Patents

Literature

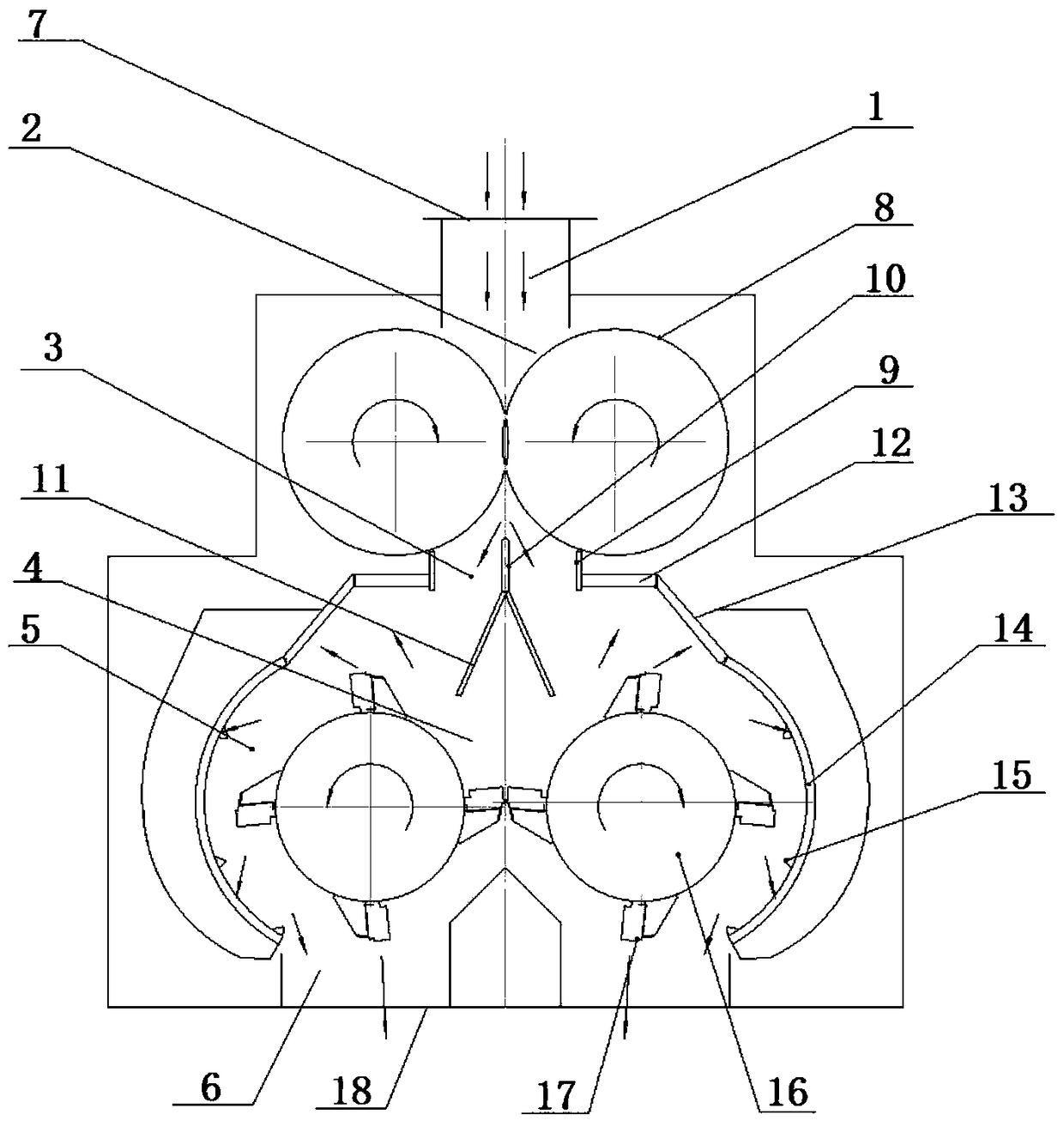

135results about How to "Guaranteed crushing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

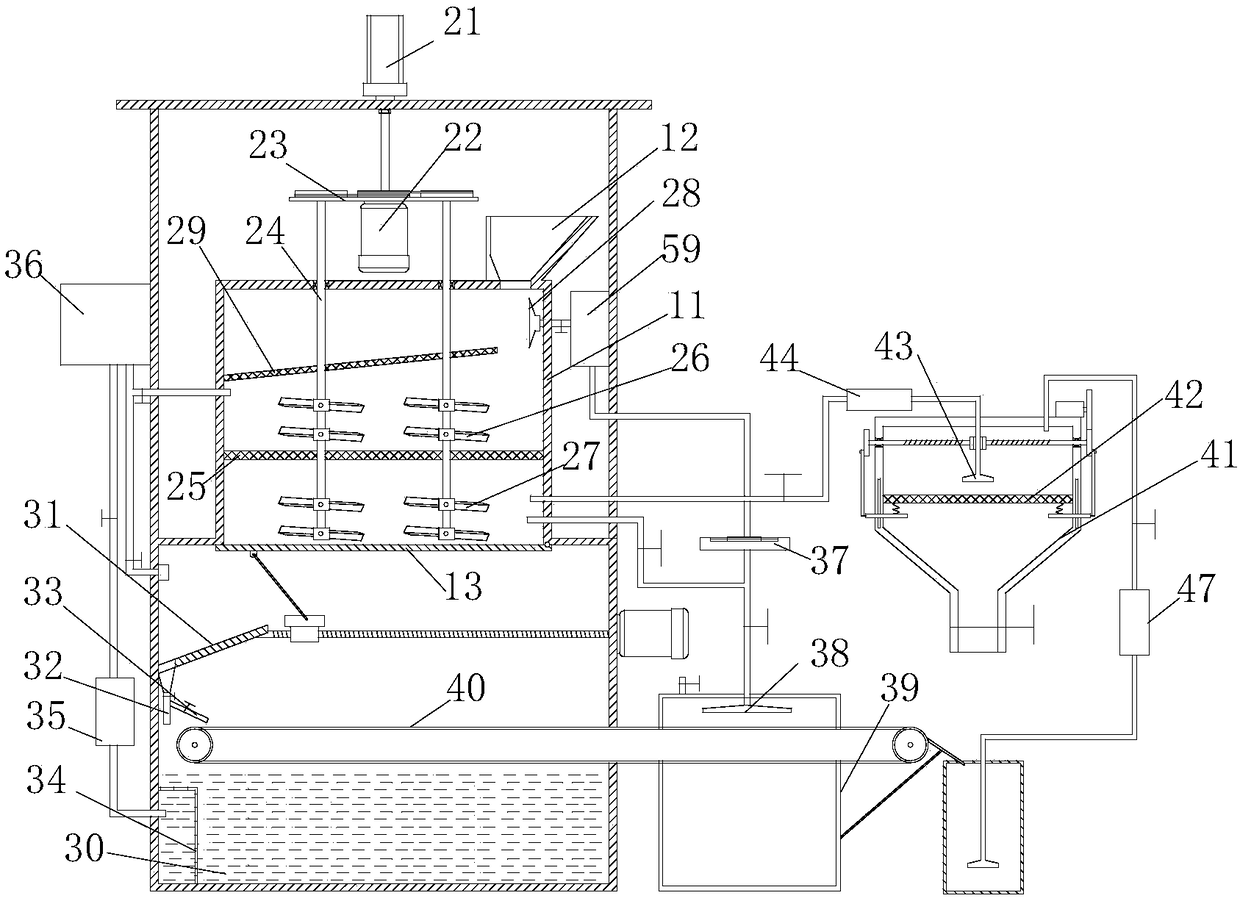

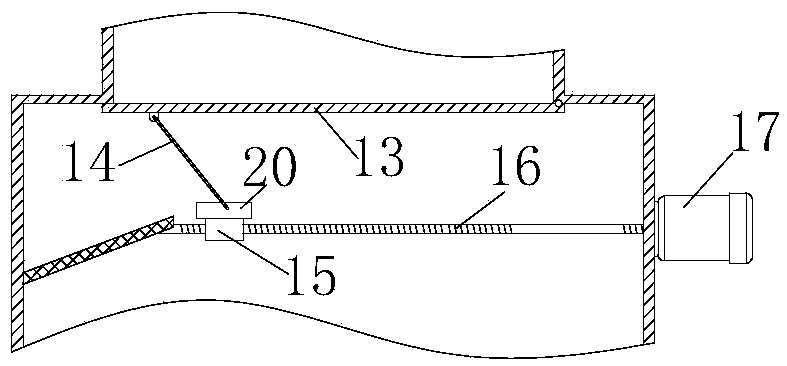

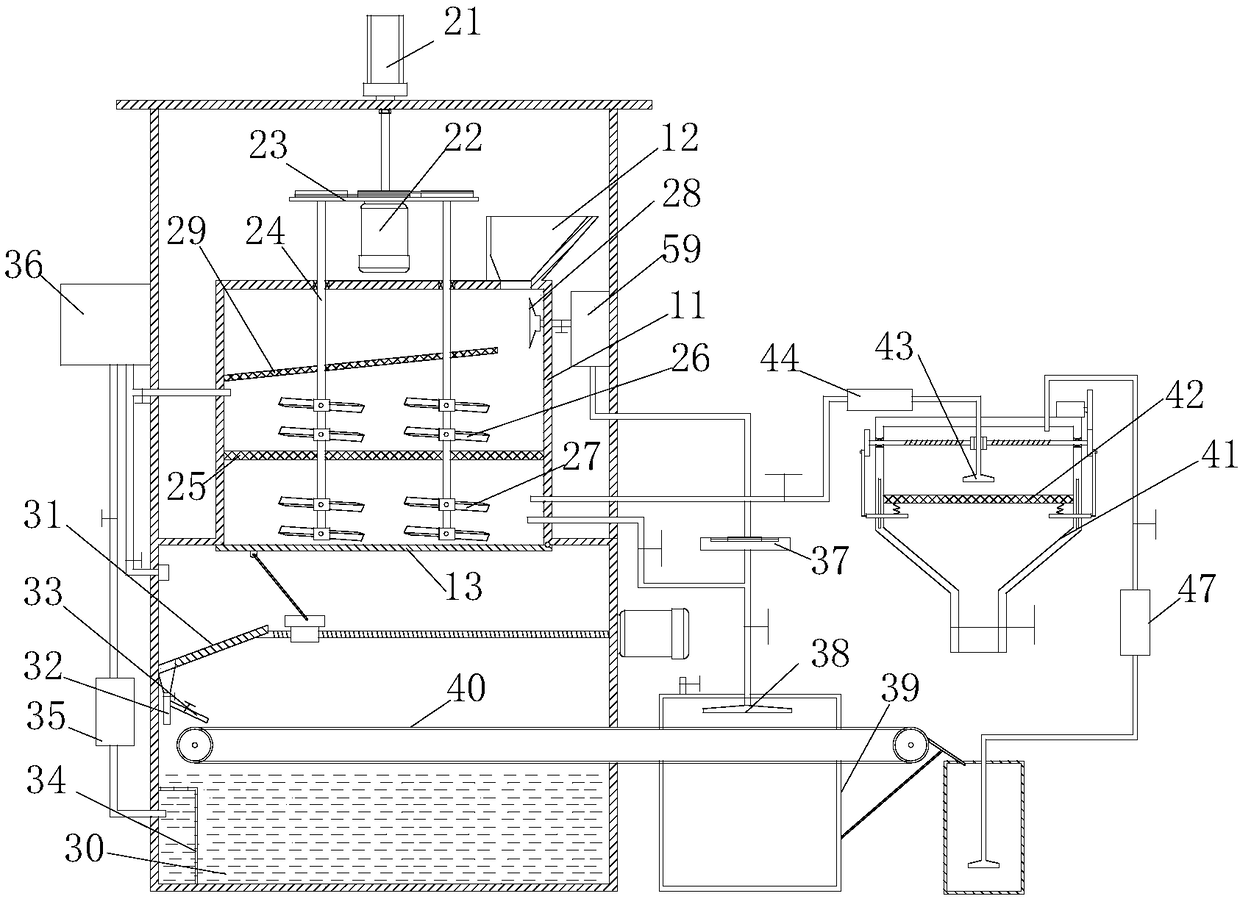

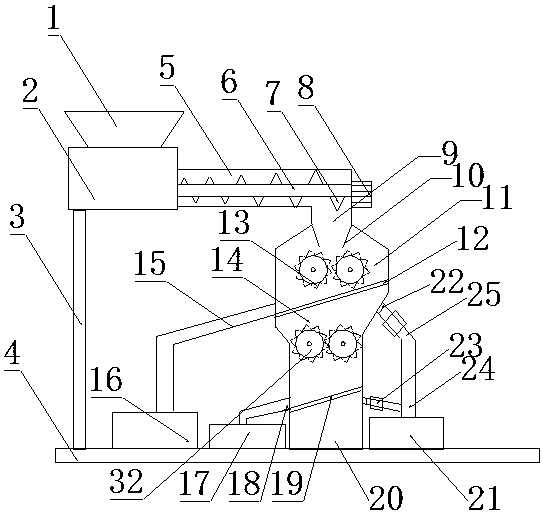

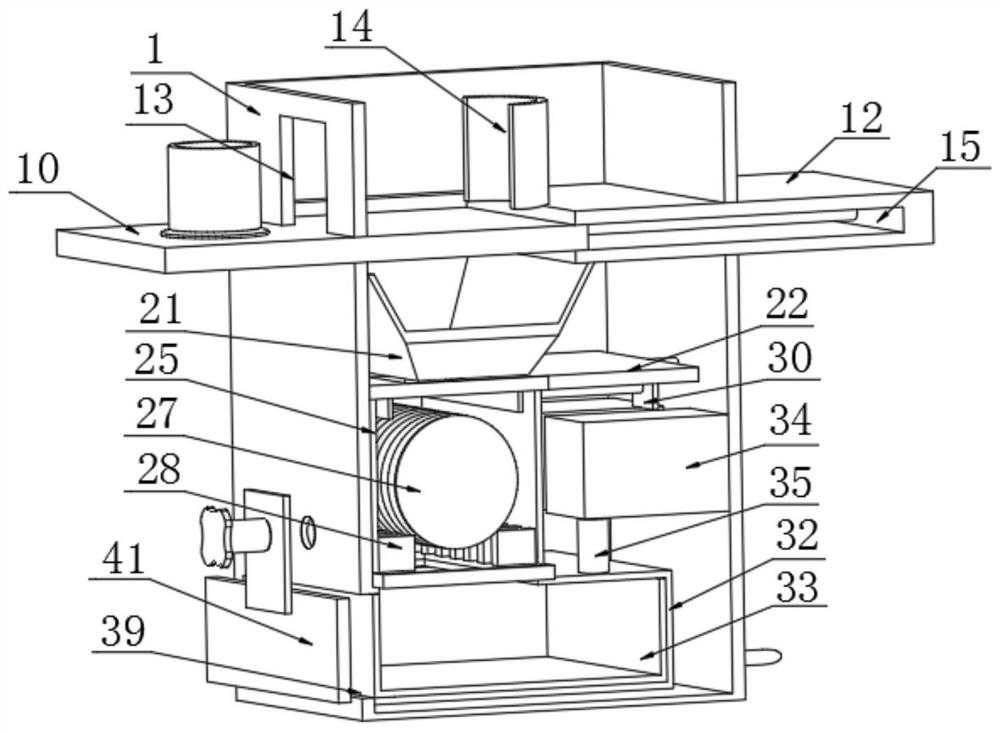

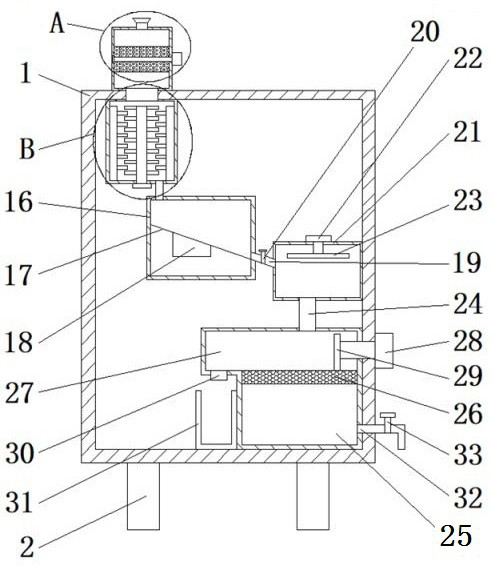

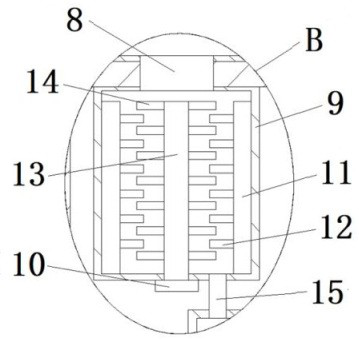

Corn flour production and processing mechanism based on multidirectional feeding

ActiveCN108654757AGuaranteed crushing efficiencyEnsure crushing efficiencySievingConveyorsCorn flourEngineering

