Patents

Literature

71results about How to "Reduce shipping risk" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Treatment process for chemical nickel plating waste liquid in circuit board industry

InactiveCN104176852ASolve in-plant processing issuesReduce the risk of excessive emissionsSludge treatment by de-watering/drying/thickeningMultistage water/sewage treatmentElectroless nickelSodium hydroxide

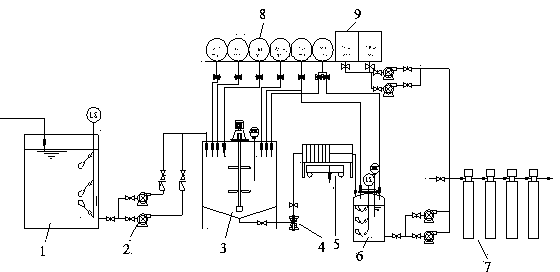

The invention provides a treatment process for a chemical nickel plating waste liquid in the circuit board industry. The treatment process comprises the following steps: pumping the chemical nickel plating waste liquid in the circuit board industry into a reaction tank; sequentially adding sulfuric acid for acidifying; adding ferrous sulfate and hydrogen peroxide for Fenton oxidation complexation; adjusting the pH by sodium hydroxide; adding sodium sulfide for a coagu-flocculation reaction; finally, adding PAM until suspended solids are just flocculently separated; after acidification, advanced oxidation complexation, and flocculation, filter-pressing all the waste liquid by a plate-frame; collecting the filtrate and regulating the pH; and sequentially carrying out sand filtering and resin adsorption and discharging after reaching standard level. The treatment process provided by the invention can be used for effectively treating the chemical nickel plating waste liquid in the circuit board industry, so that the treatment cost and the standard-reaching difficulty of the waste liquid in an enterprise are reduced.

Owner:江西红板科技股份有限公司

Self-discharging screening method of lithium ion battery

InactiveCN104466277AImprove screening accuracyReduce shipping riskSecondary cells charging/dischargingEngineeringLithium electrode

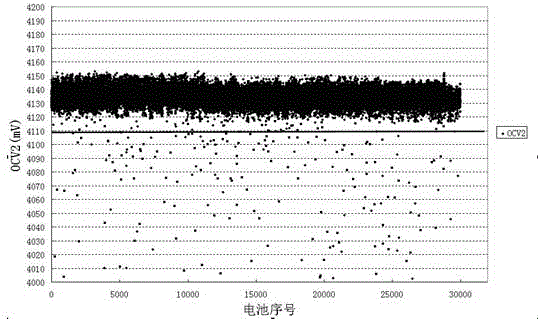

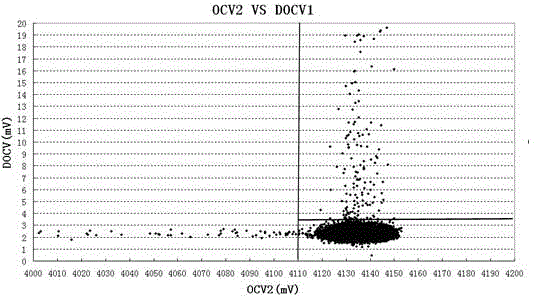

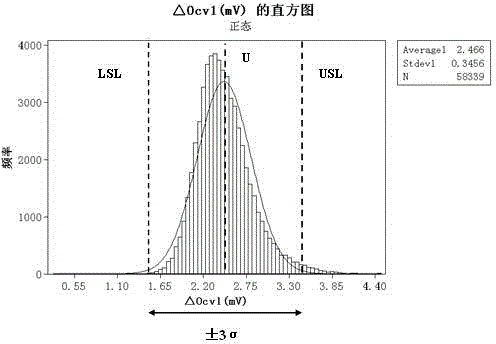

The invention provides a self-discharging screening method of a lithium ion battery. The method comprises the following steps: step 1: pre-charging a battery to be screened to be in a full or half state; performing high-temperature aging treatment and storing at constant temperature; marking detection open-circuit voltage as OCV1 and storing at constant temperature; marking detection open-circuit voltage as OCV2; calculating a voltage critical value U0 in the same phrase, wherein the battery with the condition that OCV2 is less than U0 is a serious self-discharging battery; and step 2: removing the self-discharging battery by using a 3o circulating way based on voltage pressure before / after the laying-aside of the battery removed in the step 1 in a full-charge state or a half-charge state. According to the self-discharging screening method of the lithium ion battery, the battery is screened after the battery is laid aside in the full-charge state or the half-charge state and the open-circuit voltage is determined, and the corresponding self-discharging batteries are removed by using the 3o circulating way, so that the self-discharging screening of the lithium ion battery is realized.

Owner:JIANGSU TENPOWER LITHIUM

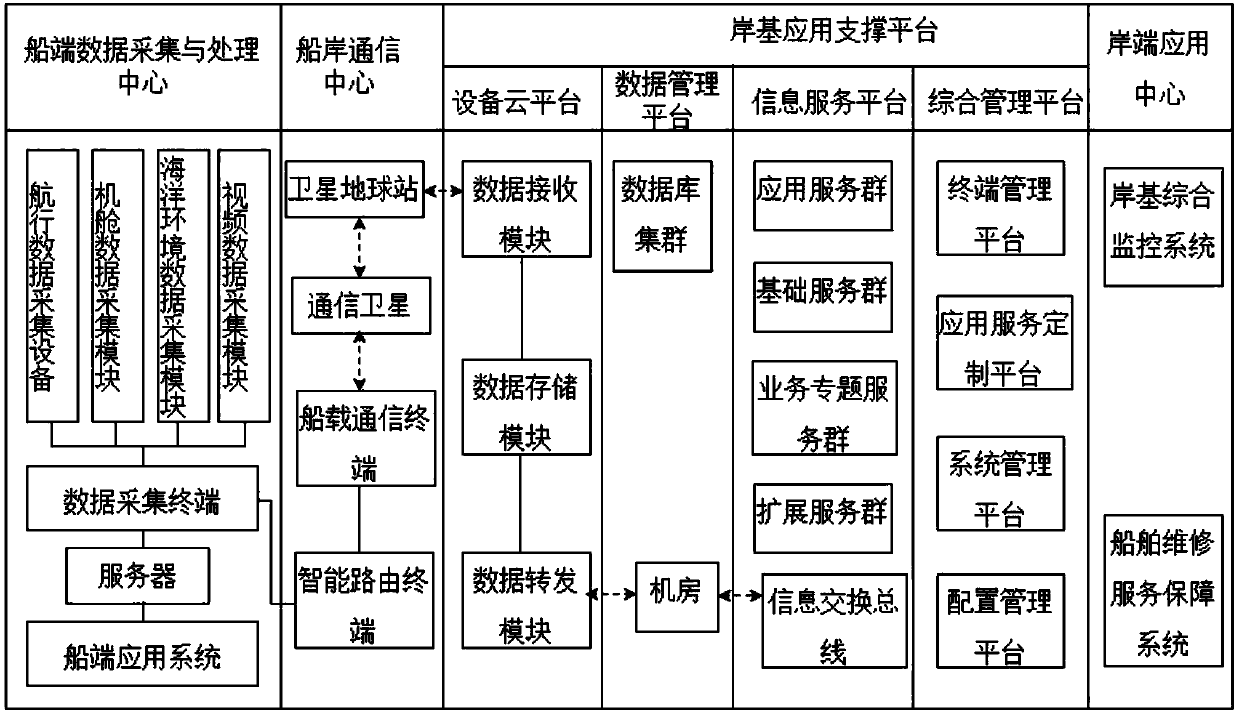

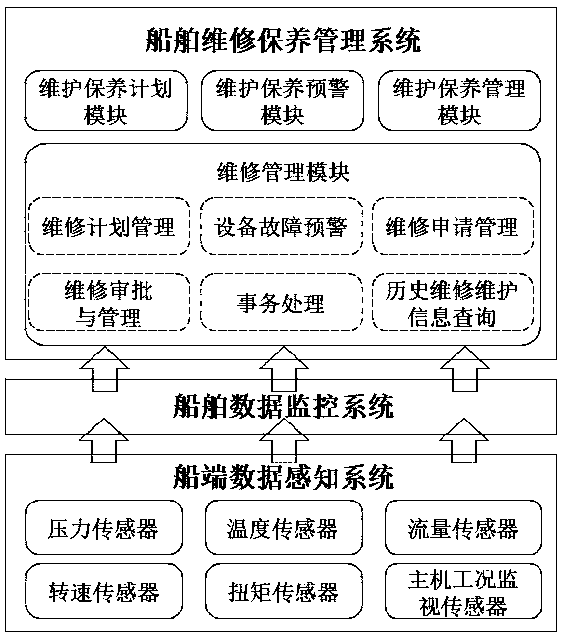

Internet of ships application support platform

InactiveCN107864226AIncrease production capacityImprove management efficiencyData processing applicationsTransmissionData acquisitionThe Internet

The invention discloses an Internet of ships application support platform, comprising a ship end data collection and processing center, a ship shore communication center, a shore base application support platform and a shore end application center. The ship end data collection and processing center comprises a data collection terminal, a server, a ship end application system, a sailing data collection device, an engine room data collection module, a marine environment data collection module and a video data collection module. The ship shore communication center comprises a satellite earth station, a communication satellite, a ship-borne communication terminal and a smart routing terminal. The shore base application support platform comprises a device cloud platform, a data management platform, an information service platform and an integrated management platform. The shore end application center comprises a shore base integrated monitoring system and a ship maintenance service safeguard system. The Internet of ships application support platform plays an important role in ocean ship navigation safety and oil consumption management, the transportation cost and risk are effectively reduced, and the operation and development of ocean ship and goods management business are powerfully supported.

Owner:北京昌飒电子科技有限公司

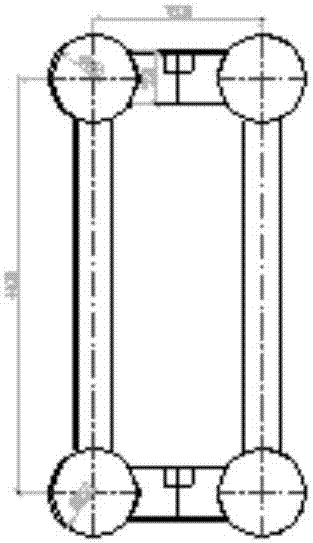

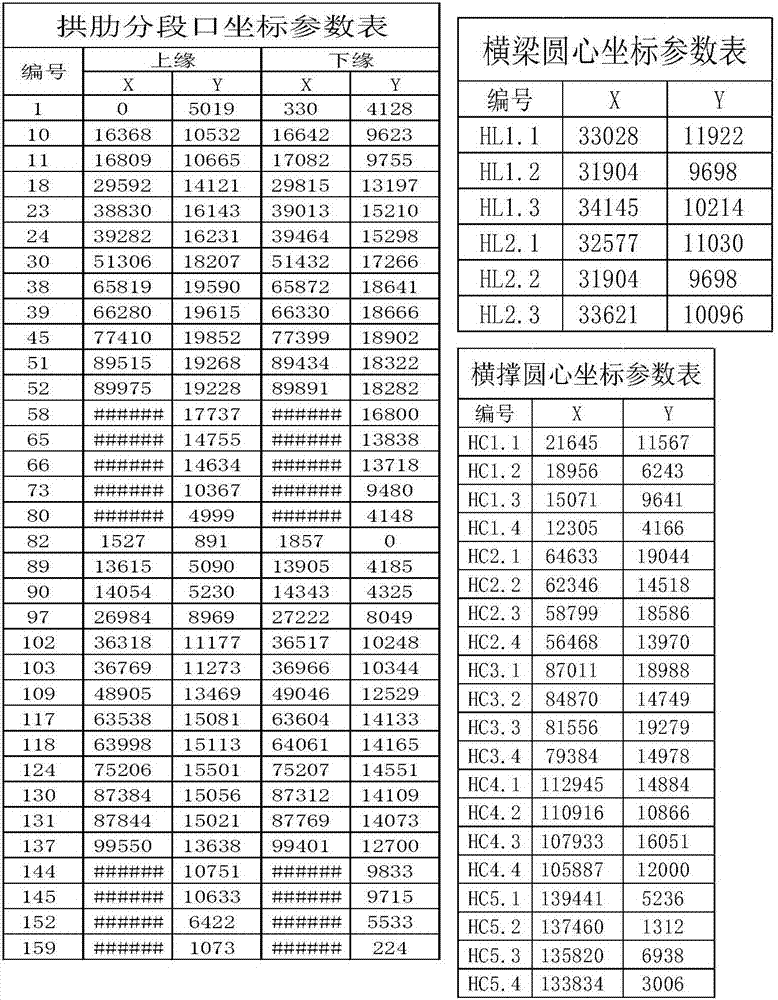

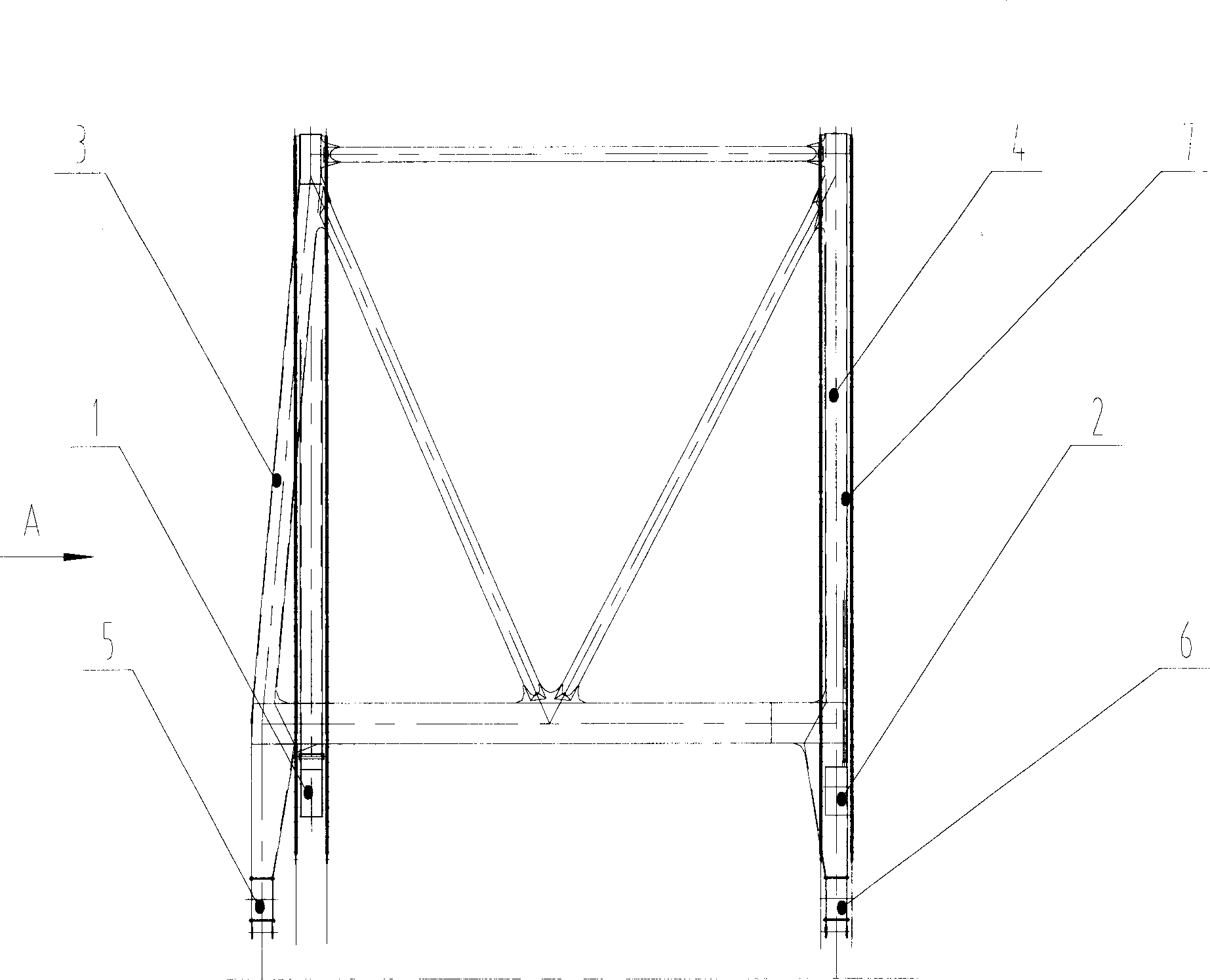

Steel pipe arch general assembly method

InactiveCN107988908AGuaranteed connection accuracyGuaranteed connection accuracy requirementsBridge erection/assemblyArch-type bridgeTheodoliteVertical plane

The invention discloses a steel pipe arch general assembly method. The steel pipe arch general assembly method comprises the steps that S1, according to setting-out collected data in pre-installed computer software, setting-out of truss arch ribs is carried out on steel plates leveled on a general assembly site using total stations, theodolites and leveling measuring equipment, and wall stall structures are arranged at the positions of the arch ribs and the positions of steel pipe joints; S2, cushion blocks of different heights are arranged on ground steel plates to meet line style requirements of planes and vertical planes of the truss arch ribs; S3, the locating positions of upper and lower anchoring boxes of the arch ribs, built-in flanges of joints and inclined struts of the arch ribsare set out at the corresponding positions of jig frames, so as to ensure assembling accuracy of the general assembly of the arch ribs and reduce errors of the general assembly; and S4, a jig mould ofthe general assembly is detected, and a test report is issued after passing the test. According to the steel pipe arch general assembly method, the manufacturing and erection precision is improved, the design intention is realized, the equipment is simple, the material preparation and purchasing are easy, and the materials can be reused; and the construction difficulty is reduced, the productionefficiency is improved, and the economic benefits are promoted.

Owner:中铁宝桥(宝鸡)路桥建设有限公司

Lithium-supplementing negative electrode piece, preparation method thereof, and lithium ion battery

ActiveCN109713215AImprove safety performanceImprove self-discharge performanceElectrode manufacturing processesNon-aqueous electrolyte accumulator electrodesLithium electrodeSelf-discharge

The invention discloses a lithium-supplementing negative electrode piece, a preparation method thereof, and a lithium ion battery. The lithium-supplementing negative electrode piece comprises a negative electrode piece body and a lithium-supplementing composite layer coated on the surface of the negative electrode piece body. The lithium-supplementing composite layer comprises the following raw materials in percentage by mass: 20%-65% of alloy lithium powder; 30%-70% of ceramic powder; and 5%-50% of a binder. According to the lithium-supplementing negative electrode piece disclosed by the invention, by arranging the lithium-supplementing composite layer, the safety performance of the lithium ion battery is enhanced, and the self-discharge performance of the battery is increased from -0.06mv / h to -0.04mv / h. The lithium alloy powder in the lithium-supplementing composite layer can effectively reduce the activity of lithium and reduce the transportation risk; and the ceramic powder can improve the electrolyte absorption performance of the electrolyte and prolong the cycle life of the battery cell.

Owner:SHENZHEN BETTERPOWER BATTERY

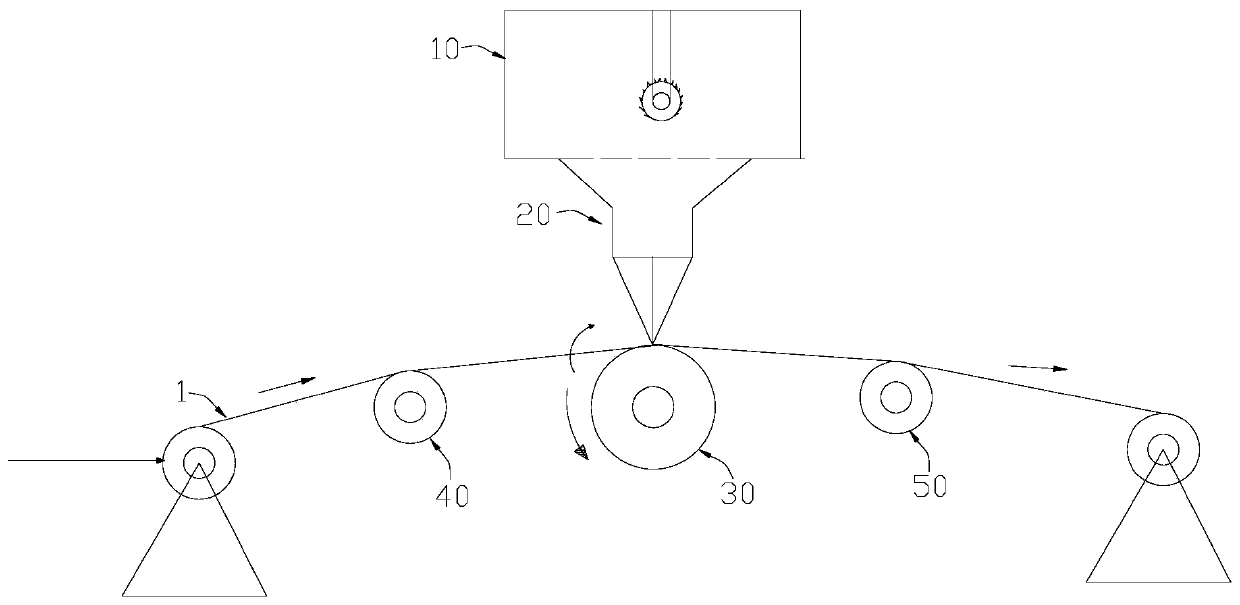

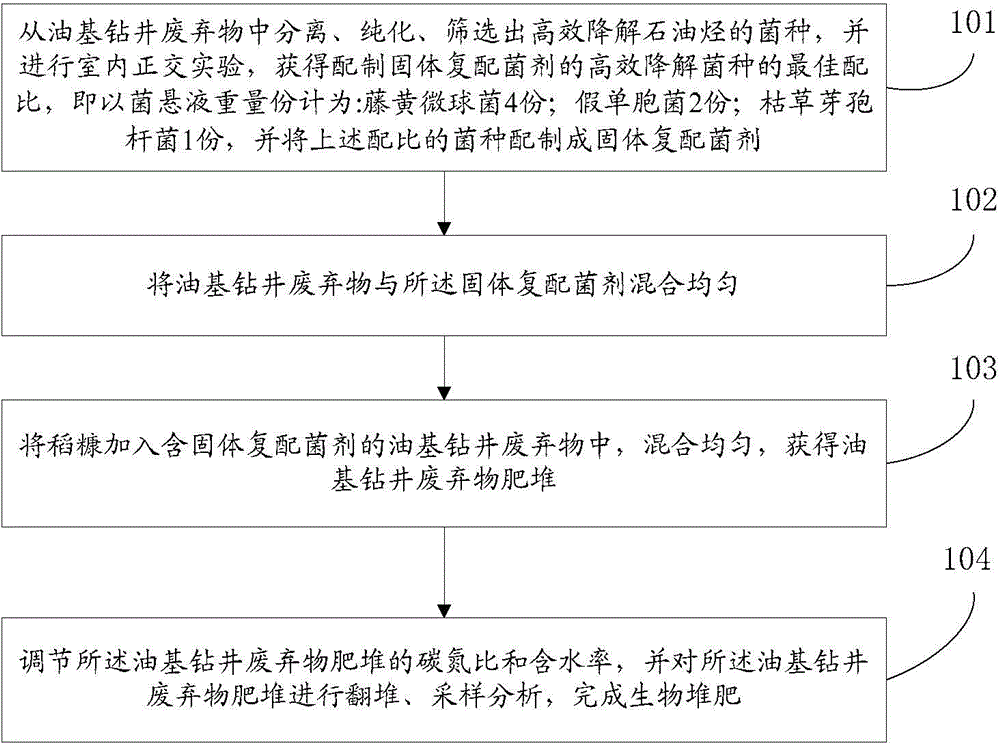

Biological composting processing method of oil-based drilling wastes

ActiveCN104803721AImprove degradation efficiencySmall footprintBio-organic fraction processingClimate change adaptationWell drillingNitrogen

The invention discloses a biological compost processing method of oil-based drilling wastes. The method comprises the following steps: screening strains capable of efficiently degrading petroleum hydrocarbons from the oil-based drilling wastes, and carrying out orthogonal experiment to prepare a solid compounded inoculant; adding the solid compounded inoculant into the oil-based drilling wastes, adding rice chaff as a supporter, and uniformly mixing to obtain compost of the oil-based drilling wastes; and adjusting the carbon / nitrogen ratio and the water content of the compost, turning, and carrying out sampling analysis to complete onsite composting. The degradation rate of total petroleum hydrocarbons in the oil-based drilling wastes reaches above 80% 1 month after the method is used to process the oil-based drilling wastes; and compost obtained in the invention can be used for planting plants, and the growth vigor of the plants is good within 3 months. The method has the advantages of simple process, simple required capital construction facility, handy enforcement surrounding a well site, short cycle, easy control, high degradation efficiency of the oil-based drilling wastes, low processing cost, and solving of troubles in economy and environmental protection for efficient exploitation of oil and gas fields.

