Coupled comb type coal screening machine

A coal screening machine and coupled technology, which is applied in the direction of filter screen, solid separation, grille, etc., can solve the problems that threaten the safe operation of coal crushers, high equipment failure rate, and low screening efficiency, and achieve protection and energy consumption reduction And normal operation, improve work efficiency, reduce the effect of coal penetration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

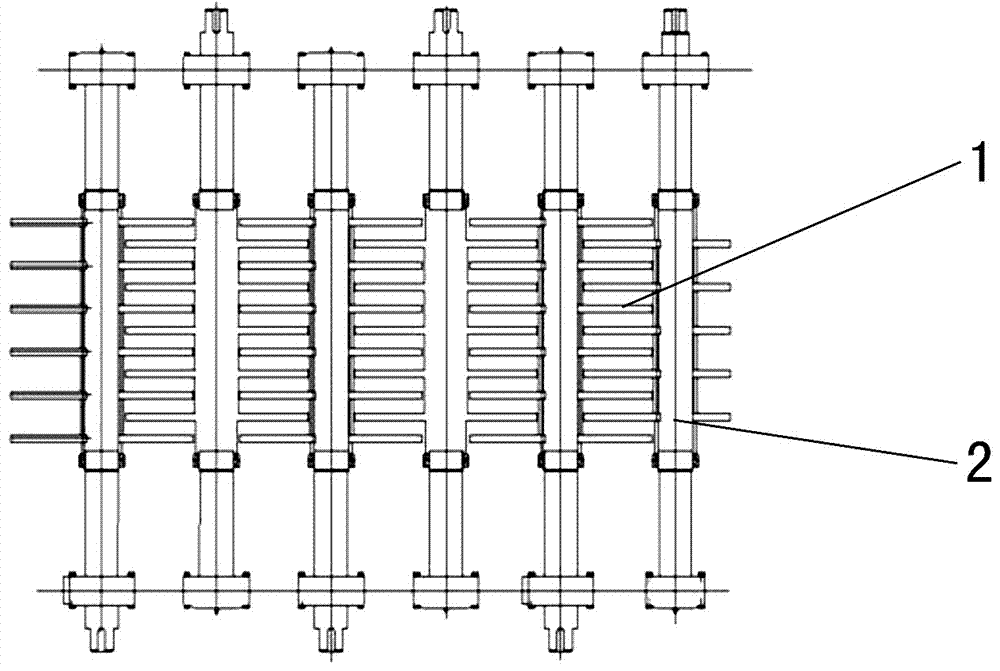

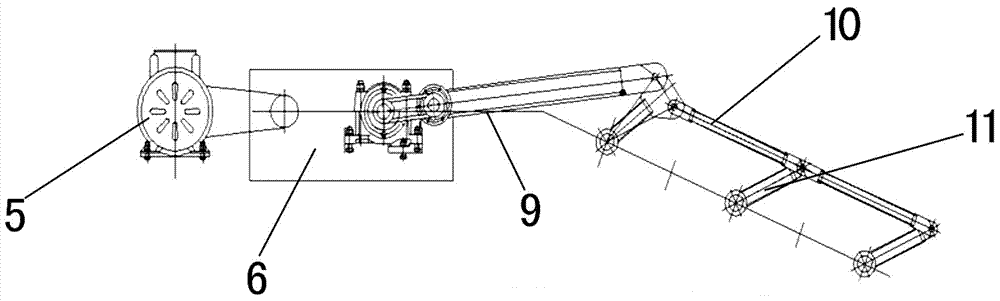

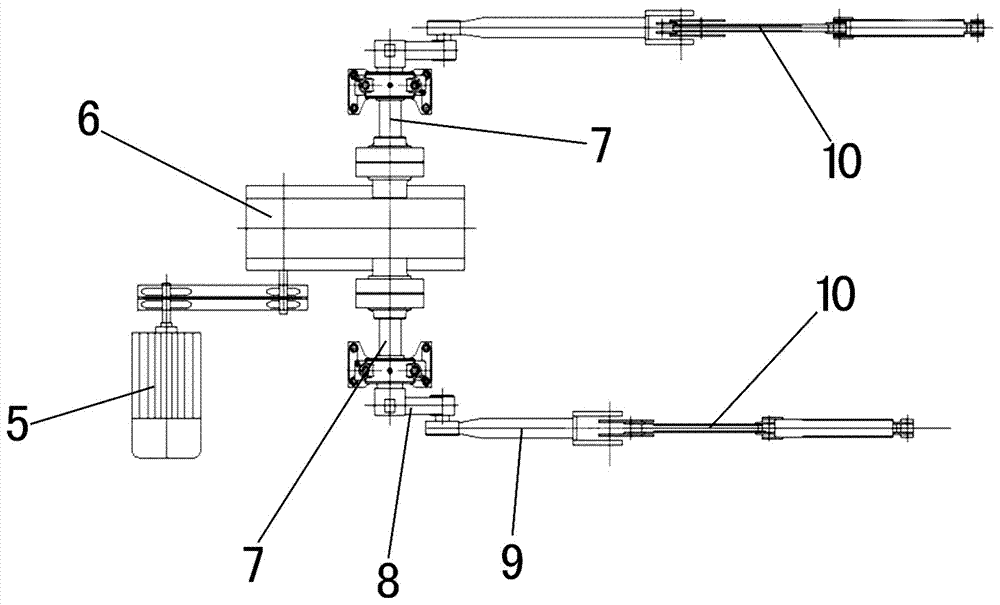

[0019] refer to figure 1 , figure 2 , the coal screening machine of the present invention comprises a frame, a screen cloth, a screen cloth driving mechanism, wherein the screen cloth is composed of a plurality of screen disc shafts 2 arranged laterally on the frame, and fixedly mounted on each screen disc shaft. It consists of a plurality of circular sieve discs 1, and there is a difference between two adjacent sieve disc shafts. The sieve disc on the sieve disc shaft with a small number of sieve discs extends into the two sieve disc shafts with a large number of sieve discs. Between adjacent sieve trays, the circumference of the sieve trays is close to the axis of the adjacent sieve trays. The sieve tray part between the two sieve tray shafts is equidistant in the axial direction of the sieve tray shafts to form sieve mesh holes of the same size. The coal inlet end of the screen on the frame is higher than the coal discharge end, forming a screen surface inclined relative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com