Patents

Literature

283results about How to "Improve screening accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

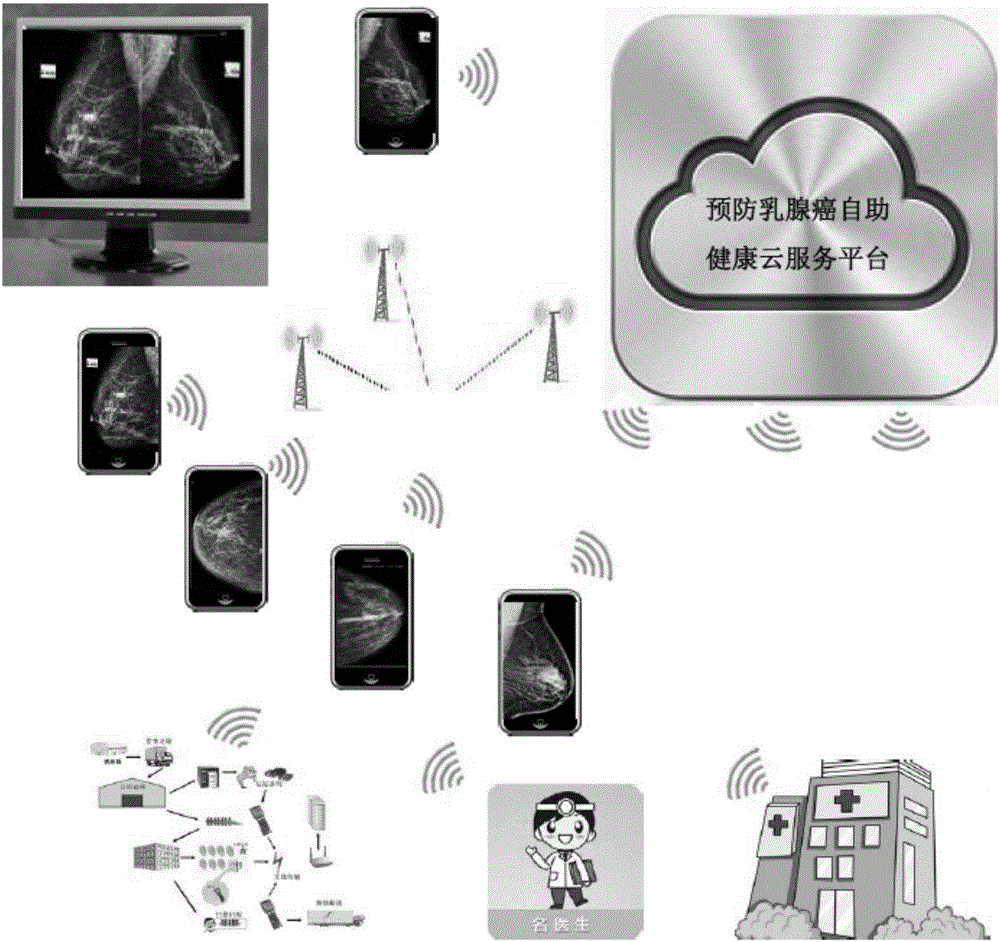

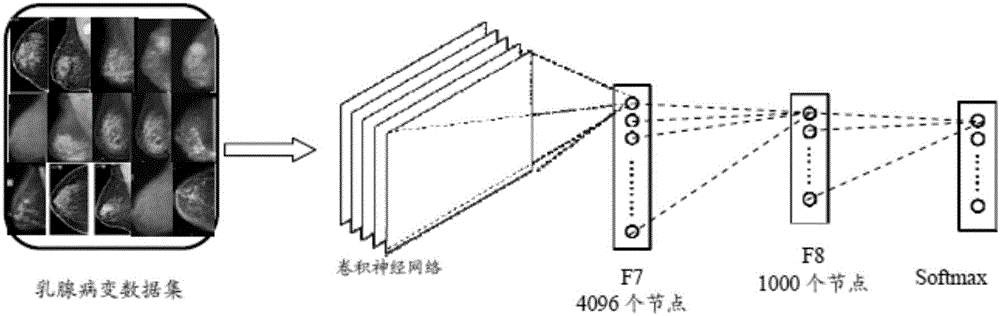

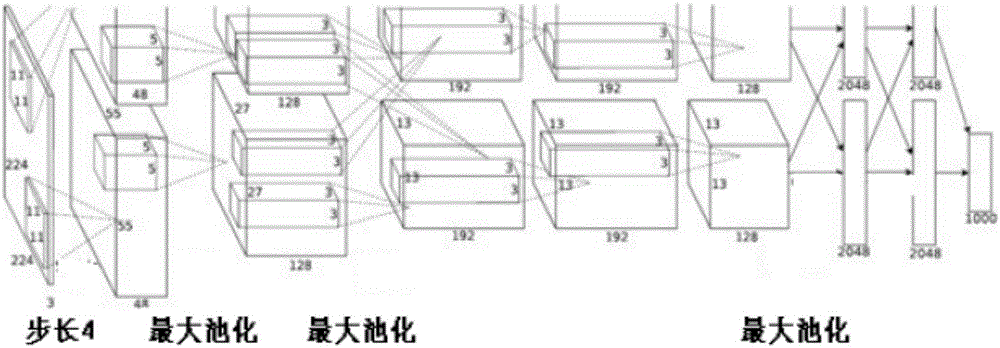

Breast cancer prevention self-service health cloud service system based on deep convolutional neural network

ActiveCN106339591AImprove informatizationIncrease health awarenessCharacter and pattern recognitionSpecial data processing applicationsImage basedMammary gland

The invention discloses a breast cancer prevention self-service health cloud service system based on a deep convolutional neural network. The self-service health cloud service system mainly comprises a convolutional neural network applied to deep learning and training recognition, a partitioning module which is used for partitioning a breast area from a mammary gland molybdenum target radiography image based on a full-convolutional neural network, the deep convolutional neural network which is applied to BI-RADS classification and evaluation, and a self-service health cloud service platform which is applied to early preventing and treating breast cancer according to a recognized mammary gland inner structure, tumor and calcification types. The self-service health cloud service system can effectively improve the automatic and intelligent level of breast cancer screening based on a mobile internet, enable more women to know and participate in self-service health detection, evaluation and guidance, further improve the health consciousness of the public, and improve self health management capacity.

Owner:汤一平

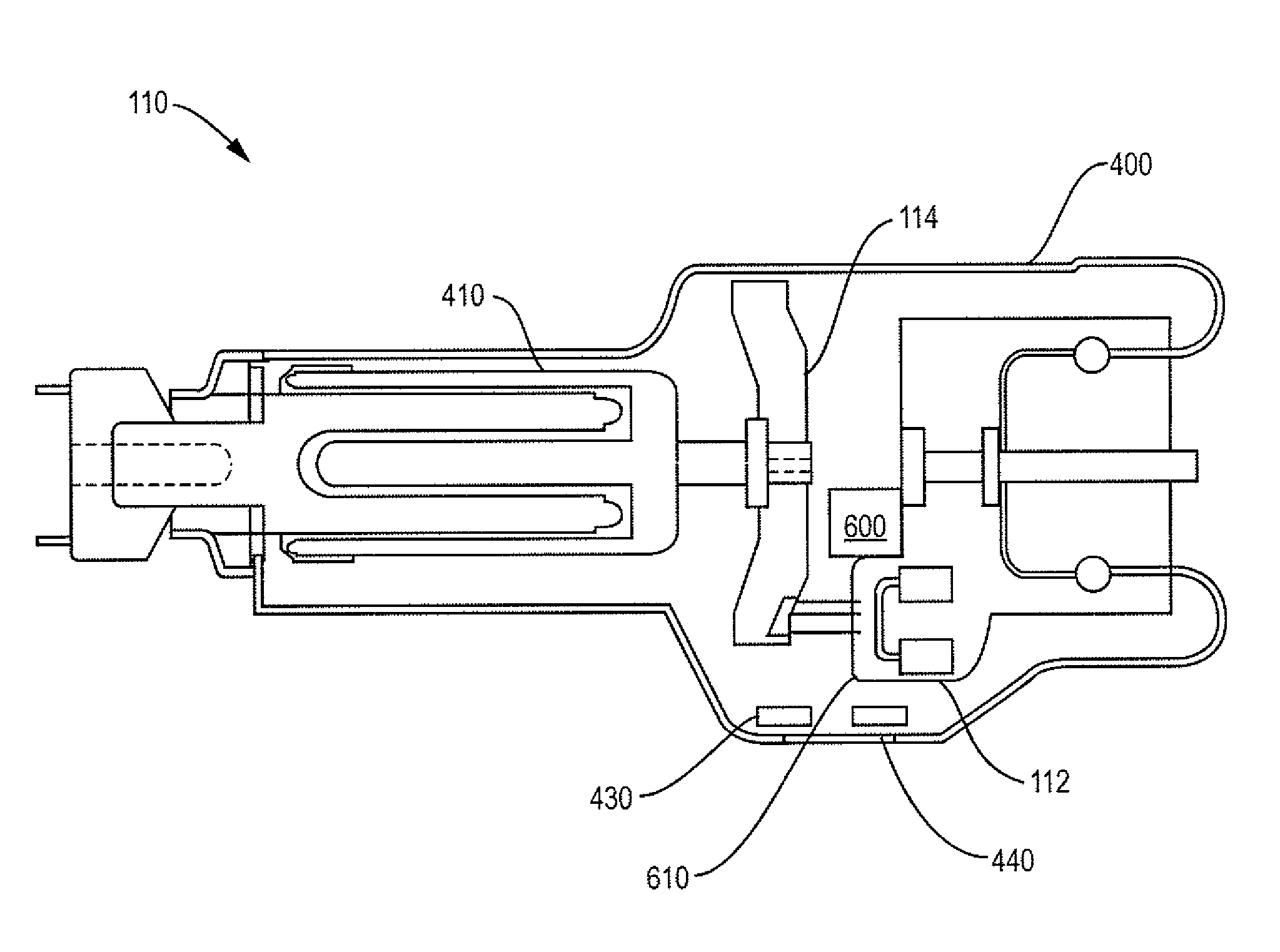

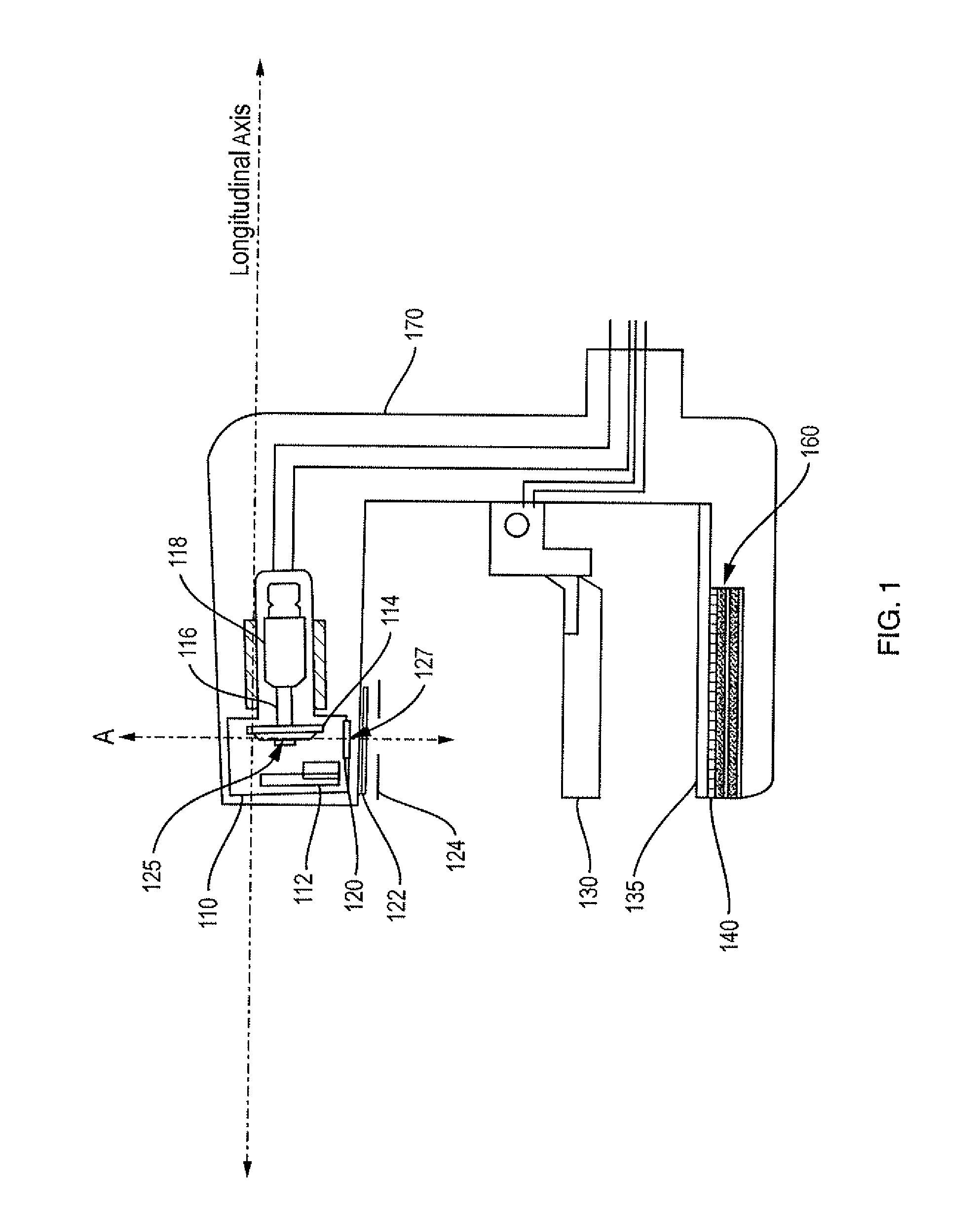

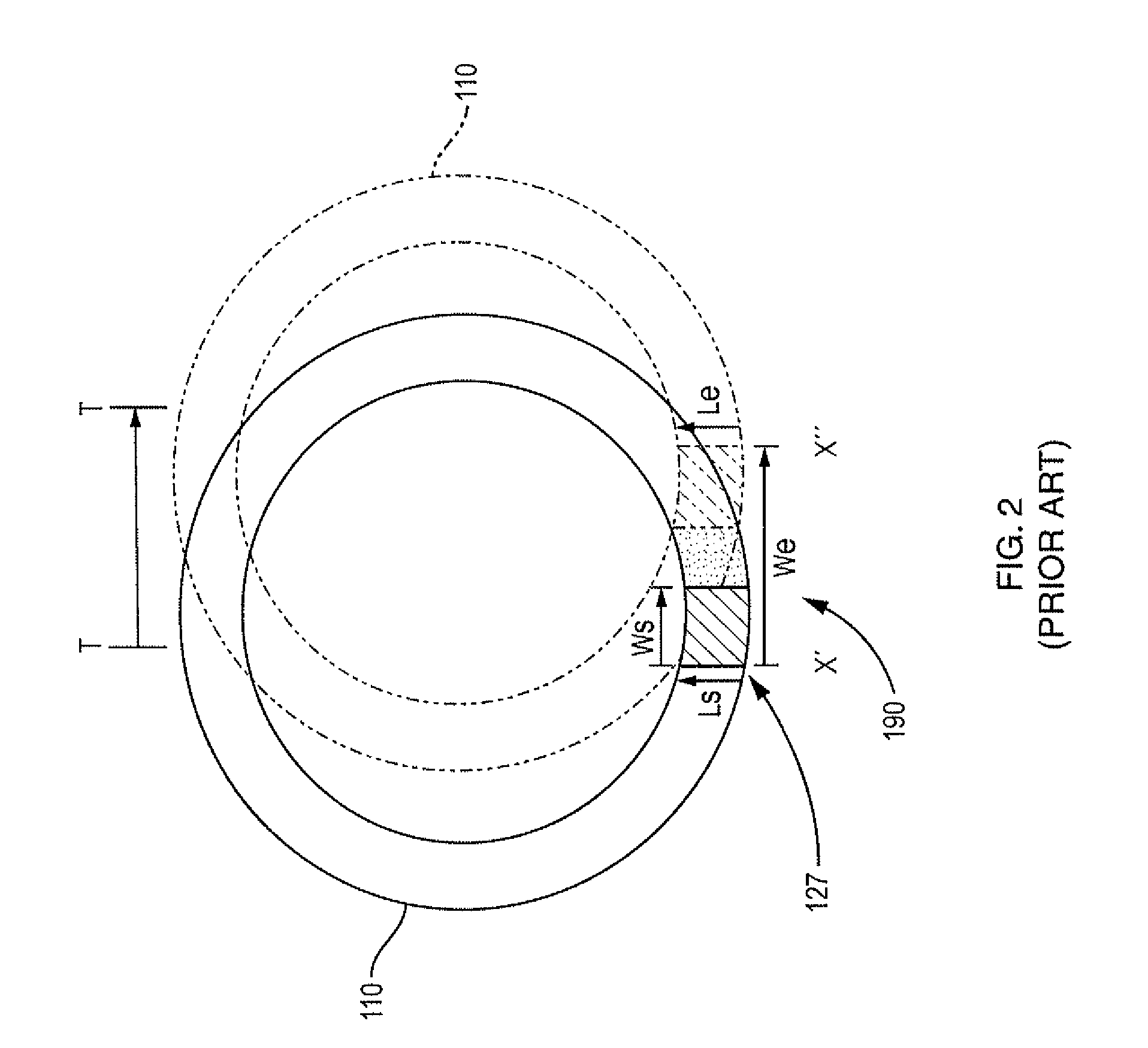

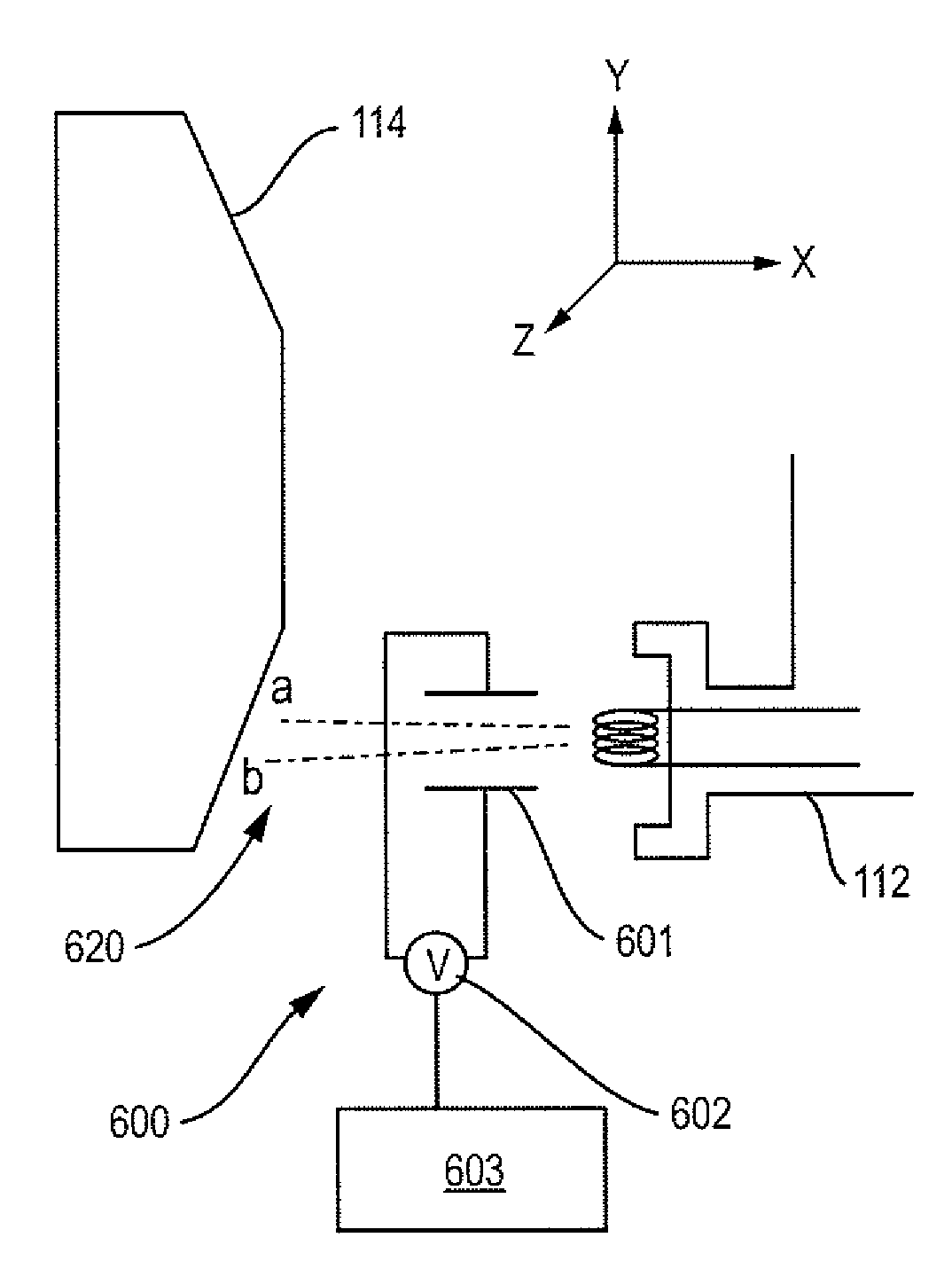

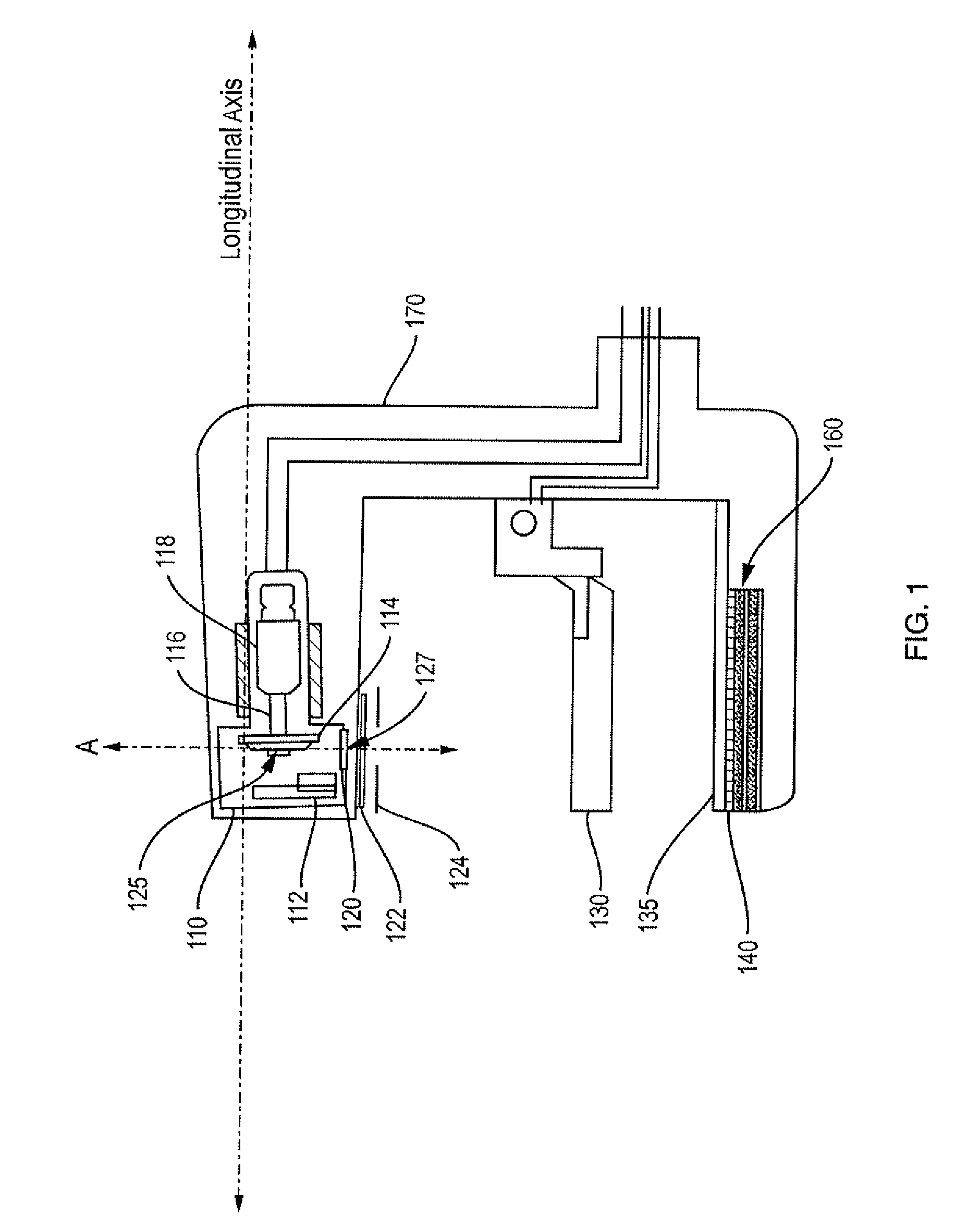

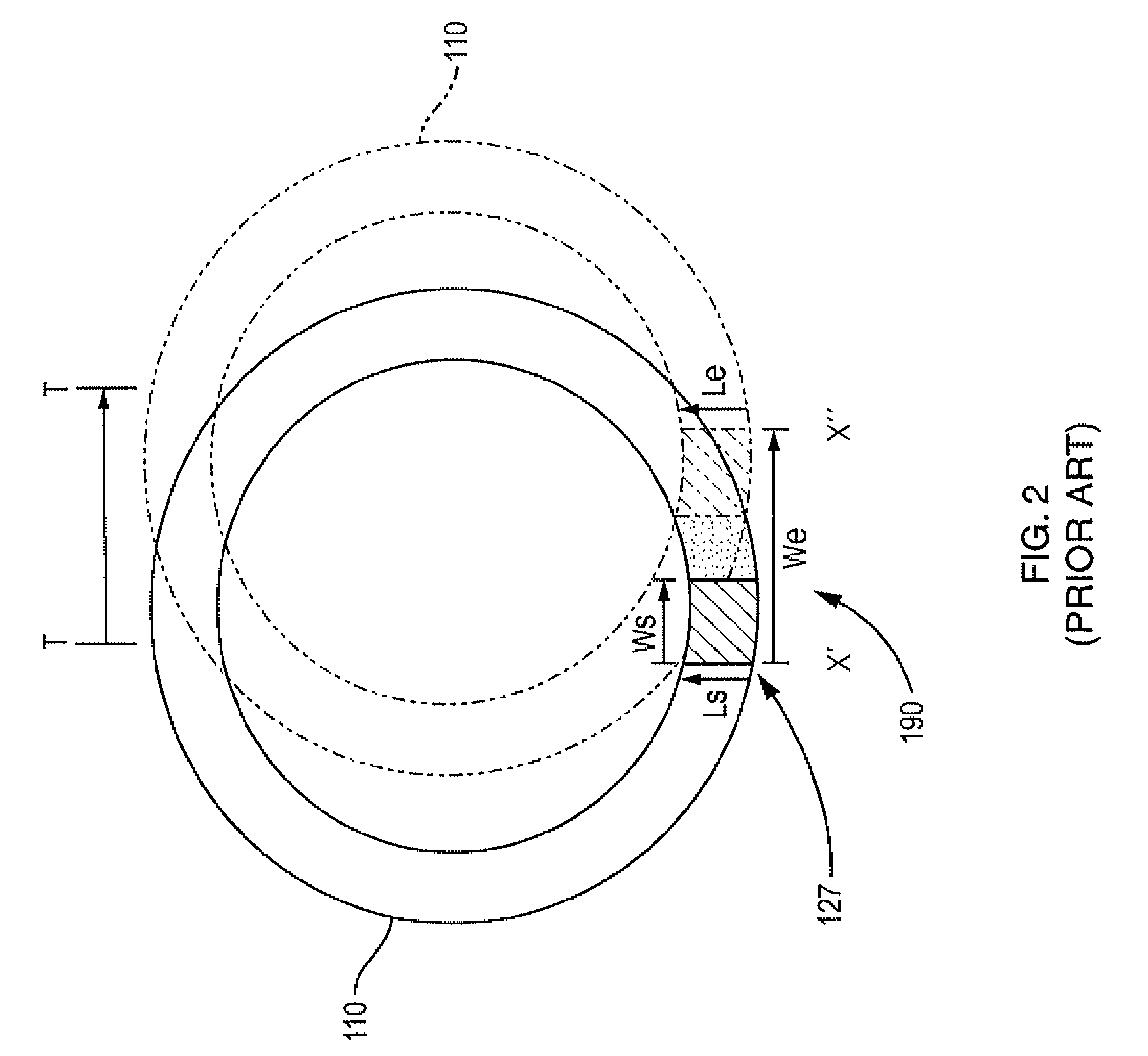

Method and System for Controlling X-Ray Focal Spot Characteristics for Tomoysythesis and Mammography Imaging

ActiveUS20100303202A1Reduce eliminateReduce compressionRadiation/particle handlingTomosynthesisTomosynthesisSoft x ray

An x-ray tube is described that includes components for increasing x-ray image clarity in the presence of a moving x-ray source by modifying focal spot characteristics, including focal spot size and focal spot position. In a first arrangement a static focal spot is moved in a direction contrary to the movement of the x-ray source so that an effective focal spot position is essentially fixed in space relative to one of the imaged object and / or detector during a tomosynthesis exposure. In a second arrangement, the size of the static focal spot is increased, and the resulting increase in tube current reduces the exposure time and concomitant blur effect. The methods may be used alone or in combination; for example an x-ray tube with a larger, moveable static focal spot will result in a system that fully utilizes the x-ray tube generator, provides a high quality image with reduced blur and, due to the decrease in exposure time, may scan the patient more quickly.

