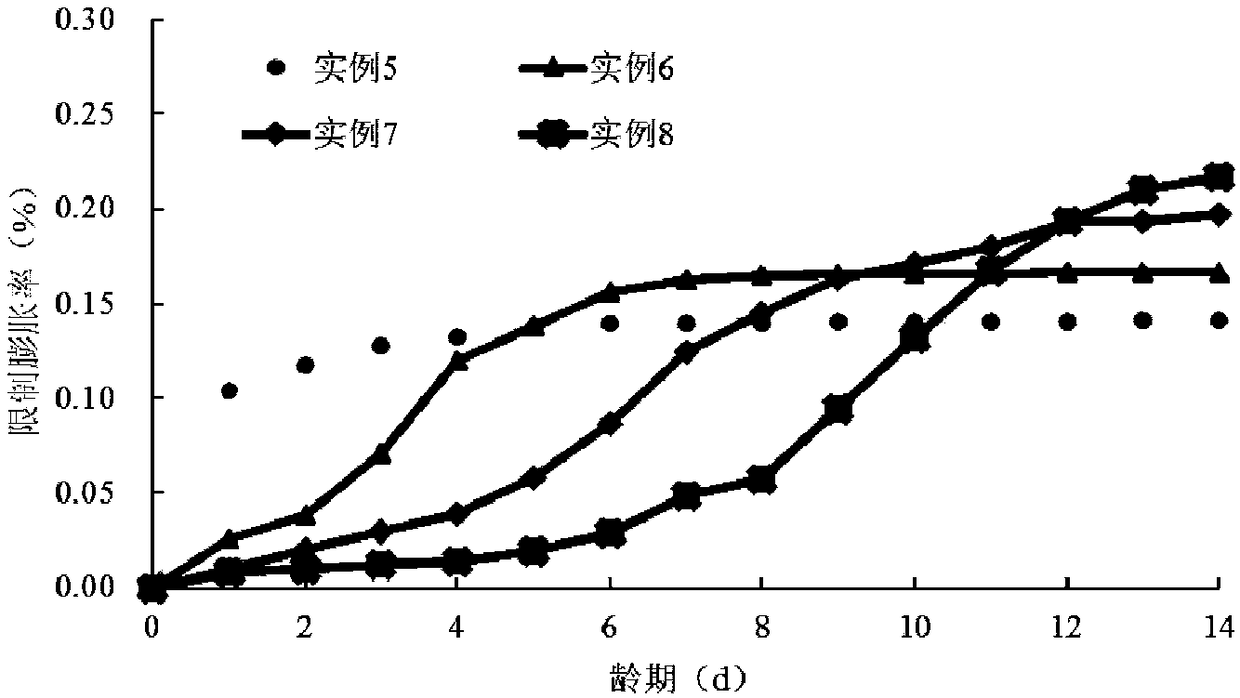

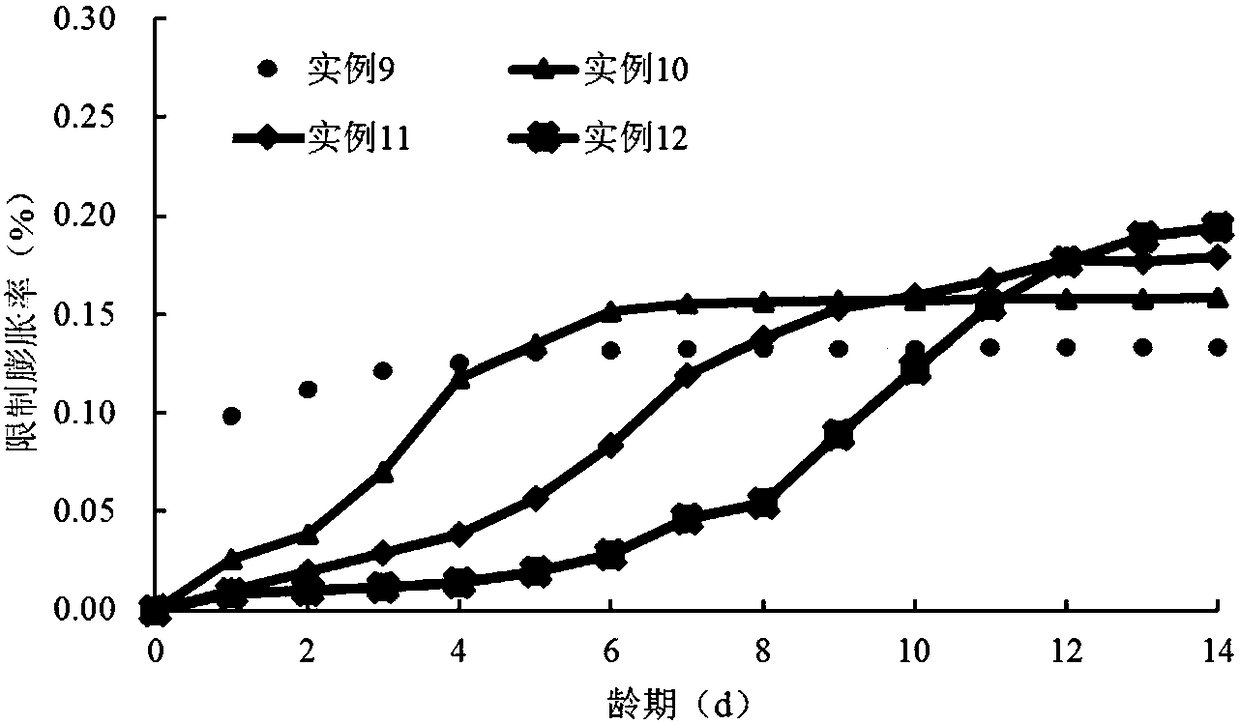

Modified calcium oxide type expanding agent with controllable expansion course and preparation method thereof

ActiveCN108328961ARegulating the expansion processEnhanced compensating shrinkage effectResin acidRosin

The invention discloses a modified calcium oxide type expanding agent with a controllable expansion course and a preparation method thereof. The specific surface area of the modified calcium oxide type expanding agent is 300m<2> / kg to 500m<2> / kg; the modified calcium oxide type expanding agent is prepared by coating calcium oxide clinker with rosin resin acid and uniformly mixing the calcium oxideclinker with a coagulation regulation component; the mass ratio of the calcium oxide clinker to the rosin resin acid to the coagulation regulation component is (990 to 996) to (2 to 8) to 2. When themodified calcium oxide type expanding agent is applied, the expansion course of the calcium oxide type expanding agent can be remarkably regulated and expansion energy loss of the calcium oxide typeexpanding agent at a concrete plastic stage is reduced; more beneficial expansion is generated in a concrete hardening process and a shrinkage compensating effect of the calcium oxide type expanding agent is efficiently expressed.

Owner:NANJING HYDRAULIC RES INST

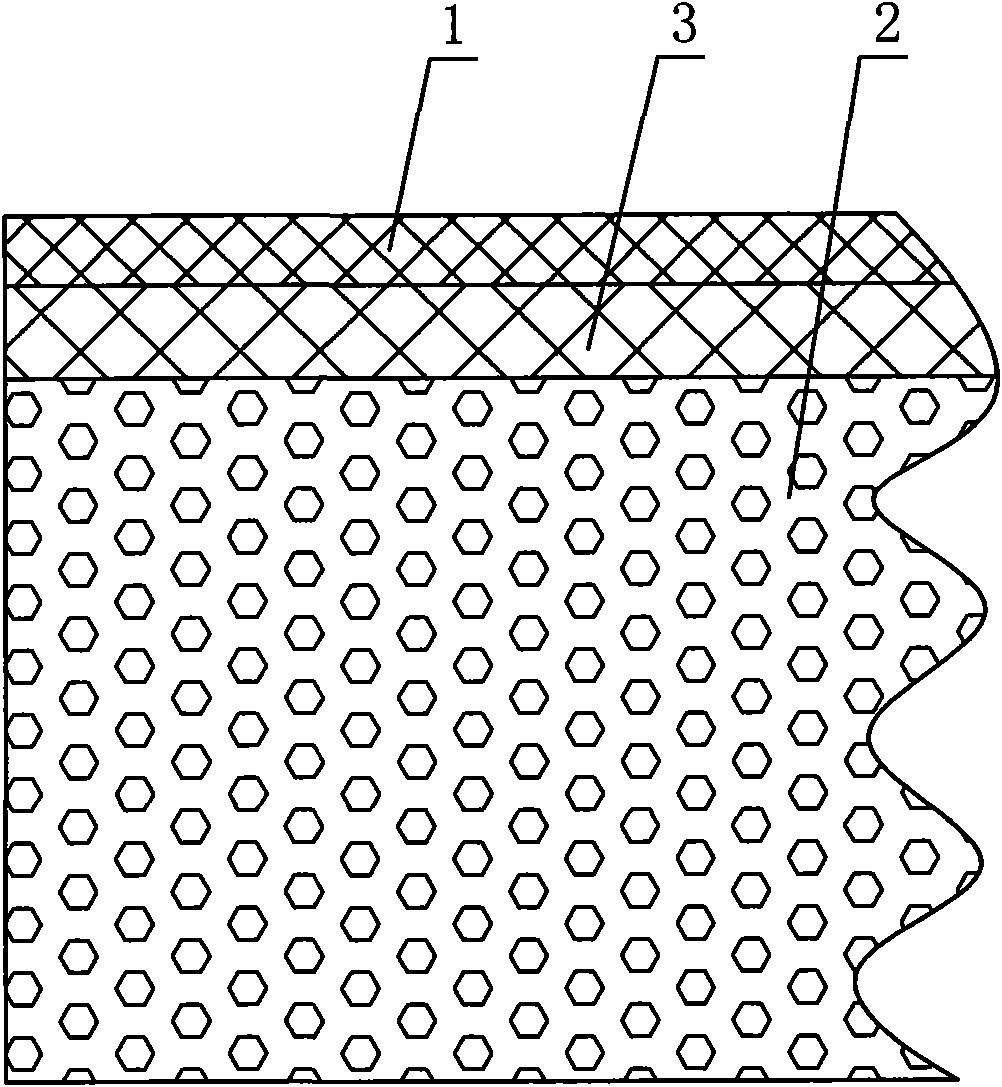

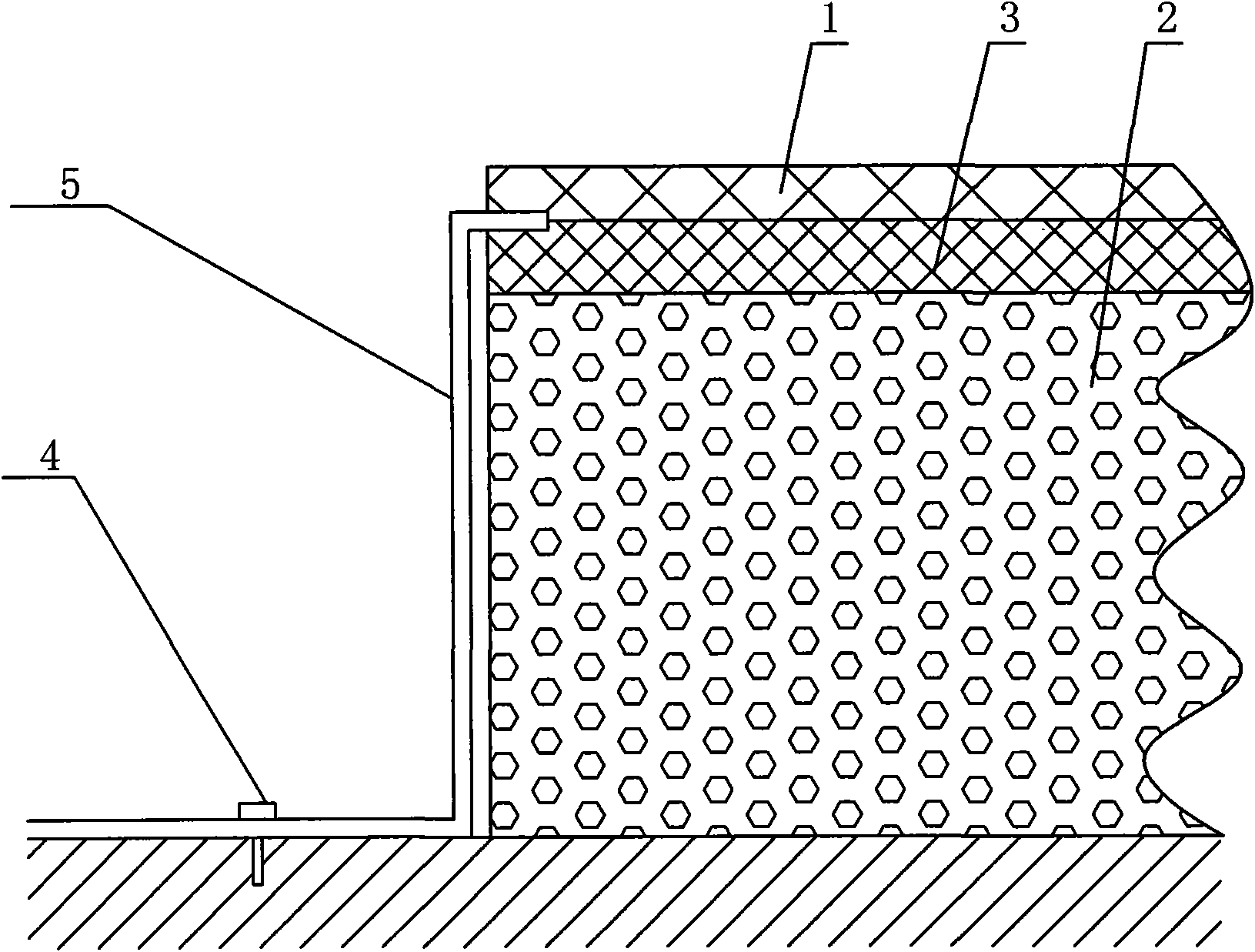

Stone thermal insulating composite panel

InactiveCN101597939ANon-flammableNot easy to burstConstruction materialCovering/liningsSurface layerHigh surface

The invention relates to a stone thermal insulating composite panel which comprises a stone surface layer and is characterized by also comprising a thermal insulating layer and a substrate, wherein a plurality of fine closed holes are distributed inside the thermal insulating layer; the substrate is arranged between the stone surface layer and the thermal insulating layer; and the stone surface layer, the substrate and the thermal insulating layer are integrally fixed by a binding agent. The stone thermal insulating composite panel has the advantages of simple structure, good thermal insulating effect, light weight, convenient installation, good weatherability and high surface rigidity. The stone thermal insulating composite panel of the invention can improve the indoor thermal insulating effect and reduce the energy consumption.