Owner:PETROCHINA CO LTD

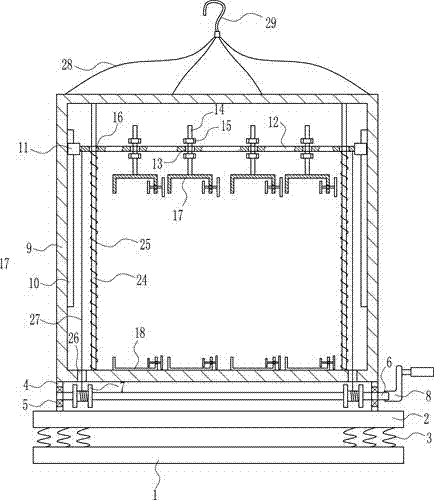

Low-E glass high-efficiency transport damping device

InactiveCN107082041AFixed withWith shock absorbing effectNon-rotating vibration suppressionLoad securingEngineeringMechanical engineering

Owner:安徽万佳节能科技有限公司

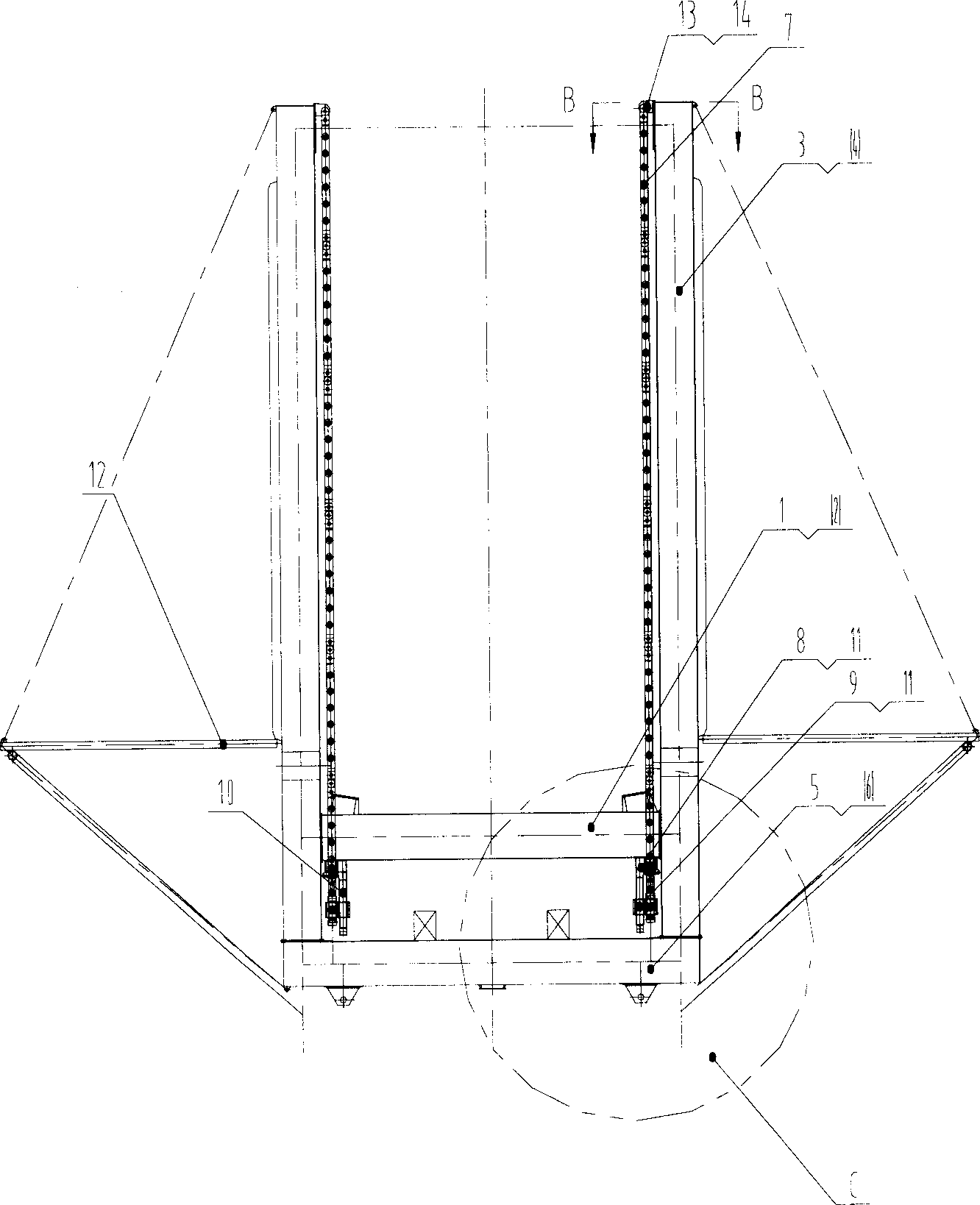

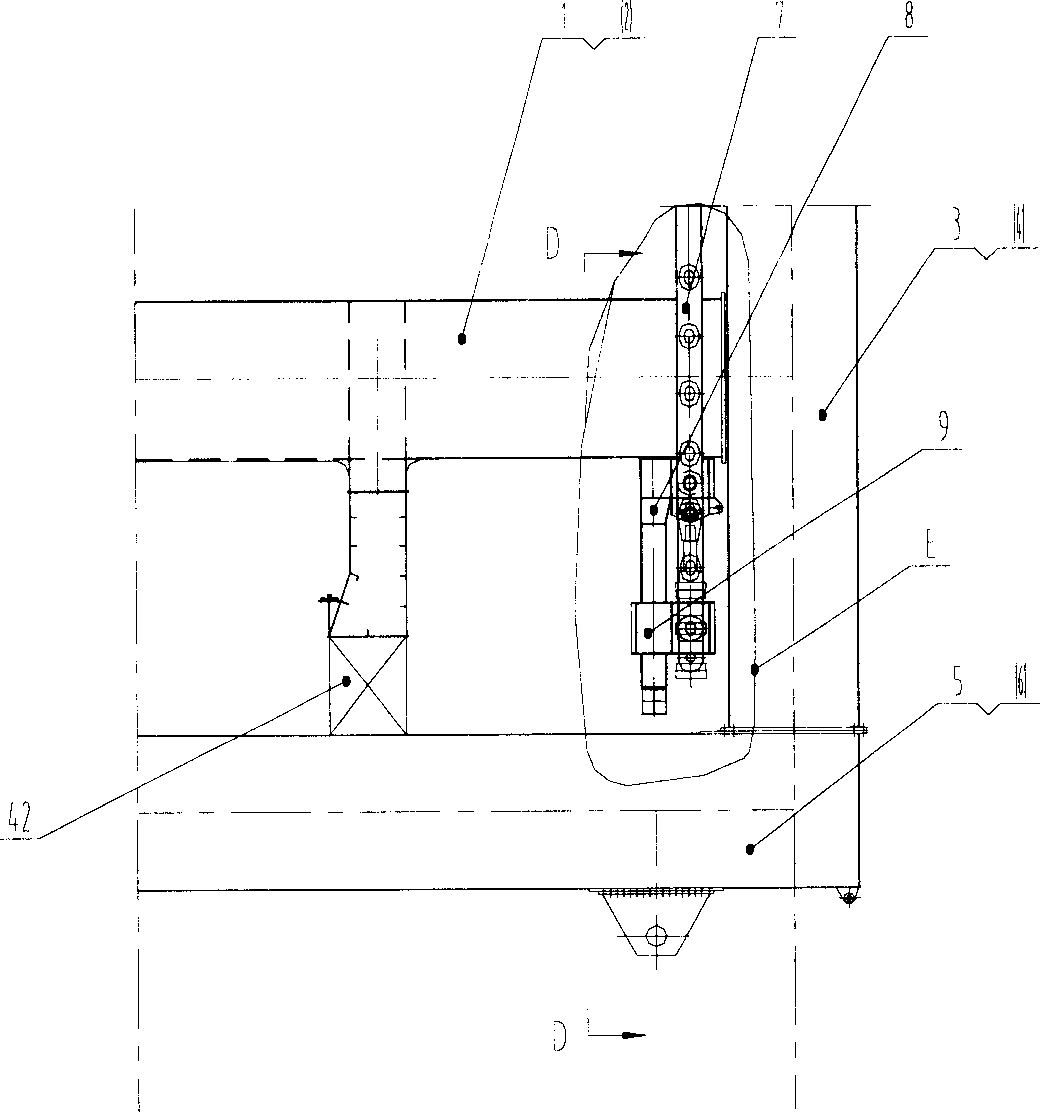

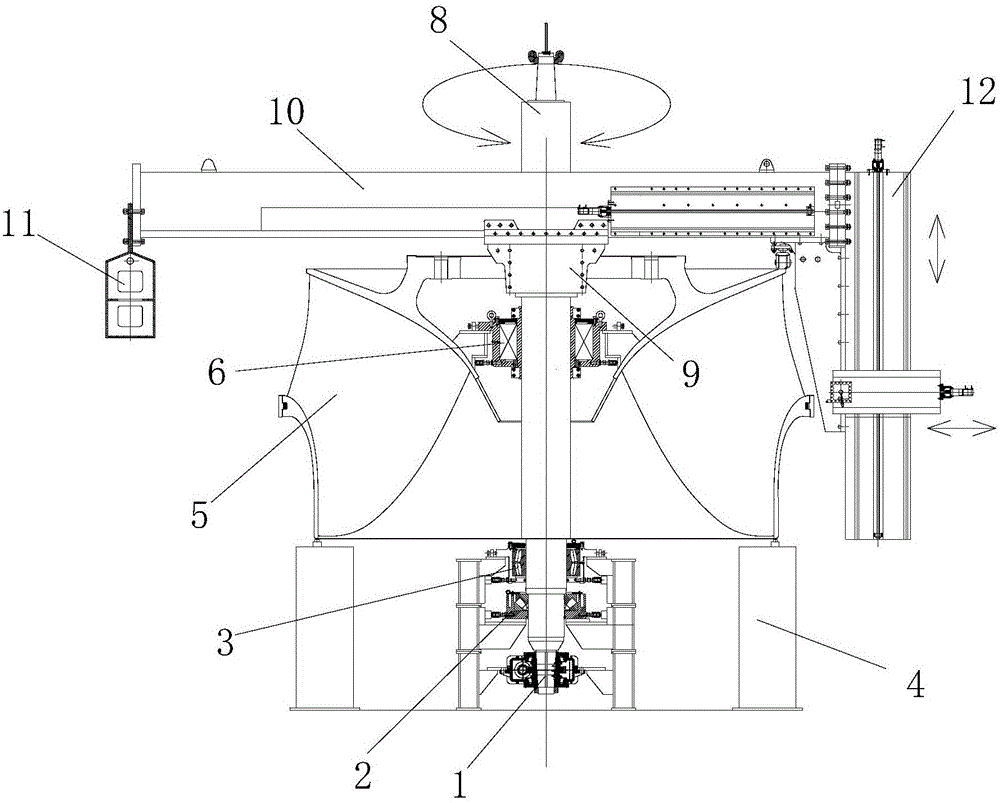

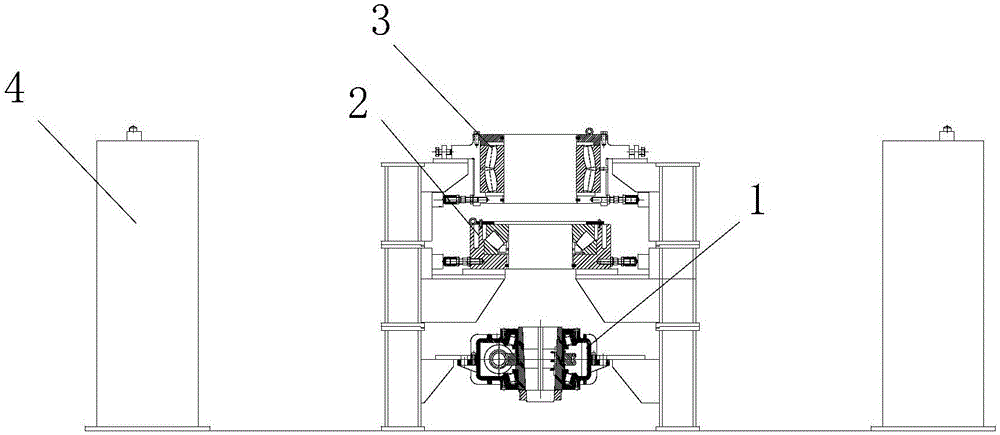

Self-lifting device for bridge crane

InactiveCN1483657AReduce shipping costsReduce installation costsTrolley cranesLoad-engaging elementsEngineeringLifting equipment

The present invention relates to an automatic lifting equipment of bridge-frame type crane, including structure supporting frame formed from upper cross-beam of bridge-frame type crane, upright post and lower cross-beam, also including lifting pull plate, pull plate beam, lifting ear, upper and lower supporting frames, lifting cylinder, plug in device and upright post reset support. Said invention also provides a method for shipping said bridge-frame type crane.

Owner:SHANGHAI PORT MACHINERY HEAVY IND +1

Low-floor vehicle transportation method and system thereof

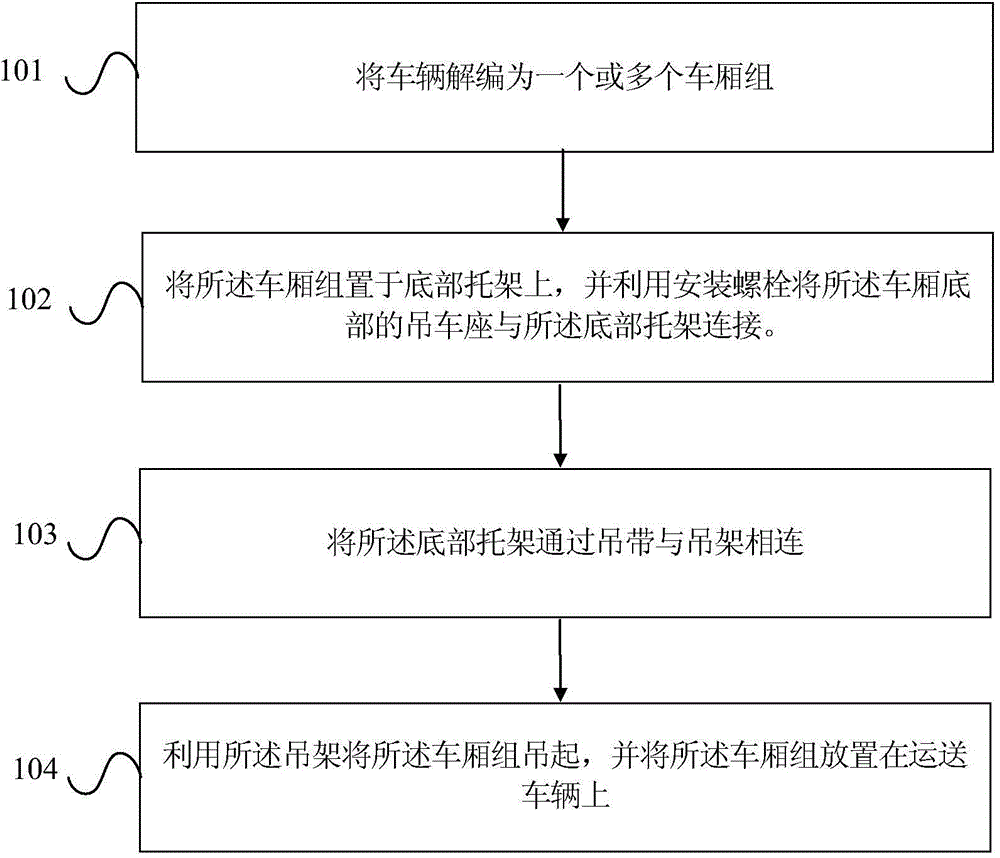

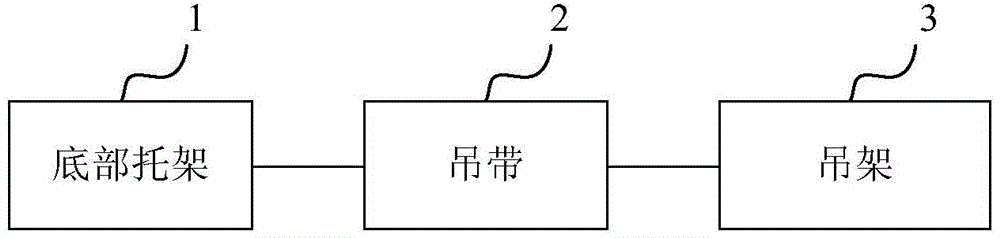

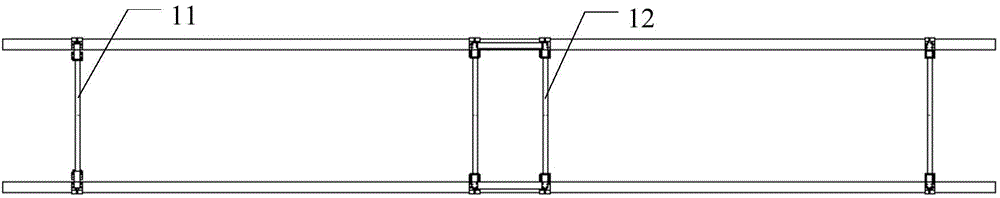

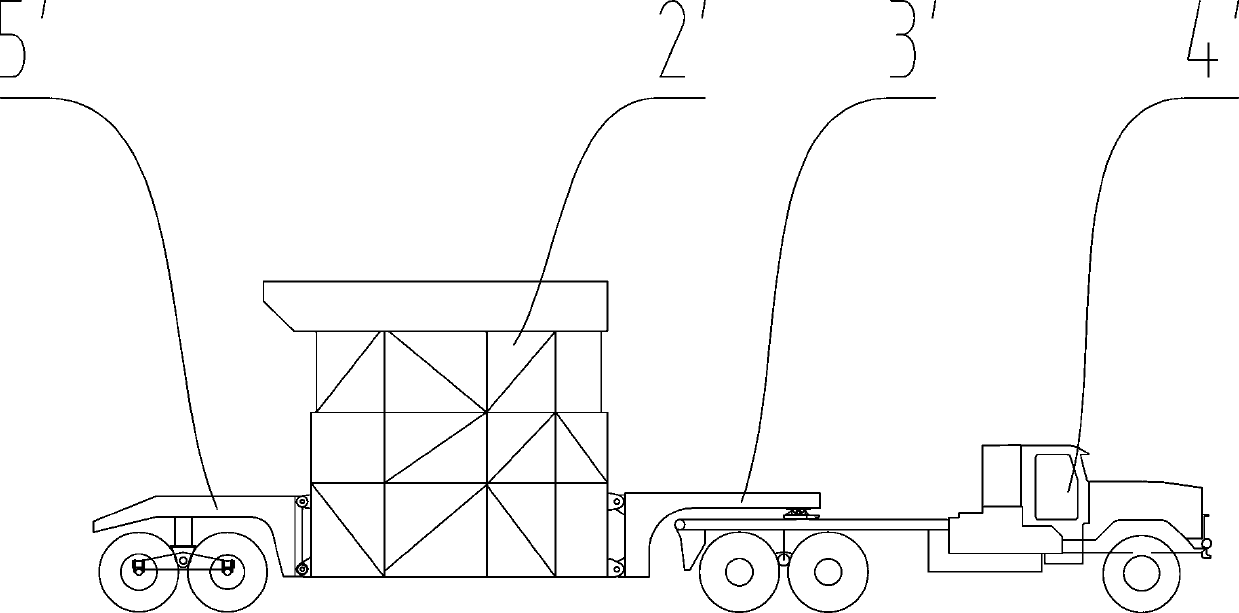

ActiveCN104649131AReduce the workload of decodingImprove transportation efficiencyLoad-engaging elementsBogieWorkload

The invention provides a low-floor vehicle transportation method and a system thereof. The method comprises the following steps: detaching a vehicle into one or multiple carriage groups, wherein each carriage group comprises at least two carriages; placing the carriage groups on a bottom bracket and connecting crane seats at bottom of the carriages with the bottom bracket by bolts; connecting the bottom bracket with a hoist frame by a sling; and hoisting the carriage groups by utilizing the hoist frame and placing the carriage groups onto a transport vehicle. According to the low-floor vehicle transportation method and the system thereof, the vehicle is detached into one or multiple carriage groups, each carriage group comprises at least two carriages, and the carriage groups are fixed on the bottom bracket and placed on transport vehicles by a hoist frame, so that workload of vehicle detaching is reduced; moreover, separation between a vehicle body and a bogie is not required before transportation, so that the transportation efficiency is effectively improved, and transportation cost and transportation risk are reduced.

Owner:CRRC TANGSHAN CO LTD

Pull-type drilling rig derrick base structure

PendingCN110185387AAvoid deformationLower transport heightDerricks/mastsDrilling machines and methodsHydraulic cylinderVehicle frame

The invention relates to the field of petroleum drilling and production equipment, in particular to an automated and modular pull-type drilling rig derrick base structure. The pull-type drilling rig derrick base structure comprises a base assembly connected with a foundation, a derrick assembly movably connected with the base assembly, and a trailer frame assembly movably connected with the base assembly and the derrick assembly, and further comprises connection fasteners movably connected with the base assembly, the derrick assembly and the trailer frame assembly correspondingly, jacking hydraulic cylinders fixedly connected with the trailer frame assembly or the base assembly, and supporting rods fixedly connected with the connection fasteners or the base assembly. The pull-type drillingrig derrick base structure has the beneficial effects that the turning radius is small, a using area is not limited, transferring can be conducted at a time, the mounting and carrying time is reduced, and automation and modularization are achieved.