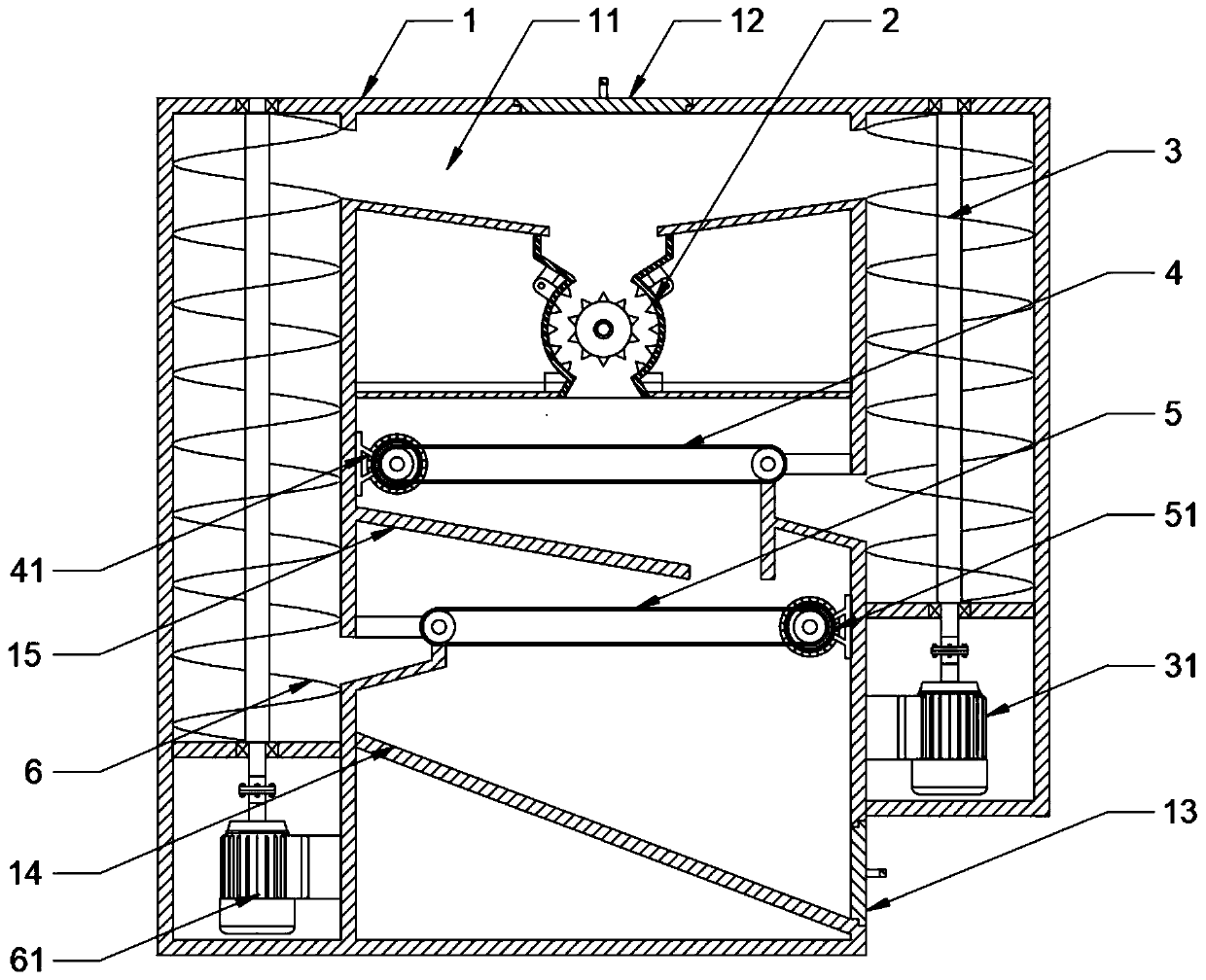

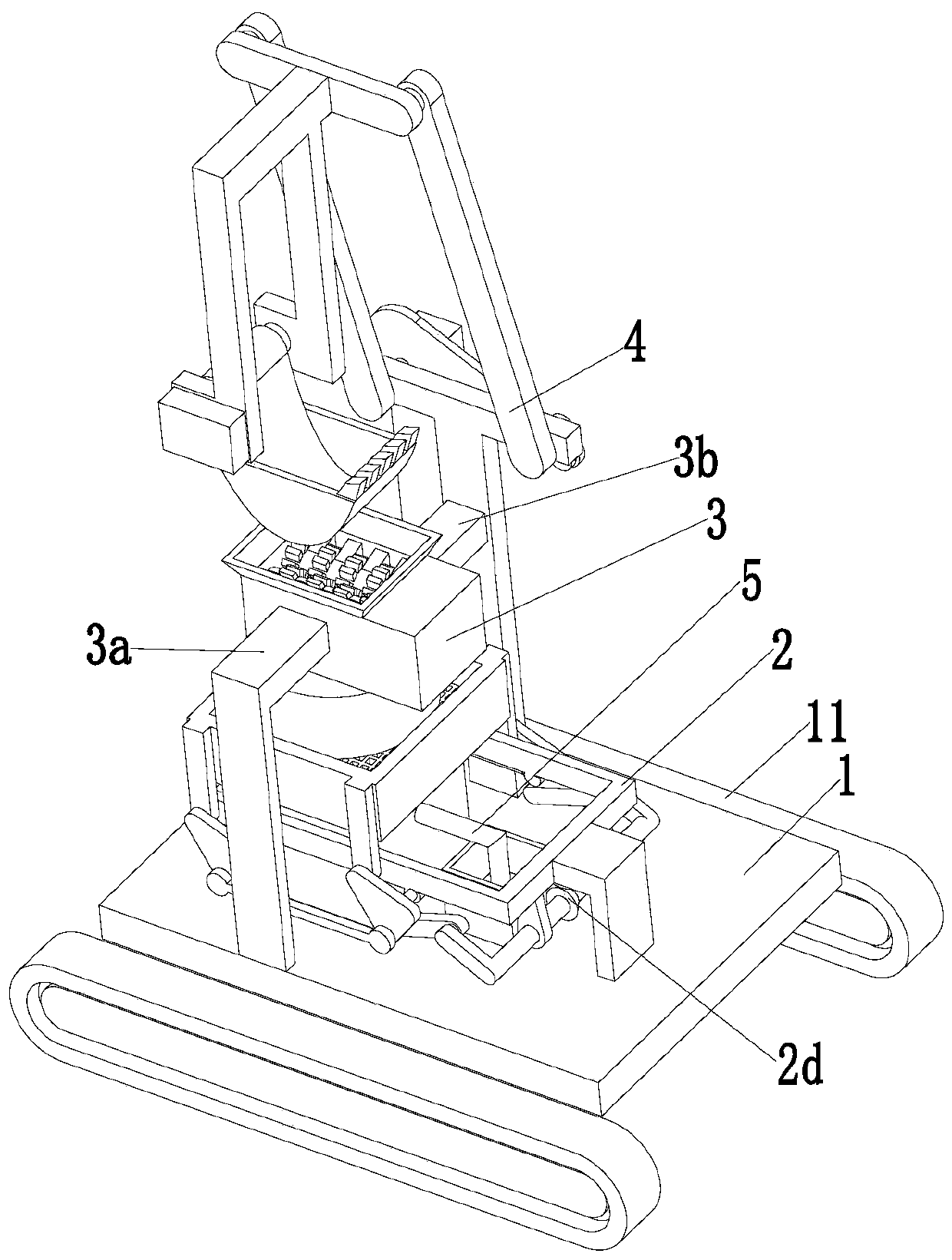

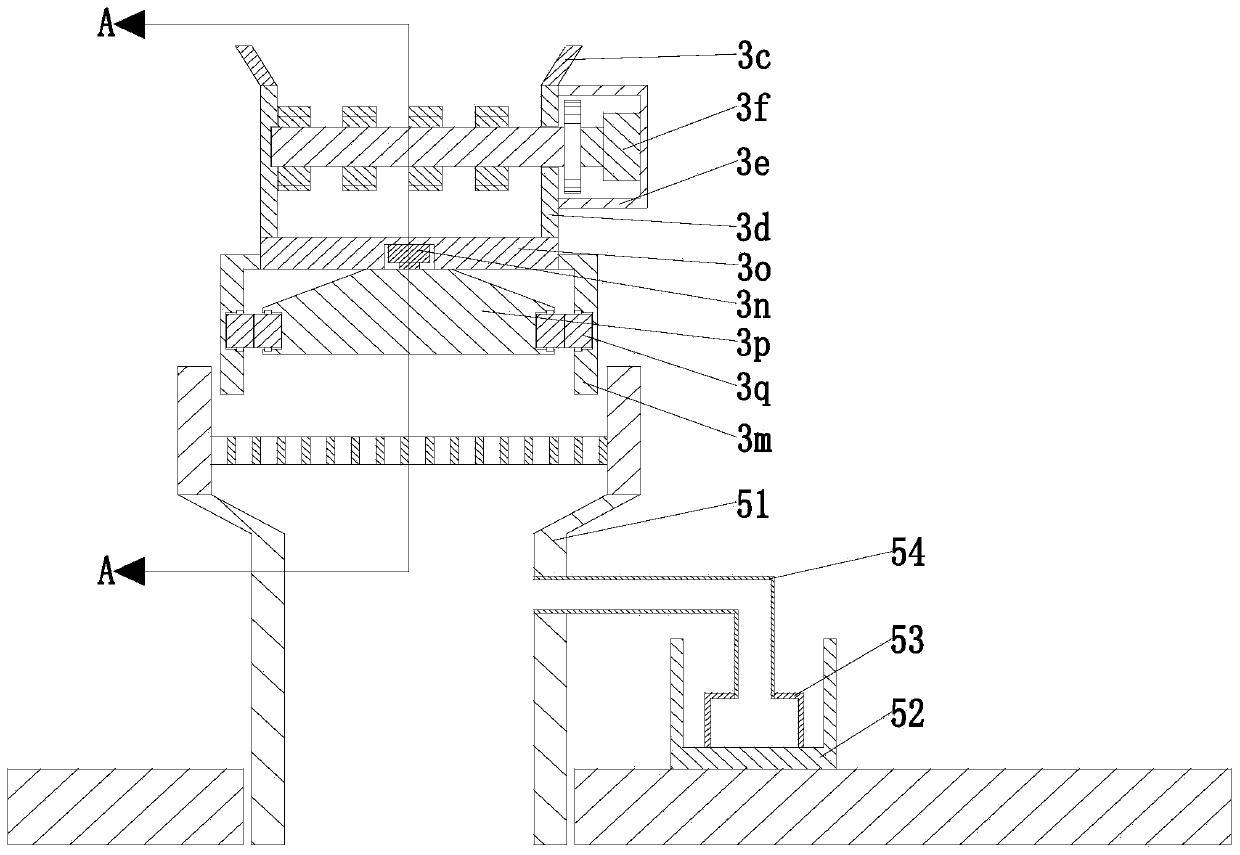

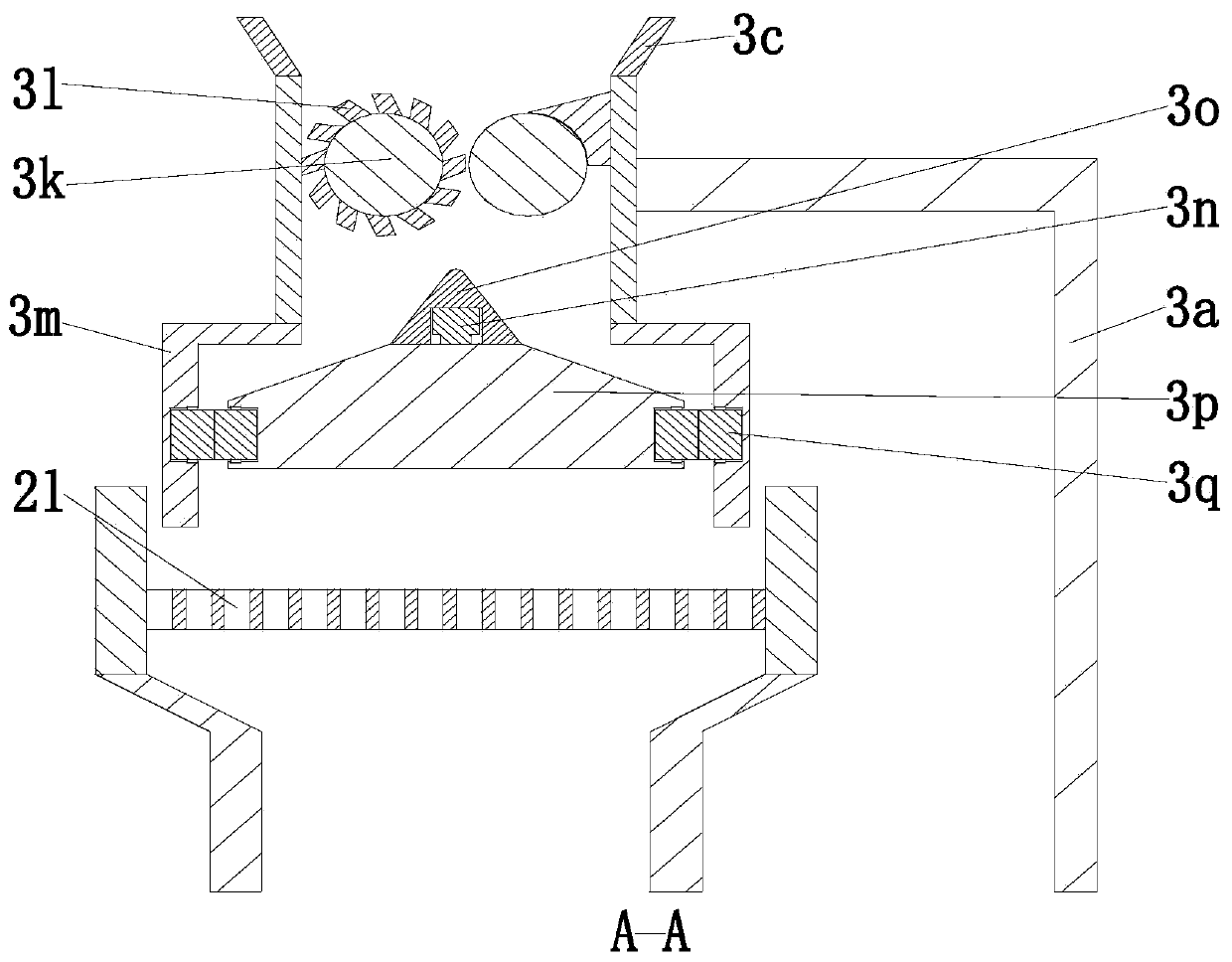

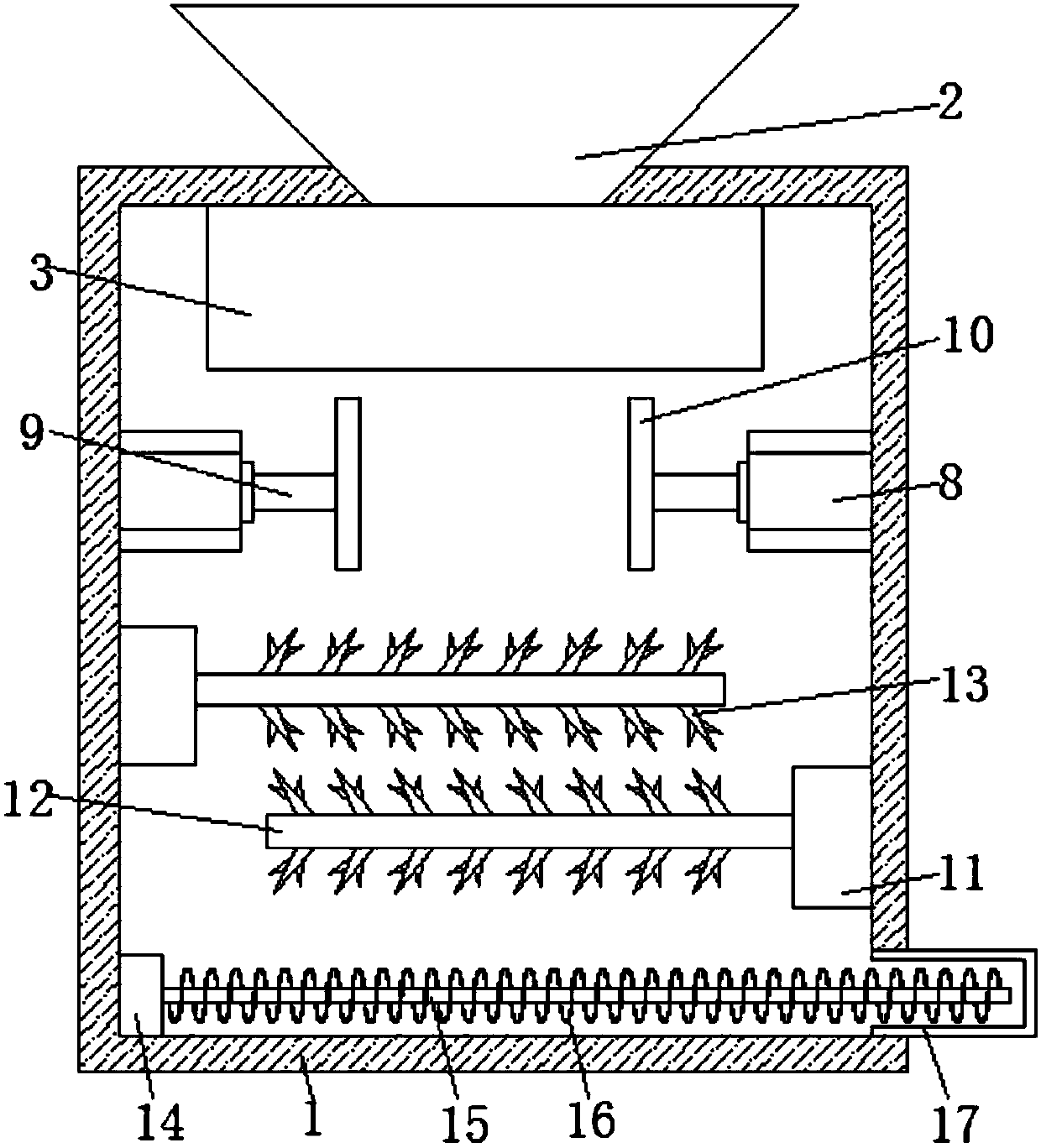

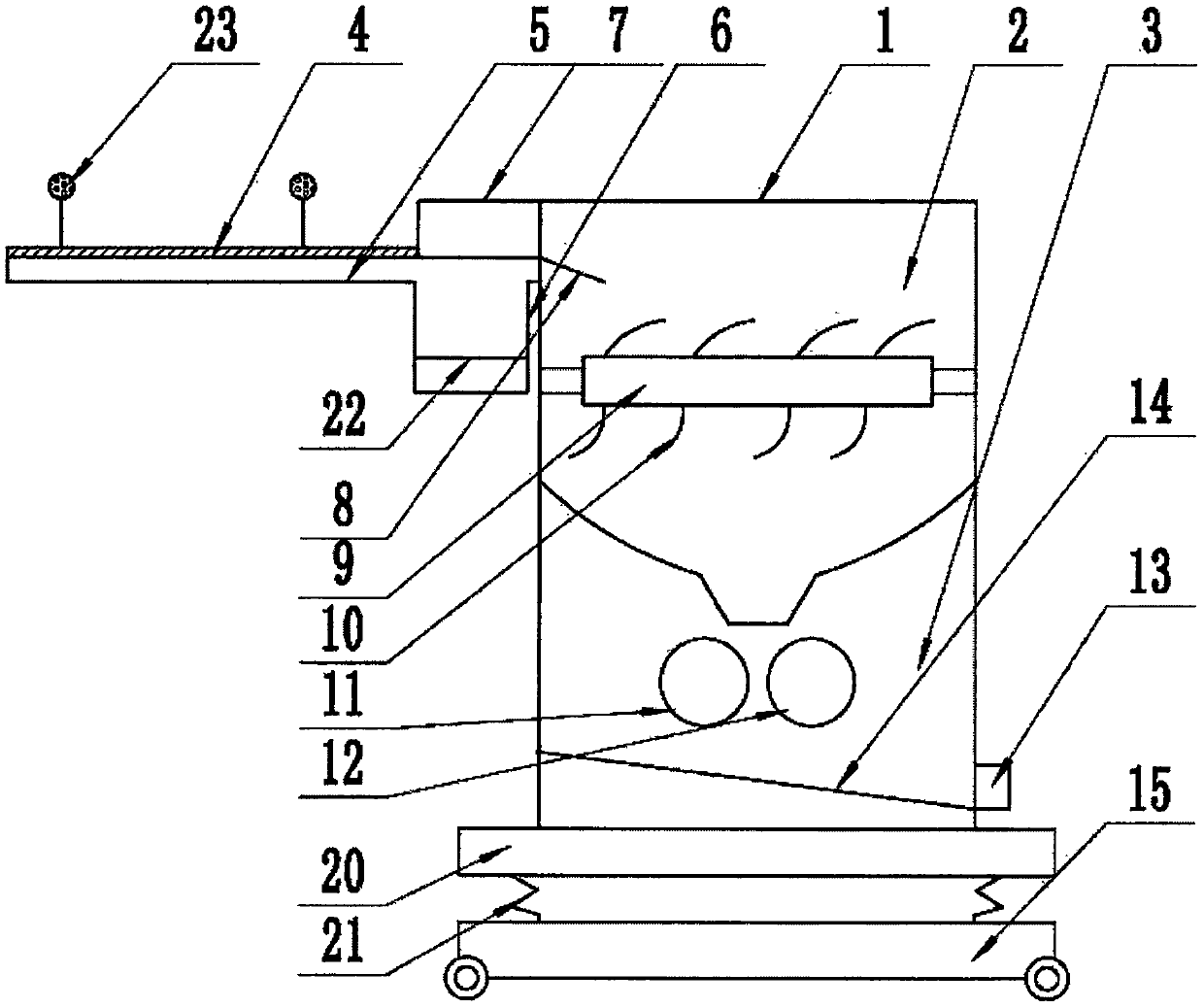

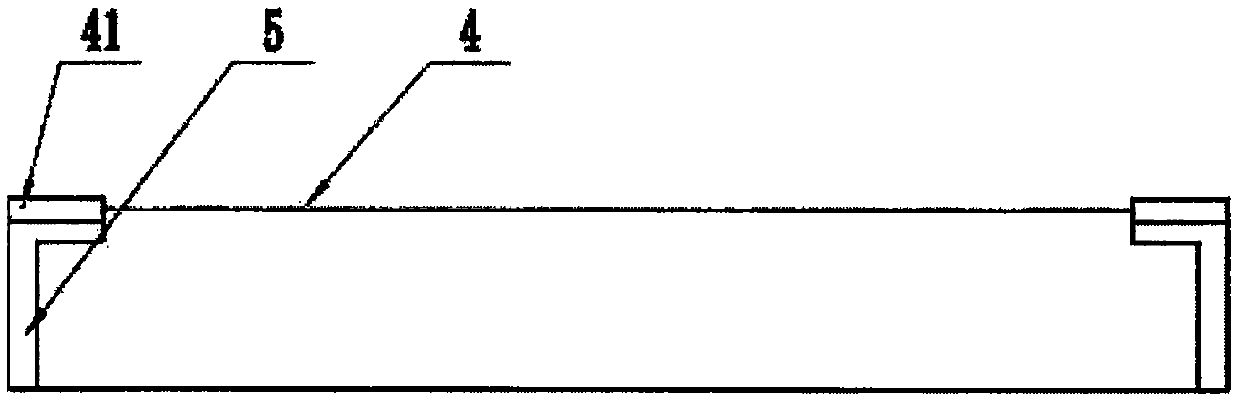

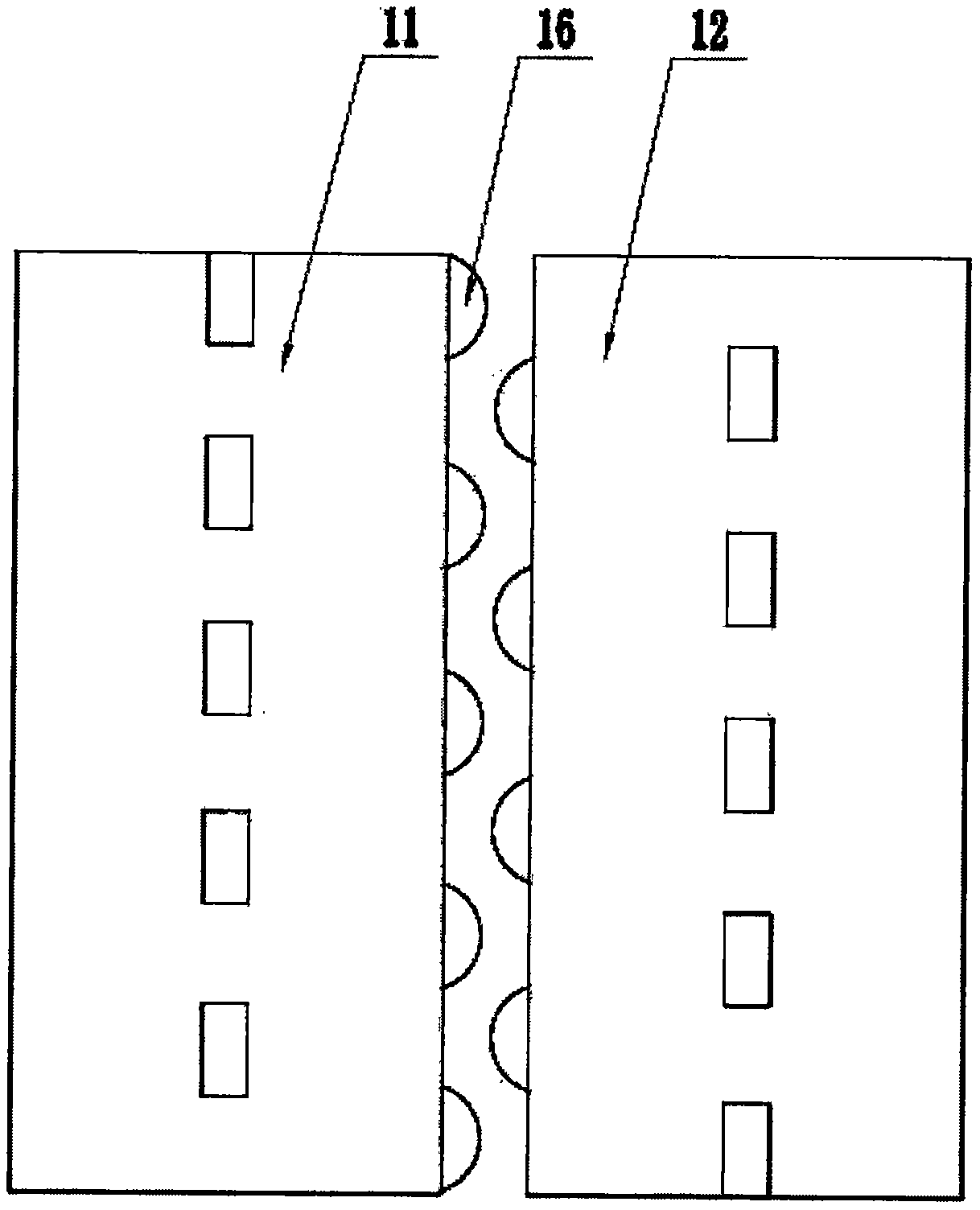

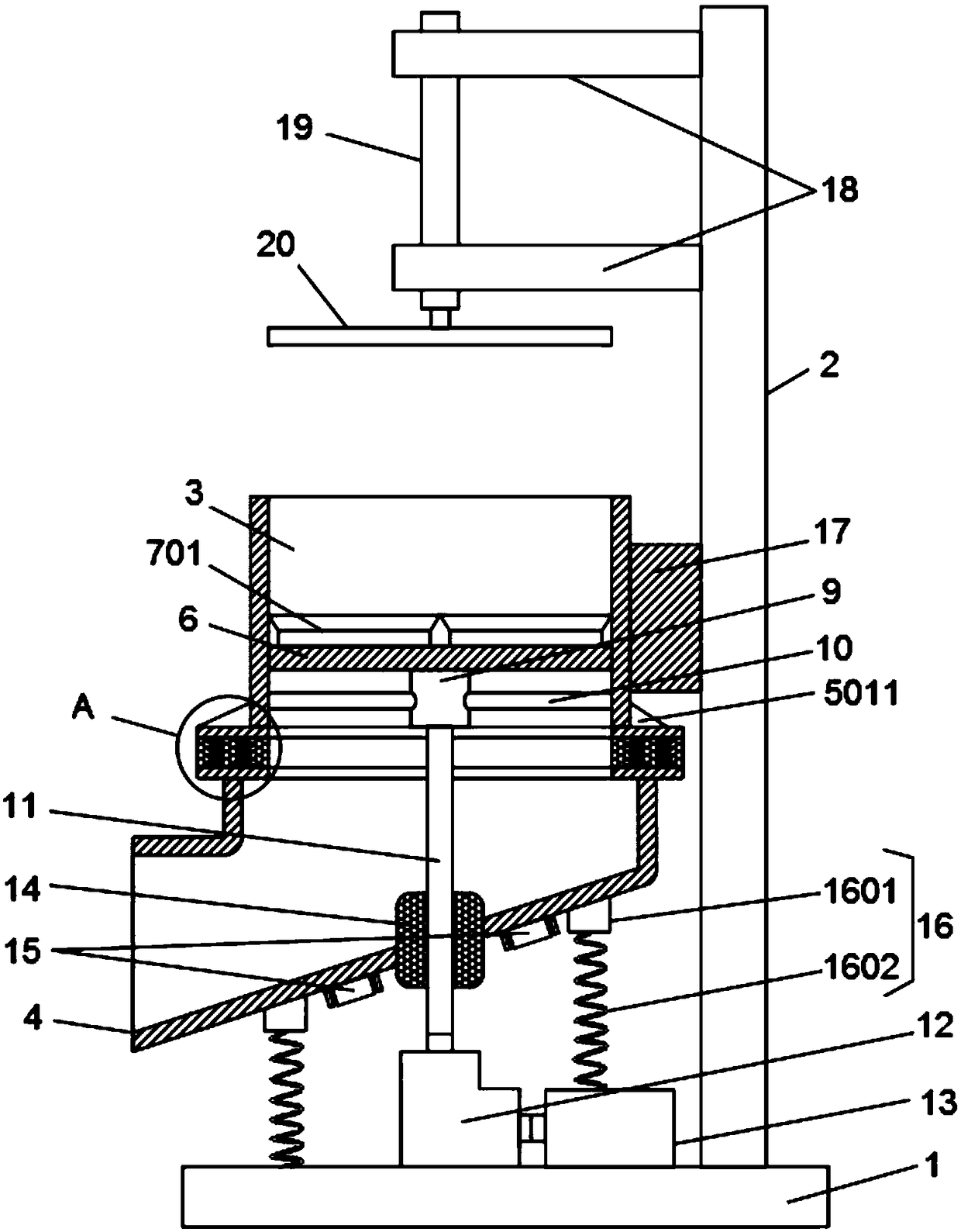

The invention discloses a corn flour production and processing mechanism based on multidirectional feeding. The corn flour production and processing mechanism comprises a corn grain crushing device, apowder mixing device and a powder transfer device according to the technological process from front to back. The corn grain crushing device comprises a crushing unit, a drying unit and a material return device according to the technological process in sequence. The powder mixing device comprises a material mixing tank and a material mixing upper cover covering the material mixing tank, and a cavity of the material mixing tank is internally provided with a first material mixing and screening plate, a first mixing chamber, a second material mixing and screening plate and a crushing / mixing integrated chamber from top to bottom in sequence. The powder transfer device comprises a transfer conveyor belt, a turnover discharging device, a transfer baffle, a conveyer bucket, a transfer elastic device and a transfer lifting base station from front to back in sequence. The corn flour production and processing mechanism has the advantages of quality guarantee of produced corn flour, good mixing effect of corn flour and flour, high continuity of operation, precise single feeding quantity and high working efficiency, and is not liable to caking or blockage.

