Patents

Literature

190results about How to "Speed up sieving" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

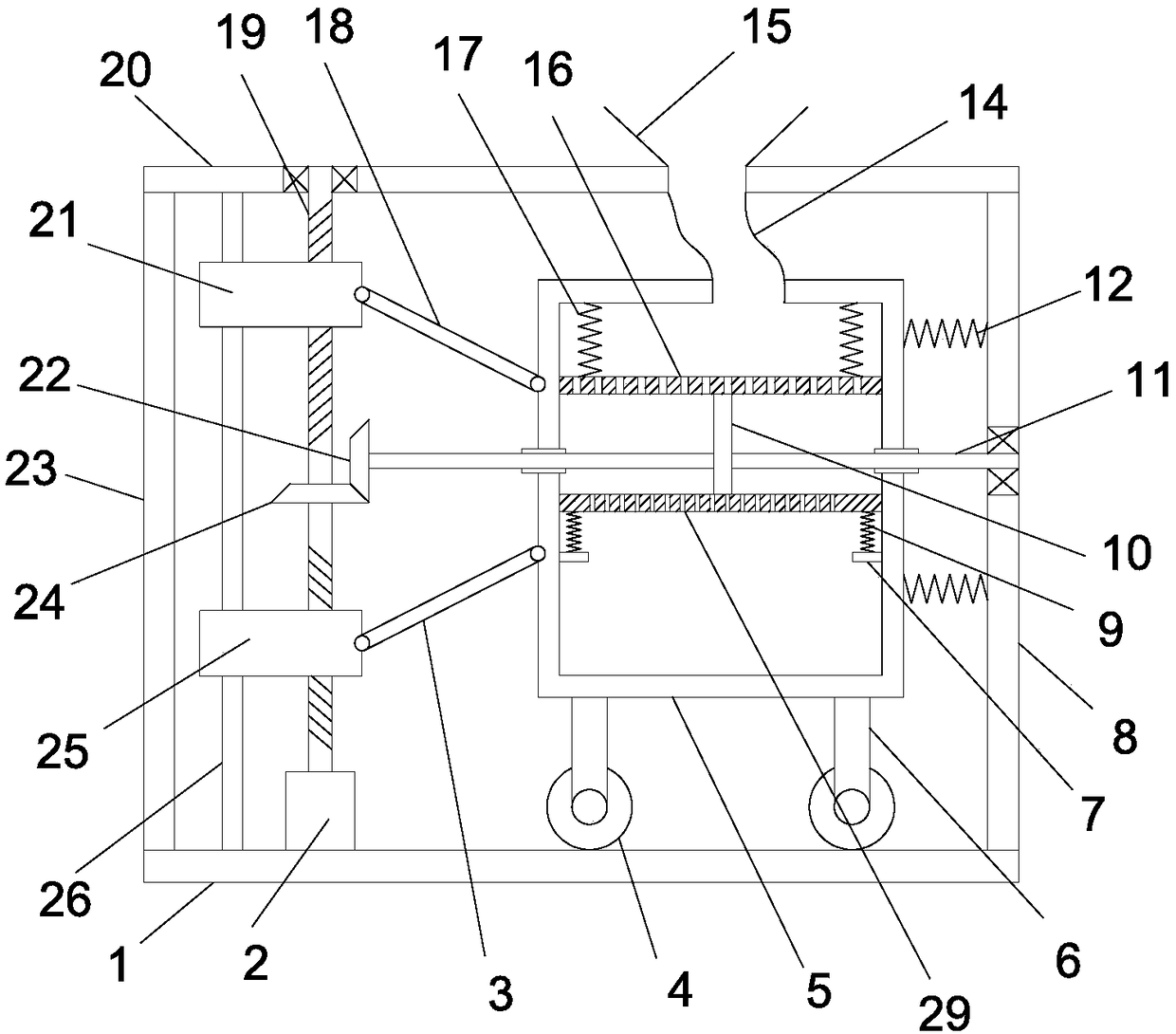

Activated carbon screening device for filter screen of purifier

The invention discloses an activated carbon screening device for a filter screen of a purifier, which comprises a base, a screening box, a first screen frame, a second screen frame, a third screen frame, a rack, a sector gear, a driving motor, a cylindrical wheel, Connecting rods, impact rods and double-axis motors, the first screen frame, the second screen frame and the third screen frame are respectively inserted and installed between the slots on the left and right sides; A toothed rack is slidably installed inside the slot, and the right end of the toothed rack is fixedly welded with an impact bar. The screening device can not only move left and right for screening, but also can vibrate up and down for screening, thereby greatly speeding up the screening speed, improving production efficiency and speeding up production tempo.

Owner:黄莉

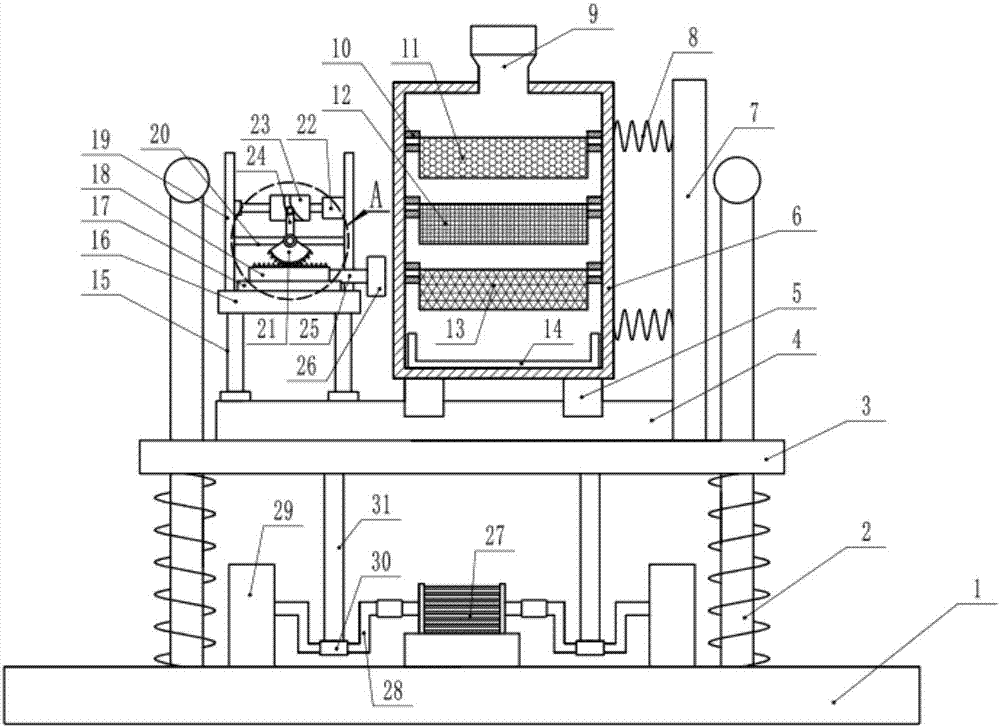

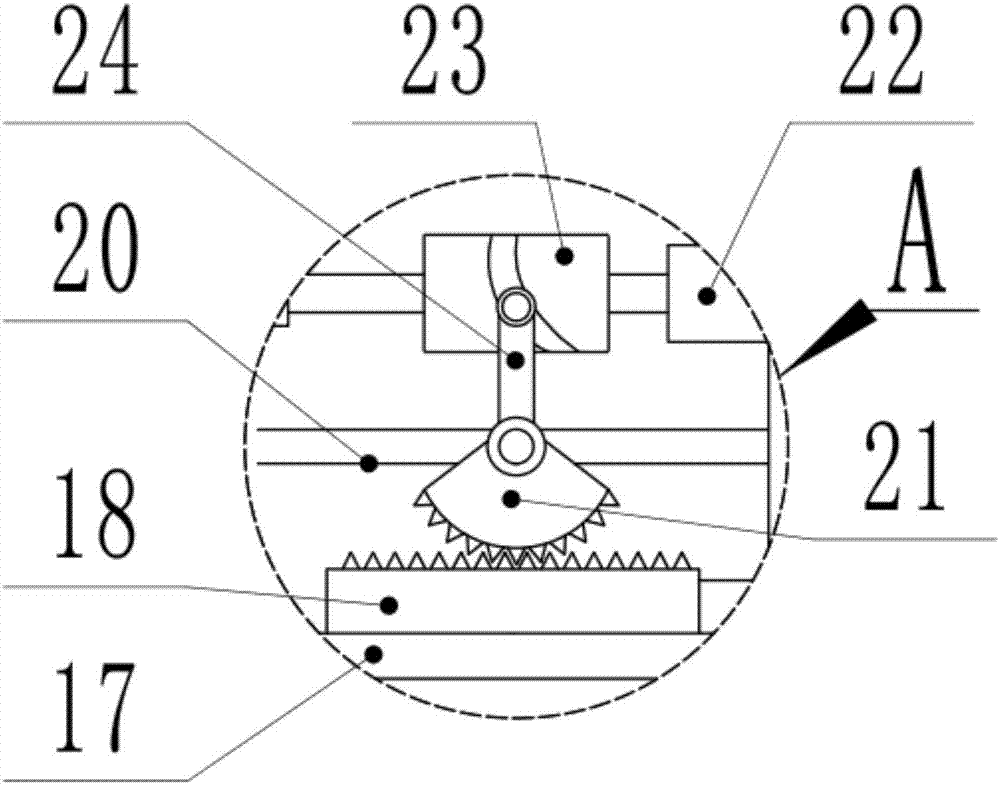

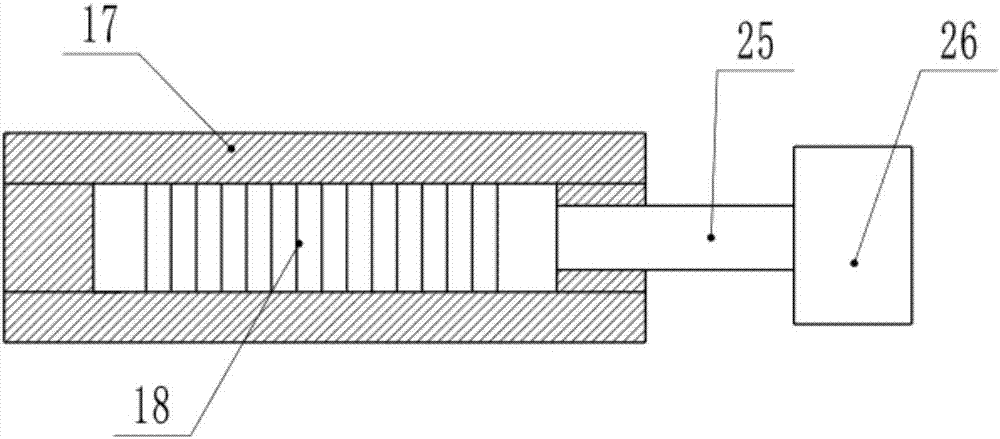

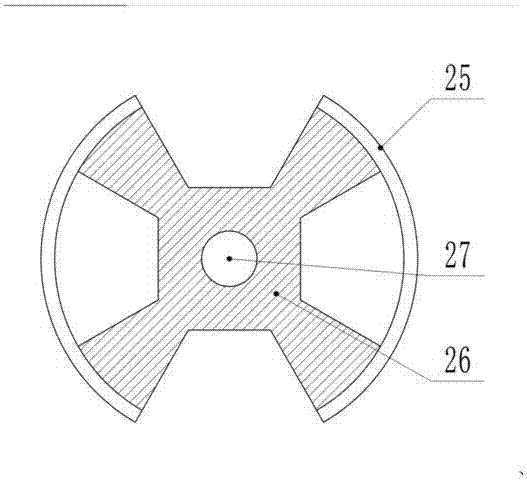

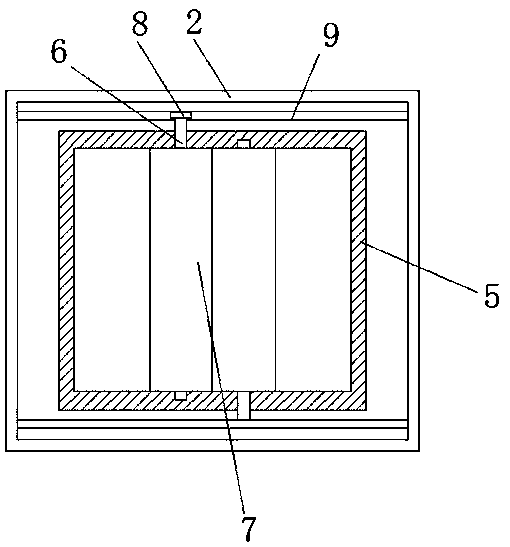

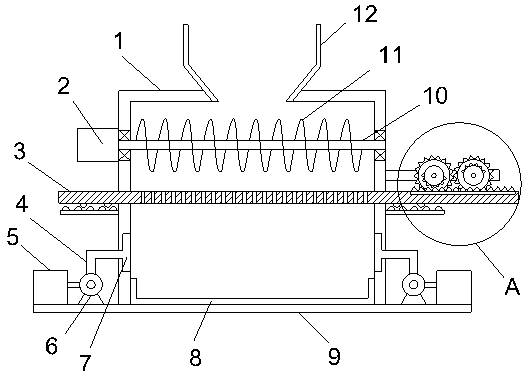

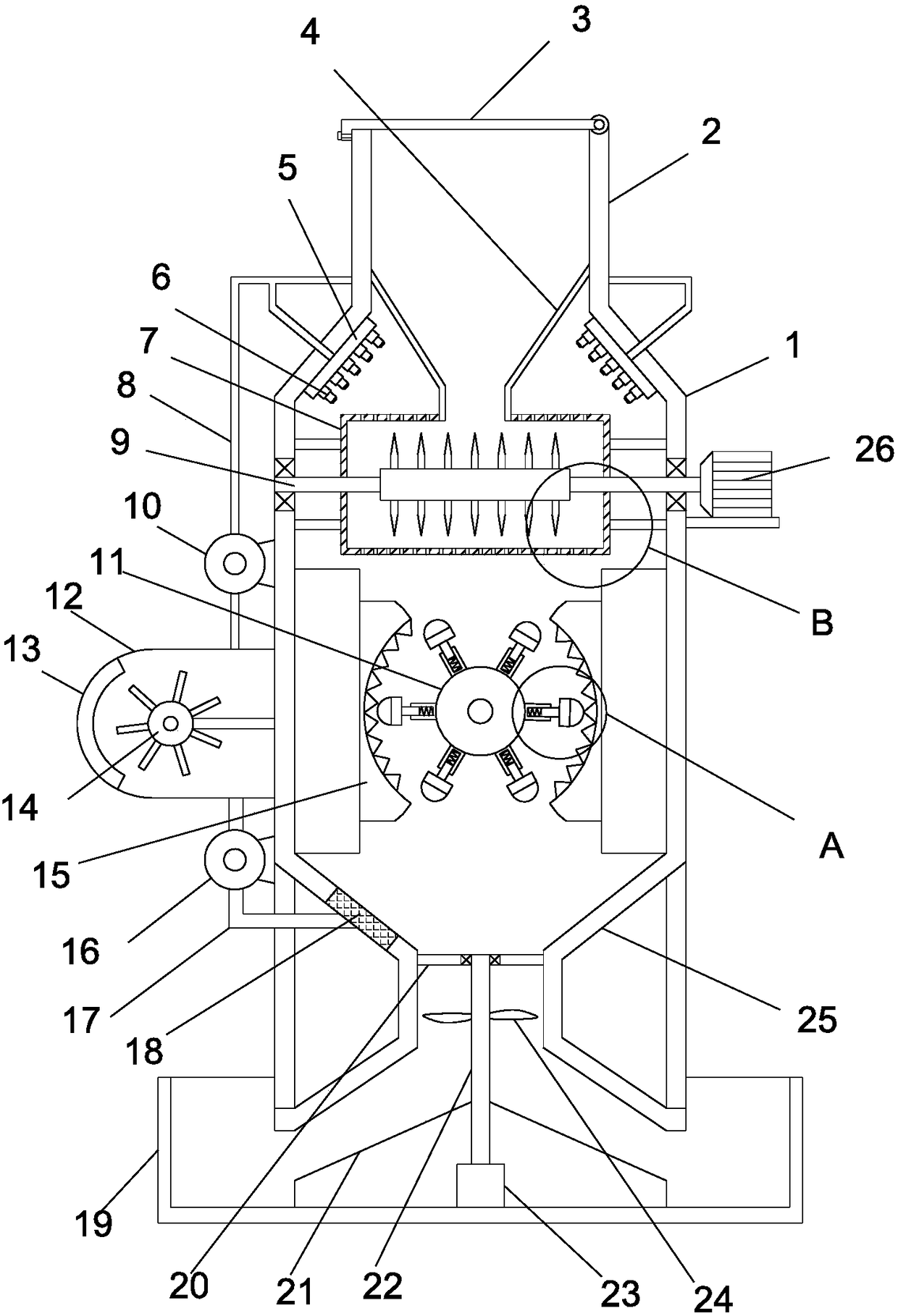

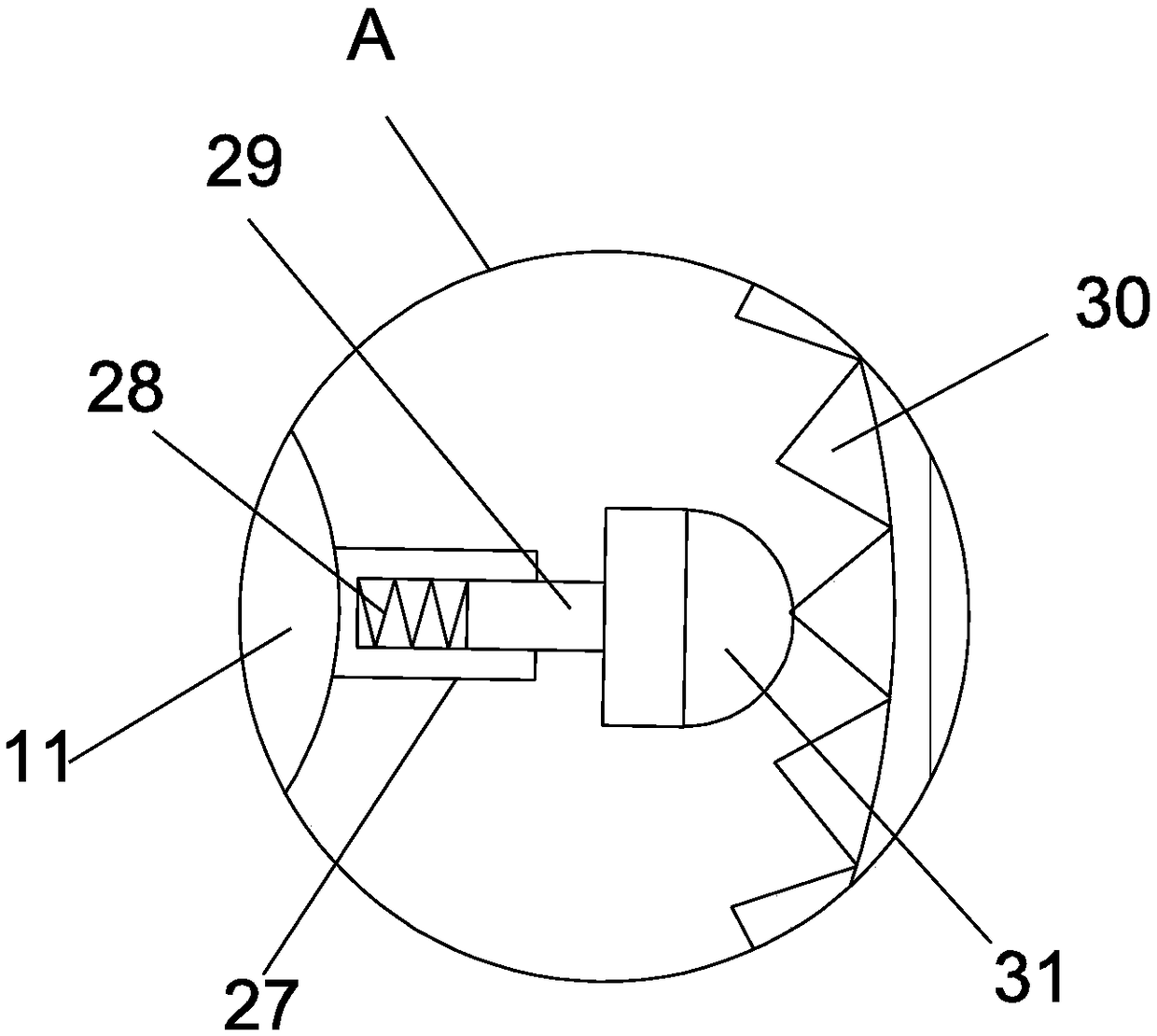

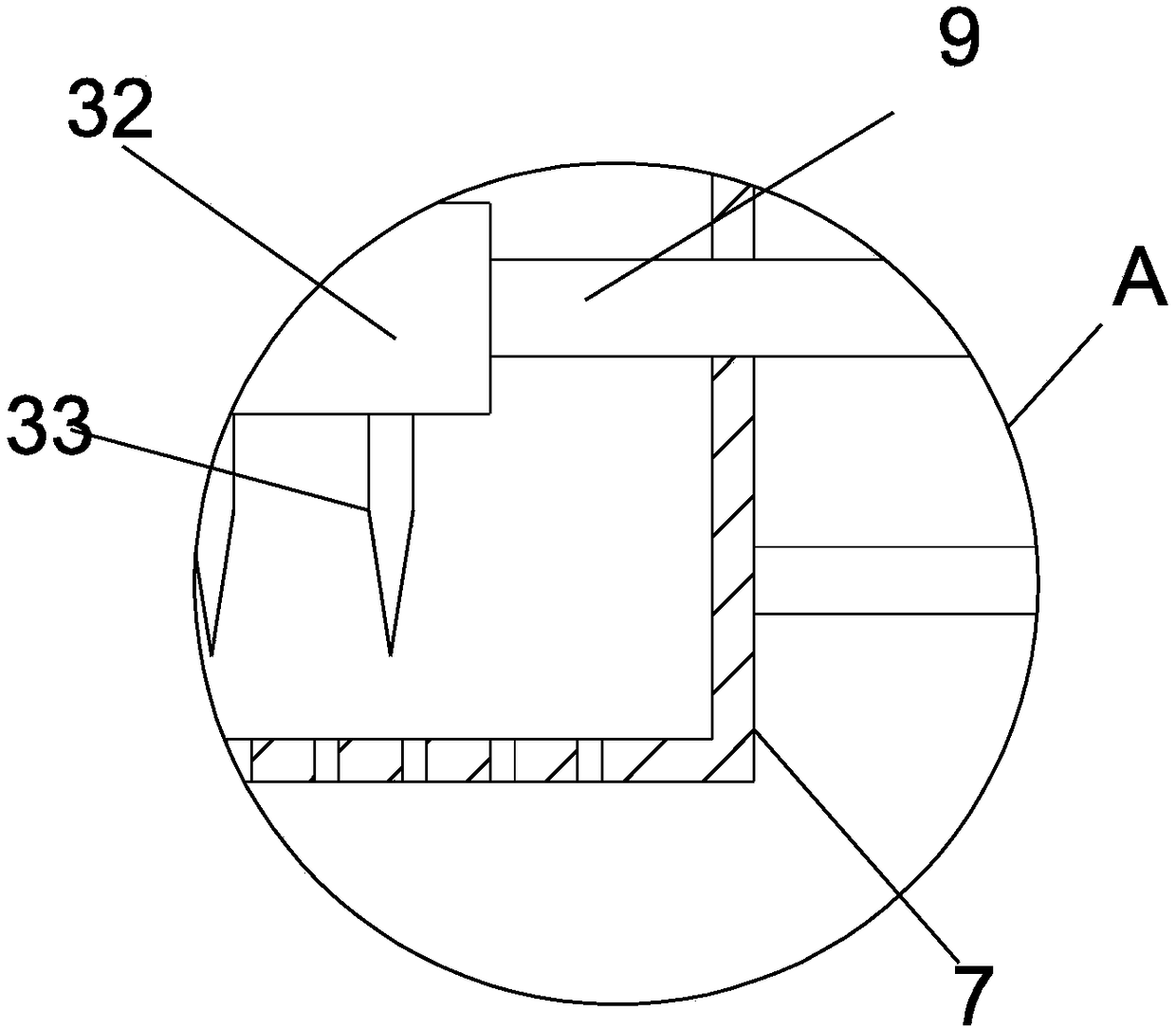

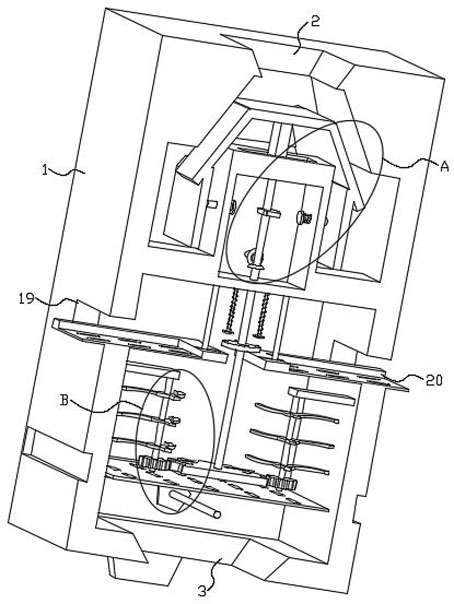

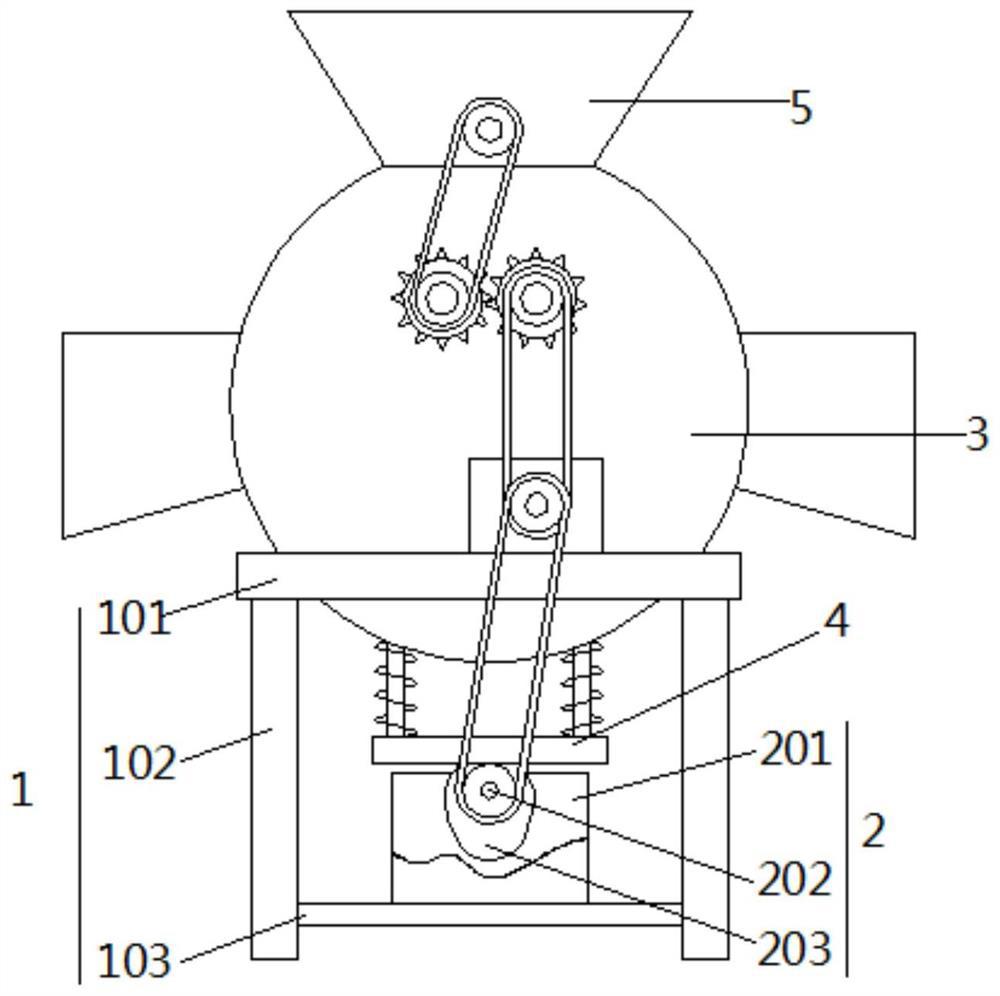

Fine feed grinding device for fry breeding

InactiveCN107377091AReduce noiseEffective shock absorptionFeeding-stuffNon-rotating vibration suppressionElectromagnet

The invention discloses a feed fine grinding device for fish fry cultivation, which comprises a shock absorbing spring, a shock absorbing cylinder, a grinding box, a grinding tank, a screening plate, a screw rod, a grinding roller, a grinding motor, a feeding trough, and a quantitative circular wheel and a magnet, the inside of the grinding box is provided with a grinding tank, a sieve plate is installed at the bottom of the grinding tank, a screw rod is installed on the front side of the grinding tank, and a guide rod is fixedly installed on the rear side of the grinding tank. Grinding rollers are also fixedly installed, and a quantitative round wheel is also rotatably installed inside the cutting trough; a magnet is fixedly installed on the lower side of the grinding box, and an electromagnet is also fixedly installed on the base. When it is necessary to grind the fish feed, the electromagnet is powered on and off intermittently, so that the grinding box moves up and down, thereby speeding up the speed of sieving the feed after grinding; after the sieving is completed, it is realized under the action of the quantitative round wheel Quantitative discharge, so as to accurately control the feeding amount of fish food, so as to achieve reasonable feeding.