Owner:SICHUAN HONGHUA PETROLEUM EQUIP

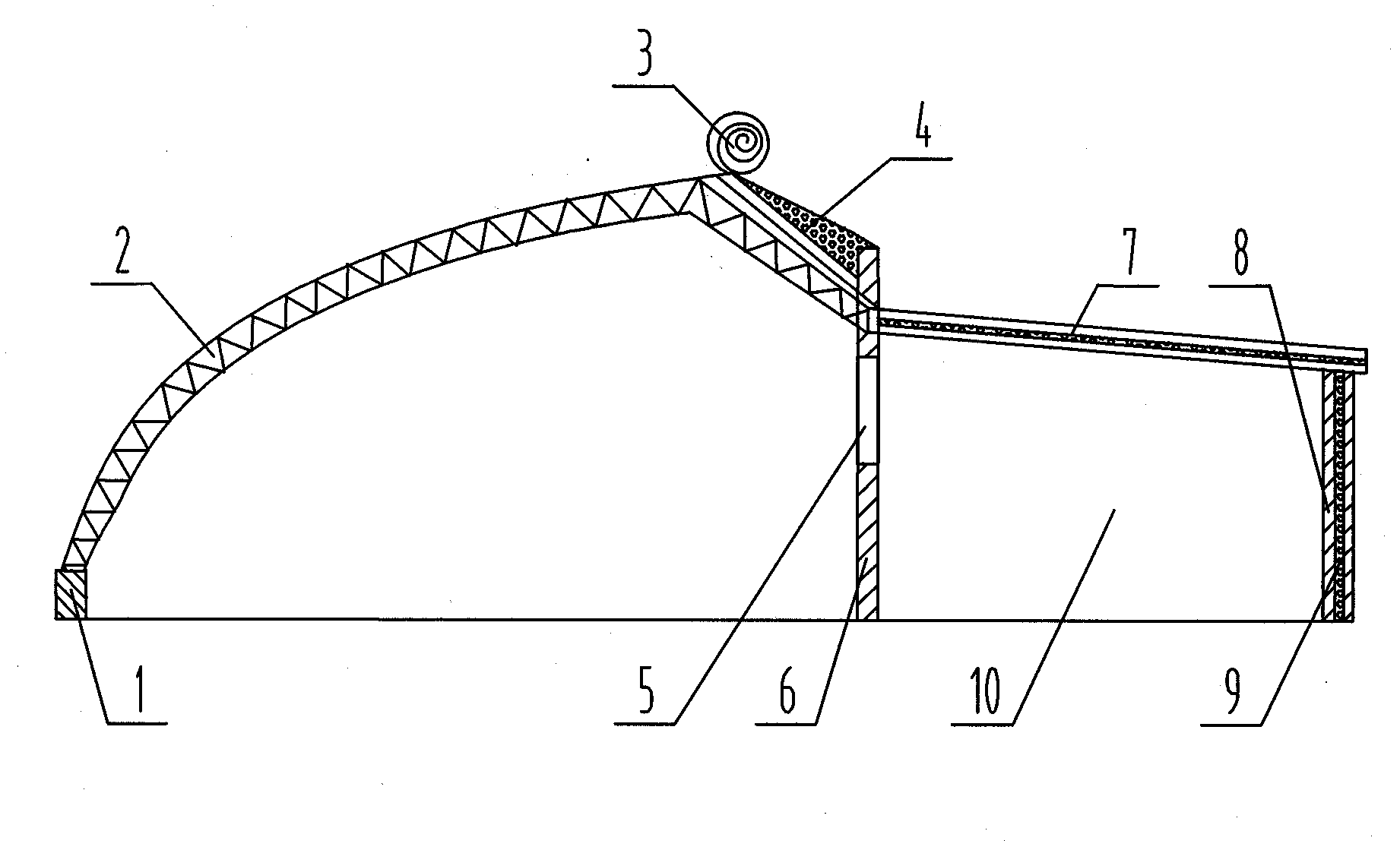

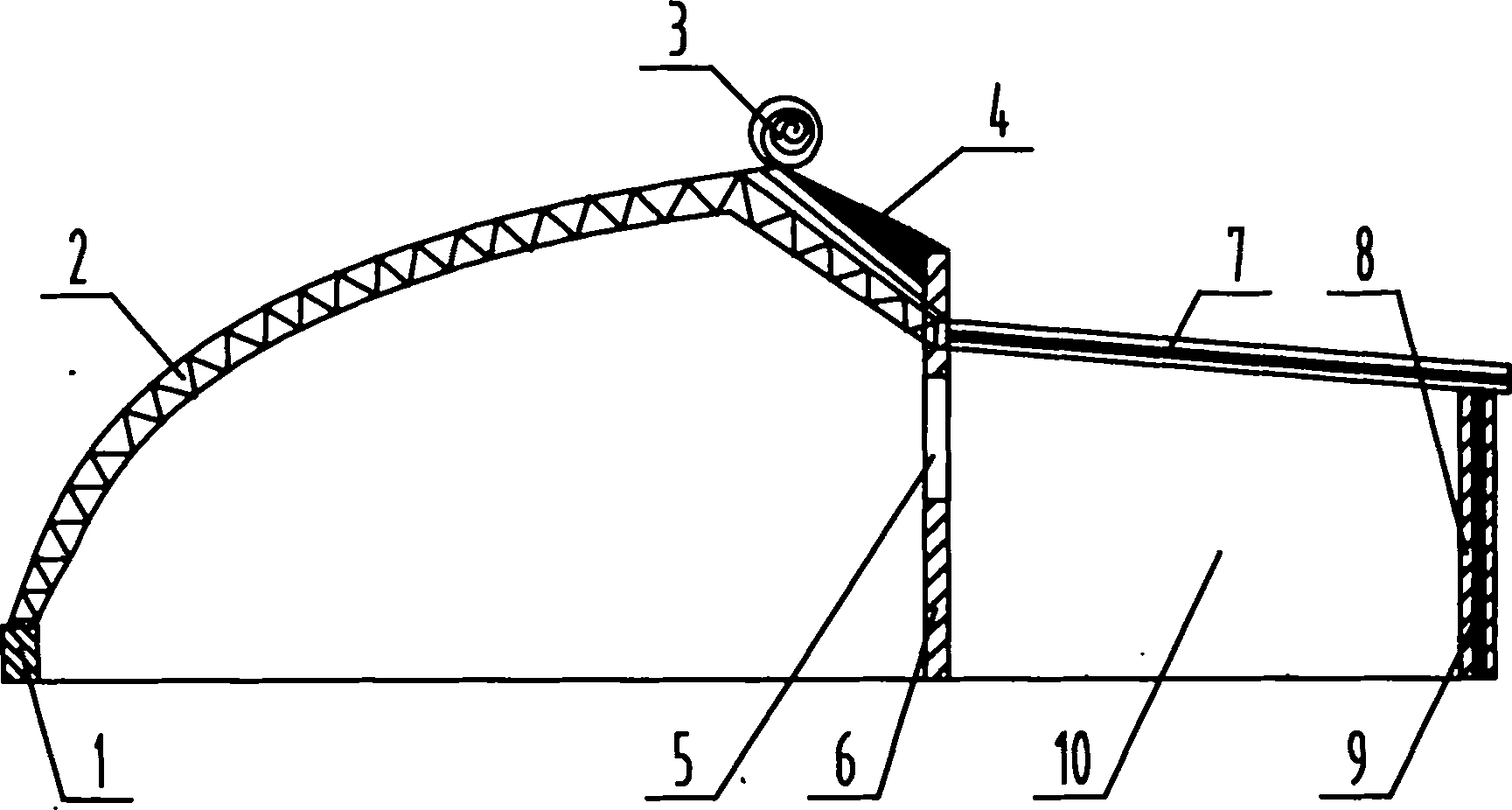

Tissue culture and seedling raising integration energy-saving sunlight conjoined greenhouse

InactiveCN102657045AReach exchangeStable temperatureClimate change adaptationGreenhouse cultivationBrickDaylight

The invention discloses a tissue culture and seedling raising integration energy-saving sunlight conjoined greenhouse which has good thermal insulating properties and energy conservation effects, saves cost and reduces the risks in tissue culture and seedling transportation. The tissue culture and seedling raising integration energy-saving sunlight conjoined greenhouse comprises a solar greenhouse consisting of a sleeper wall, a framework, a rear slope, a bearing wall and gable walls, as well as a roller shutter arranged on the roof of the framework, wherein a rear house is connected with the rear side of the solar greenhouse to form the conjoined greenhouse, the rear house and the solar greenhouse shares the bearing wall, a protective wall body of the conjoined greenhouse consists of the sleeper wall at the front bottom corner of the solar greenhouse, the gable walls at the two ends of the solar greenhouse, the bearing wall in the middle of the solar greenhouse and brick walls of the rear house, a row of tissue culture rooms is arranged in the rear house in uniform intervals along the longitudinal direction, and each tissue culture room is provided with a door and window on the bearing wall. The conjoined greenhouse is applicable to the integral energy-saving production for tissue culture and seed raising.

Owner:SHENYANG AGRI UNIV

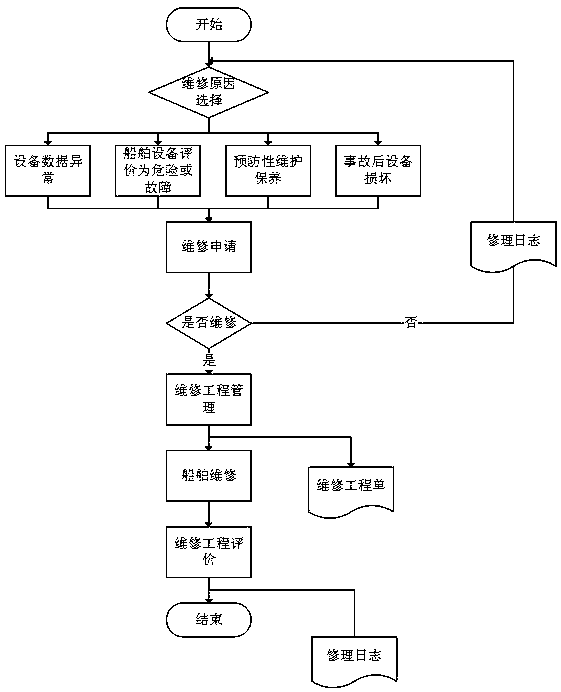

Ship maintenance platform

InactiveCN109978184AEfficient transmissionImprove ship management levelData processing applicationsData monitoringSensing data

The invention discloses a ship maintenance platform. The system comprises a ship end data sensing system and a ship data monitoring system, ship maintenance management system. The cross-end data sensing system is in data signal connection with the ship data monitoring system. The ship data monitoring system is in data signal connection with the ship maintenance management system. The ship end datasensing system collects and obtains operation state data of ship cabin equipment through ship end data sensing equipment, real-time comprehensive monitoring of the ship operation state is achieved, and the ship data monitoring system processes and analyzes the ship cabin sensing data to obtain operation state information of all the equipment of a ship. The method has the advantages that the operation state of ship cabin equipment is analyzed and displayed by collecting ship-end cabin data, and management of the whole process of ship maintenance is achieved.

Owner:中船(浙江)海洋科技有限公司

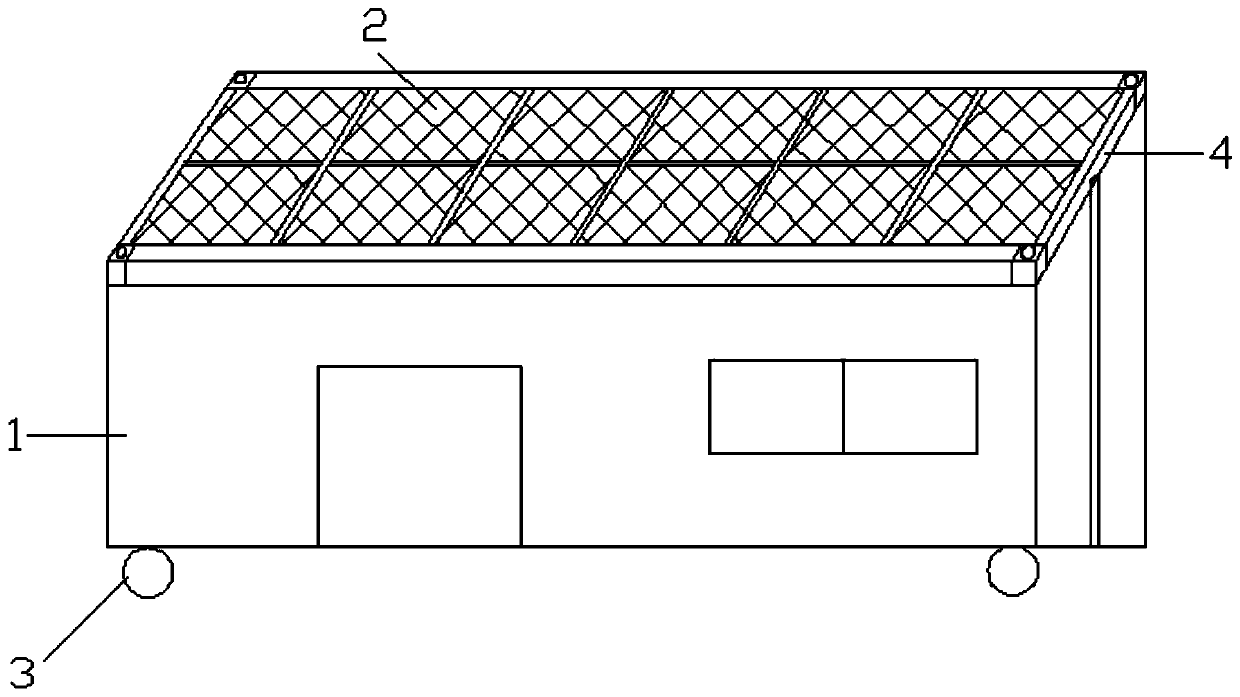

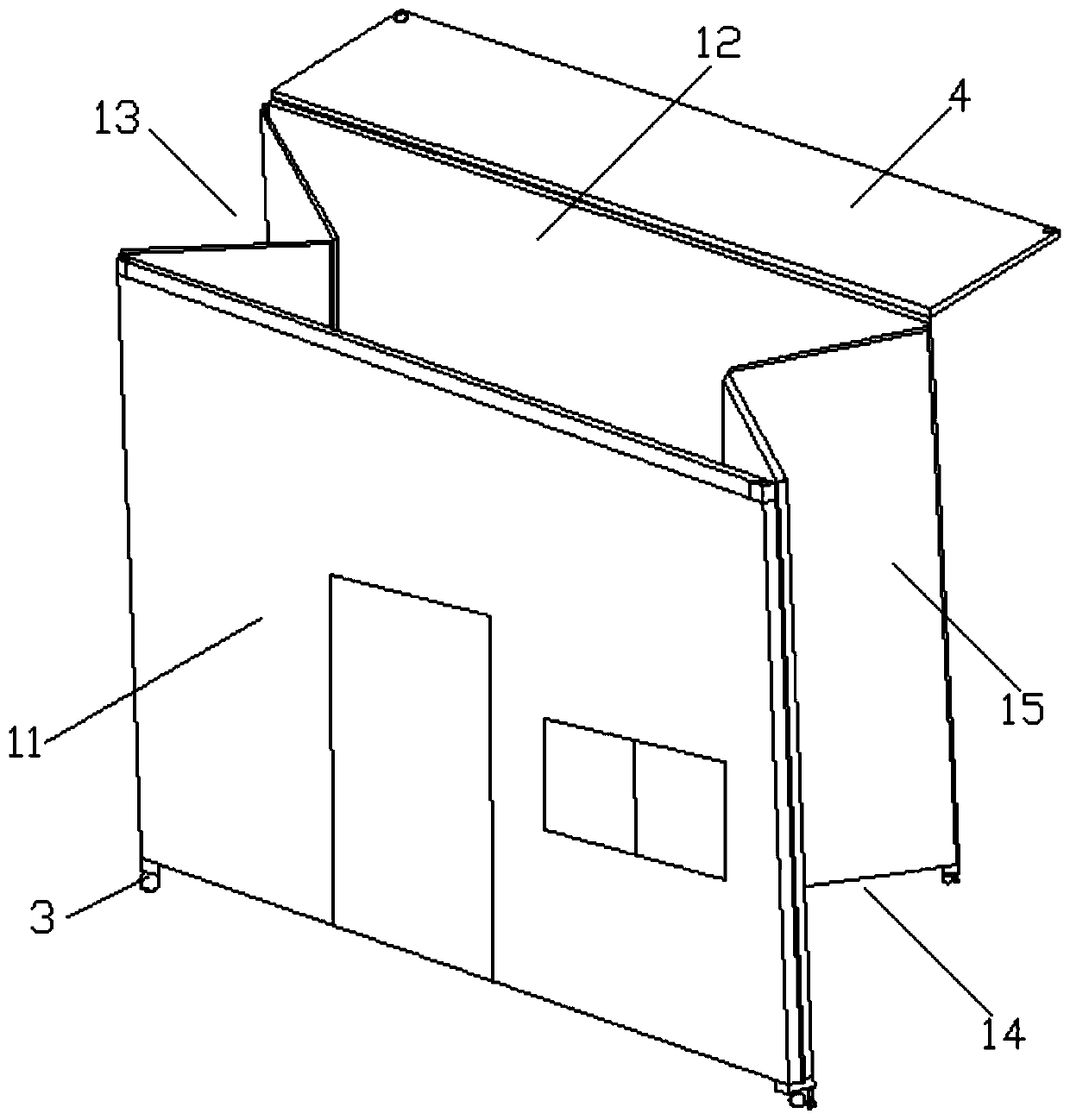

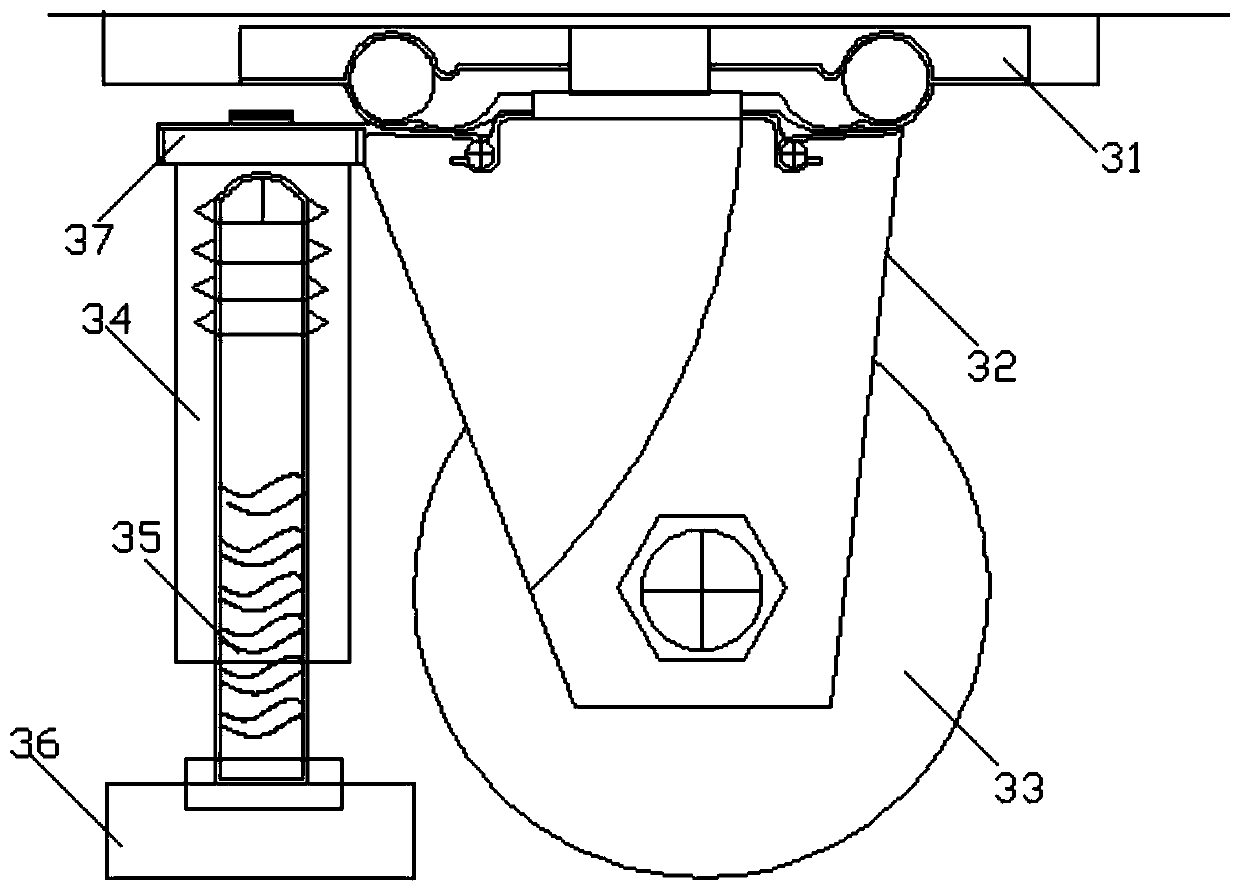

Movable folding type green board house

PendingCN109750750ASimple structureEasy to installRoof covering using slabs/sheetsRoof covering using tiles/slatesEngineeringSolar power

The invention provides a movable folding type green board house, comprising a foldable board house body, a foldable board house roof arranged at the upper end of the foldable board house body, and a solar power generation assembly is installed on the foldable board house roof. The foldable board house further comprises a plurality of adjustable trundles arranged at the lower end of the foldable board house body and used for moving the board house body, and the foldable board house body can be folded into a line shape. The board house is simple in structure and easy and convenient to install, only primary installation is needed, during subsequent transportation, the board house can be folded into a line shape for transportation, operation is convenient, and transportation and turnover are convenient. By arranging the adjustable trundles at the bottom of the board house body, the board house can be moved at will, the board house can be fixed through a supporting seat, the stability of the board house is guaranteed, and the board house is safer. A solar panel is used as a power generation assembly, so that the problem of power utilization is solved, and the board house is green, energy-saving and environment-friendly.

Owner:WUYI UNIV

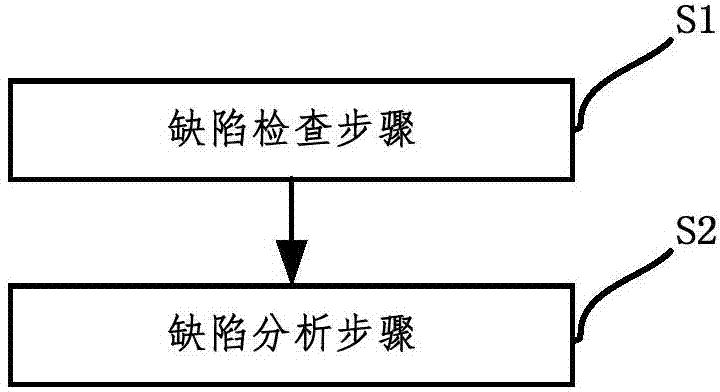

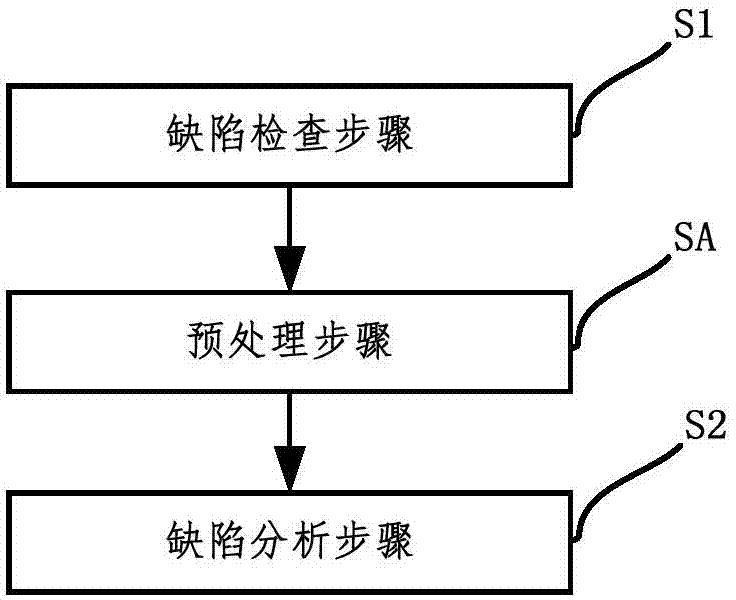

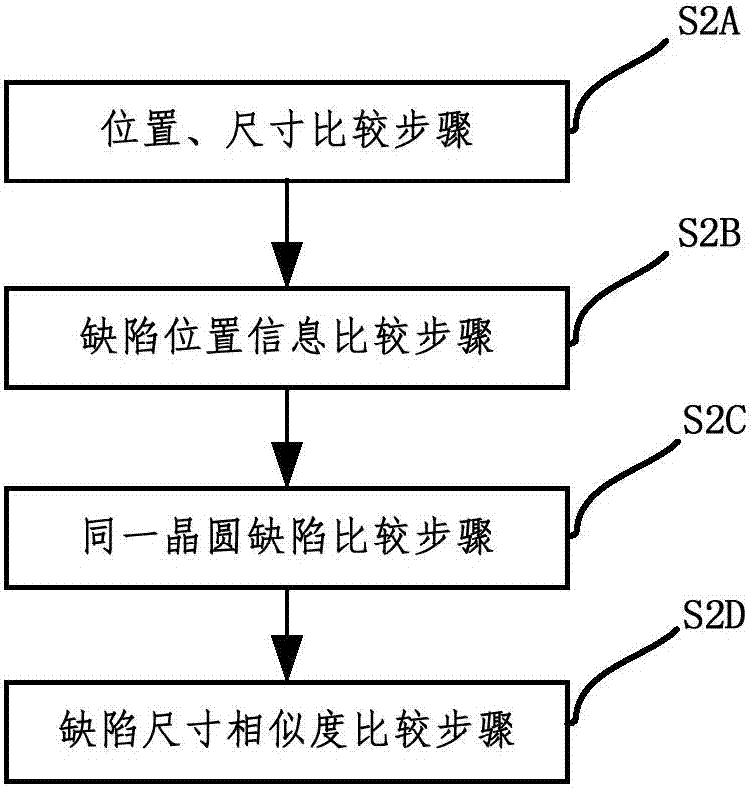

Method and system for checking and analyzing repetitive photolithography defect of wafers, and wafer production method

ActiveCN104716062AEfficient detectionFully detectedSemiconductor/solid-state device testing/measurementDelivery riskMicroscopic exam

In order to solve the problem that the repetitive photolithography defect of wafers are hard to detect effectively and missed or false detection can be easily caused due to traditional artificial microscopic examination, the embodiment of the invention provides a method and a system for checking and analyzing the repetitive photolithography defect of wafers, and a wafer production method. The method for checking and analyzing the repetitive photolithography defect of wafers comprises the following steps: S1, a defect checking step in which selected wafers are all scanned to check defects; and S2, a defect analysis step in which position information and size information of defects of the selected wafers are compared and whether the wafers in the analyzed batch have the repetitive photolithography defect is judged. According to the invention, the selected wafers are all scanned, and special comparative analysis is given to scanning data, so that the repetitive photolithography defect can be checked effectively and comprehensively, missed or false detection can be avoided, the convenience is high, the rate of finished products in the photo-etching process can be further increased, and the delivery risk can be reduced.