Owner:重庆鑫坚雅装饰材料有限公司

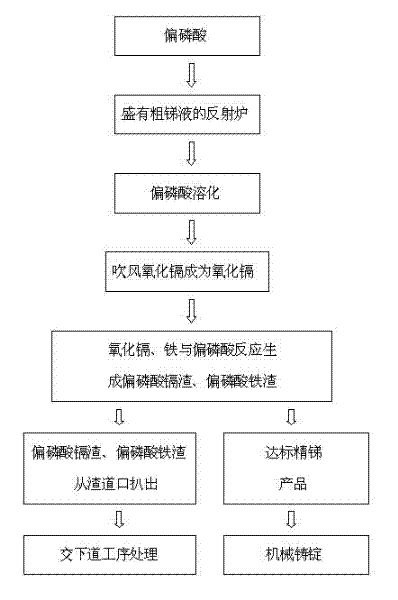

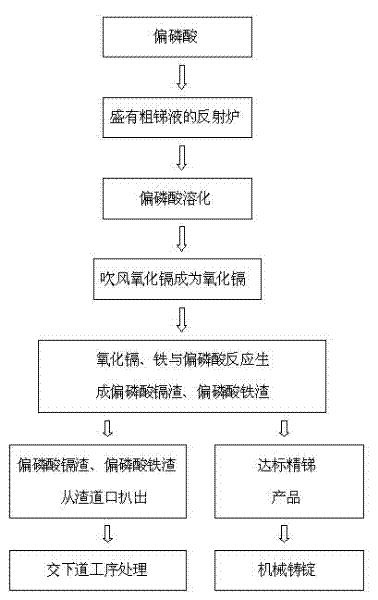

Method for removing cadmium and ferrum from crude antimony by using metaphosphoric acid

The invention discloses a method for removing cadmium and ferrum from crude antimony by using metaphosphoric acid. The method is carried out according to the following steps that: the metaphosphoric acid is added into a metallurgical furnace containing crude antimony liquid, and the furnace is continuously heated to melt the metaphosphoric acid, so that the metaphosphoric acid can cover on the surface of the antimony liquid; then, a blowing pipe is inserted into the antimony liquid to blow, the cadmium in the antimony liquid is oxidized into cadmium oxide, the temperature of the furnace is maintained, the continuous blowing is carried out, the cadmium oxide and the ferrum in the antimony liquid react with the metaphosphoric acid covering on the surface of the antimony liquid to produce cadmium metaphophate and ferrum metaphophate respectively, and the cadmium metaphophate and the ferrum metaphophate scarify with the metaphosphoric acid and float on the surface of the antimony liquid so as to realize the separation of the cadmium and the ferrum from antimony; and finally, the scum floating on the surface of the antimony liquid is removed. The method for removing the cadmium and the ferrum from the crude antimony, disclosed by the invention, belongs to an originate at home and abroad, the effect of cadmium and ferrum removal is good, the process flow is simple, the operation is convenient, the production cost is low, the pollution of environment cannot be generated, the production practicality is strong, considerable economic benefits are produced, and meanwhile, excellent environmental benefits are also brought.

Owner:HUNAN LOUDI HUAXING ANTIMONY IND

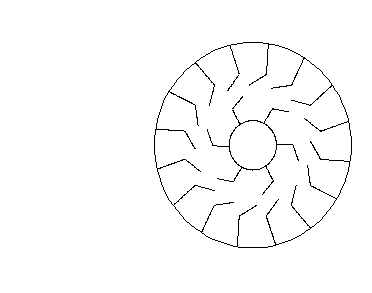

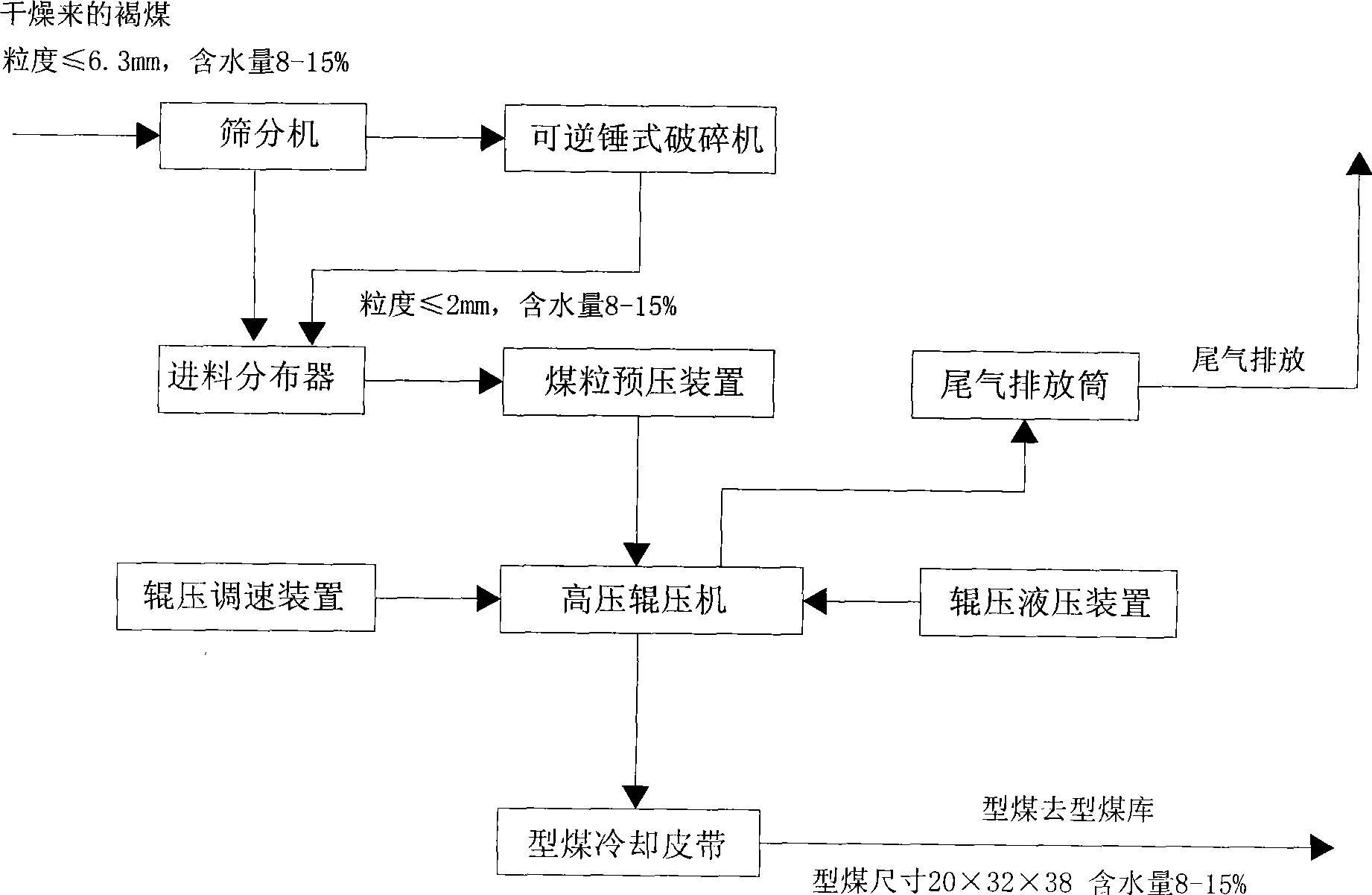

Heat pressing moulding process and equipment for lignite rich in water after drying process

InactiveCN101503641AReduced reabsorptionReduce moistureMetal-working apparatusSolid fuelsWater contentBriquette

The invention discloses hot press molding technology and equipment for water-rich lignite after drying treatment. The technology comprises the following steps that: (1) the dried water-rich lignite of which the water content is between 8 and 15wt percent and the particle size is less than or equal to 6.3mm is further crushed until the particle size is less than or equal to 2mm, and is taken as a feed raw material of a high-pressure roll squeezer; and (2) the hot press molding technology that the lignite is not needed to be added with an adhesive is adopted , the lignite raw material is sent into a material mold through two rolls with opposite rotation motion of the high-pressure roll squeezer, and is pressed into a required shape in the material mold, the temperature for the molding pressing of the lignite is between 60 and 90 DEG C, the pressure for the molding pressing of lignite briquettes is 8,000kN, and the briquette pressure in the unit length is between 24 and75KN / cm. The high-pressure roll squeezer is mainly combined by a positive movement roll shaft, a reverse movement roll shaft, the material mold, a hydraulic speed regulation device, a motor and a support. The briquette pressed by the hot press molding can meet the technological requirements of long-distance transportation and boiler combustion or pure oxygen gasification of coal chemical industry. The process of the hot press molding of the briquette is safe, reliable, economical and environment-friendly.

Owner:SHANGHAI ZEMAG MINDAC MACHINERY EQUIP +1

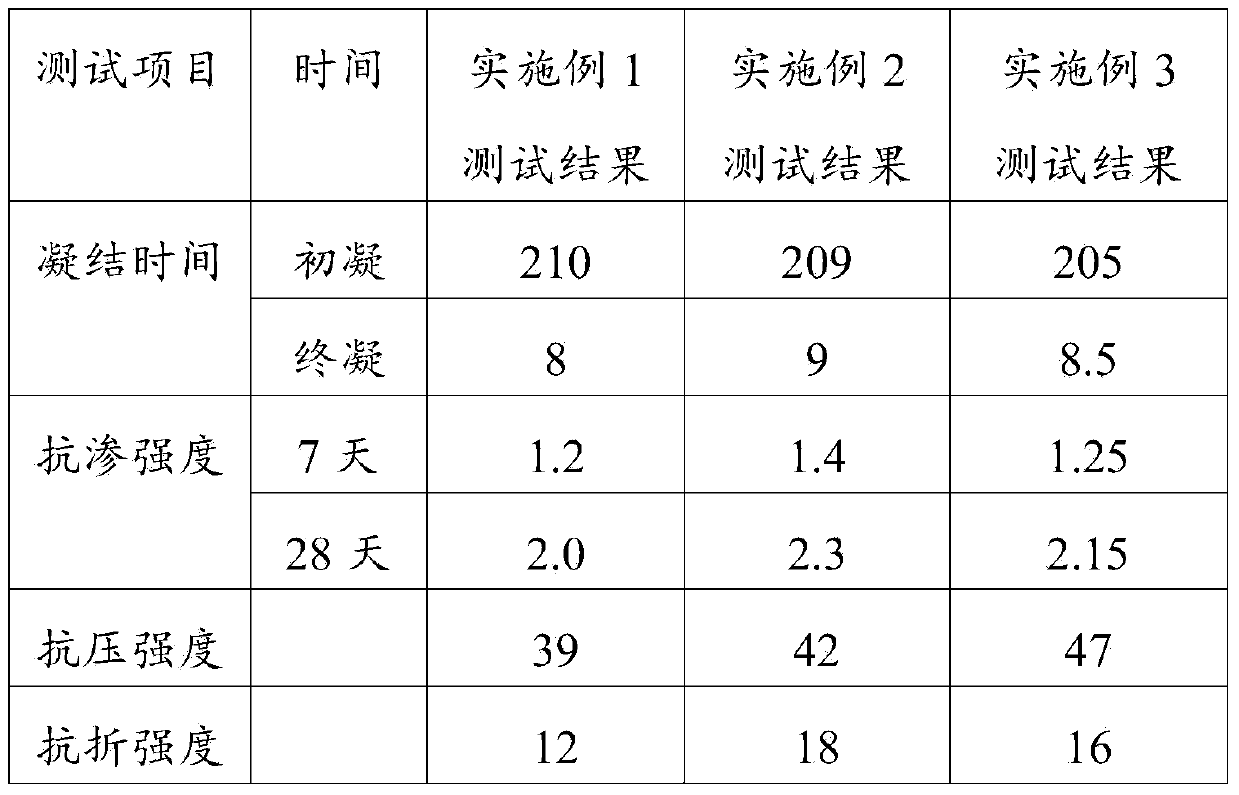

Improved anti-cracking cement

The invention relates to cement, and particularly relates to anti-cracking cement. The improved anti-cracking cement comprises the following components in parts by weight: 48-52 of Portland cement, 35-43 parts of quartz sand, 1-2 parts of water repellent, 6-12 parts of dispersibility rubber powder, 1-8 parts of nylon fiber, 2-3 parts of glass fiber, 5-8 of polyethylene rubber powder, 1-10 parts of elastic emulsion, 1-10 parts of lightweight thermal insulation material and 35-40 parts of water. After the improved anti-cracking cement is solidified, the anti-cracking function and the skid resistance function of the improved anti-cracking cement provided by the invention are further improved through reasonable combination. The toughness of a cement layer can be effectively improved, and the possibility of wall cracking and crack water entry is reduced. Meanwhile, as the water resistance of the improved anti-cracking cement is relatively good, walls are difficult to corrode, and cracking parts are difficult to further weather.