Owner:YUYAO WANZHEN HARDWARE FACTORY

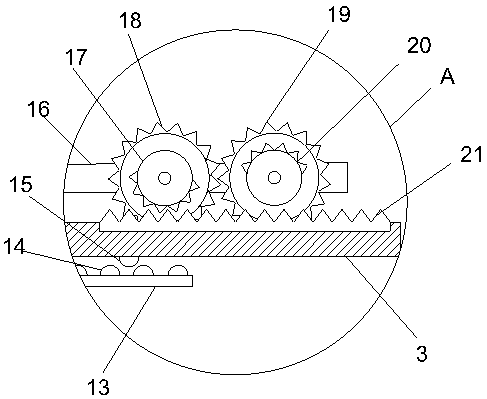

Discharging device for flour packaging machine

InactiveCN111572826ASimple structureEasy to useSievingScreeningStructural engineeringManufacturing engineering

The invention belongs to the field of flour packaging, and particularly relates to a discharging device for a flour packaging machine. For the problems that during flour packaging at present, flour screening is convenient, and consequently flour uniformity is low, the following scheme is provided at present, the discharging device comprises a support, a material box with the top opened is fixedlyarranged on the support and internally provided with a screening box, rectangular plates are fixedly arranged on the two sides of the screening box, and the two rectangular plates are in sliding connection with the material box; two rotation shafts are rotationally arranged in the screening box, and the outer sides of the two rotation shafts are fixedly sleeved with grinding rollers located in thescreening box; and first gears are fixedly arranged at one ends of the two rotation shafts, first racks are fixedly arranged in the material box, and the two first gears are engaged with the two first racks correspondingly. By means of the discharging device, flour can be screened, large flour can be ground, flour is more uniform, meanwhile, quantitative packaging can be conducted, the structureis simple, and usage is convenient.

Owner:惠安县崇武镇芳鑫茶具商行

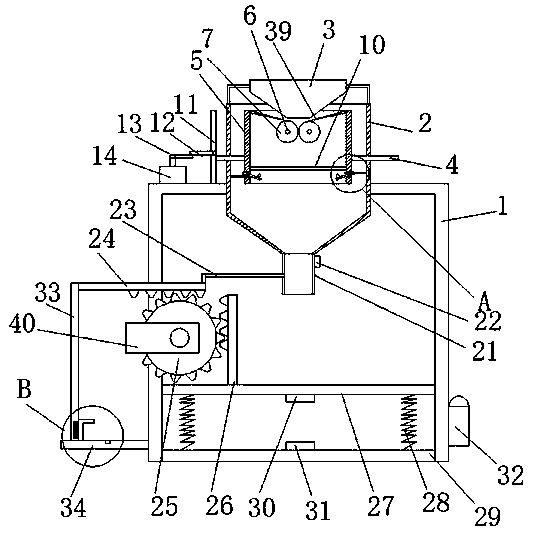

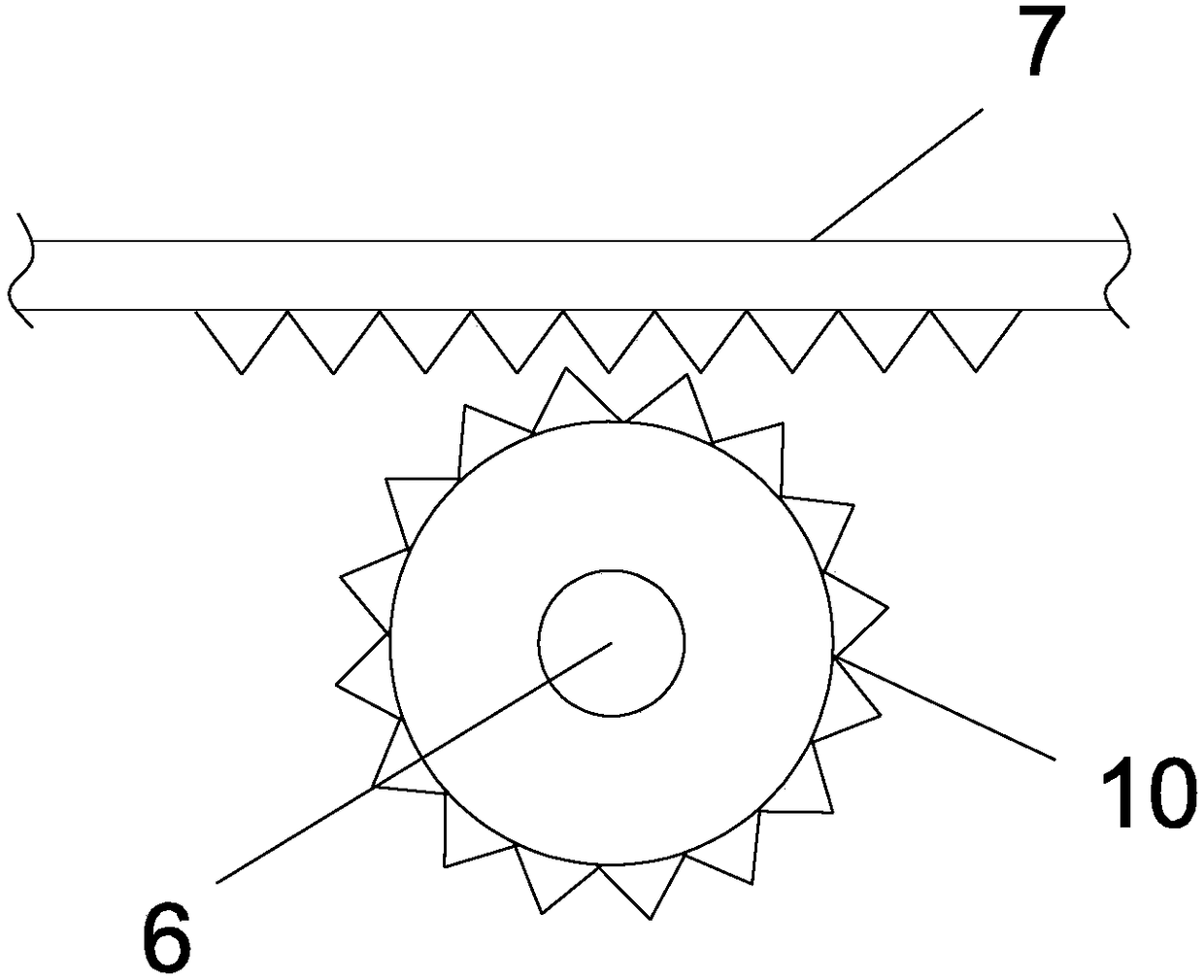

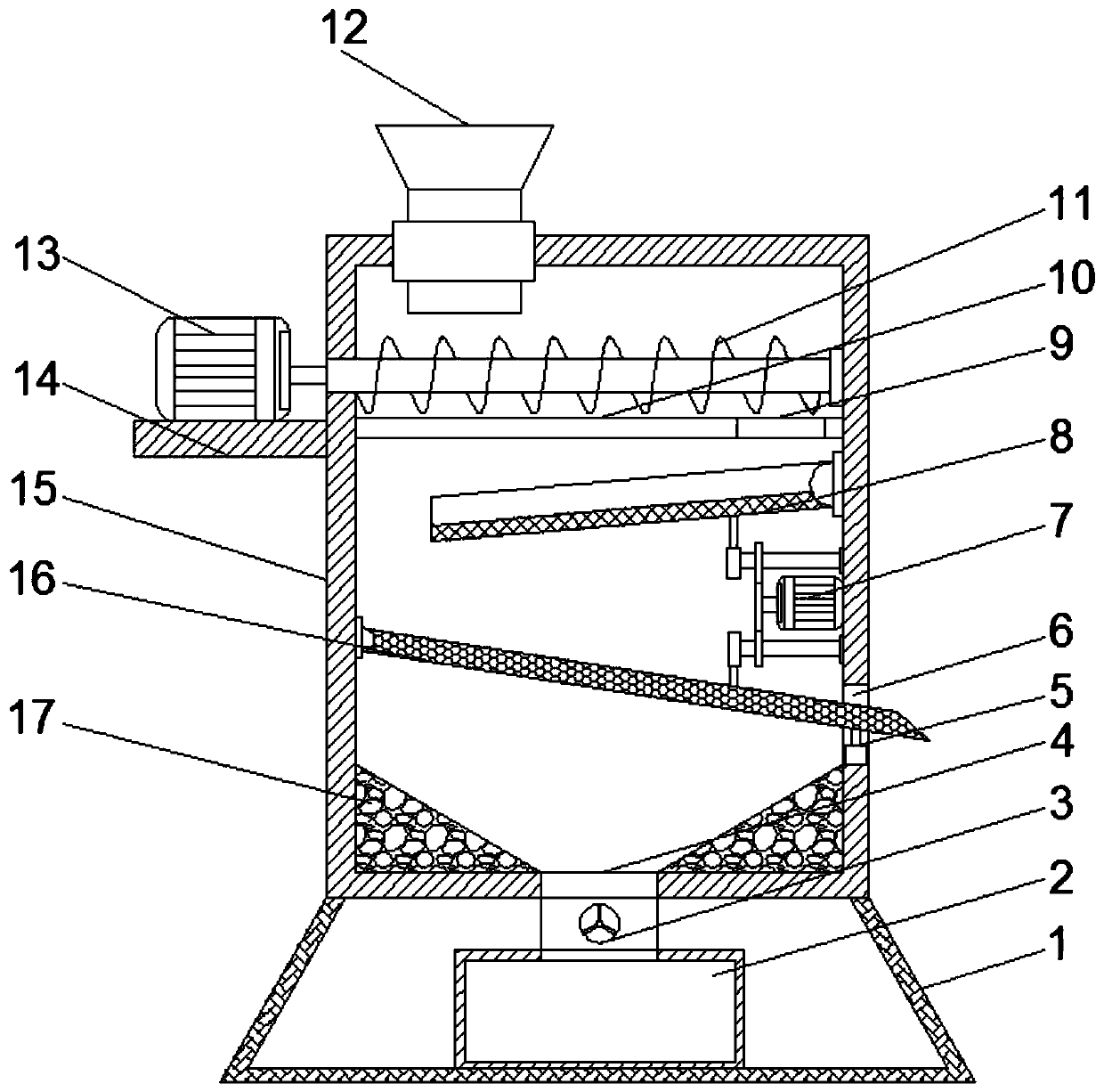

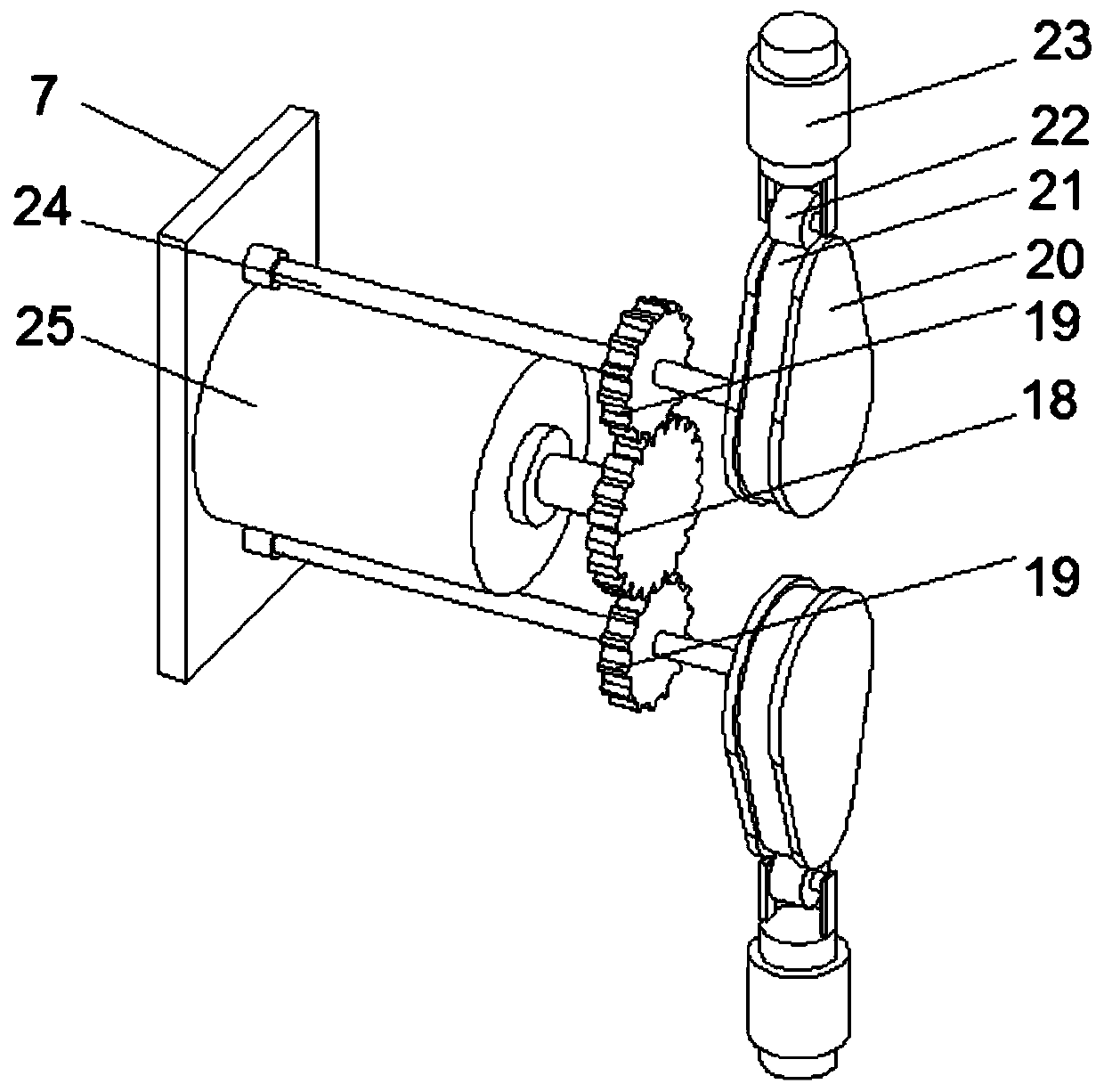

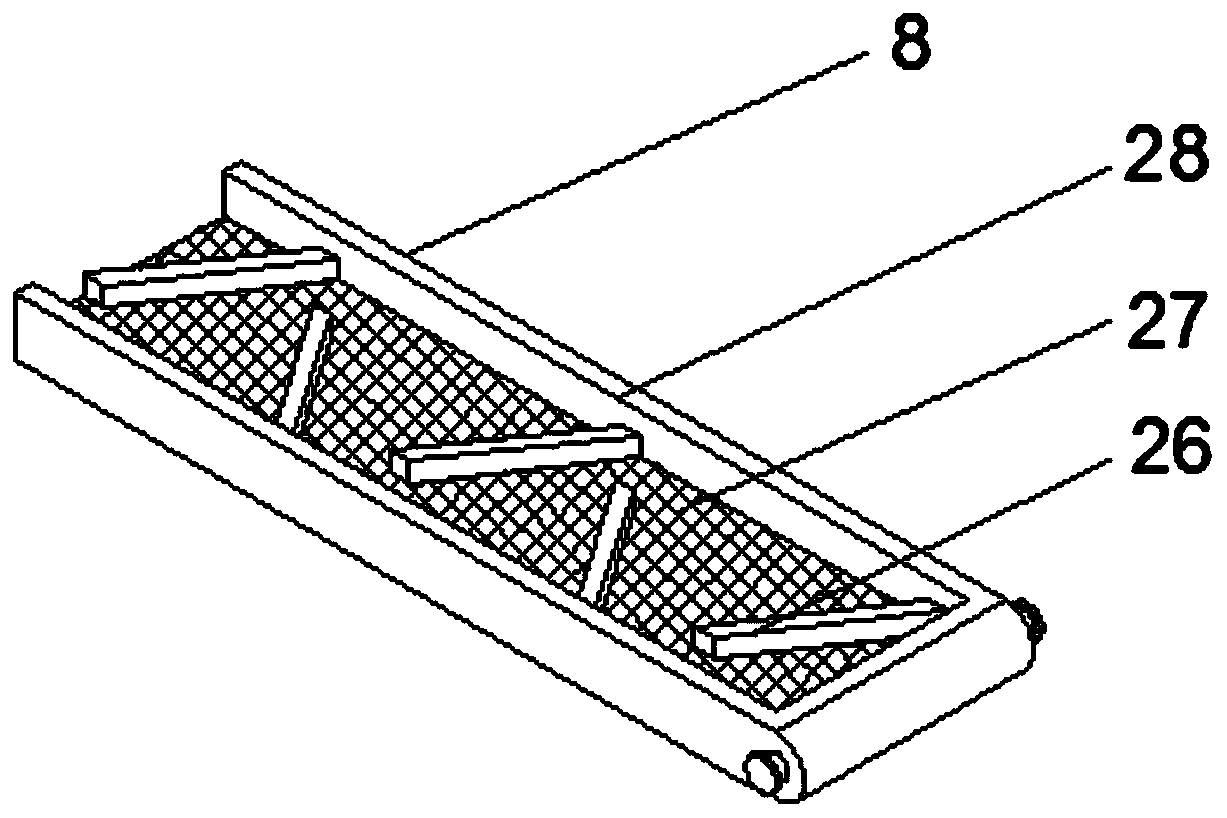

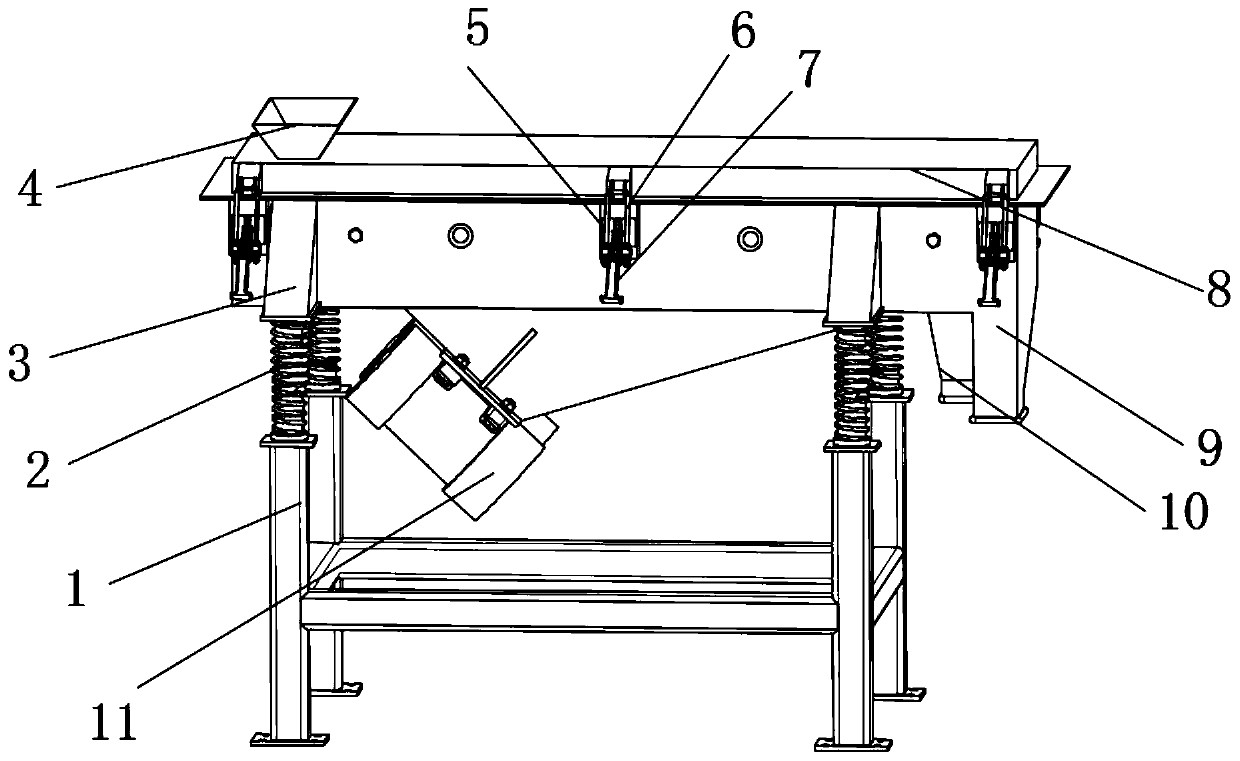

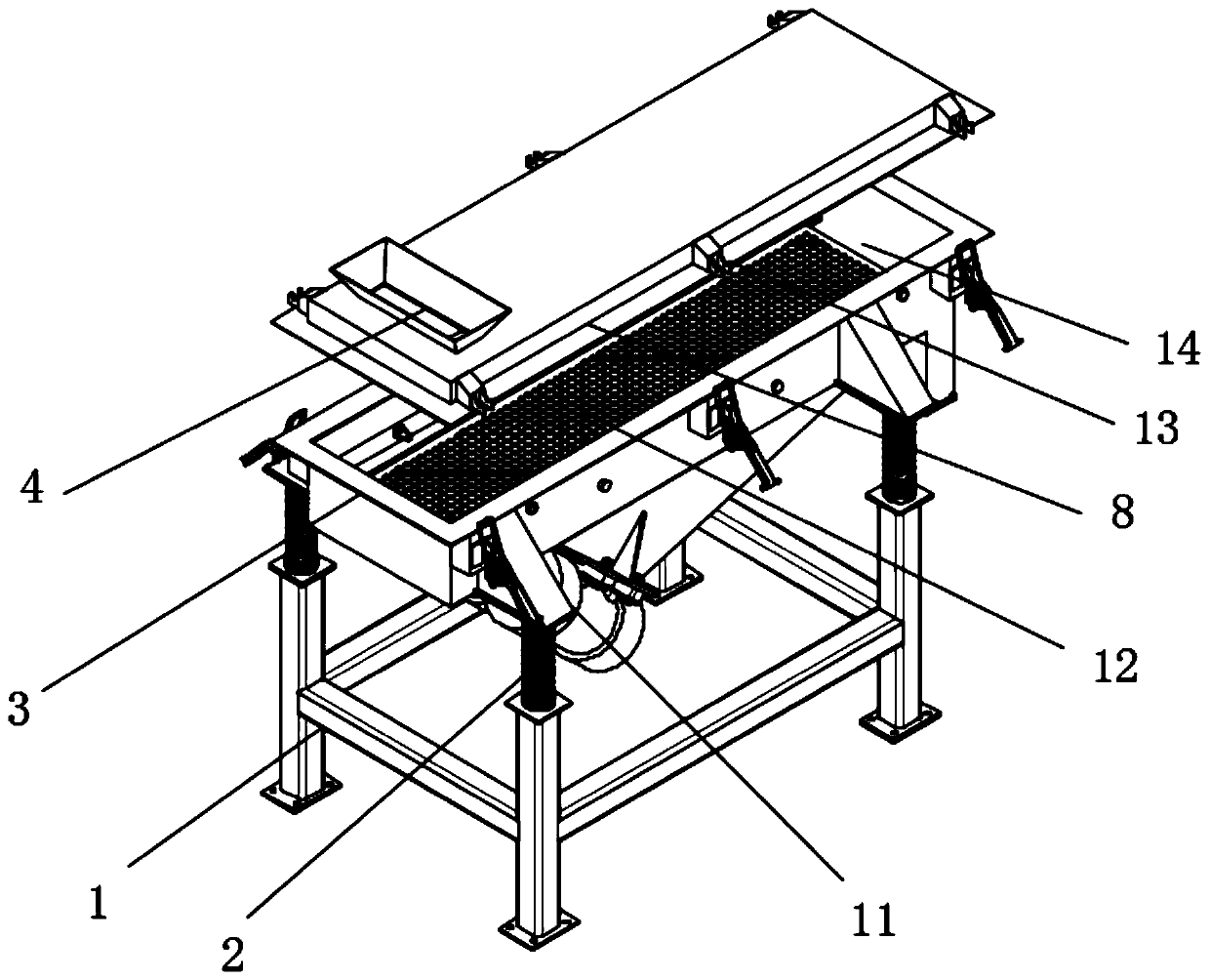

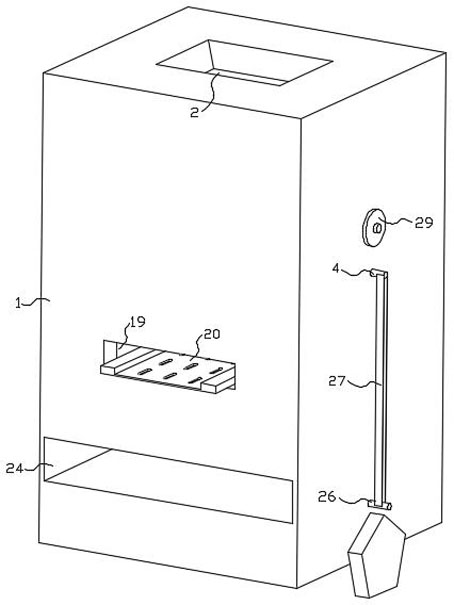

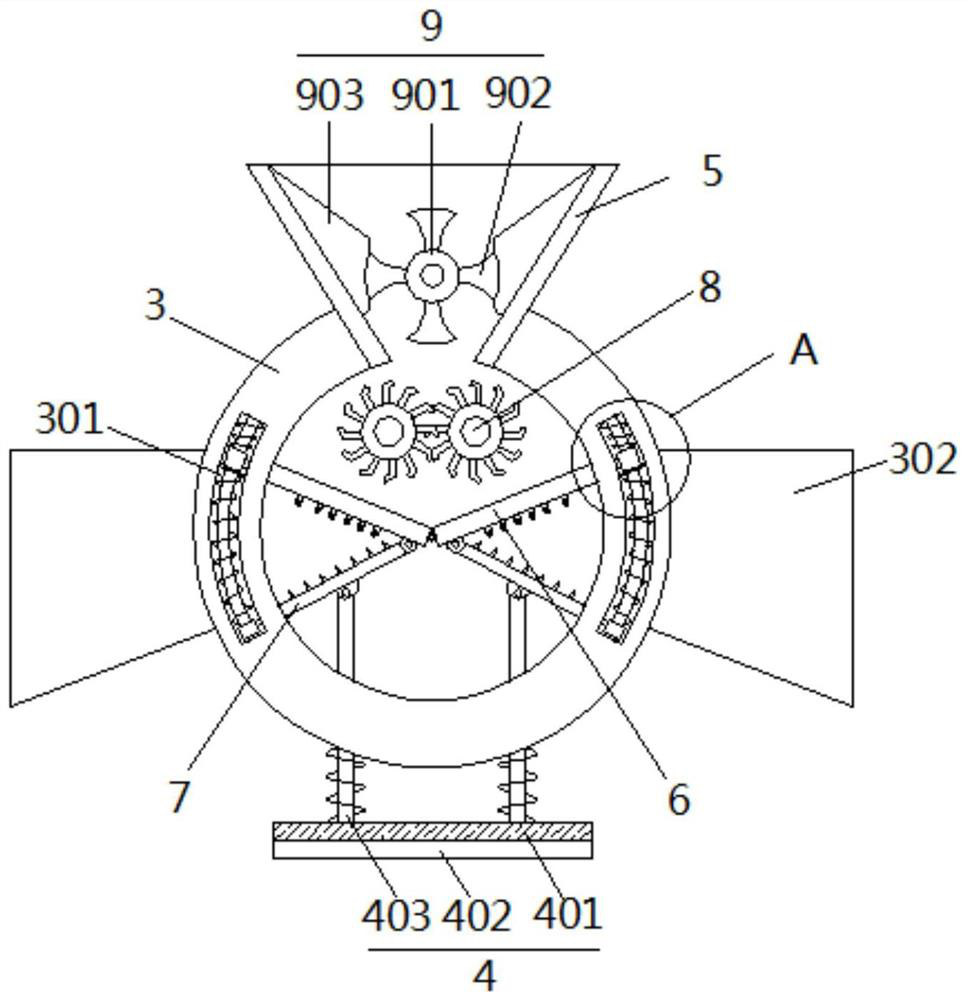

Rapid sand screening device for building construction

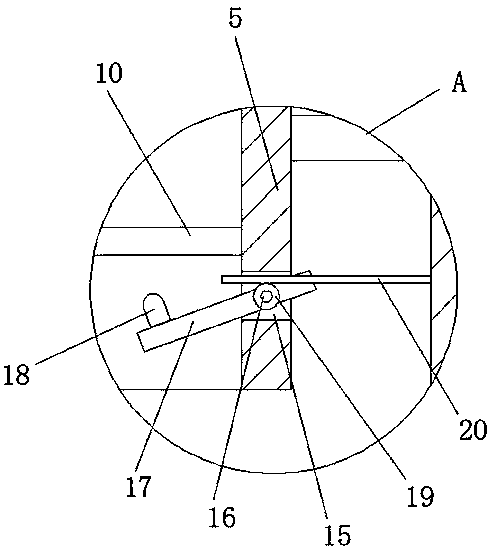

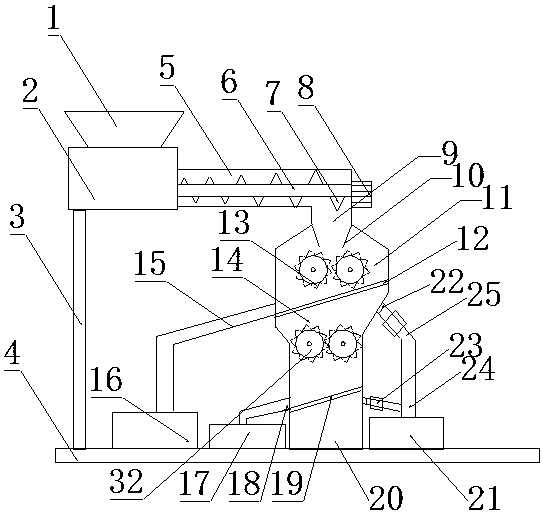

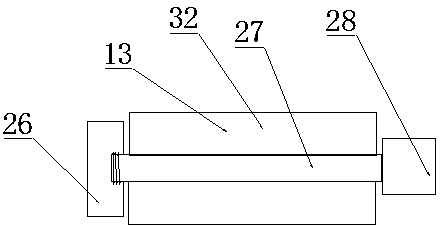

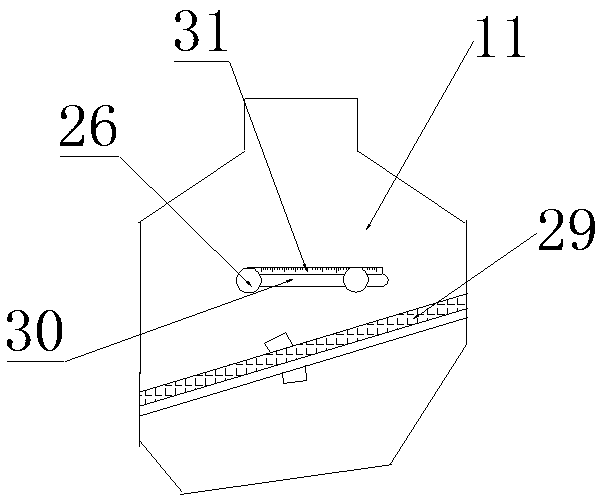

InactiveCN108097415ASpeed up sievingAchieve left and right shakingSievingScreeningScreening effectSpiral blade

The invention discloses a rapid sand screening device for building construction. The rapid sand screening device comprises a bottom plate and a screening box fixed on the bottom plate, and a feeding hopper is vertically and fixedly installed at the top part of the screening box; a sieve plate is horizontally arranged in the screening box in a sliding mode; a driving gear is connected to a horizontal support through a motor in a driving mode, and a first semicircular gear is coaxially and fixedly installed on the front side of the driving gear; and the bottom part of the bottom plate is fixedlyprovided with an air heater and a draught fan connected with the air heater through a pipeline. According to the rapid sand screening device, spiral blades are driven to rotate through forward and reverse rotation of a forward and reverse rotation motor, the spiral blades rotate and dissipate sand, sand can move back and forth in the left-right direction at the same time, so that screening of thesand is promoted; the sieve plate moves back and forth in the left-right direction, so that left and right shaking of the sand is realized; meanwhile, upper convex blocks and lower convex blocks arecoordinated with each other, so that small vibration of the sieve plate is realized, and the sand is accelerated to pass through the sieve plate; and hot air sprayed into the screening box by an air injection disc plays a role in drying the sand, so that the sand is more dispersed, and therefore the screening effect is better.