Owner:HOLOGIC INC

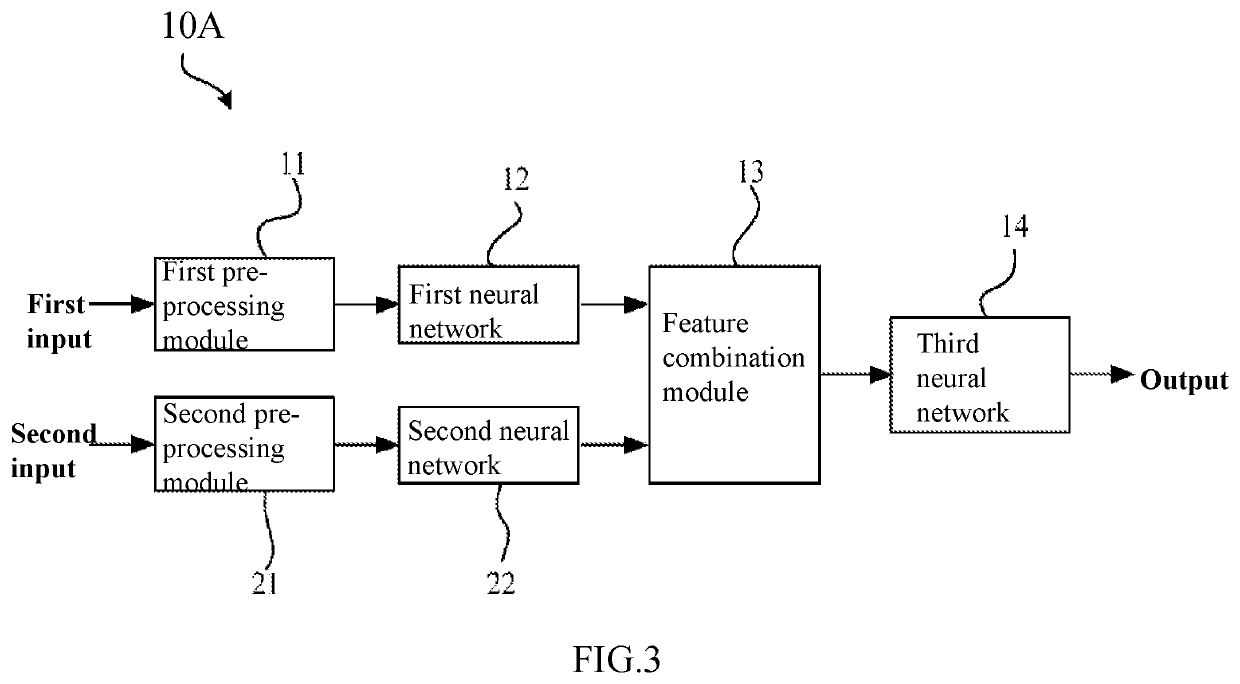

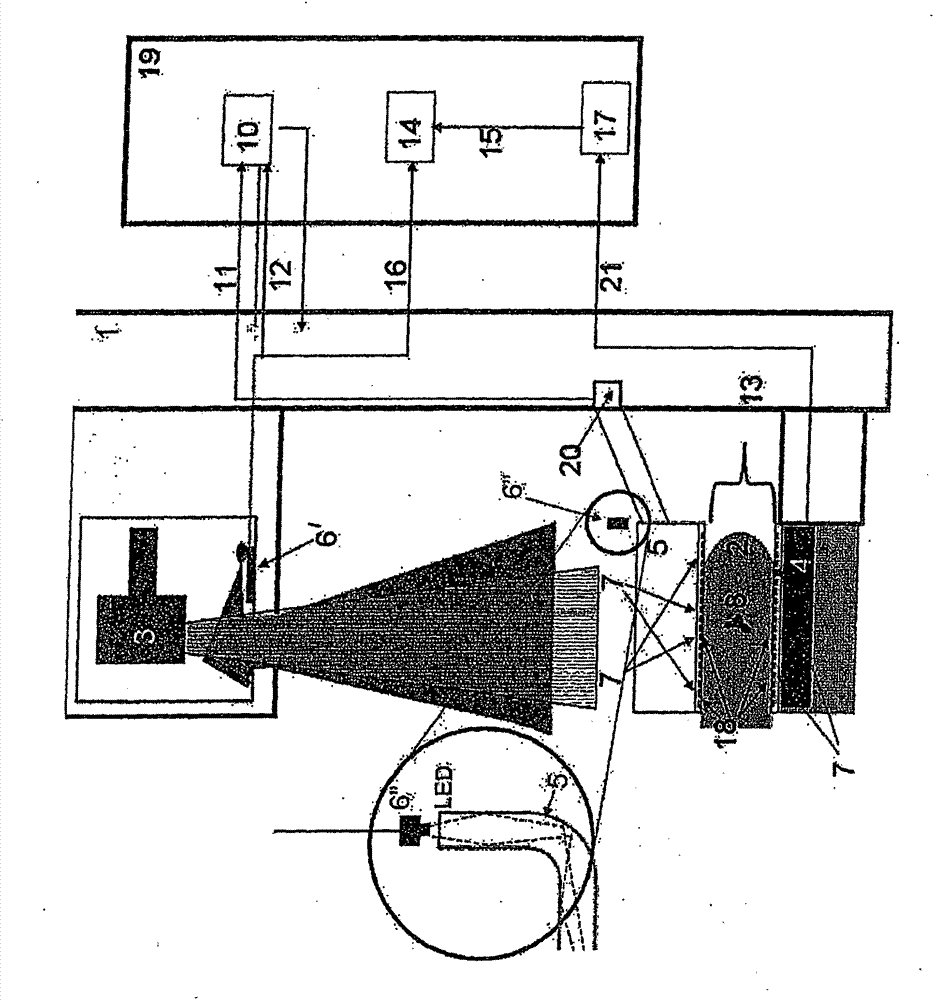

Artificial neural network and system for identifying lesion in retinal fundus image

ActiveUS20200085290A1Improve screening accuracyImprove accuracyImage enhancementImage analysisRetinaArtificial neuronal network

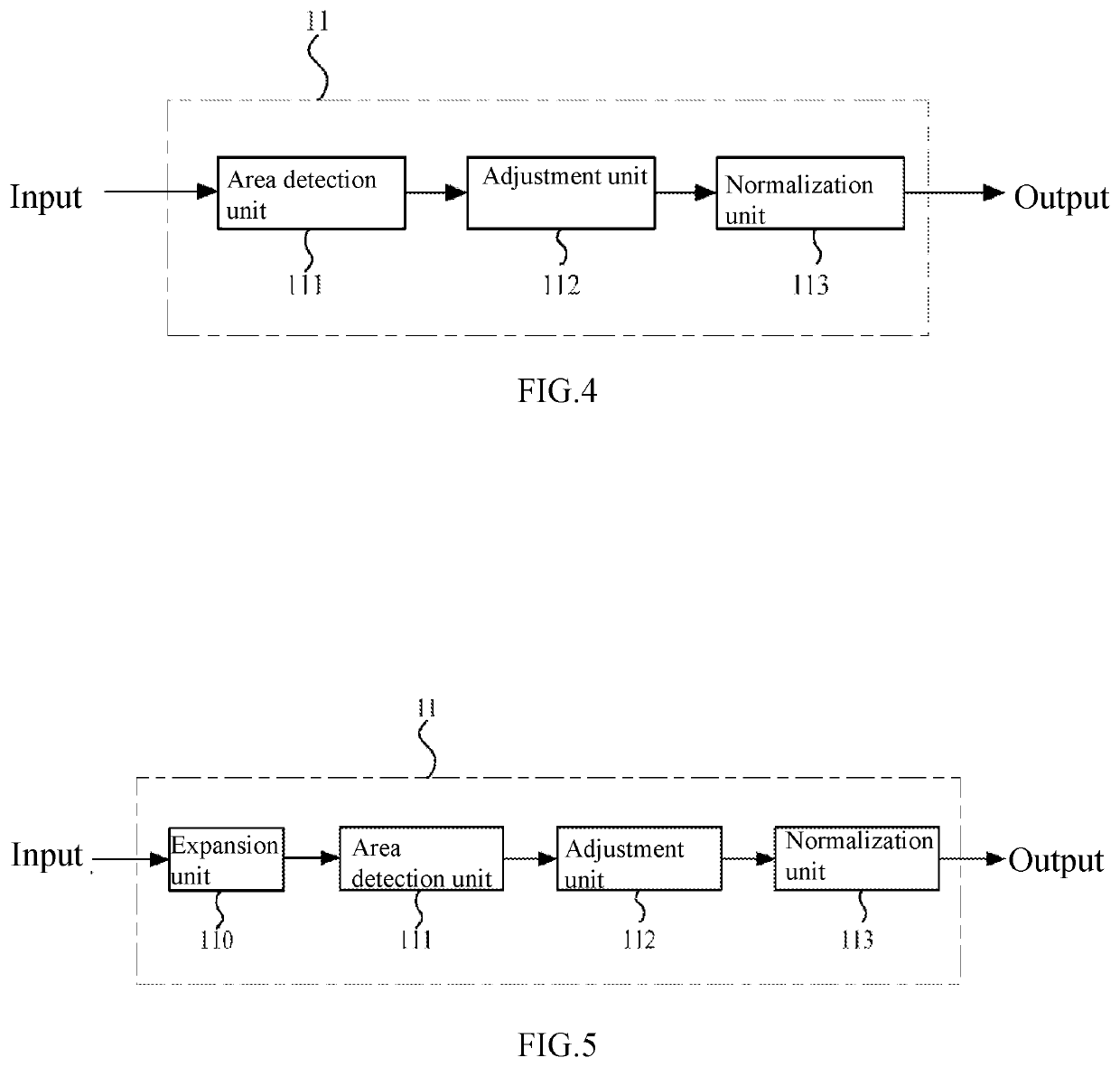

The present disclosure provides an artificial neural network system for identifying a lesion in a retinal fundus image that comprises a pre-processing module configured to separately pre-process a target retinal fundus image and a reference retinal fundus image taken from a same person; a first neural network (12) configured to generate a first advanced feature set from the target retinal fundus image; a second neural network (22) configured to generate a second advanced feature set from the reference retinal fundus image; a feature combination module (13) configured to combine the first advanced feature set and the second advanced feature set to form a feature combination set; and a third neural network (14) configured to generate, according to the feature combination set, a diagnosis result. By using a target retinal fundus image and a reference retinal fundus image as independent input information, the artificial neural network may simulate a doctor, determining lesions on the target retinal fundus image using other retinal fundus images from the same person as a reference, thereby enhancing the diagnosis accuracy.

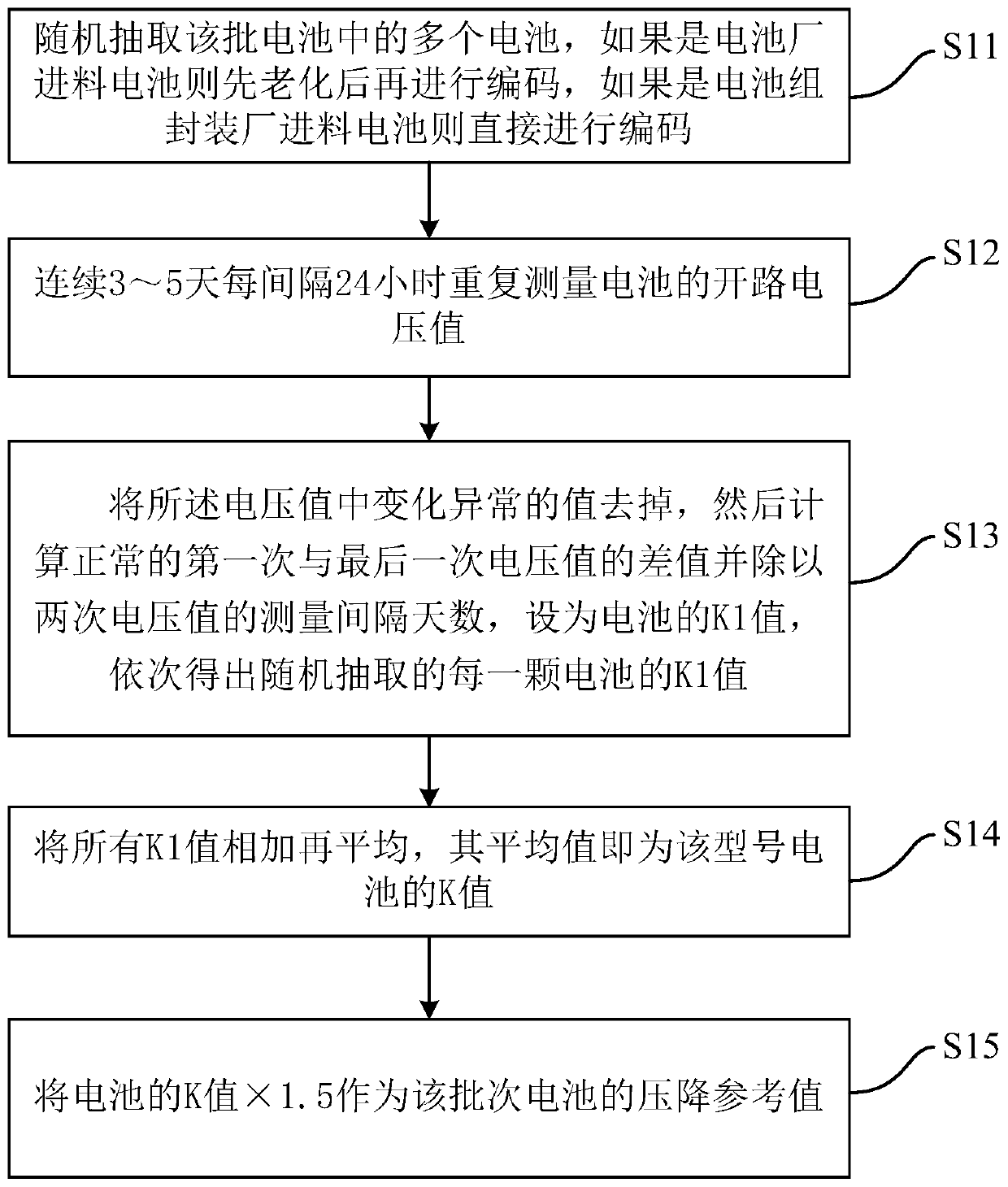

Self-discharging screening method of lithium ion battery

InactiveCN104466277AImprove screening accuracyReduce shipping riskSecondary cells charging/dischargingEngineeringLithium electrode

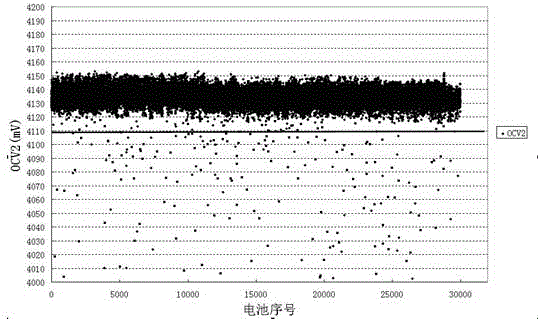

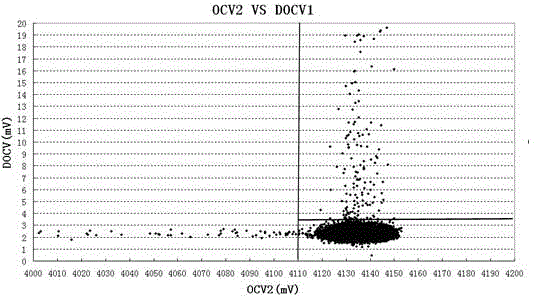

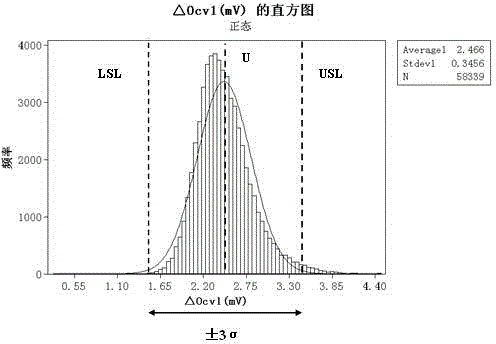

The invention provides a self-discharging screening method of a lithium ion battery. The method comprises the following steps: step 1: pre-charging a battery to be screened to be in a full or half state; performing high-temperature aging treatment and storing at constant temperature; marking detection open-circuit voltage as OCV1 and storing at constant temperature; marking detection open-circuit voltage as OCV2; calculating a voltage critical value U0 in the same phrase, wherein the battery with the condition that OCV2 is less than U0 is a serious self-discharging battery; and step 2: removing the self-discharging battery by using a 3o circulating way based on voltage pressure before / after the laying-aside of the battery removed in the step 1 in a full-charge state or a half-charge state. According to the self-discharging screening method of the lithium ion battery, the battery is screened after the battery is laid aside in the full-charge state or the half-charge state and the open-circuit voltage is determined, and the corresponding self-discharging batteries are removed by using the 3o circulating way, so that the self-discharging screening of the lithium ion battery is realized.