Owner:GUILIN FUGANG NEW MATERIAL

Granite waste rock powder ceramsite and preparation method thereof

InactiveCN107445646AHigh in silicaHigh hardnessCeramic materials productionCeramicwareExpanded clay aggregateCoal

The invention discloses granite waste rock powder ceramsite, which is prepared from the following ingredients in percentage by mass: 50.0 to 80.0 percent of granite waste rock powder, 4.0 to 15.0 percent of clay tailings, 10.0 to 20.0 percent of waste porcelain powder, 5.0 to 10.0 percent of clay and 1.0 to 5.0 percent of pulverized coal. The invention also discloses a preparation method of the granite waste rock powder ceramsite. The process is simple; the cost is low; a large amount of granite waste rock powder is consumed; the waste utilization rate is high; the performance of the prepared granite waste rock powder ceramsite is excellent; the application prospects are wide. By the process, the raw materials are directly mixed and pelletized, and are then put into a high-temperature furnace to be calcined to be prepared into the granite waste rock powder ceramsite; the formation process is simplified; the work efficiency is improved; meanwhile, the preparation method is suitable for mass production.

Owner:UNIV OF JINAN

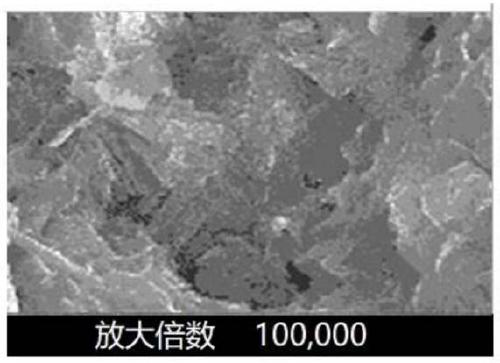

Granite waste rock powder ceramsite pervious concrete and preparation method thereof

InactiveCN107445556AHigh in silicaHigh hardnessCeramicwareExpanded clay aggregatePulverized fuel ash

The invention provides granite waste rock powder ceramsite pervious concrete and a preparation method thereof. The granite waste rock powder ceramsite pervious concrete is prepared from the following ingredients in percentage by weight: 60 to 75 percent of granite waste rock powder ceramsite, 10 to 25 percent of cement, 6 to 20 percent of pulverized fuel ash, 0.1 to 0.5 percent of water reducing agents and 7 to 8 percent of water, wherein the granite waste rock powder ceramsite has the grain diameter being 10 to 20mm, and is prepared from the following ingredients in percentage by weight: 50 to 80 percent of granite waste rock powder, 4 to 15 percent of clay tailings, 10 to 20 percent of waste porcelain powder, 5 to 10 percent of clay and 1 to 5 percent of coal dust. A large amount of granite waste rock powder ceramsite is used for replacing natural aggregate; the surface of the granite waste rock powder ceramsite is hard; fine and fine honeycomb micropores are formed at the inside; the characteristics of small density, low heat conductivity, high strength and good water permeability are realized. Meanwhile, the fireproof performance of the ceramsite sintered through high temperature is excellent; the consistency with the concrete is good; the performance of the pervious concrete can be obviously improved.

Owner:UNIV OF JINAN

Building material manufactured by mud as raw material and preparation method thereof

A building material for house, road, bridge, etc is prepared from sludge through drying, breaking, sieving, proportionally mixing it with clay and adhesive, shaping, sintering and cooling.

Owner:HARBIN INST OF TECH

Light porous artificial stone board and preparation method thereof

ActiveCN106316445ALight in massLow densityCeramic materials productionCeramicwareOn boardArtificial stone

The invention relates to the technical field of building materials and particularly discloses a light porous artificial stone board and a preparation method thereof. The density of the artificial stone board is below 2.0 g / cm<3>, and 500 or more holes are formed in every cubic centime of the artificial stone board. The artificial stone board is prepared from tile waste, kaolin, a foamer, ore sand and glaze. The stone board is low in mass, low in density and high in strength, and has good heat preservation and insulation functions, the waste recovery ratio is larger than 40%, and the stone board belongs to environment-friendly products. The surface texture of the stone board is closer to that of natural stone. The back face of the stone board is porous and is used for outer wall wet combining, a binder can permeate into gaps, engaging force is higher, and the stone board can be firmly attached to an outer wall. In addition, the stone board is calcined at high temperature, has stable physical and chemical performance, and is not prone to weather.

Owner:广州米伽新材料科技有限公司

Manufacturing method of mosaic gold Thangka

ActiveCN103481722AEasy to storeNot easy to weatherDecorative surface effectsSpecial ornamental structuresSurface finishingAfter treatment

The invention discloses a manufacturing method of a mosaic gold Thangka. The manufacturing method comprises the steps as follows: 1), drawing design based on a product program; 2), plate shearing; 3), acid washing: a sheared metal plate is subjected to surface treatment with weak acid; 4), etching: lines, textures, scenes, patterns and the like are etched with an etching technology according to the acid-washed patterns; 5), gold plating: the etched patterns are treated, and the surface of the metal plate is subjected to gold plating with a precious metal; 6), printing: printing is performed according to requirements of the gold-plated patterns; 7), color filling: concave and convex places of the printed metal plate are filled with different colors according to the design requirements; 8), baking and curing and 9), after treatment. The mosaic gold Thangka manufactured with the method is easy to preserve and uneasy to weather and strip, resistance to external environments is improved, and traditional culture can be saved and inherited favorably.

Owner:铜陵铜官府文化创意股份公司

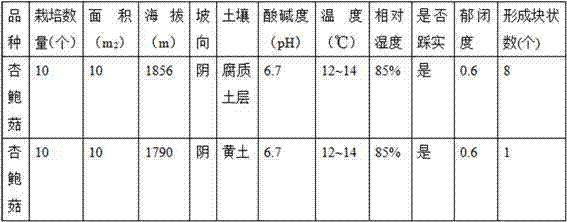

Culture method for tuber edible fungi

InactiveCN104322280ANot easy to ageAging, the mushroom body is not easy to differentiateCultivating equipmentsMushroom cultivationOxygenPollution prevention

The invention discloses a culture method for tuber edible fungi. According to the method, wild culture edible fungus fruiting body tissues are separated to obtain mother seeds, stock seeds are obtained through wheat grain strain propagation culture, the stock seeds are subjected to conventional sterilization inoculation culture, strains with high fungus growth speed and good hypha growth conditions are selected to be used as culture strains, then, sterilization inoculation is carried out, the strains are cultured to the mature state for standby, thick-stem small-cap and thick-flesh low-temperature varieties of the edible fungi are selected and are placed into a pit of a compost soil layer to be filled and buried, and the soil is compactly pedaled by feet, so that the strains naturally absorb nutrition in vegetation, the size of a soil pile jacked up by an edible mushroom pit is observed according to the planting time, whether the soil is continuously covered or not is determined, and then, the large-size blocky edible fungi are harvested. The culture method provided by the invention has the advantages that the special underground growth conditions of moisture preservation, sun shading, oxygen permeation, fertilization, pollution prevention and the like can be effectively combined, so that caps, stems and lamellae of the edible fungi are condensed into a whole in the natural growth process for forming blocky potato mushrooms.

Owner:巴中市恩阳区职业中学

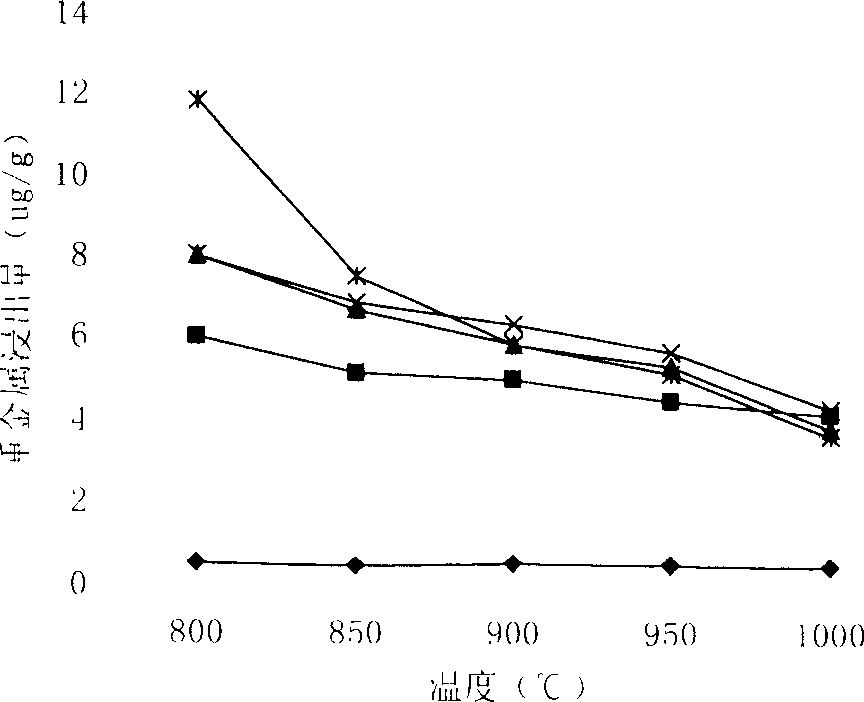

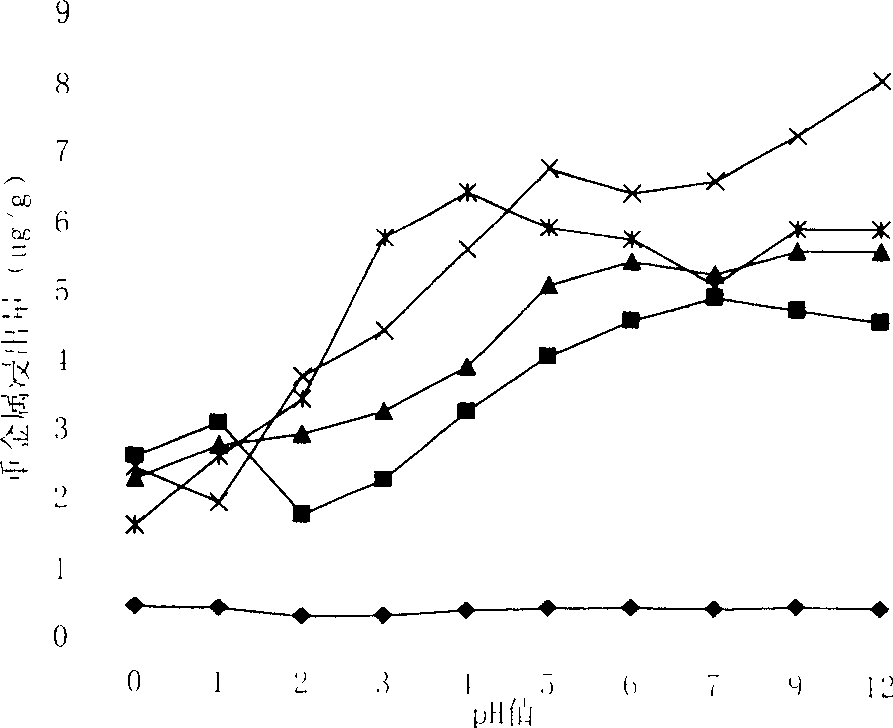

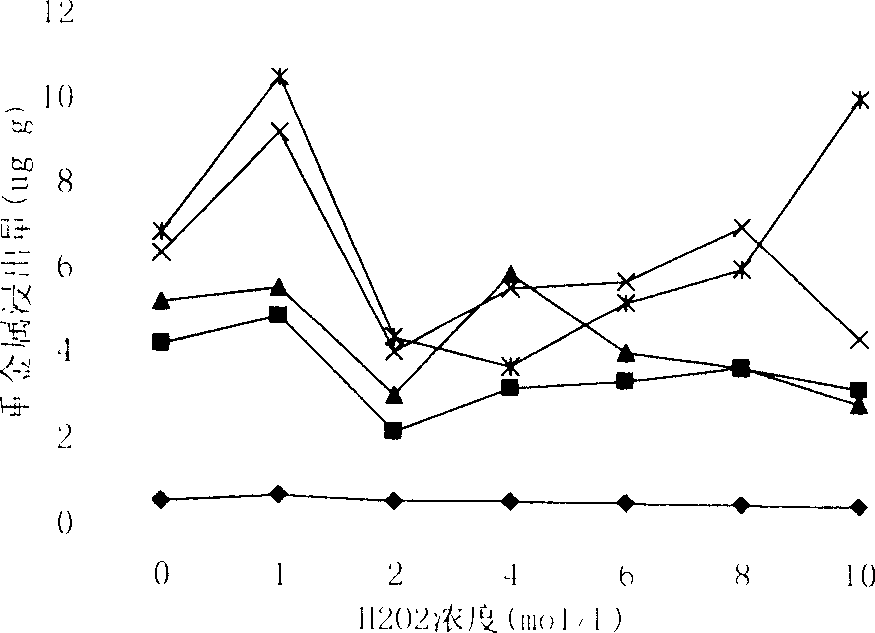

Beryllium metal polluted soil repairing agent and preparation method thereof

InactiveCN109504387AEfficient repairImprove economyAgriculture tools and machinesOrganic fertilisersBeryllium MetalMaterials science

The embodiment of the invention provides a beryllium metal polluted soil repairing agent and a preparation method thereof and belongs to the technical field of soil repairing. The repairing agent comprises 80-120 parts of a mineral microcapsule material, 10-40 parts of sepiolite powder and 30-60 parts of hydroxide. The beryllium metal polluted soil repairing agent has the technical fields of efficient soil repairing and high economy.