Owner:安徽双全面粉有限公司

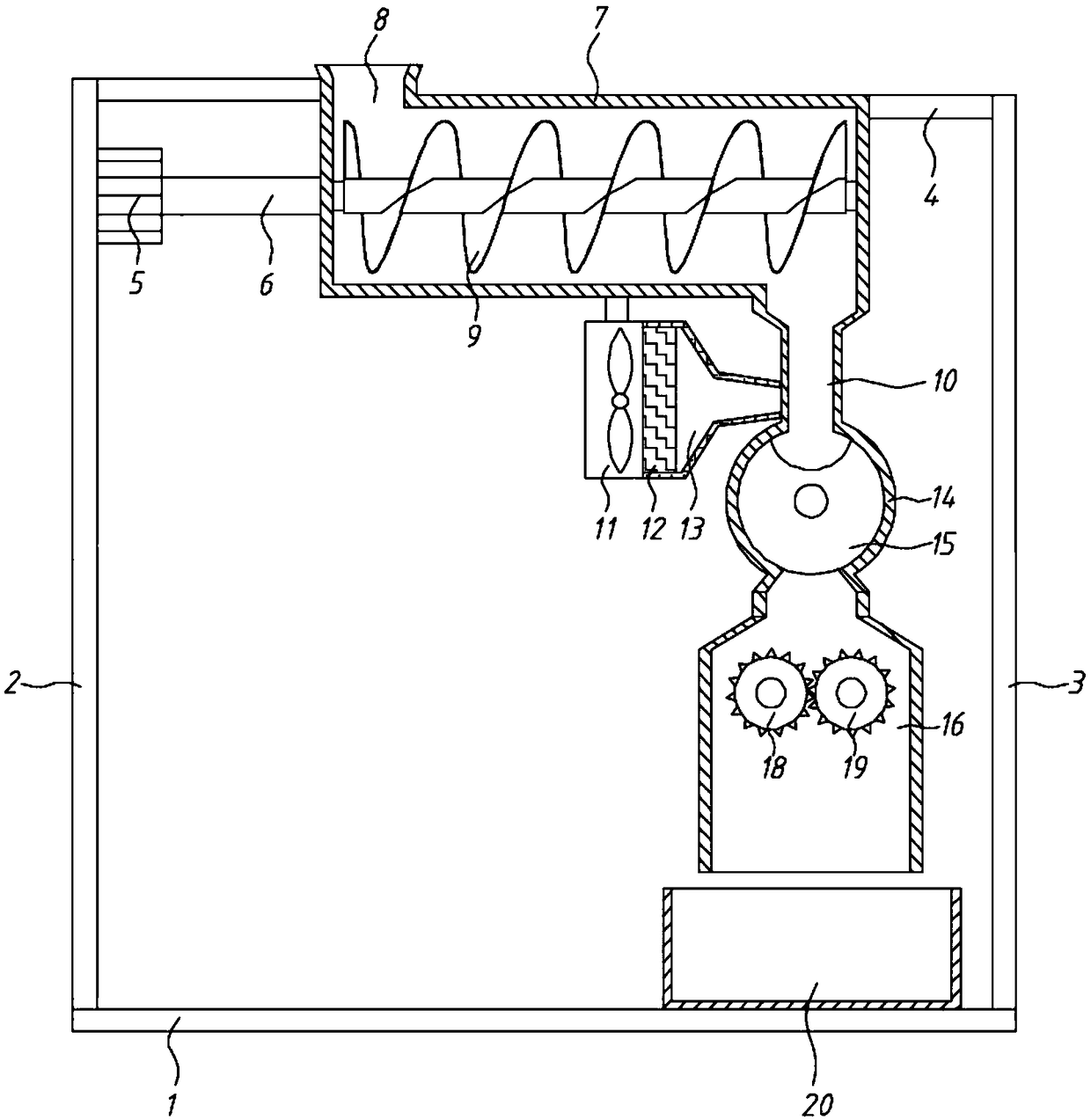

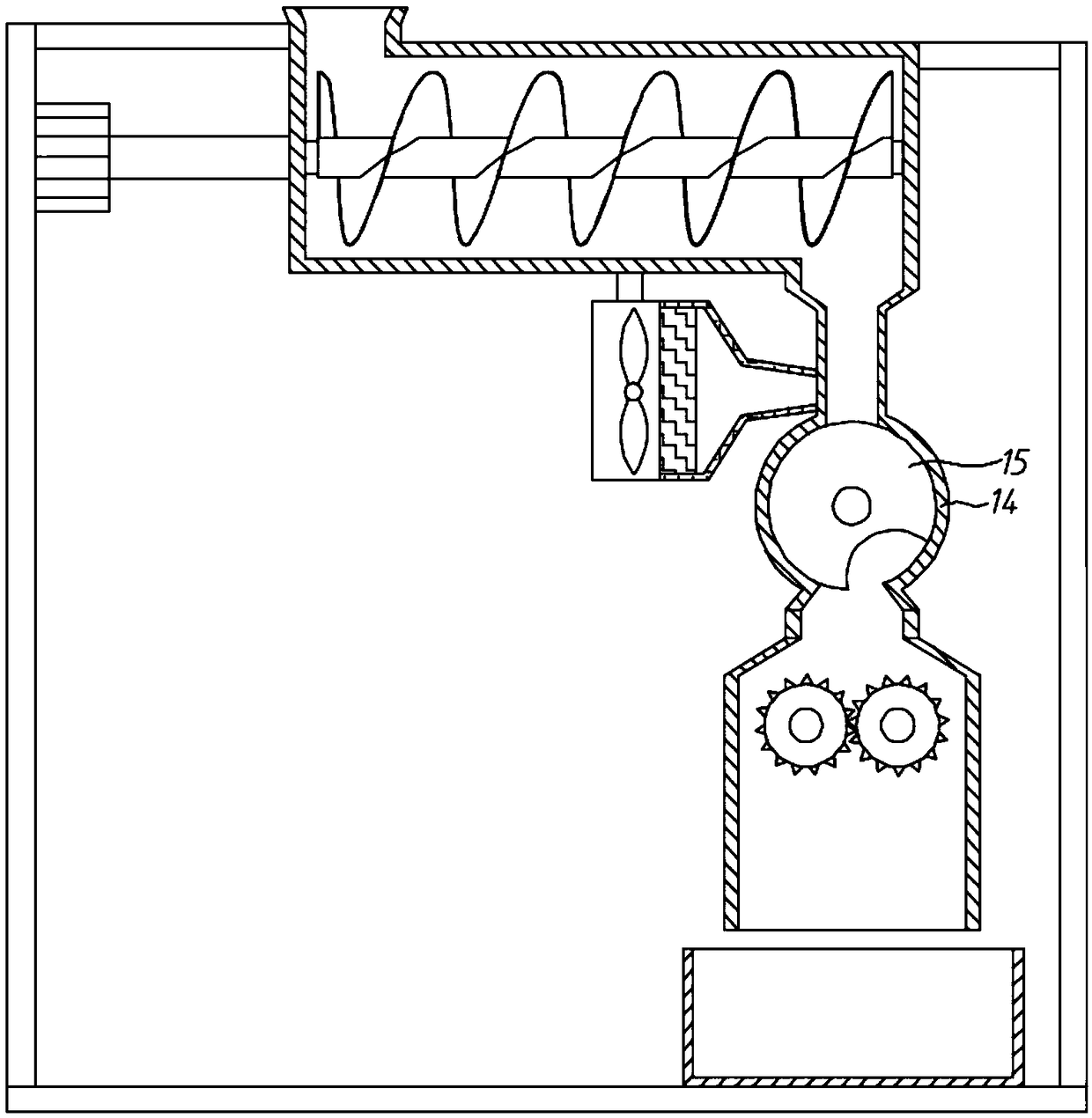

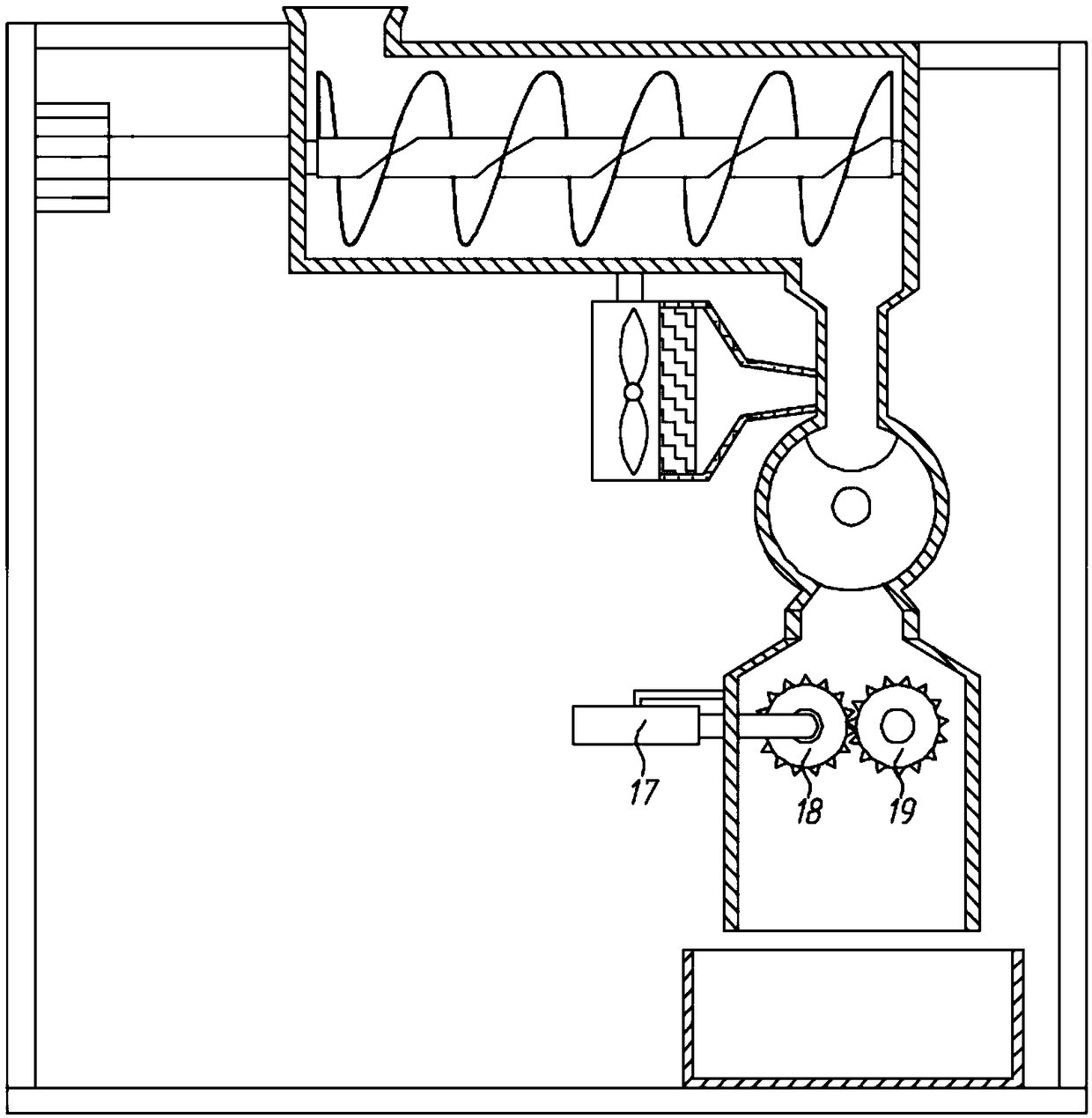

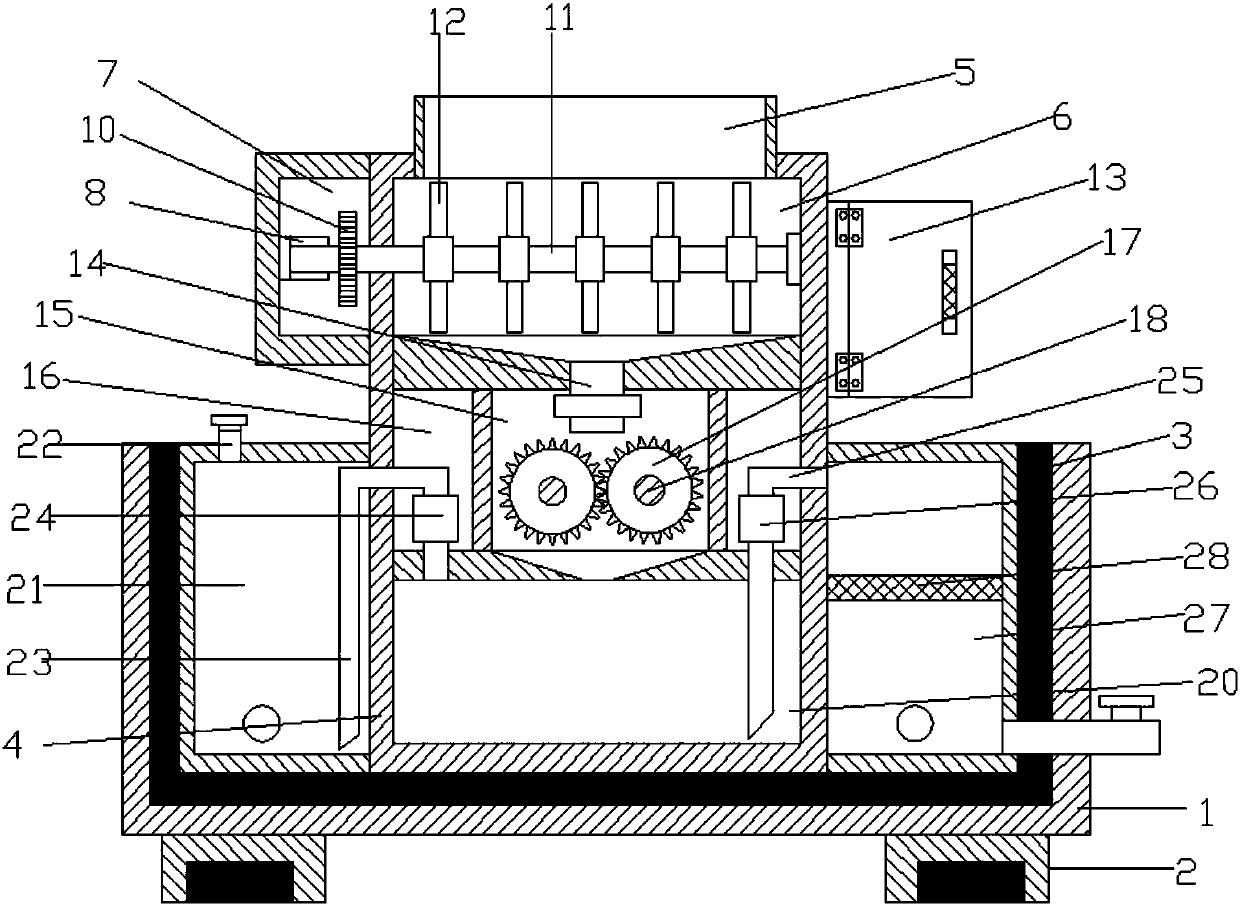

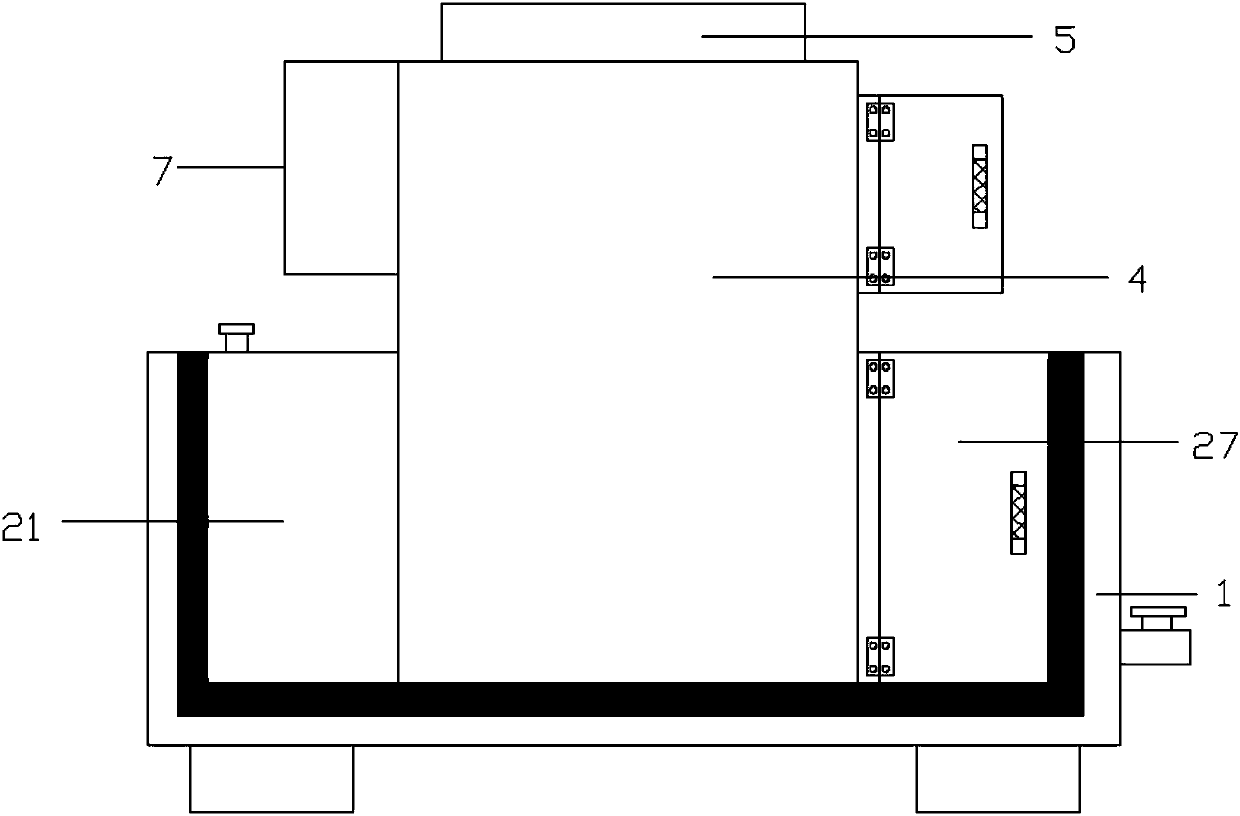

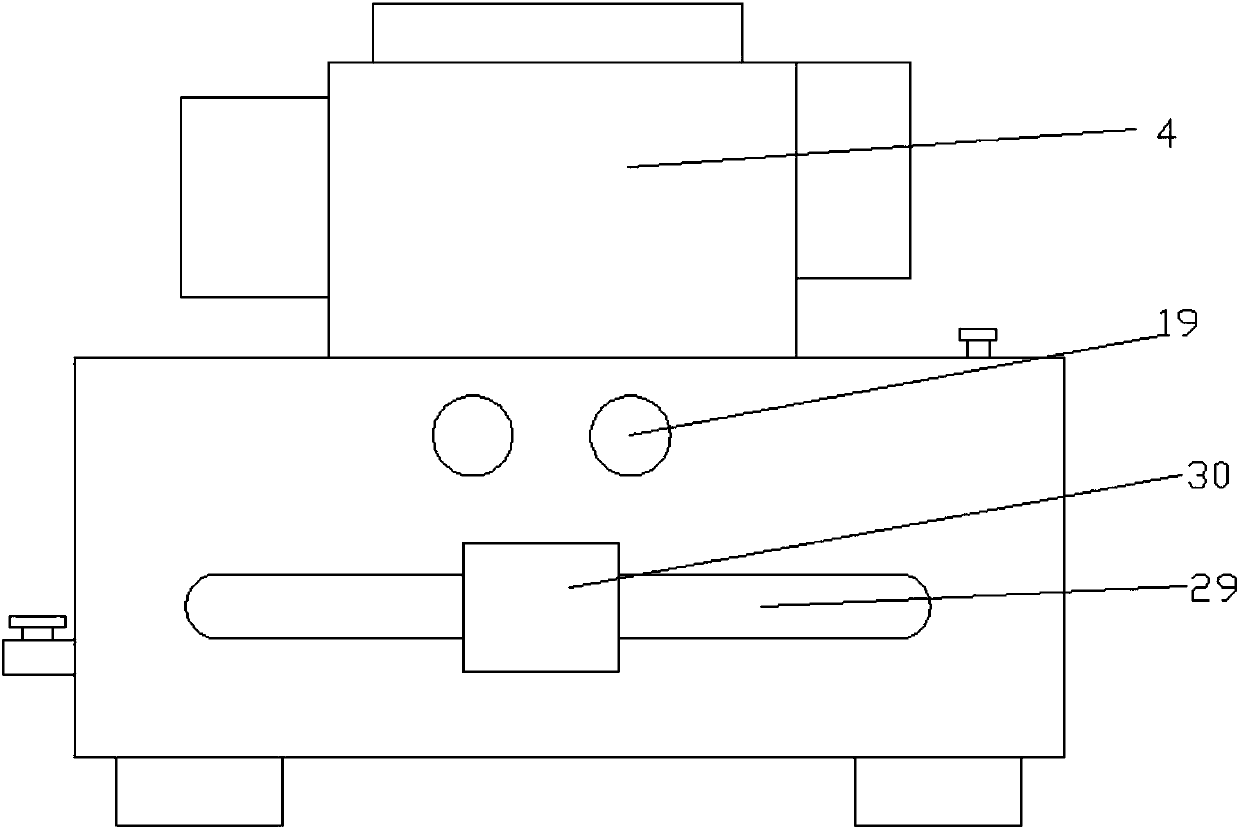

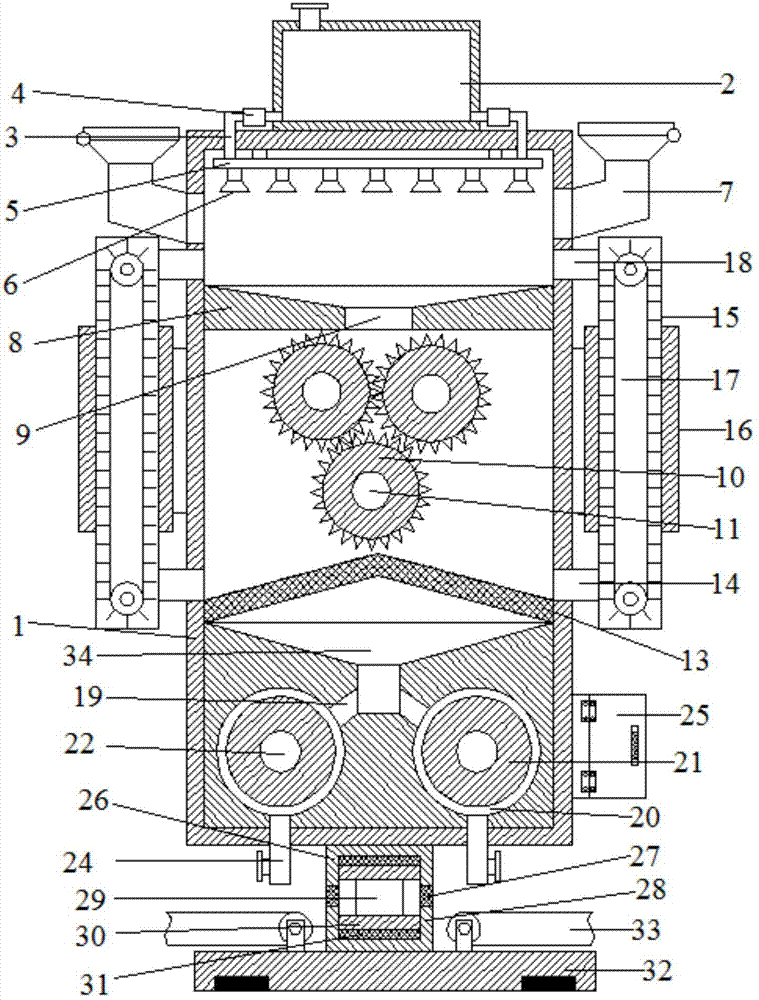

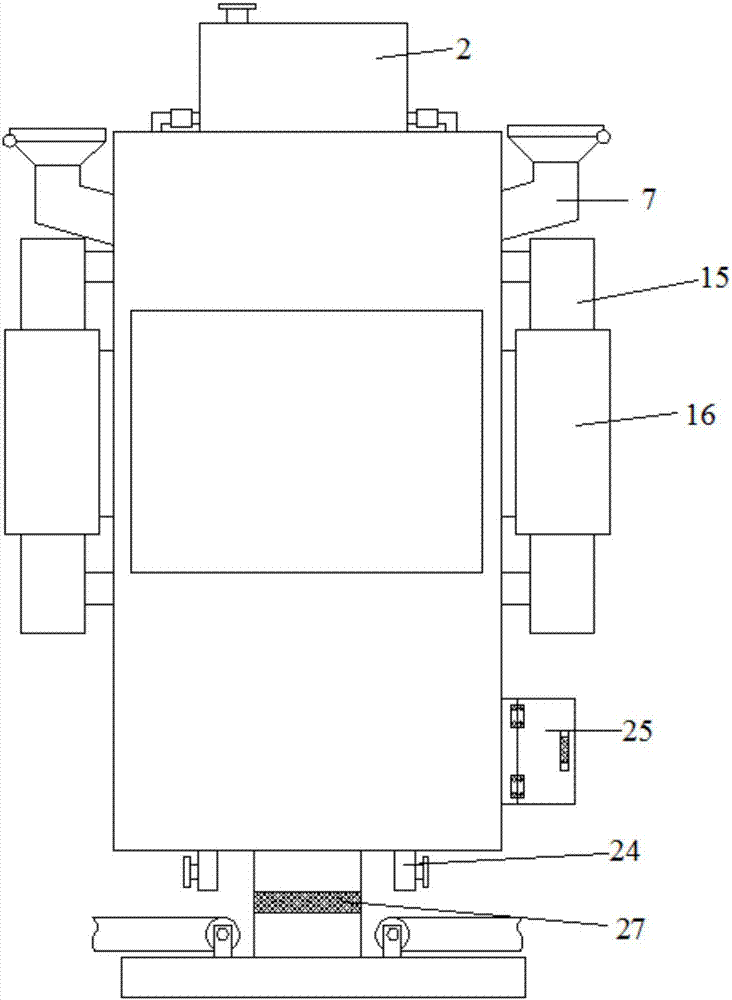

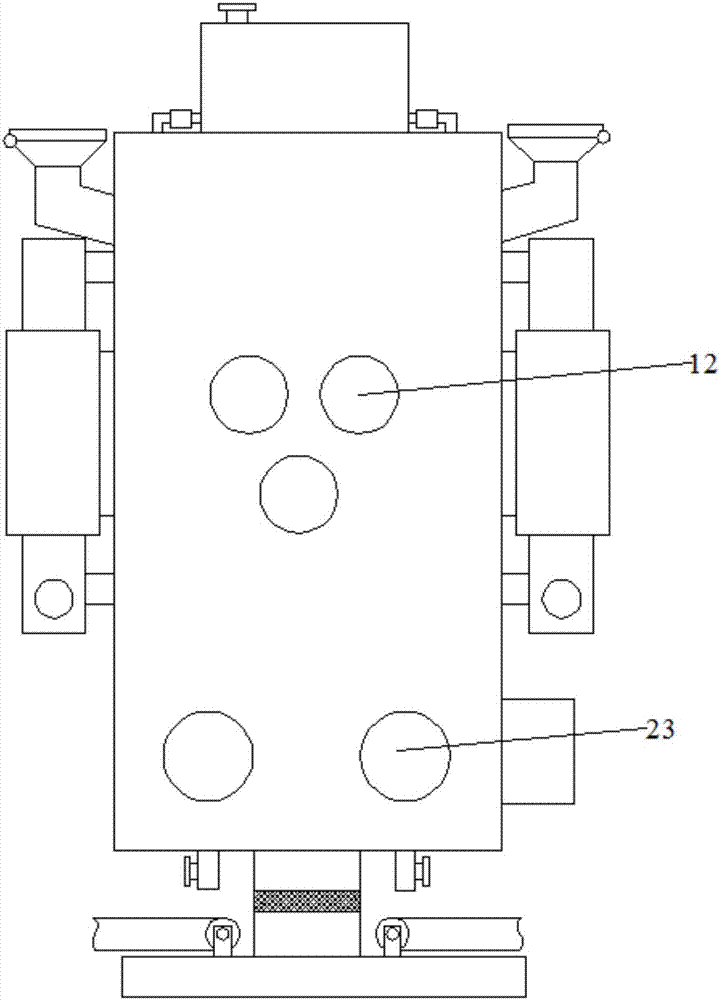

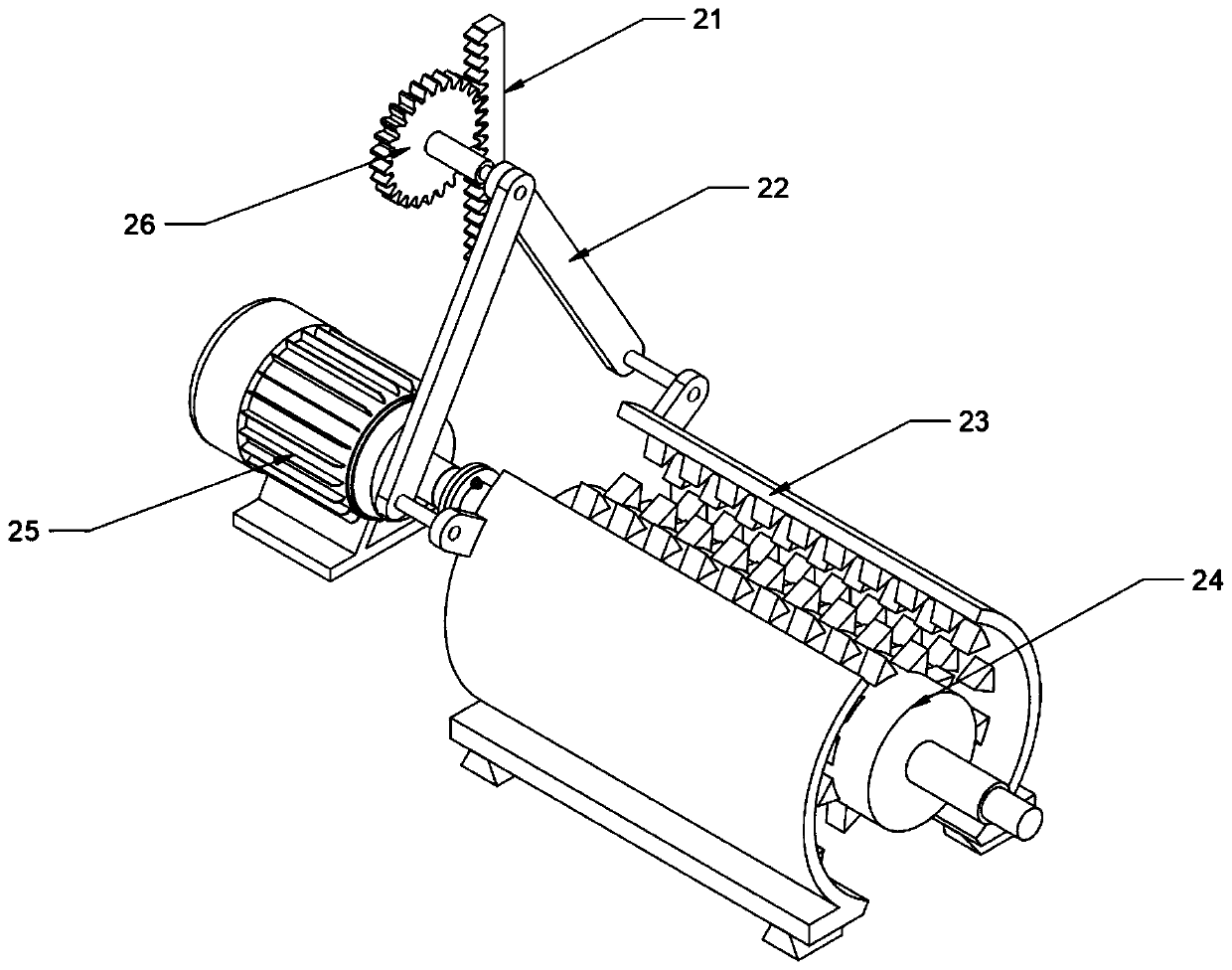

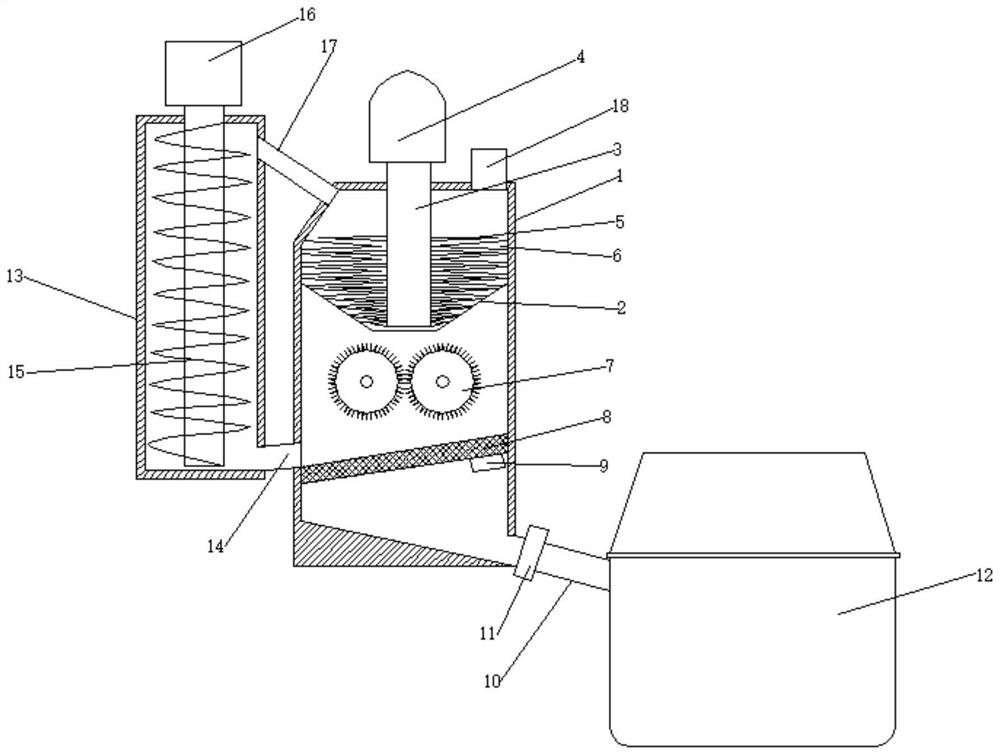

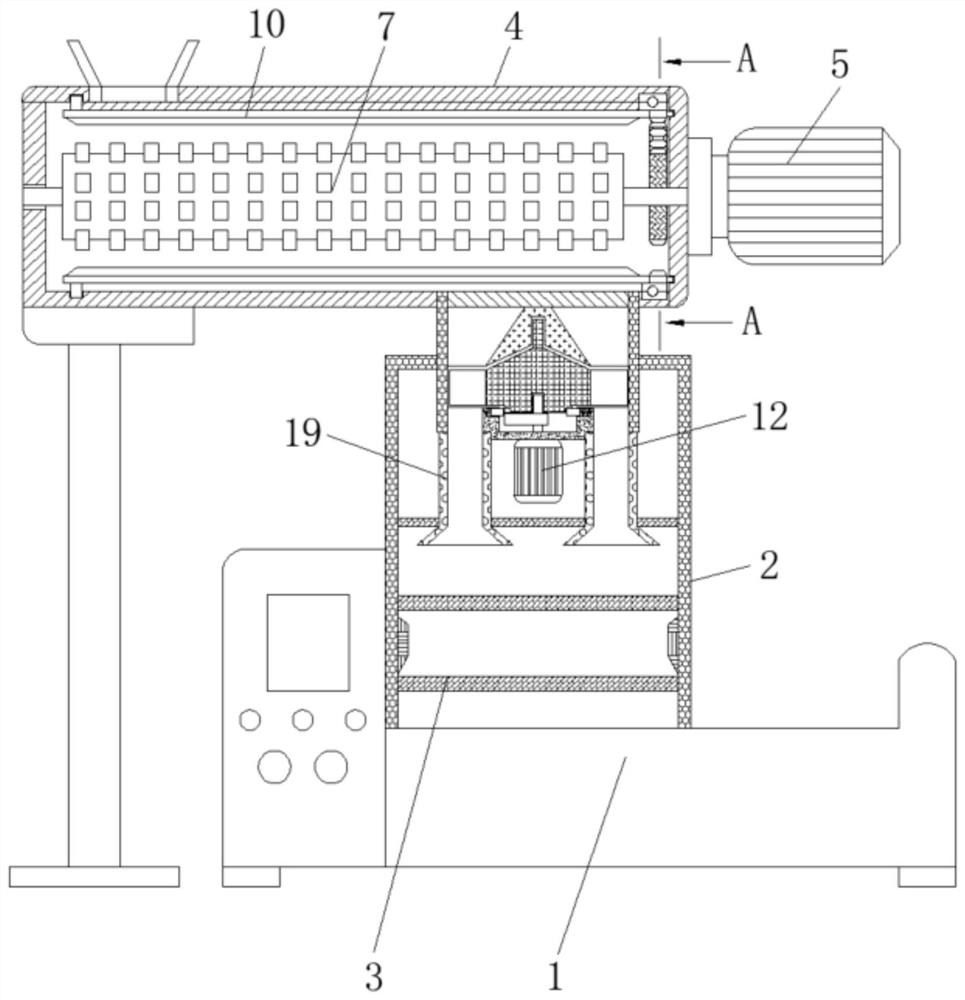

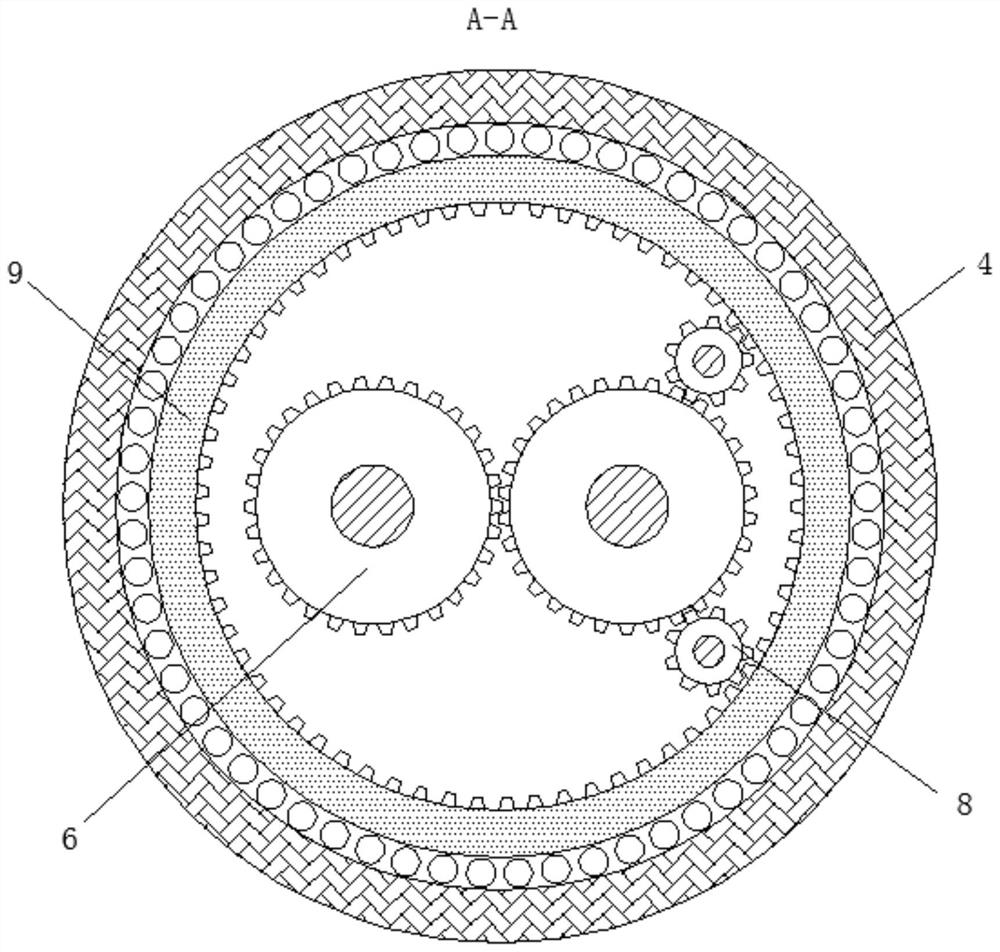

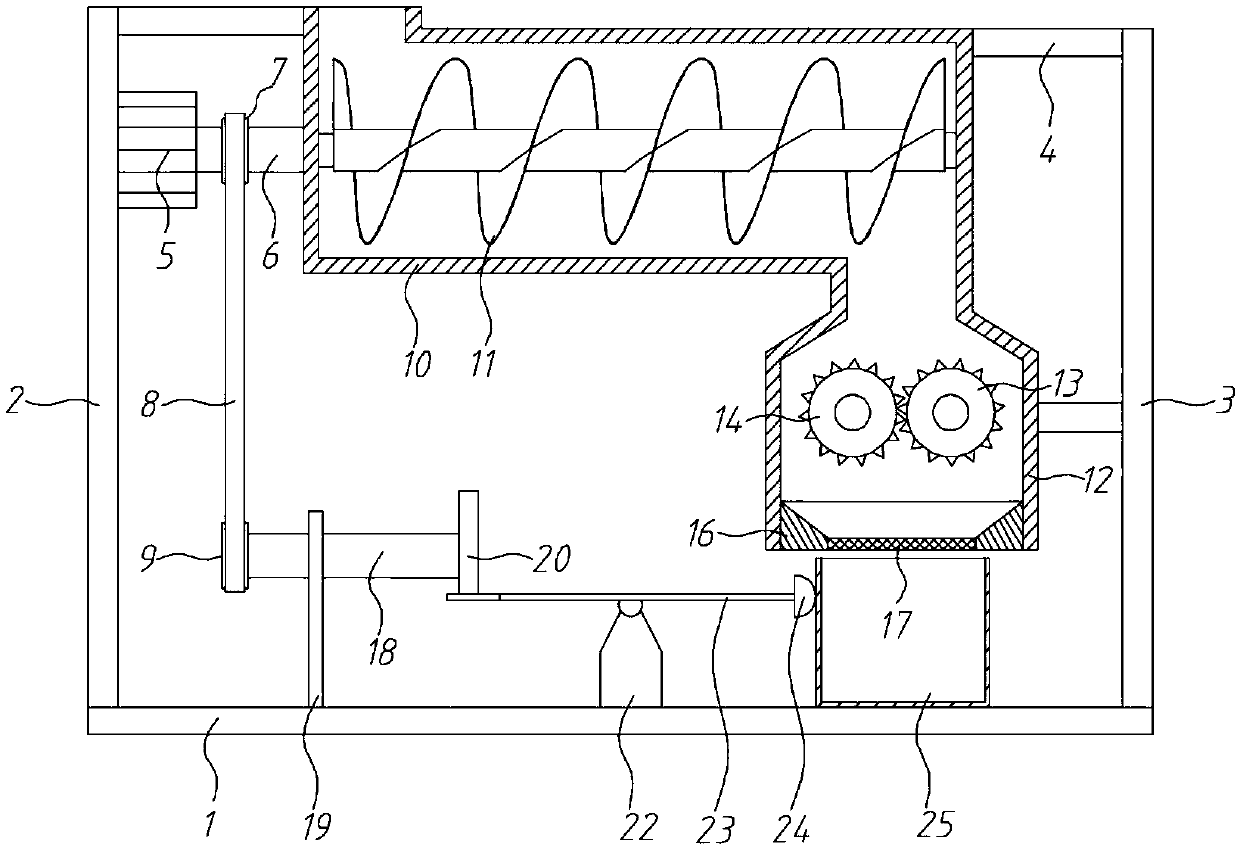

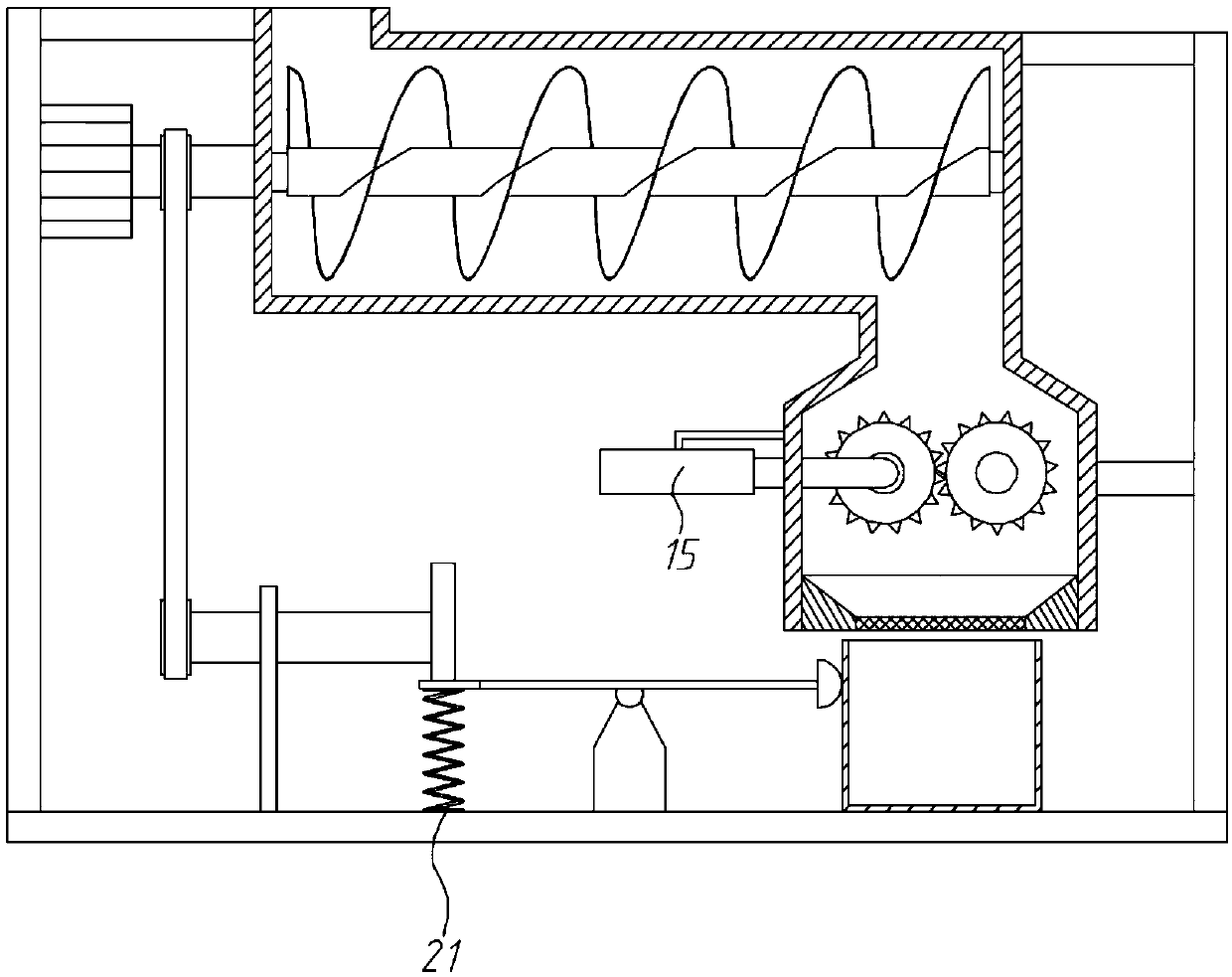

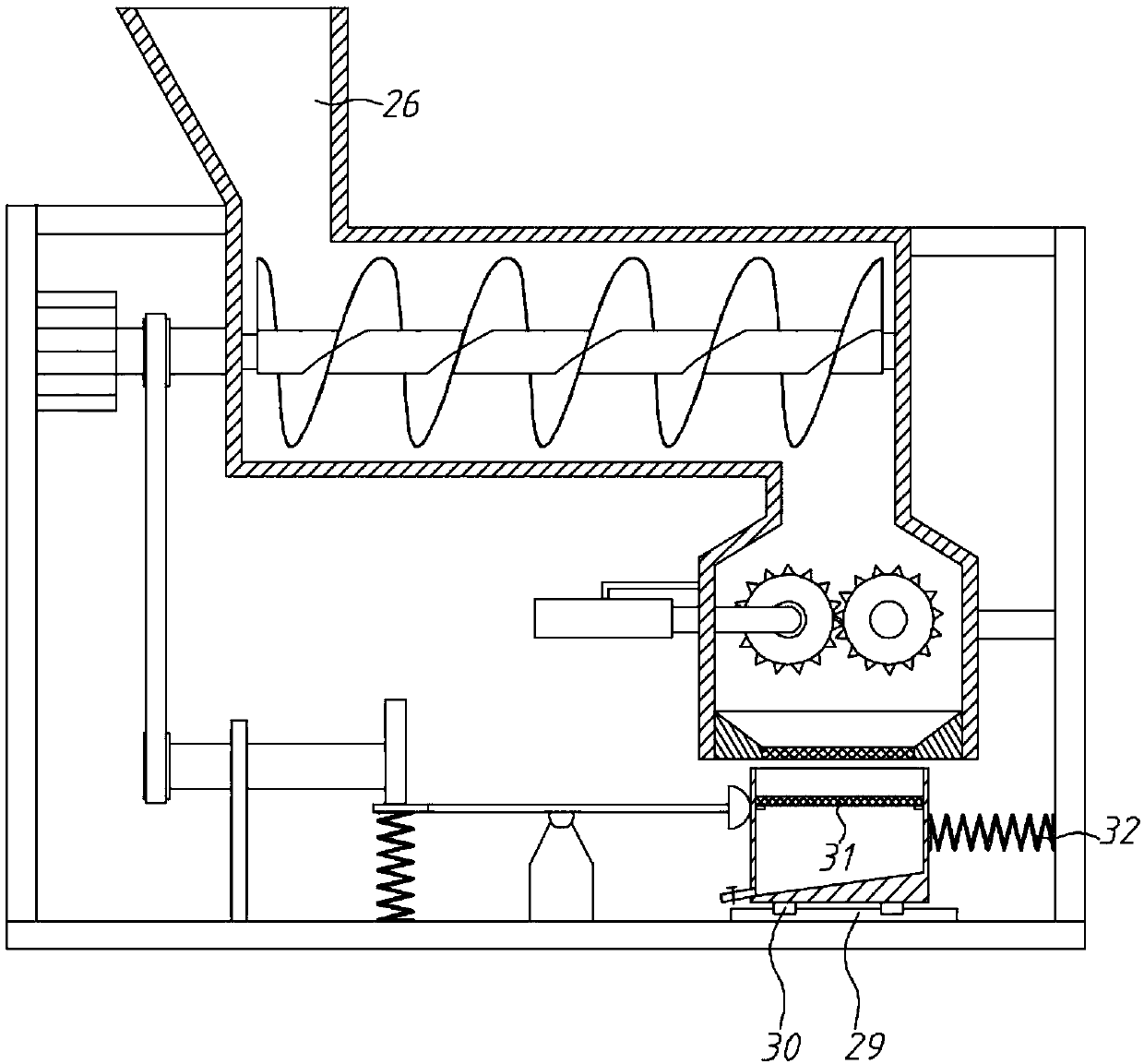

PVC tub recycling pulverizer with drying function

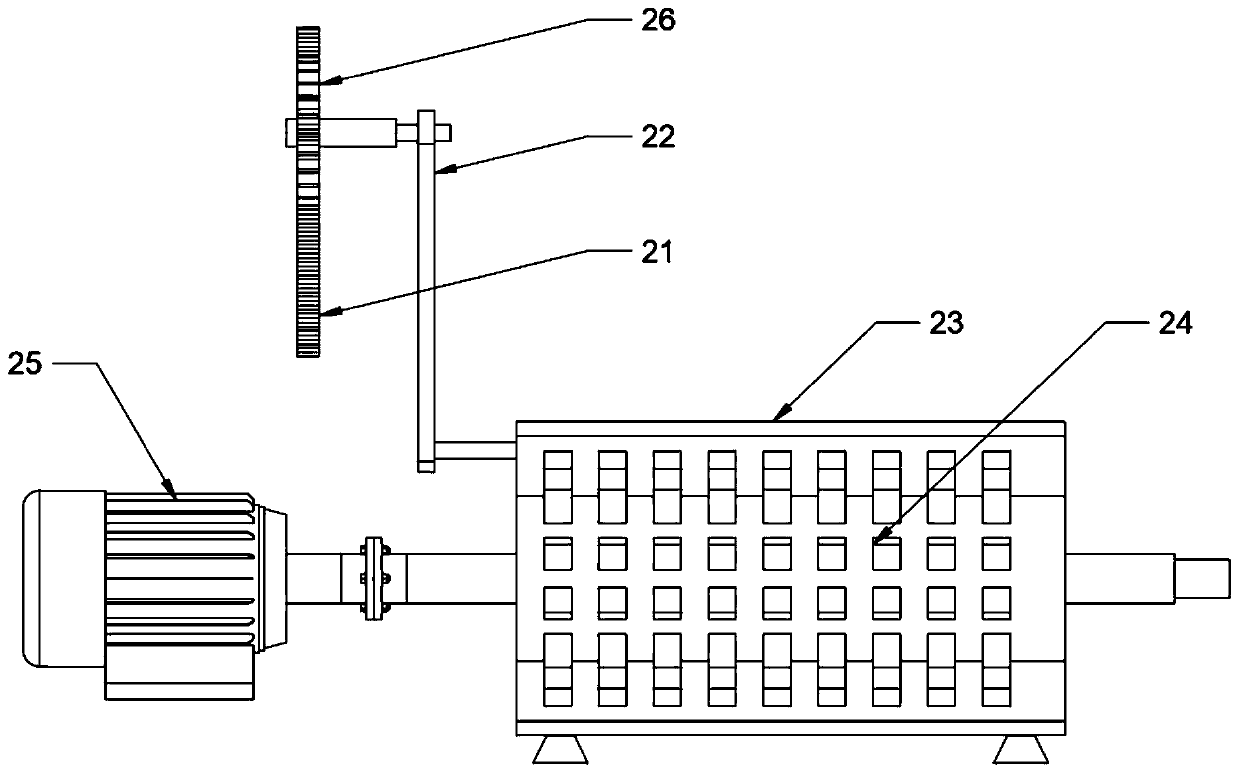

ActiveCN109397579AGuaranteed crushing efficiencyAvoid the poor effect of secondary crushingPlastic recyclingGrain treatmentsDual stageGear wheel

The invention relates to the technical field of PVC tube recycling, in particular to a PVC tube recycling pulverizer with a drying function. By adopting dual-stage pulverizing, according to first-stage pulverizing, a rotating shaft drives a spiral packaging auger to work, PVC tubes are pulverized while being conveyed, then, a pulverizing roller inside a second-stage pulverizing cylinder is adoptedfor secondary pulverizing, and the pulverizing efficiency is ensured; a storage pipe is connected to the discharging end of the primary pulverizing cylinder, a drying assembly is arranged at one sideof the storage pipe, and the preliminary pulverized PVC tubes fall into a storage tube, a fan heats air through a heating cavity and is introduced into the storage tube, and the PVC tube is dehumidified and dried; a drive motor drives a driving shaft to rotate, a driving bevel gear and a driven bevel gear act to drive the driven shaft to rotate, a connecting rod drives a push-pull rod to reciprocate, the push-pull rod periodically collides with the secondary pulverizing cylinder, PVC particles stuck to the cylinder wall are shaken down, and resides are reduced.

Owner:靖江市易凯通风设备有限公司

Paper shredder for teaching and office

ActiveCN107803257APromote fragmentationEasy to handleGrain treatmentsDraining tubePulp and paper industry

The invention discloses a paper shredder for the teaching and office. The paper shredder comprises a base. A cushion is arranged in the base. A processing cavity is formed in the middle end in the cushion. An electric control box is arranged at the upper end of the right side of the processing cavity. A paper input opening is formed in the upper side of the processing cavity. A first breaking cavity is formed in the lower side of the paper input opening. A connecting cavity is formed in the left side of the first breaking cavity. A discharging pipe is arranged on the lower side of the first breaking cavity. A second breaking cavity is formed in the lower side of the discharging pipe. Sealing cavities are correspondingly formed in the left side and the right side of the second breaking cavity. A mixing cavity is formed in the lower side of the second breaking cavity. A water storage cavity is formed in the left side of the mixing cavity. A water adding opening is formed in the upper side of the water storage cavity. A water pumping pipe is arranged at the right end of the water storage cavity. A drainage pipe is arranged on the right side of the mixing cavity. A filter cavity is formed in the right side of the drainage pipe. A filter net is arranged in the filter cavity. A connecting pipe is arranged between the filter cavity and the water storage cavity. A connecting pump is arranged on the connecting pipe. By the adoption of the paper shredder for the teaching and office, the paper can be effectively shredded twice, so that the paper shredding efficiency of the equipment can be guaranteed effectively, and treatment of shredded paper is facilitated.