Owner:JIANGSU TENPOWER LITHIUM

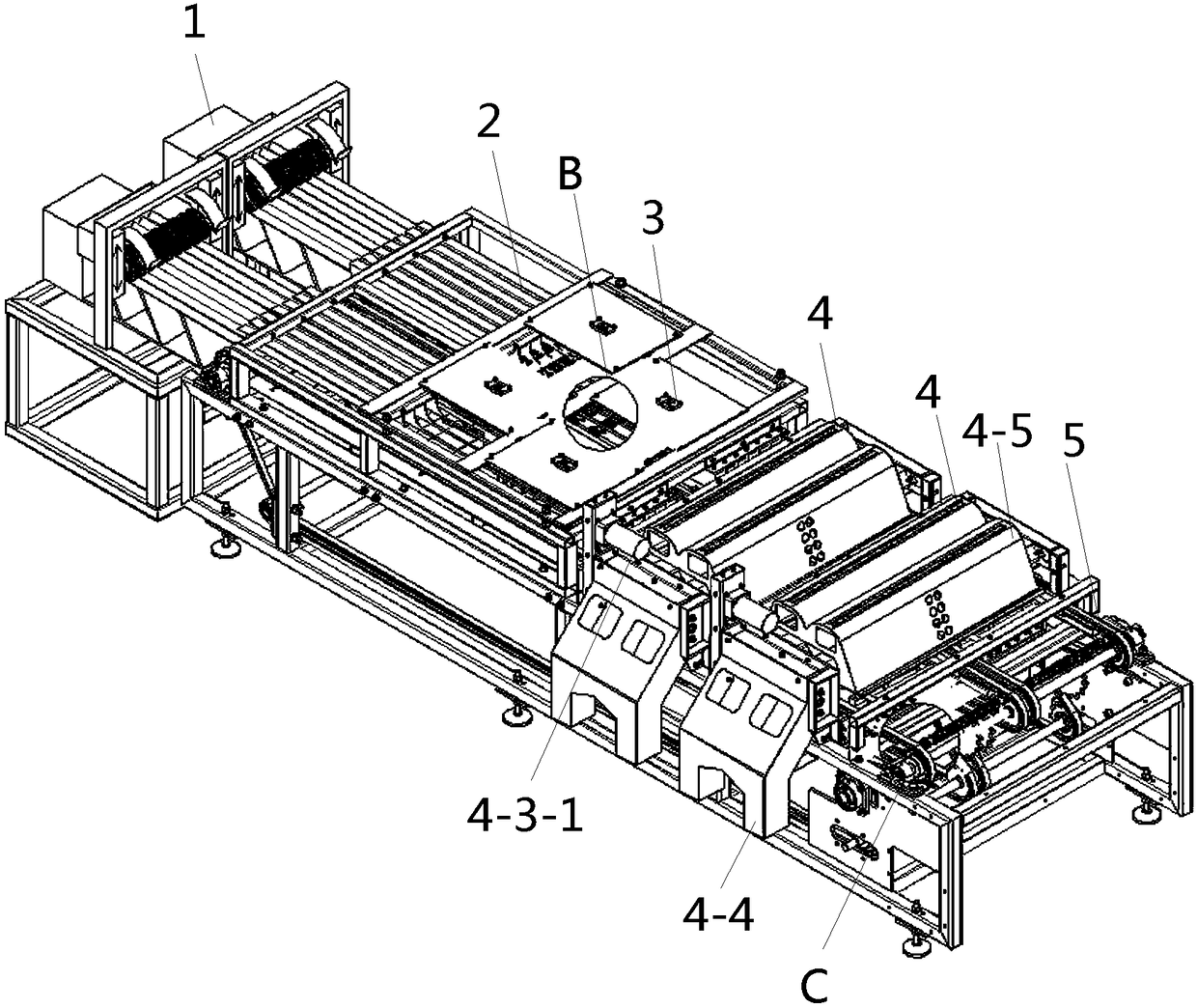

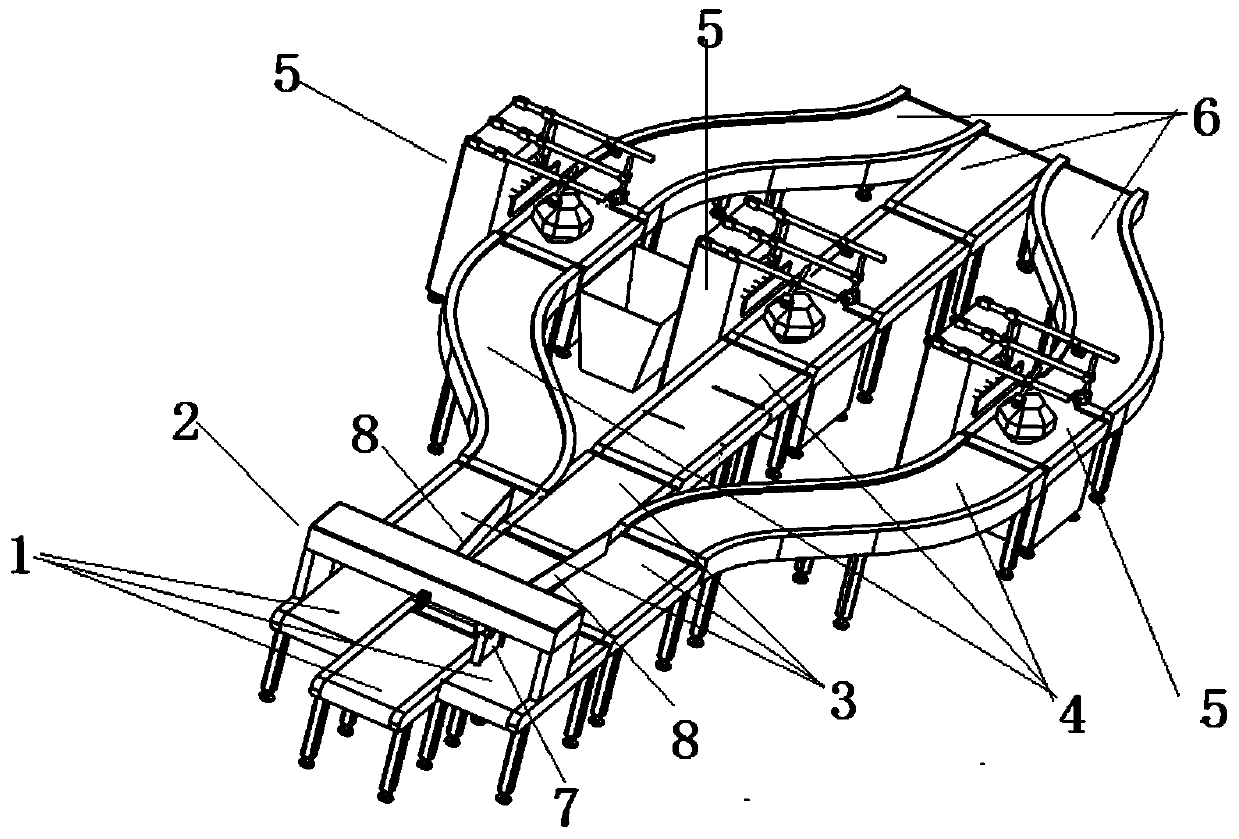

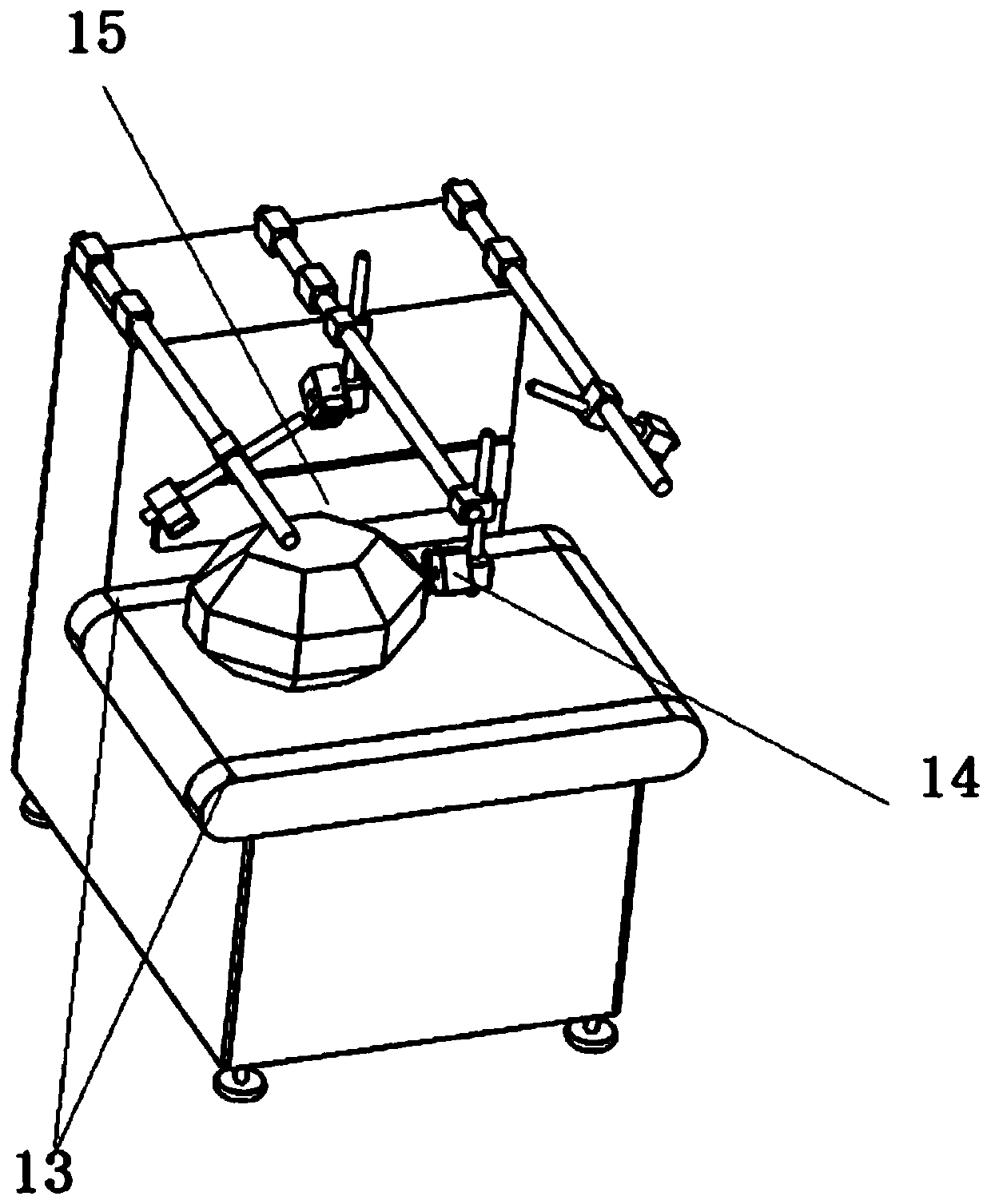

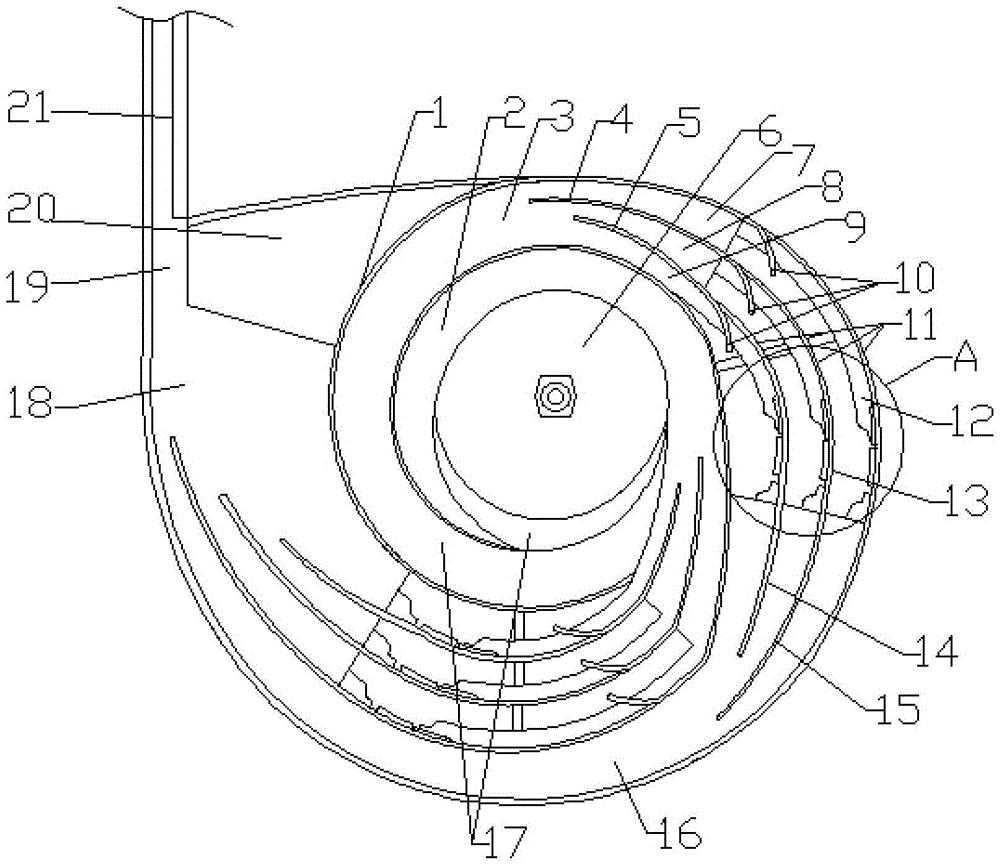

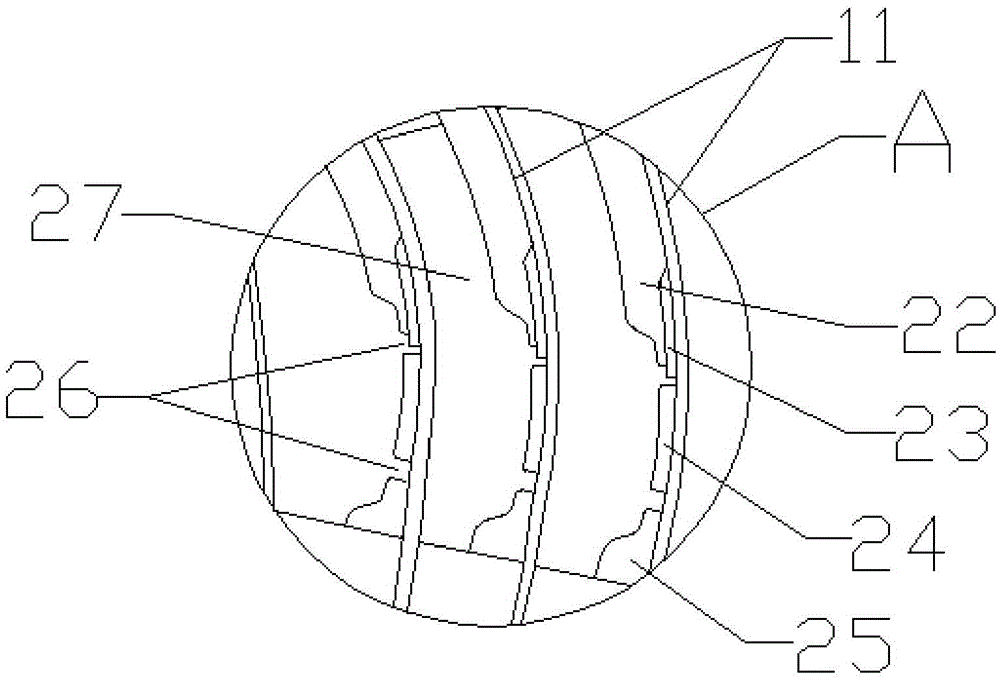

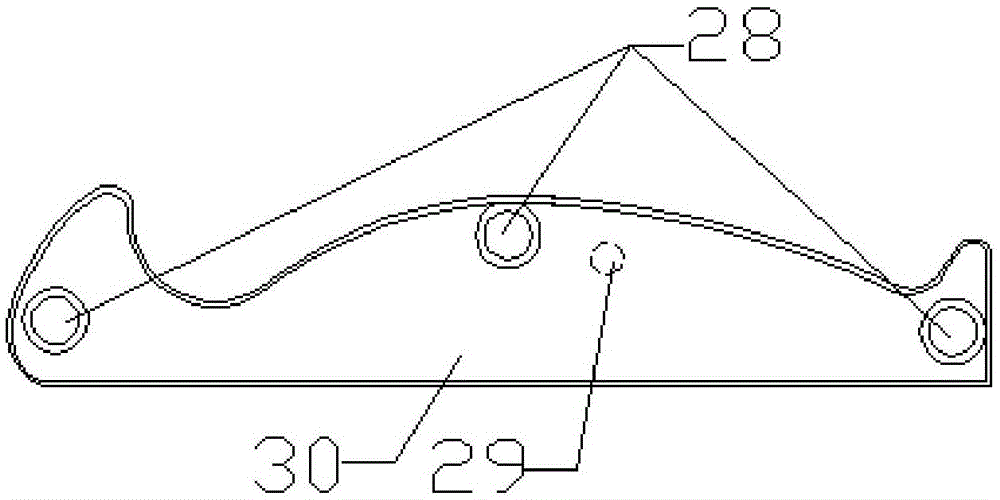

High-precision vegetable and fruit quick intelligent selecting equipment

ActiveCN109158327AAvoid efficiencyAvoid precisionClimate change adaptationSortingEngineeringRotational flow

The invention discloses high-precision vegetable and fruit quick intelligent selecting equipment. The high-precision vegetable and fruit quick intelligent selecting equipment comprises a feeding conveying device, a horizontal conveying device and a pneumatic mechanism, wherein a horizontal conveyer belt comprising rollers is arranged on the horizontal conveying device; one or more groups of screening and discharging mechanisms which are opposite to the pneumatic mechanism in an up and down manner are arranged above the horizontal conveying belt; each screening and discharging mechanism comprises a discharging platform which is fixedly arranged above the horizontal conveying device; anti-falling baffles are respectively arranged on the front side and the rear side of each discharging platform; a rotational flow cover is arranged on each discharging platform; the side edge of each rotational flow cover is arc-shaped; a substandard product blowing-out opening is formed by two side edges of each rotational flow cover and two side edges of the corresponding discharging platform; each substandard product blowing-out opening is in up-and-down correspondence with air jet holes of the pneumatic mechanism. According to the high-precision vegetable and fruit quick intelligent selecting equipment disclosed by the invention, the screening and discharging mechanisms adopting special structures, a feeding and conveying device and rollers in the horizontal conveying device are arranged, the effects of positioning and precise photographing of vegetables and fruits are increased in an omnidirectional manner, and the screening efficiency is also greatly improved.

Owner:郑州市中昕智能设备有限公司

Method and system for controlling X-ray focal spot characteristics for tomosynthesis and mammography imaging

ActiveUS8457282B2Reduce eliminateReduce compressionRadiation/particle handlingCathode ray concentrating/focusing/directingSoft x rayTomosynthesis

An x-ray tube is described that includes components for increasing x-ray image clarity in the presence of a moving x-ray source by modifying focal spot characteristics, including focal spot size and focal spot position. In a first arrangement a static focal spot is moved in a direction contrary to the movement of the x-ray source so that an effective focal spot position is essentially fixed in space relative to one of the imaged object and / or detector during a tomosynthesis exposure. In a second arrangement, the size of the static focal spot is increased, and the resulting increase in tube current reduces the exposure time and concomitant blur effect. The methods may be used alone or in combination; for example an x-ray tube with a larger, moveable static focal spot will result in a system that fully utilizes the x-ray tube generator, provides a high quality image with reduced blur and, due to the decrease in exposure time, may scan the patient more quickly.

Owner:HOLOGIC INC

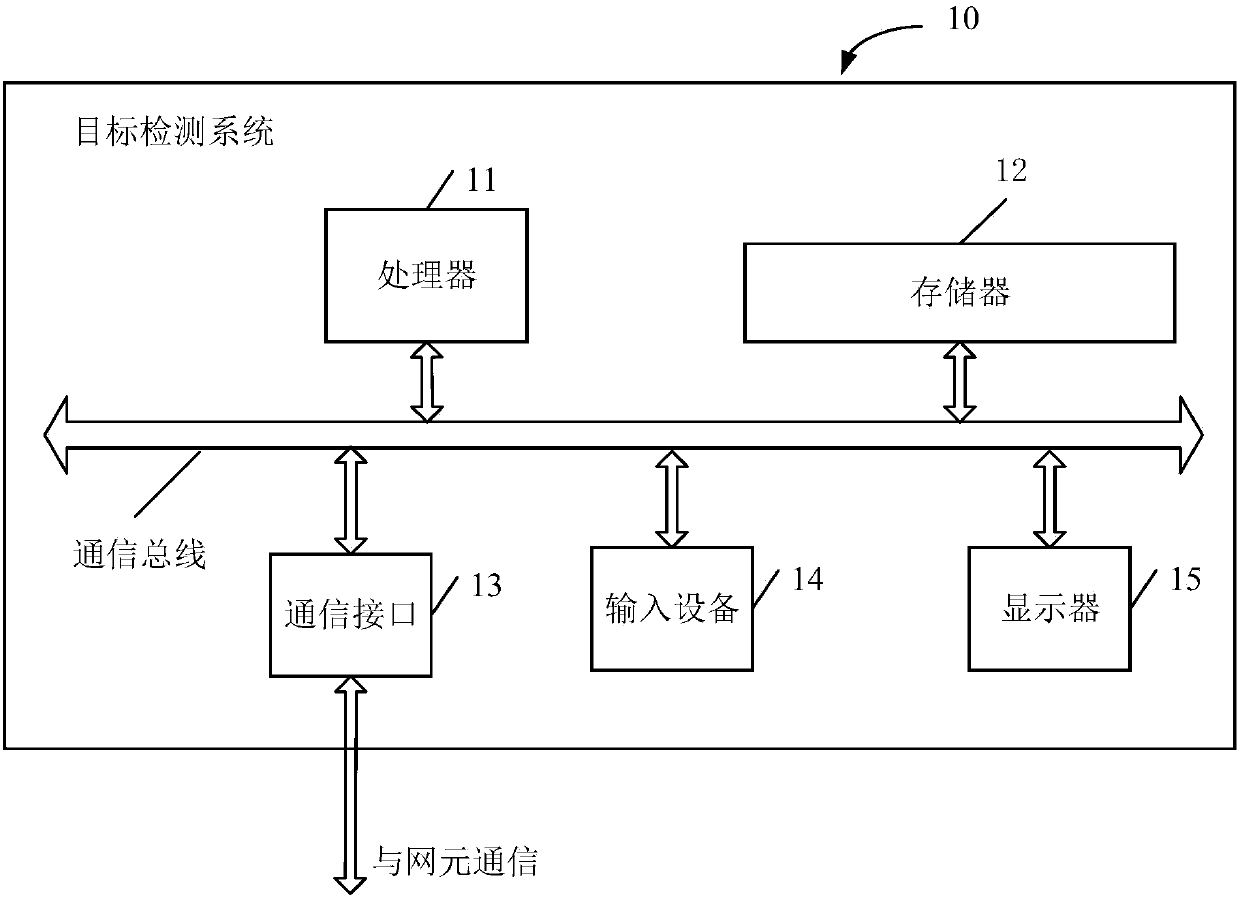

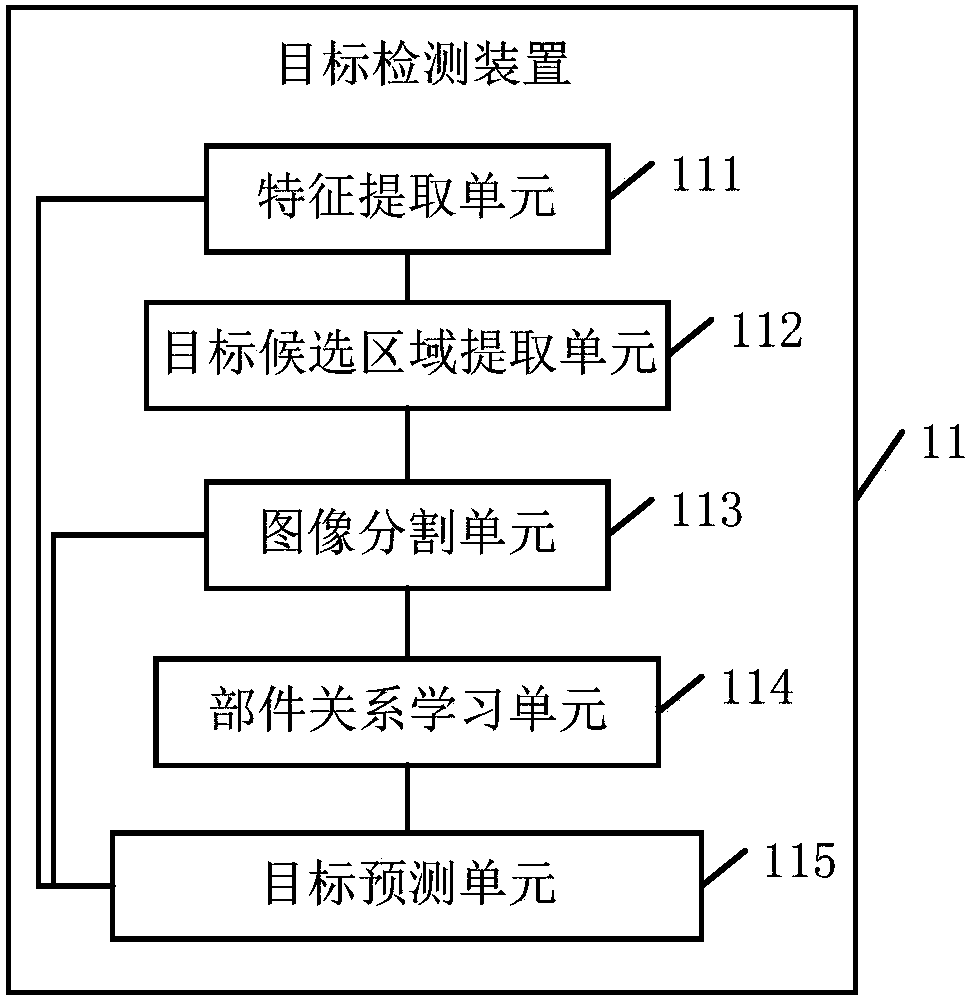

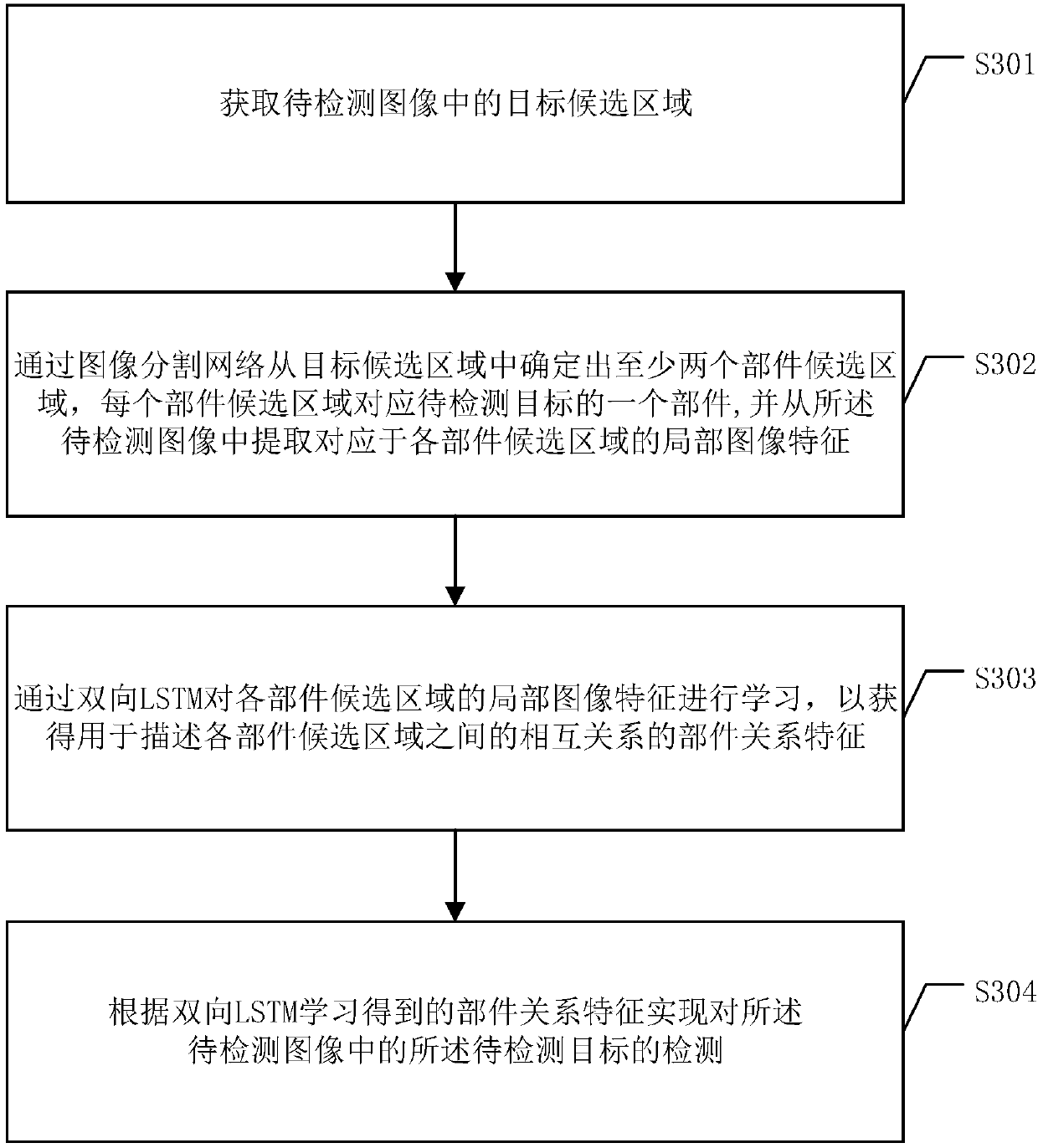

Target detection method, device and system

ActiveCN110096933AEasy to identifyHigh Target Recognition EfficiencyImage enhancementImage analysisImage segmentationImaging Feature

The invention provides a target detection method and device. The method comprises the steps of obtaining a target candidate area in a to-be-detected image; determining at least two component candidateregions from the target candidate regions through an image segmentation network, each component candidate region corresponding to one component of the to-be-detected target, and extracting the localimage features corresponding to each component candidate region from the to-be-detected image; learning each local image feature of each part candidate region through a bidirectional long short time memory network (LSTM) to obtain a part relation feature for describing a mutual relation between the part candidate regions; and detecting the to-be-detected target in the to-be-detected image according to the component relationship characteristics. According to the invention, the image data processing precision of target detection can be improved, the diversity of application scenarios of target detection is enhanced, and the accuracy of the target detection is improved.