Owner:浙江中地净土科技有限公司

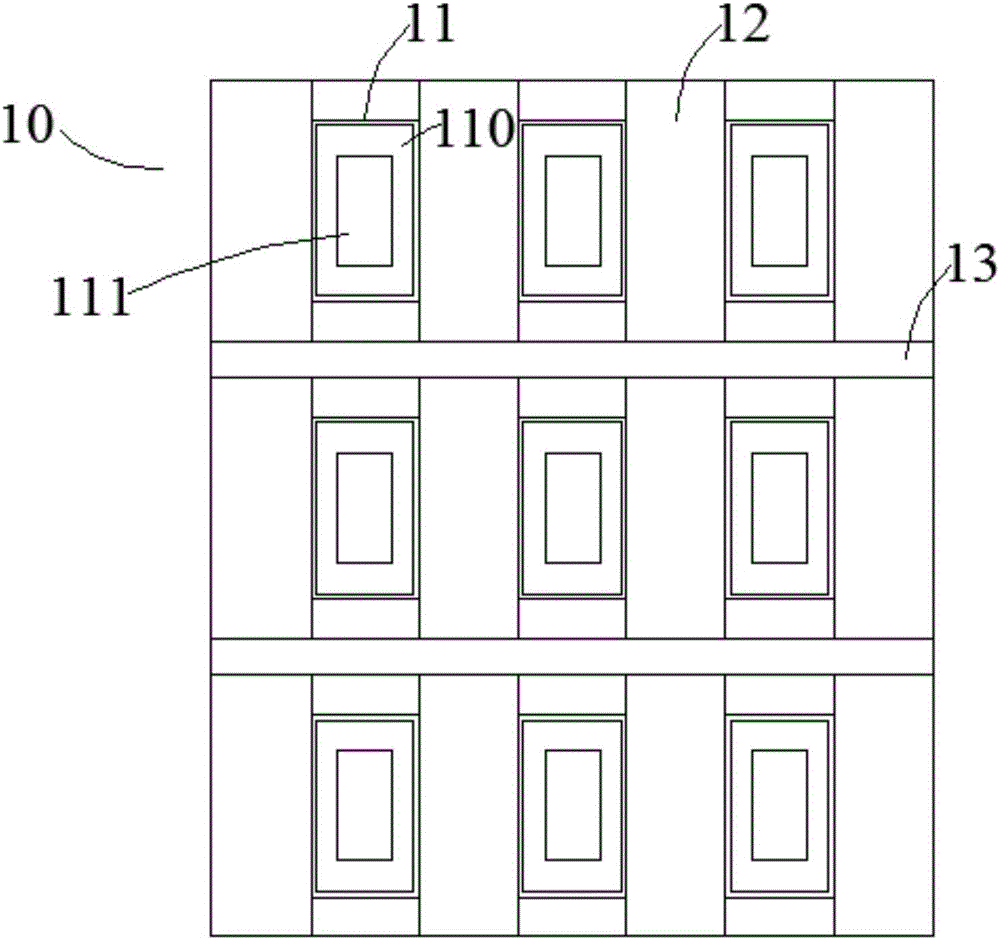

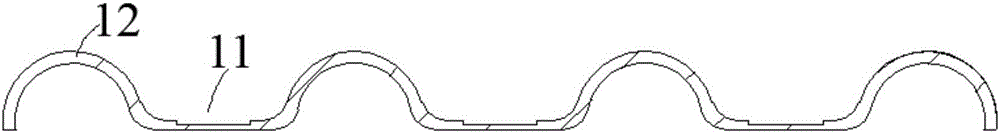

Synthetic resin solar photovoltaic tile, mounting method and production method

InactiveCN106193464AIncrease the areaEasy to installPhotovoltaic supportsRoof covering using slabs/sheetsEngineeringUltimate tensile strength

The invention provides a synthetic resin solar photovoltaic tile, a mounting method and a production method. The synthetic resin solar photovoltaic tile comprises a photovoltaic tile body which is made of synthetic resin. The photovoltaic tile body is provided with a plurality of battery piece mounting positions. A mounting groove is formed in each battery piece mounting position. A square heat dissipation hole is formed in the bottom of each mounting groove, and arch-shaped protrusions are formed on the two sides of each battery piece mounting position. The synthetic resin solar photovoltaic tile has the following advantages of (1) being formed integrally, having a large area and being convenient to install; (2) being long in service life, not prone to weathering and resistant to corrosion; (3) being high in strength, good in wind resistance and suitable for a strong wind environment; (4) being low in cost, low in weight and easy to transport; (5) being environmentally friendly and free of firing and saving precious soil resources; (6) being attractive, durable and capable of achieving the form and effect of glazed tiles after being installed; and (7) being suitable for reconstruction projects of existing rural old houses and solving the problem that existing old houses are poor in load-carrying capacity.

