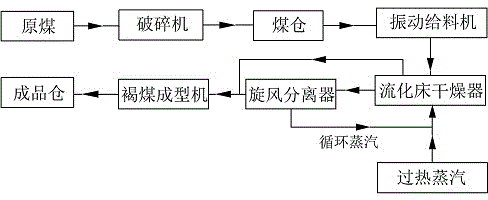

Equipment and process for lignite fluidized bed drying and upgrading

A technology for drying and lignite in a fluidized bed, applied in the field of lignite drying and upgrading equipment, lignite fluidized bed drying and upgrading equipment, can solve the problems of unfavorable furnace stable combustion, lower lignite moisture content, low drying efficiency, etc. , to achieve strong practicability and promotion value, reduce the amount of superheated steam, good safety and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and through the examples. The following examples are to explain the present invention and the present invention is not limited to the following examples.

[0024] Example.

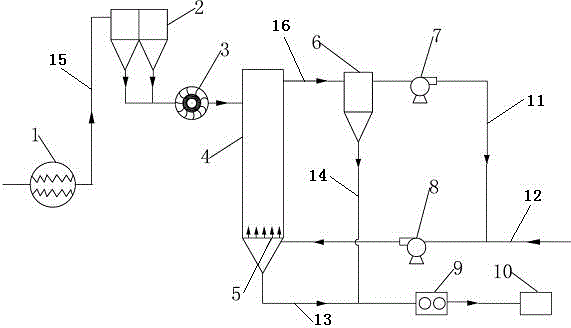

[0025] see Figure 1 to Figure 2 The lignite fluidized bed drying and upgrading device in this embodiment includes a ring hammer crusher 1, a coal bunker 2, a vibrating feeder 3, a fluidized bed dryer 4, a cyclone separator 6, a circulating fan 7, Fluidization fan 8, lignite molding machine 9, finished product warehouse 10, circulating steam pipe 11, superheated steam pipe 12, coal particle pipe 13, coal powder return pipe 14, coal particle conveying belt 15 and powder steam conveying pipe 16, wherein, flow The lower part of the bed dryer 4 is provided with an air distribution plate 5, which can effectively ensure the fluidization effect.

[0026] The ring hammer crusher 1 in the present e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com