Owner:HUAWEI TECH CO LTD

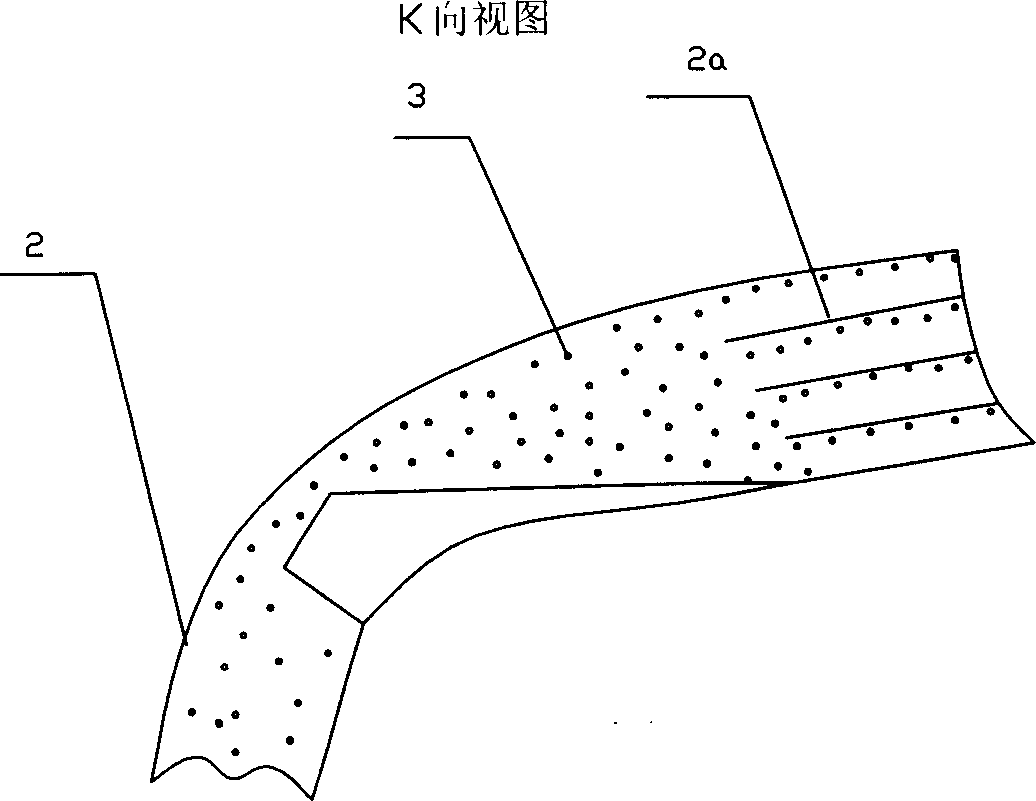

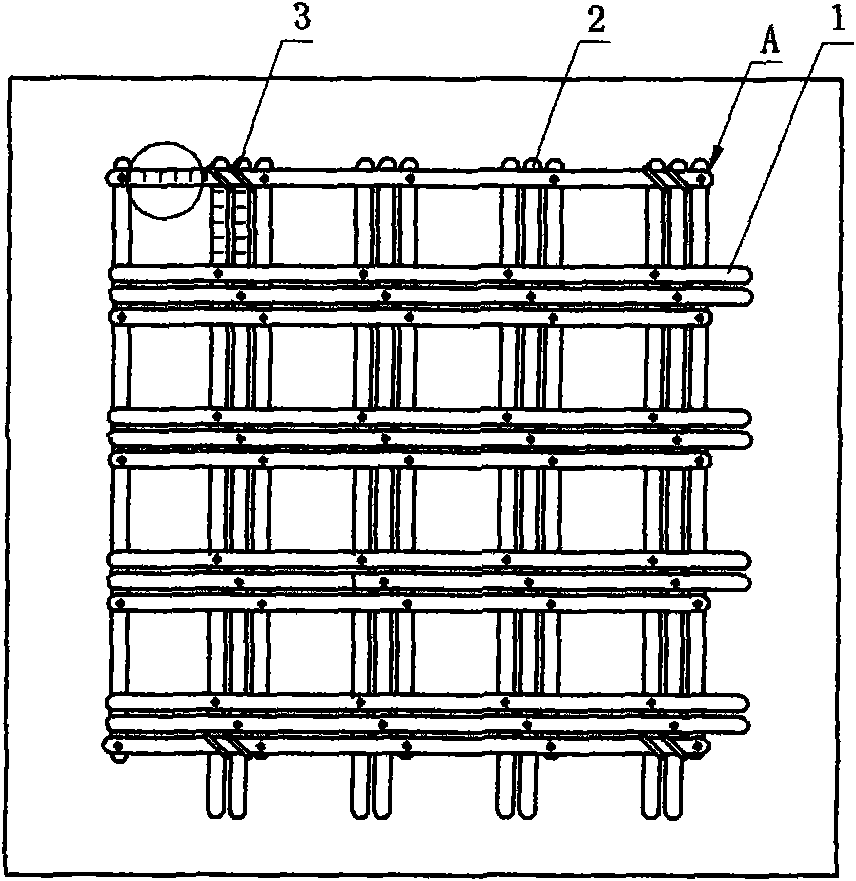

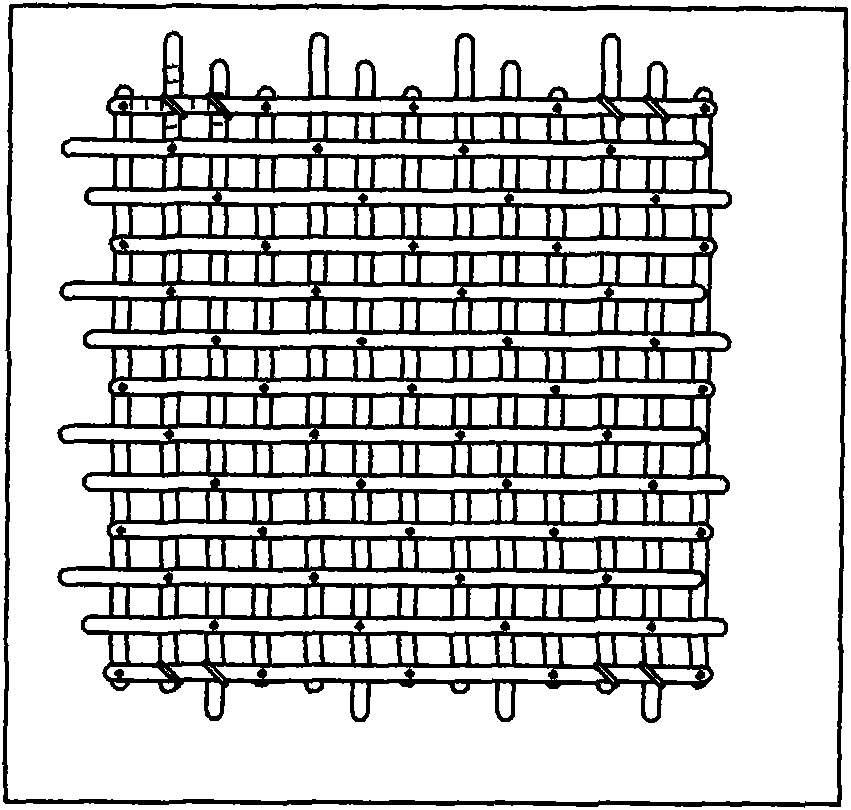

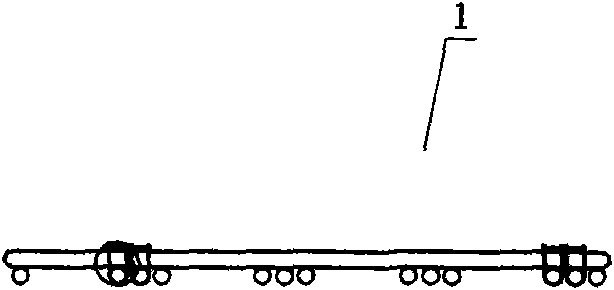

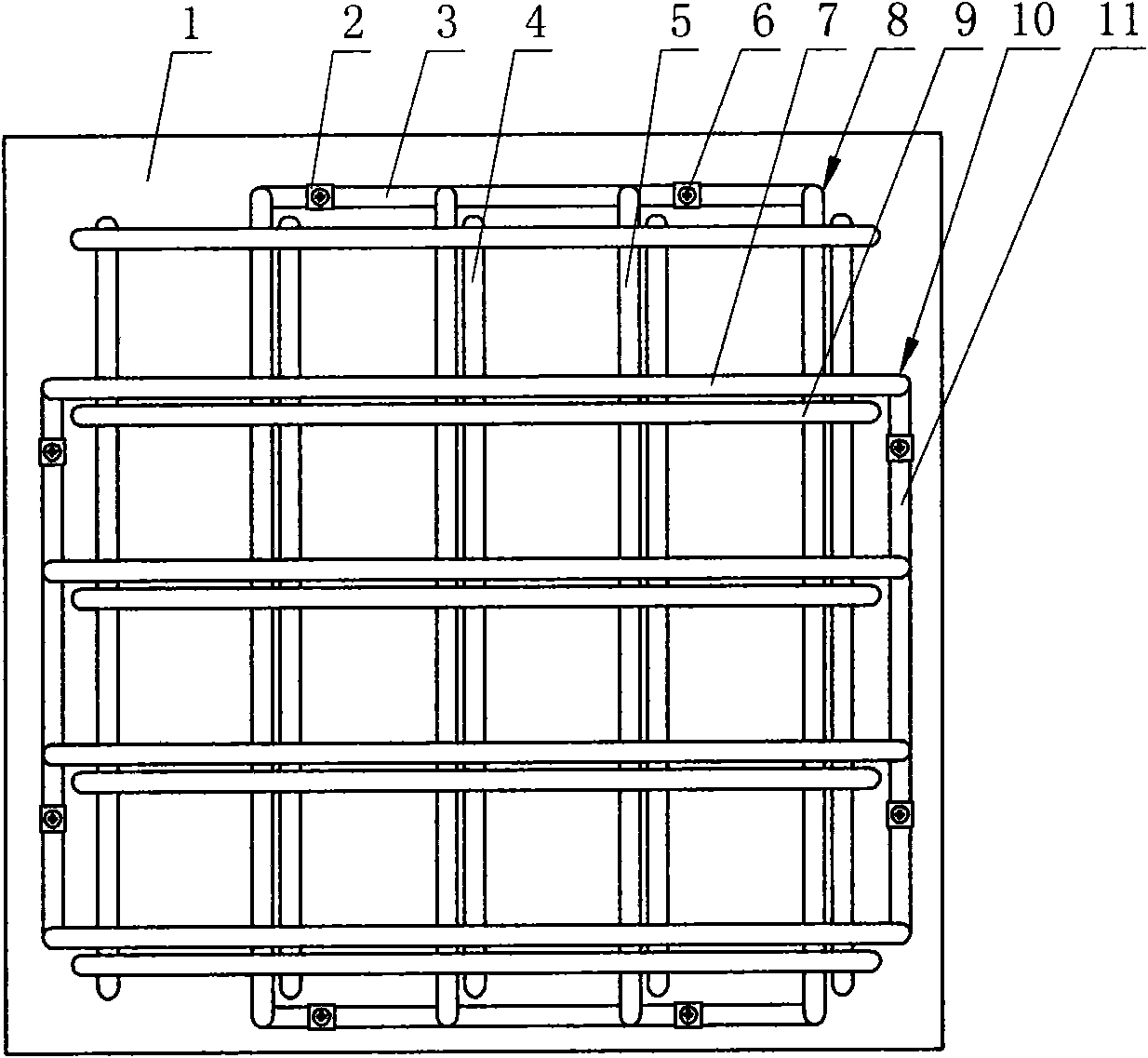

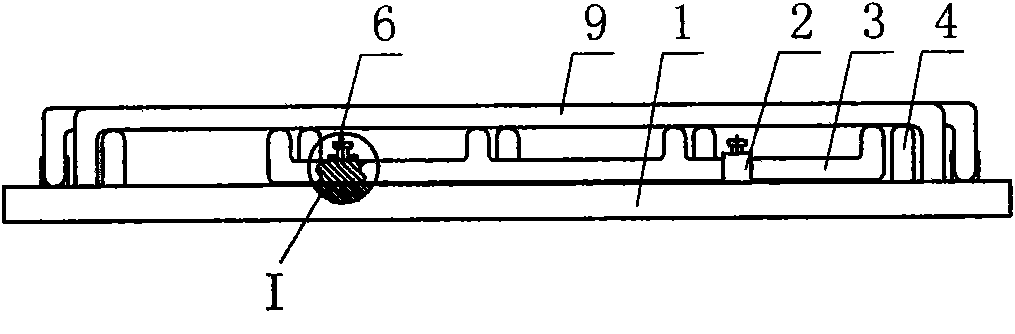

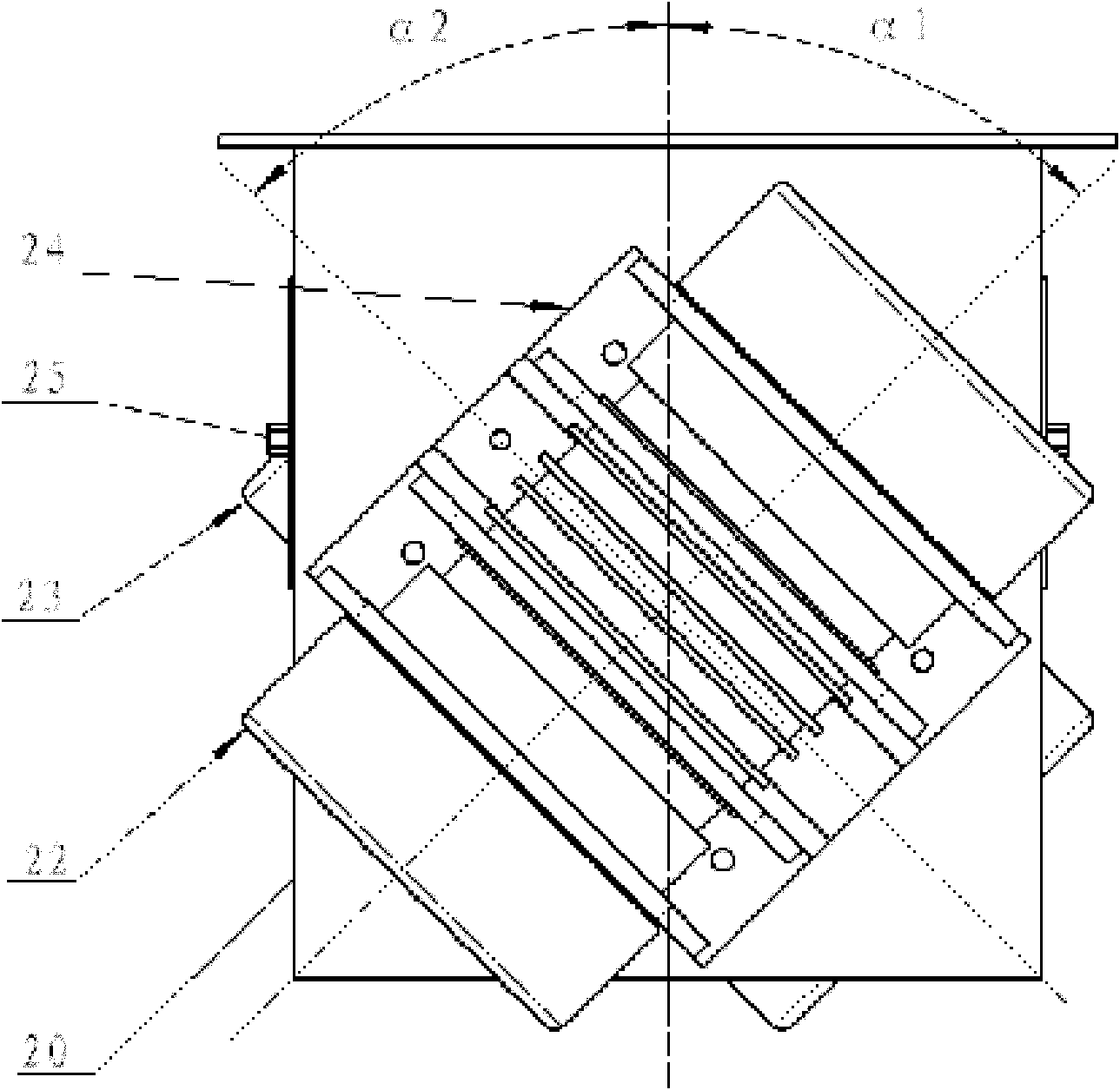

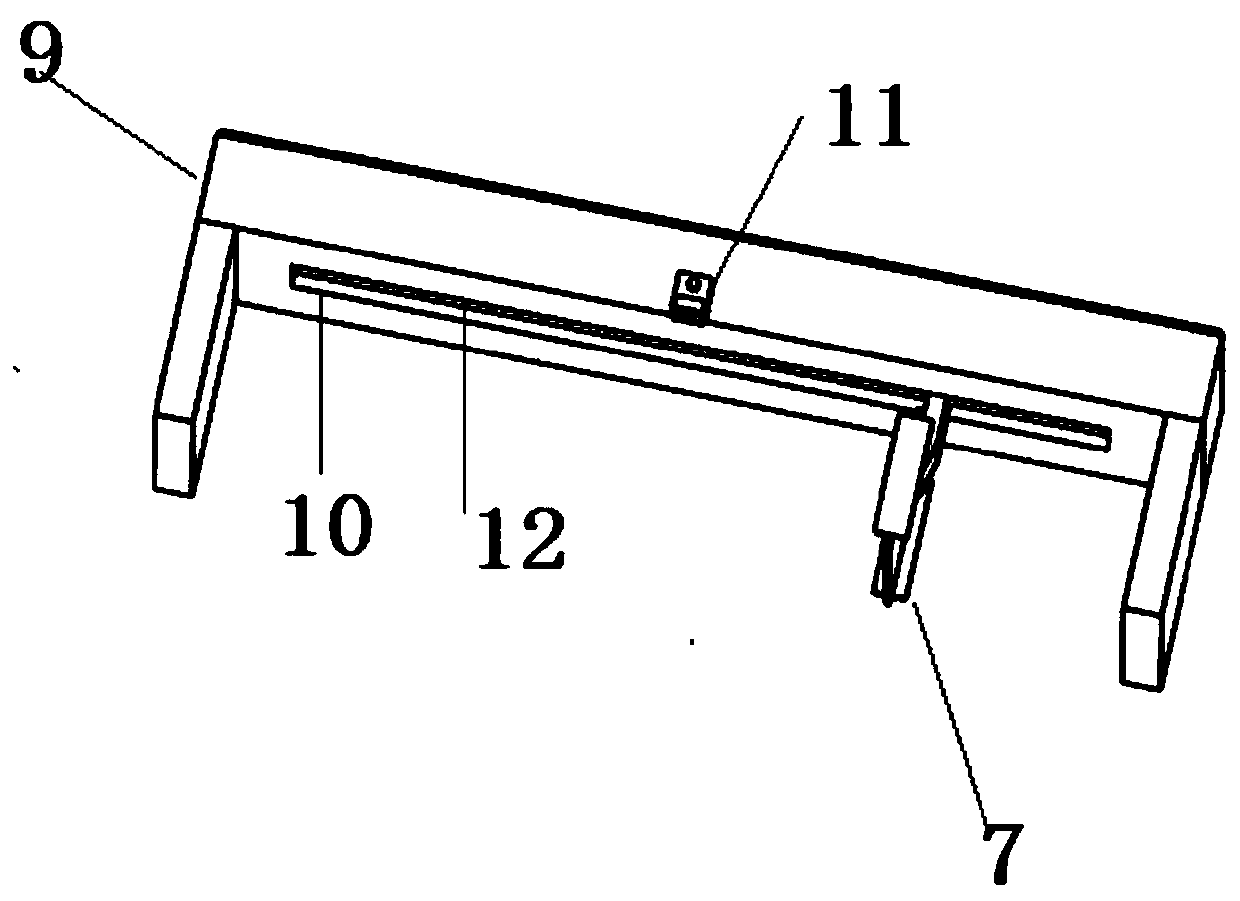

Sieve mesh with adjustable sieve pore gaps

InactiveCN101637761AImprove screening accuracySmall sizeSievingScreeningEngineeringMechanical engineering

The invention relates to a sieve mesh with adjustable sieve pore gaps. An edge frame is provided with a group of movable frames moving along an X shaft and a group of movable frames moving along a Y shaft; an upper beam which is uniformly distributed and made by each movable frame moving along the X shaft is respectively positioned between adjacent longitudinal rods, is parallel to the longitudinal rods and positioned in the same plane, and a lower beam of the movable frame slides in a guiding manner by a guide sleeve fixedly arranged on the edge frame; and an upper beam which is uniformly distributed and made by each movable frame moving along the Y shaft is respectively positioned between adjacent horizontal rods, is parallel to the horizontal rods and positioned in the same plane, and alower beam of the movable frame slides in a guiding manner by a guide sleeve fixedly arranged on the edge frame. The sieve mesh has reasonable design, convenient use, high sieving precision and highefficiency, is economical and practical, and can adjust the size of the sieve pore continuously; and the sieve mesh can adjust the size of the sieve pore in a certain range, is not limited by the specification when in use and can realize the multiuse effect with one mesh.

Owner:庞红顺

Colorectal Cell Sampling Device

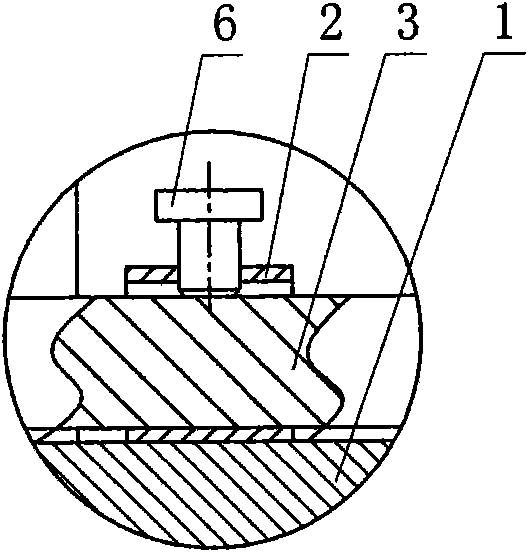

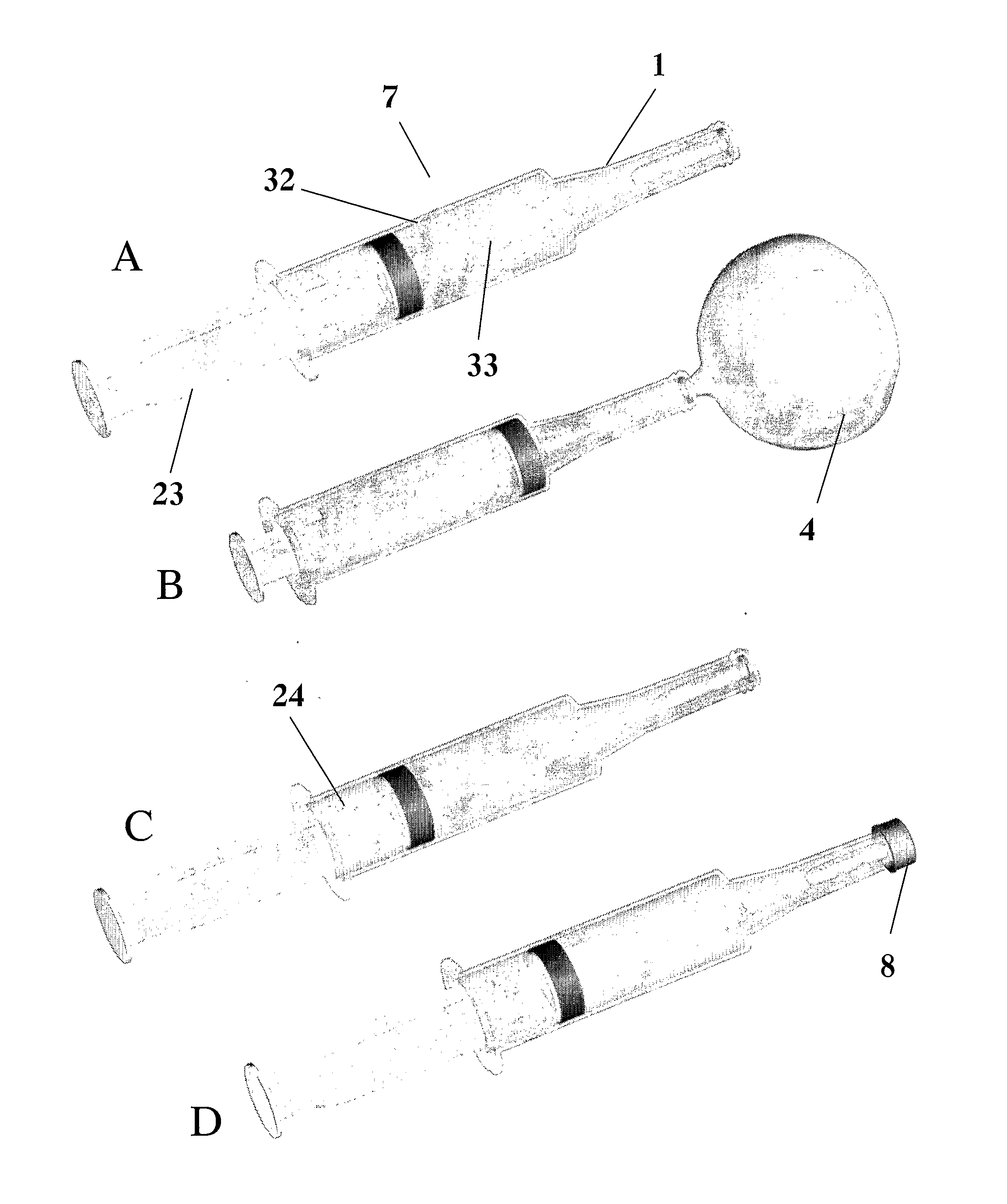

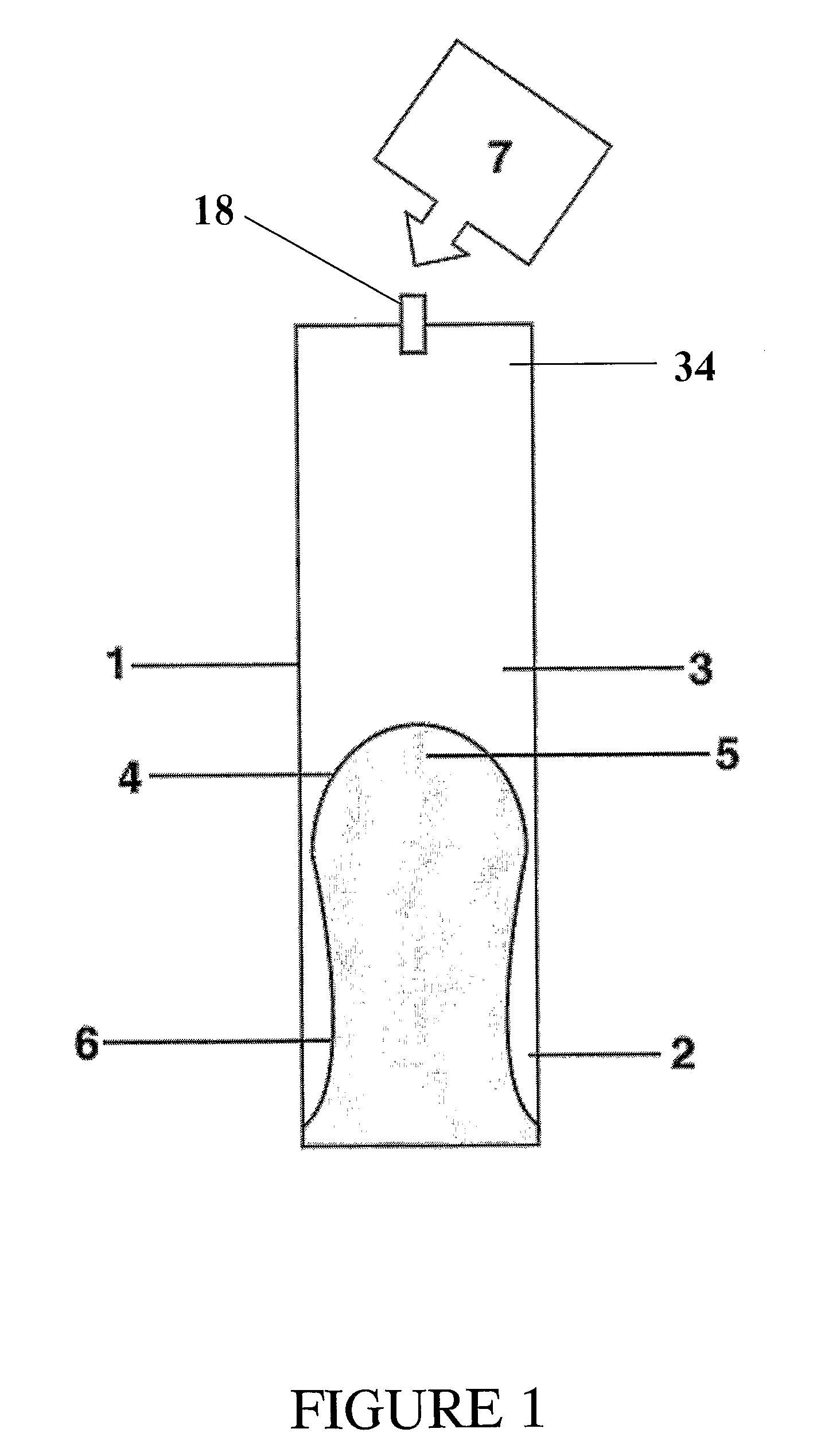

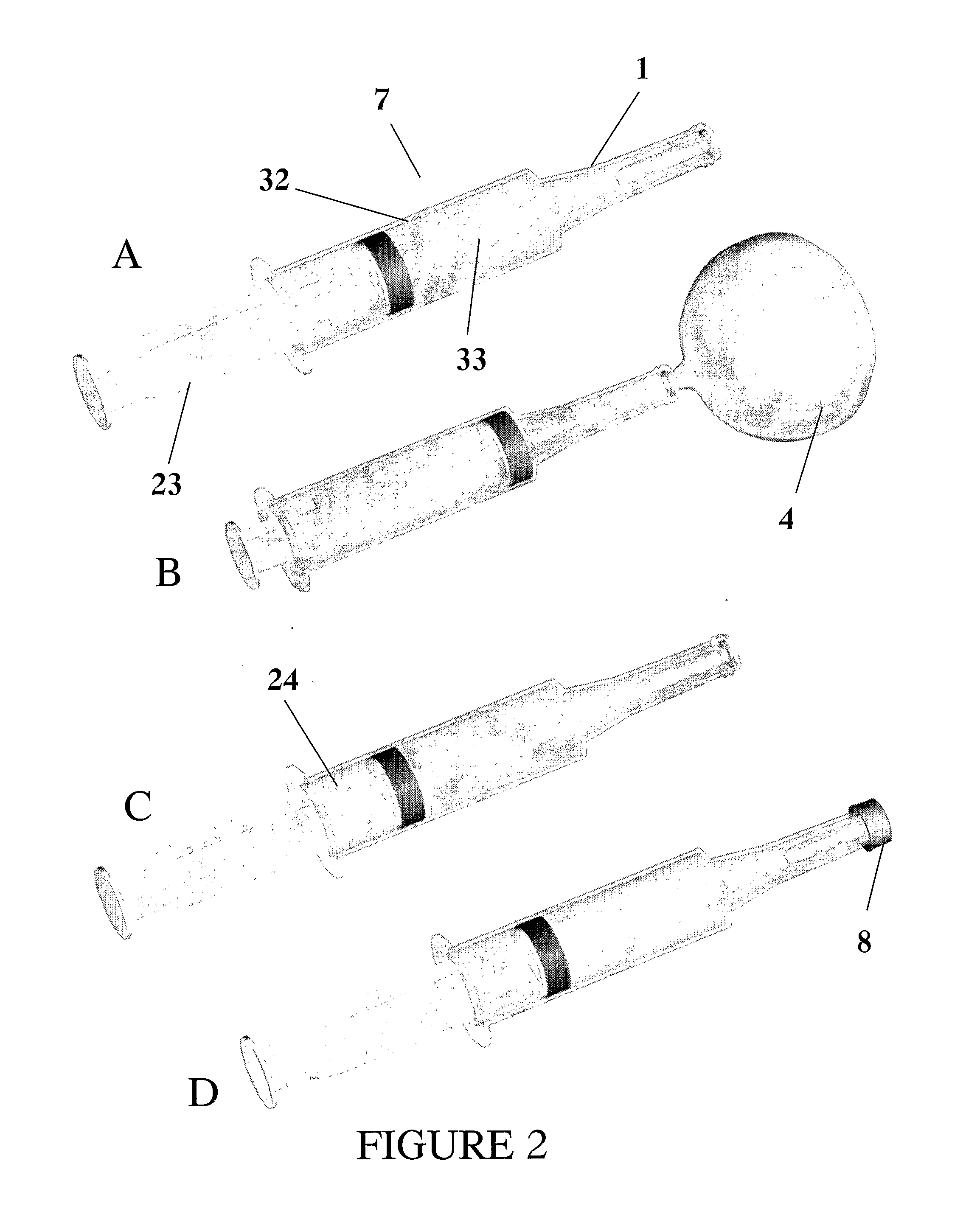

ActiveUS20080097238A1Ease discomfortComfortably insertedSurgical needlesPharmaceutical containersMembrane configurationBiomedical engineering

The present invention relates to a device for collecting a sample of exfoliated cells from a colorectal mucosal surface of a human subject which comprises a colorectal insertion member (1) having a distal, insertion end (2), a proximal end (34) and a closable interior cavity (3), a flexible membrane having an outer, cell sampling surface (5) and an inner surface, wherein said membrane is sealingly attached to the distal, insertion end of said insertion member and held within the interior cavity, such that, in use, pressurisation of the interior cavity to at least a first elevated pressure causes the membrane to emit from the distal end of said insertion member to make contact with the colorectal mucosal surface and pressurisation of the interior cavity to a second reduced pressure causes the membrane to invert and return to the interior cavity of said insertion member A kit comprising said device and methods of colorectal cell sampling using said device are also described.