Owner:品君新材料科技(苏州)有限公司

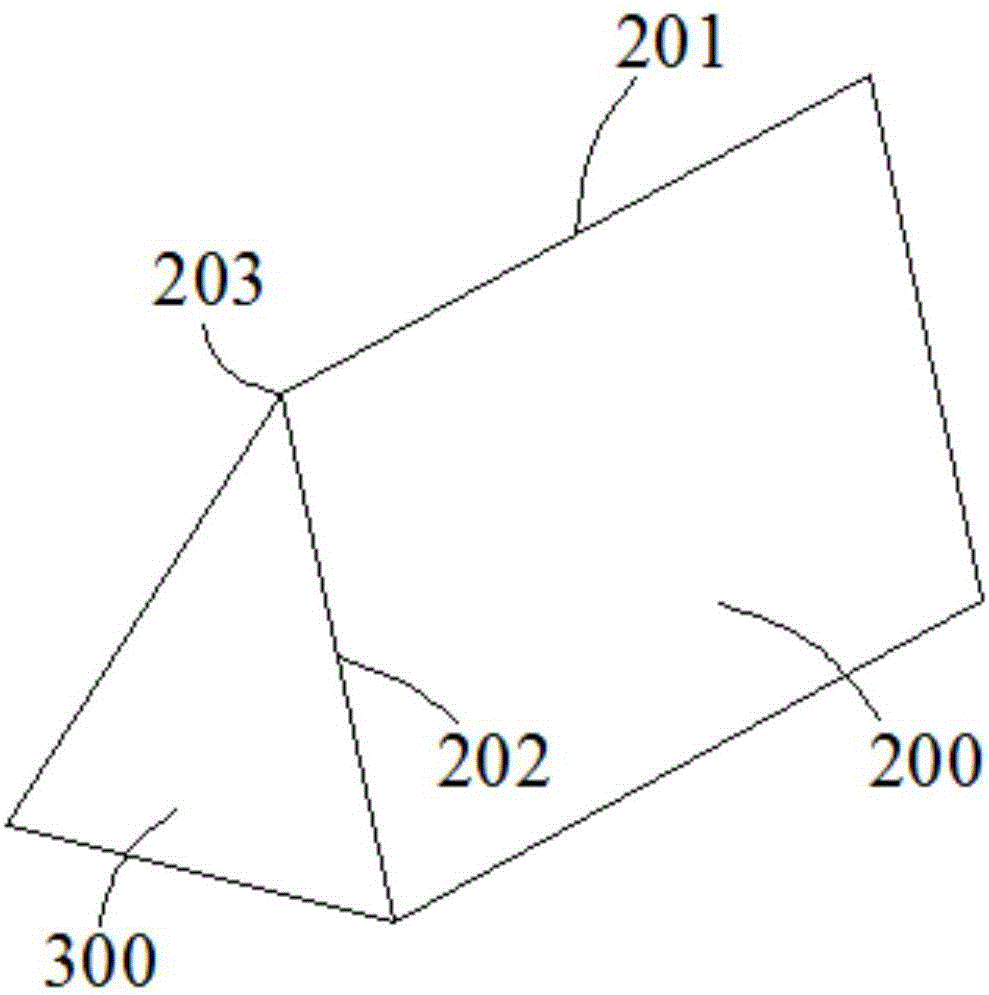

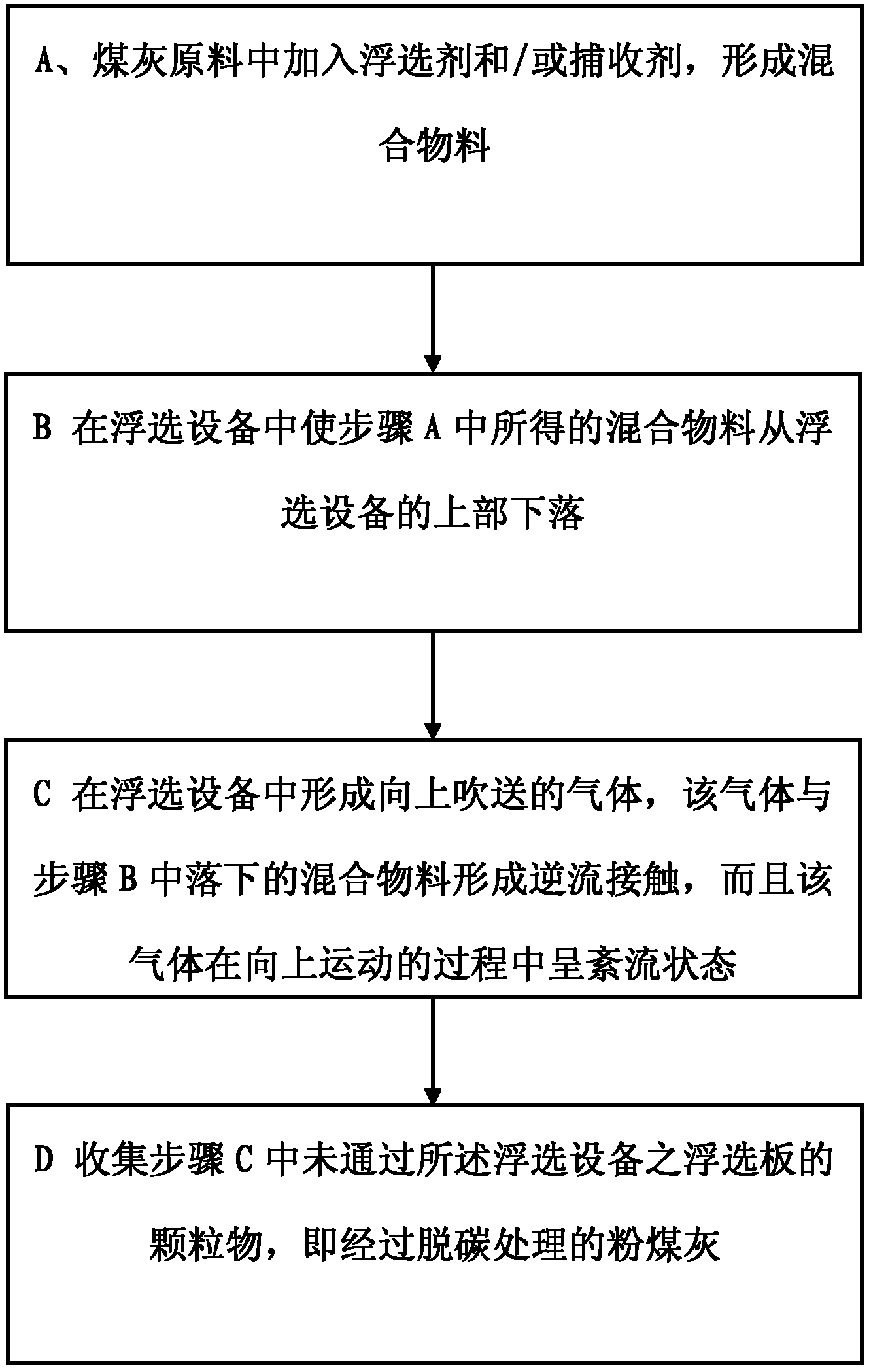

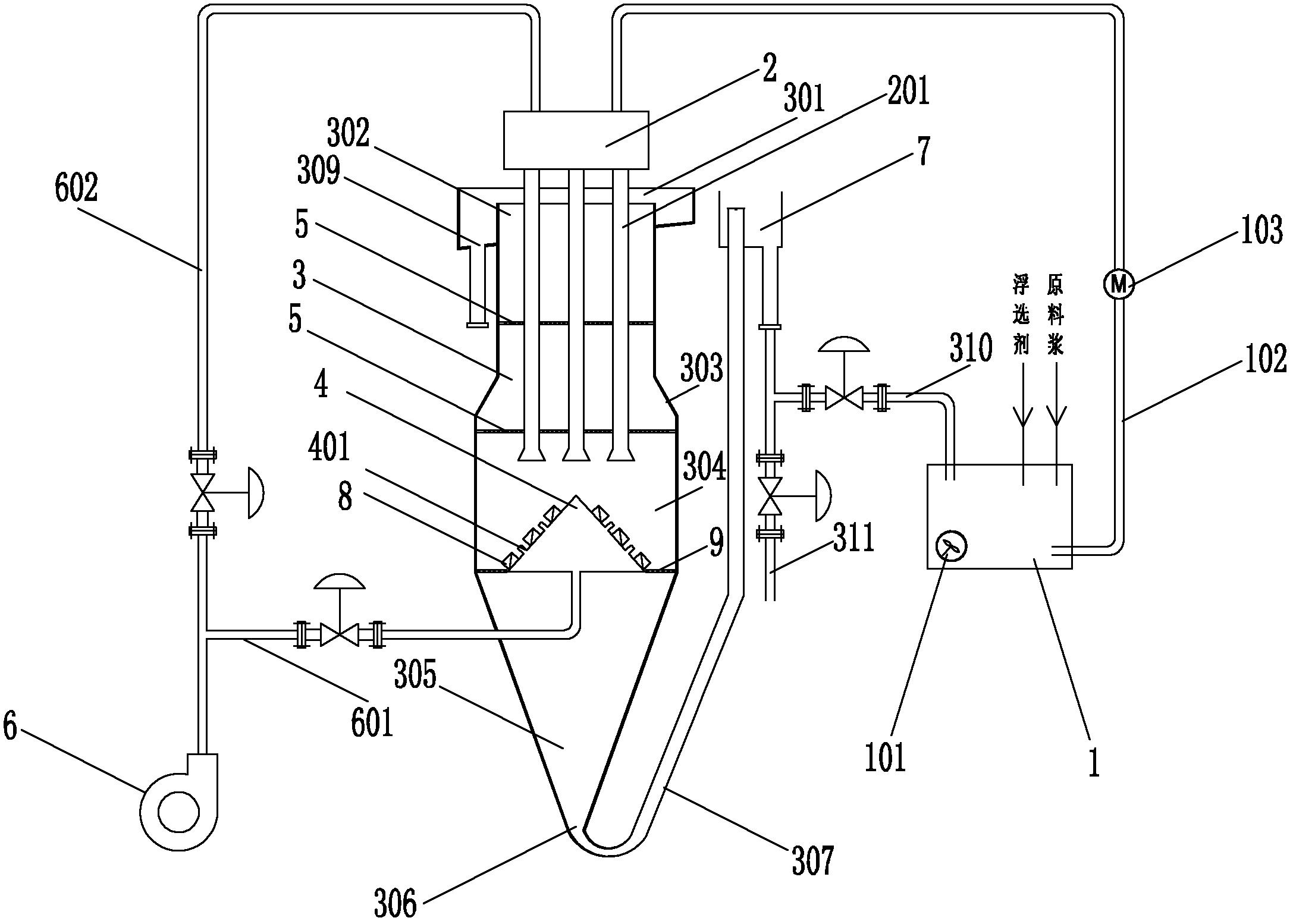

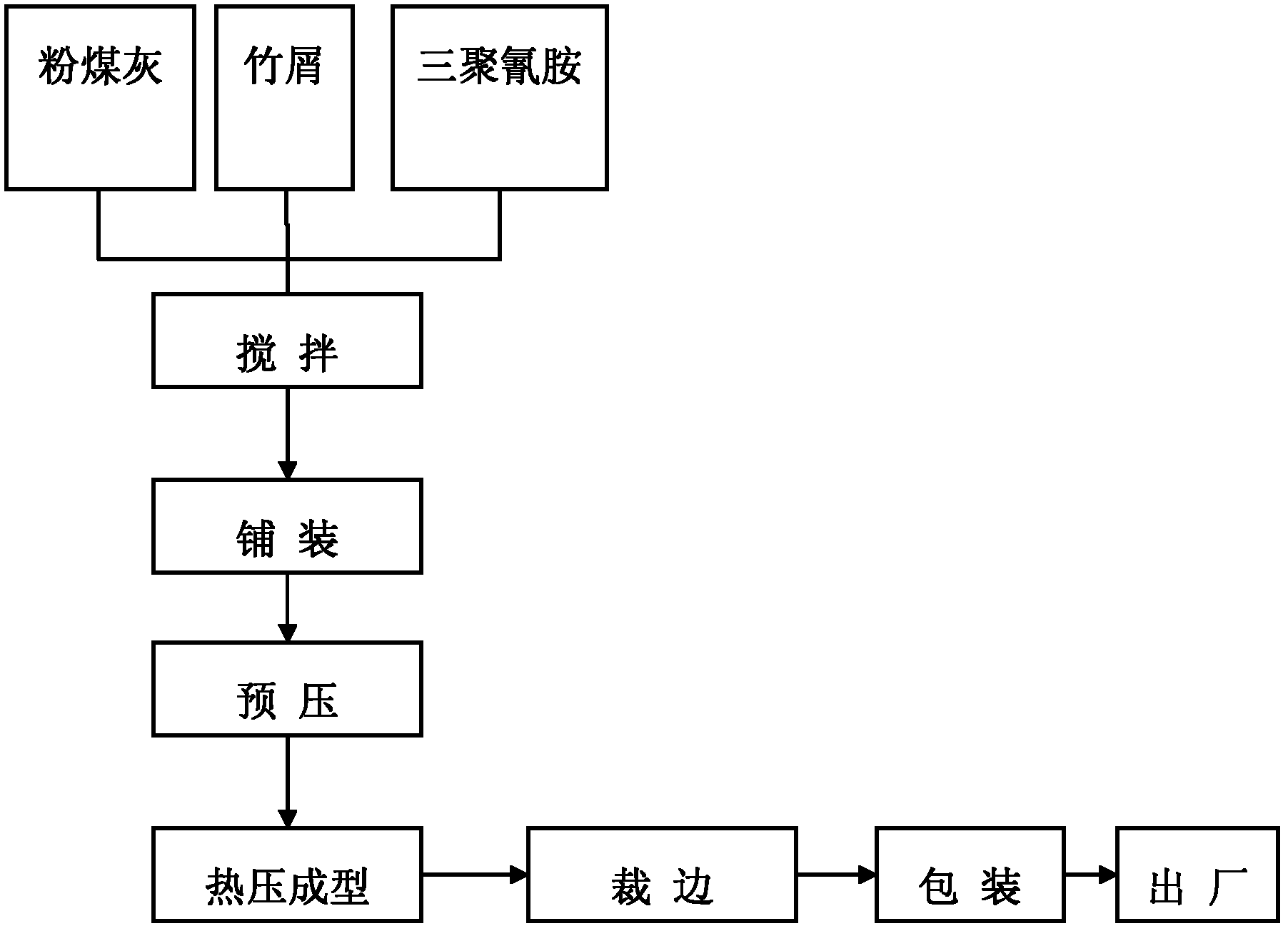

Process for preparing building template by using fly ash and prepared building template

InactiveCN102424545AReduce pollutionMake up for the small size defectSolid waste managementFly ashPollution

The invention discloses a process for preparing a building template by using fly ash, comprising the following steps: 1) mixing 35-60 wt% of fly ash, 35-60 wt% of bamboo sawdust, and 5-20 wt% of binding agent; 2) stirring the mixture obtained by the step 1);3) precompressing the stirred mixture obtained by the step 2) after paving; and 4) carrying out hot pressing on the precompressed mixture obtained by the step 3) into a template. The use of the method not only reduces the pollution of industrial fly ash to the environment, but also can replace wood building templates or steel building templates widely used in present building construction. The prepared building template disclosed herein has the advantages of low production cost, light weight, high strength, impact resistance, and easy demoulding, and can be recycled. The invention greatly accelerates the process of recycling wastes.

Owner:FUJIAN LONGYAN LONGNENG FRYASH COMPREHENSIVE UTILIZATION

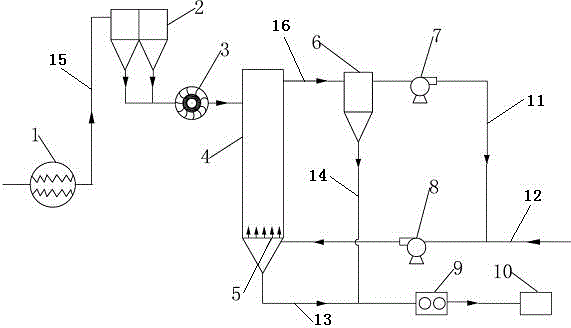

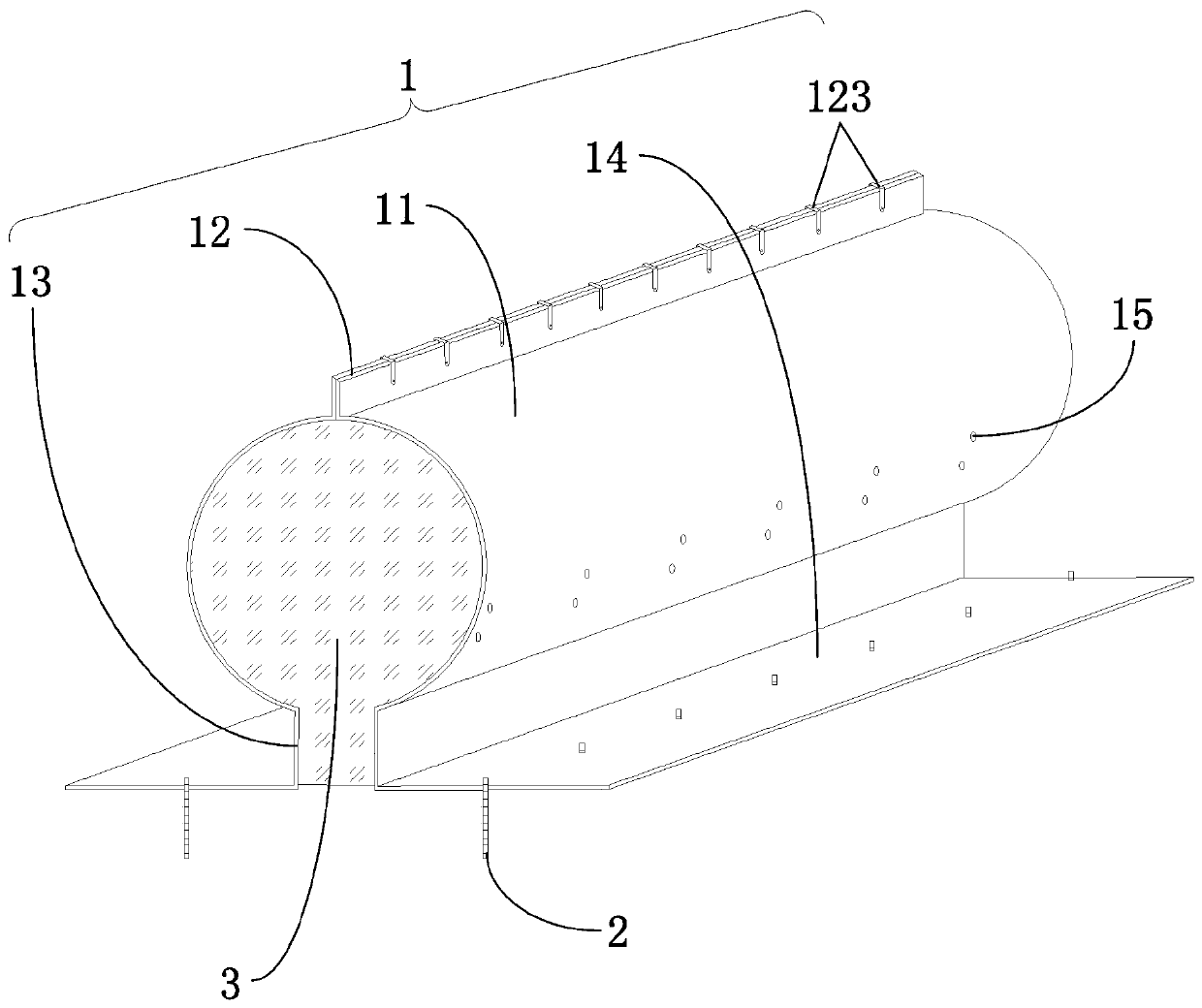

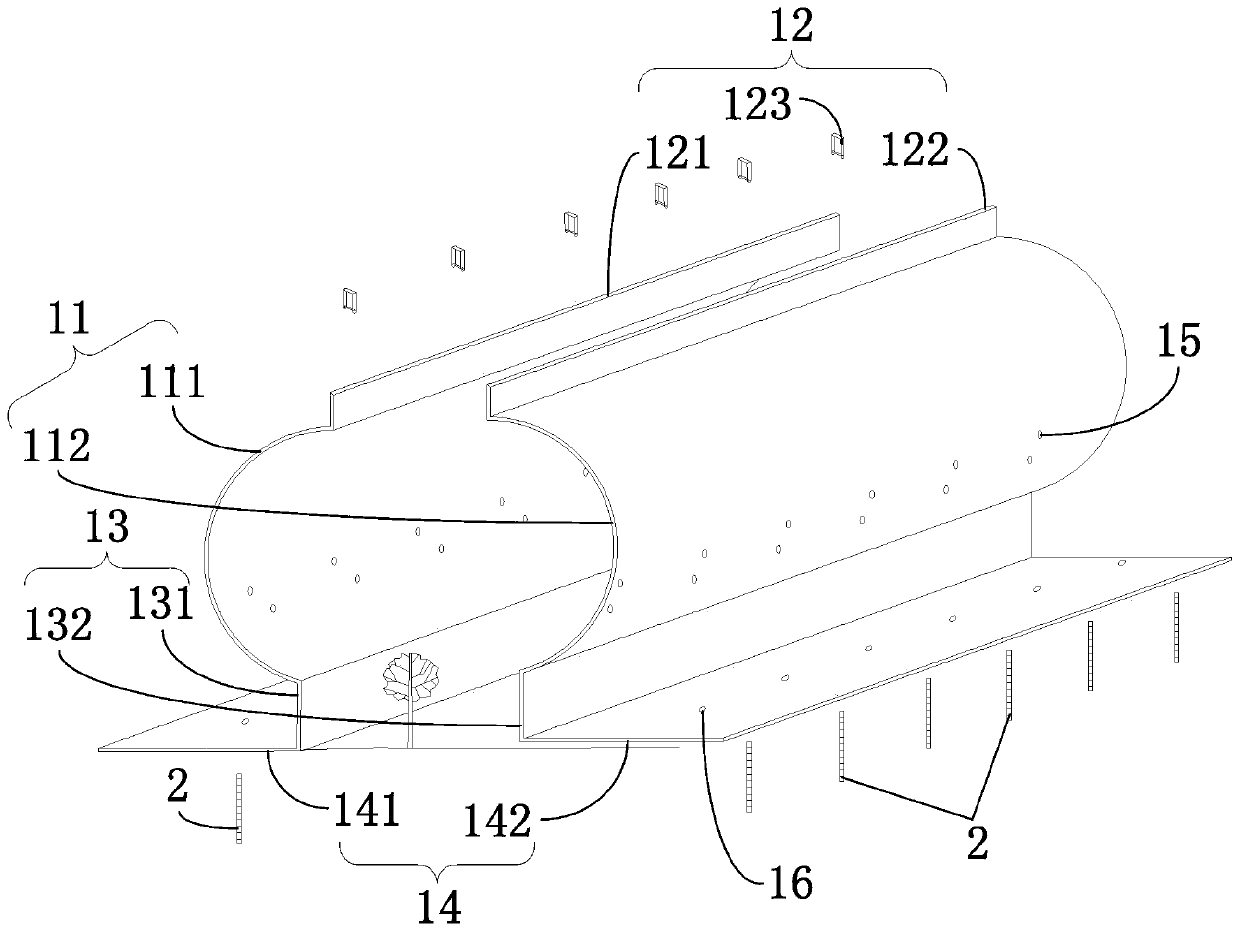

Equipment and process for lignite fluidized bed drying and upgrading

ActiveCN103602360BGuaranteed Granularity RequirementsGuaranteed crushing efficiencySolid fuelsFluidized bed dryingMolding machine

