Filtering device

A screening device and screen technology, which is applied in the direction of solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of low recovery rate of heavy specific gravity, being picked up by conveyor belt, etc., to improve recovery rate and improve screening The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

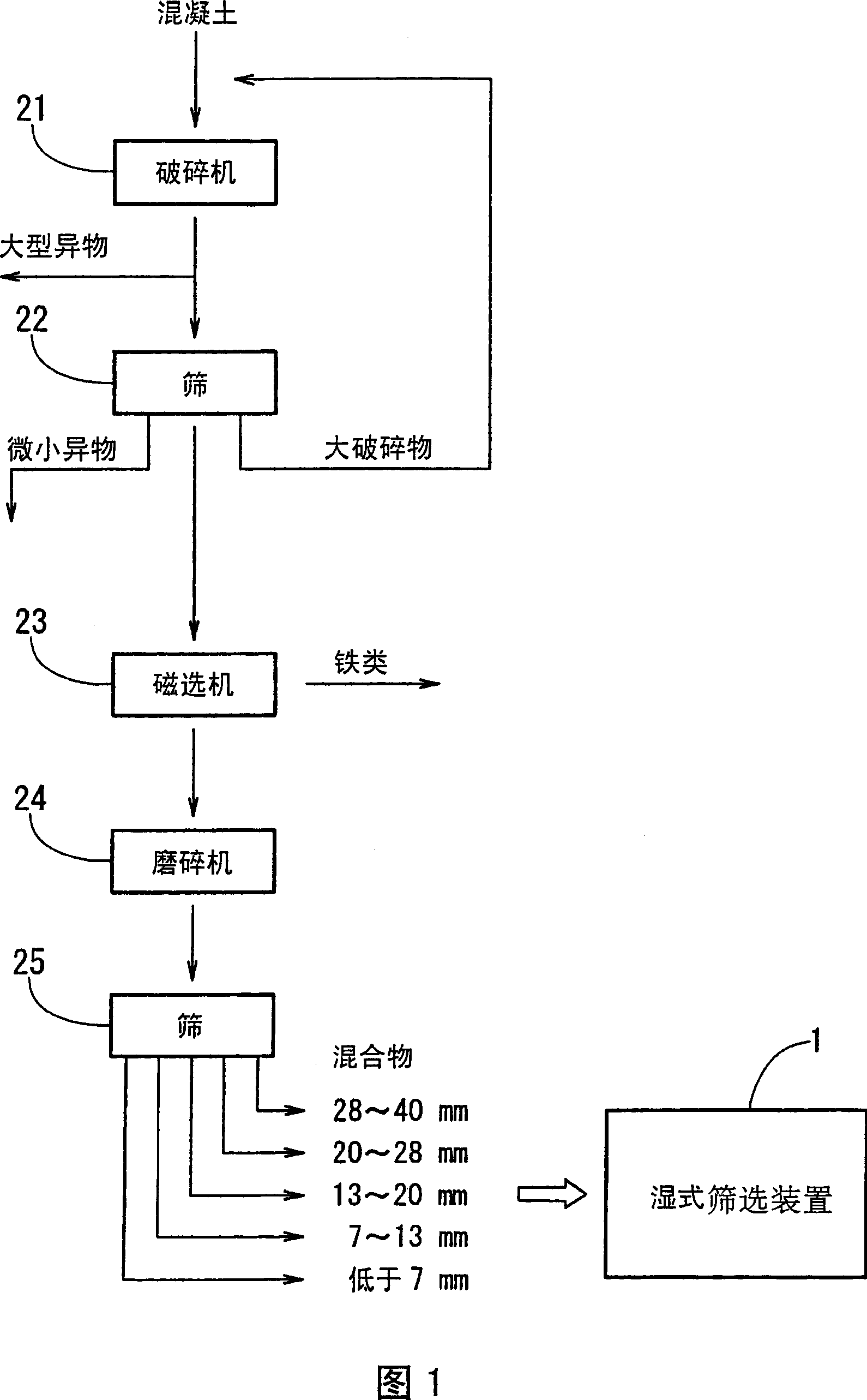

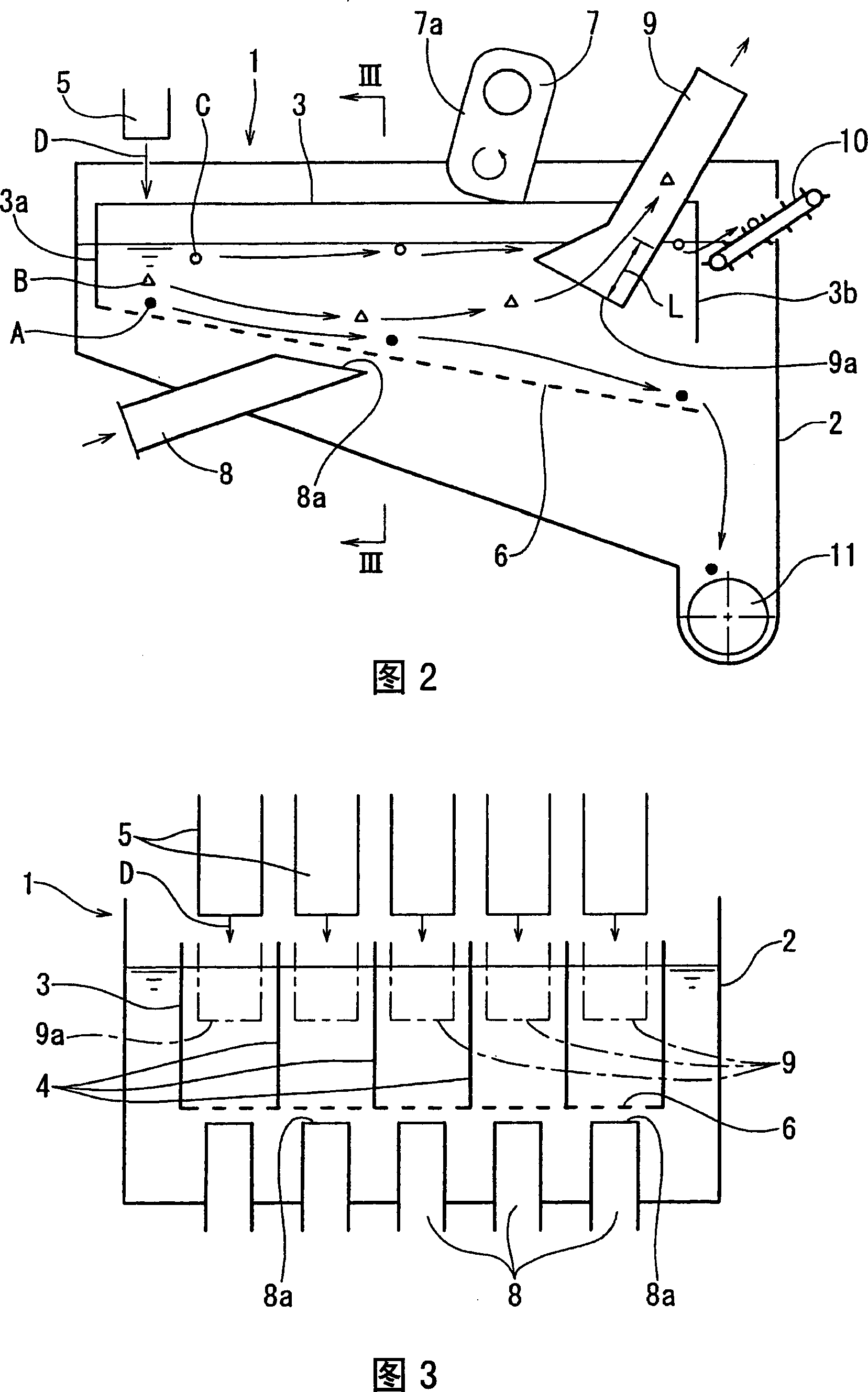

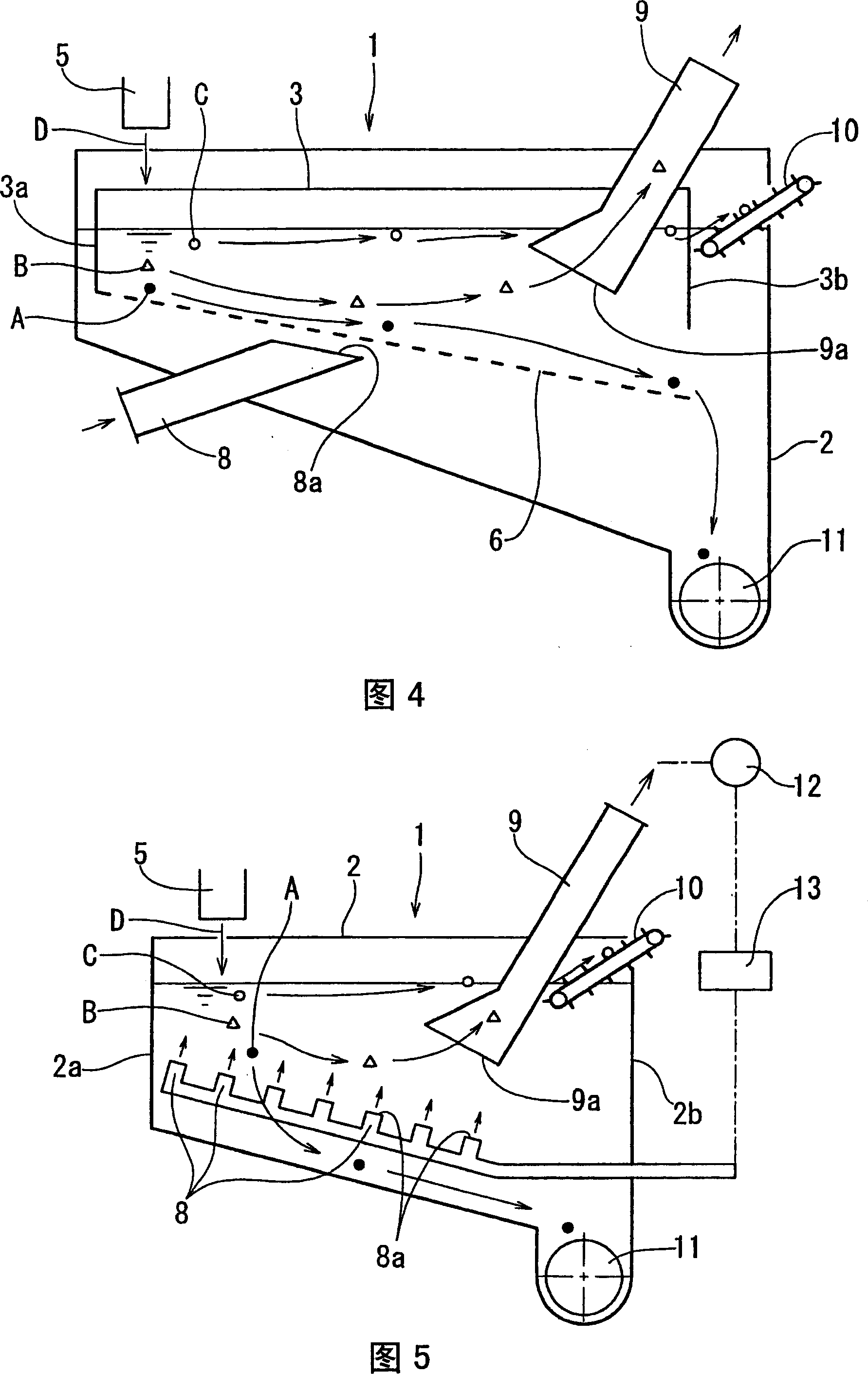

[0054] Hereinafter, embodiments of the present invention will be described based on the drawings. 1 to 3 show a first embodiment. This screening device 1 is used in a recycling plant for aggregates contained in concrete of construction waste, for removing wood chips and plastic chips mixed in the aggregates.

[0055] As shown in Fig. 1, the concrete is pulverized with a pulverizer 21, and the large foreign matter is removed by hand screening, and then put into a sieve 22 to remove tiny foreign matter with a size of about 2 mm or less, while the large pulverized matter exceeding 40 mm is put back into the pulverizer 21 Re-crushed. The pulverized material whose size is considered to be 40 mm or less is removed by a magnetic separator 23, and then ground by a grinder 24 to remove cement mortar components adhering to the aggregate, and sieved by a sieve 25 into five sizes .

[0056] In this embodiment, it is screened into sizes smaller than 7 mm, 7 to 13 mm, 13 to 20 mm, 20 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com