Owner:ORIGIN SCI

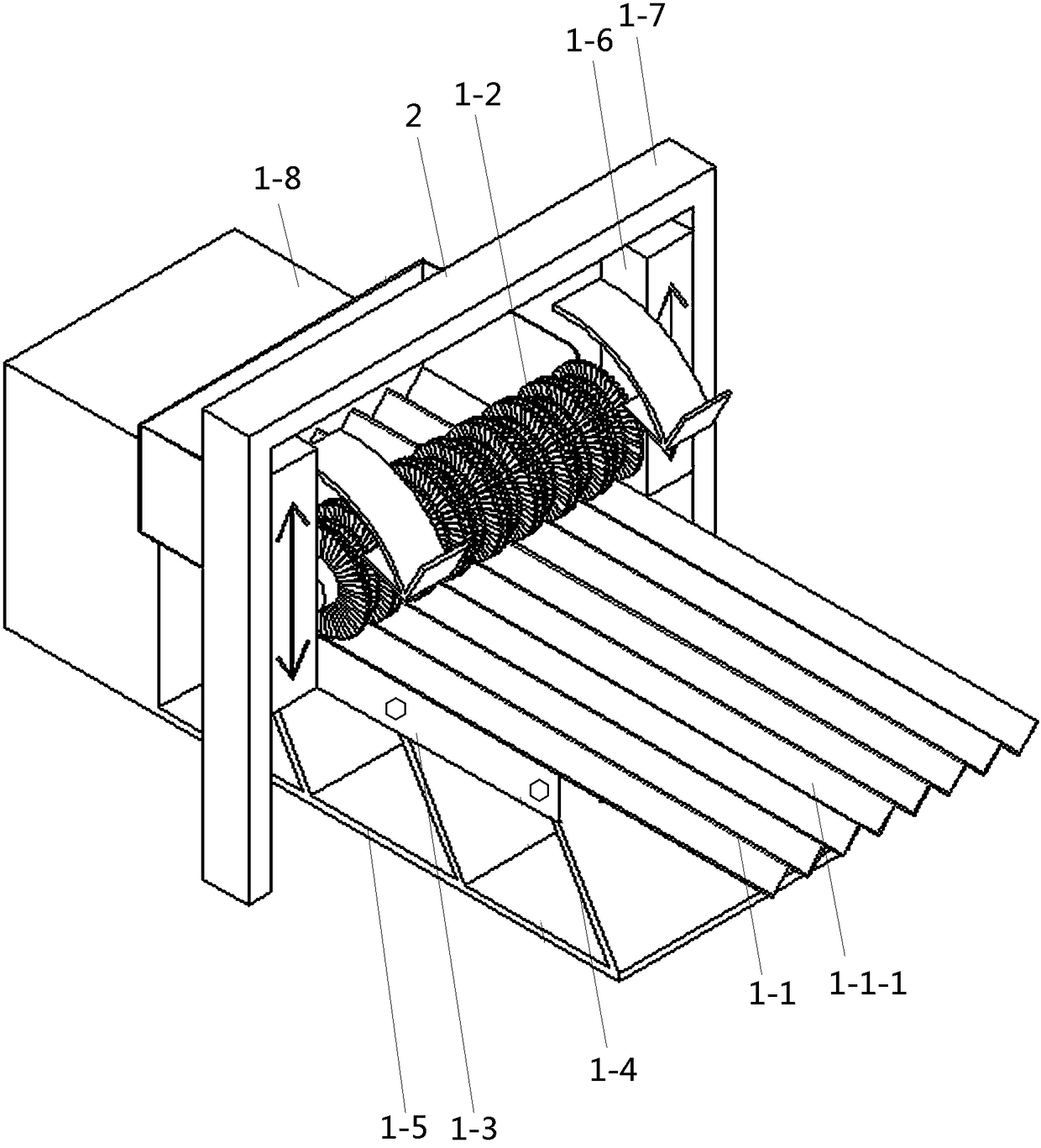

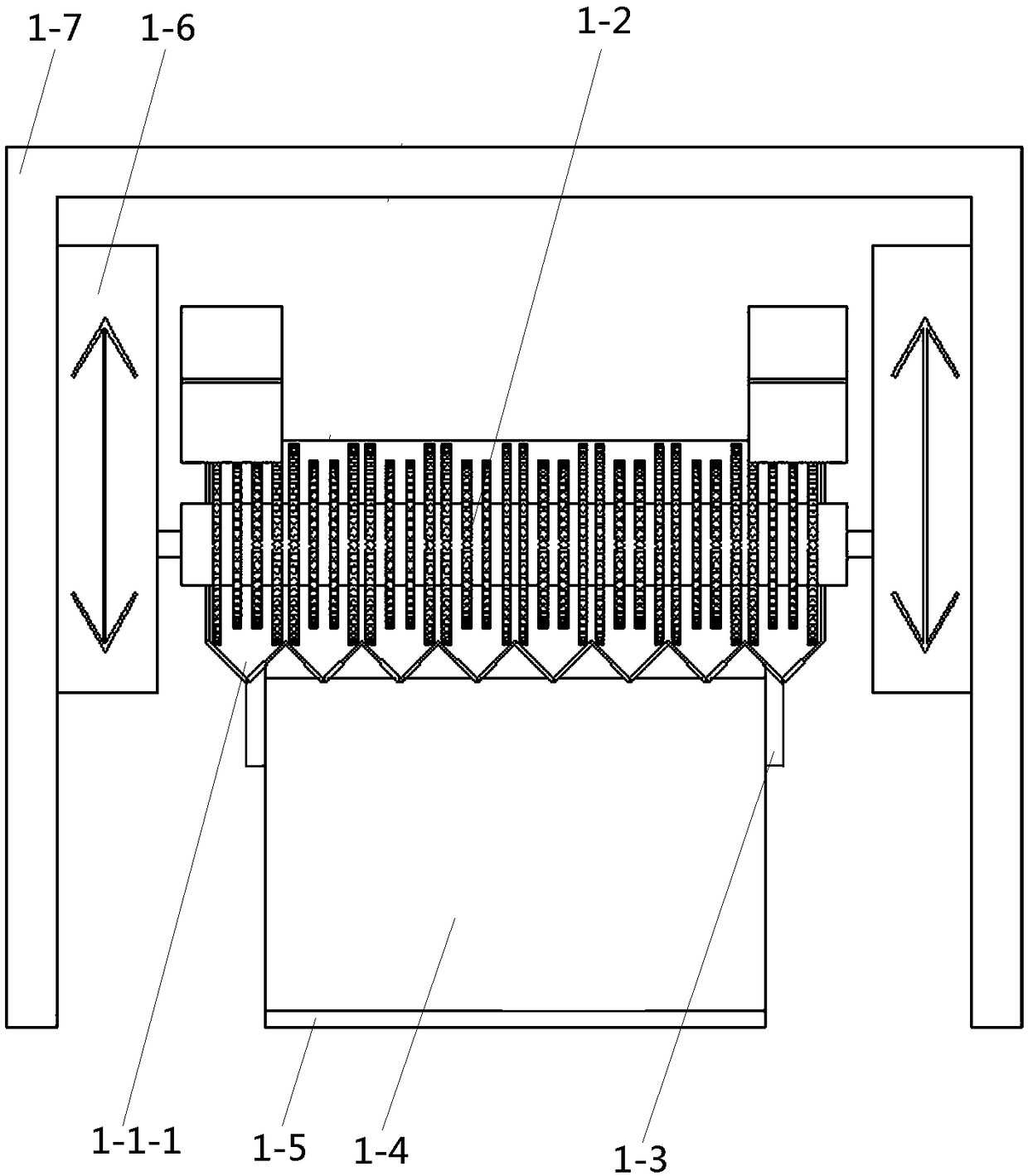

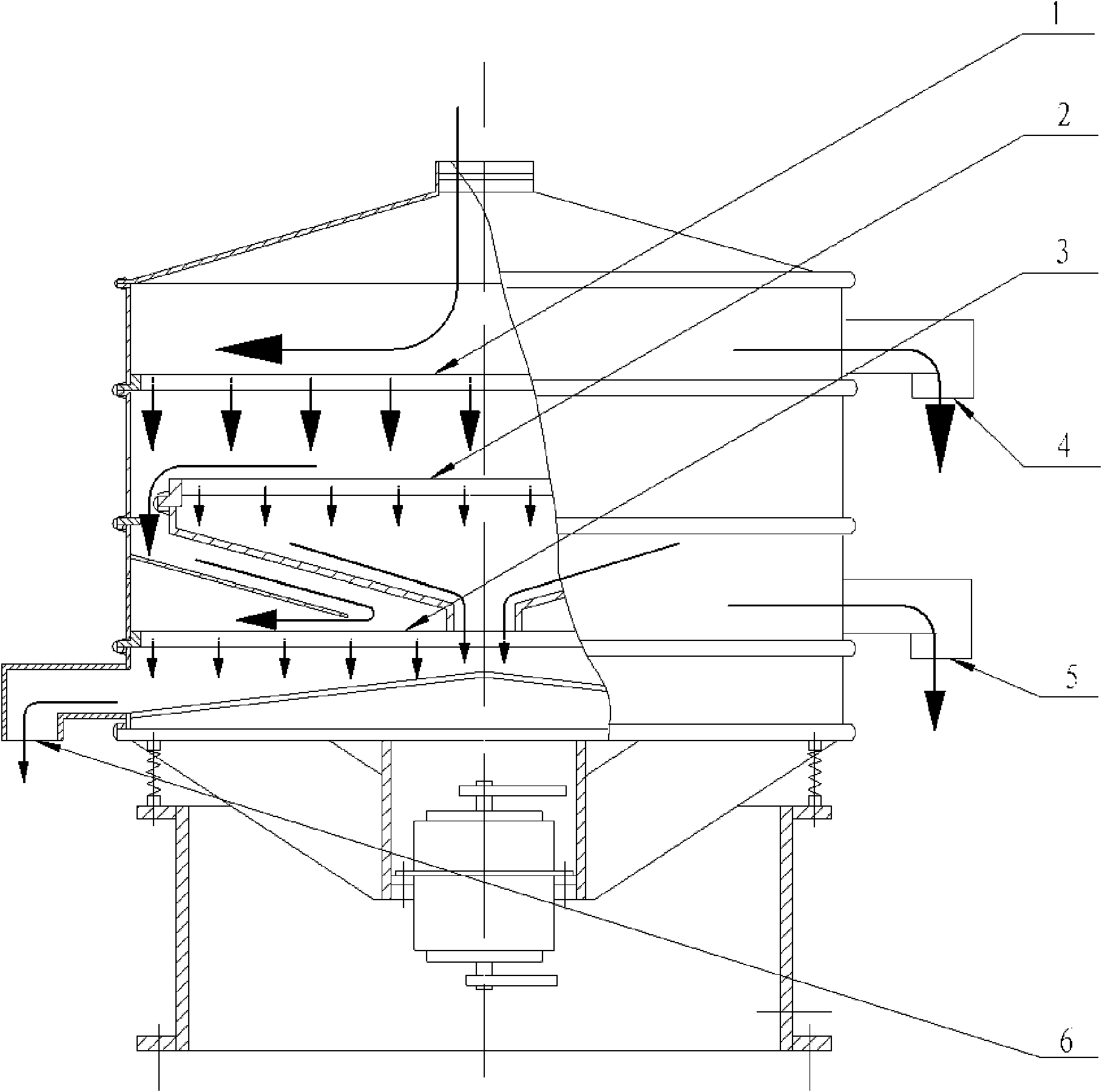

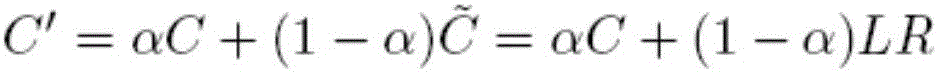

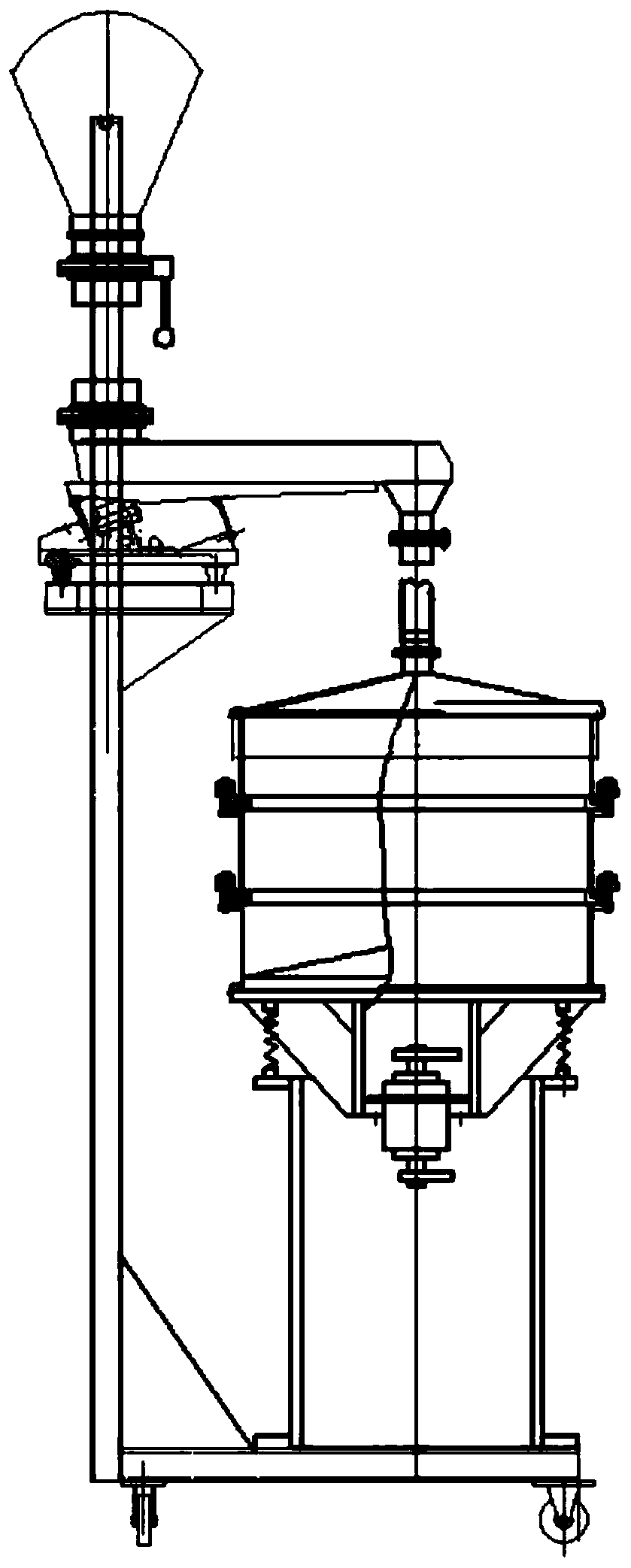

Vertical spiral vibrating screen

InactiveCN102371246AImproved resistance to fatigue vibrationIncrease the range of motionSievingScreeningEngineeringFine powder

The invention discloses a vertical spiral vibrating screen capable of greatly increasing the area of a screen and lengthening the movement stroke of powder. The vertical spiral vibrating screen comprises a base, a screen arranged on the base through a plurality of supporting springs, a vibrating device connected with the lower end of the screen and positioned in the base, a bin arranged at the upper end of the screen and a feeding valve arranged in the bin. The screen comprises a shell, a middle upright post and a screen net. The shell is a cylinder provided with a cover plate and a bottom plate, and the lower part of the shell is provided with a fine powder feeding hole and a coarse powder feeding hole; the middle upright post is vertical to the center of the shell; and the screen net comprises a bottom screen net, a lateral screen net and a top plate, wherein the inner edge of the bottom screen net is fixed on the middle upright post and is downwards spiral around the middle upright post, the lateral screen net is arranged coaxial with the middle upright post and is downwards spiral around the middle upright post, the lower end of the lateral screen net is connected with the outer edge of the bottom screen net, and the inner edge of the top plate is fixed on the middle upright post and is downwards spiral around the middle upright post.

Owner:SHANGHAI JIANSHE LUQIAO MASCH CO LTD

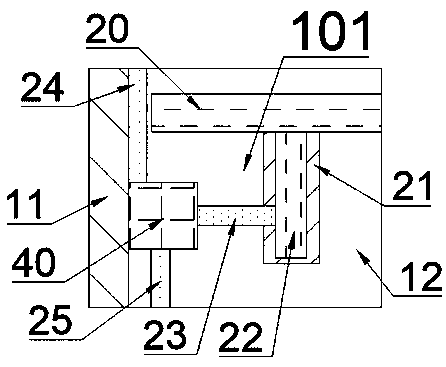

Classifying and screening device for building waste

ActiveCN110404669AImprove screening accuracyImprove recycling ratesConstruction waste recoverySolid separationArchitectural engineeringEngineering

The invention discloses a classifying and screening device for building waste. The device comprises a classifying box, wherein the classifying box is internally provided with a vibration cavity, a screening device, a steel cavity and a magnetic separation device, wherein the vibration cavity is internally provided with a vibration device which is used for vibrating and screening muck, and the screening device is located on the right side of the vibration cavity. The steel cavity is arranged below the screening device and communicates with the screening device, wherein the steel cavity is internally provided with a crushing device. The magnetic separation device is positioned at the lower side of the crushing device and used for screening stone and steel. According to the classifying and screening device for the building waste, the muck in the building waste can be screened through the vibration device, wood materials can be screened from the building waste through a buoyancy screeningmechanism, and then the crushing device is used for performing refined crushing on the building waste, and finally the magnetic separation device is used for separating the stone from the steel. Therefore, the classifying and screening device can performing classifying and screening on four main components in the building waste.

Owner:江苏瑞冠智能科技有限公司

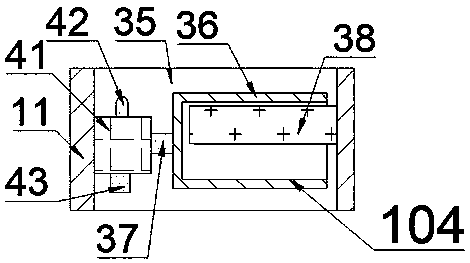

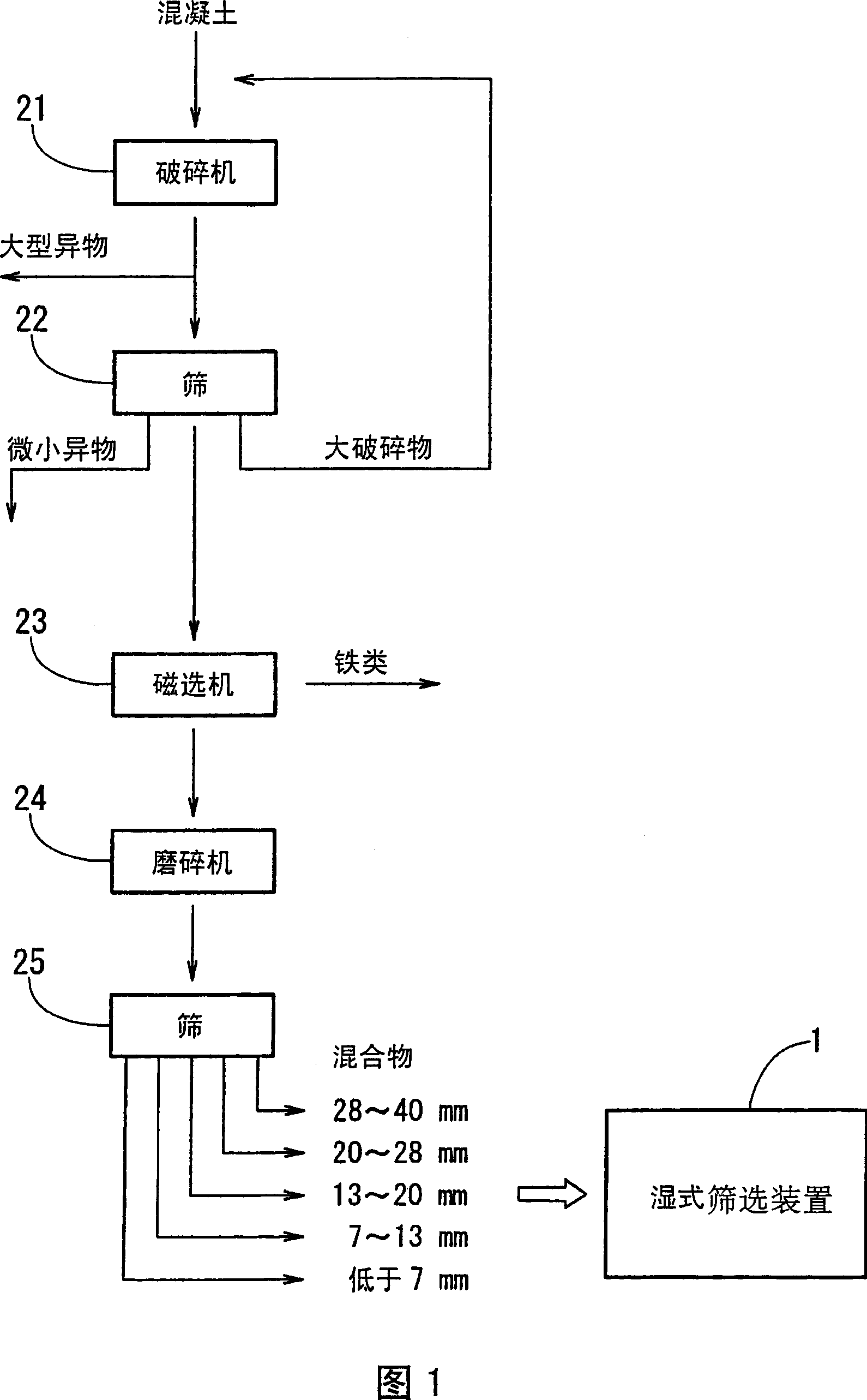

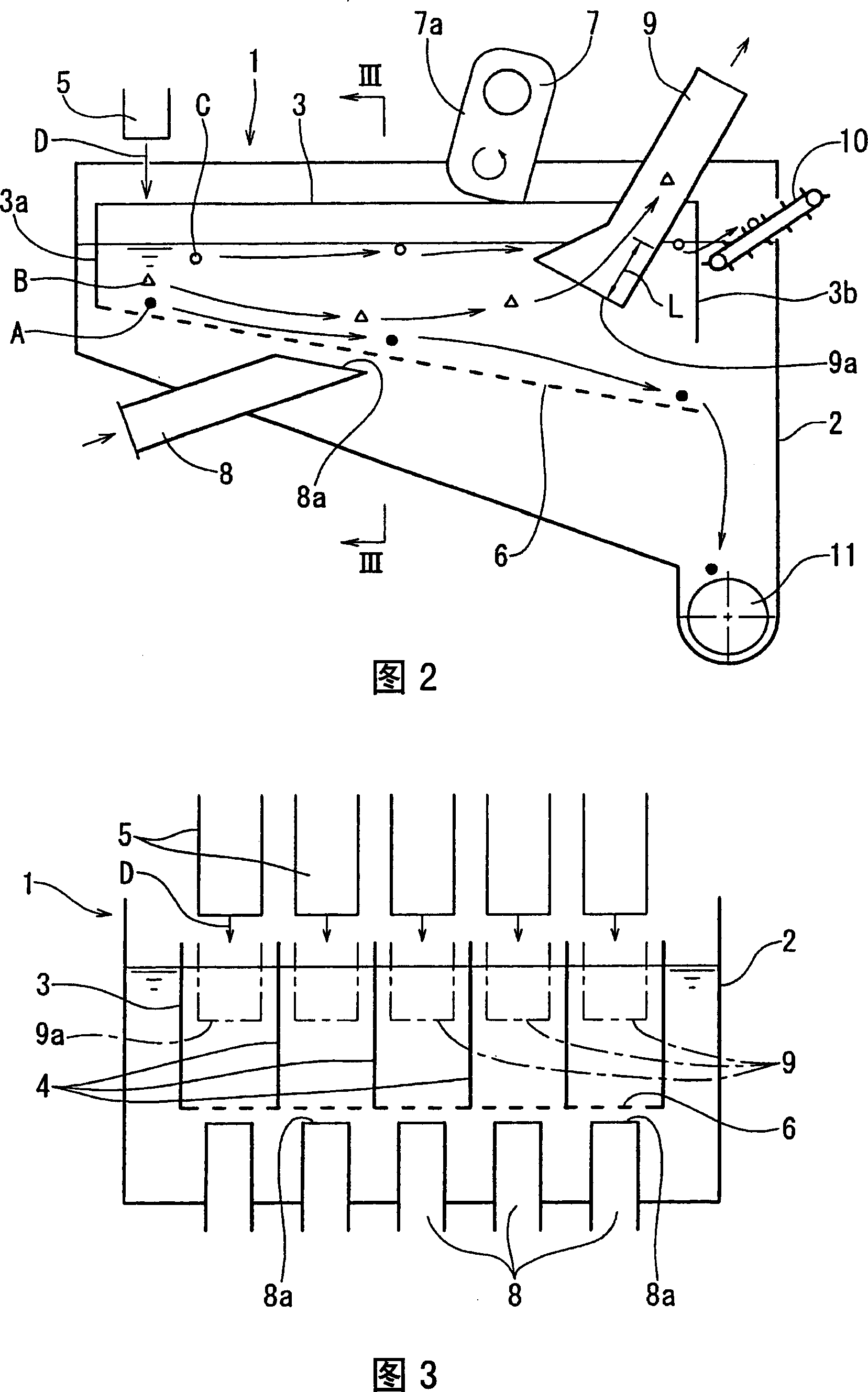

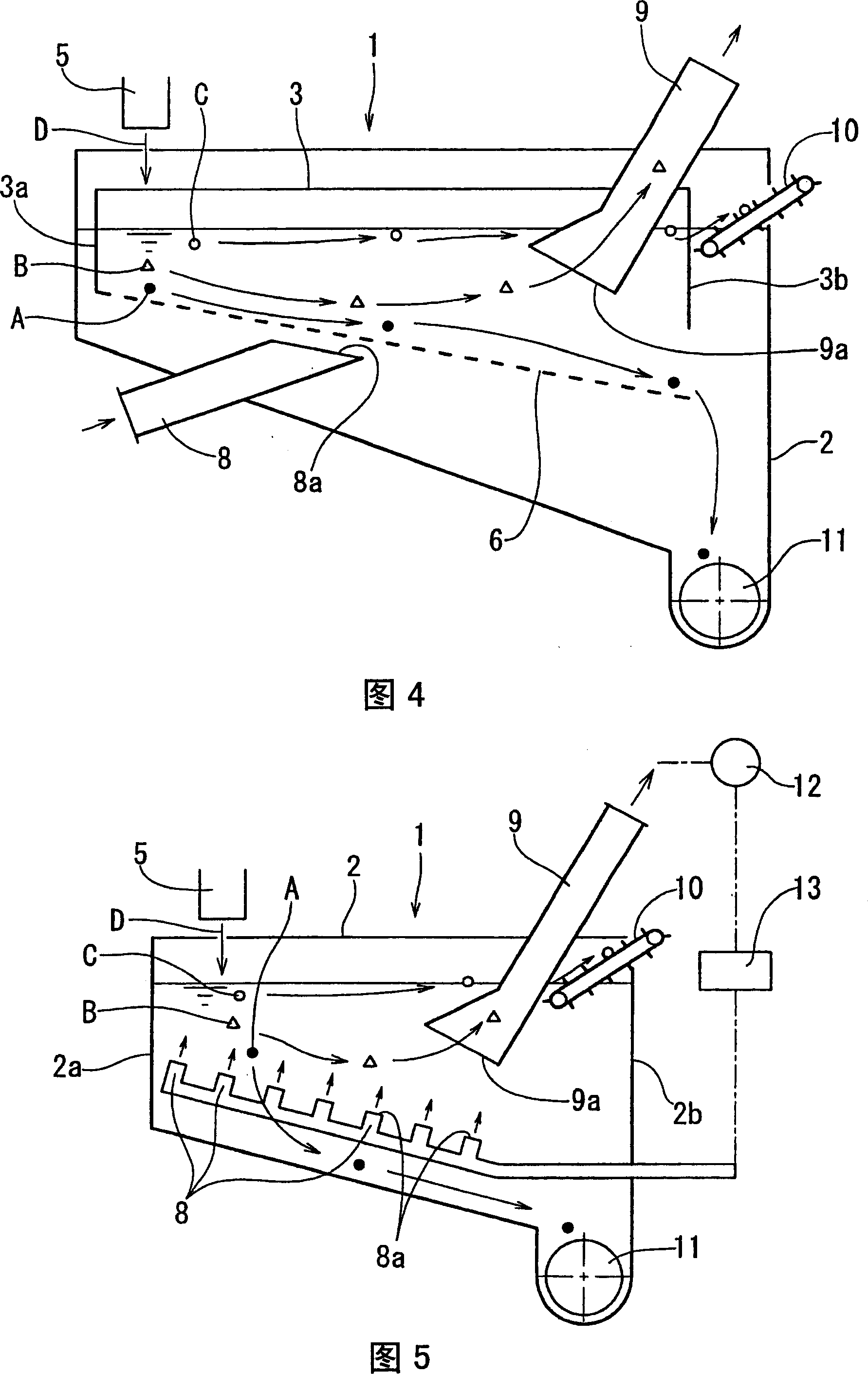

Filtering device

Provided is a filtering device, which could not reduce the recovery of the heavy proportion object, prevent mid light proportion object from mixing with heavy proportion object. Filtering device has upwelling generating tube (8) making upwelling generate inside the flume (2), and suction catheter (9) sucking mid light proportion object (B) floating undersurface in virtue of upwelling to upper, so the mid light proportion objects (B) of low deposition speed are floated undersurface by the upwelling, and are sucked and dischared to the suction catheter (9), which prevents mixing and depositing into the heavy proportion object (A) of the bottom of the flume (2), and even the heavy proportion objects (A) entering into the suction catheter (9) owing to upwelling, it could not be sucked to the upper by the suction catheter (9) but deposited to outside, without reducing the recovery of the heavy proportion object (A), and preventing mid light proportion object (B) from mixing with heavy proportion object (A).

Owner:KURIMOTO LTD

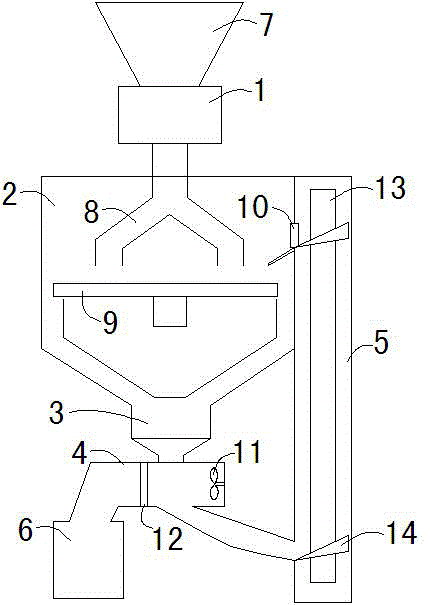

Circular grinding equipment

InactiveCN104549700ACompact structureNovel structureGas current separationGrain treatmentsEngineeringCrusher

The invention discloses circular grinding equipment, comprising a crusher, a feeder, a pulverizer, a screening device, a material returning machine and a collector, wherein a feeding hole is formed in the crusher and a discharge pipe is arranged on the crusher; the discharge pipe is connected with the feeder; the feeder is connected with the pulverizer; the pulverizer is connected with the screening device; the material returning machine and the collector are both connected with the screening device; the feeder comprises a feeding tray and a material returning opening; the screening device comprises a blast blower and a sieve plate; meshes are fully distributed in the sieve plate; the material returning machine comprises a conveyer belt and a material returning shovel; and the material returning shovel is matched with the material returning opening. The circular grinding equipment is compact and novel in structure, is in a circular structure, can full-automatically run, and is free of manpower, full to crush, high in screening accuracy, high in efficiency and low in energy consumption; and resources are saved.

Owner:HENAN GUANGJIN PLASTIC

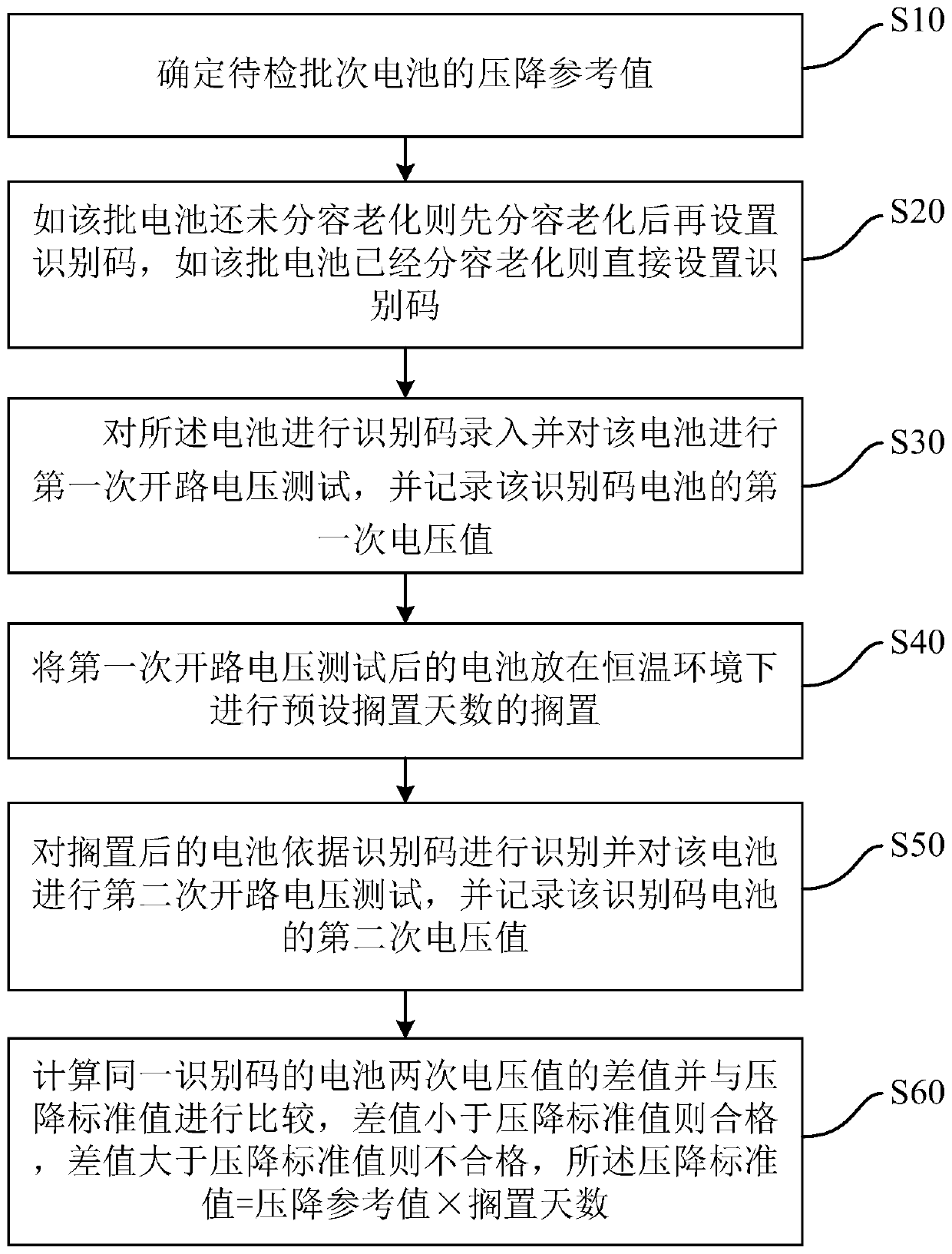

Battery self-discharge test method

InactiveCN110297191AAvoid Sifting SituationsImprove screening accuracyElectrical testingSortingElectrical batteryEngineering

The invention discloses a battery self-discharge test method. The method comprises the following steps: determining a pressure drop reference of a to-be-tested batch battery, and selecting whether toset an identification code after partial volume ageing according to different selections of the batteries; entering an identification code and performing first open-circuit voltage testing on the battery and recording the same; laying aside the battery after the first open-circuit voltage testing under a constant temperature environment at the preset laying aside days; identifying the battery laying aside according to the identification code, and performing the second open-circuit voltage testing on the battery, and recording; computing the difference of twice voltage values of the battery under the same identification code, and comparing the difference with the pressure drop standard value, regarding that the battery is qualified if the difference is less than the pressure drop standard value, and regarding that the battery is unqualified if the difference is greater than the pressure drop standard value, wherein the pressure drop standard value is equal to the pressure drop referencevalue* laying days. The screening precision of the battery self-discharge unqualified product is improved.