The invention relates to a device for drying and upgrading a lignite fluidized bed and a technology of the device. At present, the same type of device which is high in drying efficiency and high in environment friendliness and a technology of the device do not exist. The device for drying and upgrading the lignite fluidized bed is characterized by comprising a ring hammer type crusher, a cyclone separator, a lignite molding machine, a finished product storehouse, a lignite granule pipe, a lignite powder backflow pipe, a lignite granule conveying belt and a powder-steam conveying pipe, wherein one end of the lignite powder backflow pipe is connected to the bottom of the cyclone separator, and the other end of the lignite powder backflow pipe is connected to the lignite granule pipe; the lignite molding machine and the finished product storehouse are connected with each other through the belt. The technology disclosed by the invention comprises the following steps that (1) raw lignite is conveyed into the ring hammer type crusher for crushing, and the crushed lignite is conveyed into the lignite storehouse through the conveying belt; (2) overheated steam is input into a fluidized bed dryer through an overheated steam pipe; (3) the separated lignite powder is discharged from the bottom of the cyclone separator; (4) the lignite powder is molded under compression of the lignite molding machine to obtain finished lignite products. The device and the technology are high in drying efficiency and high in environment friendliness, and the steam can be recycled.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Reusable PET mulching film

PendingCN111328591ASimple structureSimple and fast operationClimate change adaptationGreenhouse cultivationAgricultural scienceGreenhouse cultivation

The invention discloses a reusable PET mulching film. The reusable PET mulching film comprises a mulching film main body, a positioning assembly and a sealing assembly, wherein the mulching film mainbody comprises a greenhouse cultivation part, a connecting part, a field ditch part and a base; the greenhouse cultivation part is of a hollow cylindrical structure with openings in two ends, and ventilation holes are formed in the side wall of the greenhouse cultivation part; the connecting part is vertically fixed at the top of the greenhouse cultivation part; an opening is formed in the bottomof the greenhouse cultivation part, and the field ditch part is vertically fixed at the opening; the base is arranged at the bottom of the field ditch part and extends outwards in the direction perpendicular to the field ditch part; a positioning hole is further formed in the base; the positioning assembly penetrates through the positioning hole and is detachably connected with the base; and the sealing assembly is adaptively mounted at the two ends of the greenhouse cultivation part, and is detachably connected with the greenhouse cultivation part. The PET mulching film is simple in structure, reasonable in design, convenient to operate, convenient to move and convenient to disassemble and assemble, can effectively realize repeated utilization of multiple times, has no pollution to the environment, and has a high market application prospect.

Owner:INST OF WATER RESOURCES FOR PASTERAL AREA MINIST OF WATER RESOURCES P R C

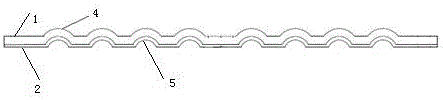

Metal fixing support capable of being embedded with multiple optical cables

PendingCN106019519AEven by forceUniform bearing surfaceOptical fibre/cable installationEngineeringMetal

The invention discloses a metal fixing support capable of being embedded with multiple optical cables, which comprises a metal outer layer and a rubber inner wall, wherein the metal outer layer and the rubber inner wall are bonded together; the rubber inner wall is convex towards the metal outer layer direction to form inner-wall circular arcs; and outer arcs are arranged at positions, corresponding to the inner-wall circular arcs, on the metal outer layer. The problem that the optical cables are likely to fall is solved.