Owner:凤阳明博信息工程有限公司

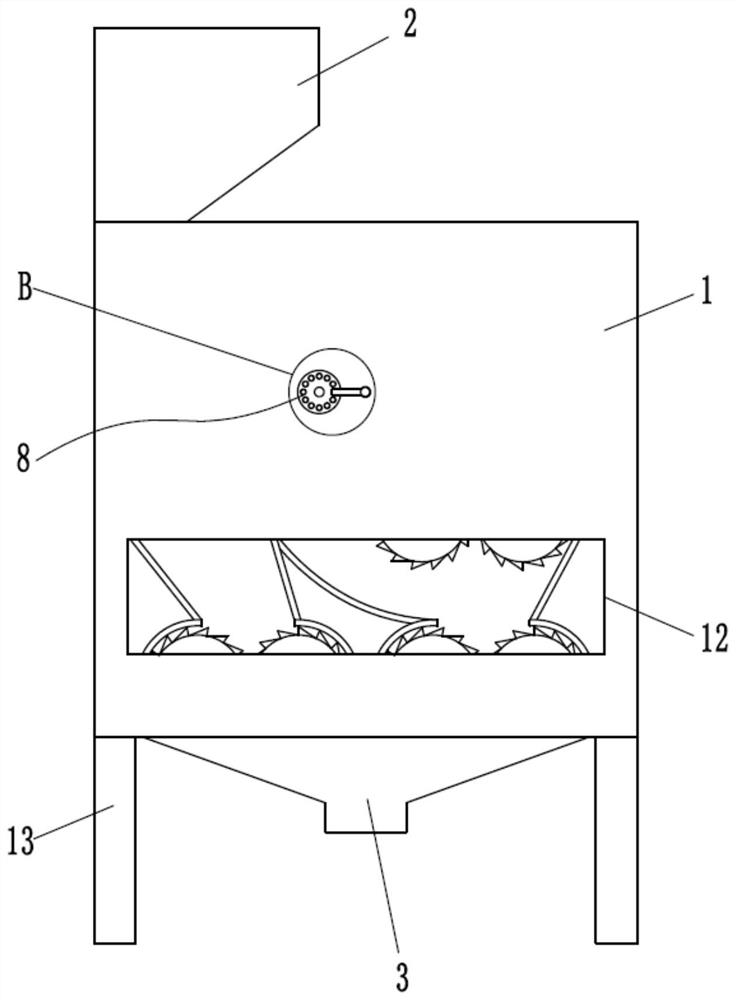

Mine crusher

InactiveCN107377078AEfficient crushingGuaranteed crushing efficiencyNon-rotating vibration suppressionGrain treatmentsWater storageWater storage tank

The invention discloses a mine crusher. The mine crusher comprises a box body. A water storage tank is arranged at the upper side of the box body. Drain pipes are arranged at the lower ends of the left side and the right side of the water storage tank. A water storage plate is arranged at the lower sides of the drain pipes. A plurality of spray heads are arranged at the lower side of the water storage plate. Charging pipes are arranged at the left end and the right end of the lower side of the spray heads. A flow guide plate is arranged at the upper end of the inside of the box body. Three crushing rollers are arranged at the lower side of the flow guide plate. A tilted filter screen is arranged at the lower side of one crushing roller. First connecting pipes are arranged at the outer side of the tilted filter screen. The outer side of each first connecting pipe is provided with a conveying cavity. The inner side of each conveying cavity is provided with a second connecting pipe. A discharging cavity is formed in the lower side of the tilted filter screen, and discharging pipes are arranged at the left side and the right side of the lower end of the discharging cavity. Grinding cavities are formed in the lower ends of the outer sides of the discharging pipes, and material outlet pipes are arranged at the lower sides of the grinding cavities. An electric cabinet is arranged at the lower end of the right side of the box body. A vibration attenuation supporting device is arranged at the lower side of the box body. A base is arranged at the lower side of the vibration attenuation supporting device. By the adoption of the mine crusher, coal can be effectively crushed, screened and ground, and crushing quality of the coal is guaranteed.

Owner:陈钦先

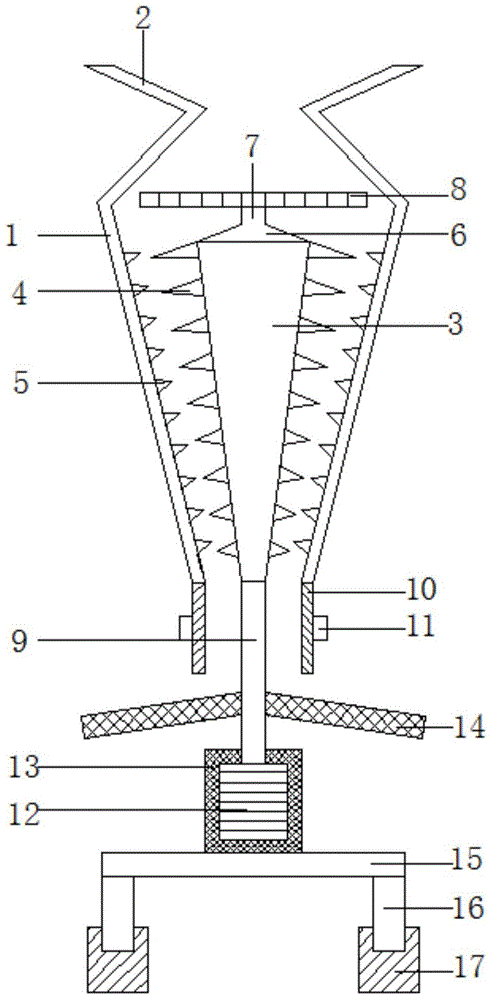

Efficient sawtooth pulverizer for ceramic production

InactiveCN104941752AGuaranteed crushing effectImprove crushing effectMagnetic separationGrain treatmentsIron removalPulp and paper industry

The invention discloses an efficient sawtooth pulverizer for ceramic production. The efficient sawtooth pulverizer comprises a pulverizer body, a pulverizing spiked roller and a pulverizing chain. A feeding hopper is arranged on the upper side of the pulverizer body, and the pulverizing spiked roller is vertically arranged on the axis of the interior of the pulverizer body; and the diameter of the top end of the spiked roller is larger than that of the bottom end of the spiked roller, and a plurality of pulverizing movable sawteeth are vertically and evenly arranged on the outer wall of the pulverizing spiked roller. According to the efficient sawtooth pulverizer for ceramic production, the pulverizing chain preliminarily pulverizes materials, and the materials enter pulverizing gaps between the pulverizing movable sawteeth and pulverizing fixed sawteeth to be pulverized; the pulverizing time is long, the pulverizing effect is good, and the pulverized materials are screened by a screen, so that the working efficiency of the pulverizer is greatly improved; electromagnets can carry out iron removal on the fallen materials, and the quality of a machined finished product is ensured; and in the pulverizing process, the vertical motion of the spiked roller is adjusted to control the size of the pulverizing gaps, so that the pulverized material is controlled, the practicability is high, and the working process of the pulverizer is low in noise.

