Viscous material filtering machine

A filter and material technology, applied in filtration and separation, moving filter element filters, separation methods, etc., can solve the problems of low calcium carbonate quality, affecting product quality, impure slurry, etc., to achieve high product quality and speed up screening. Good speed and purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

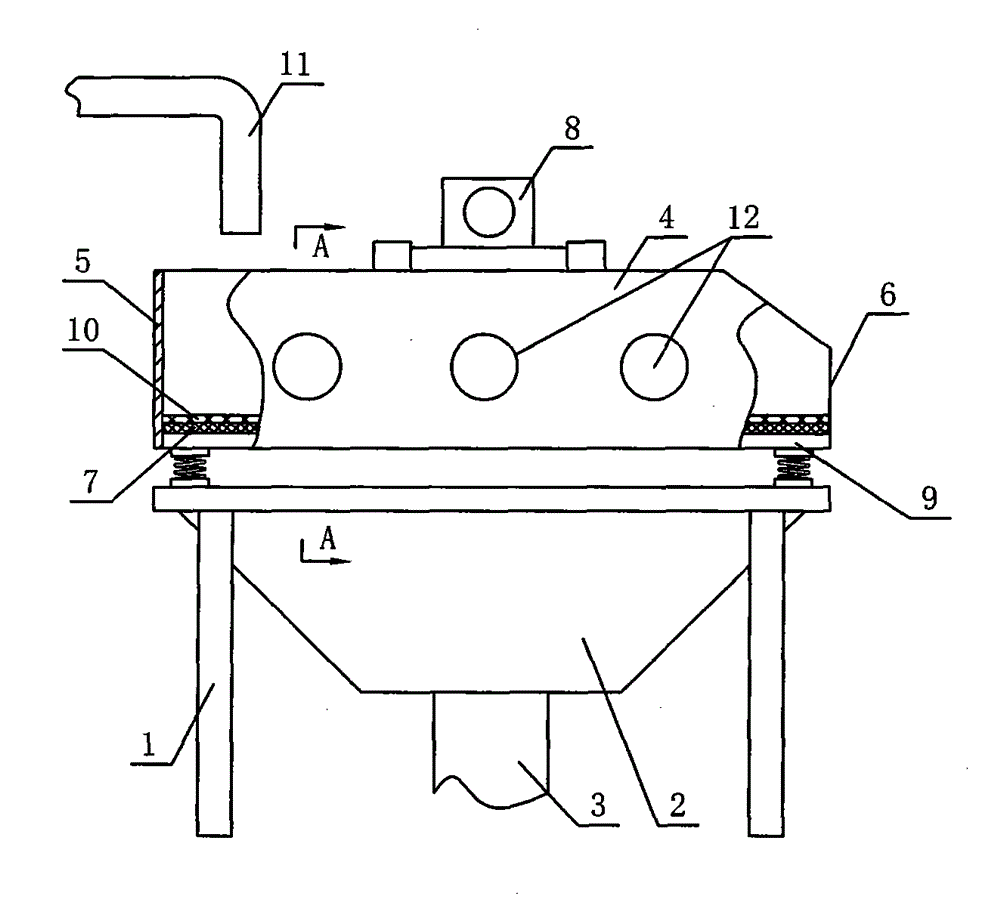

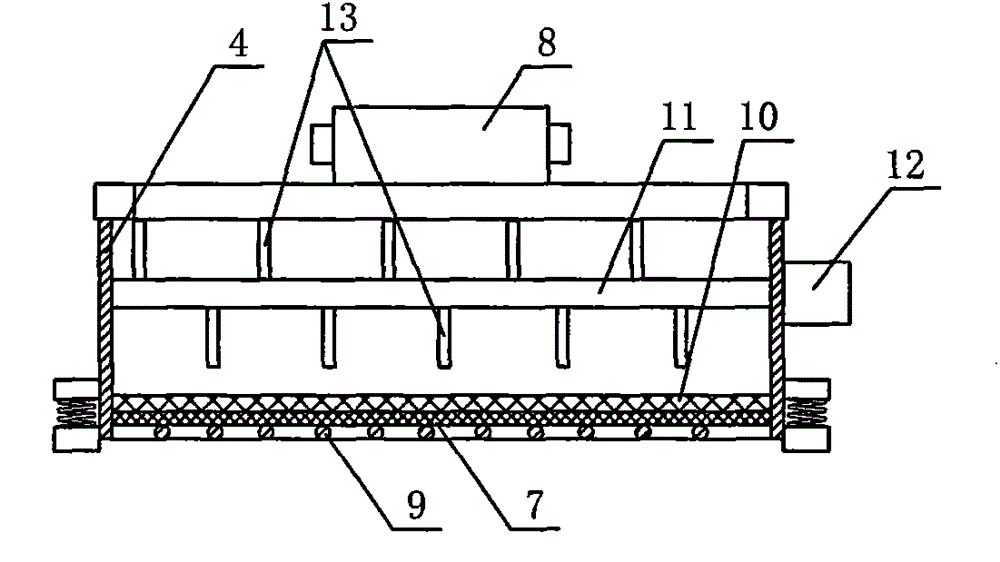

[0011] Such as figure 1 and figure 2 The viscous material filter shown includes a frame 1, a funnel-shaped lower hopper 2 is installed on the frame 1, and the bottom of the lower hopper 2 is connected with a discharge pipe 3, and the frame 1 is also elastically connected with a For the screen frame 4 above the hopper 2 and with an open top, the above-mentioned elastic connection can be adopted as shown in the figure, that is, support columns are symmetrically arranged on the frame, and a downwardly extending support cylinder is provided on the top of the screen frame 4, and the support cylinder and Springs are installed between the supporting columns, and the structure of shock absorbers can also be used. Of course, the structure of rubber springs between the screen frame 4 and the frame can also be used, the purpose of which is to make the screen frame 4 under the action of external force shake. The whole screen frame 4 is in the shape of a dustpan, the slurry outlet pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com