Owner:ECONOMIC RES INST OF STATE GRID GANSU ELECTRIC POWER +3

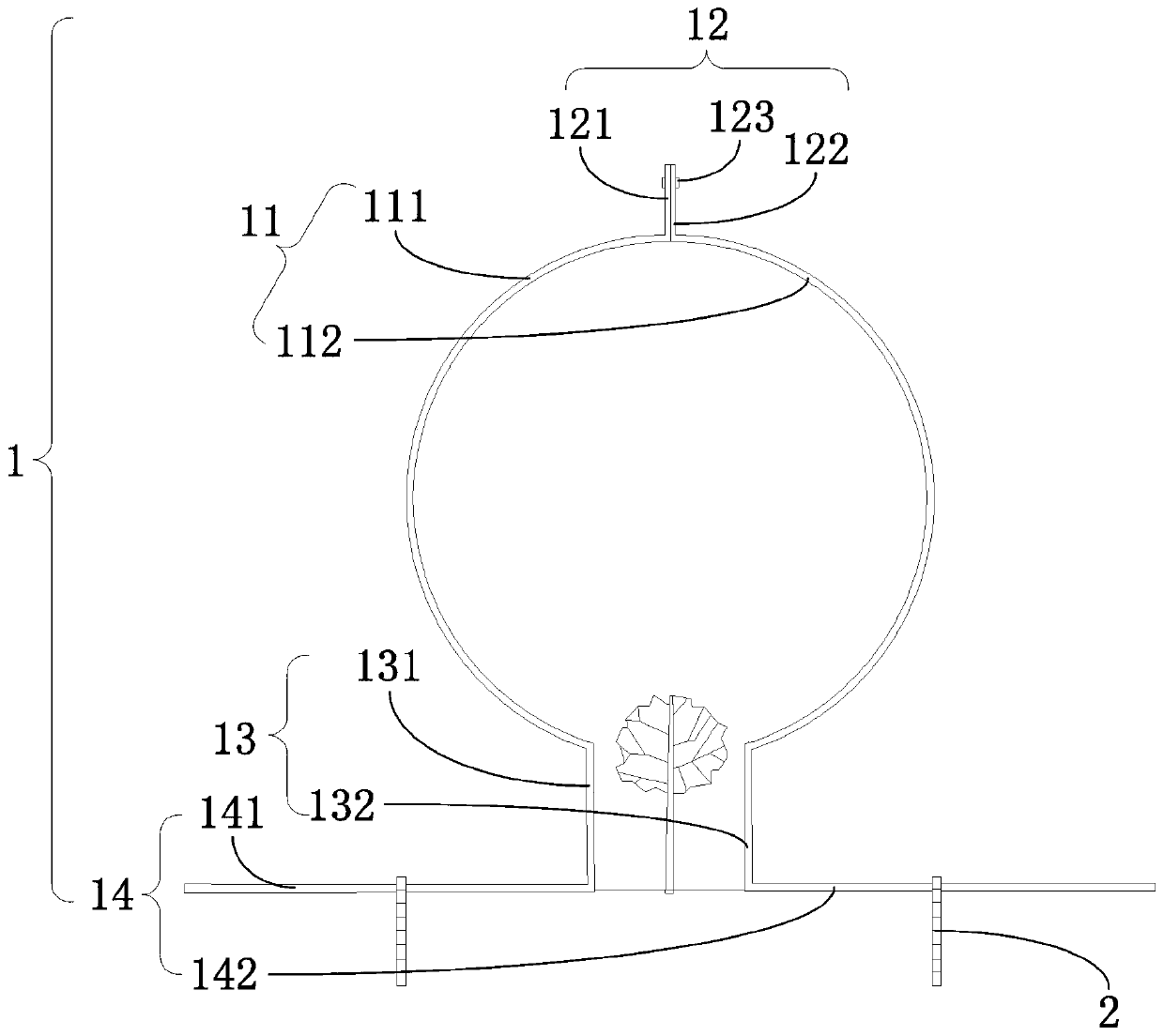

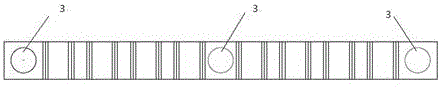

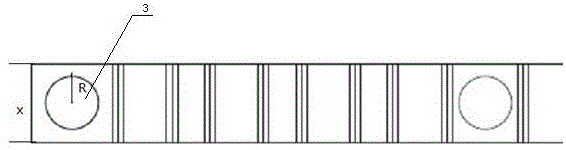

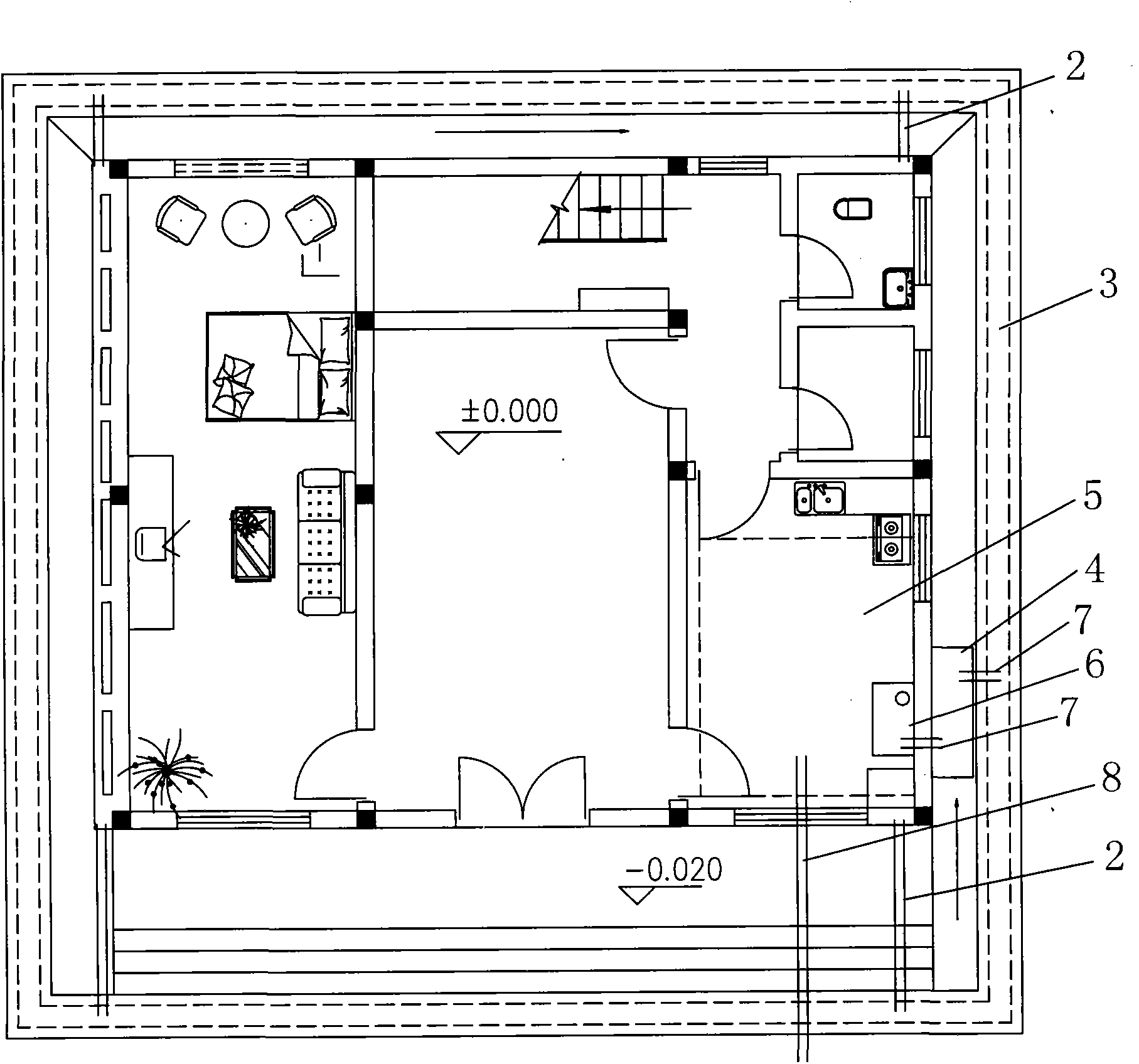

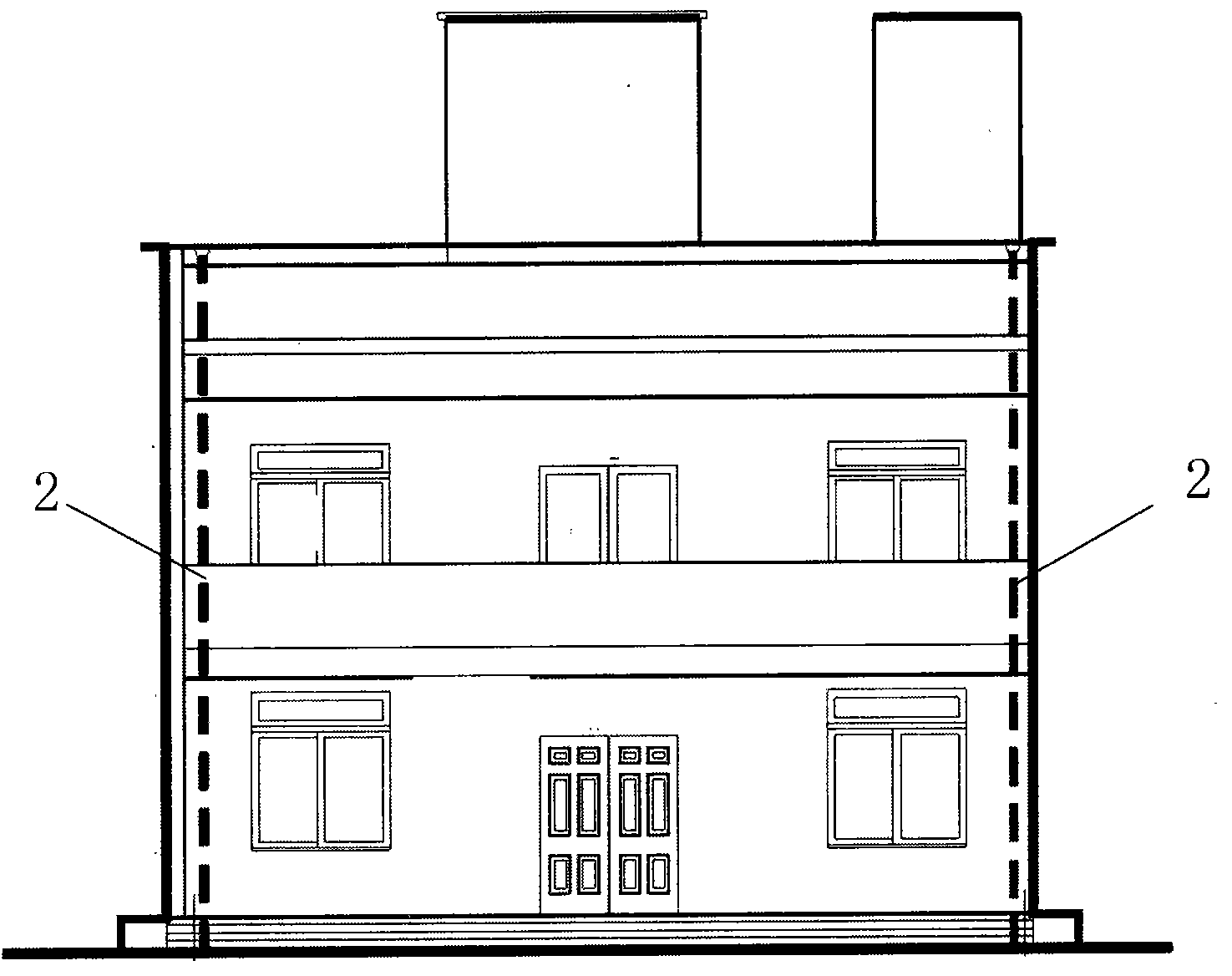

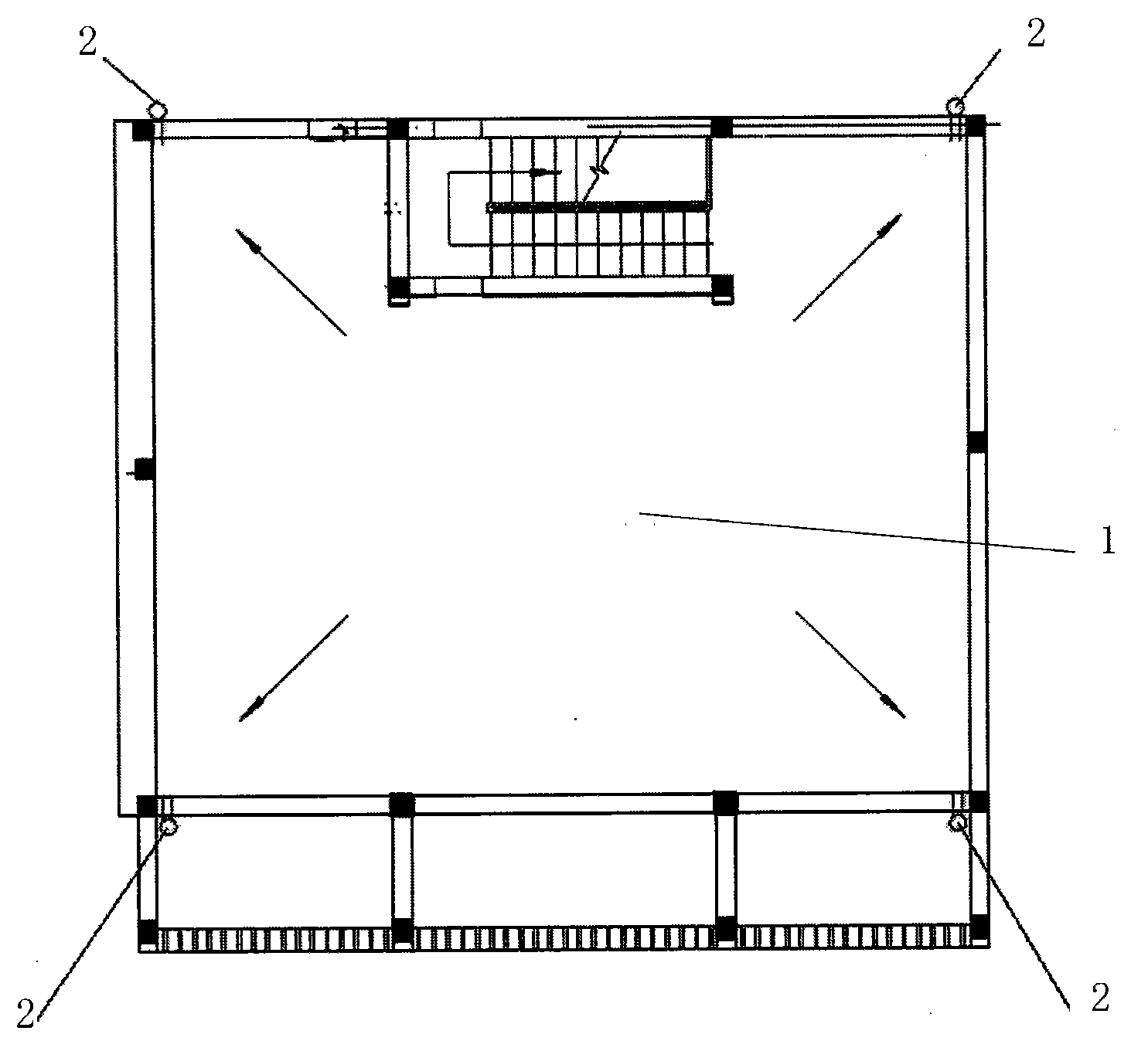

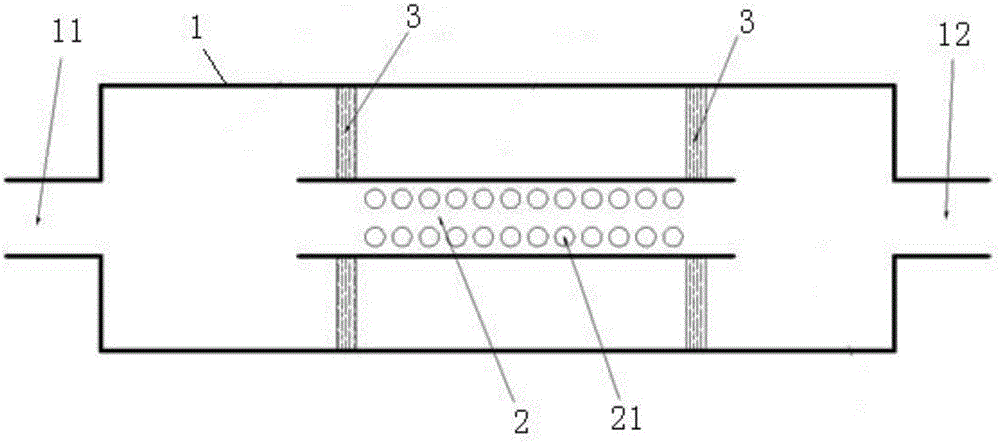

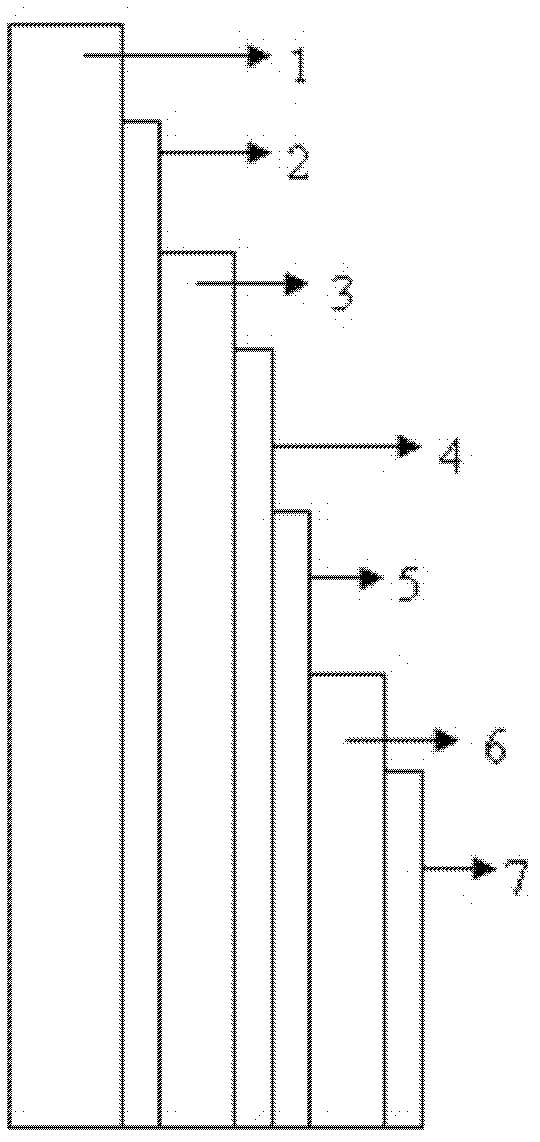

Emebded water collecting and purifying cellar system based on slow filtering principle

InactiveCN103953096AEasy to collectClean domestic waterSewerage structuresGeneral water supply conservationDry seasonKarst

The invention discloses an emebded water collecting and purifying cellar system based on a slow filtering principle, which comprises a house roof (1) for collecting rainwater, a water delivery pipeline (2), a rainwater gutter (3), a clarifier (4) and an underground cellar (5); a filtering pond (6) is arranged between the clarifier (4) and the underground cellar (5); the house roof (1) is connected with the rainwater gutter (3) through the water delivery pipeline (2); the rainwater gutter (3) is connected with the clarifier (4) through a drainage pipe (7); the clarifier (4) is connected with the filtering pond (6) through the drainage pipe (7); the filtering pond (6) is connected with the underground cellar (5) through the drainage pipe (7). The emebded water collecting and purifying cellar system has the characteristics of convenience in rainwater collection, floor area saving, clean water and the like, and the problem of domestic water in dry seasons in Karst rural communities can be effectively solved, as a result, the practical application value is high.

Owner:GUIZHOU NORMAL UNIVERSITY

Simple foamed aluminum silencer

ActiveCN106782479AImprove sound absorptionStrong sound absorptionSound producing devicesEngineeringMoisture absorption

The invention provides a simple foamed aluminum silencer. The simple foamed aluminum silencer comprises a hollow cylindrical housing. A silencer inlet is formed in one end of the cylindrical housing, and a silencer outlet is formed in the other end of the cylindrical housing. A perforated pipe and two foamed aluminum plates are arranged in the cylindrical housing. The foamed aluminum plates are provided with holes and are both perpendicular to the axis of the cylindrical housing. The two foamed aluminum plates are fixed to the inner wall of the cylindrical housing in a sealed mode. The perforated pipe and the cylindrical housing are coaxially arranged. The two ends of the perforated pipe penetrate through the two foamed aluminum plates respectively. Silencing holes are formed in the portion, between the two foamed aluminum plates, of the perforated pipe. The simple foamed aluminum silencer aims to solve the problem that existing silencer materials can cause environment pollution and endanger human health, are prone to moisture absorption and weathering, and are short in service life and poor in effect. The invention belongs to the technical field of silencers.

Owner:GUIZHOU UNIV

Two-component compound synergistic inorganic fireproof glue and preparation method thereof

ActiveCN110240867AGood dispersionTransparent appearanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesCombustionPolyphosphate

The invention relates to two-component compound synergistic inorganic fireproof glue and a preparation method thereof, the two-component compound synergistic inorganic fireproof glue comprises a material A and a material B, the material A comprises the following components in parts by weight: 50 parts of water, 12-18 parts of polyacrylamide and 1-5 parts of a dispersing aid, and the material B comprises 50 parts of water, 15-25 parts of urea, 20-30 parts of borax, 3-10 parts of a silica gel binder and 35-45 parts of polyphosphate. The fireproof glue is divided into two parts, wherein the material A is a master batch and the material B is a curing agent, and the material B is added into the material A to perform curing reaction to form the fireproof glue, and most of the components of the fireproof glue are inorganic substances, so that the fireproof glue can resist long-term flame combustion.

Owner:滁州圣好材料科技有限公司

Baking-free brick and preparation method thereof

InactiveCN106242472AHigh mechanical strengthNot easy to weatherCeramic shaping apparatusCooking & bakingBrick

The invention discloses a baking-free brick and a preparation method thereof, wherein the preparation method comprises the following steps of mixing cement, yellow sand, gypsum, polydimethylsiloxane, barium sulfate, fly ash, water and waterproof agents to prepare a mixed material M; adding the mixed material M into a shaping mold; obtaining a baking-free brick blank N through hot pressing; spraying water onto the surface of the baking-free brick blank body; then, performing natural draying; putting the naturally dried baking-free brick blank body into a baking oven to be dried; obtaining the baking-free brick. The problems that a conventional baking-free brick has weak weather resistance capability, and the cracking easily occurs after the long time use are solved.

