Apparatus and method for sorting coal and gangue

A coal gangue and equipment technology, applied in the field of coal automation equipment, can solve problems such as complex process, poor sorting rate, expensive facilities, etc., and achieve the effects of improving calculation accuracy, improving screening accuracy, and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

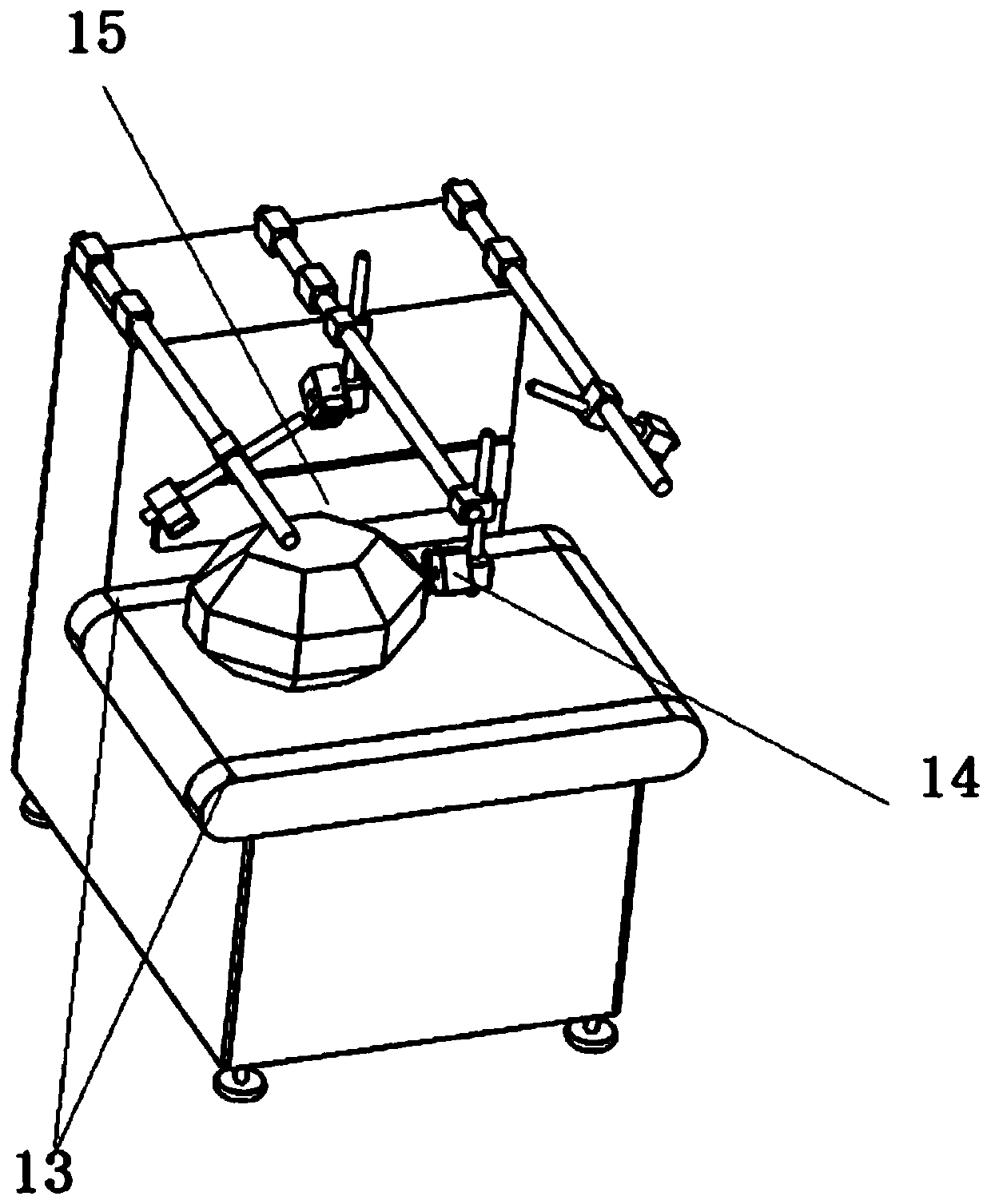

[0057] The design principle of the present invention is to use the characteristics of different densities of coal and gangue, combined with intelligent vision and image processing algorithms, to obtain the volume of coal and gangue, and then obtain the mass according to the dynamic weighing sensor installed on the rolling line, and use the density Different characteristics separate the two.