Owner:BYD SEMICON CO LTD +1

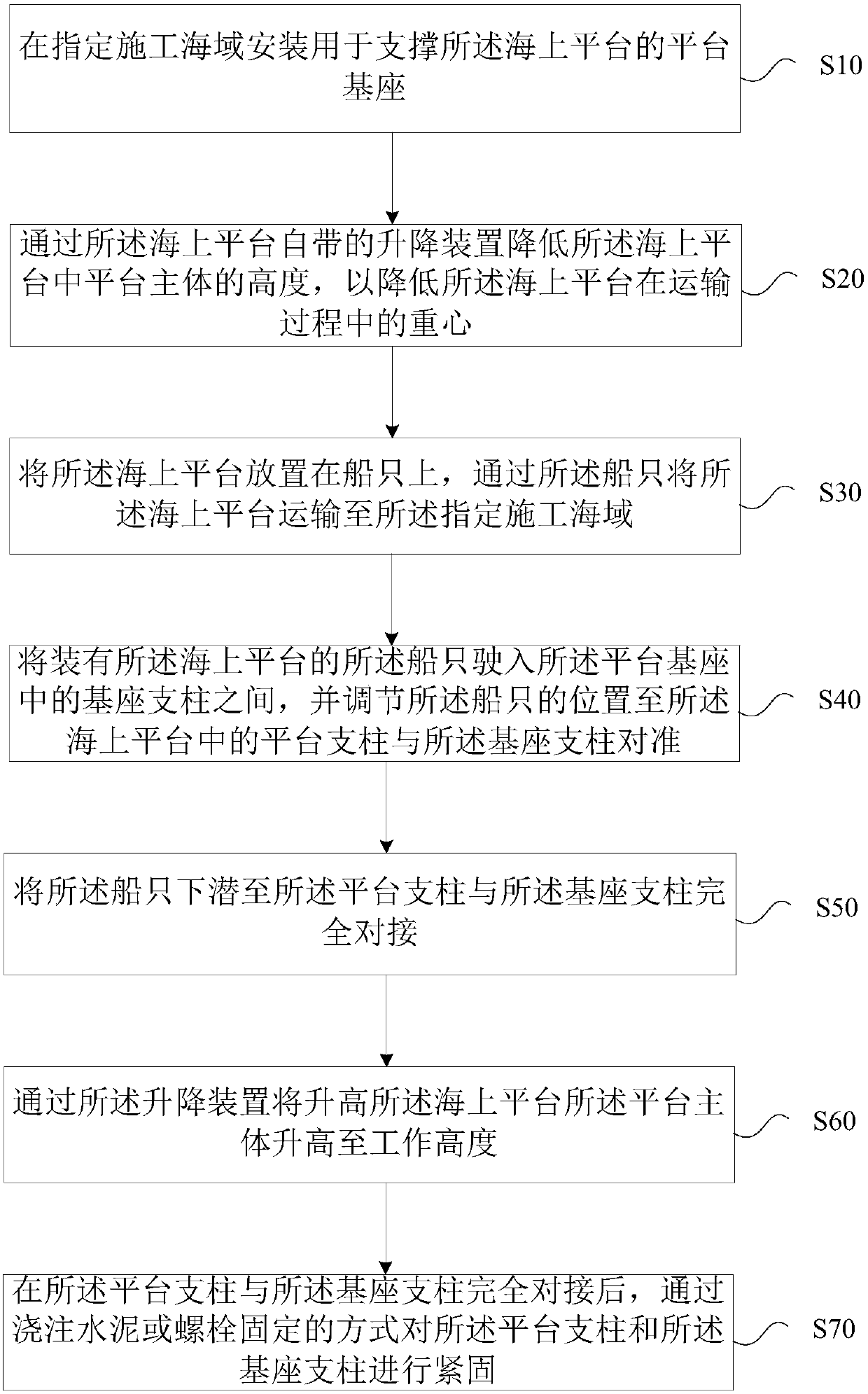

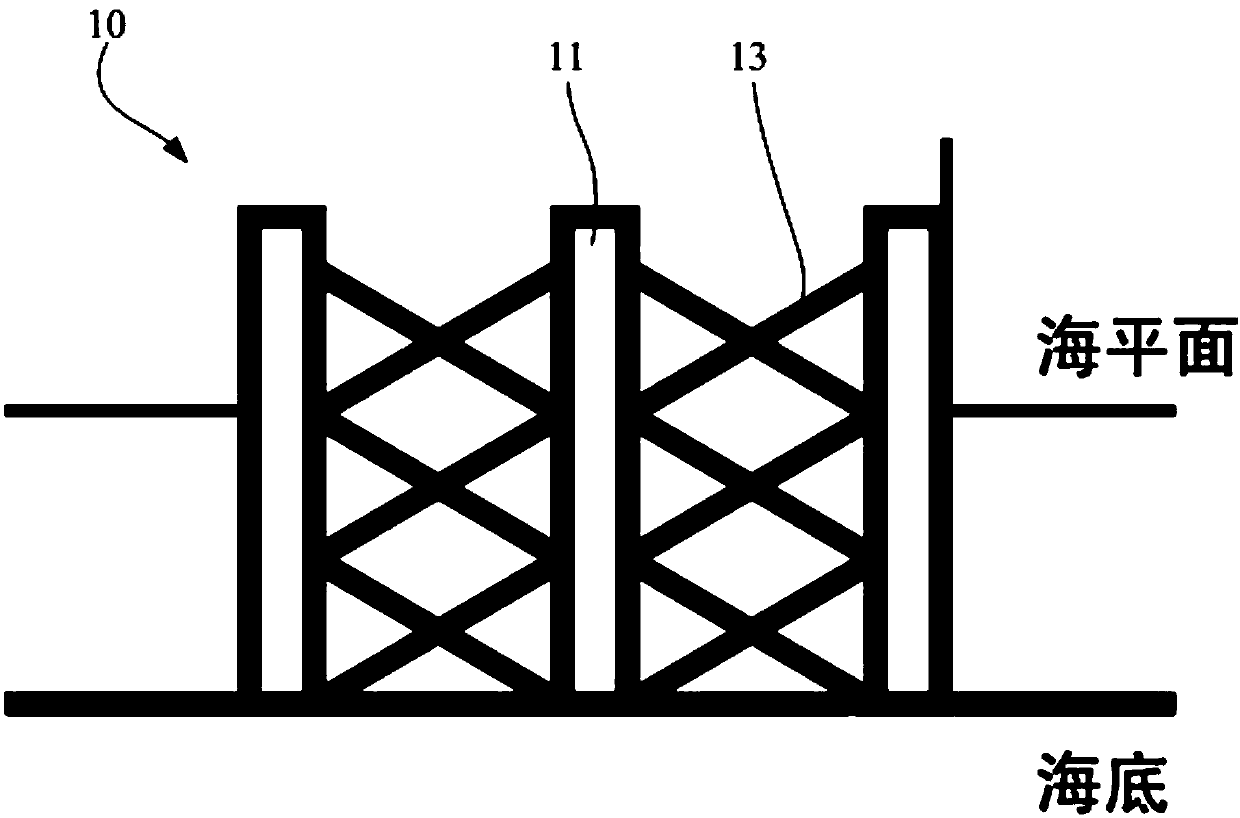

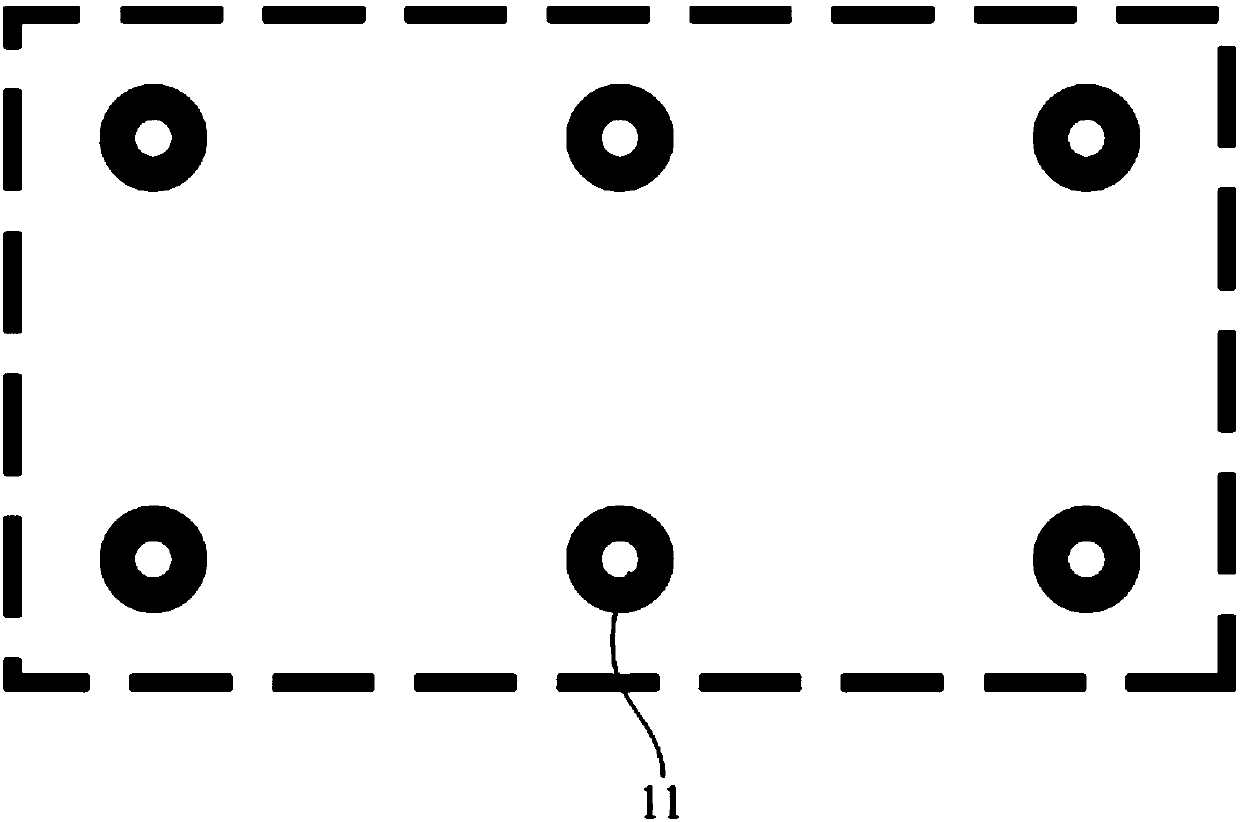

Installation method of offshore platform

InactiveCN107653857ALower the altitudeLower center of gravityArtificial islandsUnderwater structuresMarine engineeringLifting equipment

The invention provides an installation method of an offshore platform. The installation method of the offshore platform comprises the step of installing a platform base, the step of transporting the offshore platform and the step of enabling the offshore platform to be butted with the platform base, wherein before the step of transporting, the step of lowering the offshore platform is included, sothat the gravity of the offshore platform is reduced during the transporting process; and after the step of butting, the step of lifting the offshore platform is further included so as to lift the platform body to the working height. The installation method of the offshore platform has the benefits as follows: on the basis of the float-over installation method and by lowering the platform body ofthe offshore platform through the built-in lifting device of the offshore platform before the step of transporting, transportation risks are reduced without increasing the size of a ship, and after the butting step of the offshore platform is completed, the platform body is lifted by the lifting device to the working height, the normal operation of the offshore platform is ensured, and the installation cost is reduced due to that no large-sized lifting equipment is needed.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST EURO GMBH +2

Method and device for transporting thin-wall equipment in nuclear power plant

InactiveCN105416420AEasy accessReduce distortionTractor-trailer combinationsNuclear powerComputer module

The invention provides a method and device for transporting thin-wall equipment in a nuclear power plant. The device comprises four power module self-propelled modular transporters (SPMTs). The power module SPMTs are arranged in a square shape and connected through connecting racks. Steel plates are fixed to the power module SPMTs. Brackets formed through welding are laid on the steel plates. Bases are arranged on the brackets. The steel plates and the bases of the brackets are fixed through spot welding. The power module SPMTs are provided with inner blocking racks and outer blocking racks. The device has the beneficial effects that the turning radius of an equipment transporter set is reduced, the transportation stability is improved, the thin-wall equipment is protected against deformation in the transportation process, and transportation risks are reduced.

Owner:GUANGDONG ELEVATOR ENG MACHINERY

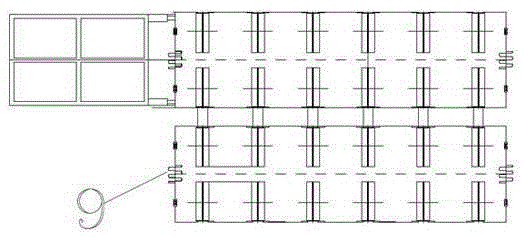

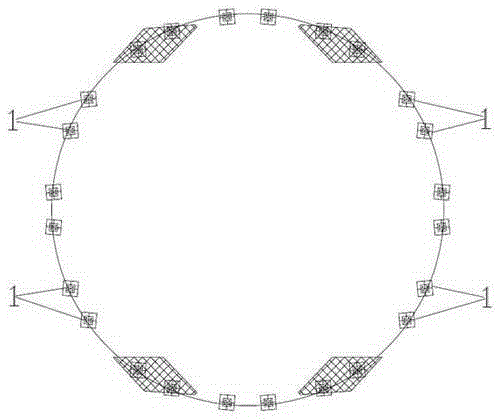

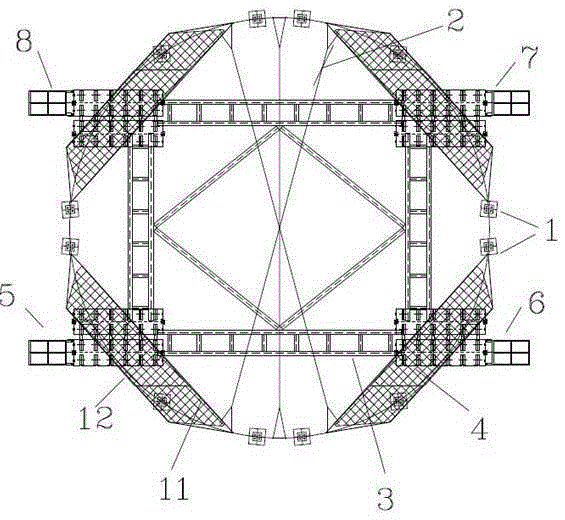

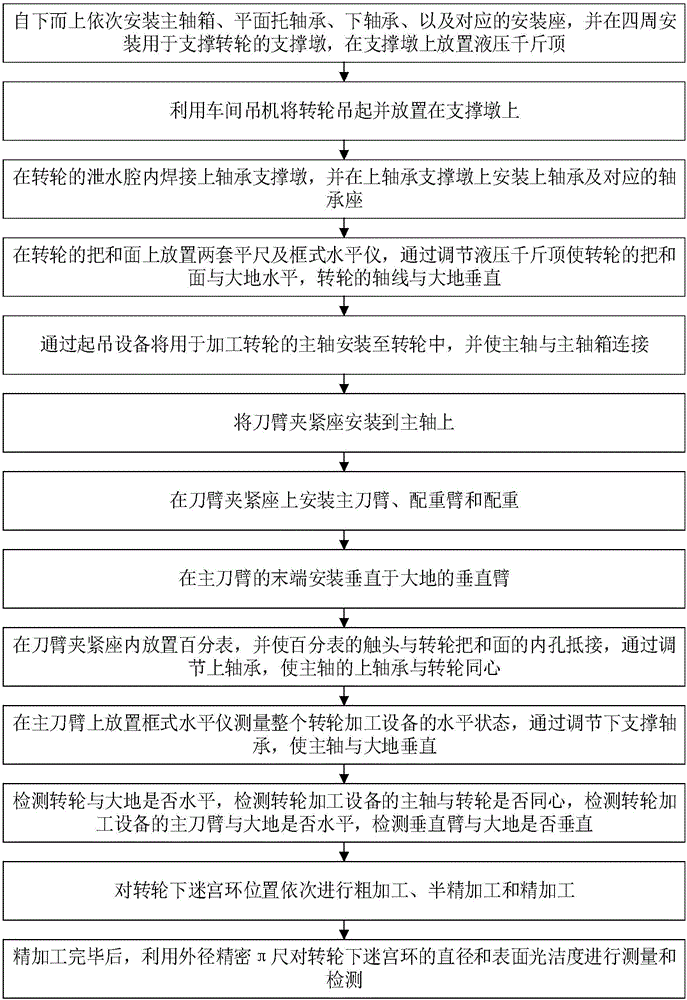

On-site repair machining process of lower labyrinth ring of rotating wheel

ActiveCN106799558AReduce processing costsReduce shipping costsFinal product manufactureHydro energy generationSurface finishMachining process

The invention discloses an on-site repair machining process of a lower labyrinth ring of a rotating wheel. The process comprises the following steps of firstly, installing a main shaft box, a plane supporting bearing, a lower bearing and a supporting pier on the ground, and installing a jack on the supporting pier; secondly, placing the rotating wheel on the jack, and keeping the rotating wheel parallel to the horizontal plane; thirdly, installing an upper bearing in a water draining cavity of the rotating wheel, installing a main shaft in the rotating wheel, connecting the main shaft to the main shaft box, adjusting the upper bearing, and ensuring that the upper bearing is concentric with the rotating wheel; fourthly, installing a tool arm clamping base, a main tool arm and a balance weight on the main shaft, installing a perpendicular arm on the main tool arm, adjusting the lower bearing, ensuring that the main shaft is perpendicular to the horizontal plane, enabling the main tool arm to be parallel to the horizontal plane, and enabling the perpendicular arm to be perpendicular to the horizontal plane; fifthly, carrying out rough machining, semi-finish machining and finish machining on the position of the lower labyrinth ring; and sixthly, detecting the outer diameter and the surface smoothness of the lower labyrinth ring and evaluating the machining effect. The on-site repair machining process is simple to operate, low in repair cost, short in machining period, high in efficiency and good in effect.

Owner:GUANGZHOU XINCHENG MECHANICAL TECH

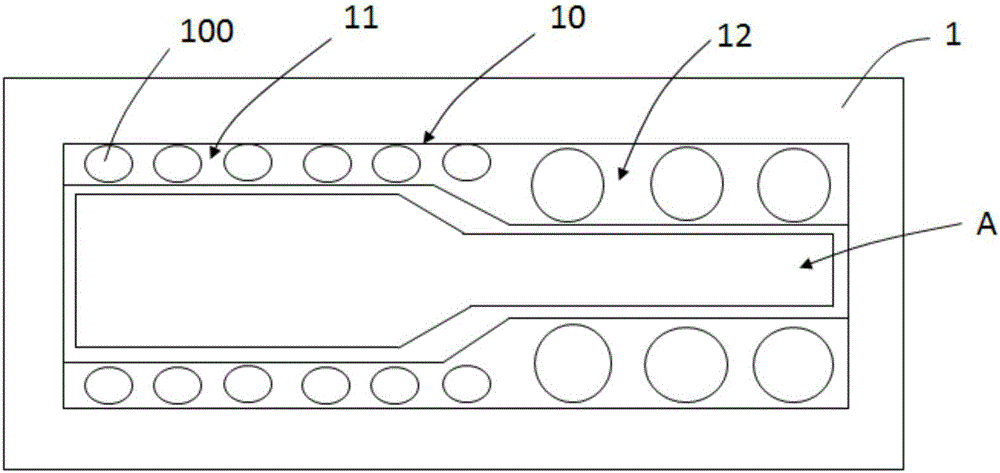

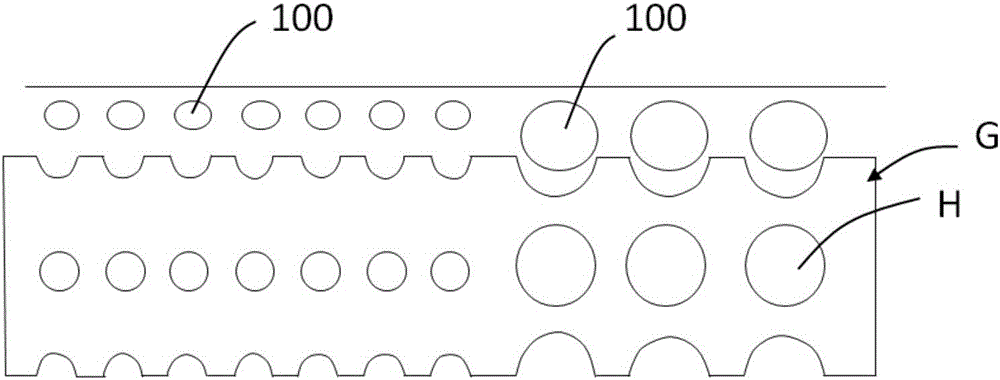

Unequal-thickness bubble pad and making method and packaging structure thereof

InactiveCN106516428AImprove protectionIncrease contact areaContainers to prevent mechanical damageEngineeringAir bubble

The invention discloses an unequal-thickness bubble pad. The unequal-thickness bubble pad comprises a bubble pad body and a thickening portion arranged at one end of the bubble pad body, wherein the bubble pad body and the thickening portion are each internally provided with bubbles filled with air, and the thickness of the thickening portion is larger than that of the bubble pad body. The invention further discloses a making method and packaging structure of the unequal-thickness bubble pad. According to the unequal-thickness bubble pad and the making method and packaging structure thereof, an unequal-thickness bubble pad structure is designed, the contact area with a packaged article can be increased, the unequal-thickness bubble pad is used for improving protection performance on the packaged article which is unequal in thickness, the transportation risk of the article which is unequal in thickness is reduced, and the product image is improved.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Container falling early warning system and method for container ship