Owner:明光市凯旋新型建材厂

Pre-oxidization thermal coloring method for verdigris

InactiveCN111549336APromote oxidationPrecisely adjust the degree of oxidationMetallic material coating processesActivated carbonFluorocarbon

Owner:福建捷思金属科技发展有限公司

PE water supply pipe and production method thereof

The invention discloses a PE water supply pipe and a production method thereof, and belongs to the field of pipes. The material is prepared from the following raw materials in parts by weight: 70-80 parts of high-density polyethylene, 40-50 parts of PVC resin, 10-20 parts of polyurethane resin, 5-10 parts of chloroprene rubber, 2-3 parts of a stabilizer, 1-2 parts of an antibacterial agent, 2-3 parts of an anti-wear agent, 3-5 parts of a dispersing agent, 1-2 parts of a coupling agent, 1-2 parts of titanium dioxide, 2-3 parts of calcium carbonate, 2-3 parts of a modifying aid, 1-2 parts of alkyl sodium sulfonate and 1-2 parts. The PE water supply pipe is high in rigidity, resistant to abrasion and not prone to weathering and has good heat preservation performance, corrosion resistance, low-temperature resistance, high-temperature resistance and scratch resistance, the flexibility, compression resistance and other performance of a finished product are improved, and the pipe has good rigidity and excellent stability.

Owner:甘肃海纳塑业有限公司

A kind of high-strength thermal insulation stone board and its preparation method

ActiveCN106278359BHigh strengthLight in massLayered productsConstructions elementsVolumetric Mass DensityNatural stone

The invention relates to the technical field of building materials, and specifically discloses a high-strength insulation stone plate and a preparation method thereof. The density of the high-strength insulation stone plate is below 1.2 g / cm<3>, and an insulation plate is combined with the back surface of the high-strength insulation stone plate; the high-strength insulation stone plate per cubic centimeter contains 2000 or more holes, and the holes are independent holes. The high-strength insulation stone plate is prepared from the following raw materials by weight percent: 40% to 60% of waste ceramic tiles, 35% to 45% of kaolin, 0.5 to 2.0% of foaming agents, 3% to 8% of ore sand and 5% to 10% of glaze. The high-strength insulation stone plate contains the independent holes, and therefore, the high-strength insulation stone plate has good insulation performance; in addition, the high-strength insulation stone plate has the advantages of light weight, small density and high strength, has a good insulation function and belongs to a green environment-friendly product because the waste recycling proportion exceeds 40%; the surface texture of the stone plate is close to natural stones, physical and chemical properties are stable, weathering is difficult, and the high-strength insulation stone plate can be firmly pasted on an outer wall.

Owner:广州米伽新材料科技有限公司

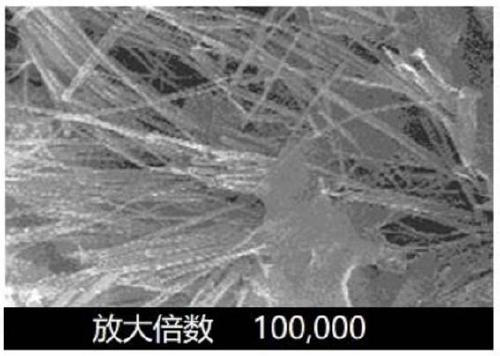

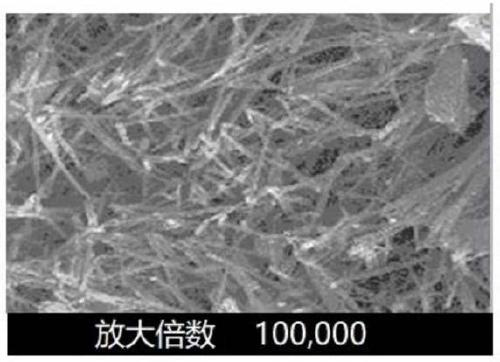

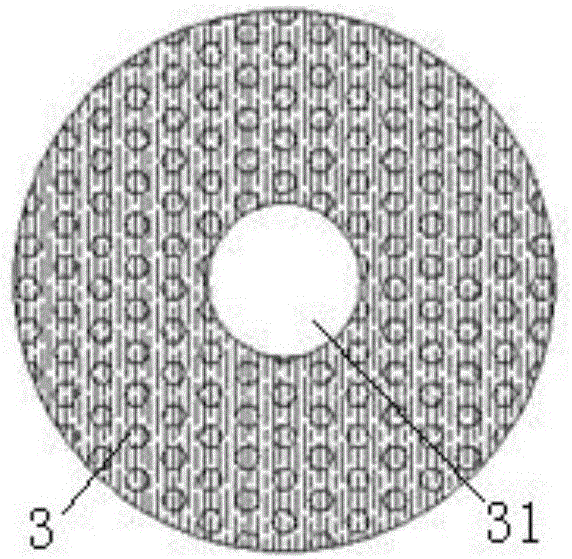

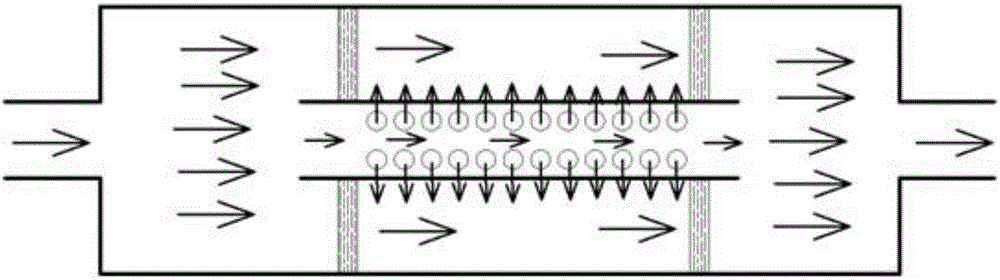

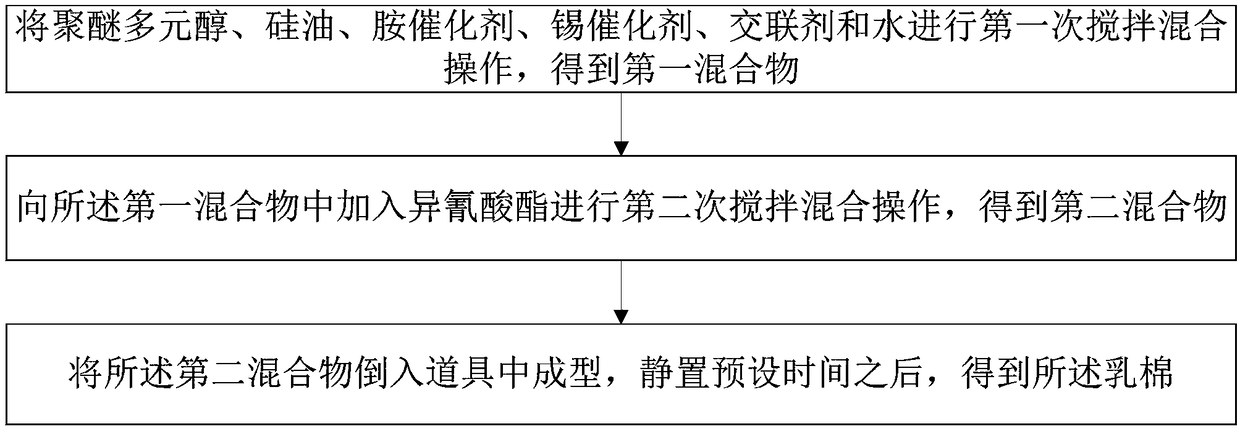

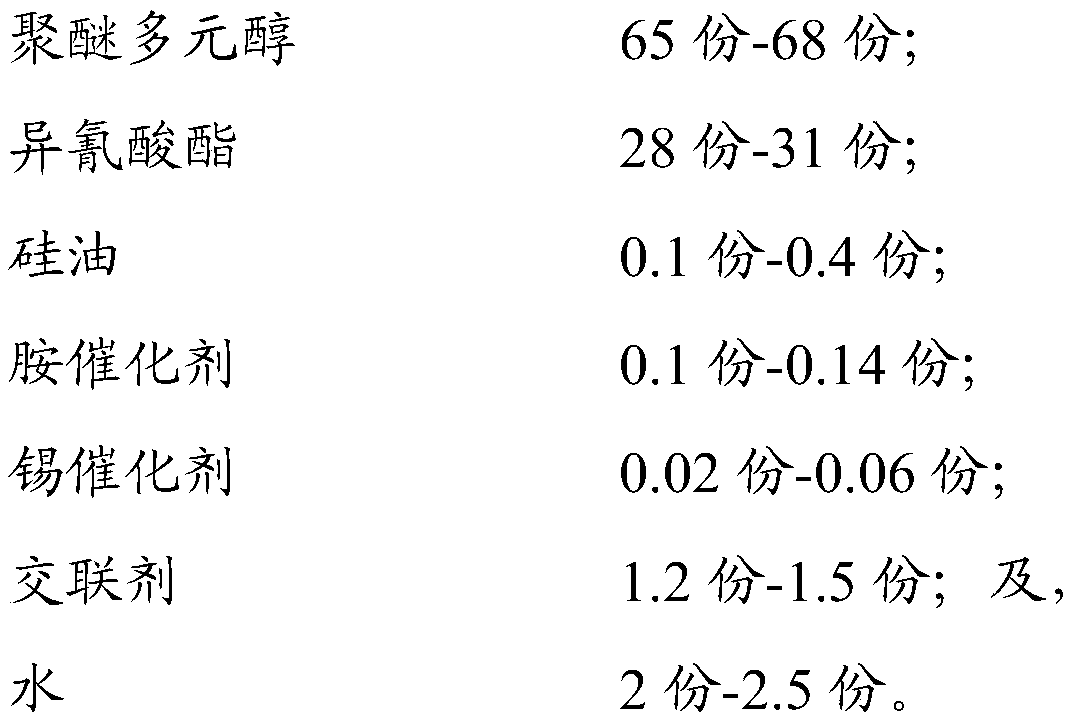

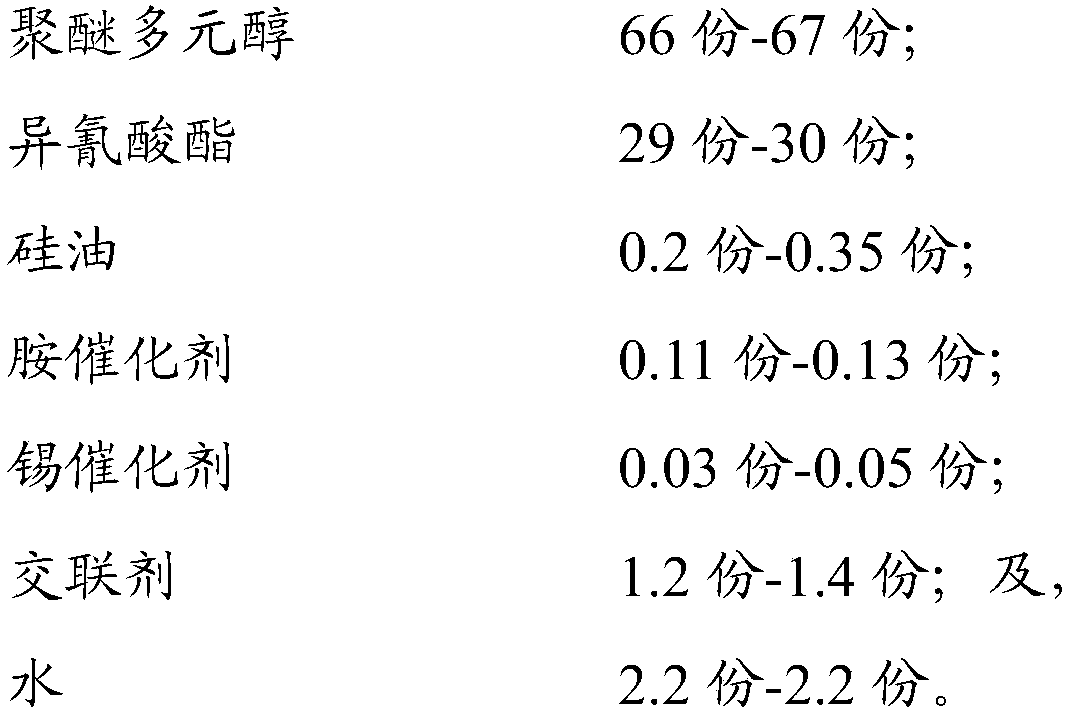

Latex-like cotton and preparation method thereof

Disclosed are a latex-like cotton and a preparation method thereof. The latex-like cotton is composed of, by weight part, 65-68 parts of polyether polyols, 28-31 parts of isocyanate, 0.1-0.4 part of silicone oil, 0.1-0.14 part of amine catalyst, 0.02-0.06 part of tin catalyst, 1.2-1.5 parts of crosslinking agent and 2-2.5 parts of water. The latex-like cotton made of the components above can achieve good resilience and have a good touch feeling like latex. Meanwhile, due to the fact of containing no natural latex materials, the latex-like cotton is less prone to weathering, long in service life and comparatively low in cost.

Owner:惠州华盛家庭用品有限公司

Composite sandstone board and preparation method and application thereof

ActiveCN102322124AStrong antifoulingNot easy to weatherCovering/liningsNatural patternsEmulsionSoil resistance

The invention discloses a composite sandstone board and a preparation method and application thereof. The composite sandstone board is sequentially formed by a blank bottom plate, a sand primer layer, a first sandstone layer, a texture cloth layer, a first transparent emulsion layer, a second sandstone layer and a second transparent emulsion layer. The composite sandstone board disclosed by the invention has strong soil resistance, is difficult to air-slake and is simple and convenient to install. Moreover, the composite sandstone board has natural texture and can reach the same decorative effect as natural sandstone. The defect that the natural sandstone has poor soil resistance and is easy to air-slake is overcome.

Owner:广州米伽新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com