Owner:徐玲燕

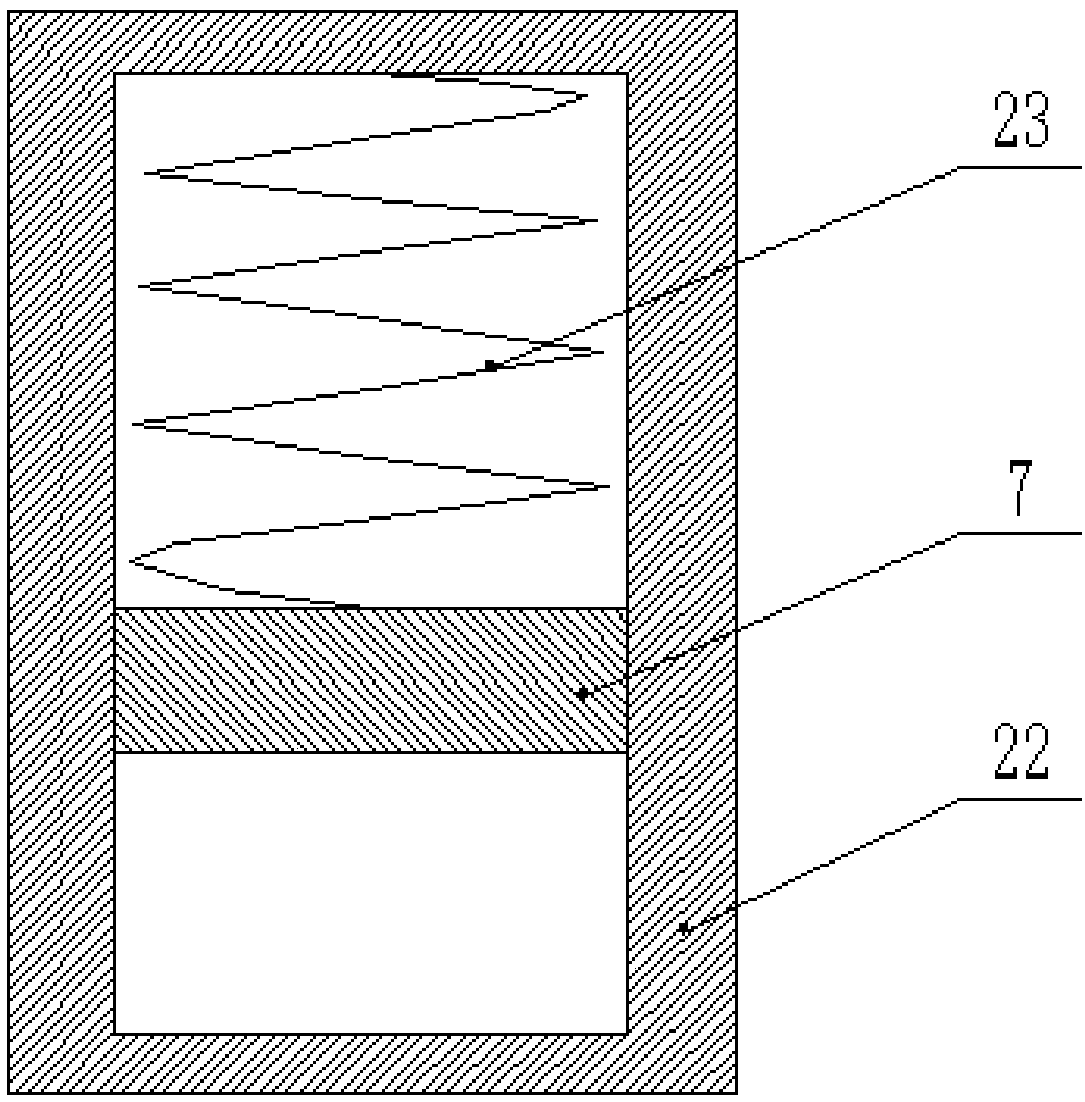

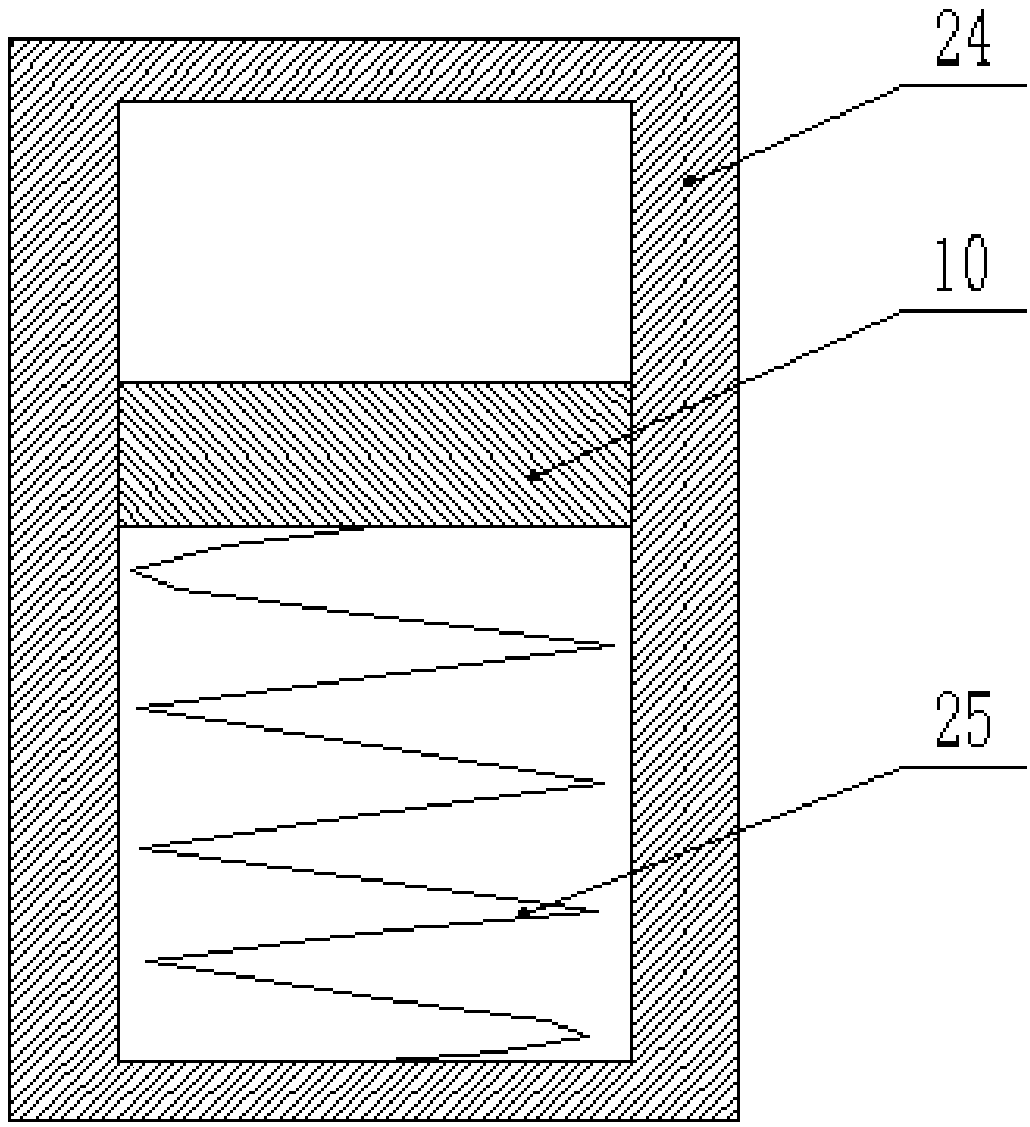

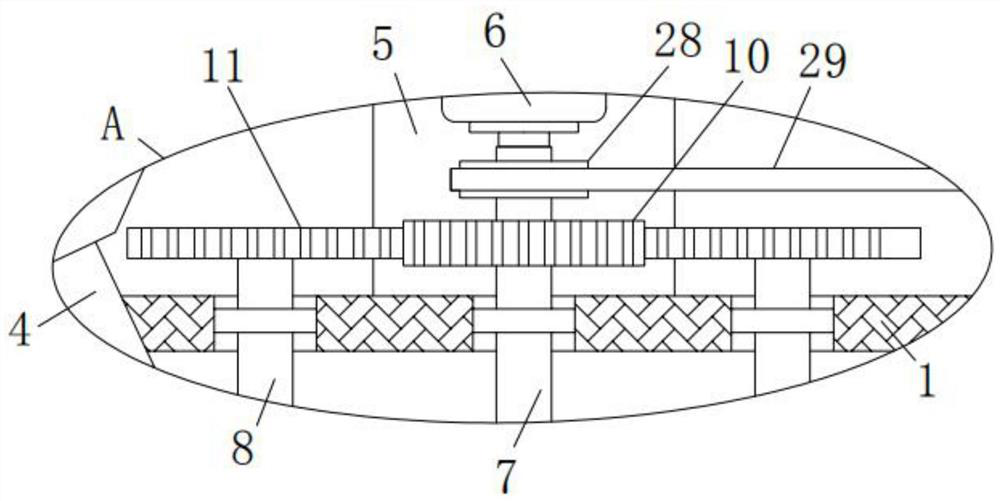

Soybean screening device with drying function

A soybean screening device with a drying function, including a main body, a second straight rack and a first straight rack are respectively arranged on the upper and lower inner walls of the zigzag frame, and incomplete gears are arranged inside the zigzagging frame, and the incomplete gears are connected to There is a driving device, the incomplete gear meshes with the second straight rack or the first straight rack, and the incomplete gear is connected with a driving device; there is a fan at the bottom of the circular frame, and a rotating wheel is installed on the inner wall on the right side of the body. A cam is set on the runner on the coaxial center, and the right end of the connecting rod is hinged on the edge of the runner; a sieve plate is pierced on the body, and the sieve plate is located below the cam; The second collection tank, the left end of the sieve plate is located inside the collection tank; the rotation of the cam drives the sieve plate to vibrate up and down to prevent soybeans from clogging the mesh of the sieve plate. points, to speed up the falling of smaller soybeans into the first collection tank, which is simple and practical, convenient and efficient.

Owner:盐城千之诺机械有限公司

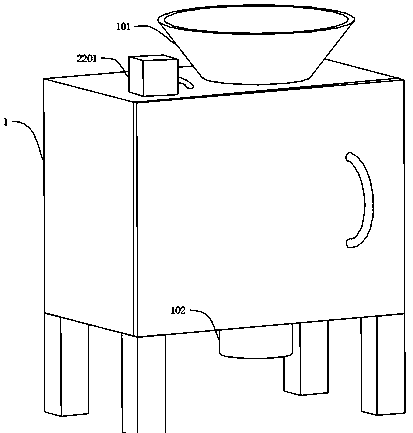

Pulverizing and sieving recycling device for waste batteries

The invention discloses a pulverizing and sieving recycling device for waste batteries. The pulverizing and sieving recycling device comprises a fixed box, wherein a fixed plate is fixedly connected between the two sides of the inner wall of the fixed box, and a material leaking opening is arranged in the fixed plate; the two sides of the top of the fixed plate are both fixedly connected with a fixing bracket; the top of the fixing bracket is fixedly connected with a first motor, an output shaft of the first motor is fixedly connected with a first belt pulley through a coupling, and the surface of the first belt pulley is in transmission connection with a second belt pulley through a belt; and the back of the second belt pulley is fixedly connected with a pulverizing wheel. The invention relates to the technical field of environmental protection. The pulverizing and sieving recycling device for the waste batteries solves the problems that the existing pulverizing recycling device for the waste batteries cannot rapidly carry out treatment and the recycling working efficiency of the waste batteries is reduced, and can thoroughly sieve the pulverized batteries, improve the sieving quality and avoid excessive repeated steps.

Owner:贵州中伟资源循环产业发展有限公司

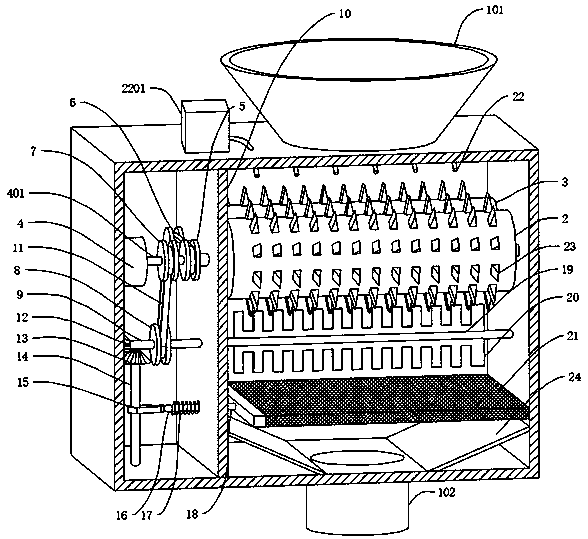

Chinese medicinal material crushing and grinding device convenient to discharging

PendingCN109012937AImprove crushing efficiencyImprove grinding qualityGrain treatmentsEngineeringGRINDING TOOTH

The invention discloses a Chinese medicinal material crushing and grinding device convenient to discharging. The Chinese medicinal material crushing and grinding device convenient to discharging comprises a shell and supporting legs. A first rotating shaft is connected with the middle of the upper end of the shell through a rotating motor, a first crushing blade is fixedly connected with the outerside of the upper end of the first rotating shaft, and a second crushing blade is arranged below the first crushing blade. A second inclined body is arranged below the second crushing blade, the outer edge of the second inclined body is fixedly connected with first grinding teeth, and the inner side wall of the shell is fixedly connected with second grinding teeth. A screen arranged obliquely isarranged below the second inclined body, elastic blocking plates are fixedly connected with the two sides of the lower end of the screen, vibrating motors are arranged below the elastic blocking plates, and a feeding barrel arranged inclined is arranged on the left side of the shell. According to the Chinese medicinal material crushing and grinding device convenient to discharging, the structure is simple, design is reasonable, automatic feeding can be completed, meanwhile, screening can be carried out after crushing and grinding, the screening speed is high, and a batch of Chinese medicinal materials which meet the requirements can be quickly produced.

