On-site repair machining process of lower labyrinth ring of rotating wheel

A processing technology and labyrinth ring technology, which is applied in the field of on-site repair processing technology and assembly of the lower labyrinth ring, can solve the problems of slow project progress, long repair cycle, low efficiency, etc., and achieves reduction of processing cost, short repair cycle and high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

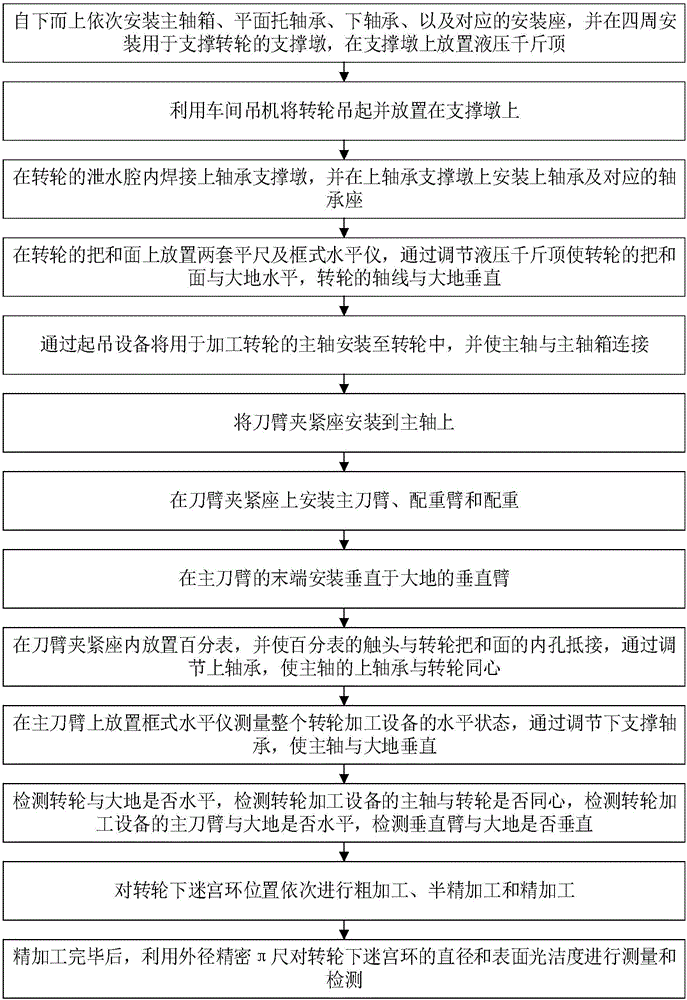

[0048] like figure 1 and figure 2 As shown, the present invention discloses a process for on-site repairing of a labyrinth ring under a runner. The process mainly includes the following steps:

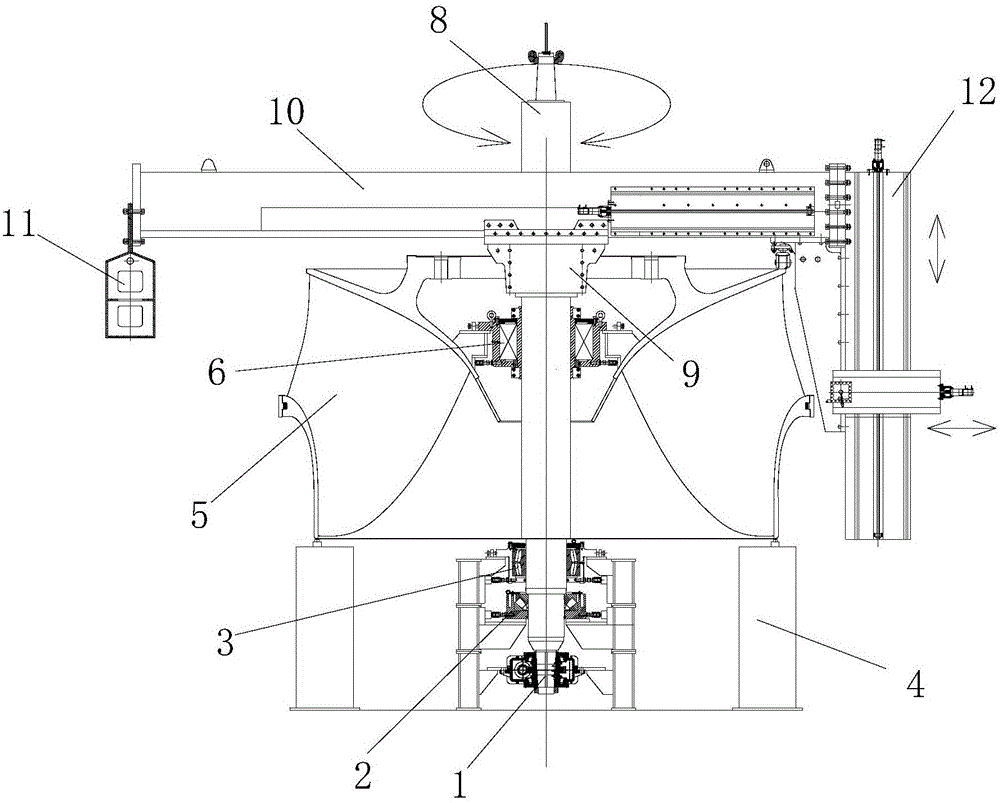

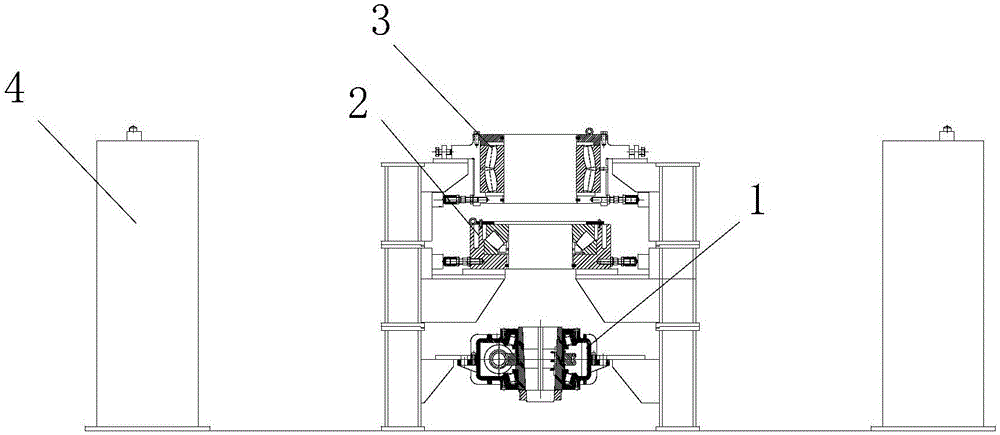

[0049] Step S1: if image 3 As shown, install the headstock 1, the plane support bearing 2, the lower bearing 3, and the corresponding mounting seat in sequence from bottom to top, and install the supporting pier 4 for supporting the runner 5 around, and place the hydraulic pressure on the supporting pier 4. jack.

[0050] The main shaft box 1 is used as a power device to drive the main shaft 8 to rotate; the plane support bearing 2 mainly supports the weight of the entire processing equipment, making the runner processing equipment more stable and more stable; the lower bearing 3 is mainly used for the main shaft 8 is positioned and centered so that the main shaft 8 is perpendicular to the earth and on the centerline of the runner 5. The main shaft box 1, the plane support bearin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com