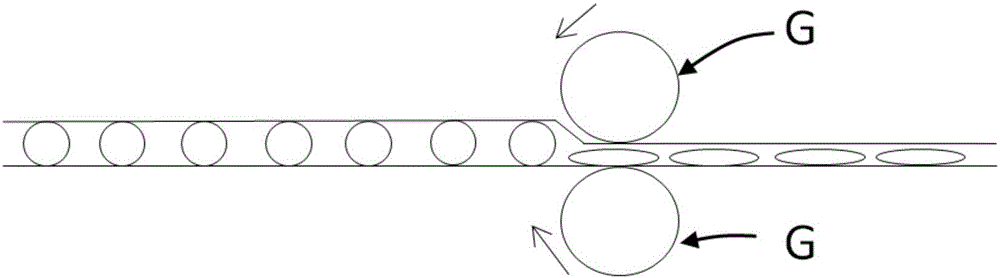

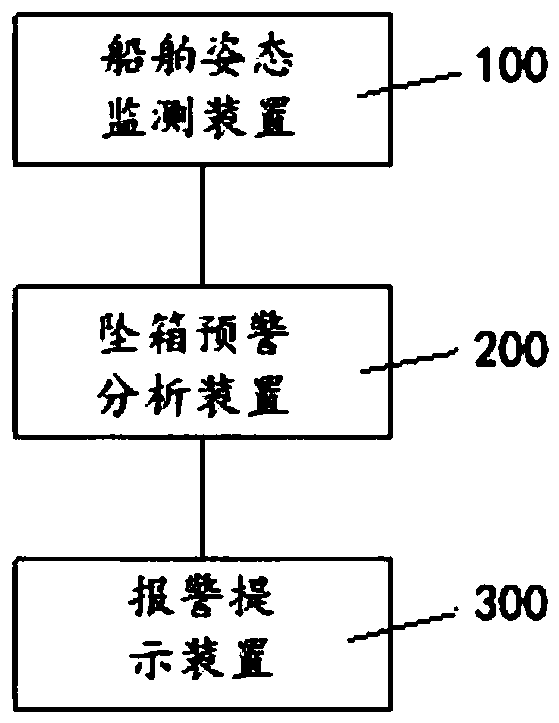

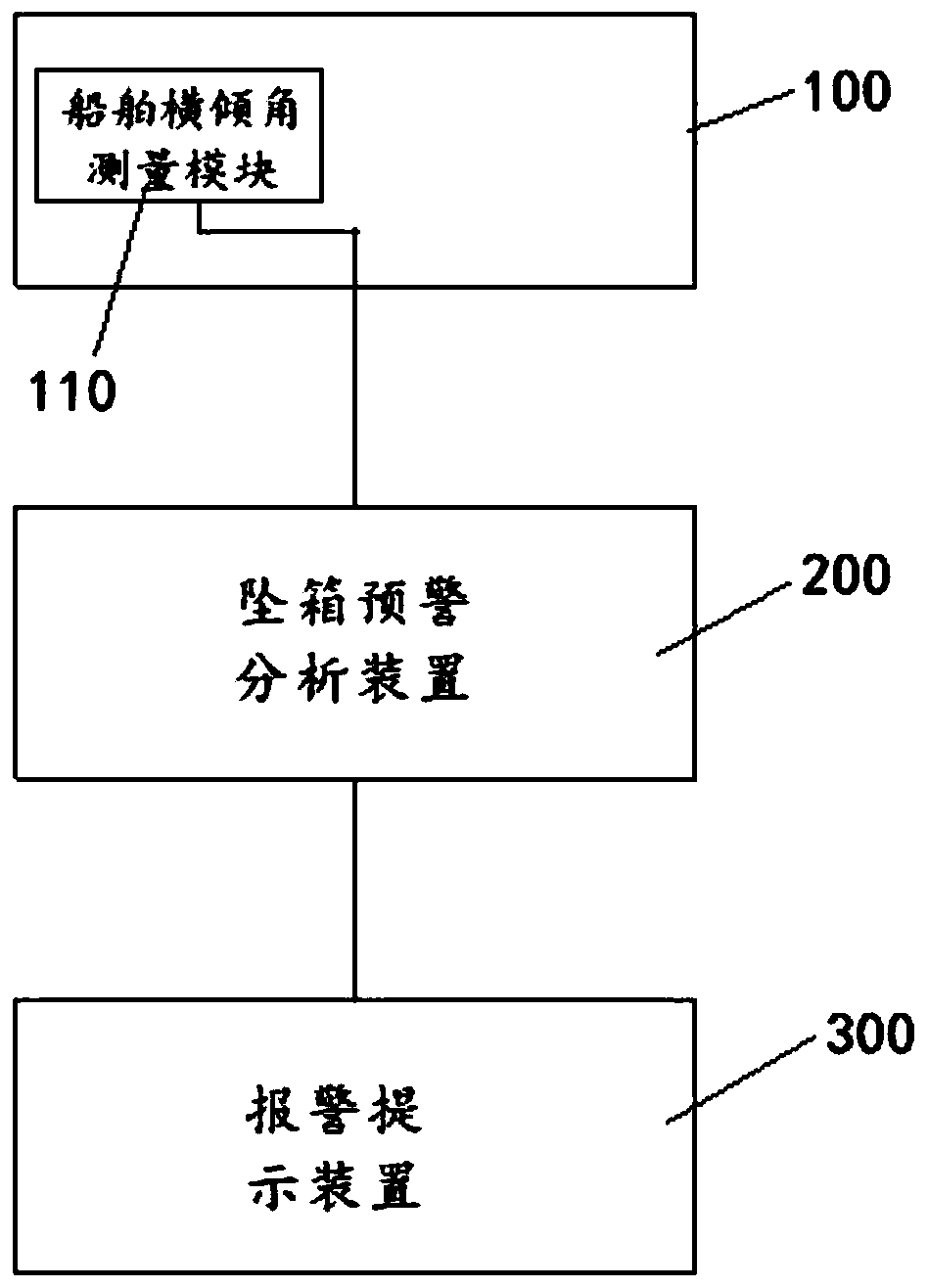

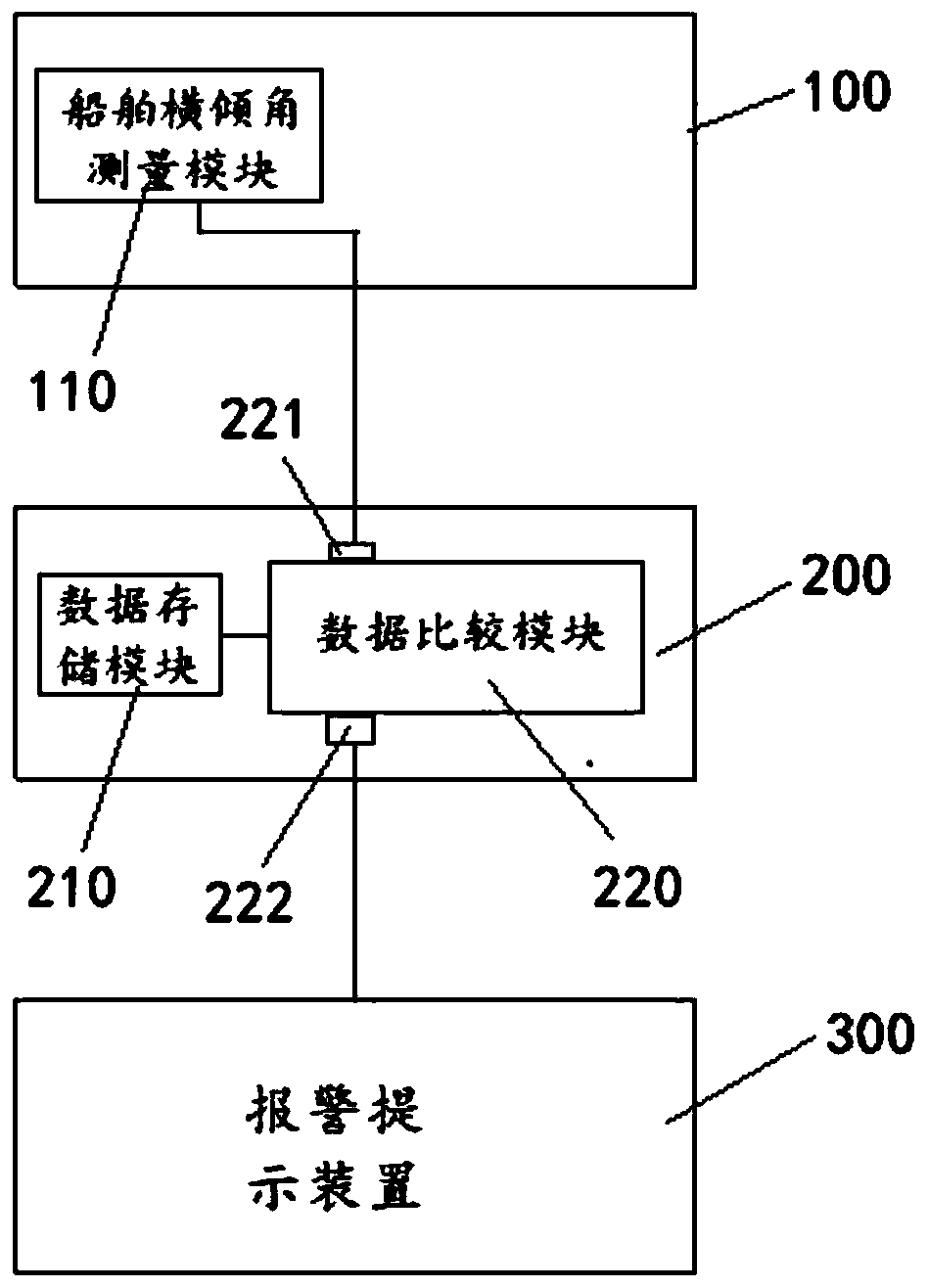

PendingCN110807903ATimely prevention of fall accidentsReduce shipping riskAlarmsIncline measurementMarine engineeringClassical mechanics

The invention aims at providing a container falling early warning system and method for a container ship, thereby solving a technical problem of reducing the probability of container falling into thesea by monitoring the rolling inclination state of a ship body. The early warning system comprises a ship attitude monitoring device, a container falling early warning and analysis device and an alarmprompt device. The ship attitude monitoring device and the alarm prompt device are connected with the container falling early warning and analysis device electrically. The ship attitude monitoring device is used for sending an obtained transverse inclination angle of a ship body to the container falling early warning and analysis device; and the container falling early warning and analysis deviceis used for acquiring a transverse inclination angle acceleration according to the transverse inclination angle and a measurement time interval of two adjacent transverse inclination angle measurement and triggering the alarm prompt device to send out alarm information under the condition that the accumulated frequency sum of exceeding a thread set in the container falling early warning and analysis device by the transverse inclination angle and the transverse inclination angle acceleration respectively exceeds a set number of times. Therefore, whether a container falls is determined in advance.

Owner:上港集团长江港口物流有限公司 +1

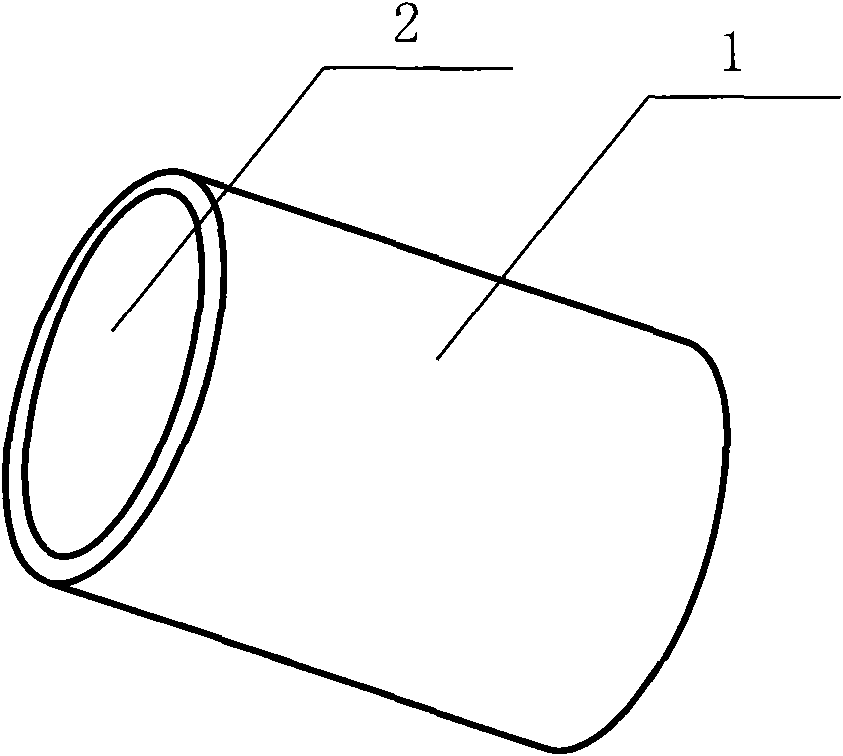

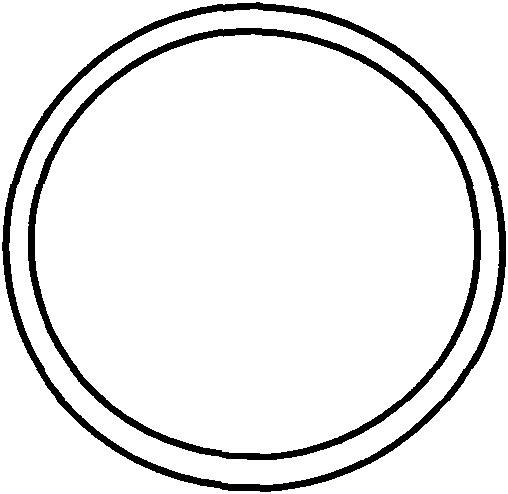

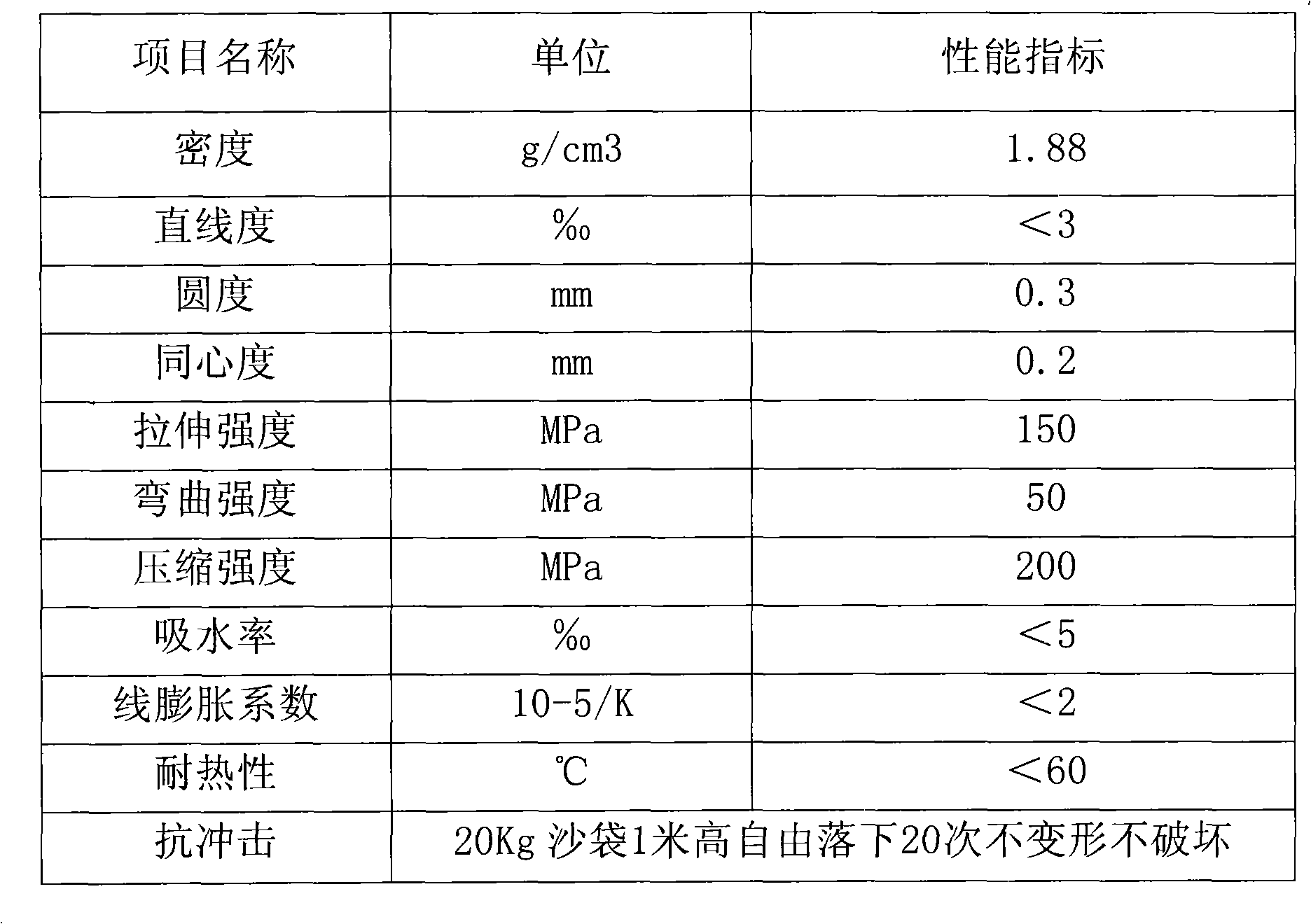

Bridge protecting pipe using unsaturated composite epoxy resin materials

The invention discloses a bridge protecting pipe using unsaturated composite epoxy resin materials, comprising a pipe body on which through holes are formed. The bridge protecting pipe is manufacturedby the following materials: 45% of unsaturated composite epoxy resins, 40% of continuous glass fiber bundles, 10% of curing agents (initiators) and 5% of coloring agents (pigments), wherein, the unsaturated composite epoxy resin comprises 50% of furan resins and 50% of organic resins; the curing agents are initiators. The invention has the characteristics of high brightness, long life, difficultdeformation, strong bearing capacity, corrosion resistance, good loss prevention property, rich colors and good capability of beautifying the environment. As the warning mark has the advantages of light weight, high strength and difficult damage, the warning mark can be installed flexibly in a labor and time saving manner. The colors are formed by blending the color paste capable of being compatible with the resins into the resins; therefore, the colors are not shown on the surface, thus keeping the colors lasting.

Owner:天津市津南公路处

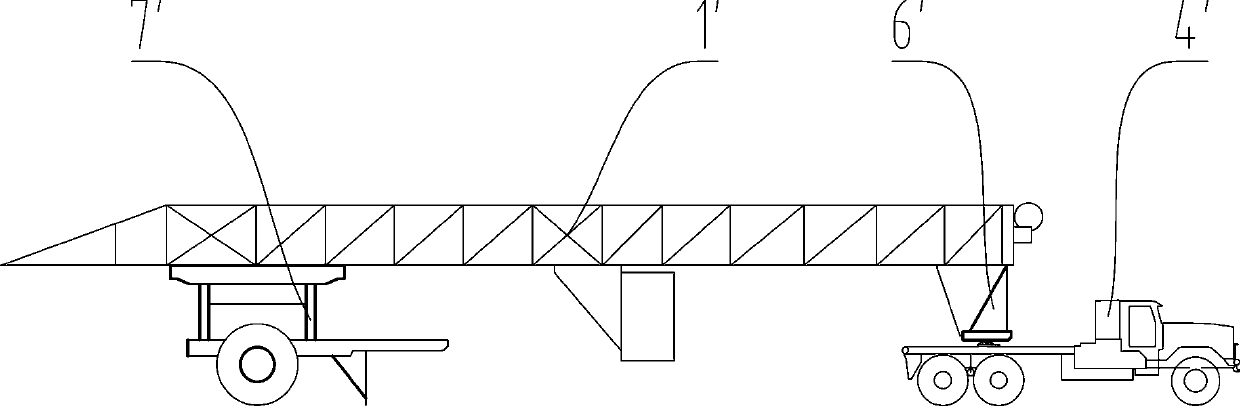

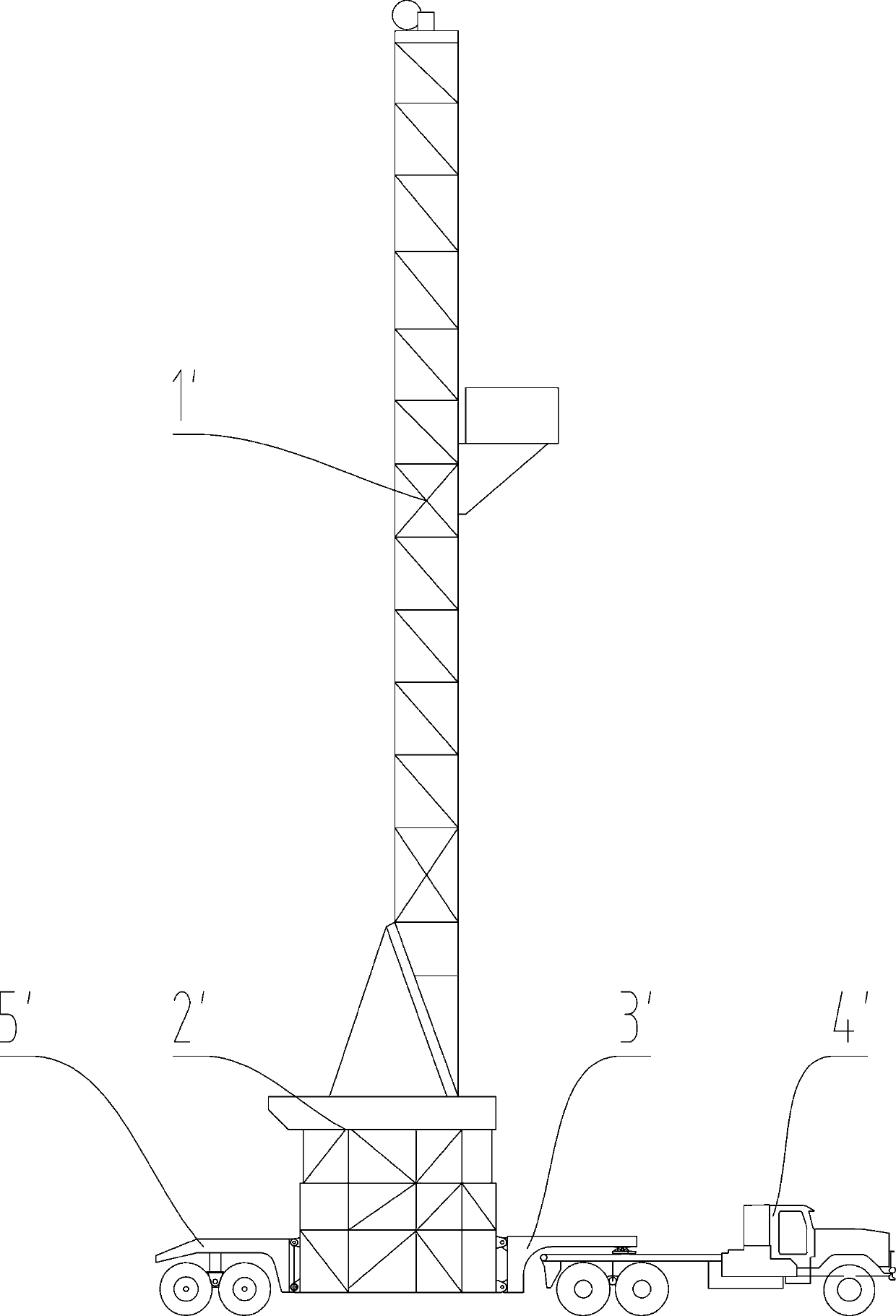

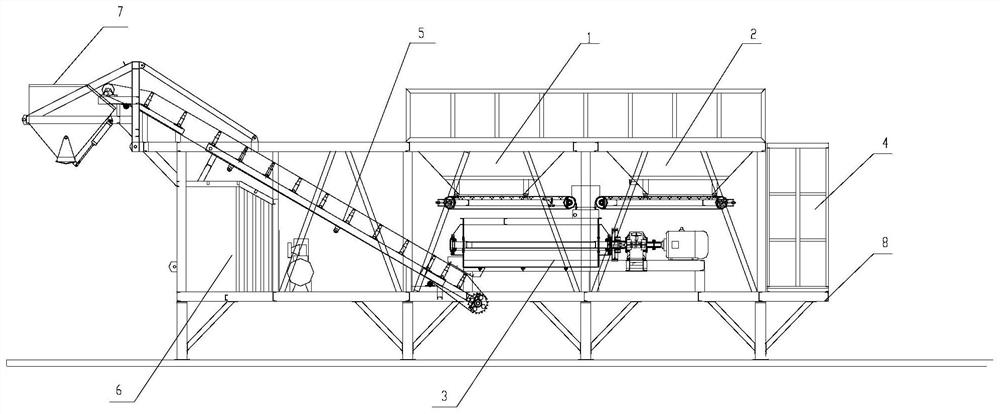

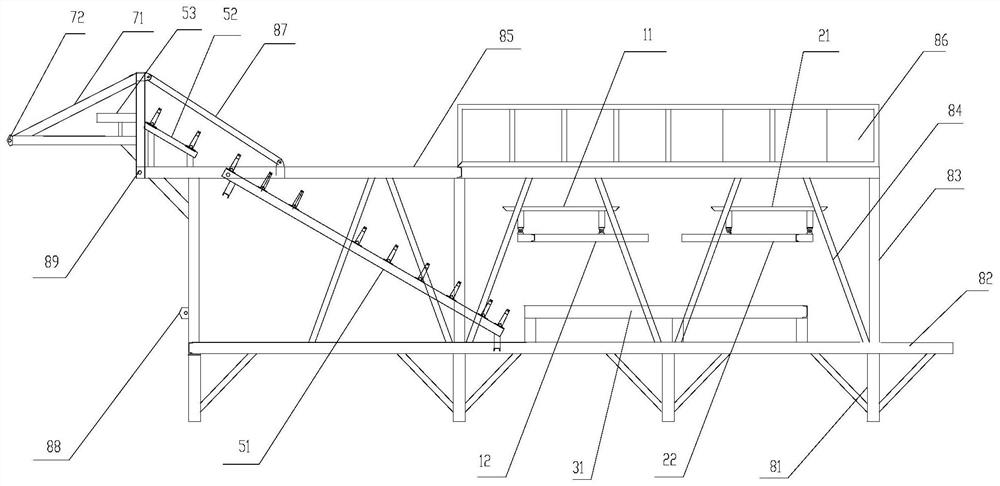

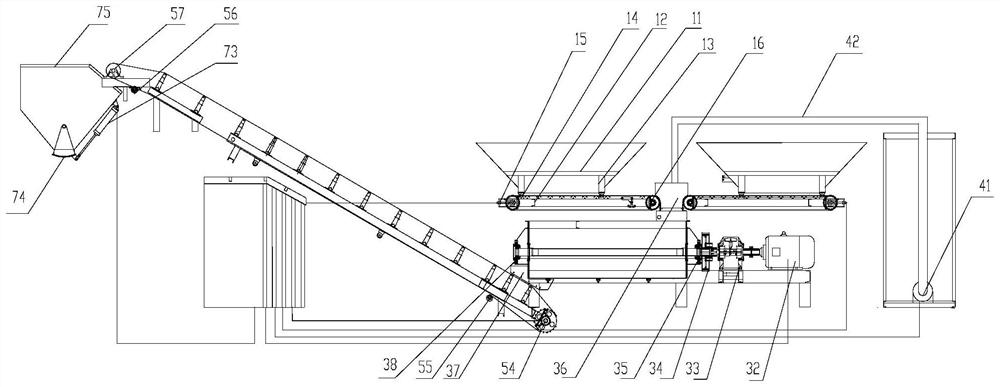

Integrated continuous discharging mobile mixing plant

PendingCN113290710AEasy to transportNot easy to bumpMixing operation control apparatusCement mixing apparatusBLENDER/MIXERControl engineering

The invention discloses an integrated continuous discharging mobile mixing plant. Functional devices comprise a first batching mechanism, a second batching mechanism, a stirring mechanism, an additive device, a conveying mechanism, a control room and a transfer bin mechanism, the functional devices are connected into an integrated device structure through a frame body, and the transfer bin mechanism can be folded. The frame body comprises a base body, an auxiliary inclined lever, supporting legs, an overturning protection plate, a traction rod, a locking rod and the like which are arranged on the base body, and a frame body structure related to all functional devices, and the frame body ensures the stability of a main body of the mixing plant, and the firmness of connection of all the devices and the convenience of overall transportation and installation are ensured. The integrated structure is adopted, all the functional devices are fixedly arranged in the frame body and protected by a foundation body steel structure, collision is avoided, the transportation risk is reduced, and the device damage maintenance cost is reduced.