Owner:TONGLING FENGDAN PLANTING TECH DEV

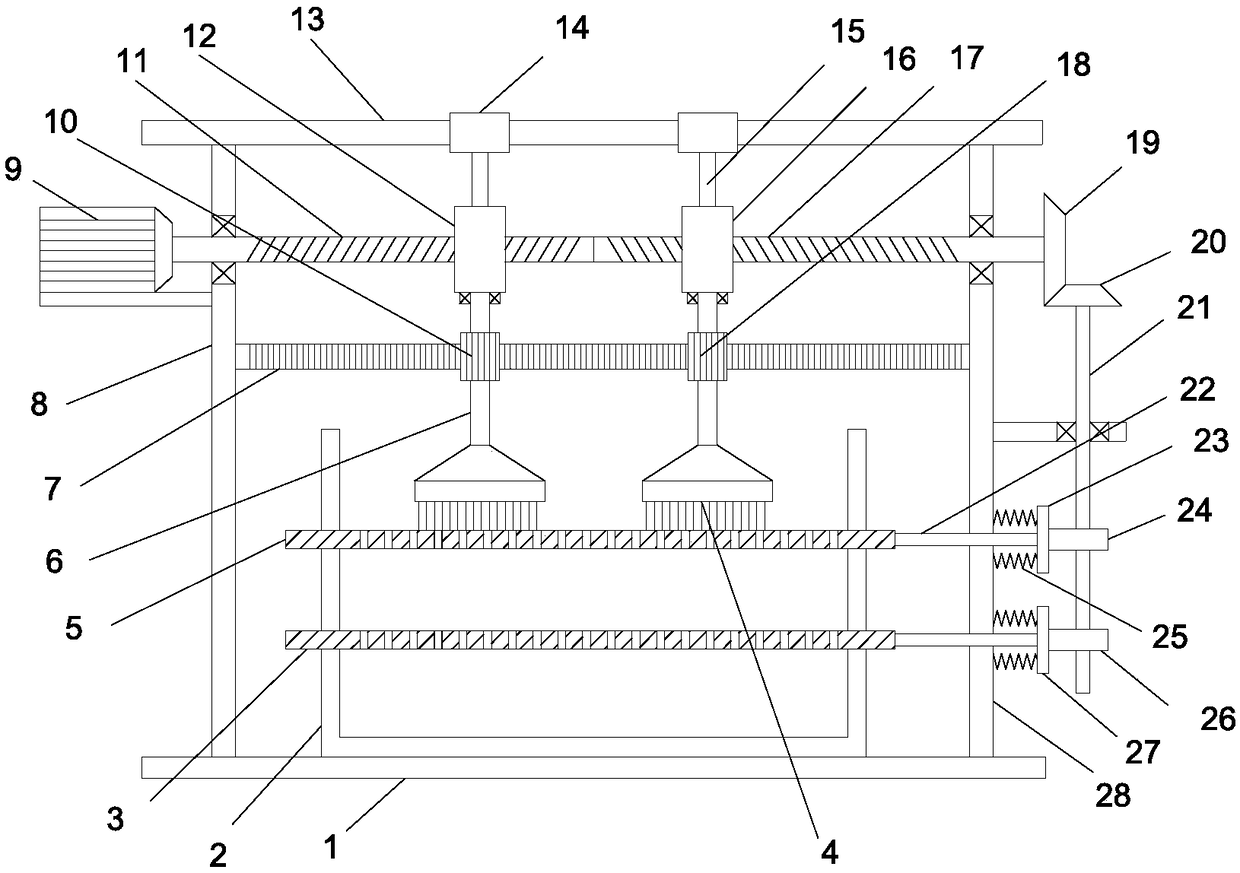

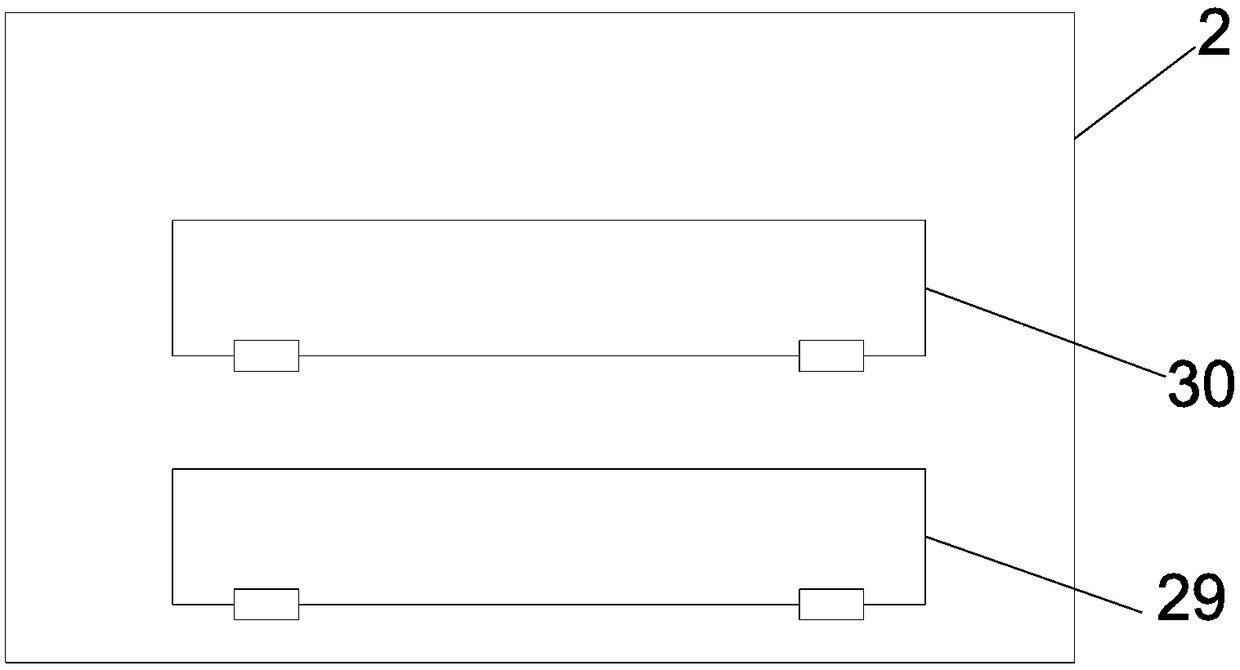

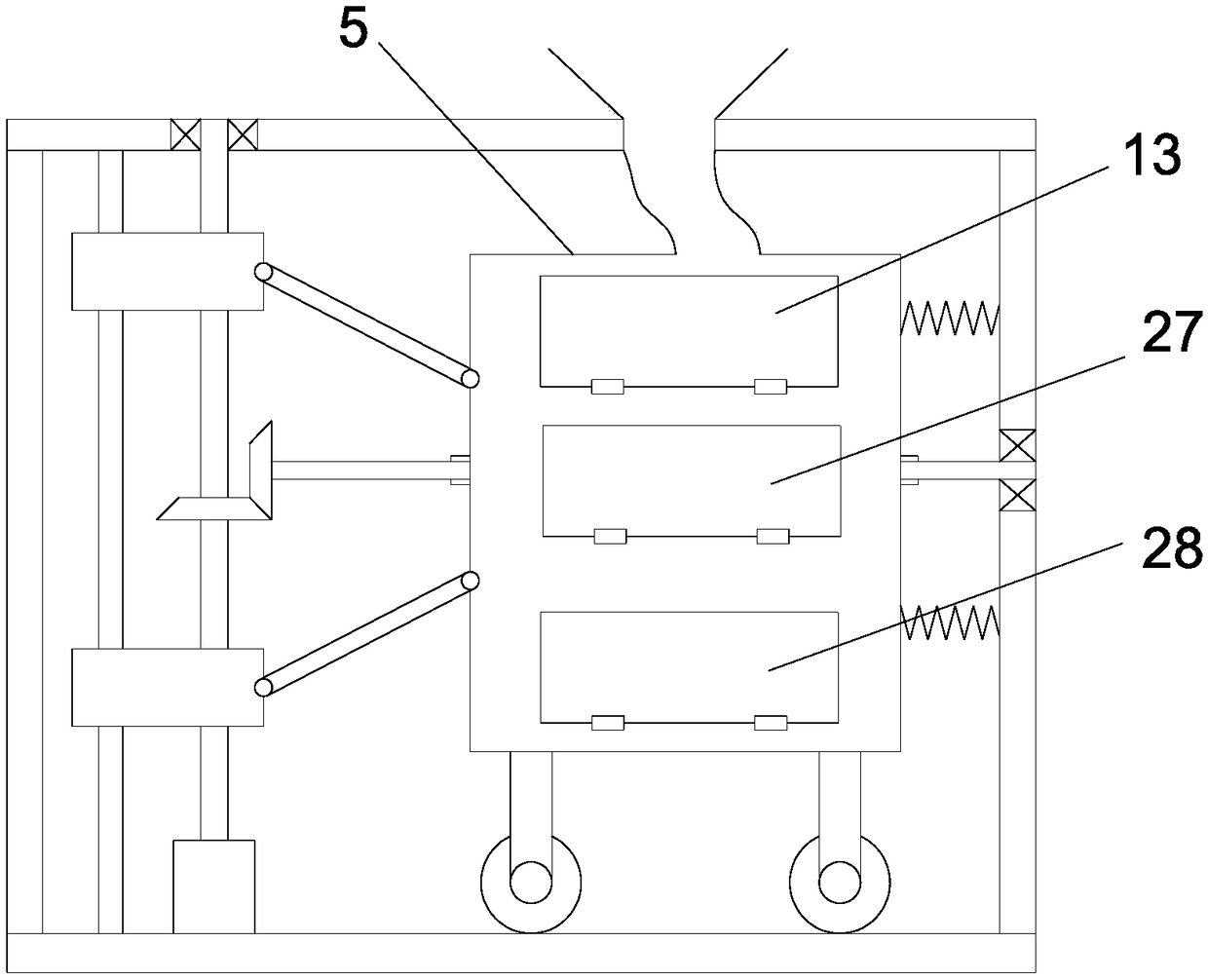

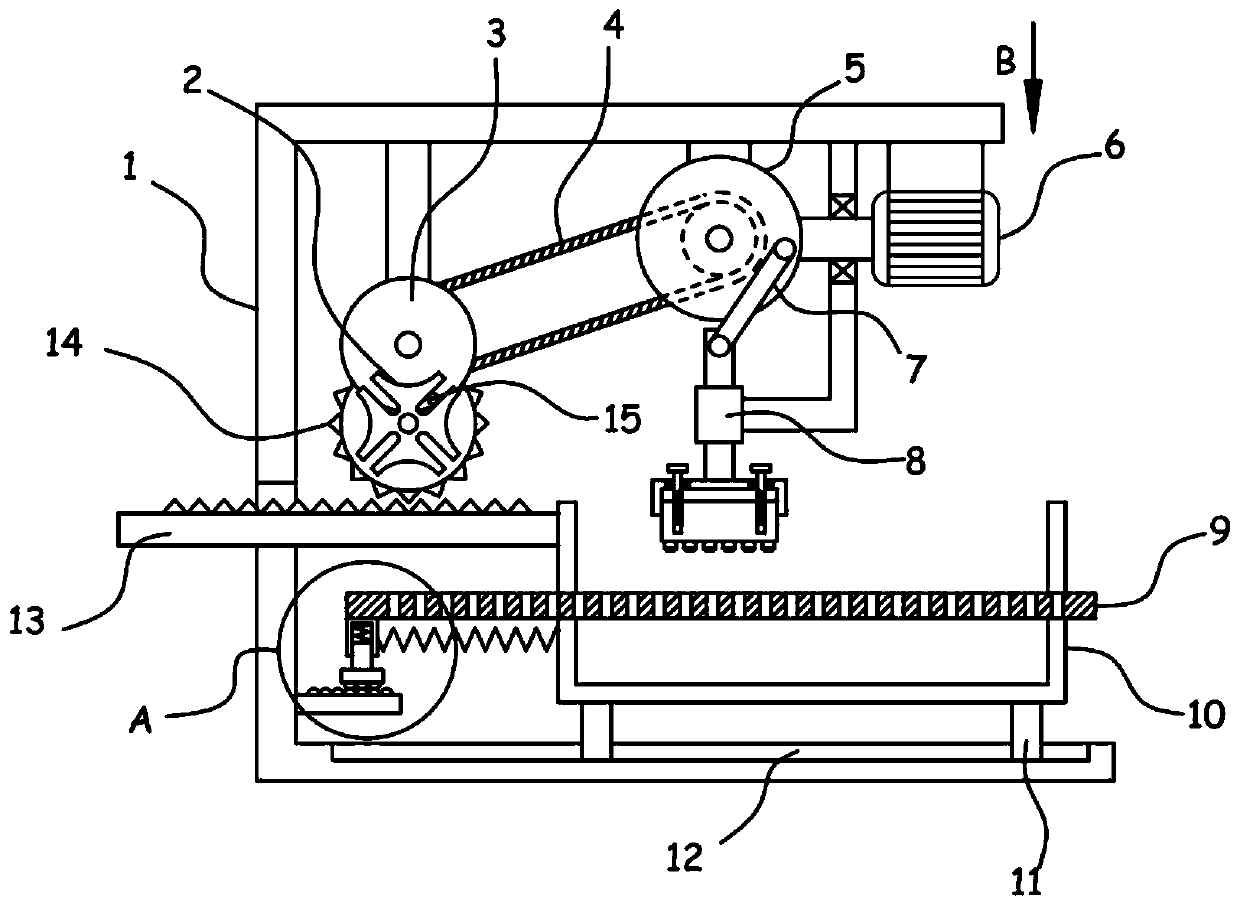

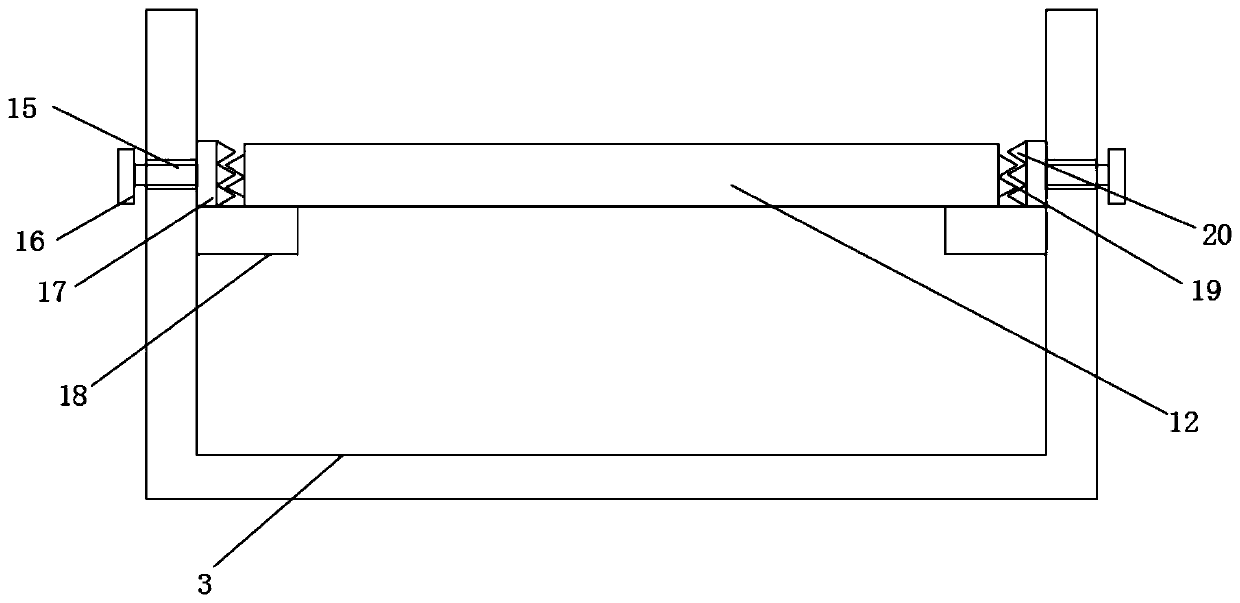

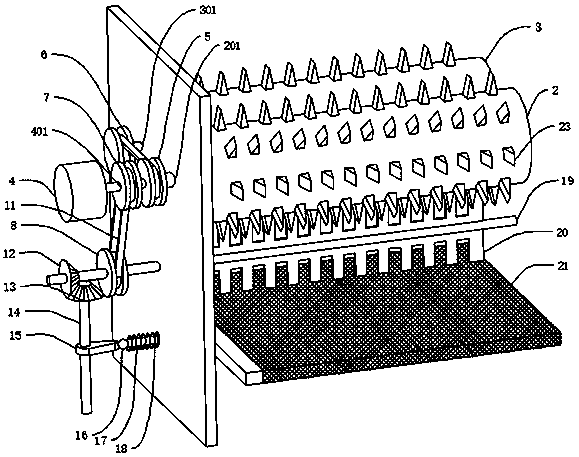

Second-level soybean screening device for agriculture processing

The invention discloses a second-level soybean screening device for agriculture processing. The second-level soybean screening device comprises a bottom plate. A left vertical plate and a right vertical plate are vertically and fixedly arranged on the bottom plate, and an ejector rod is horizontally and fixedly arranged at the upper end of the left vertical plate and the right vertical plate. Theejector rod is sleeved with two sliding sleeves in a sliding manner. The lower ends of connecting rods are fixedly provided with a first lead screw sleeve and a second lead screw sleeve correspondingly. A second lead screw extends rightwards to the right side of the right vertical plate. The right end of the second lead screw is coaxially and fixedly provided with a driving bevel gear. The diameter of sieve holes of a lower sieve plate is smaller than that of sieve holes of an upper sieve plate. The side wall of a screening groove is provided with an upper movable door and a lower movable doorthrough hinges in a connected manner. Through rotation of a first cam and a second cam, the upper sieve plate and the lower sieve plate are driven to reciprocate left and right under elastic acting force of reset springs, and soybean particle screening is promoted. Brush discs rotate while moving left and right in a reciprocating manner, scattering of soybeans on the upper sieve plate is promoted, and the soybean screening efficiency is improved.

Owner:HUIAN KELIAN AGRI TECH CO LTD

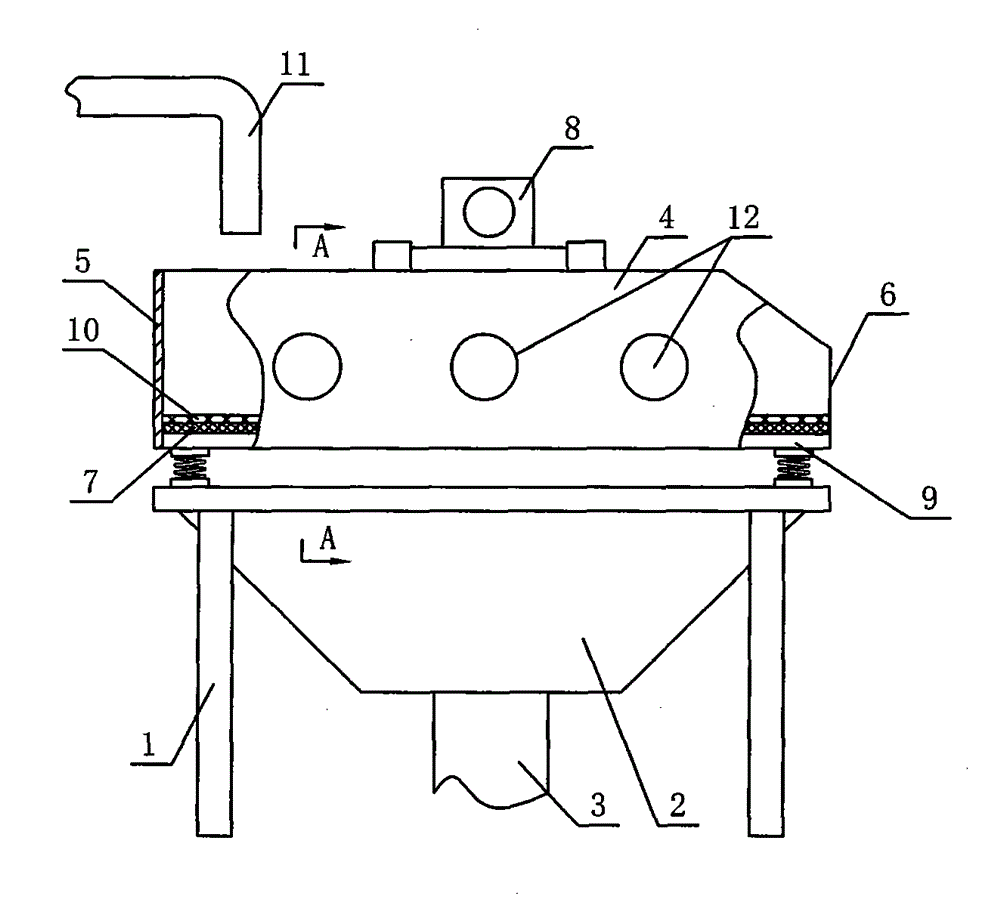

Sand screening device for construction

InactiveCN108421703AImprove screening effectIncrease screening speedSievingScreeningScreening effectReciprocating motion

The invention discloses a sand screening device for construction. The sand screening device comprises a bottom plate and a screening box. A left vertical plate and a right vertical plate are vertically and fixedly mounted on the bottom plate. A top plate is horizontally and fixedly mounted on the left vertical plate and the right vertical plate. Supporting legs are vertically and fixedly mounted at the bottom of the screening box. A feeding pipe is mounted on the top plate and communicates with the interior of the screening box through a flexible connecting pipe. Damping springs are fixedly connected between the screening box and the left side wall of the right vertical plate. The sand screening device has the obvious advantages that the screening effect on sand is good, and the screeningspeed is high; the screening box is driven through a second connecting rod and a first connecting rod to do left-and-right reciprocating motion under the elastic acting force of the damping springs,shaking of the sand in the screening box is promoted, and the sand screening rate is increased; and through rotation of an oval cam, a first screening plate and a second screening plate are driven tovibrate up and down under the elastic action of second limiting springs, and the screening speed of the first screening plate and a second screening plate on the sand is further increased.

Owner:重庆峰创科技有限公司

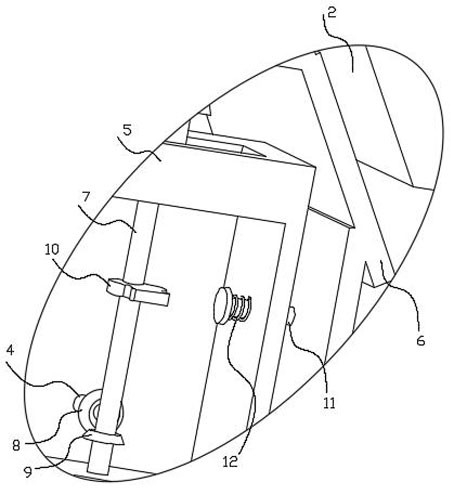

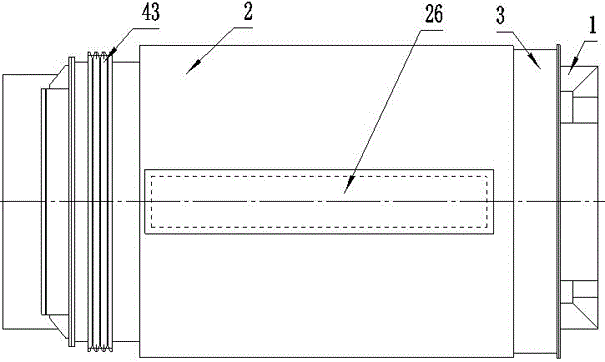

Grinding device capable of performing bilateral rotation

InactiveCN101898163APrevent movementAccess assistanceGrain treatmentsMechanical engineeringPulverizer

The invention relates to a grinding device capable of performing bilateral rotation. The grinding device mainly has the following beneficial characteristics and effects: 1) a material-fixing rack is arranged on one end of a cutter wheel A where material to be grinded enters, thus preventing that the material which is not grinded or completely grinded rotates with the cutter wheel A to move and ensuring the material to be grinded enters the cutter groove of the cutter wheel A; 2) two cutter wheels are designed to have cutter grooves with two different inclination directions, thus pressure can be applied to the material to be grinded between the material-fixing rack and a screen to perform solid cyclic grinding and the grindability of each cutter groove can be effectively utilized; 3) the screen is arranged on one end of a cutter wheel B where the grinded material is discharged, the screening speed and discharging speed of the grinded material passing through screen holes are increased owning to the pressure, the grinded material not passing through screen holes can perform cyclic grinding along with the cutter grooves; and 4) by adopting the parts of the grinding device, the grinding space of the grinding cutting tool can be reduced and the devices such as the additional vibrating screen and swinging screen can be eliminated, thus the volume of the grinding machine can be reduced and the residual quantity of the grinded material can be lowered.

Owner:叶德坚

Sand accelerated drying and screening device based on cam transmission structure

The invention relates to the technical field of sand screening, and discloses a sand accelerated drying and screening device based on a cam transmission structure. The sand accelerated drying and screening device comprises a box body, wherein a discharging opening is formed in the bottom of the interior of the box body; and a base is fixedly connected to the bottom of the box body. According to the sand accelerated drying and screening device based on the cam transmission structure, sand in a lump is smashed through a stirring roller, and heating and screening of the sand are facilitated; through a gear transmission structure, two sets of cams can be driven by a second motor to synchronously rotate, and therefore synchronous vibration of a heating plate and a filtering plate is achieved, the heating and screening speed of the sand is increased, and the screening efficiency is improved; the flow speed of the sand on the heating plate is reduced through a gear rod, the heating time of the sand is prolonged, and the drying performance of the sand is enhanced; and a buffering base buffers vibration generated by the filtering plate, the situation that the filtering plate is damaged dueto too large amplitude is prevented, and the service life of the machine is prolonged.

Owner:杭州鑫赐贸易有限公司

Building construction concrete block crushing device

InactiveCN110369020AImprove crushing efficiencySpeed up sievingGrain treatmentsWaste treatmentFixed frame

The invention discloses a building construction concrete block crushing device, and relates to the technical field of building waste treatment. The building construction concrete block crushing devicecomprises a fixed frame, and a collecting tank is slidably mounted on the fixed frame trough a guide mechanism. A net plate is arranged in the collecting tank, and the collecting tank is in driving connection with an impact crushing mechanism for crushing concrete blocks through a lifting reciprocating mechanism. The lower portion of a transmission gear is in engaged connection with a gear rack fixedly connected with the collecting tank. According to the building construction concrete block crushing device, the impact crushing mechanism is driven by the arranged lifting reciprocating mechanism to carry out repeated impact crushing on the concrete blocks in the collecting tank, the collecting tank can be driven by a maltese mechanism to do transverse stepping movement, and therefore the concrete blocks at different positions in the collecting tank can be fully crushed and refined, and the crushing efficiency is improved. The arranged net plate can vibrate in the mutual friction and butt joint process of convex blocks, screening of broken concrete on the net plate is accelerated, and the full and efficient crushing function on the concrete on the net plate is guaranteed.

Owner:文明

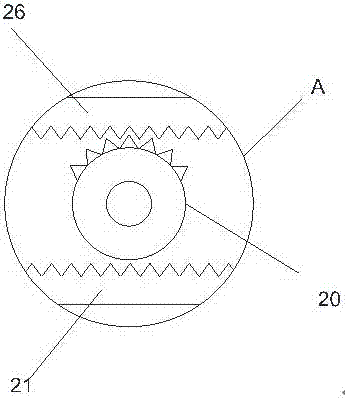

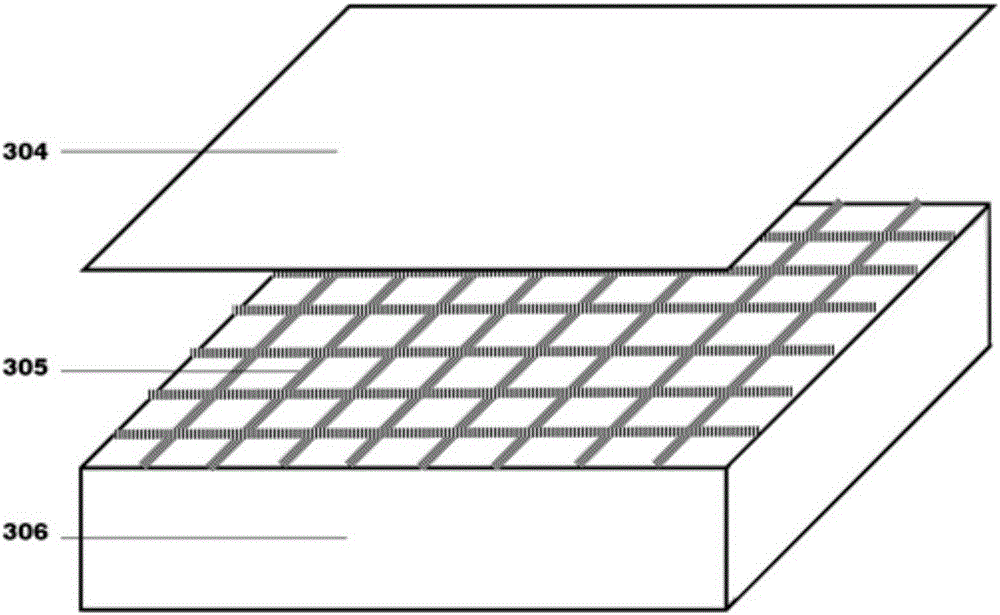

Harmless low-temperature carbonization treatment process of sludge

The invention discloses a harmless low-temperature carbonization treatment process of sludge. The treatment process comprises the following steps: selecting garbage rich in plant fibers, putting the garbage into a crushing machine, performing crushing, adding the crushed plant fiber garbage into a screening box from a material inlet hopper of a screening machine, and driving a first motor to driveoverall vibration of the screening box under the action of first springs. According to the process provided by the invention, second teeth are matched with first teeth for use, so that a filter screen is convenient to install and disassemble, and the filter screen is convenient to replace and repair and convenient to use; a conveyor belt and an inclined plate are arranged, so that particle impactforce caused by falling of a pressing mechanism can be reduced, particles can be prevented from being splashed in the falling process to cause loss, the resources can be saved, and waste can be avoided; through conveying of the conveyor belt, manpower can be saved, and the working efficiency can be improved; and a fire grate rotates, so that residues can be eliminated, the air flow can be accelerated, the particle combustion is more full, and the carbonization rate is high.

Owner:克拉玛依顺通环保科技有限责任公司

Energy-saving type grain crushing air dryer

InactiveCN108452927APromote fragmentationSpeed up sievingDrying gas arrangementsGrain treatmentsDrive shaftEngineering

The invention discloses an energy-saving type grain crushing air dryer which comprises a body, wherein a material feeding pipe is vertically and fixedly mounted on the body; a movable cover plate is arranged on the material feeding pipe in a rotatable manner; a second motor is fixedly mounted on the right side wall of the body; an output shaft of the second motor is coaxially and fixedly equippedwith a driving shaft; a conical channel is formed inside the body; a horizontal rod is arranged in the conical channel; a rotating shaft is arranged on the horizontal rod in a rotatable manner. According to the energy-saving type grain crushing air dryer disclosed by the invention, a crushing roller drives a crushing blade to crush grains in a crushing meshed barrel in a rotatable manner, so thatcrushing of the grains is promoted, in addition, a rotary dispersion effect on the grains is achieved, screening of grain particles by the crushing meshed barrel is promoted, and drying of the grainsby hot air is accelerated; a grinding convex block and crushing teeth squeeze and grind the grains in a rotatable manner, so that the crushing and refining degree is greatly increased; the hot air canbe recycled inside the body, so as to realize cyclic and repeated use of heat energy; therefore, energy is greatly saved, and the grain drying efficiency is improved.

Owner:李凯

Sand screening device for construction

InactiveCN110124991ASpeed up sievingImprove sand screening efficiencySievingScreeningDrive shaftArchitectural engineering

The invention discloses a sand screening device for construction, and belongs to the field of architectural engineering. The sand screening device for construction comprises a screening box and a vibrating screen plate, wherein the drive end of a motor is connected with a third rotary shaft; one end, away from the inner side wall of a drive cavity, of a fourth rotary shaft passes through a partition, extends into a screening cavity, and the extending end is connected with a dispersing assembly; one end, away from the third rotary shaft, of a first linking assembly is connected to one end, inside a drive shaft, of a second rotary shaft; one end, away from a rotary rod, of a transmission assembly is connected to the rod wall, inside the drive cavity, of the fourth rotary shaft; and one end,away from a rotary rod, of a reciprocating mechanism is connected to the side wall of the vibrating screen plate. The motor works to drive a first pressure roller and a second pressure roller for pressing sand through the first linking assembly, the dispersing assembly disperses pressed sand onto the vibrating screen plate, and the reciprocating mechanism drives the vibrating screen plate to shakeback and forth to perform sand screening, so that sand screening speed is quickened, and working efficiency of the device is improved.

Owner:南京市月华路小学

Agricultural wheat grain impurity removal device

The invention discloses an agricultural wheat grain impurity removal device. The device comprises a box body, wherein a feed hopper is fixedly arranged at the top end of the box body; two first fixedseats and two second fixed seats are fixedly arranged in the box body; a first screen plate is arranged between the two first fixed seats in a sliding mode; a first screen mesh is fixedly arranged onthe first screen plate; a second screen plate is arranged between the two second fixed seats in a sliding mode; a second screen mesh is fixedly arranged on the second screen plate; two ends of the bottom surface of the first screen plate are fixedly connected with first chock blocks; two ends of the top surface of the second screen plate are fixedly connected with second chock blocks; a horizontalrotating shaft is arranged between the first screen plate and the second screen plate; the rotating shaft is fixedly connected with two cams; and a driving motor is fixedly arranged at one side of the exterior of the box body. The driving motor is adopted to drive the cams to rotate so as to enable the first screen mesh and the second screen mesh to shake up and down, thereby increasing the wheatgrain impurity removal speed and efficiency; and by arranging a fan, impurities in wheat grains can be separated more perfectly.