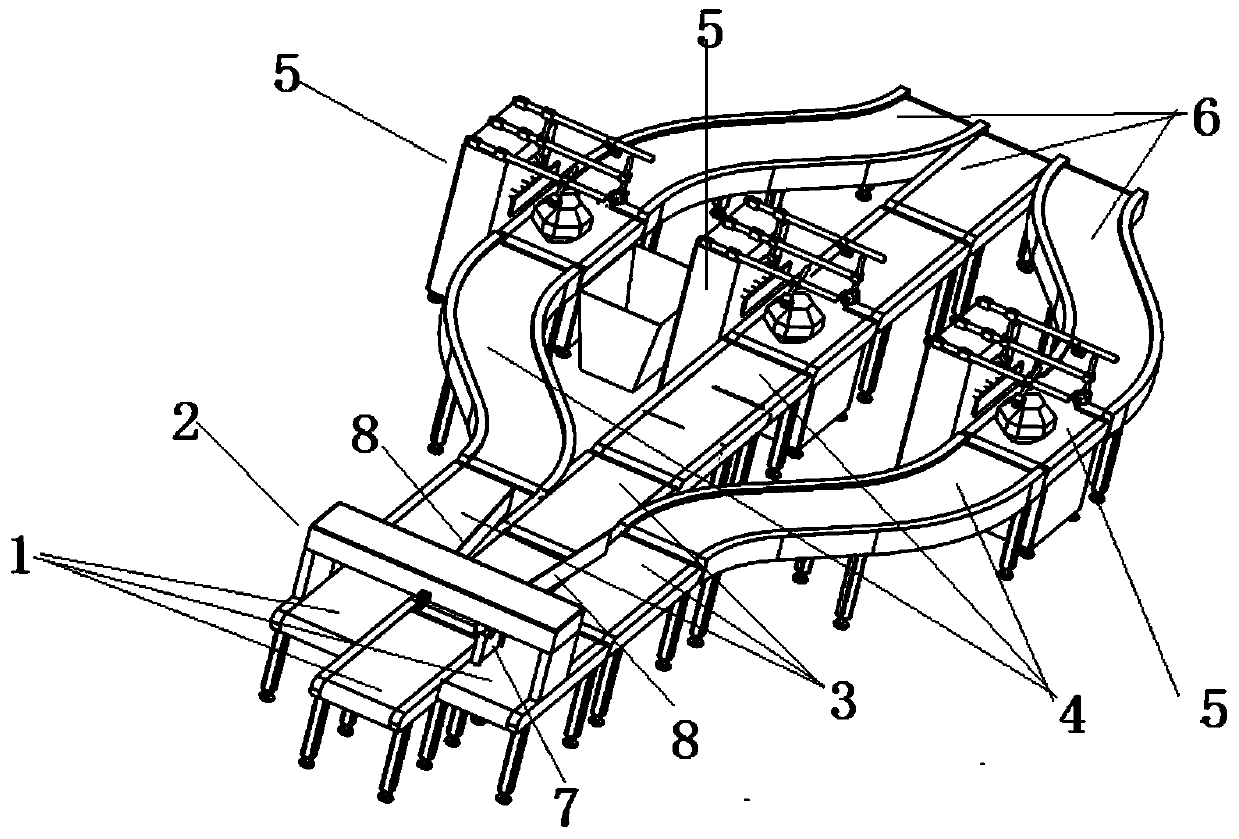

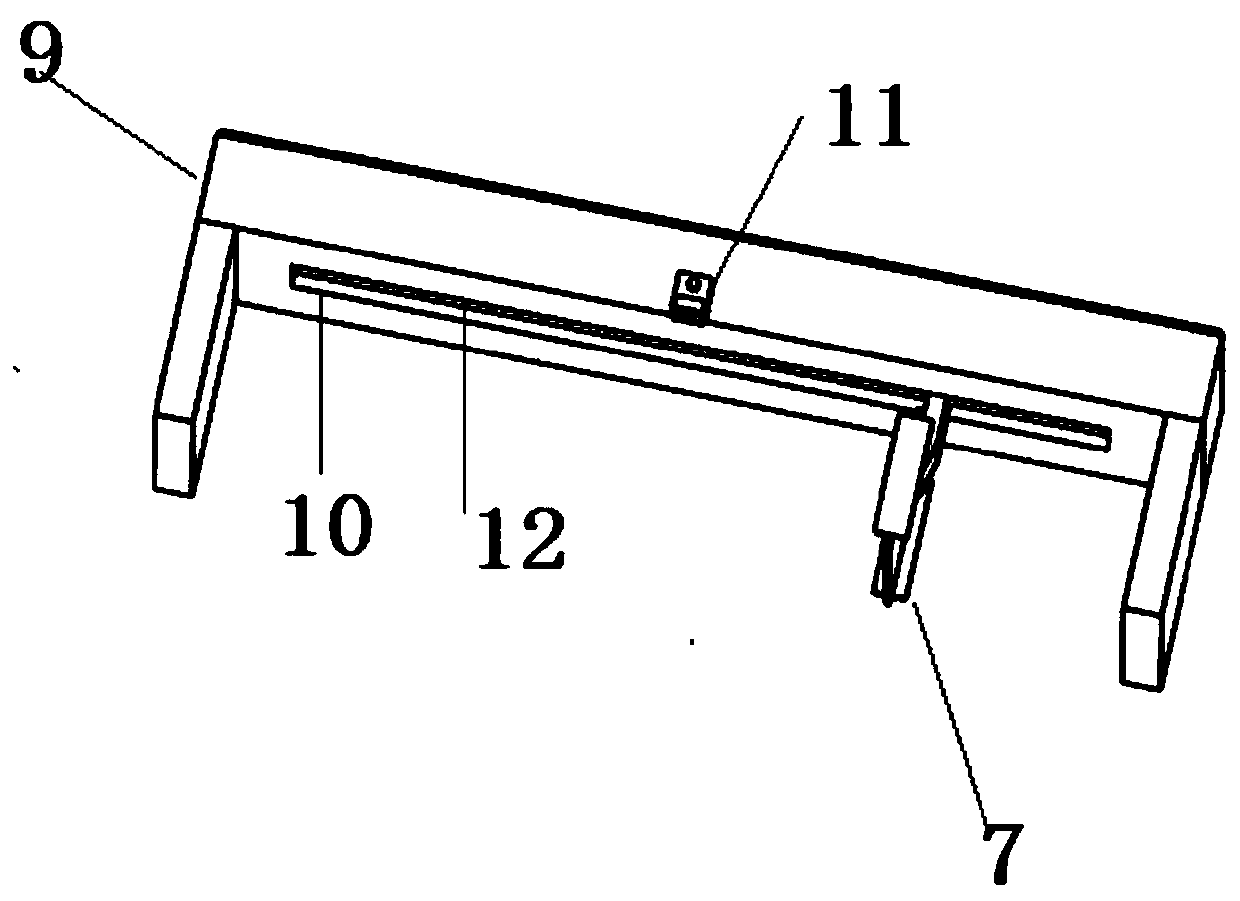

[0058] Such as figure 1 , figure 2 As shown, the present invention is made up of conveying device, queuing mechanism 2, camera shutter trigger, measuring platform 5, sorting executive mechanism, central processing unit;

[0059] The conveying device includes a feeding conveying line 1, a differential conveying line 3, a split conveying line 4, and a coal converging conveying line 6;

[0060] The queuing mechanism 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com