Owner:郑州市鑫宇机械制造有限公司

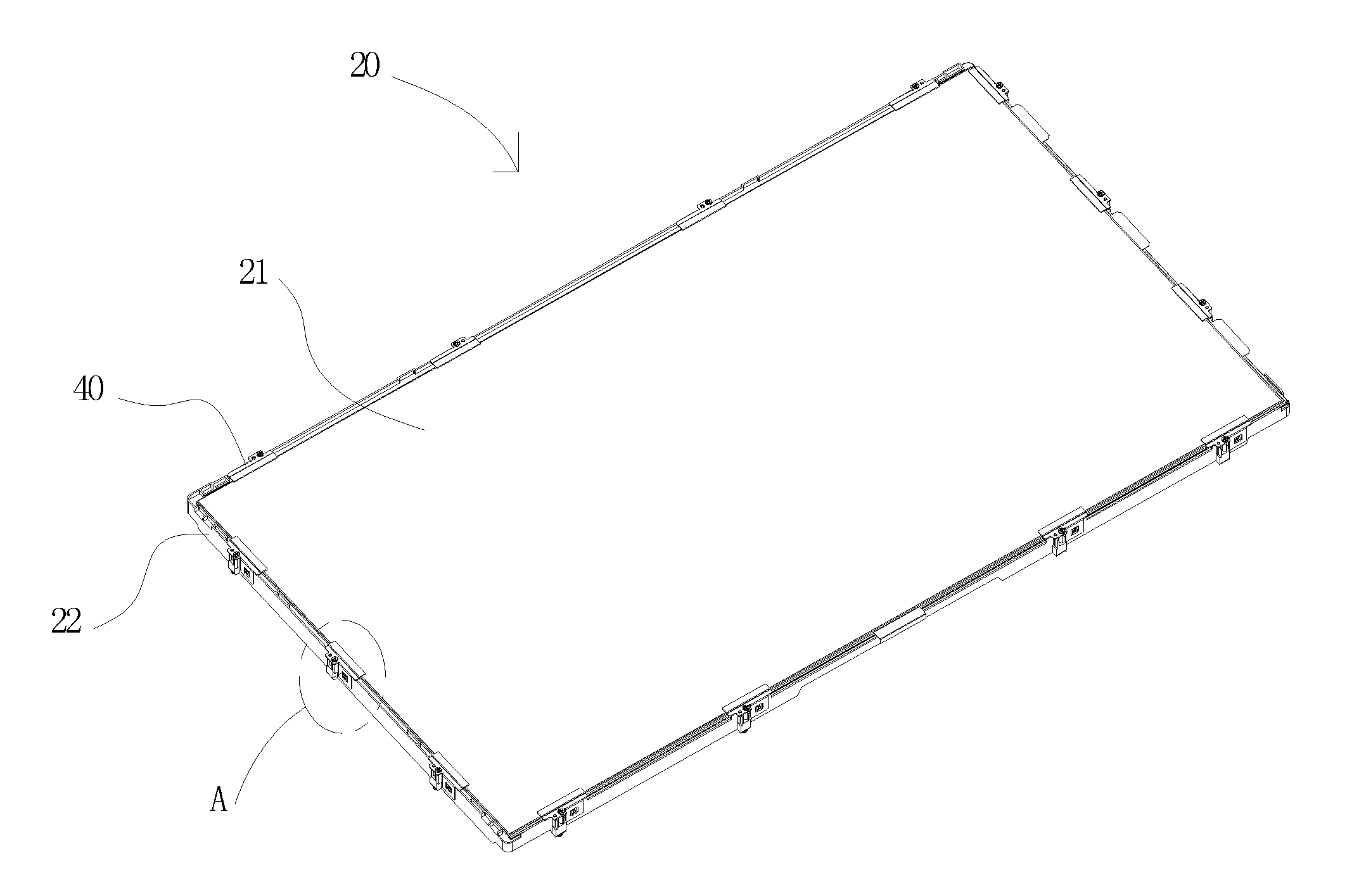

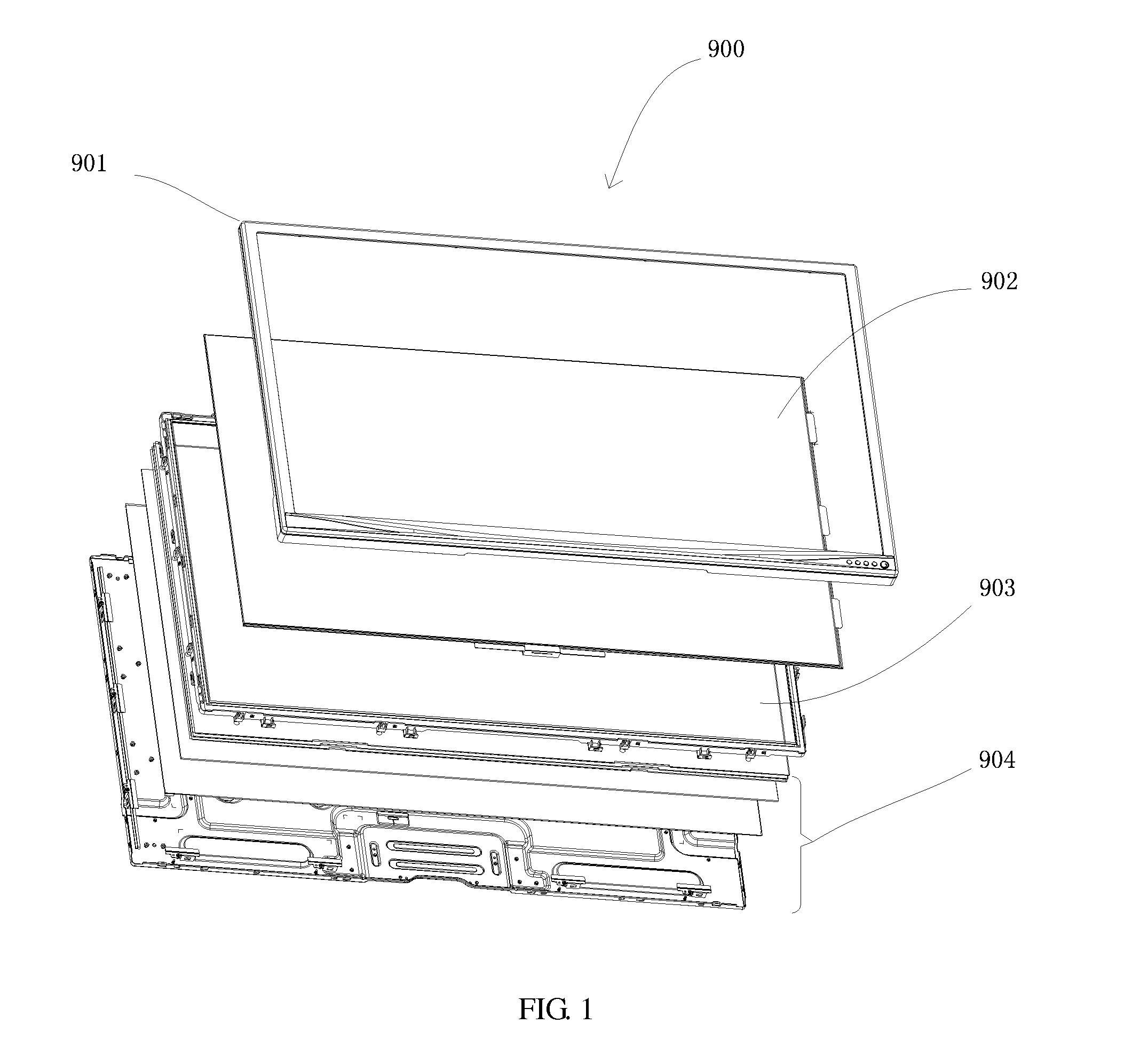

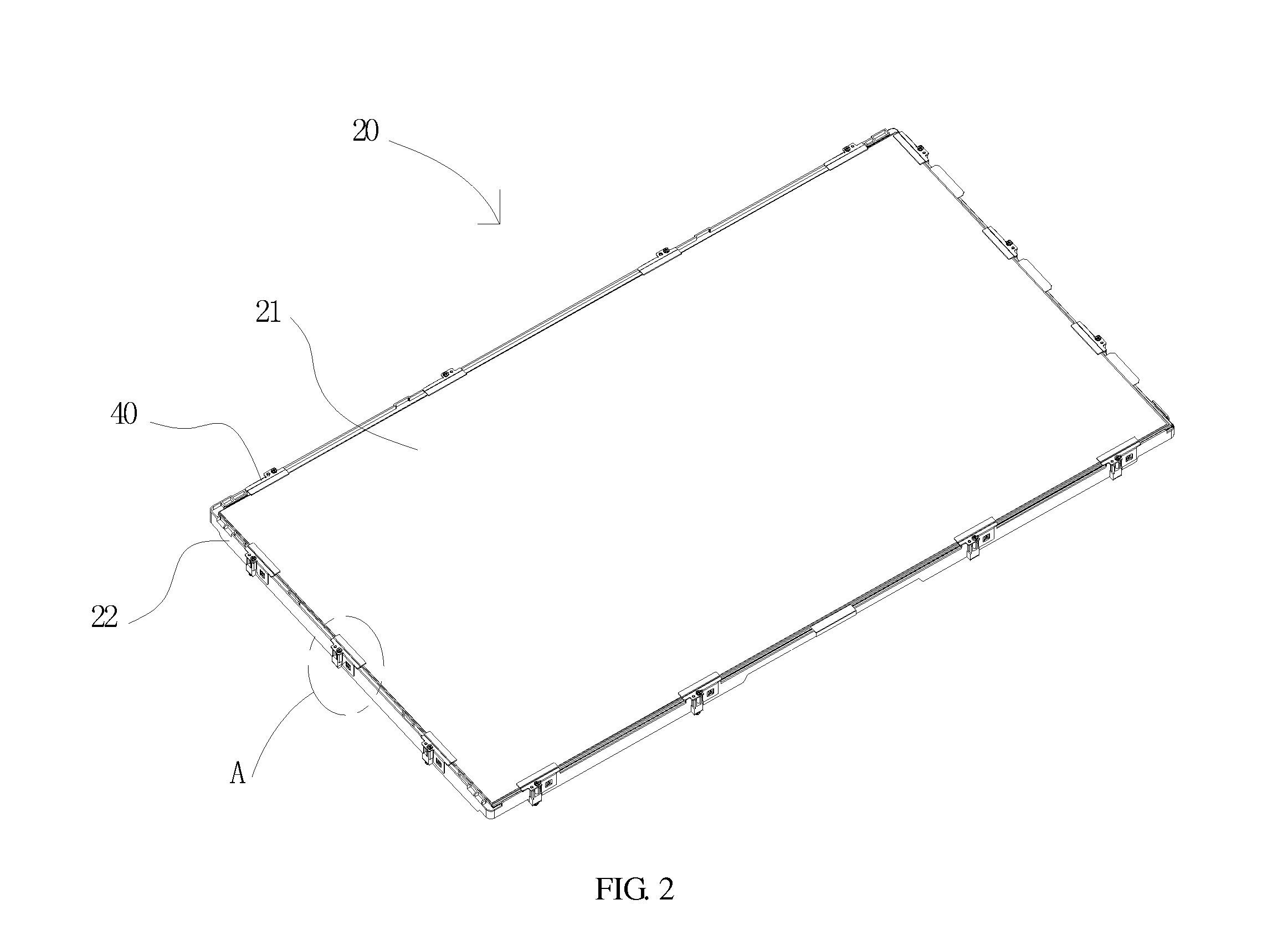

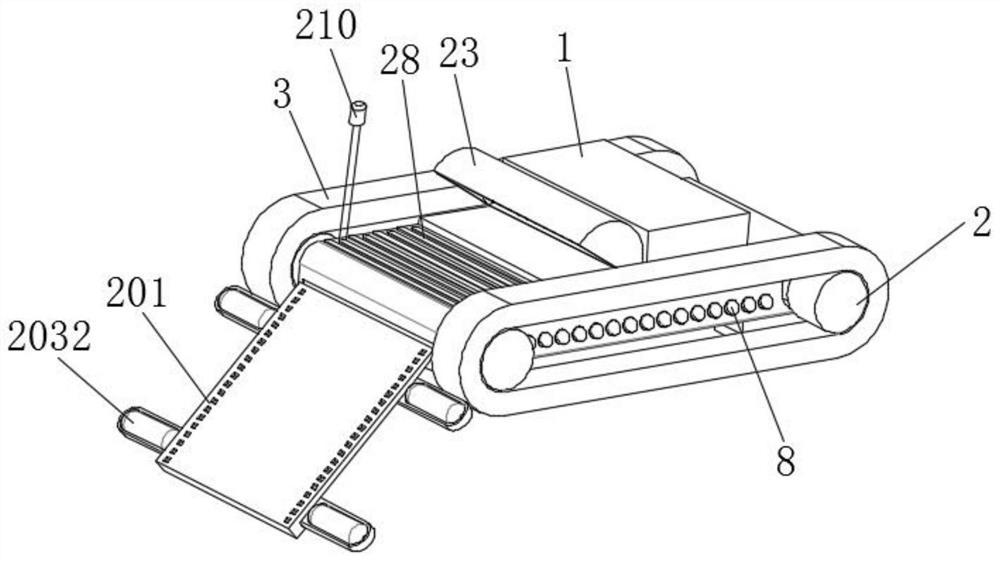

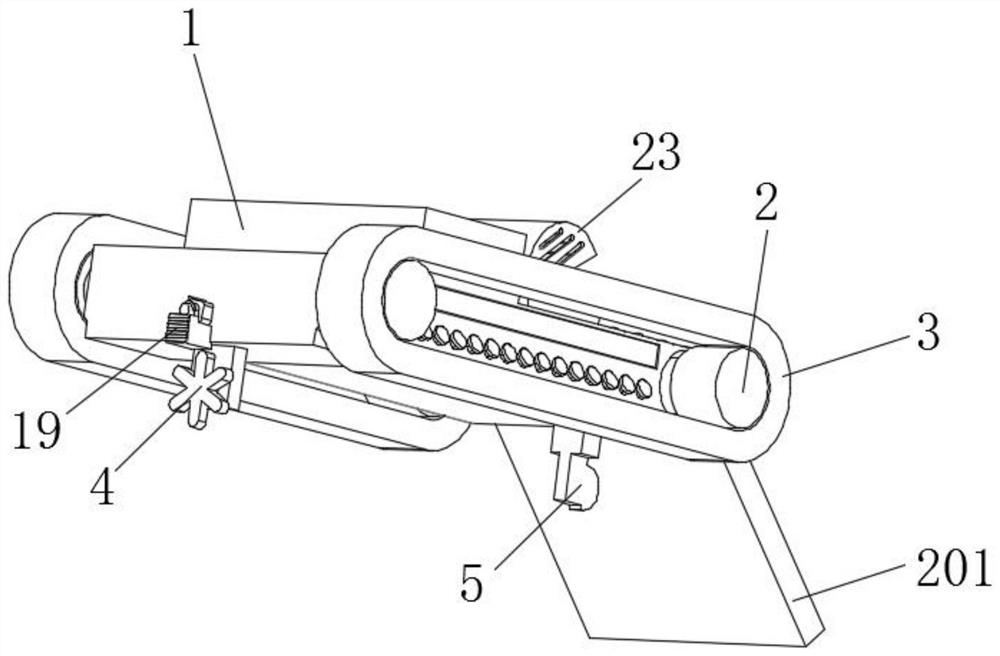

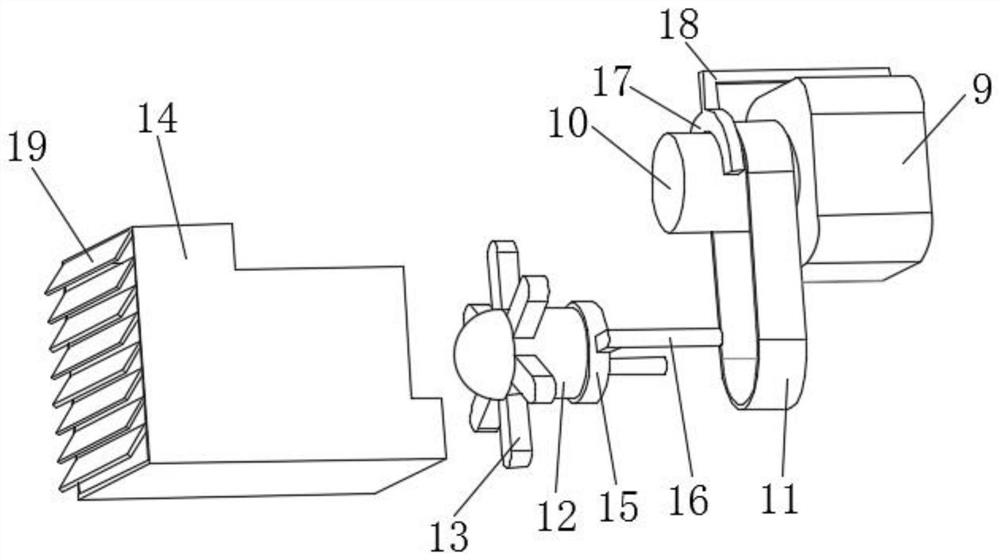

Connection structure for panel and frame, and holding member device thereof

ActiveUS20140139782A1Reduce shipping riskSimple assembly structureSnap-action fastenersScaffold connectionsAssembly structureLiquid crystal

The present invention provides a connection structure for panel and frame and holding member thereof. The connection structure includes a panel and a frame supporting the panel. The panel and the frame use a plurality of holding members to fix and hold. The holding member includes a presser and a connection part extending from one side of the presser. The connection part includes a first extension part and a second extension part. The first extension part and the second extension part connect a corresponding connection element on the side of the frame. As such, the present invention saves the front frame and fixes a liquid crystal panel and a frame of a liquid crystal module to reduce the transportation risk, protect the liquid crystal panel from damage, simplify the overall assembly structure of the liquid crystal module and reduce the assembly cost.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Crawler-type robot for biochemical environment

ActiveCN113682096AEasy accessStable floatingAmphibious vehiclesLife-savingTurbine bladeControl engineering

The invention relates to the technical field of tracked robots, in particular to a crawler-type robot for a biochemical environment; the robot comprises a vehicle body, a rolling shaft and two crawlers, the rolling shaft is rotatably connected to the inner wall of the vehicle body, the crawler are rotatably connected to the surface of the rolling shaft, the number of the crawler is two, and the crawler are arranged in a mirror image manner; a power turbine is fixedly connected to the lower surface of the vehicle body, a power motor and turbine blades are arranged in the power turbine, the turbine blades are driven to rotate when the power motor rotates, a steering block is arranged below the vehicle body and rotationally connected with the inner wall of the vehicle body, and a fixing block is fixedly connected to the inner wall of the vehicle body. The lower surface of the fixing block is fixedly connected with a hollow block. The crawler-type robot can conveniently open the air bag and enable a proper amount of water to enter the vehicle body, so that the vehicle body stably floats on the water surface, waterproof heating can be provided for the wounded and the sick in time, and the body surface temperature is kept.