Owner:朱明新

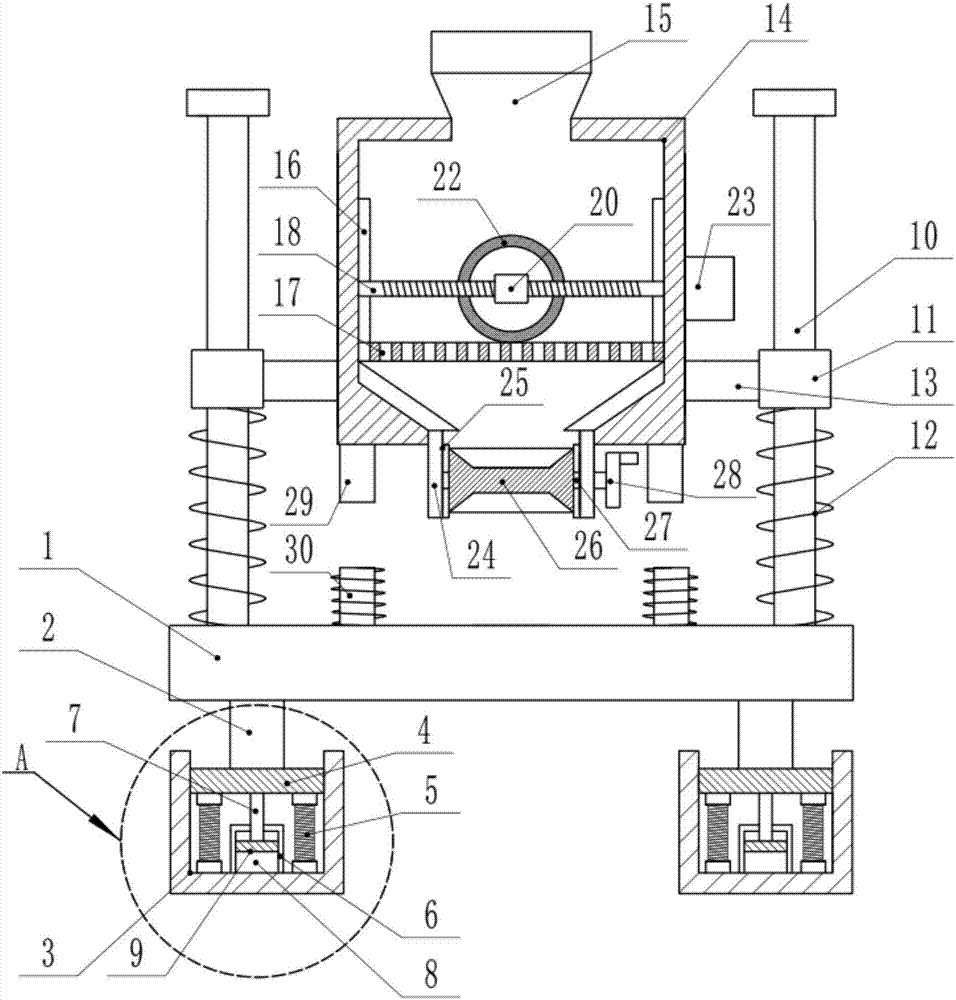

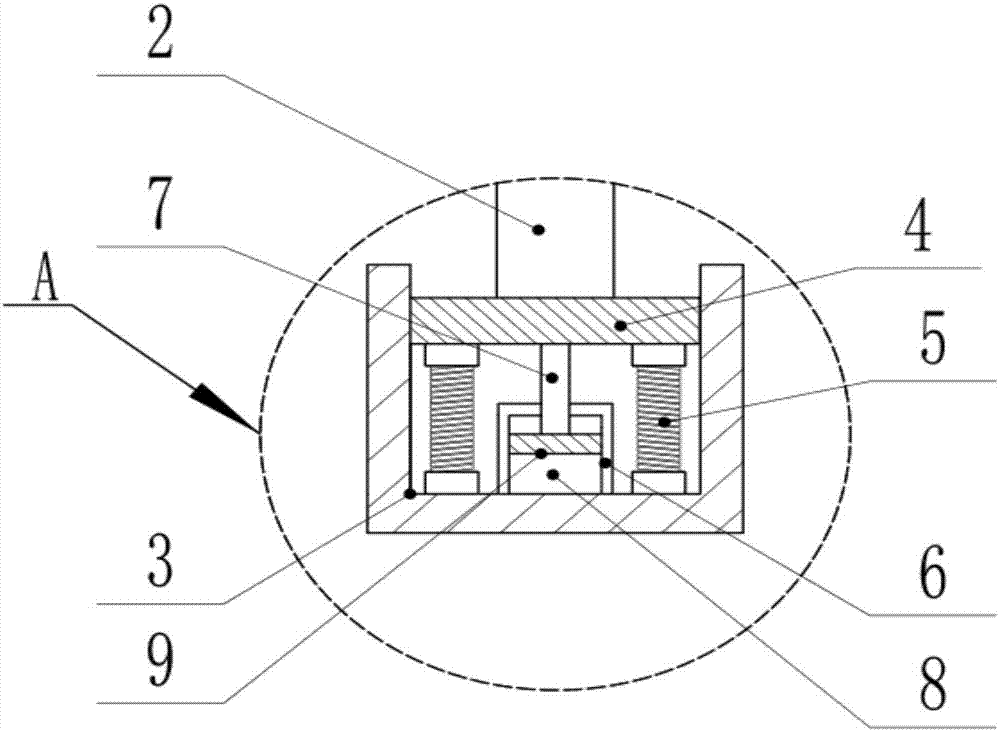

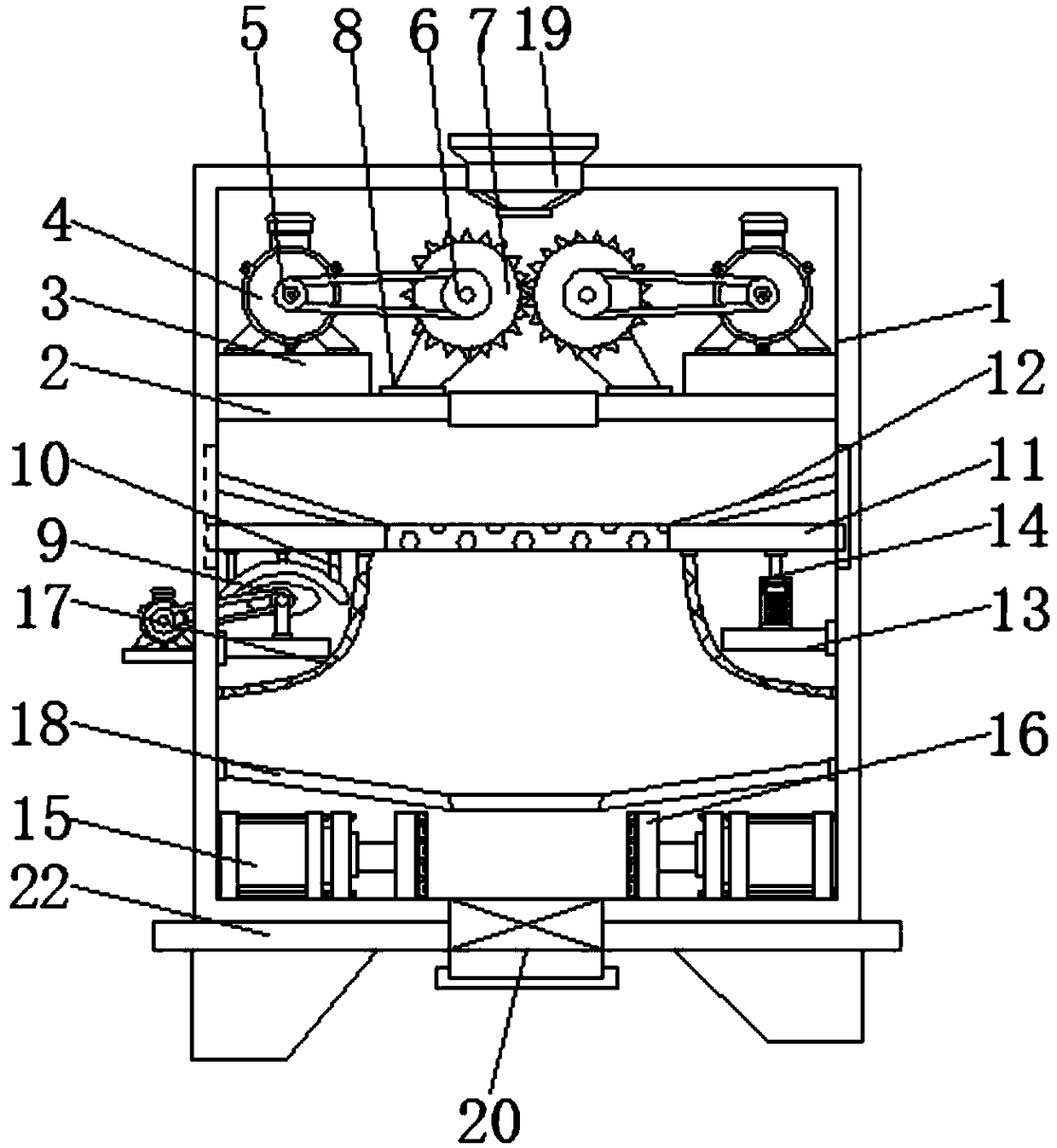

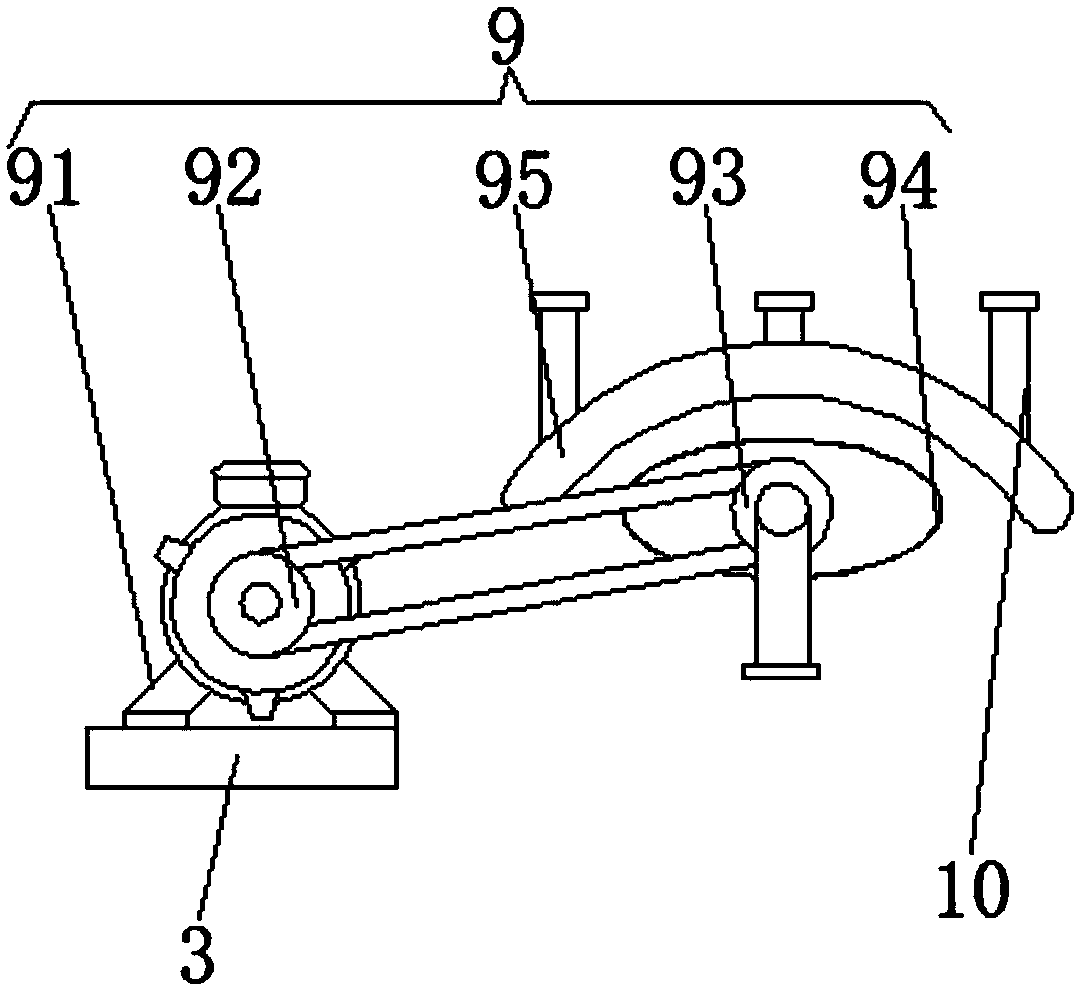

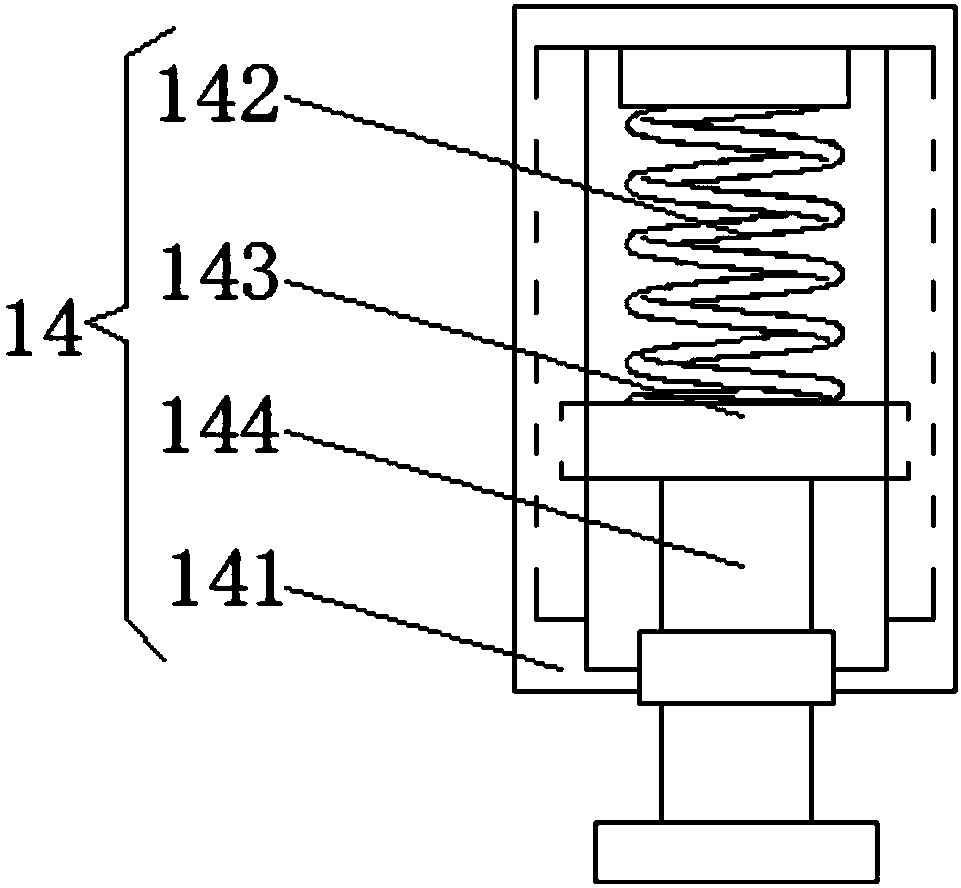

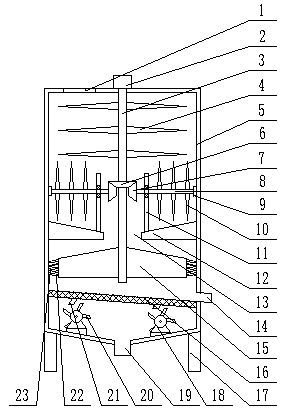

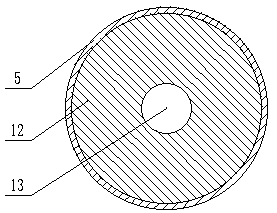

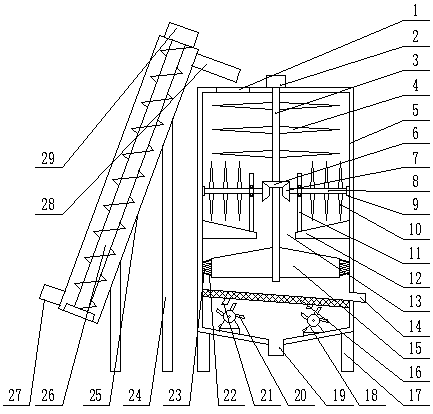

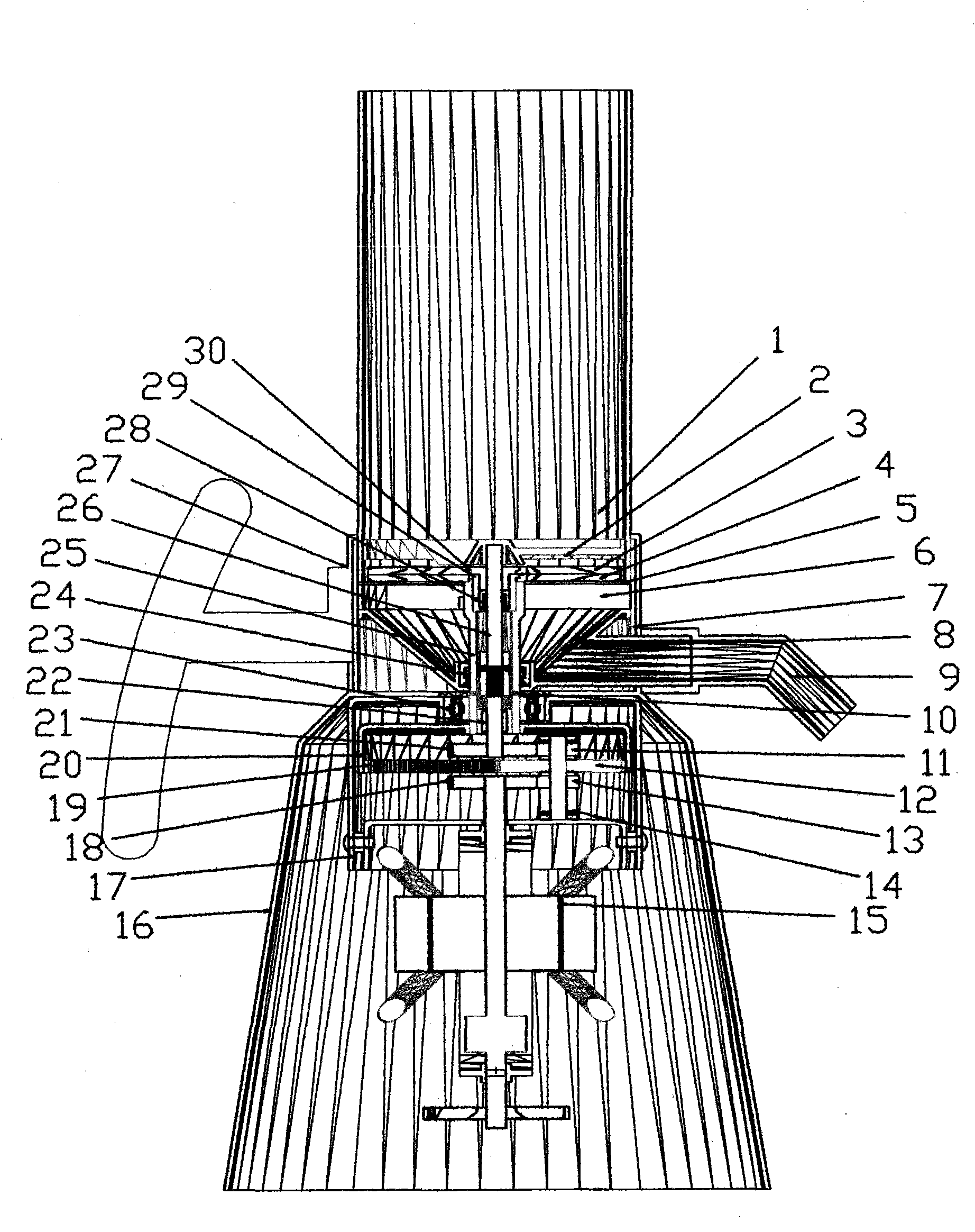

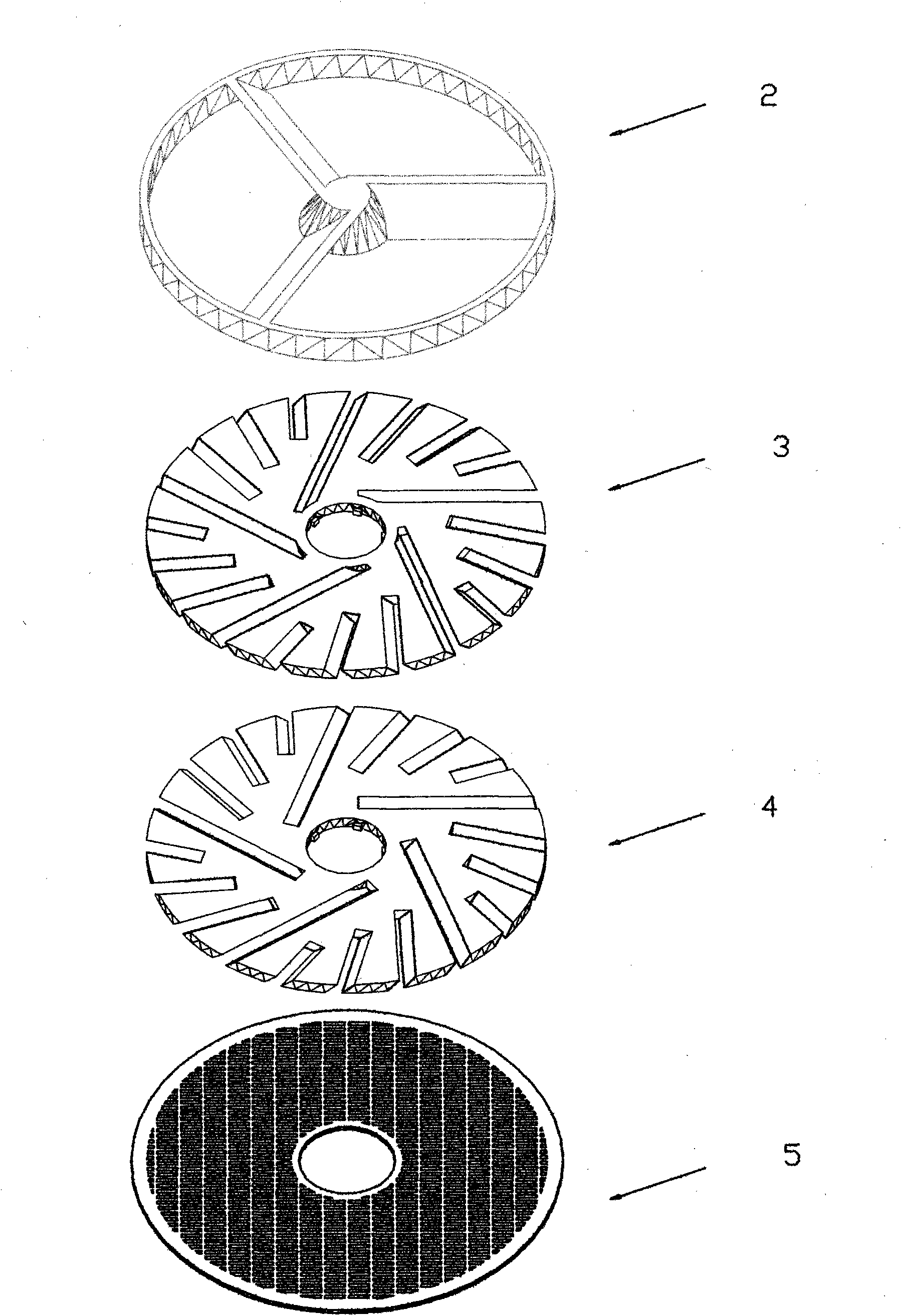

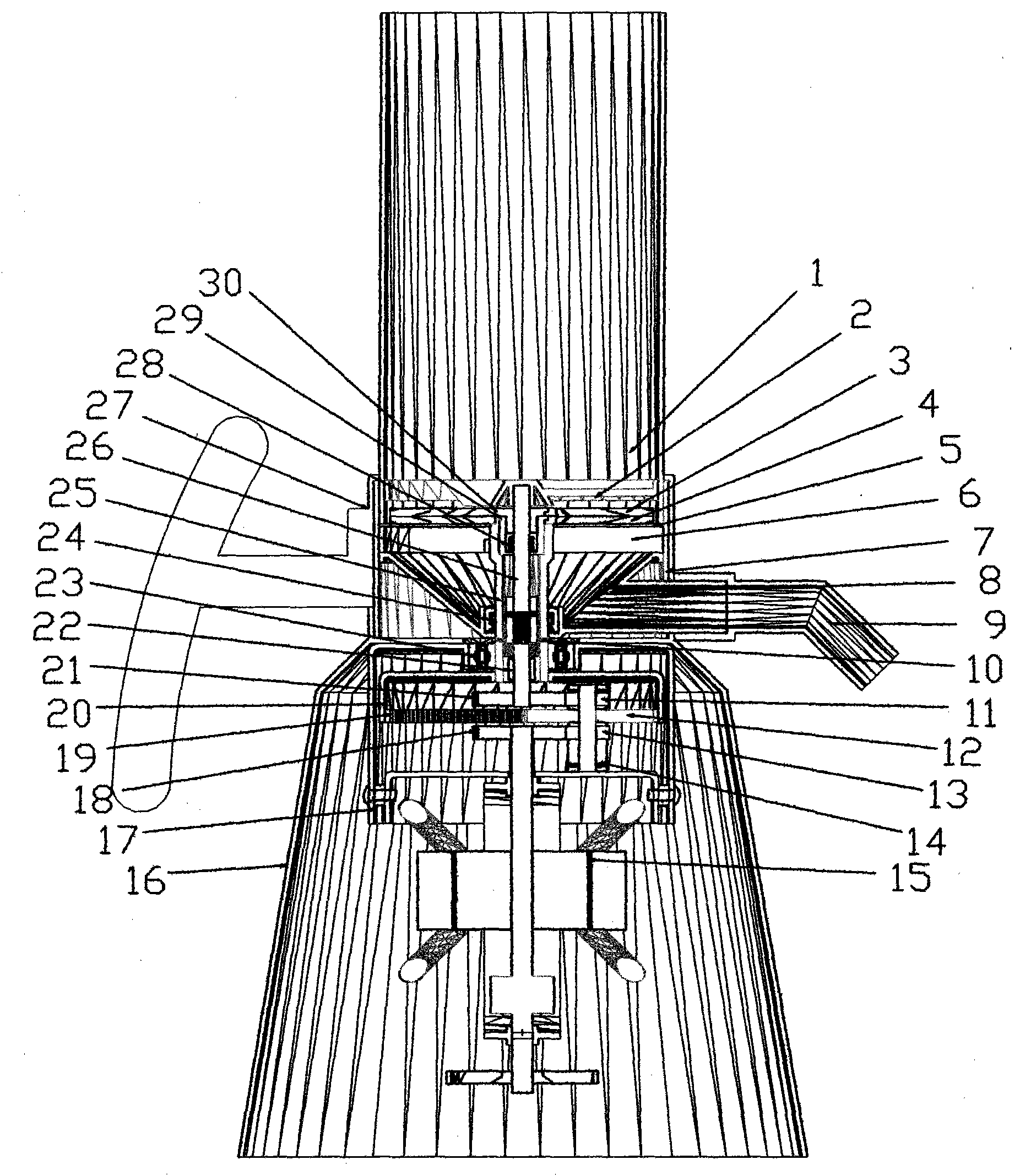

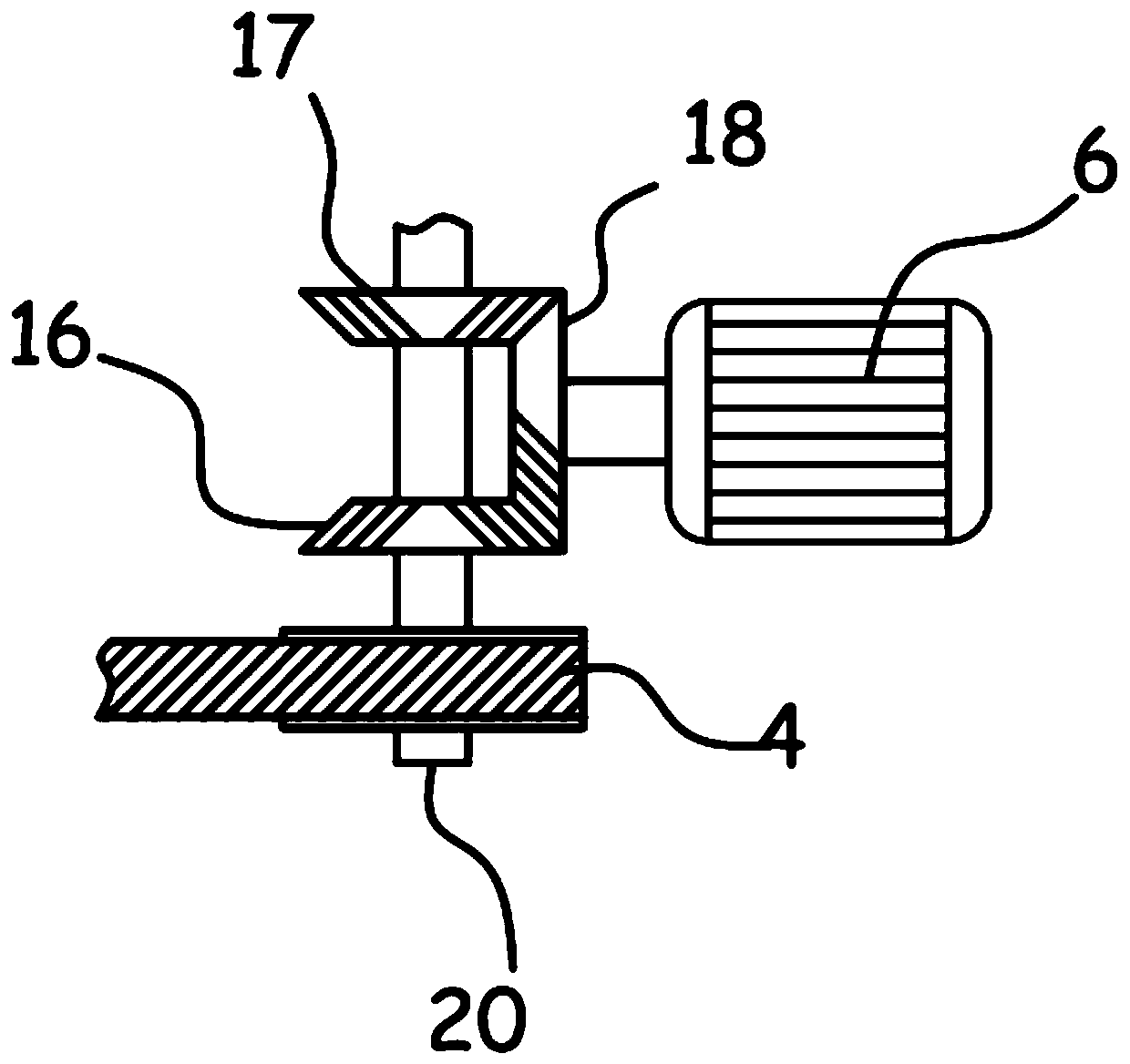

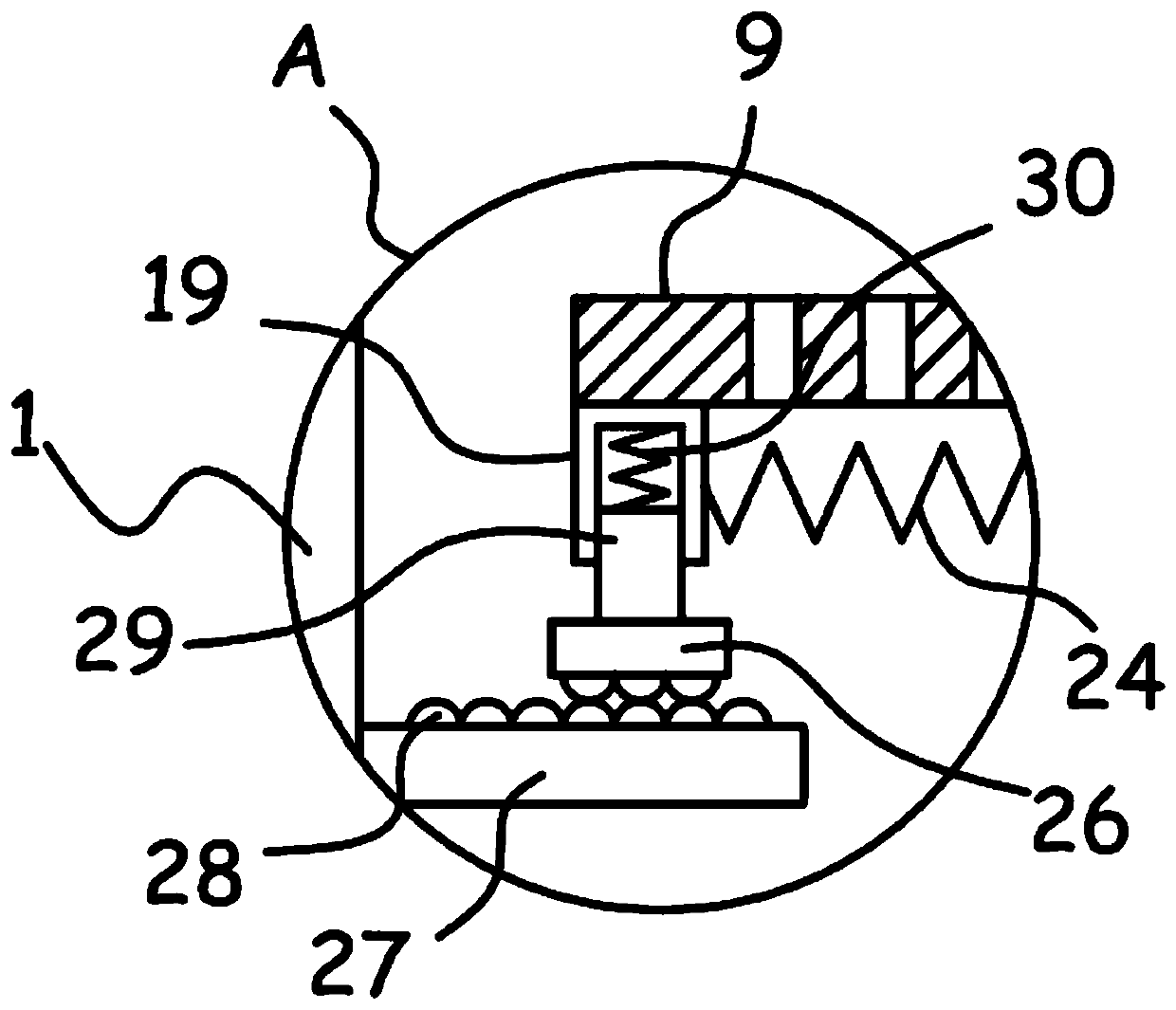

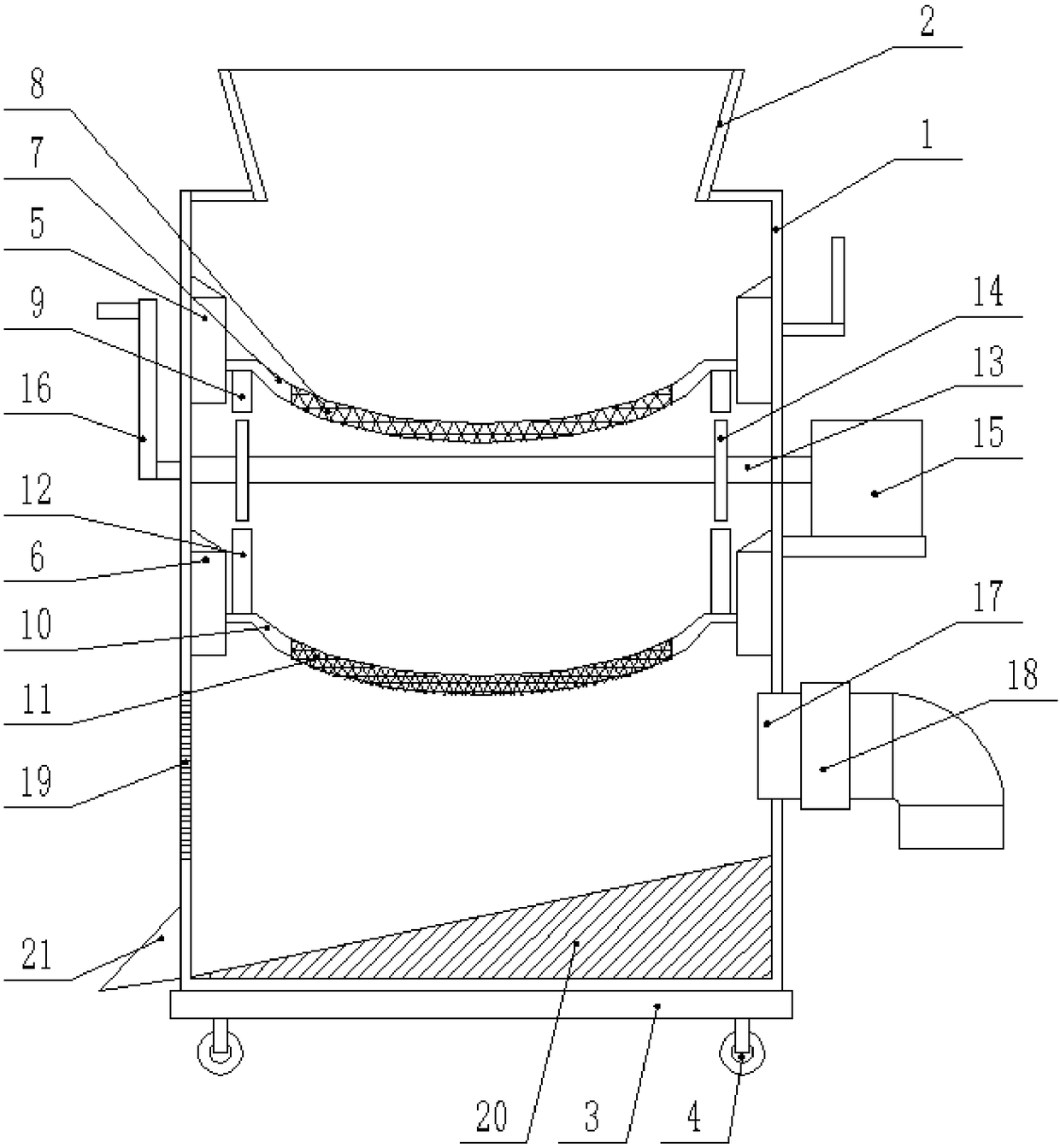

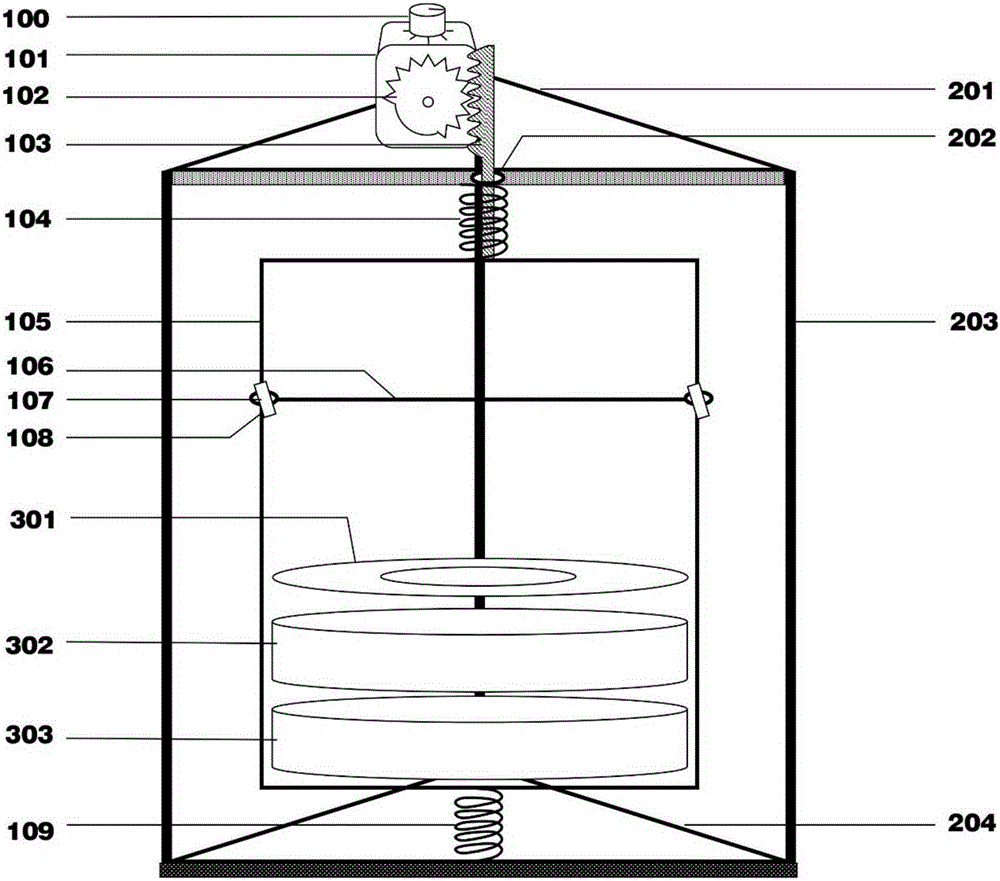

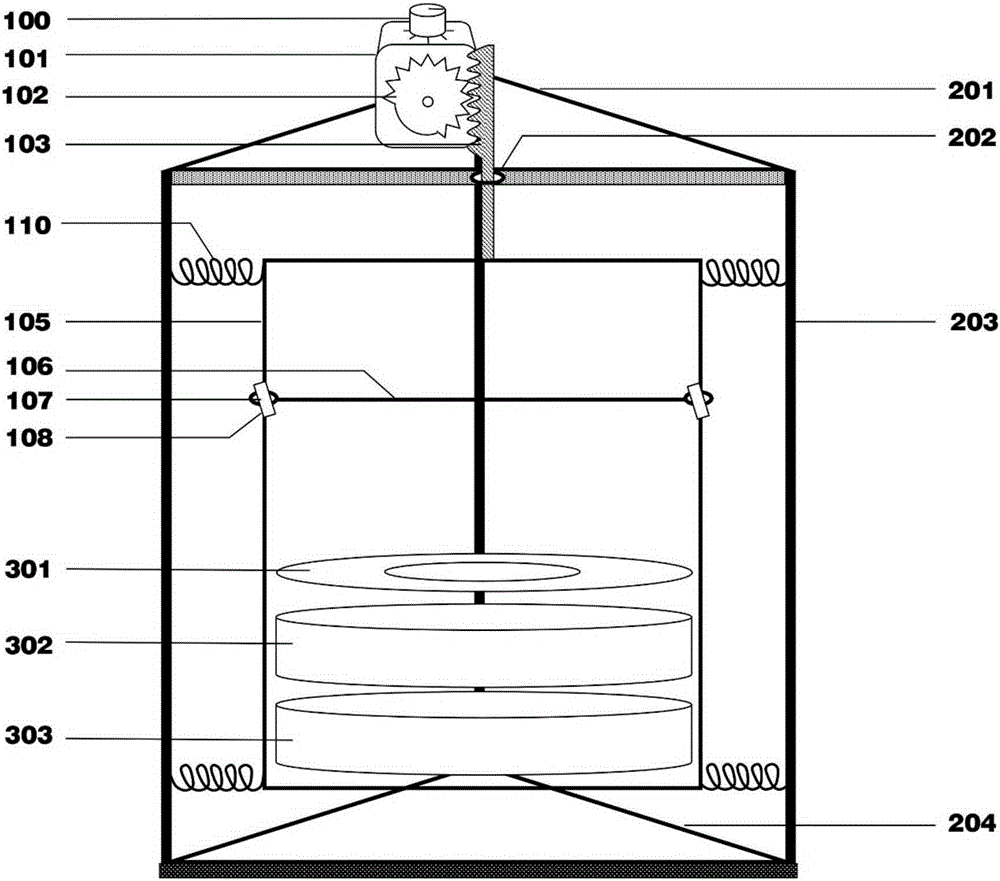

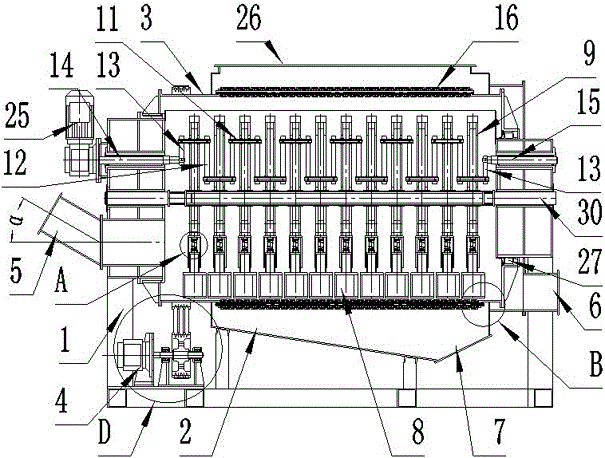

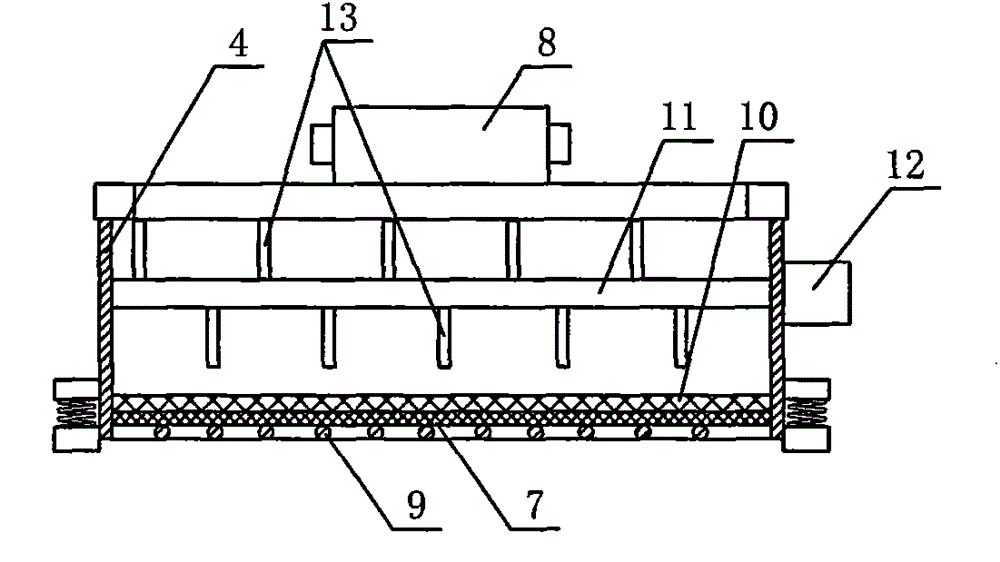

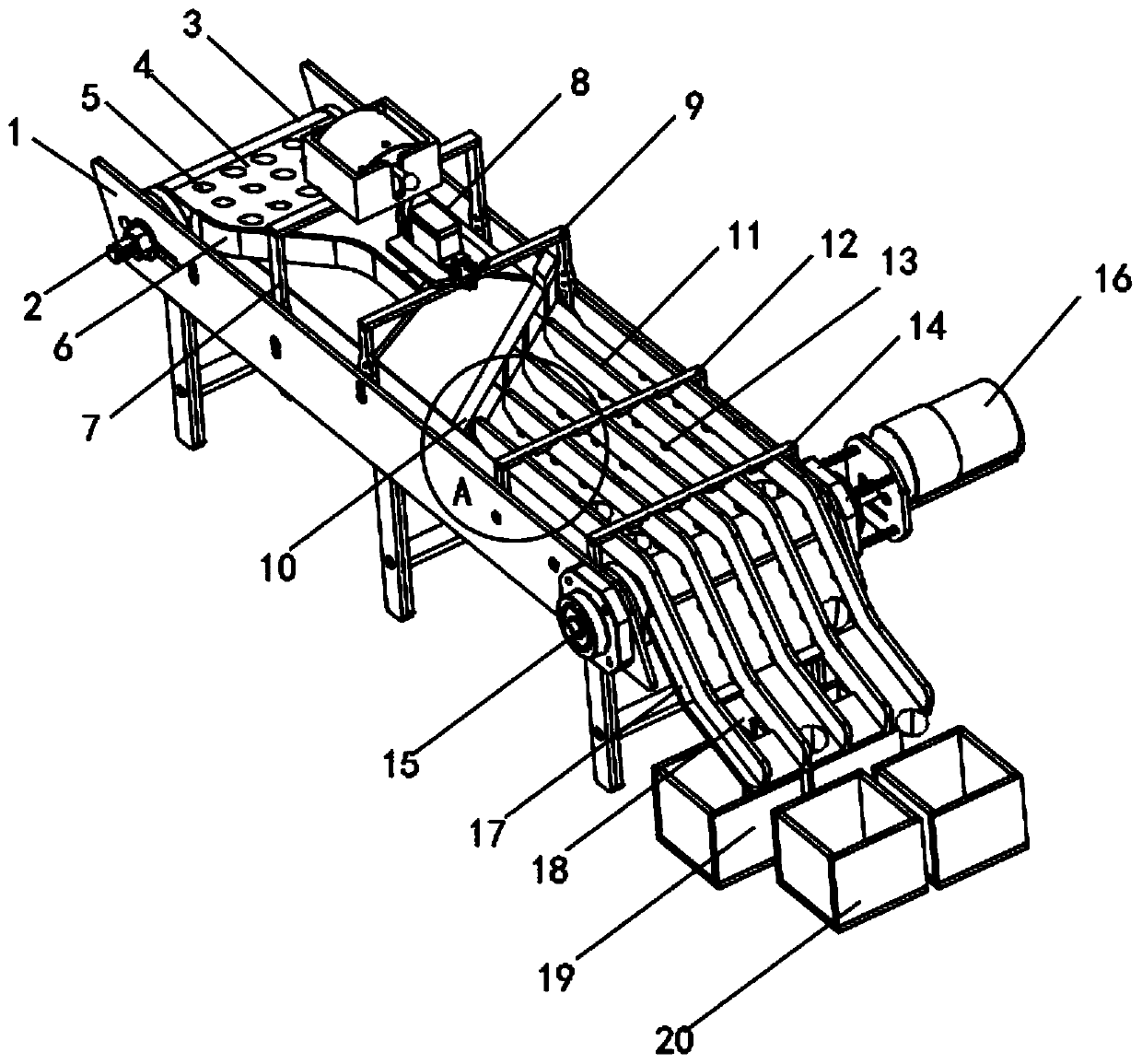

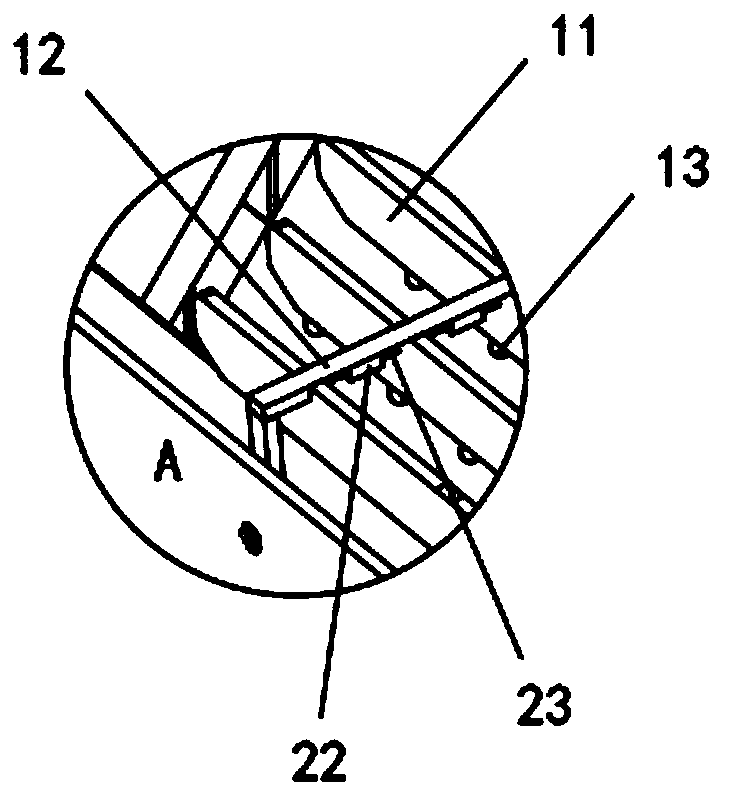

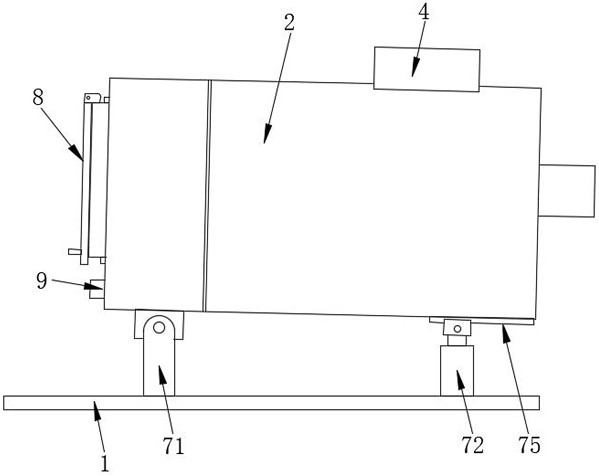

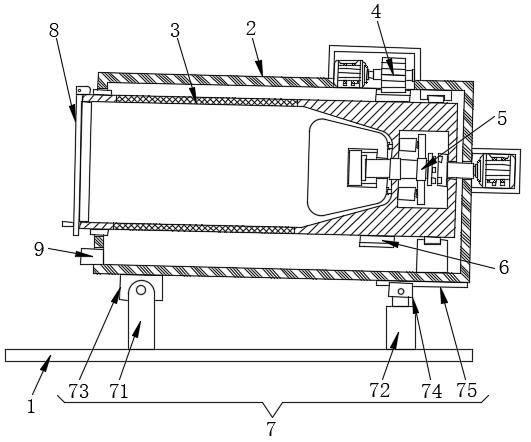

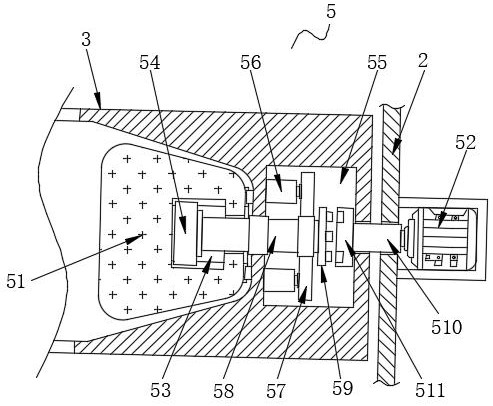

Vertical pulse type electric vibrating and screening machine and use method thereof

ActiveCN105170457AImprove general performanceLower acquisition costsSievingShaking/oscillating/vibrating mixersEngineeringOscillatory function

The invention discloses a vertical pulse type electric vibrating and screening machine and a use method thereof. The vertical pulse type electric vibrating and screening machine comprises a supporting frame, a square fixing frame, a vertical pulse driving device and a vibrating and screening device. The square fixing frame is arranged in the supporting frame and fixedly connected with the supporting frame through a plurality of elastic parts. A vertical rack is arranged on the top of the square fixing frame, an incomplete gear engaged with the rack is arranged on the upper portion of the supporting frame, and the incomplete gear, the rack and the elastic parts form the vertical pulse driving device together. The vibrating and screening device and the square fixing frame form an integrated structure and perform periodic vertical pulse movement under the action of the vertical pulse driving device. By the