Crushing and sieving machine for building waste

A construction waste and screening machine technology, applied in the direction of removing smoke and dust, cleaning methods and utensils, grain processing, etc., can solve the problems of fragile pulverizers, waste of resources, increase construction costs, etc., and achieve the effect of ensuring pulverization efficiency and convenient adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

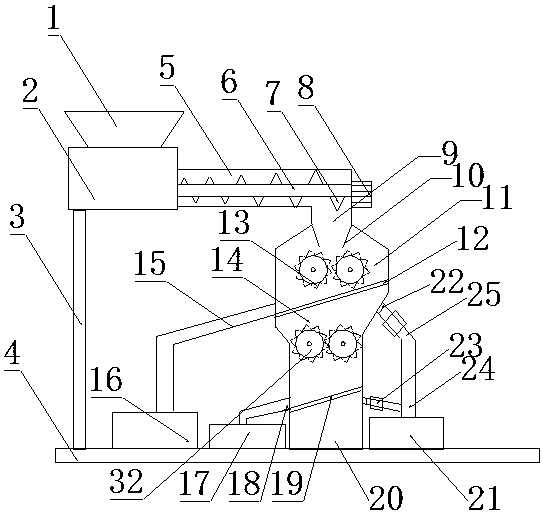

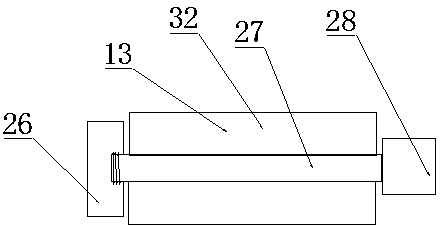

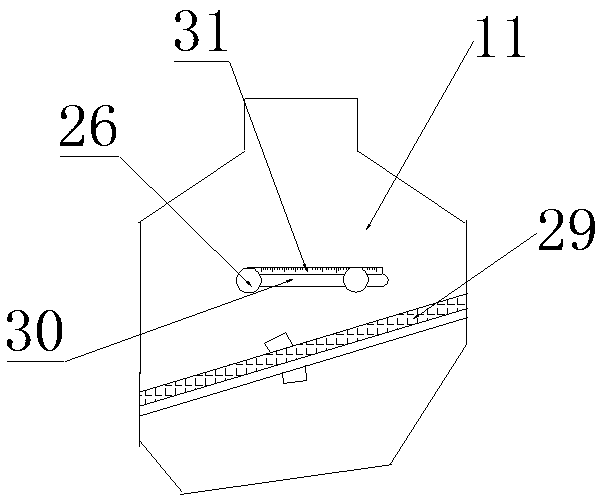

[0018] Such as Figure 1-3 As shown, a construction waste crushing and screening machine includes a base 4, a support platform 3 is arranged on the upper left of the base 4, and a magnetic separator 2 is arranged above the support platform 3, and the magnetic separator The top of the machine 2 is provided with a feeding port 1, and the right side of the magnetic separator 2 is provided with a feeding cylinder 5, and the inside of the feeding cylinder 5 is provided with a crushing feeding mechanism 7, and the crushing feeding mechanism 7 is provided. The feeding mechanism 7 is arranged on the outside of the rotating shaft 6, the right side of the rotating shaft 6 is connected with a first motor 8, the bottom of the feeding cylinder 5 is provided with a feeding port 9, and the bottom of the feeding port 9 is A first crushing chamber 11 is provided, and a group of crushing wheels A13 are arranged inside the first crushing chamber 11, and a primary screen 12 is arranged below the ...

Embodiment 2

[0021] Such as Figure 1-3As shown, a construction waste crushing and screening machine includes a base 4, a support platform 3 is arranged on the upper left of the base 4, and a magnetic separator 2 is arranged above the support platform 3, and the magnetic separator The top of the machine 2 is provided with a feeding port 1, and the right side of the magnetic separator 2 is provided with a feeding cylinder 5, and the inside of the feeding cylinder 5 is provided with a crushing feeding mechanism 7, and the crushing feeding mechanism 7 is provided. The feeding mechanism 7 is arranged on the outside of the rotating shaft 6, the right side of the rotating shaft 6 is connected with a first motor 8, the bottom of the feeding cylinder 5 is provided with a feeding port 9, and the bottom of the feeding port 9 is A first crushing chamber 11 is provided, and a group of crushing wheels A13 are arranged inside the first crushing chamber 11, and a primary screen 12 is arranged below the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com