Owner:深圳市思商科技有限公司

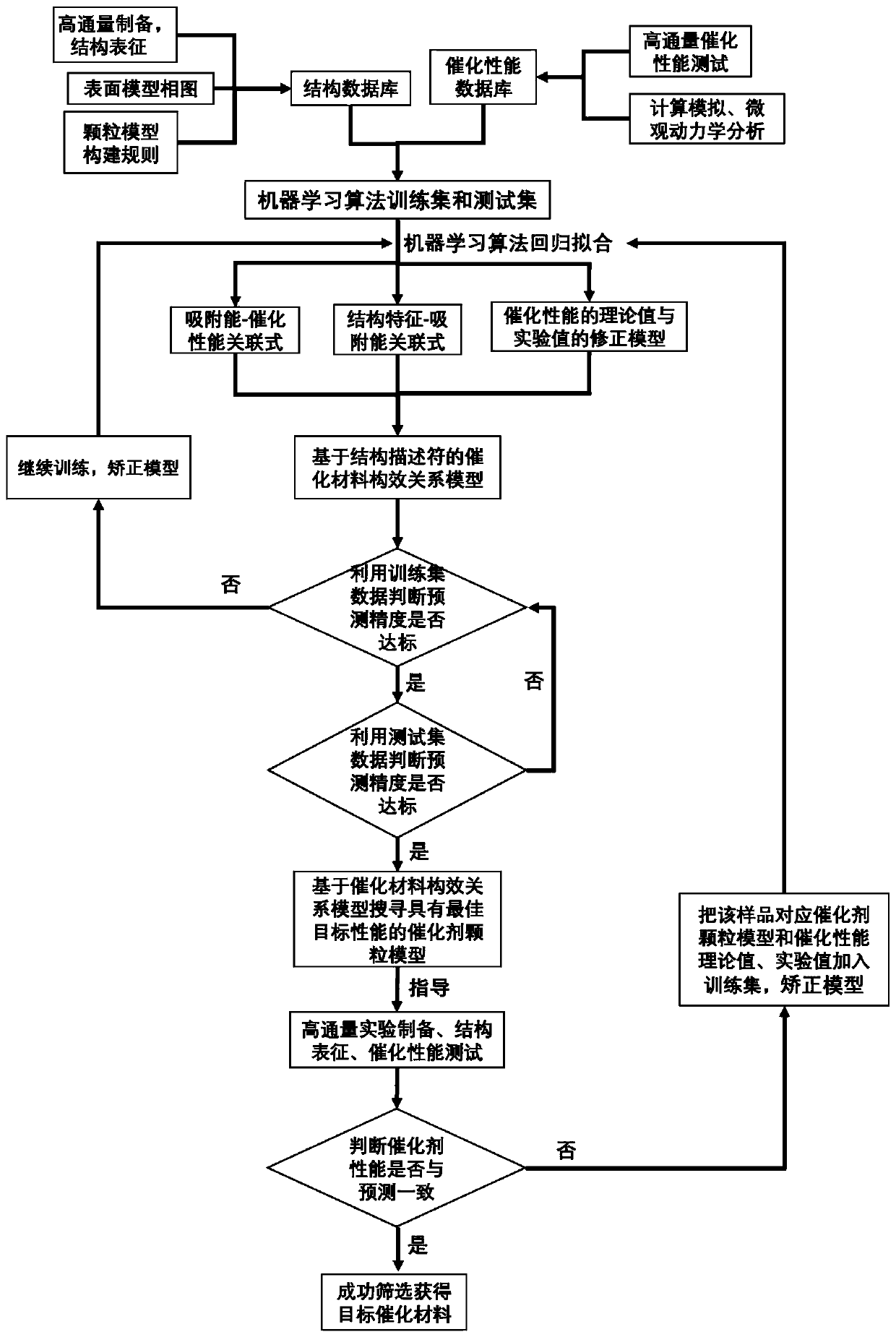

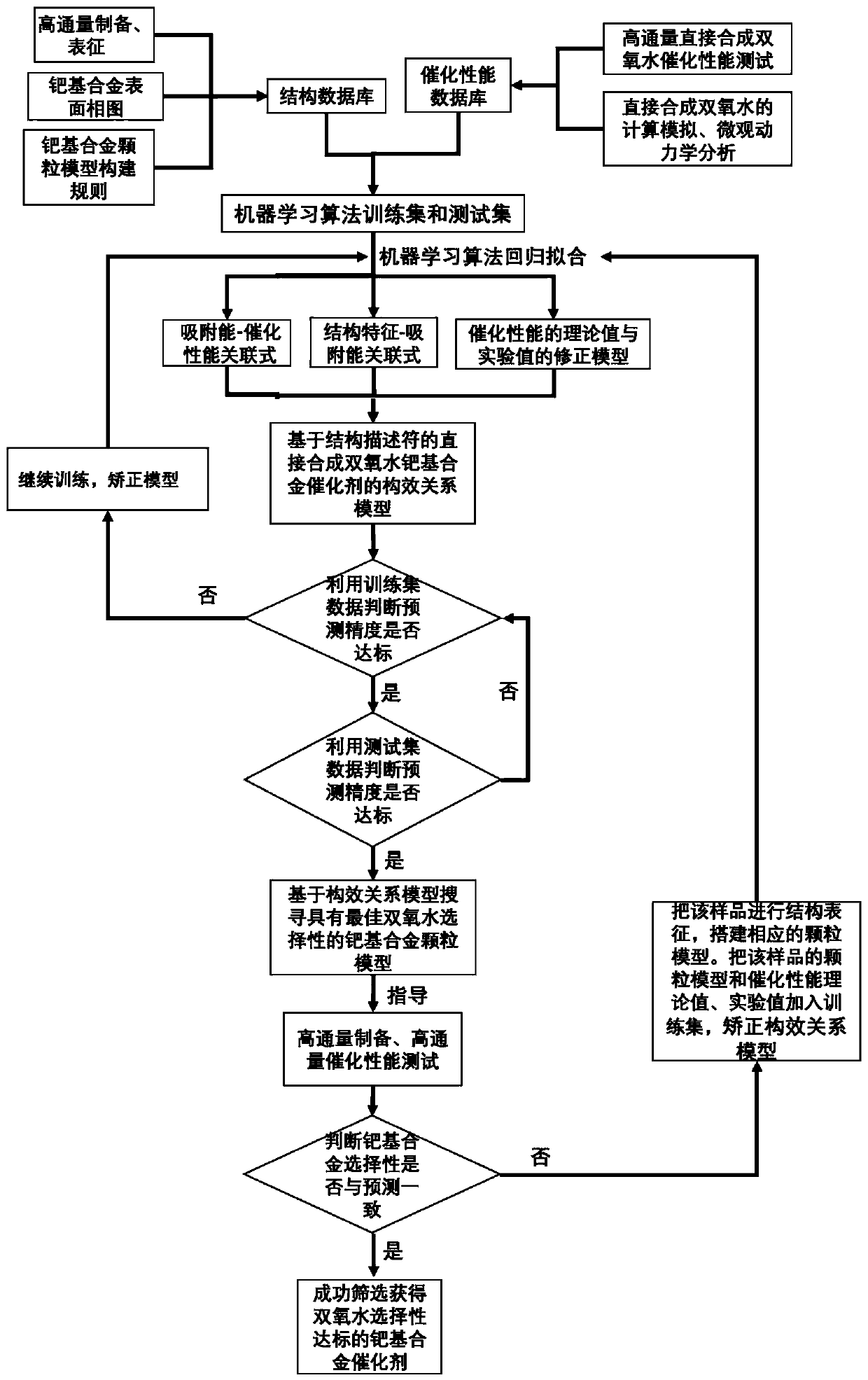

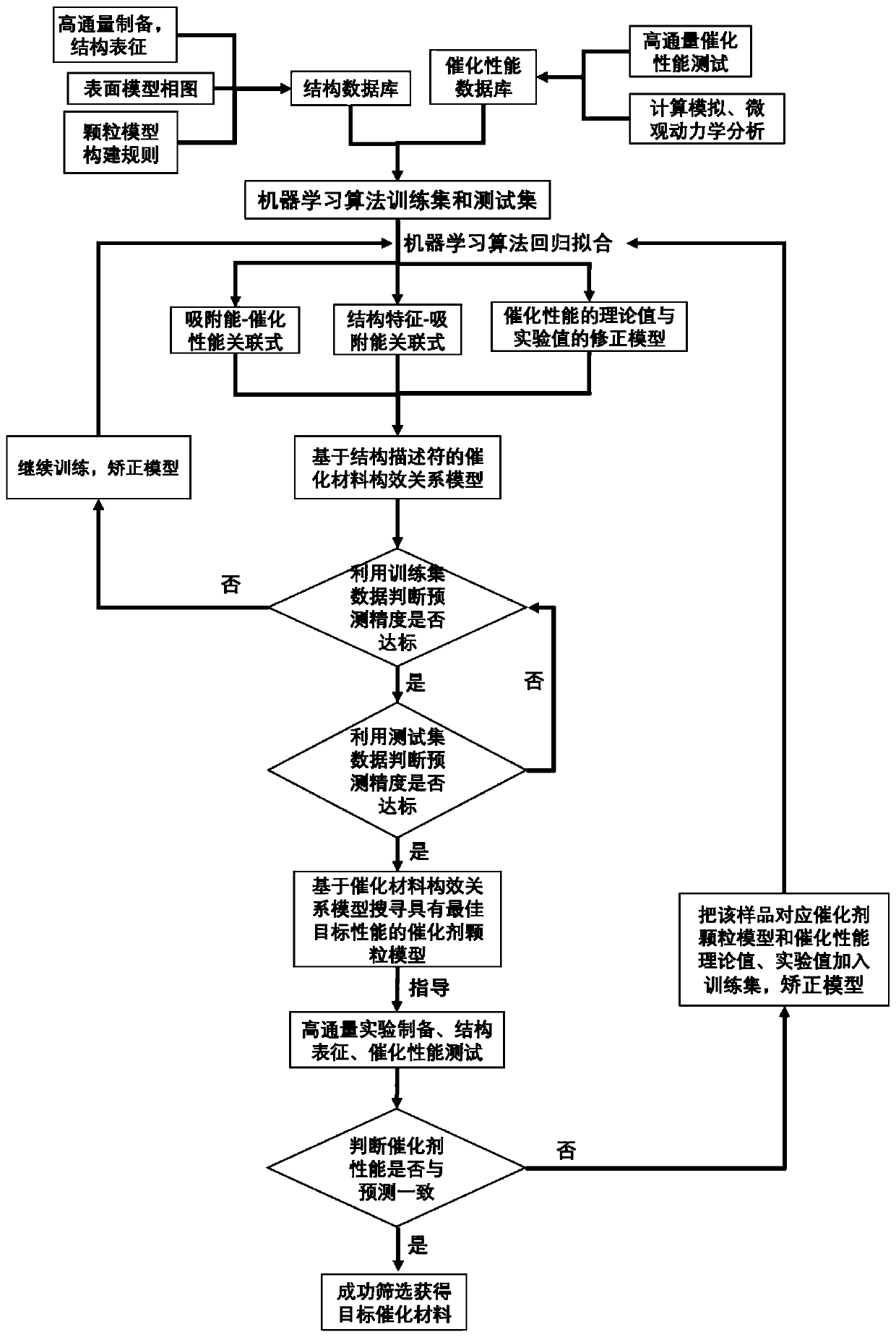

Catalytic material screening method and catalytic material screening system based on high-throughput experiment and high-throughput calculation

ActiveCN111128311AImprove screening accuracySpeed up screeningChemical processes analysis/designComputational theoretical chemistryPtru catalystPhysical chemistry

The invention provides a catalytic material screening method and a catalytic material screening system combining a high-throughput experiment and high-throughput calculation. The method comprises thesteps: screening a to-be-confirmed catalytic material meeting a target catalytic performance by using a catalyst structure-activity relation model constructed based on the data results of a high-throughput experiment and high-throughput calculation; performing high-throughput preparation and high-throughput performance evaluation on the screening result to obtain the experimental result of the to-be-confirmed catalytic material; and comparing the catalytic performance prediction result of the to-be-confirmed catalytic material with the experimental result of the to-be-confirmed catalytic material, and determining that the to-be-confirmed catalytic material is the catalytic material reaching the target catalytic performance under the condition of a predetermined deviation range. According to the scheme, the theoretical calculation simulation result, the existing experiment result and the new catalyst characterization result can form a mutual verification relationship through the catalyst structure-activity relationship model constructed based on the high-throughput experiment and the high-throughput calculation, so that the screening precision and the screening speed of the catalytic material are improved.

Owner:BEIJING UNIV OF CHEM TECH

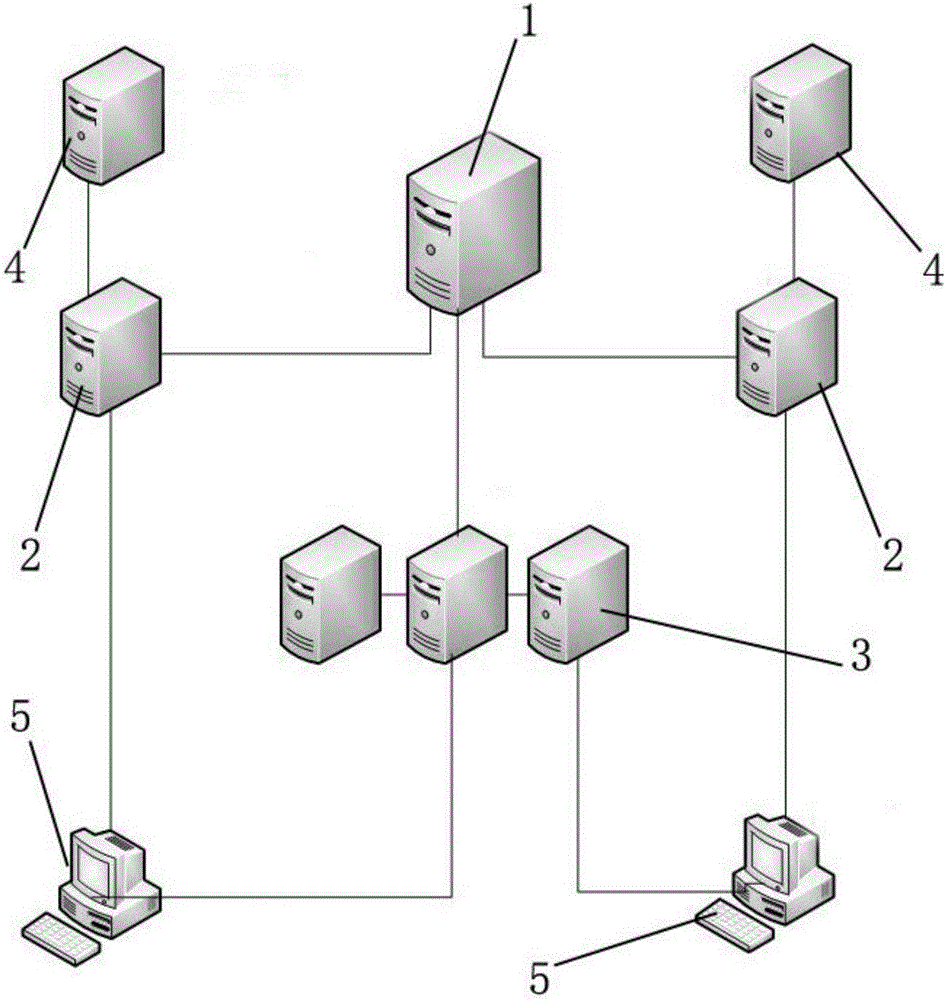

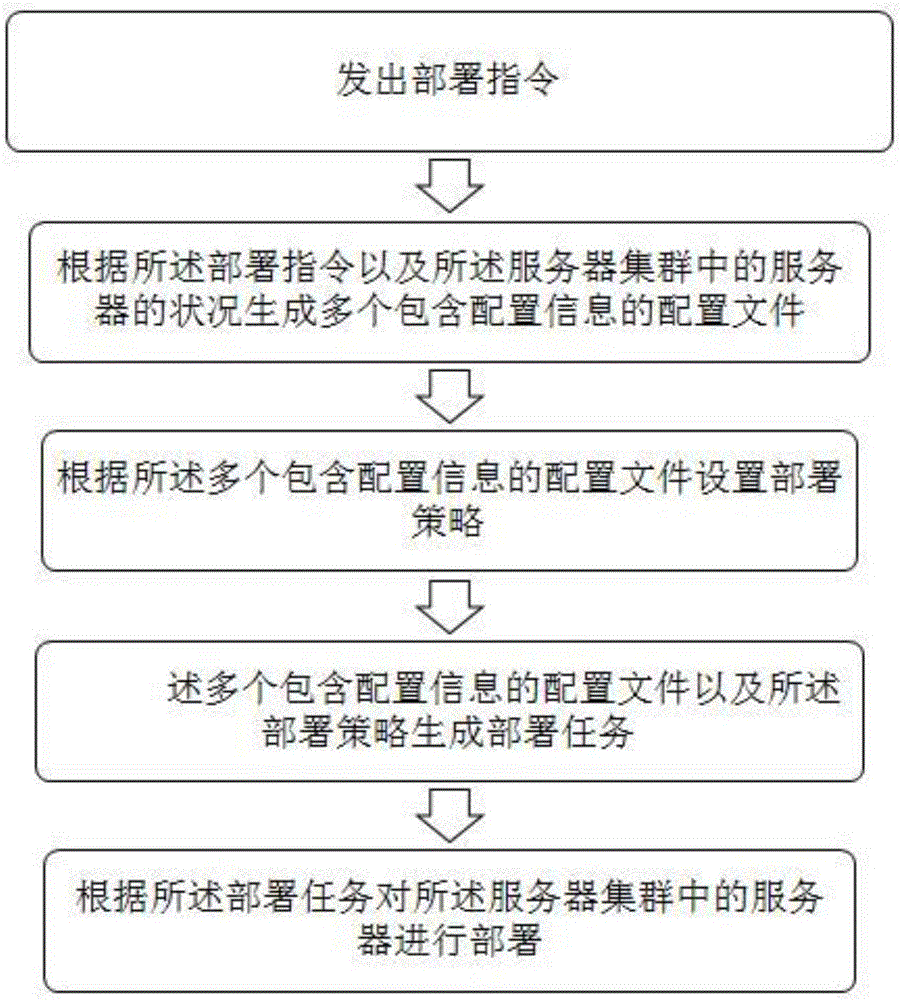

Method and system for implementing trans-regional distributed match of game

ActiveCN105903193AReasonable screening strategyImprove screening accuracyVideo gamesOperating systemCombat unit

The invention relates to the technical field of network games and specifically relates to a method and system for implementing a trans-regional distributed match of a game. The method for implementing the trans-regional distributed match of the game comprises the steps that a matching combat unit sends a command to a signaling transit and transmission server of a region; and the signaling transit and transmission server reports the command to a center matching dispatch server, and the command is transited and issued to each matching combat unit after being screened and dispatched by the center matching dispatch server. The system and the method greatly improve game experience of players.

Owner:HANGZHOU ELECTRONICS SOUL NETWORK TECH

Production method for alginate specialized for welding

ActiveCN103360510AReduce contentEliminate decalcification processWelding/cutting media/materialsSoldering mediaSulfurCalcification

The invention relates to a production method for alginate specialized for welding. In the production method, alginic acid is formed by an acidification method; then a secondary washing process is employed in a washing process after the alginic acid is formed by acidification; and a compound washing liquid is selected to wash again after the alginic acid is conversed into alginate by neutralization in a solid phase. The above improvements can effectively reduce the content of phosphorus, sulfur and chlorine in a finished product of the alginate. Acidification treatment is used to form alginic acid in the preparation method. Compared with a conventional calcification method, the production method provided by the invention omits a decalcification process, shortens a production period, and reduces working time. Besides, compared once washing in the prior art, the secondary washing process is employed after acidification, so that the content of phosphorus, sulfur and chlorine can be effectively reduced. The compound washing liquid is selected to wash the alginate after neutralization in the solid phase, so that the concentrations of inorganic ions such as phosphorus, sulfur and chlorine are reduced and the volume of the obtained alginate expands, thereby facilitating subsequent smashing. The particle size can easily reach below 75 [mu]m when the alginate is smashed, with little loss.

Owner:青岛海之林生物科技开发有限公司

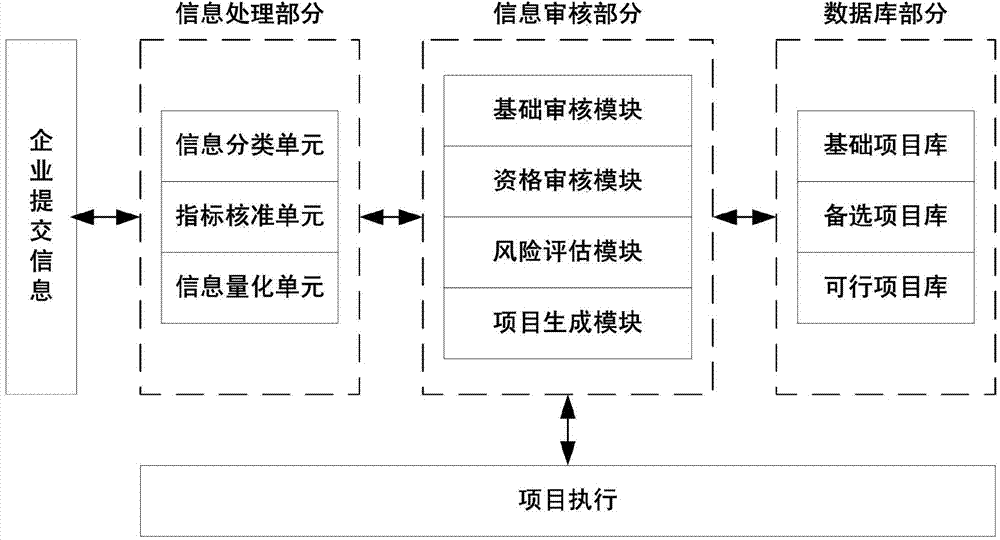

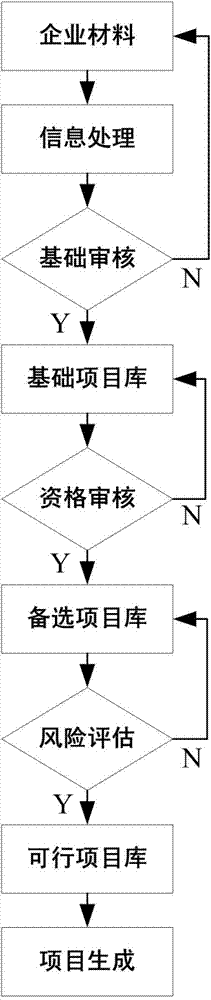

Investment and financing project screening system for facing high-tech business incubator

InactiveCN104732440AOvercoming screening inaccuraciesImprove screening accuracyFinanceRisk ControlItem generation

The invention discloses an investment and financing project screening system for facing a high-tech business incubator. The investment and financing project screening system for facing the high-tech business incubator is characterized by comprising a base auditing module, a base project library, a qualification auditing module, an alternative project library, a risk evaluation module, a practicable project library and a project generating module; the base auditing module is used for base auditing submitted enterprise information online, the base project library is used for storing the enterprise information which passes through the base auditing, the qualification auditing module is used for qualification grading, the alternative project library is used for storing the enterprise information which satisfies a qualification screening module grading standard, the risk evaluation module is used for risk evaluating, the practicable project library is used for storing the enterprise information which passes through a risk control grading of the risk evaluation module, and the project generating module is used for generating a practicable project. According to the investment and financing project screening system for facing the high-tech business incubator, all kinds of innovation and development indexes of scientific and technologic type small and micro enterprises can be quantified, evaluated and led in the risk evaluation module, the investment and financing risk is judged, so that investment and financing projects of the technologic type small and micro enterprises can be screened quickly and accurately.