adoption of the structure and the method, screening and vibrating functions can be achieved at the same time, a screen can be prevented from being blocked, and the efficiency of the screen is improved; vibrated samples can be quickly and fully mixed, so that the vibrating efficiency is improved; multiple screening functions can also be achieved through combination of different screens, so that the screening or vibrating effect is improved.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI

River sand screening device for construction

ActiveCN111054631ASmooth slidingIncrease profitSievingSand dryingEnvironmental engineeringSand filter

The invention discloses a river sand screening device for construction. The sand screening device comprises a sand feeding hopper, a drying cylinder, a primary screening device and a secondary sand screening device, the drying cylinder is mounted at the upper end of a bracket; the drying cylinder is of a double-layer hollow structure, a heating block is arranged between the outer cylinder wall andthe inner cylinder wall of the drying cylinder; one end of the drying cylinder is connected with a sand inlet hopper; the other end of the drying cylinder is communicated with the primary screening device; the primary screening device is a sand screening barrel; the sand screening barrel is installed on a supporting frame, first screening holes are formed in the side wall of the sand screening barrel, the second-stage sand screening device comprises a swing frame and a sand filtering plate, a sand screening plate is fixed to the upper end of a swing frame, second screening holes are formed inthe sand screening plate, the swing frame is connected with the supporting frame and located below the sand screening barrel, and the sand screening plate and the sand screening barrel are opposite in inclination direction. The problem that wet sands with small particles are mutually adhered is solved, the working efficiency is improved, the screening effect is improved, the utilization rate of the sand is increased, waste is avoided, and the construction cost is reduced.

