Steel pipe arch general assembly method

A steel tube arch and pre-assembled technology, which is applied to arch bridges, erecting/assembling bridges, bridge forms, etc., can solve the problems of high transportation cost of highway oversized components, damage to the paint on the surface of steel box girder, affecting the erection accuracy of components, etc. Transportation risk, beautiful line shape, and the effect of improving production accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

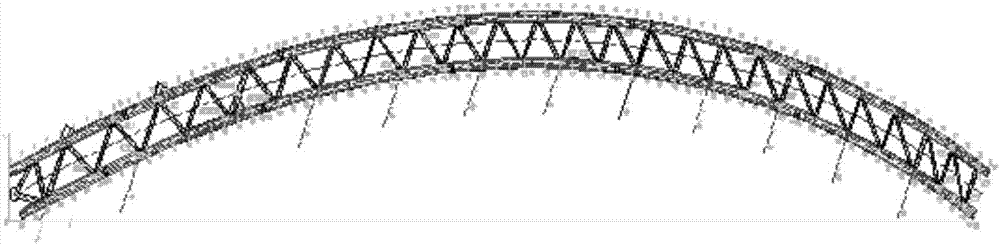

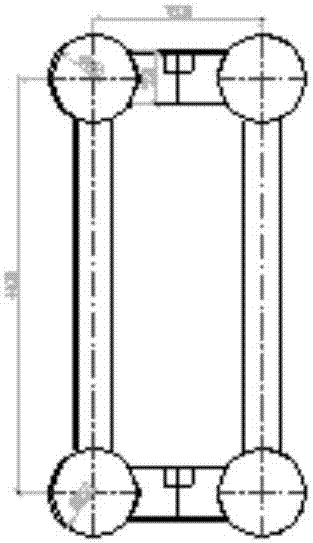

[0030] see figure 1 and figure 2 , figure 1 Schematic diagram of steel pipe arch rib setting out for the steel pipe arch general assembly method provided by the present invention; figure 2 It is a sectional view of the steel pipe arch rib of the general assembly method of the steel pipe arch provided by the present invention.

[0031] The overall assembling method of the steel pipe arch comprises the following steps:

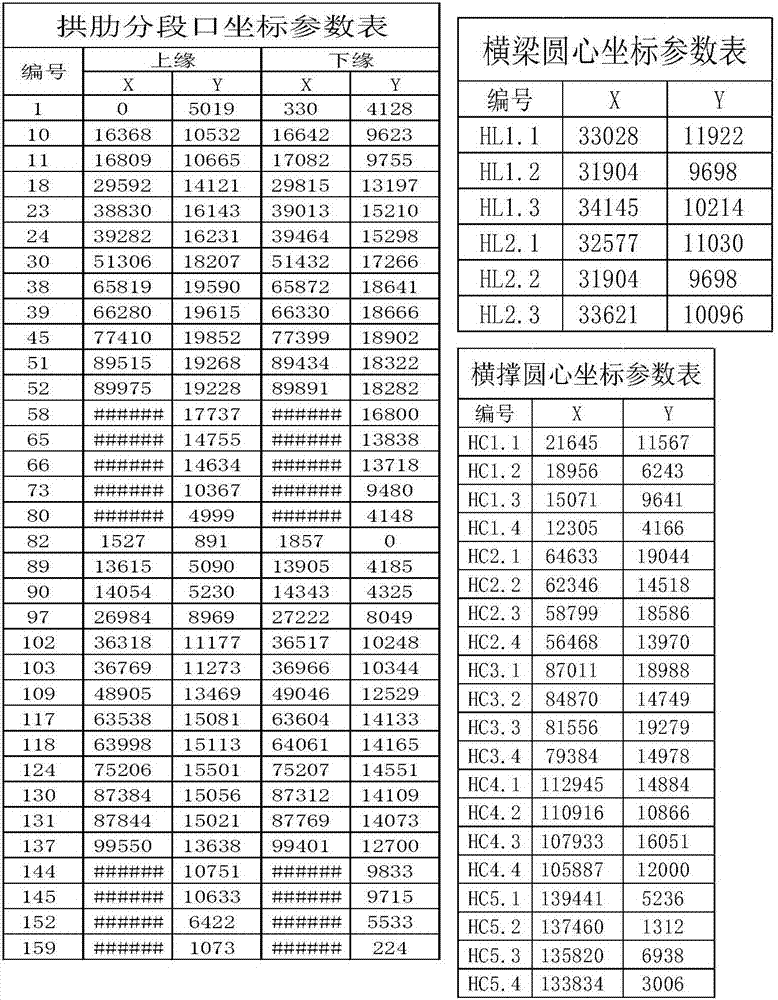

[0032] Step S1, collect data according to the pre-installed computer software, put the segments to be assembled on the workbench according to the theoretical state, list the plane coordinate dimensions of the points to be controlled, and establish a ground sample on the workbench of the workshop The coordinate system enables the workbench in the workshop to have the functions of detection, positioning, clamping, and assembly. The to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com