Owner:顾广才

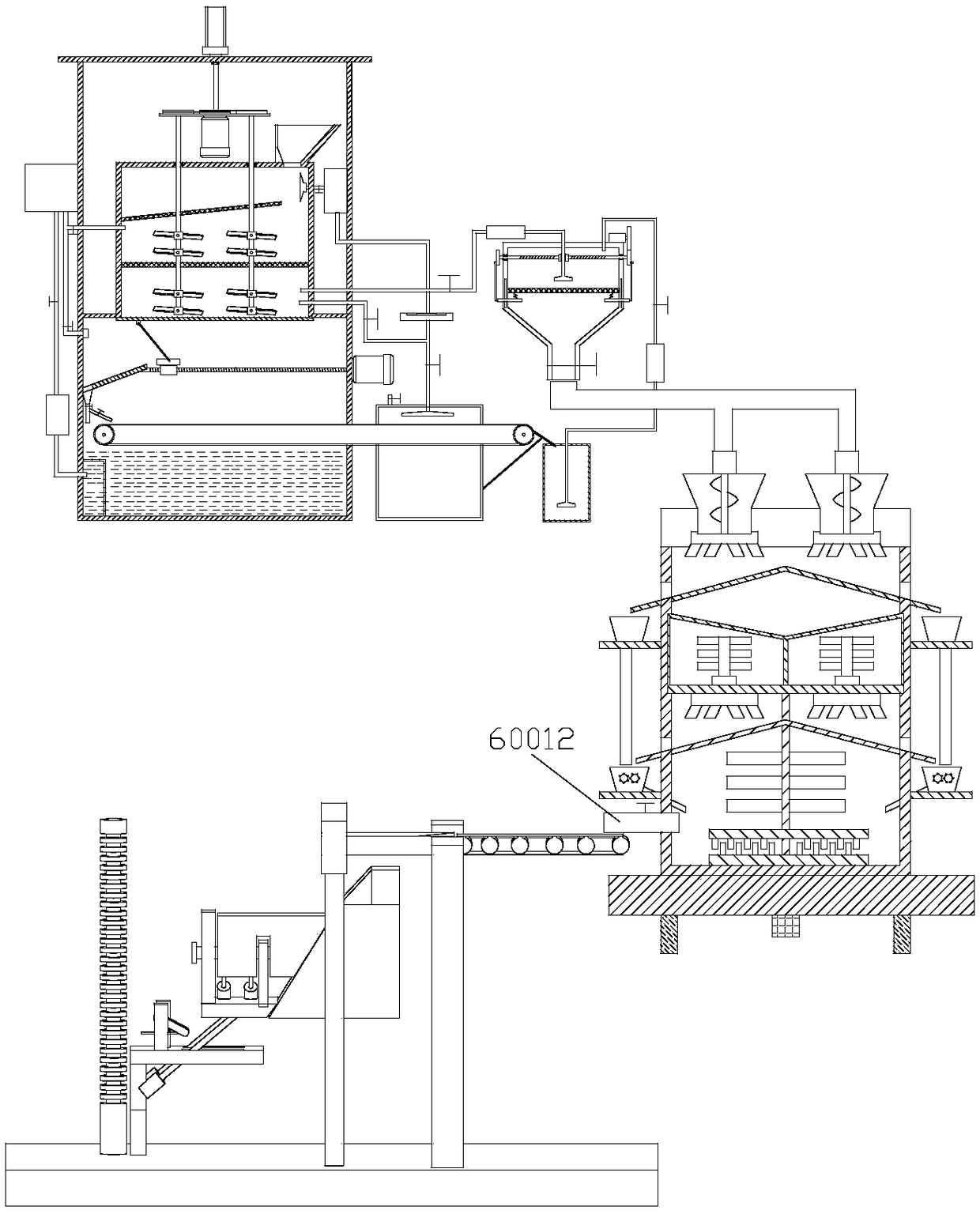

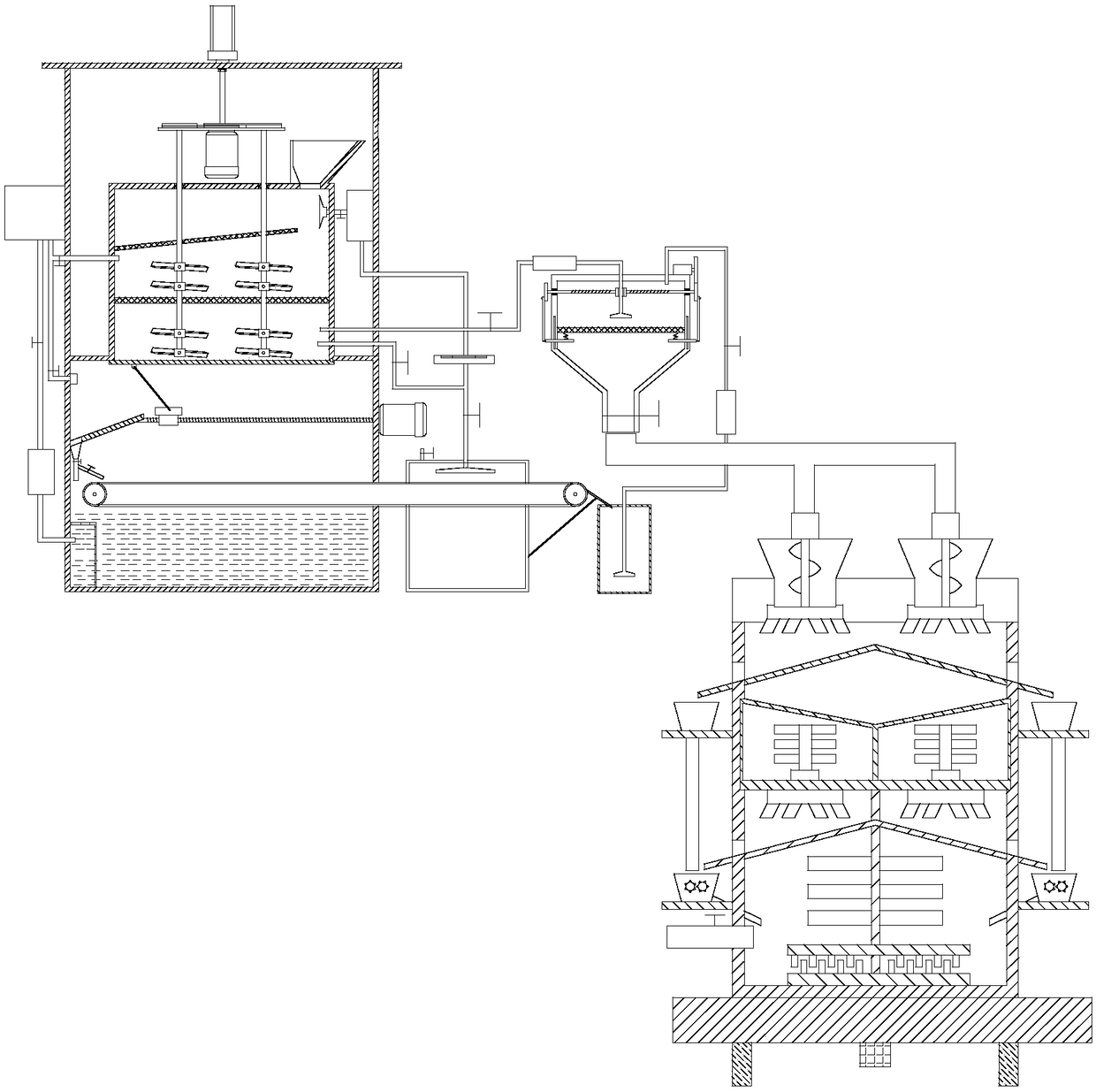

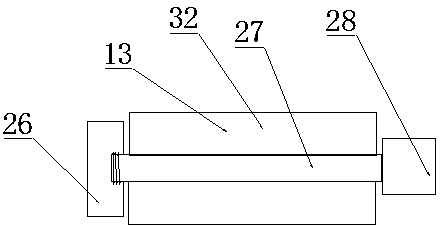

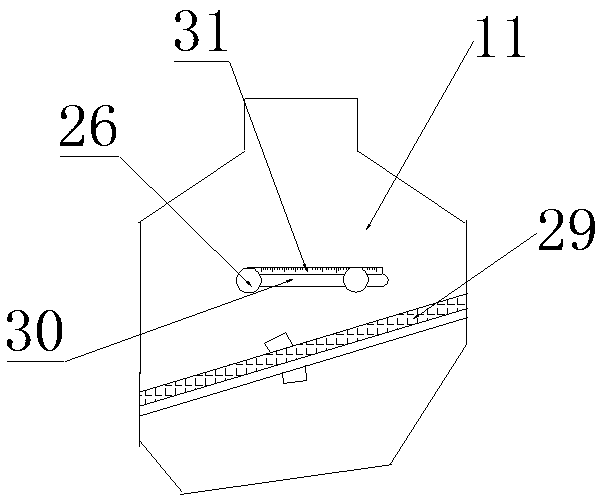

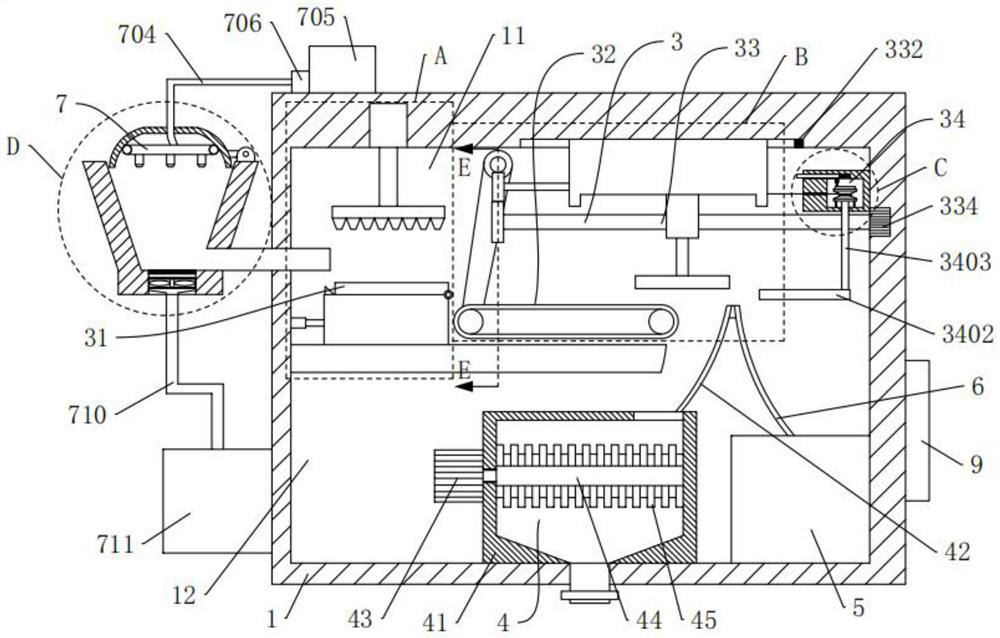

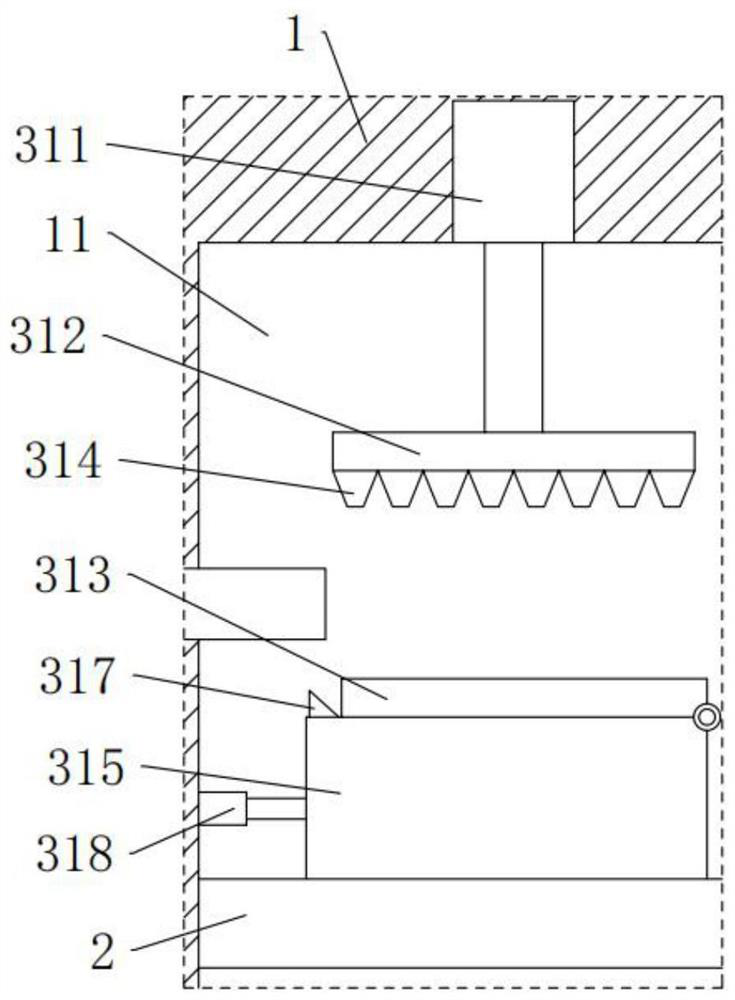

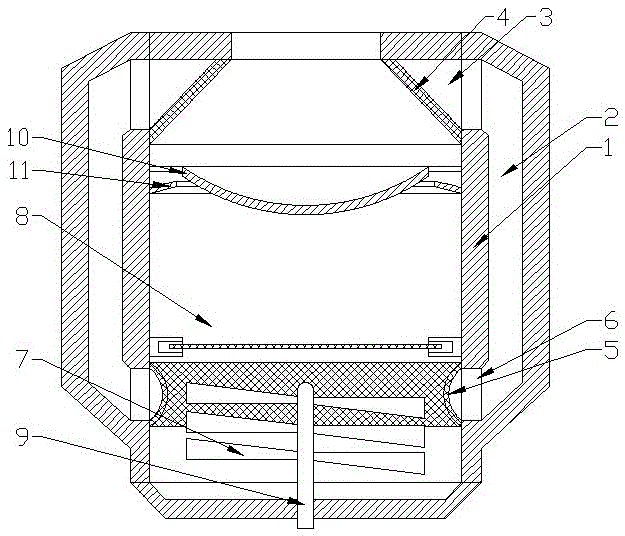

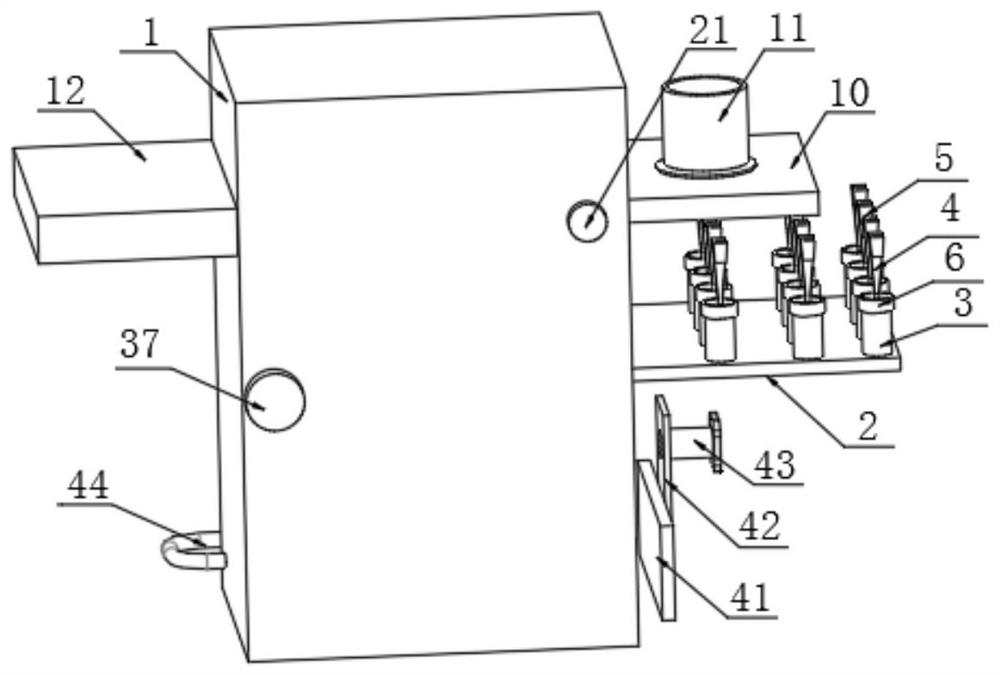

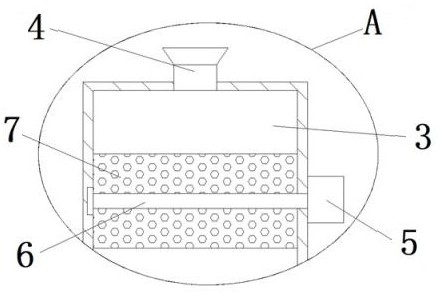

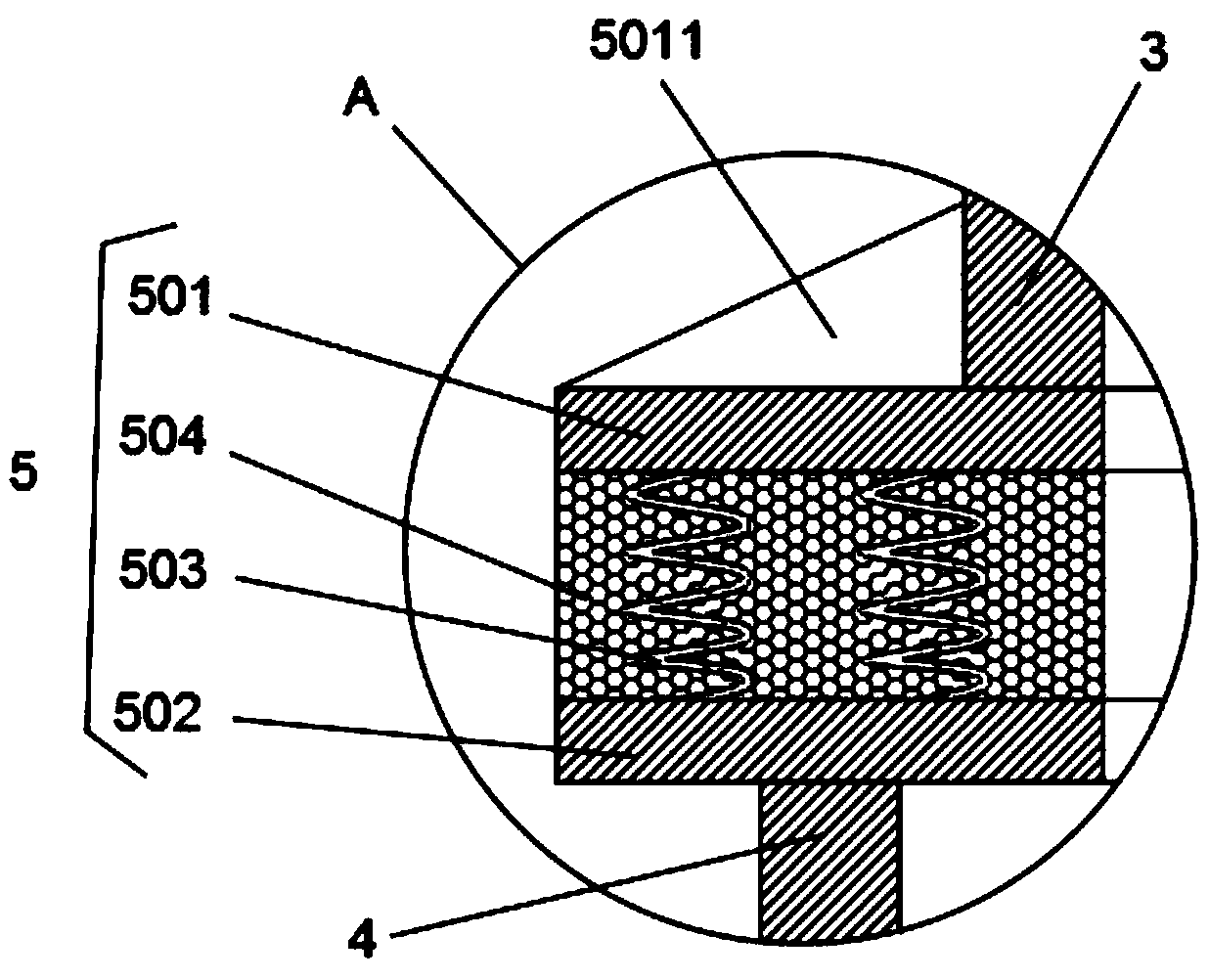

Corn flour dry-mixing mechanism

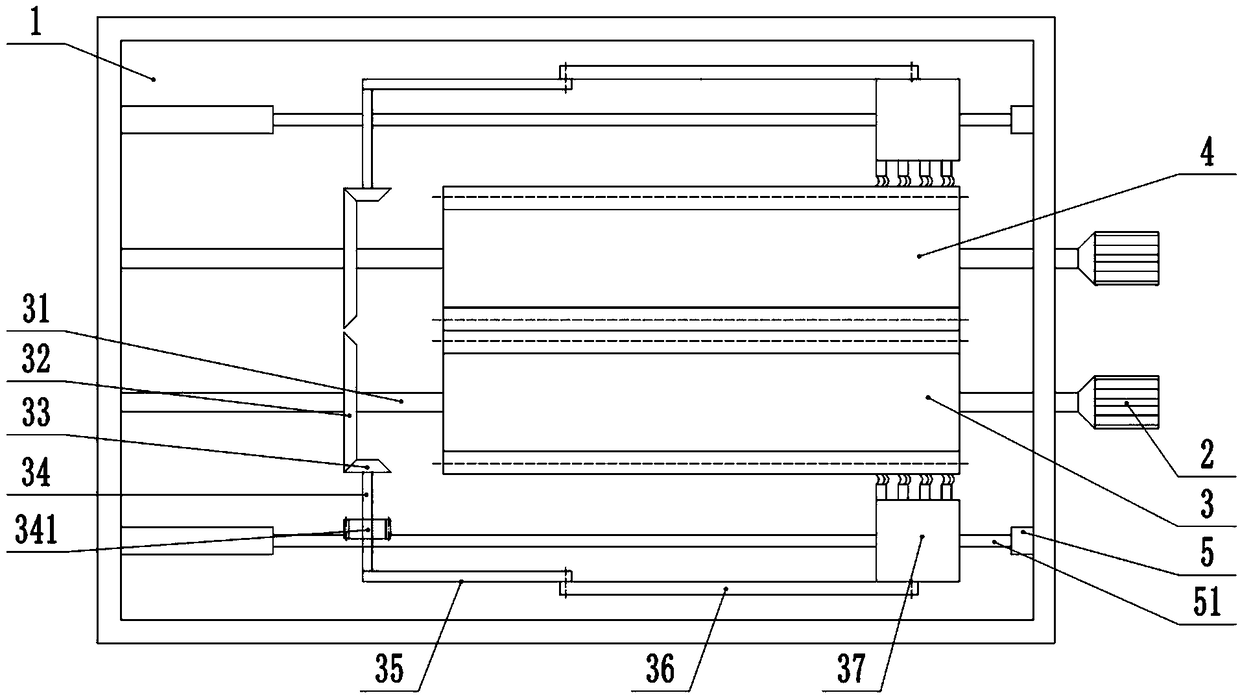

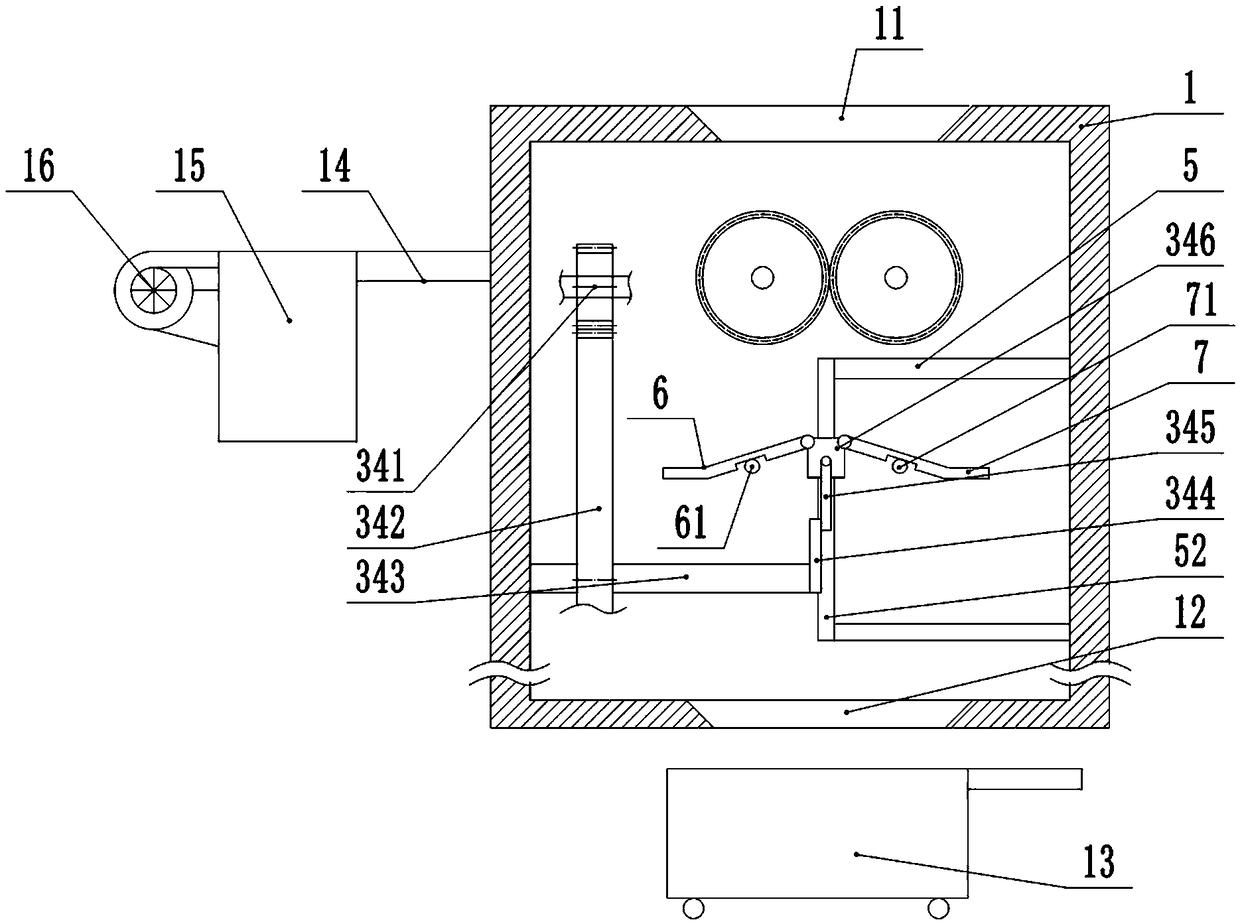

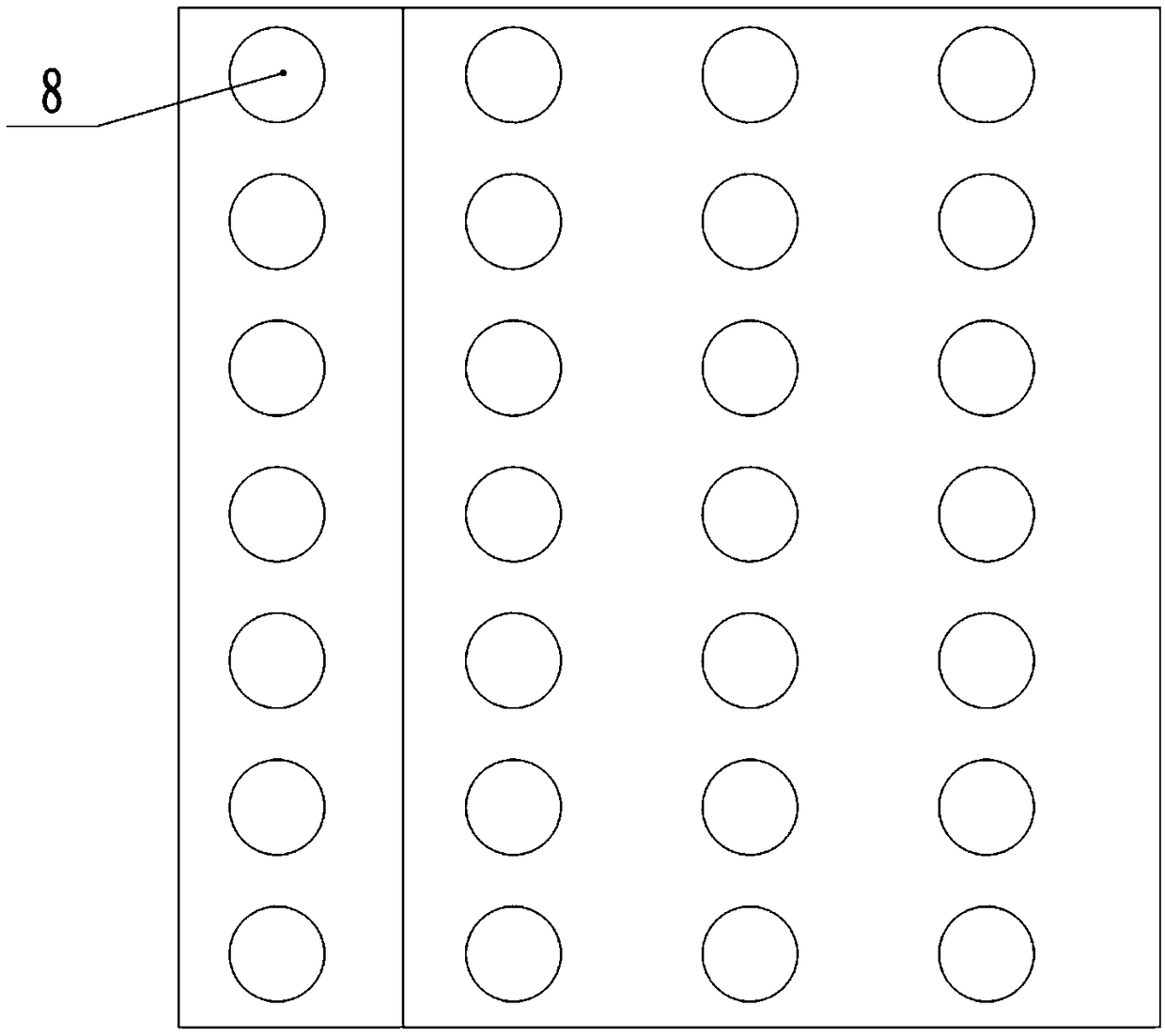

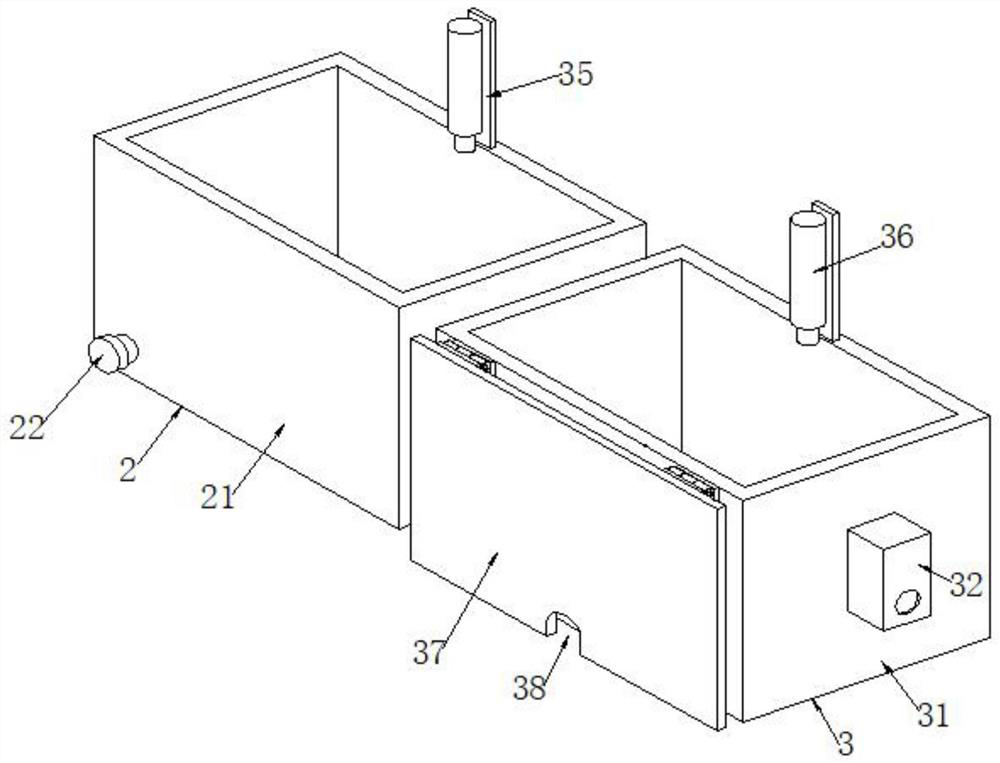

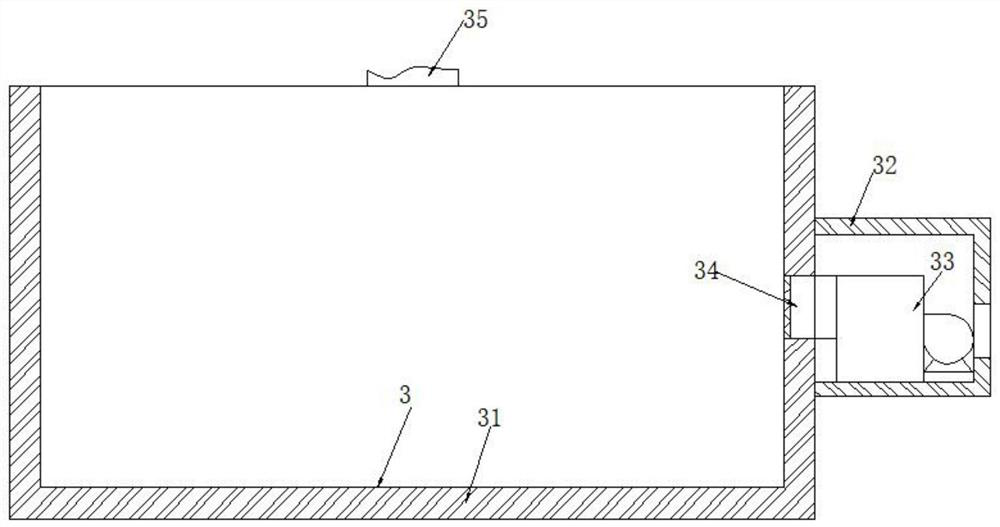

InactiveCN108435090AImprove product qualityReduce wearTransportation and packagingMixersEngineeringMixing chamber

The invention discloses a corn flour dry-mixing mechanism, which comprises a corn kernel grinding device and a powder mixing device sequentially from front to back according to a technical process. The corn kernel grinding device comprises a grinding unit, a drying unit and a return unit sequentially according to a technical process. The grinding unit comprises a grinding tank, a rotating shaft, adecontaminating mechanism, an upper grinding mechanism and a lower grinding mechanism, and the decontaminating mechanism, the upper grinding mechanism and the lower grinding mechanism are arranged inthe grinding tank. The top of the grinding tank is provided with a feeding port and an upper insertion port allowing vertical insertion of the rotating shaft, and the bottom of the grinding tank is provided with a discharging port. The powder mixing device comprises a mixing tank and an upper mixing cover which covers the mixing tank, and a cavity of the mixing tank is provided with a first mixing screen plate, a first mixing chamber, a second mixing screen plate and a grinding / mixing integrated chamber sequentially from top to bottom. The corn flour dry-mixing mechanism has advantages of guarantee of produced corn flour quality, effectiveness in mixing of corn flour and wheat flour and less proneness to caking and blockage.