Owner:中关村军民科技协同创新孵化中心北京有限公司

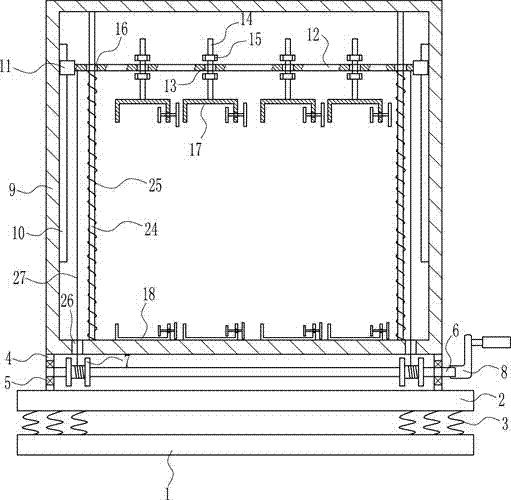

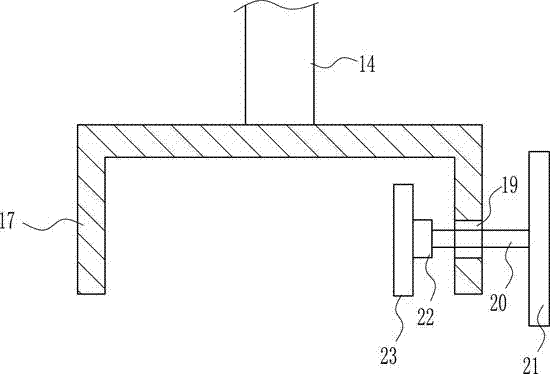

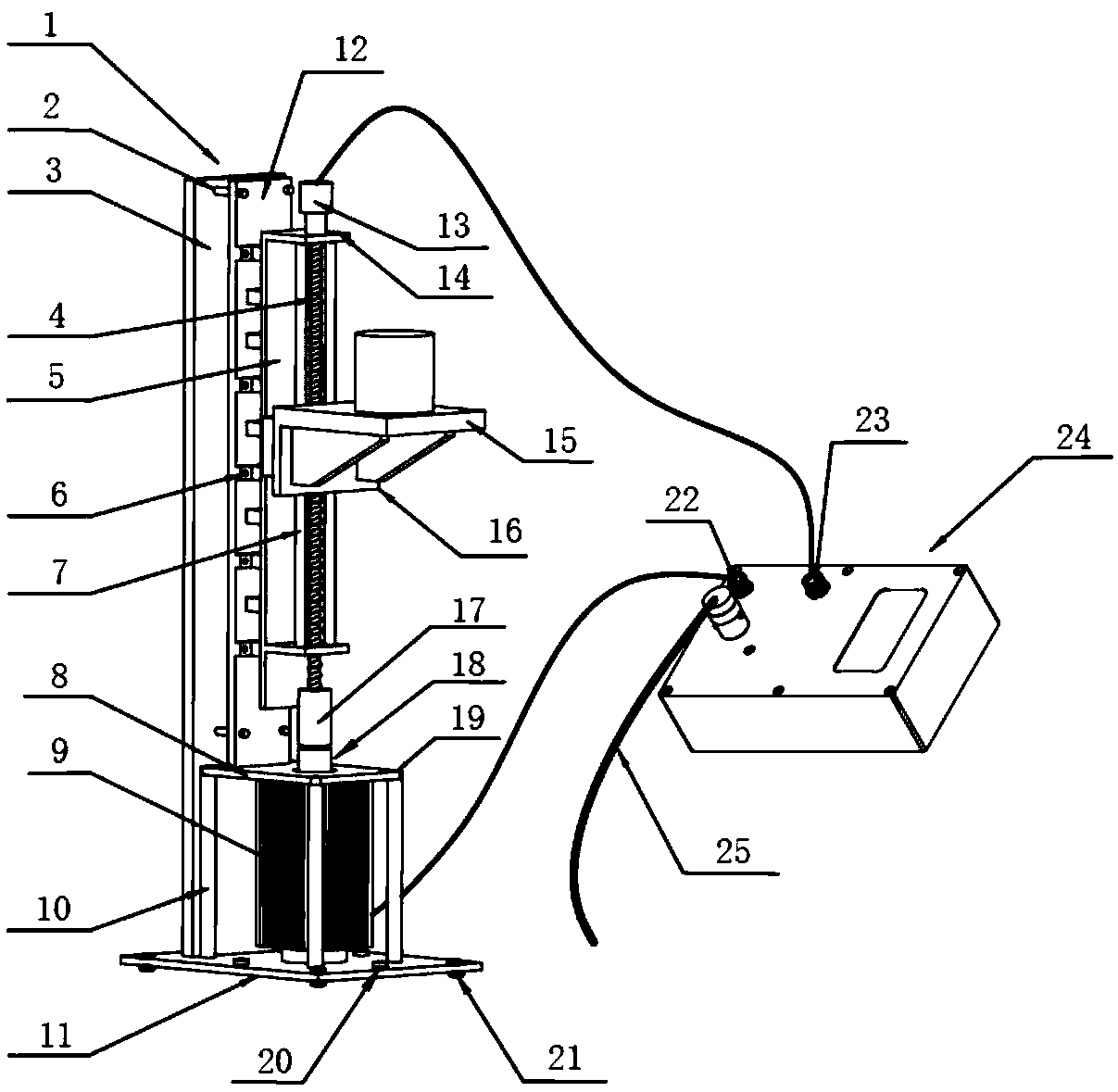

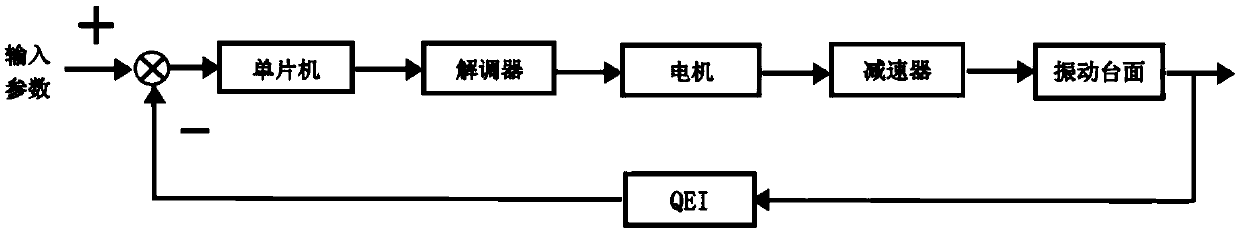

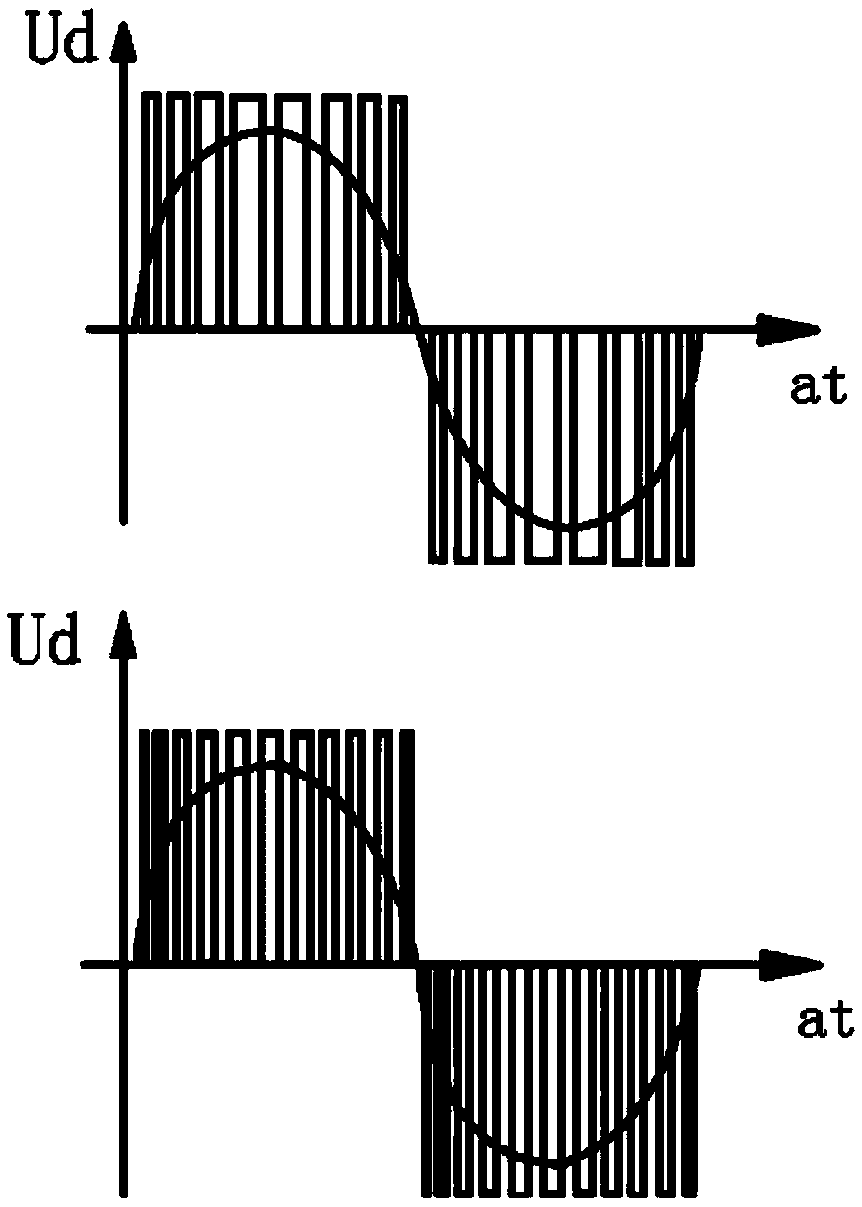

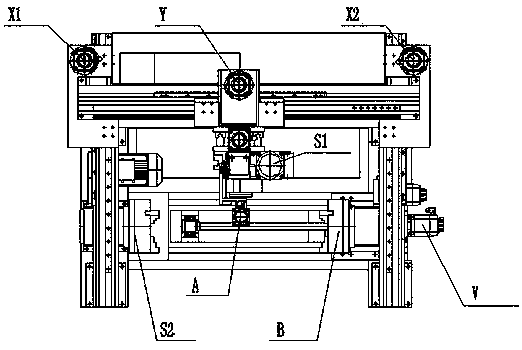

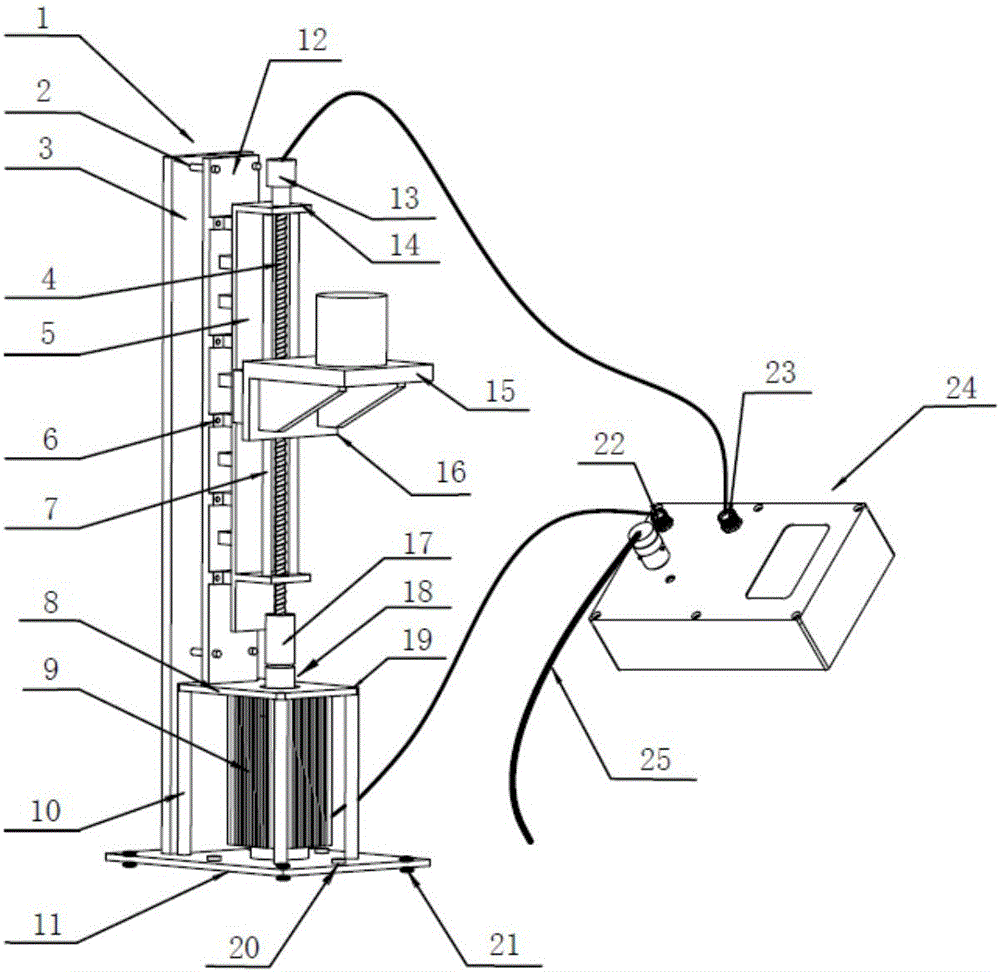

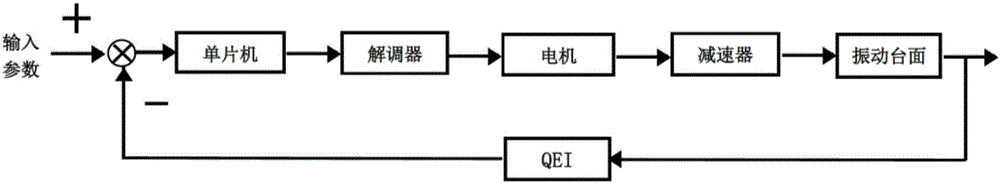

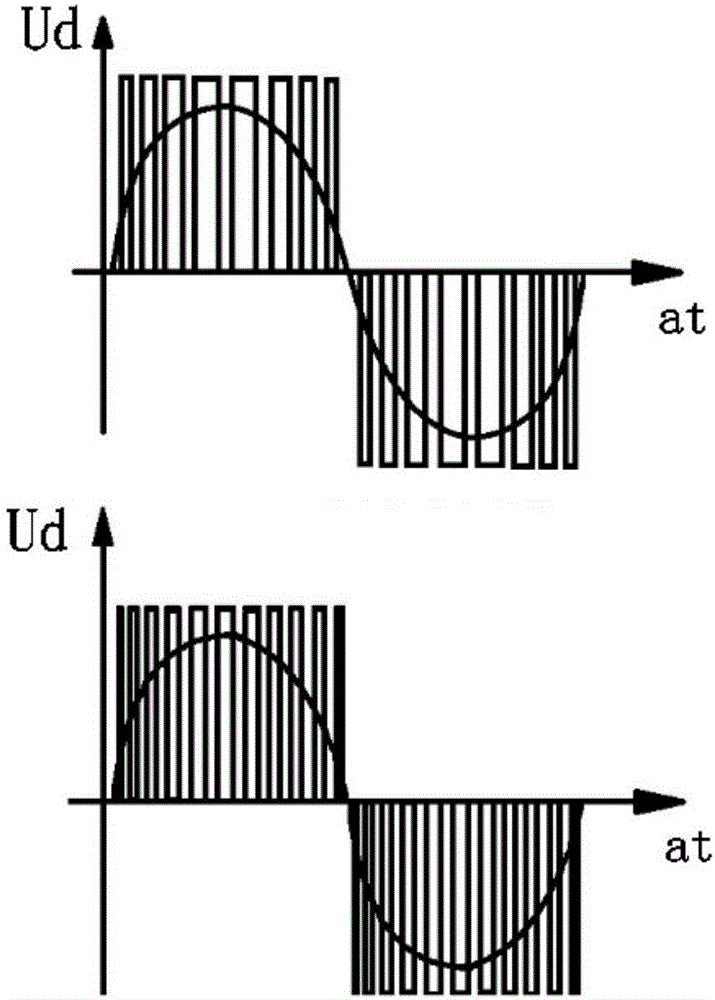

A Feedback Control Vibration Table Based on Stepping Motor

InactiveCN106768769BIncrease the itineraryWide range of measurement applicationsVibration testingMicrocomputerMicrocontroller

The invention discloses a stepper motor based feedback-control vibrating table. The vibrating table comprises a vibrating table body and a controller, wherein the vibrating table body consists of a stepper motor, a shaft coupling, a fixed guide rail, a vibrating table top, an orthogonal decoder and a base, and a control system consists of a single-chip microcomputer and a demodulator. According to the vibrating table, the stepper motor is adopted to carry out driving, and the control system adopts feedback-control regulation, so that the problems of the existing vibrating tables that the size is large, the initialized calibration is complicated, the upgrading cost is high, and the like are overcome.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

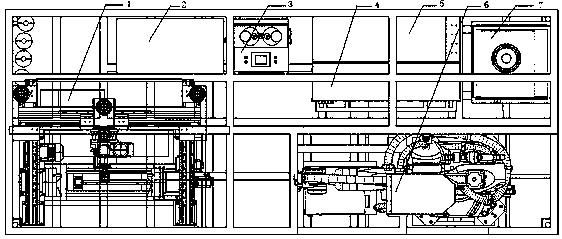

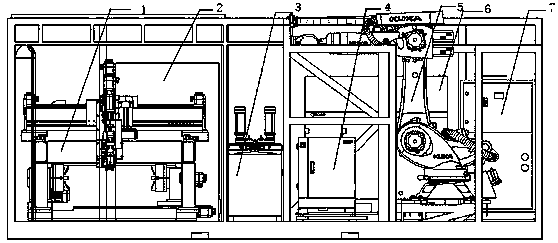

Integrated workshop of laser repairing system

PendingCN108374172AGuaranteed temperatureGuaranteed humidity stabilityMetallic material coating processesRobot controlLaser

The invention provides an integrated workshop of a laser repairing system. The integrated workshop of the laser repairing system comprises a pedestal, wherein a laser, a robot, a robot control cabinet, a powder feeding machine, a power supply control cabinet and a special 6-axis machine are arranged on the pedestal; all the devices in the workshop are arranged in two rows, the special 6-axis machine and the robot are arranged side by side, and the power supply control cabinet, the powder feeding machine and the robot control cabinet are arranged side by side; the laser is connected with the special 6-axis machine and used for controlling the special 6-axis machine to operate; the robot control cabinet is connected with the robot and used for controlling the robot to operate; a protection wall body is also arranged at the periphery of the pedestal in the workshop, a protection room is formed, the power supply control cabinet is connected with the rest of equipment, and an external powersupply connecting interface is formed in the power supply control cabinet; and the powder feeding machine is connected with the robot, and a laser cladding raw material is provided for the robot. Theintegrated workshop provided by the invention integrates equipment contained in a laser cladding integrated system together, compact type design is adopted for meeting field repairing operation, andall the devices are placed in a movable container protection room, thereby being convenient and safe.

Owner:斯普瑞科技有限公司

Stepper motor based feedback-control vibrating table

InactiveCN106768769AIncrease the itineraryWide range of measurement applicationsVibration testingMicrocomputerMicrocontroller

The invention discloses a stepper motor based feedback-control vibrating table. The vibrating table comprises a vibrating table body and a controller, wherein the vibrating table body consists of a stepper motor, a shaft coupling, a fixed guide rail, a vibrating table top, an orthogonal decoder and a base, and a control system consists of a single-chip microcomputer and a demodulator. According to the vibrating table, the stepper motor is adopted to carry out driving, and the control system adopts feedback-control regulation, so that the problems of the existing vibrating tables that the size is large, the initialized calibration is complicated, the upgrading cost is high, and the like are overcome.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

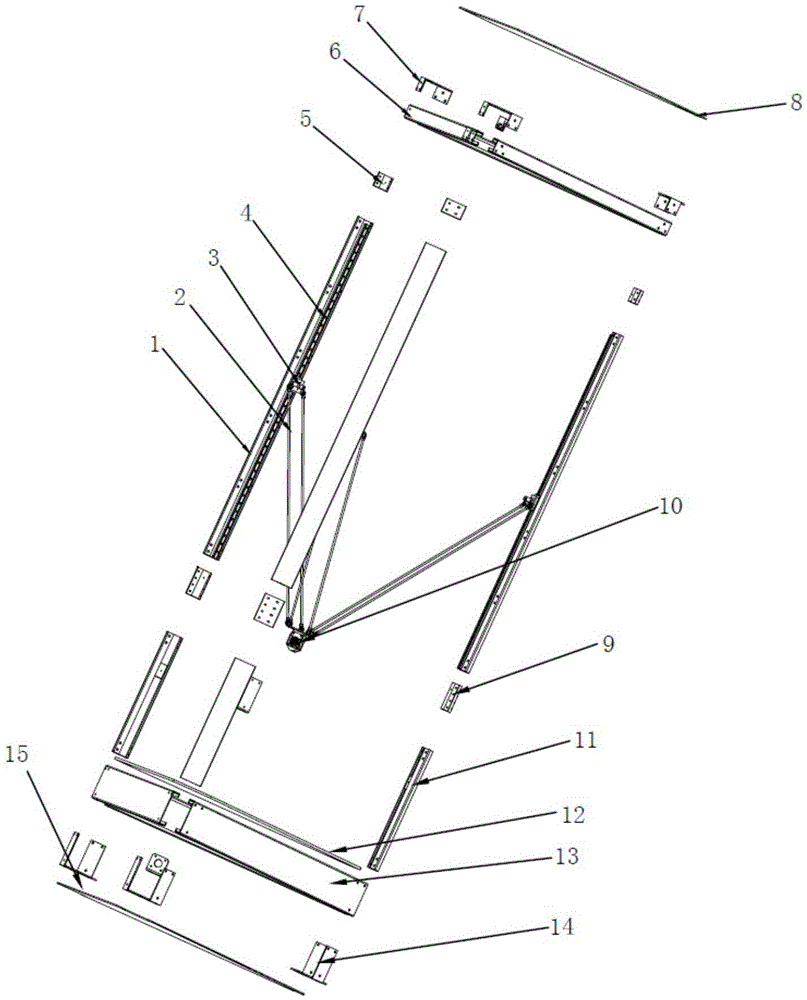

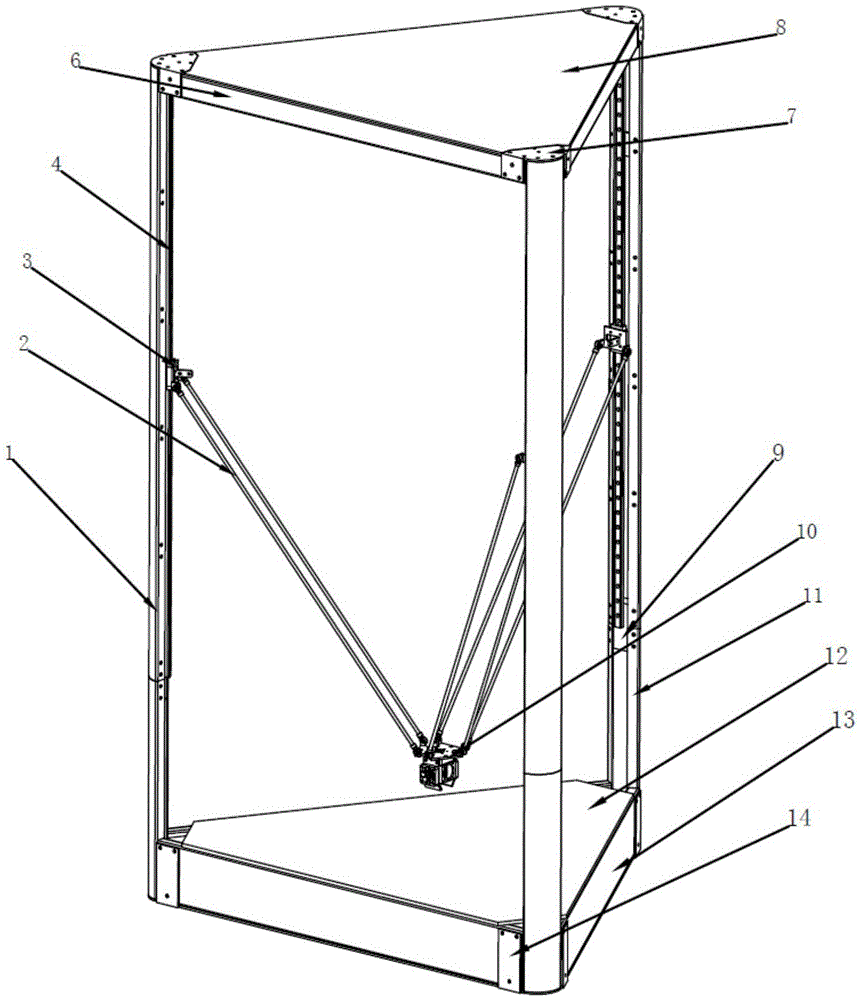

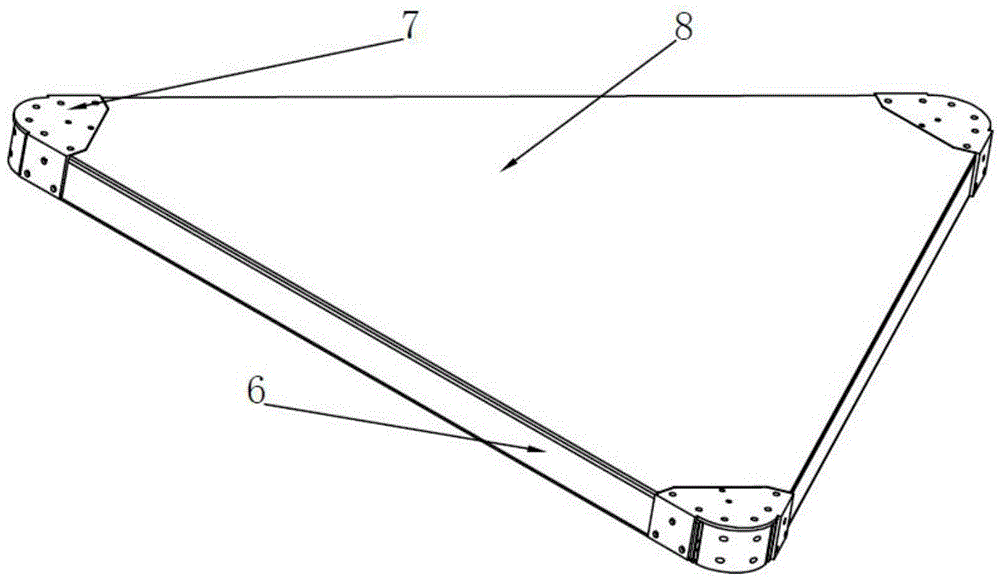

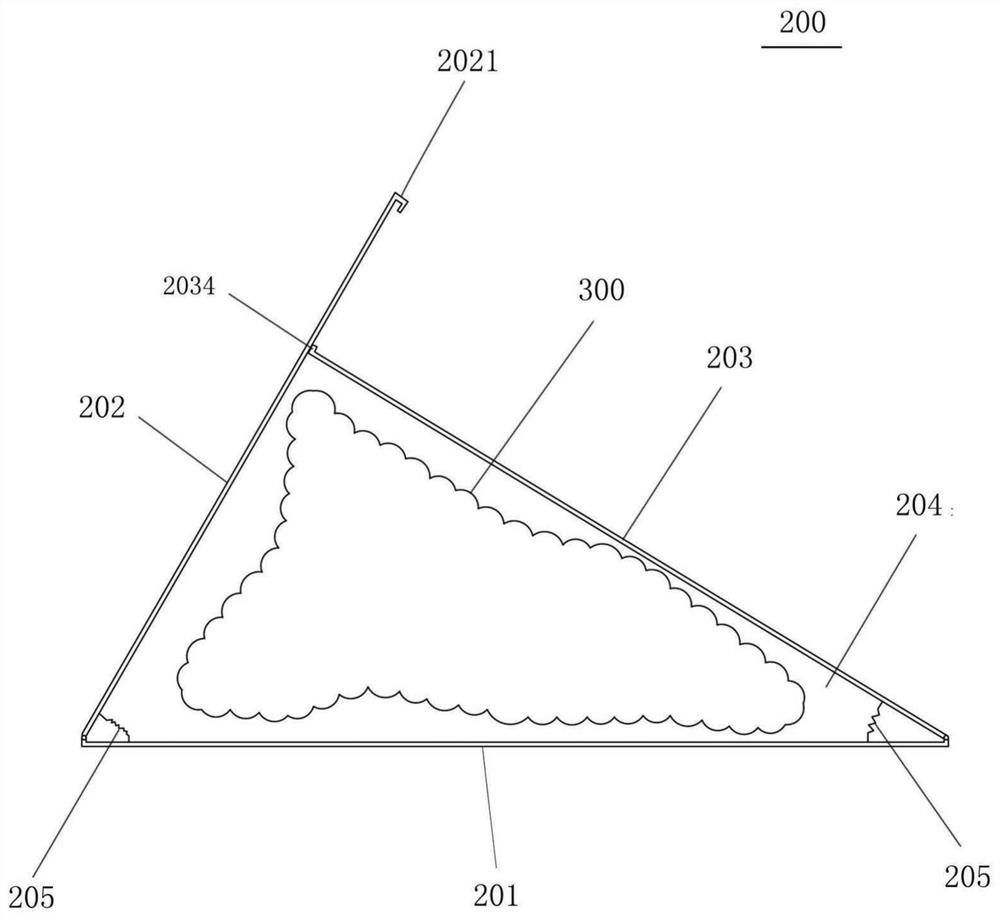

Disassembly-convenient large triangular 3D printer

InactiveCN105643940AImprove protectionGuaranteed StrengthAdditive manufacturing apparatusModular designModularity

The invention discloses a disassembly-convenient large triangular 3D printer. The disassembly-convenient large triangular 3D printer mainly consists of an upper triangular cover plate module, three detachable support rod guide rail modules, a triangular base module and a nozzle mechanism module; and all the modules can be spliced. The disassembly-convenient large triangular 3D printer designs the longest support rod as two detachable sections, so that the total packing length can be reduced to 2 / 3 of the traditional length, and the smaller package improves the transportation convenience, reduces the package transportation cost and reduces the transportation risk. The large triangular 3D printer uses the modular design, so that the packing requirement is reduced, all the modules are preferably protected in the transportation process, the scene assembly requirement is reduced, and the fool type installation is truly realized. Multiple connecting modes are designed for connection of all the modules, so that the assembly and the connection among the modules are more convenient, the installation speed is accelerated, the installation difficulty is reduced, and the strength and the stability of the whole structure are guaranteed.