Owner:HEFEI HIGH TECH STARTING UP BUSINESS INCUBATION MANAGEMENT

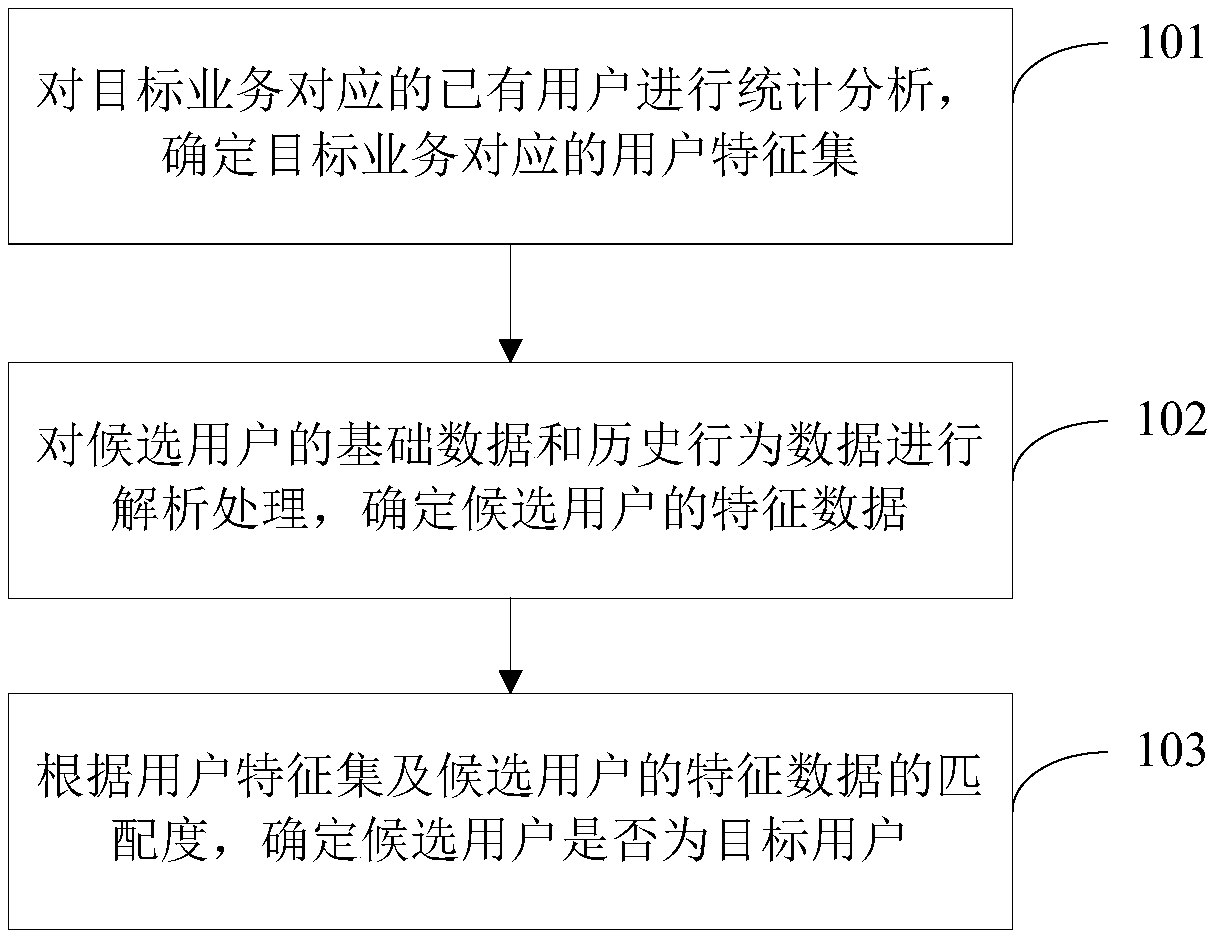

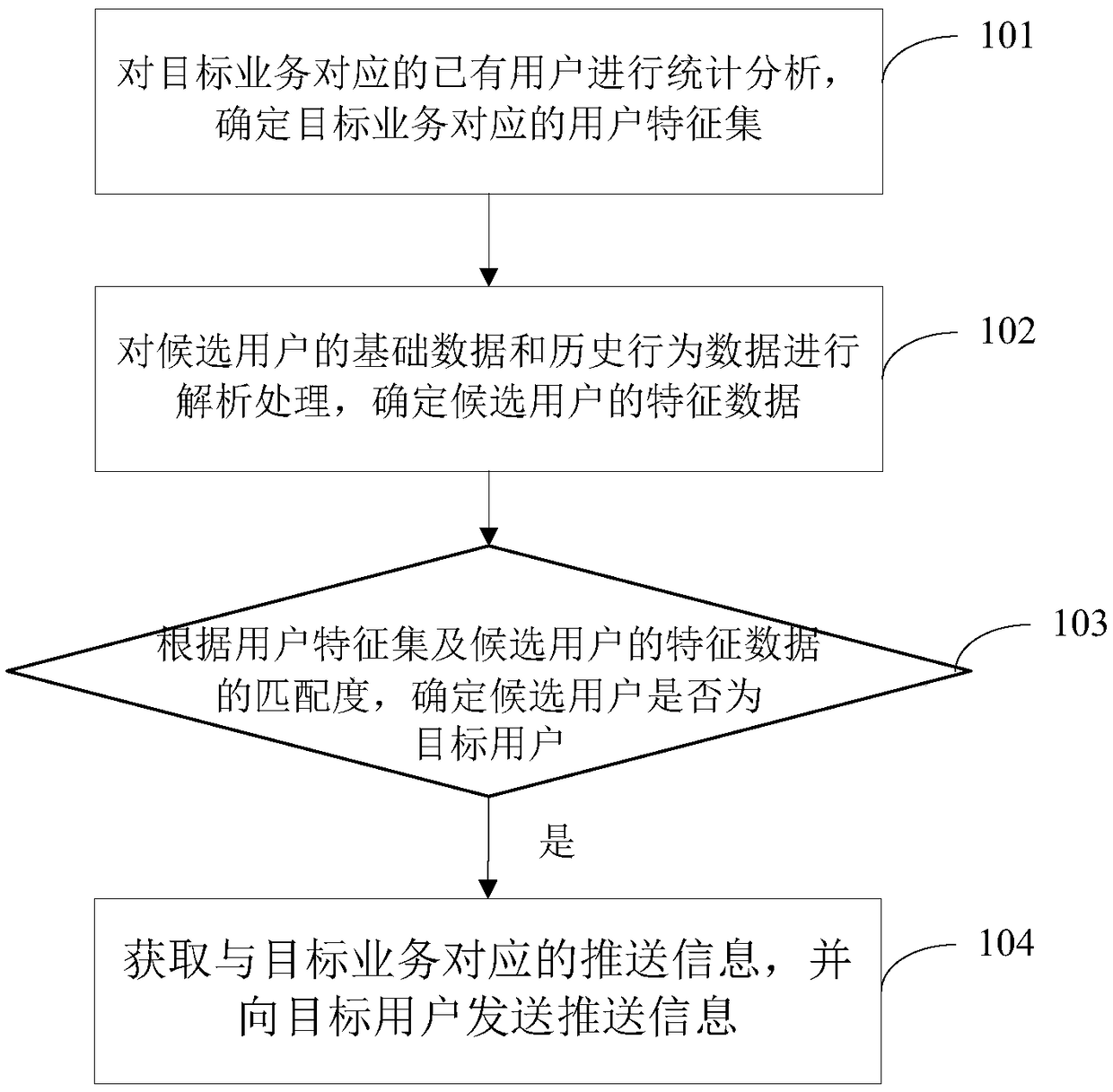

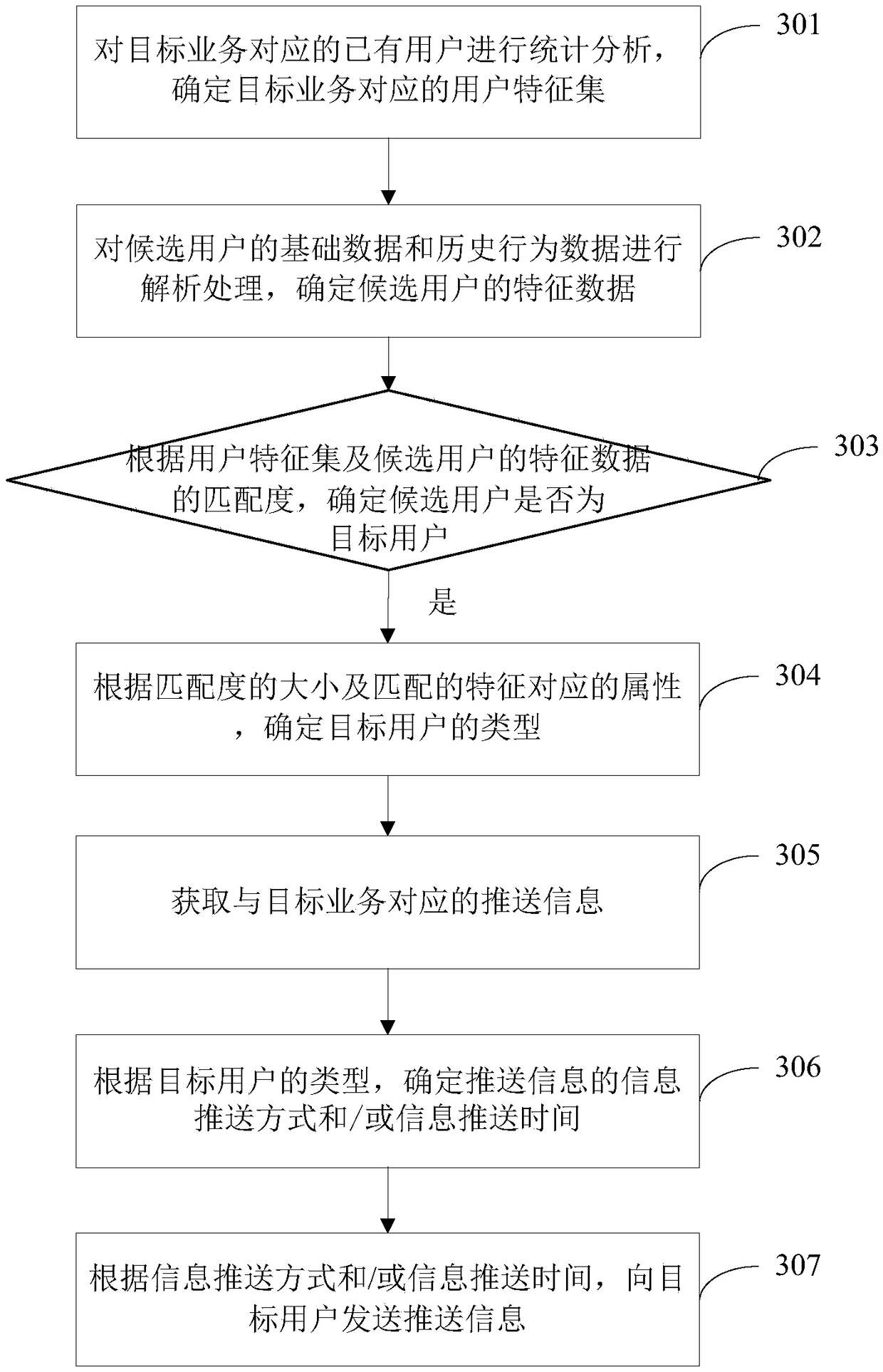

User screening method and device

ActiveCN109218390AImprove screening accuracyDigital data information retrievalBuying/selling/leasing transactionsFeature setStatistical analysis

The invention provides a user screening method and device, wherein the user screening method comprises: performing statistical analysis on existing users corresponding to a target service and determining a user feature set corresponding to the target service; analyzing the basic data and the historical behavior data of a candidate user and determining the feature data of the candidate user; and determining whether the candidate user is a target user according to the matching degree of the user feature set and the feature data of the candidate user. The user screening method and device providedby the invention accurately screen the target users of the service based on the user feature of the service and the features of the user, and improve the user screening accuracy.

Owner:北京比特智学科技有限公司

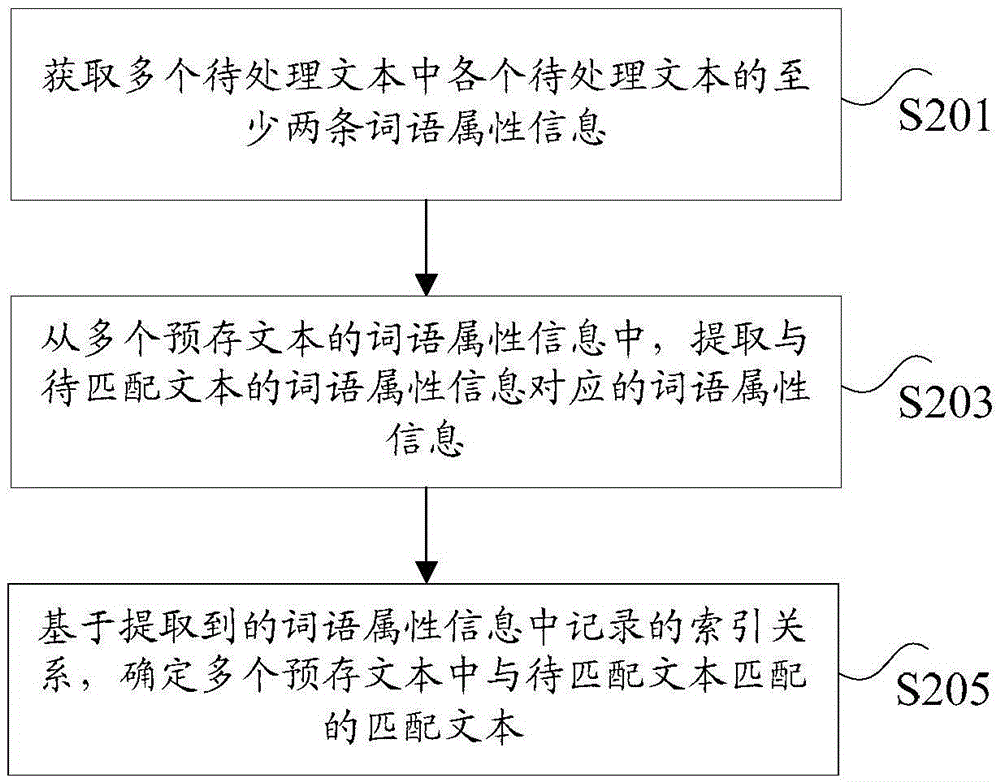

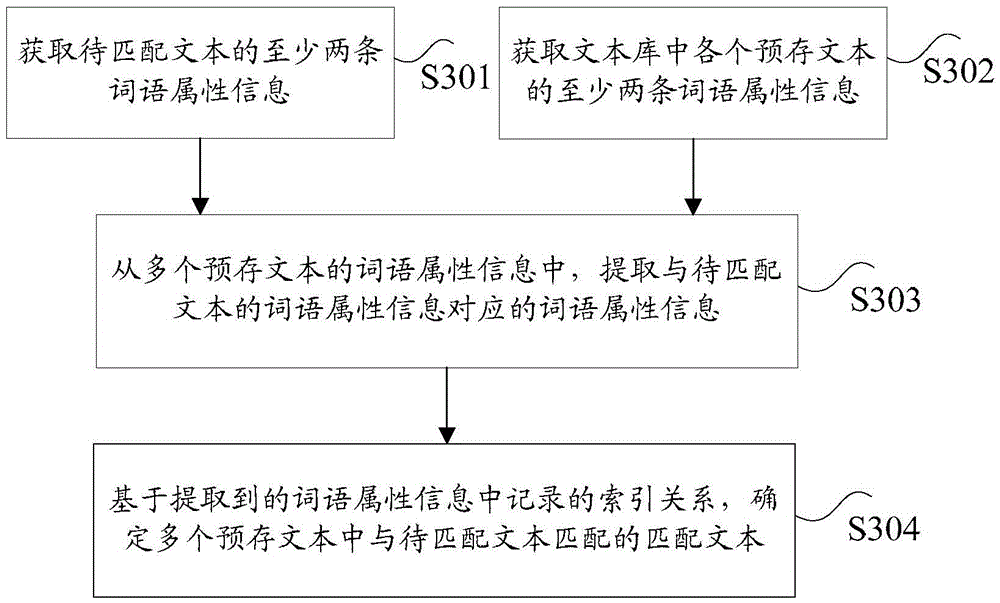

Method and device for text matching

InactiveCN106815226ASolve the problem of inaccurate matching resultsImprove screening accuracySpecial data processing applicationsPattern recognitionText matching

The application discloses a method and device for text matching. The method comprises the steps that at least two pieces of word attribute information of each to-be-processed text among multiple to-be-processed texts are acquired, wherein multiple to-be-processed texts comprise at least a to-be-matched text and multiple pre-stored texts in a text library, and each piece of word attribute information is used to record an index relation between a word contained by the to-be-processed text and the to-be-processed text; word attribute information corresponding to the word attribute information of the to-be-matched text is extracted from the word attribute information of the multiple pre-stored texts; and based on the index relations recorded in the extracted word attribute information, a matched text matched with the to-be-matched text in the multiple pre-stored texts is determined, wherein the word attribute information of the to-be-matched text and the matched text could be matched entirely or partially. According to the invention, the technical problem that matching results of text matching methods are not accurate can be solved.

Owner:ALIBABA GRP HLDG LTD

Mammography-apparatus

ActiveCN102781328AImprove standardizationAvoid painPatient positioning for diagnosticsTomographyControl systemX-ray

Mammography-apparatus for detecting malignant cells in a breast comprising an x-ray source and an x-ray detector that cooperates with the x-ray source for providing an x-ray image of said breast, and further comprising a paddle for flattening the breast by pressing it against said x-ray detector, wherein at least one sensor is applied for measuring a parameter that is used for determining the pressure at which the paddle compresses the breast, and wherein a control system is provided which controls the actuation of the paddle depending on the pressure that is applied to the breast, wherein there is a contact area measuring unit for measuring the contact area between the breast and the paddle.

Owner:UNIV OF AMSTERDAM ACADEMIC MEDICAL CENT

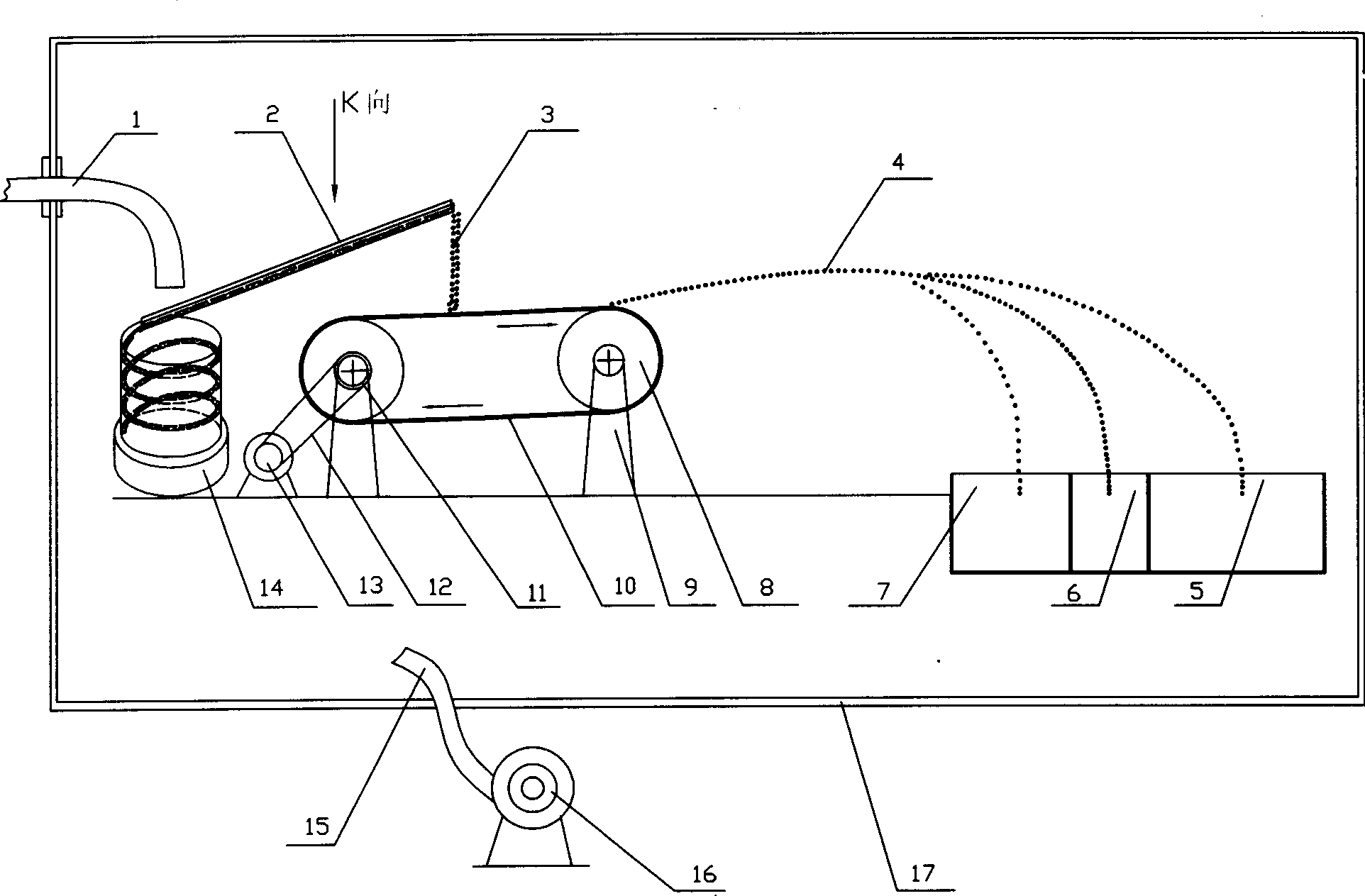

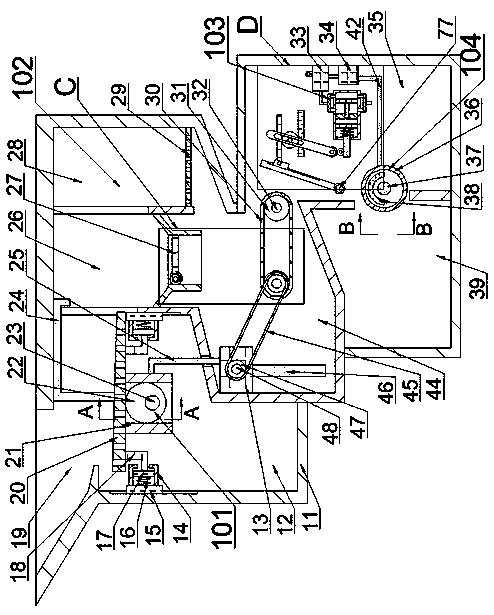

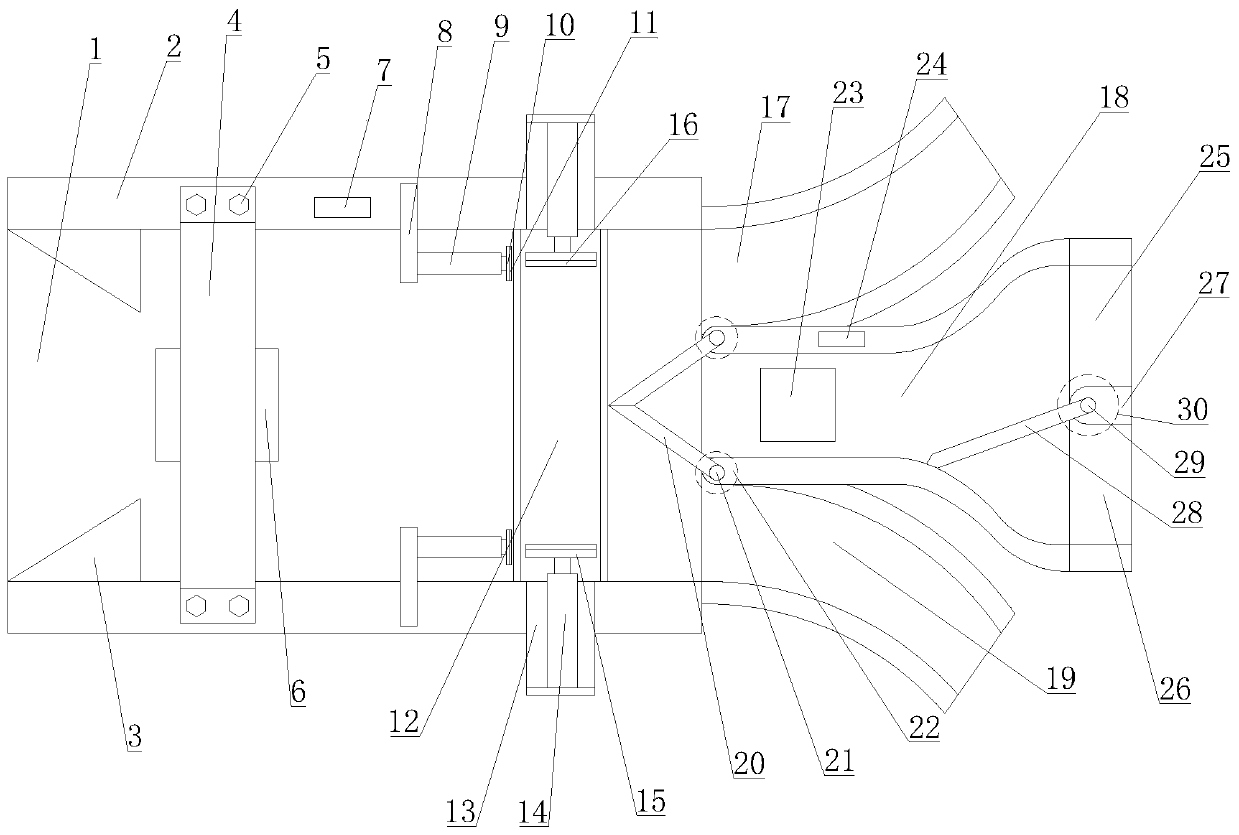

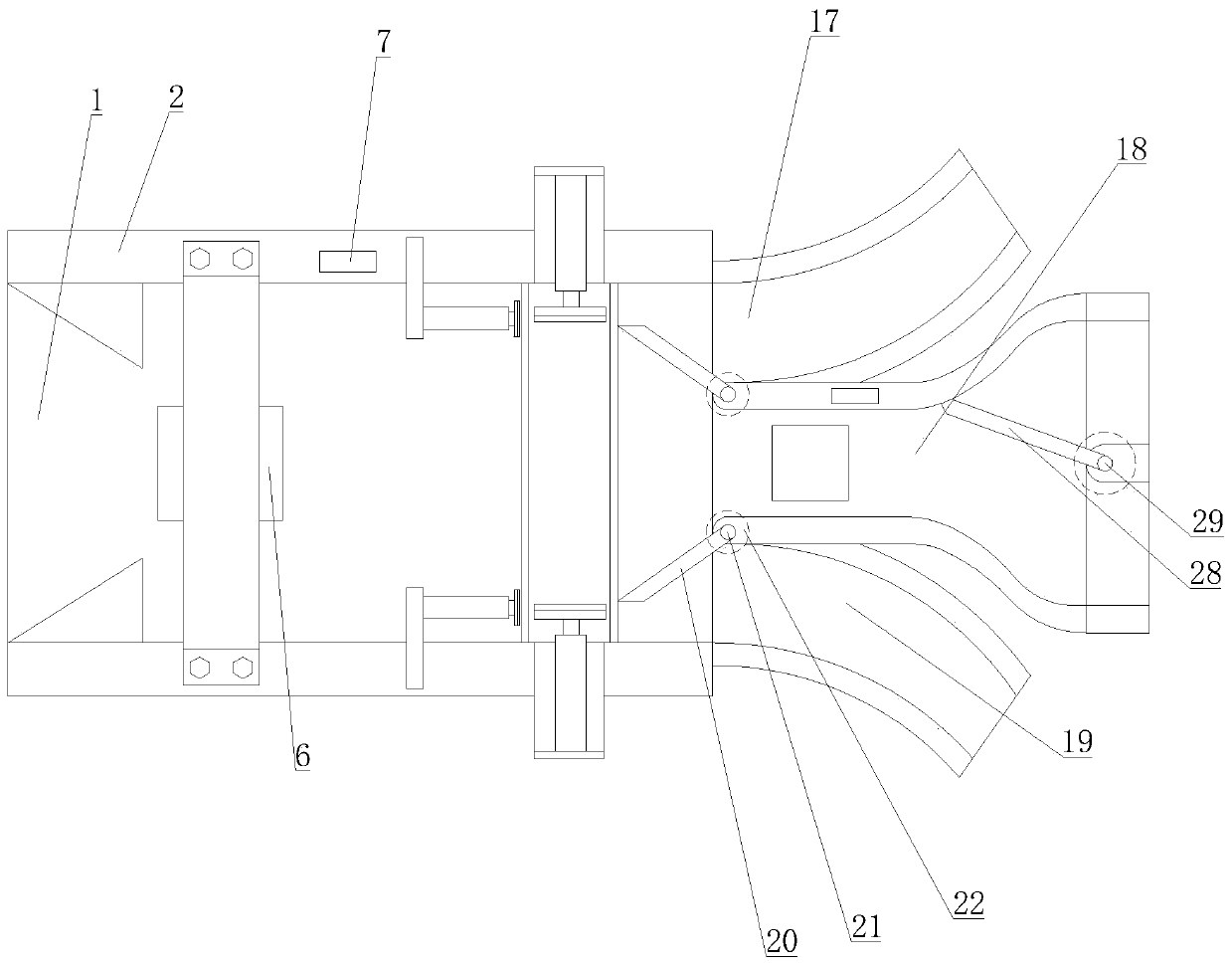

Apparatus and method for sorting coal and gangue

The present invention provides an apparatus and method for sorting coal and gangue, comprising a conveying line, a queuing mechanism, a camera shutter trigger, a measuring table and a sorting actuator. The queuing mechanism, the camera shutter trigger, the measuring table and the sorting actuator are sequentially arranged on the conveying line. Through the above-mentioned devices, the volume of the coal and the volume of gangue are obtained by utilizing the characteristics of different densities of the coal and the gangue and by combining the intelligent vision and the image processing algorithm. The mass is further obtained through a dynamic weighing sensor installed on the roll-on line, and the coal and the gangue are separated by utilizing the characteristics of different densities. Theapparatus and the method realize automatic screening of coal and gangue, reduce cost, improve screening precision, and avoid environmental pollution.

Owner:BINHAI IND TECH RES INST OF ZHEJIANG UNIV +1

Industrial logistics impurity screening device convenient for multistage screening

The invention relates to an industrial logistics impurity screening device convenient for multistage screening. A picture sensor is connected to a mounting rack; a first counter is arranged on a sideframe of a conveying belt, a first driving piece is arranged on a connecting plate, and the first driving piece is connected with a first push plate; a position moving seat is arranged on the right end of a feed conveying belt; a second driving piece is connected to a connecting frame, and the second driving piece is connected with a second push plate; a first discharge conveying belt, a second discharge conveying belt and a third discharge conveying belt are arranged on the right side of the position moving seat side by side; a first guide plate is connected with a first motor by virtue of afirst rotating shaft; a weight sensor is arranged on the second discharge conveying belt; a second counter is arranged on a side frame of the second discharge conveying belt; and a first discharge opening and a second discharge opening are arranged on the right end of the second discharge conveying belt side by side. According to the industrial logistics impurity screening device, products can bequickly screened, the screening efficiency is high, the screening precision is increased through multistage screening, and the product quality is guaranteed.

Owner:JIANGSU GREEN LEAVES MACHINERY

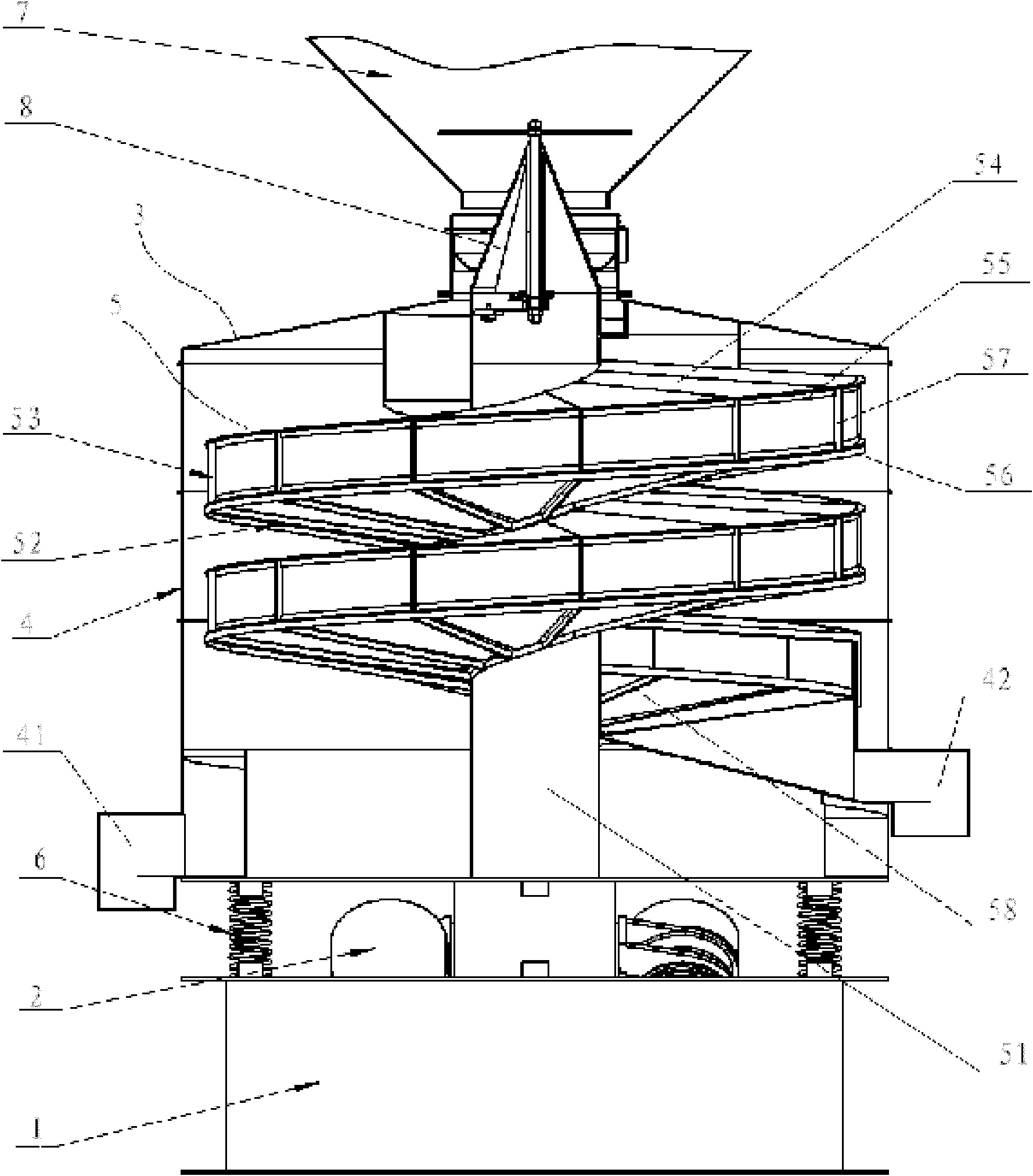

Multi-channel spiral feeding device for magnetic buckle plastic

InactiveCN105984694AGuarantee sufficiencySolve the speed problemJigging conveyorsConveyor partsEngineeringLinear vibration

The invention discloses a multi-channel spiral feeding device for magnetic buckle plastic. The multi-channel spiral feeding device comprises a vibration disc, a hopper, a feeding port, a feeding track and a linear vibration track. The multi-channel spiral feeding device is characterized by further comprising a first inner spiral track, a second inner spiral track and spiral feeding screening and sorting devices; the hopper is arranged at the bottom of the vibration disc and provided with the first inner spiral track and the second inner spiral track, and the two same spiral feeding screening and sorting devices are arranged and connected with the tail end of the upper portion of the first inner spiral track and the tail end of the upper portion of the second inner spiral track correspondingly; and each of the spiral feeding screening and sorting device comprises a discharging port, a first track, a second track and a third track. The multi-channel spiral feeding device has the beneficial effects of being simple in structure, high in automation degree and high in precision of screening of plastic buckles.