Owner:济南工程职业技术学院

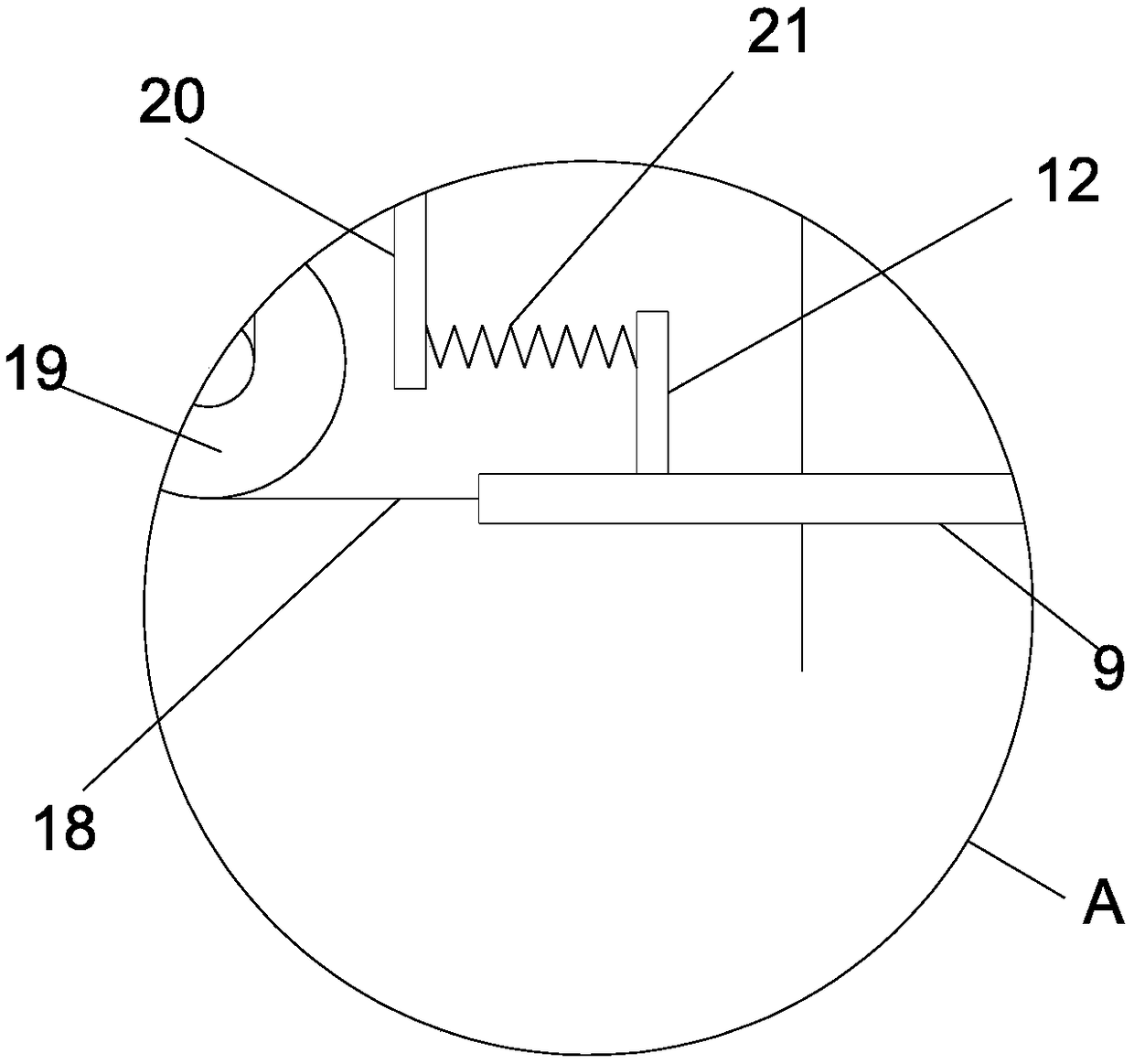

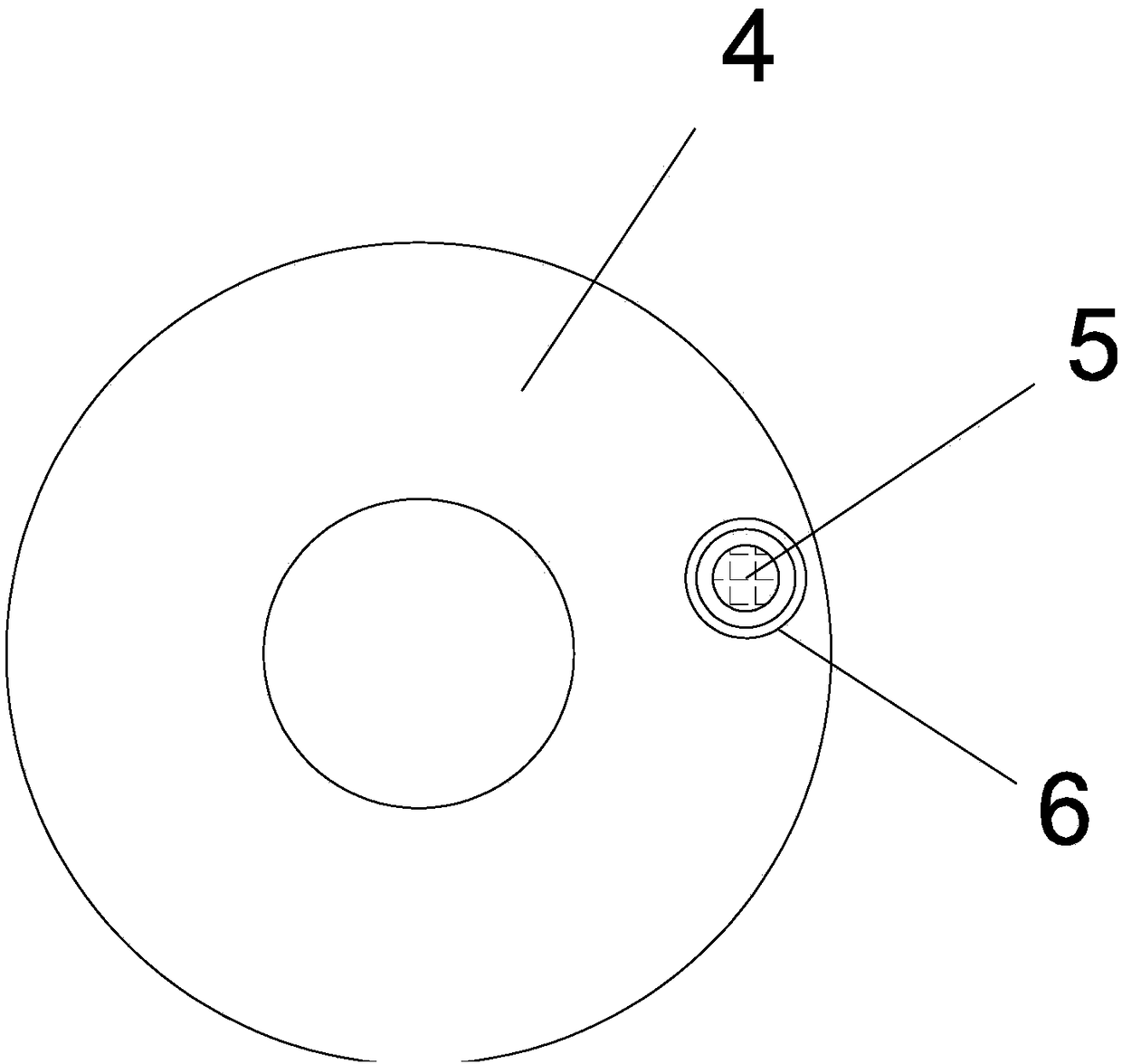

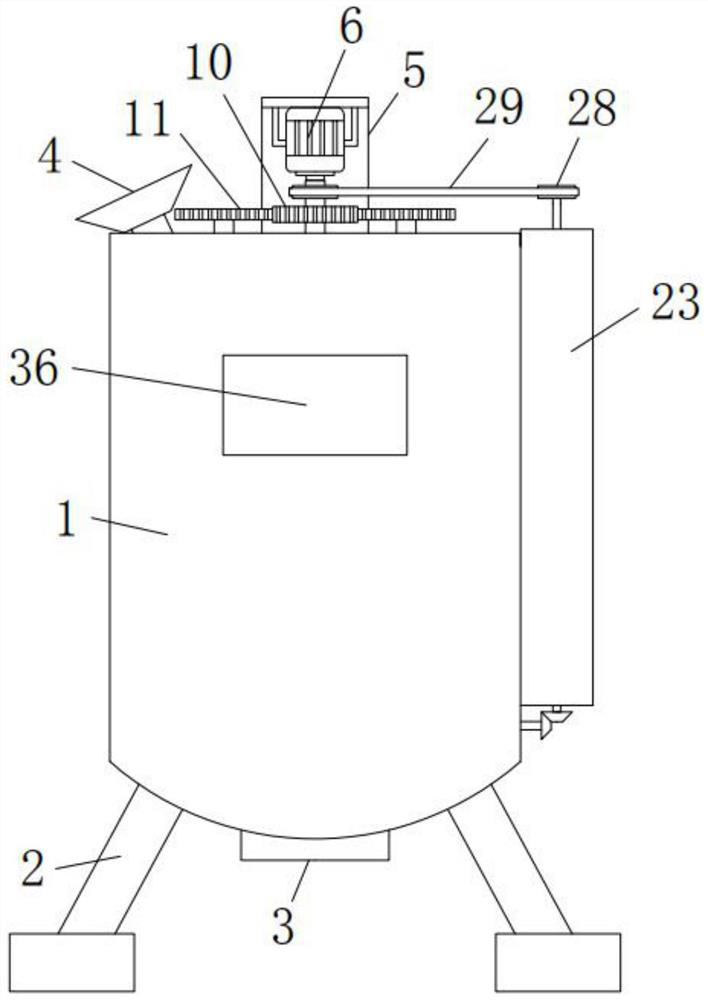

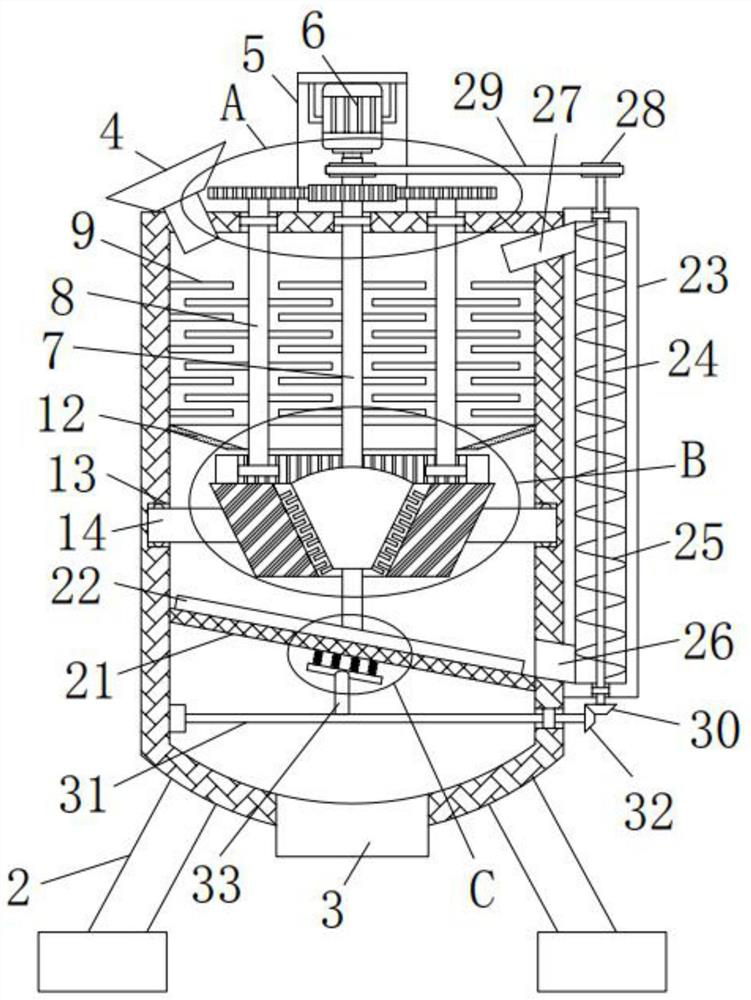

Material processing device capable of purifying agricultural crops

The invention discloses a material processing device capable of purifying agricultural crops. The material processing device comprises a machine body, wherein a feeding hole and a discharging hole are formed in the machine body respectively; a driving motor is fixedly mounted outside one side of the machine body; and the machine body is internally provided with a primary purification assembly and a deep purification assembly, which are driven by the driving motor respectively. According to the material processing device disclosed by the invention, an inner box with a hollow structure is arranged and two rotary shafts are arranged in the inner box by utilizing meshing transmission; the two rotary shafts drive a pressurizing cam to rotate horizontally so as to extrude a retractable rod which is elastically supported by a strong spring; a rotary table provided with four driving magnetic blocks is arranged in a sleeving manner, so that a piston retractable part can be vertically retracted synchronously and materials with different precision are primarily sorted; two crushing shafts are driven by utilizing the meshing transmission to rotate at a high speed so as to further crush the materials; and a deep-grade screen is extruded and supported by a rhombus convex disc which rotates along three rotary shafts, so that the crushed materials are screened for the second time and the materials meeting the precision requirement standard are selected.

Owner:NANTONG JINCHI MECHANICAL ELECTRIC

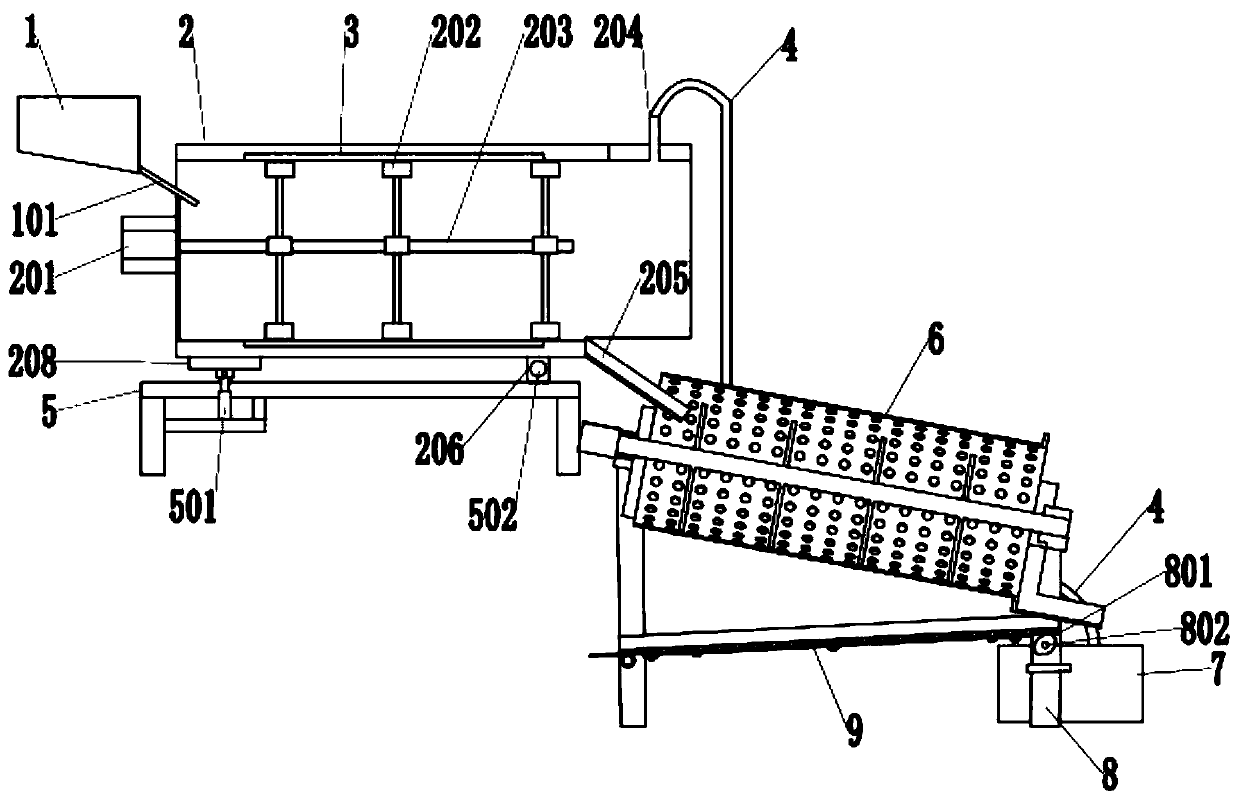

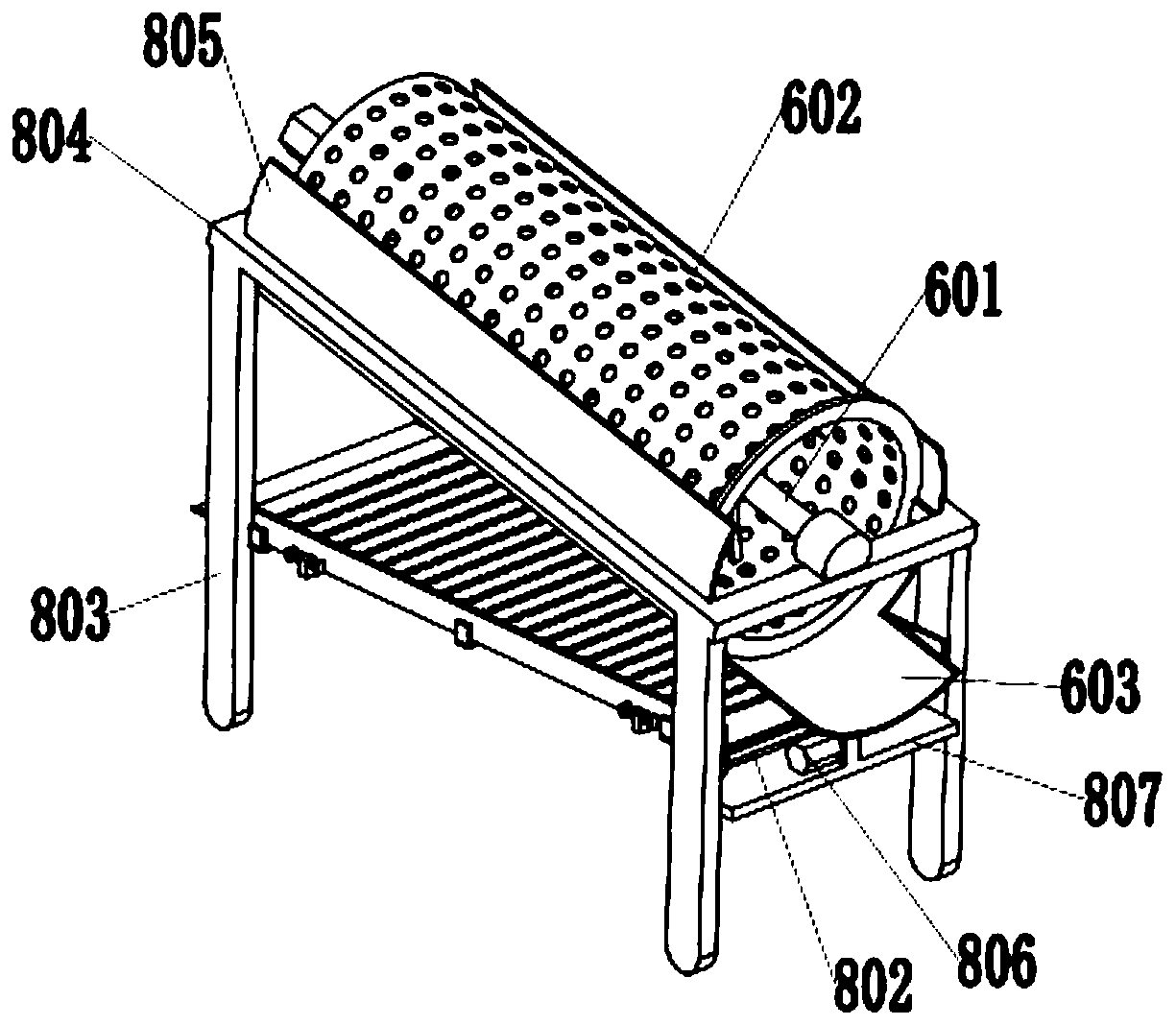

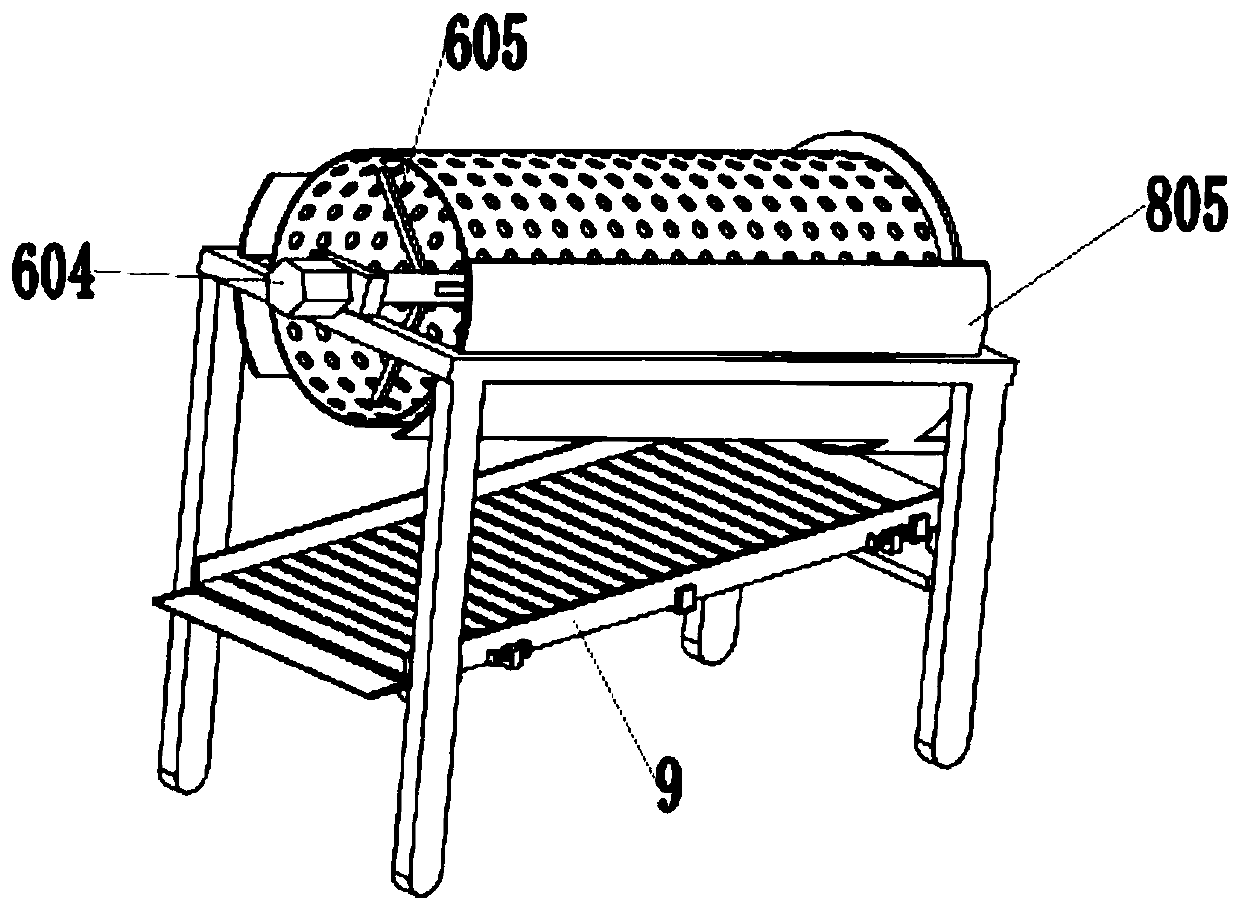

Sorting machine and kitchen waste treatment equipment

The invention discloses a sorting machine and kitchen waste treatment equipment comprising the sorting machine and relates to the technical field of garbage treatment. The sorting machine comprises a rack, a stock bin and a cylindrical roller with sieve pores at excircle. The roller is arranged in the stock bin and is driven by a first driving mechanism to rotate, the stock bin and a rotary shaft of the roller are arranged on the rack, a feed inlet is formed in one end of the stock bin while a slag outlet is formed in the other end, and a discharge port is formed in the lower portion of the stock bin; a sorting mechanism and a second driving mechanism thereof are separately arranged inside and outside the roller, the sorting mechanism in the roller is driven by the second driving mechanism to screen materials, the materials which are small in grain size enter the bottom of the stock bin from the sieve pores in the wall of the roller and are discharged from a discharge port, and the materials which are large in grain size are discharged from the slag outlet. By way of rotating the roller, the stirring and screening speeds of the materials can be accelerated, and large-grain-size materials are detained to plug the sieve pores as the materials stay on the inner wall of the roller for a long time, so that the materials are fully screened, the sorting efficiency is improved, and the sorting quality of kitchen wastes is guaranteed.

Owner:WEIDE ENVIRONMENT TECH CO LTD

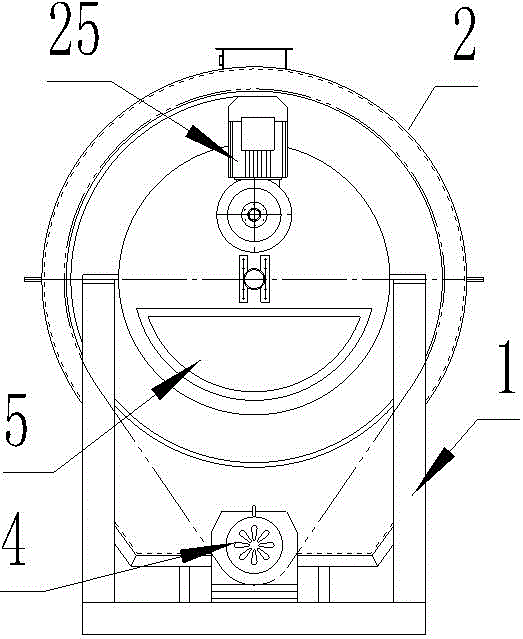

Viscous material filtering machine

InactiveCN103599656ASpeed up the flowSpeed up sievingMoving filtering element filtersCalcium hydroxideSlurry

The invention discloses a viscous material filtering machine which comprises a rack, wherein a lower material hopper is arranged on the rack; the bottom of the lower material hopper is connected with a material outlet pipe; a sieving frame which is positioned above the lower material hopper is also elastically connected with the rack; the top of the sieving frame is open; the rear part and the two side parts of the sieving frame are respectively provided with a sealing baffle; the front part of the sieving frame is provided with a taphole; the sealing baffle at the side is provided with a plurality of stirring and discharging devices; the bottom of the sieving frame is connected with a sieve net corresponding to an upper opening of the lower material hopper; a vibration motor is also arranged on the sieving frame. The viscous material filtering machine has the advantages that the structure is simple, a calcium hydroxide size can be purified in time, the purifying effect is good and the product quality is high.

Owner:GAOMI ANNAI RUBBER

Automatic screening equipment for toy production and processing

The invention discloses automatic screening equipment for toy production and processing, and can solve the problem that screening is influenced and screening missing appears easily because the currentautomatic screening equipment for toy production and processing has the defects that on one side, the width of channels for toy screening is constant, so that one device only can screen several kindsof gathered toys with specific specifications, and on the other side, a conveying belt is required to convey toys when the current equipment is in operation, and the toys are conveyed into the channels with corresponding width during conveying to realize simultaneous conveying and screening, but a large number of toys can be stacked before entering the screening channels and block inlets of the screening channels. The automatic screening equipment comprises a support and a conveying belt located on the support, wherein an auxiliary shaft is connected to one end of the conveying belt in a penetrating manner; a main shaft is connected to the other end of the conveying belt in a penetrating manner, and is connected with a driving motor located on the side wall of the support.

Owner:GUANGDONG SEMBO CULTURE IND CO LTD

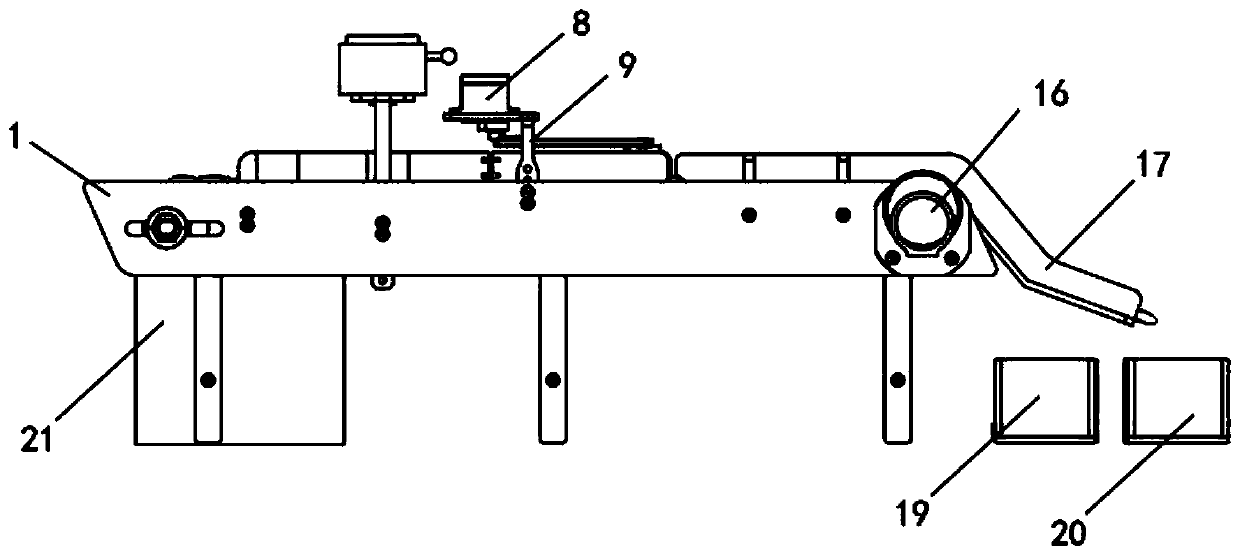

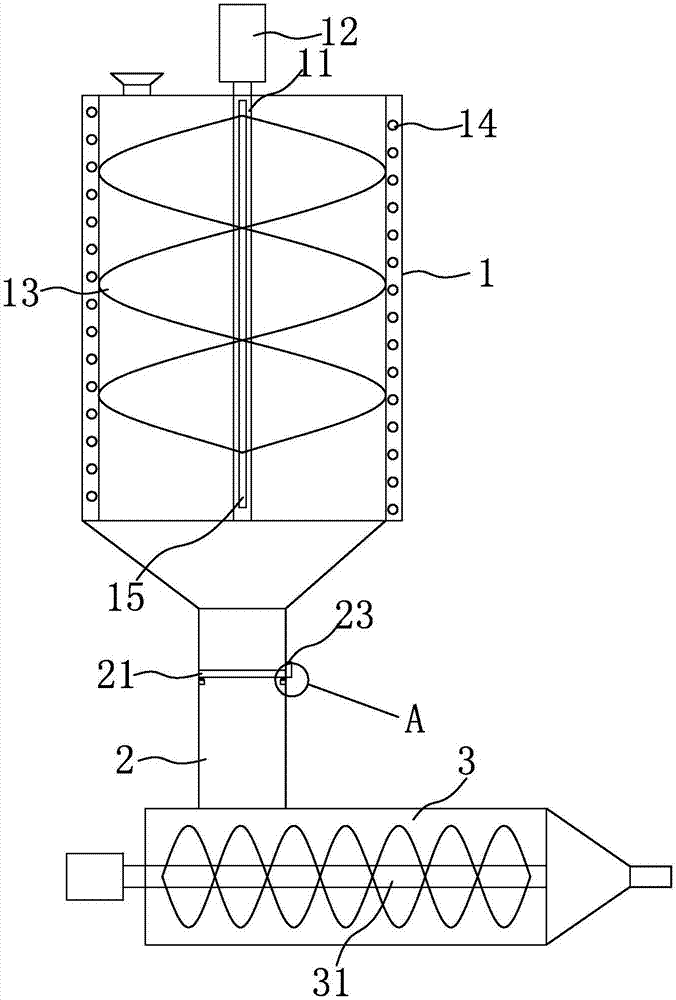

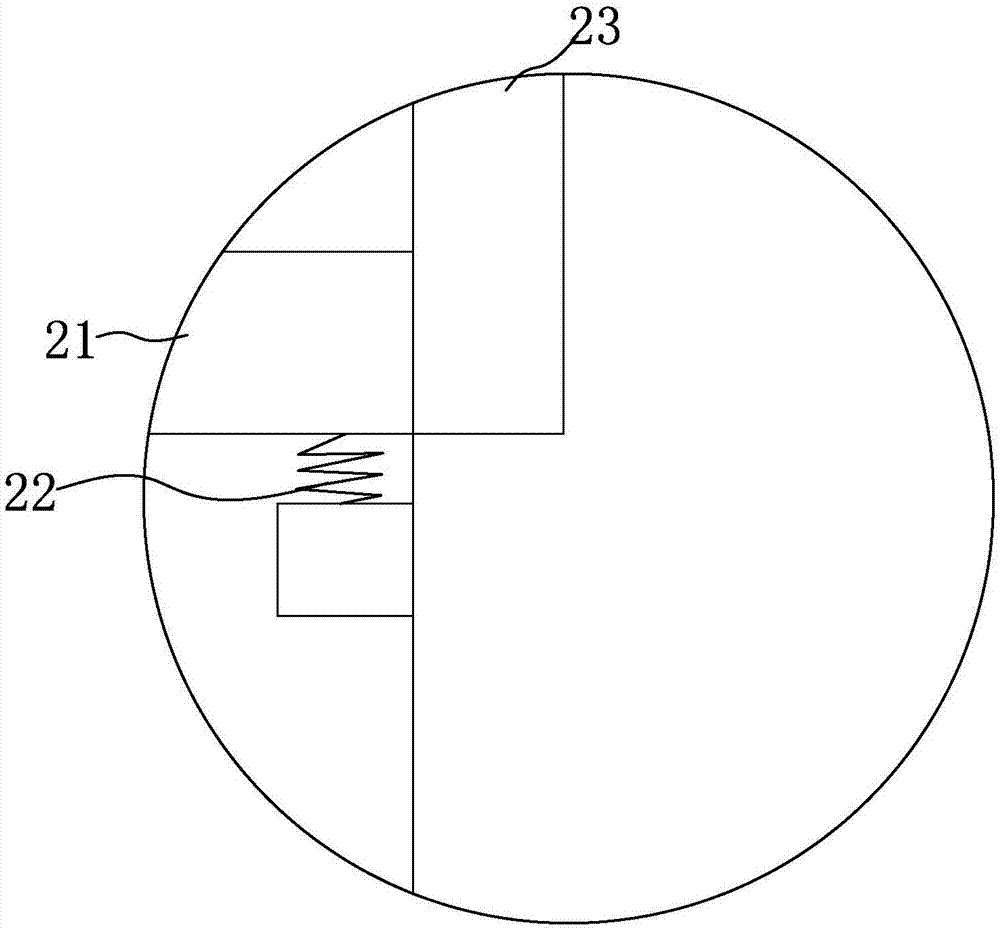

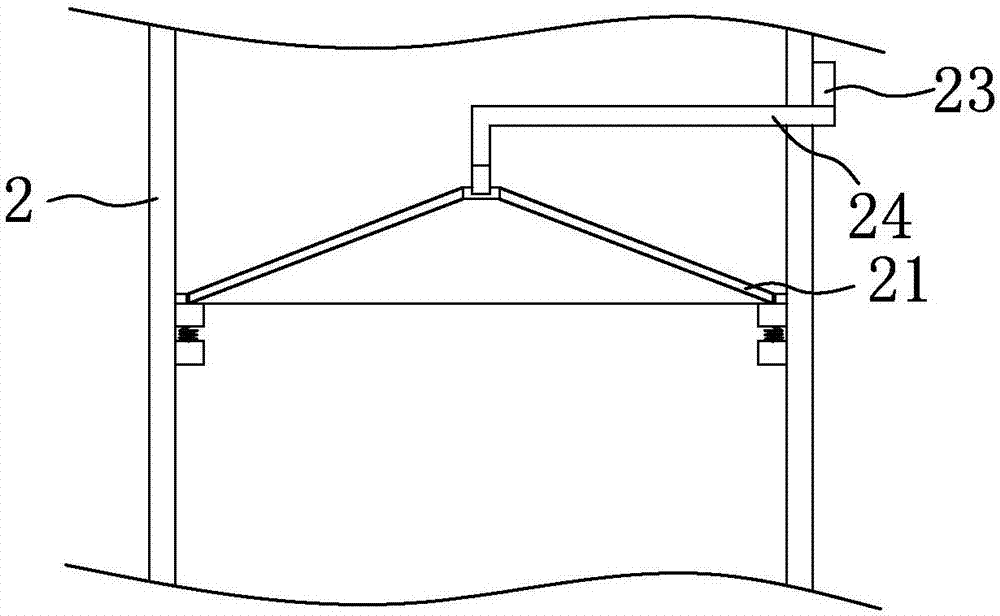

Tea processing and transporting system capable of screening tea in time and collecting tea separately

InactiveCN111841821AEvenly dispersed stateImprove screening effectSievingPre-extraction tea treatmentProcess engineeringTea leaf

The invention provides a tea processing and transporting system capable of screening tea in time and collecting the tea separately. The tea processing and transporting system capable of screening thetea in time and collecting the tea separately comprises a drying device used for drying the tea, a scattering device used for scattering the tea, a screening device used for screening the tea and a transport device used for collecting the tea separately. According to the tea processing and transporting system capable of screening the tea in time and collecting the tea separately, provided by the invention, the drying device, the scattering device, the screening device and the transport device are arranged in cooperation to constitute a tea processing and transporting device, and transport processing of the tea is realized. The scattering device can conduct scattering treatment on the dried tea and scatter part of adhering tea to make the tea in a uniform scattered state. The tea processingand transporting system ensures that different sizes of tea can be rapidly separated along with movement of a screen net, the screening speed is greatly increased, and the screening effect of the teais further improved.