Owner:SHENZHEN DONEMI SCI & TECH CO LTD

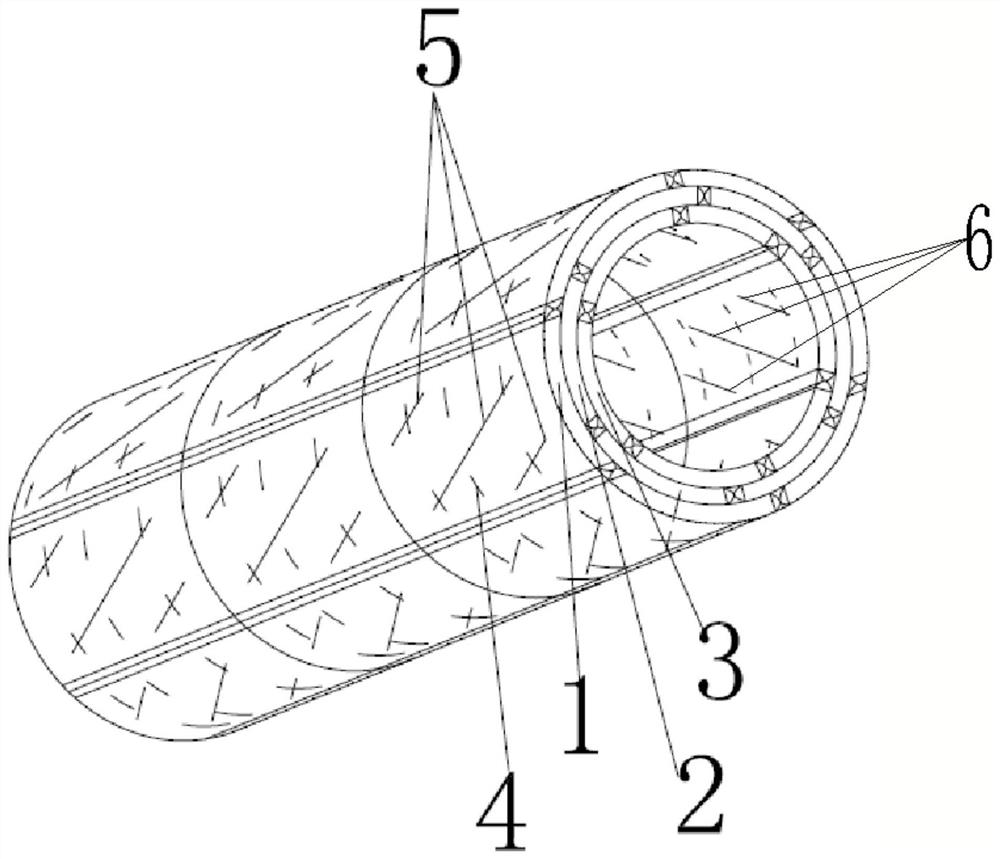

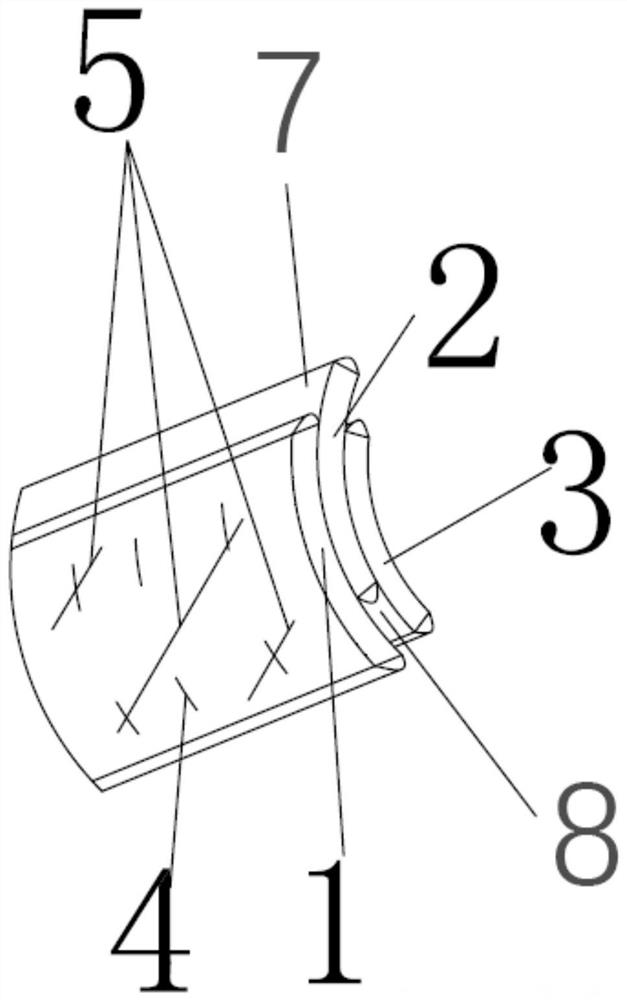

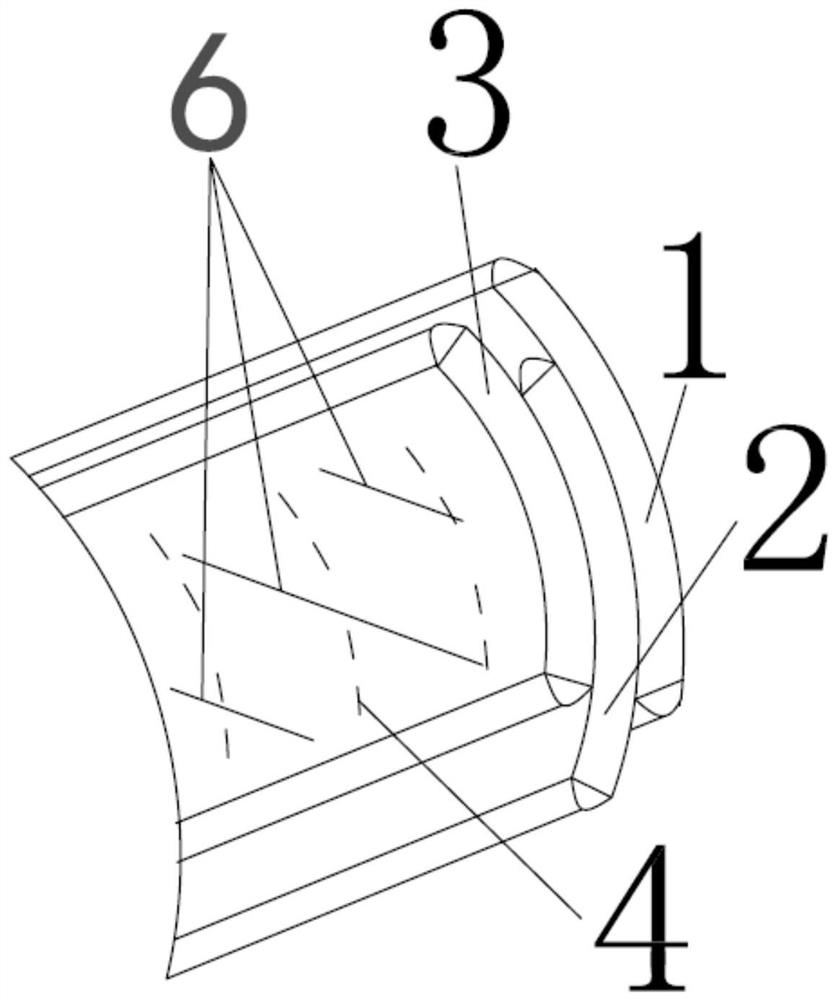

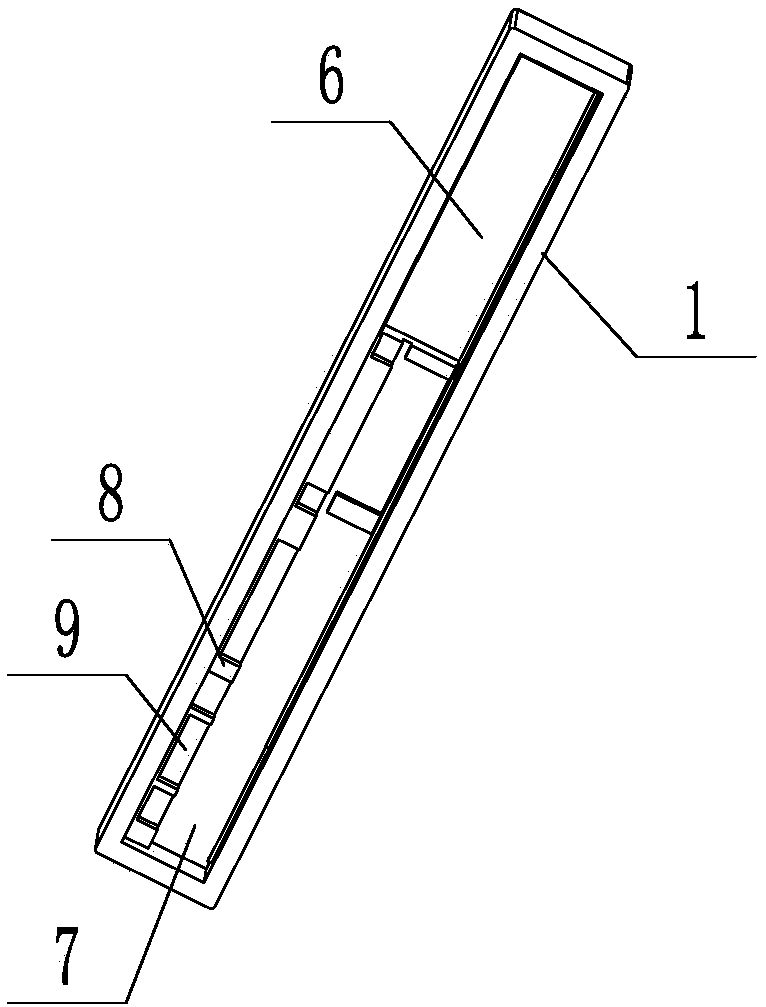

Detachable tungsten-molybdenum cylinder

PendingCN114457428AEasy to removeQuick assemblyAfter-treatment apparatusMetallic materialsUltimate tensile strength

The invention discloses a detachable tungsten-molybdenum cylinder, which belongs to the technical field of metal materials and comprises a plurality of assembly units and a fixing device. The assembling units are mutually assembled and enclosed to form a cylinder wall; each assembling unit comprises at least three tungsten-molybdenum layers, the tungsten-molybdenum layers comprise the first tungsten-molybdenum layer, the second tungsten-molybdenum layer and the third tungsten-molybdenum layer which are sequentially arranged in an overlapped mode from outside to inside, reinforcing ribs are arranged on the first tungsten-molybdenum layer, the second tungsten-molybdenum layer and the third tungsten-molybdenum layer, and the reinforcing ribs enable the first tungsten-molybdenum layer and the second tungsten-molybdenum layer to be arranged in a staggered mode. A gap is reserved between the second tungsten-molybdenum layer and the third tungsten-molybdenum layer; the fixing device sequentially penetrates through the first tungsten-molybdenum layer, the second tungsten-molybdenum layer and the third tungsten-molybdenum layer to realize fixed connection of the three tungsten-molybdenum layers; the assembling units are fixedly connected with the interior of the hearth. The reinforcing ribs in different directions are arranged inside and outside the tungsten-molybdenum layer, so that the overall strength of the whole tungsten-molybdenum layer can be enhanced, the tungsten-molybdenum layer basically does not deform at high temperature, the temperature of a thermal field is kept stable, and the service life of the thermal field is greatly prolonged.

Owner:XIAN GEMEI METAL MATERIAL

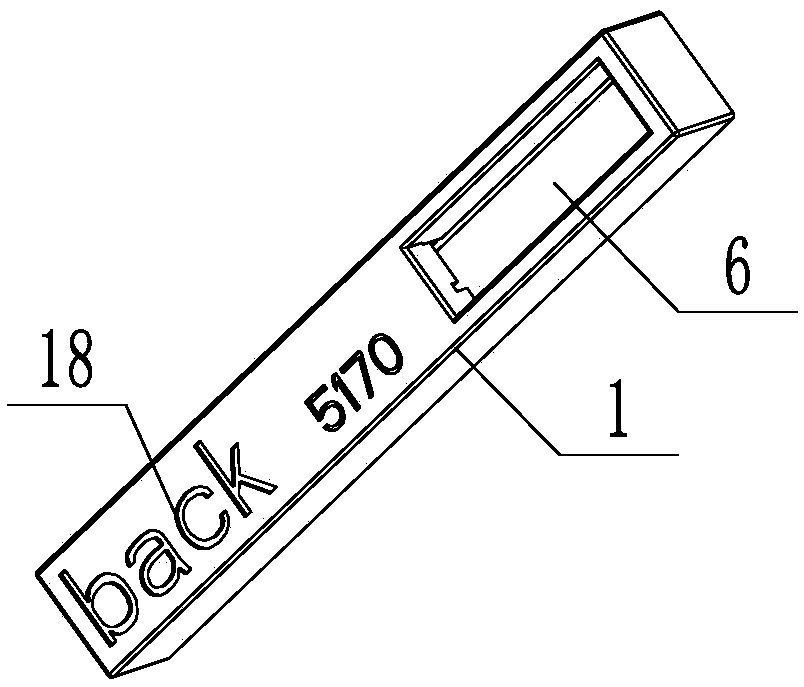

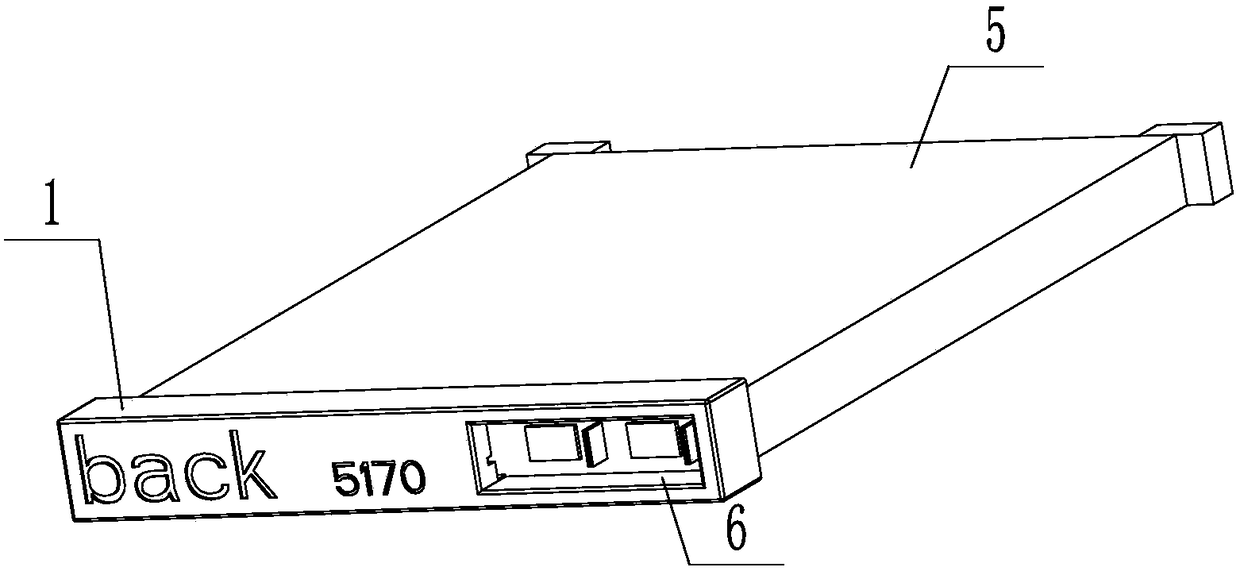

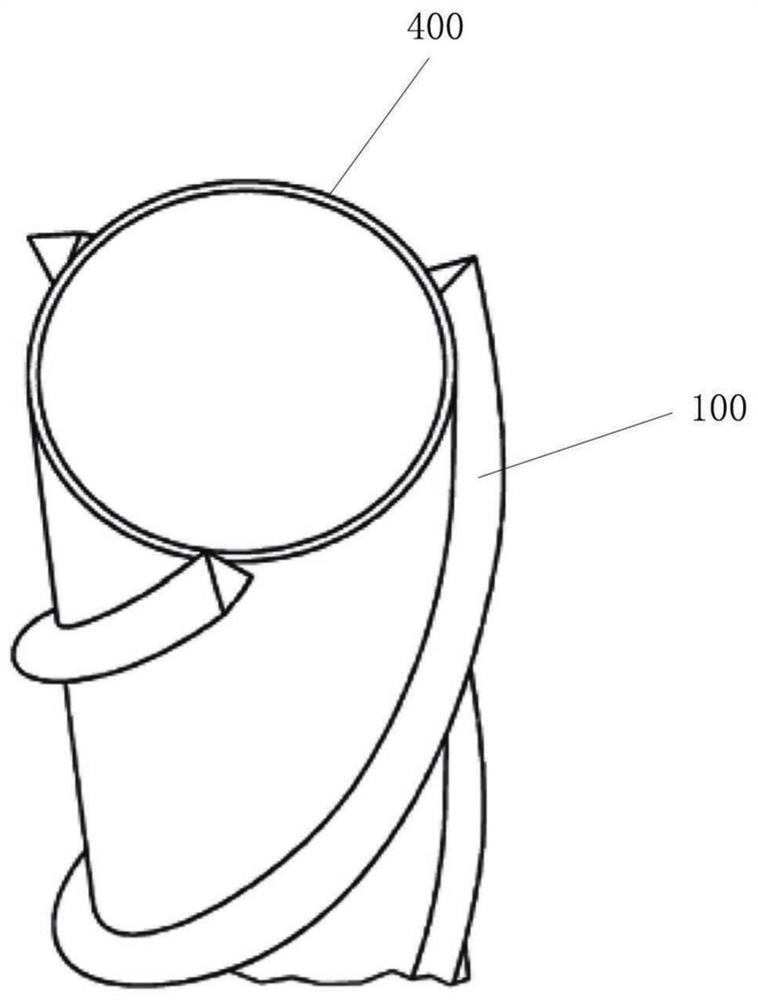

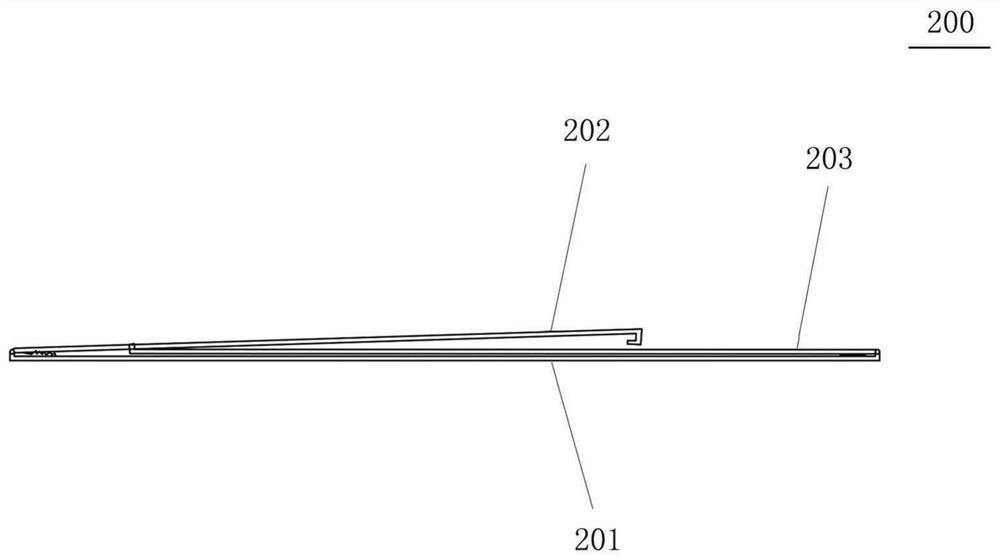

NF5170M5 mechanical impact jig

InactiveCN108088639AImprove protectionAvoid contactShock testingMechanical impactBiomedical engineering

The invention discloses an NF5170M5 mechanical impact jig, which comprises a back-surface jig, a front-surface jig, side-surface jigs and an upper-surface jig, wherein the back-surface jig is matchedwith the rear end surface of a server, the front-surface jig is matched with the front end surface of the server, the side-surface jigs are matched with the side surfaces of the server, and the upper-surface jig is matched with the upper surface of the server. The NF5170M5 mechanical impact jig simulates a contact state inside a package box at the time of shipment, the jig is in contact with rigidsheet metal parts of the server, avoids the contact at plasticity positions, better protects the server, reduces the shipment risk, and increases the preciseness of tests.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

Spoiler block and vortex-induced vibration suppression device

ActiveCN113463782AReduced shipping volumeReduce shipping riskWind motor supports/mountsProtective buildings/sheltersTowerMechanical engineering

The invention provides a spoiler block and a vortex-induced vibration suppression device. The spoiler block comprises a deformation part and an air bag, wherein the deformation part comprises a windward side, and air holes are formed in the windward side; and the air bag is arranged in the deformation part and communicates with the air holes, so that airflow entering through the air holes can enter the air bag and enable the air bag to expand, and the deformation part is deformed from a flat first state to an expanded second state. Compared with a non-deformable spoiler block with the same size in the prior art, the spoiler block in the flat first state can remarkably reduce the transportation size of a tower frame, and the transportation risk and the collision risk in the transportation process are reduced; and the use state of the spoiler block can be changed through the magnitude of wind power.

Owner:JIANGSU GOLDWIND SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com