Owner:芜湖拓云农业技术有限公司

Gear type effective crushing device for solid wastes

ActiveCN108889374ARealize the cleaning functionReduce broken areaDirt cleaningGrain treatmentsEngineeringBevel gear

The invention relates to the technical field of crushing devices, and particularly discloses a gear type effective crushing device for solid wastes. The gear type effective crushing device for solid wastes comprises a motor and a crushing chamber, wherein the crushing chamber comprises a first tooth roller, a second tooth roller and a rack; the first tooth roller is fixedly connected to the motor;one end of the first tooth roller is fixedly connected with a first straight rod; the first straight rod is fixedly connected with a first bevel gear; the first bevel gear is engaged with a second bevel gear; the bottom of the second bevel gear is fixedly connected with a second straight rod; the bottom of the second straight rod is fixedly connected with a first crank; one end of the first crankis hinged to a first connecting rod; one end of the first connecting rod is hinged to a first sliding block; the rack is fixedly connected with a first guiding rod; the first sliding block is slidably connected to the first guiding rod; and one side of the first sliding block is fixedly connected to a plurality of cleaning brushes. The invention aims to provide the gear type effective crushing device for the solid wastes so as to solve the problems that solid wastes remain on the tooth roller, and thus, the crushing efficiency of the device is low.

Owner:南京扬子环保科技有限公司

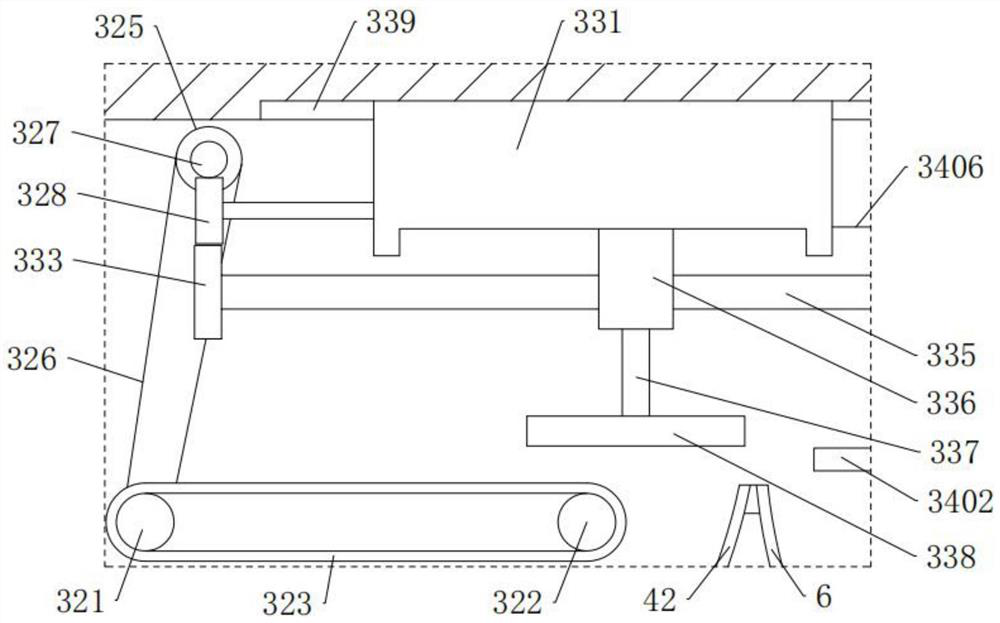

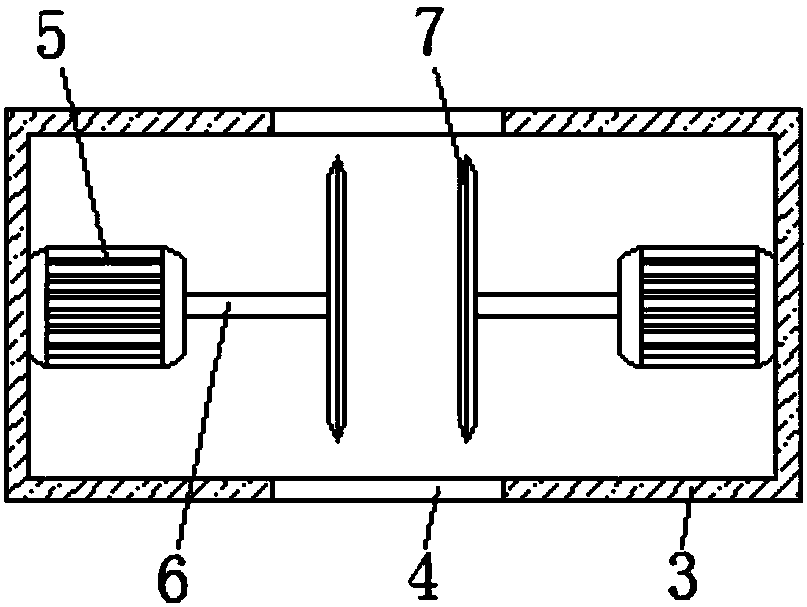

Large straw pulverizer

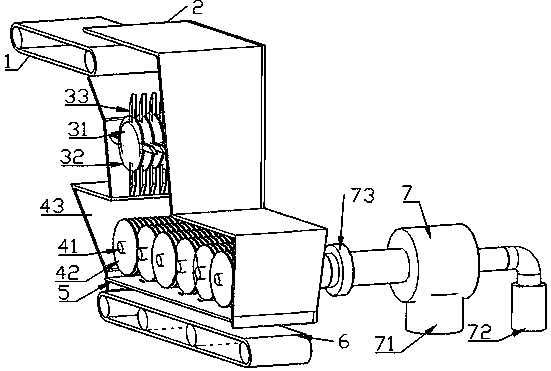

InactiveCN108271547AGuaranteed crushing efficiencyGuaranteed Particle SizeSievingScreeningEngineeringFlange

The invention discloses a large straw pulverizer. The large straw pulverizer comprises a feeding conveying belt, a first pulverizing device, a second pulverizing device, a discharge conveying belt anda dust removing device and is characterized in that the feeding conveying belt is mounted on the upper portion of the straw pulverizer, one end of the feeding conveying belt extends into a feeding inlet, the first pulverizing device is arranged below the feeding inlet and comprises a spindle, a flange plate and cutters, the flange plate is mounted on the spindle, the cutters are mounted on the flange plate, the second pulverizing device is mounted on the lower portion of a machine box, slide slopes are arranged on two sides of the second pulverizing device, the second pulverizing device comprises rotary shafts and cutting discs, the cutting discs are mounted on the rotary shafts, a filter device is arranged below the second pulverizing device, the discharge conveying belt is arranged below the filter device, the upper end of the discharge conveying belt is provided with the cyclone dust removing device, and the cyclone dust removing device is connected to an air bag and an absorptiontank through pipelines. The large straw pulverizer is reasonable in structure, simple to operate, capable of achieving straw pulverizing through the two pulverizing devices and capable of effectivelyincreasing straw pulverizing quality and efficiency.

Owner:阜阳市宏桥秸秆科技有限公司

Crushing and sieving machine for building waste

InactiveCN109225434AAvoid destructionAvoid damageDirt cleaningGrain treatmentsMagnetic separatorEngineering

The invention relates to a crushing and sieving machine for building waste. The machine comprises a magnetic separator, wherein a feeding hole is formed in the upper part of the magnetic separator, afeeding cylinder is arranged on the right side of the magnetic separator, a crushing and feeding mechanism is arranged in the feeding cylinder, a material inlet is formed in the lower part of the feeding cylinder, a first crushing chamber is formed below the material inlet, a group of crushing wheels A are arranged in the first crushing chamber, and a first-stage sieving net is arranged below thecrushing wheels A; a second crushing chamber is formed below the first crushing chamber, and a group of crushing wheels B are arranged in the second crushing chamber; adjusting rails are formed in thefront and rear sides of the outer walls of the first crushing chamber and the second crushing chamber respectively corresponding to the crushing wheels A and the crushing wheels B, and a second-stagesieving net is arranged below the crushing wheel B; and dust branched pipes are arranged below the first-stage sieving net and the second-stage sieving net, dust suction pumps are arranged on the dust branched pipes, the dust branched pipes are commonly connected with a dust pipe, and the dust pipe is connected with a dust chamber. The crushing and sieving machine has the advantages of simplicityin operation, high crushing efficiency and reasonability in use.

Owner:禹州金科再生资源有限公司

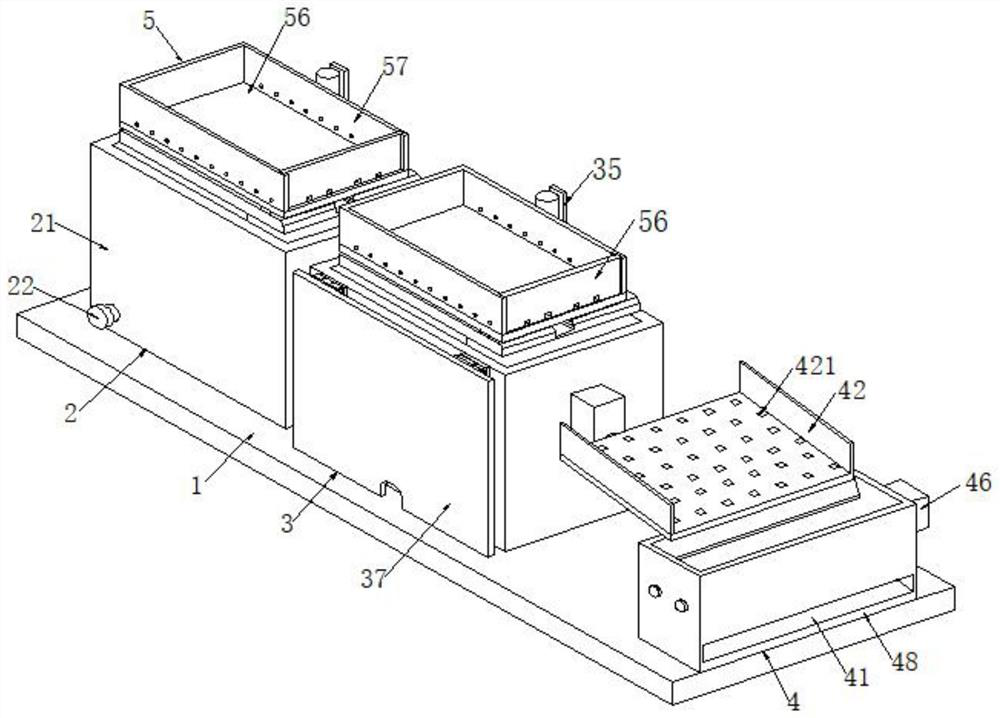

Environment-friendly recycling equipment for stone waste and waste utilization method thereof

PendingCN111633004AQuality assuranceGuaranteed crushing efficiencySolid waste disposalDrying gas arrangementsIron removalEnvironmental engineering

The invention discloses environment-friendly recycling equipment for stone waste and a waste utilization method thereof, and relates to the technical field of stone processing. The device comprises amounting base plate, a sorting mechanism, a drying mechanism, a crushing mechanism and a transferring mechanism; a sorting mechanism used for sorting non-stone impurities with the density smaller thanthat of water in stone, a drying mechanism used for drying stone waste after the stone waste is soaked in water and a smashing mechanism used for conducting iron removal, screening and smashing on the dried stone are sequentially and fixedly arranged at the top of the mounting base plate from left to right, and transfer mechanisms used for transferring stone are fixedly arranged at the tops of the sorting mechanism and the drying mechanism. The sorting mechanism is arranged, water is added into the water tank, stone to be sorted is placed on the movable plate corresponding to the water tank,the electric push rod corresponding to the water tank is started to drive the fixed plate to descend into the water tank for sorting, so that impurities with the density smaller than that of water inthe stone float on the water surface, and a worker salvages the impurities; and the quality of the product recovered in the later period is ensured.

Owner:SHENZHEN UNION STONE DECORATION TECH

Gravel crushing device for building construction

InactiveCN111013731APrevent fallingAvoid pollutionSievingScreeningSpiral bladeArchitectural engineering

The invention discloses a gravel crushing device for building construction. The device comprises a rack and a crushing assembly arranged on the rack, wherein the bottom of the crushing assembly is provided with a dovetail sliding block and is in sliding connection with a dovetail sliding groove formed in the rack, and a feeding hopper is arranged above the crushing assembly; and a screening deviceand a conveying device communicating with the screening device are arranged in the rack, wherein the screening device is located below the crushing assembly, and the conveying device is arranged on the side wall of the rack. According to the device, the feeding hopper with a feeding door is adopted, so that dust and impurities are prevented from falling in, and the dust, generated during gravel crushing, is prevented forming polluting the environment; the crushing assembly with an adjusting assembly is adopted, so that different gravel crushing requirements can be met, and the flexibility ishigh; a first conveying belt and a second conveying belt which are provided with different sieve holes are adopted, and a first spiral blade and a second spiral blade are matched, so that large-particle gravels are screened out, circulating crushing is achieved, the crushing effect is enhanced, and the uniformity of gravel particles is guaranteed.

Owner:苏肇松

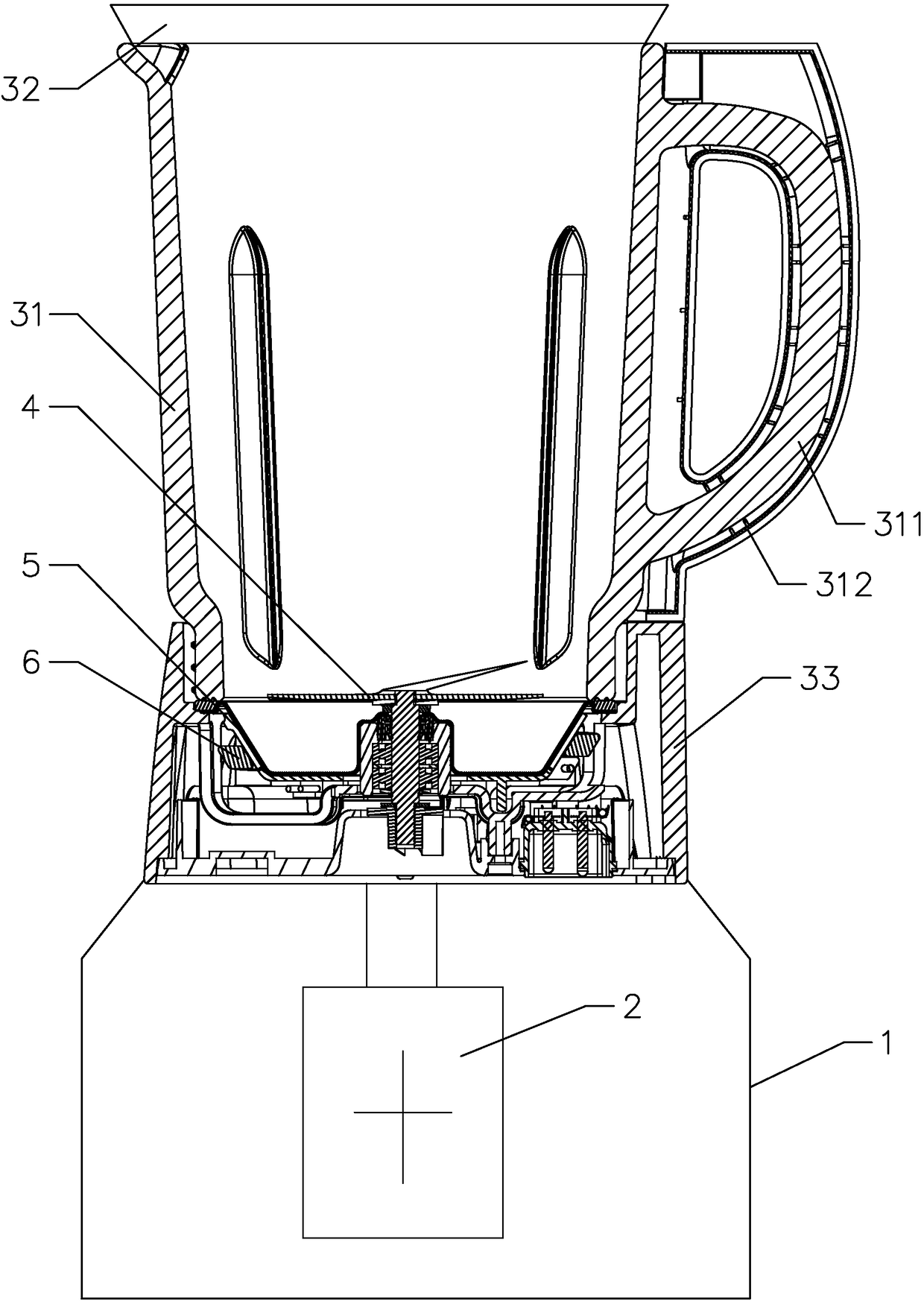

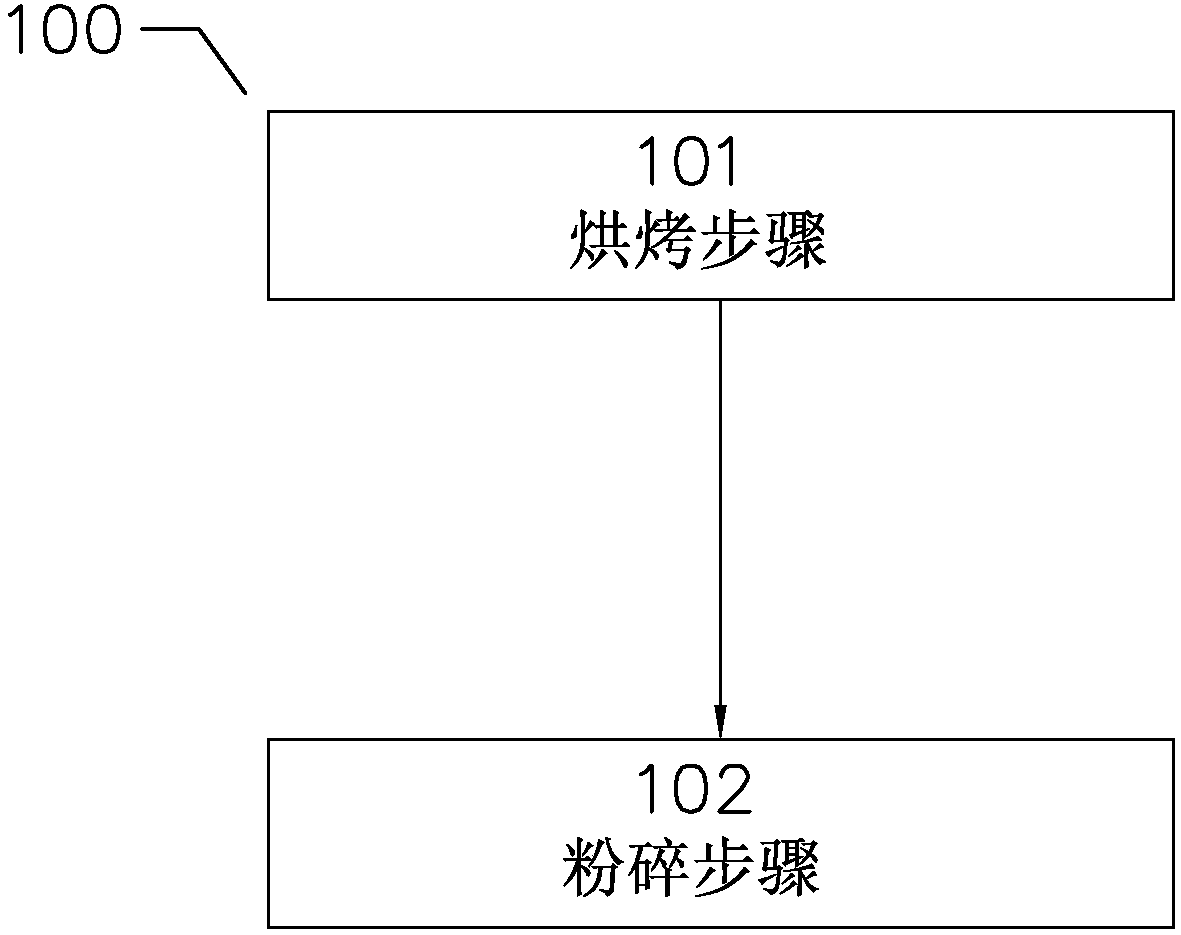

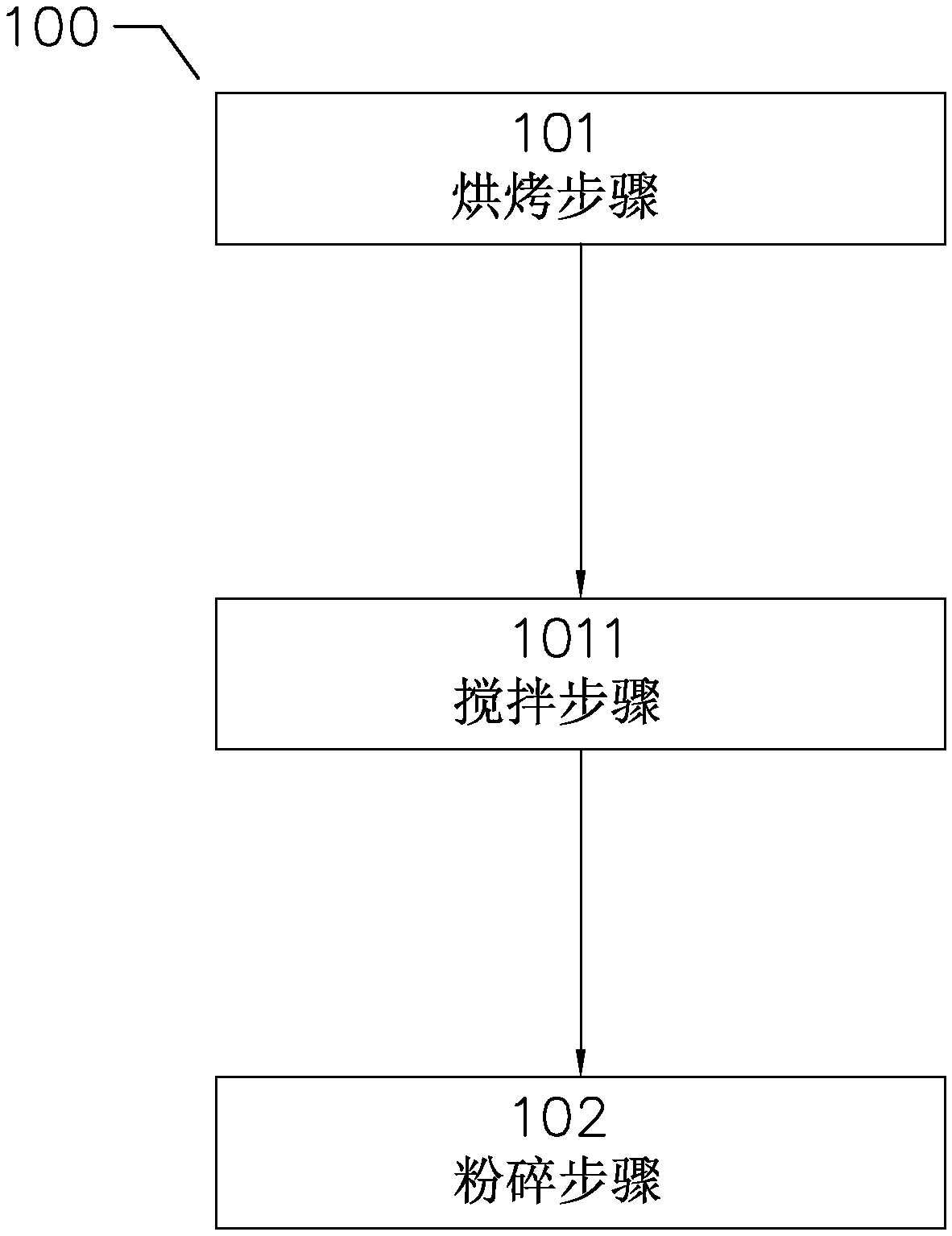

Nut paste processing method of food processer

The invention provides a nut paste processing method of a food processer. The method includes the following steps of braking and crushing, wherein in the braking step, a heating plate is used for heating nuts in a cup body until the nuts are cooked, and in the crushing step, a motor drives a crushing blade to rotate so as to crush the nuts in the cup body. The food processor is used for preparingnut paste, compared with a traditional household making method, the method is more convenient and faster, preparation steps are few, required utensils are few, the preparation process is pleasant, pleasure obtained by users in the preparation process is greatly increased, and the DIY fun of the users is increased. Meanwhile the heating plate is arranged at the lower end of the cup body, the heating plate includes a heating plate body and a heating pipe arranged on the side wall of the heating plate body, in this way, the nuts on the bottom are not burnt, the nuts are heated from the side face,the nuts can thus be heated more uniformly, it is ensured that the nuts are cooked, have no scorched flavor and also can produce strong nut fragrance, and therefore the made nut paste is more delicious and mellow.

Owner:JOYOUNG CO LTD

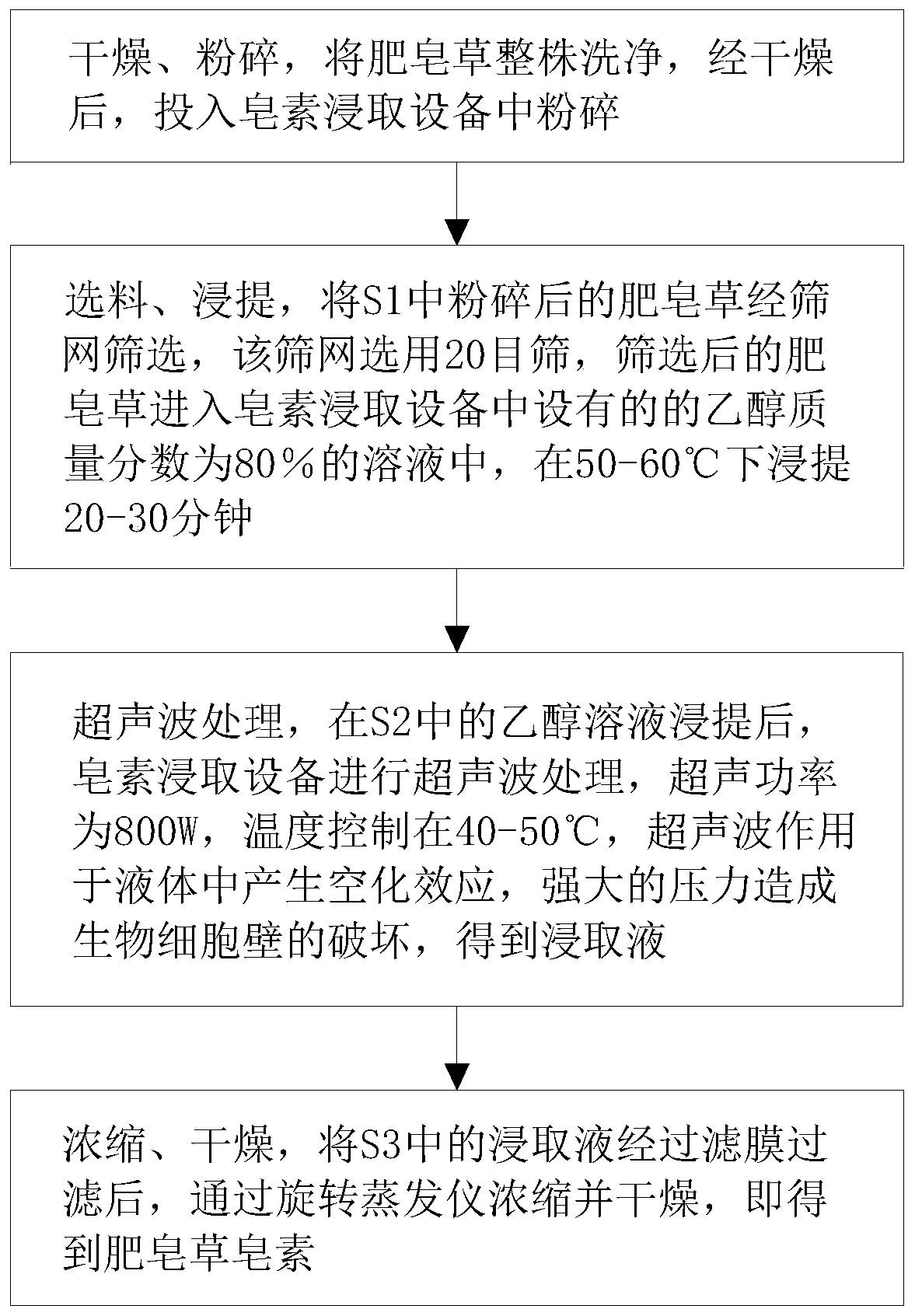

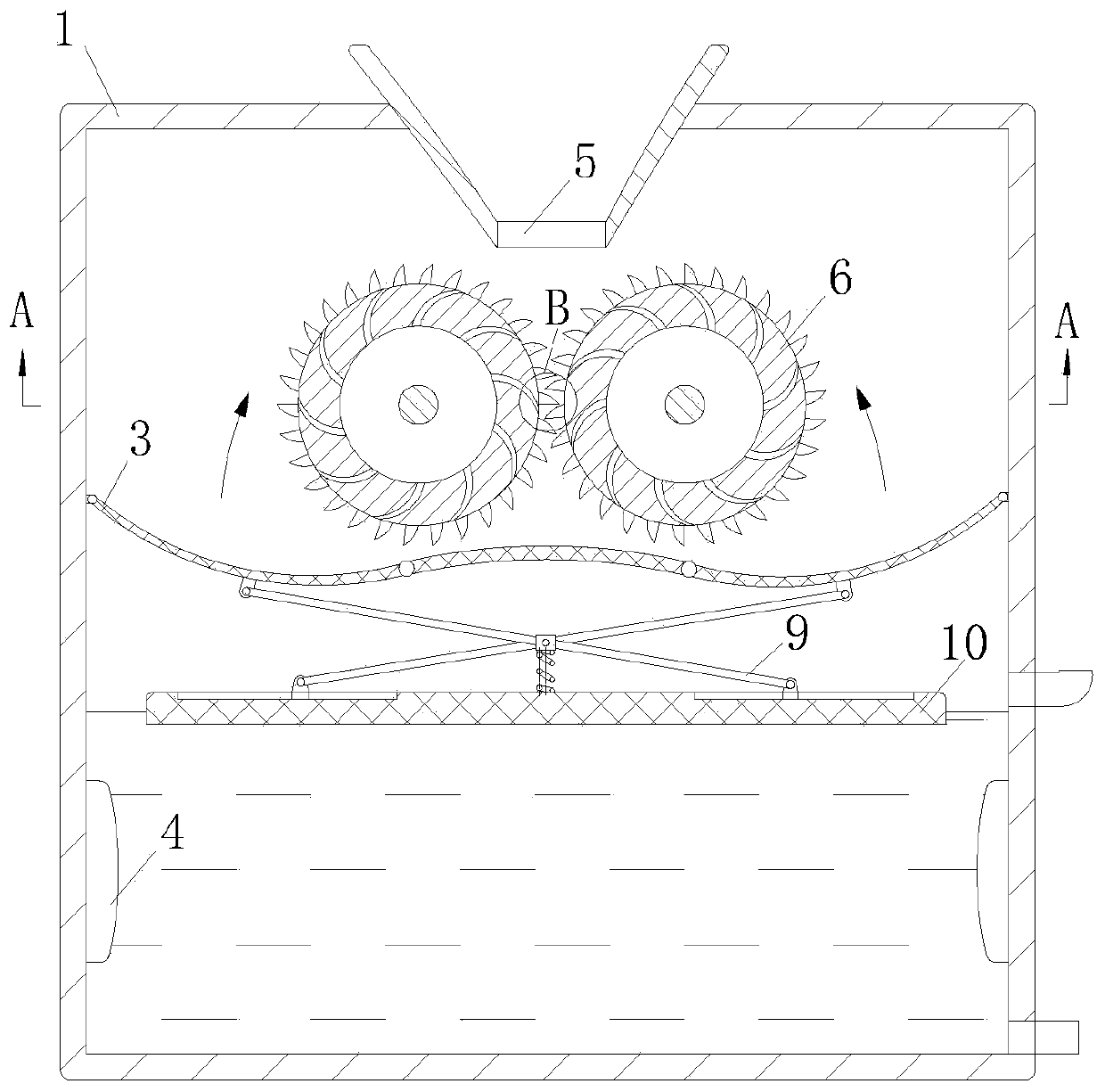

Extraction method of saponaria officinalis saponin

ActiveCN110922443AImprove extraction efficiencyAvoid cloggingSievingSugar derivativesPhysicsEngineering

The invention relates to the field of saponin extraction, and specifically relates to an extraction method of saponaria officinalis saponin. A saponin extraction facility adopted by the method comprises a casing, a motor, a breaking module, a screen mesh, a support module, an ultrasonic instrument, a thermostat, and a controller. The breaking module comprises two breaking rollers, which are engaged with each other and rotate in opposite directions. The breaking rollers are mounted on the casing through a rotation shaft. The screen mesh is arranged under the breaking rollers. The rotation shaftis arranged in the casing and is provided with a cam. The cam extrudes the screen mesh downwards intermittently. Due to the screen mesh, non-completely broken saponaria officinalis can not pass through the screen mesh, gradually the screen mesh will be obstructed by the non-completely broken saponaria officinalis; the extraction efficiency is influenced; in order to solve the problem mentioned above, an elastic telescoping rack is arranged to deform the screen mesh, non-completely broken saponaria officinalis will be bounced up to the breaking roller again and broken again, and the extractionefficiency is improved.