Owner:LIXIN FUYA GAUZE CO LTD

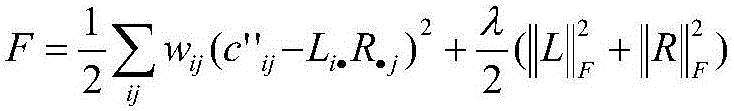

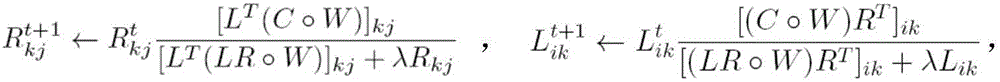

Precision enhancing method for visual media semantic indexing

ActiveCN105787045AImprove accuracyIncrease flexibilitySpecial data processing applicationsPattern recognitionData set

The invention relates to a precision enhancing method for visual media semantic indexing, and belongs to the technical field of visual media processing.The method comprises the steps that semantic indexing is carried out on objects and scenes contained in visual media at first, a confidence coefficient matrix is built, some elements are screened out through threshold value judgment, a weighing non-negative matrix factorization method is applied to reestimate the screened matrix, and overall precision is enhanced; a similarity propagating method is adopted according to an overall precision enhanced result, and a similarity relation between samples is utilized for overall precision enhancing.The precision enhancing method has the advantages that the accuracy of visual media semantic indexing is enhanced by means of various kinds of semantic relations, the method does not depend on a large number of annotation data sets and knowledge bases and has the strong flexibility and adaptability, overall precision enhancing and local precision enhancing are organically combined, and the flexibility and effect of the method are improved; the algorithm is low in calculation complexity, strong in extendibility and suitable for practical industrial application.

Owner:TSINGHUA UNIV

Roller-type self-adjusting polycrystalline silicon vibrating screening device

The invention provides a roller-type self-adjusting polycrystalline silicon vibrating screening device, and relates to the field of mechanical equipment. The device mainly comprises an underbed, a screen box is arranged on the underbed, a damping spring is arranged between the underbed and the screen box, the lower surface of the screen box is provided with a vibration motor, the screen box is provided with a screen plate, the screen plate mainly comprises a framework, the two sides of the inside of the framework are provided with automatic adjusting devices, the insides of the automatic adjusting devices are hollow, the front end of each automatic adjusting device is provided with a shaft hole, the two sides of the hollow inner side of each automatic adjusting device are provided with springs, the springs on the two sides of each automatic adjusting device are connected with a shaft sleeve in a squeezing mode, the shaft sleeve of each automatic adjusting device corresponds to the shaft hole of the corresponding automatic adjusting device, the insides of the shaft holes of the automatic adjusting devices on the two sides are connected with a shaft, the shaft is provided with a roller, the two ends of the shaft are sleeved with the shaft sleeves, and the diameter of the shaft is smaller than that of each shaft hole. The screening device is high in screening precision, strong in processing capacity, simple in structure, little in energy consumption, low in noise, good in sealing performance, free of overflowing dust, convenient to maintain and capable of being used for automatic operations; the service life of a screen cloth is long.

Owner:ANHUI SNELL MACHINERY MFG

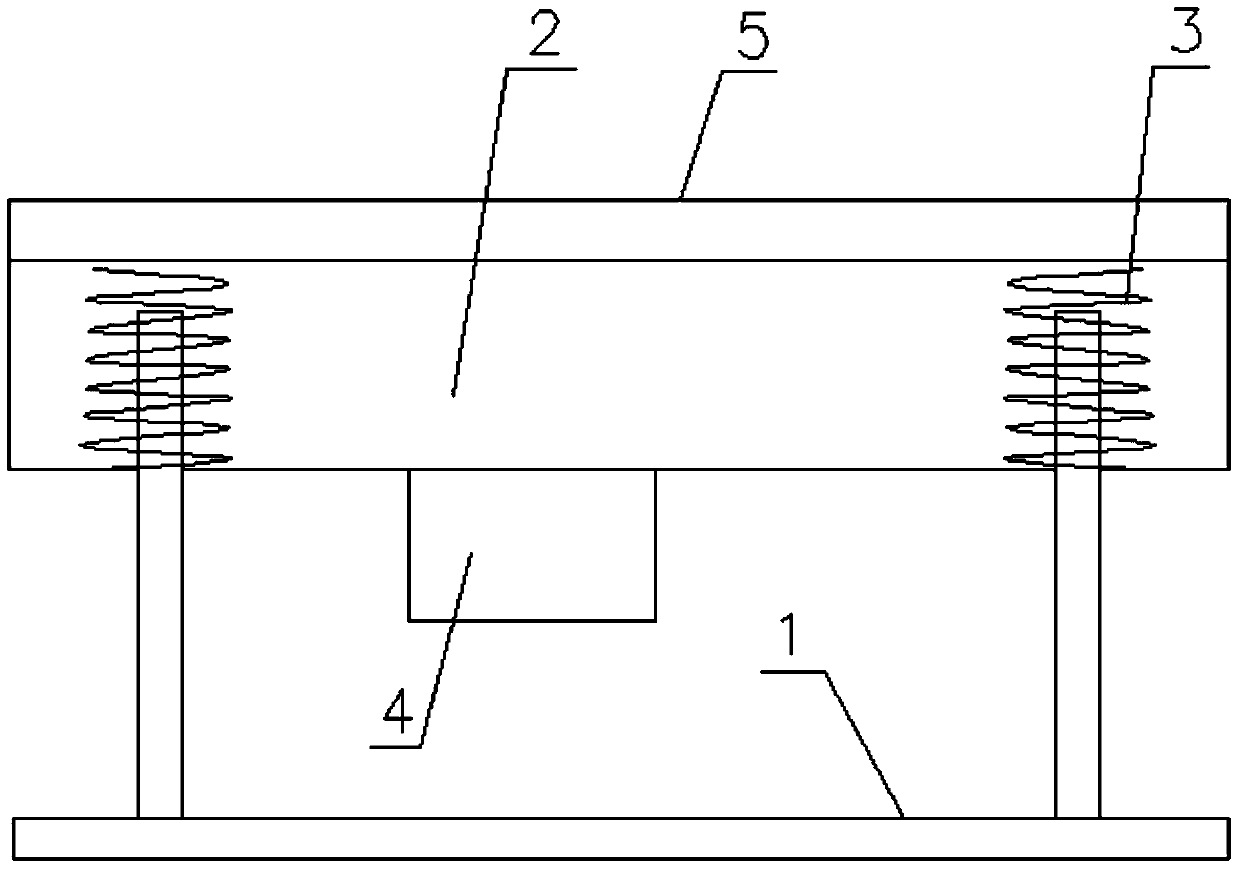

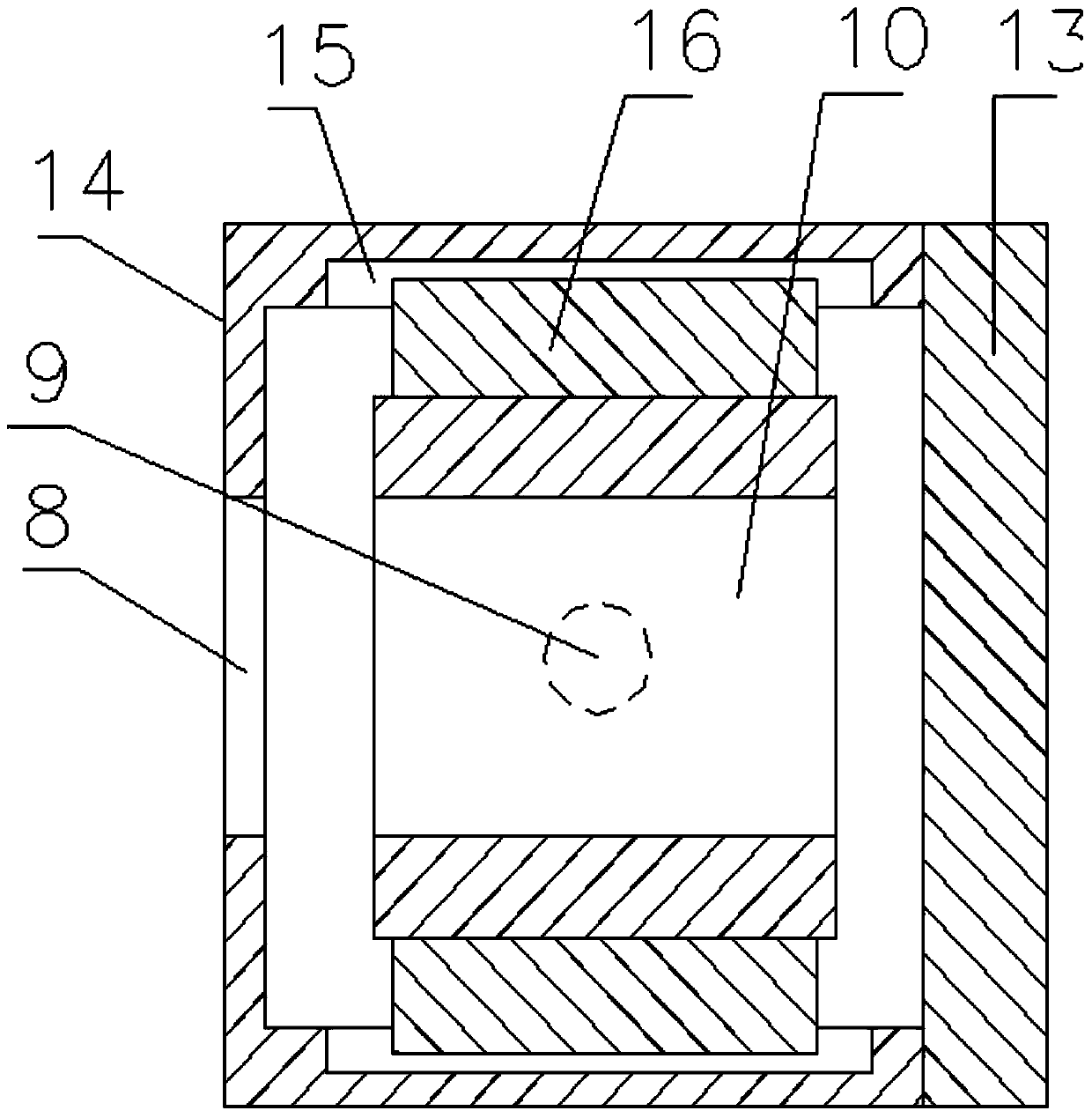

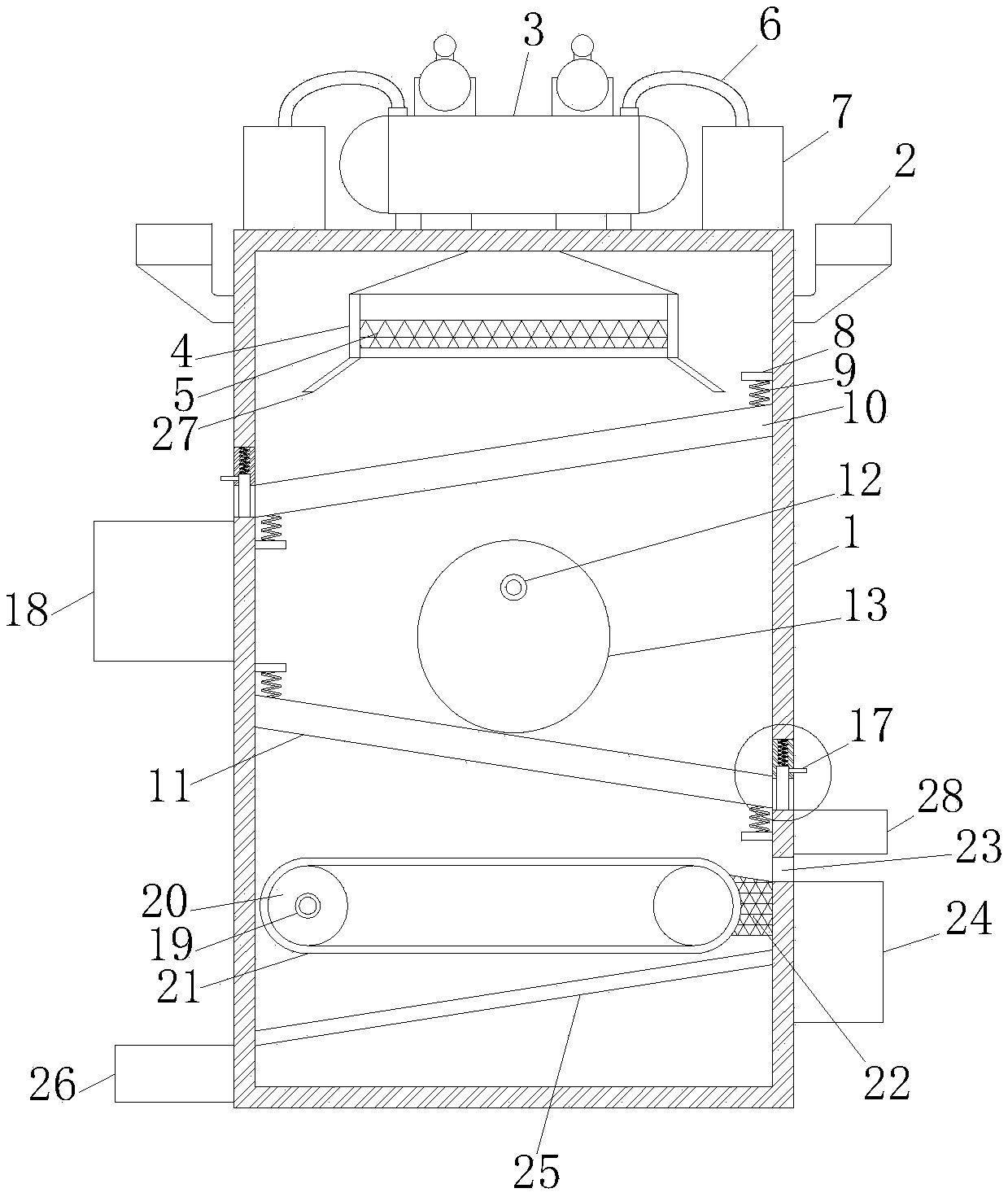

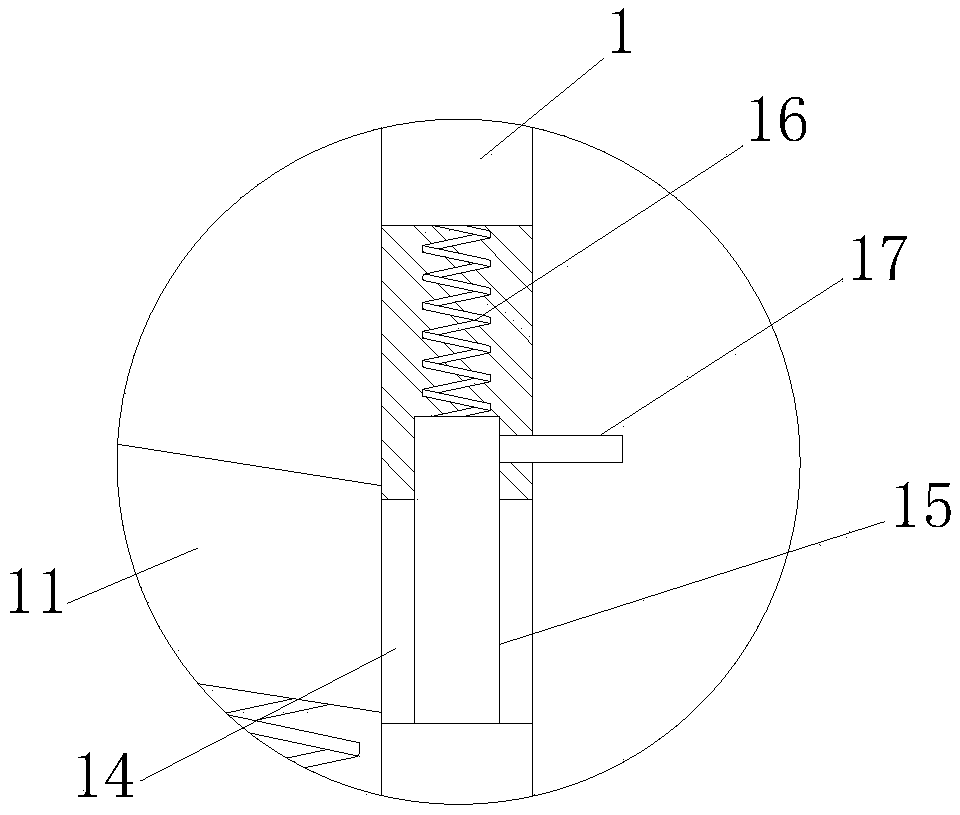

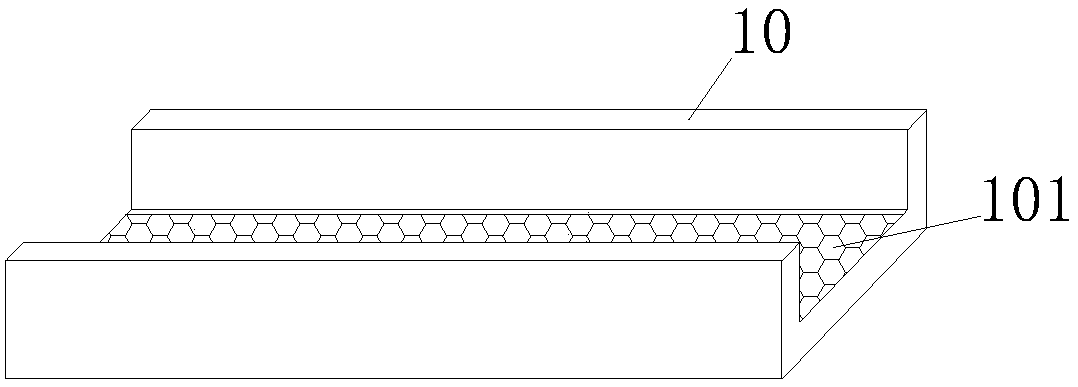

Biopharmaceutical screening device

InactiveCN108855928AImprove screening accuracyImprove screening efficiencySievingGas current separationAgricultural engineeringScreening method

The invention discloses a biopharmaceutical screening device, comprising a body, wherein feeding hoppers are welded to the left and right sides of the top of the body, a suction pump is fixedly mounted on the top of the body, a suction hopper is arranged at the top of an inner cavity of the body, the top of the suction hopper is fixedly connected with the bottom of the suction pump, a first filternet is fixedly arranged at an inner cavity of the suction hopper, discharge pipes are installed on the left and right sides of the suction pump, one end, away from the suction pump, of each dischargepipe is connected to the top of a dust box at the top of the body, and fixed seats are symmetrically welded in the inner cavity of the body. The biopharmaceutical screening device can perform multi-stage screening on pharmaceutical raw materials by a multi-stage screening mechanism, thereby improving the screening precision; the screening device can improve the screening efficiency by an eccentric screening method; at the same time, the screening device can absorb impurities such as dust in the pharmaceutical raw materials, thereby removing the impurities.

Owner:WUHAN NEW GUOFENG TECH DEV

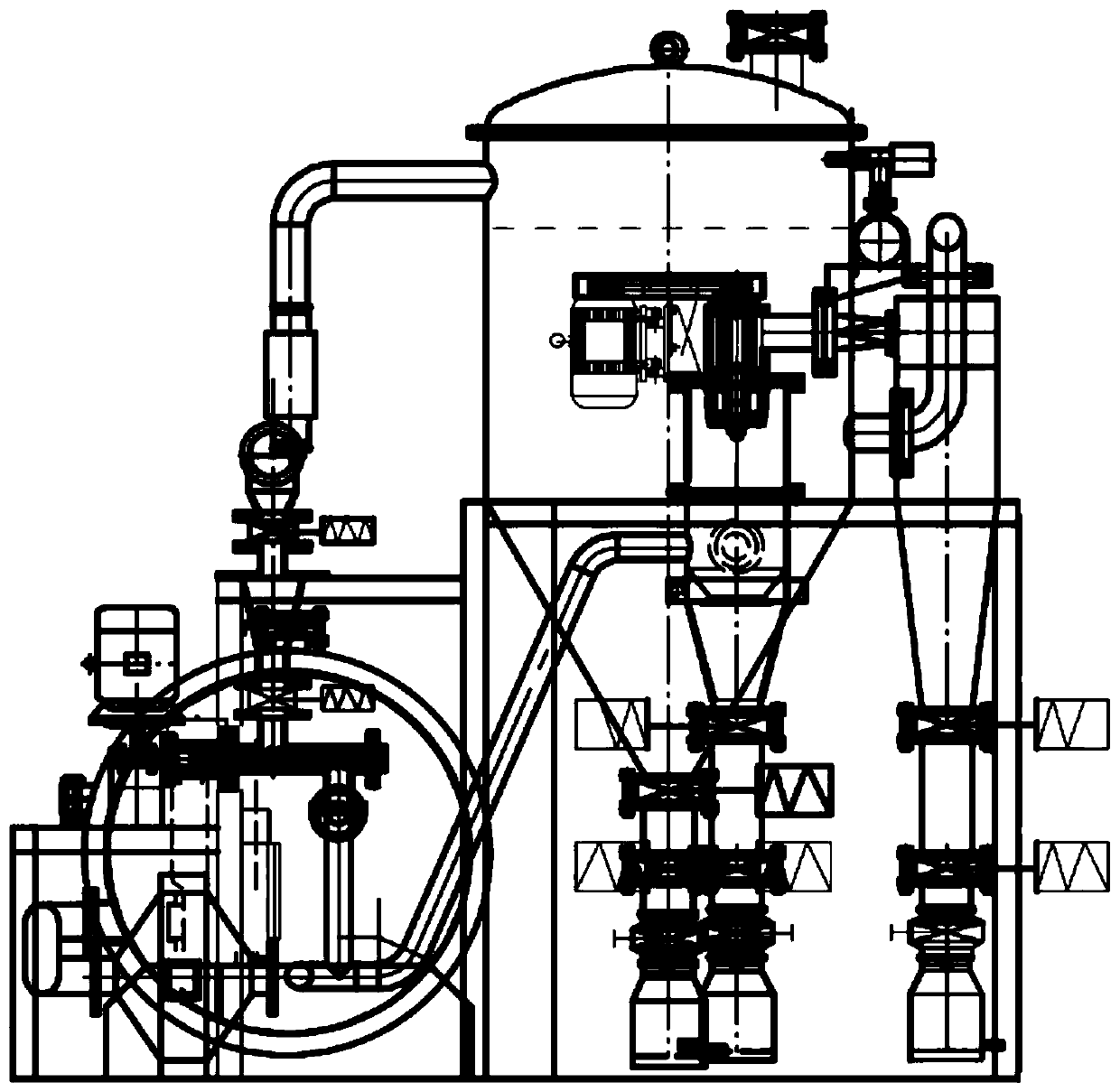

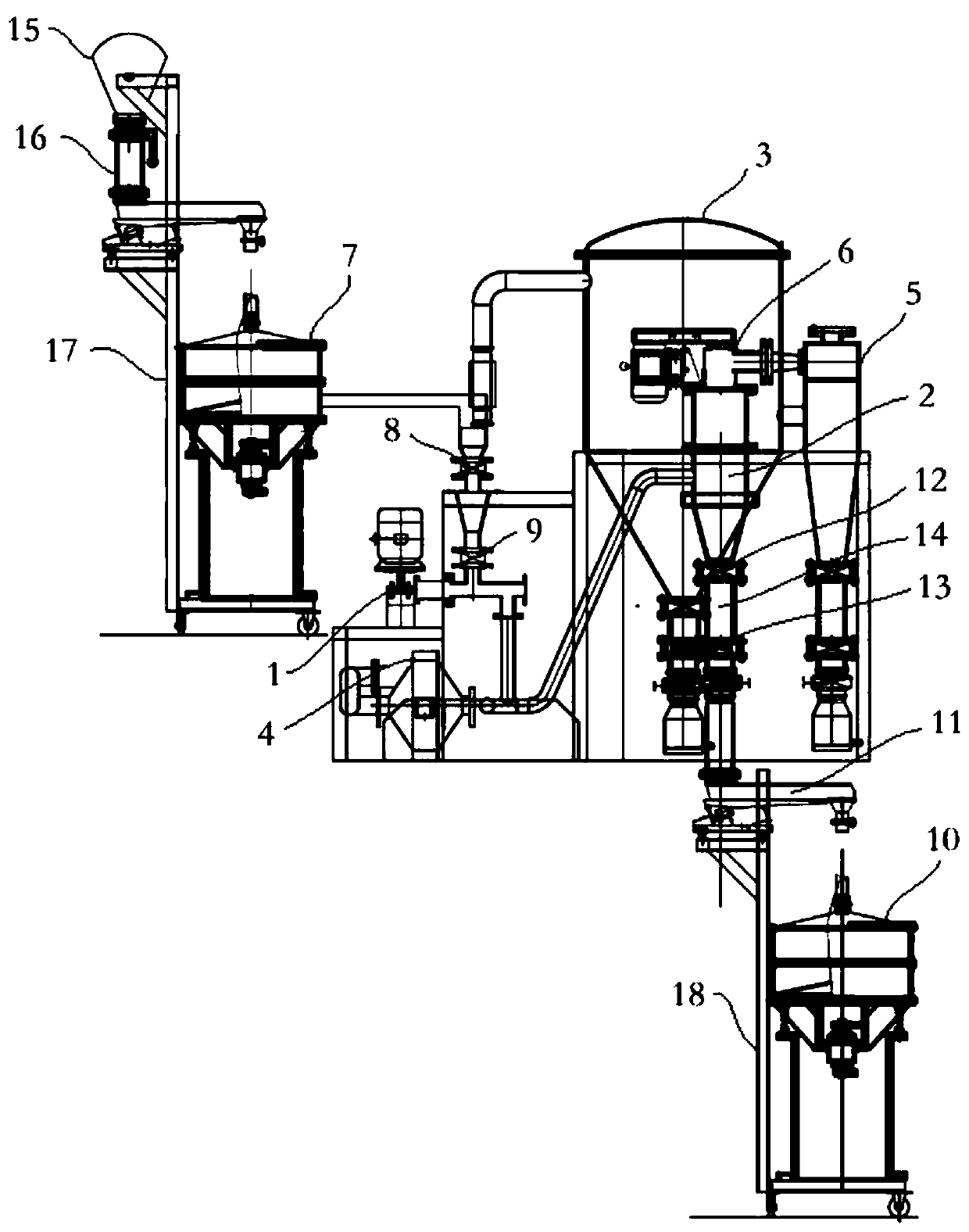

Screening system and screening method for reactive metal powder

ActiveCN110302962AThe screening process is simpleImprove screening efficiency and screening accuracySievingGas current separationAgricultural engineeringAirflow

The invention provides a screening system and screening method for reactive metal powder. The screening system comprises a first vibrating screen device, an airflow grading device, a second vibratingscreen device and a protective gas circulating system, wherein the airflow grading device comprises a spiral feeder and a grading bin, a discharging port of the first vibrating screen device is connected with the spiral feeder, the spiral feeder is connected with the grading bin through a conveying pipe, and a discharging port of the grading bin is connected with the second vibrating screen device. According to the screening system and screening method, the screening process of the screening system is simple, powder screening among different particle size ranges can be completed at one time, screening efficiency and screening precision are improved, and then the technical problems that the screening process of a screening device in the prior art is tedious, and the screening efficiency andthe screening precision are not high are solved.

Owner:中航迈特粉冶科技(北京)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com