Owner:安徽丰源机械有限公司

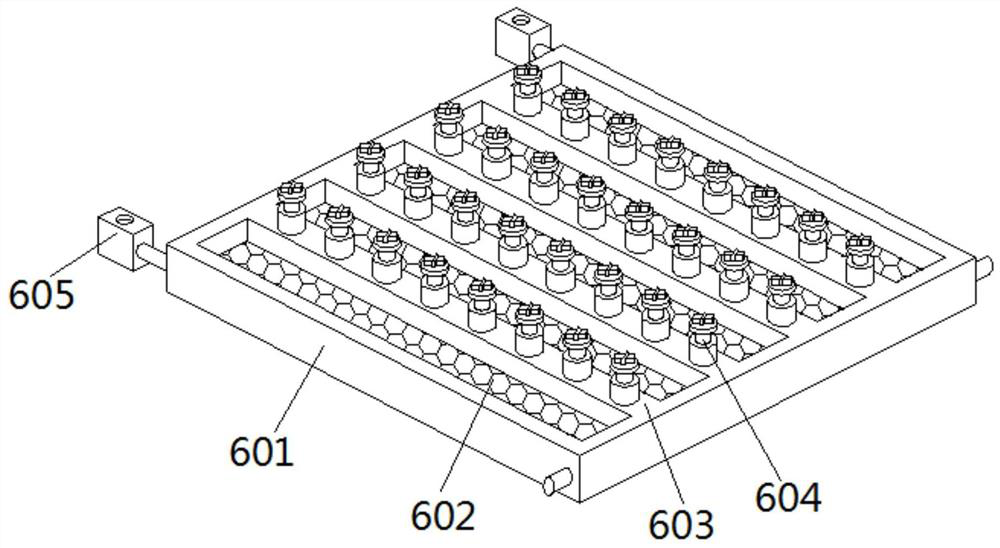

Processing equipment for environment-friendly organic fertilizer

InactiveCN112473509AControl capacityImprove product qualityTransportation and packagingMixer accessoriesAgricultural scienceAgricultural engineering

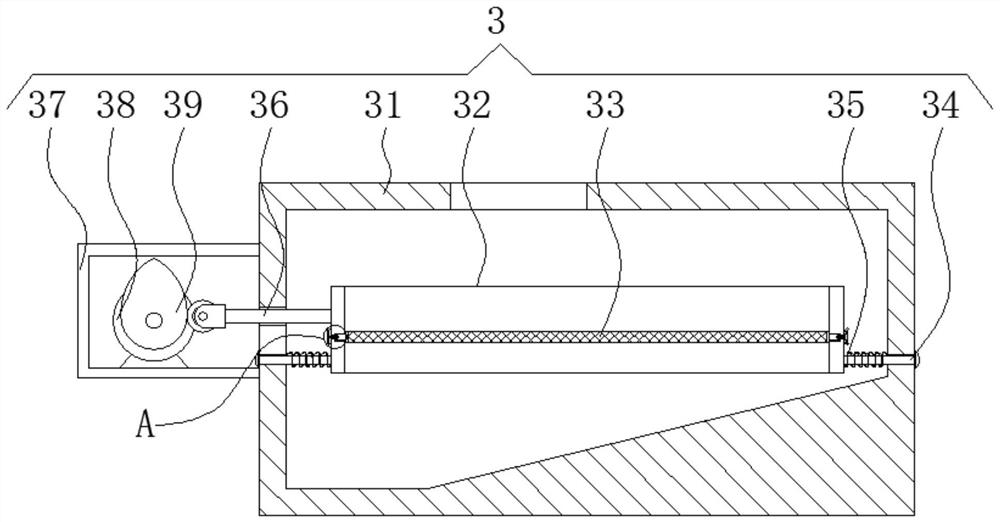

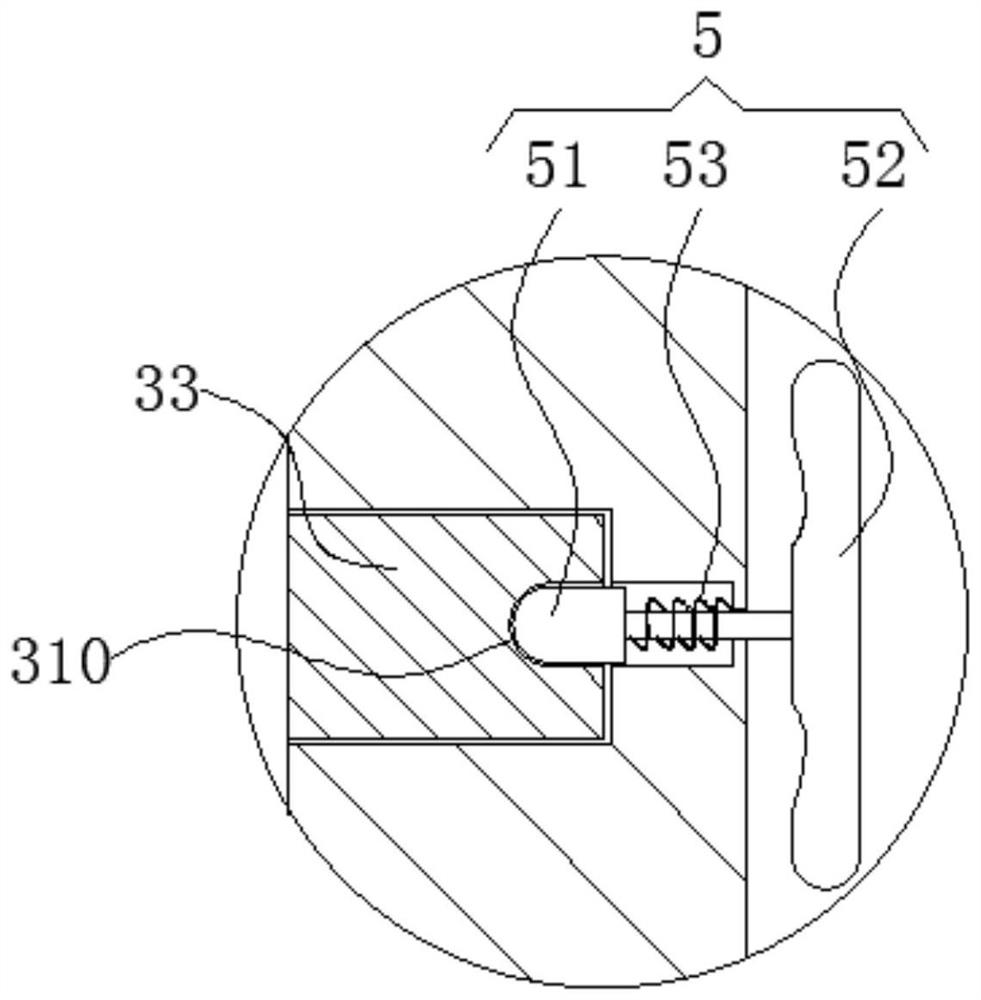

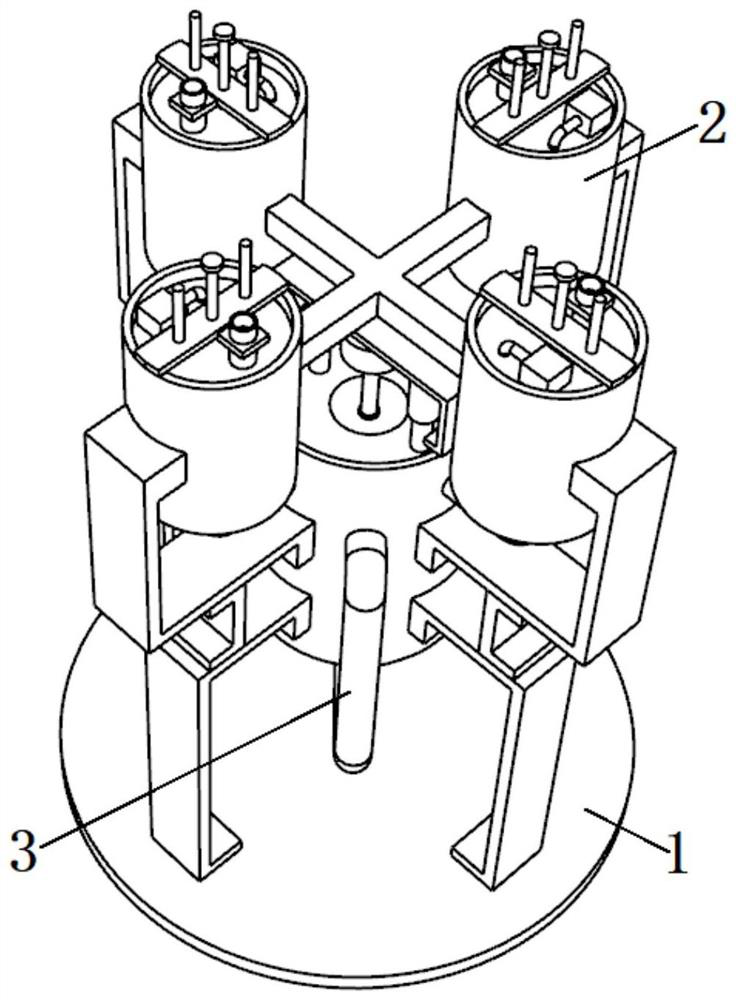

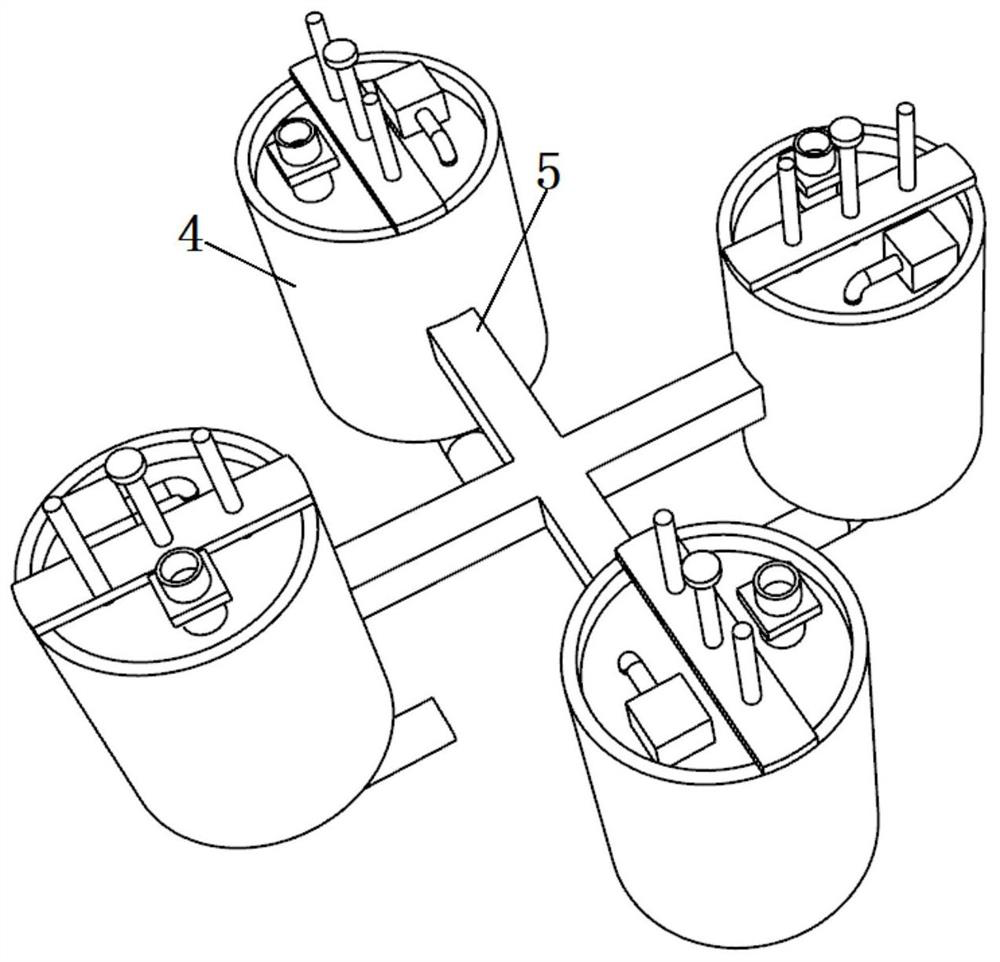

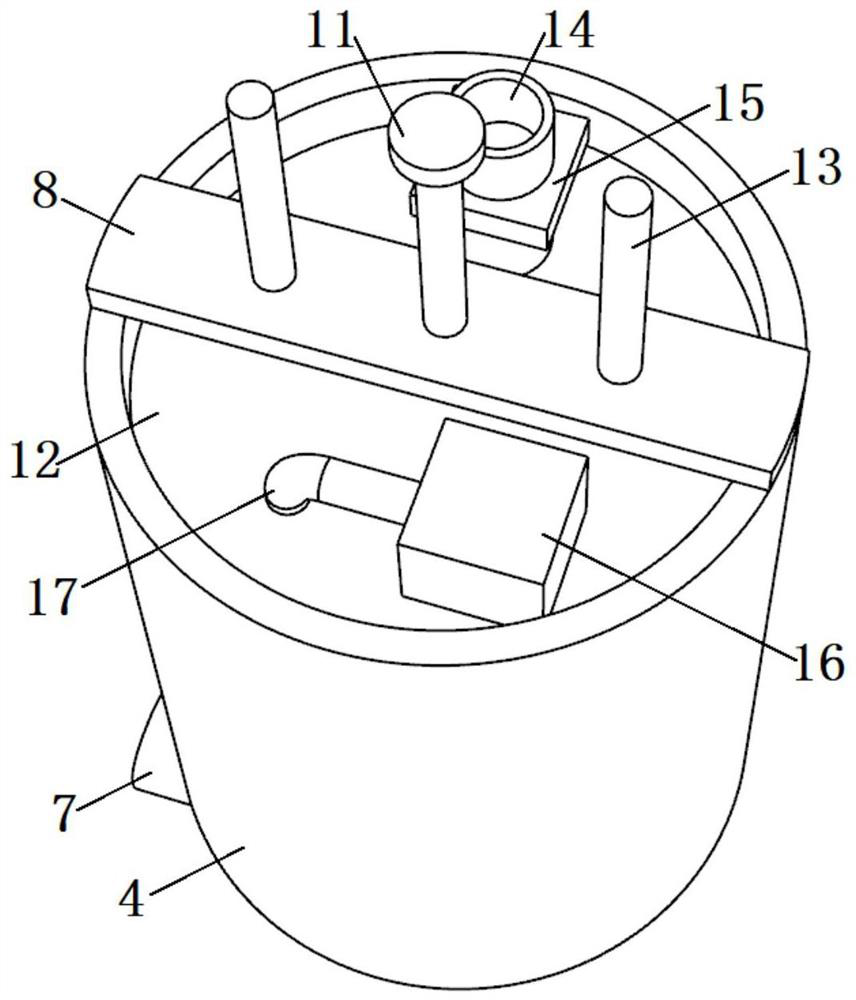

The invention discloses processing equipment for an environment-friendly organic fertilizer, and belongs to the technical field of fertilizer processing. The processing equipment comprises a supporting mechanism, wherein a quantitative feeding mechanism and a mixed material screening mechanism are fixed to the supporting mechanism, the quantitative feeding mechanism is located over the mixed material screening mechanism, the quantitative feeding mechanism comprises a plurality of feeding cylinders, the feeding cylinders are distributed in a circular array and fixedly connected through connecting plates, the bottom of each feeding cylinder is fixedly communicated with a first discharging hopper, and the bottom end of the first discharging hopper is fixedly communicated with a discharging pipe. According to the invention, the position of a first baffle in the feeding cylinder can be adjusted by screwing a bolt on the corresponding feeding cylinder, so that the capacity of the feeding cylinders for the organic fertilizer is effectively controlled, the plurality of feeding cylinders in the quantitative feeding mechanism can perform quantitative batching treatment on various kinds of organic fertilizer according to actual batching requirements, the batching accuracy is ensured, and the production quality of the organic fertilizer is better and the quality control is higher in the subsequent mixing processing production process.

Owner:肖海海

Crushing and sieving machine for building waste

InactiveCN109225434AAvoid destructionAvoid damageDirt cleaningGrain treatmentsMagnetic separatorEngineering

The invention relates to a crushing and sieving machine for building waste. The machine comprises a magnetic separator, wherein a feeding hole is formed in the upper part of the magnetic separator, afeeding cylinder is arranged on the right side of the magnetic separator, a crushing and feeding mechanism is arranged in the feeding cylinder, a material inlet is formed in the lower part of the feeding cylinder, a first crushing chamber is formed below the material inlet, a group of crushing wheels A are arranged in the first crushing chamber, and a first-stage sieving net is arranged below thecrushing wheels A; a second crushing chamber is formed below the first crushing chamber, and a group of crushing wheels B are arranged in the second crushing chamber; adjusting rails are formed in thefront and rear sides of the outer walls of the first crushing chamber and the second crushing chamber respectively corresponding to the crushing wheels A and the crushing wheels B, and a second-stagesieving net is arranged below the crushing wheel B; and dust branched pipes are arranged below the first-stage sieving net and the second-stage sieving net, dust suction pumps are arranged on the dust branched pipes, the dust branched pipes are commonly connected with a dust pipe, and the dust pipe is connected with a dust chamber. The crushing and sieving machine has the advantages of simplicityin operation, high crushing efficiency and reasonability in use.

Owner:禹州金科再生资源有限公司

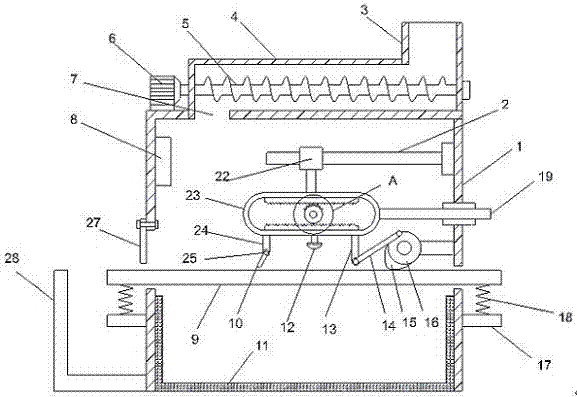

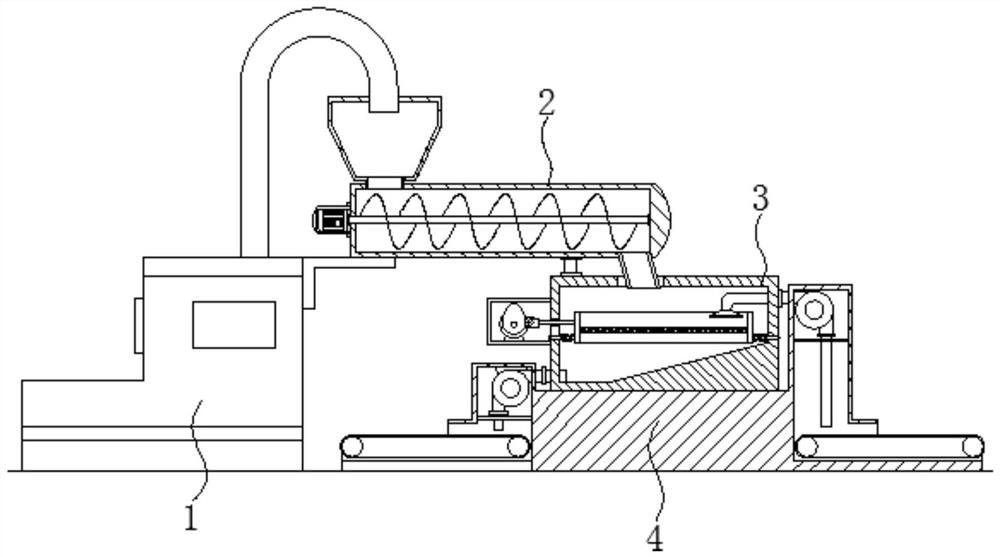

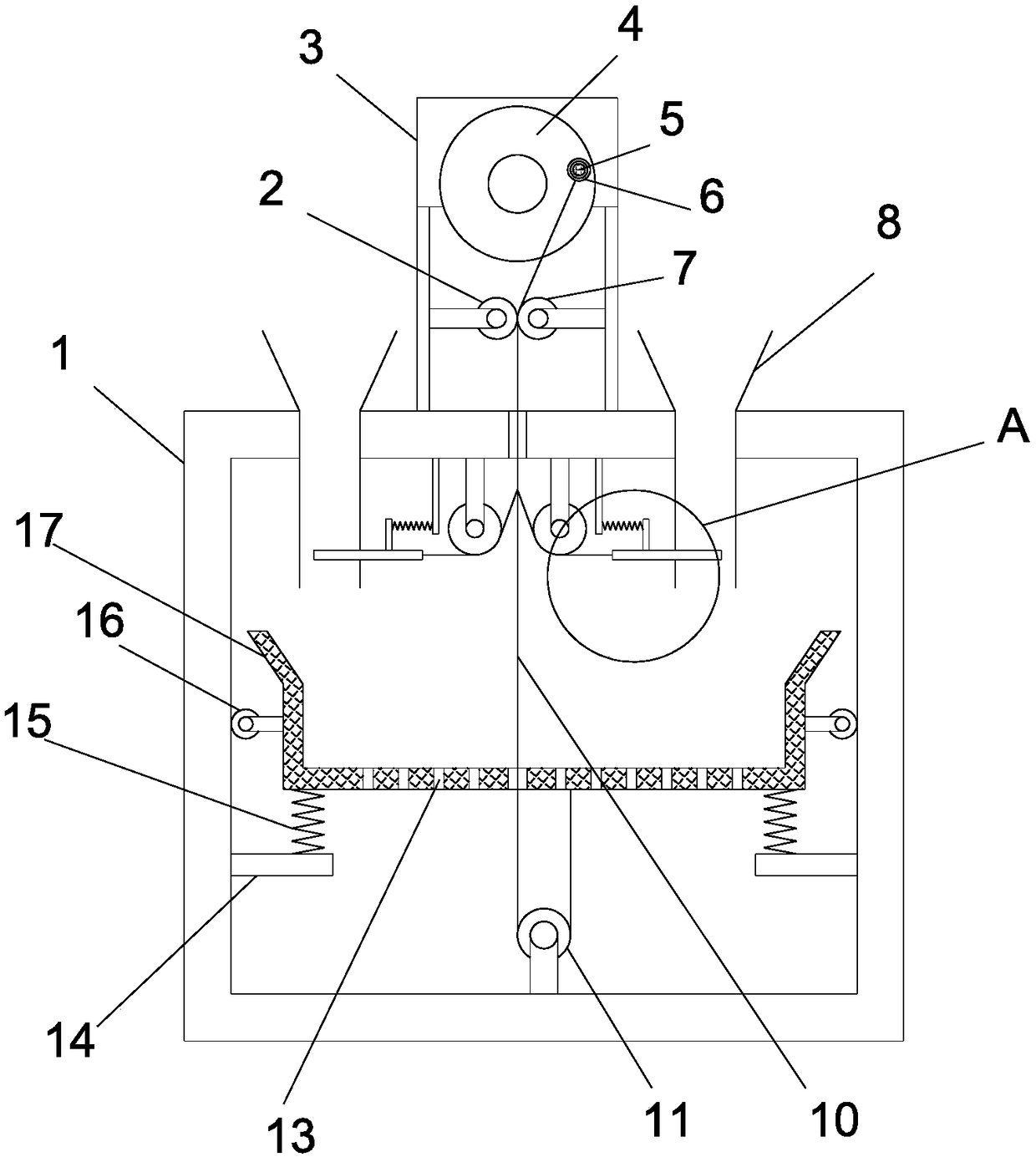

Waste plastic melt-extruding device

The invention relates to the field of recycle of waste plastic, in particular to a waste plastic melt-extruding device. The waste plastic melt-extruding device comprises a melting tank, a material tank and an extruding cylinder, wherein the extruding cylinder is provided with an extruding screw; the four sides of the melting tank are each provided with a heater; the upper end of the melting tank is provided with a feeding opening for feeding a waste plastic fragment; the lower portion of the melting tank is provided with a discharging opening and communicates with the material tank; the lowerend of the material tank communicates with the extruding cylinder; a stirring mechanism is arranged inside the melting tank; the stirring mechanism comprises a stirring shaft and a stirring motor, wherein the stirring shaft is arranged inside the melting tank; the stirring motor is used for driving the stirring shaft; the stirring shaft is provided with stirring blades; a metal filter screen is arranged inside the material tank; a peripheral frame of the metal filter screen is arranged inside the material tank; buffering springs are arranged at the joint of the metal filter screen and the material tank; the metal filter screen is connected with a vibrating motor; at least three buffering springs are arranged; and the metal filter screen is in a cone shape protruding upwards.

Owner:泉州市铭益塑料制品有限公司

Sand screening device for municipal engineering

The invention discloses a sand screening device for municipal engineering. The sand screening device comprises an operation box. A support frame is fixedly arranged at the top of the operation box. Arotating wheel is rotationally arranged on the support frame. A first limiting wheel and a second limiting wheel are rotationally and symmetrically arranged on the support frame. A positioning columnis eccentrically and fixedly arranged on the front surfaces of a first pull rope and the rotating wheel. The other end of a second pull rope is fixedly connected with the first pull rope. A screeninggroove is formed in the operation box. The first pull rope downwardly penetrates the screening groove and bypasses a fixed pulley I, and the end, far away from a lantern ring, of the first pull rope is fixed to the lower bottom surface of the screening groove. According to the sand screening device for municipal engineering, the first pull rope moves up and down through the rotation of the rotating wheel, so that the screening groove is driven to vibrate up and down under the elastic acting force of a return spring, the shaking of sand in the screening groove is promoted, and the screening speed of the sand is greatly increased; and a sliding plate slides in a left-right reciprocating manner, the sand is discharged from a feeding hopper in an intermittent manner, the sand is prevented fromfalling into the screening groove too intensively, and the screening of the sand is more fully and completely carried out.

Owner:中源宏宇建设集团有限公司

Chemical material crushing and screening device

PendingCN112718146AImprove crushing effectImprove crushing qualitySievingScreeningElectric machineryStructural engineering

The invention discloses a chemical material crushing and screening device which comprises a barrel, wherein four supporting columns are fixedly mounted at the bottom of the barrel, every two of the four supporting columns are symmetrically arranged, a discharge tube is fixedly mounted at the bottom of the barrel and communicates with the interior of the barrel, and a hopper and an L-shaped plate are fixedly mounted at the top of the barrel; the bottom end of the hopper extends into the barrel, a motor is fixedly mounted on the L-shaped plate, a first vertical shaft and two second vertical shafts are arranged in the barrel, and the two second vertical shafts are symmetrically arranged on the two sides of the first vertical shaft. The chemical material crushing and screening device is reasonable in design and good in practicability, can screen and filter materials after secondary crushing treatment, can vertically convey materials with large particles upwards for being subjected to secondary crushing treatment, further improves crushing quality of the materials, crushes the materials evenly, is better in crushing effect, is better in material screening effect, improves screening efficiency, saves time and improves work efficiency.

Owner:何静

Screening device for treating solid waste

ActiveCN111822127APrevent the problem of uneven crushingCompletely brokenSievingScreeningStructural engineeringWaste treatment

The invention provides a screening device for treating solid waste. The screening device comprises a rack assembly, a jacking device, a screening barrel, a push assembly, a feeding hopper, a screeningdevice, clamp crushing devices, smashing rollers and a discharging device. The screening barrel is fixedly connected to the top of the rack assembly, the feeding hopper is fixedly connected to the top of the screening barrel, the discharging device is installed in the feeding hopper, the smashing rollers are connected to the left sides and the right sides of the central positions of the upper ends on the front side and the rear side in the screening barrel in a rotating mode, upper end smashing teeth between the smashing rollers are oppositely arranged, the clamp smashing devices are movablyconnected to the left side and the right side at the bottom of the screening device, the push assembly is movably connected to the bottom of the screening barrel, the top of the push assembly extendsinto the screening barrel and is movably connected with the central positions at the bottoms of the clamp smashing devices, the jacking device is fixedly connected to the lower end of the rack assembly, and the top of the jacking device is connected with the bottom of the push assembly. The screening device for treating the solid waste aims to solve the problems that a screen of an existing solidwaste screening device is likely to be blocked, smashing is not thorough enough, and the working efficiency is low.

Owner:浦塔环保科技(上海)有限公司

Screening device for tea detection

ActiveCN112629973ASpeed up sievingImprove work efficiencySievingTesting beveragesMechanical engineeringTea leaf

The invention discloses a screening device for tea detection. The screening device for tea detection comprises a supporting plate and a shell, a screening barrel is arranged in the shell, the left side of the screening barrel penetrates out of the shell, a driving mechanism is arranged above the shell, and the screening barrel is divided into a left screening section and a right grinding section; and a grinding mechanism is arranged in the grinding section of the screening barrel, a gear ring is fixedly connected to the right side of the surface of the screening barrel, and an adjusting mechanism is arranged at the bottom of the shell. The invention relates to the technical field of screening devices. According to the screening device for tea detection, the driving mechanism can drive the screening barrel to rotate, so that tea in the screening barrel is turned over, the screening speed is increased, the working efficiency of the device is improved, the device can screen and grind the tea, the functions are richer, the inclination direction of the shell can be controlled through the adjusting mechanism, discharging is convenient, the screening effect is good, grinding is convenient, and the actual use requirement is met.

Owner:WUXI PROFESSIONAL COLLEGE OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com