Owner:上海洗福莱智能科技有限公司

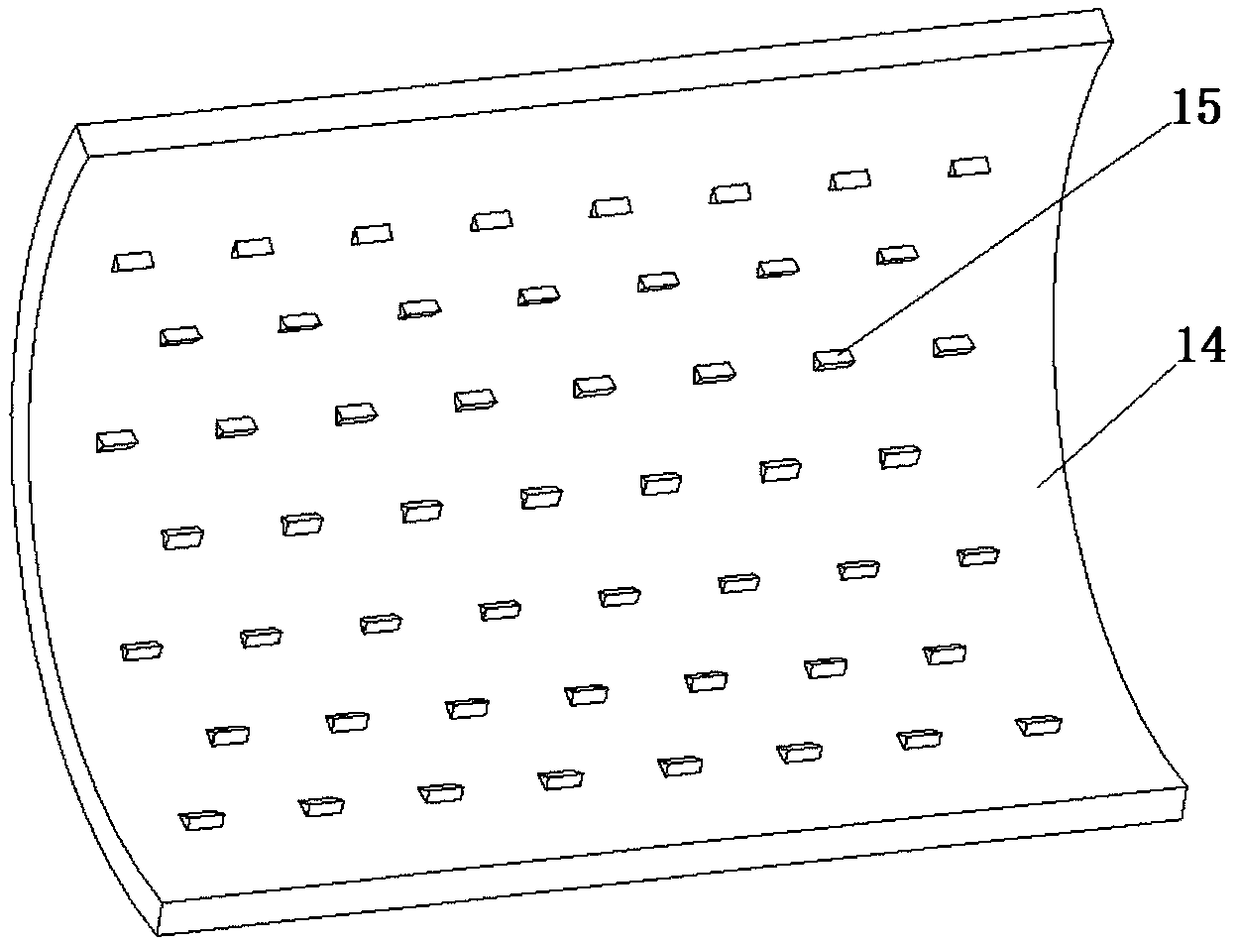

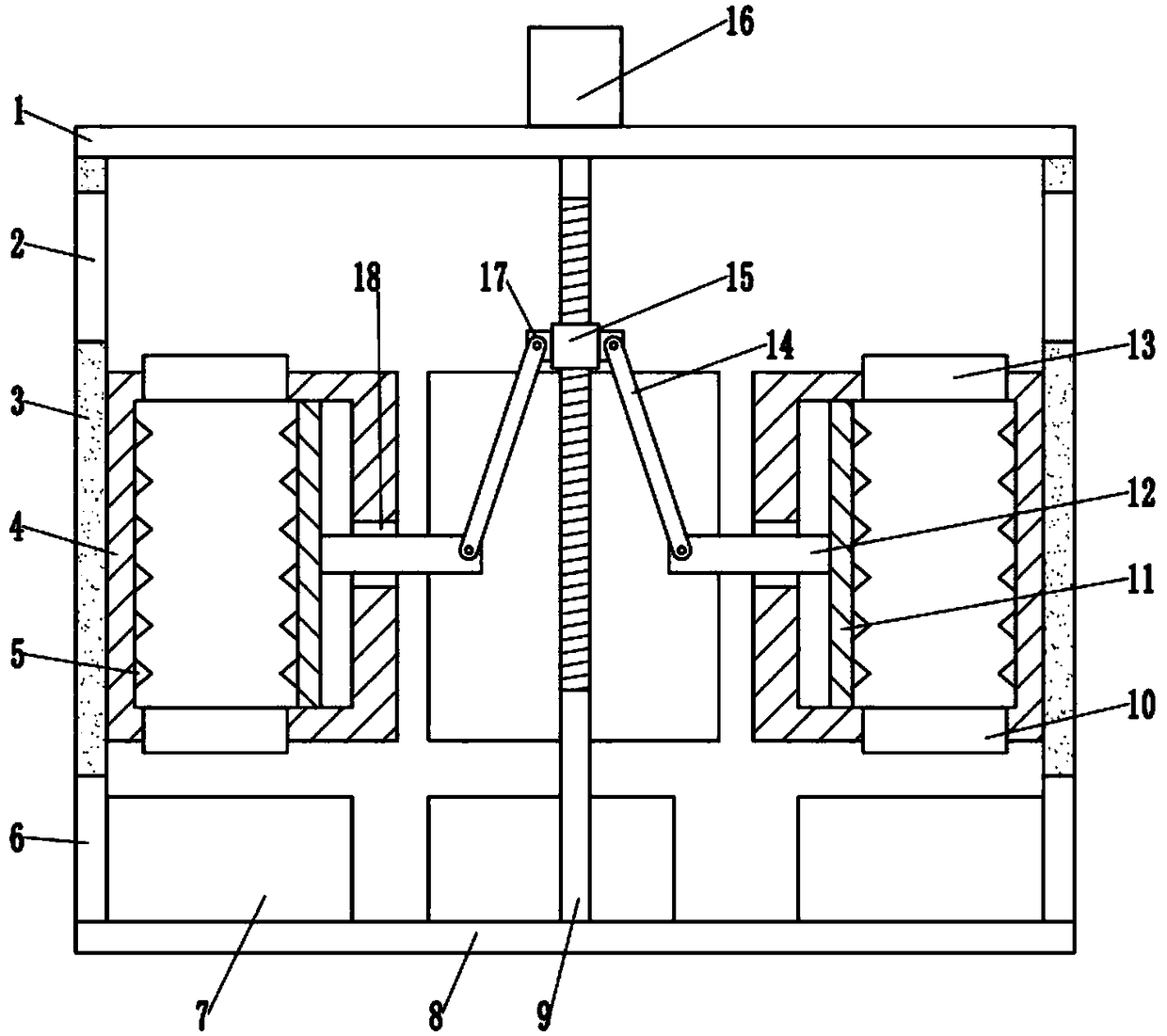

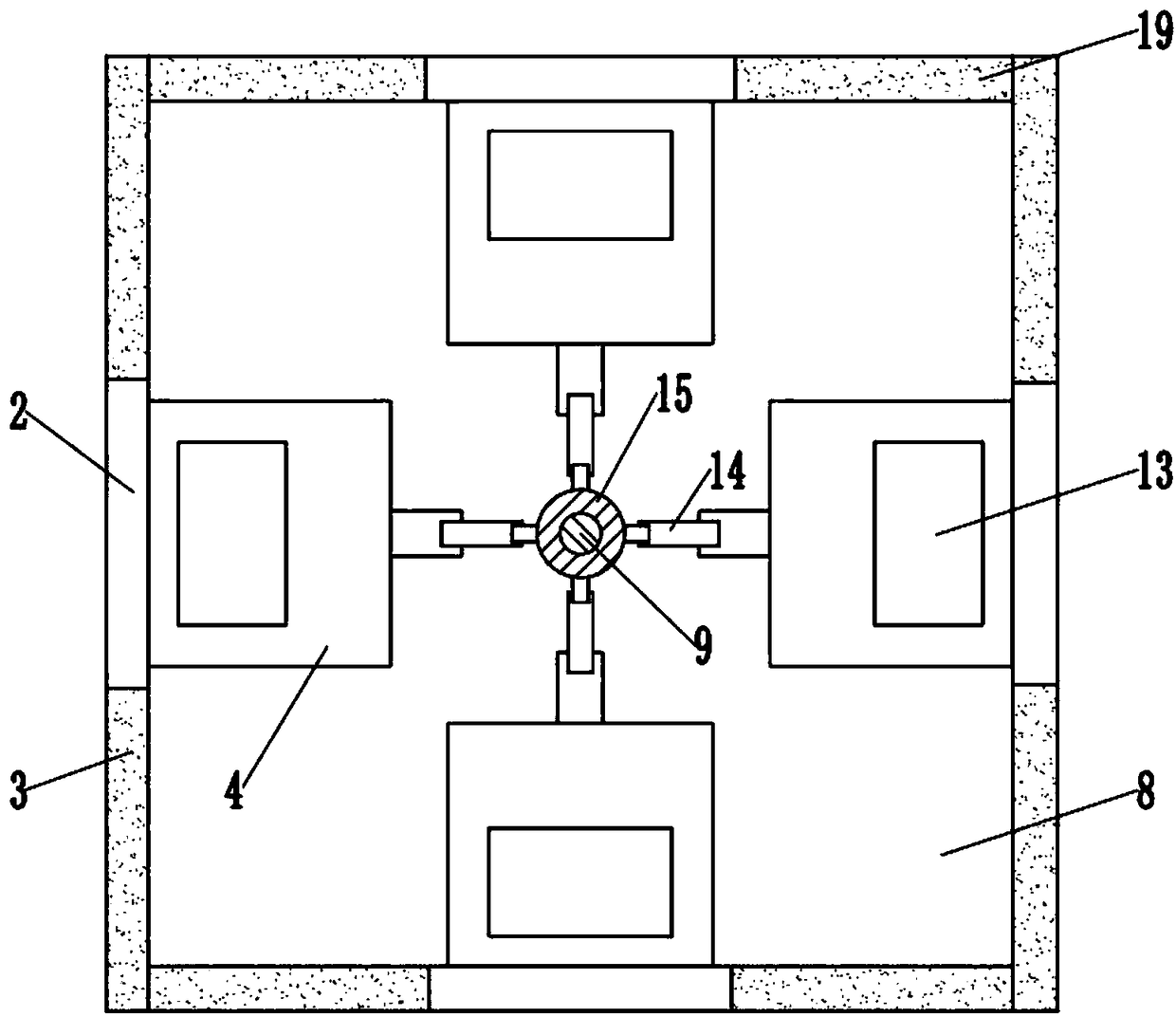

Composite large-area crusher cavity

PendingCN108654751AIncrease the initial velocityImprove crushing effectGrain treatmentsEngineeringCrusher

The invention discloses a composite large-area crusher cavity. The cavity comprises a feeding cavity, an accelerating cavity, a flow guiding cavity, a crushing cavity, finishing cavities and discharging cavities; the accelerating cavity comprises two accelerating rollers; the crushing cavity comprises two crushing rollers; the top of the feeding cavity is provided with a feeding port; the positions below the two accelerating rollers are each provided with a material guiding plate; the position between the two material guiding plates is provided with a material dividing device; first beat-backplates are fixed to the bottom ends of the two material guiding plates; the side walls of the two finishing cavities are each sequentially provided with a second beat-back plate and a third beat-backplate in sequence from top to bottom; a plurality of rows of anti-slip teeth are uniformly arranged on the third beat-back plates; and the discharging cavities with discharging ports are formed belowthe two crushing rollers correspondingly. The composite large-area crusher cavity is simple in structure, can be used for accelerating materials entering a crusher, and guides the materials to a preset path to be subjected to repeated large-area crushing, convenience is brought to crushing and finishing, the quality of crushed materials is increased, the powder amount is reduced, and the crushingefficiency is improved.

Owner:四川皇龙智能破碎技术股份有限公司

Environment-friendly garbage sorting and crushing device

Owner:ZHENGZHOU AIMOFU INFORMATION TECH CO LTD

Components of high-erosion-resistance zirconia corundum brick, melting process, and melting device

InactiveCN113072377ACompact internal structureCompact structureGrain treatmentsCompressive resistanceElectric arc furnace

The invention discloses components of a high-erosion-resistance zirconia corundum brick, a melting process and a melting device. The high-erosion-resistance zirconia corundum brick comprises the following components in percentage by mass: 63-68% of zirconium dioxide, 3-10% of silicon dioxide, 20-32% of aluminum oxide, 0.3-1% of sodium oxide and 0.5-1% of diboron trioxide. The melting process comprises the following procedures: retaining 1 / 3 to 2 / 3 of fused materials in a furnace body; mixing and smashing materials in all the components of the zirconia corundum brick into particles with particle sizes in a range of 2-3 mm; and then, introducing the particles into the upper end of the highest liquid level of the furnace body. The melting device comprises a smashing box and a three-phase electric arc furnace, wherein a feeding port is formed in the upper end of the smashing box, and a stirring cavity is formed in the inner upper end of the smashing box. According to the components of the high-erosion-resistance zirconia corundum brick, the melting process and the melting device, the high-erosion-resistance zirconia corundum brick is allowed to have the characteristics of compact internal structure, high compressive strength, high molten glass erosion resistance and low glass phase exudation amount, the service life of a glass kiln is prolonged, glass defects are reduced, and glass quality is improved.

Owner:LUOYANG DAYANG HIGH PERFORMANCE MATERIAL

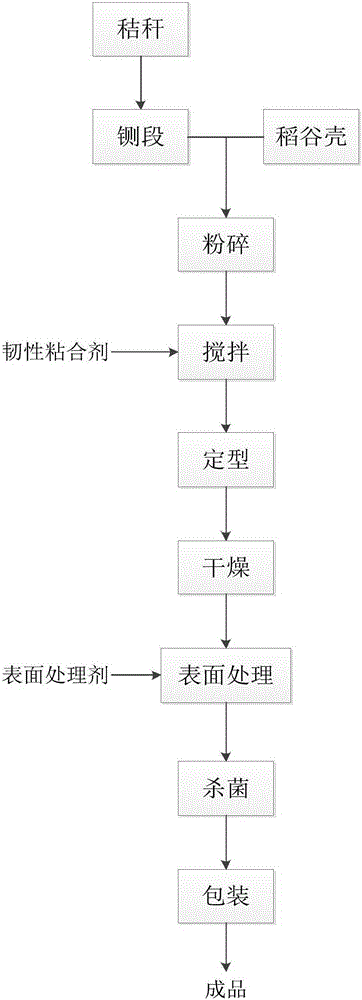

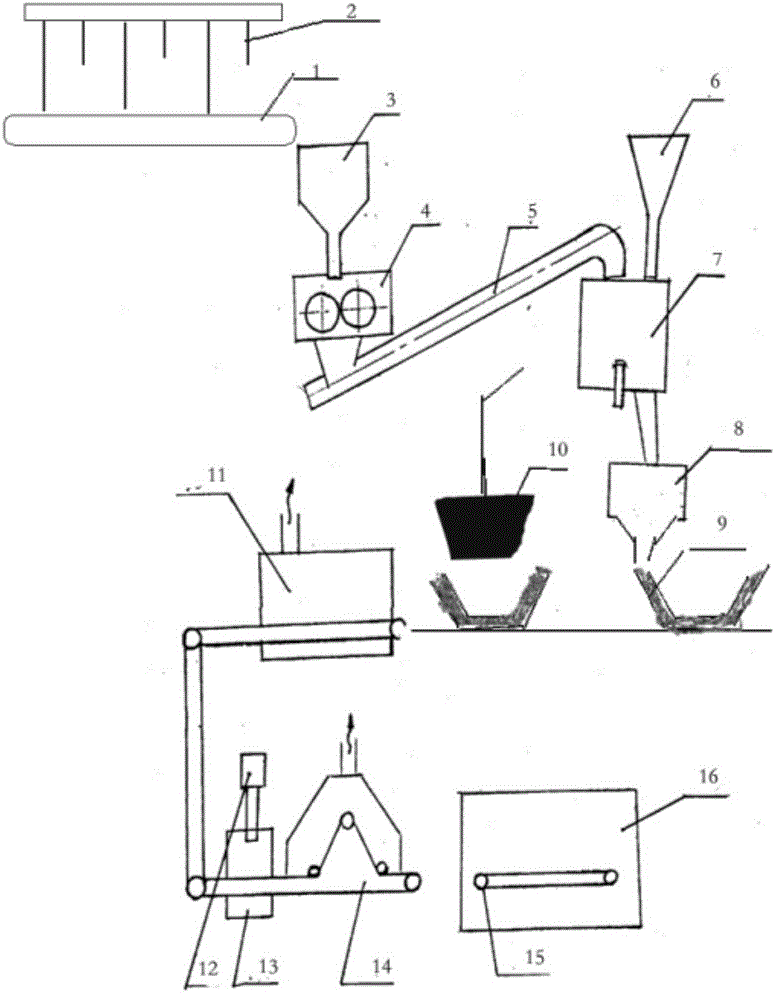

Manufacturing method for disposable novel environment-friendly utensil

InactiveCN105216087AThere will be no unevennessGuaranteed crushing efficiencyDomestic articlesHollow articlesFiberAdhesive

The invention discloses a manufacturing method for a disposable novel environment-friendly utensil. Adopted facilities and equipment comprise a conveyer belt, a straw chopper, a pulverizer, a powder conveying system, a plant fiber and adhesive mixing and stirring machine, a control storage tank, templates, a pressing machine, a drying box, a surface treatment chamber, a drying solidification chamber, an agent supplying system, a conveyer belt and a sterilizing chamber. Straw and rice hulls serve as raw materials and are subjected to section chopping through the straw chopper, pulverizing and grinding are conducted in the pulverizer, the materials are blended with a flexible adhesive for stirring, a disposable non-toxic environment-friendly and easily-degradable material is obtained, and then the material is subjected to forming, drying, surface treatment with a homemade surface treatment agent, and sterilization to be made into the environment-friendly utensil.

Owner:CHANGZHOU UNIV

Waste dust-free recovery device for building energy conservation and environmental protection

ActiveCN114558875AReduce generationGuaranteed crushing efficiencyConstruction waste recoveryUsing liquid separation agentEnvironmental resource managementBuilding energy

The invention discloses a dust-free waste recycling device for building energy conservation and environmental protection. A partition plate is transversely and fixedly arranged in a shell, an electromagnetic screening mechanism is fixedly arranged in an upper cavity, a smashing mechanism is arranged in a lower cavity, a smashing box is fixedly arranged at the bottom of the lower cavity, the bottom end of a first arc-shaped plate is fixedly connected with an inlet of the smashing box, and a collecting box is fixedly arranged on one side of the smashing box; the bottom end of the second arc-shaped plate is fixedly connected with an inlet of the collecting box, the top end of the second arc-shaped plate is fixedly connected with the free end of the first arc-shaped plate, a feeding hopper is fixedly arranged on one side of the shell and communicates with the upper cavity, the dust falling mechanism is fixedly arranged on the feeding hopper, and a master control box is fixedly arranged on the other side of the shell. According to the device, the dust falling mechanism is arranged at the discharging port, dust particles are wetted and attached to the surfaces of concrete particles, dust raising is reduced, the crushing mechanism can preliminarily crush the concrete particles, internal reinforcing steel bars and the like are exposed, then the reinforcing steel bars are screened out through the screening assembly, the crushing mechanism is prevented from being clamped, and the crushing efficiency is improved. The crushing efficiency is ensured.

Owner:深圳市城建集团科技有限公司

Self-collecting turbine dust-free crusher

The invention relates to a self-collecting turbine dust-free crusher, comprising an enclosed barrel-like crusher shell, wherein an external air channel communicating with the top and the bottom of the internal space of the crusher shell is arranged out of the crusher shell and is communicated with inner cavities of the crusher shell via a filter screen A; a crushing cavity and an air blasting cavity are arranged in the crusher shell and are communicated with each other via a filter screen B; the top of the crushing cavity is provided with a feed inlet; a seal cover is arranged on the feed inlet; the air blasting cavity comprises a turbofan used for blowing the crushing cavity; the air outlets of the external air channel are arranged around the air blasting cavity while the air inlets of the external air channel are located in the top of the crushing cavity; and a separating cover plate in the shape of a spherical surface is arranged on the top of the inner wall of the crushing cavity. According to the invention, a raw photosensitive material is circulated in the crushing cavity in virtue of an air blasting mechanism, and the raw photosensitive material is continuously abandoned and falls, so crushing is realized.

Owner:WUXI SIBORUI ELECTROMECHANICAL CO LTD

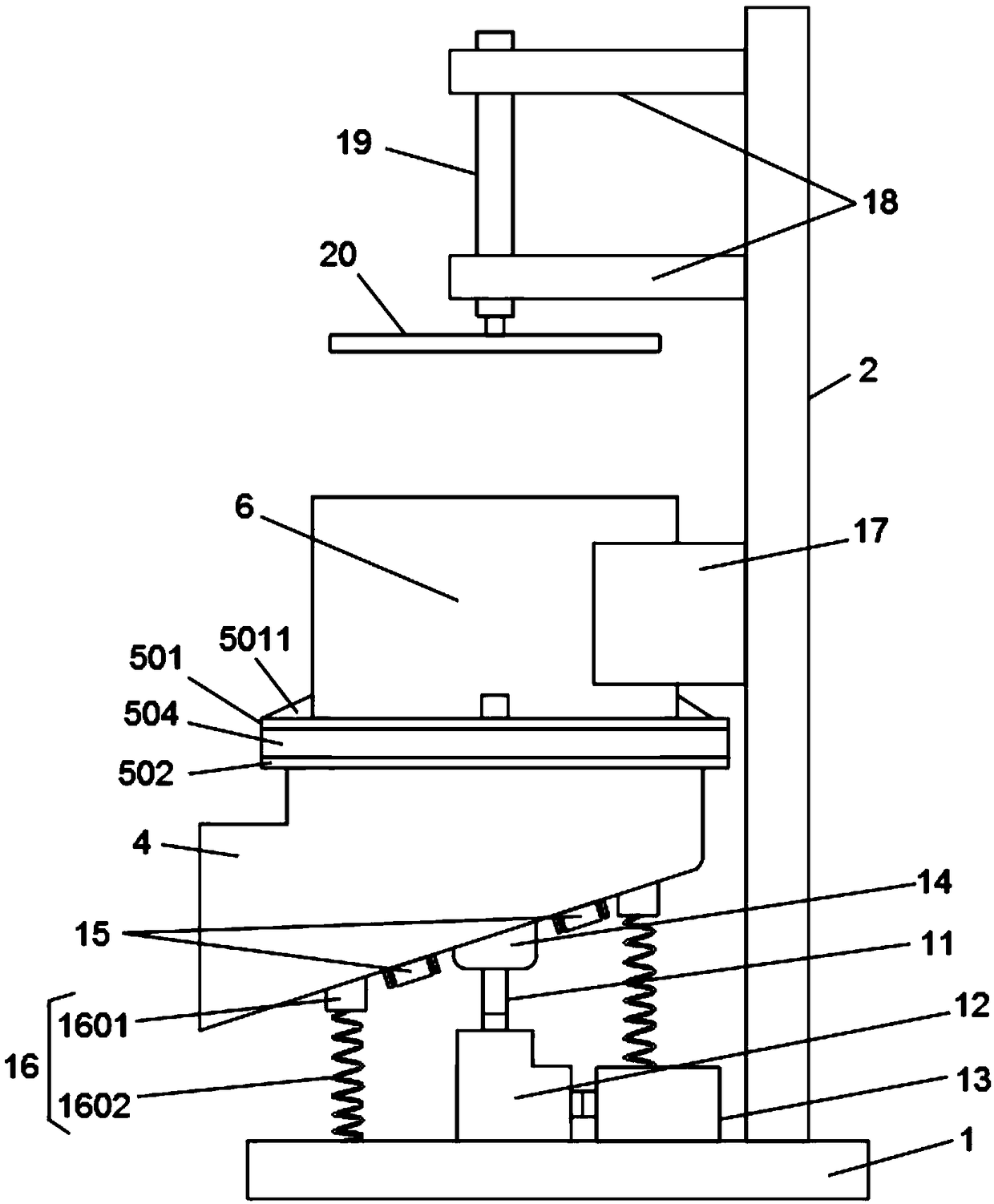

Biomass combustor capable of achieving self-smashing and intermittent equivalent feeding

InactiveCN111706852ACrushed fullyAvoid accumulationSolid fuel combustionGrain treatmentsThermodynamicsCombustion chamber

The invention relates to the technical field of combustion equipment, and discloses a biomass combustor capable of achieving self-smashing and intermittent equivalent feeding. The biomass combustor comprises a base, wherein the top of the base is fixedly connected to a combustion chamber; an inner screen board is fixedly connected inside the combustion chamber; the top of the combustion chamber isfixedly connected to a smashing chamber; the outer part of the smashing chamber is fixedly connected to a smashing motor; and the outer part of the smashing motor is fixedly connected to a main gear.According to the biomass combustor disclosed by the invention, the main gear, the smashing wheel, a connecting gear, an outer gear ring and an outer bottom frame are matched for use, so that stalks are sufficiently smashed; and meanwhile, the outer bottom frame drives the stalks inside the smashing chamber to turn over inside the smashing chamber, so that the stalks are prevented from being accumulated on the bottom of the smashing chamber, and the stalks are smashed for a second time conveniently, and therefore, the stalk smashing effect is sufficiently guaranteed, smashing speed and smashing efficiency are effectively guaranteed, the stalks are combusted sufficiently conveniently, the combustion effect is guaranteed, and sufficient combustion is effectively guaranteed.

Owner:王志强

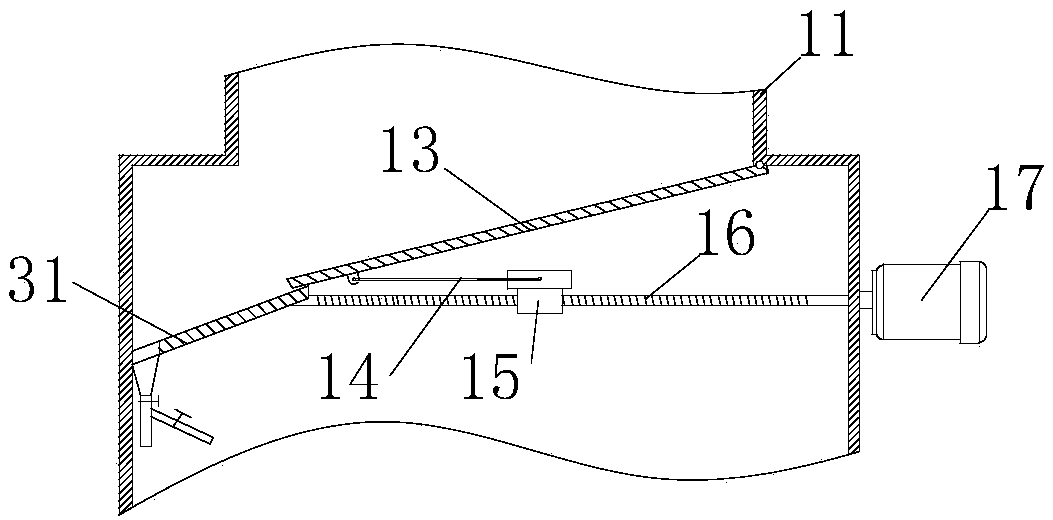

Auxiliary crushing and screening machine for PVC tube production

InactiveCN109604009AImprove screening efficiencyAvoid filter cloggingGrain treatmentsDrive motorDrive wheel

The invention relates to the technical field of PVC auxiliary production, in particular to an auxiliary crushing and screening machine for PVC tube production. Two-stage crushing is adopted, in first-stage crushing, a spiral conveyer is driven to work through a rotating shaft, PVC tubes are carried while the PVC tubes are crushed, then secondary crushing is conducted through a crushing roll in a second-stage crushing cylinder, and the crushing efficiency is guaranteed; a drive motor drives a driven wheel to rotate, at the same time, a driven shaft is driven to rotate through the action of a transmission wheel, while a driving shaft is driven through the drive motor, and a rotating rod is pressed to move swingingly through the rotation of a cam, so that an end block acts on a first filter net periodically, the screening efficiency is improved, filter net blocking is also effectively prevented; and a material receiving basket is slidably connected to a sliding rail, a second filter net is arranged on the upper part of the material receiving basket, the material receiving basket is pushed through the end block to move along the sliding rail while the rotating rod swings, and the material receiving basket also moves in a reciprocating mode due to the action of a reset spring, so that vibratory action is conducted on particles falling onto the second filter net, and the two-stage filtering effect is guaranteed.

Owner:浙江振荣新材料科技有限公司

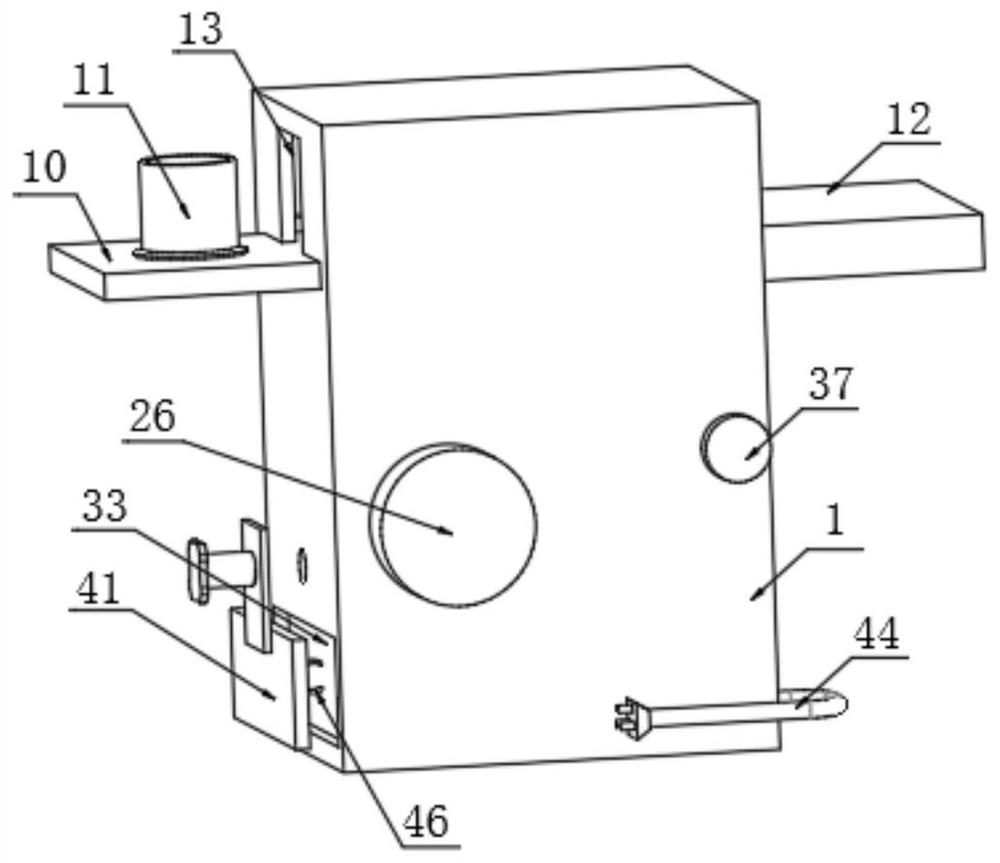

Urine testing micro-sampling and waste packaging disinfecting and sterilizing device

InactiveCN113909279AEasy to handleRapid disinfection and sterilizationSolid waste disposalTransportation and packagingMedical equipmentMedical waste

The invention provides a urine testing micro-sampling and waste packaging disinfecting and sterilizing device, and relates to the field of medical equipment application. The urine testing micro-sampling and waste packaging disinfecting and sterilizing device comprises a shell, a small container, a holding rod, an operation table and a measuring cup, the shell is fixedly connected with a power line, and one side of the top of an inner cavity of the shell is fixedly connected with a fixing frame. According to the urine testing micro-sampling and waste packaging disinfecting and sterilizing device, the crushed measuring cup and urine sample in the measuring cup are soaked in a garbage can for sterilization and disinfection, so that the measuring cup and the urine sample in the measuring cup are prevented from being massively stored and then treated, and the measuring cup and the urine sample in the measuring cup are ensured to be quickly sterilized and disinfected; and in addition, the disinfected and sterilized measuring cup and the urine sample in the measuring cup are stored in a centralized manner through the garbage can, and it is guaranteed that a worker rapidly packages and transports medical waste formed by the measuring cup and the urine sample in the measuring cup through the garbage can.

Owner:江伟

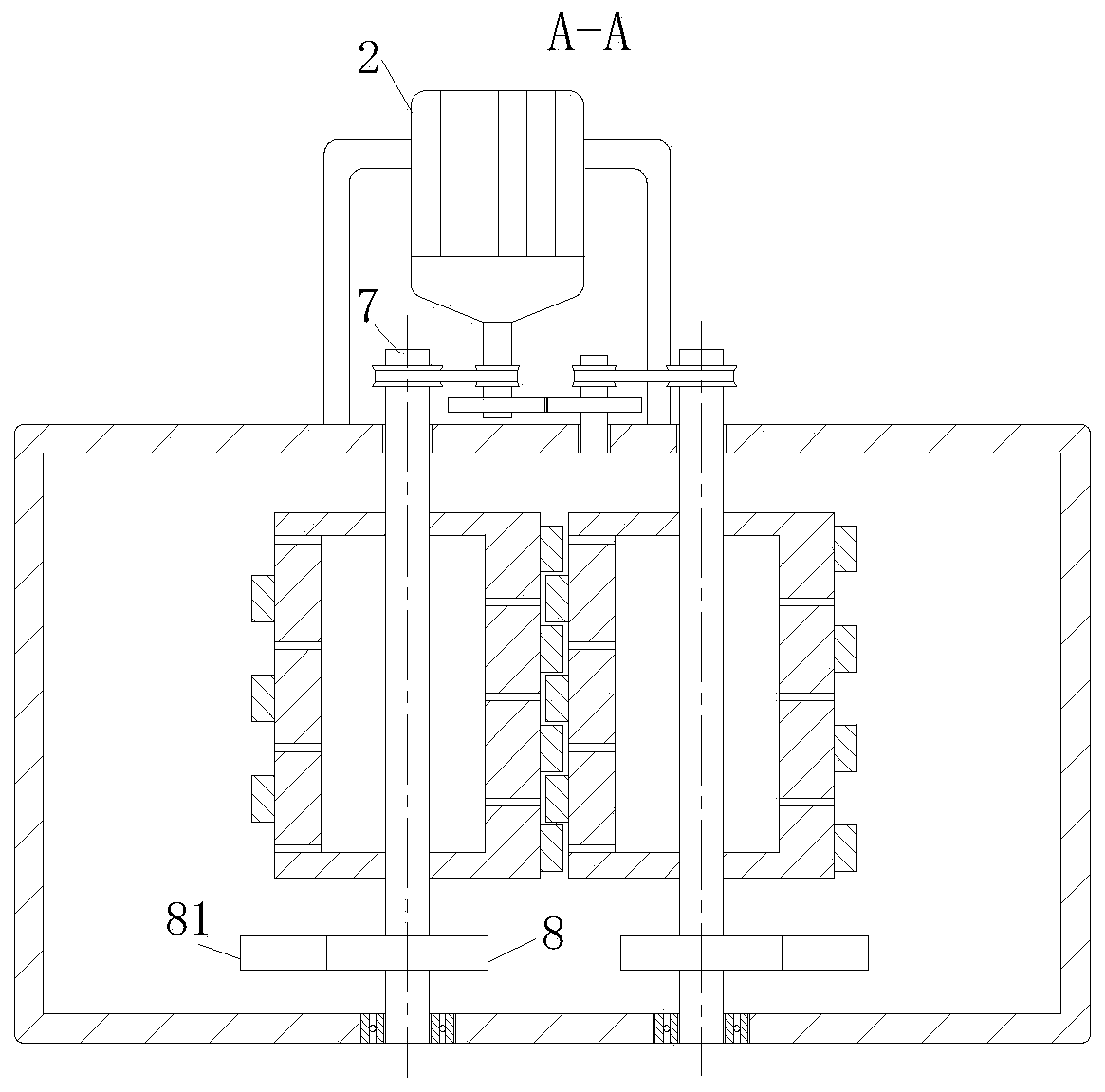

Recycling device for engineering muck treatment

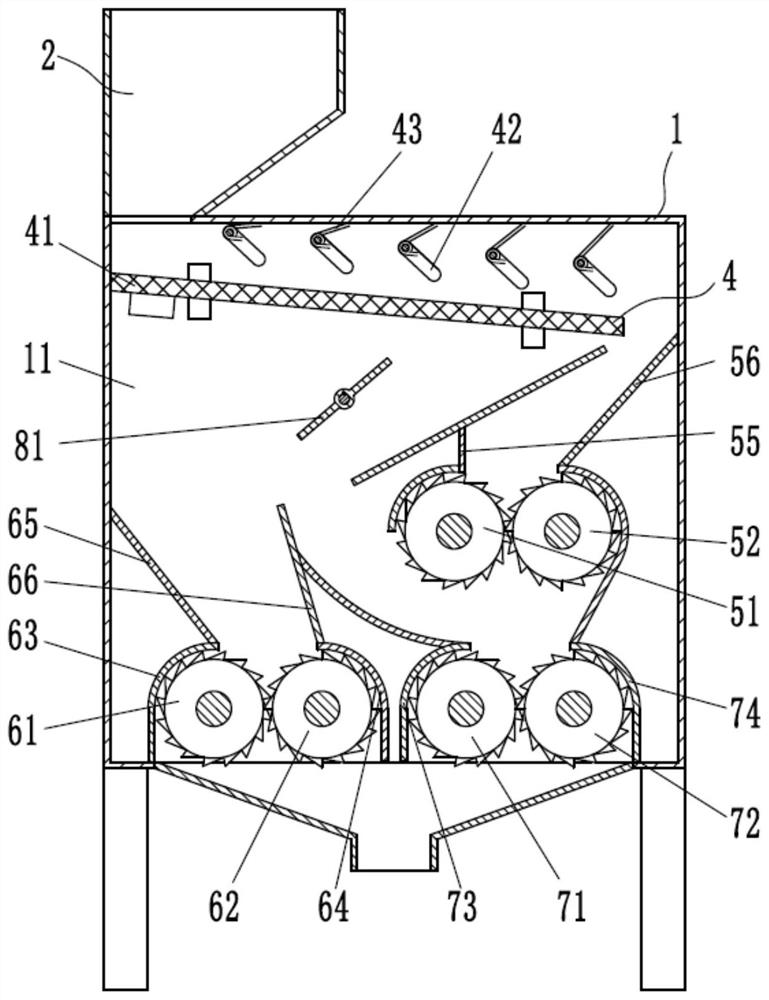

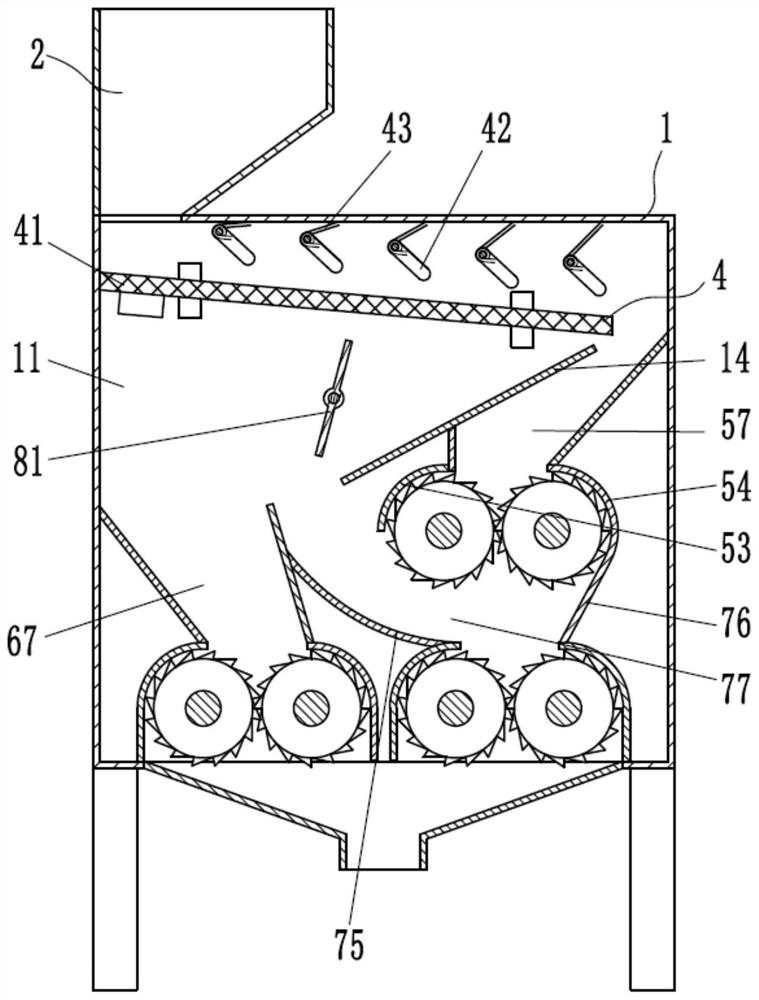

ActiveCN111871578AImprove crushing efficiencyGuaranteed crushing efficiencyGrain treatmentsThermodynamicsEngineering

The invention provides a recycling device for engineering muck treatment. The device comprises a case, a distributing mechanism, a coarse crushing mechanism, a first fine crushing mechanism, a secondfine crushing mechanism, a distributing adjusting mechanism and a driving mechanism; the interior of the case is provided with an inner cavity; the distributing mechanism is arranged at the upper portion of the inner cavity and is used for screening and classifying engineering muck into the large muck and the small muck; the coarse crushing mechanism is arranged in the middle of the inner cavity and used for crushing the large muck into small muck; the first fine crushing mechanism and the second fine crushing mechanism are arranged on the lower portion of the inner cavity side by side, and the first fine crushing mechanism and the second fine crushing mechanism are both used for crushing the small muck; the distributing adjusting mechanism is used for adjusting the amount of the small muck entering the first fine crushing mechanism and the second fine crushing mechanism; and the driving mechanism is used for driving the coarse crushing mechanism, the first fine crushing mechanism andthe second fine crushing mechanism to work. The recycling device for treating the engineering muck is good in muck crushing effect and high in working efficiency.

Owner:温州市建筑废土处置有限公司

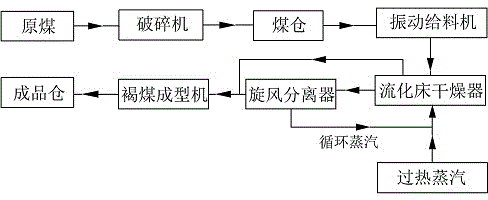

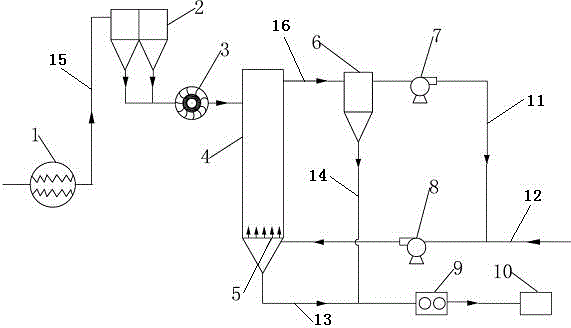

Equipment and process for lignite fluidized bed drying and upgrading

ActiveCN103602360BGuaranteed Granularity RequirementsGuaranteed crushing efficiencySolid fuelsFluidized bed dryingMolding machine

The invention relates to a device for drying and upgrading a lignite fluidized bed and a technology of the device. At present, the same type of device which is high in drying efficiency and high in environment friendliness and a technology of the device do not exist. The device for drying and upgrading the lignite fluidized bed is characterized by comprising a ring hammer type crusher, a cyclone separator, a lignite molding machine, a finished product storehouse, a lignite granule pipe, a lignite powder backflow pipe, a lignite granule conveying belt and a powder-steam conveying pipe, wherein one end of the lignite powder backflow pipe is connected to the bottom of the cyclone separator, and the other end of the lignite powder backflow pipe is connected to the lignite granule pipe; the lignite molding machine and the finished product storehouse are connected with each other through the belt. The technology disclosed by the invention comprises the following steps that (1) raw lignite is conveyed into the ring hammer type crusher for crushing, and the crushed lignite is conveyed into the lignite storehouse through the conveying belt; (2) overheated steam is input into a fluidized bed dryer through an overheated steam pipe; (3) the separated lignite powder is discharged from the bottom of the cyclone separator; (4) the lignite powder is molded under compression of the lignite molding machine to obtain finished lignite products. The device and the technology are high in drying efficiency and high in environment friendliness, and the steam can be recycled.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Soil remediation system

InactiveCN111495951AFix inefficienciesReduce labor intensitySievingMechanical machines/dredgersSoil scienceSoil remediation

The invention relates to a soil remediation system that comprises a bottom plate, a vibration device, a crushing device, a digging device and a recovery device; the digging device is mounted at the rear end of the bottom plate; the vibration device is mounted at the middle end of the bottom plate; the crushing device and the recovery device are arranged on the bottom plate; by means of the soil remediation system, the following problems existing in soil excavation and crushing of existing soil remediation can be solved: a, during soil excavation of traditional soil remediation, tools are oftenneeded to be used manually to excavate soil, compact soil needs to be beaten into particles, and time and labor are wasted during manual soil excavation; b, according to a traditional soil remediation machine, soil needs to be manually excavated and conveyed into the remediation machine, the soil remediation effect is poor due to the fact that soil cannot be dug and fed automatically and is not completely crushed, the screening net is often blocked in the soil screening process, and manual treatment is troublesome; thus, by using the invention system, the labor intensity of workers in the soil remediation process can be reduced, and the soil remediation efficiency is improved.

Owner:佛山市嘉沃农业科技合伙企业(有限合伙)

Efficient papermaking crushing machine

InactiveCN107597353AReduce volumeAvoid efficiencyWood working apparatusGrain treatmentsSynchronous motorPapermaking

The invention discloses an efficient papermaking crusher. The efficient papermaking crusher comprises a machine body; a feeding hopper is fixedly connected to the top of the machine body, and a mounting box is fixedly connected to the inner wall of the top of the machine body; two through holes which communicate with the inner wall of the mounting box and are symmetrically formed in the top and the bottom of the mounting box; and two symmetrical synchronous motors are fixedly connected to the inner walls of the left side and right side of the mounting box. According to the efficient papermaking crusher, the effect of cutting treatment for feeding materials in advance is achieved by arranging the synchronous motors, a rotating shaft and cutting blades, so that the effect of reducing the size of the feeding materials is achieved, the situations of low crushing efficiency and incomplete crushing caused by the large size are avoided, the crushing efficiency is improved greatly, and meanwhile, the effect of complete crushing on wood is achieved; and the effect of ensuring crushing efficiency in the papermaking process is achieved, and current social market orders which have urgent needfor paper are completed rapidly and accurately.

Owner:江门市新会区联垦农业经营有限公司

Oil pressing device

PendingCN112009005AImprove oil extraction efficiency and oil qualityImprove oil extraction efficiencyFatty-oils/fats refiningCleaning using toolsProcess engineeringKnife blades

The invention relates to the technical field of oil pressing equipment, in particular to an oil pressing device which comprises a processing box, wherein supporting legs are arranged at the four corners of the lower side of the processing box, a feeding box is arranged at the left end of the top of the processing box, a discharging pipe is arranged at the bottom end of the right side of the processing box, and a second electromagnetic valve is arranged on the discharging pipe. The oil pressing device is simple in structure, by arranging the feeding box, raw materials are poured into the feeding box from a feeding funnel, through cooperative use of a first motor, a rotating shaft, a baffle and a feeding port, the feeding speed can be controlled, it is avoided that too many raw materials enter a cutting box at a time, the raw material smashing degree and smashing efficiency are reduced, and the oil pressing efficiency is guaranteed; a first cutting blade and a second cutting blade are arranged to cut the raw materials multiple times in a dynamic and static combination mode, so that the raw materials are crushed more thoroughly, subsequent squeezing treatment is facilitated, and the oil pressing efficiency and the oil pressing quality are improved.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Traditional Chinese medicine crusher

The invention discloses a traditional Chinese medicine crusher, which relates to the technical field of traditional Chinese medicine crushing. The traditional Chinese medicine crusher can comprise a shell, and a crushing cavity and an extrusion cavity are sequentially arranged in the shell from top to bottom; a feeding opening is formed in the top of the crushing cavity, and a feeding device is connected to the feeding opening and used for feeding traditional Chinese medicine; a crushing mechanism is arranged below the feeding opening and is used for crushing the traditional Chinese medicines;a material passing channel is arranged below the crushing mechanism and used for communicating with the extrusion cavity, and an extrusion mechanism is arranged below the material passing channel andused for extruding the crushed traditional Chinese medicine; and a discharge opening is formed in the bottom of the extrusion cavity. Traditional Chinese medicine is crushed through the crushing mechanism, then the traditional Chinese medicine is rolled through the extrusion mechanism, cell walls are damaged, and effective components can be released conveniently; and the distance between the first extrusion roller and the second extrusion roller is adjustable, so that traditional Chinese medicines with different sizes are extruded, and the traditional Chinese medicine crushing efficiency andthe crushing effect are guaranteed.

Owner:HUBEI UNIV FOR NATITIES

Straw breaking device

The invention discloses a straw breaking device which comprises a base, a supporting rod, a smashing bin and a discharging bin. The smashing bin is arranged above the end, away from the supporting rod, of the upper surface of the base, a platen is arranged above the upper end face of the smashing bin, the discharging bin is located below the lower end face of the smashing bin, the discharging binis connected with the smashing bin through a connecting assembly, a cutterhead is arranged at the lower end inside the smashing bin, a tool assembly is installed at the upper surface of the cutterhead, a supporting base is arranged in the center of the lower surface of the cutterhead, a rotating shaft is inserted into the supporting base, the upper end of the supporting rod is fixedly connected with the center of the lower surface of the cutterhead, a commutator is arranged at the upper surface of the base, the lower end of the rotating shaft is connected to the output end of the commutator, and the input end of the commutator is connected with a motor. In the using process, cake-shaped straw blocks are rapidly crushed, so that the crushing efficiency is ensured, the length of crushed straw monomers is small, the good crushing effect is ensured, and the phenomenon that the crushing device is blocked is avoided.

Owner:颍上县聚鑫再生资源有限公司

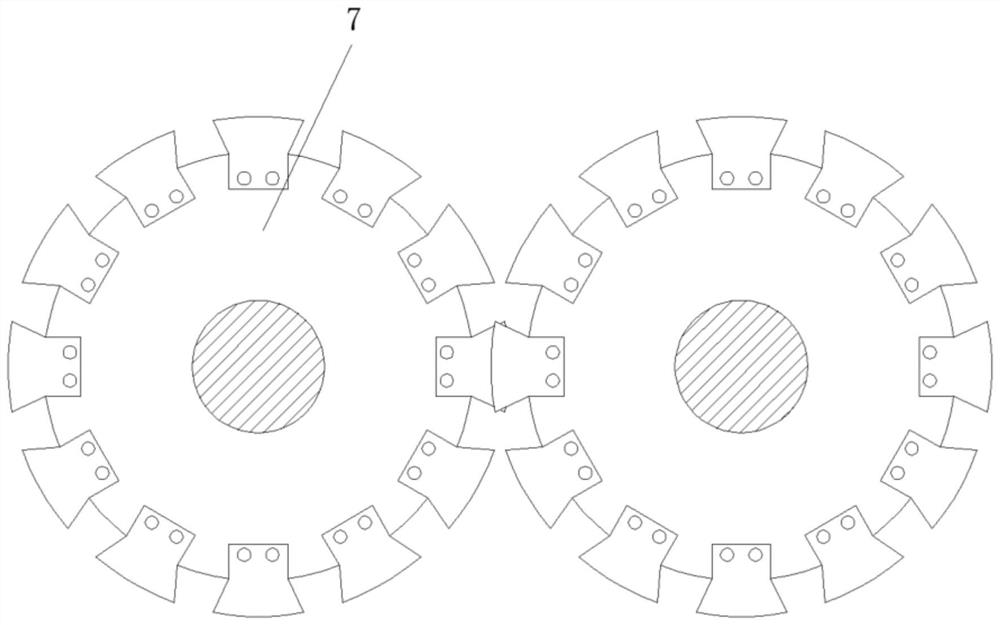

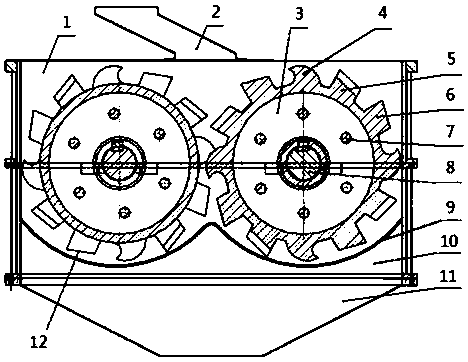

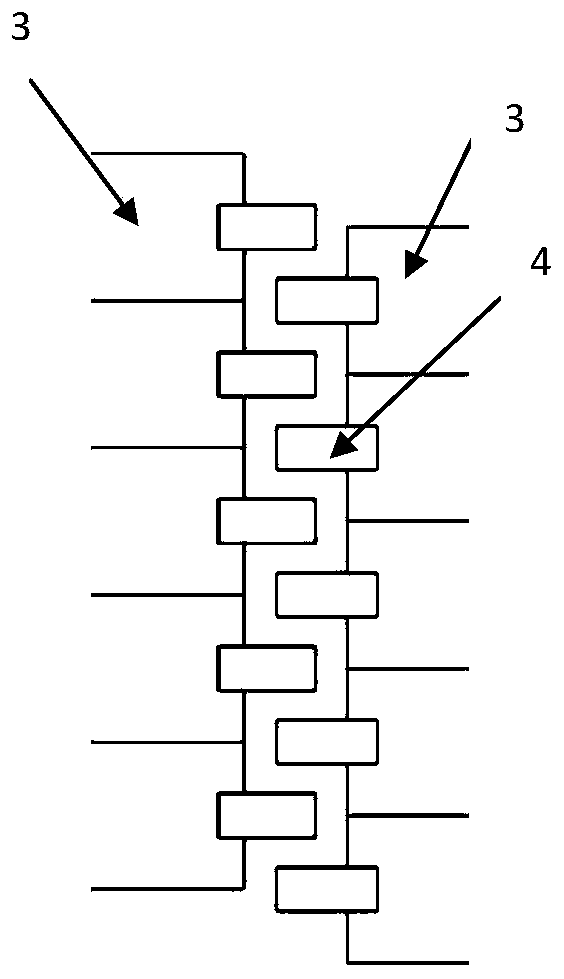

Multi-functional-tooth-form integrated high-crushing-ratio type fine crushing machine

PendingCN110252456AImprove crushing effectMeet the crushing requirementsGrain treatmentsEngineeringUnit volume

A multi-functional-tooth-form integrated high-crushing-ratio type fine crushing machine comprises a machine body and two crushing rollers, wherein each crushing roller comprises a main shaft (8), a roller tooth plate (3) and a connecting bolt (7); and roller tooth plates (3) with the same quantity are mounted on the two main shafts (8) in a staggering distribution manner. The machine is characterized in that a plurality of groups of crushing teeth are distributed at uniform intervals on an outer cylindrical surface of each roller tooth plate (3); each group of crushing teeth comprises primary crushing teeth (4), cutting crushing teeth (5) and trapezoidal teeth (6); the primary crushing teeth (4), the cutting crushing teeth (5) and the trapezoidal teeth (6) are sequentially distributed; the crushing teeth on all roller teeth plates (3) on each main shaft are distributed in the same phase; the primary crushing teeth (4) are olecranon-shaped; edges of which the top angles are 55-65 degrees are arranged at the tail ends of the cutting crushing teeth (5); and an included angle between long edges of the trapezoidal teeth (6) and tangent lines of the cylindrical surfaces of the roller teeth plates is 45-55 degrees. The machine is compact in structure, reliable to work, high in production capacity in unit volume, and convenient to maintain.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com